SINGER W1015 User Manual

E LG IN

MODEL 10i5

CONTENTS

NAMES OF PARTS....................................................................................................................................

ACCESSORIES..............................................................................................................................................

BEFORE SEWING......................................................................................................................................7

Detaching Extension Table..................................................................................................^

Connecting Foot Controller and Power Cord

Changing Foot

Changing Needle.......................................................................................................................... ^

Bobbin Winding...............................................................................................................................

Inserting Bobbin...........................................................................................................................^

Adjusting Lower Tension......................................................................................................

Drop Food Lever...........................................................................................................................

Threading Upper Thread........................................................................................................

Twin Needle Threading............................................................................................................

Decorative Tucks or Designs.............................................................................................^

Drawing Up Lower Thread.................................................................................................. °

Foot Pressure................................................................................................................................

Fabric. Thread and Needle Table................................................................................To

Pattern Setting...............................................................................................................................

STRAIGHT SEWING..............................................................................................................................

Pattern Selection Dial.............................................................................................................T8

Stitch Length Dial

Double Pressor Foot Lifter.................................................................................................

Cloth Guido.......................................................................................................................................

Adjusting Thread Tension...................................................................................................

Applications of Straight Stitch......................................................................................21

ZIGZAG SEWING.....................................................................................................................................22

Zigzag Width Control................................................................................................................

Needle Position Control

Thread Tension for Zigzag Stitch................................................................................22

MAKING BUTTONHOLES............................................................................................................ 23

Determine Length.......................................................................................................................23

Determine Width..........................................................................................................................23

Cutting Buttonholes.................................................................................................................25

Corded Buttonholes.................................................................................................................26

SEWING ON BUTTONS.....................................................................................................................26

, OVERCASTING.......................................................................................................................................27

, OVERLOCKING................................................................................................................................. 28

Application of Ultra Stretch...............................................................................................23

Application of Rick-Rack- —

Application of Decorative Fun Patterns.................................................................31

BLIND HEM STITCH.............................................................................................................................32

Elastic Blind Hem Stitch......................................................................................................33

STRETCH SEAM......................................................................................................................................34

. ZIPPER SEWING...................................................................................................................................35

. SHELL STITCHING..............................................................................................................................36

. PIN TUCKING............................................................................................................................................37

. SCALLOPING...........................................................................................................................................38

. MENDING.........................................................................................................................................................

Patching...............................................................................................................................................

Mending a Rip................................................................................................................................39

Darning.................................................................................................................................................

. APPLIQUE WORK..................................................................................................................................

.

EMBROIDERY..........................................................................................................................................^2

. MAINTENANCE..........................................................................................................................................

Cleaning..............................................................................................................................................^3

Oiling........................................................................................................................................................

.

TROUBLE CHART..................................................................................................................................

Changing Light Bulb...............................................................................................................^6

..................................................................................................................................

.......................................................................................................................

..............

^.....................................................................................22

..............._■...................................................................

.....................................................

2^

2 Z

20

I

5

®

°

...

2 2

....

.

STANDARD SEWING EQUIPMENT CORP,

Record in space provided below the Serial No.

and Model No. of this appliance.

The Serial No. is located Rear of arm.

The Model No. is located Rear of arm.

Serial No

Model No. 1015

Retain these numbers for future reference.

-------------------

---

-----------------------------

-25

-26

27

28

29

30

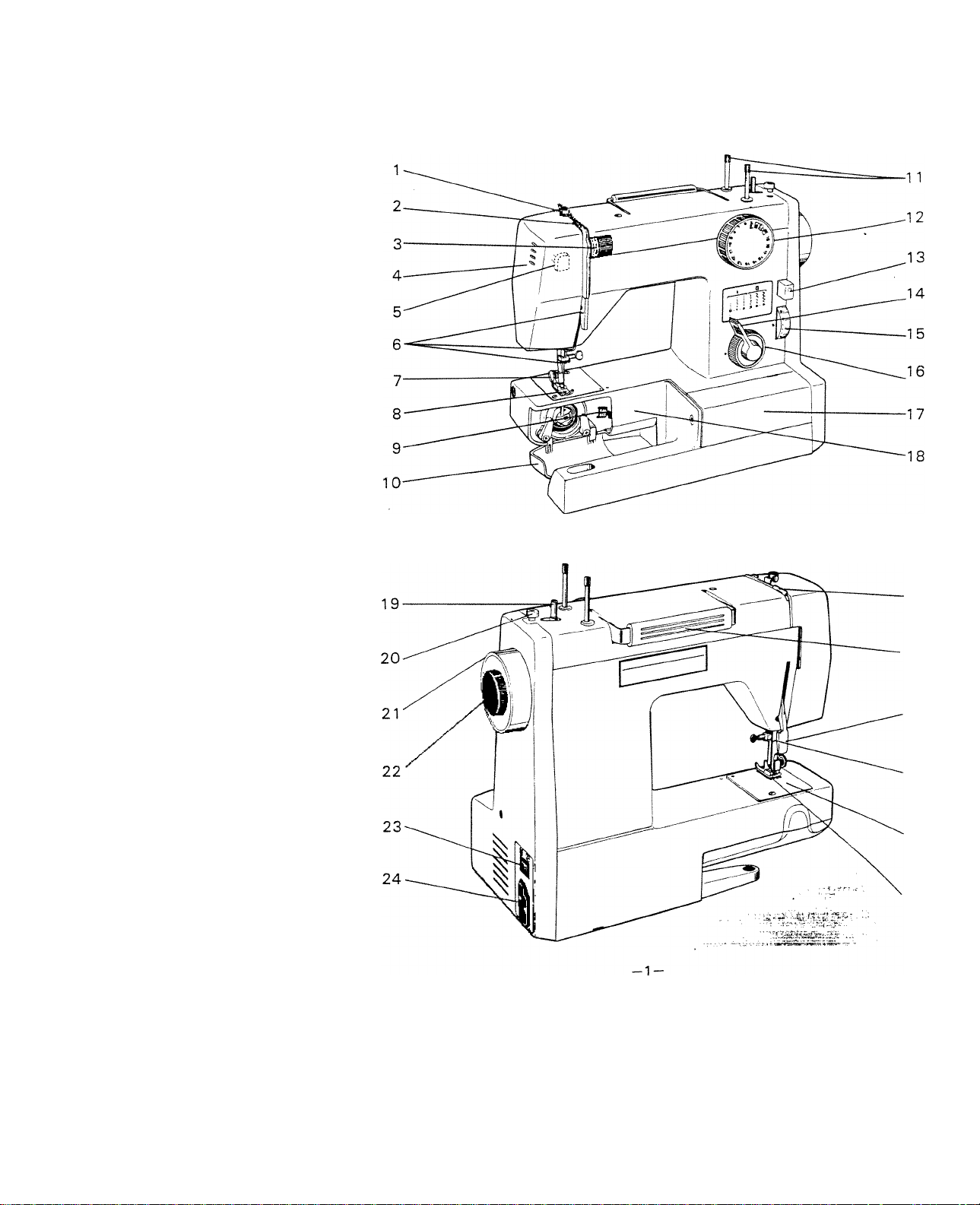

1 .NAMES OF PARTS

1 Thread guide for bobbin winding

2 Take-up lever

3 Upper thread tension dial

4 Face cover

5 Foot pressure lever.

6 Thread guide for upper threading

7 Presser foot thumb screw

8 Presser foot

9 Drop feed lever

, 1 0 Shuttle cover

1 1 Spool pins iretractablej

12 Pattern selection dial

1 3 Reverse sewing button

14 Zigzag width control

15 Stitch length dial

1 6 Needle position control

1 7 Accessory box

18 Free arm

1 9 Bobbin winding spindle

20 Bobbin winding stop

21 Handwheel

22 Stop motion knob '

23 Power supply switch

24 Socket

25 Thread guide for upper threading

26 Handle

27 Presser foot lifter

28 Thread cutter

29 Needle plate

30 Feed dog

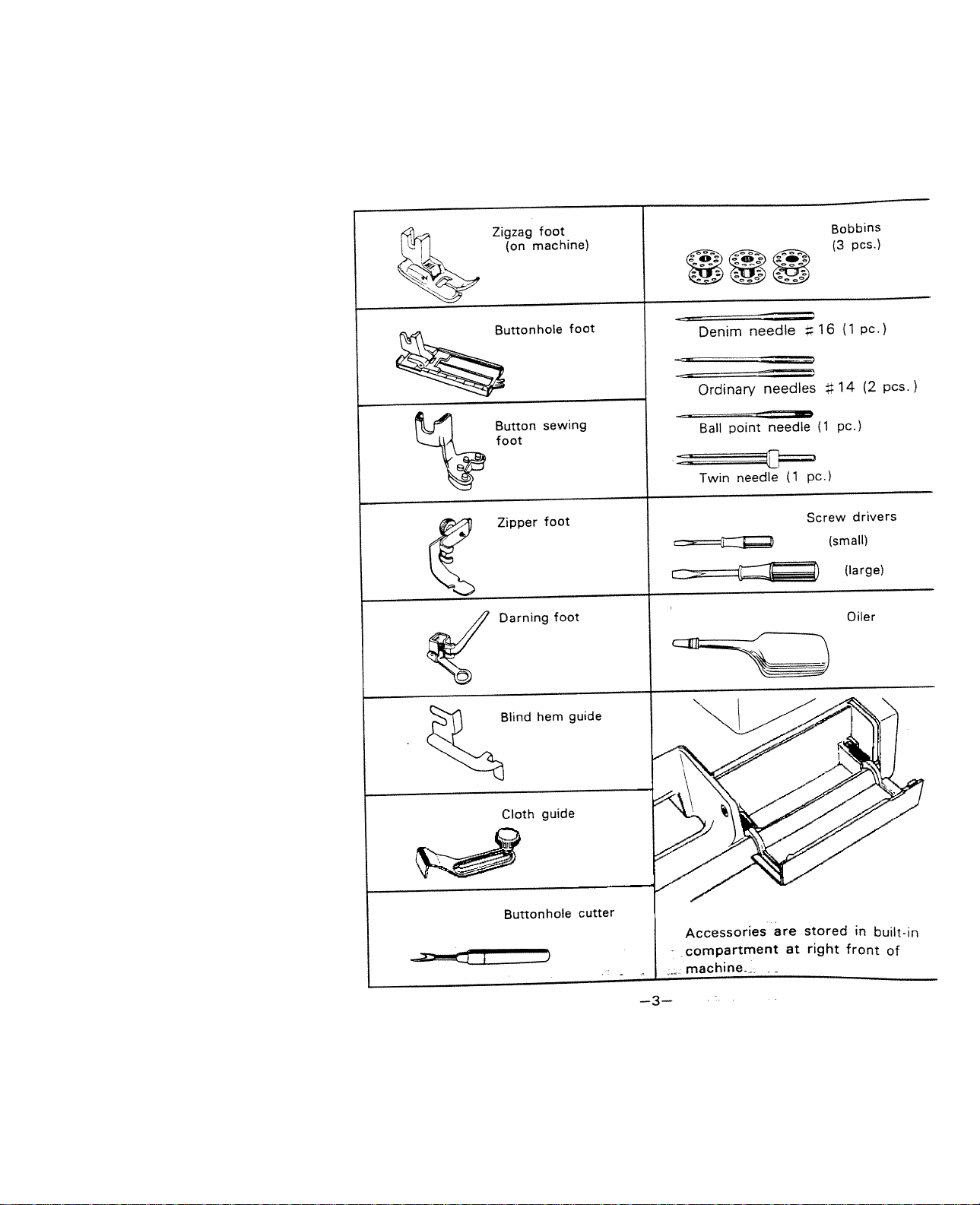

2. ACCESSORIES

3. BEFORE SEWING

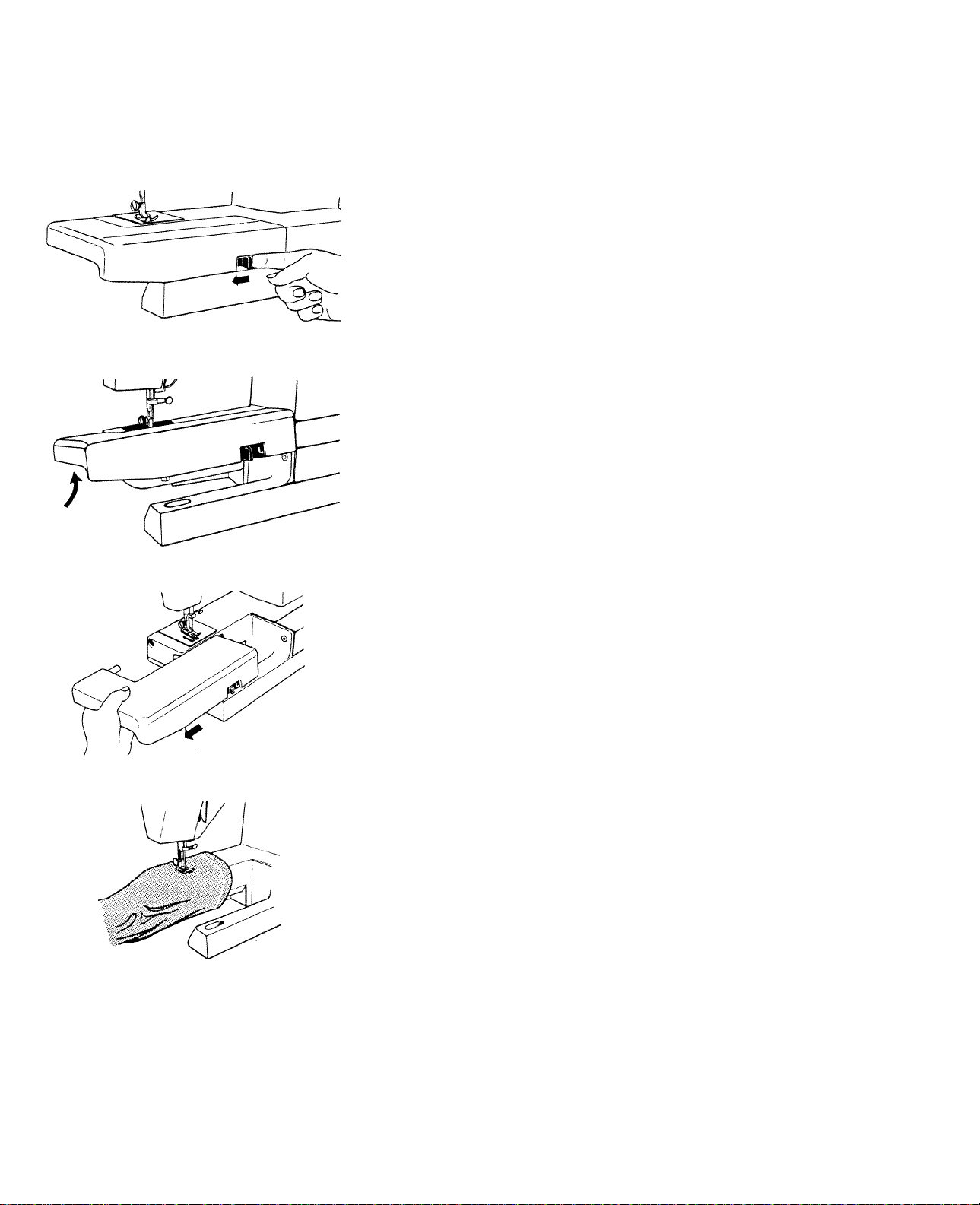

Machine is stored in flat-bed style

which makes your work easier in

ordinary sewing.

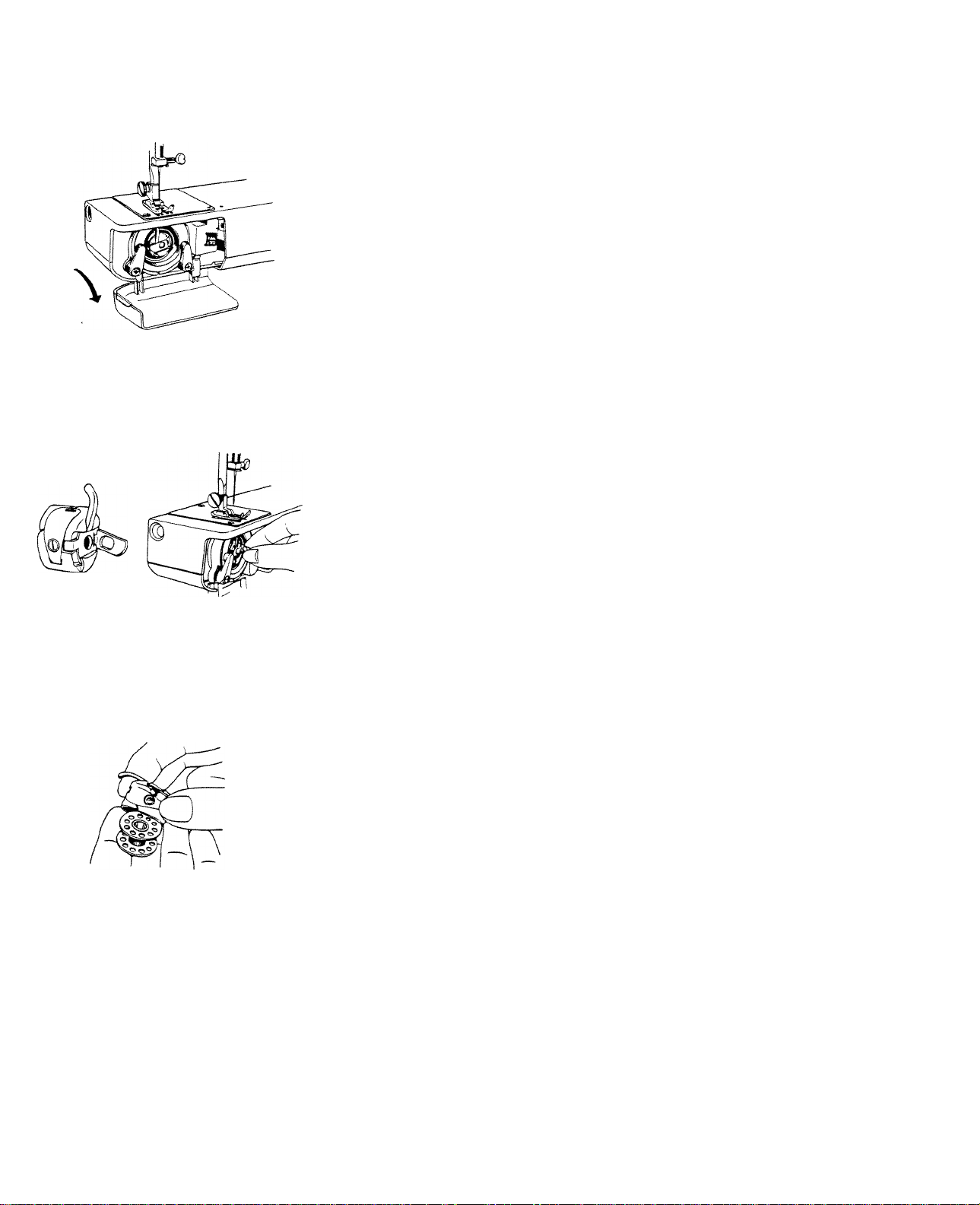

Detaching Extension Table

Push lock lever to left.

Open extension table in direction

of arrow.

Slide it off and the machine is

used as a free-arm model.

Free-arm is convenient to sew or

embroider; trousers, sleeves, cuffs

of T-shirts, blouses, etc.

Do vice-versa of above steps to

attach extension table.

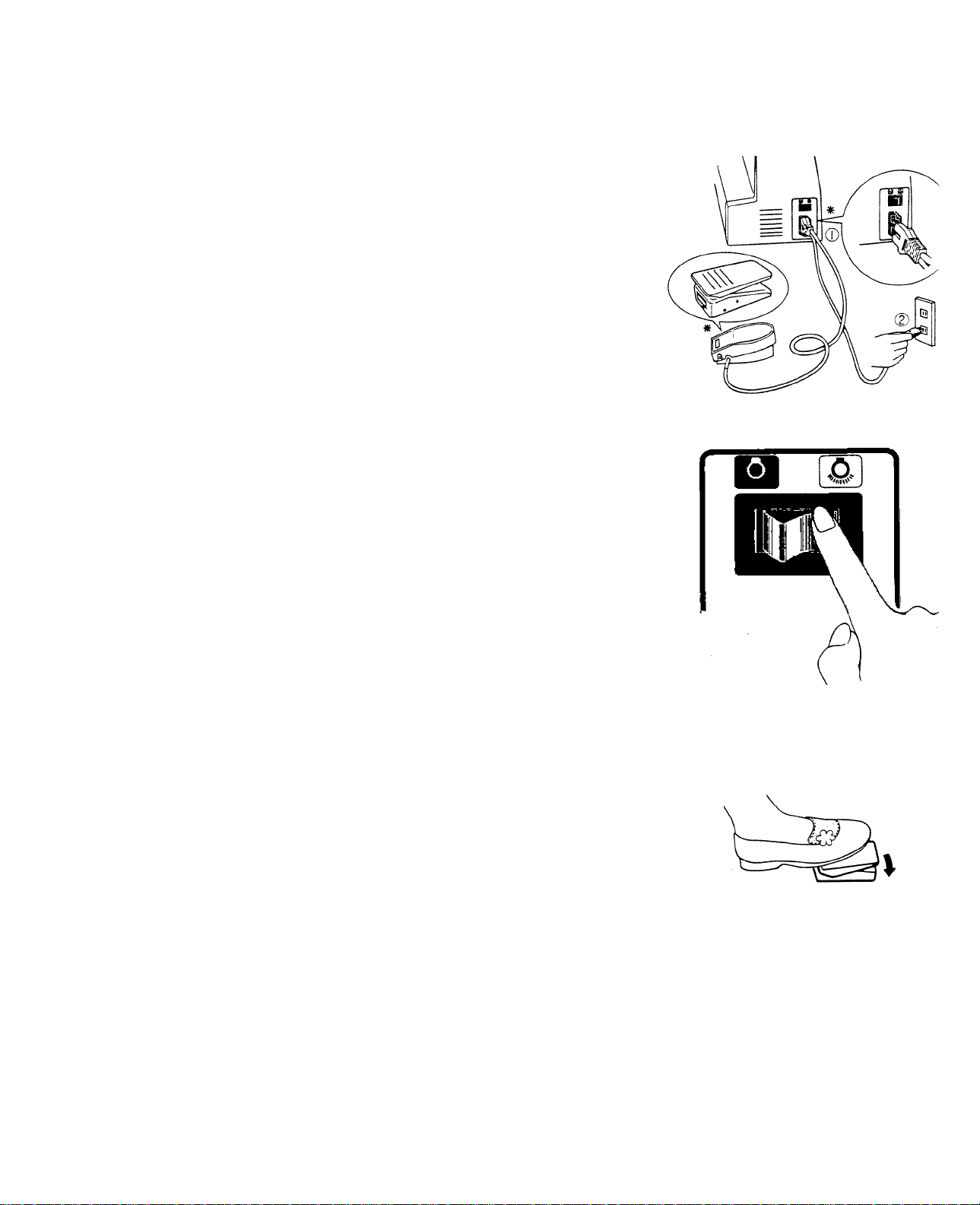

Connecting Foot Controller

and Power Cord

Connect foot controller

power cord © (2).

Before plugging in your machine,

be sure that voltage is same as

that of your machine, (written on

a plate at back of machine)

■iff Specifications vary from country

to country.

Switch on power to put on

machine and turn on sewing

light.

Always switch off or unplug

machine when not in use.

and

The more you press foot controller,

the faster the machine runs.

-5-

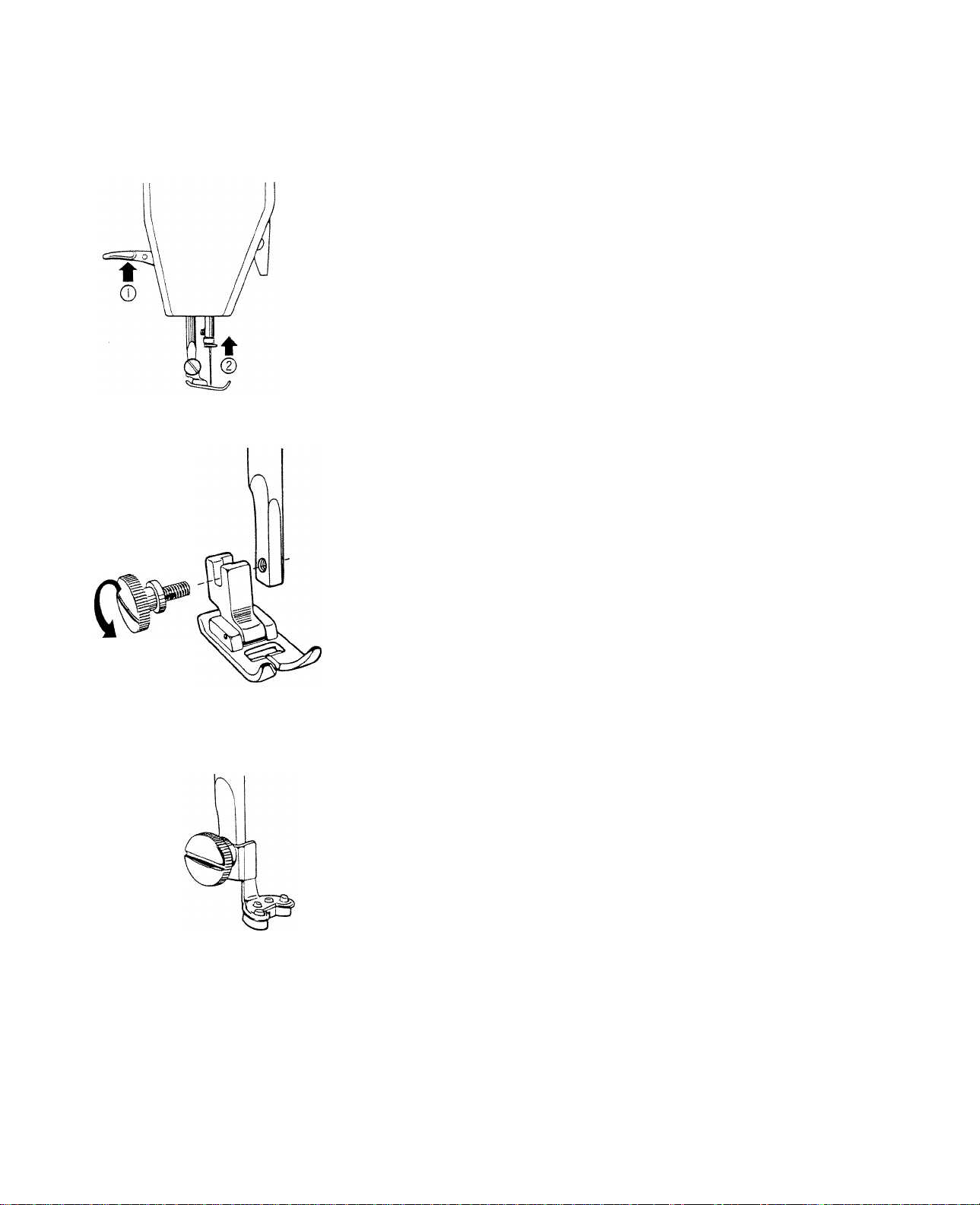

Changing Foot

Raise presser foot lifter ©.

Set needle in the highest

position by turning handwheel

towards you @ .

Remove foot by loosening screw

with screwdriver.

o

Replace new foot and tighten

screw.

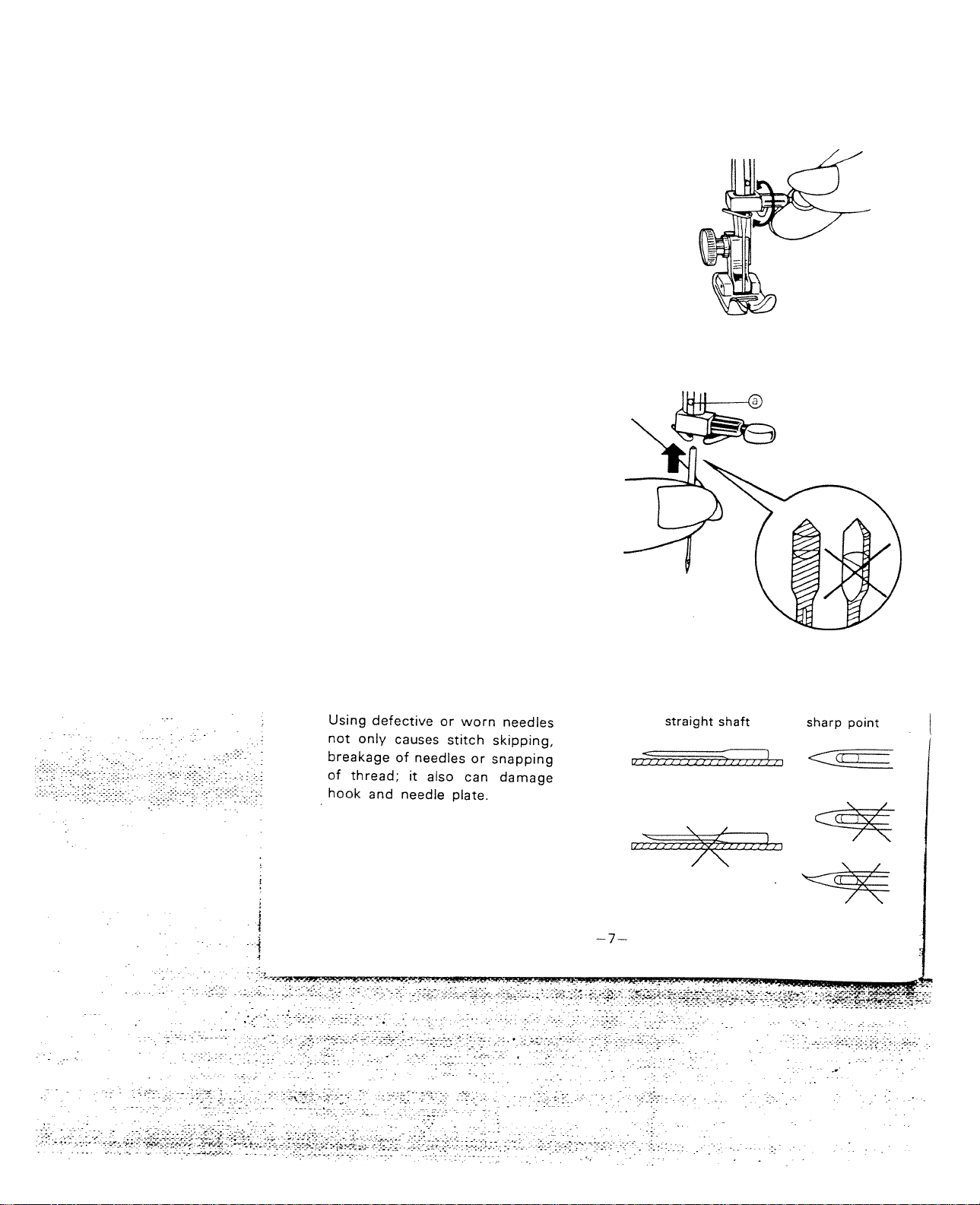

Changing Needle

Set needle in the highest

position by turning handwheel

towards you.

Loosen needle clamp screw and

take out needle.

With flat face away from you,

insert a new needle into groove

of needle bar.

Push needle until it reaches

stopper @ and tighten needle

clamp screw firmly.

Always use a straight needle with

a sharp point.

Proper needle

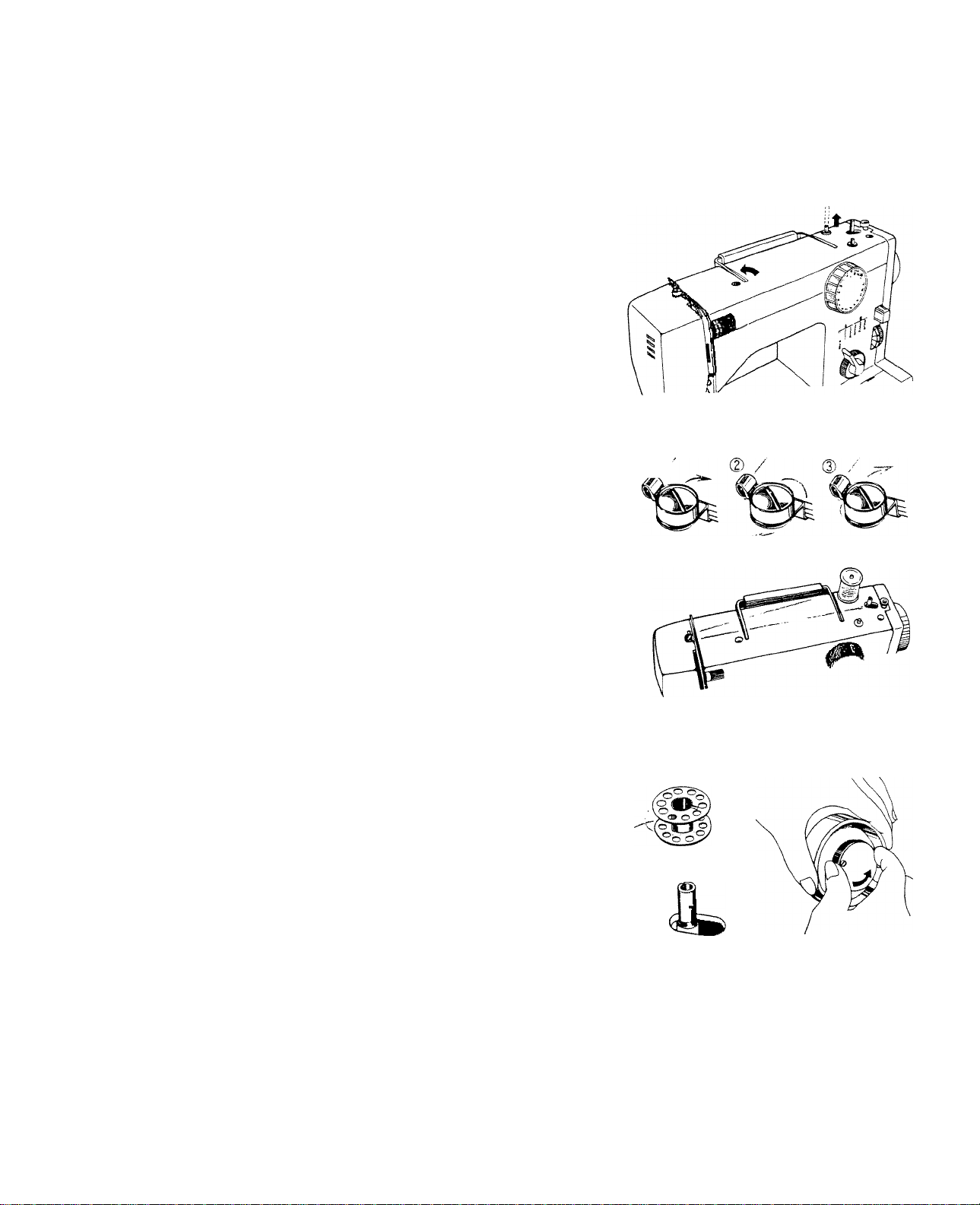

Bobbin Winding

Set needle in the highest

position by turning handwheel

towards you.

Open shuttle cover.

Open latch of bobbin case and

take it out.

V- _■.. .

Close latch of bobbin case and

bobbin comes out easily.

'••V-^

Push back to fold handle.

Pull out spool pin.

Put a spool on spool pin.

Draw thread from spool pin

through thread guide and pre

tension device, following numb

ers © ® and (3).

Wind thread clockwise around

bobbin several times.

Push bobbin on to spindle.

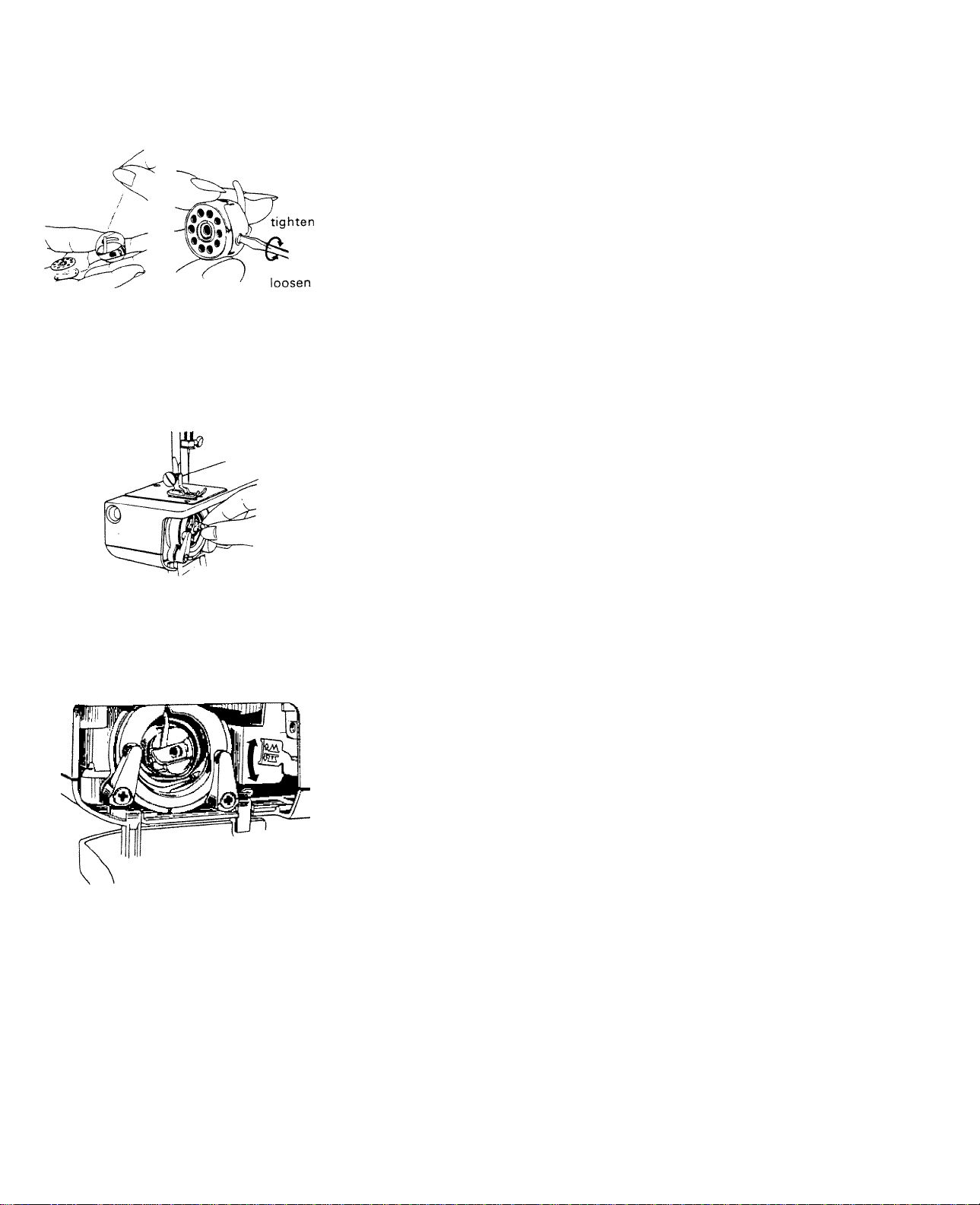

Holding handwheel with your left

hand disengage handwheel by

unscrewing stop motion knob.

.'V'. .

-9-

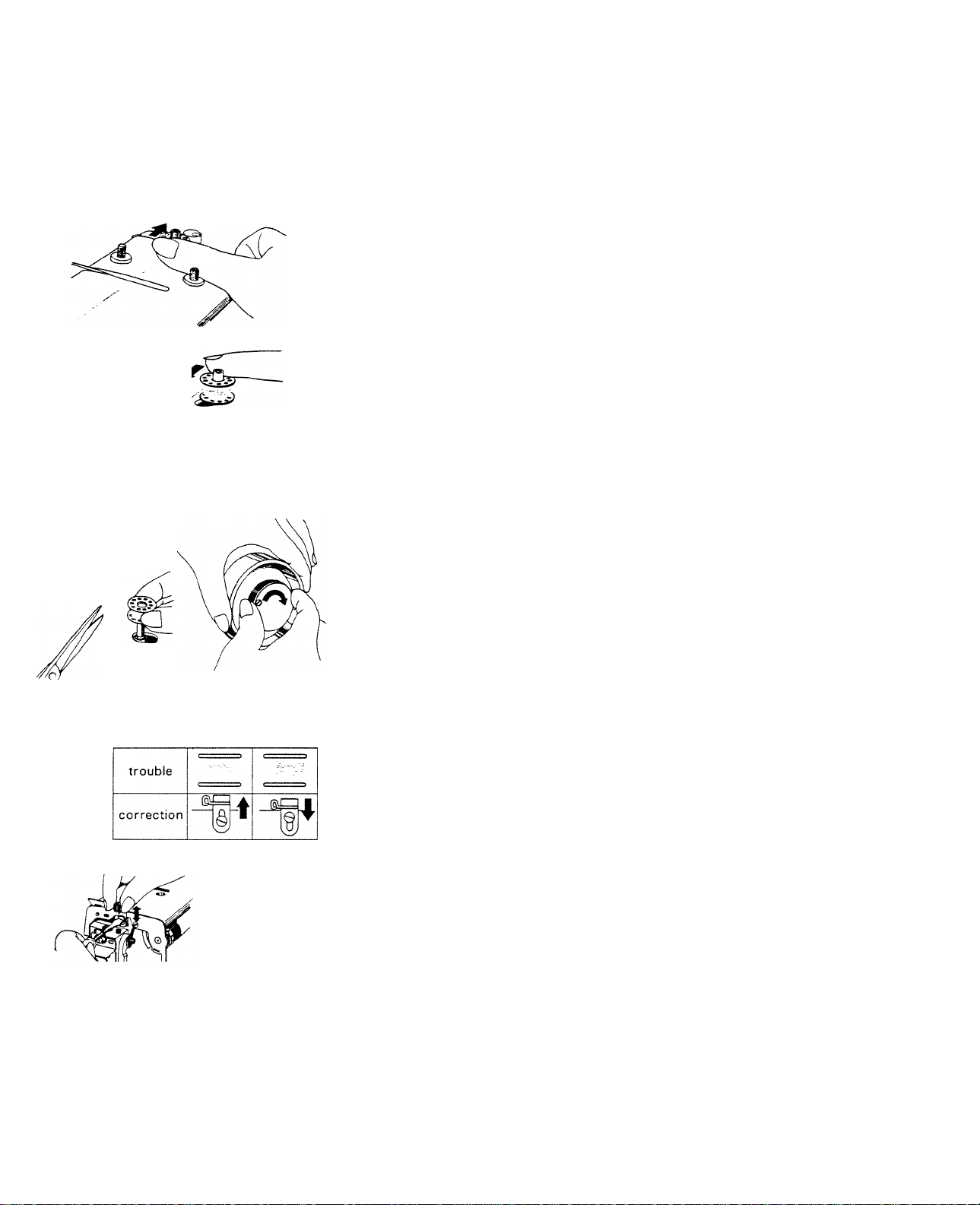

Push bobbin to right and press

down foot controller.

Machine stops automatically

when winding is full.

Push bobbin to left.

Take off bobbin from spindle

and cut thread.

Retighten stop motion knob.

-10-

If bobbin is wound unevenly

as shown, open face cover and

loosen set-screw of the guide for

bobbin winding, by using screw

driver and adjust height.

Aii"

Inserting Bobbin

Place bobbin in its case with

thread running in direction of

arrow.

Guide thread into slot ® of

bobbin case.

' Pulling thread to left, bring it

under tension spring then to

delivery eye ®.

-11-

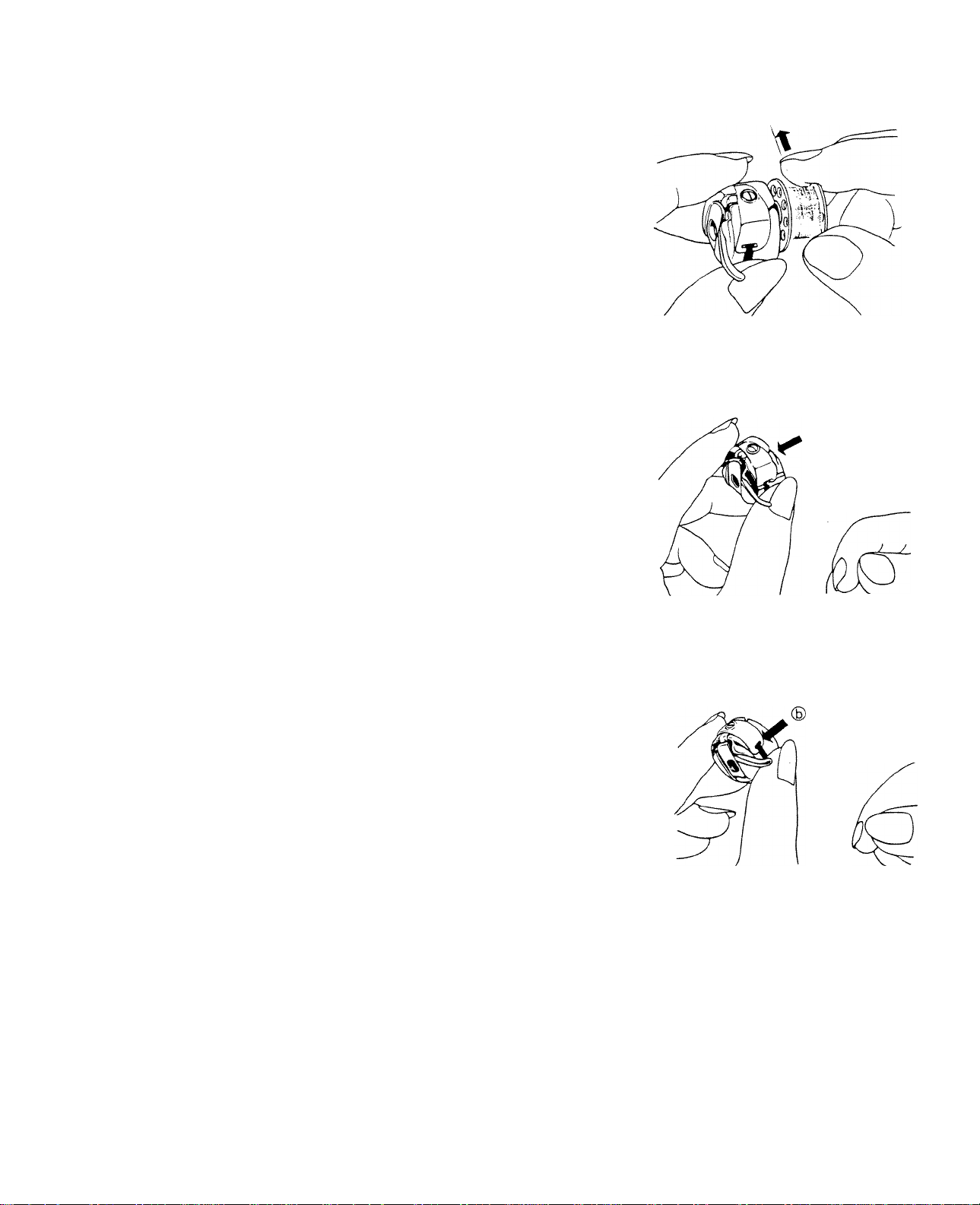

Adjusting Lower Tension

To test bobbin tension, hang and

shake bobbin case as shown.

At proper tension bobbin case

will gradually drop a small

amount.

To adjust tension, turn adjusting

screw with small screwdriver.

Raise needle

position.

Leave end of thread of about 10

cm (4") from bobbin case.

Take hold of latch and push

bobbin case into hook.

Release latch when bobbin case

is fully inserted.

the highest

Drop Feed Lever

The lever is on right side of hook.

To lower feed dog, move lever

down to AA position.

This position is for button sewing,

darning and embroidery.

12-

For normal sewing, move lever

.up to ^position.

-M

Loading...

Loading...