Page 1

18131)

INSTRUCTIONS

FOR USING

THE SINGER PORTABLE

ELECTRIC SEWING MACHINE

No. 99-13

(ATTACI liVlliN 13 I ¿0360)

WITH KNEE CONTROL

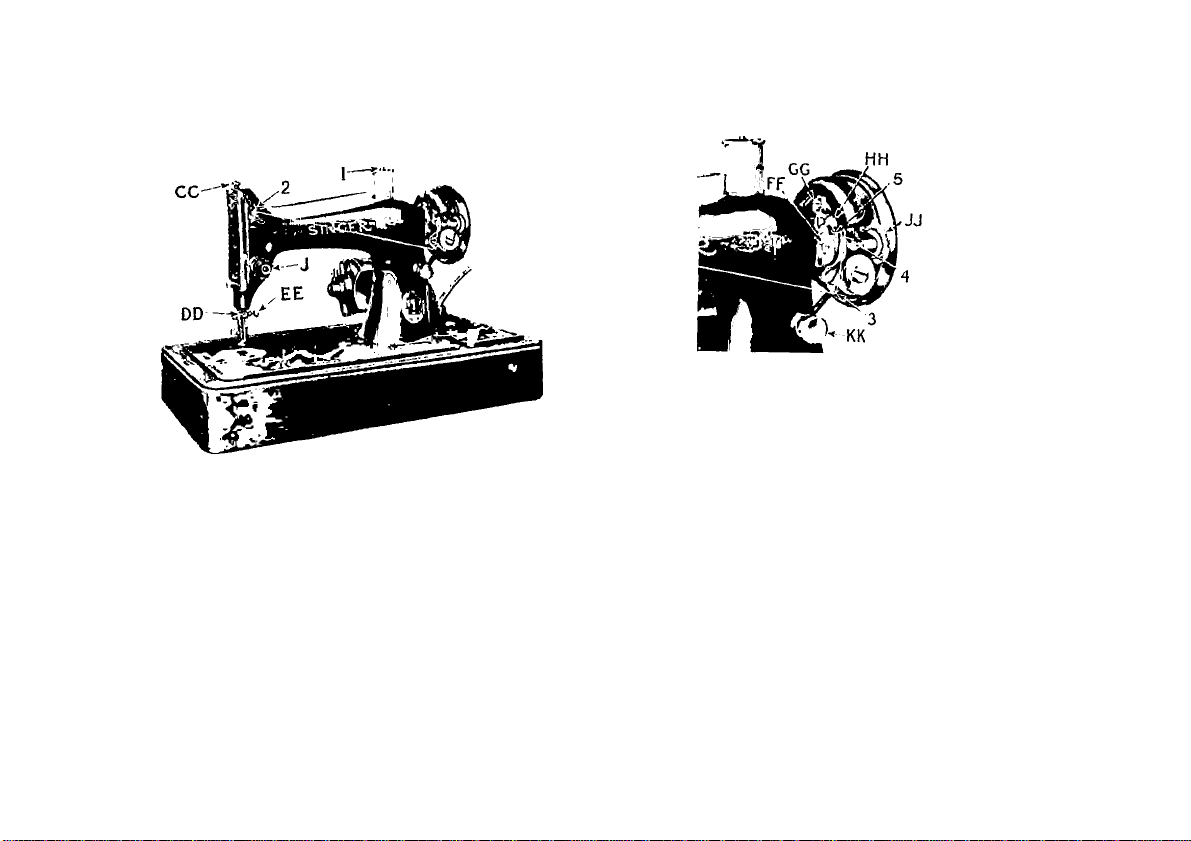

Fia. 1. KnKH I.kIVER IÍÍ PuRlTION IN CoVKU

AfUir miioviiiK llie cover, remove (he knee lever

(F, Fig. 1) from (he two cleats (K, Fig. 1).

NEVER USE OIL ANYWHERE ON THE MOTOR —

Lubricate only with Singer Motor Lubricant and use it

only in the two grease tubes provided for that purpose,

Page 2

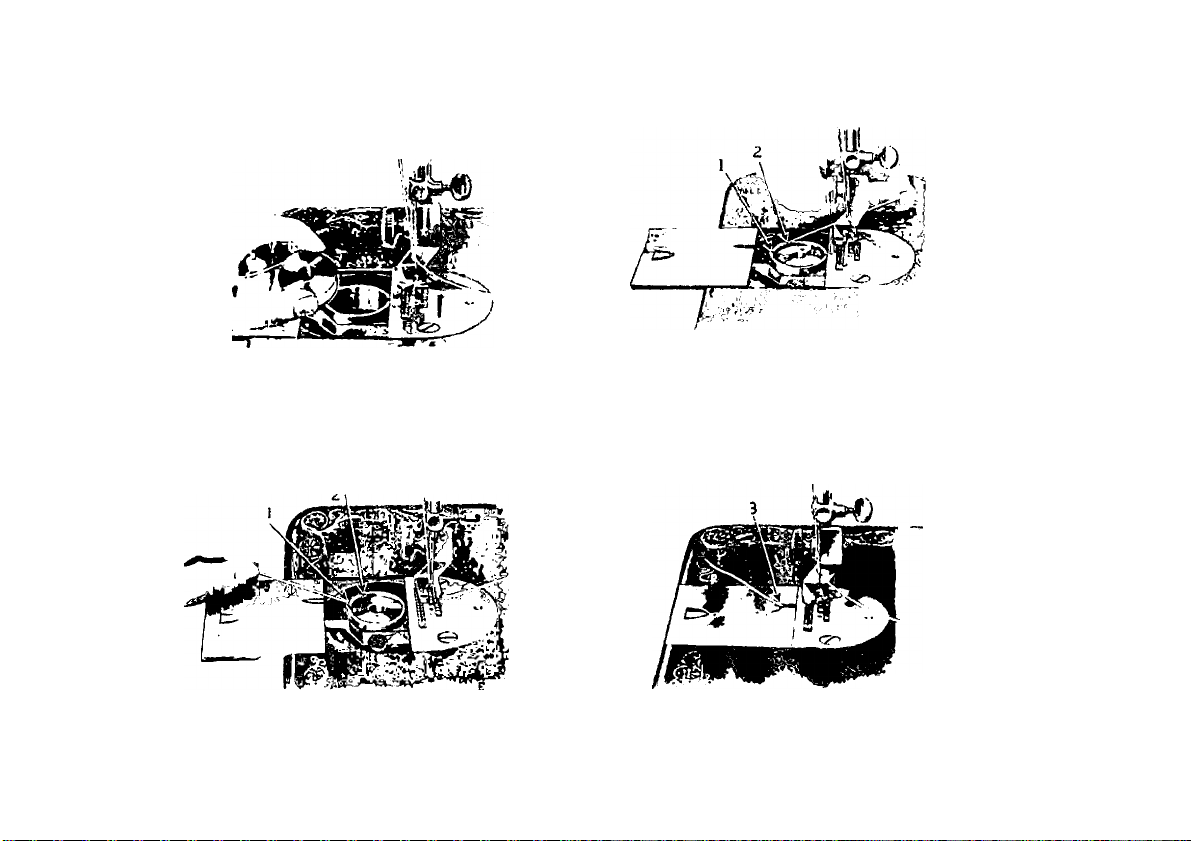

To Adjust the Knee Lever

Ilokl Uio lever iii the hurizoïilal position as sliown

in h'ig. 2, and push the soeket of the lever over

Fia. 2. Pl.\cing Knee Lever in l’osmoN

the stud (n, Fig. 2). Allow the lever to dnip

into the vertie.al i)Osilion as shown in Fig. 2, page 2.

Fiü. 3. Knee Lever in Position Heady

FOU ül'ERATIÜN

Page 3

Motor can be Operated on Either Alternating

Current or Direct Current

The ctccli'ii! iiiulor, which is located at the. liaclc

of Ihu machine, can he opcrateil on oil her altcniating emrent or direct enrrent, as desiiv<l. 'riie

slnndard windiiigs of tlio motor are for ill) volts,

and motors can he fnrnislicd tor any voltage hetweon

100 and 250.

¡Special motors for 32 volts direct current, and

for 50 volts alternating enrrent and direct cuiTont,

have also hcen developed ami aie availahle.

Points to Determine before Connecting

Motor to Electric Service Line

Obtain the following information from the Elec

tric Light ftompany which supplies the electric

current for the circuit to w'hich the mohir is to

he connected:

1. AN'hat is the voltage? 'I'he voltage must he

within the range stamped on the motor nameplate.

2. If the current is alternating, what is the num-

her of cycles? 'I'he mimher of cycles must he

within the range stamped on the motor name plate.

The voltage of any circuit and, if alternating

current, the number of cycles, can he verified by

looking at the name plate on service watt meter

installed by the local Electric Light Company.

To Make the Electrical Connection

Enwind the. electric cord, screw the plug at the

cnil into an electric light socket and turn on the

switch.

To Turn Singerlight “On” or “Off”

lieach over the toji of the machine and move

the switch lever (N, Eig. -Ij to the right or left a.s

tlcsil'dll.

4

Page 4

6

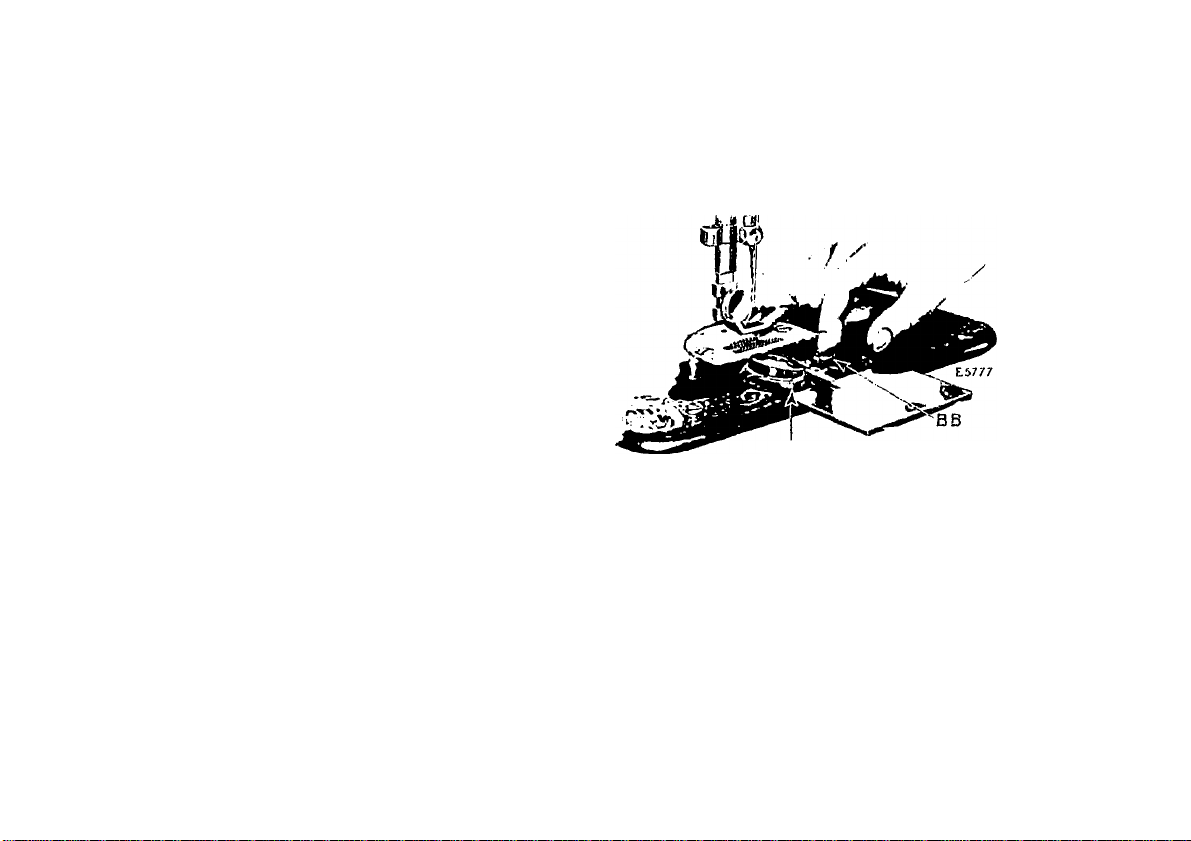

To Remove and Replace the Bulb

To remove the hull), hold the Biogerlight socket

tighllj' with one hand and with the other hand

turn I he shade halfway around until the pin tBB,

hig. ll for the shade is in the slot of the shaile, then

gently slip the shade olT and allow it to hung free as

shown in Kig. -1.

Do not attemi)t to unscrew the hiilh. It is of

the hayonet and socket type and does not unscrew.

1‘ress the hull) into the socket anil at the same

time turn it until the hull) i>in 1'1’T, Kig. 4) is out

of the notch in the socket, then withdraw the

hull) and shade.

To insert a new hull), pass the hull) through the

collar of the shade with the slot of the shade up

ward. Hold the socket tightly with one hand and

at the same time with the other hand pre.ss the

l)ulh into the socket with the hull) i)in (TT, kig.

4) in the slot and turn it until this pin is in the

notch. 'I'lien slip the shade over the socket, the pin

tS.S, I’ig. 4) for the shade entering the slot of the

shade. See that the pin (SSJ is in the groove of

the shade and turn the shade halfway around, or

until it is at the top.

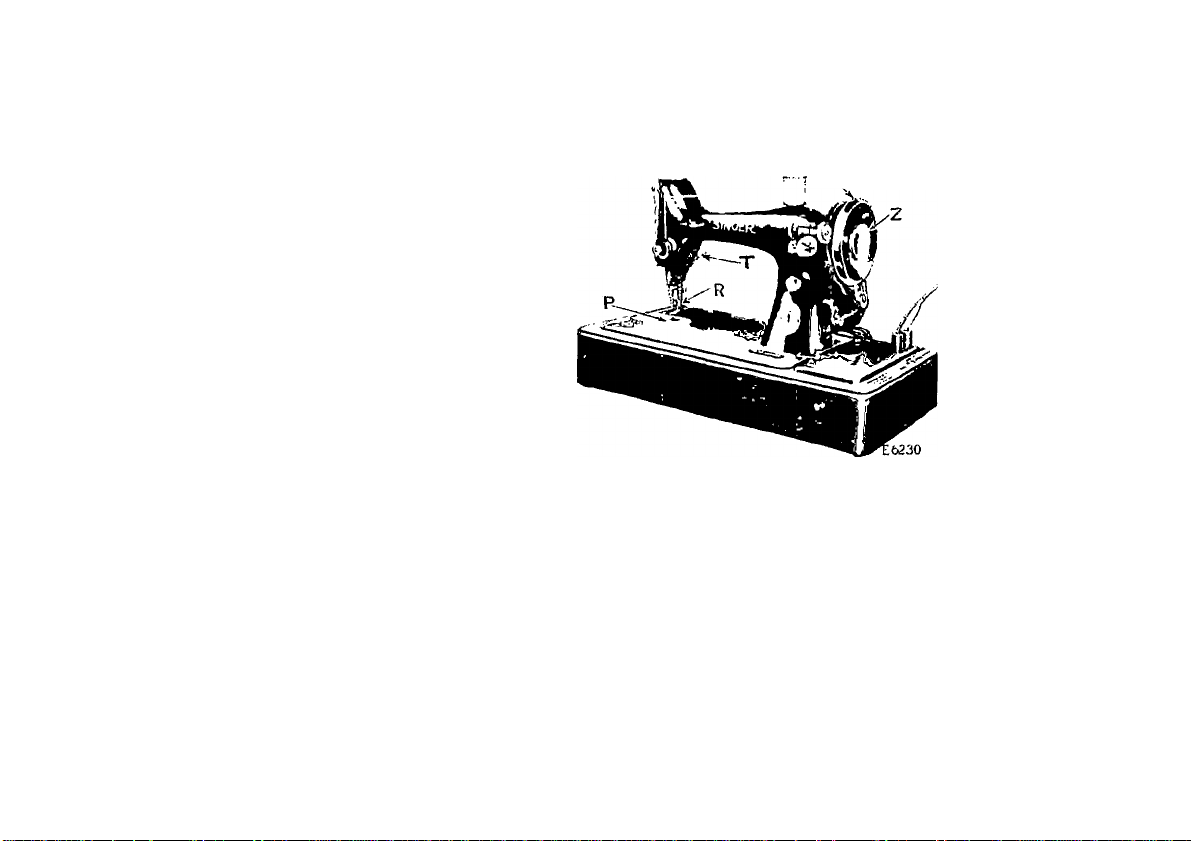

To Operate the Machine

'J’o prevent injury to the presser foot (R, Tig. 5)

and feed (P, Tig. .5), raise the presser foot (R)

hy means of the presser bar lifter (T, ]'’ig. 5).

Us

0. Tuont Vitiw ui«* TUB Macuinu

PlilCU a piece of cloth under the presser foot

and then let the foot down upon it.

Turn on the electric current and lightly press the

knee lever to the right. As you press haidcr against

the knee lever, the speed of the machine is increa.seil,

(he speed being eonirollcd entirely by the degree to

which the knee lever is pushed over. Operate the

machine in this way witliout being threaded, until

you have become accustomed to guiding the ma

terial anil operating the knee lever.

Page 5

To Ensure Perfect Action of the Machine

'I'lic Inilillice wheel iiniisl always turn over towaril

yon.

Do not rnii the luaelhno with the presser foot

resting on the Cecil without cloth nniler the jnesser

toot.

Do not run the niaehine when both bobbin ease

anil neeillo are Ihreaileil unless there is lualerial

umler the [ire.s.ser toot.

Do not try to help the jnaehine by [Killing the

fabric lest you bend Ihe needle. 'I’he inaehine feeds

the work without assistauee.

The slide over the bobbin ease should be kept

elo.sed when the inaehine is in o|)eration.

CAUTION

When through with your sewing, always

turn off the electric switch at the lamp socket.

To Take Out the Bobbin

Draw to the left the slide in the bed of the

inaehine and [iress the forelinger of the right hand

A A

To Pack Up the Outfit

Heniove the [ilng from the electric light socket

and coil the electric cord around the uiachine.

liaise the knee lever to a liorinontal position, re

move it and replace it into the cleats (li, Kig. 1,

page 1) in the cover, lleplace the cover and lock it.

Fio. 5. Tiiif: Boudin

u|ion the bobbin ejector (Bli, Pig. (>); this will

rai.se the bobbin so that it can be easily taken out.

Page 6

10

To Wind the Bobbin

lb iri iicec.ssiiU'y bo undiM’sliMul ilio slop iuol.i«)n

C/j, l’’ig. 5, pagò 7) by wliioh Lhu balaiioc wheel

11

7) then np into the lower eyelet (3, Fig. 8) of the

hobbin winder thread guide, into the notch (1, F'ig.

£5780

Flo. S, \Vr^fJ>l^ao TUB liouui.v

E»-05

MACiiiNe 'l'uite.vuKU euu WiNeise 'niK Uüuuik

(U, Fig. 5) ean l)e reloiised when leituired, bhus

peniiil.tiiig the winding of bobbiits wilhout. iiminng

llie slilehing meehanisin. It also allows yon

to wind bobbins wilhonb removing parlially sewn

work and wilhont nnthreading the machine.

To I'elease the balance wheel (U, Fig. 5), turn the

stop motion screw ('/, Fig. 5) over toward yon.

IL is iiocossury to hold the bulanco wiieol >viulc

ooscning me SLop nioiiou ai.iv.«.

loosening the stop inoLiou screw.

I Unte the bobbin on the bobbin winder spindle

(V'V I'ig. S, page 11) and push it up closely against

the shoulder, liaving the small jiin in llie spindle

enter the hole in the side of the hobbin. Fnt the

spool of thread on the spool |im (1, Fig. 7). I ass

the end of the thread into the thread guide (2, Fig.

8) ami piuss the tlinuid Ihrongii tlu* link; in tliL* loftside of the liobbin (5, Fig. 8), from the inside. I’re.ss

I he bobhin winder pulley (J.I, Fig. 8) tiown on the

halunee wheel hiih, and the latch (1111, l-'ig. 8) will

drop down and hohl it. 'I'lien start the lialanee

wheel in motion the same as for sewing.

The end of the thread niiist he held hy the hand

until a few coils are woimd and should then he

hioken oil. When siiilieient thread lues lu'en woiiinl

upon the bobhin, the bobbin winder is antomatieally

reloxsed from tlio balance wheel.

Jf the pressiiie of the rubber ring (,U, l-’ig. 8)

agaiiisl tile hub of the balance wheel is insullieienl

for winding the bobbin, loosen the adjusting screw

(GG, Fig. S) and [iress the bohhin wiiuler lightly

until the rnhher ring is in contact with the hub of

the balance wheel; then tighten the screw.

i

Page 7

13

To Replace the Bobbin

Ilukl the bobbin between the thuinl) ami fovclinger of I he left hand, tlie Uneail leacling on top

fi-oni the rijilit lowaiil the left, as shown in Fig. 9.

FlU. 1). UE1M..»C1.S'U the tiOUUIN

I’laee the bobbin into the bobl)in emse and draw

the thread into the slot (1, Fig. 10; in t-l'n bobbin

ease, as .sliown below.

i;s

Oraw the thread backward between the bobbin

case ami the tension siiring until it reaches the

l*u:. H. BoGiiiji Case n*mtBAUED

notch (2, Fig. 11) then pnll thè thread toward thè

righi, as shown in Fig. 11.

W'hcn clo.sing thè slide, see that thè thread is in

thè slot (3, Fig. 12) in thè right edge of (he slide, as

.shown below,

Fig. io. Tuiie.i.oiNa tue Bouuis Case

nao

nsr.*

Fu;. 12. UndEIC TuUEAUlNO Co.Ml'LE'rKI)

Page 8

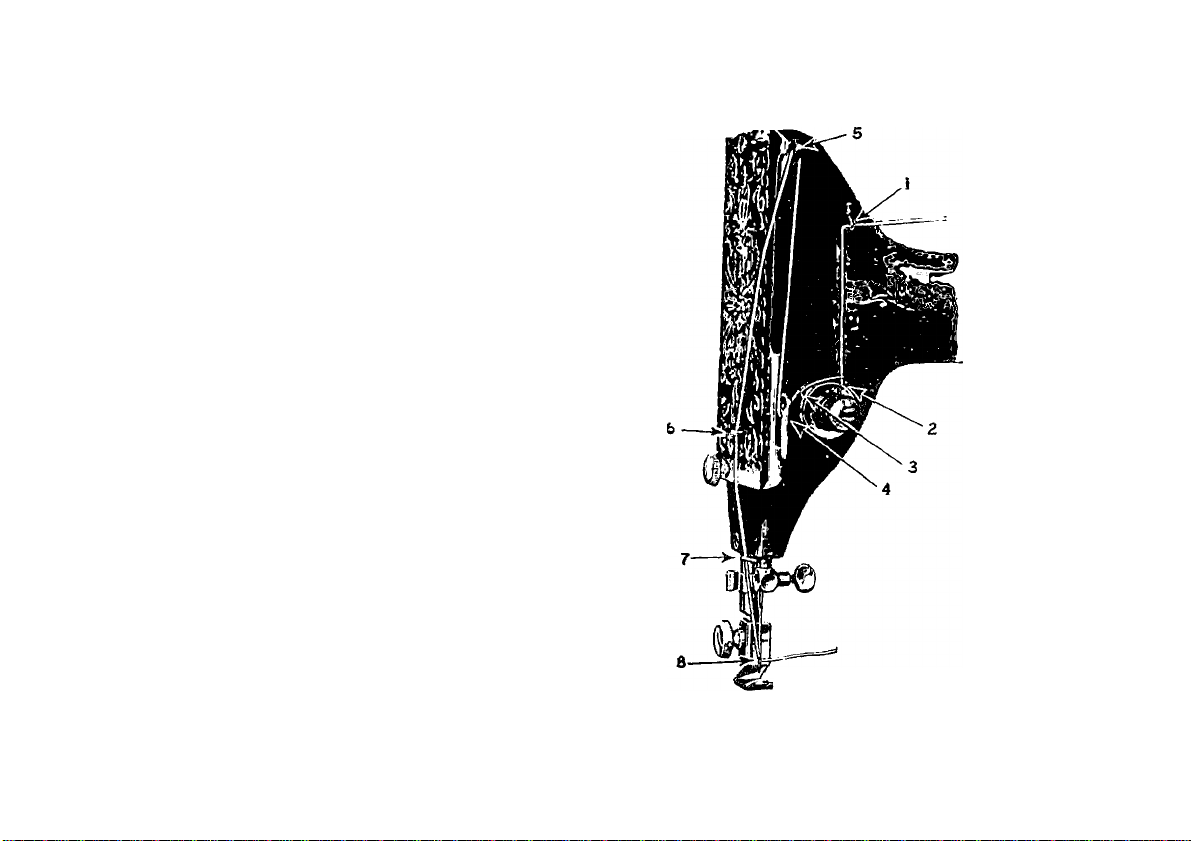

1-1

To Set the Needle

'I'uni Uic bivlmuio wliocl ovei' loward you until Iho

iiooillo l):u‘ moves u|) l.o ils lushest point, loosen

tin! (liiiinb screw (ICIi, I’ig. 7, page 10) in the nceille

cliimp (1)1), Fig. 7), limi put tin: iioeillo up into

the clamp as fiir ¡is it will go, with ils Hat side

towaiil the right, then tighten the thumb .screw.

To select the eorieet needle see page 4cS.

To Thread the Needle

See l‘'i*i. IS ON TUB Foi.lo\vjno Paob

Turn the balance wheel over towaid you until the

thread take-up lever {,5) is rai.sed to its highest

])oint. 1‘laee the spool of threail on the spool pin

at the top of the Jiiachine, lead the thread into the

Ihread guide (1) at the left, down, uiulcr and from

right to left between the tension discs (2), into the

small wire siiring (3), under the t.hrcail regulator (-1.)

at the left (not through the eye in the thread

regulator), up innl from right to left through the

hole in the end of the thread take-up lever (5), tlown

into the eyelet (ti), into the lower wire guide (7),

then from left to right through the eye of the

neeille (8).

Diaw about two inches of thread through the

eye of the jicedle with which to commence sewing.

Instructions for threading the machine for darning

and for embroidery are given on pages 41) and 47.

15

, Eó-HS

i'lij. 13. TiiJtK.1

.VDZN<} TUB

Page 9

1(5

To Prepare for Sewing

Have tlic lake-iip lever at, its liigliest point, llieii

wilh the left haml hold the end of the needle

tliread, leaving it slack from the hand to the neeille.

Fio. U. Duawinu Up tub Bouuin Tukeau

'rum the halanee wheel over towanl you until the

needle moves down and up again to its highest point,

thus catching the bohinn thread; draw up the needle

thrtaul aui.1 the bobbin threatl will come up with it

through the hole in the throat plate (.see I'ig. 1-1).

Lay both threads back under the presser fool.

To Commence Sewing

Place the material beneath the presser foot, lower

the presser foot and commence to sew', prejising the

knee lever to the right to start the machine.

17

To Remove the Work

Let the thread take-up lever rest at its highest

point, rai.se the pie.s.ser foot and draw the fabric back

ami to the left, p,a.ss the threads over the Ihreail

cutter (tj, Pig. 14, page 10) and pull dow'ii lightly to

sever them. Leave the ends of the Ihreail under

the i)ie.s.si'r fool.

Tensions

Por ordinary stitching, the needle and bol.biu

threads should be locked in the. centre of the thickness of the nmicriill, thus:

Fuj. 1;">. 1*KKKKL'T SiTivH

if the tension on l iio neetlle tln-eiul is too tight, or

if that on the bolihin limiacl is too loose, the neetlle

thieail will lie sliaight ahmg the upper surface of

the material, thus:

Fig. 10. 'I'lGiiT NcifOLh: Tension

If the Icitsion on the l>ol>I)iu thi'catl is too tight, or

if that on Iho needle thread is too loosci, the bobbin

thread will lie straight along the under side of the

inatorial, thus:

Fiu. 17. Luosu NKEULk: Tuue.\d Tension

Page 10

IS

To Regulate the Tensions

7'/i(i iensian on llio nced'ii Ihraid altoidd oidy ho

rajtdaled u'hoi llio /j/cssir fool is dtnon. Iliwiiii;

I’lG. IS. NsiiiK.ffl TmiEAO Te.msion

Idw uioiI Hie presaur luol, tuia Ilio simili llimuli aal.

(.1, sliowii ill I'ig. 18, above, and l'’Ì!5. 7, pago IO) al

Ilio frolli of Ilio LiMisiou discs over lo Ilio ri.gliL lo

iiicrcaso Ilio loiisioii. To doiaeaso Ilio toasion, turn

ibis lliiitiib mit ovor lo tho lofi.

Tlio lonsioii OH die bobbin lliioad is legiilaled by

die larger sorow fA.V, Tig. (i, |>ago !)) wliirli is

nearosl Ilio back in Ihe bobbin case lonsion spring.

To inoroase Ilio lonsion. Im a ibis sorow over loward

you. To deoroase Ilio leusion, turn lliis sorow over

from you.

Wlion the lonsion on Ilio bobbin Uiroad lias boon

ouoo pro[iorly adjn.sl.oil, il is soldoni nooo.ssary to

oliungo il, as a oorrooL sliU ll oaii usually bo obtainod

by varying die lonsion on Ilio noodle Ibroail.

To Turn a Corner

»Stop die inaoliino when the noodle is oouinionoing

its upwaril stroke. Kaiso die pressor fool and lur

die work as desired, using die noodle as a pivo'

(lion lower die pro.ssof fool.

19

To Regulate the Length of Stitch

The loiigdi of stiloli is regulated by (ho large

diunib sorow (KK, Fig. 8, page 11) at the front of

the niaeliino near llio bobbin winder.

To leiigdion die stiloli, turn lids tliiinib sorow

ovor lo die right. 'I'o shorton the stitoh, turn this

thumb .sorow ovor lo tho lofl.

To Regulate the Pressure on the Material

For ordinary family .sewing it is seldom nooos.sary

to oliaiigo the prossuro on llio material. If sowing

lino silk or lliiiisy inalorial, liglilen the prossuro by

turning tho dunnb sorow (C(t, Fig. 7, page 10) on

die lop of dio maohiiio ovor to Iho lofl. To inoroaso

the prossuro, turn this Ihunib sorow ovor lo the rigid,

d'lio pressure should be only heavy enough lo

lirevont the inalorial from ri.sing with tho noodle

and lo enable llio food to move the work along

evenly; a heavier prossuro will make tho inaehine

run hard.

To Sew Flannel or Bias Seams

Vise a.short slileh and as light a lonsion as iiossiblo

on the noodle throad so as lo leave the thread loose,

enough in the seam to allow the goods lo strololi if

noecssary.

A Stitch to Ravel Easily

can bo made if desiirod, by having the tension

on llio noodle thread so light (hat the bobbin thread

will not draw into the goods but lie straight, as

she rii in Fig. 17, page 17.

Page 11

20

To Oil the Machine

'I'd eiisui'o easy running, Llin inacliine rciiuiius

oiling, anil if usotl conLinuuusly it sliuulil bu oilud

21

To oil the movable parts in the head of the ma

chine, lake out Ihe thumb screw (VV, Kig. 10) near

E62J1

Fw. 19. Fkont View, Saowi-sc Oiling Points

each day. Willi moderati; use an occasional oiling

is suilicient. Oil should hu applied at each of Iho

places .shown by arrows in Kigs. 10 and 2!1. Om;

drop of oil at each point is snllicieut. Oil lioles

are provided in Iho inaehino for bearings which

cannot bo ilireetly reached.

To oil (he mechanisni under the slide, draw Iho

slide isee big. 10) to the left and after removing the.

lint and dust which may have accumulated (see

instruclions on [lages 23 to 2(i, inclusive), i>ut a

few drops of oil on the small piece of felt at the

right of the bobbin ejector. 'I'hc slide should then

be closed.

Pig, :ii). Oiling Points in li.isE üc M.icjiine

the lower end of the face |ilate and loosen the screw

(Idi, big. 19) near the upper end of the face |)late,

then sli]> the face )>late down; put one ilrop of oil

into each of the oil holes and joints thus uneovered,

then replace Ihe face piale and fiusten it as before.

To reach the parts underneath the bed of the

machine, turn the machine back on its hinges and

apiily oil to the oil holes and bearings indicated

by the arrows in h'ig. 20.

Page 12

■23

To Lubricate the Motor

iS’KVWK USK Oth ANYWTIlOlilO ON ТИК

МОЧ’ОИ. W lii-u the niatliiiie ia alii|)[)(;(l from the

Fic. Morou Окалае Tuues

factory, tlio two motor greaae tuhea (GO, Fig.

■Jl) are tilled with aufliiient hihricaut for appro.xiouilely aix moiiLhs’ use, under ordinary eircum-

staiieea.

At loaat once every si.x moulha thereafter, these

greaae tnhea ahoiild Ije relilled with tlie Singer

htolor l.nhrieunt, fnrniahed with the machine. 'Го

do (his, insert the li)) of the tube of lubricant into

the hole at the top of each of the grease tubes

and force the lubricant through each hole until

lioth grease lubes are lilled.

To Clean the Stitch Forming Mechanism

.After conaiilerable use, the stitch forming mechan

ism may become clogged with lint and this may

interfere with the perfect operation of the machine.

Occasionally remove the l)obbin case from the

machine, as instructed below and on the following

page, ainl remove any lint, etc., which has accumu

lated in the machine.

To Remove the Bobbin Case

{Oi-KnAion bei.NU .vr the i'lto.sT or tue Млсшпе)

liaise the needle to il.s highest point by turning

the balance wheel over tou'aril j'ou. IDiaw the

slide plate (Л1М, Fig. 22) slightly to the left, tlien

lift its right hand eiul and ilraw i t toward the neeille

until it is disengaged from the spring in the beil of

the machine.

FtC. 22. SlIDEltEMOVED

Page 13

24

To Replace the Bobbin Case

(OesuATOu BeiNC at tub Fuont or the Machine)

See that the neeille is raised to its highest point

and that the latch (N N, I' ig. 25) is raised from the

slot (UO, J'’ig. 25) and moved toward yon.

Insei't the nail of the forefiiiger of tlie left- liaiul

imdcr llic latch (.NN, Fig. laiso the lalch just

high ciumgh to cliau' the edge at (00, Fig. 211)

and then move it toward you.

Under no circumstances must the screw (PP,

Fig. 23) be loosened. 'I'ho loosening of this screw

will change the clearance for the thread between the

I'lo. Raisinu tub Latch

bobbin case and bobbin case position bracket.

Hold the bobbin ca.se between the forefinger and

the thumb of the left hand as shown in Fig. 21. Tilt

the bobbin case to the left and at the same time

slighlly turn the right or forked end toward you

so that it is moved out of engagement with the

sewing hook. Then tilt the bobbin case toward

the right and remove it (See Fig. 21).

I'lu. 21. Rbmovisg tuu Boubin Case:

Fio. 25. SaowiNO the Bobbin Case

Position Bbacket

Hold the bobbin ca.se between the forefinger and

thumb of (he left hand, a.s shown in Fig. 21. Insert

the forked end of the bobbin case under the throat

[dale so that the fork straddles the end of the

bobbin case iiosition bracket ((¿(¿, Fig. 25). Then

with a slight twisting motion of the bobbin case

to the left and to the back, lightly press it downwanlly until the edge of the sewing hook engages

in the groove under the rim of the bobbin case.

Page 14

2(5

Huviiig set Uic liulibiii ca.se into the correct

position, lock tlie lat(-h (XN, Fi^^ -Jo) in tho notch

(00, i'ig. 25) to hold the boLiljin case in place.

Fio. 26. Iii3PL.\ciN« TUB Sua-o

Thou replace the slide from the right, iis shown

in Fig. 2li, being careful to see that tho two cmls

of tho spring ( K li. Fig. 2(5) enter the grooves on the

uinUaside of the slide.

27

HINTS

Machine Working Heavily. If tho nuichine

runs hard after standing itilo for some time use a

little kerosene in the oiling places, run the machine

rapidlj', then wipe clean anil oil.

To Avoid Breaking Needles. See that tho

pressor foot or attachments are .seimroly fastened by

tho llunnb screw. Do not sew heavy seams or very

thick goods with loo lino a needle. A large needle

and thread lo corresponil .should be lused on heavy

work (.SCO Jingo 18).

See that (he needle is not bent and avoid jmlling

tho material when stitching.

Breaking of Needle Thread. If tho niasllo

thread breaks it may be caused by:

Improjier threading.

'I'ension being too tight.

Needle too lino for size of l.hroail.

I'he thread being too coarse for size of needle.

The needle being bent, having a blunt jioint,

or being .set incorrectly.

Breaking of Bobbin Thread. If the bobbin

thread bi’caks it may be caused by:

Improper threading of bobbin ease.

Tension being too tight.

Skipping of Stitches. 'I'ho needle may not be

..ecurately sot into tho ne.edle bar or tho needle may

■'unt or bent. 'I'lie needle may be too small for

•ead being used.

Page 15

INSTRUCTIONS

FOR USING

ATTACHMENTS

120360

WITH

SINGER SEWING MACHINE

No. 99-13

Page 16

31

FOOT HEMMER—Hemming

Raise the needle to its liighest point. Remove

llie piesser foot, ami attach the foot heimner in its

Imu. 27

phu;e (see Fig. 37). Olip olT the right hand corner

of the cloth, so that it will take the roll easily, turn

np the edge ahont a. (luarter of an inch, insert it in

tlie month of the heinmer and draw or push it along

until under the needle. Then let down the presser

bar ami after taking two or three stitches, draw

gently on the ends of the threiuls to help the work

along till the feeil catches it. In order to produce

a .smooth even hem, the month of the hemmer must

be kept just fell.

Fig. 27 shows also what is known as a bag seam

o" fell, iniule by pmssing two pieces of fabric through

he hemmer together and hemming them dowi|

Page 17

32

FOOT HEMMER—Hemming and Sewing

on Lace

Slart Ilio hem us jnevioiisly ex|)Iuiiicil, uml wlioa

it is well stili teli, raise the needle to its highest imint.

1‘’ш. 2S

Kaise the heiiimer to relieve its pressure on the hem,

puss the end of the luce through the slot in the side

of the heinmer, under the haek of the heumier and

over the hem, as shown in Fig. 23.

'Гаке eare that the hem is not displaced in the

heminer and that the needle goes down through the

lace anil hem together. 'I'lien let down the pressor

bar and guide the lace over the front of the hemmor,

keeiiiug it well into the slot.

FOOT HEMMER—Felling

'I'he two pieces of cloth to be felled should be laid

one over the other, right sides together, the edge

of the under piece being a little farther to the right

than the upper jiiece. Stitch them together, using

the heinmer as a [iresser foot, the front eni! of the

33

heminer forming a guide for the edges of both (lieces,

the upper piece being guided by the inside anil the

Fra. 29

under piece by the ouUide of the ])rojeeting front of

the foot hemiiier (.see Fig. 20j. Then open the work

li'ra. 30

out Hat, wrong side up, the edges standing up

straight, and taking the edges near the beginning of

Page 18

34

Ilio soam in Uic riglit liaiul, and tlie ends of llie

llireads in Un; loft haiul, iliaw l.l;u edges inl.o (lie

lieinmer whieli will Liini tliein as in heinniing. ( iuide

llie seeond l'ow of s(,il.eliiiig liy following (.lie lirst

row will; the inside of the projecting front of the

foot hennner (see h’ig. 30, page 33).

ADJUSTABLE HEMMER—Hemming

Ueinove the pros.ser foot and attach the adjustahle

heminer in its place as shown in I’ig. 31. This

E etili i

Fiu. at

hcininer will tura hems froin indi lo 1 indi wido.

The adjnslnient is made liy ìooscning thè thniiih

screw Oli thè heminer and laoving thè slide to (ho

right or loft iinlil Ilio hcm tiirned is of thè dcsircd

widlh. Entcr thè edge of thè eloth inio (he heiiiiner

under thè scale and drinv it laick and forili nntil

thè heni is forincd, stopping with (he end uinler thè

iieedle. l.owcr thè pre.sser bar and eomnicnco to sew,

heing carefid to so guide eloth as lo kecp heinincr

full. Felling cali ulso ho done wilh thè adjuslahlo

heinnier hy following instriictions oii page 3’J.

35

ADJUSTABLE HEMMER—Wide Hemming

To make ahem more than one inch wide, take out

the thuiiib screw in the heminer and remove the

r'l.:, 32

sliile and ijointer; fohl and erea.se down a hem of the

desired widlh; pass the fold under the e.'iteiisiou at

the right of the henuncr and the euge into the

folder as shown in Eij;. 3'2 and iiroeeed to stitch the

hem.

BINDER—Binding

Ueinove the presser foot and attach the hinder in

its place. Pass the hinding Ihroiigh the scroll of

I he hinder and draw it hack under the needle.

Place the etlge of the goods to he hound hetwcen

the .scrolls of the hinder and draw it under the needle,

liower the pre.sser har ami sew ns usual. T'o make

Ereiich folds (iroceed as directed for hinding e.scept

I’ at the fold is stitched on to the face of the material

Page 19

ilo

iilslcuil i)f oM tliu (st:e l’’ig. AfUir loosfiiiiig

thè biiuler set sci'iiW iiiid luljusting thè hiiiikT, (i e

37

Having ailjiisted the scales for tuck and space as

desired, fold the material anil crease by hand; iiass

kiu. 33

line of sl.itehiiig eoa he brought nearor the centre,

this being lume elTcclive when making 1''rendi fiiMs.

TUCKER

Keaiove the presser foot and attadi the tucker

ia its place. 'I'he width of tlie tuck is detcraiiacd

by the .scale of figures acaicst the needle, which

shows ia eighths and sixteeatlis of aa inch the dis

tance of the edge of the fold from the line of stitching.

'I’lie crea.se or mark for the second and following

tucks is determined by the .scale nearest the operatin'

and this is set by the line in front of the needle hole

in the presser foot. l'‘or blind tucks without spaces

set both .scales at the same figure; to make spaces

bciw.'ea the tucks, move the front scale farther to

the. left until the ilcsired space is obtained.

Fiu. 31

the folded edge between the spring and spur near

you, then between the two blades of the second

scale, and back under the presser foot; draw to the

right against the guide, lower the presser bar; see

that the lever for the nceille clamp to strike is in its

backward position so as to form a crease for the

ne.\t tuck, then i>roceed with the liist tuck.

For the second tuck, fohl carefully at the crease

made by l.he spur and place the edge of the lir.st tuck

inulerneatli .mil against the spur at the left, 'fhe

spur will serve as a guide and will also make a

distinct crease for the next tuck. .Always place the

last tuck against the spur to ensure perfect woi k.

When making the last tuck, the lever upon which

the needle clamp strikes while tucking .should be

raised to its highest point; while the lever is m this

po.silion no crease for a succeeding tuck is made

upon the goods.

Page 20

38

Rüffler

Lines 1, 2, 3, -1 and 5 slniwii in Kij{. 35 indieate

wliori! fill! iiiaUrial is to lie, planed for Various

o()erafioiis, as follows:

8

14 13 E 5152

Fiu. 35. Tue UuFt'i.tac .v.\ii u's F.vkts

Line 1—the correct po.silion for llie inalerial to

which the. riillled material js aiiplied.

Line 2—material to he (iatheroil.

Line 3—ihe facing for the rullle.

Line 4- the strip of piping material.

Line 5—the edge to be piped.

Refer to h'ig. 35 when inserting the material in

the miller.

3'J

The names and u.ses of the principal parts of the

Inltler are as follows:

(Hkis: N4>ü. tN So)

6— Foot—the part by which the rnHler is atliudied

to the presser liar.

7— Fork Arm—Ihe section that must he placed

aslrido the needle clamp.

8— Adjusting Screw the screw that regulates

the fullness of the gather.

9— Projection—the. part that projects throngli the

.slots in the adjnsling lever.

10— Adjusting Lever—the lever that Sets the

miller for plain gathering nr plaiting.

11— Heading Guide— guide for the heading of the

rnllle.

12— Separator Plate—tlie gniile on the mulerside

of the miller, containing several .slots inlo

which the edge of the inalerial is slipped to

keep the heading of the rullle even.

13 Ruffling Blade—the upper hlne steel bhule

with teeth at the end to posh the inalerial in

plails up to the needle.

14—Separator Blade —the lower blue steel lilude

without teeth, which inevenls the teeth of

the milling blade eoming into contact with

the teeth of the feed ihig.

To Attach the Ruffler to the Machine

Raise the needle liar to its highest point and relunve the pre.s.ser foot. Attach the miller foot to the

lire.sser bar by means of the thumb screw, at the

same time placing the fork-arm astride the needle

clamp as shown in Fig. 3li.

Page 21

40

To Adjust the Ruffler for Plain Gathering

liaise llic ailjiisliiij; lever (10, Fig. SOj luul move it

to (lie left so that tlio projeetioii (0, Fig. 3liJ will

enter (lie slot marked “1” in the ailjiisling lever (101

when (he lever i.s released. 'I'he milling blaile will

then move forward and baek onec at every stiteh.

liKsert the material to be riilHed between the two

blue blades, following the line 2 in Fig. Ik'S. Draw

the material slightly baek of the needle, lower the

pres.ser bar and <a)mmenee to sew.

To make a liner gather, shorlen the stroke of

the ruining blade by turning the adjusting screw

(8. Fig. 30) up, also shorten the stiteh. To make

a fidler gather, lengthen the stroke of the ruilling

blade by turning the adjusting screw (S) down,

also lengthen the stitch. By varying these a<ljustments many pleasing varietie.s of work can be

accomplished.

■11

To Make a Ruffle and Sew it to a

Garment in One Operation

Insert the material to be milled between the two

blue blades, its shown in F'ig. 37, following tlie line

1' lo. S7

2, in Fig. Place the garment to which the

rulllo is to be attached, under the. separator blade,

following the line 1, in F'ig. 3.5. Procecrl the same

as for |>lain gathering.

The edge of the milled seam can be bound by

n.sing the biiuler as instructed on (lages 35 ami 3li,

To Ruffle and Sew on a Facing

in One Operation

Insei t the material to be. milled between the two

hlne blade.s, following the line 2, in Fig. 35. I'lacc!

the gaiinent to which the rullle is to be al.tatrhed,

miller the separator blade, following the line i, in

Fig. 35. Place the material for the facing over the

upiier blue blade, as .shown in Fig. 3S, following

the line 3, in F'ig. 35. The facing may be straight

or Idas material. If the facing is to be on the

right side of the garment, place the garment and

Page 22

42

Uu) millo so Ilio wioiijí s¡(li\s aro tojíotlior. If

tilo faoiiii: is lo 1)0 Oll Ilio wrong si.lo, placo ilio right

sillos of the gaiMiwnt ami the vulHe togolhor.

Kuj.

Piping a Ruffle

Insert Ihc rnatorial lo ho riilHod hotwoon the two

hliio hiailos, following the line 2, in l'’ig. 35. 'I’liis

malorial must not he over 114 inches wide, a-s

it is carried through tho rnlllor with the linished

•43

edgo of tho rullio lo thè right of Lho altachnienb

ius shovvn in Kig. 3!).

Tho inatorial for piping must inoiusuro ahout },(

indi wido \idicn foldod in tho contro and is usually

cut oli tho hia.s. I lai'O tho liiping inatcrial in tho

rulllcr, following tho lino -1, in Kig. 35, with tho

foldod edgo of Ilio piping lo Ilio riglit. 'l’Ilo mate

rial to which tho piping ami riillliiig aro lohosown

shoiiltl ho foldod oii (ho edgo and iiisortod in tho

rulllcr, following tho lino 5, in Kig. 35.

To Adjust thè Ruffler for Plaiting

Uiiiso Lho adjusLing Icvor (1Ü, Kig. 40) and movo

it to thè right so that thè projoction (9, Kig. 4Ü)

Kn:. Il)

will Ciller tho slot marked ‘'5” in Ilio adjusting

lover when the lover is roloascd. 'I'lio rulfling hlado

will then move forward and hack once at every

live stitches. Insert the material to ho plailed

hetween the two him: hlados, following the lino

’2, ill K’ig. 35. 'riio fiilliioss of the phiils is regnlaled

hy tho adjusting .screw (8, Kig. 4D) and Ilio length

of siiteli. 'Го тако a fuller plait, turn tho adjust

ing screw (S) down, also lengthen tho siiteli. 'Го

make a Гшег plait, turn the adjusting screw (8) up,

also shorten the sliitch.

Page 23

u

To Adjust the Ruffler for Group

Plaiting and Gathering

naiting ana Vjatnering

Tlu! riililer ßim l)c adjusted for group ]>!ail.iiig hy

lifting the adjusLiiig luvor (10, Tig. and i>lac.ing

E.')l|7¡

Pro. 4t

it on top of tile projerlioti (0, Tig. 41) at the point

indicated hy the star on the ailjusting lever. 'I’liis

shouUl he done at the ])oinl.s where you wish to

make the space hetweeii the plails. The ruifler will

then .slop and plain stitching will he made. \\ hen

the desired space has been made, adjust the lever

(10) so that the projection (9) enlers the slot marked

Jly alternalely inakiiijj groups of plaits and

plain spaces, as shown in ]''ig. 41, very attractive

Work can he proiluced.

To Oil the Ruffler

Occasionally apply a drop of oil to the working

parts of the rulller at each of the places indicated hy

arrows in Tig. 41. After oiling, operate the rufller

on a waste piece of material to iirevent the oil from

soiling the work. If the rulller does not plait evenly,

a drop of oil may remedy the trouble.

45

To Use the Cloth Guide

To ensure accurate guiding of the work w'lien

sewing close to the edge of the goods, the cloth

E64№

Iffa. 12

guide (V, h’ig. 42) should be used. TasLen the

cloth guide to the bed of the machine by means

of the clami>ing thumb screw (W, Tig. 42), inserting

the thumb screw inl.o either one of the two screw

holes in the bed of the machine. The cloth guide

can be adjusted to bring the edge of the goods

as close to the lino of stitching as desired.

Page 24

-its

EMBROIDERY AND DARNING

^\’lliIc! eiiil)miili;ry iiiid ilartiltiii i;aii Ix! done on tlio

iiuif.liiiui wlien llireadiid foi’ itgidai- aiAvins, Um ! use

of feed cover i)lale ;i'2()22 (Y, l'’is. I2. paj^e, 47) is

п•elmllnended. :w movaliUs eoidael, willi llie feed in

some eases inighl. iiiOeifei'e willi Ihc handling of Uie

work.

Do not ehango the adjn.stinent of the feed dog in

any way as it is i;.sseiitial Unit iLs po-sition slioiild

remain as originally li.ved.

\Vhen feial cover plate (Y, Fig. 43) is useil, it

is neees.sary to pass the needle thread through the

eye in the ihread regulator (X, Fig. -13) at the left of

the tension ili.sir.s, and not amiev Ilia Ihnud rajntator.

With this e.veeption the threading is the same as for

regular sewing (.see Fig. 13, page IS).

Keinove the presser foot and let down the ])ies.ser

har lifter to restore the tiaision on the niu'dle thread,

which is releaseil and inoperative when the lifter is

raised.

3'o attach the feed cover plate, draw to the left the

slide that covers the hohhin ca.se anil insert the

downwardly projecting hooks on the cover plate

under the edge of the throat ]>late and push to

the right. .After hr'inging the hole at the right of

the cover plate in line with the hole in the throat

plate, pre.ss the cover into position, and close the

slide (see Fig. -13).

Feed cover plates are not included in the regular

sets of attaelnnents; they are on .sale at all ¡singer

shops.

Instructions for embroidering are contained in the

“Singer Instructions for Art F.mbroidery,” sold by

the Singer Sewing hlachine Company at a reason

able price.

47

EW36

Fic. 43. Macuink TuttB.u>Ki> roii EMunoiuBur .vnii D.uinino

Page 25

48

RELATIVE SIZES OF NEEDLES AND THREAD

(Class and Variety of Needles Used, 15 x 1)

OK

NblEHLlOa

9

n

11

ll)

18

19

21

Very thin Mualins, Cambrics,

Very iinu Culioocs, Linens,

Shirtintid, fine Silk Guuds,

etc.

S)iirliiig.s, Slicetiugs, Oulicous.

Muslins, Silk and general

dumoslic iiooila and all cluiucs

of general work.

All kind.'* of heavy Culicooa,

light Woolen GooiU, heavy

Silk, Seaming, Stitching, etc.

Tickings, Woolen Goodd,

Trouaerd, lloya’ Clothing,

Coi'dotd, Cloukd, Mantled, etc.

Heavy Woolens, Tickingd, 2-1 to 30 Colton

Bugd, Heavy Coats, 'I'rouders, E Silk I’wist 1

etc. Heavy Clothing gciteruny. GOloSOTiinen j

Bags, Coarse Cloths and Heavy

When sending Gruel'S far

the size required.

OK WUiOv Sll.K ou

Lincitii« etc.

Goods.

needles always specify

SIZES OK COll’ON, 1

LINEN TllUKAD

100 to 150 Cotton

OO & , GOO Silk

Twist

80 to lot) Colton

0 Silk Twist

GO to 80 Cotton

A & В Silk Twist

•10 to GO Cotton

C Silk Twist

30 to <10 Colton

D Silk Twist

40 to GO Linen

or very

Coarse Cotton

1

Loading...

Loading...