SINGER W3851 User Manual

(iitxiiVxtuit af (iwa rant ^^

This certifies that this Sewing Machine is thoroughly tested

and inspected in the factory and we can fully guarantee it

100% in conformity to A Grade Standard to meet user's best

facilities.

DEALER

............._..__.........._.

ADDRESS

................

_

CITY ................................_

....

.^STATE .

SIGNATURE

S-

INDEX

* general instructions *

Name of Parfcs

Introduction

Safe Guard the Action of Your Machine

To Wind the Bobbin ........................................................................... ....................................... g

To Replace the Needle ........................................

Needles and Thread ................................

To Thread the Bobbin Case ..........................................................................

Removing and Inserting the Bobbin Case .......................................

Threading Machine

To Prepare for Sewing ..................................................................

Thread Tension

Adjusting Pressure on Material

.........................................

............................................ ......................................................................

............................

4* V.

................................................................................

.....................................................................

................................................................................ ^

.............

...............................................................................

.........................................

.....................................................

Adiustng the Stitch ......................................................................................................................... |g

To Regulate the Zigiag stitch

Adjusting the Dropfeeder

To Oil the Machine................................................................................ ....................................

Sewing Hints

☆ OPERATING INSTRCTIONS * ^

Operating Instructions

Straight Stitching ................................................................................................................... 24

Zigiag stitching

For Fancy Embroidery Works ............................................................................................... gg

Embroidering and Monogramming ................................................*

Darning ..................................................................................................................................... 28

Sewing on Buttons

Hamming with Zigiag Sti iche« ................................................................................................ la

Blindstitching .......................................................................................................................... gg

Quilting ................................................................................................................................... 3Q

Cording ..................................................................................................................................... g]

Button Holes .................................................................. _ _ gi

Adjustable Cloth Stitching Guide ..................................................................................

.............................................................

..................;.......................................... ...........................................................

............*.......................

....................................................................... ..........................

.........................................................................

....

.................................

^ ^

............................................................................. 2g

.

...........................-......

........................................

..........................

.....................................

............................................

...............................

...............

.................

"..................

2

3

^

g

g

(Q

11

12

^g

2^

gg

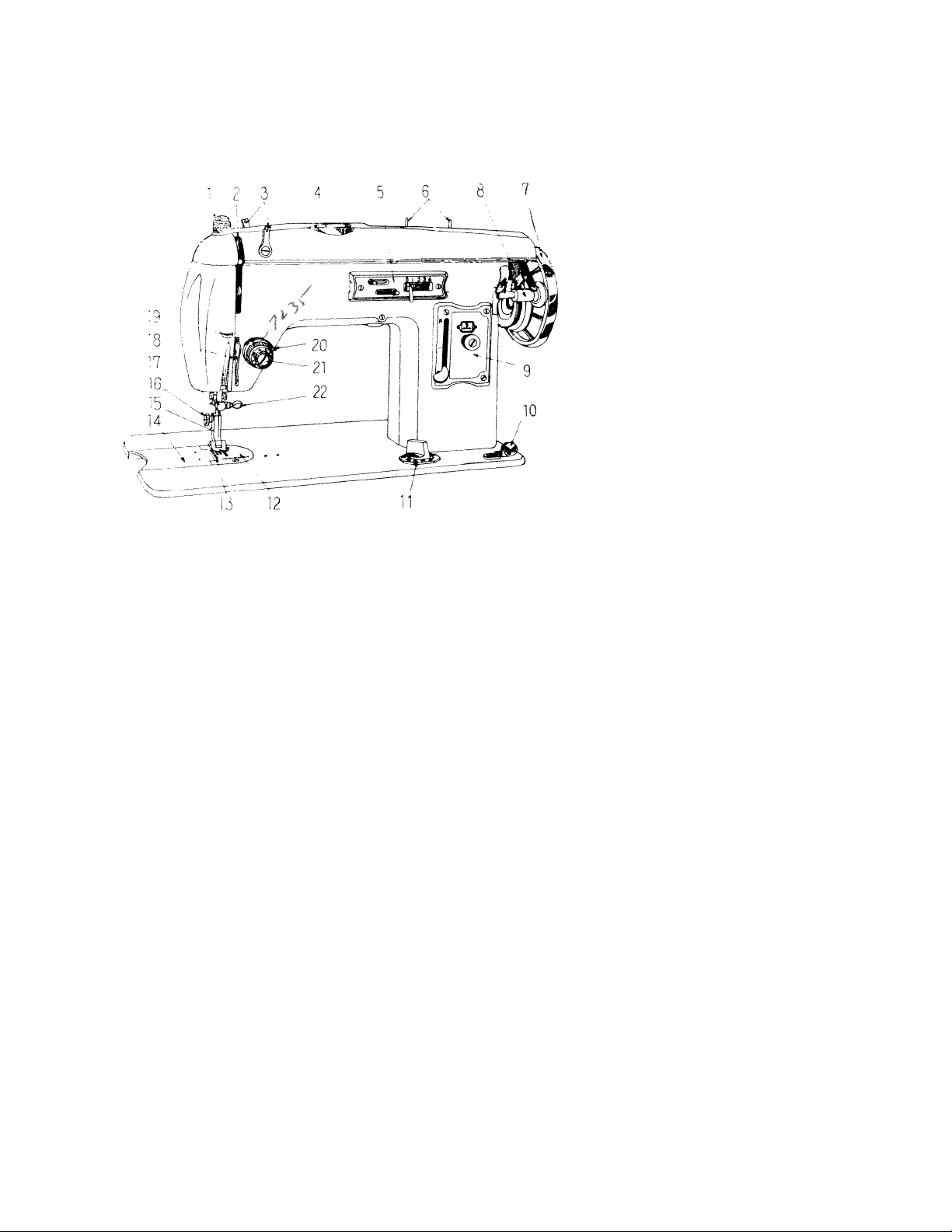

1. Patch-O-Matic Darner

2. Take- up Lever

3. Arm Thread Guide

4. Cam Holder

5. Zigzag Width Regulator

6. Spool Pin

7. Balance Wheel

8. Automatic Bobbin Winder

9. Stitch Length Regulator

10. Bobbin Winder Thread

Guide

11. Drop Feeder

12. Needle Plate

13. Feed Dog

11. Hinged Plate

15. Presser Foot

16. Presser Foot Thumb

Screw

17. Needle Clamp Thread

Guide

18. Retaining Thread Bar

19. Thread Guide

20. Wire Check Spring

21. Thread Tension Dial

22. Needle Clamp Screw

INSTRUCTION MANUAL FOR ZIGZAG

INTRODUCTION

Your Zigzag sewing machine is the product of many years of research and development in the field

of household sewing machines. It is also the ultimate in efficiency, quality and design, yet its moving

and wearing parts such as needles, bobbins, bobbin cases, hooks and so forth are standard and

interchangeable with parts immediately at sewing machine stores throughout the world.

This precision sewing head, with its simplified design and many labour saving extras, is the result

of our incessant exertion and each machine is built to the most exacting specifications under our

rigid quality control program.

You have made an excellent choice and you are deserved of the proud owner of Super De Luxe

sewing machine, which will surely lead to your happy life. You will soon realize how quickly you

will become attached to your new machine as a friend of the family who really lends you a hand.

The ingenious construction makes it possible to do many jobs on the new machine which until

now had to be done by hand.

SAFE GUARD THE ACTION OF YOUR MACHINE

Make sure the balance wheel always turns toward the operator.

Never run the machine with the presser foot in the down position without cloth between the

presser foot and the feed dog.

Never run machine when the bobbin case and the needle are threaded without first placing

material under the presser foot.

Caution, never try to help the machine feed by pulling the material through the feed. This will

create a bent needle condition. The machine’s feed is entirely automatic.

Never operate the machine without the hook race cover the bobbin case in position.

Keep a small piece of cloth underneath presser foot whenever machine is not in use. This will

prevent damage to feed dog and presser foot.

Do not operate machine when presser foot lever is raised.

Keep slide or hinged closed when operating machine.

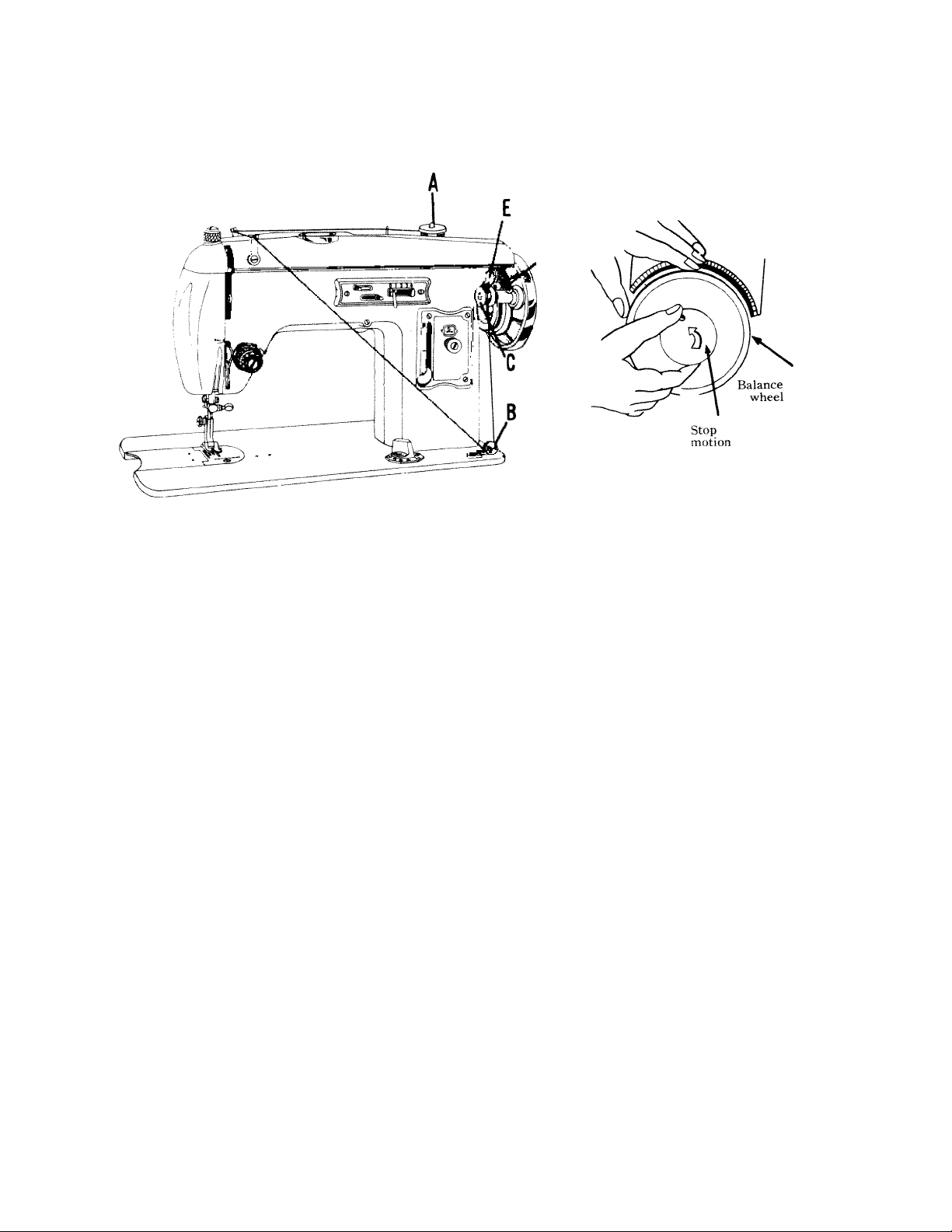

TO WIND THE BOBBIN

It is necessary to understand the function of the Stop Motion by means of which the balance

wheel is disconnected from the sewing mechanism, when required, thus permitting the winding of

the bobbin without sewing. , , , i t ■ c .u i r*

a) Turn the stop motion knob toward you while holding the balance wheel with the left hand.

This will then permit the balance wheel to turn freely while the needle bar remains motio

nless. ^

Place a spool of thread on the spool pin at backside of arm.

b)

Pass the thread through the notched thread guide (3).

c)

Draw the thread down through the bobbin winder thread guide (16) at right corner of the

d)

base of machine. . t • j i

Now wind the end of the thread around an empty bobbin seven or eight times and place

e)

threaded bobbin on the spindle (C) of the bobbin winder.

Press the bobbin into the spindle with the left hand, making sure that the Pm on the spindle

f)

fits into the slot in the bobbin. . ,

Push the bobbin winder levever (D) down until the small rubber wheel presses apmst the

g)

hub of the balance wheel and the clasp (E) falls between the sides of the bobbin holding it

Tum*the”balance wheel toward you and run the machine as in sewing. When bobbin is full,

h)

the bobbin winder will automatically stop.

Break off the thread and detach the bobbin from the spindle.

i)

Hold the balance wheel firmly with left hand and with right hand turn the stop motion knob

j)

away from you until the machine is tight and then the needle bar moves with the turning of

the balance wheel. ,

can perform this operation also when the machine is working. In this case you will operate

You

in the same way as explained above, but without disconnecting the balance wheel.

knob

TO REPLACE THE NEEDLE

li) llu- tuH‘(iie. r;nst.‘ tlu‘ i>ar iu us higiiesl

])oiiU 1>\‘ Uirniii^ ibulaius- wluu'l ii)vvar(i you i)y haiui.

Louscii llu- iR-edlc alam|) screw on ihe ne|il hand --Kie

and die needle clamp will open, allowing die old needle

!o tall oiil.

Remove die old needle and elide die new needle up

i-i„\i^ Slid-; row.xKi) idii; ii\i..\.\n-; wiikkl as

lar as U will yo, Wdu-n the needle hils die slo|) il is in

nosilion corri-clKv Now tasii-ii die needle clamp sneurely.

I-'or liesi resnils clianye ni-edli-s Ircipienlly.

FLAT

S I DE.

NEEDLES AND THREAD

Never use a bent needle, nor one vvidl a blunt point, since this cause imperleel stitches and may

cause the needle to break. Unless the needle is in clear to the stop, liât sidi- toward the baiaiue

wheel, the niaehine will be out of "'rime,'' and skipped or iinperfeet stitches will result and needles

may break.

rhe size of the needle should conlorm to the size ol the thread and both should be suitable to the

material. Use a needle suffieiently large to permit the thread to pass freely through the eye. In

general sewing, use ihe same size thread in the bobbin as is used on loi).

1)

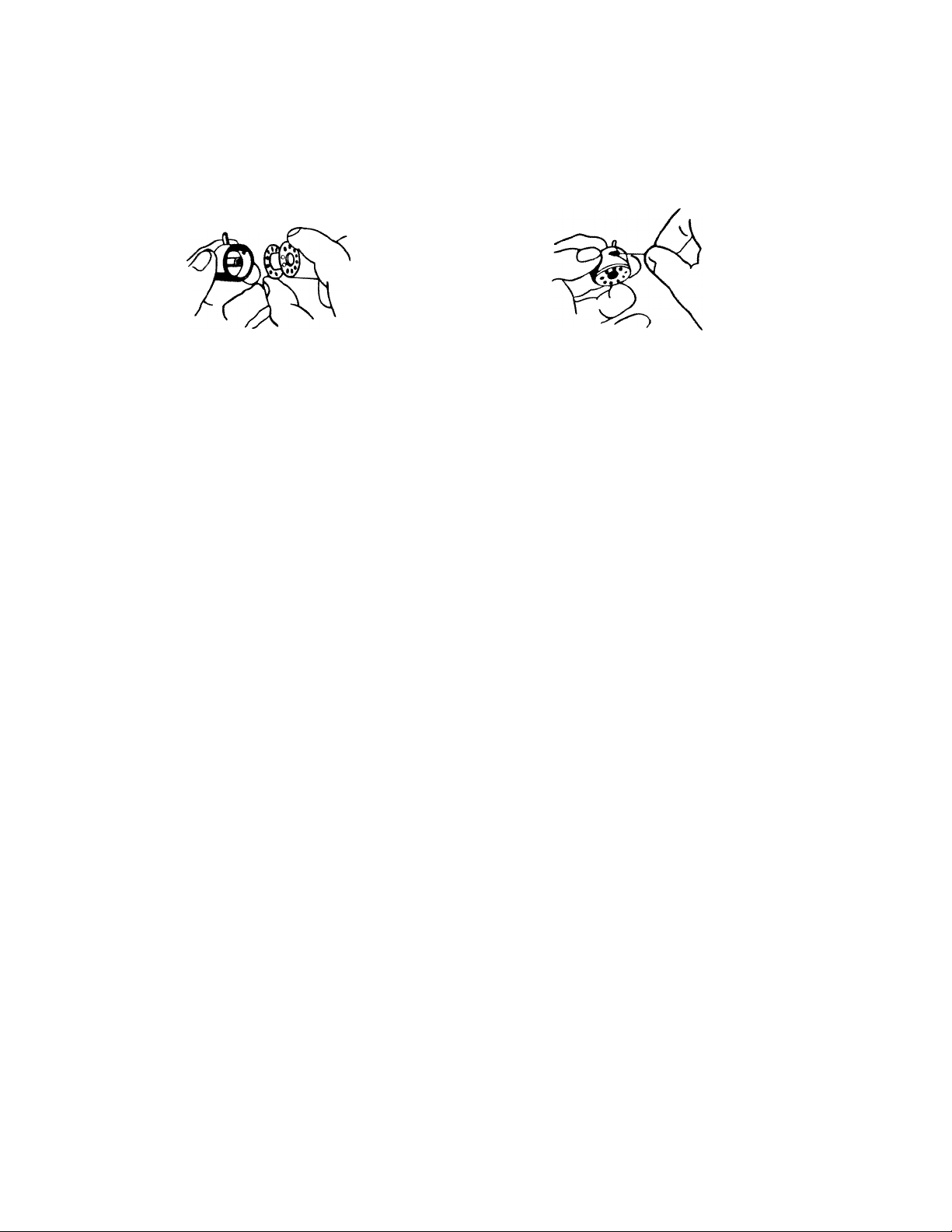

TO THREAD Tm BOBBIN CASE

(A)

(B)

Hold the bobbin case between the left thumb

and forefinger with the slot up. With 5 or 6

inches of thread trailing in the palm, hold

the bobbin between the thumb and first two

fingers of the right hand. Fig. (A)

Insert the bobbin into the bobbin case and

pull the trailing thread into the slot, down

and to the left until it enters the delivery eye

under the tension spring. (A, Fig. C)

Fig. (B)

There should be a slight tension on the thread as it

is pulled through the delivery eye and the bobbin

should unwind freely. The tension may be increased

by turning the tension screw tB) to the RIGHT and

decreased by turning the screw to the LEFT.

Fig. (C)

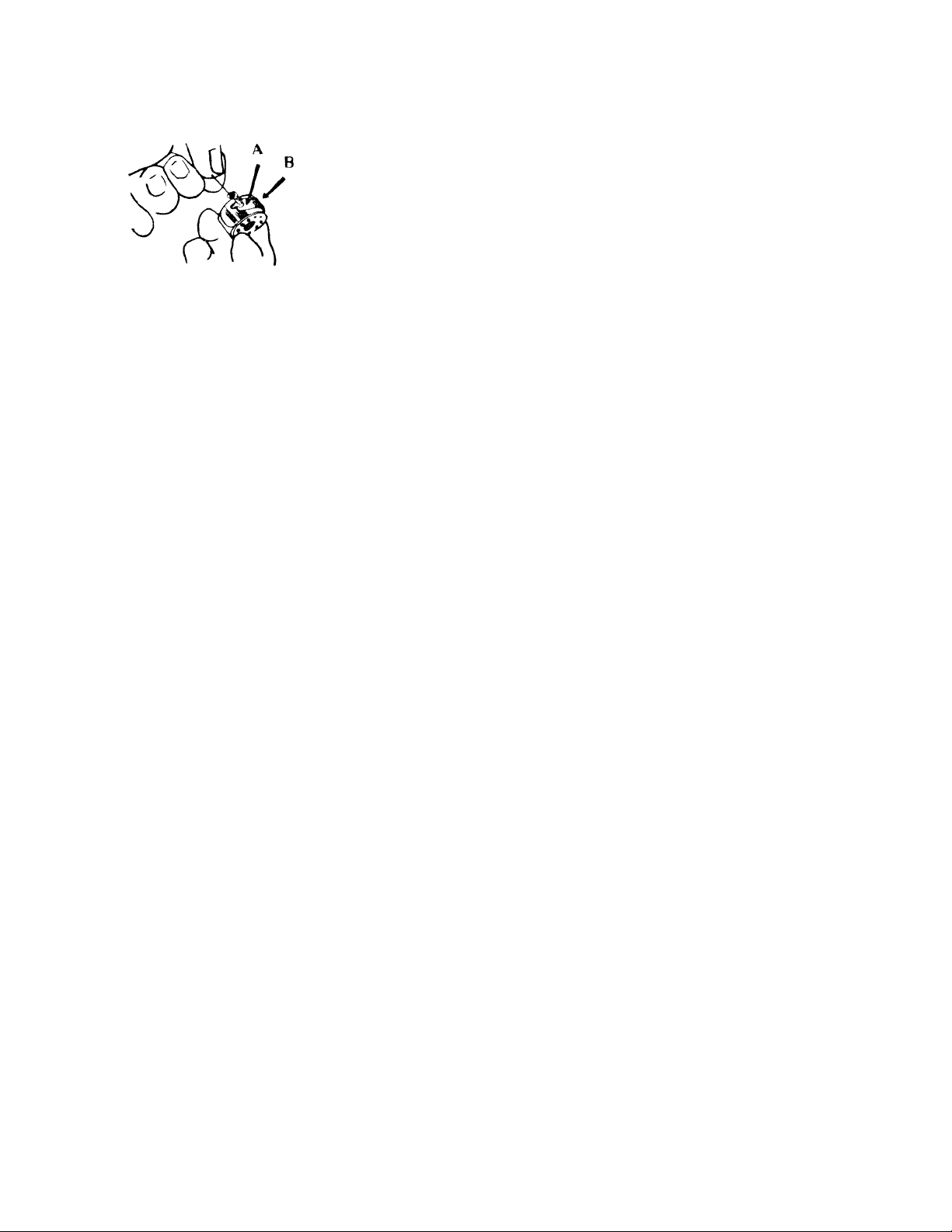

REMOVING AND INSERTING THE BOBBIN CASE

In the following operations the needle must always be ABOVE the surface of the machine.

Raise the needle by turning the balance wheel TOWARD YOU by hand.

Raise the hinged slide plate, with left thumb and forefinger, open the hinged latch (A) at the

front of the bobbin case and hold securely as you withdraw bobbin case from around the holder

post. When held in the above manner the bobbin will not fall out of the bobbin case.

After winding a fresh bobbin and threading the bobbin case, latch (A) with left thumb and

forefinger, to prevent the bobbin from falling out.

Loading...

Loading...