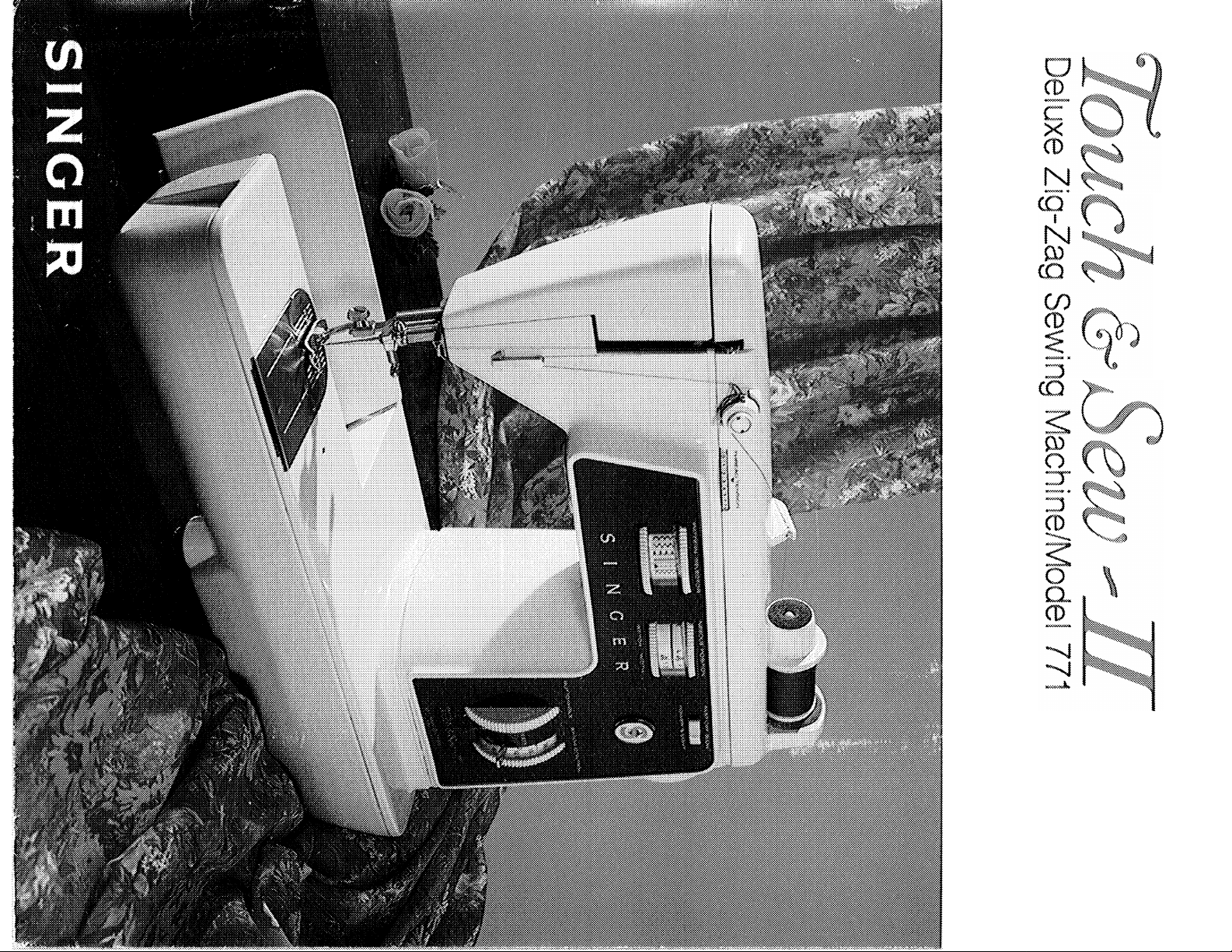

Page 1

Page 2

<iT

Deluxe Zig-Zag Sewirig Machine by SINGER

Congratulaiions...

You are about to discover the wonderfui pleasure of sewing with your new

Touch & Sew* sewing machine. The Modei 771 Flip & Sew* sewing machine

features a hinged bed lor free arm sewing. And you will also enjoy;

• the simplicity of dial controls. Now, you can simply dial a stitch length, a

stitch width, and a stitch pattern; pressure and tension settings; even

buttonhole stitching

• the versatility Oi sewing capacity that produces stitches that stretch, and

stitches that don't stretch ... permanent stitches that are firmly locked in,

and temporary stitches that pul! out easily... stitches that decorate,

embroider, mend, baste

• and, of course, the ease of the push-button bobbin, and much more!

Among the many Singer engineering and design features that ensure these

sewing pleasures are —

• buHt-in stitch patterns, which let you produce a straight stitch and a variety

of zig-zag patterns by simply turning a dial, plus Flexi-Stitch* patterns for

stitching knit and stretch fabrics and producing intricate stitch designs

• Soft-touch Fabric Feed that protects even the most delicate fabrics

• one-way needle clamp that makes it impossible to insert the needle back

wards

• stitch control dial that lets you switch from regular to s-t-r-e-t-c-h

stitching

• easy needle plate changing — needle plate secured by magnets is easy to

lift out for cleaning

• three-position presser foot lifter that lets you place bulky fabric or many

fabric layers under the presser foot

As you go through this book, you will discover how these and many other

leatures give you the ultimate in simplicity of operation and beautiful results.

sewing!

SINGEB* Service is always close at hand, if your machine should need servic

ing, call your local SINGER Sewing Center to be sure of v.'arranted SINGER

Parts and Service. You will find the address in the telephone directory under

SINGER COMPANY.

Copyright ‘ 1977 THE SiNGER COMPAN'Y

AU Rights Reserved Throughoyt the Wodd

Page 3

CONTENTS

1. Getting to Know Your Machine......................................................................

Principal Parts and What They Do..................................................................................................... 3

Accessories.......................................................................................................................................... 4

2. Getting Ready to Sew

Preliminary Steps ................................................................................................................................... 6

Choosing Needle and Thread ............................................................................................................. 7

Threading the Machine..................................................................................................................... 12

3. Straight Stitching...................................................................................................................................... 18

Preparation ..................................................................................................................................... 18

Starting to Sew.................................................................................................................................... 18

Adjusting for Your Fabric.................................................................................................................. 19

Sewing a Seam..................................................................................................................................... 21

4. Zig-Zag Stitching.................................................................................................................................... 25

Zig-Zag Stitch Patterns......................................................................................................................... 25

Adjusting Dials.................................................................................................................................... 26

Satin Stitching .................................................................................................................................... 28

5. Twin-Needle Stitching.............................................................................................................................. 29

Inserting the Needle............................................................................................................................ 29

Threading the Needle.......................................................................................................................... 30

Dial Settings ........................................................................................................................................ 31

Turning a Square Corner ..................................................................................................................... 32

.....

.......................................................................................................................... 6

.......................................

2

6. Temporary Stitching

Speed Basting ................................................................................................................................... 33

Chainstitching....................................................................................................................................... 35

7. Buttons and Buttonholes........................................................................................................................ 39

Buttons............................................................................................................................................... 39

Buttonholes....................................................................................................................................... 40

8. Free-Motion Stitching ............................................................................................................................ 46

Flower Embroidery ............................................................................................................................ 46

9. Sewing the Professional Way ............................................................................................................. 47

Construction Details......................................................................................................................... 47

Sewing Knit and Stretch Fabric .......................................................................................................

Hints on Sewing Special Fabric......................................................................................................... 58

Decorative Touches ............................................................................................................................. 60

Keeping Up Appearances................................................................................................................. 65

10. Free-Arm Sewing

11. Caring for Your Machine ................................................................................................................... 72

Cleaning the Machine ........................................................................................................................ 72

Removing Covers. Bobbin Case, and Bulb........................................................................................ 73

Performance Checklist ....................................................................................................................... 76

12. Sewing Aids

...................................................................................................................................... 78

..............

................................................................................................................................ 68

................................................................................................................ 33

52

Index................................................................................................................................................................. 80

Page 4

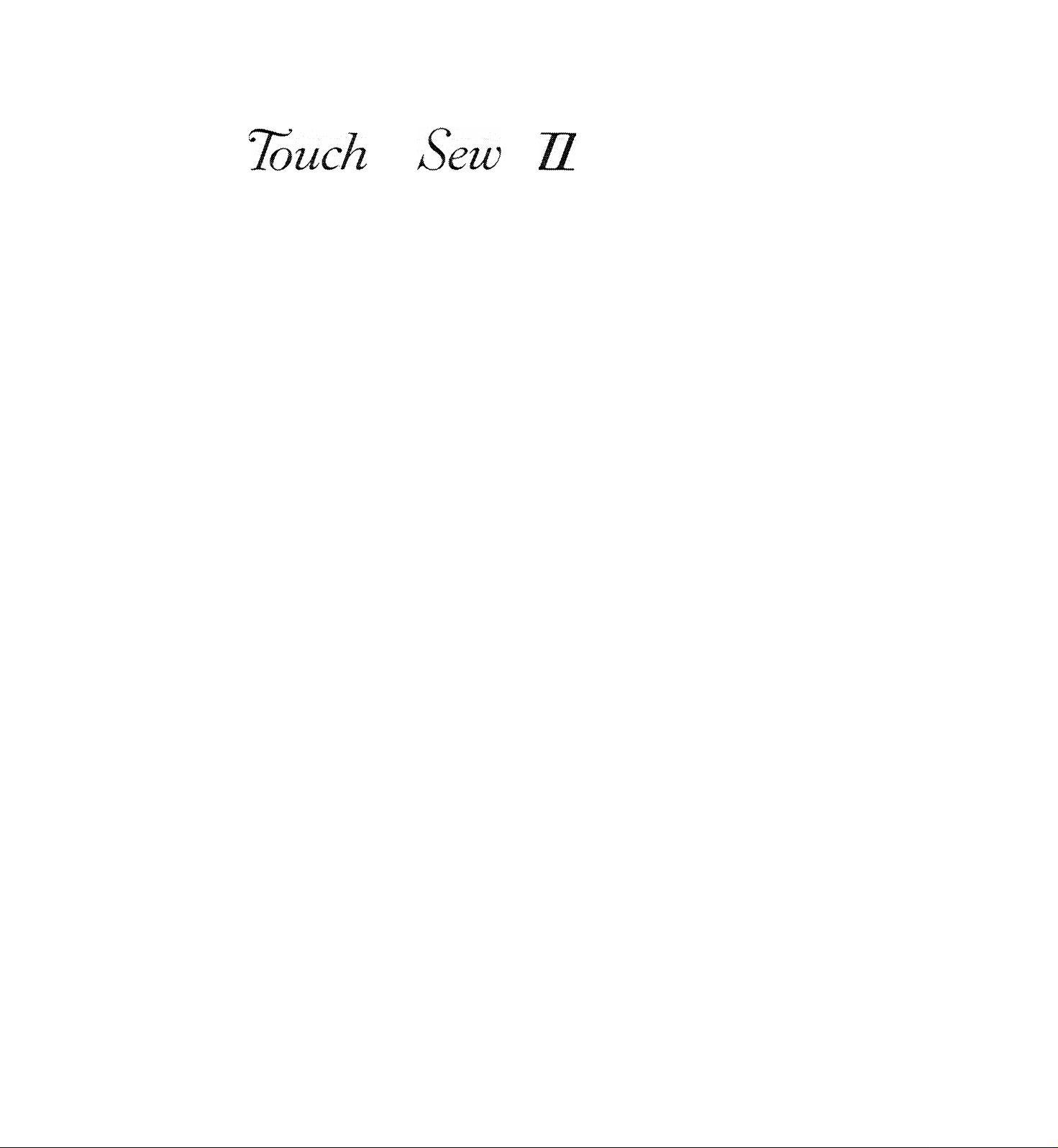

1. GETTING TO KNOW YOUR MACHINE

12, Spool Hol<ler

13. Handwheel

Switch

Dial

16. Stitch Width Dial

Dial

Lever

19* Suttonhoie Dial

20. Sewing Light

Page 5

principal parts and what they do

1. Pattern Selector Dial can be set to pro

duce a straight stitch, a decorative or

practical zig-zag stitch: or speed basting.

2. Tension Dial lets you select just the right

tension for your stitch, thread, and fabric.

The numbers eliminate guesswork in

duplicating settings,

3. Tension Discs, controlled by the tension

dial, regulate the amount of tension on

your needle thread.

4. Self-Threading Take-up Lever controls

flow of needle thread.

5. Pressure Dial regulates presser-foot

pressure on fabric. It has an all-purpose

sewing setting plus settings for extra

light and extra-heavy pressure and for

darning.

6. Face Plate swings open for access to

threading chart and pressure dial.

7. Thread Cutter is built into presser bar for

safety and convenience,

8. Presser Foot holds fabric against feed.

9. Soft-Touch Feed moves fabric under

presser foot. Soft surface does not injure

fabric, even the most delicate.

10. Needle Plate, secured by magnets, lifts

out for removal. Guidelines on right and

left sides of plate help you keep seams

straight.

11. Slide Plate opens easily, lets you see

bobbin. Releases bobbin push button

from winding to sewing position when

closed. Seam guidelines (extended from

needle plate) have cross lines to help you

turn square corners.

12. Friction-Free Spool Holder with horizon

tal pin holds spools of various sizes:

holder lets thread unwind without tug or

drag. The spool does not turn.

13. Hand Wheel controls movement of takeup lever and needle. Always turn it toward

you.

14. Power and Light Switch turns on

machine and sewing light simul

taneously. FAST and SLOW speed range

settings let you choose the best sewing

speed for your work.

15. Needle Position Dial places needle in

either L (left), A (center) or R (right)

stitching position.

16. Stitch Width Dial controls the width of

zig-zag stitching and positions the nee

dle for bobbin winding and straight

stitching.

17. Stitch Control Dial allows for a variety of

stitch lengths, including FINE for zig-zag

satin stitching. Has special settings for

buttonholing and Flexi-Stitch patterns.

18. Reverse-Stitch Lever instantly reverses

stitching direction at the touch of your

finger.

19. Buttonhole Diai controls steps in sewing

round-end buttonholes. Dial must be in

OFF position when not in use,

20. Built-in Sewing Light illuminates sewing

area. Pull-down bracket makes it easy to

replace bulb.

21. Hinged Plate converts machine for free

arm sewing.

22. Needle Clamp is designed to make nee

dles self-setting and eliminate the

possibility of inserting needle back

wards.

23. Presser Foot Lifter, at back of machine,

allows you to raise and lower presser

foot. Extra-high lift position permits easy

placement of bulky fabrics.

24. Transparent Bobbin shows thread sup

ply. Two halves can be unscrewed to

гетюуе unwanted thread.

25. Bobbin Latch holds bobbin in place. Flips

up at the touch of your finger for easy

bobbin removal.

26. Bobbin Push Button allows you to switch

from sewing to bobbin winding without

rem*oving bobbin.

27. Electrical Connections and Speed Con

troller designed for convenience and

safety.

Page 6

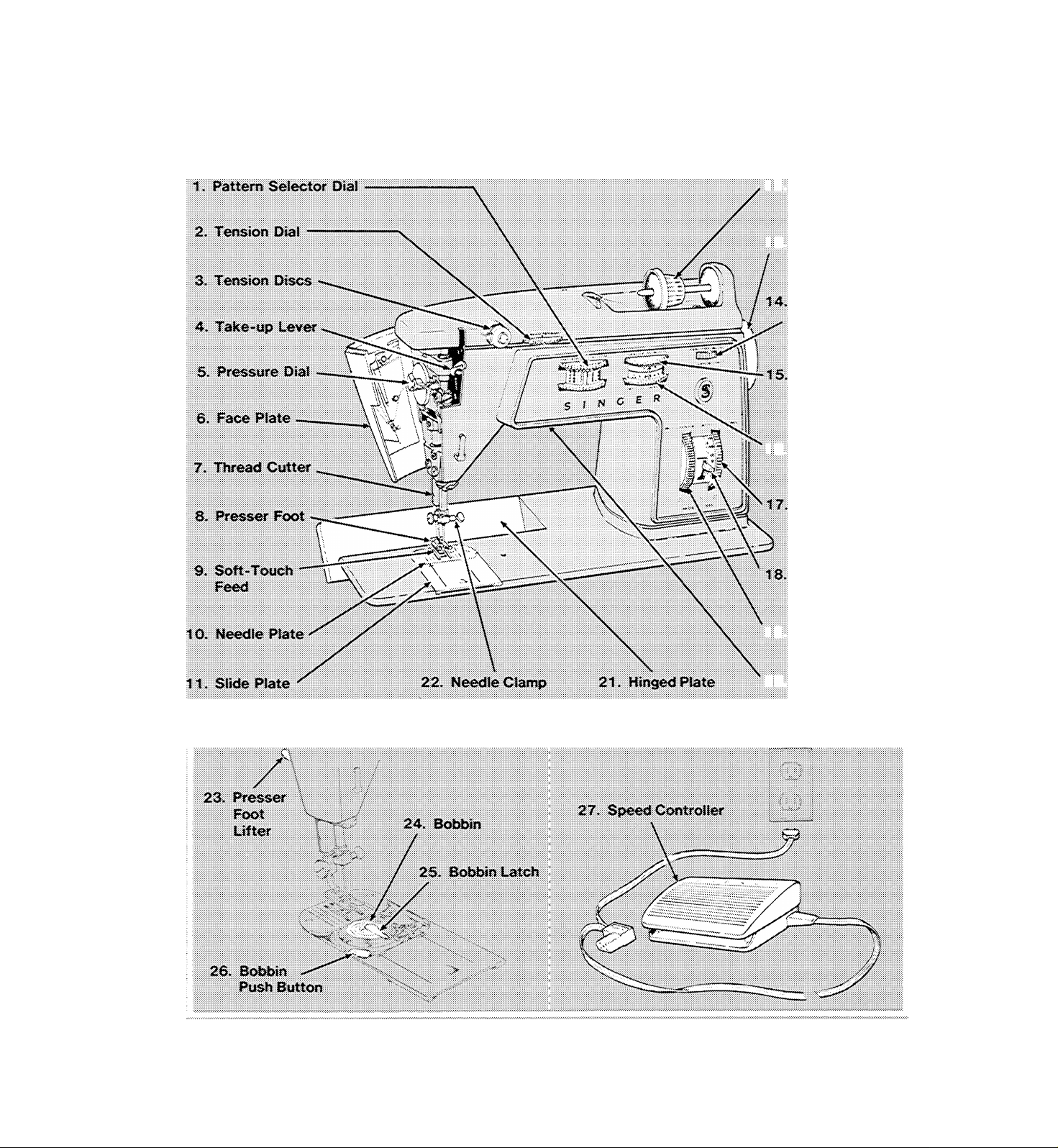

accessories

The accessories that come with your Touch &

Sew sewing machine are designed to help you

do many Kinds of sewing easily and perfectly.

To increase the versatility of your machine,

additional accessories can be purchased at

your Singer store. See page 78.

1. BOBBINS

Transparent Bobbin Seam and Biindstitch

Hem Guide

A

A

Ü

Regular Needle

Bat! Point

(Yellow Band) Needle

r

Twin Needle

• Transparent drop-in bobbin in your

machine.

• Extra transparent drop-in bobbins.

2. SEAM AND BLINDSTITCH HEM GUIDE

• Helps you stitch seams and blindstitch

hems of uniform width.

3. NEEDLES

IMPORTANT: Your SINGER sewing

machine has been designed to obtain best

results with SINGER* needles. You should

follow the recommendations in this in

struction book and on the needle package

for correct style and size of needle for

different types and weights of fabric.

• Style 2020 (15x1) needles, for all-pur

pose sewing.

• Style 2045 ball-point Yellow Band" nee

dles, for sewing synthetic knits and

stretch fabrics.

Vertical

Spool Pin

Small

Spool Holder

Lint Brush

Style 2028 needle,

decorative stitching.

4. VERTICAL SPOOL PIN

• Vertical spool pin for decorative twin-

needle stitching.

5. SMALL SPOOL HOLDER

• For use with small diameter tubes of

thread.

6. LINT BRUSH

• Lint brush for cleaning your sewing

machine.

for twin-needie

Page 7

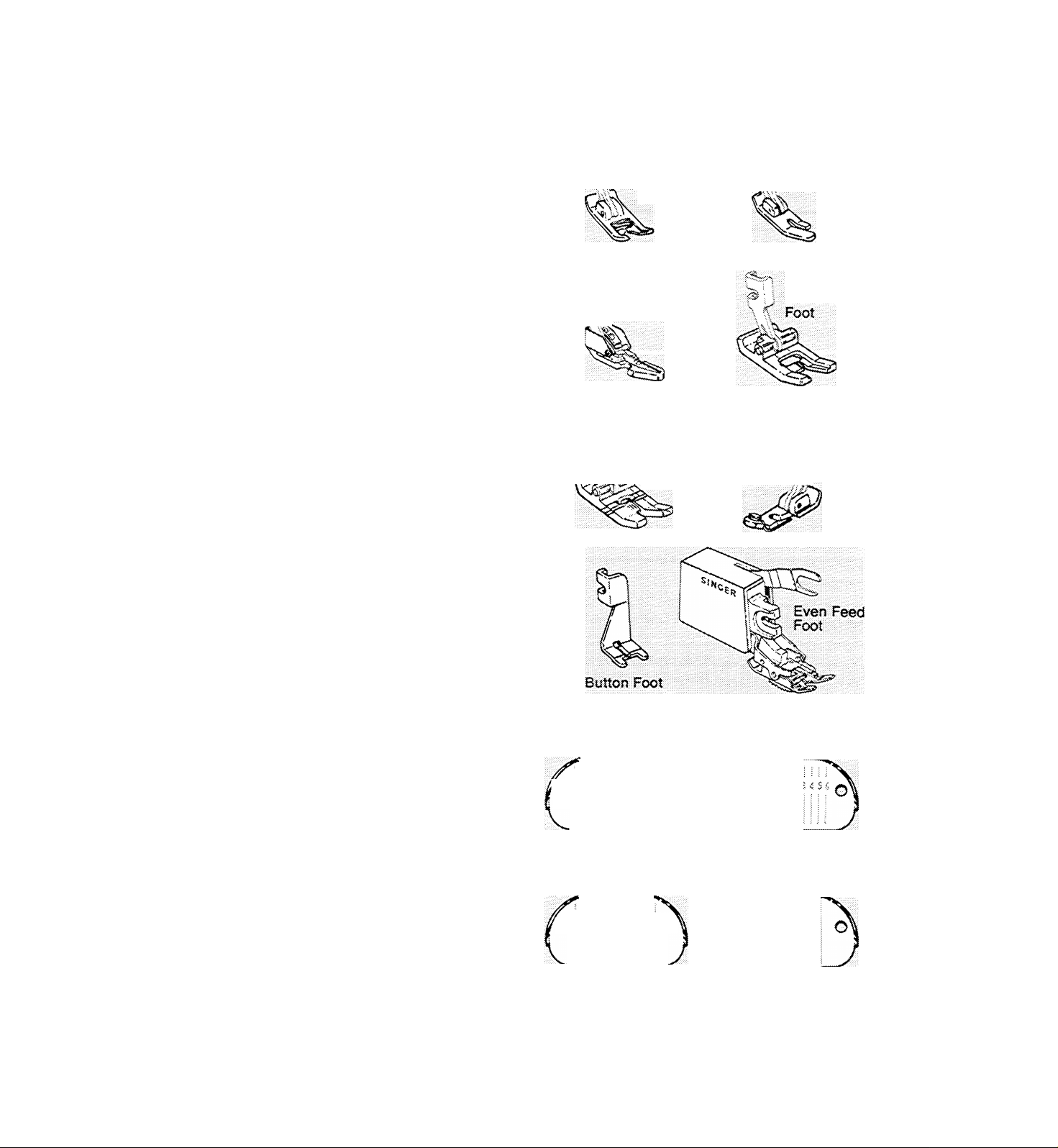

7. PRESSER FEET

• The genera! purpose foot on your

machine.

• Additionai interchangeabie snap-on

presser feet:

Straight stitch foot for close fabric

control

Zipper foot for inserting zippers and

stitching corded seams

Special purpose foot for all kinds of

decorative zig-zag stitching

Buttonhole foot to make round-end

buttonholes

Overedge foot for overedged seams in

stretch fabric

• A one-piece button foot to hold buttons

securely for stitching.

• Even Feed Foot for sewing hard-to-feed

pile, stretch, and bonded fabrics. Also

excellent for matching plaids and stripes

and for topstitching. (Cannot be used for

speed basting.)

Fresser Feet

% •: I;

. \\ General Purpose

Foot

>

P p Zipper Foot

; Buttonhole Foot

>, Straight

Stitch

Special

Purpose

ii

Overedge Foot // /

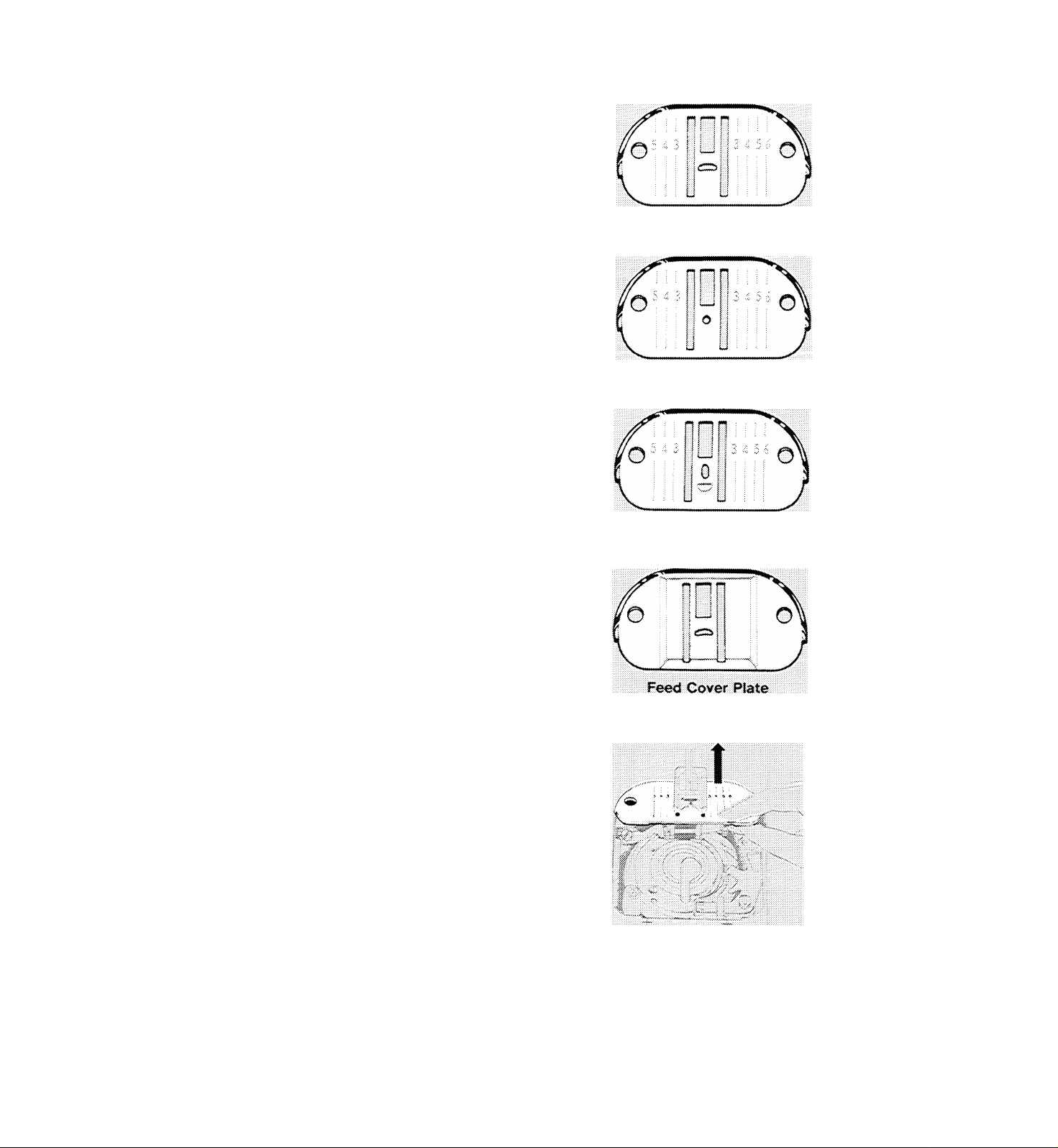

8. MEEDLE PLATES

• The general purpose needle plate in

place on your machine.

• The straight stitch needle plate for use

with the st.--aight stitch foot.

• The chainstitch needle plate for single

thread chainstitching.

• The feed-cover plate for button sewing

and free-motion work.

9. CHAINSTITCH FITTINGS

• One set of three fittings.

Thread Guide

6

Bobbin Case Cover

Needle Plate

Heedle Plates

General Purpose

Needle Plate

Straight Stitch

Needle Plate

O

ChamstiicN Fittings

Chainstitch

Needle Piate

Feed Cover

Plate

Page 8

2. GETTliyC READY TO SEW

preliminary steps

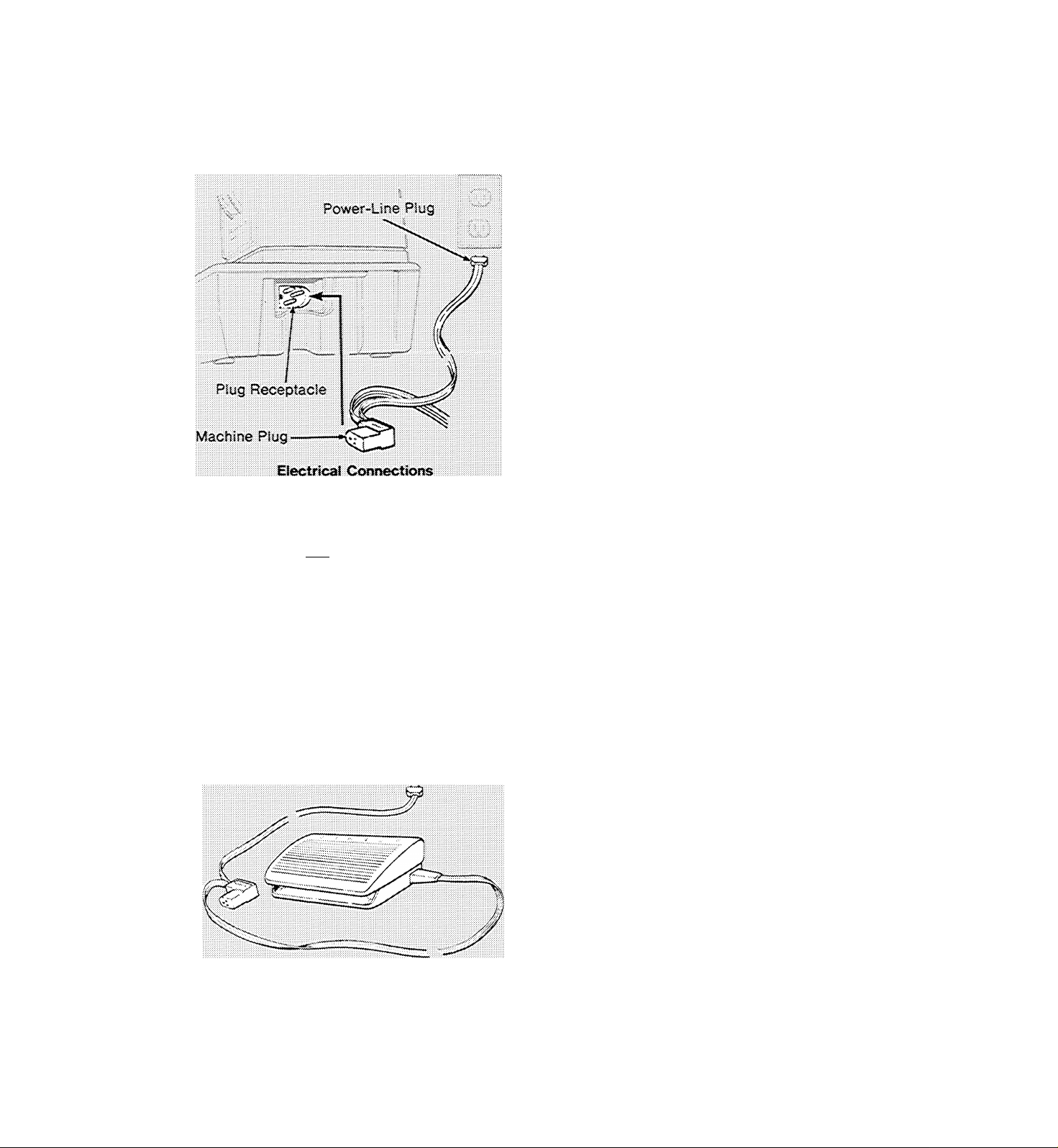

1. CONNECTING MACHINE

Before plugging in your machine, be sure that

the voltage and number of cycles indicated at

the right end of the machine or inside face

plate conform to your electrical power supply.

Push the machine plug into the machine recep

tacle. Then connect the power-line plug to

your electrical outlet

2. OPERATING MACHINE AND

CONTROLLER

To turn on both the machine and sewing light

and set speed range, slide the power and light

switch to the selected range.

F>Sv3T OFF' 3L.OW

^ i': ' T'^"rT?TTT

T¥^’T

F>OW3P^ e< L^IOMT

• The FAST setting allows for full speed ca

pacity of the machine. It is best for long,

straight seams, easy-to-handle fabrics, and

general sewing where a variety of speeds

are needed.

Power and Light Switch

Speed Controller

• The SLOW setting allows for maximum con

trol at lower sewing speeds. Use this setting

for special jobs such as button sewing, but

tonhole making, and where intricate con

struction details require close control.

CAUTION: We recommend that you turn off

the power and light switch before changing

needles, presser feet or needle plates and when

leaving the machine unattended. This elimi

nates the possibility of starting the machine by

accidentally pressing the speed controller.

To run the machine, press the speed con

troller. The harder you press, the faster the

machine will sew within the selected speed

range.

Very light pressure on the controller will oper

ate the machine very slowly, enabling you to

stop the machine with the needle In any

desired position, up or down.

Page 9

choosing needle and thread

The needle and thread you choose will depend

upon the fabric being stitched. The table below is a practical guide to needle and thread

FABRIC, THREAD AND NEEDLE TABLE t

selection. Refer to it before starting a sewing

project Be sure to use the same size and type

of thread in both needle and bobbin.

FABRIC WEIGHT AND TYPE

DELICATE — tulle, chiffon, fine lace, or

ganza, chiffon velvet

LIGHTWEIGHT - batiste, organdy, voile,

taffeta, crepe, chiffon velvet, plastic film,

satin, surah, peau de soie, shantung,

brocade

MEDIU.Vt WEIGHT - gingham, seersucker,

madras, percale, piqué, linen, chintz, faille.

fine corduroy, velveteen, suitings, vinyl,

terry doth, chains, twill

MEDIUIVI HEAVY — gabardine, tv/eed, sail

cloth. duck, denim, coatings, drapery

fabrics, vinyl, deep“pile fabrics, corduroy,

bonded fabric

HEAVY — overcoatings, upholstery fabrics,

canvas

KNITS, WOVEN STRETCH AND ELASTIC--

double knits, bonded knits, spandex, ny

lon tricot ciré tricot, jersey, panné velvet,

stretch terry

LEATHER — suede, kidskin. calf, capeskin.

buckskin, cabreita. patent, cobra, lined

leathers, simulated leathers

VINYLS (KNIT BACK)-suede, imitation

reptile, crinkle patent, patent, embossed

and printed vinyls

WOVEN FABRICS (ALL WEIGHTS) - dec

orative straight-stitch topstitchlng

LIGHT AND MEDIUM WEIGHTS (WOVEN) -

decorative twin-needle stitching

tDoes not apply to chalnstitching.

ttSize 9 needle recommended for sewing only. For

tttUse with mercerized cotton, “A” silk, or polyester

THREAD

Fine polyester, nylon,

or cotton thread

Cotton-wrapped

polyester (FINE)

100% polyester

SO mercerized cotton

’^A" nylon

‘‘A’’silk

Cotton-wrapped polyester

100% polyester

50 mercerized cotton

60 cotton

“A” silk

Cotton-wrapped polyester

100% polyester

Heavy-duty

mercerized cotton

40 to 60 cotton

Cotton-wrapped polyester

Heavy-duty

mercerized cotton

40 cotton

Cotton-wrapped polyester

100% polyester

'‘A'" nylon

50 mercerized cotton

‘‘A’' silk

Cotton-wrapped polyester

100% polyester

50 mercerized cotton

nylon

“A" silk

Cotton-wrapped polyester

100% polyester

50 mercerized cotton

nylon

Yellow Band

Yellow Band

^'A^’silk

-D'’silkttt

(Buttonhole twist)

Cotton-wrapped polyester

100% polyester

50 mercerized cotton

bobbin winding use larger size needle,

thread in bobbin.

NEEDLES

TYPE SIZE

Style 2020

(15x1)

Style 2020

,15x1)

Style 2020

(15x1)

Style 2020

(15x1)

Style 2020

(15x1)

Style 2045

Ball Polrit

Style 2032

(15x2)

Style 2045

Sail Point

Style 2020

(15x1)

Style 202$

(twin)

9tt

11

18

14

11

14

16

14

16

16

14

Page 10

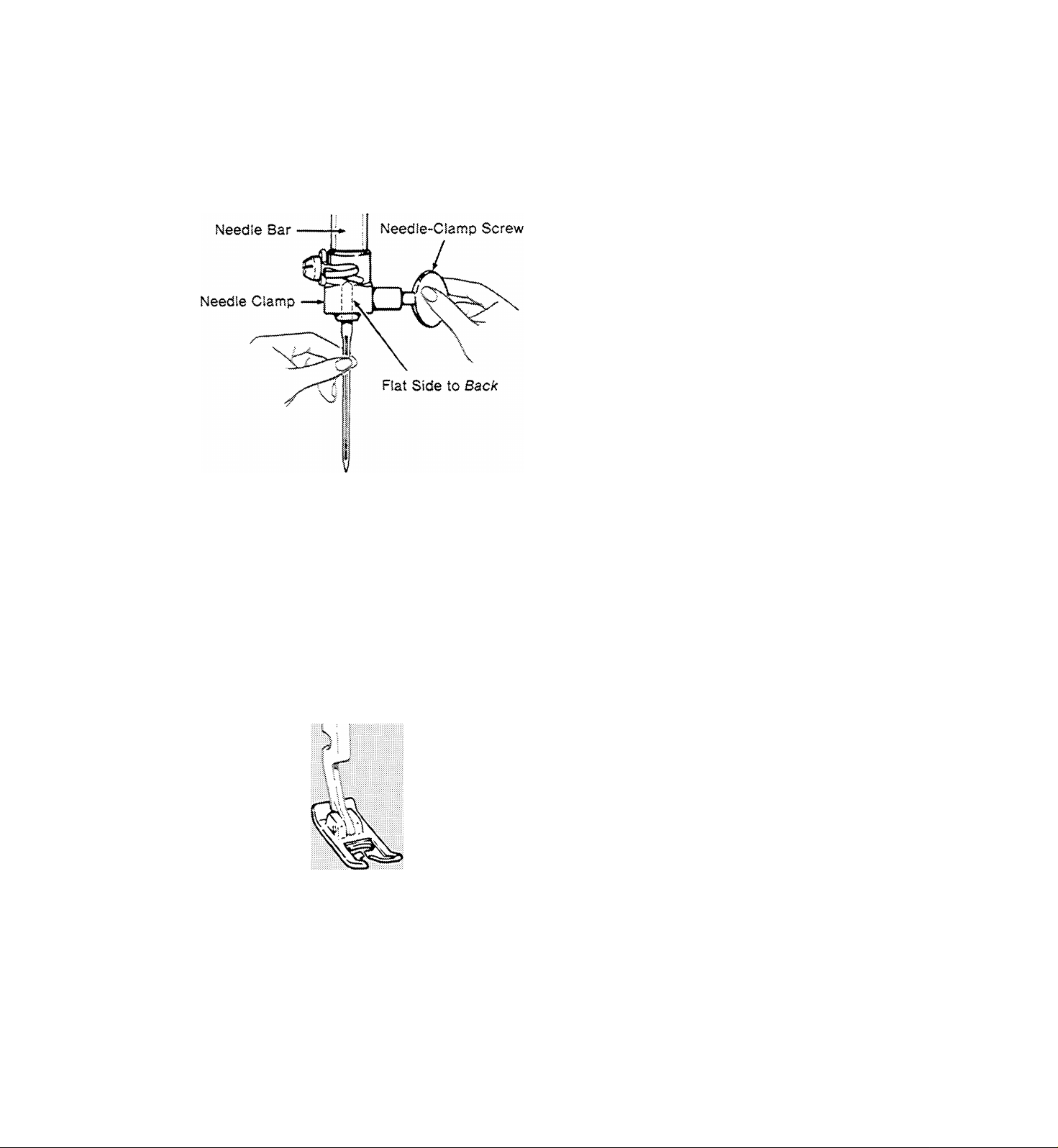

Changing the Needle

NEEDLES

The needle you use should be straight to en

sure perfect stitch formation and needle

penetration through the fabric. The needle

should also be fine enough to prevent the

fabric from being marred with large

punctures, yet heavy enough to pierce the

fabric without being bent or deflected.

Remember, too, that the eye of the needle

must be large enough for the thread to pass

through freely; too fine a needle will cause the

thread to fray.

For best results use a SINGER* needle.

Changing the Needle

1. Raise needle bar to its highest point,

loosen needle-clamp screw, and remove

needle.

2. insert new needle in clamp, with the flat

side of the needle to the back; push it up as

far as it will go.

General Purpose Foot

3. Tighten needle-clamp screw.

choosing accessories

The type of sewing you plan to do will deter

mine which presser foot and needle plate you

should use.

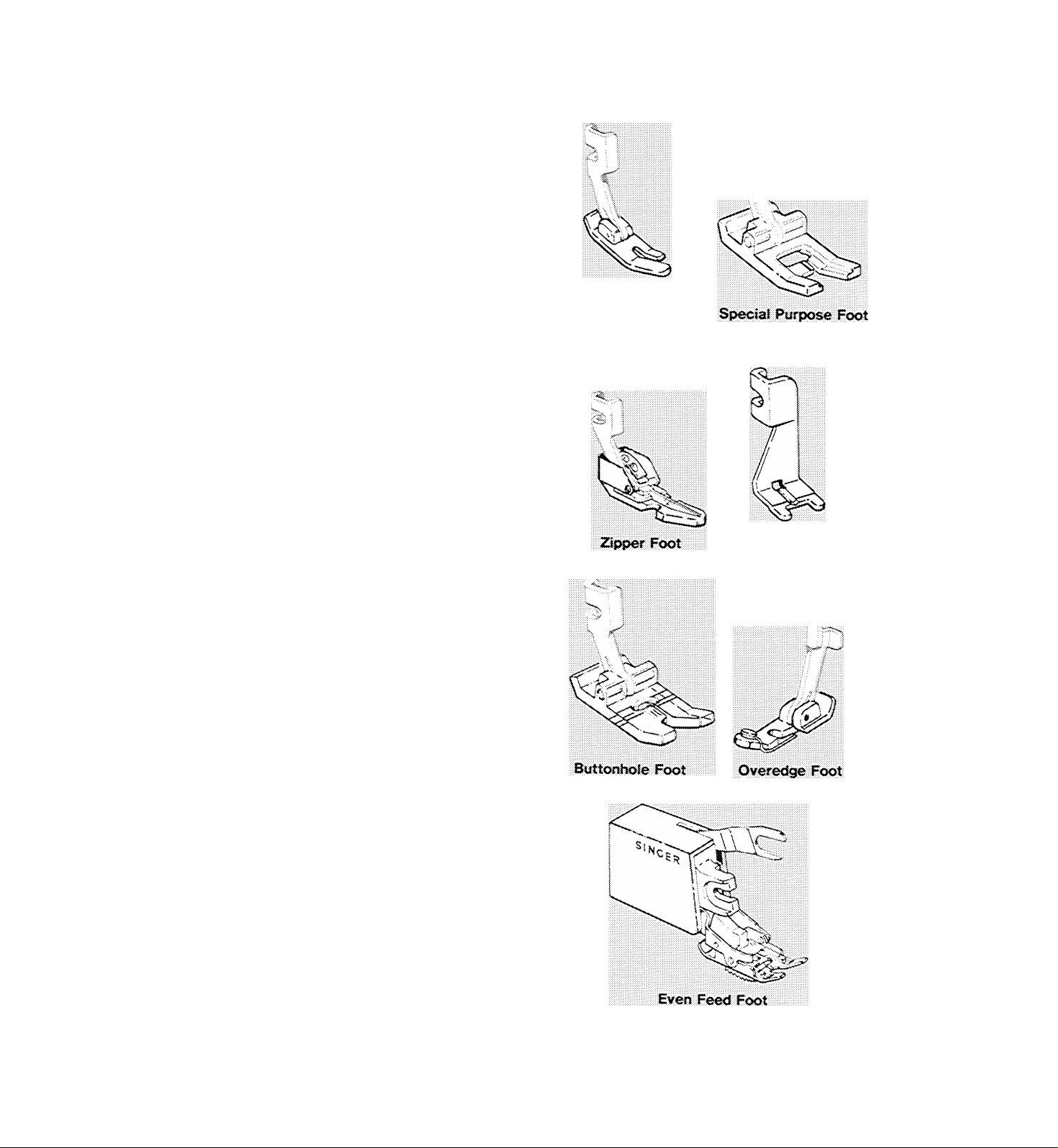

PRESSER FEET

Three Most Used Presser Feet

General purpose foot is used with the general

purpose needle plate for all utility sewing and

some decorative zig-zag stitching. These

general purpose accessories ntust be used

together when alternating between straight

and zig-zag stitching.

8

Page 11

straight stitch foot Is used with the straight

stitch needle plate when your fabric or sewing

procedure requires close control Use for:

• Precision straight stitching of curved and

scalloped edges, top stitching, edge stitch

ing. etc.

• Straight stitching delicate or spongy fabrics.

Special purpose foot is used with the general

purpose needle plate for all kinds of decora

tive zig-zag stitching. The raised center sec

tion of the foot allows closely spaced zig-zag

stitching to feed freely while the toe holds

fabric firmly for straight line feeding. Use for:

• Ornamental stitching, bar-tack buttonholes.

Flexi-Stitch pattern stitching, applique, satin

stitching,

Presser Feet for Special Sewing Needs

Zipper foot is used to place stitching close to

a raised edge. Thus, it is useful for corded

seams (page 48) as well as zipper insertion

(page 47). It can be fitted to the presser foot

shank for use on either the right or left side of

the needle.

Straight Stitch Foot

Button Foot

Sutton foot holds any two-hole or four-hole

button securely for stitching. The groove in

the foot can be used to hold a needle, over

which a thread shank can be formed.

Buttonhole foot. This snap-on transparent

foot is used to make two-step, round-end but

tonholes in fabrics of light to medium weight.

The guidelines on the sole plate simplify but

tonhole placement and make it easy to gauge

buttonhole length.

Overedge foot, used with the overedge

stretch pattern (see page 54) enables you to

produce flexible overedge seams and edge

finishes. It is particularly useful in construc

tion of garments made of knit, stretch, and

elastic fabric.

Even Feed foot improves the feeding of

fabrics that tend to stick, stretch, or slip while

being sewn. The foot feeds top and bottom

fabric layers together so that seams start

even, feed evenly, and end even.

Page 12

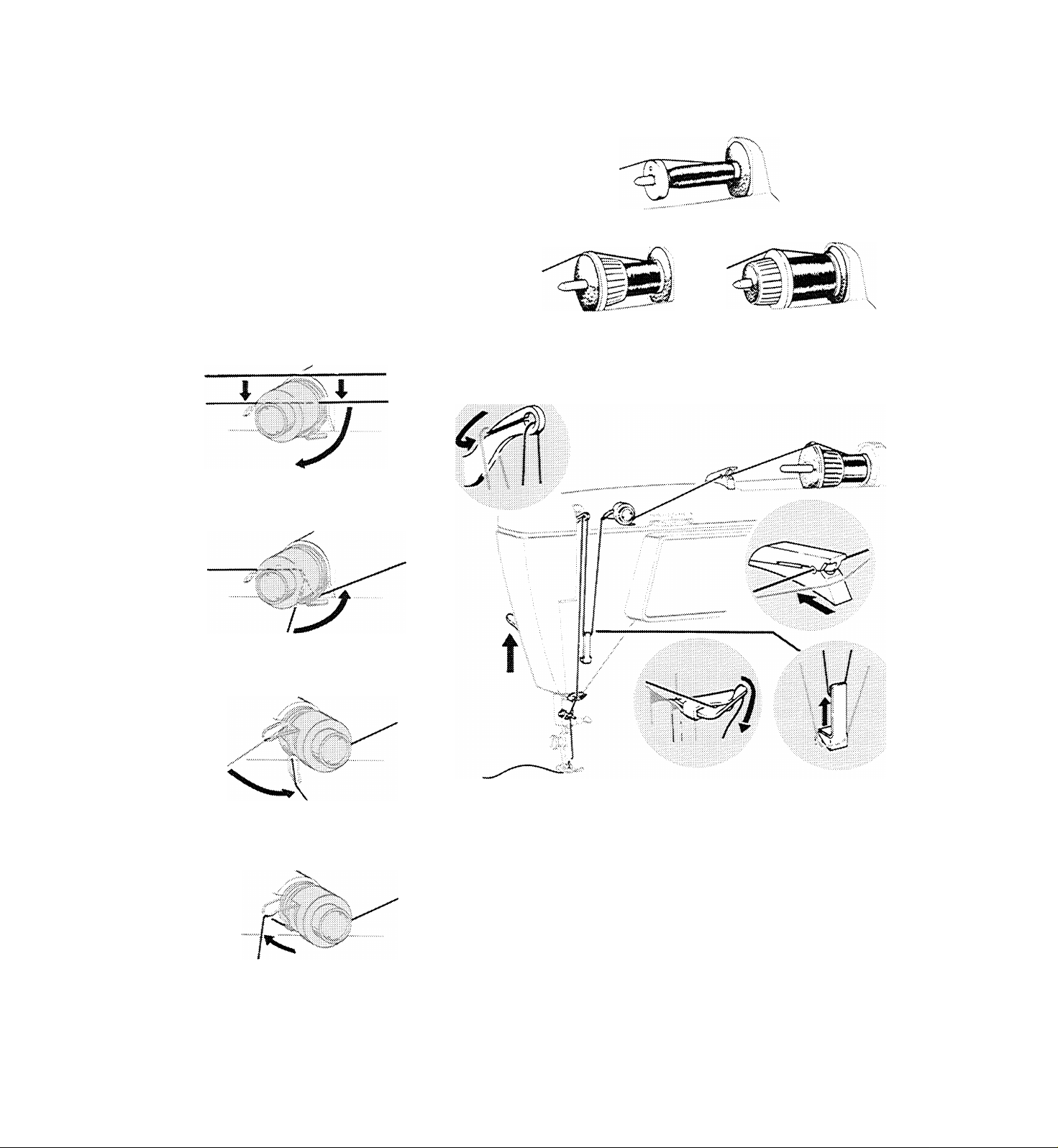

Changing Snap^on Presser Feet

press Toe Upward

for Rerr.ovai

of New Presser Foot

under Shank

■ \, Lower Presser Bar and

Press Down on Screw

; to Secure New Foot

CHANGING PRESSER FEET

Snap-on Presser Feet

These presser feet snap on and off a common

shank.

1. Raise needle to its highest position and

raise the presser foot.

2. Press toe of presser foot upward (as far as

it will go) and then snap down to remove.

3. Center the new presser foot under the

shank and lower the presser bar so that the

shank fits over the presser foot pin.

4. Press down on presser foot screw until foot

snaps into place.

To remove and replace shank of snap-on

presser feet, follow instructions below for

one-piece presser feet.

Changing One-Piece Presser Foot

Movable Arm.

One-Piece Presser Feet

1. Raise needle to its highest position and

raise the presser foot.

2. Loosen presser foot screw and remove the

foot.

3. Hook new foot around the presser bar and

tighten presser foot screw.

NOTE: When changing one-piece presser

feet, you may insert the edge of a coin in the

slot to tighten presser foot securely.

The Even Feed Foot

• Guide Even Feed foot into position from

back of machine, making sure the movable

arm straddles the needle clamp. Tighten

presser-foot screw securely with a coin.

Needle

Clamp

10

Changing Even Feed Foot

Page 13

NEEDLE PLATES

General purpose needle plate, in place in

your machine, can be used with all presser

feet.

Straight stitch needle plate for use with the

straight stitch presser foot.

Chainstitch needle plate is one of three ac

cessories that must be used together for

ohainstitching. For instructions, refer to

“Chainstitching” beginning on page 35.

General Purpose Needle Plate

Feed cover plate for use when fabric feeding

is not desired.

CHANGING NEEDLE PLATE

NOTE: Remove bobbin if it contains thread in

order to prevent thread being caught when

needle plate is replaced.

1. Raise needle to its highest point and raise

presser foot.

2. Open slide plate. Remove needle plate by

placing thumb under plate and lifting it up

and out.

Straight Stitch Needle Plate

Chainstitch Needle Plate

3. Position new needle plate over the two pins

and release. (Needle plate is drawn into

position by magnets.)

4. Close slide plate.

Changing Needle Plate

11

Page 14

threading the machine

Place spool or tube of thread on horizontal

spool pin. If spool has a retaining slit, the slit

should be placed against the spool cushion to

the right Select correct spool holder according

to the type and diameter of spool being used.

The diameter of the end of the spool holder

should always be larger than that of the spool

itself. Press holder firmly against spool to pre

vent it from turning.

With two hands, slip thread

horizontally between ten

sion discs from the top.

ÍO Hold Small Tubes

To Hold Small Spools To Hold Large Spools

THREADIMG THE NEEDLE

With right hand, lead thread

under thread guide on right

side . . .

1

Turn hand wheel to raise take-up lever to its highest posi

... and, with left hand, lead

thread over spring and un

der guide on left side.

tion, and raise presser foot to release the tension discs.

2, Lead thread through all points as shown, making sure to:

Use both hands and snap thread horizontally into thread

guide-post, making sure it enters eyelet fine thread

should be doubled for added strength.

Thread tension discs as illustrated at left.

Thread take-up lever from back to front, guiding thread

Allow spring to return to its

normal up position and con

tinue threading the machine.

down over top of lever and then up into eyelet.

Thread needle from front to back, drawing about four in

ches (10cm) of thread through eye of needle.

Note: Dotted lines in illustrations represent thread path hidden by machine.

12

Page 15

WINDING THE BOBBIN

Push-button bobbin winding wiO make your

sewing go faster than ever before — whether

you are using a lot of one kind of thread or

small quantities of blfierent threads.

You will find a bobbin in place under the slide

plate of your machine. To open slide plate,

simply slide it gently toward you. If the bobbin

runs out of thread while you are sewing, you

can rewind it without removing it from the

machine-

Bobbin

preparation for Winding

l4 R I

r 1 Ti-i

Preparation Steps

Make sure buttonhole dial is in OFF position.

1. Use genera! purpose, special purpose, or

straight stitch presser foot.

2. Raise presser foot to release tension on

thread, and raise the needie to its highest

position. (Make sure your needle is a size

11 or larger).

3. Set needle position and stitch width dials

at straight stitch setting indicated by

A symbols.

4. Open slide piate and make sure bobbin is

empty. For removal of bobbin and thread,

see page 16.

13

Page 16

Wmdirsg Steps

1. Press bobbin push button to the left to

engage it in winding position.

2. Wrap thread around pressar foot screw,

and hold end of thread firmly.

3. Start the machine.

* Run the machine at a moderate speed.

♦ Pull thread end away after a few coils

have been wound.

• Keep your eye on the bobbin as it fills. Do

not allow thread to wind beyond the out

side FULL ring.

4. Close slide plate to release push button to

sewing position.

Turn to the next page for instructions on start

ing to sew.

Winding Steps

14

Step 1

Do Not Allow

Page 17

how to start sewing

How you begin to sew after winding a bobbin

depends on whether your stitching is to start

at or away from the edge of the fabric.

TO START AT FABRIC EDGE

♦ Position needle in very edge of fabric by

pressing speed controller lightly or turning

the hand wheel

• Lower the presser foot and stitch. The con

tinuous thread, leading from the needle to

the bobbin, will 'lock” over the fabric edge.

TO START AWAY FROM FABRIC EDGE

• Puli thread back under presser foot and cut.

• Position needle in fabric where desired and

stitch.

NOTE: Should the bobbin run out of thread

after you have begun a line of stitching, re

move the fabric, rewind the bobbin, and follow

the two immediately preceding steps.

Starting at Fabric Edge

with a Continuous Thread

Starting Away from Fabric Edge

15

Page 18

Removing Bobbin

changing the bobbin

REMOVING THE BOBBIN

Raise needle to its highest position.

1. Open slide plate; leave bobbin push button

in sewing position,

2. Raise bobbin latch by inserting fingernail

under end of latch at center of bobbin.

Open Slide Plate and Raise Latch

/■^ f. V ' V -X

/ / /■ ;■' ’Vf^--:-. Ч Ч

/ / / ,/

Lift Out Bobbin

Replacing Empty Bobbin

.........

.

Л

X .

V ■ ■

> У

7 ^

/

/

■:. < /

/ /

Slip Bobbin into Case

V —

.-г'-Л,

.

'' '

3. Insert fingernail under rim of bobbin im

mediately to right of latch and remove the

bobbin.

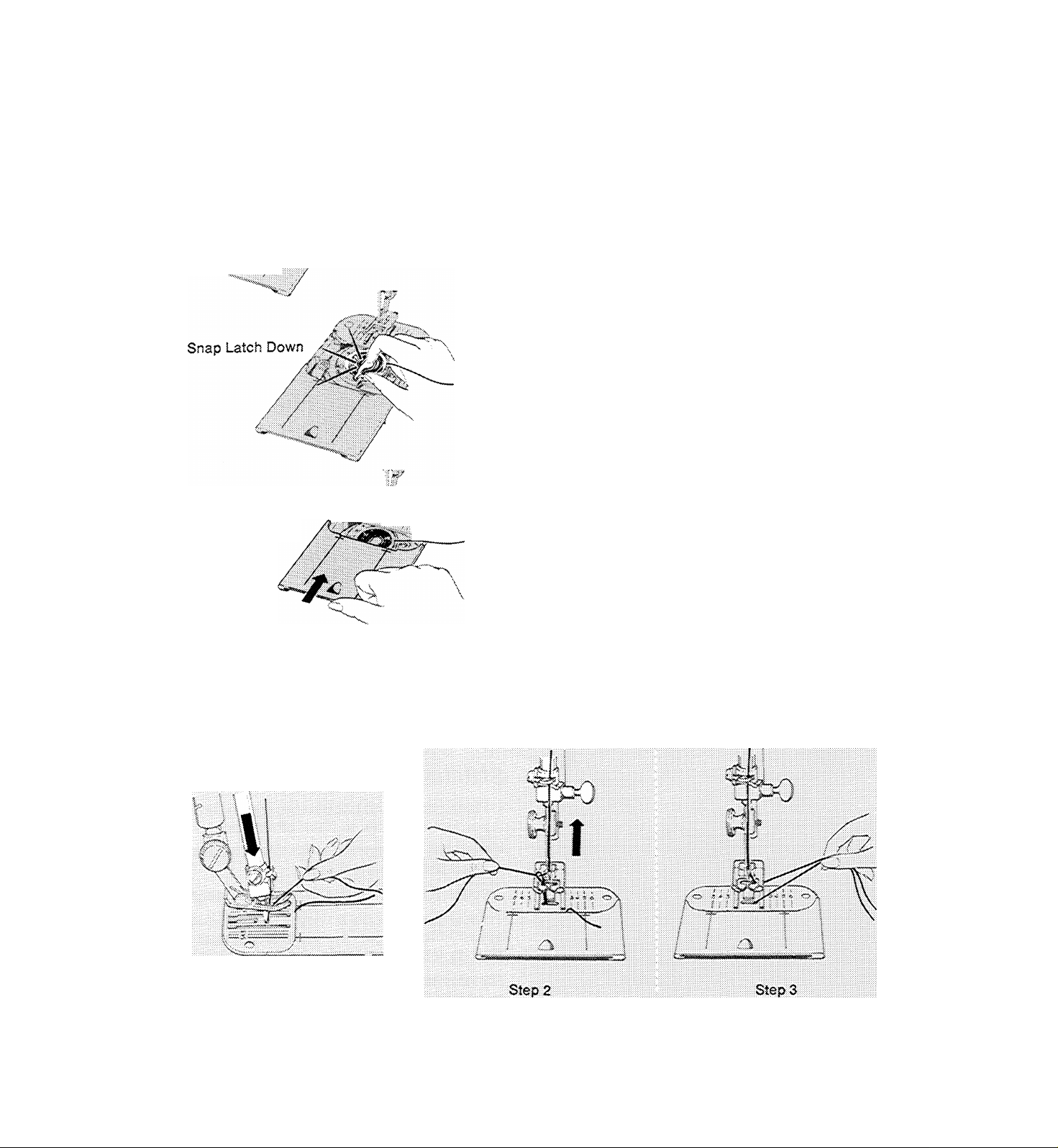

REPLACING AN EMPTY BOBBIN

1. Make sure bobbin halves are securely tight

ened.

2. With latch raised, slip bobbin (wide side

up) into bobbin case. Then snap latch down

to secure bobbin.

3. Leave the slide plate open until you have

finished winding,

REMOVING THREAD FROM BOBBIN

■\

If there is not much thread left on the bobbin,

you do not need to remove bobbin from ma

chine— simply pull the thread end through

the needle plate.

If there is a lot of thread left and you do not

wish to reserve it by setting aside the bobbin

for future use, remove the bobbin, unscrew the

two halves, and remove all the thread at once.

Then screw the two halves together, tighten

ing securely.

16

/ /'

/

■ <, /

f/ 'x..^;-^:r v-.

\

/

Snap Latch Down

/ \...

Removing Thread from Bobbin

Page 19

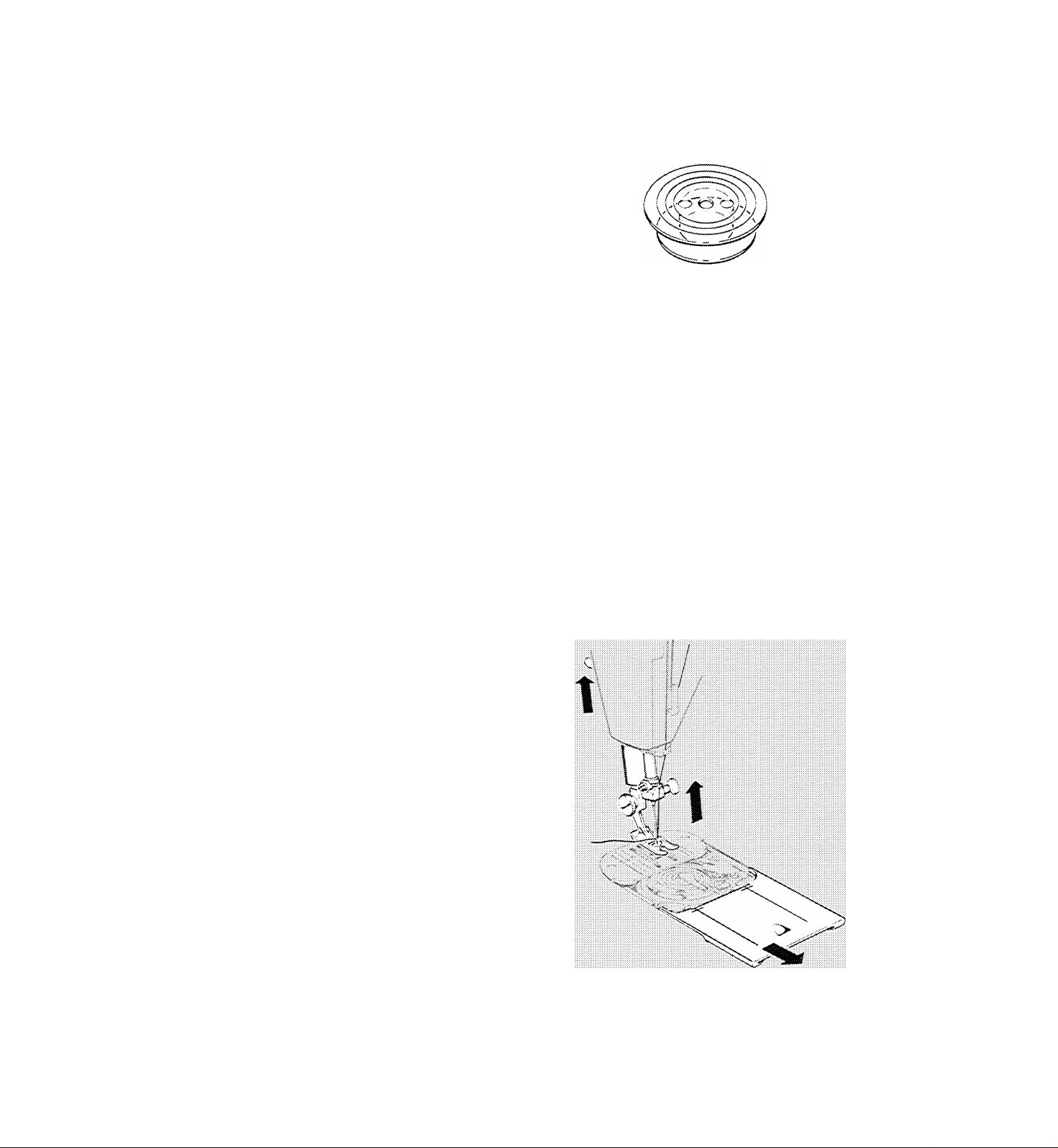

REPLACING A WOUND BOBBIN

0':4K7r>

/f

VVi

/

^ / / Insert Bobbin

Close Slide Plate

Raise needle to Its highest position.

1 Open slide plate; leave bobbin push button

in sewing position.

/

2. Draw about four inches {10cm) of thread

from bobbin and place bobbin in case with

thread leading off to right side of latch.

Snap latch down to secure bobbin.

3. Close slide plate, allowing the thread to

enter the slot in the slide plate. Then raise

the bobbin thread as instructed below.

RAISING THE BOBBIN THREAD

1. Hold needle thread lightly with left hand

/■"o

and turn hand wheel slowly toward you so

that needle enters needle plate,

2. Continue turning hand wheel until needle

rises and brings up bobbin thread in a loop.

Replacing a Wound Bobbin

Stepi

3. Undo the loop and place both threads under

the presser foot, laying them diagonally to

the right Position needle in fabric where

desired, lower the presser foot and stitch.

Raising the Bobbin Thread

17

Page 20

3. STRAIGHT STITCHING

Pattern: Straight Stitch

Needie Position: A

Stitch Width: A

Stitch Controi; To suit fabric

1 :... 4. ; A

Dials Set for Straight Stitching

Straight Stitch Needle Plate or

General Purpose Needle Plate

Straight Stitch Foot or

General Purpose Foot

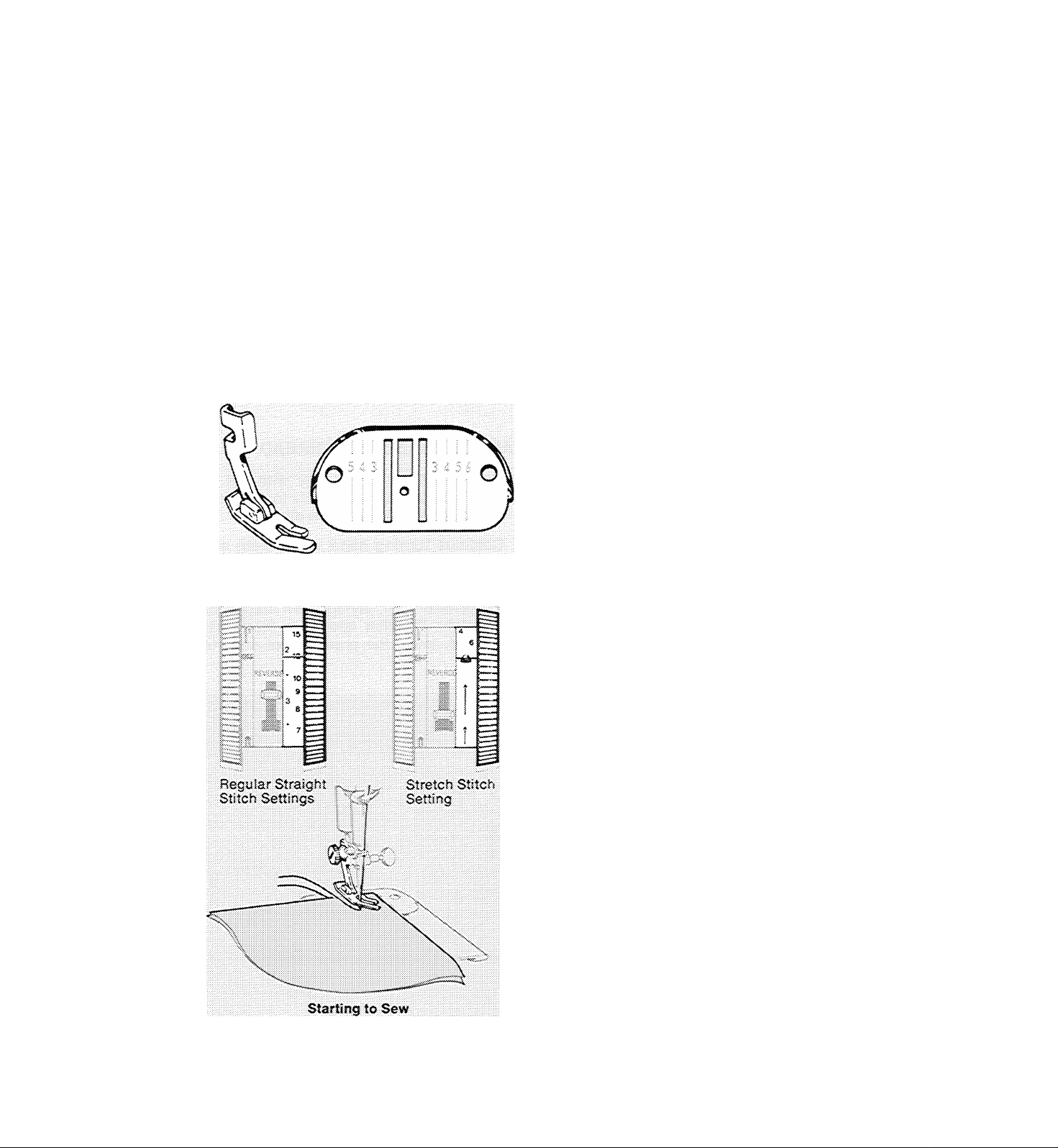

preparation

Before you set the dials for straight stitching,

turn the handwheel toward you untiltheneedle

is above the needle plate.

Straight Stitch Foot and Needle Plate

SETTING THE IVIACHINE

1. Set pattern dial selector at .

2. Move needle position dial to A .

3. Set stitch width dial on A .

4. Set stitch control for desired stitch length.

For regular straight stitching, turn dial to

a numbered setting; for straight stretch

stitching, turn dial to

^ setting.

!

CHOOSING ACCESSORIES

Best results will be obtained if you use the

straight stitch foot and needle plate. However,

the general purpose foot and needle plate

may also be used.

starting to sew

* Place needle and bobbin threads under pres-

ser foot and draw to back of machine.

• Position the needle in the fabric where de

sired for stitching start.

18

♦ Lower the presser foot and start the machine.

To sew perfectly on a wide variety of fabrics

adjust stitch length, pressure and thread ten

sion as instructed on the following pages.

For information on straight stretch stitching, turn

to page 52.

Page 21

adjusting for your fabric

SETTING STITCH LENGTH

The stitch-controi dial regulates the length of

both straight and zig-zag stitches. The num

bers 6 to 20 represent the number of straight

stitches per inch and the numbers 1 to 4

represent stitch length in milhnneters.

Generally, shorter stitches are best for light

weight fabric; longer ones for heavy fabric.

Curved seams, bias-cut seams and scallops

require short straight stitches for elasticity

and smooth contours. Bound buttonholes

should be sewn with a short stitch for

durability and strength.

The FINE area is used for the adjustment of

zig-zag satin stitching (page 28} and speed

basting {page 33}.

The ^ setting is used for straight-stretch

stitching and Flexi-Stitch patterns. For infor

mation on Flexi-Stitch patterns and straightstretch stitching, see pages 25 and 52.

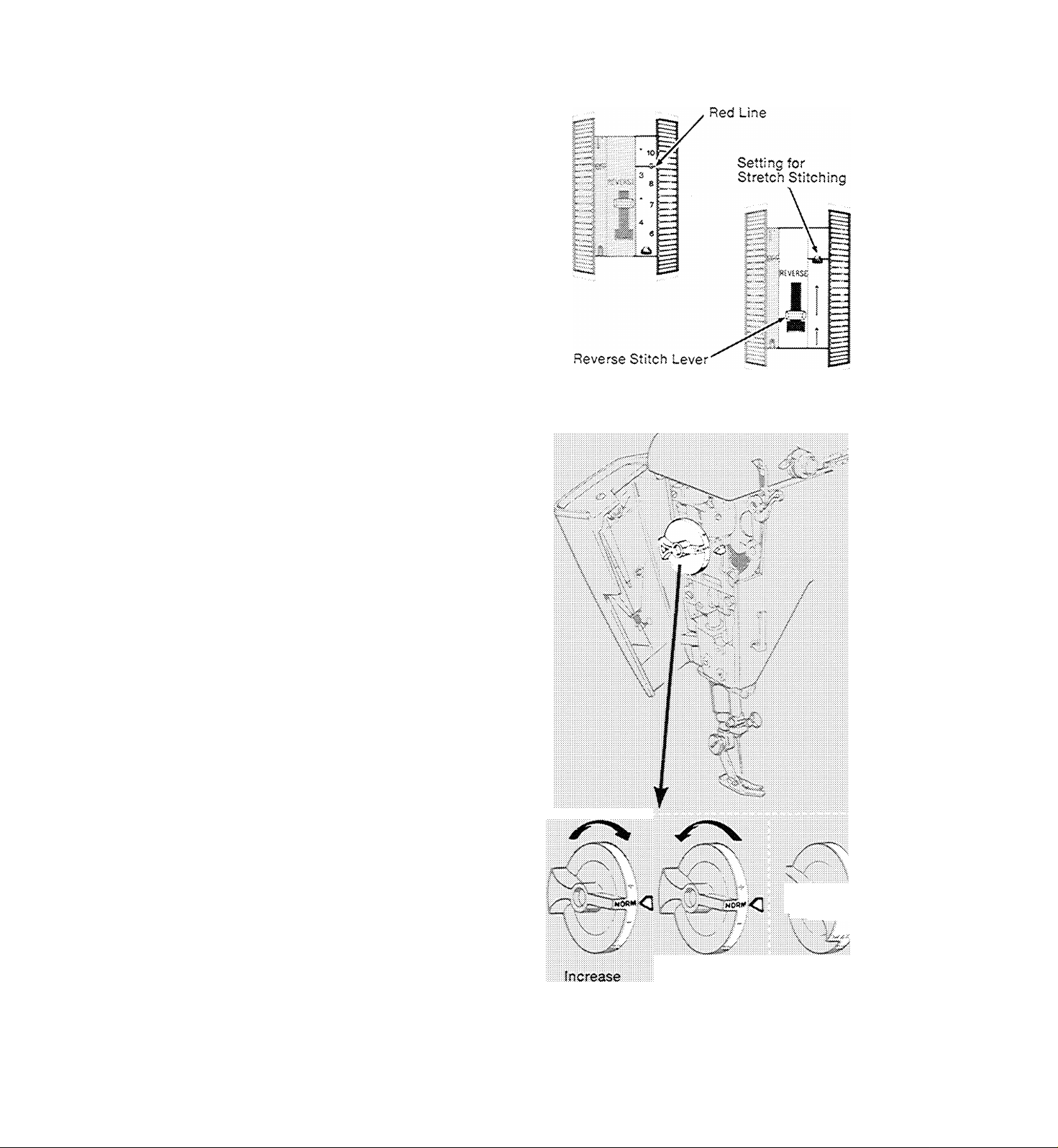

Stitch Control Dial

• To set stitch control, turn dial until setting

desired is under the red line.

For reverse stitching, simply press reversestitch lever all the way down and hold in place.

Release lever for forward stitching.

REGULATING PRESSURE

The pressure dial regulates the pressure that

the presser foot exerts on the fabric. Correct

pressure is important because it means fabric

feeds smoothly and evenly. The NORM (nor

mal} setting Is an all-purpose setting that can

be used for sewing a wide variety of fabrics

of different weights and textures. Intermediate

notched settings, above and below NORM,

are also provided. When you need extra con

trol to sew very heavy fabric, use the MAX

{maximum) setting.

Lower the presser foot before setting pressure.

♦ To increase pressure, turn dial from NORM

toward MAX.

• To decrease pressure, turn dial from NORM

toward DARN.

♦ For darniing, set dial on DARN.

Decrease

Pressure Dial

Darning

19

Page 22

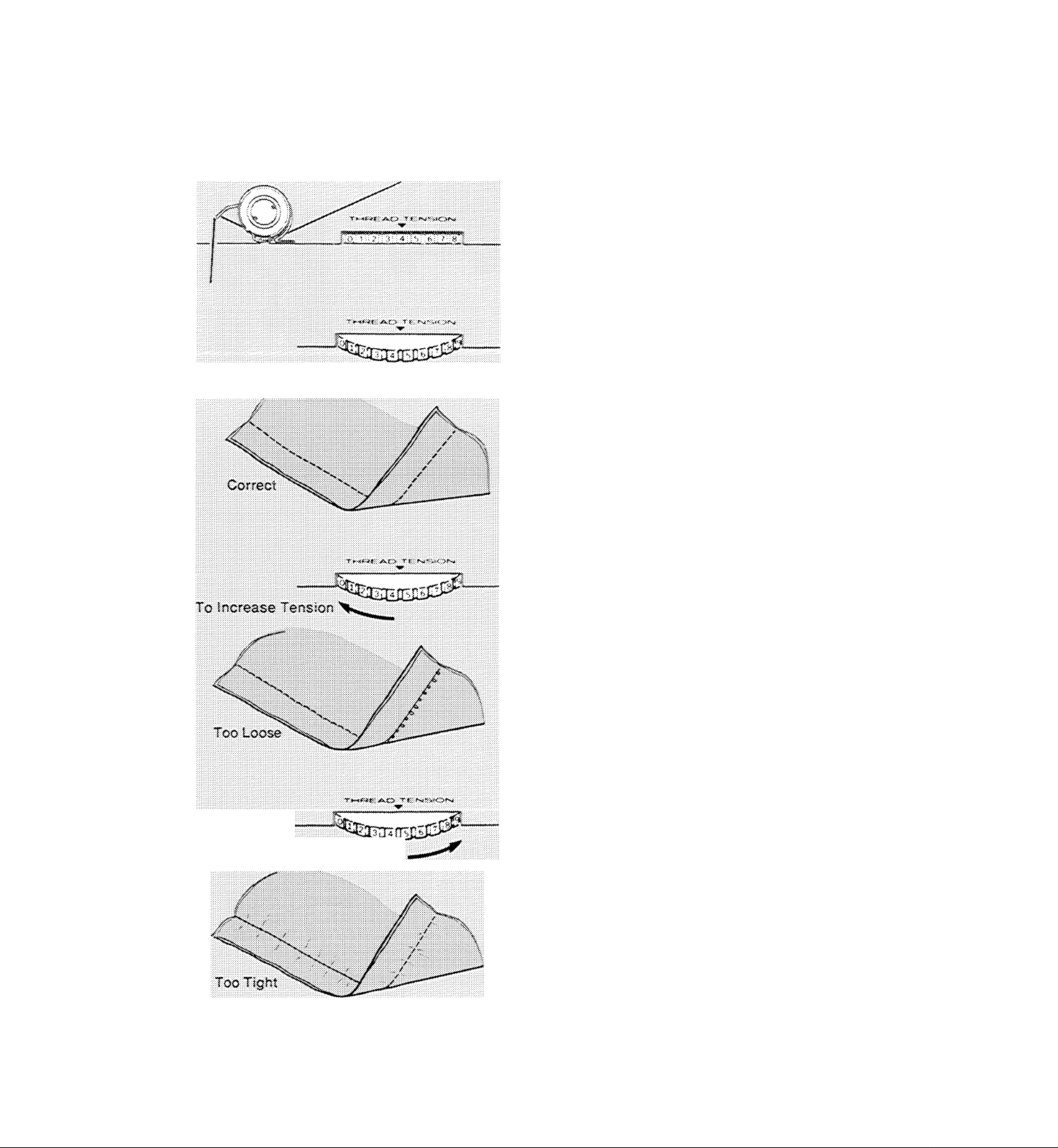

Needle-Thread Tension

REGULATING NEEDLE-THREAD TEN

SION

The tension dial regulates the degree of ten

sion on your needle thread. Set it according to

the type of thread and fabric you use. The

numbers on the dial are for reference and

eliminate guesswork in duplicating settings.

Correct tension is important because too

much or too little will weaken your seams or

cause your fabric to pucker. Be sure your

machine is threaded correctly and make a

test sample with the fabric and thread you

plan to use, and examine it.

A perfect stitch will have the needle and bob

bin threads locked between the two layers of

fabric with no loops on top or bottom and no

puckers.

To Decrease Tension

♦ If the top stitches in your test sample look

loose, increase needle-thread tension by

turning the dial to a higher number.

♦ If the fabric puckers, decrease needle-

thread tension by turning the dial to a lower

number.

20

Page 23

sewing a seam

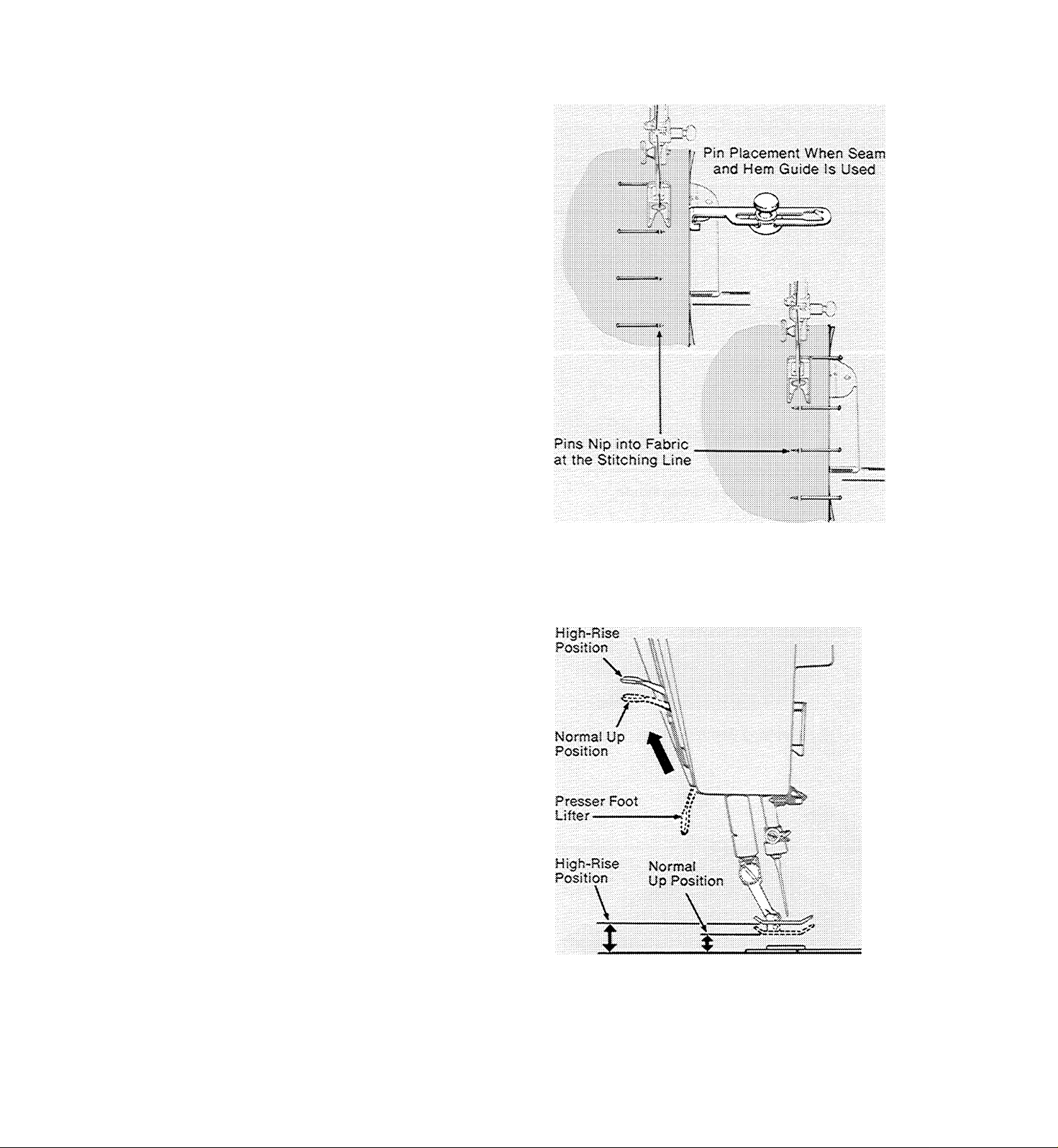

PIN BASTING

Pin basting is a time saver and can be used In

place of hand basting when you are straight

stitching seams in easy-to-handle fabric.

Use fine pins and place them so that:

• They are at right angles to the presser foot

and just nip into the fabric at the stitching

line.

• They do not extend under both sides of the

presser foot. Never place pins on the under

side of the fabric in contact with the feed.

Pin Placement When Seam

and Hem Guide Is Not Used

Pin Placement

PLACING FABRIC

Most fabric can be placed under the presser

foot by raising the presser-foot lifter to its

normal up position. When placing bulky fab

rics, such as coating, knit or terry cloth, or

multiple fabric layers, you will find it conven

ient to raise the presser-foot lifter to the highrise position. Hold lifter in position (since it

does not lock) while placing fabric under the

presser foot Make sure the lifter is all the way

down before starting to sew.

Presser Foot Lifter Settings

21

Page 24

starting a Seam

Stitching a Seam

Guiding and Supporting Fabric

Applying Gentle Tension

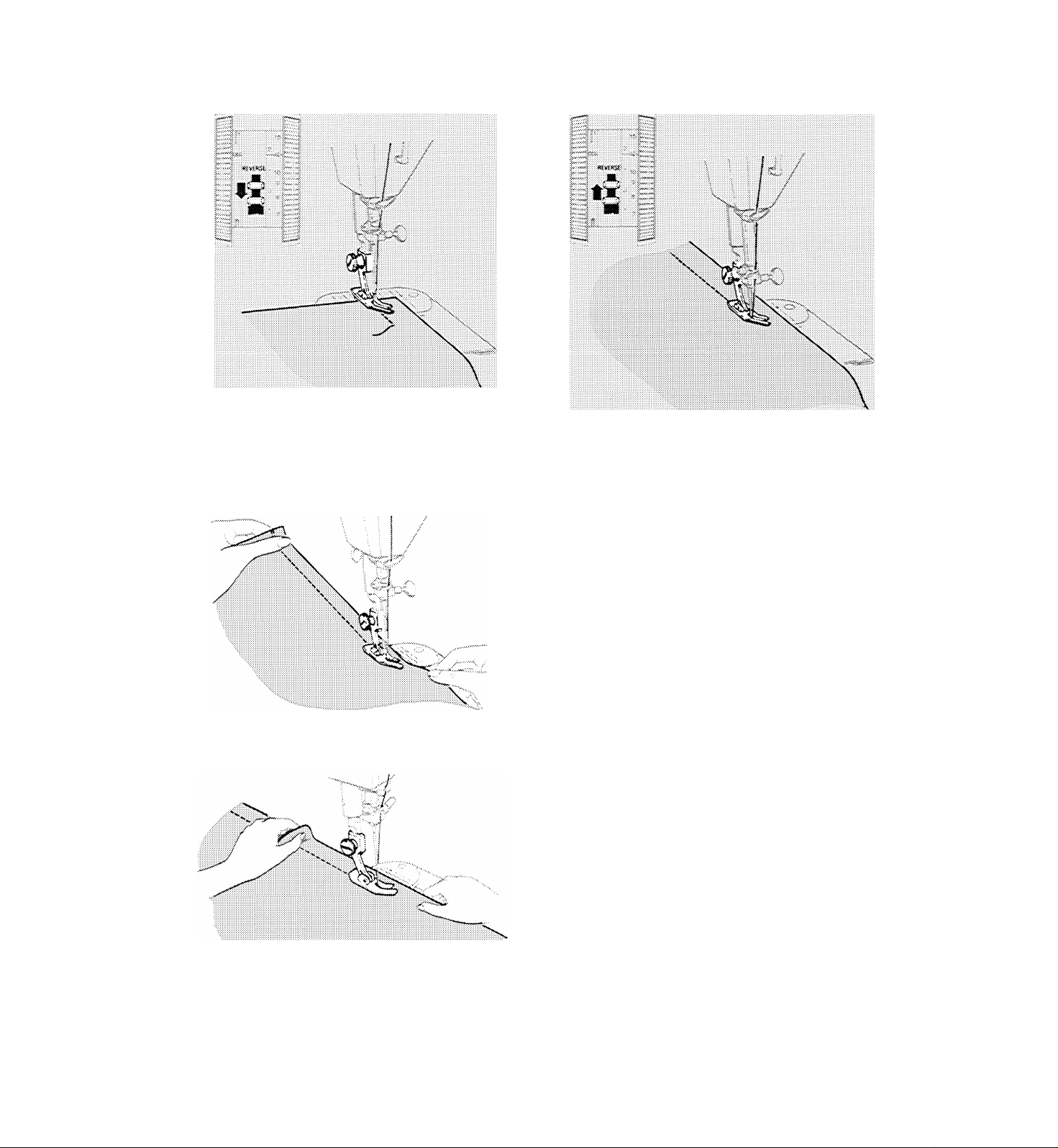

STARTING A SEAM

1. With presser foot raised, turn hand wheel

toward you to position needle in fabric about

1/2 inch (1.3cm) from starting edge.Lower

the presser foot.

2. Press reverse-stitch lever all the way down

and hold in place. Backstitch to edge of

fabric for reinforcement.

3. Release reverse-stitch lever and stitch in

forward direction.

GUIDING AND SUPPORTING FABRIC

Most fabrics need only to be guided in front of

the presser foot Some fabrics, however, re

quire support while being stitched, as shown.

These fabrics require using the straight stitch

presser foot.

CAUTION: Do not puli the fabric while you are

stitching as this may deflect the needle, caus-

ing it to break,

• For filmy sheers, knits, tricot, etc., apply

gentle tension by holding seam in front and

back of the presser foot.

22

Applying Firm Tension

♦ For stretch fabrics, apply firm tension front

and back when stitching in the same direc

tion as the stretch. For seams not on the

stretch direction, stitch in the conventional

manner, guiding fabric in front of the presser

foot.

Page 25

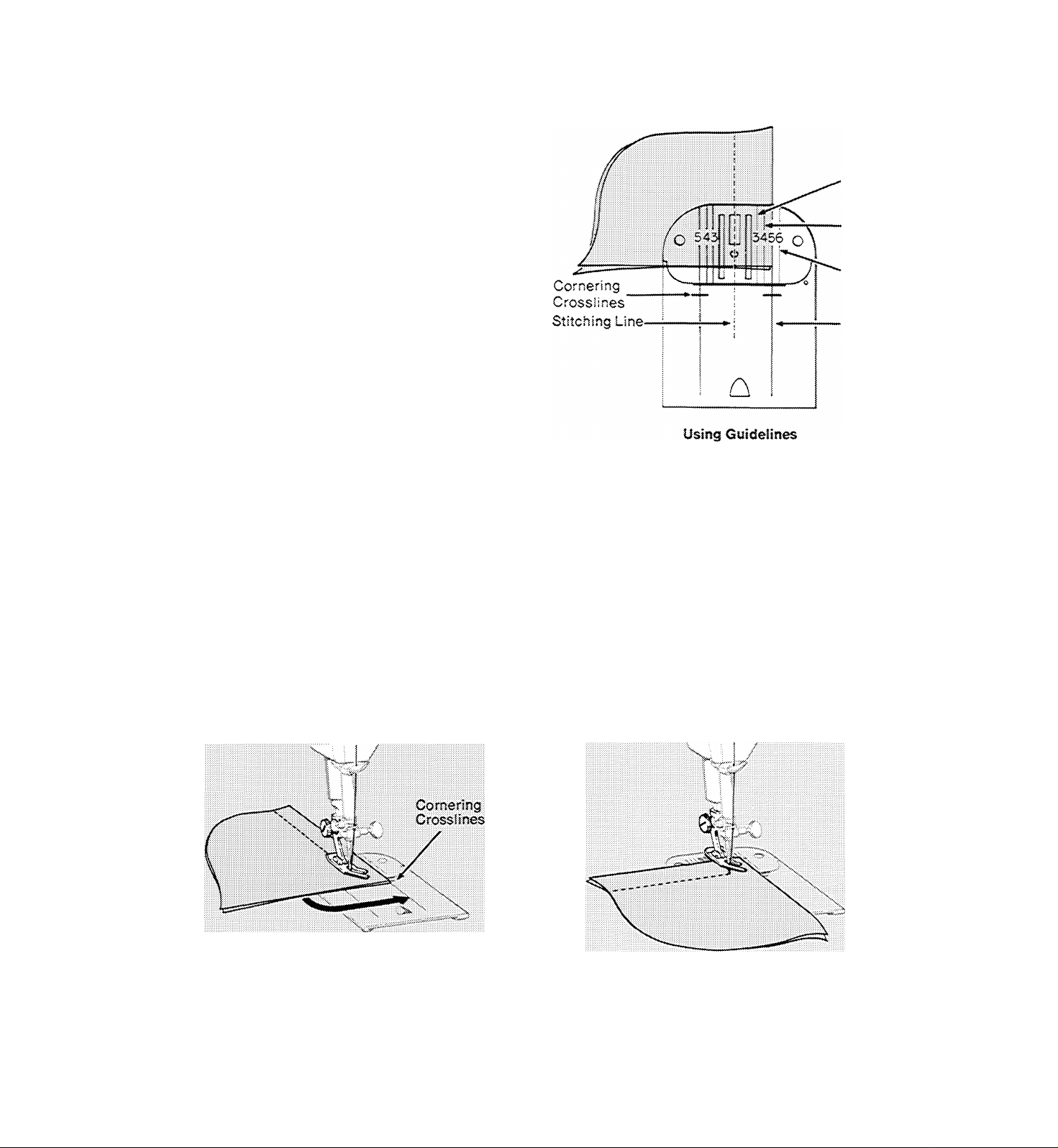

KEEPING SEAMS STRAIGHT

To keep the seam straight, use one of the

numbered guidelines on the needle plate. The

numbers indicate distance, in eighths of an

inch, from the needle. If you want a 5/8 inch

f 1.6cm) seam, for example, line up your fabric

with the number 5 guideline. Note that both

number 5 guidelines (the most commonly

used) are extended on the slide plate for your

convenience: the crosslines serve as corner

ing guides when stitching a square corner.

(9mm)

Vz"

(1.3cm)

%"

(1.9cm)

%"

(1.6cm)

TURNING SQUARE CORNERS

To turn a square corner 6/8 inch (1.6cm)

from the fabric edge, you need not

measure or mark the seam. Simply use

the crosslines on the slide plate.

• tine up your fabric with right or left

guideline 5 on the needle plate. Stitch

seam, slowing speed as you approach

corner.

Pivoting at Corner

• Stop stitching, with the needle down,

when the bottom edge of the fabric

reaches the cornering crosslines on the

slide plate.

• Raise presser foot and turn fabric on

needle, bringing bottom edge of fabric

in line with guideline 5.

• Lower the presser foot and stitch in new

direction.

Fabric at Crosslines Fabric after Turning

23

Page 26

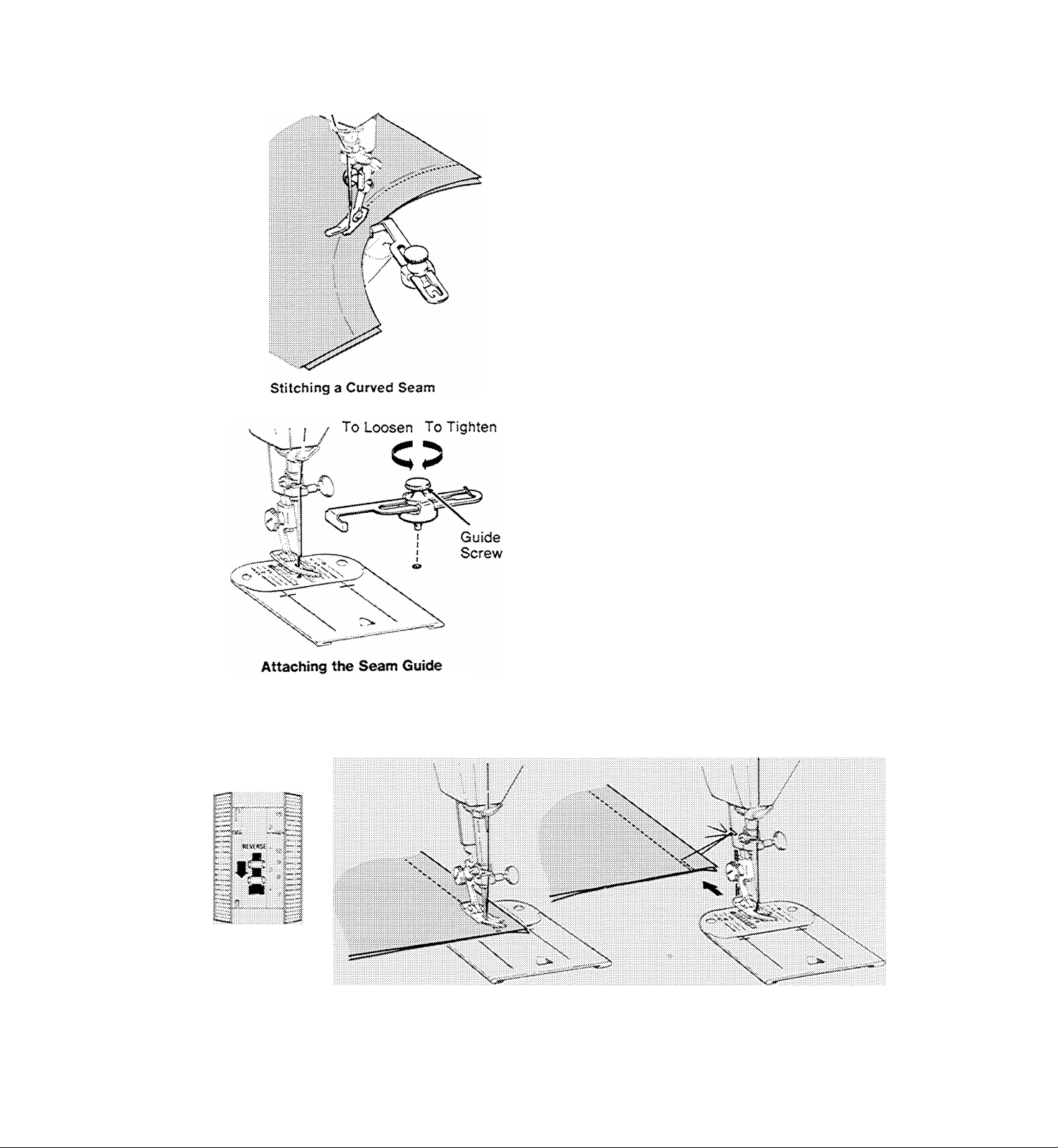

CURVED SEAMS

1. Use a fairly short stitch for elasticity and

strength. For example, if you use a medium

stitch length for straight seams, select a

slightly shorter stitch length to stitch

curved seams in the same fabric.

2, If you use the seam guide to guide stitch

ing, attach it at an angle so that the edge

that is closer to the needle acts as a guide.

TO ATTACH SEAM GUIDE

Fasten seam guide by securing guide screw

into hole provided for it in machine bed.

To adjust the seam guide, loosen the guide

screw and slide the guide to the required

seam width. Then tighten the guide screw.

REINFORCING END OF SEAM

1. Stitch to the edge of the fabric,

2. Press reverse-stitch lever all the way down

and hold in place. Backstitch approx

imately 1/2 inch (1.3 cm) to reinforce end

of seam. Release lever.

Reverse-Stitch

Lever

3. Raise needle to its highest position, raise

the presser foot, and remove the fabric by

drawing it to the back and left.

4. Cut threads on thread cutter at rear of

presser bar.

24

Ending a Seam

Cutting Threads

Page 27

4. ALL ABOUT ZIG-ZAG STITCHiiyG

two kinds of zig-zag stitches

The zig-zag stitches built into your machine

include basic zig-zag stitches and Flexi-Stitch

patterns. In addition to the obviously decora

tive uses of these stitches, some also serve

practical purposes. Under the section called

‘‘Sewing the Professional Way’' beginning on

BASIC ZIG-ZAG STITCHES AND THEIR DIAL SETTINGS

page 47, you will find instructions for both

decorative and practical uses of these stitches.

All of the basic zig-zag stitches and some of

the FiexhStitch patterns are charted below.

(When sewing Flexi-Stitch patterns, set speed

range at SLOW.)

Stitch Pattern

Tfr

Solid Pyramid Stitch

Ball Stitch

Crescent Stitch

Multi-Stitch Zig-Zag

Y'YT'YT’Y'YTY'YY

Blindstitch

mmmmmmmmmmmm

Plain Zig-Zag Stitch

FLEXl-SmCH PATTERNS AND THEIR DIAL SETTiNGS

Pattern

Otal

s

i

c

<

1

Stitch

Width

Dial

1 -s

1-5

1-5

1-5

1-5

1 -5

Needle

Position

Dial

L A H

t A R

L A R

L A R

L A R

L A R

Stitch

Control

6

thru

FINE

6

thru

FINE

e

thru

FINE

6-20

S-20

6

thru

FINE

Stitch

Width

Dial

2-5

Stitch Pattern

Semaphore Stitch

Slant Overedge Stretch Stitchtt

Pattern

Dial

<

VVWVVVVVWVVVWW

Ric-Rac Stitchtt

AAAAAAAAAAAA

Overedge Stretch Stitch t

tSîîtch width must be set at 5 when using the Overedge Foot (see page S4).

ttThis stitch is designed tor strength and permanence and cannot be readily ripped out

without risk of fabric dam^age.

i

<

R

Position

Dial

L A R

t A R

L A R

L A R

Stitch

Control

©

25

Page 28

adjusting dials

SETTING PATTERN DIAL

Before moving the dial, make sure buttonhole

dial is in OFF position and needle is above

fabric.

Push the pattern dial in and turn it until de

sired zig-zag stitch pattern is between the red

lines.

To produce a Flexi-Stitch pattern, the stitch

control dial must be turned to the ^ setting.

: X • ••y-:

»llj....

i ■: y

{

i ,,s

TTWM

........

.....

Tsffsi?

• Push in

• Rotate

• Release

........

H

Buttonhole Dial

in OFF Position

ADJUSTING STITCH PLACEMENT

Before moving needle position dial, move stitch

width dial to 5, and make sure buttonhole dial is

in OFF position and needle is above fabric.

Needle position setting A places the needle

in center stitching position. Settings t and B

place the needle in left and right stitching

positions at stitch widths less than 5.

Setting A is used most often. Settings L

and R are for special placement of stitching.

For example, an B setting is required for twostep buttonholing and an L setting for button

sewing and twin-needle work. An L or R set

ting can be used to place narrow zig-zag

stitching to the left or right of center in

decorative work.

To adjust stitch placement, turn needle posi

tion dial until desired setting is aligned with

red line.

t A «

Adjusting Stitch Piacement

i. A R

26

Left Needle Position

Center Needle Position

Right Needle Positron

Page 29

ADJUSTING WIDTH OF DESIGN

Before moving dial, make sure needle is above

the fabric.

To produce a zig-zag stitch, turn the stitch

width dial to any setting between 1 and 5. The

higher the number, the wider your stitch will

be, A stitch width setting of 2 or more is

recommended for Flexi-Stitch patterns.

Adjusims Width of Design

ADJUSTING

NEEDLE-THREAD TEN-

SION

Zig-Zag stitching usually requires less nee

dle-thread tension than straight stitching, 3e

sure your mao'mne is threaded correctly and

make a test sample with the fabric and thread

you plan to use so that you can adjust tension

to suit the stitch pattern you have chosen. The

stitches should lie fiat against the fabric with

out causing the fabric to pucker.

If the stitches are not flat and the fabric is

puckered, lower the needle-thread tension by

turning the dial to a lower num^ber.

ADJUSTING STITCH LENGTH

Any numbered stitch length setting will give

you an open zig-zag stitch of the pattern you

select except Flexi-Stitch patterns. As you

rotate the stitch control dial away from the

FINE setting (towards the numbered settings),

your stitches becomie miore open, or farther

apart. The symbol on the dial above the num

bered settings designates the FINE stitch

area and is used for the adjustment of zig-zag

satin stitching (see page 28 for specific in

structions).

To produce a Flexi-Stitch pattern (refer to

stitch pattern chart on page 25), the stitch

control dial must be set on the symbol.

Simply turn the dial downward until the sym

bol is centered under the red line. No further

adjustment is necessary.

Correct

When using the ^ setting of the stitch control,

you cannot backstitch the stitch pattern.

For instructions on using basting stitch, see

page 33.

Fiexi-Stitch

Pattern Setting

Stitch Controi Dial

27

Page 30

satin stitching

Satin stitching, a series of ciosefy spaced zig

zag stitches that form a smooth, satin-iike sur

face, is useful for both practical and decorative

work. The plain zig-zag stitch, for example, is

suitable for bar tacks and applique when

closed up to form a satin stitch. The F/ex/-

Stitch patterns, however, have a single stitch

length setting

stitched.

and cannot be satin-

Qi

Stitch Control in FINE Area

As the Dial is Rotated, Stitches Close Up

When you wish to produce a satin stitch, make

a test sample first so that you can adjust the

stitch length and thread tension properly. Soft

fabrics may require a backing to ensure firm

satin stitching. Crisp lawn or organdy is suit

able for this purpose. For best results use the

special purpose foot.

DIAL SETTINGS

Pattern: Plain Zig-Zag I

Needle Position: A *

Stitch Width: 2 to 5

Stitch Control: in FINE area

General Purpose Needle Plate

Special Purpose Foot

Adjusting Stitch Length

1. Set stitch control dial at bottom of FINE

area.

28

Adjusting Thread Tension

Correct

2. Run machine at SLOW speed.

3. Gradually turn dial downward until stitches

are closely spaced and form a sm-ooth sur

face.

Adjusting Thread Tension

Satin stitching requires less tension than

straight stitching or open zig-zag stitching.

furthermore, the wider the satin stitch, the

lighter the tension on the thread must be. No

tice the stitching on your sample, ff the fabric

is puckered, lower the needle-thread tension

by turning the tension dial to a lower number.

Page 31

5. TWiiy-iyEEDLE STITCHiiyG

By using a twin needle, you can produce two either a straight stitch or one of the decorative

parallel, closely spaced lines of decorative stitch patterns,

stitching simultaneously. You can choose

STITCH PATTERNS AND THEIR DIAL SETTINGS

To produce

patterns at right

use settings

shown below

Pattern Dial

Stitch Width Dial

Needle Position Diai

IN

Stitch Control

tThis sîiich is designed for strength and permanence and cannot de readily ripped out without risk of fabric damage.

FINE

AREA

1S-20

15-ao

inserting the twin needle

Before inserting the twin needle, place the

needle position selector at L and stitch width

selector at A •

1. Raise needle to its highest position.

2. Loosen needle-clamp screw and remove

single needle.

3. Insert twin needle into clamp with the flat

side of shank to the back.

4. Push needle up as far as it will go and

tighten needle-clamp screw.

Best twin-needle stitching

results are obtained with No.

SO mercerized cotton thread

29

Page 32

threading the needle

1, Thread as for one-needle stitching except:

♦ Pass thread between center and back

tension discs, through the thread guide

above the needle, and through right eye

of needle.

/■

2. Insert detachable vertical spool pin into

hole provided for it in top cover of machine.

3. Place spool of thread on detachable spool

pin and thread as for one-needle stitching

except:

* Pass thread between center and front

tension discs and through ¡eft eye of

needle, omitting the thread guide above

the needle.

Passing Thread

Between Tension Discs

30

Twin-needle Threading

Page 33

dial settings

STRAIGHT STITCHING WITH A

TWIN NEEDLE

♦ Pattern: Straight Stitch

♦ Stitch W\6Xh: A

♦ NeecHe Position; t or A only

♦ Stitch Control: To suit design

♦ General Purpose Needle Plate

♦ General Purpose Foot

í¿:_ -

.......

.....

m

mrnrnvfmn

i. ;k

1 r; -v.

1

3

ZIG-ZAG

STITCHING WITH A TWIN NEEDLE

♦ Pattern: Any Zig-Zag pattern t

Note: For decorative twin-needle stitching,

using a Fiexi-Stitch pattern, set stitch

control at ÚÍ, and use the SLOW

speed range.

♦ Stitch Width; 2 (Do not exceed this setting)

♦ Needle Position: Lonly

♦ Stitch Control; To suit design

♦ General Purpose Needle Plate

♦ General Purpose Foot (for open stitching)

♦ Special Purpose Foot (for satin stitching)

Í i ■ = I

tFxciuding basting stitch which cannot be produced with a twin needle.

31

Page 34

Turning a Corner with a Twin-Needle

turning a square corner

Geometric twin-needle oeslgns are easy to ac

complish with the plain zig-zag stitch and the

special purpose foot when you know how to

turn a square corner. 3e sure to practice turn

ing in right and left directions.

• Mark or baste a stitching guideline on the

fabric.

• Stitch to the corner and stop with the needle

in the fabric on the inside of the corner.

• Raise the presser foot and turn the fabric

halfway around the corner {needle in fab

ric). Lower the foot and take one stitch by

turning the hand wheel. Continue to turn the

hand wheel until needle is about to enter

fabric on the inside of the corner,

• Raise the foot again and complete the fabric

turn, positioning the work under the foot so

that the needle will enter the inside corner

needle hole a second time.

• Lower the foot and continue stitching in the

new direction.

32

Turn Fabric Halfway Around Corner

Complete Fabric Turn

Page 35

6. TEMPORARY STITCHING

speed basting

With the basting stitch that is built into your

sewing machine, you can produce basting

stitches of any length up to two inches (5cm).

Thus, you can choose just the right length for

your sewing job, considering the weight of

your fabric and how securely the pieces need

to be held together. A few of the many sewing

jobs for which you will find speed basting par

ticularly useful are:

• Joining seams for trial fittings

• Marking construction guidelines

• Basting pleats, hems and seams

DIAL SETTiNGS AND ACCESSORIES

PATTERN SELECTOR

..

Ш1,

я

|2«3 4. $

..

................

STITCH WIDTH

• Pattern: Basting Stitch |

• Stitch Width: 5 only

• Needle Position: only

• Stitch Control: Any setting thru FINE

• Speed: In SLOW range

• General Purpose Needle Plate

• General Purpose Foot

Stitch Length

The stitch-control dial regulates the length of

basting stitches, but because the basting disc

changes the interval at which the needle en

ters the fabric, the numbers on the dial no

longer represent stitches per inch or stitch

length in millimeters.

The settings of the control dial and the ap

proximate length of the basting stitches they

produce are illustrated. The very short stitches

produced in the triangle at the top of the FINE

area are used to secure the beginning and

ending of a line of basting.

Foot

Dmi Settings

STITCH CONTROL '

^ frn Щ

; :

5 43

i 1

5 i

i i

: 4

2 Ш

General Purpose

Needle Plate

■« {6ram)

----------

----------

1/2"'(1,3cm)----- 20

V'{2.5cm}

-------

1 i/2'MS.8cm)—

2" iscm)

I

i

1

‘ 10

33

Page 36

Thread Tension

Machine basting requires a light needle-

thread tension. The longer the stitch, the lighter

the tension needs to be. When tension is cor

rectly adjusted, stitches up to 1/2 inch

(1,3cm) long should He flat in firm fabrics. If

stitches are more than 1/2 inch (1.3cm) long,

place tension on the fabric by holding it in

front and back of the presser foot, as you sew,

to prevent pucker.

PREPARATION

Thread the machine and fill the bobbin in the

usual way. Select needle and thread accord

ing to your fabric: mercerized cotton threads

are particularly recommended. Choose a

thread color to contrast with your fabric so

that it can be seen easily. Make sure the

general purpose foot and general purpose nee

dle plate are on the machine and the needle is

in its highest position.

PROCEDURE

1. Set stitch control for a short stitch in the

triangle at the top of the FINE area on the

dial. Place work under the needle, lower

the presser foot, and take a few stitches to

position and secure basting start.

2. Reset stitch control dial for the length of

basting stitch desired (stitches less than 1

inch (2.5cm) long are recommended for

seam basting) and proceed as for regular

sewing. Stitch slowly, supporting the fabric

in front and back of the presser foot if

stitches are more than 1/2 inch (l.3cm)

long.

3. To secure the end of basting, turn dial

downward for a short stitch in the FINE

area and take a few stitches.

To avoid pressing marks, remove basting

stitches as soon as they have served their

purpose.

34

Page 37

chainstítching

Single-thread chainstítching looks like regular

straight stitching on top but is a series of in

terlocking loops on the underside of the fabric.

The stitches are produced by the needle

thread alone so you do not need a bobbin

thread or a bobbin. Because the stitches are

formed by a single thread, the interlocked

loops unravel easily, allowing the entire line of

stitching to be removed with just a pull on the

thread end. Also, the loop formation of the

stitches makes them less taut than regular

straight stitches. That’s what makes

chainstitching flexible.

Here are a few of the many sewing jobs for

which you will find chainstitching useful.

♦ Sewing temporary hems and tucks to extend

the life of —

Children’s clothes

Curtains and linings that might shrink

♦ Hemming curtains and draperies that may

need to be altered.

• Attaching woven and stretch hem tape.

• Making stay chains {ftench tacks) to

anchor linings or belt carriers to hold belts

in place.

• Fastening remiovable trimming —

Fur collars

White collars and cuffs

* Basting for trial fittings.

\

Insert Chainstitch Needle Plate

PREPARATION

(See page 5 for Chainstitch Fittings)

Make sure needle is at its highest point,

1. Raise presser foot, open slide plate, and

remove bobbin.

2. Remove needle plate and position chainstitch needle plate over pins from front.

3. Insert bobbin case cover in bobbin case

with flat edge toward the front as illustrated.

Snap latch down and close slide plate.

4. Open face plate and slip chainstitch thread

guide into place. Close face plate.

5. Thread your machine in the usual way

except pass thread from take-up lever

through self-threading eyelet in the chainstitch thread guide.

Select needle and thread according to your

fabric.

35

Page 38

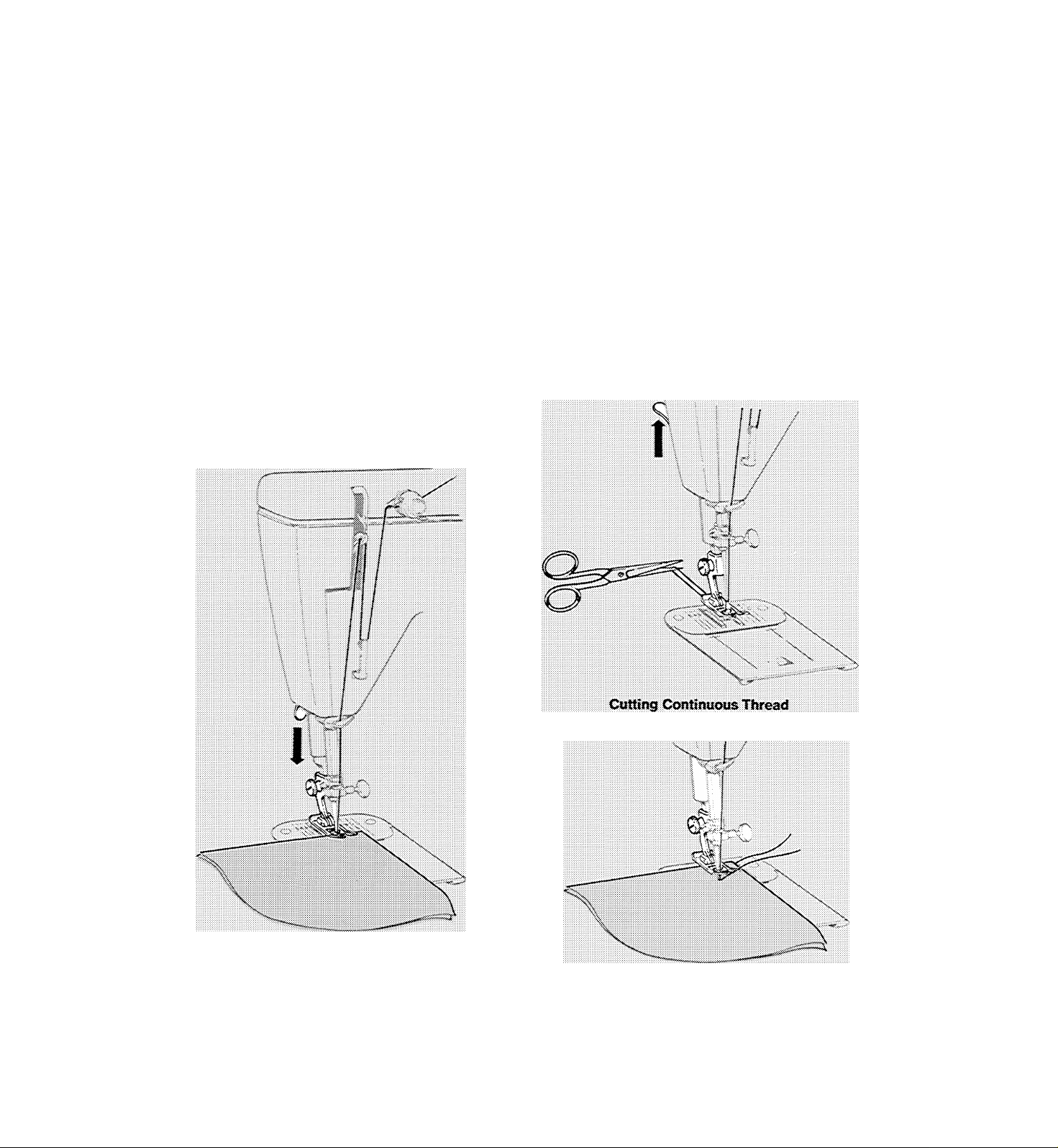

SEWING A CHAINSTITCH SEAM

• P^XtQtn: Straight Stitch ^

• Stitch Width:

• Needle Position; A

• Stitch Control: 10 to 12 (approximately 2 to 2.5)

only

• Chainstitch Needle Plate

• Straight Stitch Foot or General Purpose Foot

• Chainstitch Thread Guide

• Bobbin Case Cover

Starting and Chaining Off

1. Turn hand wheel toward you to position

needle in very edge of fabric. Lower the

presserfoot

2. Start the machine and stitch to end of

seam. Continue stitching beyond edge of

fabric, making a chain from one to tv^o in

ches {2.5cm to 5cm) long. Do not attempt to

stitch in reverse. Chainstitching can be

sev^n in a forward direction only .

Stitch Starting Point after Chaining Off

Releasing Chain from IVIachine

3. Cut chain between fabric and presser foot.

4. Check and adjust tension, if required, as

instructed on page 38. After chaining off,

start a new line of stitching by raising the

presser foot slightly and positioning the

fabric in front of the needle. Lower the

presser foot and stitch to end of seam.

Releasing the Chain from the Machine

When you finish chainstitching, the chain can

easily be removed from the machine.

1. Raise presser foot

2. Hold end of chain with your left hand.

3; Turn hand wheel slowly toward you with

your right hand until needle is all the way

down in the needle hole.

4. Then turn hand wheel slowly away from

you, pulling gently on chain, which will un

ravel as needle rises.

36

Page 39

Ending Stitching in Fabric

Draw Loop Down to Left of Foot

Ending the Stitching in the Fabric

Occasionaily, you may need to end your stitch

ing in the fabric. Temporary hems and tucks,

for example, can be completed in this way:

• Stop stitching at desired point. Make sure

take-up Sever is in its highest position.

• Raise presser foot.

1. Puli the thread through the take-up Sever,

forming a loop between the take-up lever

and chainstitch thread guide.

2. Pass scissors under the presser foot so as

to pull the slack thread down and out to

form a loop at left of foot.

3. Hold the loop and cut the thread close to

the end of the stitching.

4. Remove fabric from machine by pulling it

straight back, away from you. The thread

end will puli through the fabric to the under

side and form a temporary lock.

• If you wish to secure this temporary lock,

fold the thread end back over the chain

and fasten with hand stitching.

37

Page 40

Too Little

ADJUSTING THREAD TENSION

Adjust thread tension. Chalnstltchlng re

quires approximately the same needle-thread

tension as regular straight stitching, provided

the same kind of thread is used. When the

tension is correctly adjusted, the chain will be

flat and smooth. Puckers in the fabric and

qlnched loops indicate too much tension; turn

tension dial to a lower number. Large, irregu

lar loops indicate too little tension; turn ten

sion dial to a higher number.

REMOVING THE STITCHING

Chainstitching can be removed smoothly and

cleanly in seconds by freeing the last stitch

formed in the fabric.

1. Simply cut the last loop formed on the un

derside of the fabric.

2. Pick up the free thread end from the top

surface of the fabric.

3. Pull the free thread end, removing entire

line of stitching,

REMOVING CHAINSTITCH ACCESSORIES

Release thread chain from machine and make

sure needle is at its highest point.

1. Open slide plate and remove bobbin case

cover.

2. Replace bobbin and snap down latch,

3. Remove needle plate by pressing up and

lifting it out toward you.

4. Replace general purpose or straight stitch

needle plate.

5. Open face plate and remove chainstitch

thread guide. Close face plate.

38

Removing Needle Plate

Page 41

7. BUTTONS AND BUTTONHOLES

buttons

decrease stitch width, if necessary, so that

• Pattern: Plain Zig-Zag |

• Stitch Width; A and 4 or to suit button

♦ Needle Position: L

# Feed Cover Plate

♦ Sutton Foot

The space between the holes in the button

determines stitch width settings. The A set

ting must always be used to position the but

ton and to fasten stitching. For buttons with

standard hole spacing, settings A and 4 are

usually satisfactory. For buttons with unusual

hole spacing, use setting A and increase or

decrease the width setting (4) as necessary.

1. Position button under button foot and lower

the needle into center of left hole. Lower

the foot. Turn hand wheel toward you until

the needle rises out of the button and is

just above the foot.

2, Set stitch width at 4. Turn hand wheel

toward you until needle is just above the

right hole of the button. Increase or

needle will enter the right hole. Take six or

more zig-zag stitches at this setting. End

on left side.

3. To fasten stitching, return to stitch width

setting A sind take about three stitches.

FORMING A THREAD SHANK

Buttons sewn on coats and jackets should

have a thread shank to make them stand away

from the fabric. To form a thread shank, sew

over the blade of a regular machine needle.

• Position button and lower button foot. Place

needle in groove of foot so that point enters

the hole in the foot. The farther in you push

the needle, the longer the shank will be.

• After stitching, remove needle from groove.

Remove work from under presser foot, cut

ting threads about six inches (I5cm) from

fabric. Pull needle-thread ends to back of

button and form a firm shank between but

ton and fabric by winding threads tightly

around attaching stitches. Tie thread ends

securely.

11

ìiàiAàiàmmtéiiÉikiéiàM

jrrrrm*

4 ■■■■■'

forming Thread Shank

Pulf Needle Threads

to Back of Button

Thread Shank

Completed

39

Page 42

buttonholes

Center Line

Hound-End Buttonhole

Bar-Tack Buttonhole

Finished Edge of Garment

Diameter of Button

Horizontal Placement

on Crosswise Grain

You have a choice between two buttonhole

styles and two buttonhole-making methods:

round-end buttonholes made with the built-in

buttonhole system of your machine and bar-

tack buttonholes with square ends made man

ually in four steps. Round-end buttonhoies can

be made in light- and medium-weight fabric;

bar-tack buttonholes are best in lightweight

fabric.

BUTTOMHOLE POSITION

Accurate guidelines are essential to keep but

tonholes at a uniform distance from the edge

of the garment, evenly spaced, and on the

grain of the material.

1. Mark the center line of the garment. This

guideline can be made by hand basting or

machine speed basting. The space from the

center line to the finished edge of the gar

ment must be at least equal to three-quar

ters the diameter of the button. With this

spacing, the button will not extend beyond

the edge when the garment is buttoned.

Make sure that the center line marking fol

lows a lengthwise fabric thread.

2. Mark a position guideline for each button

hole.

40

Vertical Placement on

Lengthwise Grain

• Horizontal buttonholes are placed to ex

tend 1/8 inch {3mm) beyond the center

line of the garment, as illustrated, so that

the buttons will be in the center of the

figure when the garment is fastened,

Horizontai buttonhole guidelines should

follow a crosswise fabric thread and be

longer than the finished length of the but

tonhole. Mark ends of each buttonhole

vertically.

• Vertical buttonholes are placed so that

the center line of the garment is in the

center of the buttonhole, as illustrated.

Mark the ends of each buttonhole hori

zontally across the center line basting

and use the center line marking as the

buttonhole guide when stitching.

Page 43

BUTTONHOLE LENGTH

A buttonhole length should be just long enough

to allow the button to slip through the opening

without stretching it. You can estimate the

proper buttonhole length by measuring the

width plus the thickness of the button. To make

sure the measurement is correct, cut a slit in

a scrap of fabric the diameter of the button

you intend to use. Increase length of opening

until button slips through easily. This test is

partioularly advisable for buttons of unusual

shape or thickness.

BUTTONHOLE INTERFACING

It is almost always wise to use an interfacing

in the buttonhole area. An interfacing holds

the fabric firmly so that a neat buttonhole may

be stitched and keeps the finished buttonhole

in shape. Interfacing is essential when the fab

ric is loosely woven or is a crepe or knit that

stretches easily.

When planning your garment, remember that

both round-end and bar-tack buttonholes are

stitched through three thicknesses of fabric

(garment, interfacing and facing) after the fac

ing has been attached.

TEST SAMPLE

Always make a test buttonhole in a sample of

your fabric to determine suitability of button

hole style, buttonholing method, and machine

settings. Be sure to duplicate the number of

fabric layers in the garment and include inter

facing if appropriate. Remember, too, that

loosely woven and medium-weight fabrics re

quire buttonholes with wider side stitching

than firmly woven or lightweight fabrics. Fin

ally, check to see that the opening for the but

ton can be cut without damaging buttonhole

stitching.

CUTTING BUTTON OPENING

Place a pin across the cutting space at each

end of the buttonhole to protect end stitching.

Use a pair of small, sharp scissors to cut the

button opening. Insert blade in center of but

tonhole cutting space and cut from this point

in either direction.

Testing Suttonhote Length

41

Page 44

ROUND-END BUTTONHOLES

To stitch a buttonhole, set ail dials on red symbols.

• Attach buttonhole foot

« Use general purpose needle plate

PATTERN SELECTOR

NEEDLE POSITION

rrvmm

STITCH WiDTH

Buttonhole Length

First, decide how long the button opening must

be. This will depend on the diameter and thick

ness of the button as explained on page 41.

Then add 1 /8 inch (3mm) for end stitching (1 /16

inch or 1.5mm for each end of the buttonhole).

This end-stitching allowance is approximate

and should be increased slightly if the but

tonhole is to be stitched twice. Fabric thick

ness and thread diameter will also vary endstitching depths, so be sure to check measure

ments by making a test buttonhole. Mark but

tonhole position and length on fabric. See page

40 for placement information.

STITCH

8UTTOHHOLE

CONTROL

Make sure buttonhoie diaf

i$ m OFF position when

you set Of reset stitch con-

trol dial on red

Buttonhole

Length Guide

Markings

42

Sutton

Opening !

Length of

Button

Opening

Buttonhole

Stitching

Buttonhole Stitch Width

The stitch width setting, designated by red

— symbol, is an approximate setting; use it

to make your test buttonhole. You may need

to increase or decrease stitch width slightly to

suit your fabric, to arrive at more pleasing but

tonhole proportions, or to change the width of

the buttonhole cutting space. When making

sUtch width adjustments, remember that as

stitch width is increased, the cutting space in

the center of the buttonhole is decreased.

Page 45

--------7-------Finished Edge

of Garment

IP^l

X

Buttonhole Position I ;

Guideline

/

Center

Une of :

iJ

End

Buttonhole

Guidelines

Garment

Starting Position

Procedure

• Place garment under buttonhole foot so that

buttonhole position marking is centered.

• Align center gauge line of buttonhole foot

with center line of garment.

• Lower the presser foot, and rotate button

hole dial downward until symbol for step 1

• is centered under red line (cuck indicates

engagement).

• Start machine and let it complete step 1 of

the buttonholing cycle; that is, stitching

across the end and down the left side of

buttonhole. Stop machine when front gauge

Une on buttonhole foot reaches end-of-buU

tonhole guideline on garment,

End of

Buttonhole ^ ^

Guidelines

I

____

____________

Step 1 Dial

Setting

Presser Foot Position

at End of Step 1

St Tr

3* ÏS .ilLce«.;

Buttonhole

Guidelines

J

Line of

Garment

• Rotate buttonhole dial downward until sym

bol for step 2 is centered under red line.

• Start machine and let it com.plete step 2 of

the buttonholing cycle: that is, stitching

across the end and up the right side of but

tonhole, Stop machine when back gauge

line on buttonhole foot is in fine with the

end-of-buttonhole guideline on garment.

Take one or two stitches if necessary to

overlap stitching at starting point. For a

smooth, satiny appearance and greater dur

ability, stitch around the buttonhole a sec

ond time by

repeating the two-step dial se

quence.

• Remove work from machine, clip thread

ends and cut button opening with sharp

scissors.

When buttonholes are completed, reset dials

for regular sewing. Make sure buttonhole dial

is in OFF position.

Step 2 Dial

Setting

r|

■

1

'“'11

Off Dial Position

at End of Step 2

Presser Foot Position

at End of Step 2

End of

Buttonhole

Guideline

”\.............

Finished

Buttonhole

Stitching

......

.

End of

Buttonhole

Guideline

Center

Line of

Garment

43

Page 46

BAR-TACK BUTTONHOLES

• Pattern; Plain Zig-Zag |

• Stitch Width: 2% and 5 or to suit fabric

• Needle Position: L

• Stitch Control: In FINE area

• General Purpose Needle Plate

• Special Purpose Foot (Only)

Marking Lines

Always make a test buttonhoie on a sample of

your fabric. Be sure to duplicate the thickness

of the garment and include interfacing if ap

propriate.

BUTTONHOLE LENGTH

First decide how long the opening needs to be.

This will depend on the diameter and thickness

of the button. To find the right length, cut a small

slit in a scrap of your fabric and gradually

enlarge it until the button slips through easily.

Then add at least 1/8 inch or 3mm (1/16 inch,

or 1.5mm for each bar tack, the closing at each

end of buttonhoie), and mark the fabric as il

lustrated. This bar-tack measurement is ap

proximate; on some buttonholes, you may need

to increase it to arrive at pleasing proportions.

STiTCH WIDTH SETTINGS

Next, determine the two stitch width settings

that you wiii need: one for side stitching and

one for bar tacks. Settings 2% and 5 are il

lustrated below, although other combinations

may be used, as long as combined widths of

side stitching does not exceed the width of

the bar tacks.

44

Length of

Cutting Space

A ^ 3 A S

Selector

BÌ2VZ

Bar Tacks and

Side Stitching

A

1 {

(2-3 A J

mrTTrm

. A R

>

............................

Tmmr

1

.X

Selector

atS

Bimsmchim