SINGER W221N User Manual

ti

CONTENTS

Glossary of Sewing Terms

Glossary of Sewing Machine Features

Machine Identification

Accessories

Detaching Extension Table

Connecting Foot Control

Changing Presser Foot

Changing Needle

Bobbin Winding

Inserting Bobbin

Adjusting Lower Tension

Upper Threading

Drawing Up Lower Thread

Adjusting Pressure on Fabric

Adjusting Upper & Lower Tensions

Fabric, Needle & Thread Table

Setting the Stitch Length

Presser Foot Lifter

Cloth Guide

Basting

Staystitching

Zigzag Stitching

Edge Finishing

Interfacing Darts

Bartack

Shell Stitch Edging

Satin Stitch

Stretch Stitching

Flick Rack Stretch Stitch

Topstitching

Seaming Knits

Gathering Over Cord

Lace Applications

Making Buttonholes

Cutting Buttonholes

Corded Buttonholes

Sewing on Buttons

Blind Hot Stitch

Zipper Sewing

Mending/Patching

Mending a Rip

Darning

Lapped Seam Sewing

Applique Work

Embroidery

Maintenance/Cleaning

Oiling

Trouble Chart ,

Changing Light Bulb

Page

1A

IB

2

3

4

5

6

7

8, 9, 10

11

12

13

14

15

16

17

13

19

20

21

21

22

23

23

23

23

23

24

25

26

27

27

27

28, 29

30

30

31

32

33

34

34

35

36

37

38

39

40

41,42

42

1. GLOSSARY OF SEWING TERMS

APPLIQUE

BASTING

BUND HEM

BUTTONHOLE

COUCHING

darning .

embroidery

PACING

gathering

MEM

MONO-

GRAMMING

OVERCASTING

OVERLOCK

{STRETCH}

patching

Applying * material with a specific design

onto another material by using a straight

or zig zag stitch.

To sew with a tennporary stitch that can be

removed with easa. Tt» is possiblt

using the lot^Mt straight stitch, setting

your «3P ter«k»t on "0" and sevwr^ a

line of stitches. The stitch vM be

loose and the bottom stitch tight; ih«

allows you to be able to remove the lower

thread by puIBng. It may be necessary

to cut tha lower tivead at different pants

for easéir remcnori.

A variation of the zig zag stitch used to

finish a hem where can conb-ol the

holding stitch.

A means of stirengttw«ng the aki^ of s

hole in doth by a zig zag stitch to hold

a button.

To fasten down another material, like a

ribbon lace, witir a firw zig zag stitch.

A method of repairing a rip or tear by

stitching ovw the flaw. '

To decorate with stitching, using either a

straight or zig rag stitch.

The addition of anotiw piece of material

to Increase ttw bCKly or edge of material.

Forming a zig zag stitch ov» cord, elastic,

or any separara materlst.

Ariothef term fa shirring.

A fold, Mwn down an «íge of doth.

Using a straight stitch for tracery or zig zag

stitching va form a desi^.

The use of a zig zag stitrh to finish a seam

or edge of clotii. or to prevent the revelling

of a looara weave cloth.

A triple stretch pattern used to finish seams

Of smstch buttonholes.

Same as darning but covering the hole

viñtit a grace of doth.

SATIN STITCH

SEAM

SHELL TUCK

SHIRRING

STRAIGHT

STITCH

STRETCH

STITCH

TACKING

TAPERING

Tf^READ SHANK A space composed of thread betvwran tha

TOPSTITCHING

TRIPLE

STRETCH

A solid line of zig zag stitching formed by

zig zag stitch sewn very dose icgether.

A Kne formed wfran sewing two piecia of

material together.

The use of the zig zag or variation of

ifra zig zag stitch lo give a shall effect

to the edge of material.

To gather dotii by drawing twws or more

threads together.

A forward or reverse singtii line of rawing

which iTHly vary from 6 to 8 stitches

par inch to "0” stitches.

A comblnalton of stitcfras formed by a

forward snd bsekwsrd moticm vvhich aUows

tira stitches to flex and not break, used

on stretch nraterials, double knits, tricot,

Rngerie. etc.

A rarras of stitdtra to lock thread.

A line of zig rag rawing varykig fron i

narrow to a wride range.

butran and doth to engage button to

bunonht^ cm bulky meterial.

A fine Of serie* of Imea of straight « zig

zag rawing which enhances a border giving

the stitching a raised effect.

A rarm used for stretch patterns, a pattern

formed by a forward, sideward and back

ward combination of stitches.

QUILTING Joining raveral doths togetha to form a

RICK RACK A tr^ stretch pattern using e be»c zig zag

‘ bulk cover for becfe, furniture or clothing.

to give a RICK RACK effect.

ZIG ZAG A term which describes the side to side

motion of tfw rraedle which creatra width

to straight savring.

-1A-

2. GLOSSARY OF SEWING MACHINE FEATURES

accessory

BOX/TRAY

lower ten

sion SPRING

BOBBIN

TENSION SCREW

storaga of extra feet, neecfl«». bobbins

and acoK»ortes. Also uutd as extension

of »tn fo” a lai^ woHt surface.

Baiances uppw and lower teiosion threads-

To adKis* teruucm of bobt^ csee.

BOBBIN F« winding boW^ widi thread.

WaMDING SfnNDLE

BOBBIN for automaticaaY stopping bobt^ at full

WINDING STOP capadty.

FACE COVER open for changing the bulb pfovkaea

FEED DOG For feetft^ mabKial tfwHjgh nrachkw.

FOOT

CONTROL

HANDWHEEL For toitwng mechankun W ^«”<1 ^

NEEDLES Used to form a todi stiteh on your machine.

NEEDLE CLAMP

needle clamp

THUMB screw

NEEDLE PLATE

PORTABLE

COVER

PRESSER BAR

PRESSER FOOT

PRESSER FOOT

UFTER

easy access to neeeftes and pre^ bar

«aKNnbly for offing.

F« activating poww to toe ma<tolne,

■mount of pressure exivtod on toe foot

pedal o3ntr^ toe ape^: attach^ wires

plug into msd'wto and wall »ocket.

needle arto talcs up to high potion. Thffi

wheel torfu tovraid otH^tor.

variadons era many: example: sharp, ball,

(eatttof. etc.

For attaching the needle to the lower

end of toe needle bw.

For f^antng needle into neede clamp.

Fa suppOftifHj material when severing. This

plate is msrkoj fa several hem sizes.

A rec^ta^ to protoct s sewing machine

wim not in use.

Controhi toe pretaure exert«! on variojs

matoriels being sewn. Can be var^ by

contrt^ tever.

What towered onto nrtateriai it holds the

materiel against the feed dog.

Fa raising a towering the presw ber

end pmasa femf. When raised, the tension

(5 releaitod and when towered, the tension

is engaged.

PRESSER FOOT For fastening presser foot arto attachments

THUMB SCREW to toe presser bar.

REVERSE for changing from forward to reverse

SEWING BUTTON dlrectiiHt, button must be i»eid In for

^ comincMto raverM sawing.

SOCKET Located under the face cowu to change

SPOOL PIN One ior itowing and far windir^ bobbin.

{RETRACTABLE)

STITCH For changing tfm la\gth of stitch b ^h«^

LENGTH DIAL foward and reverse direction.

TAKE UP for drawrir^ up the top thread to form

LEVER 8 tight stitch.

THREAD For edtting exc^ toread, latated cm the

CUTTER back and mto ths piesw bar.

THREAD GUIDE Hoida thread taut for even wmding.

FOR

BOBBIN WINDING

THREAD GUIDE

FOR UPPER

THREADING

UPPER THREAD Use fa single a two tivead sewing, helps

TENSION control toread lock.

UPPER THREAD Used to change upper tension

TENSION DIAL

ZIGZAG

WIDTH DIAL

toe IHjht bulb.

Guides thread from ^>ocN pira to • toe

tortsion.

For setting width of zigzag stitching. Zgzsg

wkJto may be varied frcmi 0 w^to to 5 mm

width.

1B-

jot

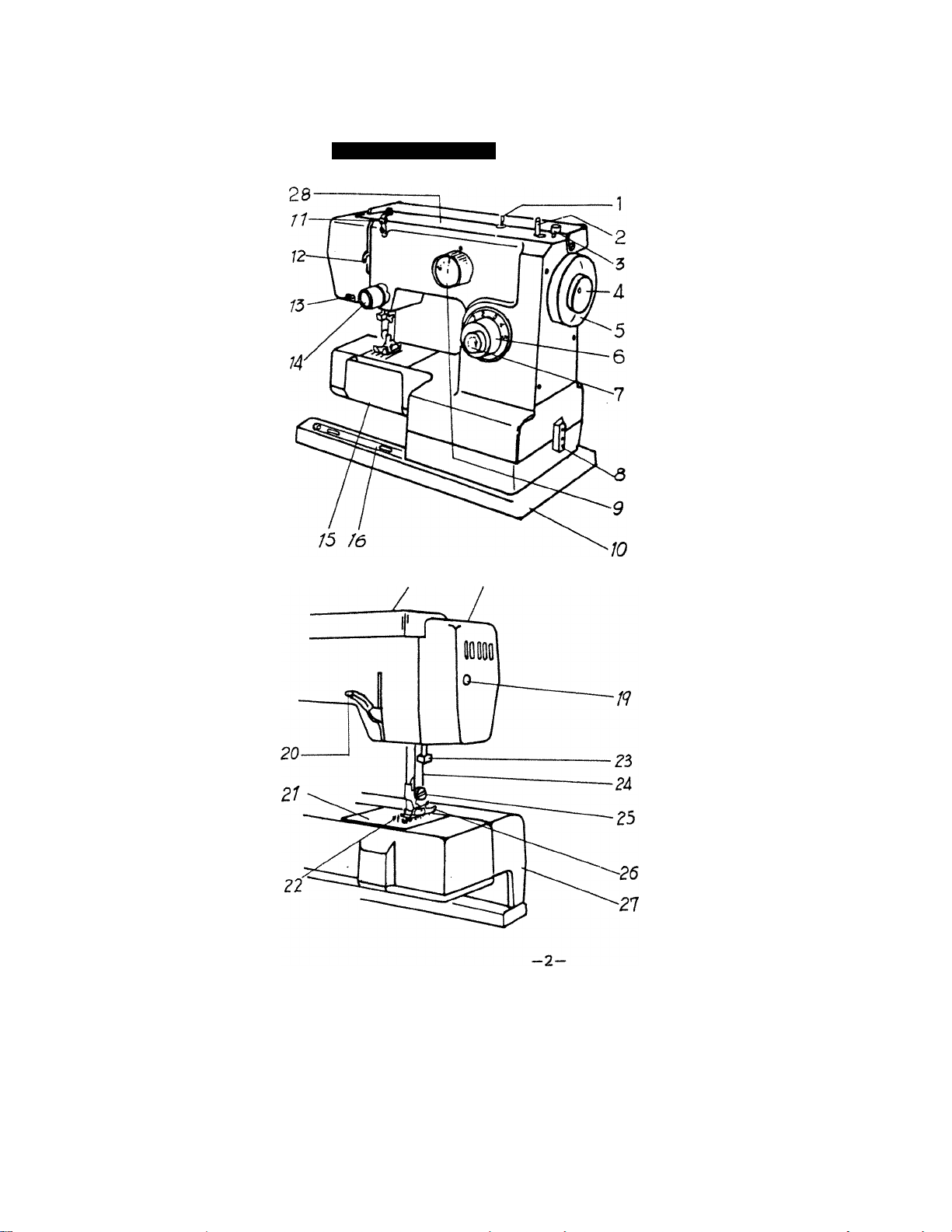

Machíne identification

1. Spool pin

2. Bobbin winder

3. Bobbin winder stop

4. Stop motion knob

5. Hand wheel

6. Stitch length knob

7. Reverse stitch button

8. Connector

9. Stitch pattern knob

10. Base plate

11. Thread guide

12. Thread take-up

13. Thread guide

14. Top tension

15. Bed cover

16. Extension plate guide

17. Handle

18. Faceplate

19. Set screw for face plate

20. Presser foot lifter

21. Needle plate

22. Feed dogs

77

/<5

23. Needle clamp

24. Needle

25. Presser foot holder screw

26. Presser foot

27. Extension plate

28. Top plate.

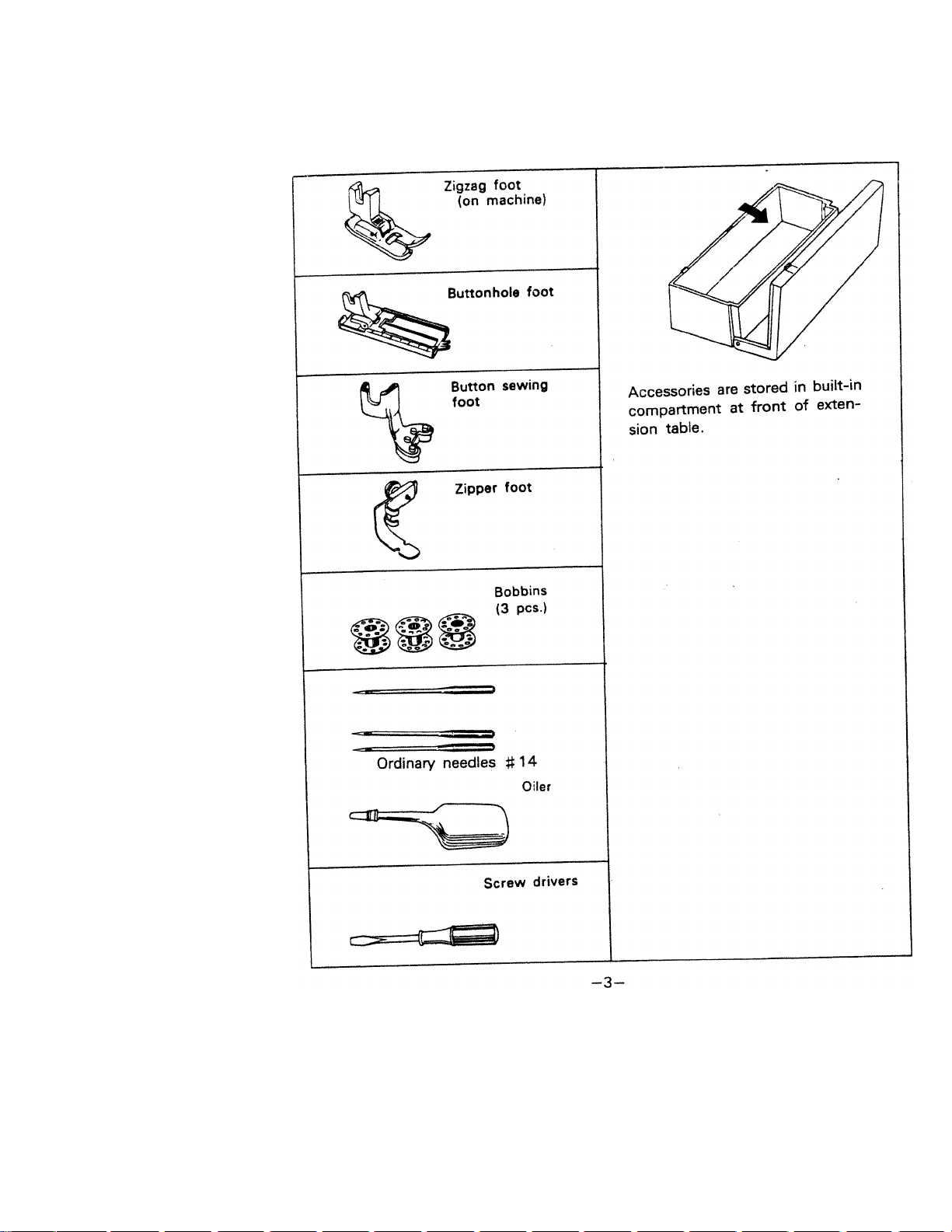

ACCESSORIES

BEFORE SEWING

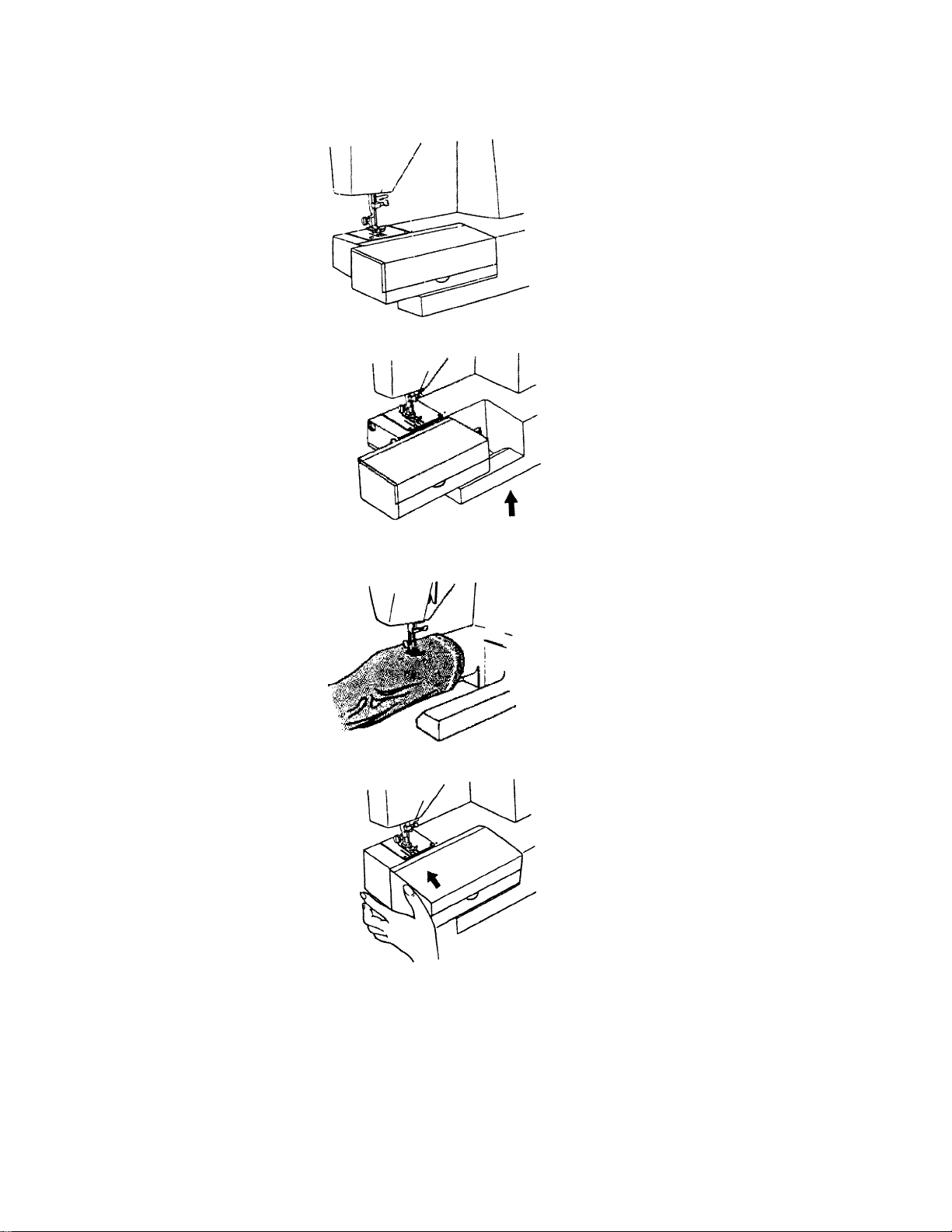

Machine is stored in flat-bed style

which makes your work easier in

ordinary sewing.

Detaching Extension Table

Pick up and slide it off and the

machine is used as a free-arm

model.

Free-arm is convenient to sew or

embroider ; trousers, sleeves, cuffs

of T-shirts, blouses, etc.

Do vice-versa of above steps to

attach extension table.

To open lid of accesory box, lift

it open, as illustrated.

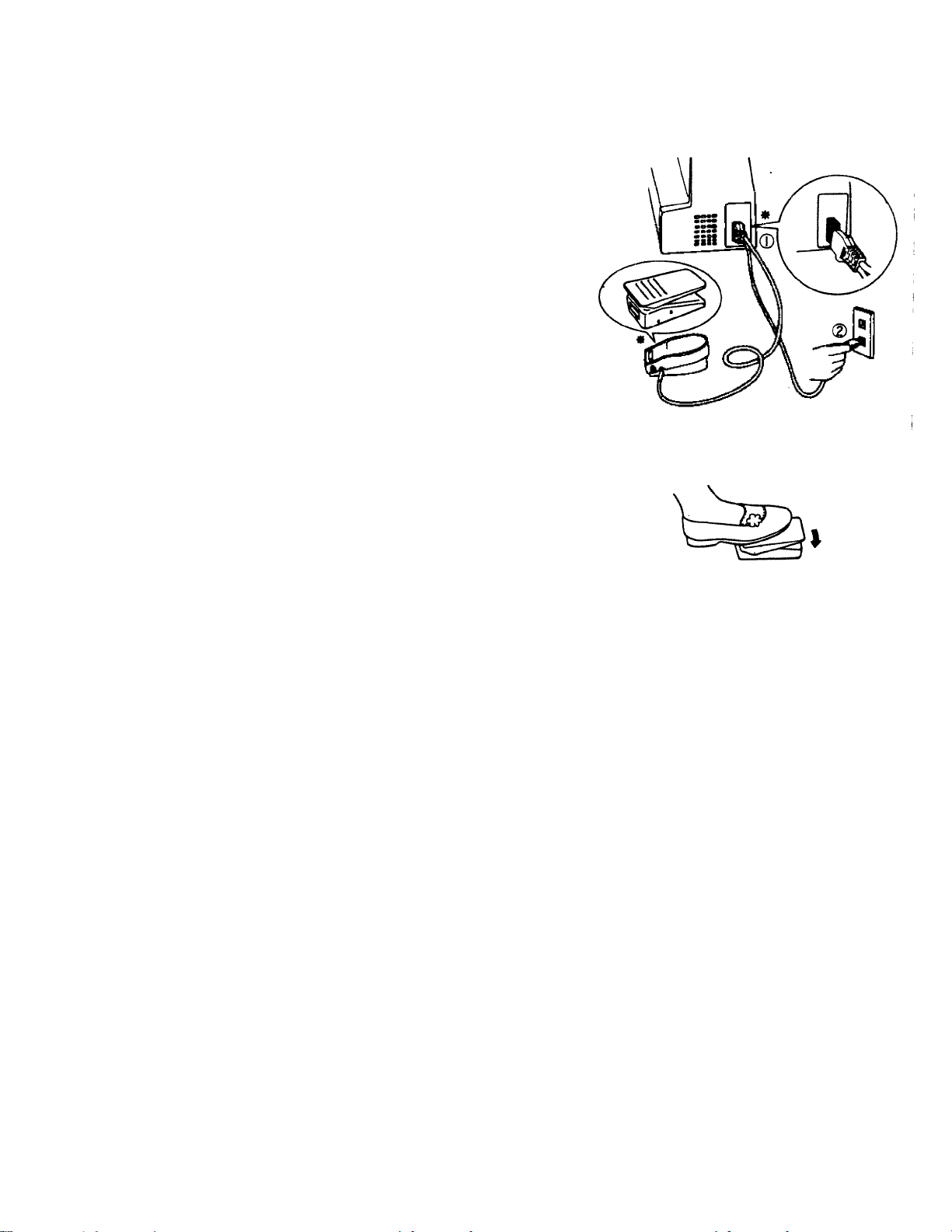

Connecting Foot Controller

and Power Cord

Connect foot controller

power cord ®

Before plugging in your machine,

be sure that voltage is same as

that of your machine, (written on

a plate at back of machine)

^ Specifications vary from country

to country.

Always unplug machine when

not in use.

The more you press foot controller,

the faster the machine runs.

WARNING;

THE FOOT CONTROLLER, FOR WHICH

ATTACHED ON THE SEWING

MACHINE MODEL 221N, IS

DESIGNATED FOR SEWING MACHINE

MODEL 221N ONLY.

FOR YOUR SAFETY, DO NOT APPLY

THIS FOOT CONTROLLER TO ANY

SEWING MACHINE AND/OR

APPLIANCE OTHER THAN MODEL

221N.

and

POLARIZED PLUGS CAUTION

This product is equipped with a polarized alternating current line plug

(a plug having one blade wider than the other). This plug will fit into

the power outlet only one way. This is a safety feature. If you are

unable to insert the plug fully into the outlet, try reversing the plug.

If the plug should still fall to fit contact an electrician to replK:e the

obsolete outlet Do not defeat the safety purpose of the polarized

plug.

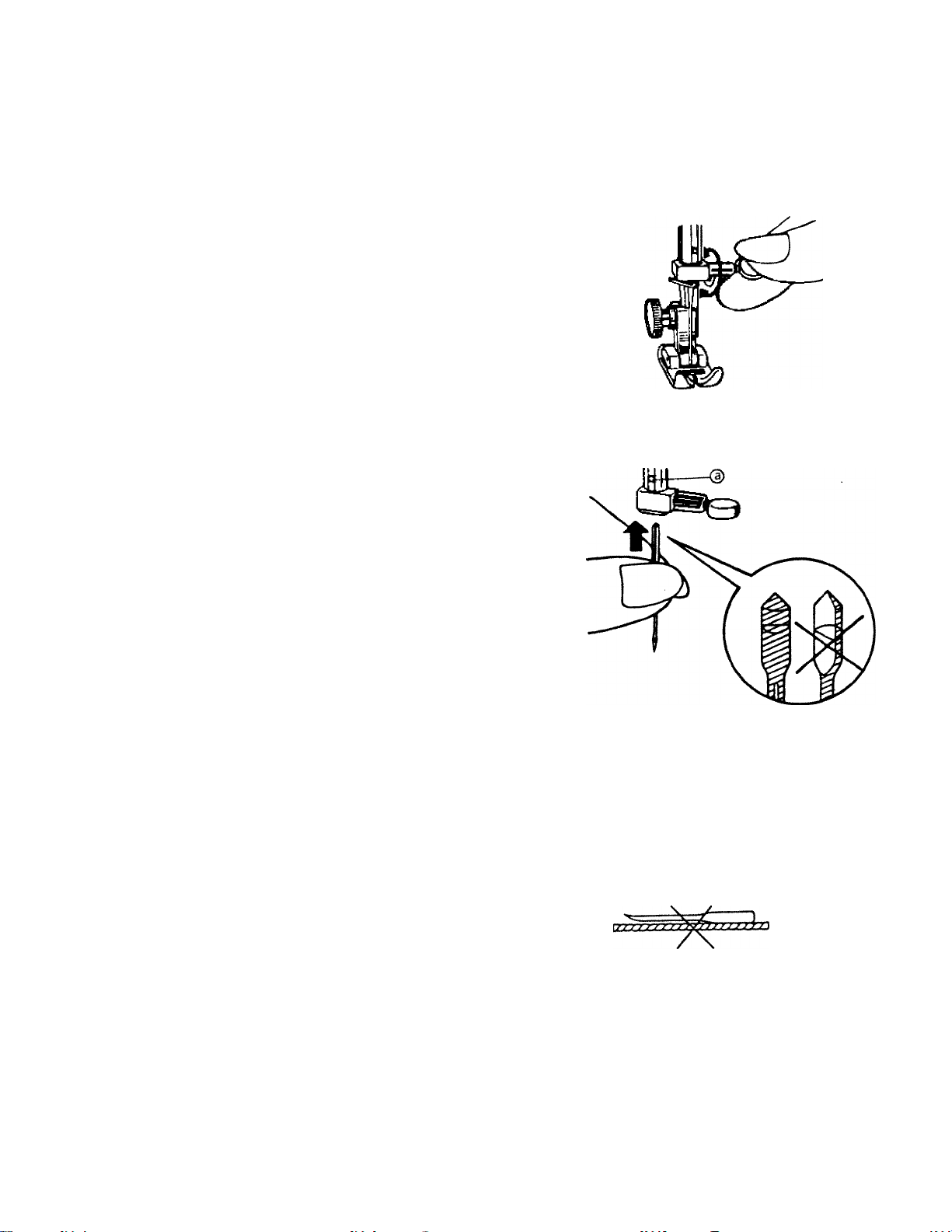

Changing Foot .

Raise presser foot lifter ©.

Set needle in the highest

position by turning handwheel

towards you (2).

Remove foot by loosening screw

with screwdriver.

Replace new foot and tighten

screw.

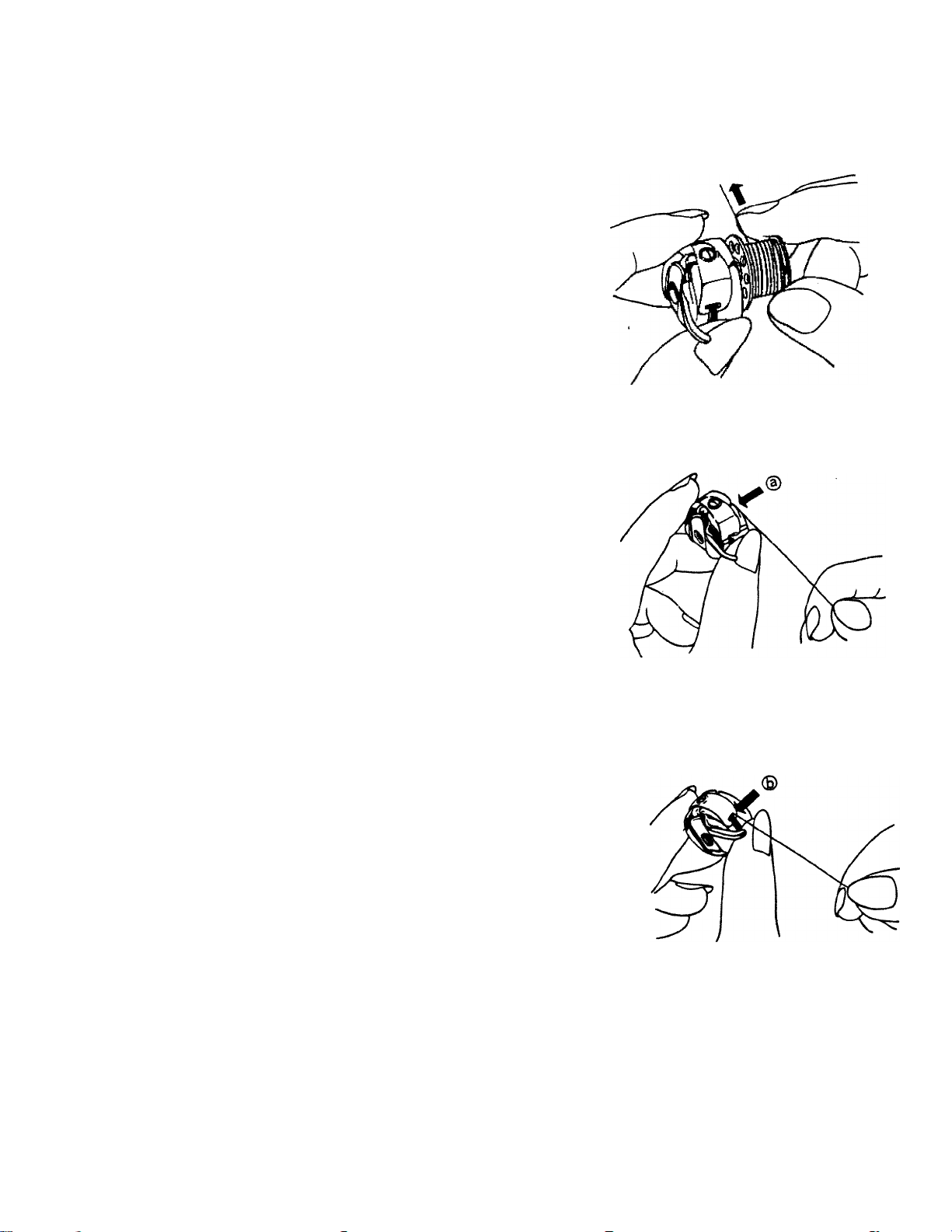

Changing Needle

Set needle

position by

towards you.

Loosen needle clamp screw and

take out needle.

With flat face away from you,

insert a new needle into groove

of needle bar.

Push needle until it reaches

stopper (D and tighten needle

clamp screw firmly.

in the highest

turning handwheel

Always use a straight needle with

a sharp point.

Using defective or worn needles

not only causes stitch skipping,

breakage of needles or snapping

of thread; it also can damage

hook and needle plate.

Proper needle

straight shaft

sharp point

cm

><s

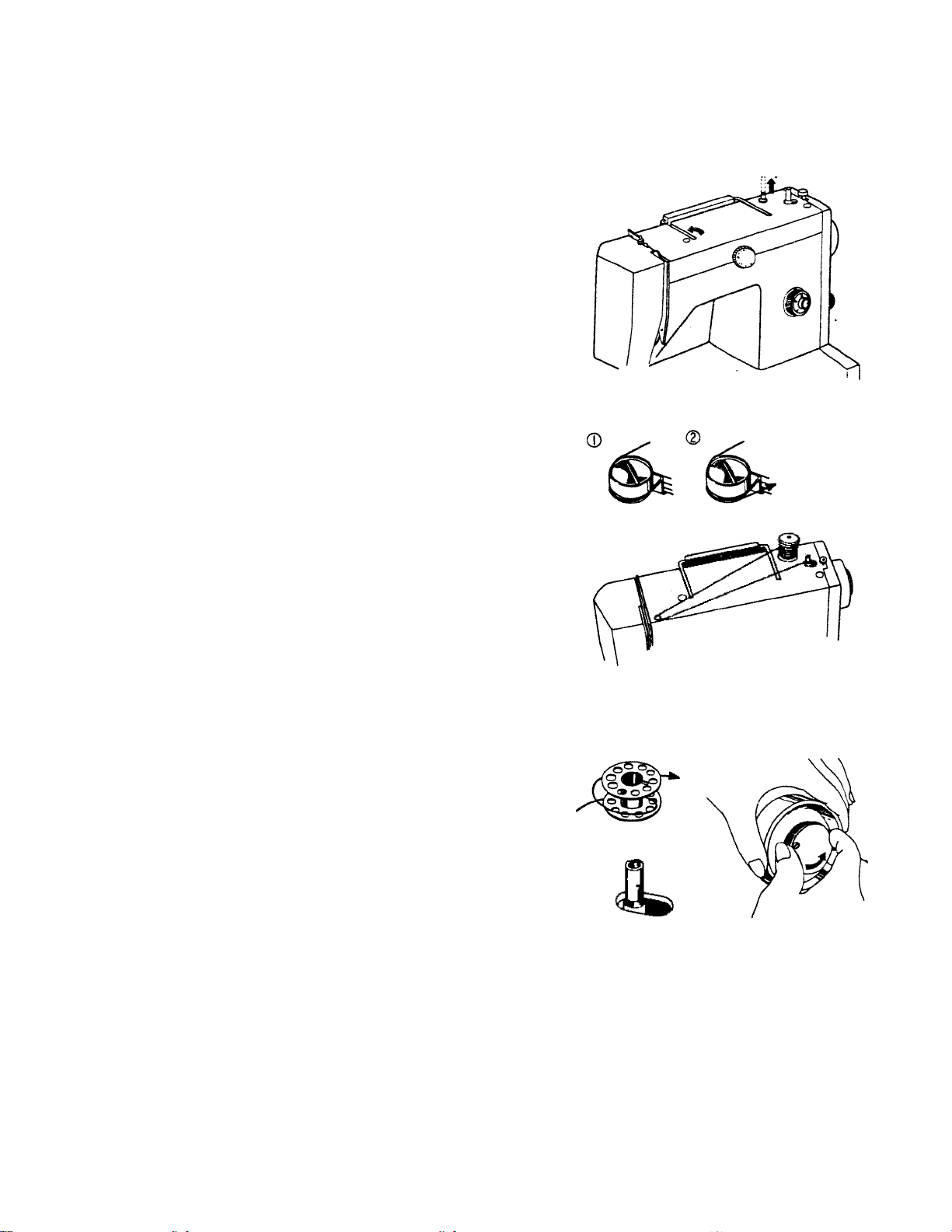

Bobbin Winding

Set needle in ths

position by turning

towards you.

Open shuttle cover.

Open latch of bobbin case and

take it out. . . .

i highest

handwheel

Close latch of bobbin case and

bobbin comes out easily.

Push back to fold handle.

Pull out spoolpin.

Put a spool on spoolpin.

Draw thread from spoolpin

through pretension device, following

numbers © ®

Wind thread clockwise around

bobbin several times.

Push bobbin on to spindle.

Holding handwheel with your left

hand disengage handwheel by

unscrewing stop motion knob.

Push bobbin to right and press

down foot controller.

Machine stops automatically

when winding is full.

Push bobbin to left.

Take off bobbin from spindle

and cut thread.

Retighten stop motion knob.

trouble

correction

m

If bobbin is wound unevenly

w

as shown, remove top cover and

loosen set-screw of the guide for

bobbin winding, by using screw

driver and adjust height.

-10-

Inserting Bobbin

Place bobbin in its case with

thread running in direction o

arrow.

Guide thread into slot ®

bobbin case.

Pulling thread to left. bHoQ It

under tension spring then to

delivery eye ®-

■11-

Loading...

Loading...