Page 1

Page 2

Certificate of Registration

INTER NAT IO NAL SEW ING MA CH INE CO RP

LIFE-TIME GUARANTEE

Each New Sewing Machine is warranted to be tree from defects , in materials and

workmanship entering into the manufacture and assembly for the life of the machine. Any part,

when returned transportation charges prepaid, will be repaired or replaced if proved to be

defective.

Parts and accessories, such as belts, needles, bobbins, pulleys, attachments, etc., which

normally require replacement, are not covered by this warranty. Electrical equipment as

supplied by the manufacturer is warranted for one (I) year against defects in materials and

workmanship.

This warranty does not cover any machine which, in our opinion, has been altered

or damaged so as to affect its performance, nor any machine not used under normal household

conditions, nor any machine not given reasonable care in accordance with the printed instructions.

Date of Purchase ;

Dealer’s Name:

Signed By :

___________________

Sewing Machine

Serial No.

Model No.

Purchaser

Address

City

Date of Purchase

Dealer’s Name

Detach and Mail—No postage necessary

Page 3

rPostage Stamp]

No

Necessary

[If Mailed in thej

kUnited Stales/

BUSINESS REPLY CARD

INTERNATIONAL SEWIN8 MACHINE CORP

1001 KIRKEBY CENTER,

10889 WILSHIRE BOULEVARD,

LOS ANGELES 24, CALIFORNIA

Page 4

Page 5

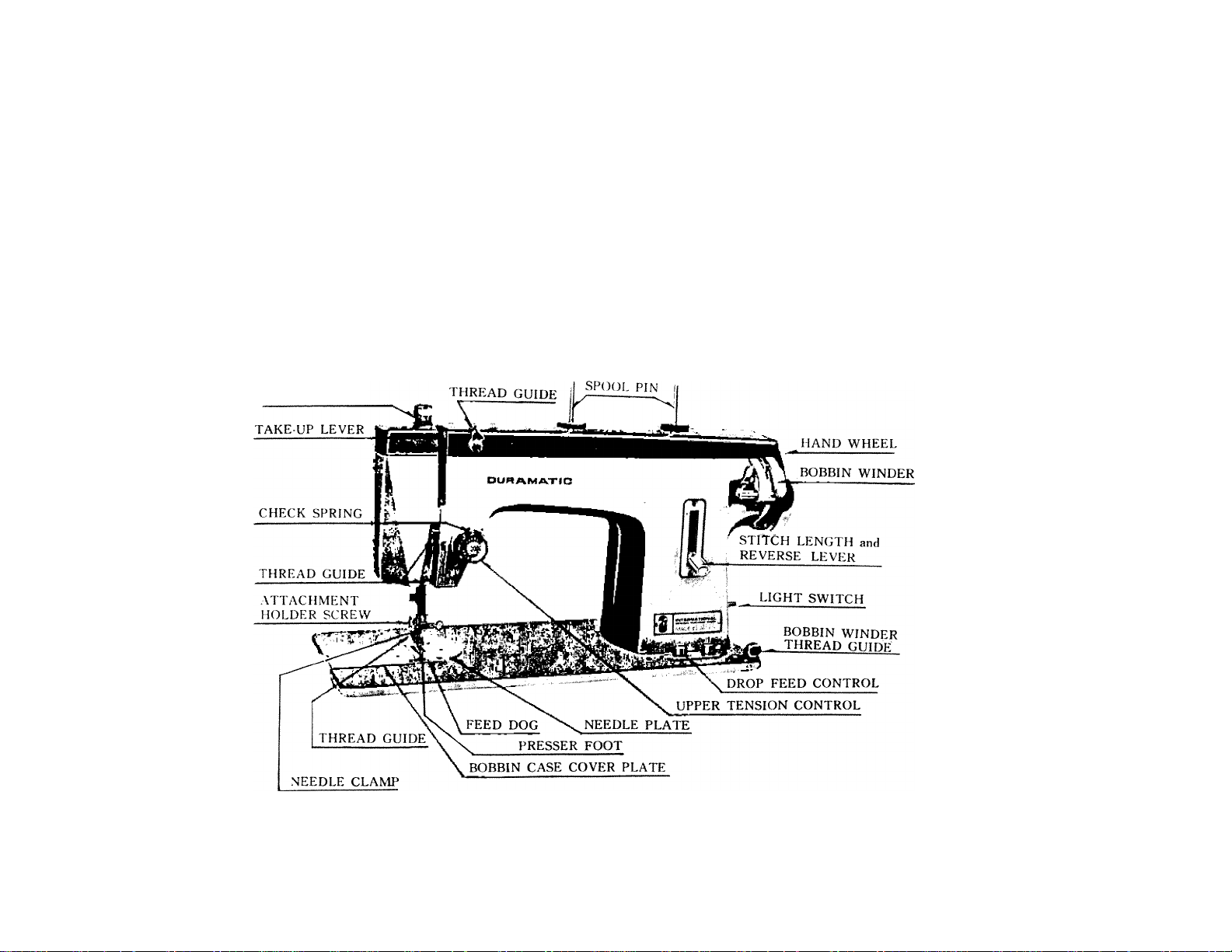

FEATURES OF THE DURAMATIC 102

1. De luxe two-tone color.

2. Clean simple lines. . . acclaimed by everyone as the most beautiful

sewing machine in the world.

3. Controls are grouped on a panel. They are well placed from

both the esthetic and practical standpoint providing an unusual

ease of control.

4. The large hinged bobbin case cover plate provides easy access to

the bobbin case.

5. Exclusive hinged face plate cover swings open to provide easy

access to sewing light. . . and easy oiling of the face plate mec

hanism.

6. Sew-light over needle spotlights your work eliminating any possi

bility of eye strain.

7. New exclusive upper tension control-esthetic and practical-adds

to the simplicity and beauty of styling.

8. Pressomatic calibrated pressure control is faster, more accurate

and instantly adjustable to the proper and correct presser foot

pressure.

9. Lifetime, dustless, slipless, tooth-type motor belt provides positive

control at all sewing speeds.

10. Cast "no-twist” motor bracket eliminates torque and vibration.

Page 6

DE LUXE SEWING MACHINE

11. Specially designed all-in-one stitch length and reverse lever prov

ides positive control both forward and backward.

12. Drop feed control designed to permit feed dog to be at proper

height for heavy materials and for thin materials. .. to be comp

letely disengaged for darning or embroidery work. . . is plunger

designed for quick positive return action.

Page 7

GENERAL CARE AND OILING

To obtain full and complete efficiency ^rom your sewing machine,

study these instructions carefully to become familiar with its operati

on and the controls and devices which are new to you.

Your sewing machine was carefully adjusted, tested on every kind of

sewing and was passed by the Chief Inspector after it was found to

be perfect in every respect.

Keep your machine cleaned and oiled. . . use thread of good quality

and of proper size and weight tor the material. . . use needles ot good

quality and of the proper size for the weight of thread you are using.

Be sure that the bobbin is evenly wound... and that the machine

is threaded correctly.

Practice sew'ing on your machine so that you will operate it easily

and naturally when you are making a garment.

Practice bobbin winding by taking the thread from one bobbin to

another.

Remove and replace the needle several times. . . thread and unthread

the machine a number of times until you can do it easily and natu

rally.

These little practice sessions will make you expert in the handling

of your machine and will pay dividends in finish and appearance

when you are dressmaking in earnest.

Page 8

ii£!E by pulling on the cloth, for your seam will be uneven...

the seam will pucker. . . the thread may break. . . and the needle will

bend.

Change needles often

The average dress has upwards of 10,000 stitches...and a needle, if

new when starting, has pierced the material this many times and the

point has become dulled. If you see lint fuzz at the eye of the

needle, replace it for it indicates that the needle eye is rough.

Proper stitch length is important, too, and a practice session for a

few minutes on a piece of the material to be sewn will tell you if

you have (a) the proper thread, (b) the right needle, (c) the correct

stitch length and (d) the right tension setting.

— 5

Page 9

PRESS-O-MATIC

Page 10

OILING INSTRUCTIONS

££k refined and prepared for sewing machines.

2. Put a drop at a time at the points shown in the illustration if

the machine is used frequently.

3. If the sewing machine is used infrequently, use several drops;

however, before sewing, practice stitching on some material scraps

until the oil has penetrated or reached all bearing surfaces and

excess oil has been wiped off.

4. Use extreme care when oiling the motor to be sure that oil does

not reach the armature, coils, etc.

Page 11

IMPORTANT NOTES

The rotation of the machine must always

be in the direction shown by the arrowy

(See illustration with the arrow curving

and pointing over the hand wheel towards

the user) and never in the opposite

direction.

The machine should never be run except

when there is material under the presser foot and when the presser

foot is dowm to avoid thread tangling and breaking.

At the end of the seam, to remove the work from machine, bring

the needle to the highest position by turning the wheel in the direc

tion of the user (never in the other direction).

Raise the presser foot (this, also releases the upper tension discs,

allowing the thread to pull out freely).

Remove the work by pulling it gently in the direction of sewing, in

sert the threads and cut them on the blade of the thread cutter.

NOTE: Raise the presser foot only when the needle is at the top

position except when you have to continue sewing in a different

direction to that of the preceding seam; in this case, take care not

to pull or bend the needle, and raise the foot a little with the

needle still piercing the material. The work can be turned around the

Fig- 1

needle, lowering the presser foot afterwards.

Page 12

UPPER THREADING

Turn the handwheel until the needle reaches its highest position.

For correct threading pass the thread through the guides and tension

regulator as follows:

Place thread on spool pin and hold spool lightly, allowing it to slip

as the thread is pulled. Bring the thread through thread guide A

down to the tension regulator B and under and between the tension

discs C from right to left and up.

Continue by placing in loop of check spring D and under retaining

bar E.

Continue up and thread

through the take-up lever

F from right to left and

down through thread

guides (2) H.

Be sure to slip thread

into the needle clamp

thread guide I and then

thread the needle from

left to right.

Page 13

WtNDING THE BOBBIN

Disengage the wheel, (Fig. 3.)

Place thread on spool pin A

(Fig. 4)and draw thread through

thread guide on top cover B

(Fig. 4.) Bring thread across the

Fig. 3

machine to bobbin winder thread guide on bed plate C.

Pull thread under and up left to right.

Wind a few turns of thread by hand around the bobbin and place

bobbin on bobbin winder spindle.

Press on lever marked PUSH and bobbin winder will engage the hand

wheel.

Start to fill bobbin by running the machine at normal speed to allow

the bobbin to wind evenly and firmly. The bobbin winder will stop

and disengage itself, when the bobbin is about eighty percent filled.

NOTE; Do not fail to

tighten the brake button

on the hand wheel

iclock-wise) to re-engage

the sewing mechanism.

Fig. 4

10

Page 14

THREADING THE BOBBIN CASE

Hold bobbin in right hand with thread running to the right from the

top. ^

Insert bobbin and pull the thread into the slot under the spring and

up into the eye.

NOTE; The tension adjustment of

the bobbin case is regulated by

partial turns of the adjustment

screw. It has been carefully and

scientifically preset and will

seldom-if ever-

need to be

changed or

Fig. «

re-set.

11

Page 15

REGULATING THREAD TENSION

NOTE: The upper tension is always released when the presser foot

is raised. Do not attempt to change or regulate upper tension until

presser foot is lowered all the way to the feed dog.

Fig. 9

To have a perfect stitch the threads must

be equally tightened from above and below

so that they join in the middle of the

material being sewn. Sheer material

requires a loose tension, while heavy

material requires more tension.

TO TIGHTEN the tension, turn the thread

tension regulator to the right.

TO LOOSEN the tension, turn the thread

tension regulator to the left.

Lower tension regulator

As all machines are

correctly adjusted before

leaving the factory and

readjusted before delivered to you, the lower tension

seldom requires changing; but if this becomes

necessary, tighten the screw in the tension spring

on the outside of the bobbin case for more tension,

or loosen the screw slightly for less tension.

12

Page 16

PRiSS-O-MATIC REGULATOR

The Press-o-matic controls the pressure of the presser foot on the

material and can be regulated to exert normal pressure when pressed

down all of the way. . .or regulated to eliminate all pressure if the

outside ring (Fig. 12) is pressed to permit the presser bar (Fig. 13)

to raise about three-quarters of an inch. If you attempt to sew

without pressure, the material must be moved by hand.

When sewing on thin or sheer materials set the presser bar to

number 2 or number 3 position. . .all the way down for normal or

heavy material.

Fig. 12

Fig. 13

13

Page 17

DROP FEED CONTROL

Fig, 1-}

1. For regular sewing press the button on the right down (See

A Fig. 14) as far as it will go.

2. For light or sheer materials press the left button (See B Fig, 14)

down until the red line is about even with the plate. (If the left

button is too far, press the right button to force the left one up

and repeat the procedure).

3. For darning or free-hand embroidery, press the left button down

¡See B Fig. 14) as far as it will go. (Best results are obtained

when the darning spring is attached to the needle clamp).

Page 18

STARTING TO SEW

When starting to sew, the

thread take-up lever must be

at its highest position to

prevent the needle from

becoming unthreaded.

Hold the free end of the

upper thread lightly and turn p¡g/ ~ ^ ’

the hand wheel towards you until the lower thread comes up.

Pull the ends to the back, being sure that the upper thread goes

down, through and under the presser foot. Place material under the

presser foot.

Lower the presser foot.

Start the machine and guide the material by letting the machine feed

itself.

Do not pull on the material.

Do not run the machine unless there is material under the presser

foot.

Do no, run the machine with

the presser foot raised.

Fig. l(i

15

Page 19

REGULATING THE STITCH LENGTH

The stitch length regulator adjusts the stitch length

from very long (about 6 stitches per inch for

very heavy material) to very short (about 30

stitches per inch for very sheer material).

Normal seaming or stitching requires a setting of

12 to 14 stitches per inch (#3).

The stitch length regulator, when raised above the center of the stitch

length panel, reverses the direction of the material and causes it to

move back to you.

Reversing the movement of the material is excellent for reinforcing

a seam by double, triple or quadruple seaming. .. excellent for backtacking the start or the end of a seam. Simply flick the lever up for

4 or 5 stitches and then bring it down again and the seam is securely

locked. (Fig. 18)

For basting, use the longest stitch by pressing the stitch length lever

all the way down and set the tension indicator to loose. (,The

expert will use a slightly heavier bobbin thread). The threads

can be easily pulled out after the permanent seam has been sewn.

NOTE: Do not neglect to return all settings to normal when basting

has been completed.

16

Page 20

Excellent darning or reinforcing can be done by adjusting the knob

on the stitch length lever to limit or stop its downward or upward

movement.

Set the stitch length to ¡ ¡^4, use a mercerized thread, and when the

machine is running move the lever Up and down in a rhythmic

movement and gently guide the

material to the side as it moves

backwards and forwards.

END OF SEAM

Stop the machine with the take-up lever and needle at their highest

positions.

Raise the presser foot (This also releases the upper tension, allow

ing the thread to pull easily.)

Remove the work by pulling it gently toward the back and to the side.

NOTE: If the material does not pull easily, rock the hand wheel

gently back and forth to release the under thread from the hook

or shuttle mechanism.

17

Page 21

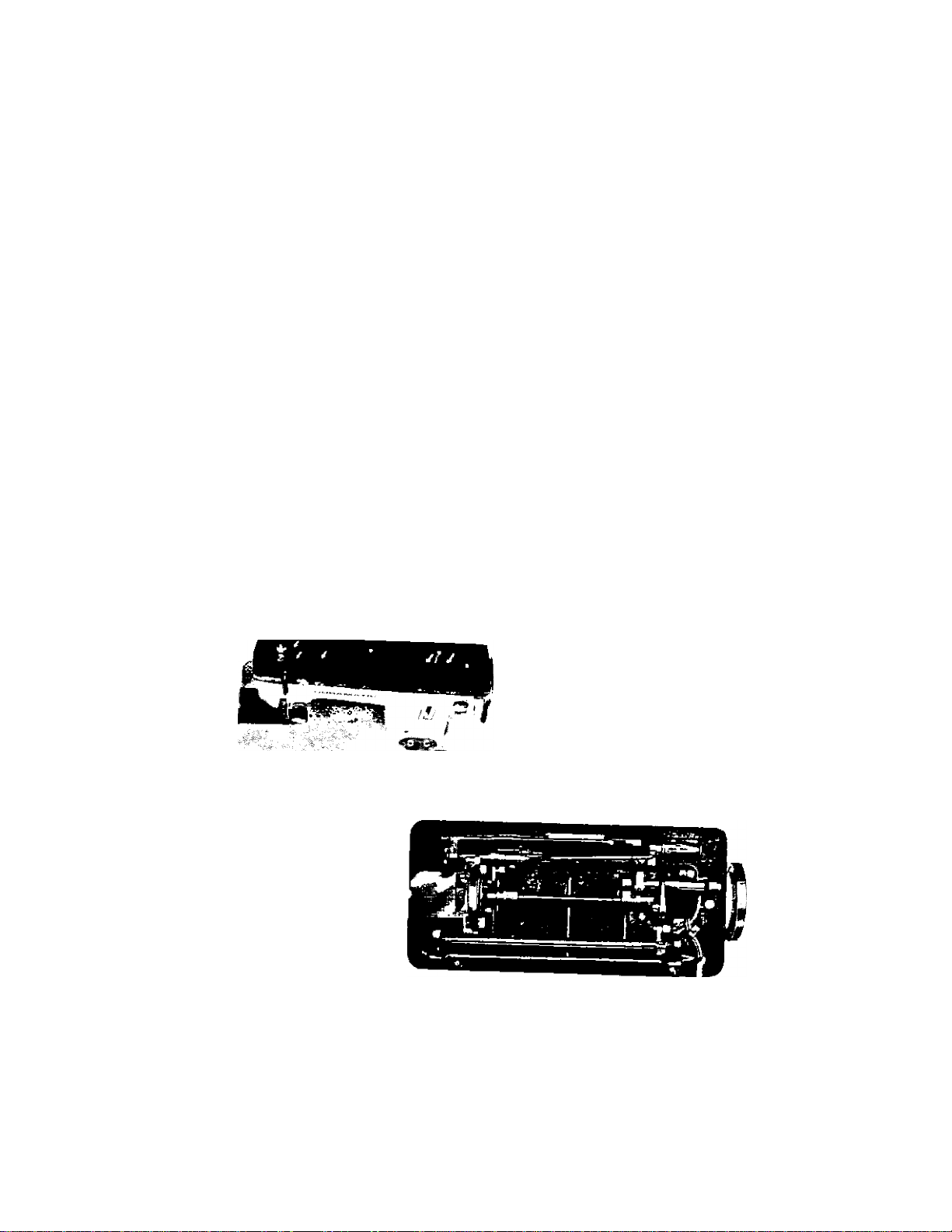

CLEANING THE SHUTTLE MECHANISM

From time to time thread ends and lint may accumulate in the shuttle

mechanism. (This problem can be noted if the sewing machine

becomes noisy and is operadng under s.rain). The removal of lint

and thread ends does not require the services of a mechanic.

It can be quickly, simply and easily done as follows;

1. Remove bobbin case.

2. Push spring loaded knobs A away from the center.

3. Lift off hook or shuttle cover ring.

4. Remove the shuttle and clean it and the inside race carefully,

removing all dirt, lint and thread ends.

5. Replace the shuttle and shuttle cover ring in reverse order.

6. Push spring loaded knobs back into their holding position.

7. Replace bobbin case.

Fig. 19

18

Page 22

REPLACING BOBBIN CASE

Hold bobbin case by grasping latch with thumb and forefinger of left

hand. Fig. 21.

Place bobbin case on hook or shuttle pin. Close latch by pushing it

until it clicks into place.

Fig. 21

STRAIGHT SEWING

Use long stitches for heavier materials-increasing in length as weight

of material increases.

Use shorter stitches for lighter weight materials-very short for thin

or sheer materials to avoid seam puckering.

NOTE: Do not pull or hold back on the material, but guide it only.

(Pulling or holding back on the material-in addition to

forming uneven stitches-will break or bend the needle).

19

Page 23

QUILTING

The quilting attachment will enable

you to sew parallel lines on padded

fabrics without the necessity of

marking them in advance.

Attach the quilter by pulling long

wire hook out of horse-shoe shaped

clamp.

Attach the clamp on the presser

bar from behind and over the presser

foot and push the wire hook into place. Adjust the curved hook to

the desired distance from the needle and adjust it to press into the

fabric. When sewing, the hook should follow the preceding line of

stitching.

The quilting attachment is available at all sewing machine stores.

NARROW HEMMER

With the needle in its highest posi

tion, replace the presser foot with

the narrow hemmer (Fig. 23).

For a plain narrow' hem make a

1/8 inch double fold for about 2

inches along the edge of fabric.

Hold each end of the 2-inch fold,

Fig. 23

hemmer, draw forward to end and fasten with point of the needle

Lower the presser foot. Gently pull the end of thread as you start

stitching. Guide the material slightly to right, and it will automatically

take a double turn through scroll. ’

NOTE: Do not crowd the material into scroll and do not leave

scroll only partly filled by the material. Feed just enough

material into the hemmer foot to fill out the scroll.

and slip underneath the hemmer.

Bring fold up into the scroll of

20

Page 24

FRENCH SEAM (FELLING)

Proceed in the following manner;

1- Lay two pieces of cloth one on top of the other with their

RIGHT sides facing each other. The right edge of the bottom

piece must extend about 1/8 inch beyond the right edge of the

top piece. See (Fig. 24).

1 Sew both pieces of cloth together. Use the right edge of long

toe of hemmer foot to guide the botton, piece of „ateri.l. while

the left edge of the same toe serves

as a guide for the top piece of

material. (Fig. 25).

3.

Open and spread out material and

put back on machine right sides

down-ward. Make sewn edges of

material stand up.

4.

Fold over the edges to the left and

insert them into the scroll of the

hemmer foot. Sew as you would

do ordinary hemming. Use left edge

of long toe of hemmer foot as guide,

having orgmal seam run alongside

of it.

TOP PIECE

BOTTOM PIECE

1ST STEP

«'IDTH OK lOF

2ND STEP

21

Page 25

FLAT FELLED SEAM

Fig. 26

TOP PIECE I ST STEP

.....

Ч

Open out French seam and ins

ert rolled edge in scroll of heni-

mer. Edge stitch to lay seam flat

(Fig. 26).

2ND STEP

SND ROW TOP PIK

/

ЮТТО.М PIECE/

BOTTOM PIECE/ /1ST ROW

LACE TRIMMED HEM

To attach the lace to the hem, insert

the lace in the slot next to needle.

Sew hem as above, guiding lace un

der needle and hem into scroll.

Fig. 27 (Fig. 27).

LACE EDGE WITH INVISIBLE STITCHING

Hold the lace % inch from raw

edge on right side of fabric. Insert

both in scroll as for plain narrow

hem. Let hem roll over and sew in

Fig. 28 lace. Press lace out flat along edge

with hem turned up. For a little fullness in lace, feed it freely under

scroll (Fig. 28).

Page 26

ATTACHING THi ZIPPER FASTENER

This adjustable zipper foot can be

moved to the left or right side of

the needle. It is used for sewing

zippers and cords.

Fig. 29

CLOTH GUIDE

This is an attachment

designed as a guide for

stitching when making

wide hems, deep tucks or

seam width which are

greater than presser foot

allows. (Fig. 30).

It IS attached to machine as illustrated

Fig. 30

Page 27

TYPES OF NEEDLES: use only 15X1 needles

RECOMMENDED NEEDLES AND THREAD SIZES

TYPES OF FABRICS

CLASSES OF WORK

Y^rZ fabrics like Muslin, Georgette

Chiffon, Batiste, fine Linens, Cambrics,

I

etc, For lingerie, infants’ wear and del

icate lace work.

Light-weight Shirting and summertime

Fabrics, Linens, fine Silk Goods and

Calicoes. For children’s and house dre

I sses, washable cottoin. dresses, aprons

and curtains.

Shirtings Sheetings, Calicoes, Dress Si^s and Cottons, light weight woollens,

Draperies, etc. For general household

sewing and all classes of general work.

Heavy CalicoeT^nd^^SEkTlighr’ii;;^^

Woollens, heavy Cretonnes, Madras, Mu- !

slin Brocades and Quilts. For men’s i

work shirts, smocks and aprons, quilting

and tabric mraishings. j

&d Tickii^s, U5hoIst5i7^iid~^^^rd^

Materials, Slip Cover Fabrics, Woolleh i

u “Cavy woven Coating, light wei- i

ght Canvas. For trousers, boys’clothing, ^

work uniforms, awnings, slip covers and '

mattresses.

I Hei i ^f^i c Fn i s ^a ^ ^W o hT i etis T ^i^^ ^ r

woven Suiting and Coating. Canvas and

backing. For heavy clothing in general i

such as heavy uniforms, coats, trousers,’ i

For heavy goods, coarse cloths. Canvas ! Very

Bags, etc. ■

supplies, bags, etc. ■

I

^ Coarse

SIZE OF THREAD

Cotton

100

: (X) and 000 :

to

; Twist =

150

80

to

100

60

to

80

40

to

60

30

to

40

24

to

3D

: E ■

■ I

A&B

Twist

Twist

Twist

Twist

Silk

0

Twist

c

D

00

and

000

50

to

00

50

: SIZES OF

NEEDLES I

8 to 10

(fine)

11

(medium fine)!

14

(medium)

16

(light-heavy)

18

:(medium-

heavy)!

19

(heavy)

21

(extra-heavy) I

--

------------

Mercerized Singer (Grade)l

Heavy

Duty

Heavy

Duty

40

to

60

40

to

60

24

Page 28

INCREASE YOUR SEWING PLEASURE

THREAD

1- Select the correct size of thread for the material you are sewing.

NOTE; The right size and weight can quickly be determined by

pulling a thread from the material and matching the spool

of thread with it.

2. Use the same kind and weight of thread for both upper and

bobbin thread.

3.

Avoid winding new thread over a partially wound bobbin.

4.

Use silk thread on woolens •••mercerized thread on fine cottons

and synthetics

........

cotton thread on heavy materials, such as

denims, work shirts, canvas, ticking, strong linens, slip covers, etc.

NOTE: Most cotton materials are preshrunk and it is wise to use

preshrunk thread when sewing on preshrunk materials for

the thread may shrink when laundered, causing the seam

to pucker.

5.

Bright colored thread is weaker than white or neutral colors.

Allow for this and use slightly larger thread size.

Proper attention to the selection of proper thread weight or size will

cause the stitches to "blend” into the material.

25

Page 29

NEEDLE

Always use highly polished chrome finished needles. The cost is

approximately the same and the workmanship is better.

Change needles often, for the point becomes dull and blunt due to

the many thousands of times that the needle pierces the material

when a dress or suit is being made. If you have a magnifying glass,

examine each new needle before putting it into your machine and

look for (1) sharp edges around the eye, > 2) blunted or broken point,

and (3) a bent or "fish-hook” point.^ Lay the needle on a flat

surface to be sure it is not bent or curved.

Choose the correct needle for the size of thread. If the needle is too

large the seam will appear to be a row of perforations.

..............

or if the

needle is too small the thread will lay on top of the material and

the tension settings will appear to be incorrect. Consult the needle

and thread guide for the correct needle and thread sizes.

26

Page 30

STITCH LENGTH

There are correct needle and thread stees for materials ...and there

IS also a correct stitch length.

A simple rule to follow is (1) short stitches for light or sheer

materials, (2) medium stitch length for medium materials, and (3)

long stitches for heavy materials.

For best results-after selecting the correct thread and installing the

right needle^practice stitching on a sample oi the material by experi

menting with the stitch length until you have found the length that

causes the thread to "blend” into the material.

The stitch length governs or controls the pace at which the material

moves under the presser foot, and when the correct length is longer

than average, more satisfactory work will be performed by operating

the machine at slower speeds.

Do not pull on the material, for it will cause uneven stitch lengths

-bend or break the needle-break the thread.

The sewing „.chine is des.gned the correc, an.„„n. of

thread in relation to the movement of the feed mechanism.

Page 31

SEWING SPEED . ■

Do not operate the machine at a speed faster than you can correctly

and properly assemble the material and properly align it tor feeding

under the presser foot.

Sew for a few inches and stop •■•assemble the material and again sew

for a few inches and stop and continue this way. You will avoid

mistakes and eliminate ripping out imperfect seams and resewing.

avoid minor troubles -

It is advisable to have periodic inspections by a competent mechanic

in order to insure perfect operation and long life of the machine.

If you are buying a new part or device take-or send-the old one

and request that it be duplicated exactly.

If you are buying a new attachment or accessory take-or send-a

sample from your box to be sure that the new one is manufactured

for and can be attached to vour machine.

28

Page 32

MEMO

Loading...

Loading...