Page 1

Page 2

USE ONLY SINGER* OILS

and LUBRICANTS

They insure freedom from lubricating trouble and give

longer life to sewing equipment

The following are the correct lubricants for this machine:

TYPE B — MANUFACTURING MACHINE OIL, HEAVY

GRADE

When a stainless oil is desired, use:

TYPE D — MANUFACTURING MACHINE OIL, STAIN

LESS, HEAVY GRADE

OTHER SINGER LUBRICANTS

TYPE E - STAINLESS THREAD LUBRICANT

For lubricating the needle thread of sewing machines for

stitching fabrics or leather where a stainless thread lubri«

cant Is required,

TYPE F ^ MOTOR OIL

For oil lubricated motors and plain bearings in power

tables and transmitters.

NOTEs All of the above oils are available in 1 qyort^

I gallon and 5 gallon cam or m 55 gallon drums,

SEAR LUBRICANT

This specially prepared grease is recommended for gear

lubrication on manufacturing sewing machines,

BALL BEAR1N6 LUBRICANT

This pure grease is specially designed for the lubrication

of ball bearings and ball thrust bearings of motors and

electric transmitters, ball bearing hangers of power tables^

©tc Fwnished in 1 lb, and 4 lb.

CopyrighI, U. S. A„ 1914, 1915, 1922, 1926, 1933, 1935, 1936 and 1937,

by The Singer Manufacturing Company

Ail Rights Reserved for oil Countries

^ Reg. U. S. Pot. Off.

Page 3

TO ALL WHOM IT MAY CONCERN:

The improper placing or renewal of the Trade-Mark “SINGER” or

any other of the Trade-Marks of The Singer Manufacturing Company

(all of which are duly Registered Trade-Marks) on any machine that

has been repaired, rebuilt, reconditioned, or altered in any way whatsoever

outside a SINGER factory or an authorized SINGER agency is forbidden.

DESGRIPTION

MACHINE: 95-30 makes the lock stitch and Is designed for sewing

light and medium weight fabrics. It has a gear-driven rotary hook.

The needle bar stroke Is 1-9/64 inches.

The machine is equipped with heavy gear shafts and three plain

bearings for the arm shaft.^^^^

MACHINE 95-100 is the same as Machine 95-80 except that it is

equipped with ball bearings at both ends of the arm shaft, the in

termediate bearing being a plain bearing.

MACHINES 95-80 and 95-100'should be run at- speeds not exceed

ing 3500 stitches per minute for the first two or three days, af

ter which they can be driven up to their maximum speed of 4200

stitches per minute, depending upon the nature of the work and the

ability of the operator.

Page 4

To Lubricate the Machine

USE "TYPE B" or "TYPE D" OIL, sold only by Singer Sewing

MacbIne company. For description of these oils, see Inside of

front cover.

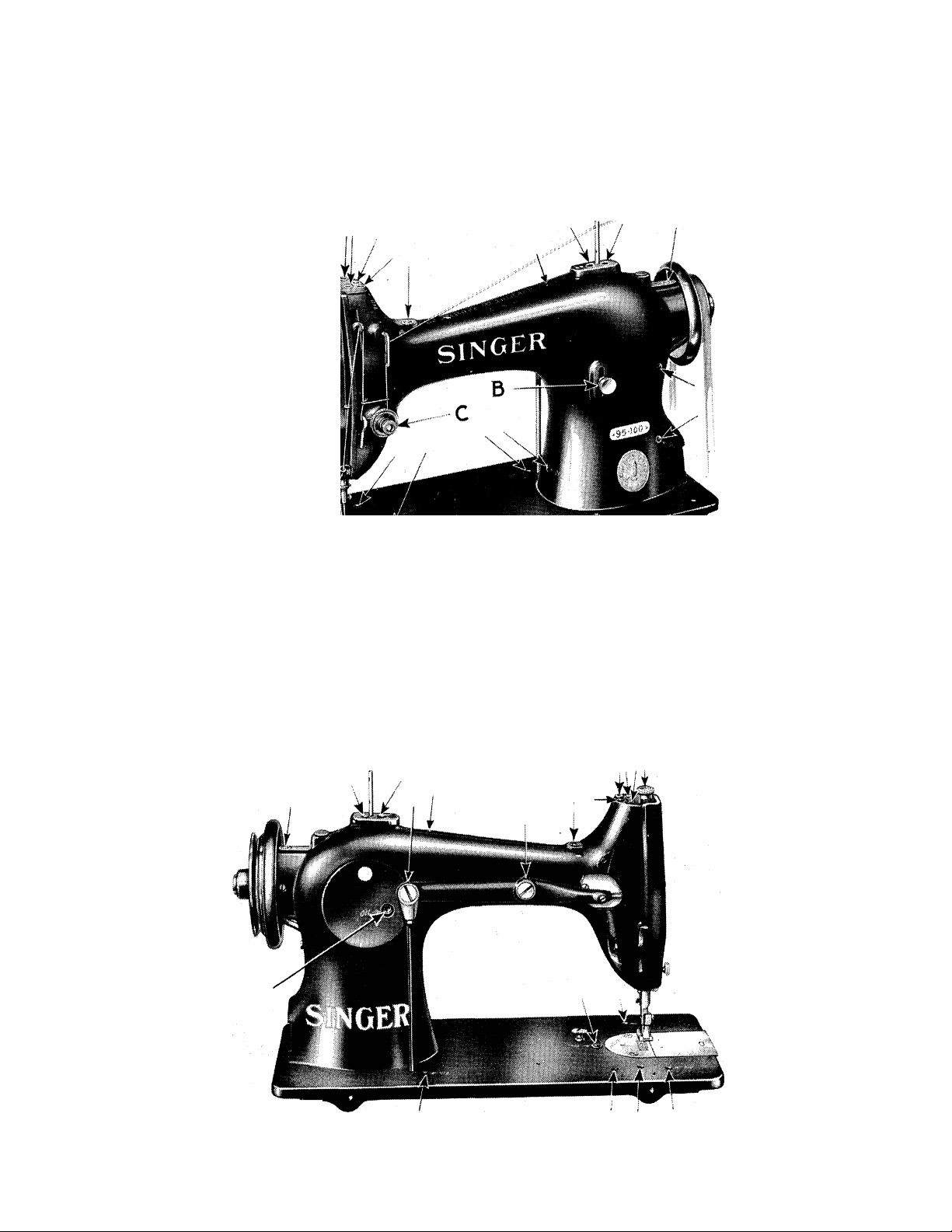

Fig.2. Oiling Points at Front of Machine

Oil should be applied as shown by arrows In Figs.2,3 and 6,

and, when used continuously, the iTEchlne should be oiled at least

four times each day. Keep all wicklng saturated with oil.

£/¿»543

Flg.3* Oiling Points at Back of №chlne

Page 5

use GEAR LUBRICANT in the gear cases of these machines.

When the machines leave the factory, the gear cases are packed

with sufficient GEAR LUBRICANT for approximately 160 hours of

of operatlcm.

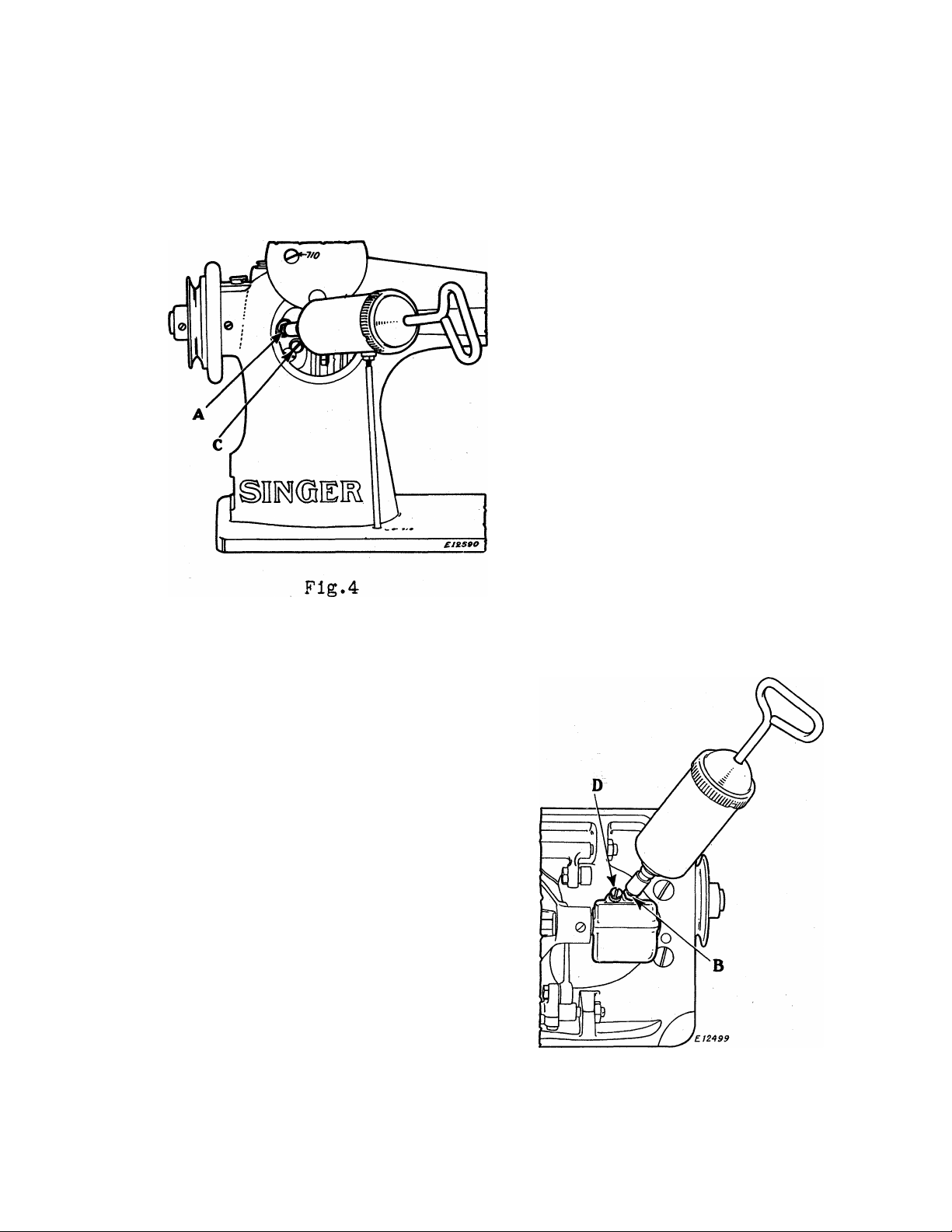

Replenish the gear cases

at (A) and (B), Figs. 4 and 5

with GEAR UJBRICANT every 160

hours of opérât im.

Alemlte Grease Guns,

SINGER NO. 121587 (3 oz. ca

pacity) or SINGER NO. 121588

(1/2 Ih. capacity) provide the

most ccxivenlent means of apply

ing GEAR LUBRICANT to the

gears.

To supply grease to the

upper gear case (Flg.4), have

the machine In its normal

working position, remove the

level hole screw (C,Fig.4) and force the lubricant into the Ale

mlte fitting (A,Fig.4) until

it emerges from the level hole

at (C), then replace the screw

(C).

To supply grease to the

lower gear case (Fig.5), lay

the machine back on the table,

remove the level hole screw

(D,Fig.5) and force the lubri

cant into the Alemlte fitting

(B,Fig.5) until it emerges

from the level hole at (D),

then replace the screw (D).

Flg.5.

CAUTION - To avoid overfilling of the gear cases, do. not turn

the balance vheel when grease is being applied through the Alemlte

fittings.

Page 6

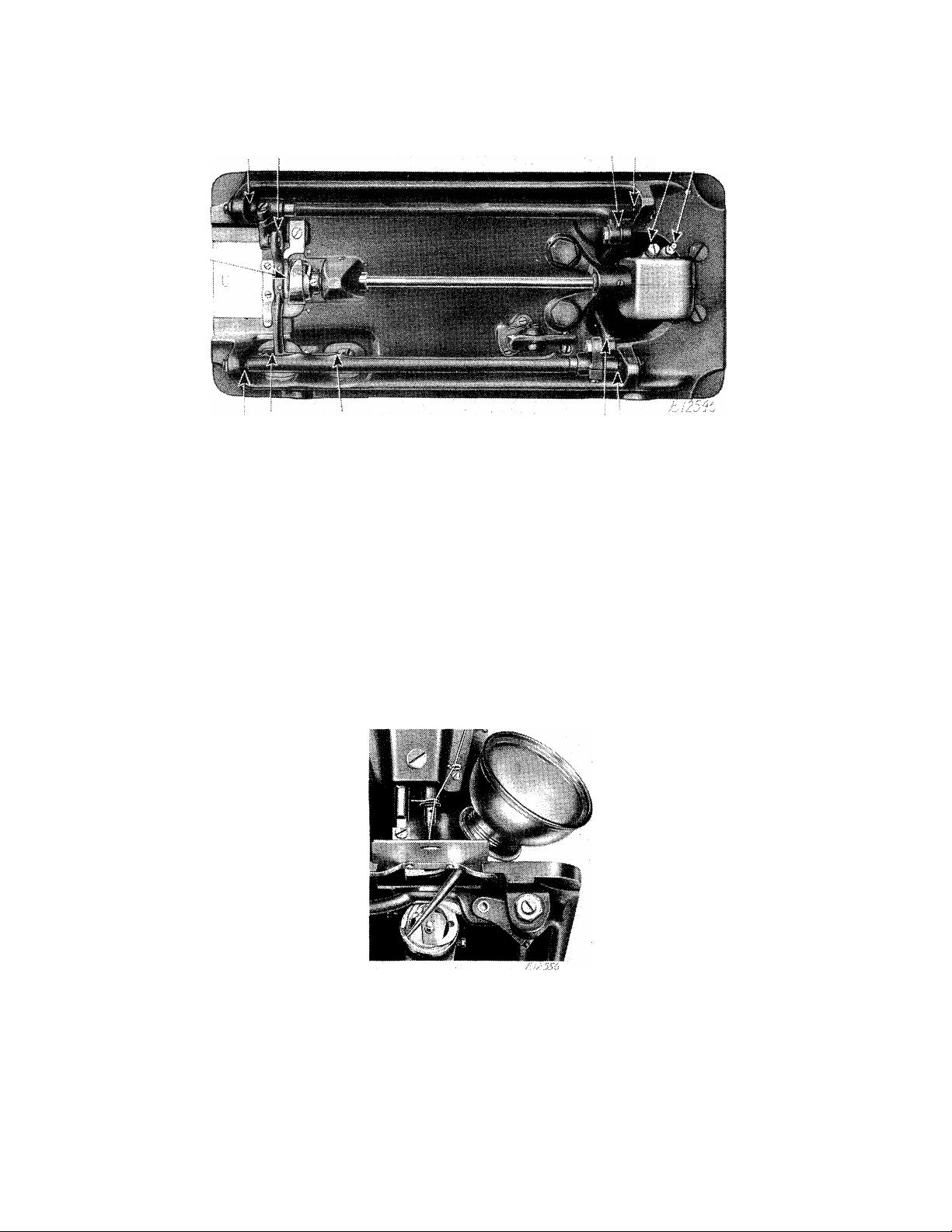

Fig.6. Oiling Points In Base of Machine

D iB

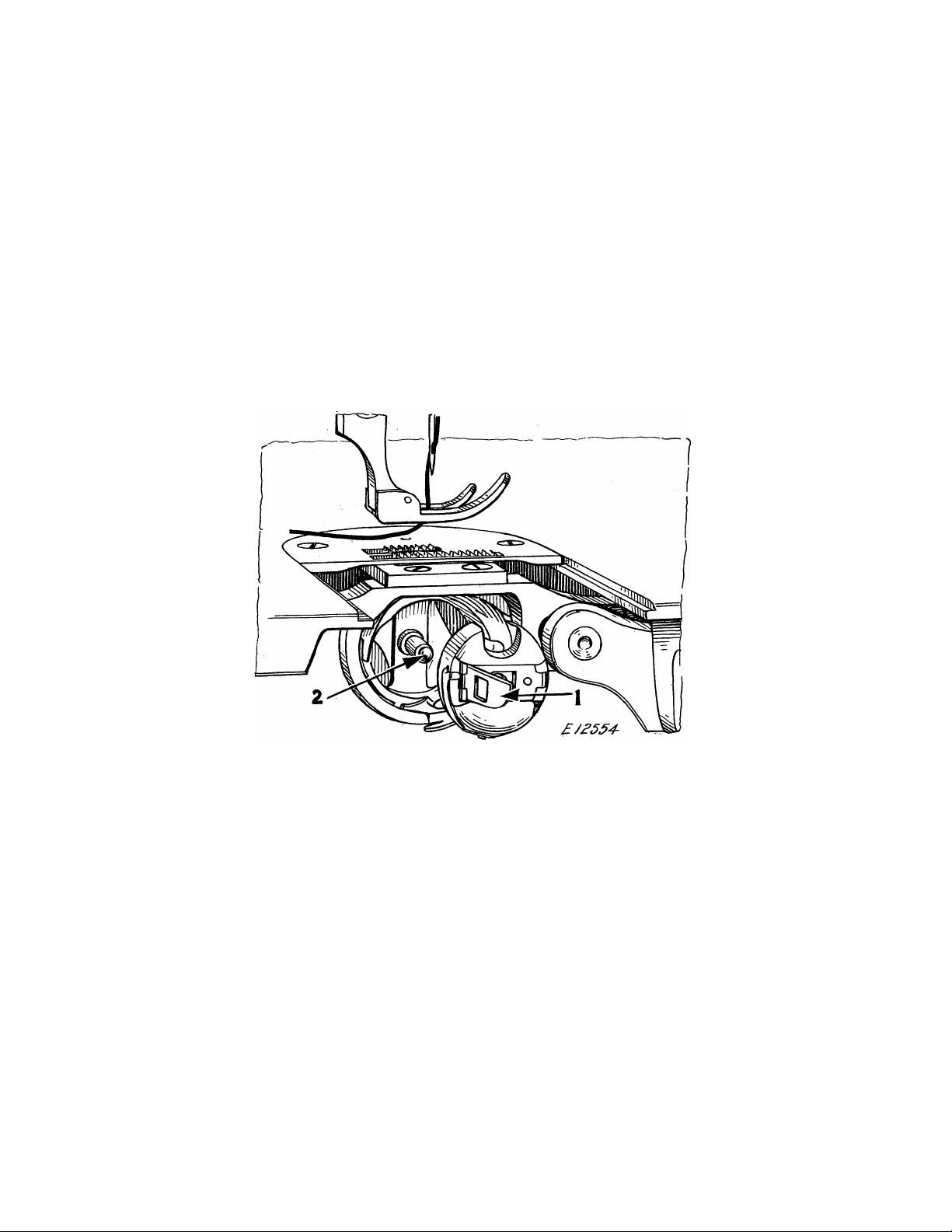

At least four times each day apply ONE DROP of oil to the

bobbin case holder bearing In the sewing hook race, as shown In

Fig.7.

Fig.7. Oiling Point In Hook xRace

CAUTION. NEVER OIL THE SEWING HOOK PJ^lCE THROUGH THE' NEEDLE

HOLE IN THE THROAT PLATE, NOR FLOOD THE HOOK WITH OIL.

Page 7

Needles

Needles for Machines 95-SO and 95-100 are of Class and Variety

S8 X 1, and are furnished In Sizes 9, 11, 13, 14, 16, 17, IS, 19

and 21.

The size of the needle to be used should be determined by the

size of the thread which must pass freely through the eye of the

needle. Rough or uneven thread, or thread which passes with dif

ficulty through the eye of the needle, will interfere with the

successful use of the machine.

Orders for needles must specify the QUANTITY required, the

SIZE NUMBER, also the CLASS and VARIETY NUMBERS separated by an x.

The following Is an example of an Intelligible order;

"100 No.16, 88 X 1 Needles"

The best stitching results will be obtained by using the

needles furnished by the Singer Sewing Machine Company.

Thread

Left twist thread should be used in the needle,

Either right

or left twist thread can be used in the bobbin.

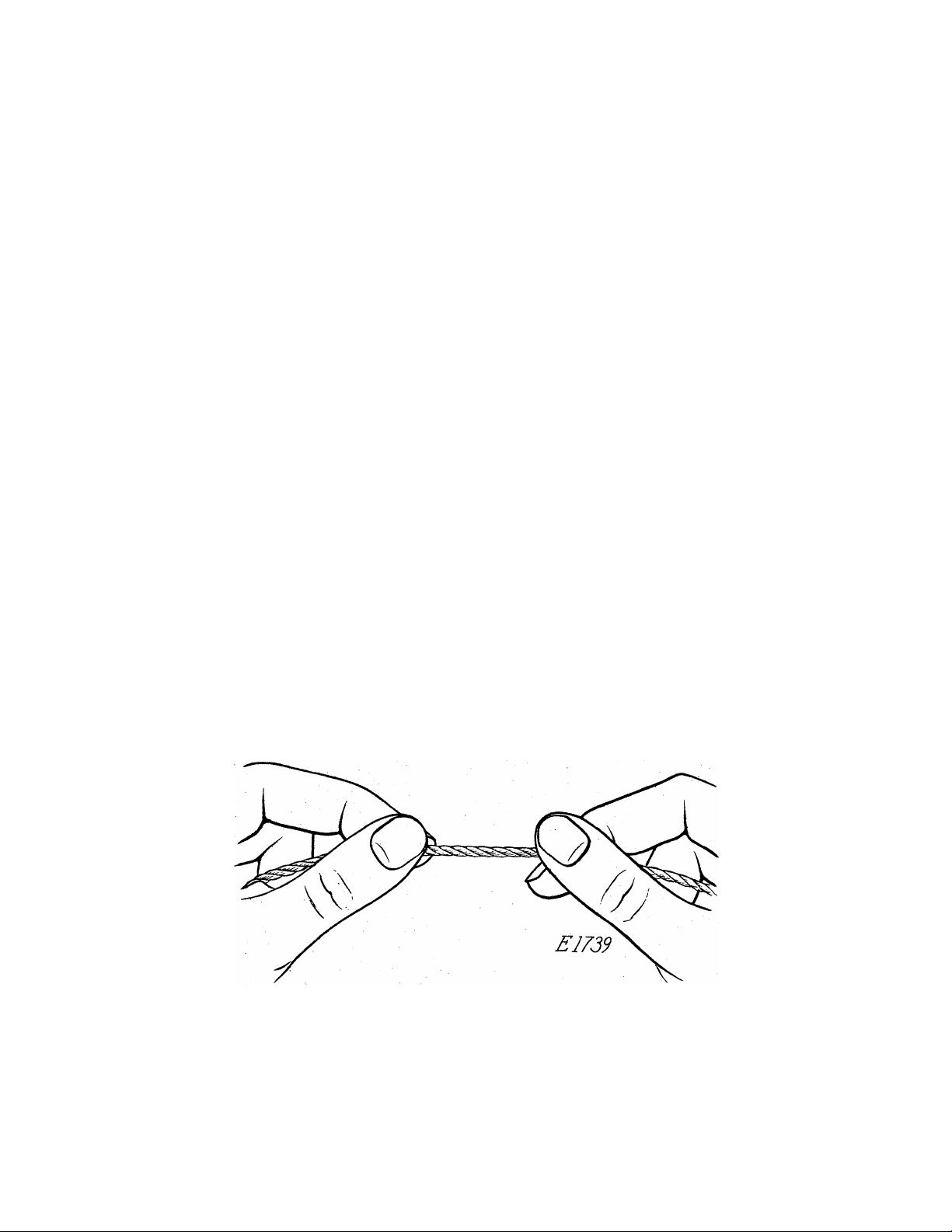

Fig.8. How to Determine the Twist

Hold the thread as shown above. Turn the thread over toward

you between the thumb and forefinger of the right hand; If left

twist, the strands will wind tighter; If right twist, the strands

will unwind.

Page 8

6

Relative Sizes of Needles and Thread

The following sizes of needles and thread are recommended ac

cording to the class of work:

Sizes

of

Needles

14

16

and

17

18

19

Classes of Work

Shirtings, Sheetings, Calicoes, Muslins,

Silks, Dress Goods and all classes of

general work.

All kinds of heavy Calicoes, light

Woolen Goods, heavy Silk, Seaming,

Stitching, etc.

Tickings, Upholstery, Woolen Goods,

Trousers, Boys^ Clothing, Cloaks, etc.

Heavy Woolens, Tickings, Bags, Heavy

Coats, Trousers, Heavy Clothing gener

ally.

Sizes of

Cotton, Linen

or Silk

60 to 80 Cotton

A and B Silk

40 to 60 Cotton

C Silk

30 to 40 Cotton

D Silk

24 to 30 Cotton

E Silk

60 to 80 Linen

21

Bags, Course Cloths and Heavy Goods.

16 to 20 Cotton

40 to 60 Linen

To Insure Perfect Action of the Machine

The balance wheel must always turn over toward the operator.

DoTiot run the machine with the presser foot resting on the

feedwithout cloth under the presser foot.

Do not run the mchlne when both bobbin case and needle are

threaded unless there Is material under the presser foot.

" Do not try to help the machine by pulling the fabric lest you

bend the needle. The machine feeds the work without assistance.

The slide over the bobbin case should be kept closed when the

machine Is In operation.

Page 9

7

To Remove the Bobbin

Turn the balance, wheel over toward you until the needle moves

up to Its highest point. Draw out the slide In the bed of the ma-

Flg.9. Removing the Bobbin

chine. Open the bobbin case latch (l,Flg.9) and, by means of

this latch, remove the bobbin case from the sewing hook.

While the latch remains open, the bobbin will be retained In

the bobbin case. Release the latch, turn the open end of the bob

bin case downward and the bobbin will drop out.

Page 10

8

To Wind the Bobbin

(See Fig.10)

Fasten the bobbin winder to the table with Its driving pulley

In front of the machine belt, so that the pulley will drop away

from the belt when sufficient thread has been wound upon the bob

bin.

£/г557

Fig.10. Winding the Bobbin

Place the bobbin on the-bobbin winder spindle and push It on

as far as It will go.

Pass the thread down through the thread guide (1) in the ten

sion bracket, around the back of, and between,the tension discs

(2). Then wind the end of the thread around the bobbin a few

times, push the bobbin winder pulley over against the machine

belt and start the machine.

When sufficient thread has been wound upon the bobbin, the

bobbin winder will stop automatically.

If the thread does not wind evenly on the bobbin, loosen the

screw (A) In the tension bracket and move the bracket to the

right or left as may be required, then tighten the screw.

The amount of thread wound on the bobbin Is regulated by the

screw (B). To wind more thread on the bobbin, turn the screw (B)

Inwardly. To wind less thread on the bobbin, turn this screw

outwardly.

Bobbins can be wound while the machine Is stitching.

Page 11

^ :0'

To Thread the Bobbin Case

Hold the bobbin between

the thumb and forefinger of

the right hand, as shown In

Fig.11, the thread drawing on

the bottom from the left to

ward the right.

C/P5

Fig.11

with the left hand hold the bob

bin case as shown in Fig.11, the

slot In the edge being near the top,

and place the bobbin Into It.

Then pull the thread Into the slot

In the edge of the bobbin case as

shown in Fig. 12; draw the thread under

the tension spring and Into the deliv

¿■72560

ery eye at the end of the tension

spring (see Fig.13).

Fig. 12

Fig.13

Page 12

10

To Replace the Bobbin Case

After threading, take the bobbin case by the latch and place

the bobbin case on the center stud (2,Fig.9) of the bobbin case

Fig.14. Bobbin Case Threaded and Replaced

holder; release the latch and press the bobbin case back until

the latch catches the groove near the end of the stud (See Fig.9).

Allow about two Inches of thread to hang free, ind replace the

slide In the bed of the machine.

To Set the Needle

Turn the balance wheel over toward you until the needle bar

moves up to Its highest point; loosen the screw In the lower end

of the needle bar and put the needle up Into the bar as far as It

will go, with the long groove of the needle toward the left and

the eye of the needle directly In line with the arm of the ma

chine, then tighten the screw.

Page 13

11

upper Threading

Pass the thread from the unwinder, or from the spool on the

spool pin on the top of the machine, from right to left through

£/2639

Fig.15. Upper Threading

the top hole (1) in the thread retainer, from left to right

through the center hole (2) in the thread retainer, and from

right to left through the bottom hole (3) in the thread retainer,

down under and from right to left between the tension discs (4),

into the thread take-up spring (5), under the slack thread regu

lator (6), up and back of the wire thread guide (7), up and from

right to left through the hole in the end of the thread take-up

''lever (8), down through the thread guide (9), down through the

thread eyelet (10), Into the thread guide (ll), and from left to

right through the eye of the needle (12). Draw about two Inches

of thread through the eye of the needle with which to commence

sewlno:.

Page 14

12

To Prepare for Sewing

Vlth the left hand hold the end of the needle thread, leaving

It: slack: fГОШ the hand to the needle^ turn the balance wheel over

Fig.16. Drawing Up the Bobbin Thread

toward you until the needle moves down and up again to its highest

point, thus catching the bobbin thread; draw up the needle thread

and the bobbin thread will come up with it through the hole in the

throat plate (see Fig.16). Lay both threads back under the presser foot.

To Commence Sewing

Place the material beneath the presser foot, lower the presser

foot and commence to sew, turning the balance wheel over toward

you. ■ .

To Remove the Work

Let the thread take-up lever rest at its highest point, raise

the presser foot, draw the work back and cut the threads close to

the goods.

Page 15

13

Tensions

For ordinary stitching, the needle and bobbin threads should

be locked in the center of the thickness of the material, thus:

Fig.17. Perfect Stitch

If the tension on the needle thread Is too tight, or If that

on the bobbin thread Is too loose, the needle thread will lie

straight along the upper surface of the mterlal, thus:

Fig.18. Tight Needle Thread Tension

If the tension on the bobbin thread is too tight, or If that

on the needle thread Is too loose, the bobbin thread will lie

straight along the under side of the material, thus:

Fig.19. Loose Needle Thread Tension

To Regulate the Tensions

THE TENSION ON THE NEEDLE THREAD SHOULD BE REGULATED ONLY

WHEN THE PRESSER FOOT IS DOWN. Having lowered the presser foot,

turn the small thumb nut (C,Flg.2), at the front of the tension

discs, over to the right to Increase the tension. To decrease

the tension, turn this thumb nut over to the left.

The tension on the bobbin thread Is regulated by the large

screw (FF,Fig.ll) In the tension spring on the outside of the

bobbin case. To increase the tension, turn this screw over to

the right. To decrease the tension, turn this screw over to the

left.

When the tension on the bobbin thread has been once properly

adjusted. It Is seldom necessary to change It, as a correct stitch

can usually be obtained by varying the tension on the needle

thread.

Page 16

14

To Regulate the Length of Stitch

The -length of stitch is regulated by the thumb screw (B,Flg.

2) in the slot on the front of the upright part of the arm. To

lengthen the stitch, loosen this thumb screw and move it down

ward. To shorten the stitch, loosen this thumb screw and move

It upward. When the desired length of stitch has been obtained,

tighten the thumb screw (B).

To Regulate the Pressure bn the Material

The pressure on the material Is regulated by the thumb screw

(D,Flg.2) . To Increase the pressure, turn this thumb screw over

to the right. To decrease the pressure, turn this thumb screw

over to the left.

SINGER Needles should be used

in SINGER Machines.

These Needles and their Containers

are marked with the

Company’s Trade-Mark “SIMANCO.*” 1

Needles in Containers marked

“FOR SINGER MACHINES”

are NOT SINGER made needles. 2

Page 17

INSTRUCTIONS

FOR

ADJUSTERS AND A\ACHINISTS

Page 18

16

To Set the Needle Bar at the Correct Height

See that the needle Is pushed up into the needle bar as far

as It will go, then remove the face plate.

The needle bar,

which is in the machine

when shipped from the

factory, has two timing

marks near its upper

end. Rotate the bal

ance whee1 unt i1 the

needle bar moves down

to its lowest position.

The UPPER TIMING MARK

on the needle bar

should then be centered

with the lower end of

the needle bar bushing,

as shown at (D) in Fig.

20. In case the needle

bar is not set at the

correct height, loosen

screw (E,Flg.20) and

move the needle bar up

or down until the UPPER

TIMING MARK is centered

with the lower end of

the needle bar bushing,

as shown at (D,Fig.20),

then securely tighten

screw (E).

Fig.20

Needle Bar Set at Correct Height

In the event that

the setting of the

needle bar bushing has

been disturbed, thus making it impossible to set the needle bar

for correct height by centering the upper timing mark with the

lower end of the needle bar bushing, turn the balance wheel to

bring the hook point to the center of the needle, loosen screw

(E) and move the needle bar up or down to bring the top of the

needle eye 1/32 inch below the point of the hook, then securely

tighten screw (E). Loosen the needle bar bushing set screw at

the top of the machine arm and, while the hook point is at the

center of the needle and 1/32 inch above the top of the needle

eye, move the needle bar bushing up or down to bring its lower

end exactly even with the LOVER TIMING MARK on the needle bar,

then securely tighten the needle bar, bushing set screw.

Page 19

17

To Time the Sewing Hook

Remove presser foot, slide plate, throat plate and bobbin

case. Take out the two screws (E2,Flg.20) and remove feed dog.

Fig.21. Needle and Sewing Hook Correctly Timed

To determine that the hook Is correctly timed, place a new

needle In the machine, then turn the balance v^eel over toward

you until the LOWER TIMING MA.RK on the needle bar Is centered

with the lower end of the needle bar bushing as shown at (Q,Flg.

21)vWhen the needle bar Is on Its upward stroke. With the

needle bar In this position, the point of the hook should be at

the center of the needle as shown at (R,Flg.21). The Inset In

circle at the left of Fig.21 plainly shows this position of the

hook point relative to the needle.

Page 20

18

In case the hook is not correctly timed, loosen the three

screws (L,Flg.22) In the hub of the hook. These three screws

can be reached from the top of the machine bed through the open-

Flg.22. View of Underside of Machine

Showing Bobbin Case Holder Position Bracket (H)

and Adjustments on Pfeichlne

Ing left by the removal of the throat plate, although, for pur

poses of Illustration, the screws are shown only In the view of

the underside of the machine In Fig.22. Rotating the balance

wheel of the machine will bring these screws, one at a time,

directly under the throat plate opening where they can be easily

reached with a screwdriver from the top of the machine bed.

After loosening the three screws (L,Flg.22) turn the hook on

Its shaft to bring the point of the hook at the center of the

needle as shown at (R,Fig.21), then tighten the three screws (L,

Fig.22).

The hook should be set as close as possible to the needle

without touching. If the hook Is too close to the needle or too

far away from It, loosen the three screws (L,Fig.22) and the bush

ing screw (J,Fig.22) and drive the bushing (K,Fig.22) In or out,

as may be required, until the hook Just clears the needle, being

very careful not to damage the bushing, then securely tighten the

bushing screw (J) and the three screws (L).

Page 21

19

To Remove and Replace the Sewing Hook

Remove the needle, slide plate and bobbin case. Take out the

screw (G,Fig.22) and remove the bobbin case holder position

Fig.23. Showing Correct Position of Thread Guard (U) and

Bobbin Case Holder (P) for Removal of Sewing Hook

bracket (H,Fig.22). Loosen the three set screws (L,Fig.22) in

the hub of the hook, then turn the balance vdieel over toward you

until the feed bar (S,Fig. 23) is raised to its highest point.

Turn the sewing hook until the thread guard (U,Fig.23) is at the

bottom, as shown in Fig.23, and turn the bobbin case holder (P,

Fig.23) until it is in the position shown in Fig.23. The sewing

hook can then be removed from the hook shaft.

When placing a new sewing hook on the shaft, have the thread

guard (U) of the hook at the bottom and the bobbin case holder

(P) turned to the position shown in Fig.23, so that the hook will

clear the feed bar (S).

When the hook is in position on the shaft, turn the bobbin

case holder (P,Fig.23) until the notch (T,Fig.23) is at the top,

then replace the bobbin case holder position bracket (H,Fig.22)

being careful to see that the position stud (M,Fig.22) enters the

notch at the top of the bobbin case holder, as shown in Fig.22,

Page 22

20

then securely fasten the position bracket by means of the screw

(G,Fig.22). Replace the needle and time the sewing hook as In

structed on pages 17 and 18. When tightening the three screws

(L,Fig.22) In the hub of the hook, draw the hook shaft toward the

needle bar end of the mchlne and press the hook toward the bal

ance wheel to take up the end play In the shaft. Then replace

the bobbin case and slide plate.

To Remove and Replace the

Sewing Hook Shaft

Remove the sewing

hook as Instructed on

page 19. Take out

the screw (V,Flg.24)

and remove both sec

tions of the gear

case (V,Fig.24), then

wipe the grease away

from the gears.

Before removing

the hook shaft (X,Flg.

25) from the machine,

the gears (Y and Z,

Fig.25) should be

marked with chalk or

red pencil on one of

the teeth of the gear

(Y) and the space of

the gear (Z) In which

the marked tooth

meshes. This Is Im

portant, as the gears

may become dislodged

when removing the

hook shaft, and the

marks will enable you

to retain the origin

al relative positions

Fig.24. Vlev^k of Underside of №chlne of the gears.

Showing Gear Case

To remove the hook shaft, loosen the two set screws in the

gear (Y,Fig.25), then insert the new hook shaft Into the gear

Page 23

SI ■

(y), from the right hand end, pushing thp old shaft out of the

gear toward the needle bar by means of the new shaft, as shown

Fig.85. Removing and Replacing Sewing Hook Shaft

In Fig.25. By removing the old shaft In this manner, the rela

tive positions of the gears (Y and Z) will not be disturbed.

When placing the new shaft In position In the machine, see that

the flat portion near one end of the shaft Is at the right so

that one of the set screws In the gear (Y,Flg.25) will bear

against It when the gear Is fastened In position on the shaft.

The shaft should be set so that Its left end Is flush with the

front (left hand) side of the body of the sewing hook.

When the shaft Is correctly positioned, securely tighten the

two set screws In the gear (Y), making sure that one of these two

screws bears against the flat portion of the shaft.

Time the sewing hook as Instructed on pages 17 and 18.

Replace the gear case and securely fasten It In position by

means of the screw (V,Flg.24).

Page 24

22

To Adjust the Thread Take-up Spring

The thread take-up spring (Ci2,Flg.26) should be set so that

when the eye of the needle reaches the goods on the downward

Fig.26. Adjustment of Thread Take-up Spring

stroke of the needle bar, the spring will be through acting and

will rest against the stop on-the thread take-up spring regulator.

If the thread take-up spring Is not correctly set, as Instructed

above, loosen the set screw (R2,Flg.26) In the arm of the machine,

and turn the tension stud (S2,Flg.26) to the right for more move

ment of the spring or to the left for less movement. When the

spring Is-correctly set, securely tighten the set screw (R2).

The tension on the thread take-up spring (Q2) Is regulated

by turning the tension stud (S2) to the right to Increase the

tension, or to the left to decrease the tension. The tension on

the thread take-up spring should be just sufficient to take up

the Slack of^the needle thread until the eye of the needle

reaches the goods In Its descent.

Timing of the Feeding Mechanism

When the machine leaves the factory, the feed eccentric Is

correctly set by having the timing screw In the eccentric enter

the groove In the arm shaft. If, for any reason. It may be nec

essary to alter the timing of the feed eccentric, loosen the

timing screw and the set screw, turn the eccentric as required

tighten the set screw only.

Page 25

THE IMPORTANCE OF

USING SINGER* PARTS AND NEEDLES

IN SINGER MACHINES

The successful operation of SINGER machines can only be assured

if SINGER parts and needles are used. Supplies are available at all

SINGER Shops for the Manufacturing Trade, and mail orders will receive

prompt attention.

Page 26

Page 27

SINGER Needles should be used

In SINGER Machines.

These Needles and fheir Confolrsers

are marked with the

Gomparsy*$ Trode«Mark“SiMANCO.^

Needles In Containers marked

"FOR SINGER MACHINES**

are NOT SINGER made needles»

Page 28

Loading...

Loading...