Singer 82387 User Manual

82387 No. 66

Singer Sewing Machine

No. 66

Oscillating Hook, For Family Use

INSTRUCTION MANUAL

Table of Contents | Next Page

82387 No. 66

Table of Contents

Main Parts

Parts of the Machine Stand

Instructions for Operating the Machine

To Ensure Perfect Action of the Machine

To Take Out the Bobbin

To Wind the Bobbin

To Replace the Bobbin

To Set the Needle

To Thread the Needle

To Prepare for Sewing

To Commence Sewing

To Remove the Work

Tensions

To Regulate Tensions

To Turn a Corner

To Regulate the Length of Stitch

To Regulate the Pressure on the Material

To Sew Flannel or Bias Seams

A Stitch to Ravel Easily

To Oil the Machine

Hints

The Belt

Machine WOrking Heavily

To Avoid Breaking Needles

Breaking of Needle Thread

Breaking of Bobbin Thread

Skipping of Stitches

Attachments with the Machine

Instructions for Using the Attachments

Foot Hemmer

-- Hemming

-- Hemming and

Sewing on Lace

-- Felling

Adjustable Hemmer

-- Hemming

-- Wide Hemming

Binder -- Binding

Bias Gauge

-- To Bind with Dress Braid

Ruffling

Ruffler -- Ruffling Between Bands

To Ruffle and Sew On

-- Five Stitch Ruffling or Paiting

Ruffler with Shirring Plate -- Shirring

Quilter

Tucker

Under Braider

Embroidary and Darning

Relative Sizes of Needles and Thread

Previous Page | Next Page

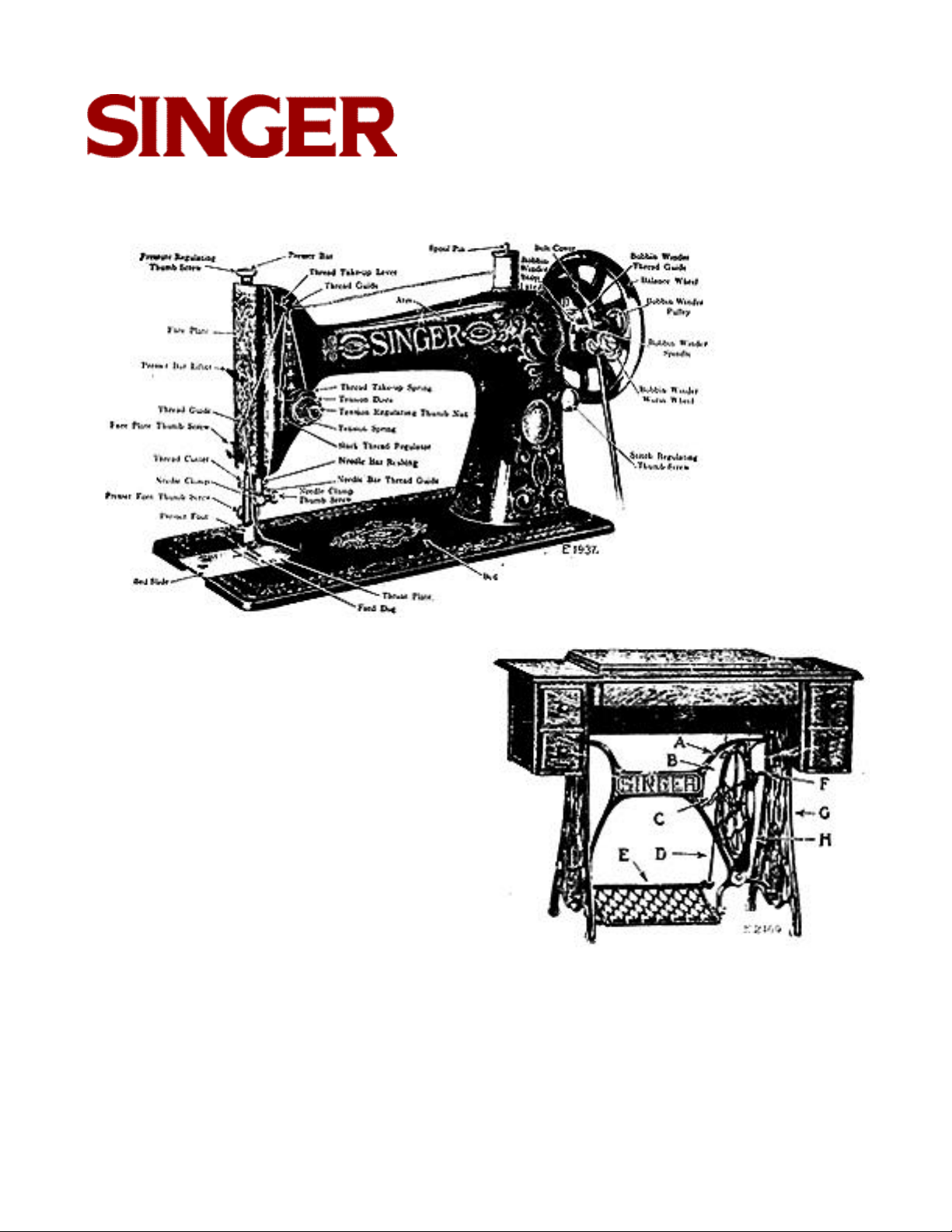

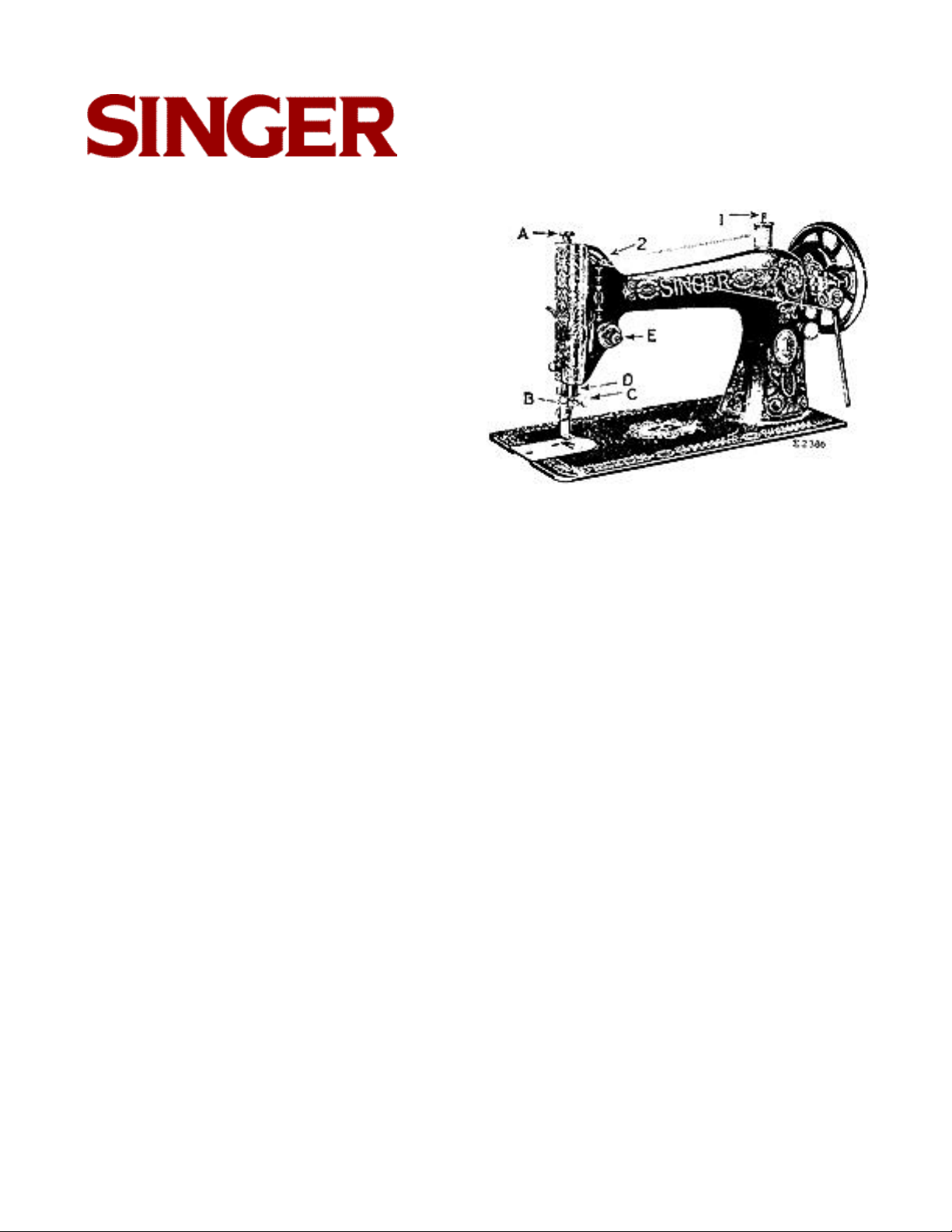

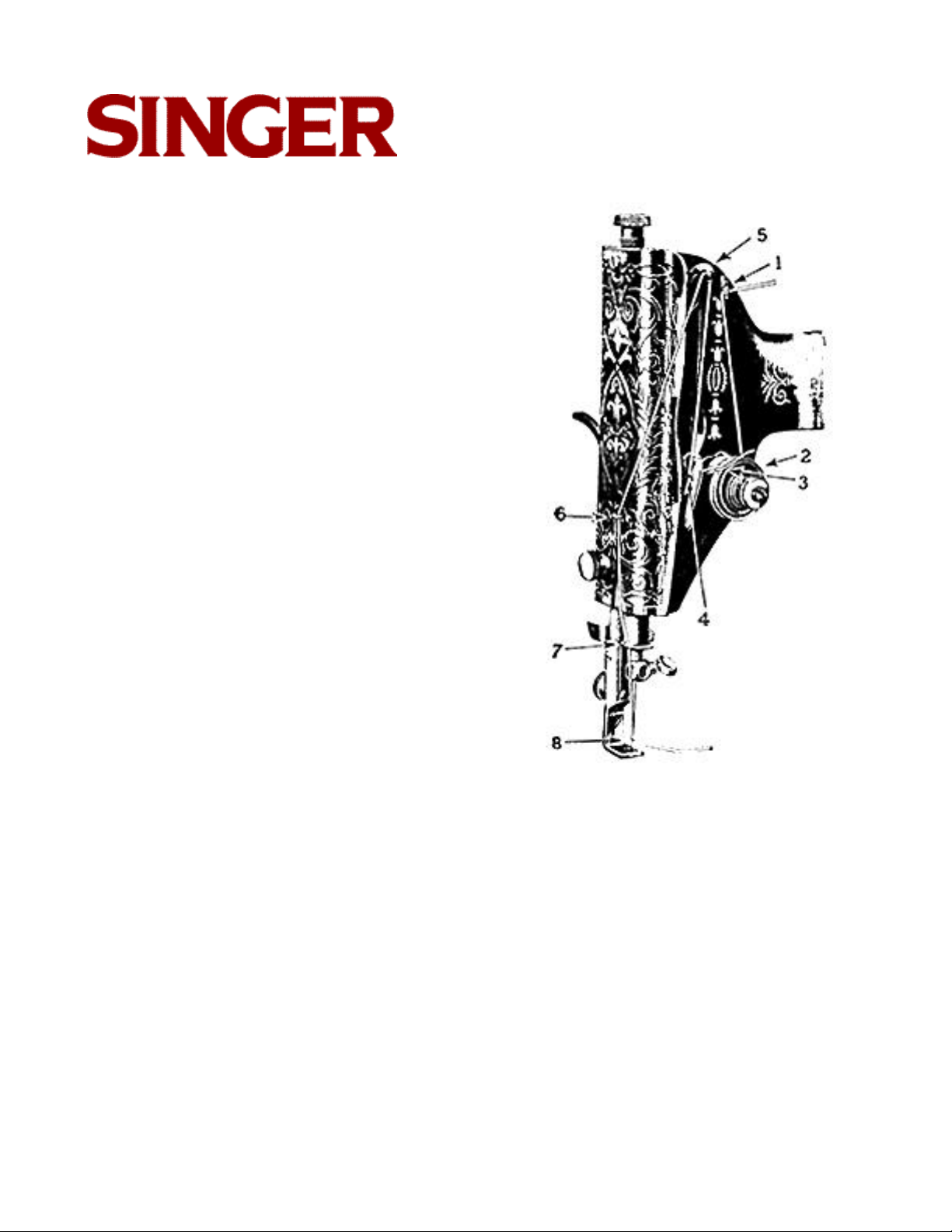

Main Parts

82387 No. 66

Parts of the Machine Stand

A. BELT GUIDE

B. BAND WHEEL

C. BAND WHEEL CRANK

D. PITMAN

E. TREADLE

F. BELT SHIFTER

G. LEG

H. DRESS GUARD

Table of Contents Previous Page | Next Page

3

82387 No. 66

INSTRUCTIONS FOR

OPERATING THE MACHINE

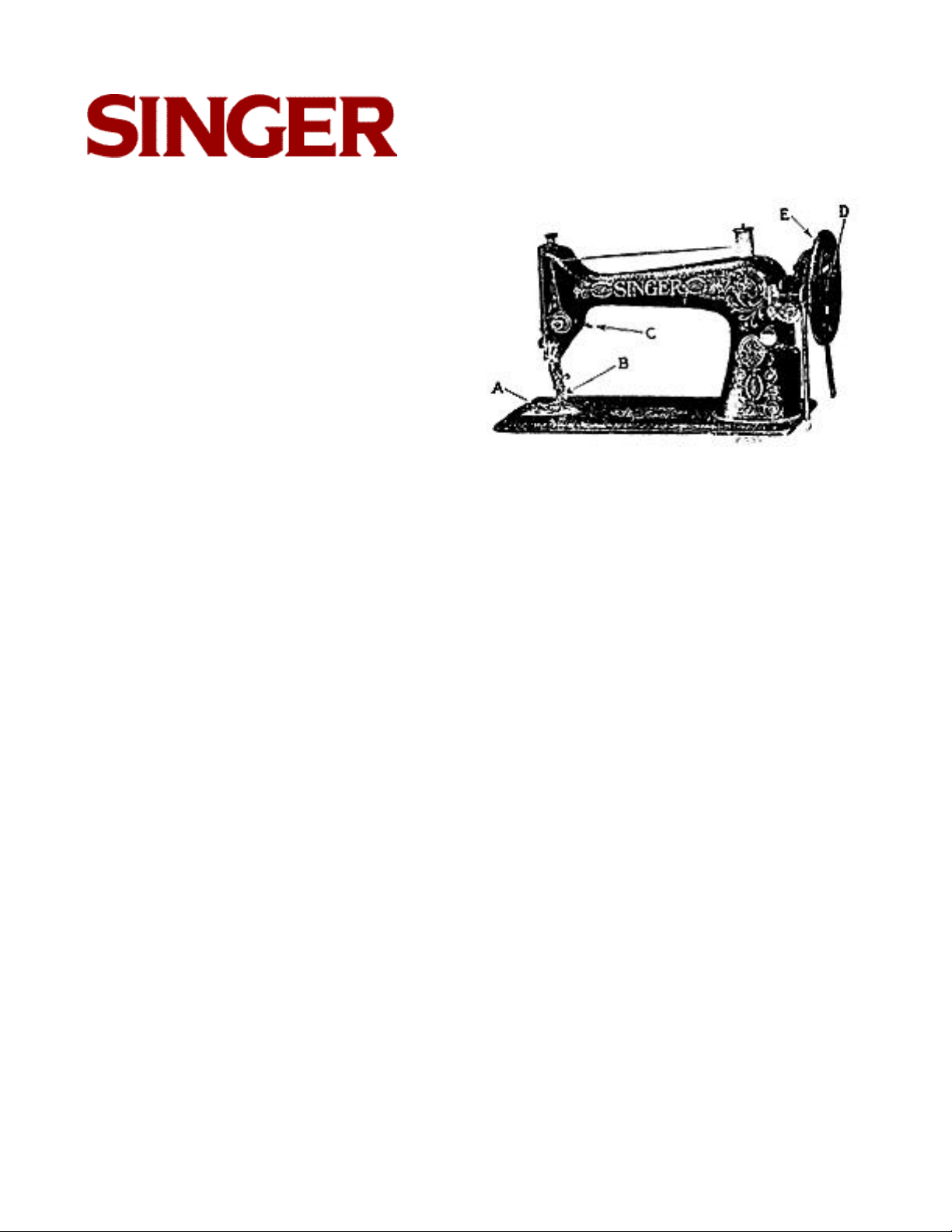

Raise the presser foot (B. Fig. 3) by means of

the presser bar lifter (C, Fig. 3) to prevent

injury to the foot (B. Fig. 3) and feed (A, Fig.

.3).

It is necessary to understand the stop motion

(D, Fig. 3) by which the balance wheel (E,

Fig. 3) can be released when required, thus

enabling the operator to become proficient in

the use of the treadle and permitting the

winding of bobbins without running the stitching mechanism. It also allows the operator to

wind bobbins without removing partially sewn

work and without unthreading the machine.

To release the balance wheel (E, Fig. 3) turn

the stop motion screw (D, Fig. 3, page 3)

over toward you. It may be necessary to hold

the balance wheel while loosening the stop

motion screw.

After releasing the balance wheel place your

feet upon the treadle and with the right hand,

turn the balance wheel over toward you. This

will start the band wheel, treadle and pitman,

the sewing mechanism having been disconnected.

FIG.3. FRONT VIEW OF THE MACHINE

Continue the motion thus begun by an alternate pressure of heel and toe, until a regular

and easy movement is acquired, and the balance wheel kept in continuous rotation by use

of the feet alone.

When you are thoroughly familiar with the

treadle movement, and can restart the

machine without turning the balance wheel in

the wrong direction, tighten the stop motion

screw to connect the balance wheel with the

stitching mechanism.

Place a piece of cloth under the presser foot,

let the foot down upon it, and operate the

machine in this way without being threaded,

until you have become accustomed to guiding

the material.

Table of Contents Previous Page | Next Page

4

82387 No. 66

To Ensure Perfect Action of the Machine

The balance wheel must always turn over

toward the operator.

Do not run the machine with the presser foot

resting on the feed without cloth under the

presser foot.

Do not run the machine when both bobbin

case and needle are threaded unless there is

material under the presser foot.

Do not try to help the machine by pulling the

fabric lest you bend the needle. The machine

feeds the work without assistance.

The slide over the bobbin case should be

kept closed when the machine is in operation.

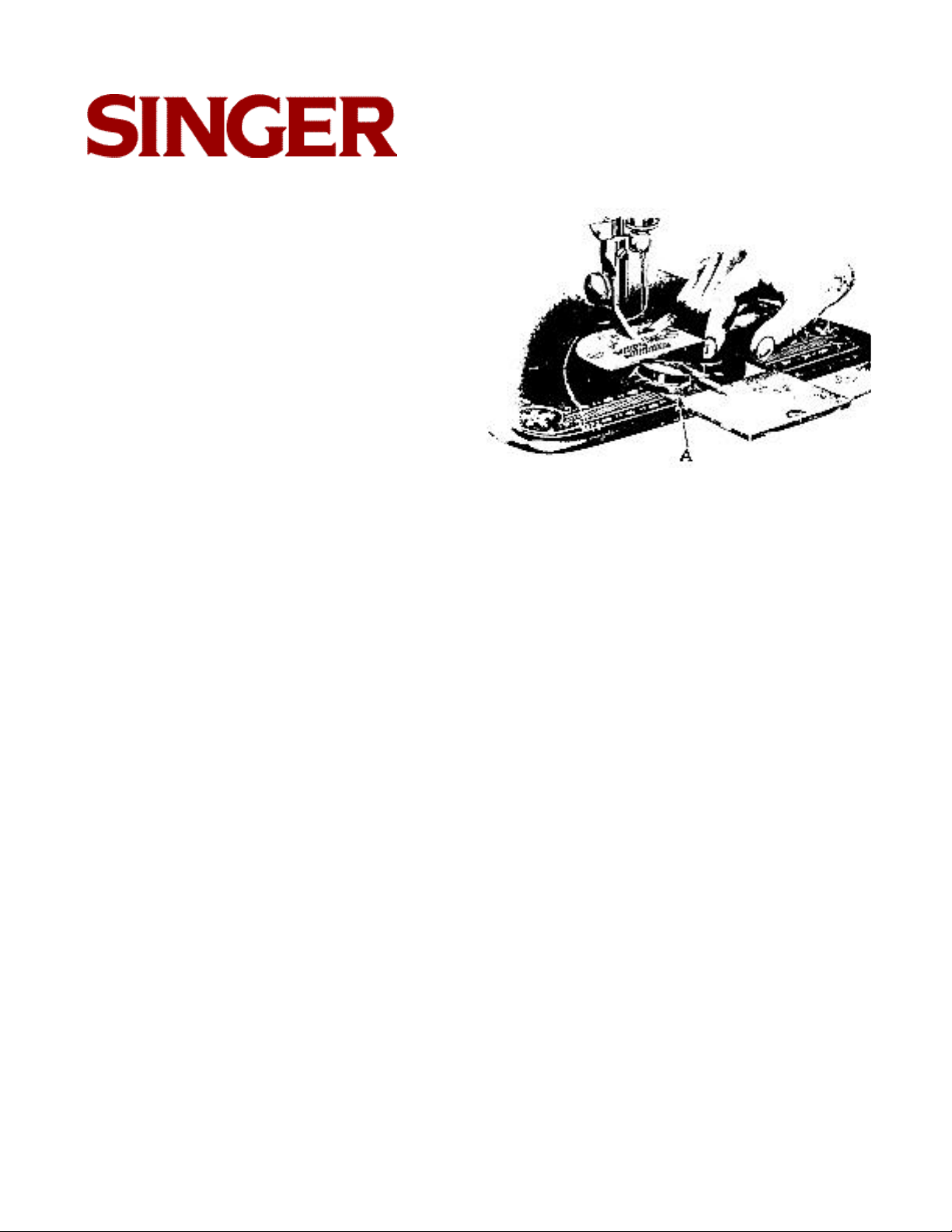

FIG. 4. REMOVING THE BOBBIN

To Take Out the Bobbin

Draw to the left the slide in the bed of the

machine and press the forefinger of the right

hand upon the bobbin ejected as shown

above; this will raise the bobbin so that it can

be easily taken out.

Table of Contents Previous Page | Next Page

5

82387 No. 66

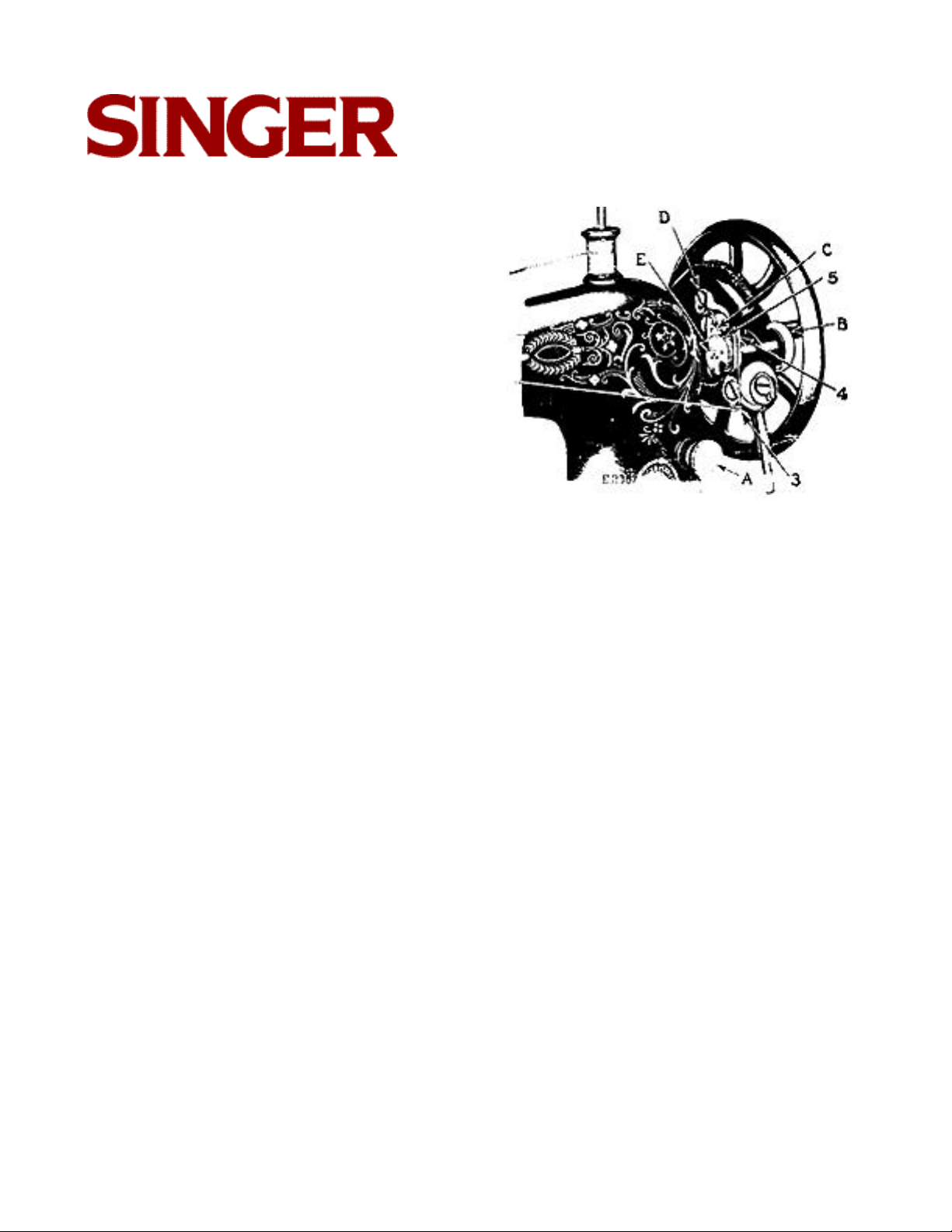

To Wind the Bobbin

Release the balance wheel (E, Fig. 3, page

3) by turning the stop motion screw (D, Fig.

3, page 3) over toward you.

Place the bobbin on the bobbin winder spindle (E, Fig. 6, page 7) and push it up closely

against the shoulder, having the small pin in

the spindle enter the hole in the side of the

bobbin. Put the spool of thread on the spool

pin (1, Fig. 5). Pass the end of the thread into

the thread guide (2, Fig. 5) then up into the

lower eyelet (3, Fig. 6) of the bobbin winder

thread guide, into the notch (4, Fig. 6) and

pass the thread through the hole in the left

side of the bobbin (5, Fig. 6) from the inside.

Press the bobbin winder pulley (B, FIG. 6)

down on the balance wheel hub and the latch

(C, Fig. 6) will drop down and hold it. Then

operate the treadle the same as for sewing.

FIG. 5. MACHINE THREADED

FOR WINDING THE BOBBIN

Table of Contents Previous Page | Next Page

6

82387 No. 66

To Wind the Bobbin continued...

The end of the thread must be held by the

hand unti1 a few coils are wound and should

then be broken off. Figs. 5 and 6 show the

bobbin winder properly threaded and in position for winding. When sufficient thread has

been wound upon the bobbin it is automatically released from the stop latch (C, Fig. 6).

If the pressure of the rubber ring (B, Fig. 6)

against the hub of the balance wheel is insufficient for winding the bobbin, loosen the

adjusting screw (D, Fig. 6) and press the bobbin winder lightly until the rubber ring is in

contact with the hub of the balance wheel;

then tighten the screw.

FIG. 6. WINDING THE BOBBIN

Table of Contents Previous Page | Next Page

7

82387 No. 66

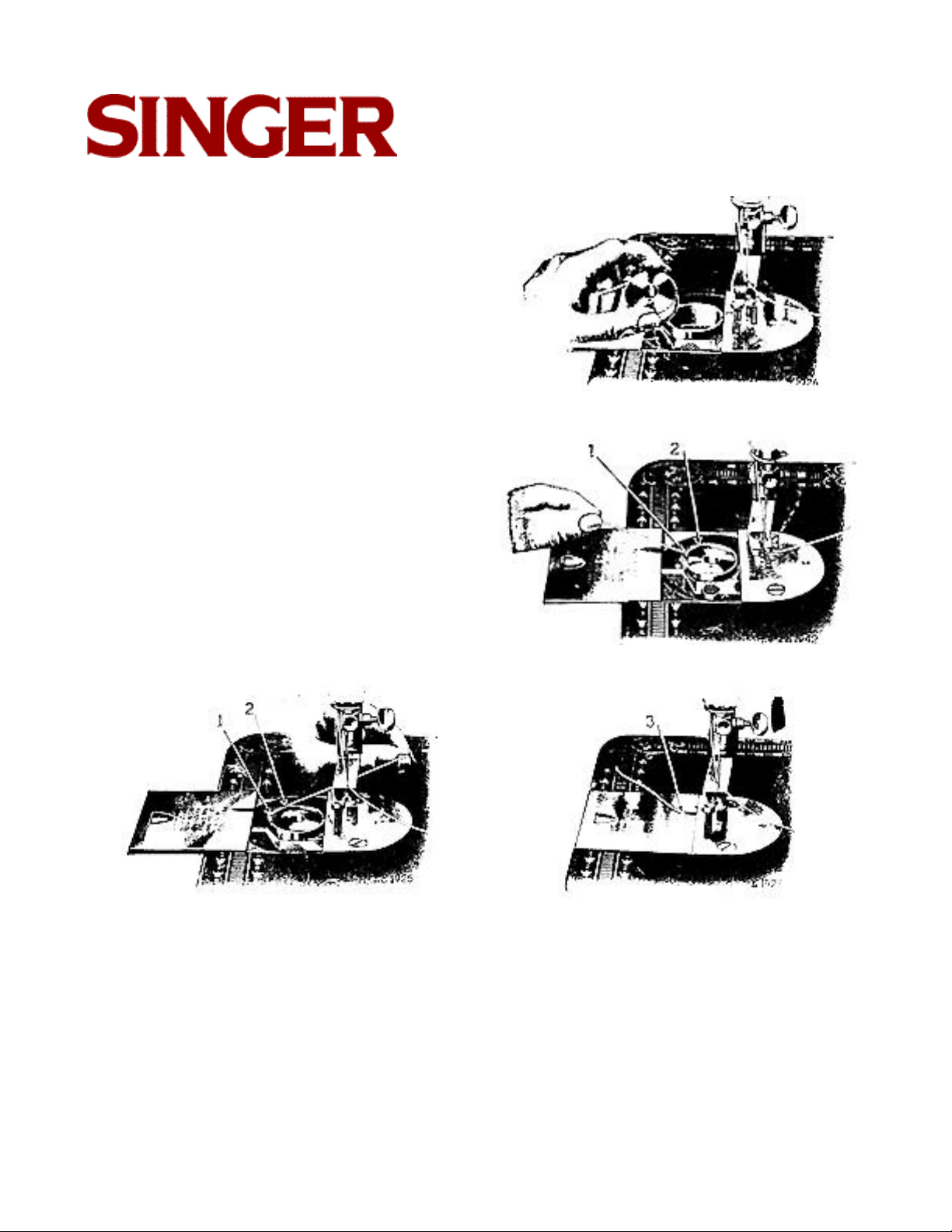

To Replace the Bobbin

Hold the bobbin between the thumb and forefinger of the left hand, the thread leading on

top from the right toward the left, as shown in

Fig. 7.

Place the bobbin into the bobbin case and

draw the thread into the slot (1, Fig. 8) in the

bobbin case, as shown below.

Draw the thread backward between the bobbin case and the tension spring until it reaches the notch (2, Fig. 9) then pull the thread

toward the right as shown in Fig. 9.

When closing the slide see that the thread is

in the slot (3, Fig. 10) in the right edge of the

slide, as shown below.

FIG. 7.REPLACING THE BOBBIN

FIG. 8. THREADING the BOBBIN CASE

FIG. 9. BOBBIN CASE THREADED

FIG. 10. UNDER THREADING COMPLETED

Table of Contents Previous Page | Next Page

8

82387 No. 66

To Set the Needle

Turn the balance wheel over toward you until

the needle bar moves up to its highest point

in the sleeve (D, Fig. 5), loosen the thumb

screw (C, Fig. 5) in the needle clamp (B. Fig.

5) and put the needle up into the clamp as far

as it will go, with its flat side toward the right,

then tighten the thumb screw.

To Thread the Needle

SEE FIG. 11

Turn the balance wheel over toward you until

the thread take-up lever (5) is raised to its

highest point. Place the spool of thread on

the spool pin at the top of the machine; lead

the thread into the thread guide (1) at the left,

down, under and from right to left between

the tension discs (2), into the small wire

spring (3), under the thread regulator (4) at

the left (not through the eye in the thread regulator), up and from right to left through the

hole in the end of the thread take-up lever

(5), down into the eyelet (6), into the lower

wire guide (7), then from left to right through

the eye of the needle (8).

FIG. 11. THREADING THE NEEDLE

Draw about two inches of thread through the

eye of the needle with which to commence

sewing.

Instructions for threading the machine for

darning and for embroidery are given on

pages 34 and 35.

Table of Contents Previous Page | Next Page

9