SINGER 9910 User Manual

QUANTUM 9910

WORKBOOK

Congratulations on the purchase of

your new Quantum® 9910 sewing

machine! We are certain that you

will have many hours of sewing

enjoyment with this easy-to-use,

feature-packed machine.

This workbook has been designed

as a tool for learning various

sewing techniques, which you can

apply to your own projects. We

hope that it inspires you and

stimulates even more creativity.

Enjoy!

The SINGER® Education Department

SINGER® and Quantum® are registered trademarks of the Singer Company Ltd.

© 2004 Singer Sewing Company

Part #640—505255OGH

SINGER

Quantum® 9910

Features and Benefits

169 Built-In Stitches

Built-In Stretch Stitches

Built-In Quilting Stitch

Built-In Heirloom-Friendly

Stitch Selection

Built-In Cross Stitches

7mm Stitch Width

Built-In Alphabet

One Step Built-In

Buttonholes

Exclusive

Buttonhole Underplate

Balance Adjustment Dial

2-Line, 820 square mm

Liquid Crystal Display

(LCD)

A large variety of stitches for construction, decorative

sewing, heirloom sewing and quilting always ensures

the perfect stitch for every project.

Specially designed stitches that add strength and

flexibility to seams, especially useful when sewing on

knitwear.

Create a hand sewn look with this unique stitch.

Pin Stitch, Blanket Stitch and Entredeux are a few of the

popular heirloom stitches available.

An excellent selection of cross stitches.

Most stitches can be set for a maximum width of 7mm.

When sewing decorative stitches or satin stitches the

wide stitches are bolder and more pronounced.

The alphabet can be made in upper and lower case, as

well as numbers. Personalize projects by adding a

monogram, name or phrase with the built-in alphabet.

Choose from 4 different one step buttonholes.

Buttonhole sewing is a one step simple process that

provides reliable results.

The Underplate helps secure and hold in place bulky or

thick fabrics, as well as difficult-to-work-with fabrics.

Effectively this is a bit like a mini-embroidery hoop in

which the machine feeds the attachment rather than the

fabric.

Guarantees control for even stitching of buttonholes and

stretch stitches, regardless of fabrics type.

The LCD provides clear and easy viewing of the stitch

pattern number, as well as the stitch’s correct width and

length.

Stitch Length and Width

Adjustment

Needle Up and Down

25 Needle Positions

Optimal settings for length and width are automatically

adjusted when choosing a stitch. They can be

overridden to personalize length and width choice.

Select whether the needle is up or down when the

machine stops. It is beneficial to have the needle stop

in the down position when appliqu¿ing, quilting or

pivoting the fabric. When removing the fabric from the

machine, it is easier if the needle is raised to highest

position.

Needle position can be changed for individual projects,

such as inserting zippers or cording and topstitching.

Automatic Reverse

Sewing Speed

Automatic Needle Threader

Automatic Tension

Top Loading Jam-Resistant

Bobbin System With Clear

Cover

Extra-High Presser Foot

Lifter

LED White Lamp

7-Segment Feeding System 7 individual feed dogs work in unison to feed fabric

Drop Feed Dogs

Presser Foot Adjustment

Optimal Power Control

Twin Needle

Mirror Image*

20 Space Memory

Self-Lubricating No need to lubricate the machine.

Push to sew in reverse, reinforcing the stitch.

With a maximum sewing speed of 900 spm, projects

can be sewn quickly.

Effortless threading of the machine, including

automatic threading of the eye of the needle!

This system ensures stable stitch quality, whatever

the type of fabric being used.

This mechanism incorporates a magnet-type vertical

axis rotating hook that ensures smooth, quiet, thread

jam-resistant sewing. The bobbin loads from the top

so it is easy to insert the bobbin. The clear cover

makes monitoring the bobbin thread a simple

process.

There are two heights to the presser foot lifter. The

second height offers a 1/4” more clearance which is

needed when placing multiple layers or bulky fabric

under the presser foot.

The lamp illuminate the sewing surface for optimal

viewing. The long-lasting bulb stays cool,

regardless how long the machine is operated.

effortlessly regardless of fabric type.

A conveniently located lever will lower the feed dogs

for free-motion embroidery, monograms and for

attaching buttons.

Easily change the pressure of the presser foot for

smooth seams all types of fabrics.

The Optimal Power Control provides precise piercing

power when sewing multiple layers or dense fabrics.

The piercing power is the same regardless of sewing

speed.

Stitches are automatically adjusted for twin needle

sewing with just a touch of a button.

With just a touch of a button, stitches can be mirror

imaged.

A large memory holds full names and

simple phases.

Warning Signals

Visual warning messages alerts the sewer.

The messages make for trouble-free sewing.

Box Feed

Electronically Controlled

Stepper Motors

This is a feed dog that moves the feed dogs in a box

motion rather than the historic arc motion. Box mo

tion assures perfect feeding throughout the entire

feed process as the feed dogs are always in perfect

and equal contact with the fabric and presser foot.

All stepper motors are electronically controlled. Digi

tal electronic control of the stepper motors that con

trol the pattern formation allow for perfectly formed

patterns every time.

Aluminum Frame

Accessories

Dust Cover

Warranty

The internal skeleton of the sewing machine. This

rigid support holds all the mechanisms in perfect

alignment for perfect, skip free sewing.

Auxiliary Spool Pin

Overcasting Foot

Blind Hem Foot

Zipper Foot

Button Sewing Foot

Satin Foot

Straight Stitch/Patchwork Foot

Buttonhole Foot and Underplate

General Purpose Foot

Needles, Bobbins, Screwdrivers

Lint Brush and Seam Ripper

Covers the machine when it is not in use.

The Quantum 9910 has a 25 year limited warranty.

*If the stitches can be mirror imaged it will be highlighted.

Quantum® 9910

Table of Contents

Garment Conslruetion Tgehnigugs:

Automatic Bartack

Blind Hem on Woven Fabrics

Button Sewing

Buttonholes

Corded One-Step Buttonhole

Keyhole One-Step Buttonhole

Lightweight One-Step Buttonhole

One-Step Buttonhole

Elastic Application

Narrow Elastic

Wide Elastic

Elastic Straight Stitching as a Topstitch on Woven Fabrics

Elastic Straight Stitching Seam on Stretch Fabrics

Multi-Stitch Zigzag

Multiple Needle Positions

Overcasting

Overcasting Edge Finish

Overcasting Edge Finish for a Flat Seam

Overcasting Finish for Stretch Rib Knit Collar/Cuff

Sewing Heavy or Thick Fabrics

Straight Stitching

1

3

5

7

9

11

13

15

16

17

18

19

20

21

22

23

24

25

Free-Motion Embroidery

Free-Motion Stippling

Patchwork or Fagoting

Quarter-Inch Foot

Quilting Stitch as a Topstitch

26

28

fabric 6mbelli§hmCTt

Attaching Beaded or Fringed Trims 31

Blanket Stitch Edge 32

Built-In Letters 33

Cross Stitches

Decorative Stitching

Decorative Stitching (mirror image) 37

Free-Motion Embroidery

Free-Motion Monogramming 38

Lace Insertion 40

Patchwork or Fagoting

Piping

Applying

Creating 43

Satin Stitch Appliqué

Scalloped Edge Finish

Twin Needle

Applying Ribbon with a Twin Needle 46

Pintucking with a Twin Needle 47

Topstitching with a Twin Needle

35

36

26

29

42

44

45

48

tlcirloom

Lace Insertion 40

Heirloom One-Step Buttonhole 49

Patchwork or Fagoting 29

Pin Stitch Appliqué 51

Twin Needle Pintucks 47

Wing Needle 52

Automatic Bartack

Blanket Stitch Edge

Blind Hem on Woven Fabrics

Button Sewing

Buttonholes

Corded One-Step Buttonhole

One-Step Buttonhole

Elastic Application

Narrow Elastic

Wide Elastic

Elastic Straight Stitching as a Topstitch on Woven Fabrics

Free-Motion Embroidery

Free-Motion Monogramming

Piping

Applying

Creating

Overcasting

Overcasting Edge Finish

Overcasting Edge Finish for a Flat Seam

Sewing Heavy or Thick Fabrics

Straight Stitching

Twin Needle Topstitching

The Automatic Bartack Stitch is ideal for fastening tabs, belt loops,

or attaching ribbons to projects. It is also perfect for reinforcing a pocket.

The Bartack automatically sews 4 to 5 stitches in one place and then

stops.

__

Machine Set-up:

Stitch:

Stitch Width:

Stitch Length:

Presser Foot:

#59, Bartack

Pre-set

Pre-set

Buttonhole Foot

Materials:

Cut a mock pocket from medium weight fabric

Base Fabric

Procedure:

♦ Pin the pocket to the base fabric.

♦Stitch the pocket into place with a Straight Stitch.

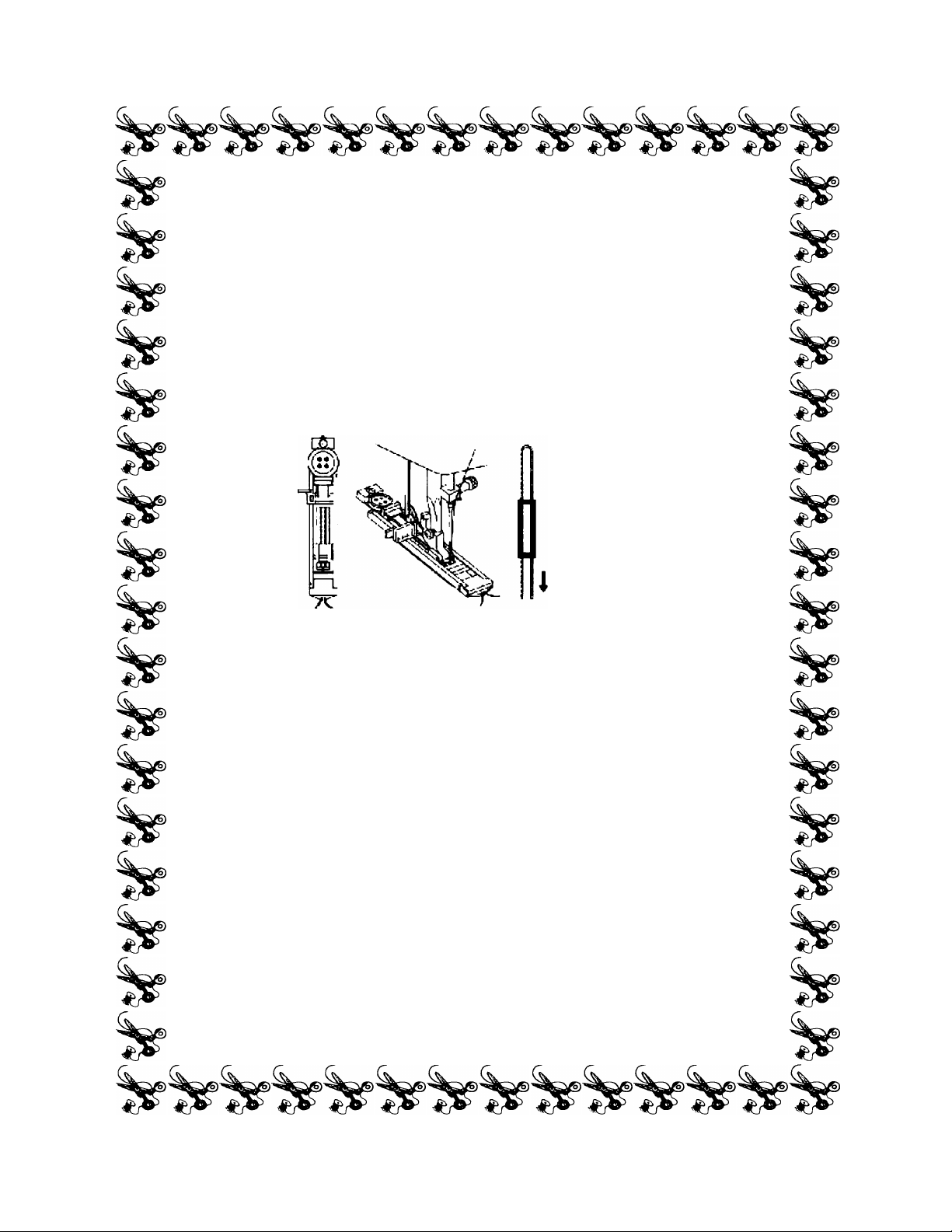

♦Open the buttonplate to approximately 1”.

Open approximately 1”

►Align the mock pocket’s top corner under the presser foot.

.Lower the buttonhole lever and gently push it back.

♦Lightly hold the threads and begin to sew.

♦When the bartack is finished, stop sewing.

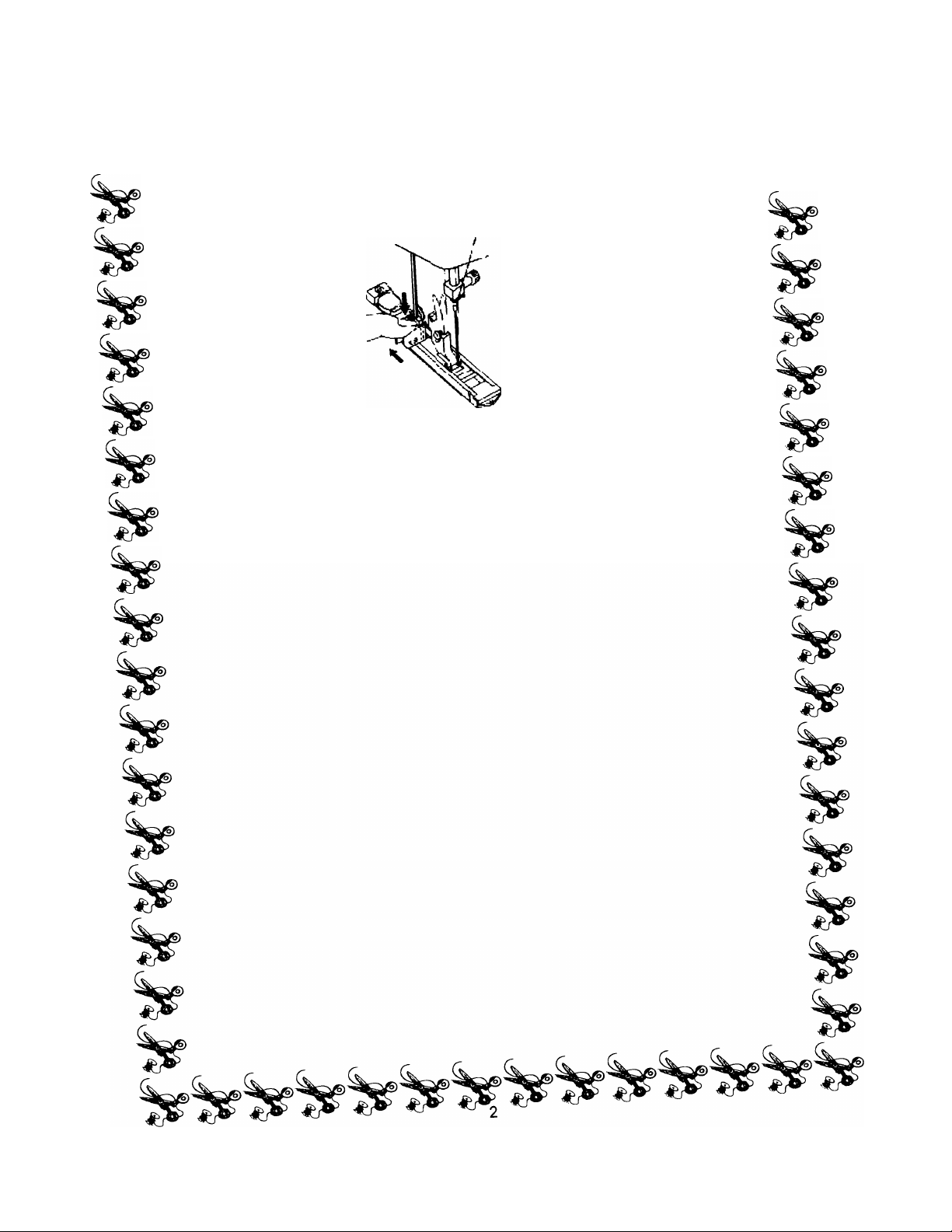

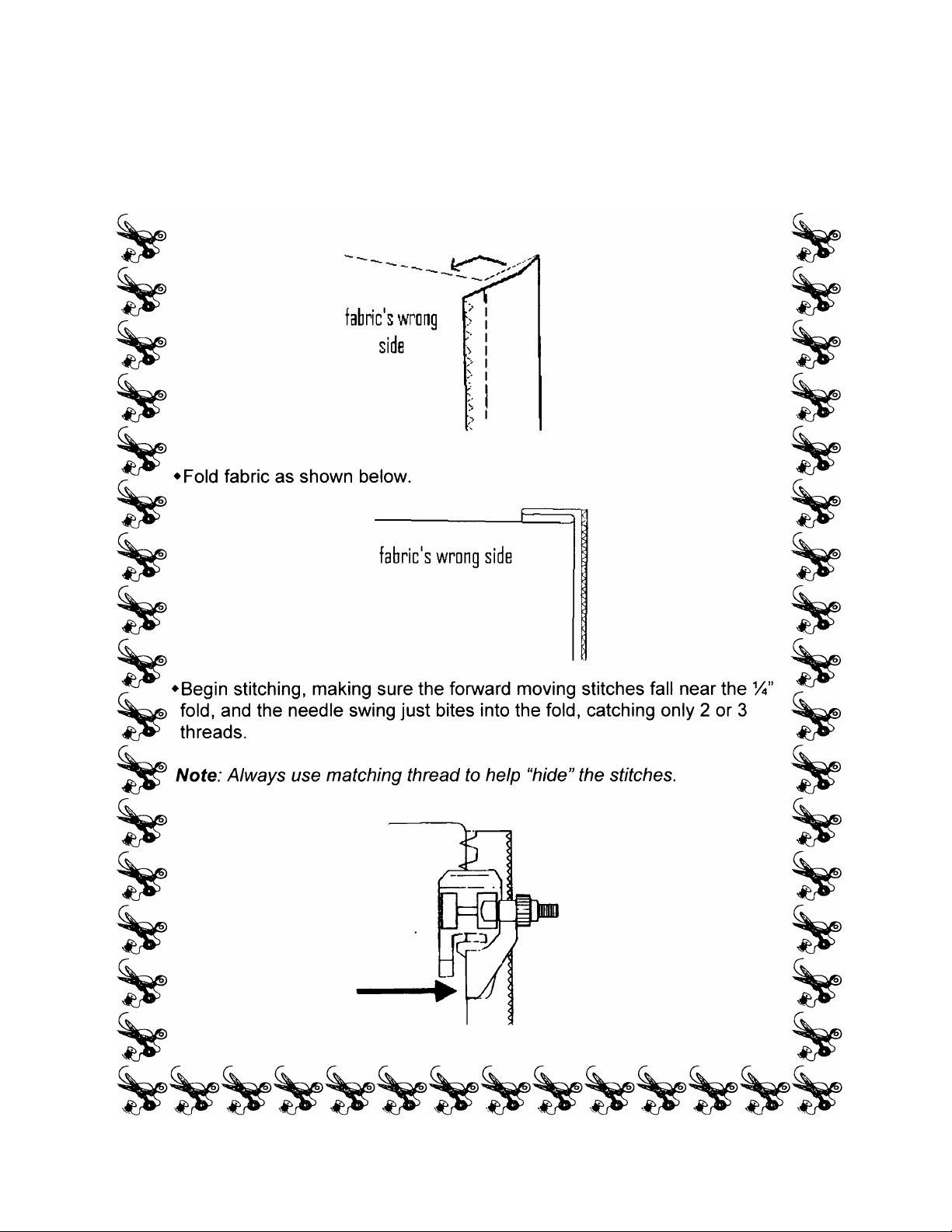

A Blind Hem is a fast way to finish hems securely on garments such as

skirts or pants. It is also a great choice when hemming larger projects

such as curtains or bed skirts. Use matching thread to help the stitches

blend into the fabric, hence becoming “blind” or invisible.

Machine Set-Up:

Set-up for Step 1 (to finish raw edges)

Stitch: #6, Zigzag

Stitch Length: 2.0

Stitch Width: 5.0

Presser Foot: Standard Foot

Set-up for Step 2 (to baste the fold)

Stitch:

Stitch Length:

Stitch Width:

Tension Dial:

Presser Foot:

#1, Straight Stitch

3.5

4.0

Turn the tension dial to the left (-)

Standard Foot

Set-up for Step 3 (to create the hem)

Stitch: #8, Blindhem

Stitch Length: 1.8

Stitch Width: 3.0

Presser Foot: Blindhem Foot

Materials:

Medium weight woven fabric

Procedure:

Sew a Zigzag to finish one of the fabric’s raw edges.

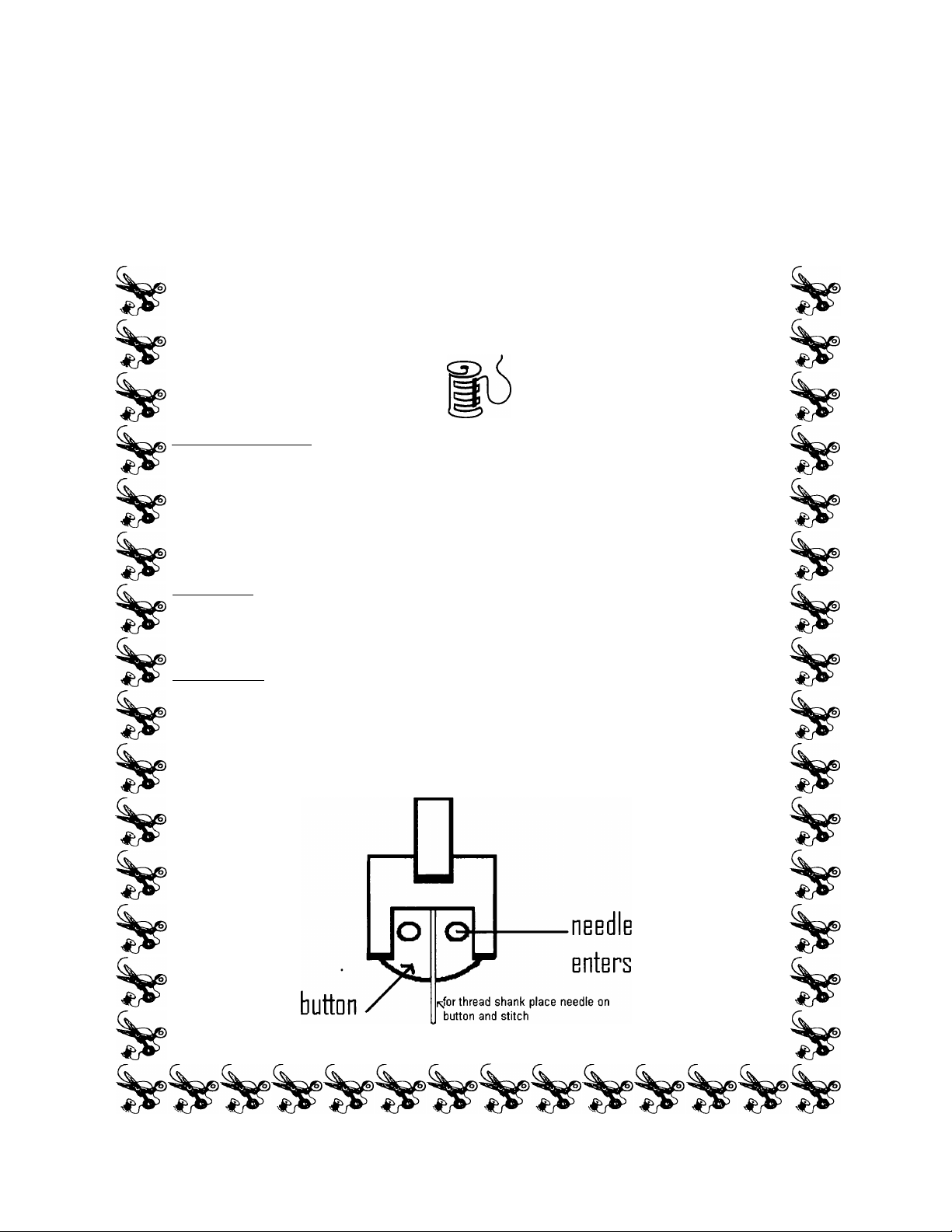

Use your sewing machine to sew on buttons, snaps or hooks with ease.

This is especially helpful when making a large project where several

buttons need to be attached, such as curtains that have button tabs or

duvet covers

Machine Set-Up:

Stitch:

Stitch Width:

Stitch Length:

Feed Dogs:

Presser Foot:

Materials:

4” X 4” Shirting

(1) 2-hole button

Procedure:

♦ Fold fabric in half and place under foot.

♦ Position the button on the fabric so that the holes of the button are

between the toes of the foot.

#10, Button Sewing Stitch

3.0

N/A

Lowered

Button Sewing Foot

Note: For a 4-hole button, repeat the process for the second set of holes.

♦Lower the presser foot to hold the button in place.

♦Turn the hand wheel forward; adjust so that the needle goes into either

the right or left hole.

♦Adjust the stitch width dial to fine tune the swing of the needle into the

other hole.

♦ Recheck the swing of the needle into the other hole and then use the

foot control to stitch 5-6 stitches.

♦ Before removing the button and fabric from the machine, change to

straight stitch. Leave width at current setting and stitch in place for

three stitches. This forms a tie-off on the back side to secure the

button.

♦Apply a liquid fray-preventer on the backside of fabric on the knots.

Trim threads after they dry, being careful not to cut thread knots.

Note: Remember to raise the feed dogs when finished.

A Corded Buttonhole adds strength and stability to the buttonhole. This

type of buttonhole is especially important when sewing stretch fabrics or

fabrics that easily ravel. The “cord” can be a heavy thread, several

strands of regular thread, lightweight yarns, etc. The buttonhole is stitched

over the cord, creating a reinforced buttonhole.

Machine Set-Up:

Stitch:

Stitch Width:

Stitch Length:

Presser Foot:

(See manual for complete machine set-up for buttonholes)

Materials:

Knit fabric with interfacing or tear-away stabilizer

Disappearing marking pen or tailor chalk (for marking start of buttonhole)

Button (to establish length of buttonhole)

8” strand of cord

#62, Buttonhole symbol

5.0

0.5

Buttonhole Foot

Procedure:

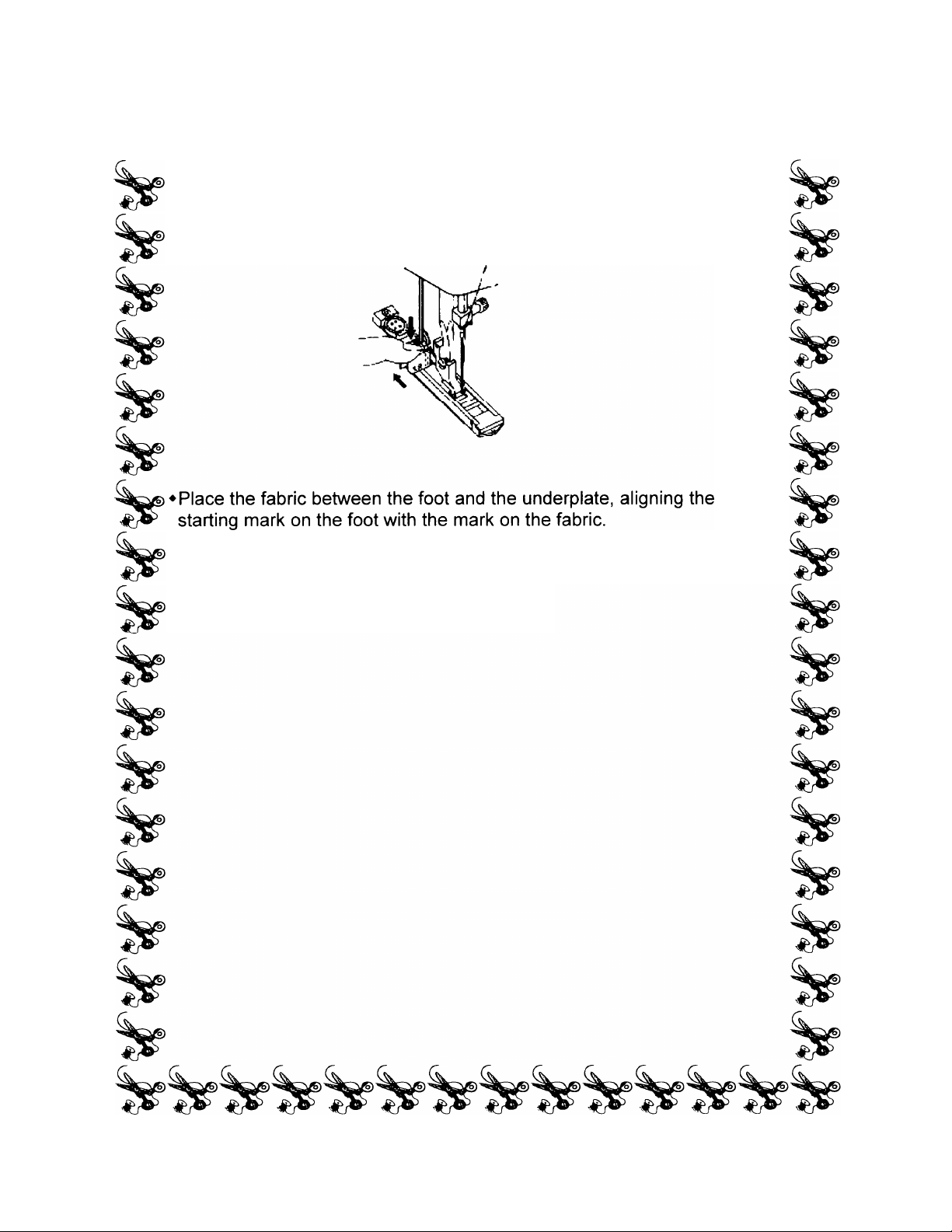

♦ Hook or loop the cord around the small prong at the back end of the

buttonhole foot.

♦ Bring both ends of the cord under the foot and pull them forward. Tie

the cords to secure them.

Hook ooid at

lhi£ point

/

i

"Oord

{Unctorsido)

♦Attach the buttonhole foot to the machine, taking care not to displace

the cord. (See sewing machine instructional manual)

♦The foot will hold the cord in the correct place as the machine stitches

the buttonhole.

♦Sew the buttonhole, following the One-Step Buttonhole instructions

and the machine instructional manual.

♦The zigzag section of the buttonhole will stitch over the cord.

♦After stitching is completed, pull the excess cord tails tight. This will

pull the cord into the buttonhole.

♦Cut off the excess cord.

The built-in One-Step Keyhole Buttonhole measures the button’s length

and then automatically sews a beautiful buttonhole. The Keyhole

Buttonhole is an attractive closure for coats, jackets and sportswear.

It is often used on menswear.

Machine Set-up

Stitch:

Stitch Width:

Stitch Length:

Presser Foot:

(See manual for complete machine set-up for buttonholes)

Materials:

Heavy weight woven fabric

Interfacing or tear-away stabilizer

Disappearing marking pen or tailor chalk (for marking start of buttonhole)

Button (to establish length of buttonhole)

Procedure:

♦ Fold fabric in half crosswise, with interfacing or stabilizer between layers.

♦ Make a mark with the disappearing marking pen to indicate where the

bottom or first bartack should be sewn.

#63, Buttonhole

5.0

0.5

Buttonhole Foot

Open the button plate and insert the button.

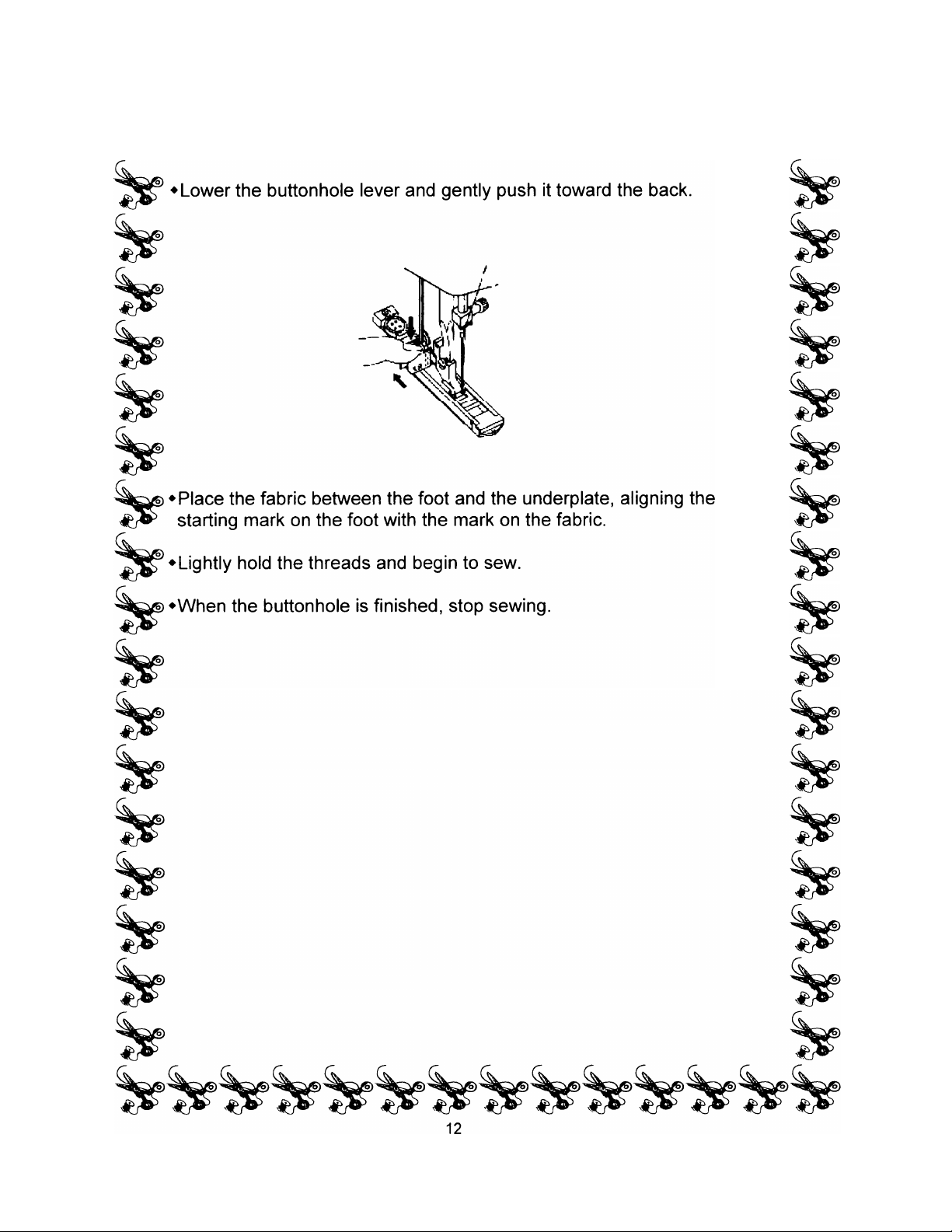

Lower the buttonhole lever and gently push it back.

♦ Lightly hold the threads and begin to sew.

When the buttonhole is finished, stop sewing.

10

The built-in One-Step Lightweight Buttonhole measures the button’s length

and then automatically sews a beautiful buttonhole. The sides of the

Lightweight Buttonhole are thinner or more narrow than the regular

buttonhole. This is an appropriate buttonhole for lightweight blouses,

shirts, baby clothing or heirloom sewing.

Machine Set-up:

Stitch: #61, Buttonhole

Stitch Width: 5.0

Stitch Length: 0.5

Presser Foot: Buttonhole Foot

(See manual for complete machine set-up for buttonholes)

Materials:

Lightweight fabric such as batiste

Interfacing or tear-away stabilizer between fold

Disappearing marking pen or tailor chalk (for marking start of buttonhole)

Button (to establish length of buttonhole)

Procedure:

♦ Fold fabric in half crosswise, with interfacing or stabilizer between layers.

♦Make a mark with the disappearing marking pen to indicate where the

bottom or first bartack should be sewn.

Loading...

Loading...