Page 1

Page 2

CONTENTS

1. Description of Machine

2. Sewiight

3. Installing Head into Cabinet

4. Threading the Machine & Needle

5. Threading the Bobbin Case ................................................. 5

........................................................................................................

........................................... ?

............................................................

.......

......................... ..............

” 3

...............

3

4

6. Inserting and Removing the Bobbin Case ......................’T” 6

7. Cleaning the Shuttle Race

8. Preparing for Sewing

9. Starting Sewing

10. Setting the Needle

11. Pushbutt jn Drop Feed (Feed Dog Position Regulator)

12. Regulating the Thread Tension

13. Pushbutton Darner (Presser Foot Pressure Reguiator) .,.’rr 11

14. Winding the Bobbin................................................................................

15. Regulating the Stitch Length for Forward Sewing.

16. Regulating the Stitch Length for Reverse Sewing

I!- Regulating the Stitch Length for Zig-Zag Sewing

18. Regulating Width of Zig-Zag Stitch

19. Regulating Length of Zig-Zag Stitch

20. Inserting the Disc

21-22. Sewing Design

¿0, Oiling...................

24. Button Sewing

25. Making Buttonholes..

26. Darning, Embroidering & Monogramming................. , 2I

27. Narrow Hemmer

28. Sewing Braids............................................................................................ oa

29. Felling........................................

30. Cloth Guide................................................................................................. 24

31. Quilting.......................................................................................................... 24

32. Causes of Common Difficulties

33. Needle & Thread Size

..........................................................

....

.......................................

.

.......................................

............................................’......

....

.............................................................................

...........................................................

........................................

.......

..............................

..................... . . * '

....................................................................................

.................................................................................... 22

......................................................................

..................................................................

...................................................................................

' 9

........................................................ jq

................! ..

....................................................... 14

.ZZ’''.'.','.’.'.'.'' 16.'' 17

......

....... 18

........................................... 19

........................

'.

...............................

..............................

...................................

' ’ ‘ 14

..................

..............'13

...

...............

7

g

g

9

‘‘‘] 12

13

13

«

20

25

26

Page 3

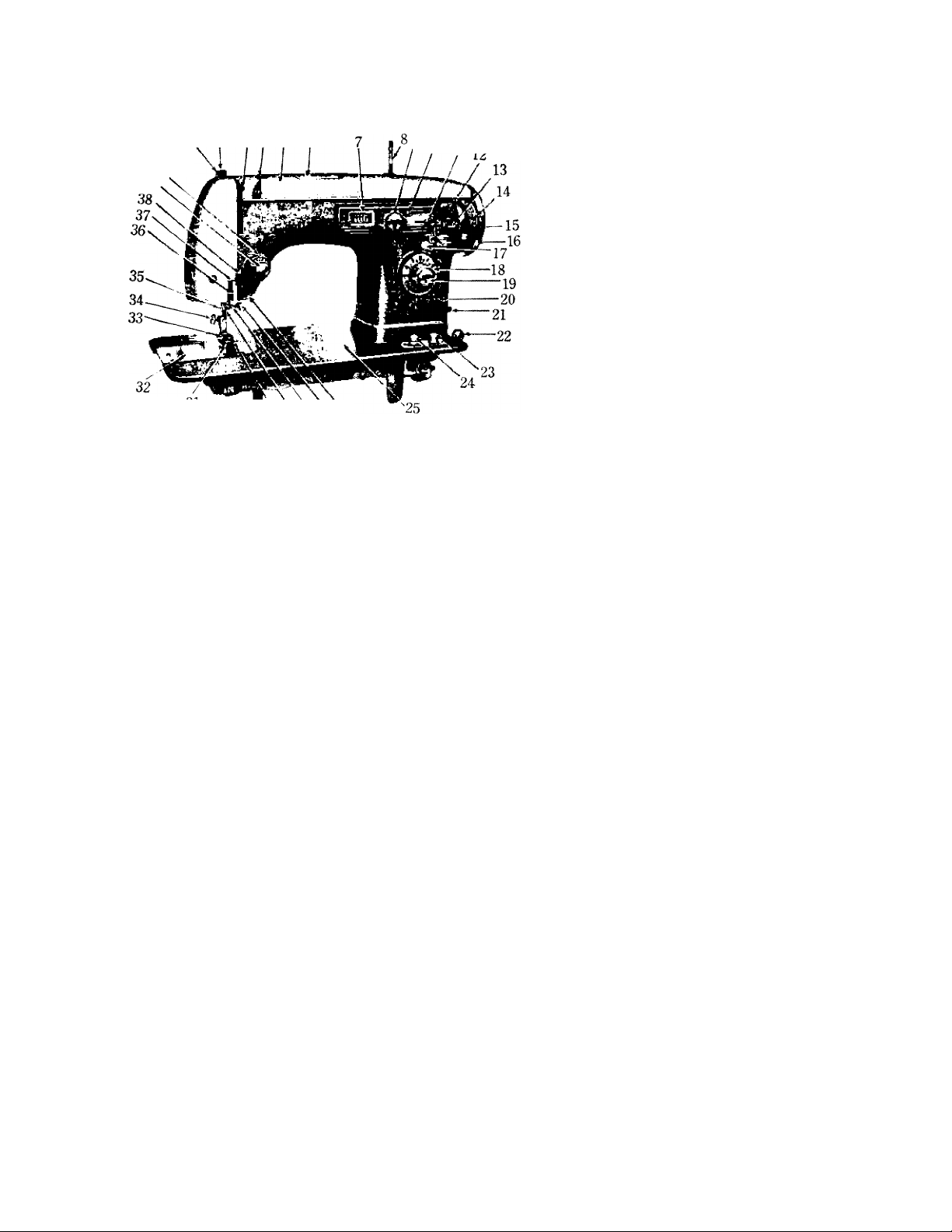

MacJtme.

1 2 3 4 5 6

40

39

10 29 28 27^6

1-2 Pushbutton darner

3 Thread take up lever

4 Upper arm thread guide

5 Arm cover

6 Automatic stitch cam puli lid

7 Zigzag width indicator

9 10 11

8 Spool pin

9 Zigzag width dial

10-11 Zigzag width stoppers

12 Bobbin winder release lever

13 Bobbin winder shaft

14 Bobbin winder push plate

15 Bobbin winder rubber wheel

16 Balance wheel (hand wheel)

17 Pushbutton stitch reverse

18 Stitch length indicator

19 Stitch length dial

20 Vertical arm

21 Sewlight switch knob

22 Bobbin winder thread guide

23-24 Pushbutton drop feed

25 Bed-plate

26 Vertical arm ,

27 Needle clamp screw

28 Needle clamp

29 Needle

30 Needle plate

31 Feed dog

32 Slide plate

33 Hinged presser foot

34 Presser foot thumb screw

35 Presser bar

36-37 Face plate thread guides

38 Thread retainer bar

39 Calibrated thread tension dial

40 Thread take-up spring

Page 4

Beudlfiii

I'he lamp housing is located at the front side

of the arm under the arm cover (Fig. 2).

The light switch knob is located at the riglit

side of the vertical arm. To switch on the

light turn the light-switch knob clockwise or

counter-clockwise. To switch off the light

turn the light-switch knob clockwise or

counter-clockwise. In order to replace a

burnt out bulb with a new one, loosen the

two screws on the top of the arm-cover and

remove the cover. Bulbs (15w) may be

obtained at dealers, department stores and

electricals stores.

Sewlight Switch knob

Fig. 2

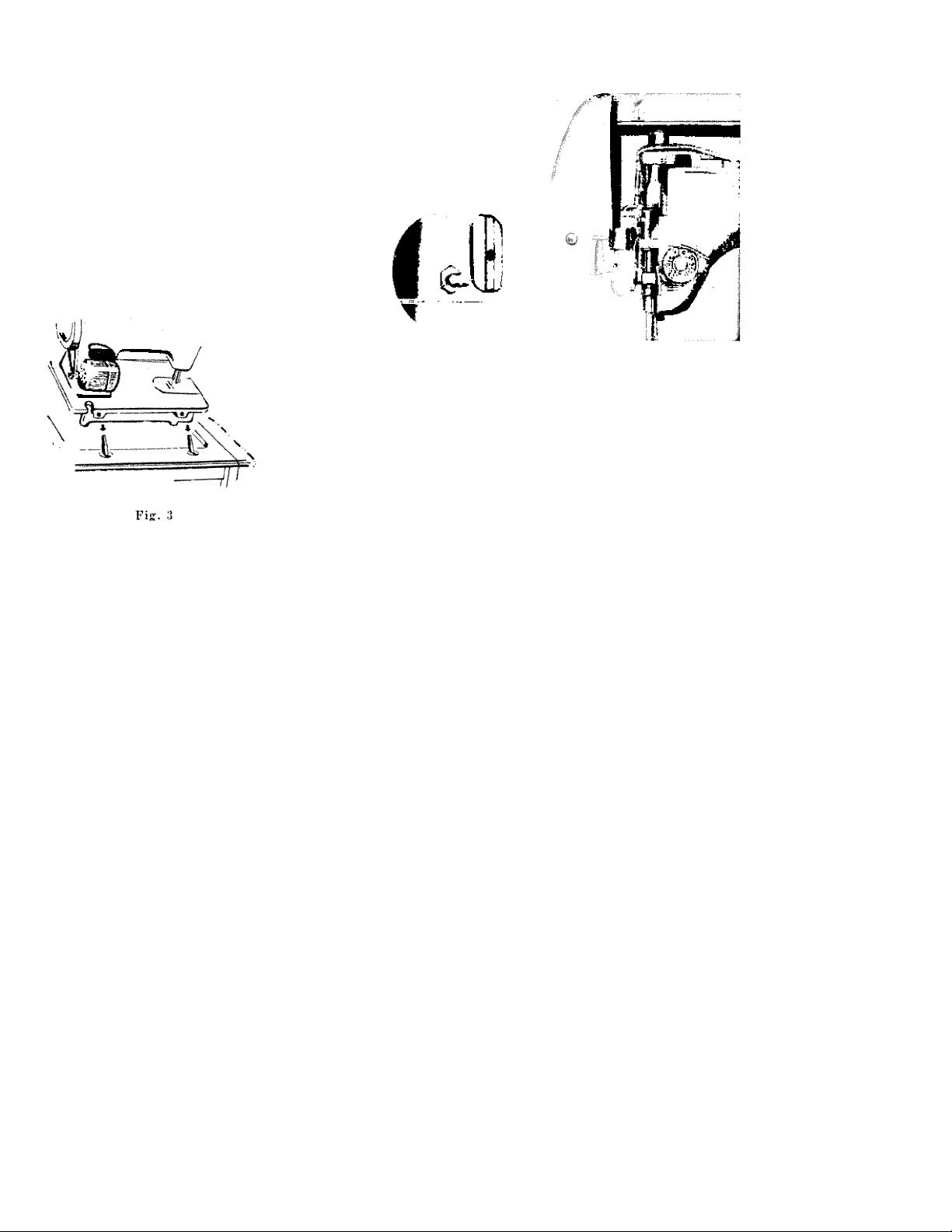

9*ti4kUUHi(^ eMead ¿*tta QaJUaet

1. Loosen the two hinge screws under the holes in the rear

edge of the machine bed. (Fig. 3)

2. Raise hinge pins in the cabinet cutout. Slip machine head

on to the pins and tighten hinge screws securely.

3. Lower machine head to front cabinet flap.

Page 5

*JU^eadiHf the Maokine. & Needle

1. Turn the balance wheel toward you to raise the needle

bar to its highest position.

2. Place a spool of thread on the spool pin.

3. Lead the thread through the arm thread-guide Fig. 4).

4. Draw the thread down through the thread-guide to the

tension discs from right to left and up.

5. Draw the thread up through the check spring.

6. Draw the thread under the thread retainer bar and take

the thread up, and run the end through the eye of the

thread take-up lever from right to left.

7. Draw the thread down through the face plate guides and

then through the needle clamp thread guide.

8. Draw the end of the thread through the eye of the needle

FROM LEFT TO RIGHT, drawing it through about 3 or

4 inches. You are now ready to sew.

Pig. 4

Page 6

Ute BoJfJUn Qaie.

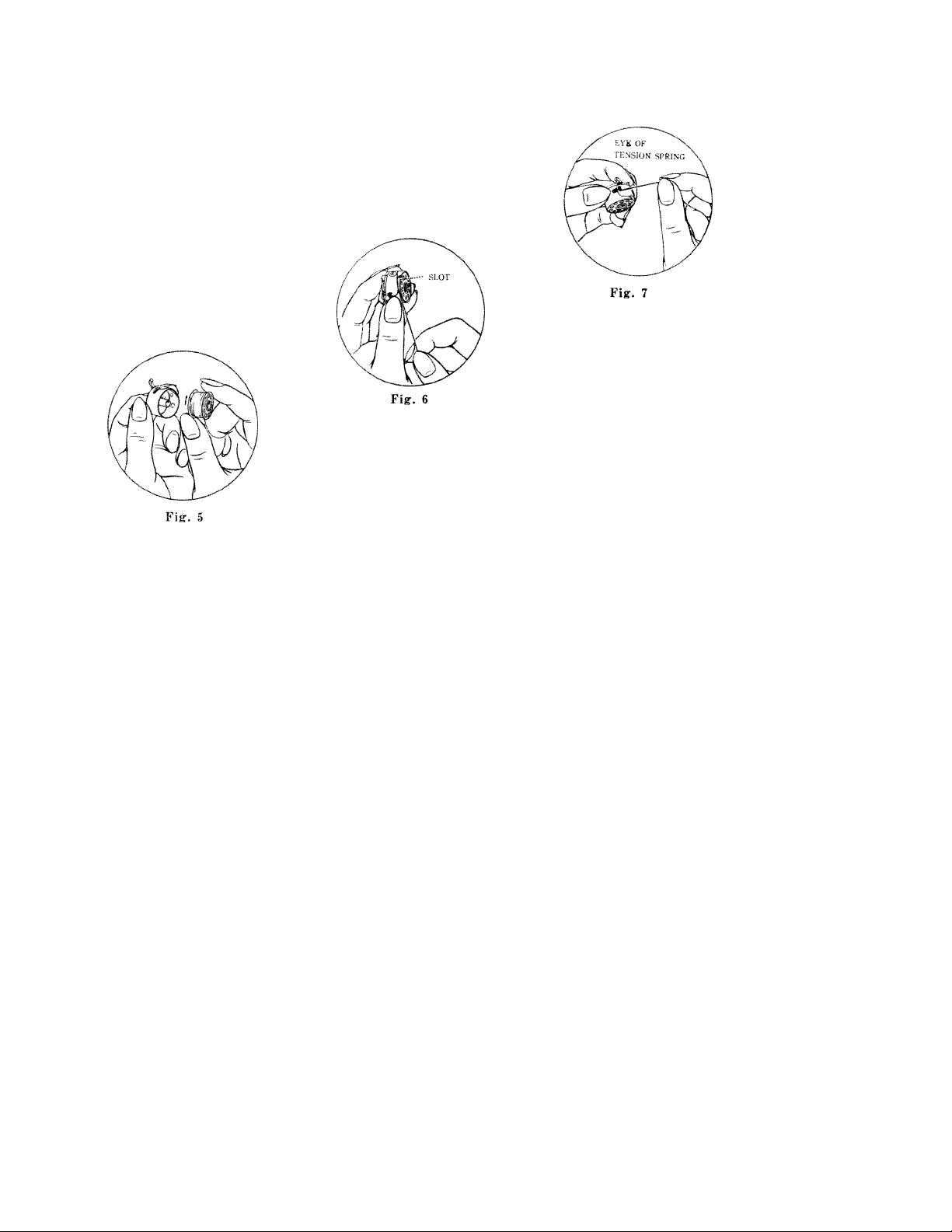

Before threadinji the bobbin case, study Fig. 5, 6 and 7 to get a

general idea as to how it is done.

1. Hold the bobbin case with your left hand and put the bobbin

into the bobbin case with your right, leaving about two inches

of the thread end unwound

(Fig. 5). As the bobbin is

being inserted in the bob

bin case, the thread flow,

you will note, in clockw'ise

(Fig. 5).

3, I'hen pull it through under the tension spring of the

bobbin case (P'ig. 6) until it enters the delivery eye

(Fig. 7).

2. While holding the bobbin

case as before, grasp the

thread end with your right

hand, guide it into the

cross slot (Fig. 6).

...

Page 7

and I\em04un(f, tite RaUt-in Gale

1, Raise the presser bar by lifting the presser bar lifter.

2. Raise the needle bar to its highest position by turning the

balance wheel toward you.

3, - Pull out slide plate (Fig. 8).

4. .‘\fter threading the bobbin case, hold its latch (Fig. 9) betw^een

the thumb and forefinger of left hand, with its position finger

, . opposite the notch at

the top of the shuttle

race and replace it on

the center stud of the

shuttle (Fig. 9).

5. Then release the latch

and press the bobbin case back until the latch catches the

groove near the end of the stud.

6. Allow the end of the thread to hang free.

7. Pull back slide plate.

Fig. 8

To remove the bobbin case do all the above in reverse order.

Pig. 8

Page 8

ClzaH.i4Uf, tlm Slu4>tile Rjcux.

When the thread is tangled in the race or lint gets into the

space between the shuttle and shuttle-race, this will cause

abrupt heavy running or complete stoppage of the machine.

When this occurs

L Raise the needle bar to its highest position and take the

bobbin case out.

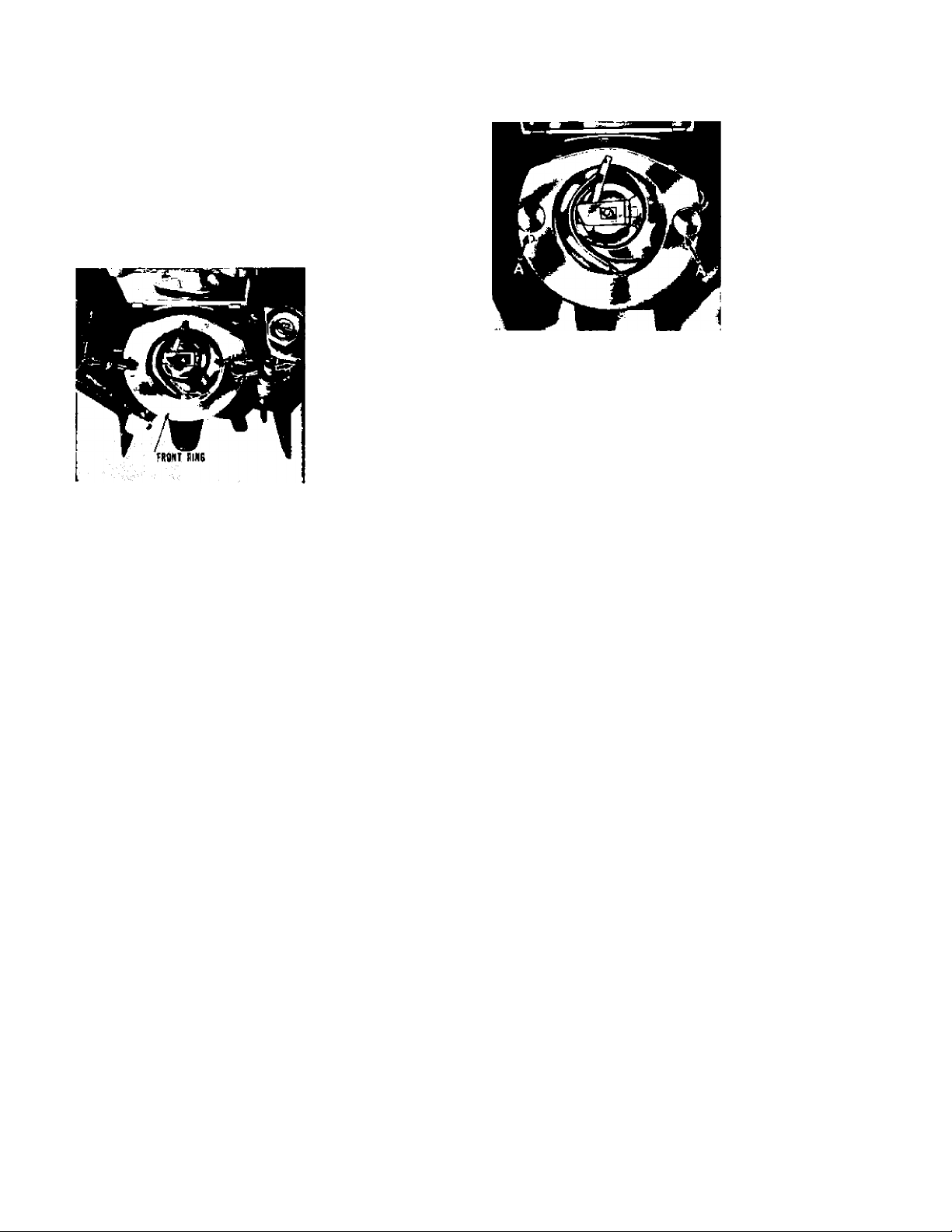

2. Pull the KNOBS (A) on both side of shuttle race (Fig.

10 & 11) aside, then take out the outside ring and the

shuttle body with your fingers.

Fig. 11

3. After shuttle-race and bobbin case have been cleaned,

put all of them back in reverse order

Fig. 10

Page 9

Pfmpxs/UajSf Se4AU4t^

1. Hold the end of the upper-thread with the left hand, leaving

it slack from the hand to the needle.

2. Turn the balance wheel toward you to raise the needle bar to

its highest position.

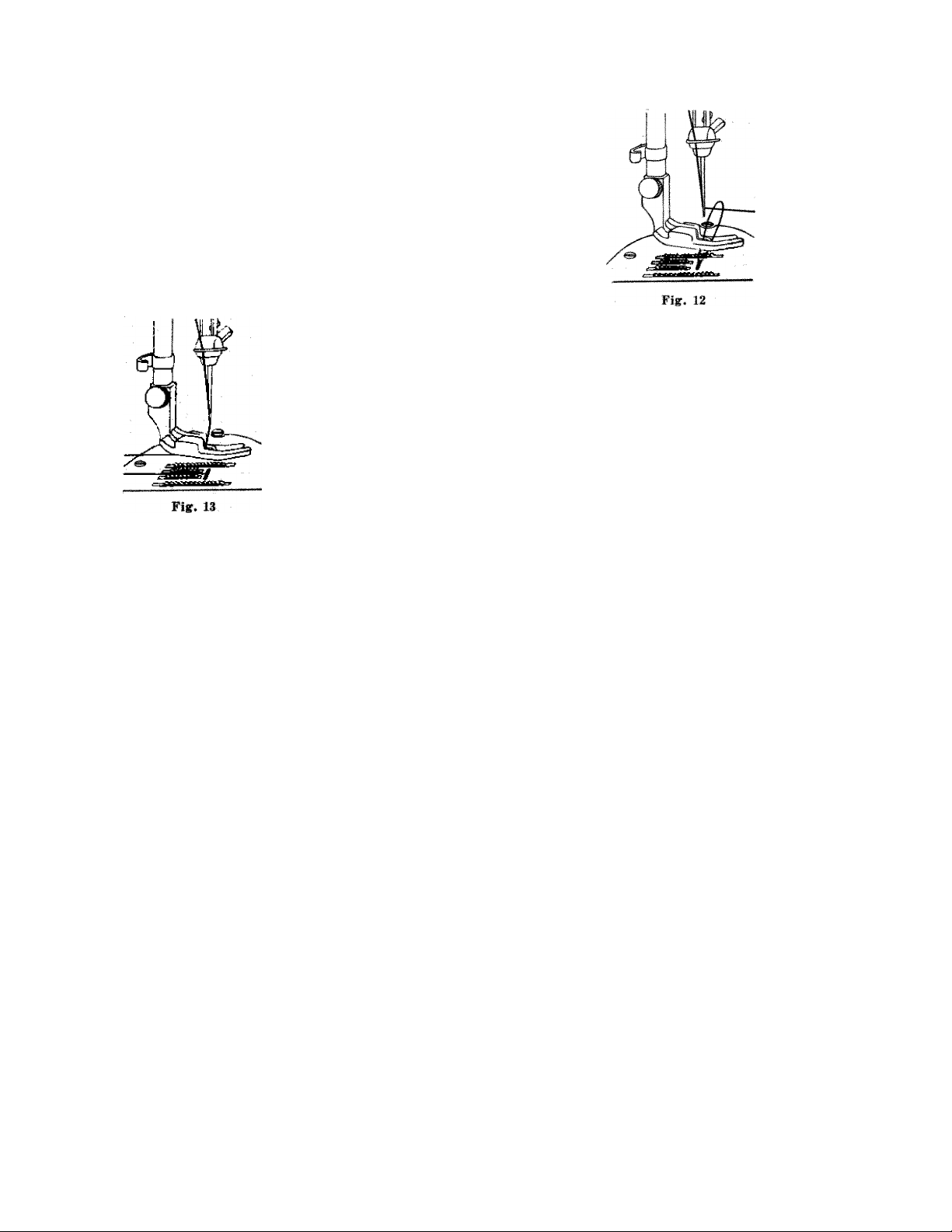

3. Pull the thread you are holding, as the lower thread will be

brought up with it through the hole in the needle plate, as

shown (Fig. 12).

4 Place both ends of the upper and lower thread to the back of

the presser foot (Fig. 13).

1. Place the fabric to be sewn beneath the presser foot.

2. Lower the presser foot by lowering the presser bar lifter.

3. Start sewing by slowly turning the balance wheel in directic n

toward you while gradually working the foot or knee control

ALWAYS TURN BALANCE WHEEL TOWARD YOU !

Page 10

Setii4iXf, tlte /Needle

1. Turn the balance wheel toward you. raising needle bar to its

highest position, and loosen the needle clamp screw.

2- Hold the needle in the left hand with the point down, and

insert the needle up into the needle clamp as far as it will go,

with its flat surface to the right; then retighten the clamp

screw (Fig. 14).

Puikh*iiio4t ^nofi ^eed i^eed Paidtla*i Pefulatan.)

The PUSHBUTTON DROP FEED is located on the bed of the machine.

It regulates the position of the feed dog for sewing very thin

material and for darning and embroidering.

1. For sewing very thin material, push down the left side

knob (B) until the red mark line reaches the surface of

the plate.

2. For darning, embroidering and tnonogramrning, push

down the left side knob (B) completely and the feed

mechanism will be lowered under the lever of the stitch

plate, so that the material can be moved freely.

3. For normal sewing, push down the right knob (A) com

pletely.

(Fig. 15)

Fif. 16

Page 11

the *7lpiead

Correct Stitch

Needle Thread Tension too strong

Needle Thread Tension too weak

Fig. 18

As all machines are correctly adjusted

before leaving the factory and read

justed before the dealer delivers them

to you, the lower tension seldom re

quires to be altered, but, if this

becomes necessary, tighten the screw

in the tension spring on the outside of

the bobbin case for more tension, or

loosen the screw slightly for lesser

tension (Fig. 16).

For ordinary stitching the tension of the upper and lower

threads should be equal so as to lock both threads in the

center of the material (Fig. 18). If one tension is stronger

than the other, imperfect stitching will result. Fine

materials require a light tension, while heavy materials

require more tension to obtain a perfect stitch.

TO INCREASE the tension, turn the thread tension dial

(Fig. 17) clockwise.

TO LE)SSEN the tension, turn the thread tension dial in

the opposite direction. (When regulating the tension

always have the presser foot down).

\

fig. U

Fig. 17

Page 12

PudJiiuitoH, (PfieAde^ ^oot PnoAiMne. Pe^niaton,]

The PUSHBUTTON DARNER is located on top of the machine

directly over the presser bar (FiR. 19 & 20). It regulates the

pressure of the presser foot for sewing very heavy material, very

thin material, and for darning and embroidering.

1. To eliminate the pressure of the presser foot for darning,

11

embroidering and inonogramming, push down the OUTSIDE

RING of the PUSHBUTTON DARNER (A) and the material

can be moved by hand while the machine is running at a

fair speed. (Fig. 19)

2. To increase the pressure of the presser foot for sewing very

heavy material, normal material and very thin material, push

the PUSHBUTTON DARNER (B) gradually down to increase

the pressure of the presser foot accordingly. (Fig. 20)

Fig. 19

Fig. 20

Page 13

12

Windiw^ the BaLLUi

3|§ To wind the bobbin, the balance wheel must be disconnected from the stitching mechanism,

the balance wheel with your left hand and turn the

stop motion knob (Fig. 22) toward you with your right

hand. This will permit the balance wheel to turn freely

while the needle bar remains motionless. The balance

wheel is now disconnected for the bobbin winding

, operation.

2. Place a spool of thread on the spool pin. Draw thread

from the spool over arm guide down ward across

,, machine from left to right. (Fig. 21)

Pass the thread through the tension disc of the bobbin

winder thread guide located at the right corner of the

machine bed.

4. Now wind the end of the thread around an empty

' bobbin seven or eight times and place the threaded

bobbin on the spindle of the bobbin winder.

5. By pressing on the bobbin winder lever, the small

rubber wheel is brought in contact with the balance

wheel. To lock into position, press bobbin winder lever

until a click is heard. The bobbin winder stop latch

is now touching the shaft of the bobbin. It holds the

bobbin in place.

6. Now manipulate your foot control or knee control in

the same manner as in sewing and when the bobbin is

completely full it will release automatically and stop

turning. Detach bobbin from spindle. Hold balance

wheel firmly with left hand and with the^ right hand

turn stop motion knob away from you until it can not

be moved any further and the needle bar moves with

the turning of the balance wheel.

Page 14

R.e^i4icUiM4f the StUcU Jle*ix^tlt

^ondAMsAxi SeiuiHif

The length of the stitch can be changed with the stitch length

dial (Fig. 23). In order to set a certain length of stitch, turn

the dial from 0~4 until the selected number on the scale is

facing the alignment mark on the stitch length dial. The

length of the stitch is increasing from 0~4. The normal

stitch is 2.

(leAfXxJatiHAf tUe. StitcU jHetUftU

/^e4*e^Ue SetiUAtf

a. Regulate the length of the stitch as for forward sewing

(see above).

b. Push reverse stitch button located above the stitch length

(Fig. 23) as far as it will go. The machine will then sew

in reverse with the same stitch length as previously select

ed. During reverse sewing, push the reverse stitch button

all the time. After release the machine resumes forward

sewing with the same stitch length.

UtA StiioU JBexu^tU Sewixuf

The stitch length dial regulates the length of the zigzag stitch for zigzag sewing in the same

manner as for straight sewing. In order to produce the "Satin Stitch” which is the closest zigzag

stitch, set the stitch length dial close to 0.

Fig. 23

13

Page 15

14

(le^44latit€c^ WuJUlt StitcU

The width of the zigzag stitch is regulated by the zigzag

width dial (Fig. 24). By turning the zigzag width dial,

the zig-zag width indicator appearing in the zigzag

width window, will move from 0~4 and the width of

the zigzag stitch will increase accordingly. In order to

revert to the previously used zigzag wddth, for ex

ample, for sewing on buttons, making buttonholes,

tacking, etc., use the twa> stoppers hw'ated above the

zigzag width wdndow. Untighten the stoppers by turn

ing the lock screw to the left. I'he stoppers can be

moved freely and set at the desired stitch width number.

Fighten the stoppers and fix them at the desired stitch

width number by turning the lock screw to the right.

Fig. 24

The stitch length dial regulaters the length of the zigzag stitch tor zigzag sewing in the same

manner as for straight sewing (See page 13). To produce the "Satin Stitch” which is the closest

zigzag stitch, set the stitch length dial close to 0 and adjust the pushbutton drop feed (feed dog

position regulator) according to the material you are sewing. (See page 9)

Page 16

tUe ^i4jc

To insert a zigzag disc into the machine follow these instructions;

1. Pull lid ;A) open.

2. Push zig zag width dial :Bi to the e.xtrenie right, and keep it

there during insertion. ‘

3. Insert disc onto a.xle ;Ci. Turn disc until it slips down and

the retaining pin ;D) enters hole ; E; in disc.

4. Release dial (B).

5. Close lid (Ah

To remove the disc, open the lid, push dial B) to the right and

pull disc up.

Now you can insert .another disc to produce another design.

Cams attached to the machine)

Fig. 26

Page 17

!î^

<> ■■ . ■■ . ' . . ' >

'' Л >

,;:Â- ^

'Afsli, #‘Éit Ai Aflfc .«A#* ASfc .;4A Sîi-A, A*'aft мЛь, A3fc, ■àais», a,«¡а*,

тМш Я0Щ mßm -»Фт. шпш. srfftwi :мФш »SA,# -тЛт :«Фёш. 5«âlfR xÆim xmiititi хчЯШк x¿:k

Cam No, 1-

Саш No. Hi:

Cam No. 3

Cam Nor !

Cain No. 5 ^

Cam No. 6 ^

Cam No. 7 i

Cam No. Й

Cam No. 9

' ..---. A -f ■■

Page 18

II» Nf'- Ш

li) Nm,. !i

ii: No. Ì3

m iio. 15

m No, 14

in No.' 15

17

./

/ \ / 'Ч .4^'

Ш No. IS

BiNo'i?

!ii No- tS

' -'ï'

Page 19

òdtHtf

To see that your machine is always in smooth running condition

you must keep it oiled at all times. No grease is required. Just

a drop of oil is sufficient at each time of oiling. Points to be oiled

are illustrated in Fig. 28A & 28B. To oil your machine thoroughly,

it will be necessary for you to open arm cover and to turn the

machine over to get to parts underneath the bed.

After oiling, run the machine at high speed for a few minutes to

let the oil penetrate to all parts.

Fig. 2XA

Fig. 2.SB

Page 20

BuiioH. Se44MH^

Turn balance wheel toward you to get needle to its highest

position. Raise presser bar and remove regular presser foot,

attach button sewing foot instead, as shown in Fig. 29. Drop

the feed dog as required for darning and embroidering. Upper

and lower thread tensions remain the same as for ordinary sewing.

Place material or garment with button under the presser foot,

so that holes in button line up with oblong hole in presser foot.

Adjust width of zigzag stitch to permit needle to pass through

center of holes in button.

Before sewing with power, turn balance wheel by hand (toward

you) making one stitch into each hole in the button and be sure that needle will not hit

Then sew five to six stitches to attach button.

When attaching four-hole buttons, first sew one set of two holes, then stitch into second

two holes and lock thread with two or three plain stitches in last hole same as described

same.

set of

:ibove.

Page 21

m

Mahitu^ /¿utionJuUed.

" ¡::L:r ^ ^ a..d set t,. 3.,,... t,^.

.u„..„,.„,e ,„, „„;;;™'I'::::"' '-»'• --

' "i:;:':„s:r;: :™;:‘,T"-';: , ■■' - ^“••“-''<

to « b,K, P„,.,b|.. ,,p„„„-,„pe „1 • ' “" »' «“'>■ W «««r:

":f ir:: 'r: :::srr:b:.r“r:::r - -»

the desired results are obtained.

NOTE: It is suKRested that you make one or two sample button

holes on a clipping of fabric, same as your garment, to test

adiustments of machine and to make corrections, if needed

Also mark with pencil or chalk the position and e.xact length

of buttonhole on garment.

To sow buttonholo, place garmoni under the b,m„„h„|e

pressor (Ob, and start the work with one end „1 ,l,e mark

Page 22

in center of half-moon shaped stitch hole of the presser foot. End of marking must point toward

you. Now start sewing left buttonhole seam and continue sewing until it reaches the gauge of

the buttonhole foot. (This gauge must be set in advance of sewing. Its distance from the needle

should be equal to the desired length of your buttonhole). Leave needle in fabric, raise presser foot

and sew'ing garment half-way around in clockwise direction. Let presser foot down and set zigzag

width as far as it can be moved. Sew four or five stitches which constitute the bar at one end of the

buttonhole. Return zig-zag width to the position between markings 1 and 2 and sew other side of

buttonhole. When arriving at end of buttonhole, again set zig-zag wfidth for sewing second bar with

also four to five stitches. , . .

Remove garment from machine and open buttonhole with buttonhole cutter included m accessories,

or use buttonhole scissors. Work cutting blades only against wooden block and be careful to ayoid

cutting the buttonhole stitching. To make reinforced buttonholes introduce gimp of propei size into

small hole right infront of the half-moon shaped stitch hole of the buttonhole presser foot.

Sew over gimp as machine makes buttonhole seams. For flat buttonholes leave thread tension pretty

much the same as for ordinary sewing.

Push dowm left pushbutton of your pushbutton drop feed, then the feed dog of the machine will drop

and permit the work to be moved by hand in any direction desired. Also remove presser foot and

raise foot lifting lever into horizontal line, and your machine is ready for embroidering and darning.

Embroidery will be done most successfully when material is strectched in an embroidery hoop.

Hold the hoop closely on the machine base with both hands and press the material with your left

index finger in the vicinity of the needle. This will help in holding down the material an wi

prevent the machine from making skip stitches. Manipulate work carefully and be sure to keep finger

out of path of needle to avoid injury. Adjust thread tensions for best appearance ^

work and slightly increase the lower thread tension (bobbin thread) to avoid the lower thieacl trom

being pulled up.

Page 23

22

^a^t/v04At tMemmefi

Turn balance wheel toward you until needle reaches its highest

point. Raise presser bar and remove regular presser foot.

Attach hemmer foot (Fig. 31). Now handle material as follows:

1. Fold over edge of material approximately %" wide, then

fold it over again in the same way for a length of about

2". Insert this folded end from beneath into spiral formed

opening (scroll) of hemmer foot. Move material back and

forth until the hem forms itself in the scroll.

2. Pull material toward you until the beginning of the hem is

Pig. 31

just below the needle.

3. Lower presser foot and begin to sew. Guide material into

hemmer foot while proceeding with work (Fig. 31).

NOTE: Do not crowd material into scroll and do not leave scroll only partly filled by material.

Feed just enough material into the hemmer foot to fill out the scroll.

Instead of a straight stitch, you can also use a zig-zag stitch for this hemming operation. Be

sure however, to adjust the width of the zig-zag stitch to be as wide as the hem itself. Using

a very long .stitch and tight tensions will produce a shell stitch.

Page 24

Se44M4i^ B^aidd,

CS': tlrX -.ach b.-,„li„,

you are sewing. Using neefe thre- d‘’1f ">«erial

enhance the beauty of your brfidinlJ;'“^ contrasting color wdl

Use the hemrner foot for doin,r f at- ,

manner: "■‘f ^^tlling and proceed ... ,u„uwmg

1.

sices facing each other. The right edire of

S™!T '>'>'""'1 'te nghOdg,. Se'°™ pC'”

2.

Sew bo,h piec» of doth „.pdhoo ,pp ^

eTiJe Of lonTf -I 'he right

gufde the hoff of.hemmer foot to

whit tie le '"«enal

while the iSredt'crf the same'iS

mmeria? "hff top pTe^ of

Onen a , ^ ""hows this detail.

^ pen and spread out material and r

FSTii thSofrortfS“' n'atd-iaTiia;;;!

hemrner foot. Sew as yt wo?id'*dn 'he scroll of the

of long toe of hemmer^ftt as hemming. Use left edge

side of it (Fig. 34). «'■'»¡"^1 seam run alonf

in the iollowing

TOP PIECE

BOTTOM PIECE -

--------

Fig:. .33

back on machine right sides

Page 25

24

Qlatk Qi44d&

I'tK' dolh Kuide (FiR. 35) serves as a .ijuitle for straigiu stitch

ing when making wide licms, deep tucks or seam widths which

are greater than presscr foot allows.

It is attaclied to machine as illustnited.

'Fhe (itiiller (Fig. ?S) will enable you to sew e{|ui-distant lines on

jtadded ftibrics without the necessity of marking them in .adwince.

'Fo atlacli the ciuilter to the presser bar of the macliine, first pull long

wire hook out of horse-shoe shtijted clamp. Slide the clamp oti the

presser bar from behind and above ordinary ¡tresser foot, and push

the wire liook into its previous place.

Adjust wire fiook to desired disttince from needle :uid bring it to press

into ftibric. d'hen lighten thumb screw e.xlending bttekward from

horse-shoe shnperl chimp to lock quiller ¡illachment into [tlace. When

sewdiig, wire hook should follow preceding hue of stitching.

Zig-zag stitch (|uilling is done the same as sirthglu stilcii (|uilting with

Fig. 36

the exception of the position of the zig-zag stitch dial vvh.ich should

be set loi' tiny desired width of zig-zag stitch.

2.HiU4*t£^

Page 26

Ga444ei, Q<mu$um %i^ic44lUei.

BREAKING OP THE UPPER THREAD:

1. Incorrect threading

3. Faulty needle, or needle set incorrectly

v5. Needle eye too small for thread used

7. Starting the machine with the take up lever at its highest position

2. Upper thread tension too tight

4. Needle brushing against presser foot or other

attachments

rt. Starting the machine suddenly or with a jerk

BREAKING OF THE LOWER THREAD:

1. Incorrect threading of the bobbin case 2 Lower thread tension too tight

3. Bobbin being wound too fully # Rough edge of hole in needle plate caused by

improper needle action

BREAKING OF THE NEEDLE:

1. Pulling the fabric while machine is running, thus causing the needle to strike the needle plate

2. Using bent needle

SKIPPING STITCHES:

1. Using bent or blunt needles 2. Needle inserted incorrectly

3. Needle threaded improperly 4. Using wrong sized needle

5. Pressure of presser foot insufficient, especially when sewing heavy material

UNEVEN STITCHES:

^ Presser foot not resting evenly on material 2. Feed dog not being high enough

^ Too short stitches used 4. Pulling the cloth while the machine is running

9 Using a too fine a needle with a too coarse thread

Page 27

Sizes & Grades of

-Needles

B or 11

(Medium-Fine)

V2 or 14

(Medium)

_ 1 or 16

(Light-Heavy)

2 or 18

(Medium-Heavy)

3 or 19

(Heavy)

4 or 21

(Extra- Heavy)

needle and thread sizes (USE 1S , .

--------------‘L'SE 15>1 needle ONLY)

Q /vf ' ~r '

"TypTSTFaBriT

....:.........

For house fabrics.

dresses, aprons, curtains^ «'askable cotton

fatoc «'eight woolens,'draperies. '

........................

Lor ba,s. canvas, coarse cloths and heavy ,oods.

__

Done

A& B

Twist

Frimed in Japa„

Loading...

Loading...