Singer 831U, 832U Instruction Manual

INSTRUCTION

FOR

MANUAL

SINGER

fl

831U

•

832U

High

Speed

THE

f^gg^jg

SINGER

Overedge

COMPANY

Machine

LA.

INSTALLATION]

CONTENTS

Machine

Sewing

Motor

Belt

Thread

Eye

speed

pulley

and

unwinder

guard

head

installation

and

belt

cover

installation

belt

installation

installation

tB.LUBRICATIONl

m.

Type

[2]. Lubrication and oil change

[31. Needle

rC.OPERATIONl

Needle

Setting

Threading

of

cooler

and

needle

Thread

How

Bight

Stitch

Differential

tension

to

adjustment

length

oil

sew

thread

adjustment

feed

adjustment

•••

9

10

12

12

13

13

Left

hand

Right

Knives

Feed

Differential

hand

adjustment

dogs

looper

adjustment

feed

looper

and

adjustment

ratio

E.INSTALLATION

OF

ATTACHMENTS

[T]. Blind hemming guide

[2]. Serging

[3]. Turn-down hemming

[4]. Taping

needle

adjustment

bar

AND

adjustment

ADJUSTMENT!

1.

Fully

2.

Pushbutton

the

automatic

face

plate

lubricating

controls

scale.

permit

system

easy

and

needle

adjustmentofstitch

cooler

for

reliable high-speed sewing.

length

with

a simple

setting

of

Differential

3.

4. Blade engaging angle can be easily

feed

ratio

can

be

easily

adjusted

adjusted

for

with

a lever.

sharp

cutting

performance.

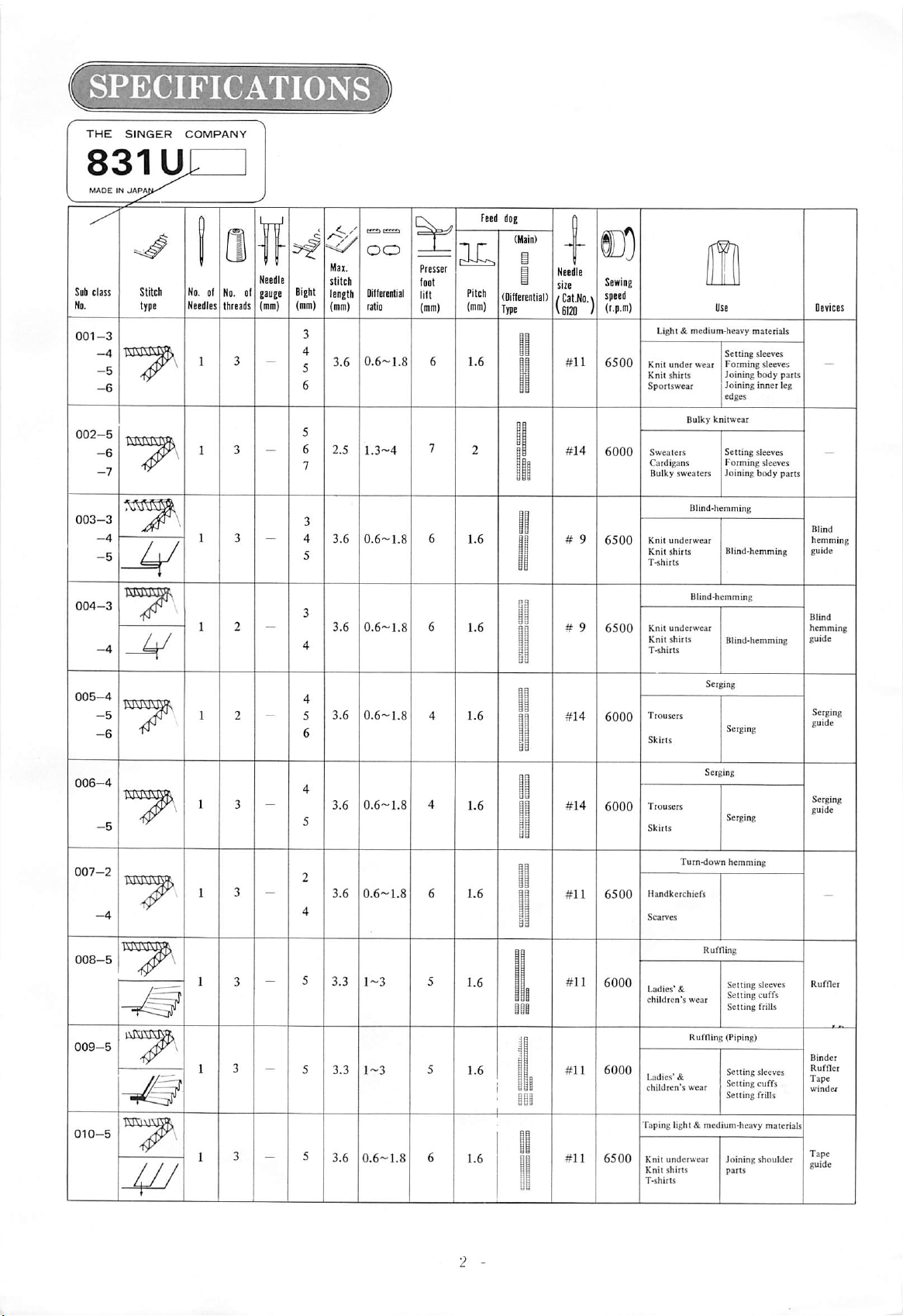

SPECIFICATIONS

THE

SINGER

COMPANY

831

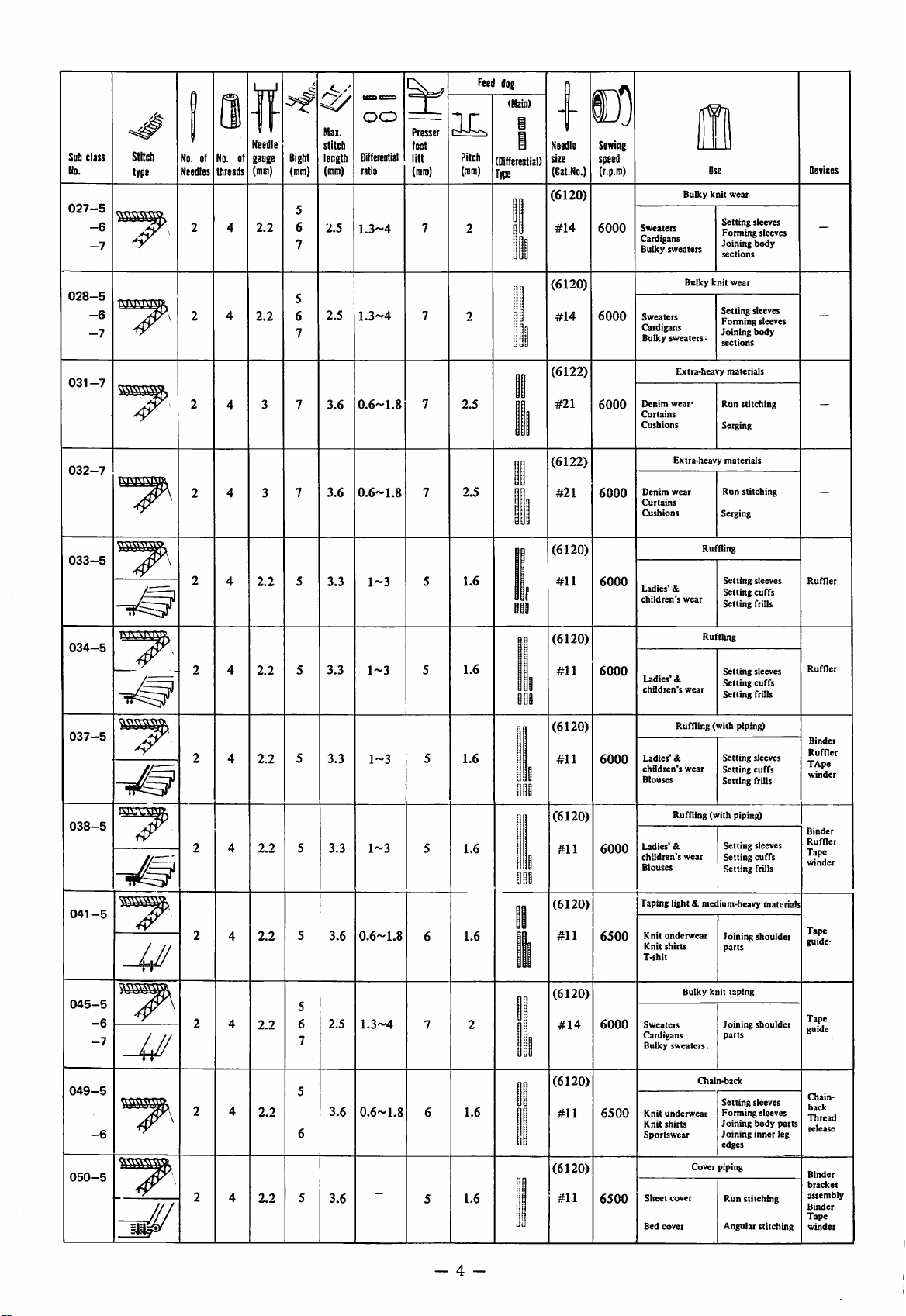

Sub class Stitch No. of No. of

No.

001-3

-4

5

6

type

Ua

Needles

threads

m

r\

^

r-'/y

OO

U..

stitch fool §

B'Eht

length

(mm] (mm)

Oiffereirtia!

ratio

' I

3.6

0.6~1.8

3.6

0.6-1.8

•==p'

:iz!=

n S

lift

(mm) (mm)

ir

Pitch

Feed

dog

(Main)

(Differential)

Type

a

Use

Light &

Knit

under

Knit

shirts

Sportswear

Sweaters

Cardigans

Bulky

sweaters

Knit

underwear

Knit

shirts

T-shirts

medium-heavy

wear

Bulky

Blind-hemming

Blind-hemming

materials

Setting

sleeves

Forming

sleeves

Joining

body

Joining

inner

i

edges

knitwear

Setting

sleeves

Forming sleeves

Joining btxly parts

Blind-hemming

r

Blind-hemming

parts

leg

Blind

hemining

005-4

Serging

-5

-6

3.6

0.6-1.8

6

0.6-1.8

#11

6500

Trousers

Skirts

Trousers

Skirts

Turn-down hemming

Handketchiefs

Scarves

Ladles'

4

children-swear

Ladies'

4 |

children's

Taping

light 4

Serging

Ruffling

wear

medium-heavy

' Serging

Serging

Setting

Setimg

Setting frills

(Piping)

Setting

Setting

,

Setting

sleeves

cuffs

sleeves

cuffs

frills

materials

Knit

Knit

T-shirts

underwear

shirts

Joining

parts

shoulder

Sab

Ka.

011-6

class

-7

Stitcb

type

4Z/

No. of

Needles

No. of

threads

Needle

gauge

(mm)

Bight

(tnui)

Max.

stitcb

length

(aim)

2.5

OO

Diflereotial

ratio

1.3-4

Presser

foot

lift

(mm)

Pitch

(mm)

Feed

(Differential)

Type

dog

(Main)

Needle

size

/GatJlo.X

\G120

#14

I

Sewing

speed

(r.p.ra)

6000

Bulky

Sweaters

Cardigans,

Bulky

sweaters

Use

knitwear

taping

Joining

parts

shoulder

Devices

Tape

guide

012-3

-4

-5

-6

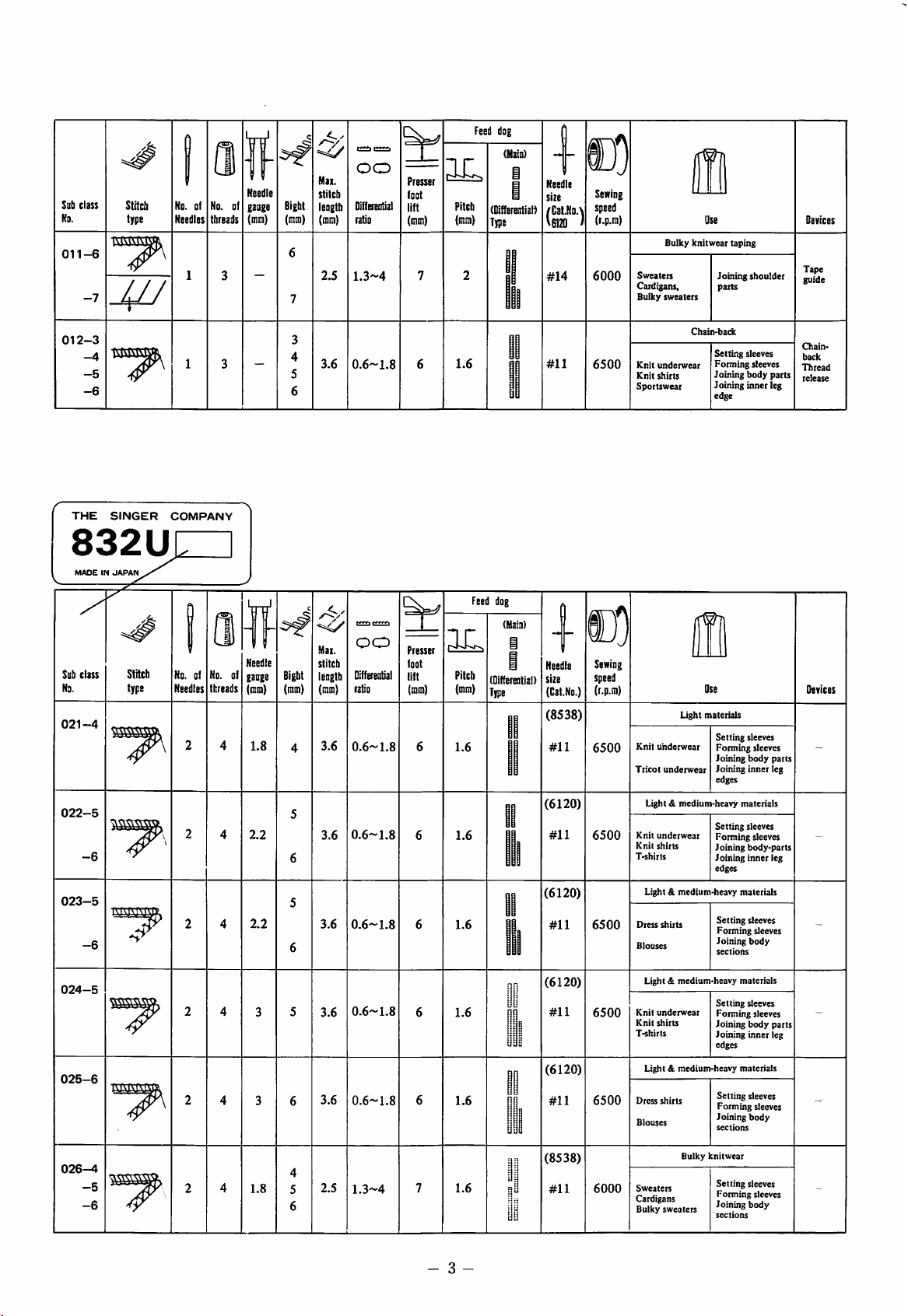

THE

MADEINJAPAN

Suh class

No.

021-4

022-5

-6

SINGER

Stitcb

type

COIirtPANY

No. of

No. of

threads

Needles

Needle

gauge

(mm)

1.8

2.2

Bight

(mm)

3.6

.A.

Max.

stitch

length

(mm)

3.6

3.6

0.6-1.8

OO

Differential

ratio

0.6-1.8

0.6-1.8

Presser

foot

lift

(mm)

1.6

IL

Pitch

(mm)

1.6

1.6

Feed

(Differential)

Type

dog

(Main)

#11

Needle

size

(Cat.No.)

(8538)

#11

(6120)

#11

6500

tn

Sewing

speed

(r.p.ra)

6500

6500

Chain-back

Setting sleeves

Knit

underwear

Knit

shirts

Sportswear

Knit

uhdctwear

Tricot

underwear

Light & medium-heavy materials

Knit

underwear

Knit

shirts

T-shirts

Forming sleeves

Joining body parts

Joining inner leg

edge

Light materials

Setting sleeves

Forming sleeves

Joining

Joining

edges

Setting sleeves

Forming

Joining

Joining

body

parts

inner

teg

sleeves

body-parts

inner

leg

Chainback

Thread

release

Devices

023-5

024-5

025-6

026-4

(6120)

2.2

-6

3.6

0.6-1.8

1.6

#11

6500

(6120)

3.6

0.6-1.8

1.6

#11

6500

lids

(6120)

3.6

0.6-1.8

1.6

#11

6500

(8538)

-5

-6

1.8

2.5

1.3-4

1.6

#11

6000

Light & medium-heavy materials

Dress

Blouses

Light & medium-heavy materials

Knit

Knit

T-shirts

Light &

Dress

Blouses

Sweaters

Cardigans

Bulky

- 3 -

shirts

underwear

shirts

medium-heavy

shirts

Bulky

sweaters

Setting sleeves

Forming sleeves

body

Joining

Setting

sleeves

Forming

sleeves

Joining

body

Joining inner leg

edges

materials

Setting sleeves

Forming sleeves

body

Joining

knitwear

Setting sleeves

Forming

Joining

body

sections

parts

sleeves

Sob class

No.

027-5

-6

-7

028-5

-6

-7

Stitch

type

No. of

Needles

Ho. of

threads

Needle

gauge

(nun)

2.2

2.2

Bight

(mm)

Max.

stitch

length

(mm)

2.5

2.5

CO

Differential

ratio

1.3-4

1.3-4

Presser

foot

lift

(mm)

Pitch

(mm)

Feed

(Differential)

Type

dog

(Main)

tiuii

Needle

size

(G3t.No.)

(6120)

#14

(6120)

#14

Sewing

speed

(r.p.ra)

6000

6000

Sweaters

Cardigans

sweaters

Bulky

Sweaters

Cardigans

Bulky

BuUcy

Bulky

sweaters

Use

knit

wear

Setting

Forming sleeves

Joining

sections

knit

wear

Setting

Forming

Joining

•

sections

sleeves

body

sleeves

sleeves

body

Devices

031-7

032-7

033-5

034-5

037-5

038-5

2.2

2.2

2.2

2.2

3.6

3.6

3.3

3.3

3.3

3.3

0.6-1.8

0.6-1.8

1-3

1-3

1-3

1-3

2.5

2.5

1.6

1.6

1.6

1.6

(6122)

#21

(6122)

#21

(6120)

#11

(6120)

#11

(6120)

#11

(6120)

#11

6000

6000

6000

6000

6000

6000

Extra-heavy

Denim

wear-

Curtains

Cushions

Extra-heavy materials

Denim

wear

Curtains

Cushions

Ladies'

&

children's

wear

Ladies'

&

children's

Ruffling

Ladies'

&

children's

Blouses

Ruffling (with piping)

Ladies'

&

children's

wear

Blouses

wear

wear

Run

Serging

Run

Serging

Ruffling

Setting

Setting

Setting

Ruffling

Setting

Setting

Setting

(with

Setting

Setting

Setting

Setting

Setting cuffs

Setting frills

materials

stitching

stitching

piping)

sleeves

cuffs

frills

sleeves

cuffs

frills

sleeves

cuffs

frills

sleeves

Ruffler

Binder

Ruffler

TApe

winder

Binder

Ruffler

Tape

winder

041-5

045-5

049-5

050-5

(6120)

2.2

3.6

0.6-1.8

1.6

#11

(6120)

-6

-7

2.2

2.5

1.3-4

#14

(6120)

2.2

-6

3.6

0.6-1.8

1.6

#11

(6120)

2.2

3.6

1.6

#11

Taping light & medium-heavy materials

Knit

6500

Knit

T-shit

Sweaters

6000

Cardigans

Bulky

Knit

6500

Knit

Sportswear

Sheet

6500

Bed

_ 4 _

underwear

shirts

sweaters.

underwear

shirts

cover

cover

Bulky

Cover

Joining shoulder

parts

knit

taping

Joining

parts

Setting

Forming

Joining

Joining inner leg

edges

piping

Run

stitching

Angular stitching

shoulder

sleeves

sleeves

body

parts

Tape

guide-

Tape

guide

Chain-

back

Thread

release

Binder

bracket

assembly

Binder

Tape

winder

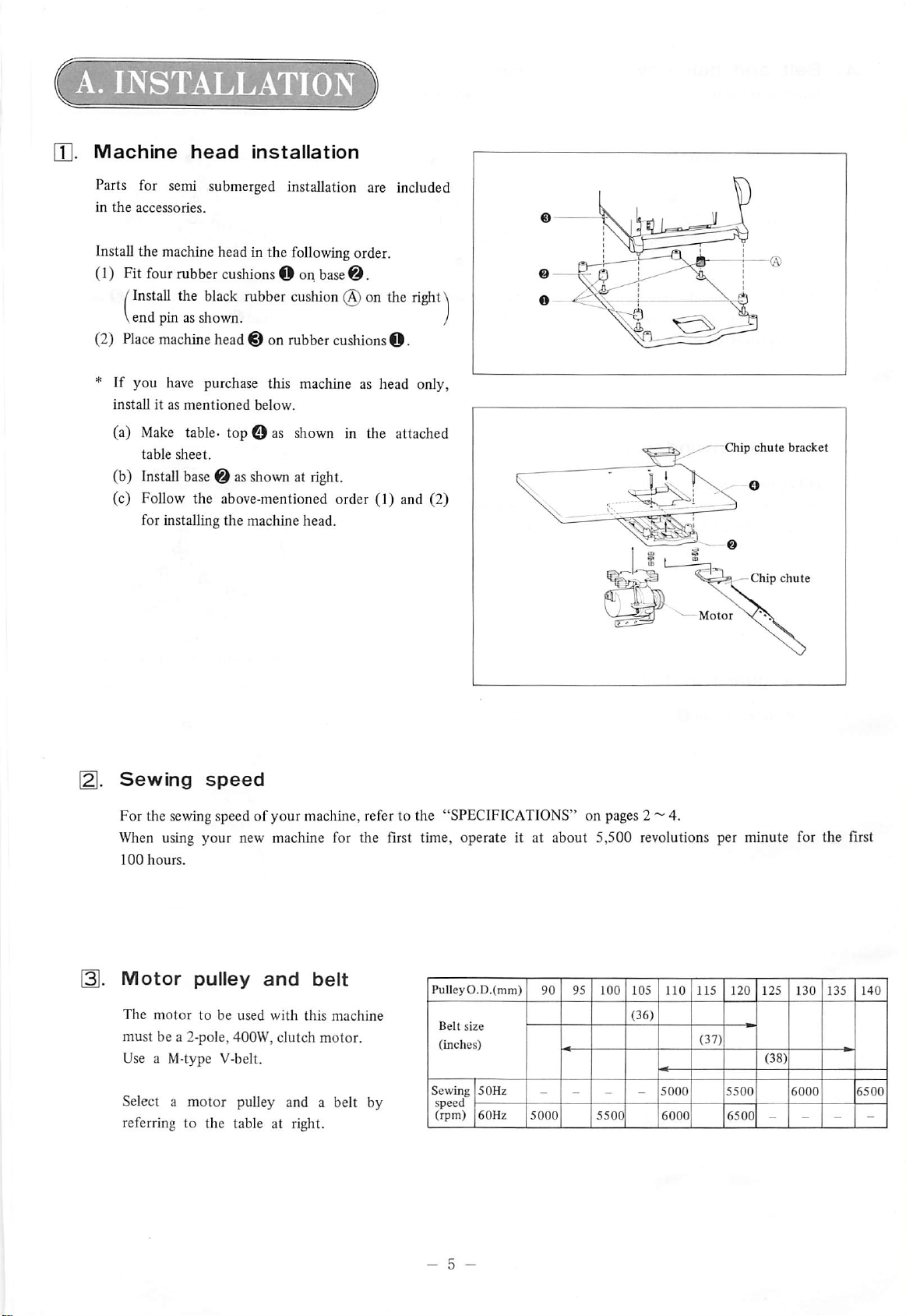

A.

INSTALLATION

[T].

Machine

head

installation

Parts for semi submerged installation are included

in

the

accessories.

Installthe

(1) Fit four rubbercushions© oil

machine

/Install the

headin the

black

rubber

following

base®.

cushion

order.

@ on the right\

Vendpin as shown. /

(2) Placemachine head ® on rubbercushionso

* If you have purchase this machine as head only,

installitas

(a)

(b)

Make

table

Install

mentioned

table, top

sheet.

base

® as

below.

©as

shown

shownatright.

in the attached

(c) Follow the above-mentioned order (1) and (2)

for installing the machine head.

Motor

Chip

Chip

x'X

chute

bracket

chute

Sewing

For the sewing speedofyour

speed

machine, refer to the "SPECIFICATIONS" on pages 2 ~ 4.

When using your new machine for the first time, operate it at about 5,500 revolutions per minute for the first

100

hours.

Motor

The

must be a 2-poIe, 400W, clutch

Use a M-type V-belt.

Select a motor pulley and a belt by

referring to the table at right.

motor

pulley

tobeused

and

with

belt

this

machine

motor.

PuUeyO.D.(mm)

Belt

size

(inches)

Sewing

50Hz

speed

(rpm)

60Hz

90

95 ICQ

I ^ I

5000

105

5000

6000

120

5500

6500

125

- 5 -

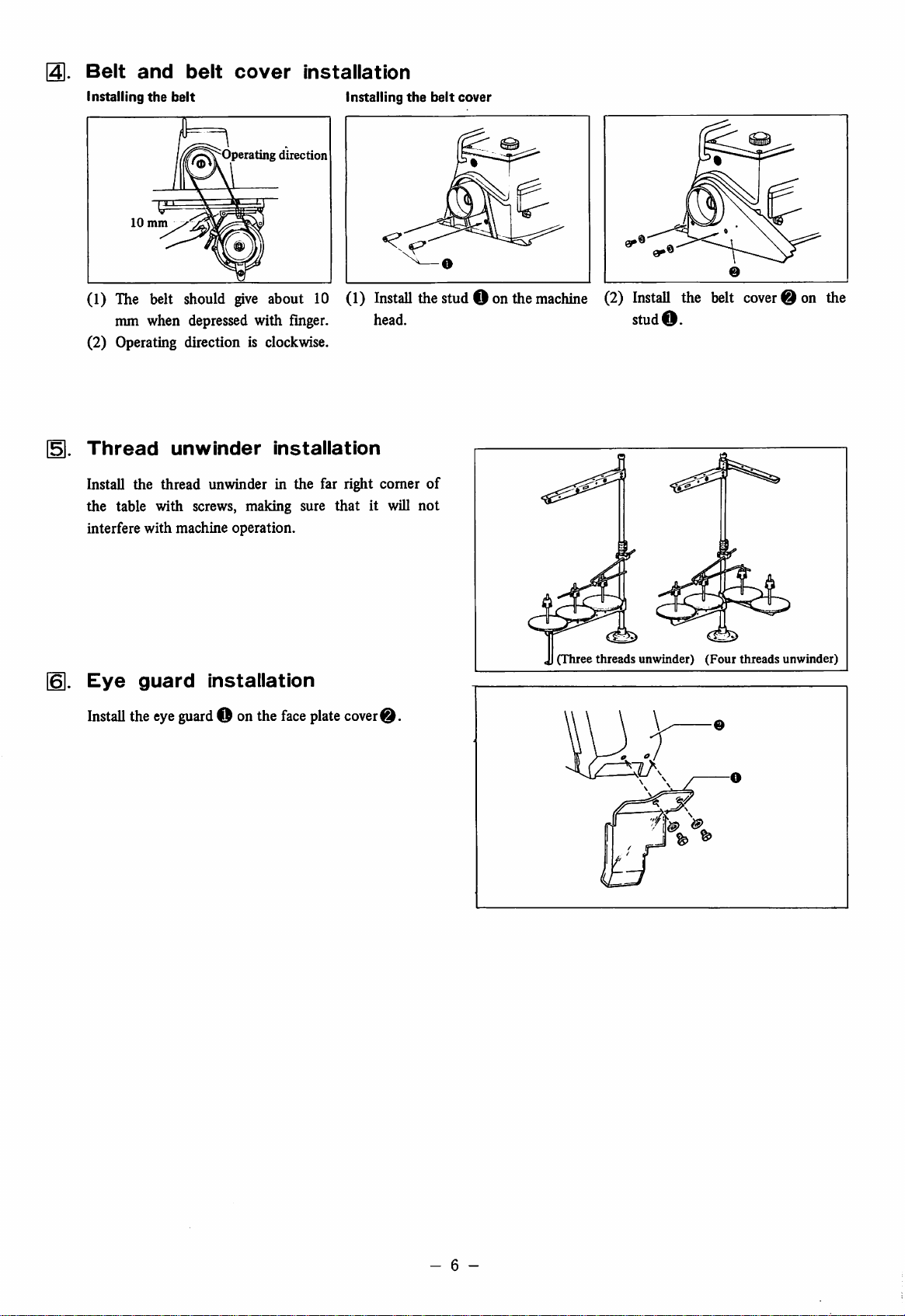

Belt

Installing

and

the

belt

belt

cover

installation

Installing

the

belt

cover

/^^^Operating

10

mm

(1)

The

belt

should

mm when depressed with finger.

(2) Operating direction is clockwise.

Thread

Install the thread unwinder in the far right

the table with screws, making sure

interfere with machine operation.

unwinder

give

direction

about

10 (1)

installation

that

Install

head.

comer

it will

thestudO onthe

of

not

machine

(2)

Install

studO.

the

belt

cover

@ on the

6].

Eye

Install

guard

theeye

installation

guard

O onthe

face

plate

cover

(Three

threads

unwmder)

(Four

threads

unwinder)

6 -

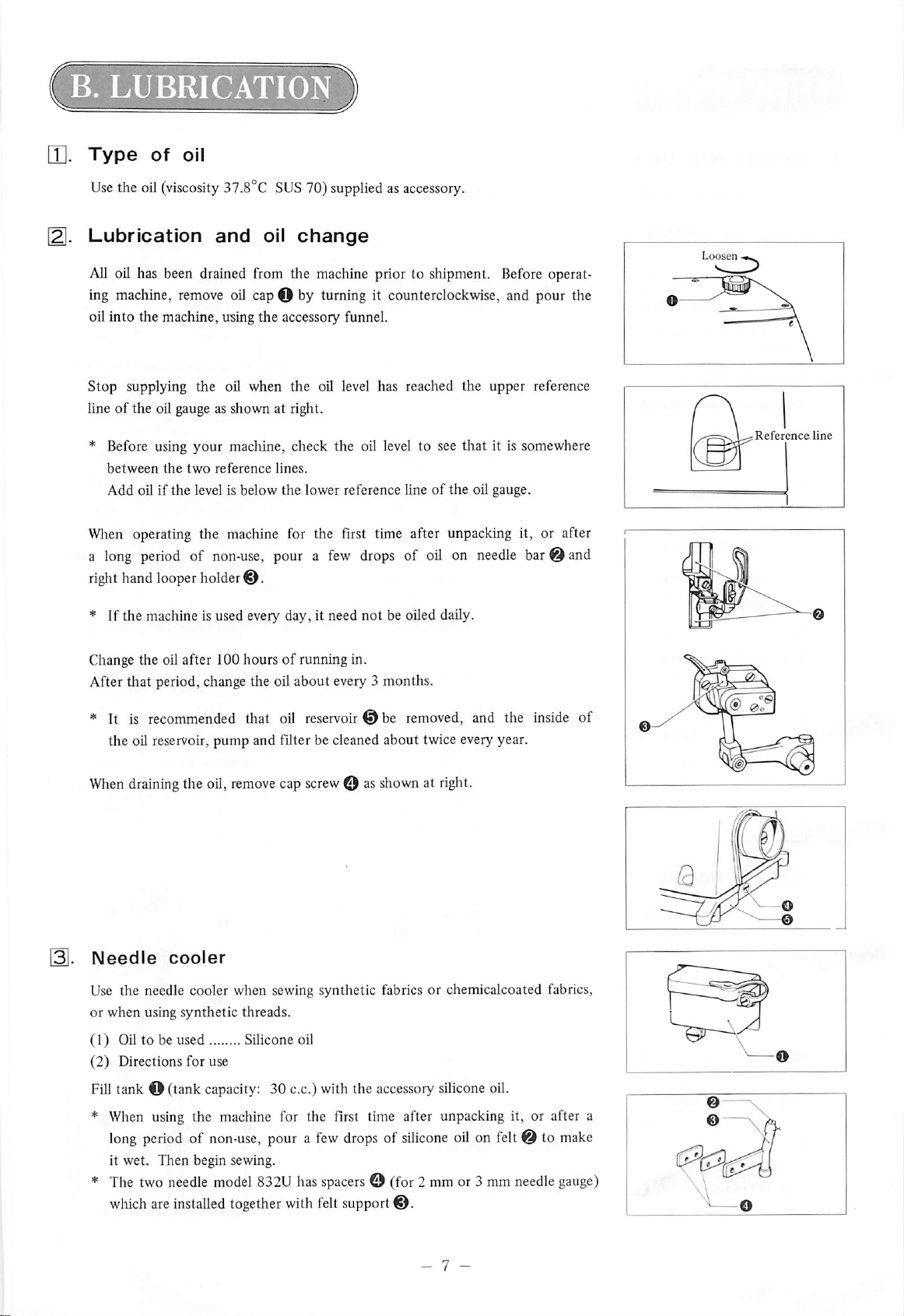

B.

LUBRICATION

Use

the oil

(viscosity

].

Lubrication

All oil has been drained from the machine prior to shipment. Before operat

ing

machine,

oil into the machine, using the accessory funnel.

Stop supplying the oil when the oil level has reached the upper reference

of

the oil gauge as shown at right.

line

* Before using your machine, check the oil level to see that it is somewhere

between

Add

When

a

long

right

the

oil if the level is below

operating the machine for the first time after unpacking it, or after

period

hand

looper

remove

two

of

holder

37.8°C

and

oil

reference

non-use,

®.

SUS

oil

capOhy

lines.

the

pour a

change

j

70)

suppliedasaccessory.

turning it counterclockwise, and pour the

lower reference lineofthe

few

drops

of oil on

oil gauge.

needle

bar@ and

Reference

line

* If the machine is used every day, it need not be oiled daily.

Change the oil after 100 hoursofrunning in.

After that period, change the oil about every 3 months.

* It is recommended that oil reservoir ® be removed, and the inside of

the oil reservoir,

When

draining

Needle

Use the needle cooler when sewing synthetic fabrics or chemicalcoated fabrics,

or

when

using

(1)

Oil to be used Silicone oil

(2) Directions for use

the oil,

cooler

synthetic

pump

and filter be cleaned about twice every year.

remove

threads.

cap

screw

0 as

shownatriglit.

Filltank O (tank capacity: 30 c.c.)with the

* When using the machine for the first lime after unpacking it, or after a

long

*

periodofnon-use,

it wet.

Then

The

two

needle

which

are

installed

begin sewing.

model

pour a

832U

has

few

spacers

together withfeltsupport®.

accessory

dropsofsilicone

0 (for2

mm

- 7 -

silicone

oil.

oil on felt® to

or3

mm

needle

make

gauge)

C.

QPERATIO^

|T|.

Needle

and

thread

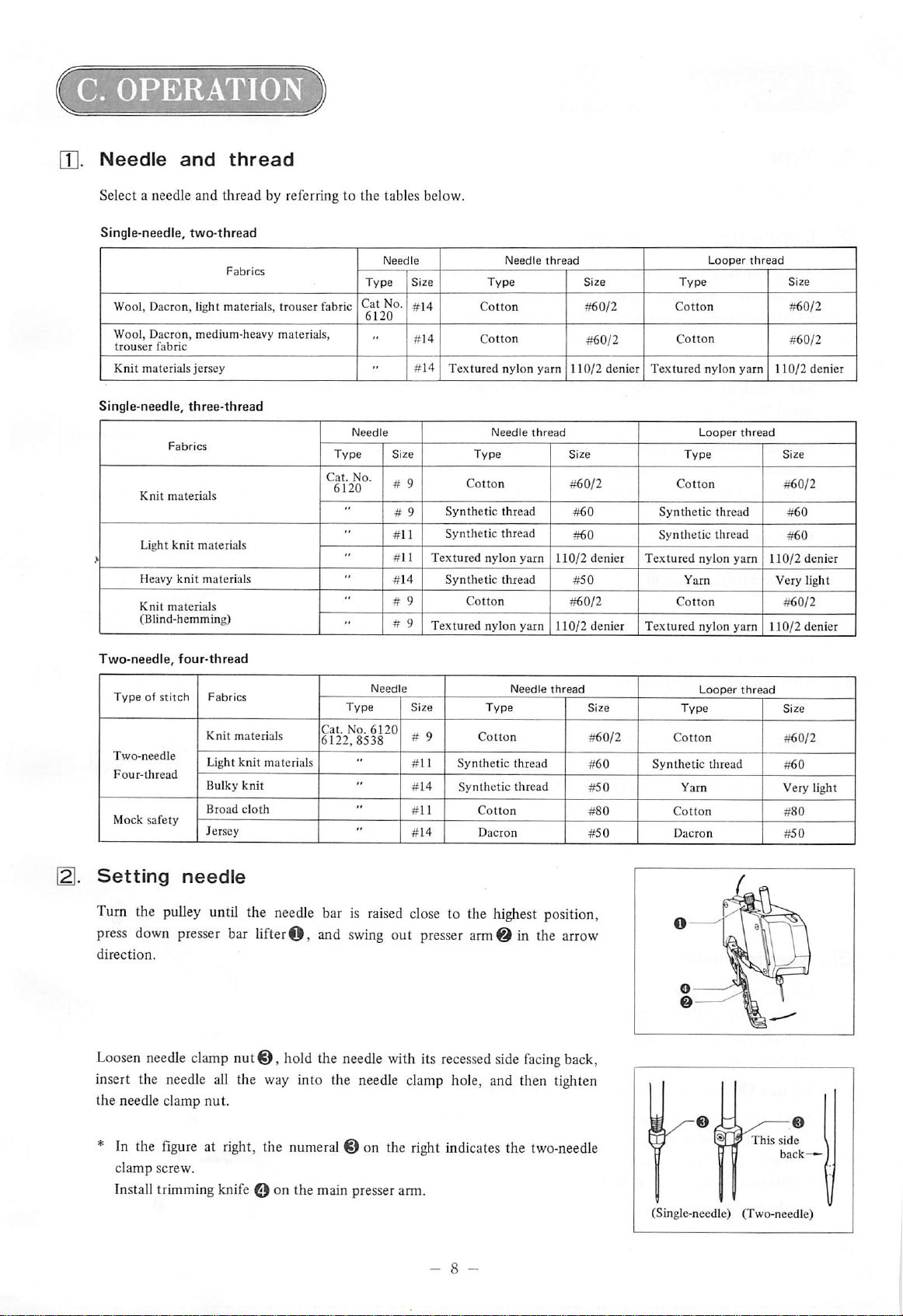

Select a needle and thread by referring to the tables below.

Single-needle,

Wool,

Dacron,

Wool,

Dacron,

trouser

fabric

Knit

materials

Single-needle,

Knit

materials

Light

Heavy

Knit

materials

(Blind-hemming)

Two-needle,

two-thread

light

medium-heavy

jersey

three-thread

knit

materials

knit

materials

four-thread

Fabrics

materials,

trouser

materials,

Needle

1

Type

Size

fabric

Needle Needle

Cat.

Type

6120

No.

Size

# 9

#11

#11

Textured

#14

# 9

*9

Textured nylon yarn 110/2 denier

Cotton

Type

Cotton

Synthetic

Synthetic

Synthetic

Cotton

Type

thread

nylon

thread

Needle

thread

yarn

thread

thread

110/2

Size

#60/2

Size

#60/2

#60

#60

#50

#60/2

denier

1

Cotton

Cotton

Synthetic

Synthetic

Textured

Cotton

Textured

Type

Type

Yam

Looper

Looper

thread

thread

nylon

nylon

thread

yam

yam

thread

1

110/2

110/2

Size

#60/2

#60/2

110/2

Size

#60/2

#60

#60

Very

#60/2

denier

denier

light

denier

Needle

thread

thread

facing

thread

position,

arrow

back,

Typeofstitch

Two-needle

Four-thread

Mock

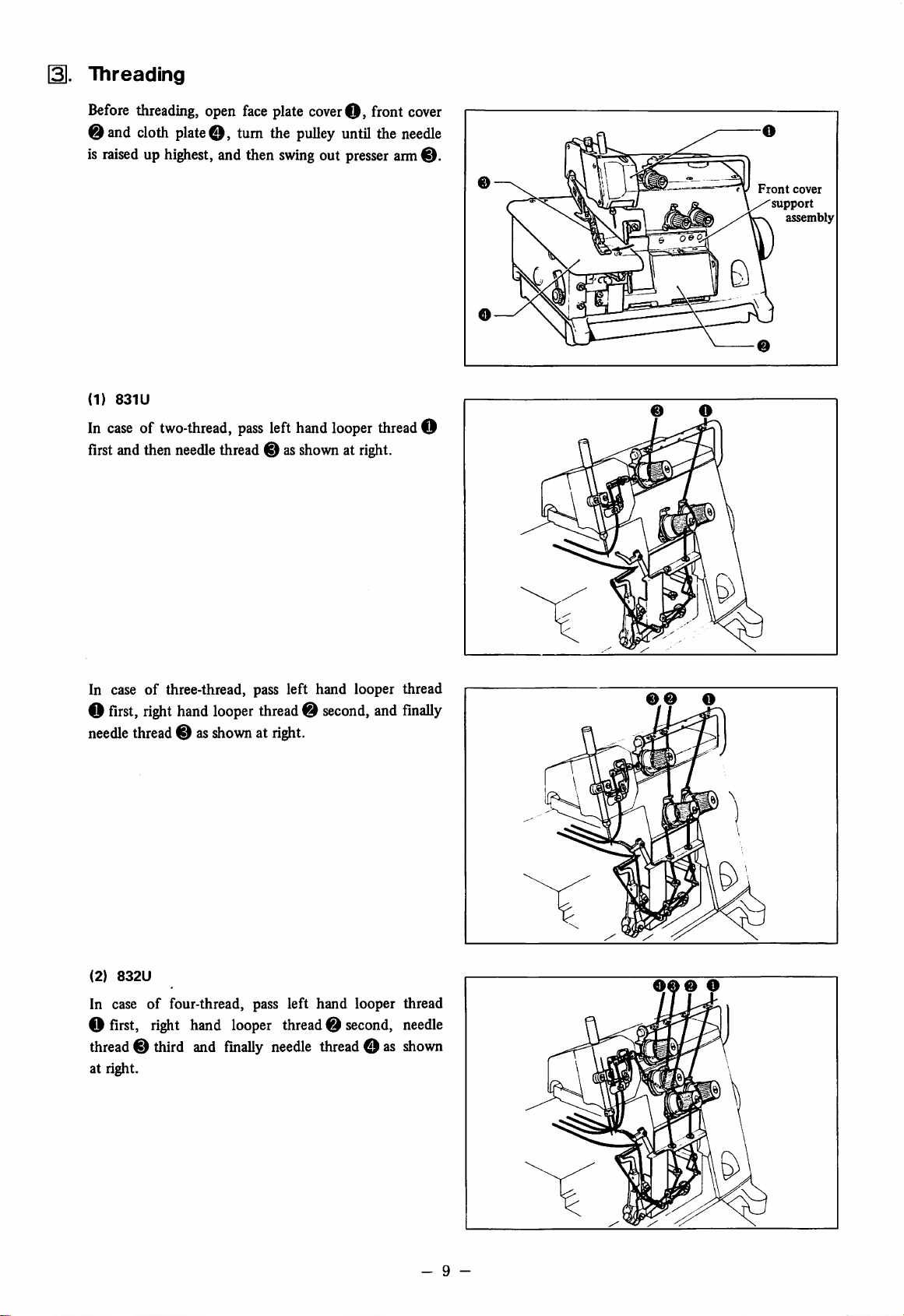

Setting

Turn the

press

down

direction.

Loosen

safety

pulley

needle

Fabrics

Knit

Light

Bulky

Broad

Jersey

needle

until the

presser

clamp

materials

knit

materials

knit

cloth

needle

bar lifterO,

nut®,

hold

Cat.

No.

6122,8538

bar is

and

swing

the

needle

6120

raised

out

with

Size

„

#9

#11

#14

close

presser

its

I

Type

Cotton

Synthetic

Synthetic

Cotton

Dacron

to the

arm® in the

recessed

highest

side

insert the needle all the way into the needle clamp hole, and then tighten

the needle clamp nut.

* In the

figureatright,

the

numeral

® on the

right

indicates

the

two-needle

clamp screw.

Installtrimming knife 0 on the main presserarm.

Looper

thread

Type

Cotton

Synthetic

(Single-needle) (Two-needle)

thread

Yarn

Cotton

Dacron

O

This

Size

#60/2

#60

Very

#80

#50

®

side

back—

light

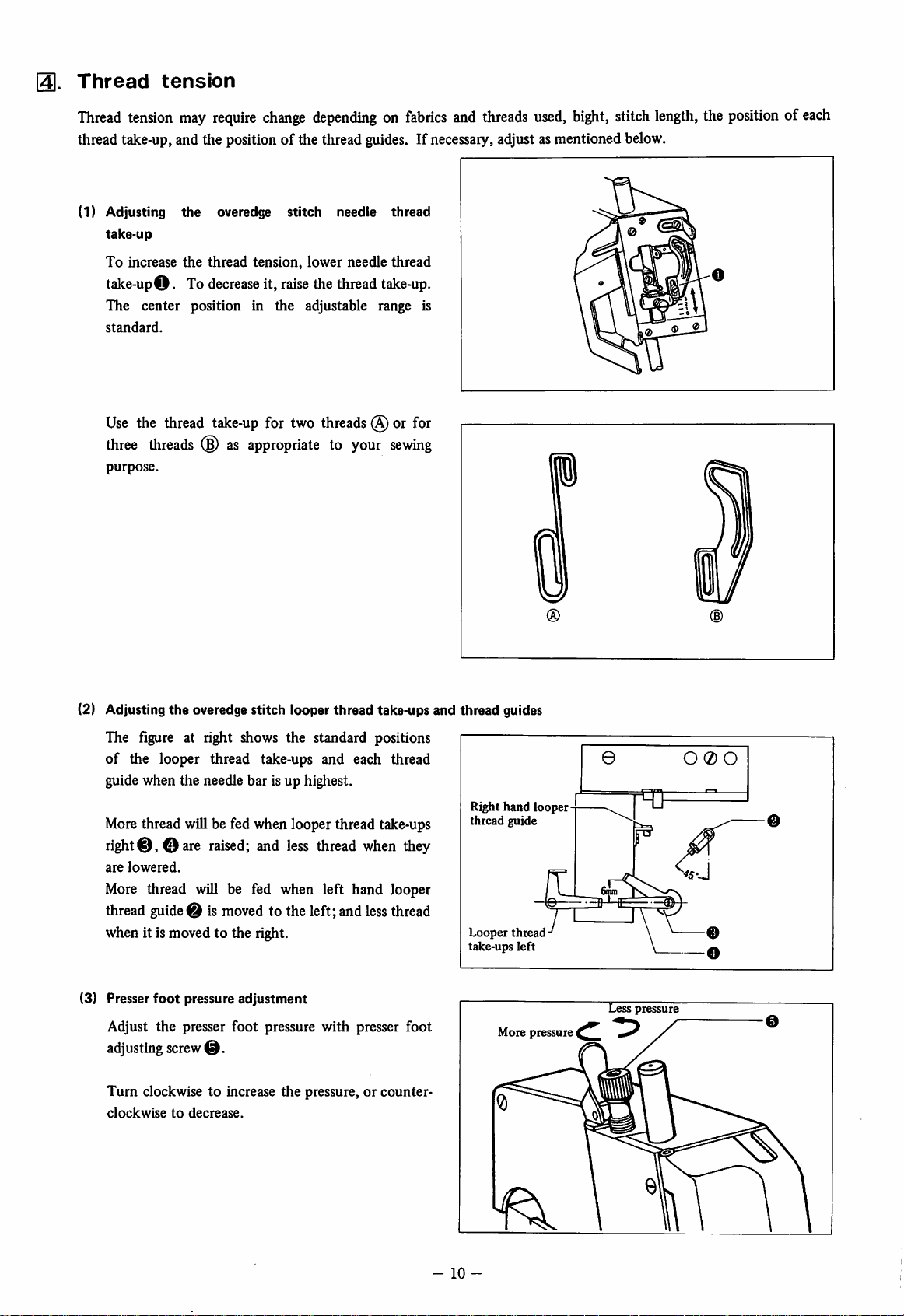

3].

Threading

Before

@ and

is

(1)

In

firstandthen

threading, open

cloth

plate0,turn the

raiseduphighest,

831U

caseoftwo-thread,

needle

face

plate

and then

pass

swing

left

thread0 as

cover0>front

pulley

until

out

presser

hand

looper

shownatright.

the

needle

arm

thread

cover

0.

O

Front

cover

support

assembly

In caseofthree-thread, pass left hand looper thread

o

first,

right

hand

looper

needle

thread

0 as

(2)

832U

In case

O

first,

of

four-thread, pass left hand looper thread

right

hand

thread0 third and

at right.

thread0second,

shownatright.

looper

finally

thread0

needle

thread0 as

and

second,

finally

needle

shown

- 9 -

Thread

tension

Thread

tension

may

require

change

dependingonfabrics

and

threads

used,

bight,

stitch

thread take-up, and the position of the thread guides. If necessary,adjust as mentioned below.

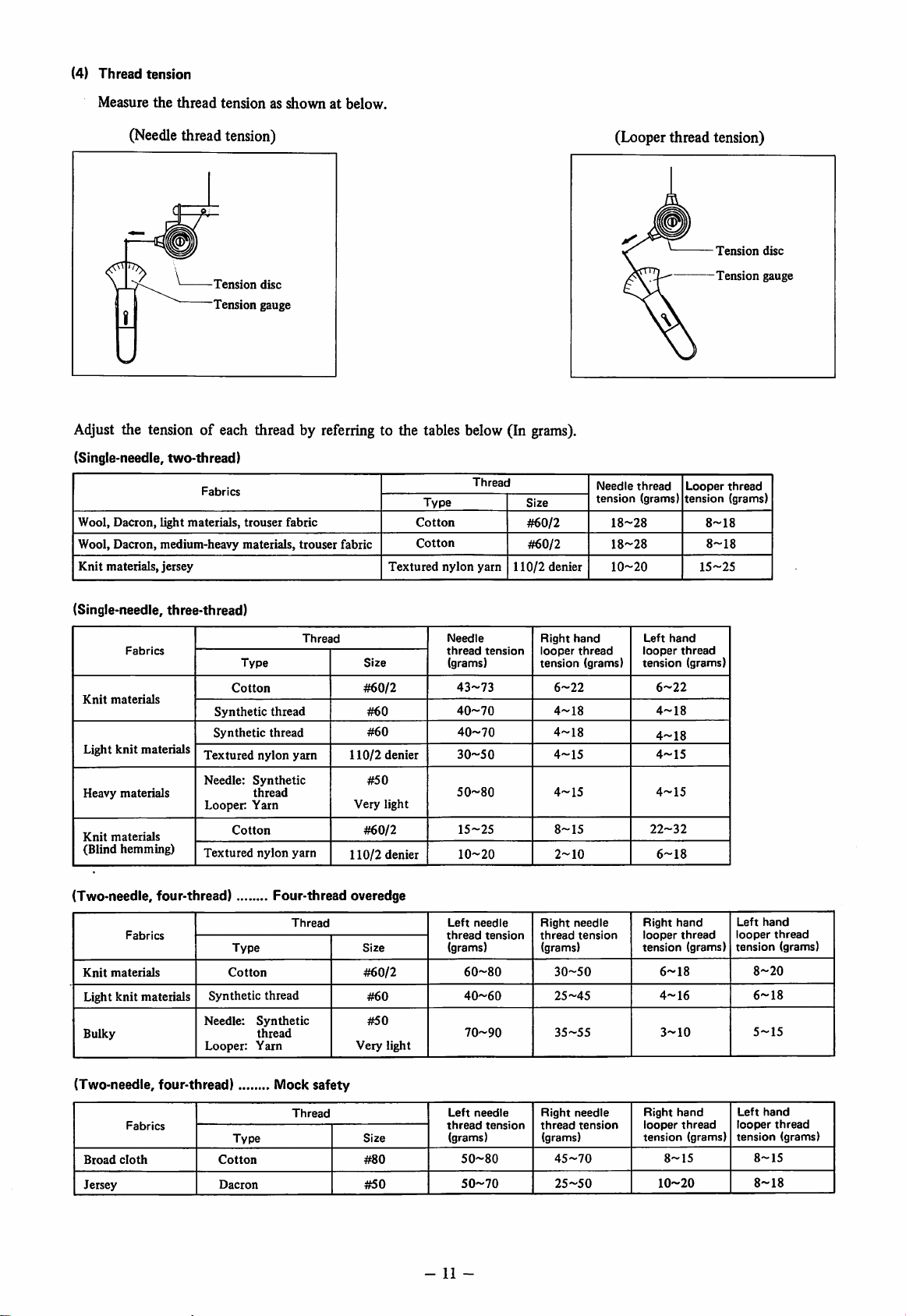

(1) Adjusting

take-up

To increase

take-upO. To

The center position in

standard.

Use

three

purpose.

the

the

overedge

thread

decrease

stitch

tension,

it,

raise

the

needle

lower

the

thread

adjustable range is

needle

thread

thread

take-up.

the thread take-up for two threads(S) or for

threads

(g) as appropriate to your

sewing

length,

the

positionofeach

(2) Adjusting the overedge stitch looper thread take-ups and thread guides

The figure at right shows the standard positions

of

the looper thread take-ups and each thread

guide when the needle bar is up highest.

Right

hand

thread

Looper

take-ups

More

guide

thread

left

More thread will be fed when looper thread take-ups

right®,

are

More thread will be fed when left hand looper

thread

when it is moved to the right.

(3) Presser

Adjust

adjusting

Turn

clockwisetodecrease.

©are

lowered.

guide

foot

the

clockwisetoincrease

raised;

© is

moved

pressure

presser foot pressure with presser foot

screw

©.

and

less

to the left; and

adjustment

the

thread

when

pressure, or

less

they

thread

counter

looper

pressure

©

Less

O0O

pressure

-

10

-

(4)

Thread

tension

Measure

the

(Needle

thread

tensionasshownatbelow.

threadtension)

-Tension

'Tension

disc

gauge

Adjust the tension of each thread by referring to the tables below (In

(Single-needle, two-thread)

nylon

Thread

yarn

110/2

Wool,

Wool,

Knit

Dacion,

Dacron,

materials,

Fabrics

light

materials,

medium-heavy

jersey

trouser

materials,

fabric

trouser

fabric

Type

Cotton

Cotton

Textured

grams).

Size

#60/2

#60/2

denier

(Looper thread tension)

-Tension

-Tension

Needle

thread

tension (grams)

18~28

18-28

10-20

Looper

tension

8-18

8-18

15-25

thread

(grams)

disc

gauge

(Single-needle, three-thread)

Knit

Light

Heavy

Knit

(Blind

Fabrics

materials

knit

materials

materials

hemming)

materials

Cotton

Synthetic

Synthetic

Textured

Needle:

Looper:

Cotton

Textured

Type

Synthetic

thread

Yarn

thread

thread

nylon

nylon

yarn

yarn

Thread

Size

#60/2

#60

#60

110/2

#50

Very

#60/2

110/2

denier

light

denier

(Two-needle, four-thread) Four-thread overedge

thread

Synthetic

thread

Yarn

Thread

Size

#60/2

#60

#50

Very

light

Knit

Light

Bulky

Fabrics

materials

knit

materials

Type

Cotton

Synthetic

Needle:

Looper:

Needle

thread

(grams)

43-73

40-70

40-70

30-50

50-80

15-25

10-20

Left

needle

thread

(grams)

60-80

40-60

70-90

tension

tension

Right

hand

looper

thread

tension (grams)

6-22

4-18

4-18

4-15

4-15

8-15

2-10

Right

needle

thread

tension

(grams)

30-50

25-45

35-55

Left

looper

tension

6-22

4-18

4-18

4-15

4-15

22-32

6-18

Right

looper

tension

6-18

4-16

3-10

hand

hand

thread

thread

(grams)

(grams)

Left

looper

tension

8-20

6-18

5-15

hand

thread

(grams)

(Two-needle, four-thread) Mock safety

Right

looper

tension

Broad

Jersey

Fabrics

cloth

Type

Cotton

Dacron

Thread

Size

#80

#50

-

Left

thread

(grams)

50-80

50-70

11

-

needle

tension

Right

thread

(grams)

45-70

25-50

needle

tension

8-15

10-20

hand

thread

(grams)

Left

looper

tension

8-15

8-18

hand

thread

(grams)

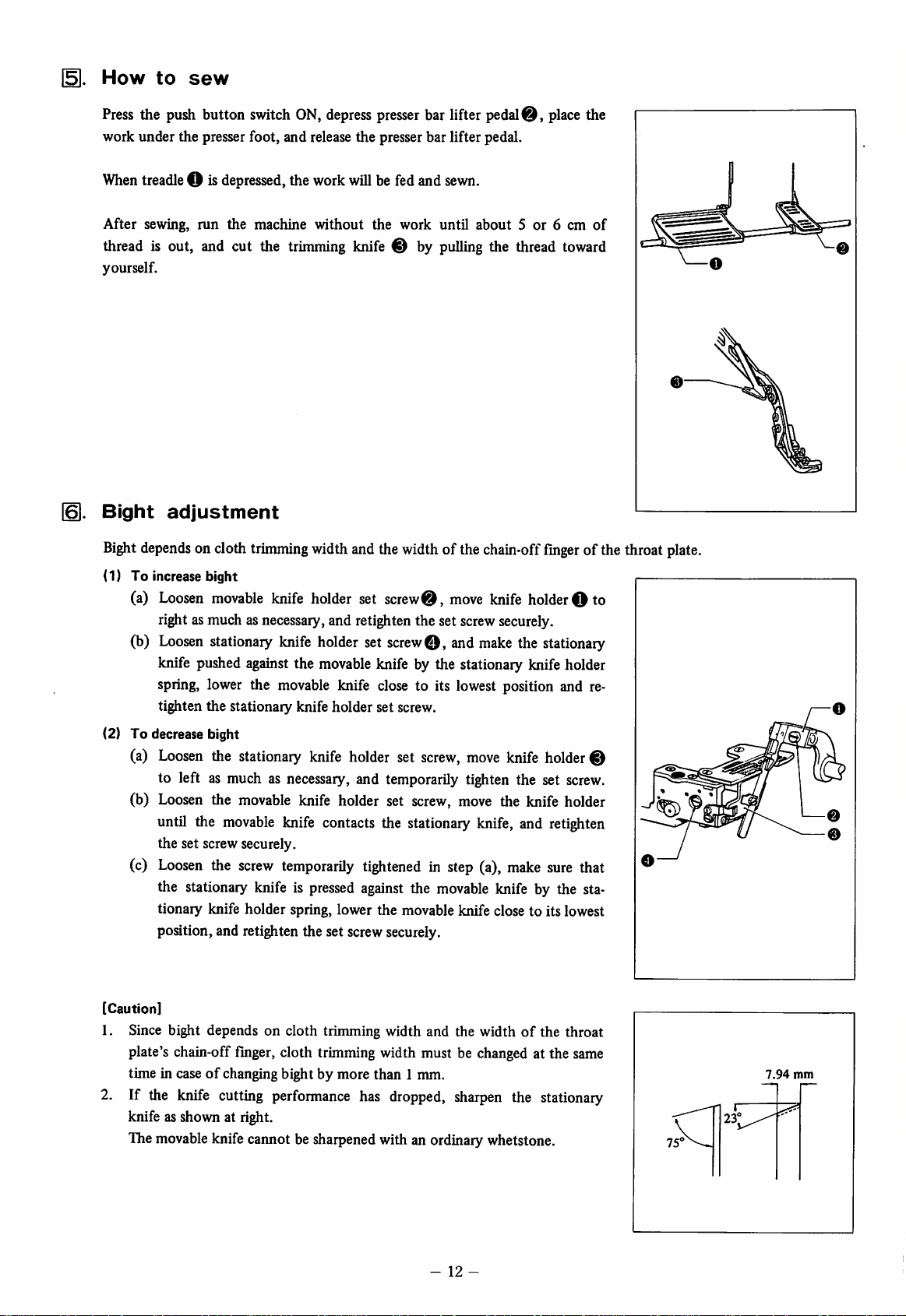

51.

How

Press

work under the presser foot, and release the presser bar lifter pedal.

When

to

the

push

treadle

sew

button

o is

switch

depressed,

ON,

the

depress

work

presser

willbefed

barlifterpedal®,

and

sewn.

place

the

After sewing, run the machine without the work until about 5 or 6 cm

thread

yourself.

Bight

Bight

(1) To increase bight

is out, and cut the

trimming

knife

adjustment

depends

(a)

(b)

on cloth

Loosen

rightas muchasnecessary, and retighten the set

Loosen

knife pushed against the

spring, lower the

tighten the stationary knife holder set screw.

trimming

movable

stationary

widthand the width of the chain-off

knife

holder

knife

movable

set screw®,

holder

set screw®, and

movable

knife by the stationary knife holder

knife close to its lowest position and re-

® by

pulling

move

screw

the

knife

securely.

make

thread

toward

finger

holder

the stationary

of

of the throat plate

O to

(2) To decrease bight

(a)

Loosen

to left as much as necessary, and temporarily tighten the set

(b) Loosen the

until the

the set screwsecurely.

(c)

Loosen

the stationary knife is

tionary knife holder spring, lower the movable knife close to its lowest

position, and

[Caution]

1. Since bight depends on cloth trimming width and the widthofthe throat

plate's chain-off

time in caseofchanging bight by more than 1 mm.

2. If the

knife as shown at right.

The

movable

the

stationary

movable

movable

the

screw

reti^ten

finger,

knife

cutting

knifecaimotbe sharpened with an ordinarywhetstone.

knife

holder

knife holder set screw, move the knife holder

knife

contacts the stationary

temporarily

pressed

the set screwsecurely.

cloth trimming width must be changed at the same

performance

set

tightened

against

has

dropped,

screw,

in step (a),

the

movable

move

sharpen

knife

holder

knife,

and retighten

make

sure

knife by the sta

the stationary

screw.

that

®

7.94

mm

-

12

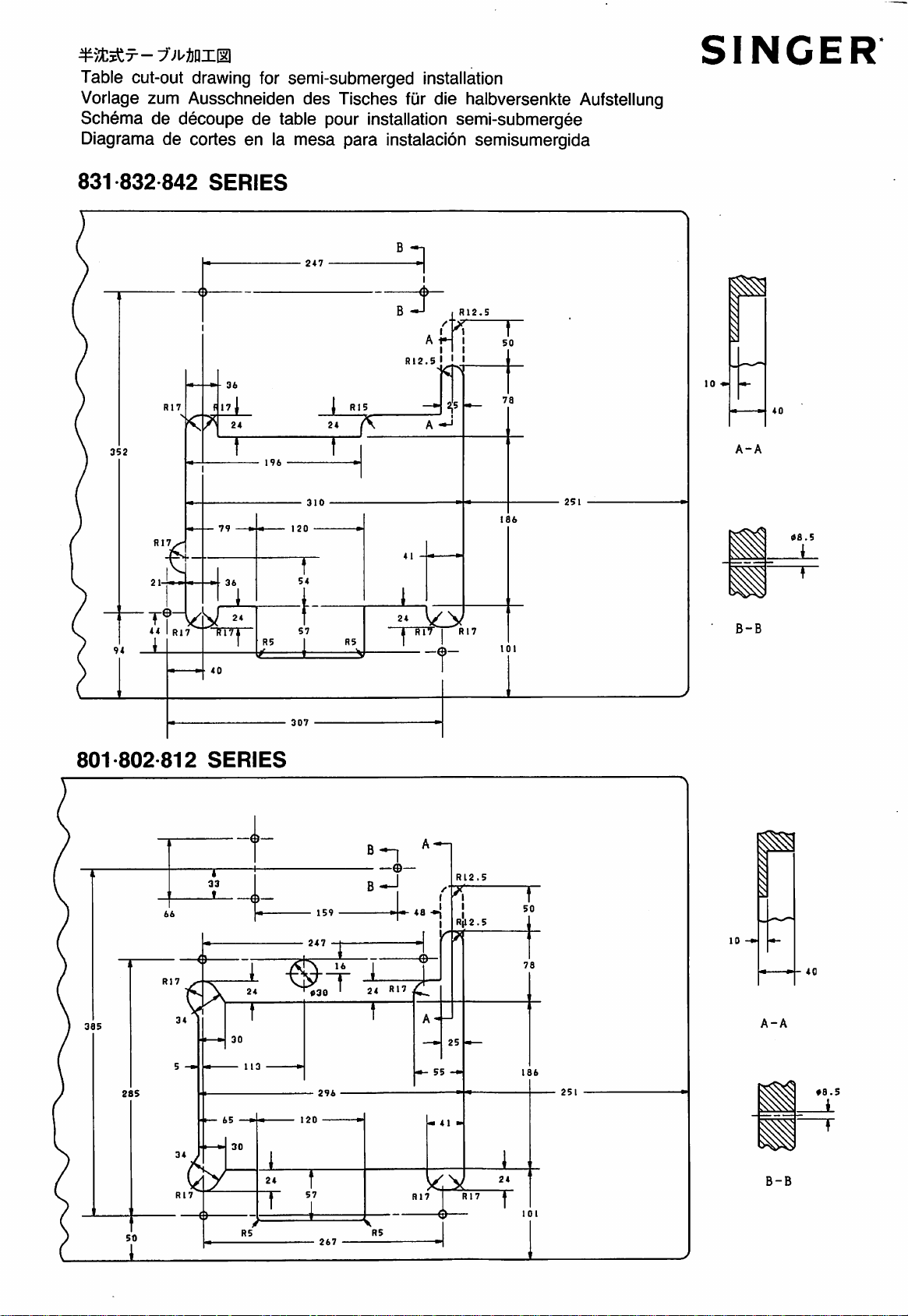

4^>5t5tx-7;uiinx[ll

Table cut-out drawing for semi-submerged installation

Vorlage zum Ausschneiden

des

Tisches fur die halbversenkte Aufstellung

Schema de decoupe de table pour installation semi-submergee

Diagrama de cortes en la

mesa

para instalacion semisumergida

SINGER

831-832-842

R17

3S2

94

SERIES

36

17

,

24

79

TTITT

40

2*7

A 1-

RI2.5

I <

I

RIS

310

120

S7

TTT

2,5

I R17

T

so

10

•

78

A-A

251

186

08.

S

B-B

801

802 812

SERIES

24

307

^^^0 '

24

«!'

jC

R12.5

Ril

2.5

40

A-A

•8.5

_JL

B-B

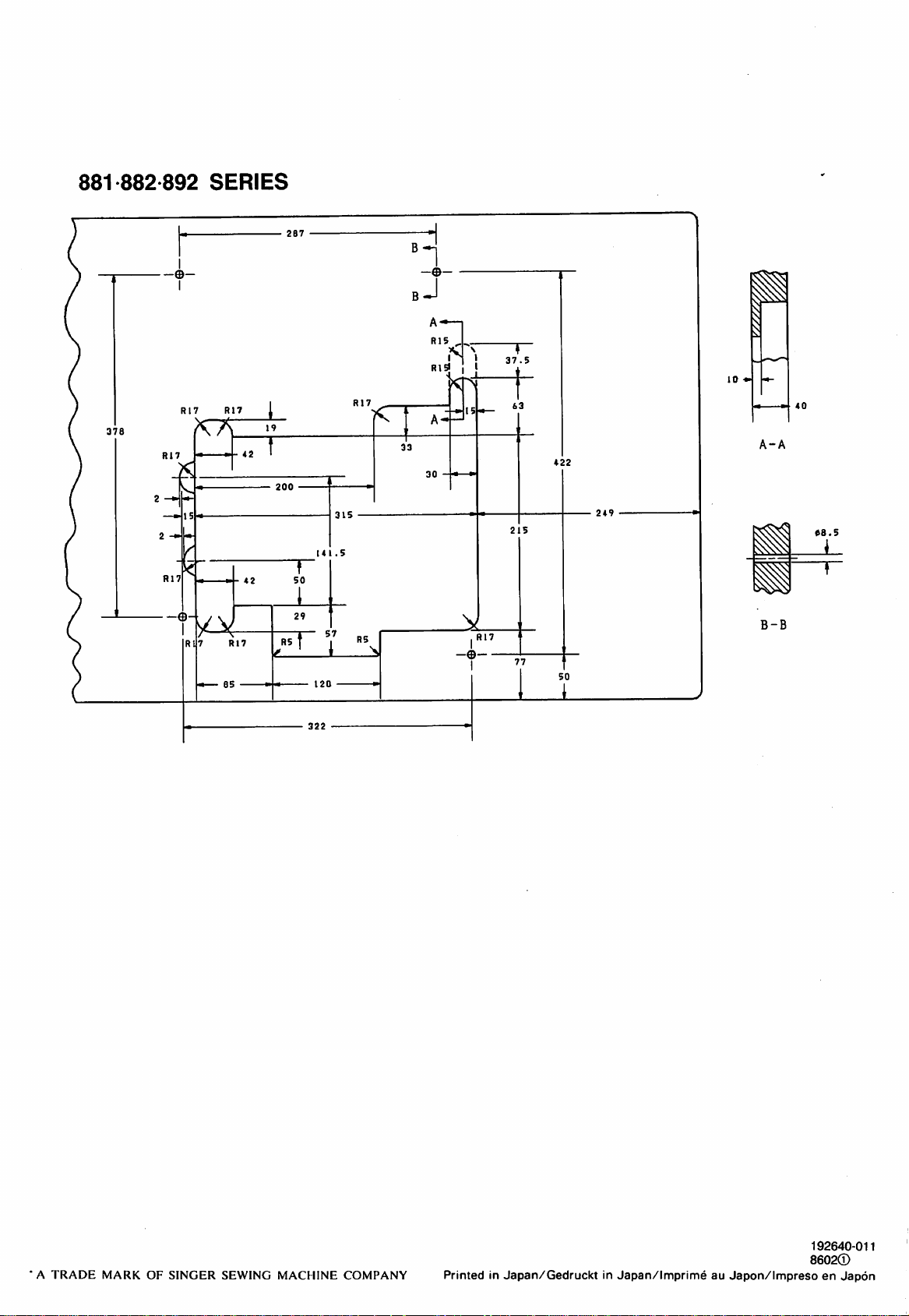

881

882-892

SERIES

378

-e-

R17 R17

i

15

2

-•

1

J

RI5

I •

RlSi

R17

?c

33

315

141.5

TTT

42

1

19

200

50

_L

29

57

7

R17

65

R5

120

37

37.5

.

A-A

215

«8.5

_L_

B-B

50

A

TRADE

MARK OF SINGER SEWING MACHINE COMPANY

PrintedinJapan/GedrucktinJapan/lmprimeauJapon/impreso

192640-011

8602®

en

Japon

Loading...

Loading...