8007/8019

SINGER

/8002

Important safeguards

1. Unplug the machine at the socket when changing needles, feet, or needle plates, or when

leaving the machine unattended. This eliminates the possibility of starting the machine

by accidentally pressing the speed controller.

2. Before removing the bobbin case, unplug the machine at the socket.

3. Because of the up and down movement of the needle, you must work carefully and watch

the sewing area when operating the machine.

4. Do not pull the fabric while you are stitching as this may deflect the needle, causing it

to break.

5. Before cleaning your machine, it must be unplugged at the socket.

6. Do not attempt to adjust the motor belt. Contact your nearest Service Centre or an authorized

SINGER dealer should any adjustment be required.

7. Before changing light bulb, make sure you have removed plug from socket outlet. Be sure

to replace the face plate which covers the light bulb before operating the machine.

8. This machine is designed to use a 15-watt maximum light bulb.

This product is suppressed for radio and television interference with the International Electro

technical Commission requirements of the CISPR.

Machines for Great Britain and some other countries having similar wiring standards are

shipped from the factory without a plug for connection to the mains. The wires in this mains

lead are coloured in accordance with the following code:

Blue: neutral (N) Brown: live (L)

As the colours of the wires In the mains lead of this appliance may not correspond with

the coloured markings identifying the terminals in your plug, proceed as follows:

The wire which is coloured blue must be connected to the terminal which is marked with

the letter N or coloured black. The wire which is coloured brown must be connected to

the terminal which Is marked with letter L or coloured red. If a 13 Amp. (BS 1363) plug is

used, a 3 Amp. fuse must be fitted, or If any other type of plug is used, a 5 Amp. fuse must

be fitted either in the plug or adaptor or at the distribution board,

Neither core Is to be connected to the earth terminal of a three-pin plug.

Index

1. Getting to Know Your Machine

.................

Nncipal Parts............................................2/3

Accessories

Optional Accessories

Changing the Needle

.................................................

.................................

.................................

Changing Presser Feet...............................7

Removing and Replacing Needle Plate

Attaching Snap-in Feed Cover

2. Getting Ready to Sew

Preliminary Steps

.......................................

.................................

..................

Connecting and Operating Machine

Threading the Machine..........................9/10

Winding the Bobbin....................................11

Inserting a Bobbin

Raising the Bobbin Thread

How to Start Sewing

Fabric, Thread and Needle Table

....................................

......................

.................................

............

Setting Selectors.......................................14

Setting Stitch Width..................................14

Setting a Needle Position

........

................

Regulating Needle-Thread Tension

Setting Stitch Length................................16

Setting Pattern Group Selector

Setting Stitch Pattern Selector

3. Straight Stitching

......................................

...............

................

Sewing a Seam..........................................18

Pin Basting • Starting a Seam • Ending a

Seam • Guiding and Supporting Fabric

4. Zig-Zag Stitching

How Patterns are Produced

......................................

..................

Selecting and Adjusting

Zig-Zag Stitches

........................................

• Selecting a Pattern Group • Selecting a

Stitch Pattern

• Adjusting Width of Design • Adjusting

Stitch Placement

• Adjusting a Stitch Length • Adjusting

Needle-Thread Tension

• Adjusting a Stitch Balance

• Satin Stitching

.........

........

......

12

12

13

13

15

16

17

17

18

21

..21

22

6

5. Twin-Needle Stitching

2

Threading the Twin-Needle

4

5

Machine Settings

Decorative Twin-Needle Stitching

..............................

......................

......................................

6. Free-Motion Stitching...............................28

7

7

Preparation............................................... 28

Floral Designs...........................................29

8

7. Sewing the Professional Way..................30

8

8

Sewing Knit and Stretch Fabric

Stitch Pattern Chart • Guiding and

Supporting Fabric • Plain Stretch Seams

• Overedged Seams • Attaching Elastic

• Finishes for Hems and Facings

Handling Special Fabrics.........................35

Construction Details.............................. ..36

Zippers • Corded Seams • Blindstitch Hems

Buttons

....................................................

Buttonholes...............................................40

Four-Step Buttonholing

.........................

Adjusting Forward-Reverse Stitch

Balance..................................................... 43

Buttonholes (Manual Method)

Decorative Touches

.................................

Topstitching • Applique’

Keeping up Appearances

........................

Mending • Darning

8. Free-Arm Sewing.....................................48

9. Caring for Your Machine.........................49

Cleaning and Lubricating

........................

Removing and Replacing Bobbin Case....50

To Remove and Replace Face Plate

To Remove Top Cover and Bottom

Cover....................................................... 51

Changing the Light Bulb

..........................

Replacing the Slide Plate.........................52

Hints for Home Service

Index....................................................................1

..........

..............

.................

.........

26

26

27

27

30

39

41

43

45

46

49

51

52

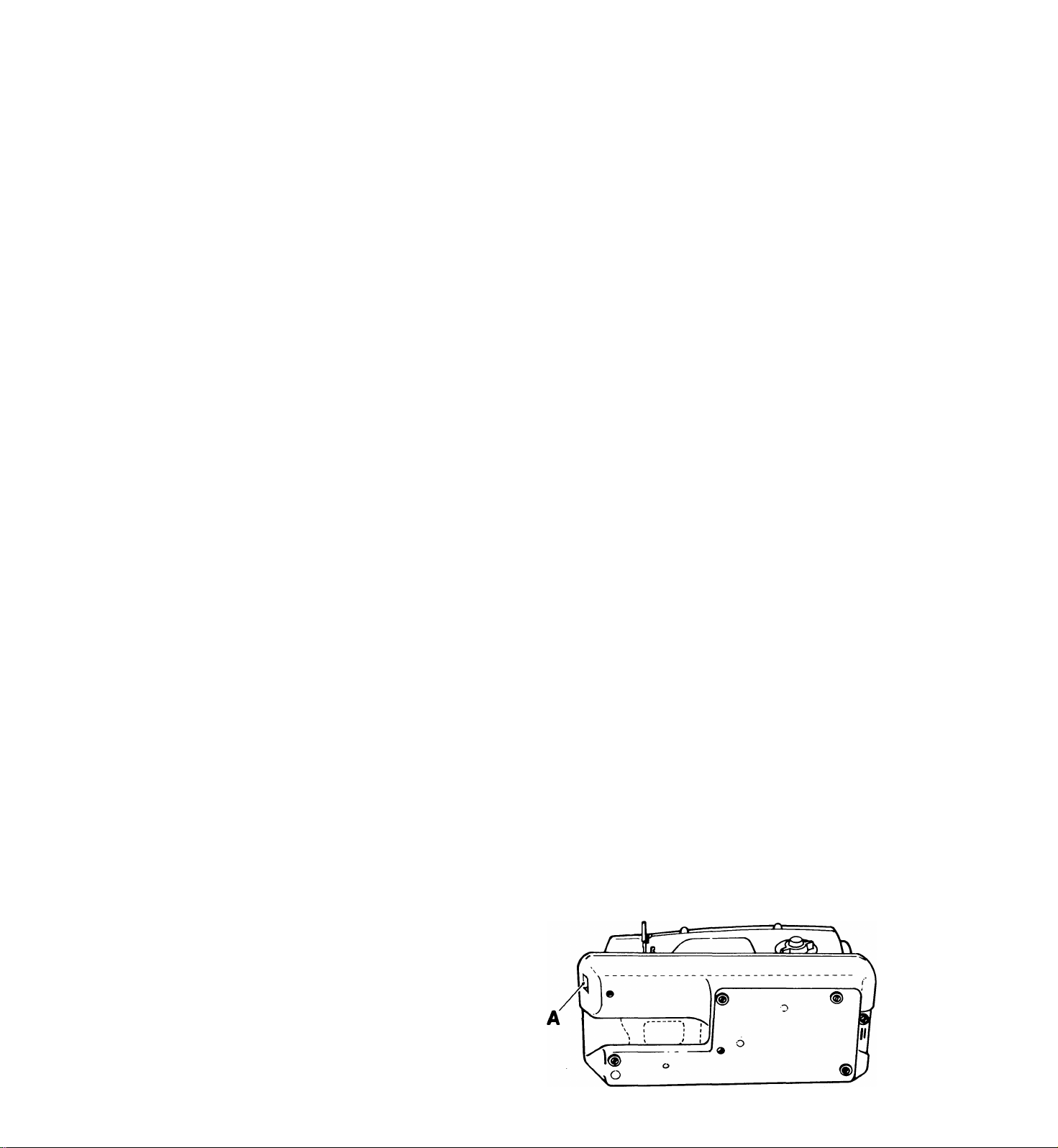

Dear Customer:

We recommend that for the future reference

you record the serial number of your Sewing

Machine in the space provided.

Refer to illustration for location of serial

number, A, on your machine.

Serial No. _______________________________

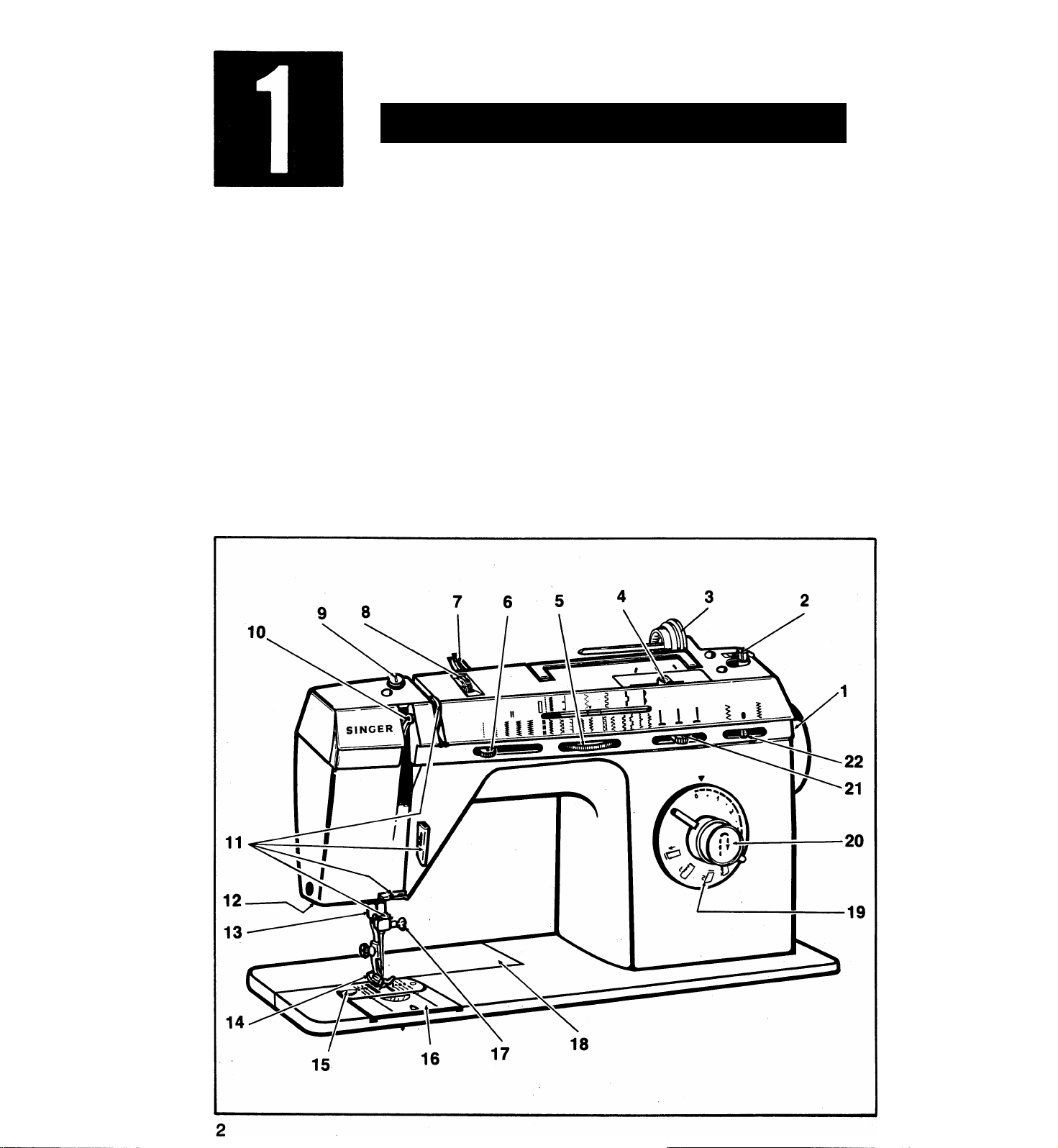

principal parts-

Getting to Know Your Machine

I.Hand Wheel

2. Bobbin Winder

3. Spool Holder

4. Stitch Pattern Selector

(only 8019)

5. Pattern Group Selector

(only 8007 and 8019)

6. Stitch Width Selector

7. Snap-in Thread Guide

8. Tension Dial

9. Bobbin Winder Tension

10. Take-up Lever

11. Thread Guides

12. Built-in Sewing Light

13. Thread Cutter

14. Presser Foot

15. Zig-Zag Needle Plate

16. Slide Plate

17. Needle Clamp

18. Flip and Sew* Panel

19. • Stitch Length Selector

• Built-in-Four-Step

Buttonhole Dial

(except 8002)

20. • Reverse-Stitch Push Button

• Buttonhole Stitch Balancing

Control (except 8002)

21. Needle Position Selector

22. Stitch Balance Control

(except 8002/8007)

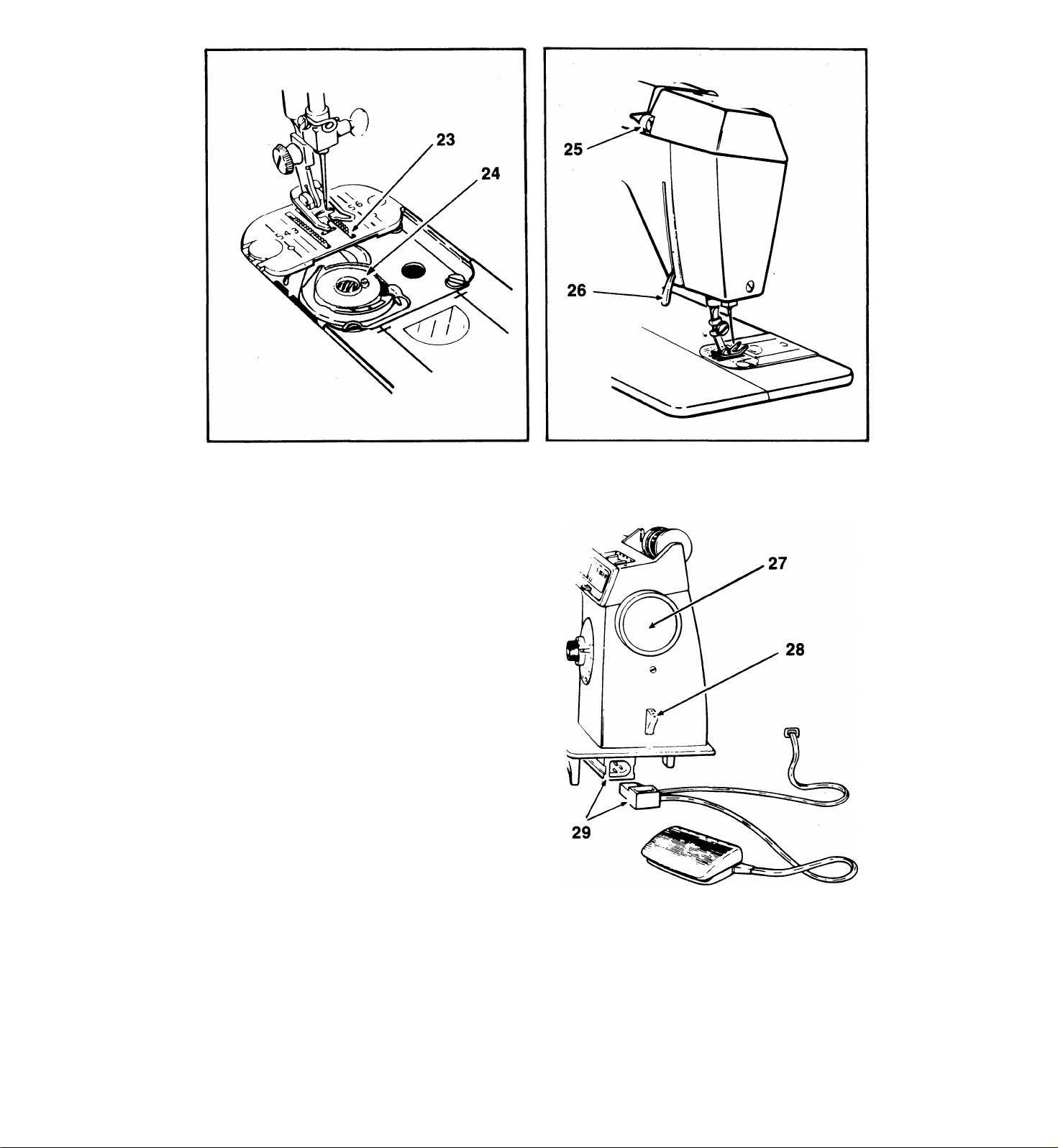

23. Feed System

24. Transparent Bobbin

25. Rear Thread Guide

26. Presser Foot Lifter

27. Bobbin Winding Indent

28. Power and Light Switch

29. Electrical Connections and

Speed Controller

To ensure that you are always pro

vided with the most modern sewing capa

bilities, the Manufacturer reserves the right

to change the appearance, design or

accessories of this sewing machine when

considered necessary.

* A Trademark of The Singer Company

Copyright © 1990 Singer Sewing Machine Company

All rights reserved throughout the world.

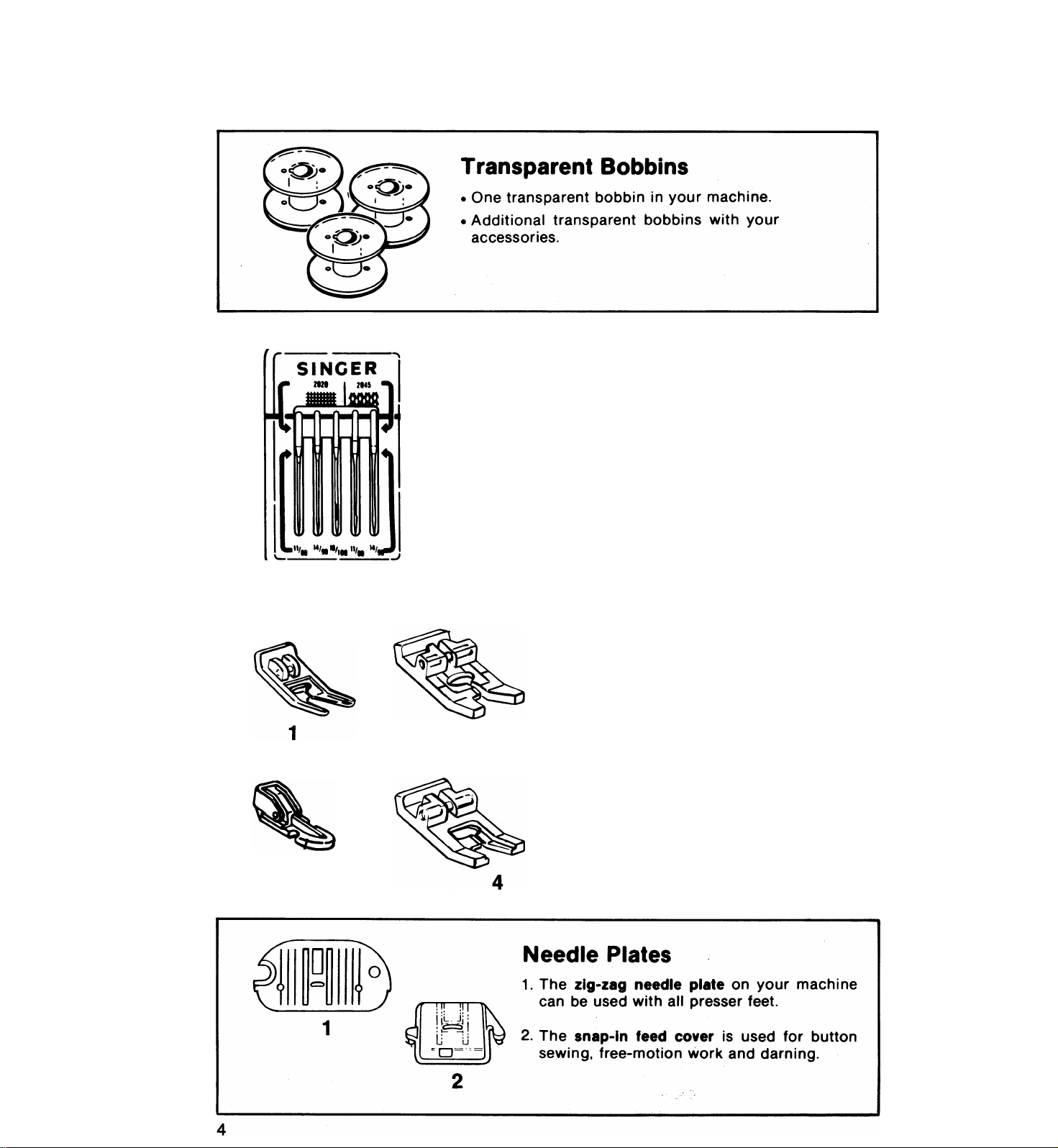

accessories

The accessories that come with your sewing machine will help you to sew with ease

and comfort.

Needles

IMPORTANT: Yoursewing machine has been

designed to obtain best results with SINGER*

needles. You should follow the recommenda

tions in this instruction book and on the nee

dle package for correct style and size of nee

dle for different types and weights of fabric.

• Catalog 2020 needles, for all-purpose sewing.

• Catalog 2045 needles, for sewing synthetic

knit and stretch fabrics.

Presser Feet

Additional interchangeable snap-on presser

feet:

1. The zig-zag foot on your machine.

2. Buttonhole foot to make square-end

buttonholes, (only 8007 and 8019)

3. Zipper foot for inserting zippers and

stitching corded seams.

4. Special purpose foot for all kinds of

decorative zig-zag stitching.

Thread Lead-Off

This lead-off holds narrow-diameter spools

of thread on the spool pin. (See page 9)

Container Of Oil

One container of oil.

Your machine will serve you perfectly for

many years if you will take a few moments to

keep it In good operating condition.

Blindstitch Hem Guide

The blindstitch hem guide, used with the

zig-zag foot, positions the hem fold in front of

the needle for blindstitch hemming. To attach

guide, loosen presser foot shank. Make sure

underside of guide ctears the slide plate and

front of foot.

Tighten presser-foot screw.

(only 8007 and 8019)

Optional Accessories

1

• Catalog 2025f needle for twin-needle work.

tCAUTION: Use this needle with the zig-zag

plate and zig-zag foot or special-purpose foot

only. Do not use any other accessories with

this needle as needle breakage will occur.

Straight stitch foot for close fabric control.

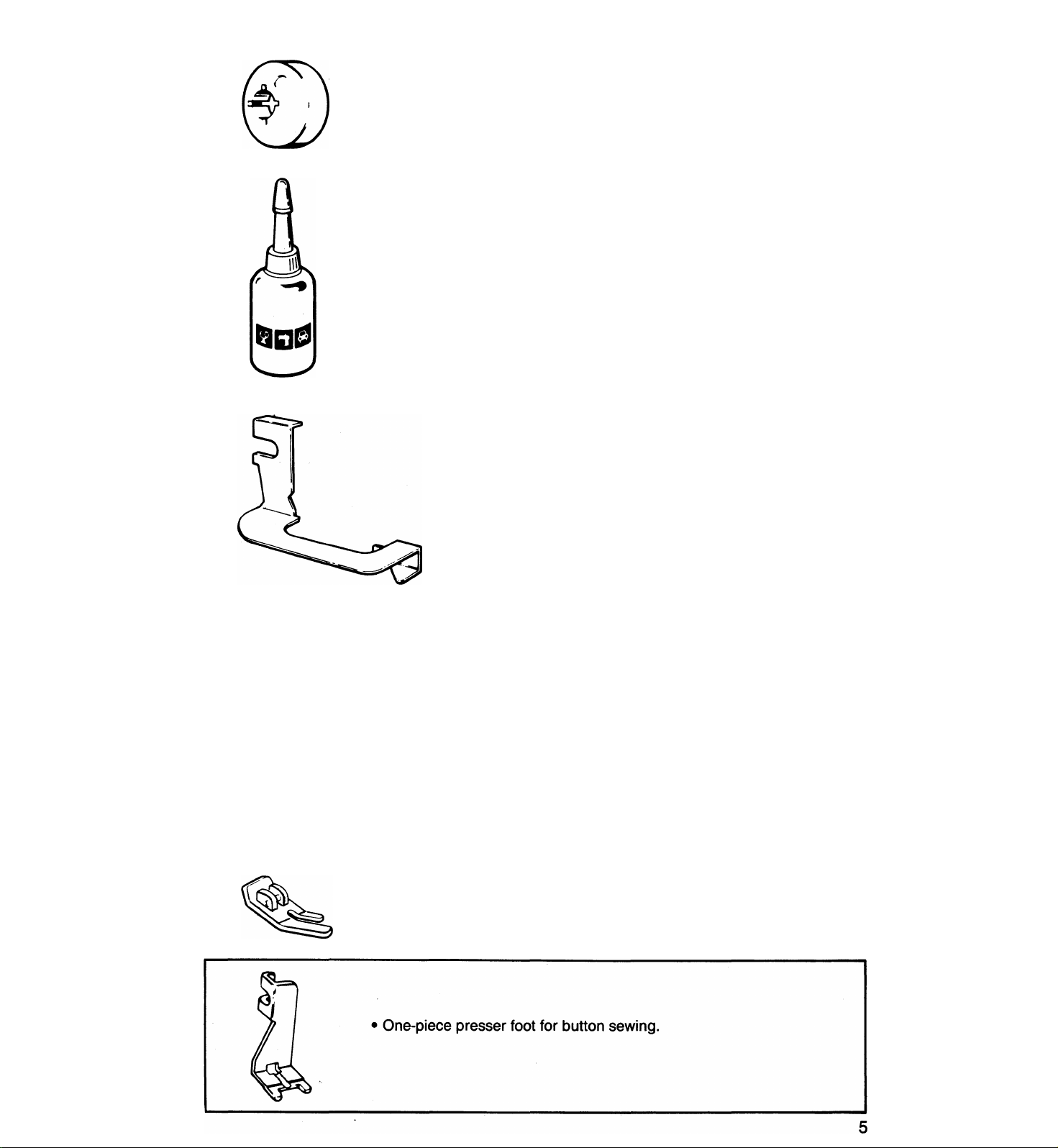

Changing The Needle

1. Raise the needle to its highest position by

turning the hand wheel toward you.

2. Loosen the needle-clamp screw A and

remove needle.

3. Insert new needle in clamp B with the flat

side C of the needle to the back; push it up

as far as it will go.

4. Tighten the needle-clamp screw.

Changing Presser Feet

Most presser feet furnished with your machine

snap on and off a common shank.

e Raise needle and take-up lever to highest

position by turning hand wheel toward you.

• Raise presser foot.

To remove the complete presser foot (with

shank), of snap-on presser feet and one-

piece presser foot for button sewing, loosen

the presser foot screw and remove shank and

foot together.

2. Center the new presser foot under the

shank J.

Lower the presser foot lifter K so that the

shank fits over the presser foot pin.

1. Press toe of presser foot upward as far as it

will go. Then snap down to remove.

3. Press presser foot screw down firmly until

foot snaps into place.

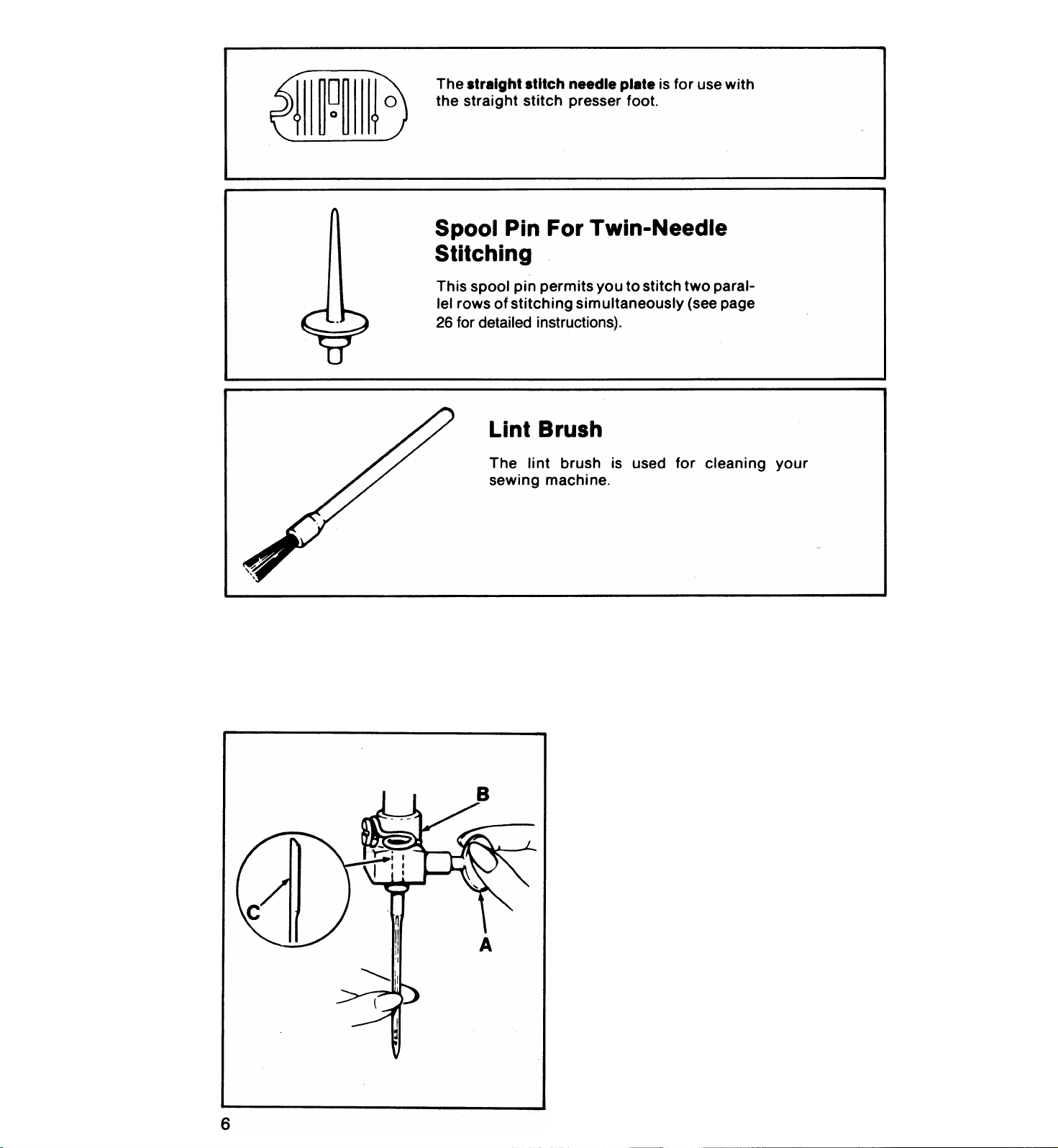

Removing and Repiacing Needie Plate

e Raise presser foot.

e Turn hand wheel toward you until the needle

is in its highest position.

• Open the slide plate. Lift needle plate up and to

the right until it snaps free.

• Insert new needle plate by placing it under the

clamping pin (1) push it gently to the left and

press down until it snaps into place.

a Close slide plate.

Attaching Snap-In

Feed Cover

• Raise needle to highest position by turning

hand wheel toward you.

• Raise presser foot, open slide plate and in

sert zig-zag needle plate.

• Slide snap-in feed cover away from you over

needle plate until points (1) and (2) are positioned

directly over holes in needle plate as illustrated.

Snap in point (1). Then push (2) in toward point

(1) until it snaps into place. Close slide plate.

• To remove, open slide plate then simply lift

up front edge of feed cover, and remove.

Close slide plate.

2

preliminary steps

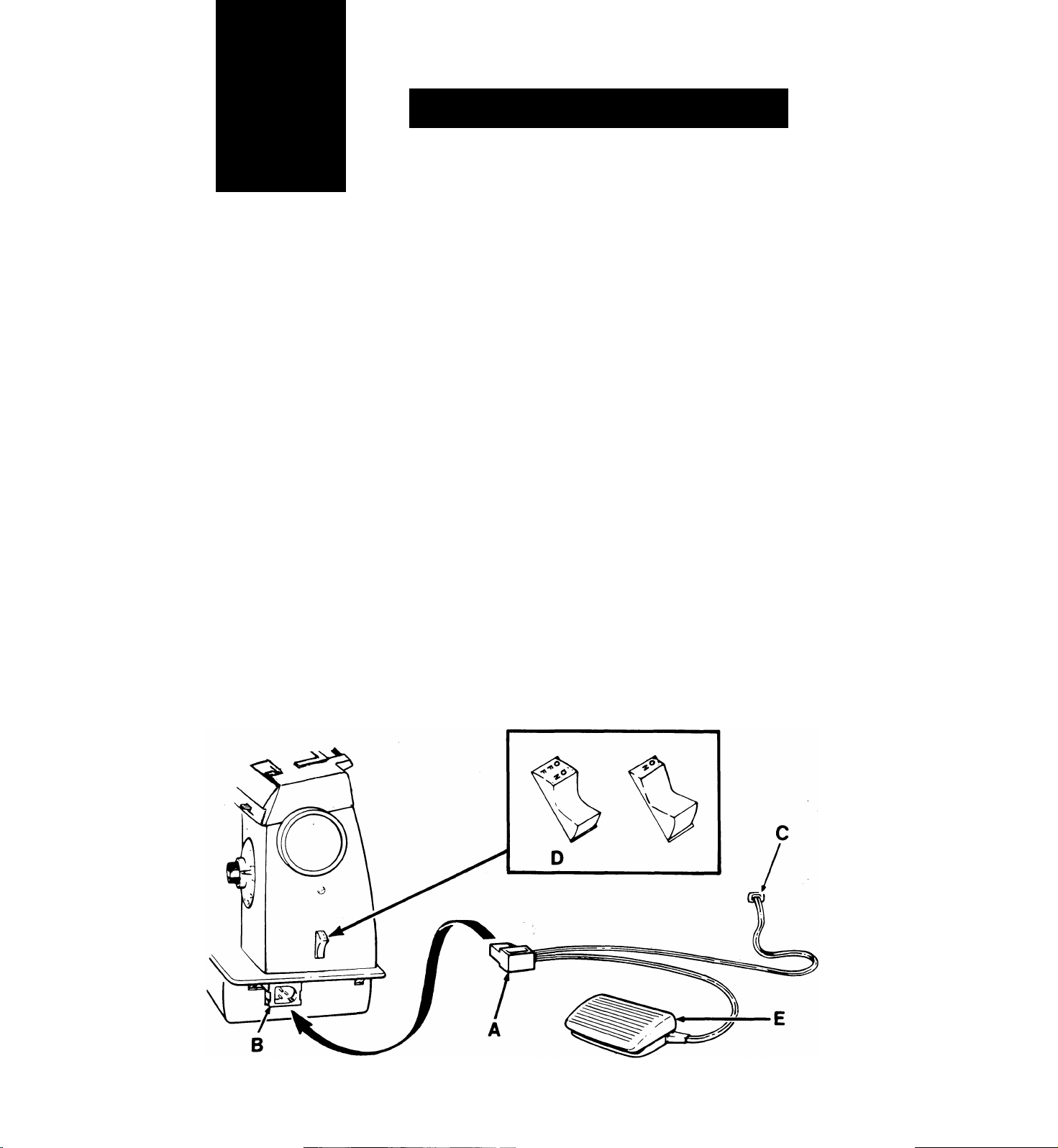

Connecting Machine

Getting Ready to Sew

Before plugging in your machine, be sure that

the voltage and frequency indicated on the

right end of the machine are within the range

marked on the electric meter installed by your

power company.

Insert the machine plug A into the machine

socket B at the right end of the machine, and

connect the power-line plug C to your elec

trical outlet.

Operating Machine

To turn on the machine and sewing light, press

upper portion of power switch (D).

CAUTION: Disconnect the power-line plug

from the socket outlet when changing needle,

feet or needle plates or when leaving the

machine unattended. This eliminates the

possibility of starting the machine by acci

dentally pressing the speed controller.

To run the machine, press the speed controller

E with your foot. The harder you press, the faster

the machine will sew. To stop machine, remove

foot from controller.

CAUTION: Because of the up and down

movement of the needle, you must work care

fully and watch the sewing area when operat

ing the machine.

8

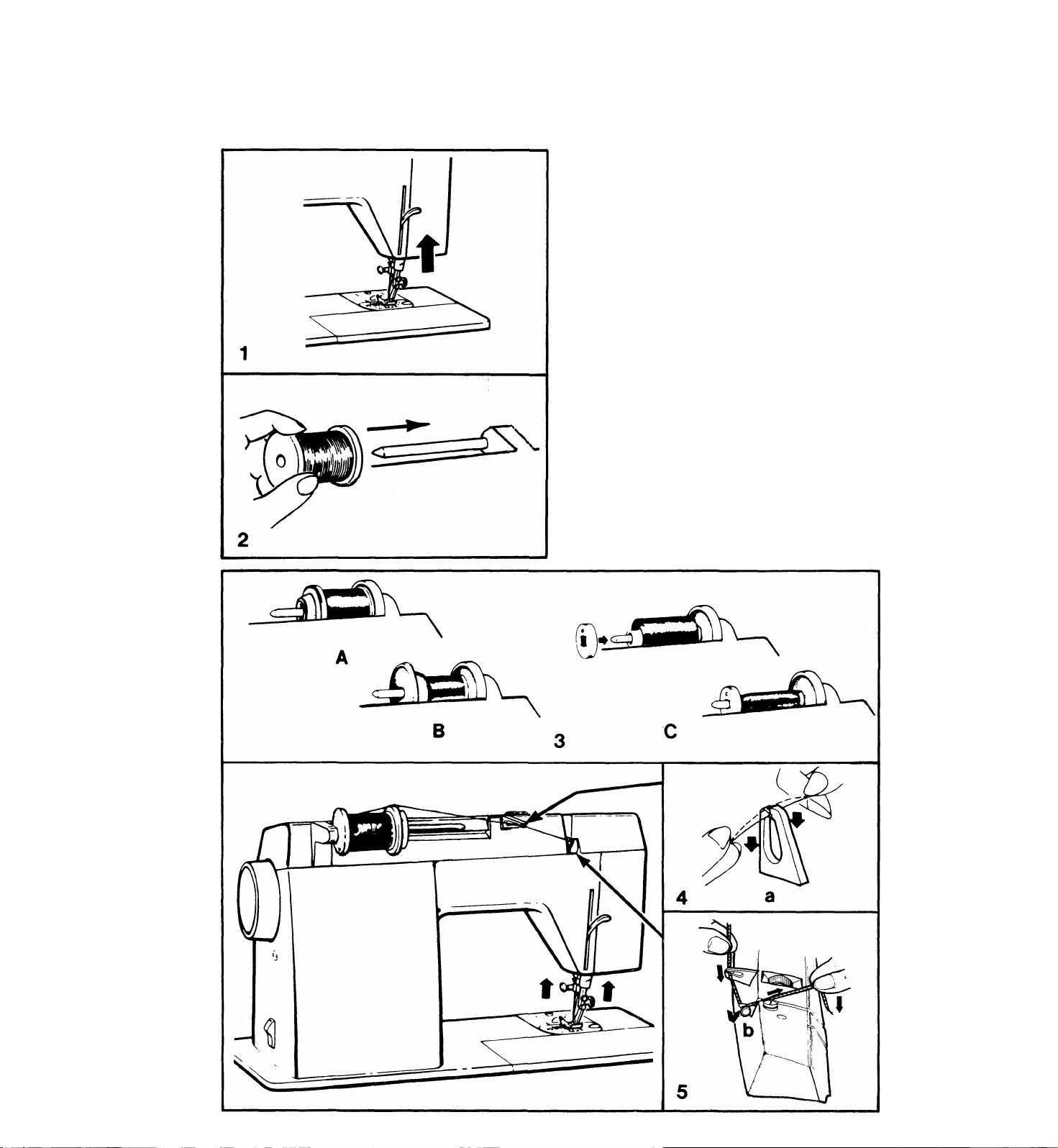

Threading The Machine

1. Raise presser foot and be sure needle is in

its highest position.

2. Place spool of thread on horizontal spool

pin. If spool being used has a retaining slit,

this should be placed to the right.

3. Press appropriate thread lead-off holder

firmly against spool.

A. For large spools of thread, use the large

holder with the wide end against the

spool.

B. For medium size spools, use the large

holder with the narrow end against the

spool.

C. For small diameters spools with either

large or small quantities of thread, use

the small lead-off which comes in your

accessory box.

4. Lead thread from spool holder and snap It

down Into guidepost eyelet a.

5. Hold thread down under finger, as illus

trated, and lead thread-under rear thread

guide b, behind pre-tension disc, and

across slot in top of machine.

6. Draw thread firmly between left tension

disc c and tension separator d, then down

around thread guide e on front of machine.

( Presser foot must be raised to allow

thread to enter discs.)

7. Thread take-up lever f by guiding thread

through slot g and into eyelet h.

8. Lead thread from take-up lever down to

lower thread guides I. as shown, and

thread needle from front to back. Draw

10cm (4") of thread through needle eye j.

10

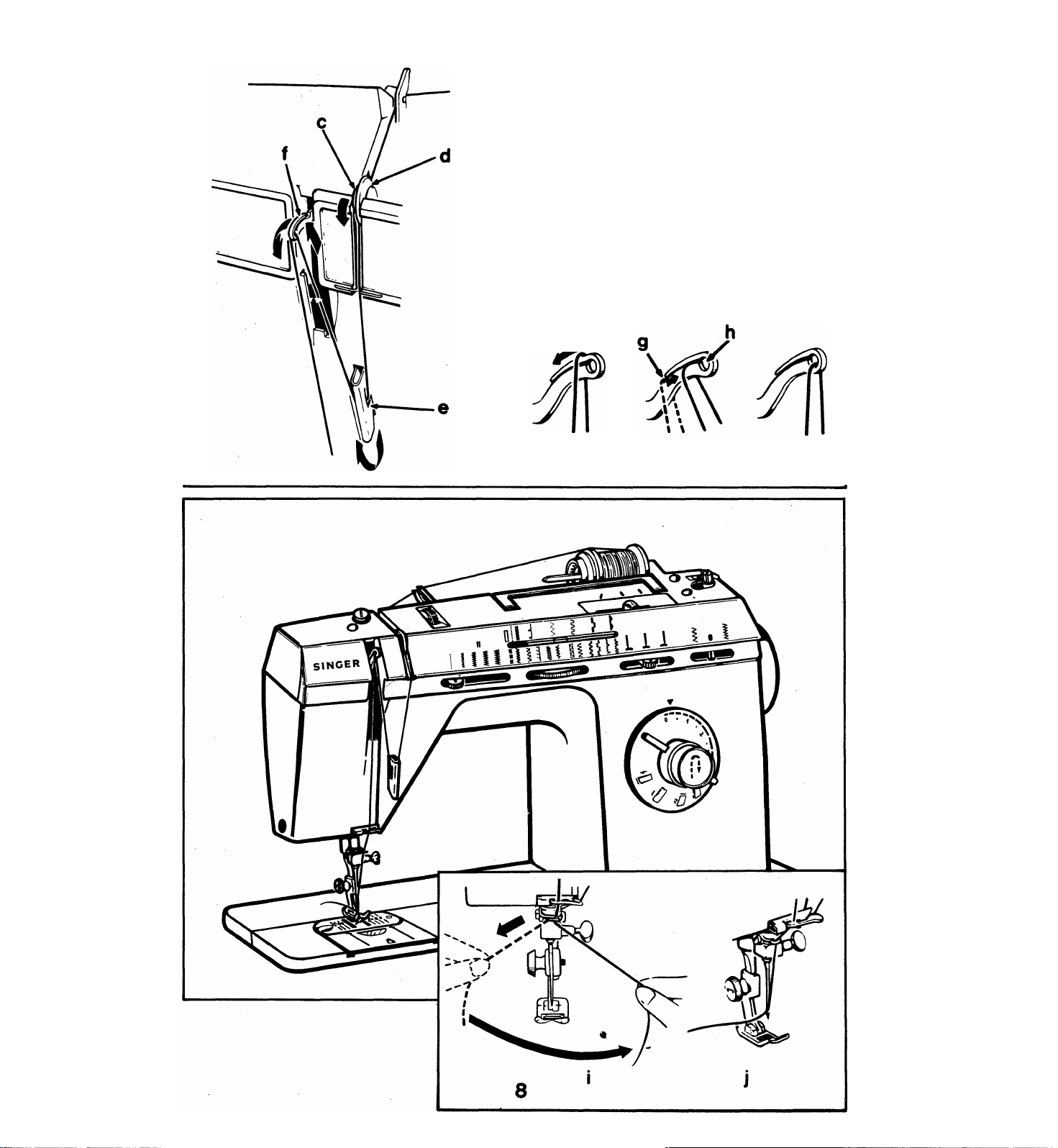

Winding a bobbin

Winding a bobbin is quick and easy when you follow the directions below. Always wind

the bobbin before threading the machine and needle.

• Push in indent (1) on hand wheel disc. This will stop the needle from moving.

• Place spool of thread on spool pin.

• Slide spool cap (2) firmly over rim of spool to prevent thread tangling.

• Lead thread from spool and snap into thread guide post (3).

• Wind thread clockwise around front of bobbin winder tension disc (4).

• Pass thread end, from inside, through small hole in rim of bobbin.

• Place bobbin on spindle and push it to the right.

• Holding thread end, step on speed controller to run machine until desired amount of thread

is wound. (Winding stops automatically onpe bobbin is full.)

• Cut thread; push bobbin to the left and remove it from spindle.

• Trim thread end from top of bobbin.

• Return hand wheel disc to sewing position by pressing on side opposite indent.

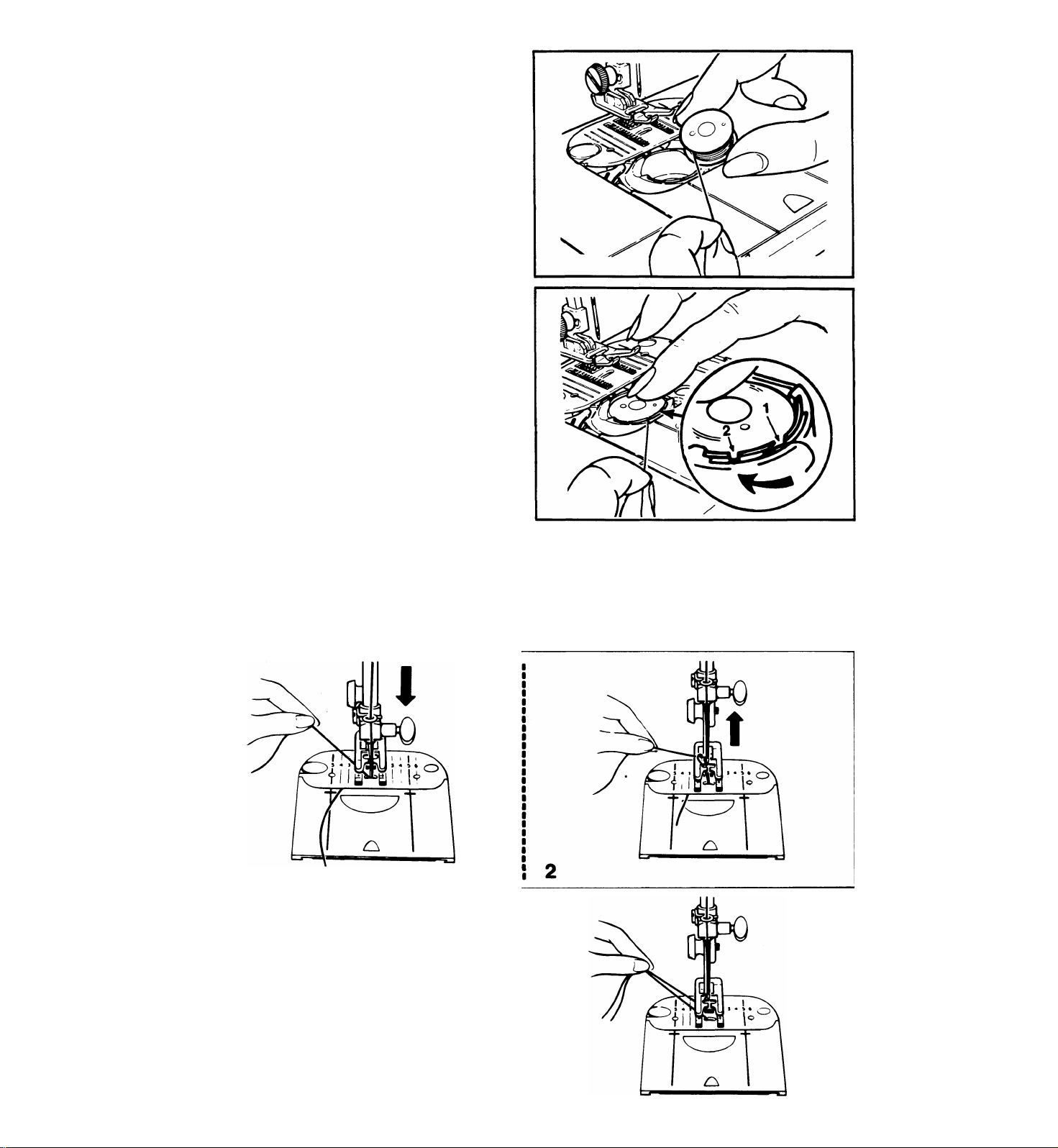

Inserting a bobbin

To insert a bobbin, follow the instructions

below:

• Raise presser foot.

• Turn hand wheel toward you until needle

is in its highest position.

• Open slide plate and remove empty bobbin.

1. Pull 4" (10cm) of thread from replacement

bobbin and insert bobbin into case, as

shown.

2. Holding bobbin in place, guide thread into

notch (1) and then down the slot to the

left and guide around into notch (2).

• Draw several inches of thread diagonally

across the bobbin toward the back of the

machine.

• While holding thread on outside, close the

slide plate, allowing thread to extend

through the slot between the slide plate

and needle plate.

• Follow directions for “Raising Bobbin Thread”

below.

Raising the Bobbin Thread

1. Hold needle thread lightly with left hand

and turn hand wheel slowly toward you

so that needle enters needle plate.

2. Continue turning hand wheel until needle

rises and brings up bobbin thread in a loop.

3. Undo the loop and place both threads

under the presser foot, drawing them to

the back of the machine. Position needle

In fabric where desired, lower the presser

foot and stitch.

12

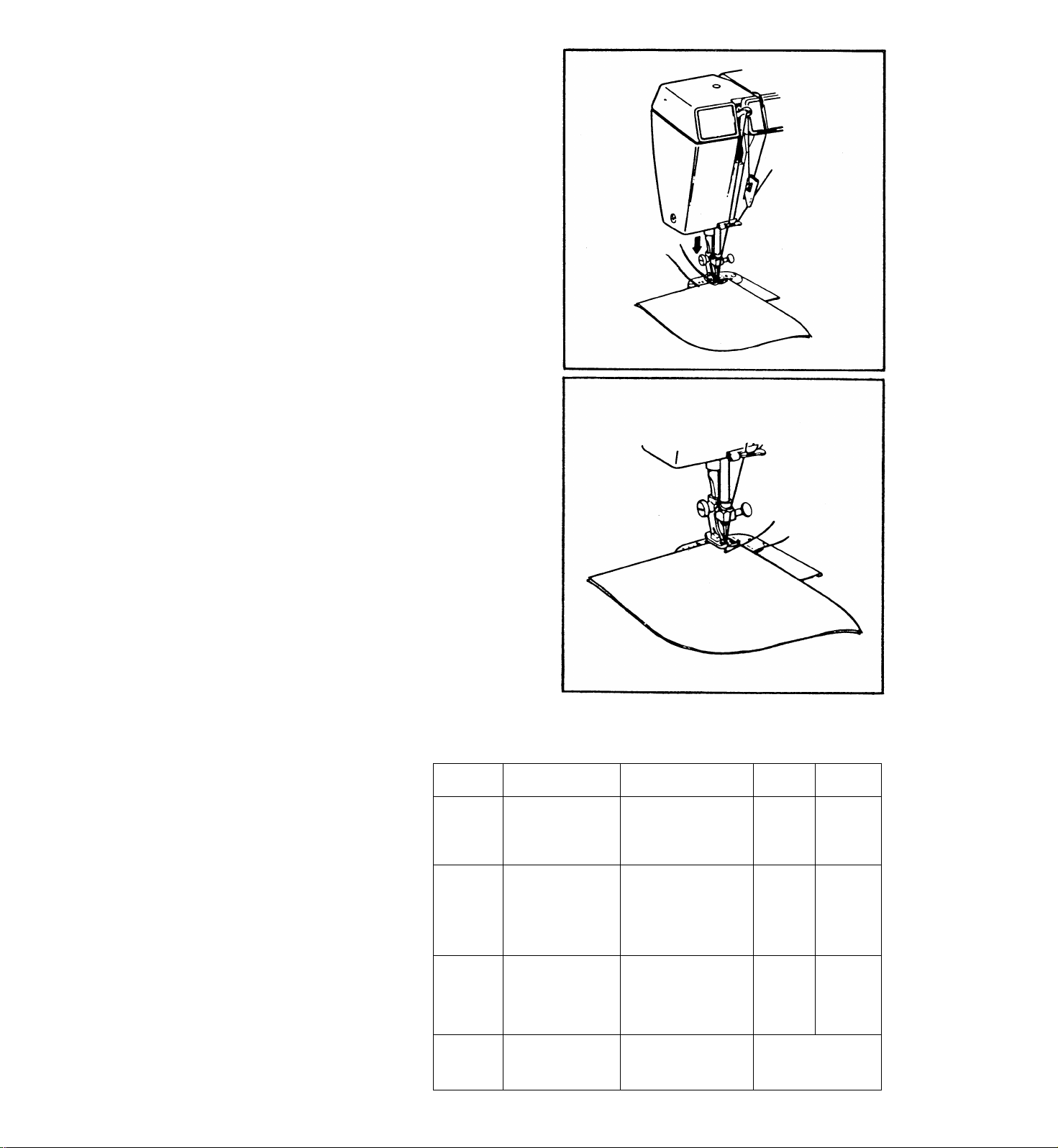

how to start sewing

How you begin to sew after winding a bobbin

depends on whether your stitching is to start

at or away from the edge of the fabric.

To start At Fabric Edge

• Pull thread back under presser foot.

• Position needle in very edge of fabric by

pressing speed controller lightly or turning

the hand wheel.

• Lower the presser foot and stitch.

To start Away From

Fabric Edge

• Pull thread back under presser foot.

• Position needle in fabric where desired

• Lower the presser foot and stitch.

The fabrics below can be of any fiber; cotton, linen, silk, wool,

synthetic, rayon, blends. They are listed as examples of weight. NEEDLES

Fabric, thread

and needle table

The needle and thread you

choose will depend upon the

fabric being sewn.

The table is a practical

guide to needle and thread

selection.

Always refer to it before

beginning a sewing project. Be

sure to use the same size and

type of thread in both needle

and bobbin.

LightWeight

MediumWeight

MediumHeavy

Knits

tNot recommended on stretch fabrics

Fabrics Thread

Batiste

Chiffon

Crepe

Corduroy

Flannel

Gabardine

Gingham

Linen

Muslin

Wool Crepe

Bonded Wovens

Canvas

Coating

Denim

Duck

Sailcloth

Bonded Knits

Double Knit

Jersey

Tricot

Cotton-wrapped

Polyester

100% Polyester

tMercerized Size 50

Nylon

Cotton-wrapped

Polyester

100% Polyester

tMercerized Size 50

Nylon

Cotton-wrapped

Polyester

100% Polyester

tMercerized Size 40

t“Heavy Duty" 2020

Cotton-wrapped

Polyester

Polyester

Nylon

Type

2020

2020

2020

Bail-Point 2045

Size 11/80, 14/90,

16/100

Size

11/80

14/90

16/100

18/110

13

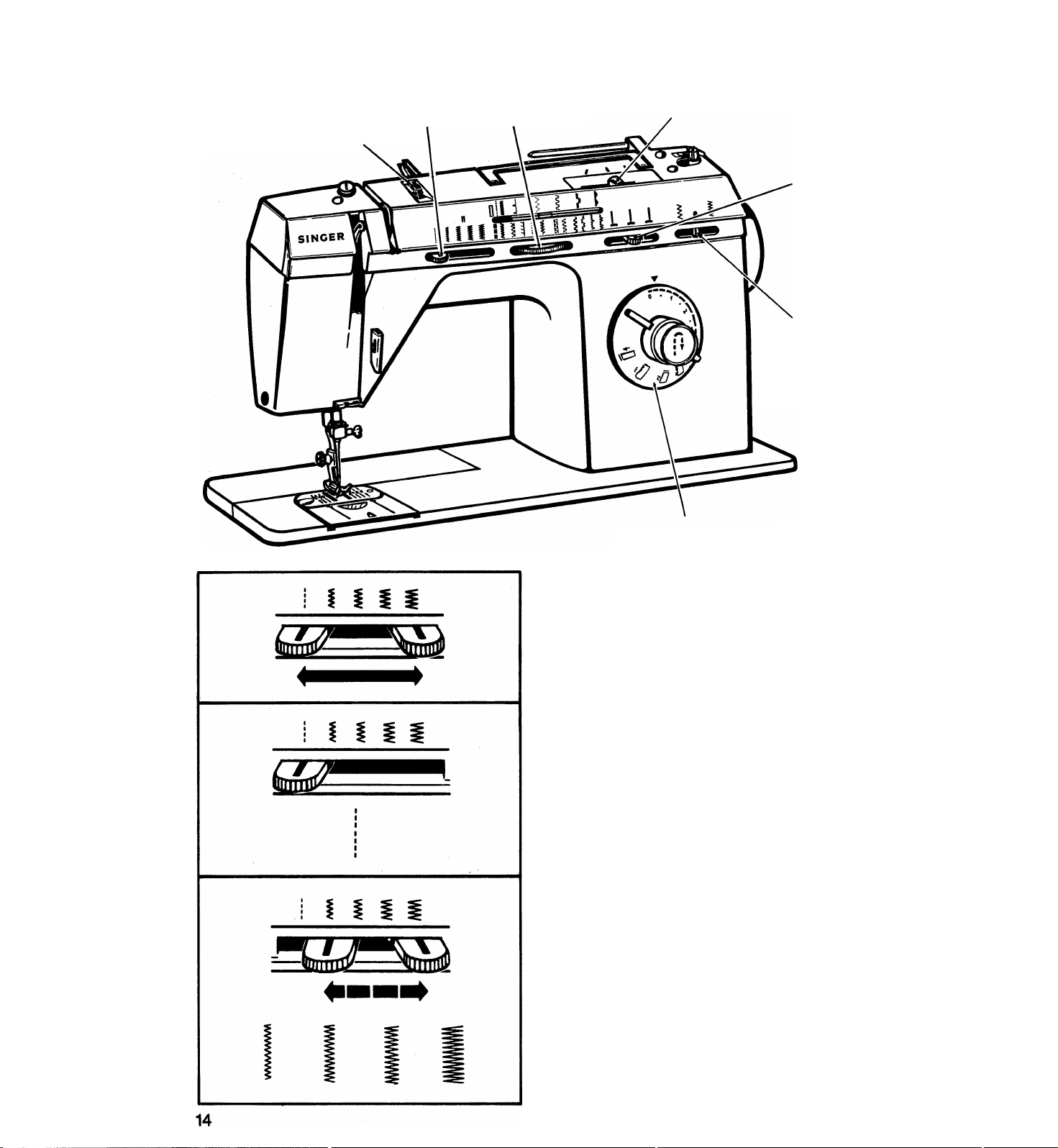

setting selectors

Needle-Thread

Tension Dial

Stitch

Width Pattern

Selector Group Selector

Stitch Pattern

Selector

Needle

Position

Seiector

Stitch

Baiance

Control

Stitch Length Selector

Setting Stitch Width

The Stitch width selector does two jobs: it

sets the machine for straight stitching, and

it controls the width of zig-zag stitching. Four

stitch width settings are indicated plus a

setting for straight stitching.

Before moving the selector, make sure needle

is above the fabric.

To set stitch width, slide the seiector lever

until indicator line is aligned with desired

setting.

Straight Stitching: Set the selector at

Zig-Zag Stitching: To suit sewing

application, set the selector at any zig-zag

position between | (narrow-position) and

S (wide-position).

Setting a Needle Position

The needle position selector B places the

needle in left ( ), center ( X ) or right

( X ) stitching position. You will need to set

it before you start running the machine.

Before moving the selector, always make

sure the needle is out of the fabric.

To position the needle, slide the lever to left or

right until indicator line is under desired

setting.

1 1 -L

B

Straight-Stitching: Normally you will use the

center ( X ) needle position. But if you wish

to place the stitching at left or right of center,

slide the lever to desired position. The zig-zag

needle plate and zig-zag foot must be used if

left or right needle positions are selected.

Zig-Zag Stitching: You will use center ( X )

position most often. Left ( X )

( X ) positions are for special stitch

placement. For example: A X setting is

used for button sewing. Settings X ^nd

X

are used to place narrow zig-zag

stitching to the left and right of center in

decorative work.

111

111

111

15

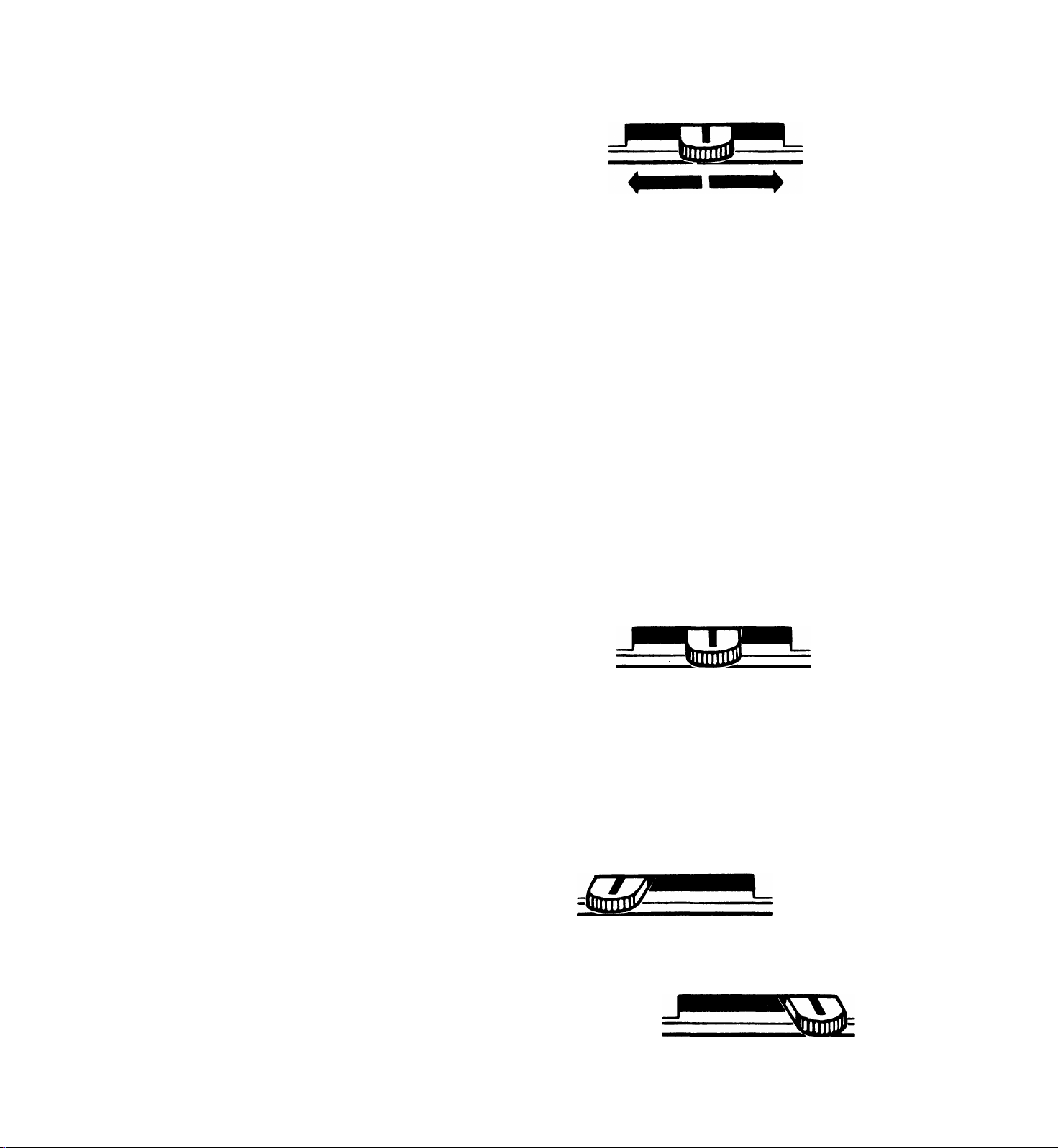

Regulating Needle-Thread

Tension

The needle-thread tension dial regulates the

amount of tension on the needle thread and

lets you select just the right setting for your

fabric and thread. The numbers on the dial

eliminate guesswork in duplicating settings.

Correct A tension is important because too

much or too little will weaken your seams or

mar the appearance of decorative work. To

determine the correct tension, make a test on

a sample of your fabric. If the stitches look

loose B, increase tension. If the fabric

puckers C, decrease tension.

(For instructions on adjusting zig-zag stitch tension,

see page 24.)

• To increase tension, turn to higher number.

• To decrease tension, turn to lower number.

Setting stitch Length

The stitch length selector dial controls the

length of both straight and zig-zag stitching.

The numerals from 1 to 4 represent the length

of each stitch in millimeters: the higher the

number, the longer the stitch. Generally,

shorter stitches are best for lightweight fabric,

longer ones for heavier fabric.

The area between 0 and 1 represents stitches less

than 1 mm long, and is used for closed zig-zag or

satin stitching.

• To shorten stitch iength, turn dial clockwise

A to a lower number.

• To lengthen stitch iength, turn dial coun

terclockwise B to a higher number.

For reverse stitching, depress push button C

located in center of dial, hold in until reverse

stitching is completed, then release push but

ton. Push button can be depressed while

machine is sewing.

Note: Reverse stitching cannot be done

when using a Flexi-Stitch* pattern

16

Dll i i t

A (only 8007 and 8019)

Setting Pattern Group Selector (A)

The pattern group selector A gives you a

choice of six groups each containing

three patterns.

Raise the needle to its highest position.

(only 8019)

i! L i J

• Set the stitch width selector to the

straight position ( j ). (This allows the

pattern selector to be moved easily).

• Rotate the pattern group selector to

the centre of the desired pattern group.

Select a pattern group before you set the

stitch pattern selector B.

To select a pattern group, rotate

selector until the indicator C show the

group you have selected.

Then set stitch pattern selector for the

selected pattern colour following the

directions below.

Setting Stitch Pattern Selector (B)

The Stitch pattern selector lets you choose

one of the three stitches from the pattern

group you have chosen.

17

straight Stitching

3

setting selectors

Before making any setting adjustments, raise

the needle out of the fabric.

• Pattern Group; Any Yellow Pattern

• stitch Width: 0] I fit

• Needle Position: L «L

• Stitch Length: To suit fabric

• Zig-Zag or Straight Stitch Foot

When your fabric or sewing procedure re

quires close control, you may wish to use the

straight stitch presser foot and the straight

stitch needle plate that come with your ac

cessories.

L X 1

sewing a seam

Pin Basting

Pin basting is a time saver and can be used in

place of hand basting when you are sewing

seams in easy-to-handle fabrics. When sew

ing with pins it is important to use fine pins

and to place them correctly in relation to the

stitching line.

Place pins so that:

• They are at right angles to the stitching line.

• They just nip Into the fabric at the stitching

line.

• They do not extend under both sides of the

presser foot. Never place pins on the

underside of the fabric in contact with

the feed.

•

(optional)

• Sew, pulling pins out of fabric as you stitch.

We do not recommend sewing over pins.

18

9mm (3/8")

1.3cm (1/2")

9cm (3/4")

1.6cm (5/8")

Starting a Seam

1. Set Stitch length selector for desired length

of stitch.

2. Align edge of fabric along one of the num

bered guidelines on the needle plate.

3. Position needle in fabric about 1.3cm (’/2")

from the edge.

4. Lower the presser foot. Depress and hold

reverse-stitch push button, and run the

machine at a slow speed.

• While holding reverse-stitch push button,

back-stitch to edge of fabric for reinforce

ment. (Do not sew beyond edge of fabric).

5. Release push button and stitch forward

to end of fabric, using the selected guide

line to keep seam straight.

19

Ending A Seam

1. Leave presser foot in down position.

Depress and hold reverse-stitch push but

ton and run the machine at slow speed.

• While holding reverse-stitch push button,

back-stitch about 1.3cm (1/2") in from

edge of fabric to reinforce end of seam.

2. Then release push button. With the takeup lever at its highest point, raise the

presser foot and remove the fabric by

drawing it back and to the left.

3. Cut thread ends on thread cutter at rear of

presser bar.

Guiding and Supporting Fabric

4. Most fabrics need only to be guided in

front of the presser foot.

CAUTION: Do not pull the fabric as you

apply gentle or firm tension while stitch

ing, as this may deflect the needle, causing

it to break.

Some fabrics, such as filmy sheers, knits,

5.

etc., require support in front and back of

the presser foot while being stitched.

20

Zig-Zag Stitching

4

how patterns are produced

There are two kinds of stitch patterns built into your

machine: Fashion * Stitch patterns A (only 8007

and 80T9) and Flexi-Stitch* patterns B (only

8019).

The Fashion Stitch patterns, colour-coded yellow

on your machine are produced by the side to side

movement of the needle. The Flexi-Stitch patterns,

colour-coded green and blue (identified by t in the

illustration below) are produced by both the side

to side movement of the needle and the back and

forth movement of the feed to produce multi

purpose and decorative stitch patterns.

The six groups of three stitches each that

are built into your machine are illustrated

below.

tSLOW speed setting is recommended for sewing

Flexi-Stitch patterns.

This stitch is designed for strength and performance

and cannot readily be ripped out without risk of fabric

damage.

Stitch Pattern Groups

(only 8007 and 8019 — Yellow)

\

III

t t

t t

B (only 8019 — Green and Blue)

t t

21

selecting and adjusting zig-zag stitches

Selecting a Pattern Group

(only 8007 and 8019)

When you rotate the pattern group selector C selector as required, sliding the indicator through

one of six different groups of pattern stitches the panel, until it positions one of the pattern groups

Is available to you. Rotate the pattern group you’ve chosen.

Selecting a Stitch Pattern

(only 8019)

The stitch pattern selector D lets you choose one

of the three stitches from the group you have

selected. Notice the colour of the stitch you have

chosen: green (1), yellow (2), or blue (3). To select

any pattern, slide pattern selector until it is

aligned with corresponding colour.

22

1. Adjusting Width

Of The Design

Before moving stitch width selector, always

raise needle above fabric.

To produce a zig-zag stitch, the stitch

width selector must be moved from I

toward the right. The further you move the

selector lever toward the right, the wider

your stitch will be.

2. Adjusting Stitch Piacement

Before moving needle position selector,

make sure needle is above fabric.

A needle position selector setting of

places the needle in centre stitching posi

tion. Selector settings and J[ place

the needle in left and right stitching posi

tion at stitch width settings narrower than

the maximum width.

Selector setting JL (centre) is used most

often. Settings (left) and (right) are

for special placement of stitching. For ex

ample, a (left) or setting is used for

button sewing. A (left) or (right)

setting is used to place narrow zig-zag

stitching to the left or right of centre In

decorative work.

3. Adjusting Stitch Length

When you are preparing to do zig-zag

stitching, make a test sample with the

fabric and thread you plan to use so that

you can adjust the stitch length correctly.

Any stitch length setting from 1 to 4 will give

you an open zig-zag stitch of whichever

Fashion Stitch pattern you select. The higher

the number, the more open , or farther apart,

your stitch will be.

The area between 1 and 0 of the selector is used

for the fine adjustment of zig-zag satin stitching.

For information on satin stitch length adjustment,

see page 25.

For all green or blue Flexi-Stitch patterns, stitch

length is controlled with a single setting of the stitch

length selector. Simply rotate it until the

(Green/Blue) mark A is under the triangle above

the selector.

23

4. Adjusting Needle-Thread Tension

When you are preparing to do zig-zag

stitching, make a test sample with the

fabric and thread you plan to use so that

you can adjust the needle-thread tension

correctly.

Zig-zag stitching requires less tension

than straight stitching. Notice the stitching

on your test sample. The stitchesshould lie

flat Bagainstthefabric without causingthe

fabric to pucker. If the stitches are not flat

C and thefabric is puckering, lower the ten

sion by turning the dial to a lower number.

5. Adjusting Stitch Balance

(only 8019)

When you are using a Flexi-Stitch pattern

you may need to balance your stitching in

order to achieve the correct pattern D (see

illustration).

Before you movethestitch balancecontrol

lever E from Its neutral position (lever at

center of | ),makeatest sample. If adjust

ment Is required, stitch slowly and move

the stitch balance control lever as you sew.

pattern together.

24

the pattern.

Satin Stitching

Satin Stitching is a series of closely spaced

zig-zag stitches that form a smooth satin-like

surface. It is useful for both utility and decora

tive work. Always make a test sample first so

that you can adjust the stitch length and

thread tension properly.

Soft fabrics may require a backing to ensure

firm satin stitching. Crisp organdy and lawn

are suitable for this purpose.

• Pattern Group: iiilU^ Yellow

• Stitch Width: i ii I I il

• Needle Position: J* [X] A

• Stitch Length: Between 0 and 1

• Special Purpose Presser Foot

• Zig-Zag Needle Plate

ill

Adjusting Stitch Length

1. Turn selector dial to 1 and runthe machine.

2. While running machine, gradually turn dial

toward 0 until stitches are closely spaced

and form a smooth satin stitch.

When a smooth satin stitch has been obtained,

you may run the machine at any desired speed.

Adjusting Thread Tension

Satin stitching requires less tension than

straight stitching or open zig-zag stitching.

Furthermore, the wider the stitch, the lighter

the tension on the thread must be.

Notice the stitching on your sample. If the stitching

appears to be too tight or the fabric is puckering,

lower the thread tension by turning the dial to a

lower number.

25

5

Twin-Needle Stitching

By using a twin needle, you can produce

simultaneously two parallel, closely spaced lines

of straight or zig-zag stitching. Effective for

decoration, twin-needle stitching is not

recommended for seams or for use on knits.

Your machine is not supplied with the twin needle

or spool pin. These may be obtained from your local

SINGER stockist as optional accessories.

Before inserting the twin needle, place the needle

position selector at centre and stitch width

selector at ; and, remove the single needle.

4. Pass the horizontal spool pin thread through left

5. Place vertical spool of thread on detachable

threading the twin needle

1. Thread machine with first thread from horizontal

spool pin as instructed on page 9, making certain

thread passes between tension separator and

left-hand tension disc.

2. Raise presser foot.

3. Insert twin-needle spool pin (optional) into hole

provided for it in machine top cover.

26

6. Draw both threads under the foot and back

7. Slowly lower the needle into the hole in the

8. Make sure not to use a stitch width greater than

eye of needle.

spool pin and thread machine as for one-needle

stitbhing except;

• Pass thread between tension separator and

right-hand tension disc. Continue to thread

all other threading points.

• Pass thread through right eye of needle.

along with the bobbin thread.

needle plate by turning the hand wheel toward

you to make sure the needle clears the plate.

that what is recommended when twin needle

stitching.

machine settings

Straight Stitching With a

Twin Needie

.stitch Width: [Dilli

• Needle Position: [2 ^

• Stitch Pattern: Any Yellow Pattern

• Zig-Zag Pressar Foot

• Zig-Zag Needle Plate

Zig-Zag Stitching With a Twin Needie

• Pattern Group: Any Zig-Zag Pattern

.stitchWidth:! [Ql i

Note: Do not exceed this stitch width setting.

• Needle Position: [2 Jl

• Zig-Zag Pressar Foot (open patterns or

Special Purpose Foot (satin stitching)

• Zig-Zag Needle Plate

tCAUTION: Do not use a stitch width greater than what is recommended.

A wider stitch will result In needle breakage.

27

Free-Motion Stitching

In tree-motion stitching, you sew without a

presser foot and control fabric movement by

means of an embroidery hoop. Either a

straight stitch or a plain zig-zag stitch can be

used. Because you can move the hoop in any

direction—forward or backward, from side to

side, or even diagonally — tree-motion stitch

ing is extremely useful for embroidery de

signs. On the other hand, it is equally useful

for darning.

If you are embroidering, you can vary the

length of stitches simply by moving the hoop

faster or slower under the needle. The faster

you move the hoop, the longer the stitches

will be. You can also vary the width of zig-zag

stitches from wide to narrow by controlling

the angle at which the hoop is placed and

moved under the needle.

For darning, the embroidery hoop used In

free-motion stitching enables you to hold

fabric taut — a real advantage when your

fabric is lightweight or soft and thus likely to

pucker. See page 47 for directions.

preparation

1. Have available an embroidery hoop

designed for machine use, large enough

to encompass the entire design, but small

enough so that hoop is easily managed.

2. Remove the presser foot.

3. Insert zig-zag heedle plate and snap-in

feed cover.

4. Rotate stitch length selector dial clock

wise to 0.

28

floral designs

• Pattern Group: hi

• Stitch Width:

• Needle Position: i. «L

• Stitch Length:©

• Presser Foot: None

• Snap-In Feed Cover

• Speed Range: To suit operator

With a little practice on yoursewing machine,

you will be able to embroider flowers to decor

ate table linens and other household Items, as

well as dresses and blouses. If you have de

signing skill, you will enjoy creating your own

designs. Otherwise, you can buy attractive

transfer patterns.

III

III

lili

Yellow

* •

To embroider flower designs, prepare the machine

and your fabric by following the same steps as for

free-motion stitching (page28).

On your test sample, try out different stitch

width settings to determine the one or more

best suited to your design.

When filling in outlines, place stitches in

parallel lines, shifting the hoop movement as

appropriate to the design.

• For a smooth satin stitch that will catch the

light, place the parallel stitches close to

gether, moving the hoop slowly and

steadily.

For an irregular texture, move the hoop

more rapidly, allowing some stitches to

overlap.

A series of bar tacks can be used to form

spray-like leaves or flowers.

Sewing the Professional Way

sewing knit and stretch fabric

When you sew stretch fabrics, doubleknit,

tricot and jersey, choose one of the stretch

patterns that sews stretch into the seam.

The table below will help you to select the

right stitch pattern for your fabric and sew

stitch Pattern Chart

Stitch Pattern

Pattern Group

Stitch

Length

■

Straight Stretchf

Plain Zig-Zag

[sjl t

ill

Optional

A/WWVW\

Ric-Rac Stitchf

7VVVVVV

Overedge Stretch

Stitchf

ill'“”’

j|jj^ (Green)

r M

ing job. Remember to useaSINGER*ball

point (yellow band) needle. Catalog 2045,

in your machine when you sew synthetic

knit or stretch fabric.

Where to use

Heavy-duty construction seams — Seam reinforce

ment — Dungaree seams — Crotch seams.

General-purpose stretch sewing — Lingerie seams

— Attaching stay tape — Seam finishing — Edge

finishing — Attaching stretch lace.

Heavy-duty, general-purpose sewing.

Overedge seams that stretch — Crotch seams —

Waistband and seam finishes in shorts and slacks —

Swimsuit construction.

y-VY'V

(Yellow)

Blindstitch

/77777777777

Slant Overedge

Stretch Stitchf

1 j|

1 (Green)

Honeycomb Stitchf

V A ,A A /

V V V v'

Multi-Stitch

Zig-Zag

V>V9>>y

Feather Stitchf

Straight Feather

Stitchf

tThis stitch is designed for strength and permanence and

cannot readily be ripped out without risk of fabric damage.

30

l[||l

k i

II

(Blue)

I

(Blue)

Optional

fH

Optional

M

ËÜ

Blindstitch hemming — Overcast seam finishing —

Shell hems in lingerie.

Sweater and swimsuit construction — Overcast

seams in bulky knits and stretch terry cloth —

Attaching elastic and stretch lace — Edge finishes

for seams, hems, and facings.

Attaching elastic and stretch lace — Lingerie and

girdle repair — Swimsuit construction — Edge

finishes for seams, hems and facings — Blanket

binding.

Attaching elastic and stretch lace — Lingerie and

swimsuit construction — Girdle seams — Seam

finishes — Casings and waistband finishes —

Blanket bindings.

Swimsuit seams — Attaching stretch lace —

Lingerie and girdle seams — Blanket binding

Ideal for flat-butted seams, and where extra

strength is required.

Guiding and Supporting Fabric

Most fabrics of Stretch or knit construction

need only to be guided in front of the presser

foot. Some fabrics, however, require support

while being stitched.

CAUTION: Do not pull the fabric as you apply

gentle or firm tension while stitching, as this

may deflect the needle, causing it to break.

1. For nylon tricot and similar synthetic knits,

stpply gentle tension by holding fabric in

front and back of presser foot as you sew.

31

Plain Stretch Seams

• Pattern Group: gil (Green)

• Stitch Width: [T] I I I i

• Needle Position: L [XI *1

• Stitch Length |p (Green/Blue)

• Special Purpose Presser Foot

• Zig-Zag Needle Plate

When you use the straight stretch stitch for 2.

stress seams or to seam knit stretch, and

elasticized fabric, stretch and strength are

built into the seam as it is being sewn. Be sure

to insert a bail-point (yellow band) needle,

Catalog 2045, in the machine if you are stitch

ing a synthetic knit fabric.

1. Make a test with a sample of your fabric so

that you can adjust thread tension and 3.

stitch balance correctly (see page 24).

Lingerie Seams

• Pattern Group

• stitch Width:

• Needle Position: ^

: II

Yellow

Stitch and guide the fabric as you do for

plain seams stitched with the regular

straight stitch, letting the machine make

the back-and-forth stitches that give

stretch to the seam. If the fabric has an

unusual amount of elasticity, it should be

guided and supported as instructed on

page 31.

After stitching, press seam as when using

the regular straight stitch.

• Stitch Length: To suit fabric

• Zig-Zag Presser Foot

• Zig-Zag Needle Plate

To make a lingerie seam both durable and

flexible, use a zig-zag stitch. This treatment is

particularly suitable for bias seams.

1. Straight-stitch the seam (with stitch width

selector at i ) on the wrong side.

2. Press both seam allowances In the same

direction.

3. From the right side, top-stitch with zig-zag

pattern, letting the needle alternately

enter the seam line and seam thickness.

32

Overedged Seams

Seams in knit and stretch fabric can be joined

and finished in one operation. Two different

methods may be used. Method No. 1 is

recommended for firm fabrics where a 6mm

(1/4”) seam allowance Is adequate. Method

No. 2 is' recommended for bulky knits and

fabrics that have a tendency to curl or fray

and where a wider seam allowance is needed

for support. Make a test sample to help you

decide which method is best for your fabric

and garment. Remember to use a Catalog

2045 ball-point (yellow band) needle if you

are sewing a synthetic knit.

Pattern Group:

Stitch Width:

• Needle Position: JL

. stitch Length: “ (Green/Blue)

• Special Purpose Presser Foot

• Zig-Zag Needle Plate

I:

(Green)

Method No. 1 — Overedging

1. Cut and fit the garment, allowing for a

1.6cm (5/8”) seam allowance. Baste seam

line.

2. Trim seam edge evenly to a scant 6mm

(1/4”) from seam line basting.

3. Place seam under the presser foot so that

the straight stitches fall on the basted

seam line and zig-zag stitches toward the

seam edge A, as illustrated.

Method No. 2 — Mock Overedging

1. Cut and fit garment, allowing for a 1.6cm

(5/8”) seam allowance. Baste seam line.

2. Place seam under presser foot so that the

straight stitches fall on the basted seam

line and zig-zag stitches toward the seam

edge B.

3. Press after stitching and trim away excess

fabric to produce a narrow seam edge.

When seam supports the garment, omit

the trimming step.

33

Attaching Elastic

Pattern Group:

Stitch Width:

• Needle Position: Jw

• Stitch Length: Approx. 1.5

(for Yellow pattern)

or (Green/Blue) |ji

• Zig-Zag Presser Foot and Needle Plate

(Green) (Blue) or

(Yellow)

To Attach Waistline Elastic

e Fit elastic for desired snugness at waistline,

allowing 1 inch (2.5cm) for joining. Lap

ends to form a band and straight stitch

together as shown using a ball point needle.

• Divide elastic band into four equal segments

and mark with pins. Do the same to the gar

ment. Then pin together at corresponding

points, pinning elastic over right side of

fabric, top edges even.

• Sew a few straight stitches to anchor elastic

to fabric.

• Select honeycomb.

• Then hold elastic and garment edge taut as

you stitch so that it will remain stretchable

after stitching is completed.

CAUTION: Do not pull the fabric while you

are stitching as this may deflect the needle,

causing it to break.

Finishes For Hems And Facings

» Pattern Group: ffl i (Green) or (Yellow)

• Stitch Width: : I I i

• Needle Position: J» \J^ A

• Stitch Length: to suit fabric and stitch

• Special Purpose Presser Foot

• Zig-Zag Needle Plate

• Make a test sample first.

• Place stitching about 3mm (1/8") in from

hem or facing edge.

• Press after stitching and trim away excess

fabric close to the stitching line.

* •

34

handling special fabrics

Many fabrics because of their construction or finish, demand special atten

tion in sewing. Techniques used in stitching and handling, and choice of

machine accessories, will vary with the fabric. Let the table below guide your

selection.

Fabric Handling Table

Fabric

Vinyl -

leather-look.

patent.

suede.

reptile

Pile-

velvet.

velveteen.

corduroy

Deep Pile -

fake fur

percale,

broadcloth,

shirting

Permanent

Press -

percale

broadcloth

shirting

Special Handling

Use transparent tape as a substi

tute for pins or basting—Topstitch

to hold seams and edges flat—

Avoid worked (machine button

holes. Use bound buttonholes.

Stitch in direction of nap—Use plain

seams—Zig-Zag or bind seam

edges to prevent fraying—Press

over a self-fabric cloth.

Pin rather than baste seams—Stitch

in direction of nap—Use plain seams

for short-hair furs; narrow over

edged seams for shaggy, bulky furs

—Shear pile from seam allowances

to reduce bulk.

Control seam tension manually by

holding fabric taut as it passes un

der the presser foot. Sew at mod

erate speed.

Stitch

Length-type

Long

Straight-Stitch

Medium Straight

Stitch for seams

Medium Zig-Zag or

Honeycomb stitch

for overcasting

Long Straight

Stitch for plain

seams Medium to

Short Zig-Zag

Stitch for over

edged seams

Medium

Straight Stitch

Needle

Style-Size

style 2020 Size 14

or 16 for woven

backing Style 2045

Size 14 or 16

for knit backing

Style 2020 Size 14

Style 2045 Size

14 or 16

for panne' velvet

Style 2020 Size 16

Style 2020 Size 11

or 14

Machine

Accettorlet

General Purpose Foott

General Purpose Needle plate

General Purpose Foott

(General Purpose Foot

only for overcasting)

General Purpose Needle plate

General Purpose Foott

General Purpose Needle plate

Straight Stitch Foot

and Needle Plate

Fine Knits -

tricot, jersey

Blanket

Binding •

satin face

Soft Sheer -

chiffon.

voile.

China silk

Napped

Fabric-

cashmere,

mohair,

camel hair

Use narrow overedged, double

stitched, or French seams—Hold

thread ends securely for a few

stitches at start of seam—Support

seams while stitching.

Hand-baste binding to blanket (pin

marks show) — Miter corners.

Use French seams, double stitched

—Hold ends of upper and lower

thread when you begin to stitch

—Support fabric while stitching.

Cut with nap running down—Sew

in direction of nap—Topstitch to

hold seams and edges flat.

t For best results when sewing this fabric, we recommend use of the

Medium

Straight Stitch

Medium to Short

Narrow Zig-Zag or

Narrow Overedge

Long Straight

Stitch Medium to

Long Zig-Zag

Stitch or Decora

tive Stitch

Medium to Short

Straight Stitch

Medium to Long

Straight Stitch

Style 2045

Size 11 or 14

Style 2020

Size 11 or 14

Style 2020

Size 9 or 11

Style 2020

Size 11 or 14

Straight Stitch Foot and Needle

General Purpose Foot and

stitching)

General Purpose Foott

General Purpose Needle plate

Straight Stitch Foot

and Needle Plate

Even Feed Foot, available at your Sewing Centre.

Plate (for straight stitching)

Needle Plate (for zig-zag

General Purpose Foott

General Purpose Needle plate

35

construction details

zipper Insertion

How the zipper is inserted will depend on the

type of the garment and the location of the

zipper. With the adjustable zipper foot, you

will find It easy to sew an even line of stitching

close to the zipper. For Inserting the zipper

foot on machine see pages 4 and 7.

• Pattern Group:

• Stitch Width: [71 I I I j

• Needle Position: L [X] ^

• Stitch Length: To suit fabric

• Zipper Foot

The zipper foot can be used either to the left

or right of the needle—depending on where

the bulk of the garment Is placed.

Attaching the Zipper Foot

When the zipper foot is to the right of the needle:

• Attach left side of zipper foot to shank (needle

will enter left notch in foot)—see Illustration A.

When thezipperfoot istothe left of the needle:

e Attach right side of zipper foot to shank

(needle will enter right notch in foot)—see

illustration B.

ji|j|

Any Yellow Pattern

Zipper inserted under ieft Lapped Seam

• Baste the seam line the exact length of the

garment opening and press the seam open.

e Attach the zipper foot to the right of the nee

dle (illustration A).

e Open the zipper.

e Flatten out the back seam allowance and

place the zipper face down on it, as illustrated,

with the edge of the zipper teeth following

the seam line.

• Stitch the zipper tape onto the seam

allowance.

• Adjust the foot to the left of the needle (il

lustration B).

• Close the zipper and turn it face up.

• Smooth back the seam allowance at the

edge of the zipper.

• Top stitch to the tape close to the folded

edge.

• Spread garment flat and turn zipper face

down over front seam allowance.

• Hand baste zipper to garment from wrong

side, through zipper tape, seam allowance,

and front of garment.

• Turn garment right side out.

• Adjust zipper foot to right side of needle and

stitch across the lower end of the zipper and

up to the waistline, using the basting stitches

as a guide.

• Remove bastings. Press.

Corded Seams

The corded seam is a professional treatment

for slipcovers, children’s clothes, blouses,

and lingerie. To make a corded seam, make

the welting first (or buy it ready-made), then

stitch it into the seam. For both steps, use the

following settings and accessories:

• Pattern Group: ly

. stitch Width: [J]

• Needle Position: i» H

• Stitch Length: Slightly longer than for

regular seaming

• Zipper Foot

• Zig-Zag or Straight Stitch Needle Plate

I I i I

Yellow

1. Making the welting

1. Buy cable cord (at a notions counter) of

desired size.

2. Cut bias strips of fabric (width: three times

the diameter of the cord plus 3cm (1-1/4").

3. Sew strips together on the lengthwise

grain to obtain desired length.

4. Fold resulting strip over cord with raw

edges even.

5. Attach zipper foot to the left of the needle.

(For Instructions on attaching zipper foot,

see page 36).

6. Lower the presser foot.

7. Stitch close to the cord (but do not crowd

stitching against cord), pulling gently on

the strip, both in front and in backof the

zipper foot.

2. Stitching weiting into seam

1. Attach zipper foot to the right of the

needle so that the bulk of the fabric will fall

to the left.

2. Stitch welting to the right side of a single

seam edge; guide the edge of the foot next

to the cord but do not crowd.

3. Place the attached

second seam edge,

together.

4. Place the work under the needle, with the

first stitching on top so that you can use it

as a guide.

5. Stitch, this time crowding the foot against

the cord.

welting over the

and pin or baste

37

Blindstitch Hems

(only 8007 and 8019)

Blindstitching provides a durable hem finish

that is almost invisible. It is best suited to

straight hems. Taped, bound, turned, or un

finished hem edges can be blindstitched with

equal ease. Blindstitching takes a little prac

tice, however, so make a test sample first.

• Pattern Group: Yellow

• Stitch Width: To suit fabric

• Needle Position: J* [X] «1

• Stitch Length: 1 to 2.5

• Zig-Zag Presser Foot

• Zig-Zag Needle Plate

• Blindstitch Hem Guide

1. Mark, turn, and press hem in the usual way.

2. Baste a guideline at least 1.3cm (1/2") from

the top edge of the hem so that the basting

will not be caught by theflangeof the blind

stitch hem guide.

3. Attach the blindstitch hem guide to the

presser bar (see Page 5).

4. With the work wrongsideupandthebulkof

the fabric to the left, turn the hem under,

creating a soft fold about 6mm (1/4") from

top edge of the hem.

5. Position the hem under the presser foot

with the flange on the front of the guide

resting on the 6mm (1/4") hem edge and

the soft fold against the wall of the flange.

6. Stitch so that straight stitches fall on the

hem edge and the sideward stitches pierce

the soft fold. While stitching, feed the soft

fold against thewall of theflangeand guide

the hem edge in a straight line.

38

buttons

• Pattern Group: ijjlill Yellow

• Stitch Width: To suit button

• Needle Position:

• Button Foot

• Snap-In Feed Cover

Flat buttons can be sewn on quickly and easi ly

using the plain zig-zag stitch.

The space between the holes In the button

determines stitch width settings.

• Attach snap-in feed cover to zig-zag needle

plate.

1. Set stitch width at | and needle position

selector at . Position button under foot

and lower the needle Into the center of the

left hole. Lower the foot. Turn hand wheel

toward you until needle rises out of button

and is above the foot.

III

[jJ J L

2. Move stitch width selector until needle is

over the other hole in the button. Continue

turning hand wheel until the needle is

above right hole, adjust stitch width, as

necessary, until needle enters center of

the right hole. Take six or more zig-zag

stitches and finish with the needle on the

left side.

3. To fasten stitching, adjust stitch width to

i and take three or four stitches.

I

• Remove work, draw threads to underside of

fabric, fasten, and trim.

39

buttonholes

You have a choice between two methods of

making bar-tack buttonholes; using the builtin four-step system, or manually controlling

the selectors.

On pages 41 and 43 you will find detailed

instructions for using the two methods; but you will

find the following information basic to both.

1. Always make a test buttonhole on a

sample of your fabric. Be sure to duplicate

the thickness of the garment. Include inter

facing if appropriate.

2. Use No. 50 or finer mercerized cotton

thread or embroidery thread, and reduce

needle-thread tension to slightly less than

normal.

3. Use a size 11 needle for embroidery thread

and a size 14 needle for mercerized cotton

thread.

Buttonhole Position

Accurate guidelines are essential to keep but

tonholes A at a uniform distance from the edge

of the garment, evenly spaced, and on the

grain of the material.

Mark the centre line B of the garment. This

guideline can be made by hand basting. The

space from the centre line to the finishededge

of the garment C must be from 1.9cm (3/4") to

the full diameter of the button. D With this

spacing, the button will not extend beyond the

edge when the garment is buttoned. Make

sure the centre line marking follows a

lengthwise fabric thread.

Marking the Garment

e Mark a position guideline with hand basting

for each buttonhole.

e Horizontal buttonholes 1 are placed to

extend 4mm (1/8") beyond the centre line of

the garment E, as illustrated, so that buttons

will be in the centre of the figure when the

garment is fastened. Horizontal buttonhole

guidelines should follow a crosswise fabric

thread and should be longer than the

finished length of buttonhole. Mark ends of

buttonhole vertically.

• Vertical buttonholes 2 are placed on centre

line of garment E, as illustrated. Mark ends

of buttonhole horizontally across the centre

line basting and use the centre line marking

as the buttonhole guide when stitching.

Spaces between buttonholes should be equal.

When a line of buttonholes crosses the waist

line, be sure that one buttonhole will fall ex

actly on the waistline. Then measure the

other buttonhole markings from that point.

40

Buttonhole Length

A buttonhole length should be just long

enough to allow the button to slip through the

opening without stretching. You can esti

mate the proper buttonhole length by mea

suring the width plus the thickness of the

button. To make sure the measurements is

correct, cut a slit in a scrap of fabric the

diameter of the button you intend to use.

Increase length of opening until button slips

through easily. This test Is particularly ad

visable for buttons of unusual shape or

thickness.

Cutting Button Opening

Place a pin across the cutting space at each

end of the buttonhole to protect the end

stitching. Use a pair of small sharp scissors to

cut button opening. Insert blade in center of

cutting space and cut from this point in either

direction.

Four-Step Buttonhoiing

(only 8007 and 8019)

The four dial settings for buttonholing are lo

cated on the opposite side of the stitch length

selector. As you turn the dial for each step,

your machine is automatically set for the cor

rect needle position, stitch width, and stitch

length, as well as for stitching direction for

that step. You need not turn the fabric during

buttonholing.

• Pattern Group: ¡|f Yellow

• Buttonhole Foot

• Zig-Zag Needle Plate

Procedure:

• Follow the Instructions beginning on page

40 for preparing and marking the garment.

• Raise the needle above the fabric.

• Position the work under the buttonhole foot

aligning centre marking A of buttonhole

with centre red line B on the foot.

• Align end marking C of buttonhole with the

horizontal red lines on the foot.

• Set reverse-stitch push button in neutral

position D. Adjust if necessary to equalize

difference in stitch density between left and

right side of test buttonhole. Turn to page 43

for detailed instructions.

* •

41

step 1: Side Stitching

With the needle raised above the fabric, turn

the buttonhole dial clockwise to step 1. Posi

tion needle in fabric at point A. Lower the foot

and stitch to end of buttonhole (point B). The

end marking should be aligned with the

horizontal red lines on the foot.

step 2: Bar Tack

Raise the needle above the fabric. Turn but

tonhole dial counterclockwise to step 2. Take

about six stitches to point C.

step 3: Side Stitching

Raise the needle above the fabric. Turn but

tonhole dial counterclockwise tostep3. Stitch

to within two stitches of the end of the but

tonhole (point D).

step 4: Bar Tack

Raise the needle above the fabric. Turn but

tonhole dial counterclockwise to step 4. Take

about six stitches to point E. For a smooth,

satin appearance and greater durability, stitch

around the buttonhole a second time by re

peating the four-step sequence.

Remove the work, draw threads to the under

side, tie. and trim. Cut button opening with

sharp scissors as instructed on page 41.

When buttonholes are completed, rotate dial

counterclockwise to stitch length settings to

set machine for regular stitching.

42

Adjusting

Forward-Reverse Stitch

Balance

Difference in stitch density between the left

and right sides of the buttonhole (forward

and reverse stitching) are equalized by ad

justing the reverse-stitch push button. A very

slight rotation of the button will produce a

noticeable change.

1. Make a test buttonhole with the push but

ton in neutral position (indicator dot

directly below ^ symbol on control

panel).

2. If the stitches on the left side of the button

hole are too open, rotate the push button

clockwise from Its neutral position to In

crease density of stitching.

3. If the stitches on the right side of the but

tonhole are too open, rotate the push

button counterclockwise from its neutral

position to Increase density of stitching.

t

After buttonhole stitching Is completed,

return push button to its neutral position

(Indicator dot directly below ^ symbol on

control panel).

Buttonholes (Manual Method)

Settings

. Pattern Group: ill Yellow

e Stitch Width: See Below

• Needle Position: [Q «L «1

• Stitch Length: Between 0 and 1

• Special Purpose Presser Foot

• Zig-Zag Needle Plate

Always make a test buttonhole on a sample of

your fabric. Be sure to duplicate the thick

ness of the garment and include Interfacing If

appropriate..

Follow the instructions beginning on page 40

for preparing and marking the garment.

Stitch Width Settings

You will use two stitch width settings: one for

side stitching A and one for the bar tacks B

(the closing at each end of the buttonhole).

These stitch widths may vary according to the

size of the buttonhole required. Two possible

combinations are illustrated at the right.

CB'

Procedure

Place work under needle, aligning centre

marking of buttonhole with the black line in

the center of the special purpose foot.

step 1: Side Stitching

Position needle in fabric at point A. Lower the

foot and stitch to end of marking. Leave

needle in fabric at point B. Raise foot and

pivot work on needle. Lower the foot. Take

one stitch without changing stitch width

setting, bringing work to point C.

step 2: Bar Tack

Adjust stitch width selector for bar tacks, and

take about six stitches. Stop at point D.

step 3: Side Stitching

Readjust stitch width selector for side stitch

ing. Complete work to point E. Leave needle

in fabric,

step 4: Finai Bar Tack

Adjust Stitch width selector for bar tacks, and

take about six stitches ending at point F.

step 5: Fastening Stitch

To secure stitching, move stitch width selec

tor to i and take three stitches. Remove

work, draw threads to underside, fasten, and

trim. Cut opening for button with sharp

scissors.

44

Top Stitching

A practical simple way to accent the lines of

dress or coat is to place one or more rows of

stitching along collars, lapels, facing edges,

pockets, sleeves, etc. For a tailored look, use

rows of straight stitching. For decorative in

terest. use stitch pattern.

Appiique

Applique' adds beauty and interest to clothes

and household linens. Either contrasting or

self fabric can be used effectively.

The stitch most commonly used applique'ing

is the plain zig-zag stitch (see page 25),

closely spaced to form a satin stitch. The

width of this stitch can be varied to accommo

date fabrics of different weaves and textures.

Many of the other stitch patterns can be used

to applique' with decorative stitching.

To prepare for applique'ing. make a sample

to help you decide which of the following two

methods Is more appropriate for your fabric

and design.

• Mark design on piece of fabric to be

applique'd.

• Cut out design leaving about 2cm (3/4")

margin all around.

• Position the design.

• Baste it to the fabric.

• Attach special purpose foot.

Method No. 1

1. Select a stitch patterti suitable for the

desired sewing application. Set stitch

width selector for the desired width. For

white patterns, set stitch length dial for

satin stitching between 0 and 1; for green and

blue patterns, set it on position 4 (Green/Blue).

2. Outline the entire design with applique'

stitching.

3. Trim away excess fabric on the outer

edges of the stitching. Remove basting.

Method No. 2

1. Select a stitch pattern suitable for the

desired sewing application.

2. Adjust stitch width selector for regular

straight stitching and outline the entire

design with a short stitch.

3. Trim raw edges to the stitching.

4. Adjust stitch width selector to desired width

setting for applique’ pattern, and set stitch

length selector between0and 1 (or on po

sition 4 (Green/Blue) if using one of the green

or blue Flexi-Stitch patterns.)

5. Stitch, following and covering straightstitch outline. This step will produce

smooth overedged finish with no raw

edges to be trimmed.

Top Stitching

Method No. 3

• Purchased motifs can be applique'd quickly

and easily by using a straight or decorative

stitch.

45

Keeping up appearance

Mending

Many of the zig-zag stitch patterns are just as useful

for mending as they are for creative sewing. The

multi-stitch zig-zag yellow ( ) forms a firm,

flexible bond for repairing tears and for replacing

elastic. The plain zig-zag (yellow ^ ) is useful for

making bar tacks to repair lingerie.

1. Tears

e Pattern Group: Yellow

e Stitch Width:

• Needle Position: 1 [I] 1

• Stitch Length: About 1 or to suit fabric

• Zig-Zag Presser Foot

• Zig-Zag Needle Plate

1. Trim ragged edges.

2. Place underlay on the wrong side of tear

for reinforcement. (It is best not to baste or

pin the underlay since you will be bringing

the edges of the tear together in the next

step).

3. Stitch on the right side, bringing the edges

of the tear together.

4. Shorten stitch length at ends and corners

to give extra strength.

5. Trim underlay.

46

Darning

You may choose to darn either with or with

out an embroidery hoop. When greater con

trol is needed, an embroidery hoop is usu

ally best.

Darning Without Embroidery Hoop

• Pattern Group; lllll

. Stitch Width: [T] I I

• Needle Position; i*

• Stitch Length: 1.5

• Zig-Zag Presser Foot

• Zig-Zag Needle Plate

1. If area to be darned is open, baste an un

derlay in place.

2. Place area to be darned under the presser

foot. Lower the presser foot and start

stitching, alternately drawing the fabric

toward you and gently pulling it away from

you until area is filled with parallel lines of

stitching.

3. For additional strength, cover area with

crosswise lines of stitching.

(Yellow)

1 1

Darning With an Embroidery Hoop

• Pattern Group; !ll! (Yellow)

• Stitch Width: [T] 111^

• Needle Position: 1» JL

• Stitch Length; 0

• Presser Foot: None

• Snap-In Feed Cover

1. Trim ragged edges from area to be darned

and center worn area in embroidery hoop

designed for machine use.

2. Carefully position work under needle and

lower presser bar to engage tension.

3. Hold needle thread loosely with left hand,

turn hand wheel toward you, and draw

bobbin thread up through fabric. Hold

both thread ends and lower needle into

fabric.

4. Reinforce the area to be darned with

stitching 6mm (1/4") from theedge. Stitch

across opening, moving hoop under nee

dle at a slight angle from lower left to up

per right. Keep lines of stitching closely

spaced and even in length.

5. When opening is filled, cover area with

crosswise lines of stitching.

47

Free-Arm Sewing

Fabric handling, when sewing tubular and

hard to reach garment areas, is simplified

when you convert your sewing machine to

tree-arm sewing. Some of the sewing jobs for

which you will find the free arm particularly

useful are shown on this and the following

pages. You will discover many more for your

self.

preparation

To convert to free-arm sewing, simply press

down on corner of Flip & Sew panel on sewing

machine with heel of right hand.

To raise Flip & Sew panel, place hand under

panel and lift up until it locks into place. A

click will be heard when panel is locked in

position.

applications

Buttons

Sewing buttons on a cuff or neckband is no

longer a task when the free-arm surface Is

used. Cuffs slip around the sewing surface

without being pulled out of shape, so you can

see and handle the stitching area easily.

Sleeves

Free-arm sewing takes the difficulty out of topstitching a sleeve. The armhole rotates

smoothly under the needle so that you can

place stitching accurately. The extra control

afforded by the free arm is especially helpful

for topstitching flat-fell seams.

Badges, emblems and insignias can be

attached to shirts and uniforms by slipping

sleeve or hard-to-reach area over the sewing

surface.

48

Caring for

Your Sewing Machine

cleaning and lubricating

How often you will need to clean and lubricate

the machine will depend on how often you use

It and where you keep it. The following gen

eral guidelines assume that you will be sewing

several times a week. But if you use your

machine more frequently, lubricate It more

often than the guidelines suggest.

CAUTION: Before cleaning and lubricating

your machine, disconnect the power-line

plug from your electrical outlet.

8

Every Few Weeks—

Remove lint or fluff from exposed parts.

With the lint brush, and a soft cloth, clean:

• Tension discs

• Take-up lever and thread guides

• Presser bar and needle bar

Remove needle plate, as Instructed on page 7

and clean:

• Feed and hook area

• Bobbin case. Removal of lint from groove on

outer edge of bobbin case is important. Lint

accumulation could prevent machine from

operating properly. (See next page for

removal of bobbin case.)

• All machine surfaces (if necessary, dampen

the cloth. Do not use detergents.)

49

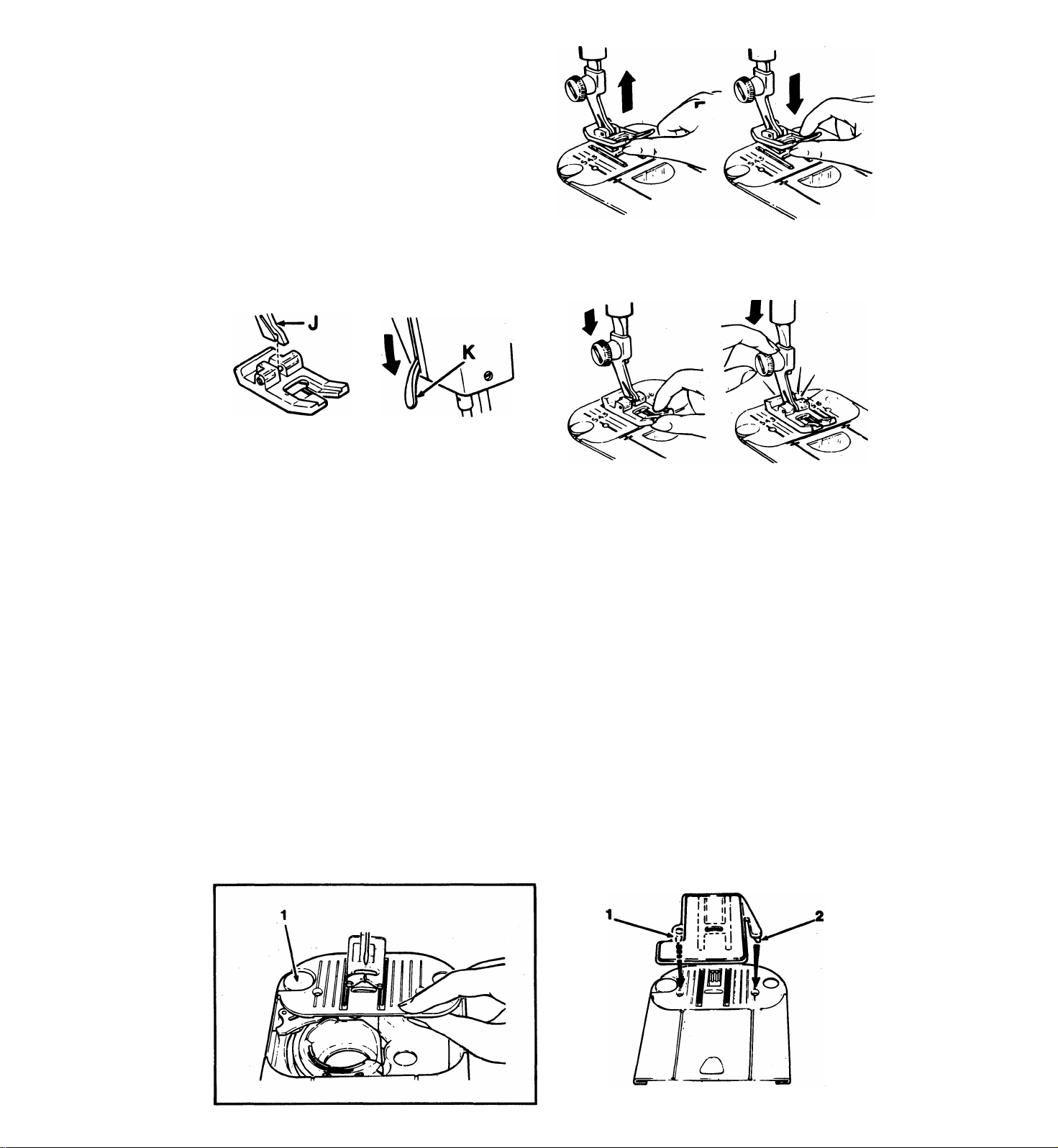

Removing and replacing

bobbin case

Caution: Before cleaning or adjusting the

machine, remove plug from the socket outlet.

• Raise presser foot and needle.

• Open slide plate, remove bobbin and

remove needle plate (see instruction on

page 7).

To remove bobbin case

e With a small screwdriver, turn bobbin case

holder (1) to the rear as far as it will go.

e Lifting the left side of the bobbin case, slide

it out from machine.

To replace bobbin case

• Guide forked end (2) of bobbin case under

feed (3).

• Draw rim of bobbin case under position

plate (4). Be sure bobbin case is freely

seated on hook race.

e Turn bobbin case holder (1) forward as far

as it will go, locking bobbin case in place.

Note: Turn handwheel towards you to check

to make sure it is properly replaced.

• Replace needle plate (see Instruction on

page 7).

• Insert bobbin and close slide plate.

50

every few months—

Caution: Before lubricating your machine,

disconnect the power-line plug from your

electrical outlet.

Lubricate parts behind the face plate, under

the arm top cover, and bottom of machine.

• Apply a drop of oil (but no more than a drop)

to all places indicated.

To Remove Face Plate

• Lower presser-foot lifter.

• Loosen screw A.

• Remove face plate by grasping it around

the bottom edge and pulling toward the left,

then down and away from machine.

To Replace Face Plate

• Replace face plate and tighten screw A.

• Return Presser-foot lifter to up position.

To Remove Top Cover

• Loosen Screws B, C, D, and E.

• Lift top cover up and remove it from machine.

To Remove Bottom Cover

—c :

Ij

-

i

1

Remove bottom cover from machine.

y

• Apply one drop of oil all to places indi

cated.

• Occasionally apply one drop of oil to all

other rotating or moving machine connec

tions to ensure freedom of movement.

After oiling, replace face plate and arm top

cover. Sew a few lines of stitching on a scrap

of material to remove excess oil.

If Machine Is To Be Stored

Disconnect power-line plug from electric

outlet.

Clean all exposed parts and area behind

face plate.

CAUTION: Do not attempt to adjust the motor

belt. Contact your nearest Service Centre

should any adjustment be required.

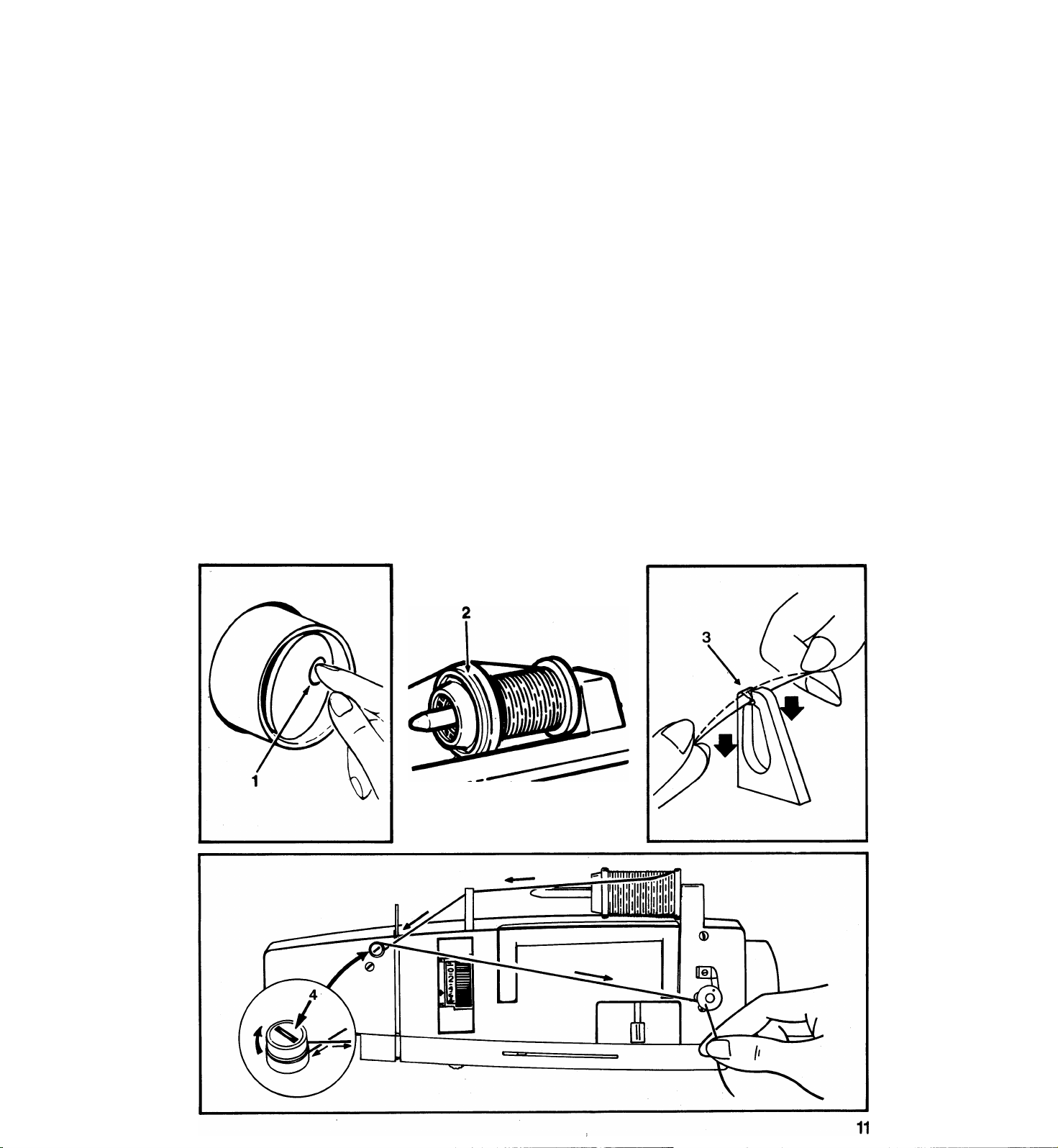

Changing The Light Buib

CAUTION: Disconnect the power-line plug

from the socket outlet before changing light

bulb.

This machine is designed to use a 15 watt

maximum bayonet base bulb only.

Remove face plate, as instructed on page 51.

1. Removing Bulb: Press bulb into socket and

at the same time turn bulb in direction

shown to unlock bulb pin (do not attempt

to unscrew the light bulb).

2. Replacing Bulb: Press new bulb into soc

ket, with bulb pin entering slot of socket,

and turn it in direction shown to lock bulb