Page 1

SINCE 1876 machines

TO OBTAIN THE BEST PERFORMANCE FROM

YOUR MACHINE BE SURE THE CABINET,

CARRYING CASE OR OTHER ITEMS USED

WITH YOUR MACHINE ARE GENUINE WHITE

PRODUCTS.

V^'

Printed in USA

Page 2

You are now the owner of a new zigzag sewing

machine, the most versatile type of its kind you can

possess.

Buttonholes, monogramming, stretch stitching,

overcasting and creative embroidery are done with ease

and speed.

To aid you in obtaining the greatest performance

from your new WHITE this book on its care and use

has been written for you. Read the instructions

carefully, as a thorough understanding of your machine

W

if

will reward you with many hours of trouble free,

creative sewing.

Time-saving attachments such as rufflers, binders,

edgestitchers, hemmers and others to complement

the accessories furnished with your WHITE are

available from the store where you purchased your

machine.

WHITE SEWING MACHINE COMPANY

Cleveland, Ohio 44111

WHITE CONSOLIDATED INDUSTRIES, LTD.

Toronto, Ontario, Canada

Page 3

co"4'm

SEttiOta.f -'PfiEOlSjMftiA=R‘Y-4nSIFG!l^M

i

Parts Indentification

Principle Parts.........................................................................................................^

Accessories ............................................................................................................ ^

Installing Machine onto portable case

or cabinet and Connecting Machine........................................................................7

.........

^

Selection of Needles and Threads

Needle-Thread-Fabric-Stitching Guide

Changing Needle.............................................................................................................^9

Changing Needle Plate ................................................................................................. ^9

Selection of Presser Foot..................................i

Winding Bobbin ................................................................................................................

Threading Bobbin Case....................................................................................................

Placing Bobbin Case in Shuttle .......................................................................................

Selection of Stitch

Stitch Length Control

Reverse Push Button.............................................................................................15

Stitch Width Control.............................................................................................. 16

Relating Stitch Length to Stitch Width ..................................................................16

Stretch Stitch Lever ............................................................................................... 17

Stitch Pattern Selector [MODEL 426]....................................................................17

Blind Stitch Selector [MODEL 415] .......................................................................18

Controls

Adjusting Thread Tensions....................................................................................18

Adjusting Pressure on Fabric and Feed Dog Height

Sewing Light...........................................................................................................

Buttonholer [MODELS 415 & 426] 20

Creative Embroidery Control ................................................................................20

...............................................................................

...................................................................................

...................................................................

..............................................................

■•■•15

.............................................

19

8

9

..

Preparing to Sew .............................................................................................................21

Guiding Fabric................................................................................................................. 21

Turning Corners...............................................................................................................21

Curved Seams................................................................................................................. 22

Sewing Across Heavy Seams..........................................................................................22

Removing the Work.........................................................................................................22

Straight Stitch

Seam......................................................................................................................23

Basting/Topstitching...............................................................................................23

Darning.................................................................................................................. 23

Cording/Sewing on Zipper

Quilting...................................................................................................................24

Zigzag Stitch

Overcasting ...........................................................................................................25

....................................................................................

24

Page 4

"AGE

. 8

. 9

.10

.10

.11

.12

.13

.14

.14

•15

■15

•16

•16

•17

•17

•18

■18

•19

■20

■20

•20

21

21

21

22

22

22

•23

23

23

24

24

25

PAGE

Seaming Knits.........................................................................................................25

Seaming on Buttons ...............................................................................................25

4

6

Sewing Tips............................................................................................................3q

Shaping Dart in Interfacing ..............................................................3q

Multiple Zigzag Stitch [MODEL 426]..................................................................................30

Buttonholes

Preparation ............................................................................................................ 31

Built-In Buttonhole [MODELS 415 & 426]...............................................................32

Turn-Round Buttonhole..........................................................................................33

Corded Buttonhole..................................................................................................33

Blind Hem Stitch [MODELS 415 & 426]

Straight Stretch Stitch .......................................................................................................35

Topstitching

Ultra-Stretch Stitch ,

Rick-Rack Stretch..................

Pine-Leaf Stretch [MODELS 415 & 426]

Special (Jltra-Stretch [MODEL 426] ................................................36

Elastic Application

Overlook Application ......................................................................................... 37

With a Thread Shank.....................................................................................26

Satin Stitching............................................................................

Tapering/Creative Embroidery ...............................................................................27

Manual Embroidery Designs...................................................................................27

Freehand Monogramming.......................................................................................28

Applique/Patching...................................................................................................28

Gathering Over a Cord ...........................................................................................29

Lace Application.................................................................................................... 29

Flutter Hem ............................................................................................................29

...........................................................................

...........................................................................................................

..............................

........................................................

...................................................35

3-7

.............................

26

34

35

N VI CARE AND MAINTENANCE OF YOUR MACHINE

Oiling Machine................................................................................................................. 33

Cleaning and Oiling Shuttle Area................................................................................... _39

Adjusting Bobbin Winder.................................................................................................^40

Adjusting and Changing Motor Belt..........................................................................! ! ! AO

Problem and Remedies................................................................................................... 41

SECTION VII SPECIAL STTACH

Attachment Foot................................................................................................................43

Edgestitcher.................................................................^....................................................43

Binder.................................................................................................................................44

Folded Binding.......................................................................................................44

Two-Tone Binding..................................................................................................44

Hand-Cut Bias Binding ..........................................................................................44

The Set of Hemmers .......................................................................................................4g

Ruffler

Narrow Hemmer............................................................................................ 47

Lace Trimmed Hems............................................................................................43

Lace Edge with Invisible Stitching

French Seam

Hemming Across A Seam ............................................................................. ... .48

.................................................................................................... . *48

........................................................

..!...! A8

.46

Page 5

SECTIOW I

PARTS IDENTIFICATION

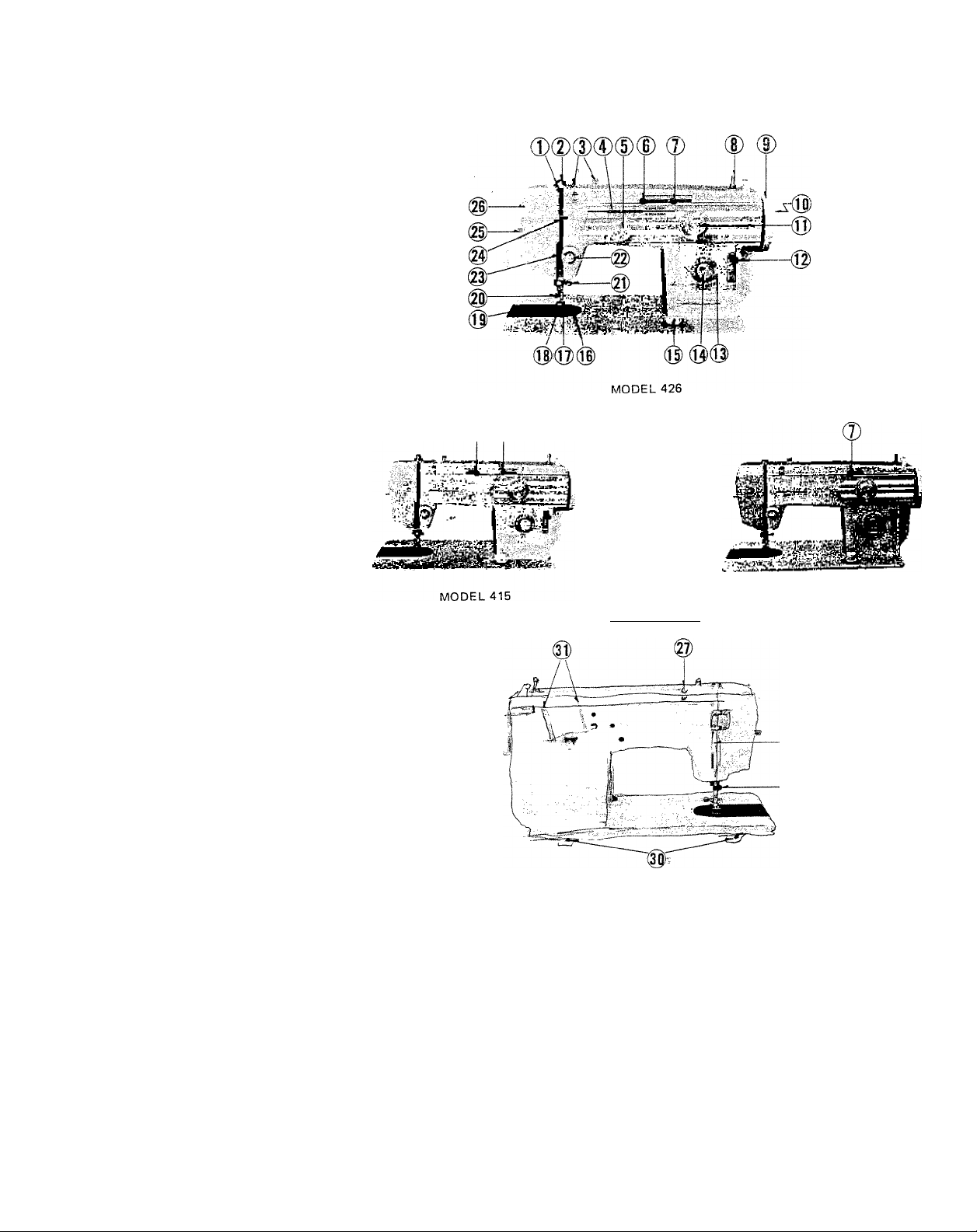

PRINCIPLE PARTS

(D®

FRONT VIEW

BACK VIEW

MODEL 404

Page 6

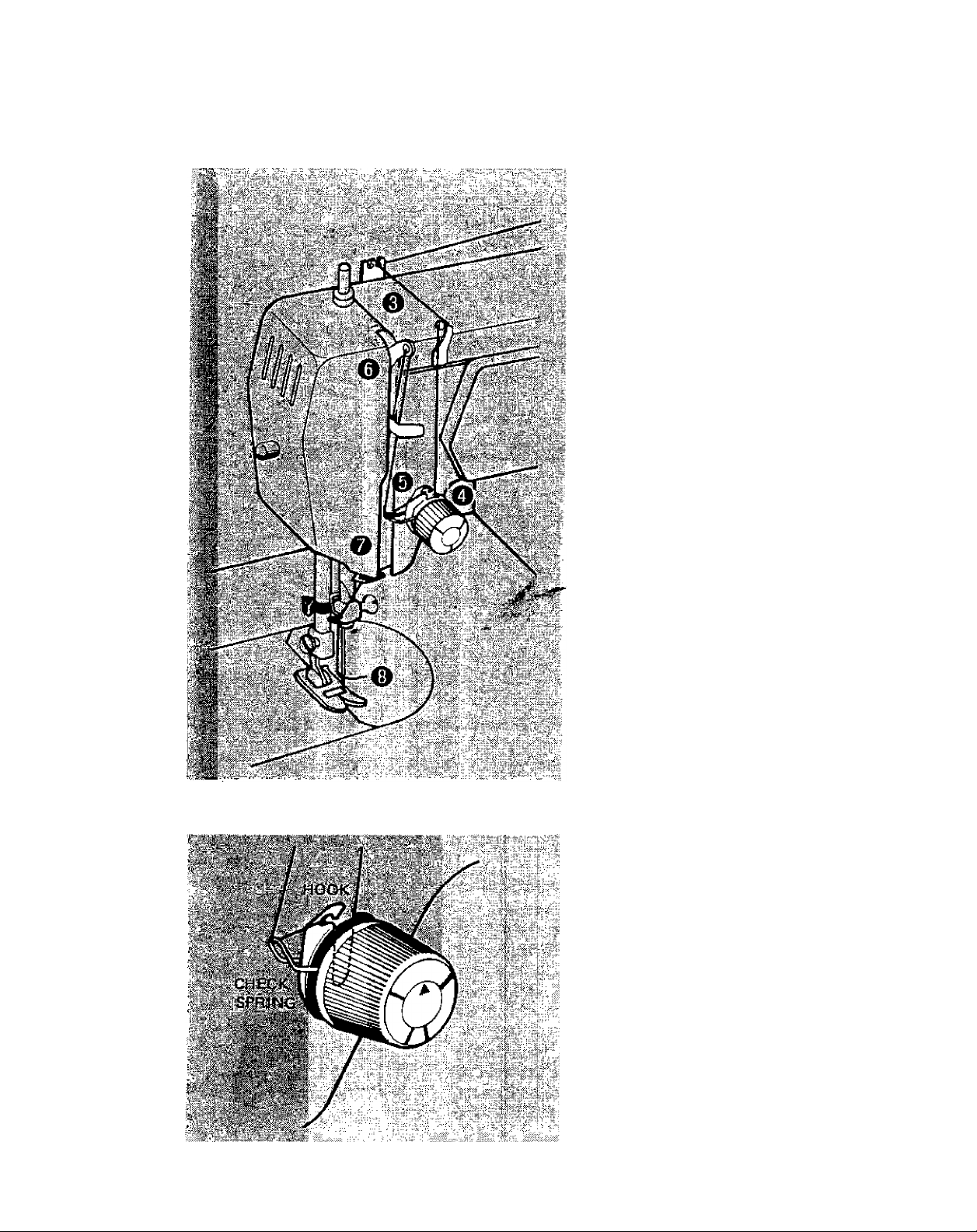

1. Take-up

2. Pressure Control

3. Top Thread Guides

4. Stitch Pattern Window

[Model 426]

5. Stitch Pattern Selector

[Model 426] .

6. Selector Release

[Model 426]

Blind Stitch Selector

[Model 415] ,

7. Creative Embroidery

Control

8. Bobbin Winder

9. :' Hand Wheel

10. Clutch nut

11. Stitch Width Control

12. Stretch Stitch Lever

Aiwayl _ ,

eadi^Jli№ "

.ForinSicatihc

13. Stitch Length Control

14. Reverse Push Button

S'

15. Feed Dog Height

Control •

16. Needle Plate

17. Feed Dog ,

18. Presser Foot

19. Slide Plate

20. Thumb Screw

21. Needle Clamp

22. Tension Clamp

23. Check spring

24. Thread Guard

[Model 426]

25. Light Switch

26. Face Cover

27. Bobbin Winder

Tension disc

28. Presser Foot Lever

29. Thread Cutter

30. Head Hinge Holes

31. Spool Pins

Page 7

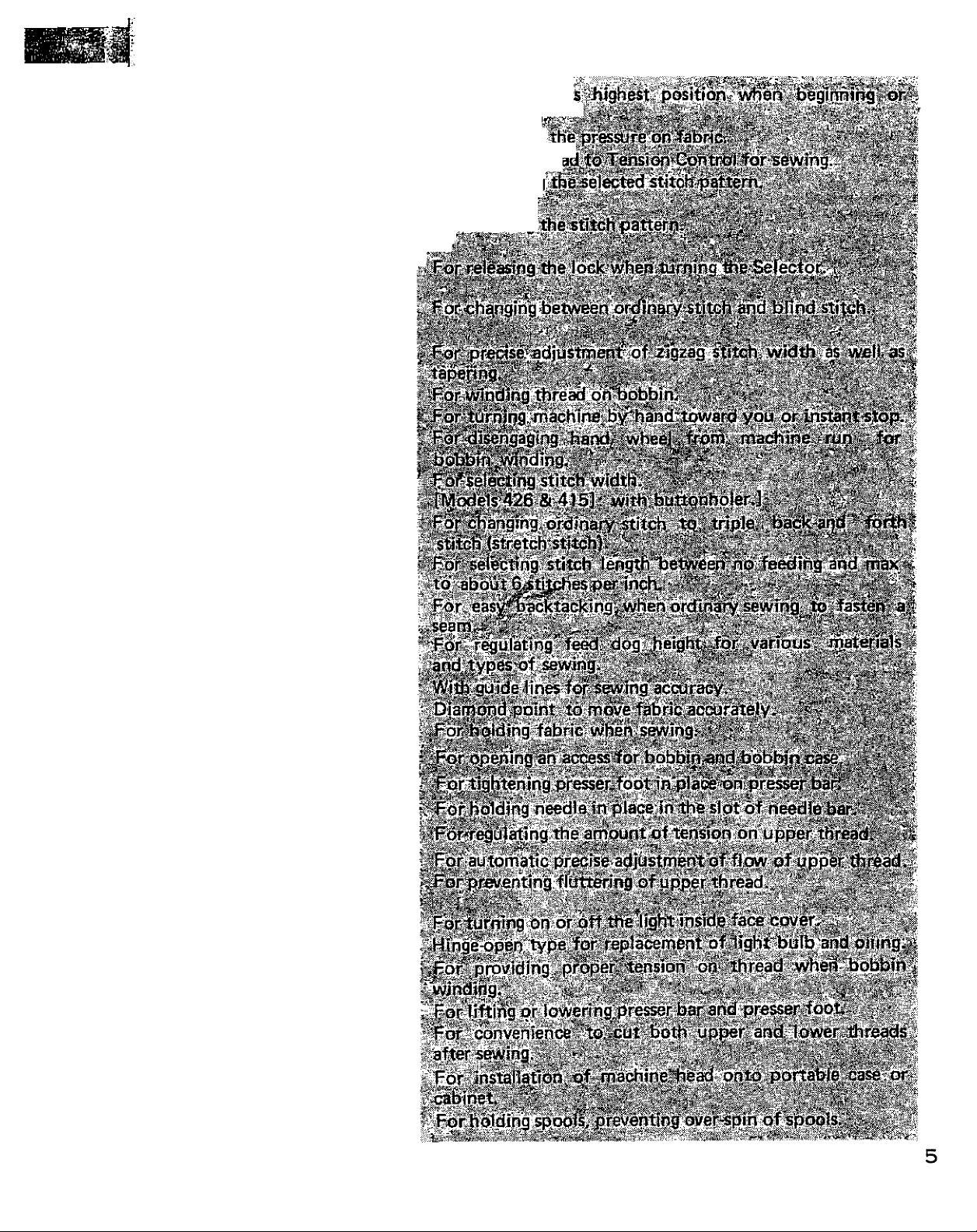

ACCESSORIES 77AfiT

Your nevil White sewing machine comes equipped with the following set of accessories

to make your stitchings the best to suit with your fabric and sewing purpose.

METAL BOBBINS

For your j^re bdb?,

bins \ * ’

various color t

A PACK OF NEEDLES

For.

assortfn

. 'h"'.

, .TegMJsu.-

needle

SPOOL CUSHIONS

STRAIGHT STITCH FOOT& NEEDLE PLATE

straight stitch

-in i very s^ieer

:Sir,.,'vei^'. light

r^gHi ■ stretchy' ,nii7;'

-.where -'■■■extra

'needed. ■'■- ■ ^

'--■■■■■ '

BUTTON FOOT

ivy-: ■ ■■ . -...

"^^"i^^ihg’buttdns-"

- '-'at;: sbtch-

‘ ^ ^ ^

BUTTONHOLE FOOT

...A-

■ .■'!

SCREW DRIVERS

Srnall pne^^QriM'iO*^^ '

% bobbin,-. tfifead^en-:

I Sion' ' '■ l adju^rtment.

^ Large ope fof^;^ion

^ thumbiiscreWi'titMdle«

■> clampj etc. '--f'S ■

OILER

CLOTH GUIDE WITH SCREW

QUILTING GUIDE

CORDING AND ZIPPER FOOT

■i'A'

... fe-siitching very

'■JijldleP'to Ythe edge

or: z i ppe r.

■•■ f-

№■;;■■■ B---

-V:;

•V- «■ *

Page 8

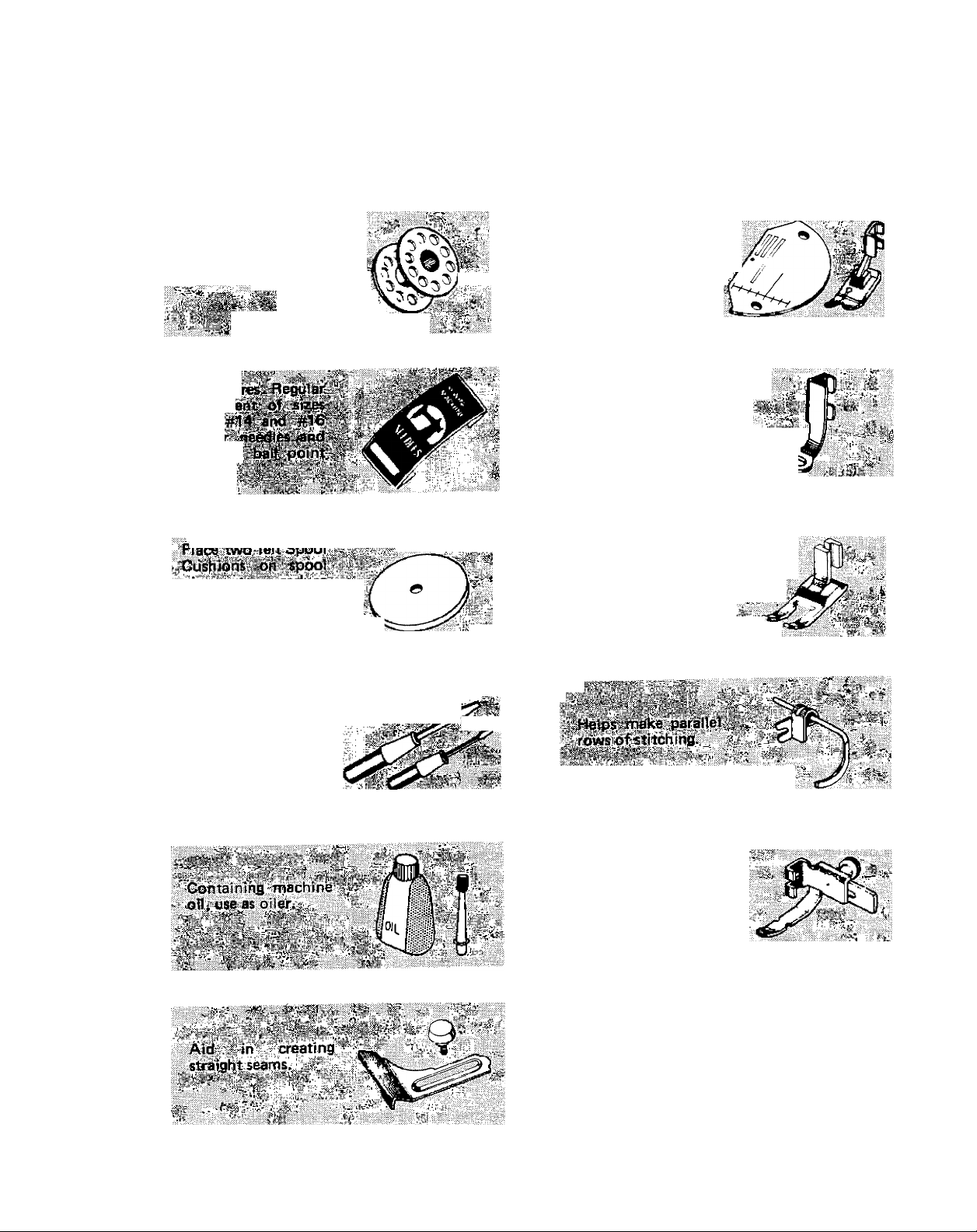

INSTALLING MACHINE HEAD ONTO PORTABLE CASE

'les

LATE

OR CABINET-AND CONNECTING MACHINE

Loosen both head hinge set screws

on the rear side back of machine

bed plate until head hinge holes

are clear.

Tilt head hinge pins up and back

as far as they will go.

Carefully slip machine head onto

hinges — making sure the head

hinge pins are inserted as far as

they can go into head hinge holes.

Allow machine head to rest in its

tilted back position.

Tighten both set screws securely

with screwdriver.

*1

-.’y-Sl

1

-^tf

JÌR

Cl

iv-y

_ f A

Plug electrical leads from machine

head into sockets located inside

cabinet or portable case. Cord

identified with "motor” tag must

be plugged into socket marked

"motor”. Untagged cord goes to

"light” socket.

Insert plug into a wall outlet of

110-115 Volts.

NOTE: Where three wire ground

ing is provided connect the plug

from the sewing machine to the

connection leading from the speed

control. One prong is larger than

the other three, eliminating the

possibility of error. Insert plug

into a wall outlet of 110—115

Volts.

Page 9

SiiCTtGiv

SELECTION OF NEEDLES AND THREADS

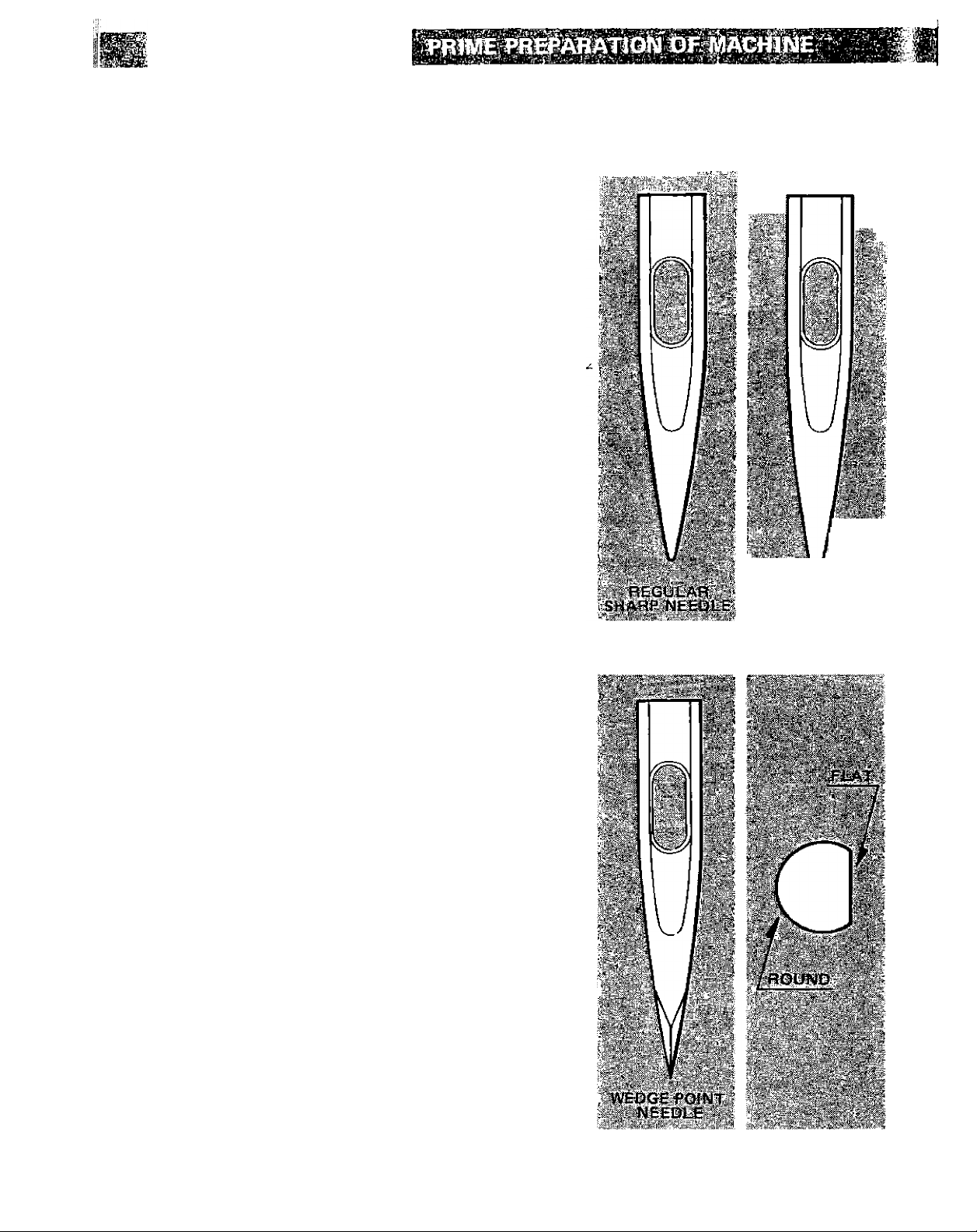

The needle and thread you choose depends

upon the fabric you are stitching. The correct

selection of needle and thread is very important

to avoid damaging the fabrics of light weight,

or tightly woven fabrics, and to prevent

skipstitches when sewing on very sheer stretchy

fabrics or needle breakage when stitching heavy

or stiff fabrics. For best results, sewing machine

needles should be replaced when they become

even slightly dull or bent or at the completion

of every other garment.

A regular needle is suggested for use with

woven fabrics. Needles, style 15 x 1, of the

range in size from 8 to 20 are used on this

machine. The lower number indicates the finer

needle. The most commonly used sizes are 11

and 14.

.

..........

A ball point needle fs recommended for use

with tricots, jerseys, lingeries and power nets.

Unlike sharp pointed needles, which pierce

fibers of knit fabrics destroying elasticity,the

ball point needle slips between fibers without

damage to fabric and skipped stitches.

A wedge point needle is recommended for use

with leather and leather-look vinyls. A wedge

cutting point pierces leather more easily than

ordinary sewing machine needles, resulting in

more satisfactory stitching.

Although it is recommended to use a ball point

needle for knit fabrics, when sewing on very

stretchy fabrics of knits, the underlay of a thin

paper below the fabric and the use of a finer

needle are suggested to prevent skip stitches.

Always use the same type and size of thread

in both needle and bobbin. Use good

quality thread without knots for best stitches.

8

Page 10

NEEDLE - THREAD - FABRIC - STITCHING GUIDE

JT

Extremely heavy

tarpaulin, sacking,

canvas, duck, etc.

Heavy upholstery

fabric, ticking,

denim, leatherette.

Medium heavy drapery

fabric, velveteen,

suiting, felt, terry, etc.

Medium broadcloth,

percale, gingham, linen,

chintz, taffeta, sheer

wool, shantung, etc.

Sheer voile, lawn, ^

dimity, crepe,

handkerchief linen.

Plastic film, etc.

18

18

16

14

11

6

to

8

8

to"

10

10

to

12

12

to

14

14

to

16

(plastic film)

8 to 10

Heavy Duty

Heavy Duty

Heavy Duty

50

50

O

o

AT

Very sheer chiffon,

batiste, lace, organdy,

nylon net, marquisette, etc.

16

to

20

60

o

Page 11

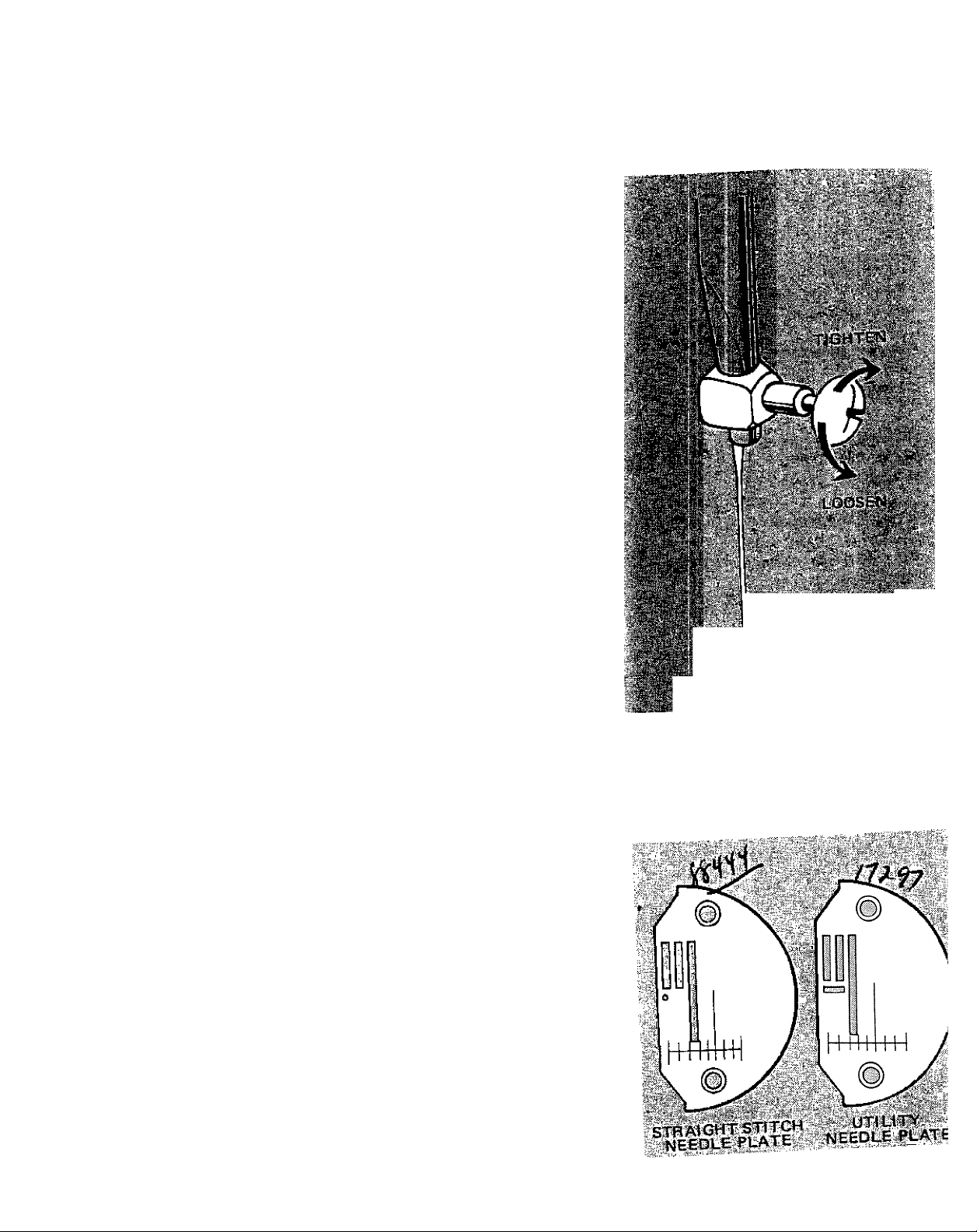

CHANGING NEEDLE

Aiwavs change the needle after every

other garment especially when

..^к;p.;ter and nylon fabrics whmh dull

needles much faster. When needles are

Hull or bent, they damage both your

fabric and the machine. A general rule

when placing sewing machine needles is

Tharthe flat side oi the needle is placed

to the right of the machme when the

bobbin is put in from- the 1^- ' ^

needle is inserted incorrectly, the stitches

will not form.

To change the needle . - u

1 Raise the needle bar to its highest

■ position by turning the hand wheel

toward you.

2. Loosen needle clamp to remove the

3. Rafe'^needle (flat side to the rightjnd

long groove to the left) in the J»eed1€

clamp and push it upward as far as it

will go, tighten needle clamp.

4 After changing the needle, make one

■ complete turn of the hand wheel by

hand to be sure the needle is clearing

the needle plate.

CHANGING NEEDLE PLATE

Although an all-purpose utility needle

Zlte is fixed on your machine for

Haight sewing on fine fabric or soft or

very stretchy fabric, you may want to use

the straight stitch ne^^ plate togethe

with the straight stitch foot, both ot

which are included in your accessory box.

To change the needle dimply shde

the slide plate as far

Remove the two screws holding the

plate in place. Lift the needle plate and

replace. _

The needle plate is removed for cleaning^

"int which may pile up between

needle plate and feed dogs.

0

Page 12

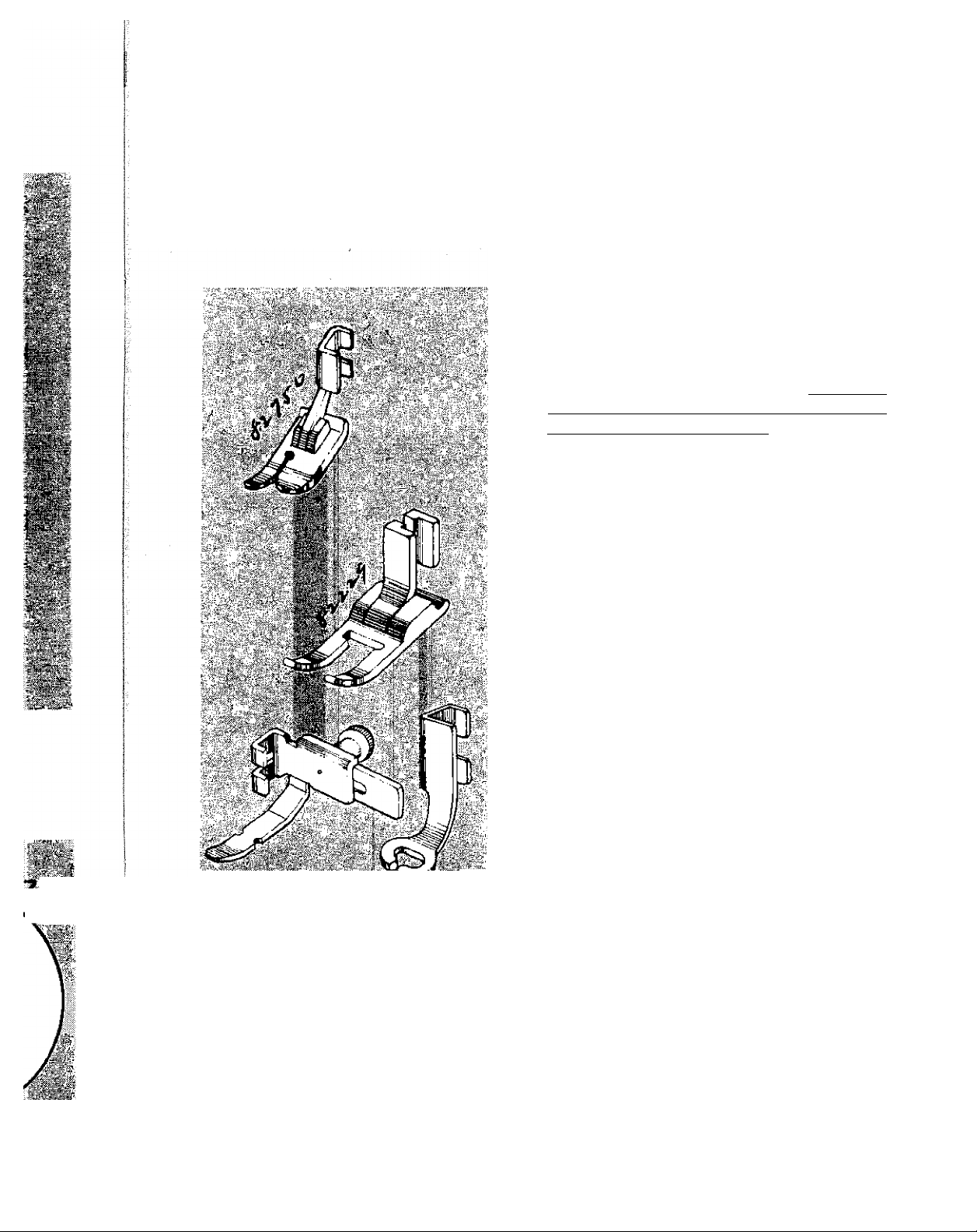

SELECTION OF PRESSER FOOT

For most ordinary stitchings the original all-purpose foot can be used. However,

it is recommended to use following special foot in your accessory box whenever

you want better stitching result.

Straight Stitch Foot

This has only a narrow hole to ac

comodate only straight stitching. It may

be used on sheer or soft fabrics for more

control. When using this foot, the Stitch

Width should be "0" to avoid hitting the

foot and breaking the needle.

Buttonhole Foot

This foot has a groove underneath, to

allow the narrow satin stitch or button-

^Jiole to form evenly. However, if

skip-stitch occurs with this foot,

apply the underlay of a thin paper below

the fabric.

m

^TE jj

.

’■ • V-■■■ -n-

■■ rt ',

■ ■■■■ ■■■ ■;

:■ :V;v ■ '■

.......

-t.

...............................................................

■ J

I,.

Cording or Zipper Foot, and Button Foot

Use for sewing very close to the edge of a

cord or zipper, and sewing on buttons

respectively.

CHANGING FOOT

Use the large screwdriver to loosen thumb

screw. Turn the screw backward until the

foot becomes loose. Then, lift up on

presser foot lever until it is in its highest

position in order to remove the foot.

Replace with desired foot and tighten

thumb screw securely.

Page 13

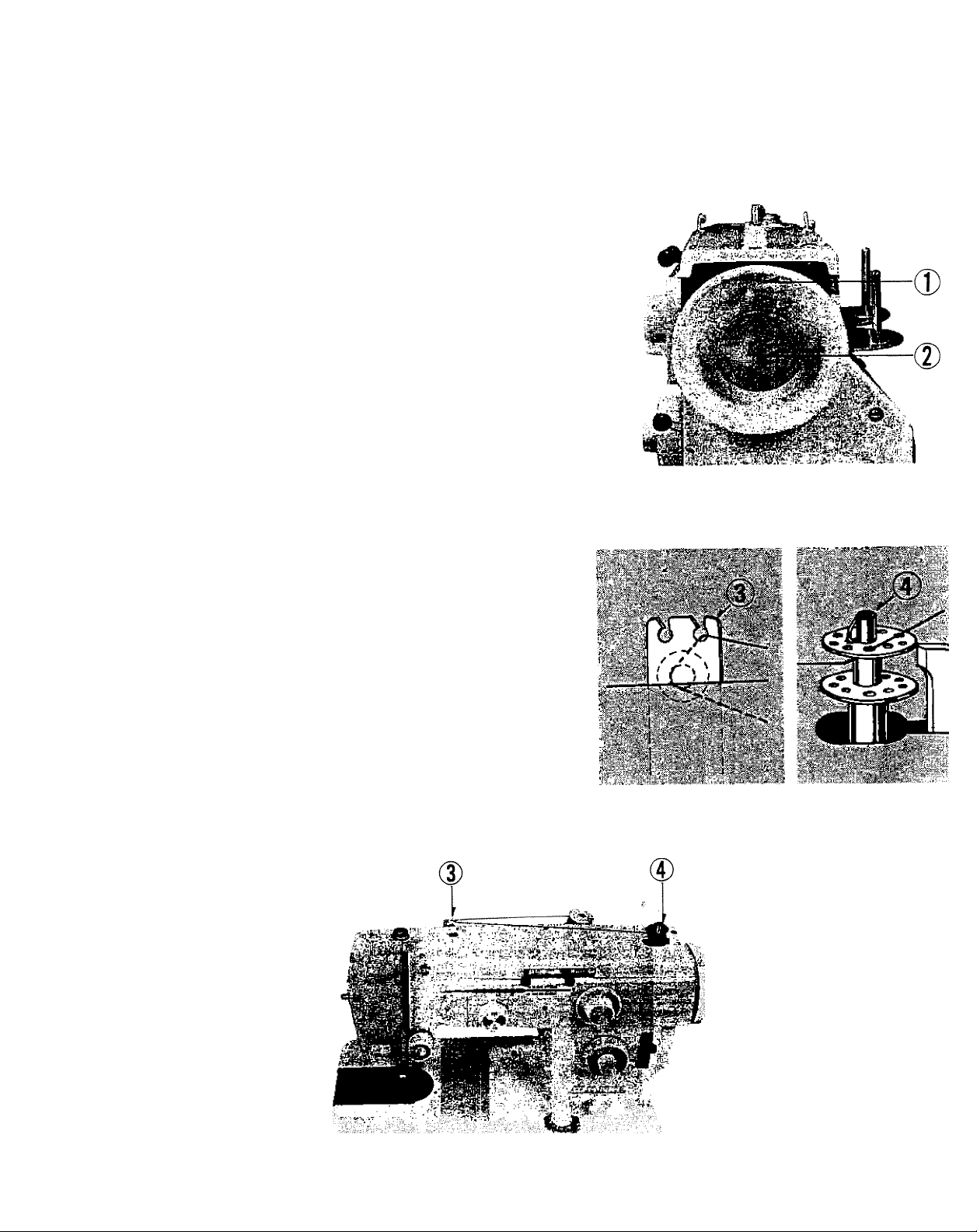

WINDING BOBBIN

Disengage the hand wheel (1) frpm

the stitching mechanism by turning

the clutch nut (2) toward you or

counter-clockwise.

Place a spool of thread on one of

the spool pins and lead thread

through the rear Top Thread Guide

(3) after hooking on Bobbin Winder

Tension Disc •

Run the end of thread through a

hole in the bobbin edge and place

bobbin on spindle of bobbin winder

(4) fitting the notch on bobbin over

small spring click on spindle.

Push bobbin winder (4) to the

right, and hold the thread end

loosely then start machine slowly.

Bobbin will stop winding when it is

filled. Push bobbin winder (4) to»

the left.

Turn clutch nut away from you

until sewing mechanism is again

engaged so that needle moves when

you turn the hand wheel.

Break off loose thread end used to

start the winding and cut other

thread end. Then remove bobbin

from bobbin winder.

12

Page 14

D

UPPER THREADING

1. Turn the hand wheel toward you

to raise the take-up lever to its

highest position.

2. Place a spool of thread on the

spool pin.

3. Lead the thread through the top

thread guides.

4. Down and between the tension

discs, from right to left.

5. Draw the thread up through the

check-spring and with a slight

tug into the hook.

mw

6. Up (Model 426 only .... behind

the front thread guard) and

through the eye of take-up lever

from right to left.

Lead thread down, through the

thread guide at the bottom of

the threading slot (Model 426

only ... .after drawing thread

behind the front thread guard),

then, through the needle bar

thread guide from the back.

8. Thread the needle FROM LEFT

TO RIGHT, drawing it through

about 3 or 4 inches. Hold the

end of the upper thread loosely

and turn the hand wheel toward

you until the needle goes all the

way down and comes back up. A

thread loop will form over

the upper thread which then can

be pulled out straight. Place

both thread ends under presser

foot and draw toward the back

of the machine, leaving both

threads three or four inches

long.

Page 15

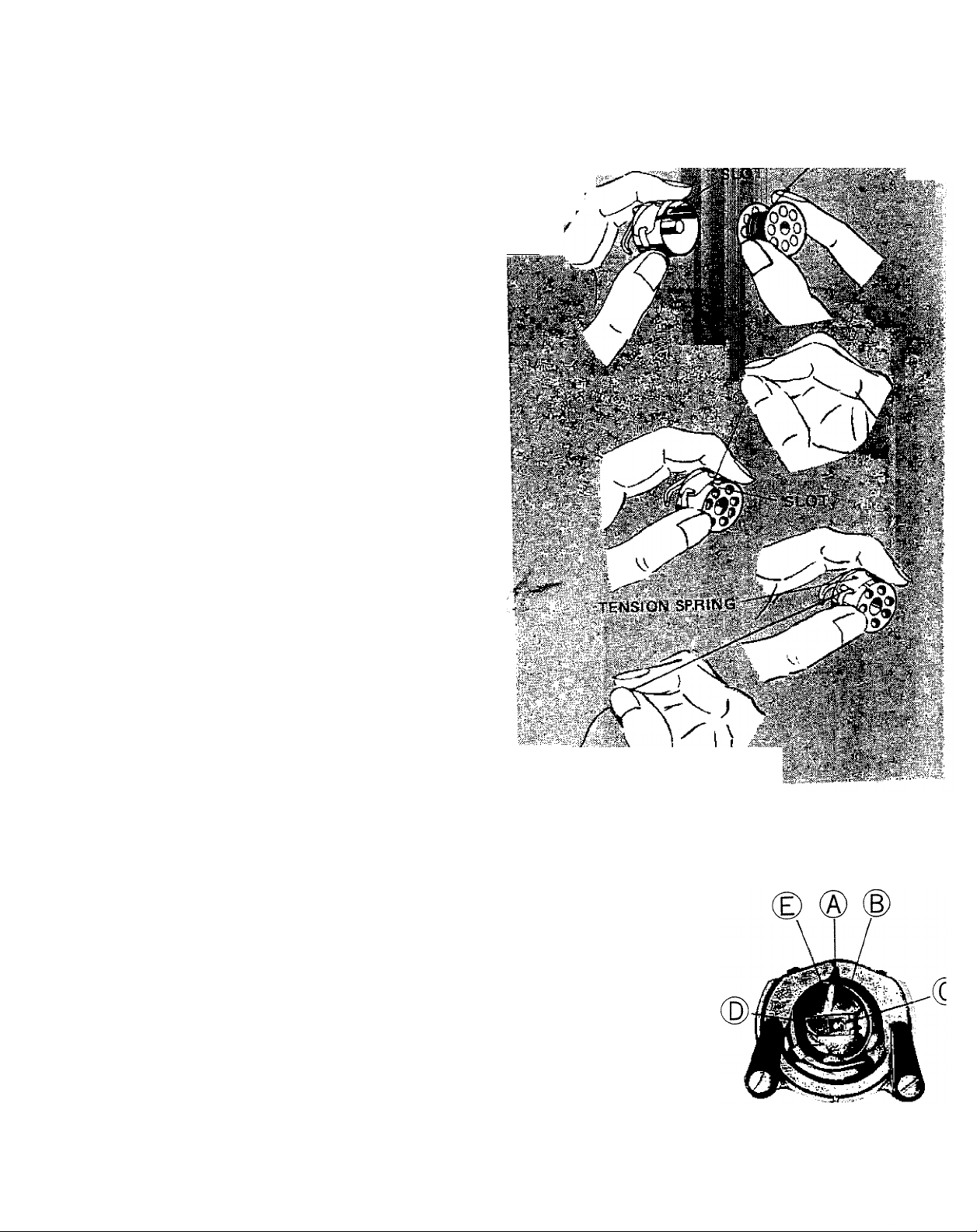

THREADING BOBBIN CASE

1. Hold bobbin case be

tween thumb and fore

finger of left hand, so

that the slot in the edge

of the bobbin case is on

top. Take the bobbin

between thumb and fore

finger of right hand so

that the thread on top

leads from left to right.

2. Insert bobbin into bob

bin case, pull the thread

into the slot of the

bobbin case and draw it

under tension spring and

into the fork-shaped

opening of the spring.

mim.

i -'i rifirfv

PLACING BOBBIN CASE IN SHUTTLE

Raise needle bar to its highest position, and slide plate to

the left. Hold the bobbin case latch (D) between the

thumb and forefinger of the left hand, with at least three

inches of thread running from the top of the bobbin case

to the right. Insert and center the bobbin case on the

stud of the shuttle body (C). Be sure the bobbin case

finger (E), is opposite the shuttle race notch (A). Press

the bobbin case (B) into the shuttle as far as possible

until the latch catches on the center post of the shuttle.

Then release the bobbin case latch (D). Press the bobbin

case again after the latch has been released to make sure

the bobbin case is locked securely in place. Close the

slide plate.

14

Page 16

ITT

Uj

sss

SELECTION.OF STITCH

STITCH LENGTH CONTROL

ivV;': Ai

■Ai

Ì.-Y

c-l

»

The stitch length control controls the forward feeding of

the fabric in ordinary sewing.

At 0, the fabric does not feed at all. With the control

around the red mark for buttonhole, the shortest stitch

is available. At 5 is the longest — about 6 stitches per

inch on ordinary fabrics - but the control may be set at

any desired spot between 0 and 5 for a variety of length,

except when ^tretch stitching ( triple back-and-forth

stitching), the cóntro! should be always at 5. Turn

the control to the left to lengthen and to the right to

shorten the stitch.

The stitch length number you choose is indicated by the

pointer above the control.

The stitch length in stretch stitching (triple back-andforth stitching)can not be altered by the control, but it is

fixed about 3/64 inch of trouble-free stretch stitch

length on most kinds of fabrics with the stretch stitch

control iV'S'' and the stitch length control at "5”.

Ife

iiiSif

I'AA-A'K

REVERSE PUSH BUTTON

When you wish to sew backward to tie the threads at the beginning or end of a seam

in ordinary sewing, press the Reverse Push Button as far as it will go, so that your

machine sews in reverse at approximately the same stitch length as forward stitch

length. The machine will sew backward as long as the button is held in.

Cross reference table between numeral on the control and number of actual stitches

per inch

-■

■■■= T.'.- J ■■ ».'.-a-:-:- V

....

: :■ ■ v... ■■■* t--'- ..

........... '-i.-v./fv... -y;-'

Number. Qf;^ti^è?:per;incl:i.Ja ^Ì)Jó,Ì;F;éedii^;.::: ^.26/;

15

Page 17

STITCH WIDTH CONTROL

This control controls the swing of the

needle from left to right for various width

of stitches. At 0, the straight stitch line

results in ordinary sewing. Also, the

special stitch patterns as per those shown

in the stitch pattern window of Model

426 are made with this control at 0.

With the control at any other point than

"0", ordinary straight stitches varies to

zigzag stitches. Also, every special pattern

stitch varies in complex pattern with^

stitch width variation, on Model 426.

At 1, the needle takes a narrow sewing

resulting in a narrow column of stitching

in ordinary sewing. At 4, the needle takes

a large swing resulting in a wide column

of stitches no matter which pattern is

selected.

V'i r-!

I

RELATING STITCH LENGTH TO

STITCH WIDTH

When the Stitch width control is set at

one particular width (such as 4), the

stitch length control will now control how

close those stitches come together. At

length 0, the fabric does not move,

resulting in a bar of stitches formed one

on top of the other, as is used in button

sewing. At red bar mark or near 0, the

feed pulls the fabric through slowly,

resulting in a dense column of stitches

called a satin stitch. At length 5, a very

long open zigzag results.

Page 18

STRETCH STITCH LEVER

Selection between ordinary stitching and triple automatic back-and-

forth stitching called stretch stitch is made by the stretch stitch lever.

With the lever up at M position, ordinary sewing is performed. With

the lever down at S position, your machine performs automatically

the stretch stitch with the repetition of two forward and one

backward stitch combination.

A reinforced seam of stretch stitch that will stretch considerably

more than the fabric used.is the most wanted feature in a sewing

machine today.

Its uses are almost unlimited and the more you use your machine the

more it will become apparent to you.

When stretch stitching, the stitch length control should be always set

at 5.

STITCH PATTERN SELECTOR [MODEL 426]:

In addition to ordinary straight and zigzag stitches, six special utility pattern stitches

of forward sewing, also, with stretch stitch lever at S position, six those complex

special stretch pattern stitches of triple back-and-forth stitching can be selected by

stitch pattern selector.

The stitch pattern you choose is shown by the indicator in stitch pattern window

above the pattern selector; '

To turn the stitch pattern selector to,cha«ge the stitch pattern of your selection;

1. Raise the needle bar to its highest position by turning hand wheel toward you.

2. Pushing the selector release lever to the right by your right hand, turn the pattern

selector to the right for stitch patterns shown right from the original stitch pattern

in stitch pattern window and to the left for stitch patterns shown left.

3. Release your right hand from selector release lever to return it to original stitch

pattern selector lock position.

For ordinary zigzag and straight sewing, set the indicator at the left end "Manual"

position, with stretch stitch lever at M.

The stitch patterns shown upper side in the row of "Elastic Stitches" in stitch

pattern window are available with stretch stitch lever at M, and those shown lower

row marked "Stretch Stitches" are available with stretch stitch lever at S. For those

special pattern stitchings other than ordinary zigzag and Rick-Rack stretch (triple

back-and-forth zigzag) stitching, stitch width control should be at 0.

,:i#s

17

Page 19

BLIND STITCH SELECTOR [MODEL 415]

Automatic blind hem stitching and Pine-leaf stretch

hem stitching is available on Model 415 with blind

stitch selector to the left. The former is made with ^

stretch stitch lever at M and the latter is with it at S.

For both, stitch width control should be at 0.

In ordinary stitching, this control be at M position. In shifting the control to

position, lift the control up a little bit, then shift it to the right.

CONTROLS:

ADJUSTING THREAD TENSIONS

Always adjust the upper thread

tension with the presser foot down, ^

as the tension is released when it is

raised. To increase the tension on

the upper thread, turn tension

control to the right. To decrease,

turn to the left. Before adjusting

the tension be sure that the

machine is threaded properly.

It is seldom required to adjust

the bobbin thread tension,

however, when necessary to change

bobbin thread tension, turn |Riall

screw on side of the bobbin'*^cafe

clockwise to tighten , counterclock

wise to lobsen.

I ;,r-' ■■■■■ ■ ■■ ■ ’■ ’ yi'"';.'«

■ .■.■.■■:■'■■-.■/ r • \ ;>i-■■.;

■ ■ ■■';i ; ■.■

■:: ■. ■ ■■' '. i ■■■ I ; ;':

V: \ '"v: K1 ■. -i.'.

■ ■ ■ V-.: • .3 •i.J: ■

i

When both tensions are properly

balanced, a perfect stitch will be

formed with both threads interlock

ing in fabric (A).

When the upper tension is too tight,

the bobbin thread is pulled up over

the upper thread which is lying flat

on the fabric (B).

When the upper tension is too

loose, the upper thread forms loops

over the bobbin thread lying flat on

the fabric (C).

When the upper and bobbin thread

tensions are balanced but fabric is

puckered in sewing direction on

sheer fabrics, both tensions are too

tight. Loosen both tensions evenly.

It is recommended to adjust the

tension balance under medium

stitch length. In case of satin

stitching for buttonholes and em

broidery, slightly loosen the upper

thread tension.

8

Page 20

M

3 M

ADJUSTING PRESSURE ON FABRIC AND FEED DOG HEIGHT

• GENERAL SEWING

Usually for normal sewing, except for sewing on

very sheer soft or very stretchy fabrics, the

center pin (B) of the pressure control be at its

lowest position and the feed dog height control

be turned to the right, "HIGH” position.

For sewing on such very sheer. soft medium or

lightweight stretchy fabrics as very sheer

voil, lawn, silk geogette crepe, plastic film,

organdy, nylon net, very stretchy synthetic tricot

and jersey, etc., reduce half the pressure on the

fabric ancF the feed dog height. To reduce half

the pressure, press the outer ring (A) of the

pressure control, then press the center pin (B)

down again to halfway spot. To reduce half the

feed dog height, turn the feed dog height control

to "LOW" position.

.¿Teed rdpg

;^heightf '

Heavy and ^medium weight fabrics .

M ed i u m weight^ very: stretch y; fa brfc

> /s'

if”"; •

, Very sheer ioft fabrics and lightweight

M':..and sheer very stretchy synthetic fabrics:

"X^'.'Half

-.'jX"'- . ■ ■

-

Half •::? f Jflsi*««

'jVi’i:-,'. '

■

• MENDING AND DARNING:

In order to move the fabric freely in any direction for darning and mending, release

the center pin (B) completely by pressing down on the outer ring (A). Turn the feed

dog height control to "DOWN" position, which drops the feed dog well below the

if'

needle plate. To return the feed dog height to normal, turn the control to "HIGH"

position.

Page 21

SEWING LIGHT

The sewing light is located in face cover directly over the

needle so as to better illuminate the stitching area.

Turn the light on and off by pushing the switch

on face cover. •

To replace bulb, turn light off and open face cover to

the left. Unscrew bulb as you do a conventional light

bulb. Place new bulb in socket and screw in place.

BUTTONHOLER (MODELS 415^ AND 426)

On models 415 and 426, the stitch width control knob is

used also for buttonholing. With the control at the red

square mark (1), the machine sews forward on the 'eft

edge of buttonhole with the stitch width of about 1/1 b

inch. At the red square mark (2—4), the buttonhole end

is bartacked about 5/32 inch wide without feeding. At

the red mark (3), the right edge of buttonhole is stitched

in reverse with same about 1/16 inch width as the left

edge of buttonhole. / i •

Therefore, simply by turning^thir control from 1 to 4 in

sequence for every step of fttittonholing, a very fine

buttonhofe of the size about 5/32 inch wide with a

center open cut space of about 2/32 inch is produced.

The stitch length control should be set at the satin stitch

position in the red mark "Bottonhole" there.

I t. ■: : :T V-;

■ ■■■ V

CREATIVE EMBROIDERY CONTROL

This is the alternative stitch width control capable of varying the stitch wid

while sewing. With the machine set for a short stitch length, different esigns c

be made by simply applying pressure on the creative embroidery lever flow k

to rTght This lever is spring controlled and will always return to straight sewinc

i -rst.

f, ■■■■

riVE EMBBPlt^:^

'rr>'-.yl

-, . -.-.-i

•r-. /ii

^ ■ • • ' • - - f'T: .

20

Page 22

SECTION 0

PREPARING TO SEW

Have take-up lever at highest position before starting to sew. Pinning may be used

as a time saver instead of hand basting. It is possible to sew over pins when placed at

right angles to the edge of fabric with the pin head at the raw edge, but for best

results it is recommended that the pins be removed as you approach the presser foot.

Sewing over pins can result in damaged needles.

Place material and threads under presser foot and lower the presser foot. Lovyer the

needle by turning hand wheel by hand to check if the needle will pierce the stitching

line you want to sew. You are now ready to begin sewing. Press the speed control.

The speed of the machine running is regulated by increasing or decreasing the amount

of pressure exerted on the control. Never run machine without material under

presser foot.

GUIDING FABRIC

width

IS can

left

ving.

Except blind stitching and pine-leaf stretch hem stitching, also, buttonhole-stitching

by buttonholer of models 415 and 426, straight stitch seam and the left line of zigzag

stitch column is run over the left end etched scale on needle plate. The scale is etched

with every 1/8 inch distance. Let the edgf,of fabric follow the line selected for the

seam, and let your eyes follow the efched line you selected for the seam, not the

needie, during seyving. To help youT guiding fabric, place cloth guide attachment

securing it by the extra thumb screw onto machine bedplate. Cloth guide and extra

thumb screw are included in your accessary box.

Do not try to help the feeding by pulling the material as this may deflect the needle

and cause it to break.

TURNING CORNERS

To pivot at a corner, leave the needle in the fabric while its upward stroke. Lift the

presser foot, turn the fabric, then lower the presser foot and continue sewing.

Page 23

CURVED SEAMS

Use slightly shorter stitch length

than that of the rest of the seams.

On the part where elasticity is

required on the seam, sew by

stretch stitch. The cloth guide may

be used an angle as shown.

SEWING ACROSS HEAVY

SEAMS

When approaching heavy searn,

hold the fabric upward on an angle

so that the heavy seam falls under

the front curved sled of presser

foot.

■ t' ■

REMOVING THE WORK

Be, sure to stop the machine when

the thread take-up lever or needle

bar is at the highest position.

Now raise the presser foot and draw

the fabric back and to the left

and pass the threads over the

thread cutter.

Pull down slightly, holding thr®^°

in both hands, so as not to bend the

noodle

Leave the ends of threads under

the presser foot.

IT t'

22

Page 24

SECTION V

STRAIGHT STITCH; ,

SEAMS

[Pattern: M or Manual

models 415 & 426]

Length; 2—3

Width: 0

Feed Dog: High

Pressure; Full

Foot; Straight Stitch or

All Purpose

Stretch Control; M

[Pattern: M or Manual

models 415 & 426]

Length: 4—5

Width: 0

Feed Dog: High

Pressure: Full

Foot: Straight Stitch

Stretch Control: M"

The normal stitch length for most fabrics

is between 2—3 but the length chosen

should depend on the fabric and area of

usage. Usually, heavier fabrics require

longer stitches, and lighter weight fabrics

require shorter stitches. For curved seams

and bias cut areas use a shorter stitch

length. Be sure to set the stitch width

control at 0.

B ASTI NG/TOPSTITCHING

Sewing a seam with a longer stitch is

useful for temporary seams prior to

fitting. Basting stitches also may be used

when gathering in fullness.

Topstitching can be done very effectively

with the long straight stitch. For a bolder

stitch, two threads of the same type can

be threaded through one needle (size 14

or 16). A heavier thread such as

buttonhole twist may be used for

topstitching, but be sure to use a larger

needle (size 16 or 18).

%

'■■y

[ Pattern: M or Manual

models 415 & 426]

Length:0

Width: 0

Feed Dog: Down

Pressure: 0

Foot: All Purpose, or

DarningSpring of White

Special attachment

Stretch Control: M

DARNING

Worn spots or small holes can be darned

very easily. Use of an embroidery hoop is

optional depending on the fabric. A fine

thread is recommended so that the fabric

and thread will blend together invisibly.

Trim the ragged edges from the area to be

darned. Hold the threads to start, then

move the fabric slowly backwards and

forwards while running the machine very

fast to fill the area. More professional

results will be attained by moving the

fabric in a figure eight pattern while

sewing. After filling in the area length

wise, reweave with crosswise stitches in

the same manner.

23

Page 25

CORDING/SEWING IN ZIPPER

• INSERT CORDING

(A) Fold bias strip of fabric over

cord. Loosen the adjusting

screw on the back of cording/

zipper foot and set the foot to

the left of needle.

(B) Sandwich the welting between

two layers of fabric with right

sides together. Stitch a second

time with cording/zipper foot

to the right of needle so that

the needle stitches close to the

cord through all thicknesses.

• ZIPPERS

Swing the foot to left, or right of

the needle as needed so that the

foot sews very close to zipper teeth.

QUILTING

Parallel straight lines are easy to

sew with the quilting guide. To

attach the guide, loosen thumb

screw and slip the U-shaped holder

of the guide between presser foot

and thumb screw. Tighten the

thumb screw securely. Adjust the

curved bar to the desired distance

from the needle. Sew the first line

of stitching as desired, then, for the

succeeding rows let the guide

follow along the previous stitch

line. A straight stitch, zigzag, or any

other stitch may be used.

24

Page 26

ZIGZAG STITCH:

OVERCASTING

[Pattern: M or Manual

models 415 and 426]

Length: 1—3

Width: 3-4

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

[Pattern: M or Manual

models 415 and 426]

Length: 1

Width: 1-3

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

Place the edge of the material underneath

the opening of the sewing foot and guide

raw edge along the center slot of the foot

allowing stitch to form half on and half

off the fabric.

The multiple stitch zigzag is a wiser

choice on Model 426 for most fabrics.

See page 30.

SEAMING KNITS

The narrow zigzag can be used in seams

of firm knits for added strength. After

sewing, open seam and press flat. Tiny

zigzag stitches can hardly be seen and the

seam will give when stretched.

[Pattern: M or Manual-

models 415 and 426]

Length: 0

Width: 2-4

Feed Dog: Down

Pressure: Full

Foot: Button Foot

Stretch Control: M

SEWING ON BOTTONS

Place the button so its left hole comes

directly under the needle of its left zigzag

swing then gently lower the button foot.

Take a stitch into the hole.

Raise the needle from the left hole, and

move zigzag width control to the right

until the needle comes down exactly over

the right hole in the button.

Note: Be sure the needle clears the holes

of the button by moving the wheel by

hand before running the machine fast.

Usually 6 to 8 stitches are adequate for

securing a button in place. Stop with the

needle in the left hole. To lock the

threads, set the stitch width at 0, and

take a few stitches in the left hand hole.

<¡3

21

Page 27

f

M

SEWING ON BUTTON

WITH A THREAD SHANK

Buttons sewn on coats

have a thread shank o JP^«^^,ead

away from the fabric. To form

shank, sew over a pm or

toothpick. K.ittnn to the fabric.

After stitching the bu«o foot

remove work inches from

ill

leaving threads pull the

™ri Ttock of bittorrnd form =

rSierPoli &s to back of the

and tie thread ends securely.

■. V-.: > ■■■ ■ . :■■■ ■

. - ■!■ ‘Ibw. ^ Jyi •

I

I

SATIN STITCHING

monogrammingand app ique. ^

The seam stitch which is realiy^l ^

ill

very close zigzag stitc , ,,q„

setting the stitch leng feeding

possible w.thout stopp^ bar marked

action or at for

"buttonhole . ^ desirable to

different fabrics. I Y .. . ^o cause

loosen the upper ension shg^J

the threads to '0^^ "jn ggpecially

to make the top su x juries place a

snrooth. For ''9';“X /at f for best

paper underneath the taor

results.

[Pattern-. Wl or Manual-rnodels 415 and 426]

Length: % or "Buttonhole

Width: 1-4

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

26

Page 28

|i^№p

mm0

TAPERING/CREATiVE

EMBROIDERY

Tapering is done by gradually increasing

and decreasing the stitch width by

moving creative embroidery control while

sewing. By this method, tapered mono

grams and other interesting designs can be

created. For tapered monogram run the

machine fast while sliding the creative

embroidery control slowly from left to

right and from right to left.

First, learn this stroke by letting the

fabric guide straight. Then, learn to pivot

the fabric as you are tapering by holding

the fabric at one point. Various strokes

can be combined to form letters and

designs. Variegated thread can give

attractive results.

[Pattern; M or Manual-models 415 and 426]

Length: Near 0

Width: 0

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

MANUAL EMBROIDERY DESIGNS

Different designs can be made by sliding

the creative embroidery control between

left and right. By running the machine at

a constant speed and sliding the creative

embroidery control in a definite rhythum, various designs can be created.

[Pattern: M or Manual-models 415 and 426]

Length': near 0

Width: 0

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

■■■

Page 29

FREEHAND MONOGRAMM ING

For giving garments and linens a per

sonalized touch, first transfer the design

to the right side of the fabric. An

embroidery hoop is recommended es

pecially for soft fabrics and toweling.

In order to monogram, you must move

the fabric slowly and run the machine

rapidly. Monogramming is like writing by

moving the paper under a stationary pen.

Guide the fabric slowly so that the zigzag

falls close together like a satin stitch, but

be careful that the stitches do not pile up.

When guiding from side to side, mov§,

fabric slightly faster to avoid a heavy

area.

Practice by forming loops. Once this is

accomplished any letter is easy.

Sometimes the use of paper or non-woven

interfacing under the fabric may make

guiding the fabric easier. The paper or

interfacing may be torn or cut away at

the completion of the monograrn.When

monogramming towels, plastic film plac

ed on the top will help cover lc|pp^and

make the monogram smooth. BilH 'br cut

away remaining plastic film wTieri finish

ed.

t Pattern: M or Manual -

models 415 and 426]

Length:0

Width: 1-4

Feed Dog; Down

Pressure: 0

Foot; All Purpose or

Darning Spring of

White special

attachment

Stretch Control: M

APPLIQUE/PATCHING

Applying decorative shapes of fabric

scraps to household articles and clothing

is a very interesting way of trimming an

otherwise plain article. First, trace the

design on fabric to be appliqued, or

patched then pin or baste it securely in

place on garment. With a small straight

stitch or narrow zigzag, sew around the

transferred design or patch.

After excess fabric is trimmed away, sew

around the applique or patch with a satin

stitch or short length zigzag stitch. For a

smooth curve, stop frequently at the

inside edge of the curve to pivot the

fabric slightly. Corners look much better

when the point is stitched by pivoting

rather than just turned.

As with all decorative stitches, paper may

be used to give more body to the fabric

when stitching and can be torn away

when the applique is completed.

Step 1

[Pattern: M or Manual

models 415 and 426]

Length: 1

Width; 0-1

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

Step 2

[Pattern; M or Manual

models 415 and 426]

Length: 'A—h

Width: 2-4

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

28

Page 30

:-i -| .

щЩ'л- Щ

iJ .* • »i

г ■■. ^*'Ч j;k ■^■^т:^■yVl^ ■4^,-=:<i;•;«*i>-'5:: ”1-уЛ'(

/ ■ ■■.■■:7‘r ¿i'.; iii-jji^^i?^

GATHERING OVER A CORD

Ordinary gathering with a basting stitch

often breaks while pulling in fullness,

small zigzag across a cord such as crochei

thread or carpet thread, gives a much

stronger cord for gathering fullness intc

fabrics. Once the gathers have beer

stitched in place, the cord can be pullec

out in order to eliminate bulk.

[Pattern: M or Manual-models 415 and 426]

Length; 2

Width: 2

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

LACE APPLICATION

Attaching laces or trims adds a specia

touch to lingerie, dresses, or linens. Pin oi

baste lace in place easing or miterinc

corners where neccessary.

A straight edged lace or braid has г

convenient line to follow when sewing

When using a scalloped edged lace follov\

the design of the lace for an almos

invisible application.

[Pattern: M or Manual-models 415 and 426]

Length: ’Л—1

Width: 1-2

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

'&Ш‘

i/; 'К-':;

FLUTTER HEM

An unusual way of hemming of finishini

edges of tricot or soft knits is by a fluttei

edge. Hemming in this manner is just lik(

overcasting an edge, but the fabric i:

stretched in back and in front of the

needle as you sew. For best results, pul

the fabric equally, making sure the needle

goes over the edge. When you stop tc

reposition your hands, keep the needle ir

the fabric.

[Pattern: M or Manual-.models 415 and 426]

Length; Va—'A

Width: 4

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

Page 31

SEWING TIPS

When a dainty hair line finish is

particularly desirable for the inside seams

of sheer collars, facings, and yokes, seam

allowance that would ordinarily show

through is eliminated by following the

seam outline with a narrow zigzag stitch.

Trim seam allowance close to line of

stitching. Turn and press.

[Pattern; Manual or M-models 415 & 426]

Length: 'A—l

Width: 'A-1

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

SHAPING DARTS IN

INTERFACINGS

Cut interfacing down center between dart

lines. Overlap cut edges, matching dart

lines. Zigzag stitch along marking line

from point to wide end of dart. Trim

both raw edges close to stitching.

[Pattern: Manual or M-models 415 & 426]

Length: A—i

Width:’/2-1 .

Feed Dog: High

Pressure: Full

Foot: All Purpose

Stretch Control: M

MULTIPLE ZIGZAG STITCH [MODEL 426]

The multiple zigzag stitch can be used for

hundreds of various kinds of sewing applications,

such as replacing worn blanket bindings for both

a decorative and' durable finish, overcasting an

edge to prevent fraying, applying elastic waist

bands to skirts and dresses, sewing a zigzag stitch

on soft or sheer material preventing puckering,

etc.

Just sew like ordinary zigzag stitching.

[ Pattern:

Stitch Length; 4—5

Width: 0

Feed Dog: High

Pressure; Full

Foot: All Purpose

Stretch Control; M

30

Page 32

BUTTONHOLES

Various fabrics require various methods of sewing

buttonholes. Four different methods are given below,

with suggested uses. If you are in doubt as to which

method is best for your fabric, test the methods in

question and choose the best according to the finished

appearance.

■■■

PREPARATION

For the best results, a good quality mercerized cotton

thread should^be used. Polyester threads often result in

puckered or lieavy unattractive buttonholes. The finer

your fabric is, the finer your cotton thread should be.

An interfacing should be used under the buttonholes to

give body, to strengthen, and to help them withstand

wear.

To establish the correct length of the buttonhole, add

the length of the button (A), plus the thickness of the

button (B), plus 1/32 inch for the bartacks. The length

may be marked on the garment with a basting stitch,

tailor's chalk, or an invisible cellophane tape, as shown.

HorizontSTbuttonholes should extend 1/8 inch beyond

the centerline of the garment. Vertical buttonholes are

placed so that the cutting space of the buttonhole is

directly on the center line.

Always make a practice buttonhole on a scrap of the

garment fabric before making any buttonholes on your

garment. On your test sample, duplicate the thicknesses

found in the garment and be sure to include the

interfacing. The test sample should help determine the

length needed for the button to pass through the hole

easily, as well as the stitch length needed for the

particular fabric. As with the satin stitch, the stitches

should be close together, but not so close that they pile

up. Be sure to use the buttonhole foot.

TER UNE-, .. ,■

3ARMENT .. :

S

Page 33

t

BUILT-IN BUTTONHOLE

Pattern: M or manual

[MODELS 415 & 426]

This buttonhole eliminates the need for pivoting

the fabric. It is used most often on light and

medium woven fabrics.

1. Set the stitch width control for the red square

marked (1) buttonhole position. Lower needle

into the mark at the top left end of buttorv

hole Lower jarosser foot and sew on the left

edge of buttonhole until you reach the bottom

end of buttonhole.

2 Stitch width control to the (2-4) position

take a few stitch to bartack the bottom end

of buttonhole.

Length: Buttonhole

Width: 1-2-3-4

Feed Dog: High-Down

Pressure: Full

Foot: Buttonhole Foot

Stretch Stitch: M

3. With the needle up, turn the stitch width

control to the (3) position. Sew on the right

edge of buttonhole.At this position the ma

chine is feeding in reverse.- ' •

4. With the needle out of the cloth, turn again to

the (2-4) position and complete the button

hole by barracking on the top edge

of

buttonhole.

To lock the stitches, make sure the needle is

out of the fabric and set width at 0 and feed

dog height down. Then take a few stitches.

6. To prevent cutting through the bartack insert

a straight pin through the bartack. Cut

buttonhole open.

32

Page 34

[Pattern: M or Manual*- Models 415 and 4263^

Length: Buttonhole ' '

Width: 2—0 ‘

Feed Dog: Down-High-Down-High-Down

Pressure: Full,,

Foot: Buttonhole Foot

Stretch Control: M

TURN-ROUND BUTTONHOLE '

1. Place material under presser foot to sew the

top or low end of marked buttonhole. Turn

feed dog height control to DOWN, hold

creative embroidery control at its right end

position, take few stitches to bartack the end

of marked buttonhole.

2. Turn feed dog height to HIGH, release

creative embroidery lever, set stitch width

control at 2, then, sew down the left edge of

marked buttonhole and finish stitching with

needle in fabric at the right side of stitches.

Set. feed dog at DOWN.

3. Lift presser foot and pivot the fabric around,

then lower presser foot and take one stitch to

left turning hand wheel by hand.

4. Pushing creative embroidery control to right,

take few stitches to bartack another end of

marked buttonhole.

5. Up feed dog to HIGH and sew down another

edge of marked buttonhole.

6. Lock thread by stitching a few stitches at 0

width and DOWN feed dog height. Cut center

" ,,open space of buttonhole carefully not to cut

into the stitches, as illustrated previously.

rK-y-

i

CORDED BUTTONHOLE

Cording gives a reinforced raised buttonhole. It is

excellent for use on bulky, woven fabric, or knits

in which the stitching often gets buried and

makes cutting difficult. On knits, a corded

buttonhole will help keep the fabric from

stretching out of shape.

Choose a heavy cotton crochet thread or

buttonhole twist to use for the cording. Proceed

as for the turn-around buttonhole having cord

the under the presser foot in such a way that

[Pattern: M or Manual-models 415 and 426]

Length: Buttonhole

Width: 2-0

Feed Dog: Down-High-Down-High-Down

Pressure: Full

Foot: Buttonhole Foot

Stretch Control: M

the zigzag stitch covers the cord.

At the completion of the buttonhole snip the

excess cord close to the bartack on woven

fabrics. For knitted garments, always pull the

cords to the wrong side by using a darning needle

or needle threader, and knot the cord ends

before clipping.

3:

Page 35

BLIND НЕМ STITCH [MODELS 415

& 426)

The blind hem stitch provides a durable hem

finish that is almost invisible on garments

drapes and curtains. It is done eas.ly w, h

Straight or slightly curved hems. With a little

nractice it will be a very quick and easy hern

practice It w^^^

application

repairing. .

n raw edge of hem in desired manner,

‘"’Lcr L overcast, 1/4 inch stitched under

pinked, hem tape, or just plaim (Step )

(2) Fold hem up desired length. Baste ot Pm 1/2

' inch from upper edge. Press m P'f f«/ 2'

(3) Fold hem back toward "Pht side of abr,c

' leaving about 1/4 inch ,e,

(4) Guide the fold of the fabric into the center

cut of the presser foot so that the zigzag bite

of the stitch comes just sl'9Ty to *e Jeft f

the center cut of the presser foot. ™ ale

<;tiches should be formed on the singe

thickness of fabric, and the zigzag||t^hou

catch just barely into the fold ofThe fabric at

'^it’l^rhra^ndrn"rrigrsTd:.'pm'^

WherhOTmlng^an A-line skirt,

basting stitch along the raw edge of the hem. At

an ironing board, fold up hem, matching the

seams Ease in the excess fabric by PU» ng on

basting thread. Press with steam, then apply hem

?ape. Baste or pin hem 1/2” from taped edge,

then continue into step 3.

Pattern; Blind Stitch or^

Length; 2

Width; 0

Feed Dog; High

Pressure; Full

Foot; All Purpose

Stretch Control; M

Ш

i»'

1

1|

!C:

34

Page 36

STRAIGHT STRETCH STITCH:

^ L *.■■■ ■■

> ^ ■:;

> ■■

■ ■ L *^.- .

mi

■ *-/.<:.s, . ■!

This stitch may be used on knits and wovens in

areas of stress as a reinforcement stitch. It is

excellent for curved seams such as armholes and

crotch seams. For active wear such as ski pants and

girdle fabrics which endure a lot of stress in

bending and stretching, this stitch may be used for

seaming throughout the garment.

[Pattern; Manual or M

—models 415 & 416]

Length; 5

Width; 0

Feed Dog; High

Pressure; Full

Foot; All Purpose

Stretch Control; S

CAUTION - It is difficult to remove this stitch

from fabric. Pre-fit garment before using this stitch.

• TOPSTITCHINQ

Because this stitch is heavier

than an ordinary straight

stitch, it is ideal for topsthching, particularly on

knits.

ULTRA-STRETCH STITCH;

The Ultra-Stretch Stitches are excellent for stretch fabrics such as lingerie, sweater

knits, bathing suit knits, and cotton knits. It has the greatest strength and elasticity

of all.

i£#.'

• RICK-RACK STRETCH

This is most common utility ultrastretch of a triple

back-and-forth zigzag stitches with more elasticity

than regular zigzag.

• PINE-LEAF STRETCH [MODELS 415 & 426]

This is the combined stitch of straight stretch and

single sideward stitches, useful for hemming on

most knits and stretchy fabrics.

• SPECIAL ULTRA-STRETCHES [MODEL 426]

These are very useful ultra-stretch stitches called smocking,

shown on pattern window, for various purpose.

Pattern; Manual or M

-models 415 & 426]

Length; 5

Width; 2-4

Feed Dog; High

Pressure; Full

Foot; All purpose

Stretch Control; S

Pattern; Blind

stitch or<!

Length; 5

Width;0

Feed Dog; High

Pressure; Full—Half

Foot; All purpose

Stretch Control; S

digger. Feather, etc, as

Pattern; Other than

above

Length; 5

Width; 0

Feed Dog; High

Pressure; Full

Foot; All Purpose

Stretch Control; S

Page 37

ECT'C^,'

OILING MACHINE

Use only a good sewing machine

oil, do not use any common

household oils. : ' _

Your machine should be oiled

occasionally to keep it operating

smoothly. How often depends on

the amount of sewing you do.

Once a year oil ;yo,ur machine

thoroughly as indicated by the

arrows on illustrations.

Avoid over oiling.

I- ■■ ■■

I 38

Page 38

MACH1N

•illf

mi

~

i»';

CLEANING AND OILING THE SHUTTLE

The stitch forming mechanism occasional

ly becomes clogged with loose threads

and lint. This will interfere with the

efficient operation of the machine.

Cleaning and removal of the lint will

safeguard the performance.

To remove the shuttle assembly, proceed

as follows:

1. Turn hand wheel until the needle

reaches its highest position. Tilt head

" back on its hinges.

2. Remove bobbin case (A).

3. Turn the two shuttle race cover clamps

(f) outward and remove the shuttle

race cover (C) and the shuttle body

(E) and the lint cleaner (D).

4. Clean the shuttle race, the shuttle, and

shuttle race cover by removing all

threads, lint, etc.

When the cleaning has been'completed, proceed as follows to replace the shut

tle assembly:

1. Turn hand wheel until the needle reaches its highest position.

2. Place lint cleaner (D) to shuttle driver and shuttle body (E) in race (F)

against shuttle driver and adjust into position.

3. Replace shuttle race cover (C), fitting pin at lower edge into notch, and lock

into position with shuttle race cover clamps, (f), making certain the clamps have

been snapped securely into position.

4. Put bobbin (B) into bobbin case (A).

5. Put the bobbin case into the shuttle, fitting tongue (a) into notch (c) of race

cover (C).

Page 39

ADJUSTING BOBBIN WINDER

It may be sometime required to adjust

the level of rear top thread guide to

conform with the level of bobbin winder,

especially, when thread winds unevenly

on bobbin.

If the thread winds unevenly on bobbin

as shown (A), loosen set screw of rear top

thread guide and move the thread guide

up slightly. If the thread winds as shown

(B), move the thread guide down slightly.

ADJUSTING AND CHANGING MOTOR BELT

te' V.: ■■

Following are the instructions for adjust

ing and changing the motor belt:

(1) Remove four screws holding rear

cover by tipping it out at the bottom

and pivoting around the hand wheel

away from the'front of the machine.

(2) To adjust motor belt, loosen screws

(A) and move bracket B up to loosen

belt and down to tighten.

(3) To remove motor belt:

• Remove top cover.

• Loosen clutch (C).

• Loosen screws (A) and move

bracket (B) to its highest posi

tion.

• Slip belt off motor pulley and

then over hand wheel.

• Replace motor belt by slipping it

over hand wheel and then over

motor pulley.

• Adjust as noted under No. 2.

--sf' ■'••V -»i-

40

Page 40

s '‘fp.'-.

■■

»

wm

№.

PROBLEM AND REMEDIES

i

41

Page 41

P-'Si

,n addition to the baaic set of a—rU«";,?;

:iai,^bTe"at‘:od::;"cosffo."voutd^

ifTecS ?he genu“ne°part desTgn^ for best performance wifo your machine. If a

"ewfng machine dealer is not available, mail your .nqmry direct to.

WHITE SEWING MACHINE COMPANY, 11750 BereaRoad, Cleveland,

Ohio 44111

or

WHITE CONSOLIDATED INDUSTRIES, LTD., 1470 Birchmount Rd,

Scarborough, Ontario, Canada.

ruffler

PART #1403

ATTACHMENT FOOT

DARNING SPRING

PART #4990

BINDER

NARROW HEMMER

PART #76316

EDGE-STITCHER

42

PART #82528

HEMMERS:

7/8"HEM

PART #76553

PART #74159

5/8"HEM

PART #76552

3/8"HEM

PART #76551

1/4"HEM

PART #76550

Page 42

ATTACHMENT FOOT

In order to attach binder, edgestitcher and the

hemmers, it is necessary to remove the presser

foot and replace it with the attachment foot.

Mount binder, edgestitcher or hemmers by

sliding the attachment to the left as far as

possible and tightening the screw.

The mounting slot enables you to sew as close to

or as far away from the edge as desired. Just

move the attachment to the correct position

before tightening the mounting screw.

EDGESTITCHER

The edgestitcher is used in making dainty lace

insertions, edgings and piping.

The slots in the edgestitcher serve as guides in

sewing together various pieces of material. If you

want to sew lace, lace and embroidery, or lace

and tucked strips together, place the piece of

material that will be on top in slot 1 and the

lower fabric in slot 4. For instance, if you are

sewing lace edging to a finished edge of fabric,

place the fabric in slot 1 and the lace in slot 4.

Be fSUrje'to draw the lace and material under the

needle and back of the edgestitcher so that the

feed will carry it backward as you stitch. Hold

the fabric in the left hand and the lace in the

right, being sure the fabric overlaps the lace

slightly.

Rick-rack-stretch can be sewn to the edge of the

material in the same manner.

To trim with wide piping place the fabric in slot

4, and the fold of the piping to the left in solt 3,

for a narrow piping place fabric in slot 2 and the

folded edge of the piping to the right in slot 3.

Slot 5 may be used as a guide in stitching a

French seam.

43

Page 43

BINDER

This attachment folds bias binding

and applies it to the edge of

material in one operation. Slots on

scroll of the binder are for corres

ponding widths of commercially

folded bias binding. '

The open mouth of binder scroll is

used for unfolded bias strips cut

15-16 inch wide.

FOLDED binding;

Cut folded binding to a point,

insert in appropriate slot. Draw

through slot and under binder with

strong pin. Test stitching to be sure

it is on the edge. Adjust by sliding

binder to right or left.

TWO-TONE BINDING

Two bindings can be sewn on fabric

edge also in one operation. When

two are used always skip one size

between widths, inserting each in

correct size slot.

HAND-CUT BIAS BINDING

Cut 15-16 inch bias binding fold in

half for a couple of inches. Cut

binding diagonally toward end,

almost to fold. Slip fold into center

of binder. Draw back until cut

opens and binding encircles open

end of scroll. Test stitching to be

sure it is on the edge, adjust if

necessary.

See suggestions on how to use the

binder. There are hundreds of other

uses.

44

Page 44

THE SET OF HEMMERS

Before attaching any of the hemmers, be sure bobbin thread is pulled up.

Then, with hemmer in place, hold top thread loosely and turn

handwheel one full turn toward you, making a loop under

hemmer. Grasp bobbin thread with both hands and slip horizontally under hemmer

toward back. Bobbin thread, will catch loop and carry upper thread to back of

hemmer.

Fold material to suit for two inches along edge, hold at each end of fold. Slip fold

into guide and up over spoon. Fold hem in material back of hemmer. Draw forward

to end of hem and fasten with point of needle. Pull on threads gently as you start

stitching. 1

If

i

' !if0.

You can make a hem 1/4", 3/8", 5/8" or 7/8" in width, depending upon which

hemmer you use. A few uses are shown below.

Page 45

RÜFFLER

The ruffler will produce yards of delicate ruffling or precision pleating.

Ruffling can also be done and sewn to another piece of fabric at the same time.

This highly versatile attachment despite its wide range of use, is simple to use.

Use the ruffler for making aprons, curtains, pleating a skirt, adding fullness to the

bodice of a dress etc. .

46

Page 46

to the

NARROW HEMMER

With needle at its highest position replace re

gular presser foot with narrow hemmer and ti

ghten it securely in place. Set stitch pattern se

lector of model 426 or blind stitch selector of

model 415 at mannual or M position. Zigzag

stitch width control at 0 for straight stitched

hem or at number 3 for zigzag stitched hem. Set

stitch length control to suit.

For a plain narrow hem make a 1/8 inch double

fold for about two inches along edge of fabric.

Hold each end of the two inch fold, slip

underneath hemmer. Bring fold up into the scroll

of hemmer, draw fabric forward to end and

fasten with point of needle. Lower presser bar

lifter. Gently pull end of thread as you start

stitching.

Guide material slightly to left and it will take a

double turn through scroll. - • . i

The narrow hem provides an excellent finish for

edges of ruffles or any other dainty work.

Page 47

LACE TRIMMED HEM

To sew a narrow hem and attach

lace in one stitching, insert lace in

the slot next to needle.Sew hem as

shown, guiding lace under needle

and hem into scroll. Rickrack

/

stretch may be used in the same

way.

LACE EDGE WITH INVISI

BLE STITCHING

Hold lace 1/8 inch from raw edge

on right hand side of fabric. Insert

both in scroll, as for plain narrow

hem, let hem roll over and sew in

lace. When the stitching is complet

ed the hem is pressed on the wrong

side.

FRENCH SEAM

Place material with right sides

facing each other and the top piece

of material 1/8 inch from right

hand edge of lower piece. Insert in

hemmer scroll allowing hem to roll

over and sew in top fabric making

French seam. For cording effect,

use zigzag stitch wide enough to

catch both edges of the narrow

rolled hem and sew with satin

stitch. This can be used for covering

chairs and so forth.

HEMMING ACROSS A SEAM

To hem across a seam, cut the seam

folds at an angle so they will lead

into the hemmer gradually. Press

seam open. Stitch across the seam

at the extreme edge to hold it

together and for added firmness. It

may be necessary to pull the

material slightly when hemming

over the seam.

48

Page 48

Loading...

Loading...