Singer 7640 Instruction Manual

INSTRUCTION MANUAL

7640

INTRODUCTION

2

Welcome

Welcome to the SINGER® family and CONGRATULATIONS on purchasing a

®

brand new SINGER

sewing machine!

The SINGER

design our machines for sewists of all skill levels so that the joy of sewing,

creating, do-it-yourself, crafting and more can be enjoyed by all. It is important

to us that you have the easiest and most successful sewing experience, so

we have provided a wide array of helpful resources:

1. An instruction manual with easy-to-understand graphics and

step-by-step instructions.

2. Assistance on the web at www.singerco.com

3. Personal assistance via email: talktous@singerco.com

4. Live, one-on-one help from one of our SINGER

at 1-800-474-6437. (North America Only)

We’re ready to help and hope that you enjoy your SINGER

Happy Sewing!

®

brand has stood for quality in sewing for over 160 years. We

®

Sewing Assistants,

®

sewing machine.

2

INTRODUCTION

Important Safety Instructions

This household sewing machine is designed to comply with IEC/EN 60335-2-28

and UL1594.

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be

followed, including the following:

Read all instructions before using this household sewing machine. Keep the

instructions in a suitable place close to the machine. Make sure to hand them

over if the machine is given to a third party.

DANGER - To reduce the risk of electric shock :

- A sewing machine should never be left unattended when plugged in. Always

unplug this sewing machine from the electric outlet immediately after using

and before cleaning, removing covers, lubricating or when making any other

user servicing adjustments mentioned in the instruction manual.

WARNING 7RUHGXFHWKHULVNRIEXUQV¿UHHOHFWULF

shock, or injury to person :

- Do not allow to be used as a toy. Close attention is necessary when this

sewing machine is used by or near children.

- Use this sewing machine only for its intended use as described in this

manual. Use only attachments recommended by the manufacturer as

contained in this manual.

- Never operate this sewing machine if it has a damaged cord or plug, if it is not

working properly, if it has been dropped or damaged, or dropped into water.

Return the sewing machine to the nearest authorized dealer or service center

for examination, repair, electrical or mechanical adjustment.

- Never operate the sewing machine with any air openings blocked. Keep

ventilation openings of the sewing machine and foot control free from the

accumulation of lint, dust, and loose cloth.

- Keep ¿ngers away from all moving parts. Special care is required around the

sewing machine needle.

- Always use the proper needle plate. The wrong plate can cause the needle to

break.

- Do not use bent needles.

- Do not pull or push fabric while stitching. It may deÀect the needle causing it

to break.

- Wear safety glasses.

- Switch the sewing machine off (“O”) when making any adjustment in the

needle area, such as threading needle, changing needle, threading bobbin, or

changing presser foot, etc.

- Never drop or insert any object into any opening.

- Do not use outdoors.

- Do not operate where aerosol (spray) products are being used or where

3

INTRODUCTION

2

Important Safety Instructions

oxygen is being administrated.

- To disconnect, turn all controls to the off (“O”) position, then remove plug from

outlet.

- Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

- The foot control is used to operate the machine. Avoid placing other objects

on the foot control.

- Do not use the machine if it is wet.

- If the LED lamp is damaged or broken, it must be replaced by the

manufacturer or its service agent or a similarly quali¿ed person, in order to

avoid a hazard.

- If the supply cord connected with the foot control is damaged, it must be

replaced by the manufacturer or its service agent or a similarly quali¿ed

person, in order to avoid a hazard.

- This sewing machine is provided with double insulation. Use only identical

replacement parts. See instructions for Servicing of Double-Insulated

Appliances.

SAVE THESE INSTRUCTIONS

For Europe only :

This appliance can be used by children aged from 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of

experience

concerning use of the appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance. Cleaning and user

maintenance shall not be made by children without supervision.

The noise level under normal operating conditions is less than 75dB(A).

The machine must only be used with foot control of type C-8000 manufactured

by ZENG HSING TAIWAN, LTD.

and knowledge if they have been given supervision or instruction

For outside Europe :

This sewing machine is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning

use of the sewing machine by a person responsible for their safety. Children

should be supervised to ensure that they do not play with the sewing machine.

The noise level under normal operating conditions is less than 75dB(A).

The machine must only be used with foot control of type C-8000 manufactured

by ZENG HSING TAIWAN, LTD.

SERVICING OF DOUBLE INSULATED

PRODUCTS

In a double-insulated product, two systems of insulation are provided instead

of grounding. No ground means is provided on a double-insulated product, nor

should a means for grounding be added to the product. Servicing of a double-

4

INTRODUCTION

Important Safety Instructions

insulated product requires extreme care and knowledge of the system and

should be done only by quali¿ed service personnel. Replacement parts for

a double-insulated product must be identical to those parts in the product. A

double-insulated product is marked with the words “DOUBLE INSULATION” or

“DOUBLE INSULATED”.

5

INTRODUCTION

2

Table of Contents

INTRODUCTION .............................................................................................................2-6

Welcome .........................................................................................................................................2

Important Safety Instructions .......................................................................................................3-5

Table of Contents ............................................................................................................................6

1. ABOUT YOUR MACHINE ......................................................................................... 7-11

Main Parts of the Machine Front ..................................................................................................... 7

Main Parts of the Machine Back .....................................................................................................8

Needle and Presser Foot Area ........................................................................................................ 9

Removable Storage Compartment and Accessories ............................................................... 10-11

2. GETTING READY TO SEW ....................................................................................12-17

Powering Your Machine ................................................................................................................12

Winding the Bobbin ....................................................................................................................... 13

Inserting the Bobbin ......................................................................................................................14

Threading the Upper Thread ......................................................................................................... 15

Automatic Needle Threader .......................................................................................................... 16

Drawing Up the Bobbin Thread ..................................................................................................... 17

3. START SEWING .....................................................................................................18-31

Before You Start Sewing ...............................................................................................................18

Stitch Formation ............................................................................................................................ 19

Operation Buttons and Function Buttons ...................................................................................... 20

LCD Screen................................................................................................................................... 20

Combining Characters into Memory.............................................................................................. 21

Stitch Selection ............................................................................................................................. 22

Sewing a Straight Stitch ................................................................................................................ 23

Sewing a Decorative Stitch ........................................................................................................... 24

Sewing a Stretch Stitch ................................................................................................................. 25

Sewing a 1-Step Buttonhole.......................................................................................................... 26

Sewing a Button ............................................................................................................................ 27

Inserting and Changing Needles ................................................................................................... 28

Changing the Presser Foot and Presser Foot Lift ......................................................................... 29

Two-Step Extra Presser Foot Lift .................................................................................................. 29

Presser Feet.............................................................................................................................30-31

4. TROUBLESHOOTING AND MAINTENANCE ........................................................32-37

Troubleshooting .......................................................................................................................32-36

Maintenance.................................................................................................................................. 37

5. APPENDIX - GLOSSARY ............................................................................................ 38

Glossary of Key Sewing Terms ..................................................................................................... 38

Explanation key to notations in this manual:

= Helpful information

⚠ = Could cause harm

= Impacts sewing results

¤

To ensure that you are always provided with the most modern sewing capabilities, the manufacturer reserves the right to change

SINGER

appearance, design or accessories of this sewing machine when considered necessary.

®

& Singer is Sewing Made Easy is a registered trademark of The SINGER® Company Limited or its af¿liates.

© 2016 The SINGER

6

®

Company Limited or its af¿liates. All rights reserved.

ABOUT YOUR MACHINE

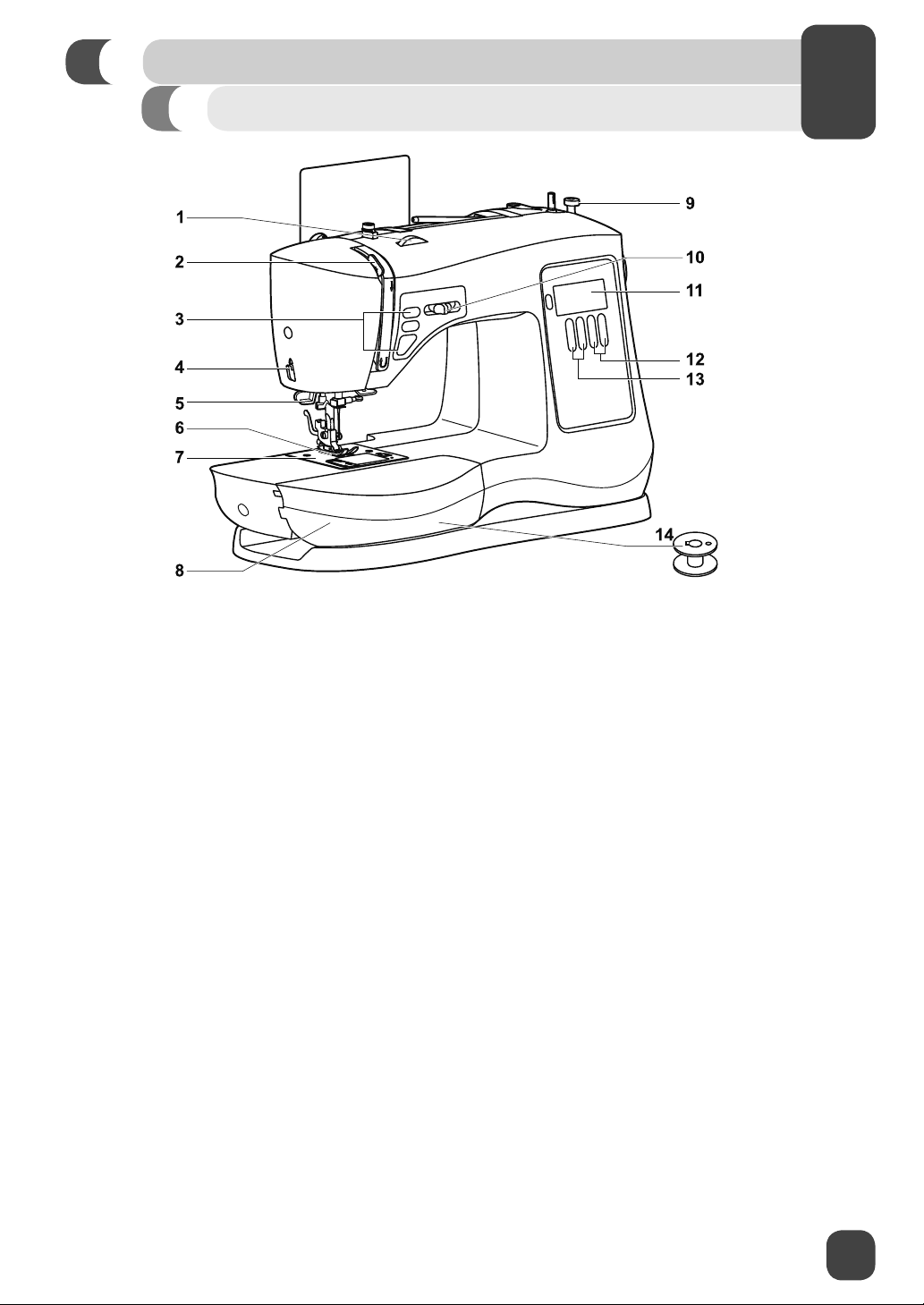

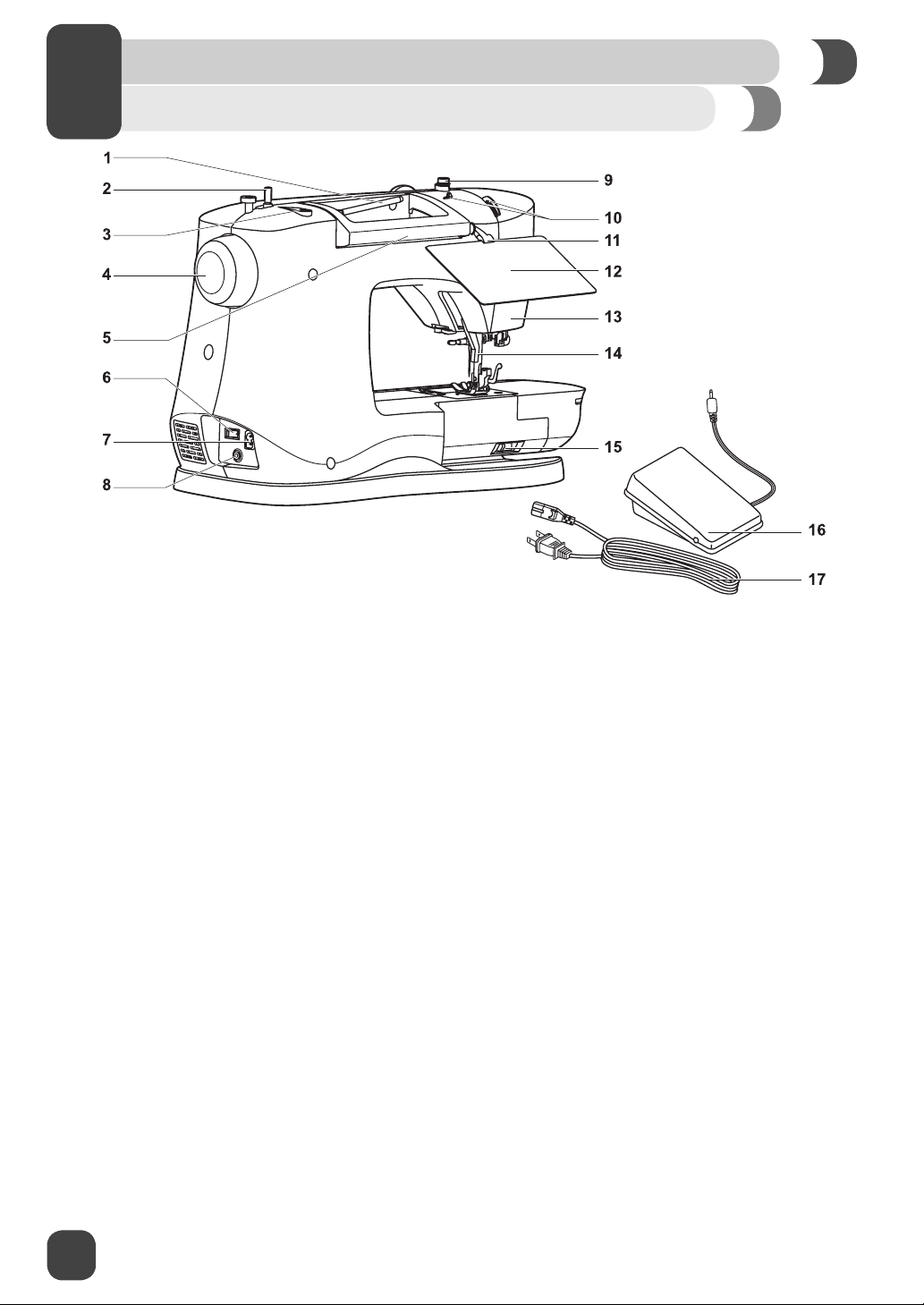

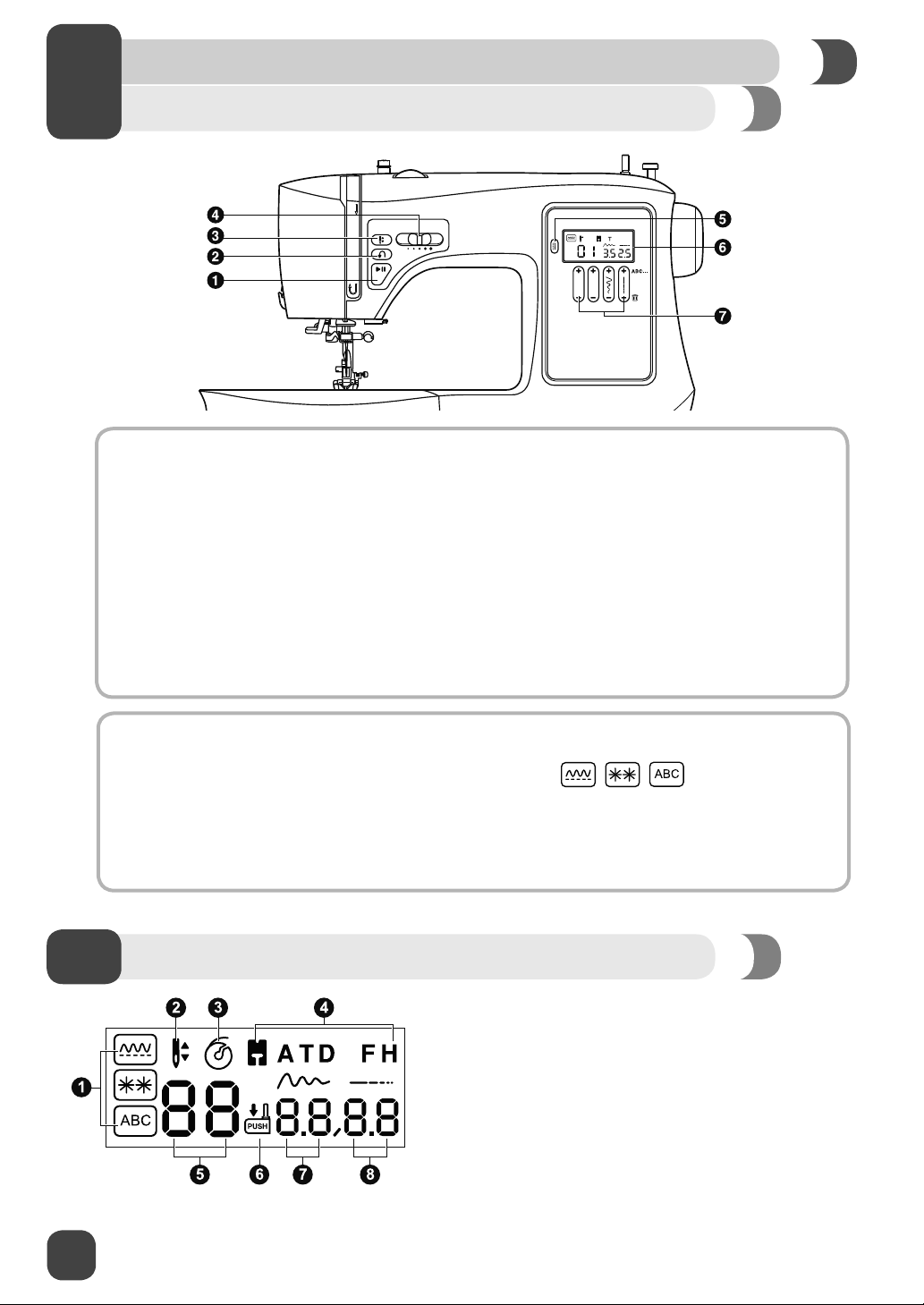

Main Parts of the Machine Front

1

1. THREAD TENSION DIAL allows you to select just the right tension for your stitch, thread and

fabric. (See Page 19)

2. THREAD TAKE-UP LEVER controls the Àow of the upper thread while sewing. (See Page 15)

3. OPERATION BUTTONS control the needle up/down and Start/Stop functions, as well as the

reverse function. (See Page 20)

4. THREAD CUTTER is conveniently located for trimming thread ends at the end of sewing.

5. NEEDLE THREADER LEVER is used to engage the automatic needle threader. (See Page 16)

6. PRESSER FOOT holds fabric against feed teeth, drawing fabric under the foot for you as you sew.

(See Page 29)

7. NEEDLE PLATE has guidelines to help you keep seams straight. (See Page 9)

8. REMOVABLE STORAGE COMPARTMENT provides Àat surface for sewing, storage for

accessories, and provides access to the free arm. (See Page 10)

9. BOBBIN WINDING STOPPER determines when bobbin is full and disengages automatically. (See

Page 13)

10. SPEED CONTROL ADJUSTMENT LEVER controls the speed at which the machine sews when

using the Foot Control or the manual Start/Stop Button. (See Page 20)

11. LCD SCREEN visually displays the stitch number, the stitch length or the stitch width depending

on what Mode you have selected (See Page 20)

12. FUNCTION BUTTONS control the stitch width and the stitch length, as well as the pattern memory

for alpha and numerical stitches. (See Page 21 and 22)

13. PATTERN ADJUSTMENT BUTTONS control the selection of the stitch patterns. The left button

controls the left digit and the right button controls the right digit. (See Page 20 and 22)

14. BOBBIN holds the thread that forms the stitching that appears on the bottom side of the fabric.

(See Page 14)

7

2

1

ABOUT YOUR MACHINE

Main Parts of the Machine Back

1. HORIZONTAL SPOOL PIN holds the thread spool and spool cap for the upper thread.

2. BOBBIN WINDING SPINDLE holds bobbin as it winds. (See Page 13)

3. HOLE FOR SECOND SPOOL PIN is used to hold an additional spool pin, for thread spools to be

used in upright position or for using two spools at once for twin needle sewing.

HANDWHEEL (ALWAYS TURN IT TOWARD YOU)

4.

thread take-up lever

5. HANDLE is used for lifting and transporting the machine.

6.

POWER AND LIGHT SWITCH turns on machine and sewing light simultaneously. (See Page 12)

7.

MAIN PLUG SOCKET is used to connect the power cord. (See Page 12)

8.

FOOT CONTROL CONNECTOR is where the foot control connects to the machine. (See Page 12)

9.

BOBBIN WINDING TENSION DISK

bobbin winding. (See Page 13)

10. PRE-TENSION THREAD GUIDES help maintain the Àow of the thread during sewing. (See Page

15)

STITCH CHART HOLDER is inserted into the left side of the handle to hold the Pattern Stitch Chart.

11.

STITCH PATTERN CHART

12.

to view the stitches. This chart is located in the bag where the instruction manual is stored.

13. F

ACE PLATE houses and protects the interior mechanisms of the machine.

PRESSER FOOT LIFTER

14.

threading and down for sewing. (See Page 29)

DROP FEED LEVER

15.

button. (See Page 27)

16. FOOT

17. POWER

CONTROL controls sewing speed by the amount of pressure applied by user. (See Page 12)

CORD connects the machine to the power source. (See Page 12)

.

holds the thread snuggly to help ensure smooth and even

shows all available stitches for easy selection. Flip it toward you in order

raises and lowers presser foot. It should be placed up for machine

controls whether the feed teeth are up for sewing or down for attaching a

, controls movement of the needle and the

8

ABOUT YOUR MACHINE

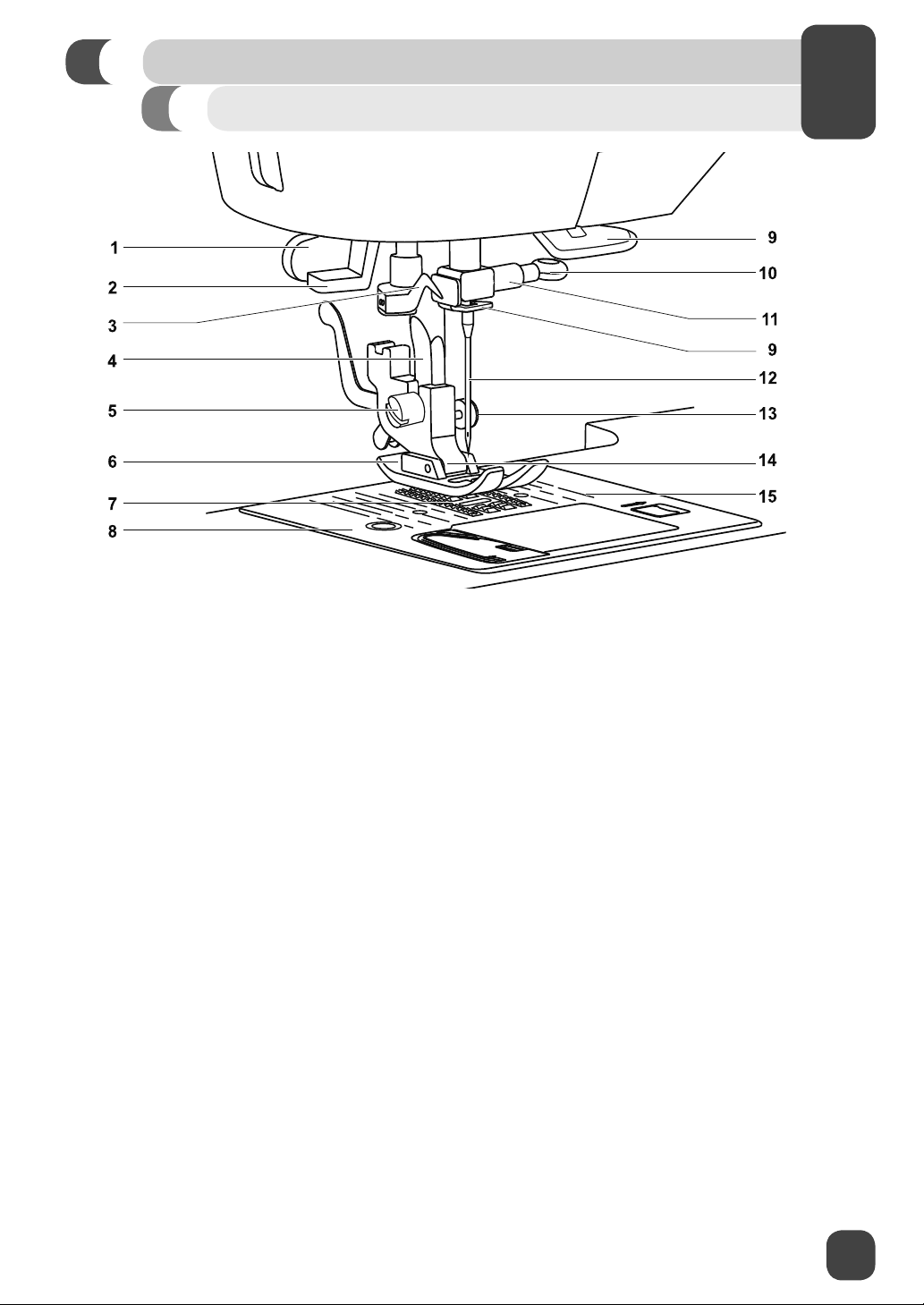

Needle and Presser Foot Area

1

1. ONE STEP BUTTONHOLE LEVER automatically determines the length of the buttonhole when

lowered. (See Page 26)

2. NEEDLE THREADER LEVER is used to engage the automatic needle threader mechanism.

3. NEEDLE THREADER GUIDE holds thread securely before placing it in hook pin.

4. PRESSER BAR accommodates the presser foot holder.

5. PRESSER FOOT SCREW secures the presser foot holder (shank) onto the presser bar.

6. PRESSER FOOT holds fabric against the feed teeth while sewing. Various optional presser feet

are available, depending on fabric sewn and sewing techniques. (See Page 11)

7. FEED TEETH (OR FEED DOGS), which look like rows of teeth under the presser foot, control the

movement of the fabric under the presser foot.

8. NEEDLE PLATE covers the bobbin area and provides Àat area around presser foot for sewing.

9. THREAD GUIDE controls movement of upper thread.

10. NEEDLE CLAMP SCREW secures the needle when placed in needle clamp.

11. NEEDLE CLAMP holds the machine’s needle in position.

12. NEEDLE holds thread during stitch formation.

13. LOCK IN PLACE BUTTON helps with even feeding over extra thick seams.

14. PRESSER FOOT HOLDER (OR SHANK) holds presser foot.

15. STITCHING GUIDELINES are used as a visual reference for guiding fabric straight while sewing.

The ¿rst line is 3/8” (10mm) from center needle position. The most popular seam allowance

measurements are 1/2” (13mm) and 5/8” (16mm). The 1/2” seam allowance is the 2nd line, and

the 5/8” seam allowance is the 3rd line from center needle position.

9

ABOUT YOUR MACHINE

2

1

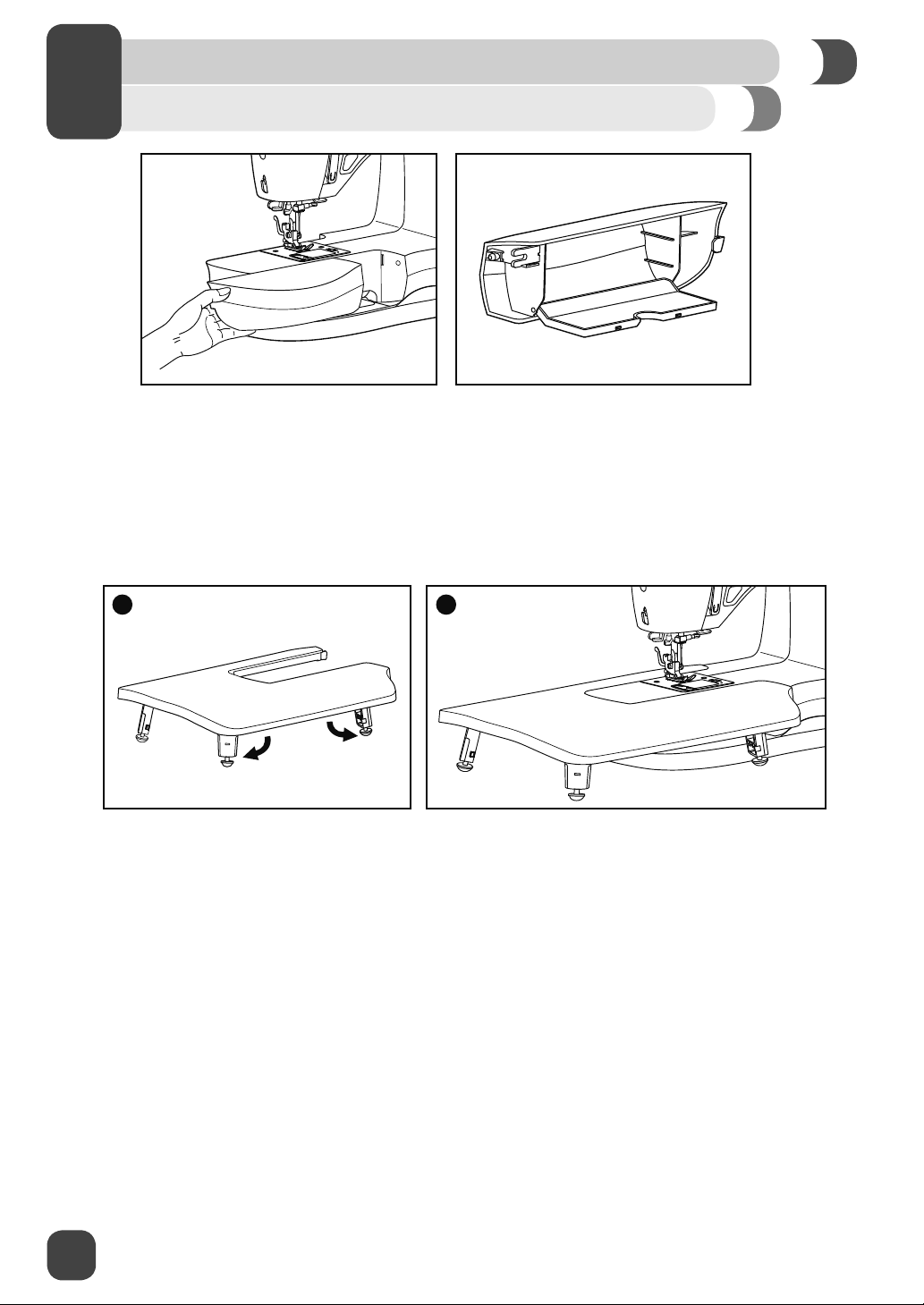

Removable Storage Compartment and Accessories

Hold the Removable Storage Compartment horizontally, then pull toward the left to remove it from the

machine. Doing this, you will have access to the free arm, which makes it easy to sew tubular projects

like pant hems or sleeves. Additionally, you will ¿nd the machine’s accessories stored here (See Page

11).

To replace the Removable Storage Compartment, hold it as shown in the illustration, and then push it

to the right.

A B

The extension table provides additional sewing space when sewing bulky items.

To install, extend the legs as indicated in photo (A).

Remove the storage compartment and slip the table onto the free arm (B).

Extension table rubber feet can be adjusted by turning left or right to ensure that the table is level for

the surface on which you are sewing.

10

ABOUT YOUR MACHINE

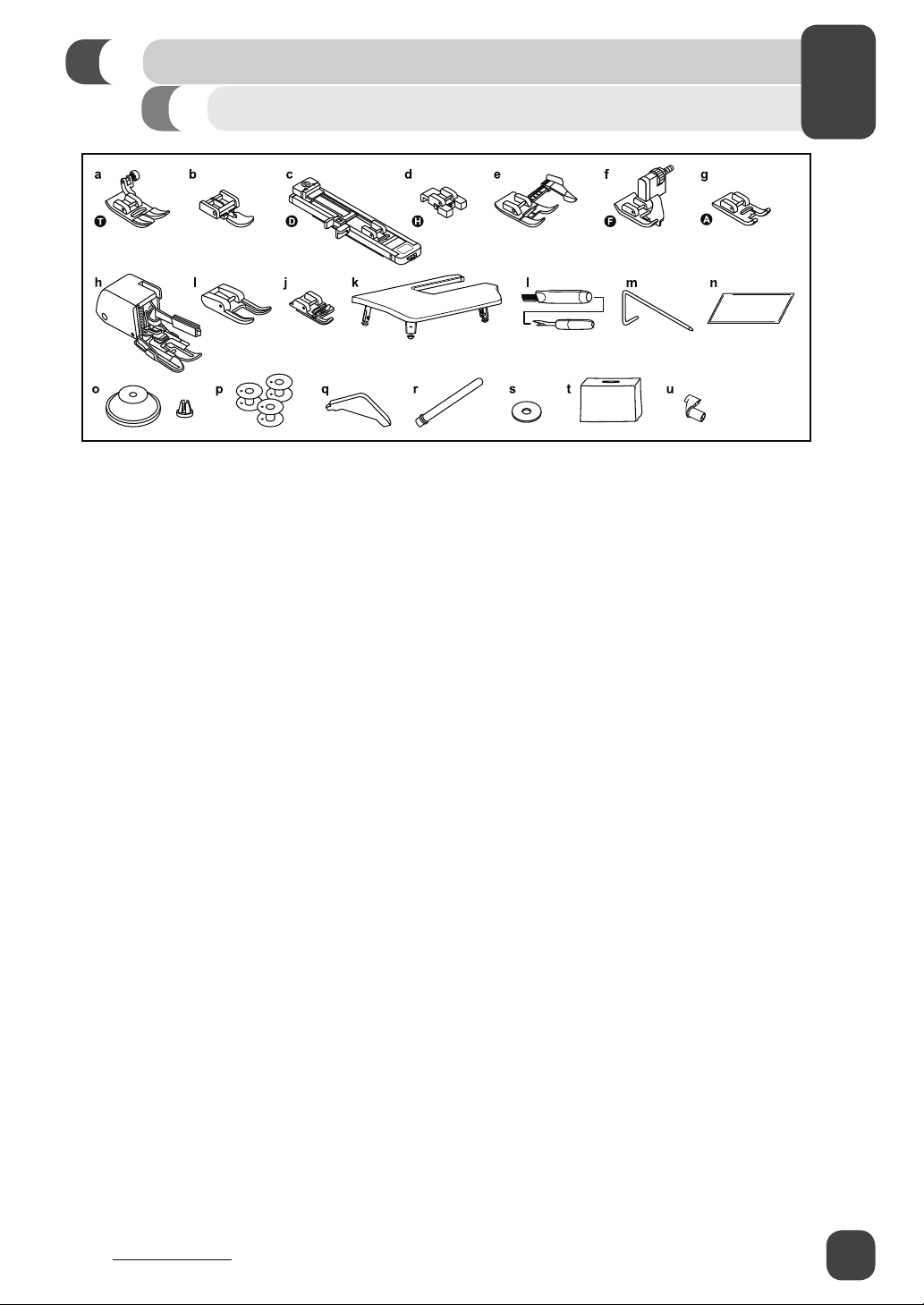

Accessories

This machine comes with a standard assortment of presser feet and accessories.

Most accessories are located in the storage compartment. The Even Feed Foot can be found in the

Styrofoam that holds the Extension Table.

Standard Accessories Included:

a. All Purpose Foot (for general sewing)

b. Zipper Foot (for inserting a zipper)

c. Buttonhole Foot (for making buttonholes)

d. Button Sewing Foot (for attaching buttons) (* This foot may be optional with machines sold in

some areas)

e. Sew Easy Foot (for sewing accurate seams) (* This foot may be optional with machines sold in

some areas)

f. Blind Hem Foot (for sewing a blind hem)

g. Satin Stitch Foot (for satin stitches and other decorative stitches)

h. Even Feed Foot (for even feeding of plaid, velvet and other napped fabrics) (* This foot may be

optional with machines sold in some areas)

i. Open Toe Foot (for satin stitches and other embellishments) (* This foot may be optional with

machines sold in some areas)

j. Cording Foot (for decorative cord application) (* This foot may be optional with machines sold

in some areas)

k. Extension Table (provides a larger level sewing surface). Remove the storage compartment to

connect the table to the machine.

l. Seam Ripper/Brush (remove stitches/brush out lint)

m. Edge/Quilting guide (for straight & accurate quilting) (* This guide may be optional with

machines sold in some areas)

n. Pack of Needles (replacement needles)

o. Spool Holders (2 sizes for various thread spool styles)

p. Bobbins (Class 15 transparent bobbins)

q. L-Screwdriver (to remove needle plate for cleaning)

r. Second Spool Pin (for sewing with an optional twin needle)

s. Spool Pin Felt (to cushion the spool of thread when using the second spool pin)

t. Soft Cover (to protect your machine from dust and lint while not in use)

u. Stitch Chart Holder (holds the Stitch Pattern Chart for easy viewing)

Optional Accessories:

Some of the presser feet listed above may not be included with machines sold in certain areas. If these presser feet

were not included with your machine, they may be purchased separately. See the Optional Accessories information

below.

1

For information about additional presser feet, attachments and accessories that may be available for your machine,

visit www.singerco.com.

11

GETTING READY TO SEW

2

2

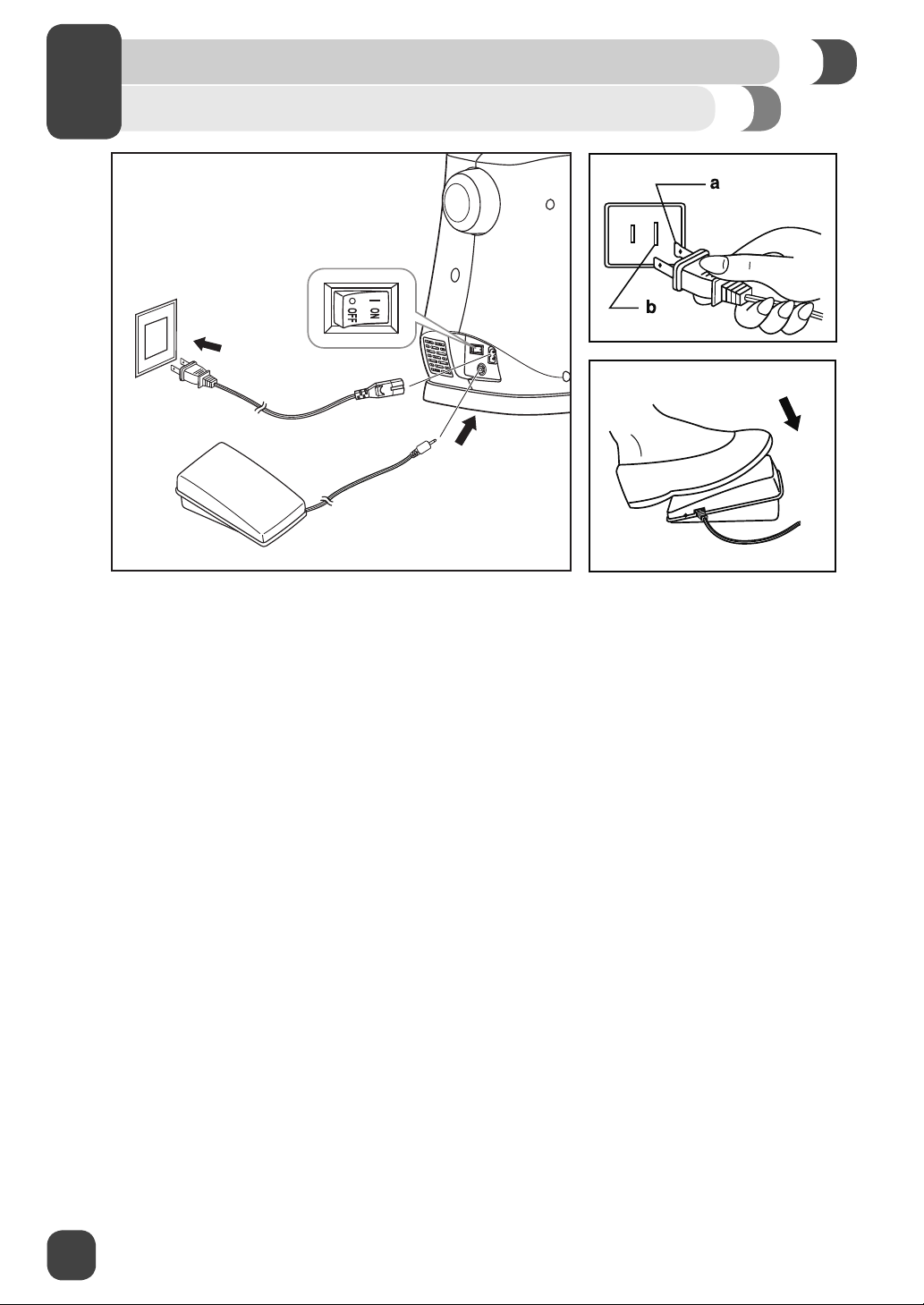

Powering Your Machine

Connect the machine to a power source as illustrated. This machine is equipped with a polarized plug

which must be used with the appropriate polarized outlet. (a and b)

⚠ Unplug power cord when machine is not in use.

Foot Control

The foot control regulates the sewing speed. When foot control is disconnected, use the Start/Stop

Button to operate the machine.

Sewing Light

Press main switch from OFF(o) to ON (-) for power and light.

⚠ For machine with a polarized plug (one blade is wider than the other). To reduce the risk of

electric shock, this plug is intended to ¿t in a polarized outlet only one way

outlet, reverse the plug. If it still does not ¿t, contact a quali¿ed electrician to install the proper outlet.

Do not modify the plug in any way

⚠ Your SINGER

Extreme hot and cold temperatures can affect the sewing results.

®

machine is adjusted to provide the best stitch results at normal room temperature.

.

. If it does not ¿

t fully in the

⚠After switching off, residual power may still remain in the machine. This may cause the light to

stay on for a few seconds while the power is consumed.

appliance.

This is normal behavior for an energy ef¿

cient

12

GETTING READY TO SEW

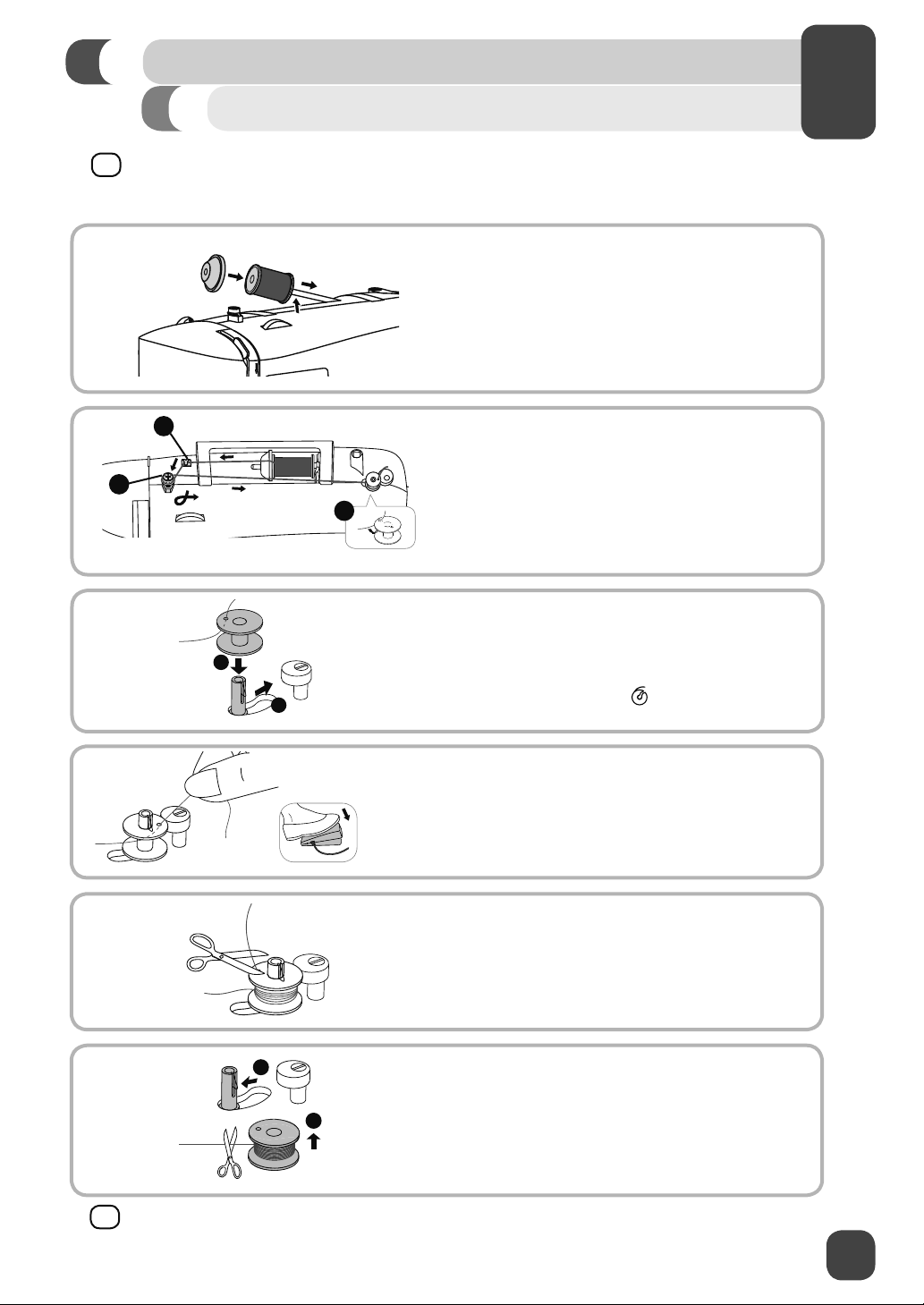

Winding the Bobbin

¤

This machine uses Class 15 transparent bobbins.

Use only this style of bobbin when purchasing additional bobbins for your machine. Do not substitute

with metal bobbins.

1. Place thread spool and corresponding size

spool holder onto spool pin. Spool holder

should be large enough to cover the end of the

thread spool so thread unreels smoothly. For

smaller, narrower spools, use the small spool

cap, which can be found in the removable

storage compartment.

2

A

B

C

A

B

7

2. (A) Snap thread into guide at top of machine.

(B) Place thread snuggly around bobbin

winding tension disk to ensure that thread

winds onto bobbin smoothly and consistently.

(C) Thread bobbin as shown, then place it onto

the bobbin winding spindle.

3. Check that bobbin is pushed down ¿rmly (A).

If it is not, the thread could begin winding

under the bobbin. Push the bobbin and spindle

¿rmly to the right (B).

When the bobbin winding spindle is pushed to

the right, the symbol “

screen.

4. Hold the thread end to get ready to wind.

Step on the foot control gently or press the

Start/Stop Button as you hold the thread end.

Allow it to wind a few revolutions slowly, then

remove your foot from the foot control or press

the Start/Stop Button to stop.

5. Trim the thread end close to the top of the

bobbin, then resume winding by stepping on

the foot control or pressing the Start/Stop

Button.

“ appears on the LCD

A

B

¤

When the bobbin winding spindle is pushed to the right, the machine will NOT sew. Make sure

to push the bobbin winding spindle back to the left once bobbin winding is complete.

6. The bobbin will stop winding when it is full. Lift

your foot off the foot control or press the Start/

Stop Button. Push the bobbin to the left (A),

then trim the thread and remove the bobbin

from the spindle (B).

13

GETTING READY TO SEW

2

2

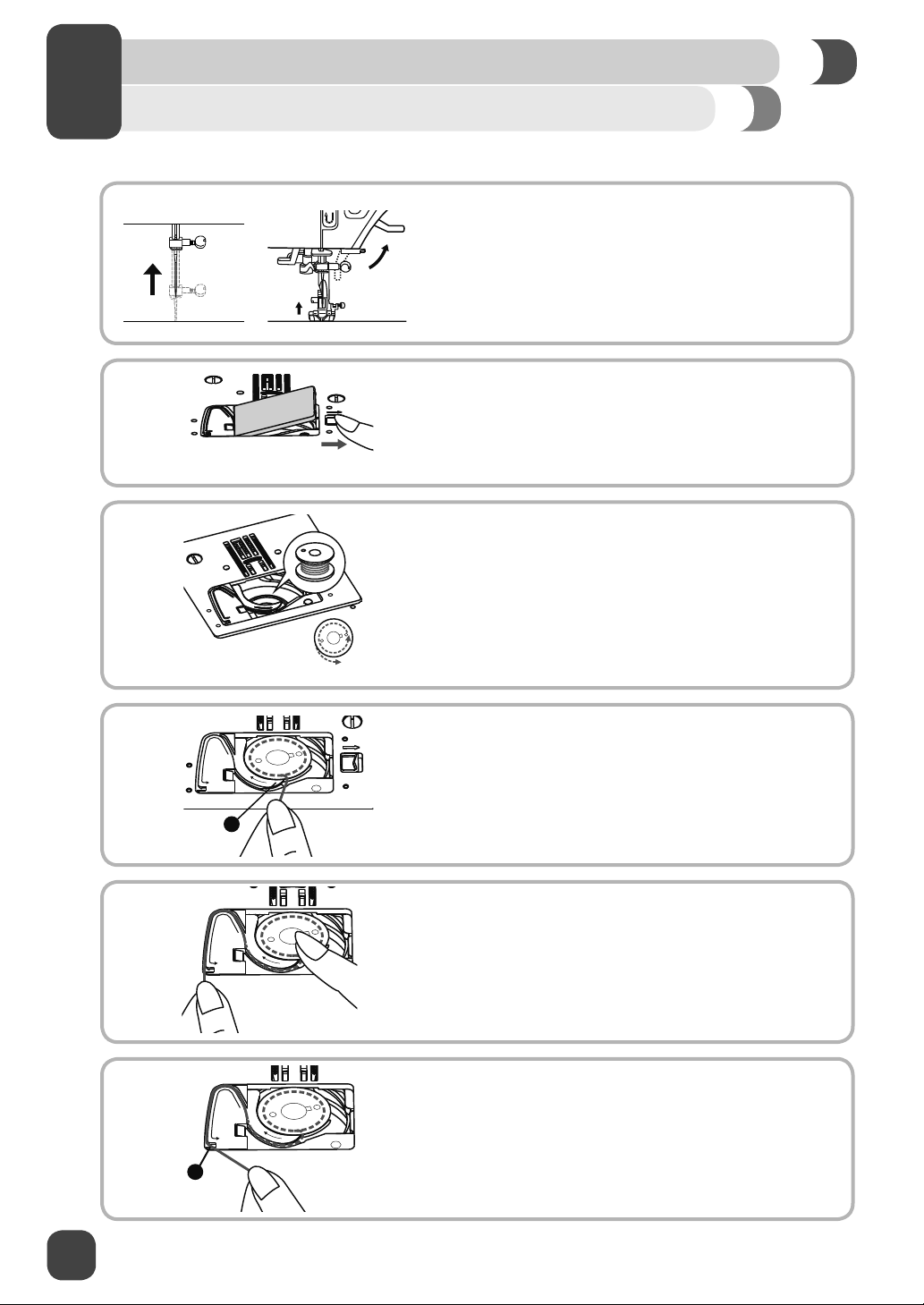

Inserting the Bobbin

⚠ Turn power switch off before inserting or removing the bobbin.

1. When inserting or removing the bobbin, the needle and

presser foot must be fully raised.

2. Push the bobbin cover release button to remove the

bobbin cover plate. Remove the empty bobbin.

3. Insert the wound bobbin in the bobbin case with the

thread running in a counterclockwise direction (arrow).

14

4. Pull the thread through the slit (A).

A

5. With a ¿nger held gently on top of the bobbin, place

thread ¿rmly into guides as shown.

6. To cut off excess thread pull it toward you to cut it with

the cutter at point (B). Replace the bobbin cover plate.

B

GETTING READY TO SEW

Threading the Upper Thread

⚠ For safety, turn off the power before threading the machine.

2

A B C

1. Start by turning the handwheel (A) toward you

to raise the needle (B) and the thread take up

lever (C).

lever

¤

2.

necessary in order for the machine to be

threaded correctly

3. Place the thread spool and spool cap onto the

spool holder

4.

Draw thread from the spool through the two pretension guides at the top of the machine (see

page 8). Hold the thread with both hands and

pull it into each of the guides.

ou should be able to see the take up

Y

.

Raise the presser foot lifter. This is

.

.

A B C

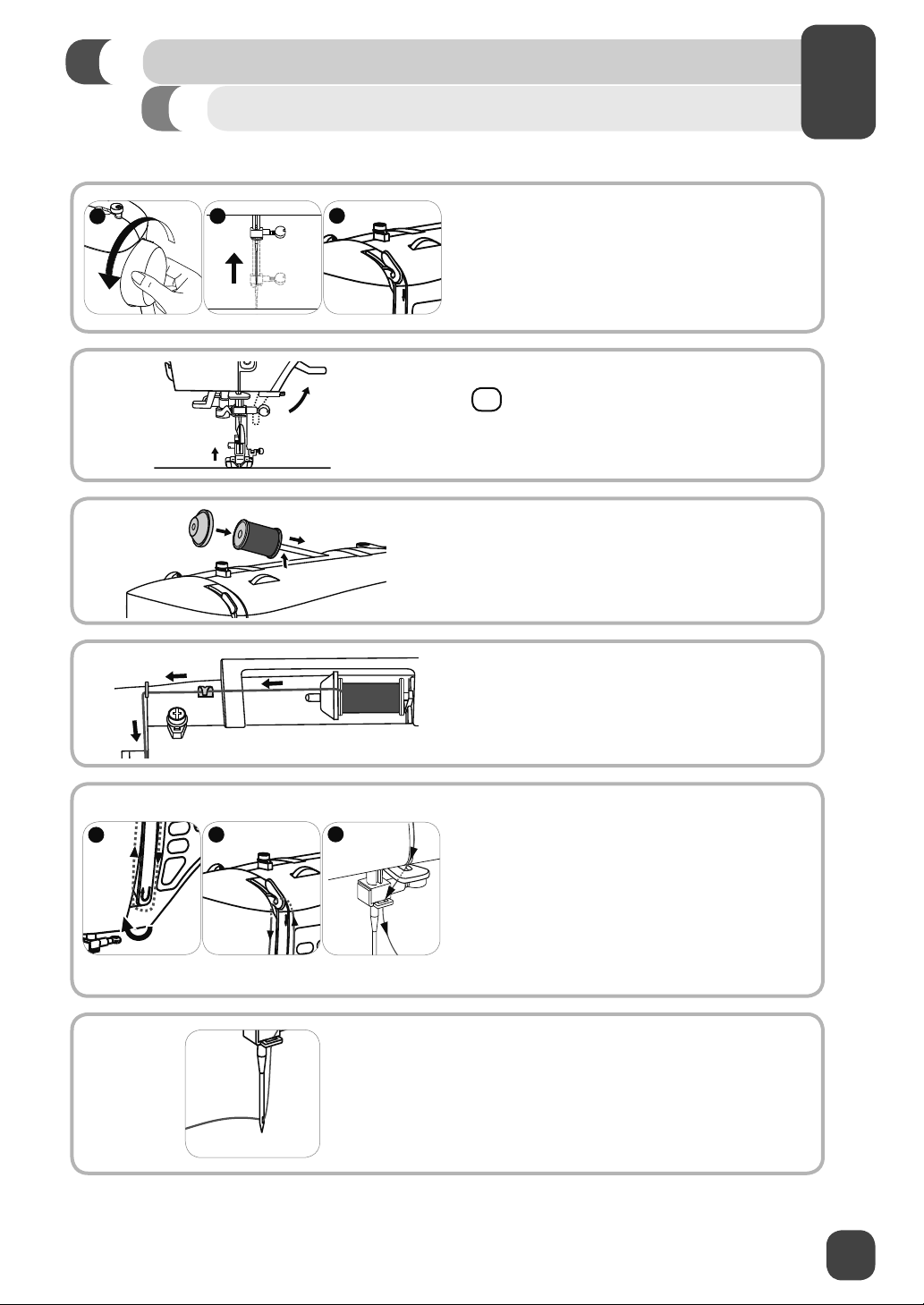

5. (A) Bring the thread down the right channel,

around the U-turn, and up the left channel.

(B) At the top of the left channel, slip the thread

from back to front through the slotted eye of the

thread take-up lever. If the thread does not pass

into the eye of the take-up lever, the machine

will jam when you start to sew. After threading

the take-up lever, bring the thread downward

again. (C) Pass the thread behind the metal

thread guides and then down to the needle.

6.

If you want to thread the needle manually

thread it from front to back. Pull about 6-8

inches of thread to the back beyond the needle

eye.

Alternatively

needle threader to thread the eye of the needle.

(see page 16)

, you can use the automatic

,

15

GETTING READY TO SEW

2

2

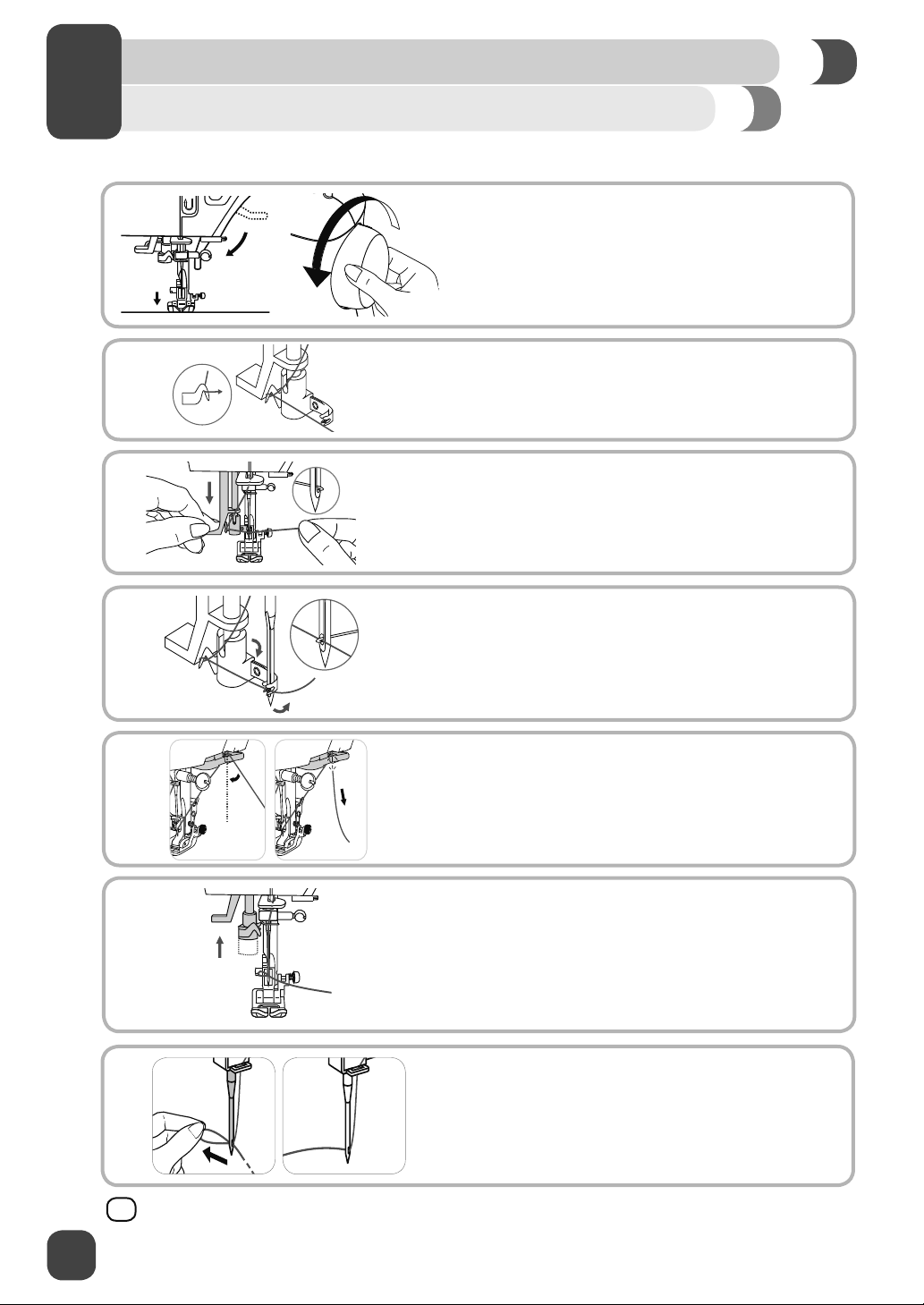

Automatic Needle Threader

⚠ For safety, turn off the power before using the automatic needle threader.

1. Lower the presser foot lifter. Raise the

needle to its highest position by turning

the handwheel toward you. If you turn the

handwheel backward, the machine will jam

when you start to sew.

2. Pass thread around thread guide.

3. Press lever down as far as it will go. The

threader automatically swings to the threading

position.

4. Pass the thread in front of the needle and under

the hook.

5. To cut the excess thread, take thread tail and

gently slip it over the thread cutter located to the

right of the needle.

6. Release the lever & the thread tail at the same

time, this will form a loop at the back of the

needle.

7. Pull the thread through the needle eye. While

holding the thread, raise the presser foot lifter

and pull the thread under the foot toward the

back.

¤

Pull about 6-8” of thread to the back beyond the eye of the needle. This will help prevent the needle

from becoming unthreaded when you start to sew.

16

GETTING READY TO SEW

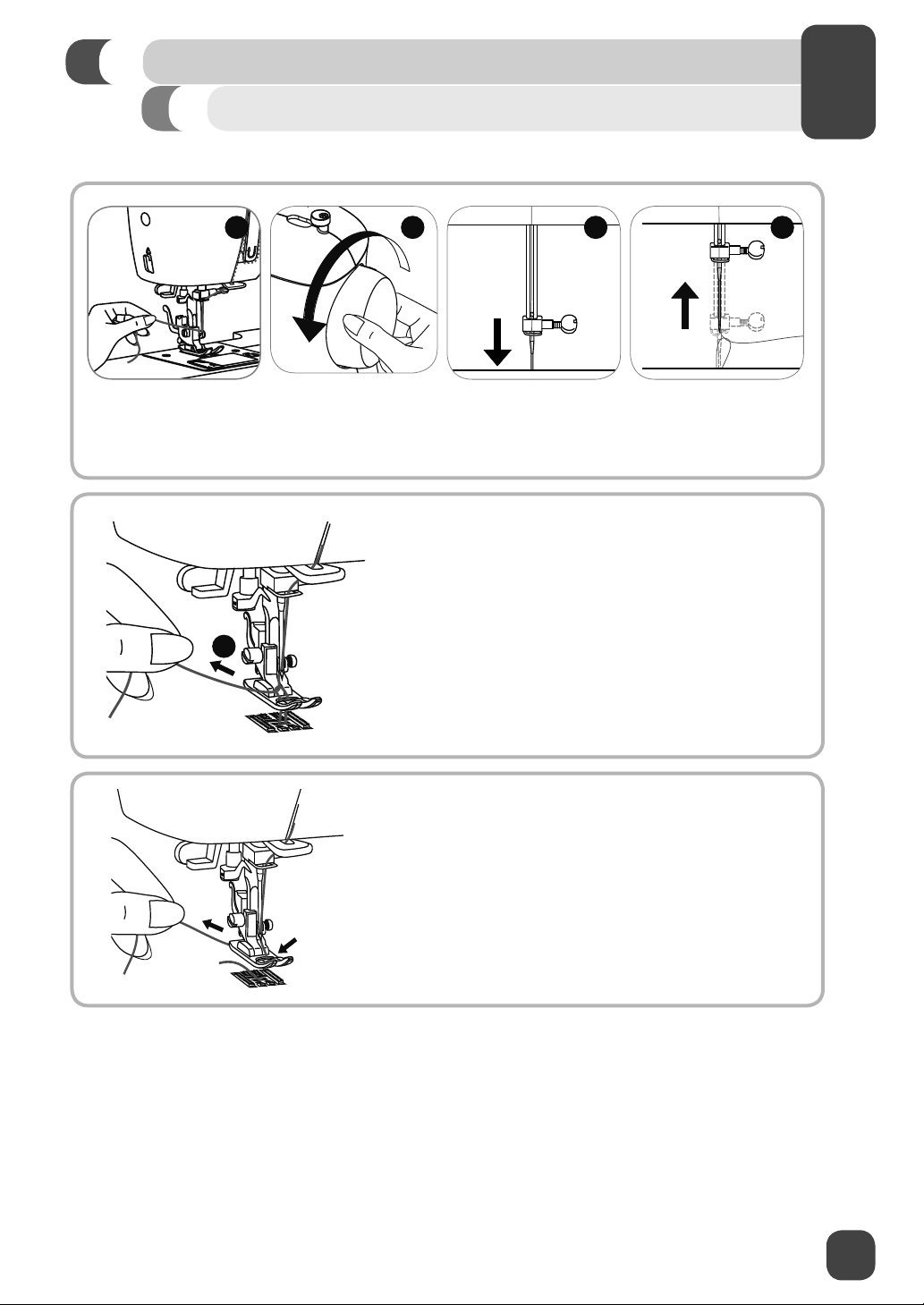

Drawing Up the Bobbin Thread

⚠ For safety, turn off the power before threading the machine.

B C DA

1. Hold the upper thread tail with the left hand (A). Turn the handwheel toward you (B), ¿rst lowering

(C) and then raising the needle (D).

2. As you turn the handwheel, gently pull the upper

thread, which will bring a loop of the bobbin thread

up through the hole of the needle plate (E). If a

loop doesn’t pull up, turn the handwheel toward

E

you one more time. If it still doesn’t come up,

check that the bobbin thread is not trapped by the

bobbin cover.

2

3. Bring the upper thread under the presser foot and

toward the back of the machine.

17

START SEWING

2

3

Before You Start Sewing

Now that your machine is threaded, we will show how to set up the machine for basic sewing

techniques such as: sewing a straight stitch, sewing a decorative stitch, sewing a stretch stitch,

sewing a buttonhole and sewing a button. With each technique, you have the opportunity to sew

along.

For more information about the various stitches on your machine and how to use them, refer to the

Stitch Reference Guide by visiting www.singerco.com.

Here are a few other tips that you may ¿nd helpful before you begin:

When unpacking the machine, you may have noticed some small traces of oil around the needle plate

or presser foot area. If so, wipe off any excess oil with a soft, dry cloth before you start sewing. It is

also recommended that you sew on a piece of scrap fabric to remove excess oil.

The Speed Control Adjustment Lever is used to control the speed of your machine. This is the

case whether you are using the Foot Control or the Start/Stop Button to start sewing. To increase

the sewing speed slide the lever to the right, to reduce the speed slide the lever to the left. When

you remove your foot from the foot control or you press the Start/Stop Button the machine will stop

sewing.

Needles are an important part of sewing. Using old, damaged or incorrect needles for your projects

can affect sewing results. For information about which needle to use for your project, refer to the

Stitch Reference Guide at www.singerco.com. For information on how to change the needle, see

page 28.

Depending on the sewing technique you want to do, it may be necessary to change to a different

presser foot. For information on how to do this, see page 29.

Review the page about Stitch Formation (See Page 19). This will help you understand what the

stitching should look like when you sew.

Use the thread cutter on the machine (See Page 7) to trim thread tails when ¿nished sewing. This

is helpful because thread tails are left long enough so that the needle does not become unthreaded

when you start sewing again.

18

START SEWING

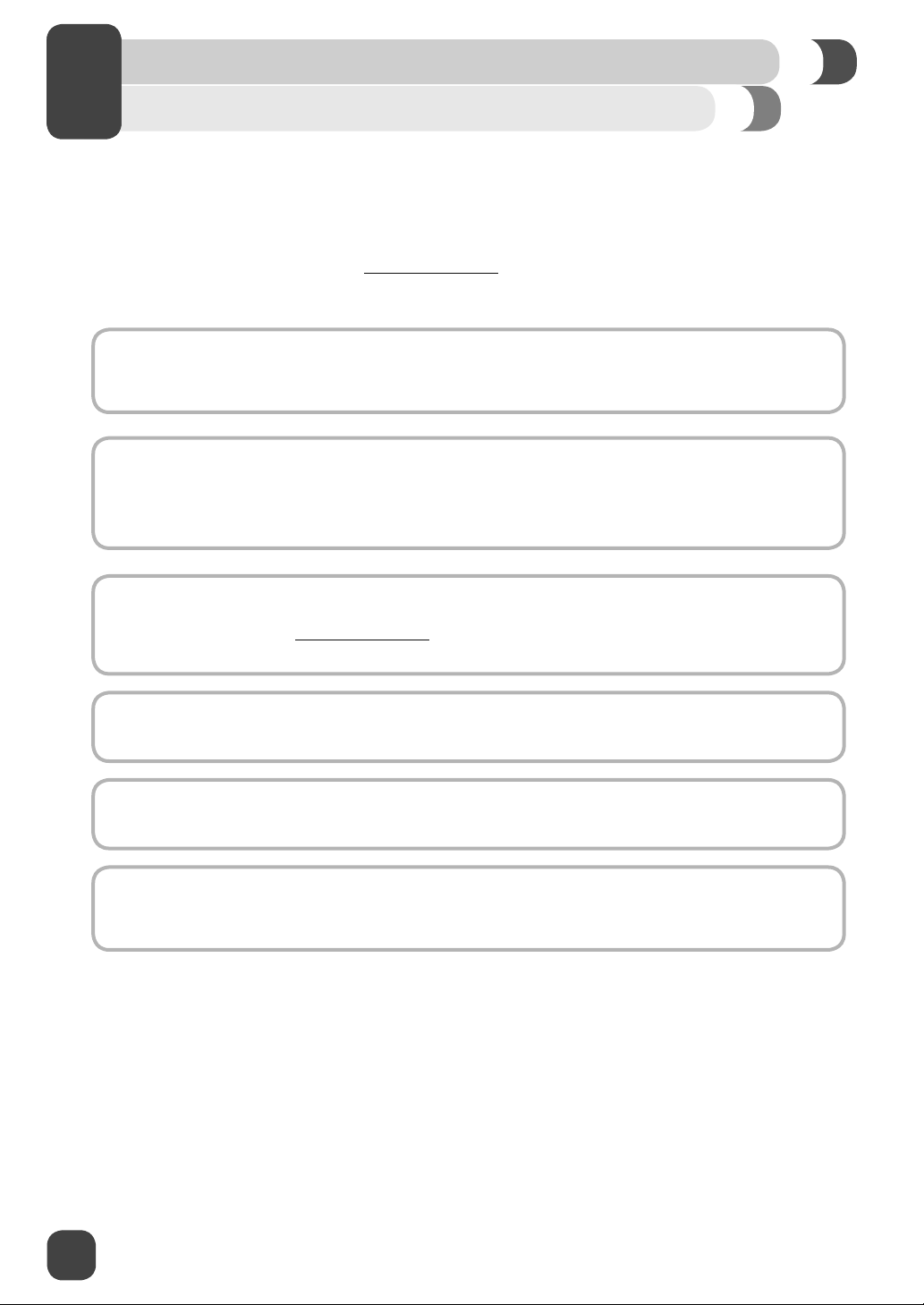

Stitch Formation

3

Reverse

side

Upper thread

Bobbin thread

Reverse

side

Upper thread

Bobbin thread

Reverse

side

Upper thread

Bobbin thread

Surface

Surface

Surface

1. How Stitches Form

Stitches are formed when the upper thread

and the bobbin thread interlock between the

fabric layers. Stitching is well balanced when

the needle thread appears on the top and the

bobbin thread appears on the bottom.

2. Thread Tension Dial

The Thread Tension Dial has a range of

settings between 0 and 9. Most of your sewing

will be done with your Thread Tension Dial set

between 3 and 5. It can be adjusted to a higher

number for more tension on the upper thread,

if the upper thread seems too loose. It can be

adjusted to a lower number for less tension on

the upper thread, if the bobbin thread seems to

be showing on the top side of the fabric.

Adjusting Tension

Thread tension can also be adjusted for

various sewing techniques. For basting (see

Appendix), you can loosen it to a lower number

so that the stitches can easily be removed. For

gathering, you can turn it to a higher number.

¤

3.

When you sew, if you see large loops

on the underside of the fabric, this is actually

an indication that the upper thread was

not threaded correctly, as it has no tension

controlling it. For information on how to correct

this, see the Troubleshooting and Maintenance

section of this manual.

19

START SEWING

2

3

Operation Buttons and Function Buttons

A. Operation Buttons

1. Start/Stop Button

Press this button to start or to stop the machine when the foot control is not being used.

2. Reverse Button

Hold down this button to sew stitches in reverse at the start and at the end of a seam, as well

as most stitch patterns. The Reverse Button is also used for saving characters from the ABC

Mode. (See Page 21)

3. Needle Up/ Needle Down Position Button

Press this button to move the needle to either the up or the down position. Needle will be

programmed to stop in selected position until the button is pressed again.

4. Speed Control Adjustment Lever

Slide this lever to the left to slow the machine and to the right to increase the speed of the

machine.

B. Function Buttons

5. Mode Button

Allows you to toggle between the three mode selections:

6. LCD Screen

Displays instructions pertaining to the stitch you have selected.

7. Function Buttons

Control stitch number selection, as well as the width and the length of the stitches.

, , .

LCD Screen

1. Mode indicator

2. Needle up/down

3. Bobbin winding indicator

4. Presser foot indicator

5. Stitch number

6. Buttonhole lever indicator

7. Stitch width

8. Stitch length

20

START SEWING

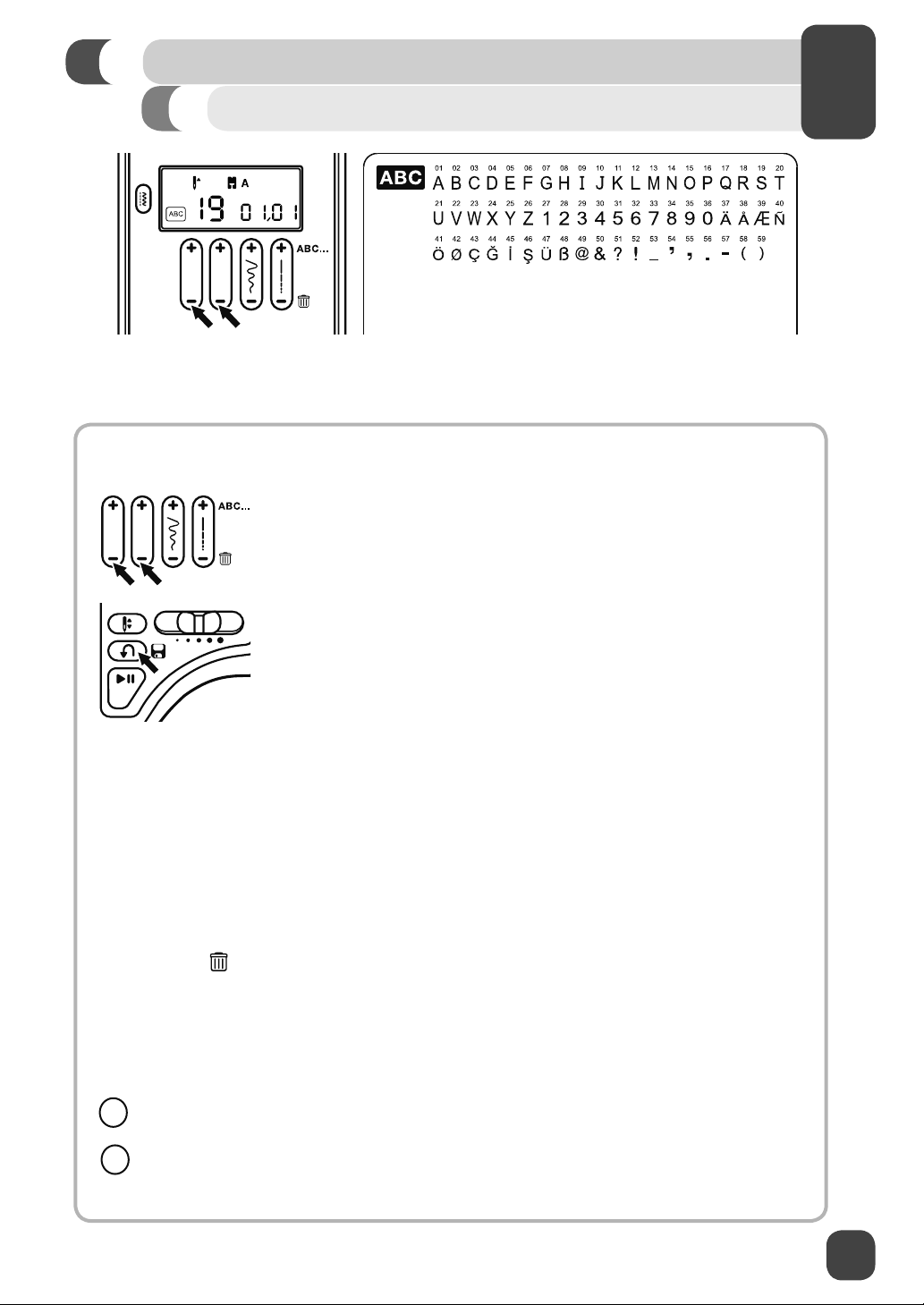

Combining Characters into Memory

Your machine has the capability of combining characters from the ABC. Up to 40 alpha or

numerical stitches from the ABC mode can be combined.

Combining Stitches:

Example – SINGER – Combining stitch numbers 19, 09, 14, 07, 05, 18

1. Letters are selected by pressing the + and - of the two Function

Buttons located on the left. After selecting each letter press the + side

of the ABC Function Button located all the way to the right.

2. After all letters are selected, save the letter sequence by pressing the

Reverse Button.

3

3. You are now ready to sew out the word SINGER. It will stitch the

letter sequence that was saved and will stop when the sequence is

completed. In order to repeat the sequence, press the Foot Control or

the Start/Stop Button.

Inserting a Stitch:

1. When an error is made, for example you leave out the “E” in SINGR.

2. Using the +/- Stitch Width Function Button scroll to the 4th letter of the 5 stitches entered

(04/05). (These numbers are displayed under the width and length icons on the LCD screen)

3. Using the +/- side of the Pattern Adjustment Buttons, scroll to letter E, number 05. Press the +

side of the ABC Button to enter the letter.

4. Save the new spelling of the word by pressing the Reverse Button. You are now ready to sew

out the word SINGER

Delete a stitch:

1. Using the +/- Stitch Width Function Button scroll to the position of the stitch you want to delete.

2. Press the –

3. Save the edited sequence by pressing the Reverse Button.

Clear the Memory:

1. Press and hold the – side of the ABC Function Button until all programmed stitches are gone.

2. Save by pressing the Reverse Button.

When the Mode or the Function Buttons are touched, the machine will sound one warning

beep.

The machine will emit 3 short beeps to alert you if a function has been selected in error or if

the machine is jammed as a result of incorrect threading or the bobbin winding shaft is in the

winding position.

®

.

side of the ABC Function Button.

21

START SEWING

2

3

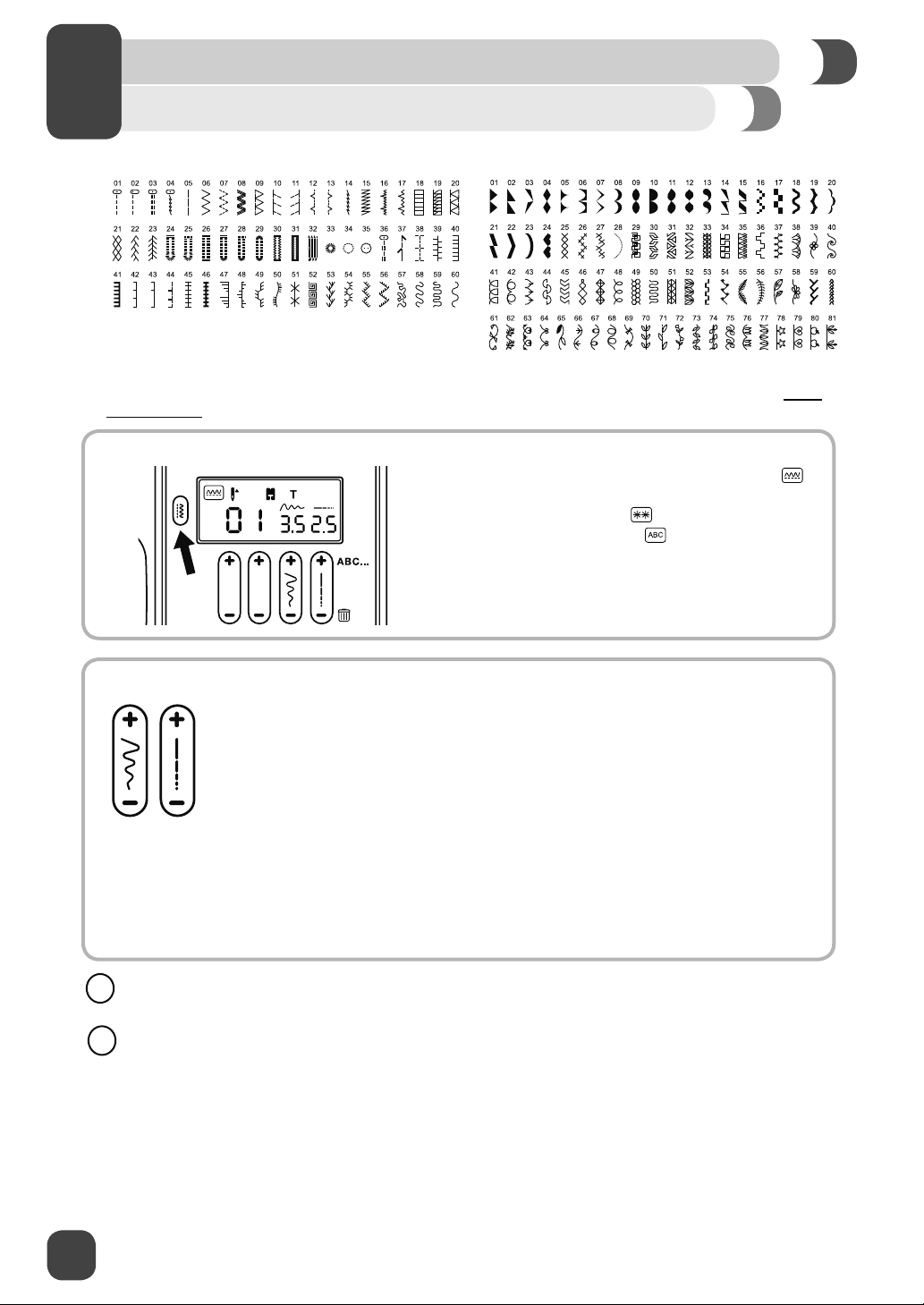

Stitch Selection

A. Utility Stitch Patterns B. Decorative Stitch Patterns

For examples of other stitch patterns and further instruction, see the Stitch Reference Guide at www.

singerco.com.

Choosing Utility and Decorative Stitch Patterns:

The machine will automatically default to the

Pattern Mode and Straight Stitch when turned on.

You can also select the

decorative stitches or the

Numeric Stitch Patterns.

Choose the mode and then press the two left + or

- Pattern Adjustment Buttons to select the number

of the stitch that you desire.

mode for additional

mode for Alpha-

Adjusting the Width or the Length of the Stitch:

The machine will automatically default to a preset stitch width and stitch length for

optimum results. These settings are displayed on the LCD screen.

You can adjust the width or the length of most stitches by toggling between the

Stitch Width and the Stitch Length Buttons. The button on the left controls the width

and the button on the right controls the length.

1. To increase the width of the stitch press the + button, and to decrease the

width of the stitch, press the – button. When Utility Stitch Patterns 01 to 05 are

selected, the needle position is regulated by the Stitch Width Adjustment Button.

Pressing – will move the needle to the left and pressing + will move the needle

to the right. On 3.5 the needle is positioned in the center for straight stitch.

2. To increase the length of the stitch press the + button and to decrease the length

of the stitch, press the – button.

The stitch width can be adjusted to 7.0 for most stitches. Some stitches have a limited stitch

width.

The stitch length can be adjusted from 0.0 to 4.5 for most stitches. Some stitches have a limited

stitch length.

22

START SEWING

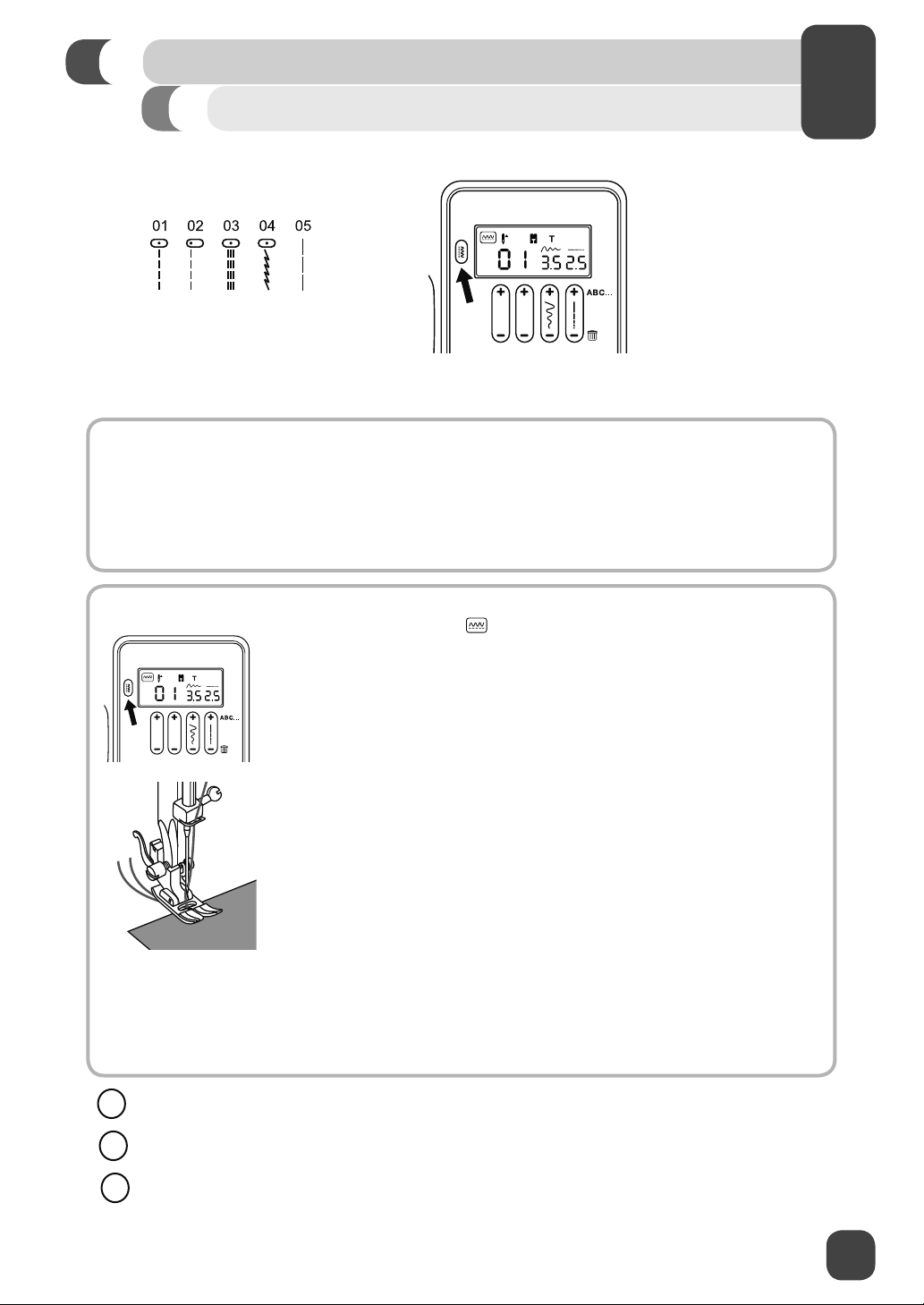

Sewing a Straight Stitch

Mode Button and Function Buttons

A straight stitch is used for sewing seams and topstitching.

HOW TO:

1. Set the machine to Straight stitch. The machine will automatically default to straight stitch when it

is turned on. (See Page 22)

2. The Stitch Length can be set at the stitch length that you desire. (See Page 22)

3. The Stitch Width can be set at either 0.0 or 3.5 depending on the needle position. (See Page 22)

3

SEW ALONG:

Use a slightly shorter stitch length for lightweight fabrics, ¿ner threads and needles. Use a longer

stitch length such as 3 or 4 for heavy weight fabrics.

It may be helpful to gently hold the thread tails with your left hand for the ¿rst few stitches, as this

will help guide the fabric under the foot as you begin to sew.

For sewing heavy weight fabrics, use the Lock In Place Button on the presser foot. (See Page

30)

1. Set Mode Button to

machine will automatically default to stitch 01 when you power it on.

2. Set the Stitch Length to 2.5. This is an average stitch length setting

for regular sewing. Your machine will automatically default to a stitch

length of 2.5, you can shorten or lengthen the stitch if you desire using

the Stitch Length Function Button.

3. Set the Stitch Width to 3.5. Your machine will automatically default to a

Stitch Width of 3.5 when you power it on. This will position the needle

in the center. Use the Stitch Width Button to move the position of the

needle.

4. Place the fabric under the All Purpose Foot or the Sew Easy Foot

(See Page 30) with the right-hand edge of the fabric lined up with the

desired seam guide line on the right side of the needle plate. Lower

the presser foot, then step on the Foot Control or press the Start/Stop

Button to begin sewing. Always make sure that the presser foot is

lowered before you begin to sew. If you fail to do so, the machine will

jam as you begin to sew. Start your seam by sewing 2 to 3 stitches.

Press and hold the Reverse Button to sew backwards 2 to 3 stitches,

which will lock the end of the seam so the stitches don’t come undone.

Release the Reverse Button to sew forward again. Continue sewing

the length of the seam. Press and hold the Reverse Button at the end

of the seam and sew backwards 2 to 3 stitches. Release the Reverse

Button to sew forward again to ¿nish.

and choose Straight Stitch number 01. Your

23

START SEWING

2

3

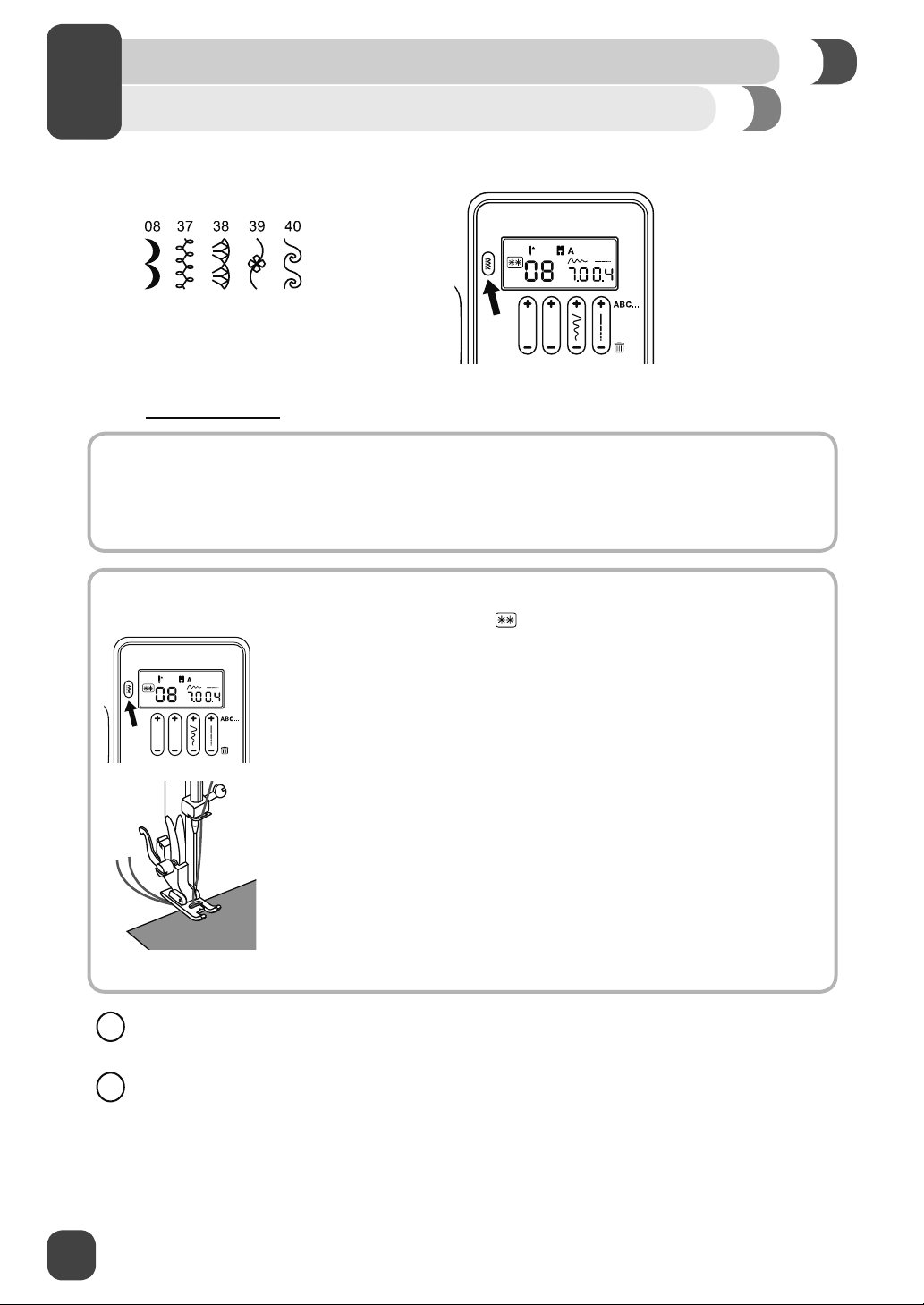

Sewing a Decorative Stitch

Mode Button and Function Buttons

A decorative stitch is used for embellishing and adding Àair to your sewing projects.

(Go to www.singerco.com to view other decorative stitches that can be used).

HOW TO:

1. Set the machine to the desired stitch by entering the number of the desired stitch. (See Page 22)

2.

Set the Stitch Length between 0.4 and 1.0. (See Page 22)

3.

Set the Stitch Width between 2.0 and 7.0. (See Page 22)

SEW ALONG: Scallop Stitch

1. Set the Mode Button to

2. The LCD screen on your machine displays the foot that is

recommended for the stitch selected. Remove the All Purpose Foot

and attach the Satin Foot (A). (See Page 29)

Set the Stitch Length to number 0.4. Y

3.

default to a stitch length of 0.4 when you select stitch # 08.

4.

Set the Stitch Width to 7.0. Yo

stitch width 7.0 when you select stitch # 08.

5. Place the fabric under the presser foot with the right-hand edge of the

fabric lined up with the desired seam guide line on the right side of the

needle plate. Lower the presser foot, then step on the Foot Control or

press the Start/Stop Button to begin sewing. Sew 2 to 3 stitches and

then backstitch (See Page 23) to reinforce the seam.

Use a stabilizer (see Appendix) on the underside of the fabric if there is gathering or puckering as

you sew. Decorative stitching can be used almost anywhere on your project!

It may be helpful to decrease the upper tension by 1 or 2 numbers when sewing decorative

stitches. This will help prevent the bobbin thread from possibly showing on the top when sewing

denser stitches.

and select stitch number 08.

our machine will automatically

ur machine will automatically default to

24

START SEWING

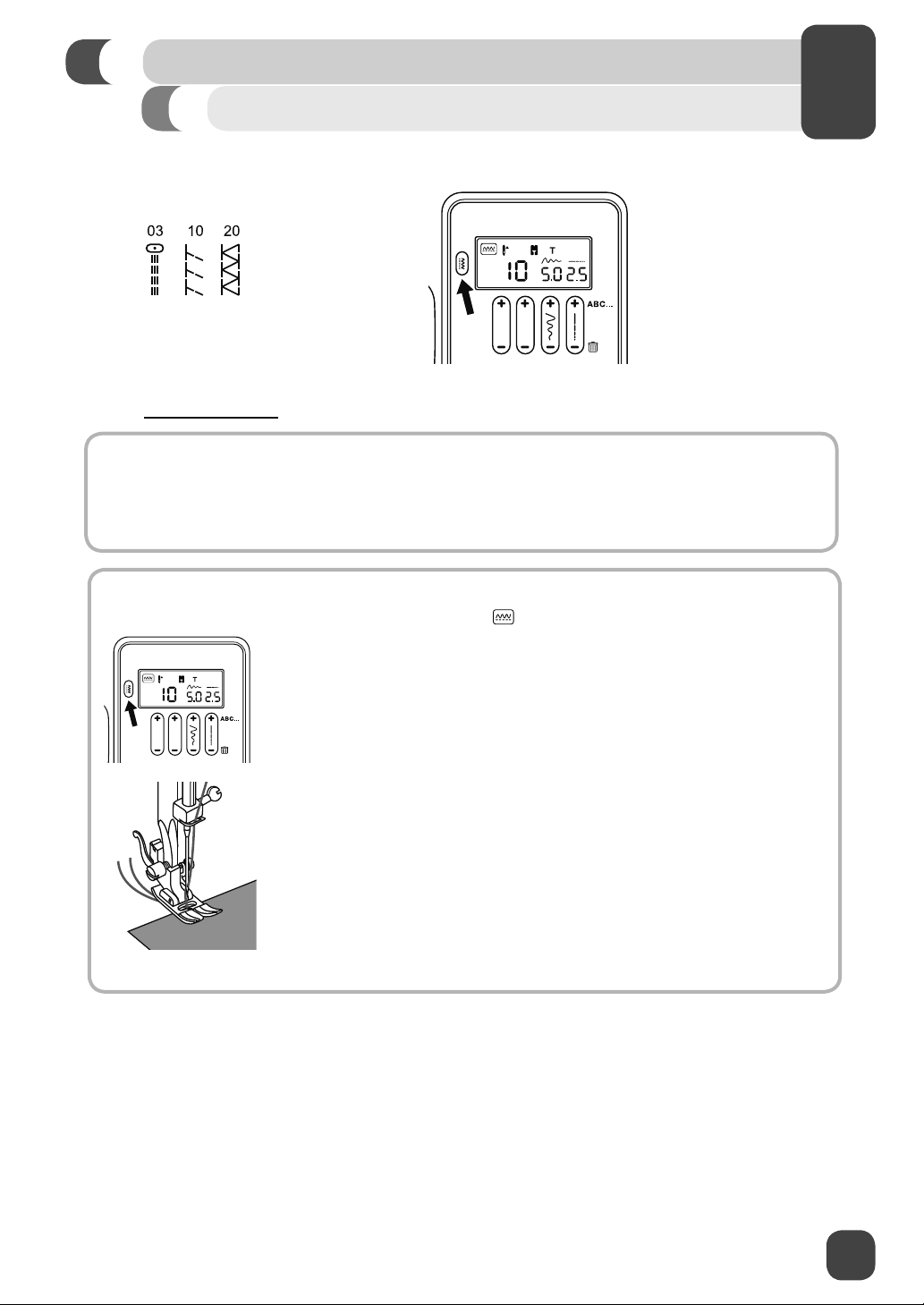

Sewing a Stretch Stitch

Mode Button and Function Buttons

A stretch stitch is used for stretch knit fabrics. This type of seam will stretch with the fabric.

(Go to www.singerco.com to view other stretch stitches that can be used).

HOW TO:

1. Set the machine to the desired stitch by entering the number of the desired stitch. (See Page 22)

2. Set the Stitch Length between 0.5 and 4.5. (See Page22)

3. Set the Stitch Width between 0.0 and 7.0. (See Page 22)

3

SEW ALONG: Overedge Stitch

1. Set the Mode Button to

2. Set the Stitch Length to number 2.5. Your machine will automatically

3. Set the Stitch Width to 5.0. Your machine will automatically default to

4. Place the fabric under the All Purpose Foot with the right-hand edge of

and select stitch number 10.

default to stitch length 2.5 when you select stitch # 10.

stitch width 5.0 when you select stitch # 10.

the fabric lined up with the desired seam guide line on the right side of

the needle plate. Lower the presser foot, then step on the Foot Control

or press the Start/Stop Button to begin sewing.

25

START SEWING

2

3

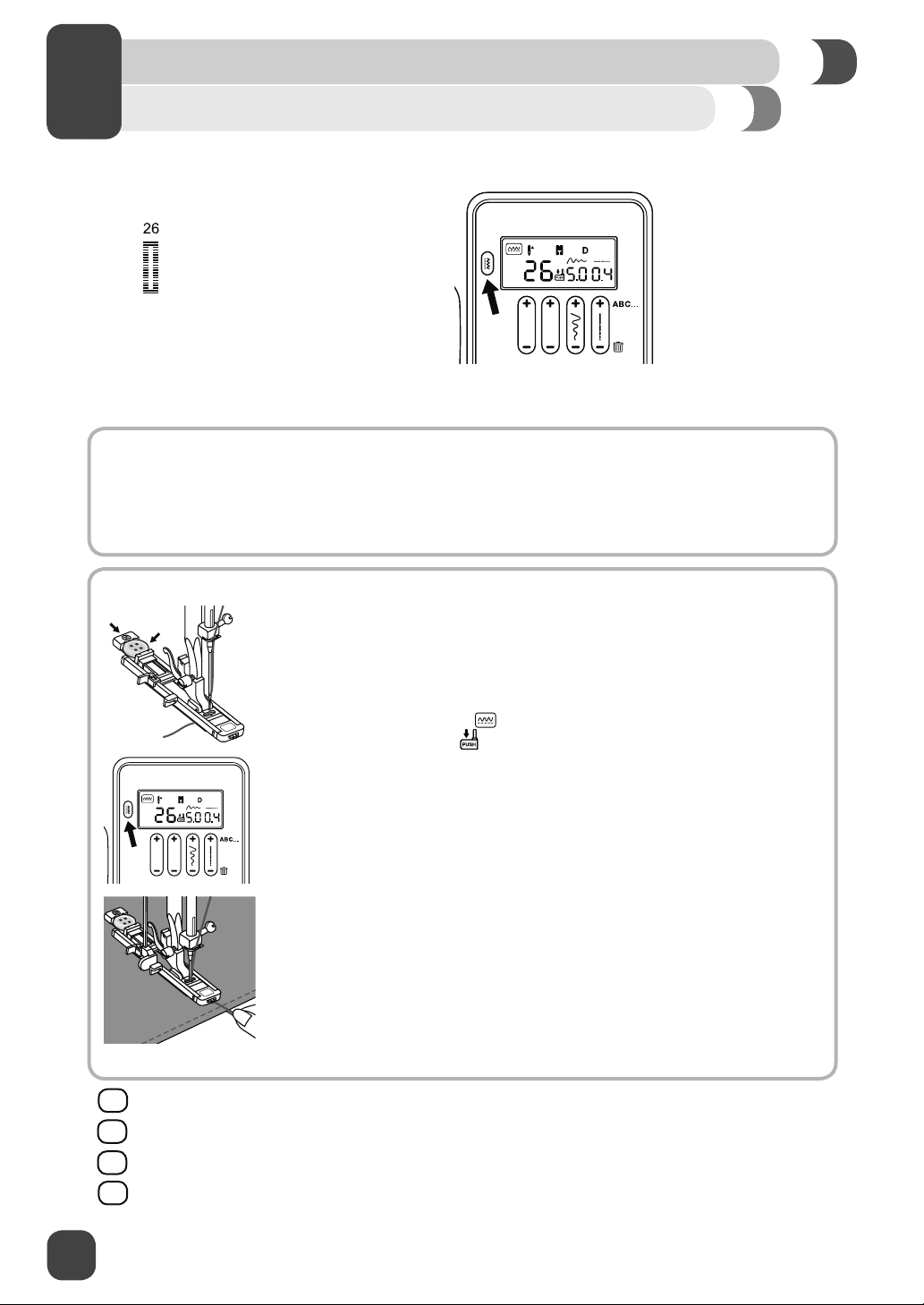

Sewing a 1-Step Buttonhole

Mode Button and Function Buttons

This machine has built-in buttonholes, allowing you to sew buttonholes in one easy step. The

buttonhole stitches are numbered 24 to 31.

HOW TO:

1. Set the machine to the desired stitch by entering the number of the desired buttonhole stitch. (See

Page 22)

The Stitch Length is automatically selected by the machine for optimum results. (See Page 22)

2.

The Stitch Width is automatically selected by the machine for optimum results. (See Page 22)

3.

SEW ALONG: Buttonhole Stitch

Place the button at the back of the buttonhole foot. Mark position and

1.

length of buttonhole on the fabric.

Remove the All Purpose Foot and attach the Buttonhole Foot (See

2.

2

9). Pass upper thread through the hole of the foot and bring thread to

the left.

3. Set the Mode Button to

will display the ¿gure

Set the Stitch Length to number 0.4. Your machine will automatically

4.

default to stitch length 0.4 when you select stitch # 26.

5.

Set the Stitch Width to 5.0. Your machine will automatically default to stitch

width 5.0 when you select stitch # 26.

6.

Place the fabric under the foot so that the center line mark on your fabric

is aligned with the center of the Buttonhole Foot and that the cross line

mark on the fabric aligns with the center hole of the Buttonhole Foot.

Lower the presser foot.

Pull the Buttonhole Lever all the way down and then carefully push it back.

7.

The Buttonhole Lever must sit behind the bracket located on the left of the

Buttonhole Foot.

Hold upper thread slightly and start to sew until the buttonhole is

8.

completed.

Return the Buttonhole Lever to its original position once all buttonholes

9.

are completed.

¤

Use a stabilizer to support the stitches.

¤

Slightly reducing your upper tension by 1 or 2 numbers will improve results.

¤

Always test sew on a scrap piece of your fabric.

¤

The density of the buttonhole can be adjusted by using the Stitch Length Adjustment Button.

and select stitch number 26, the LCD screen

, to remind you to lower the Buttonhole Lever.

Page

26

START SEWING

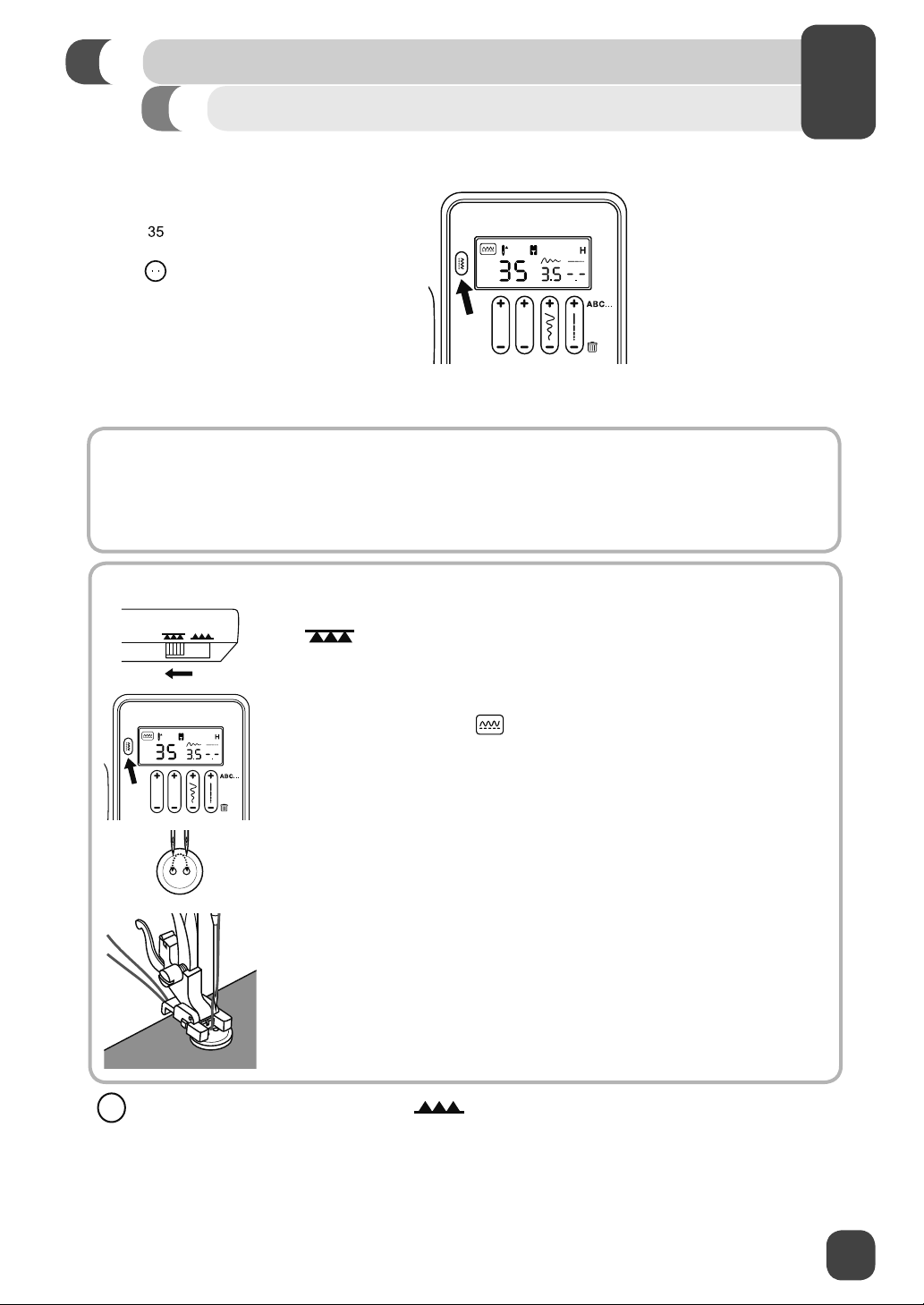

Sewing a Button

Mode Button and Function Buttons

This machine includes a Button Sewing Foot, allowing you to attach buttons to your projects easily and

quickly.

HOW TO:

1. Set the machine to Straight Stitch by entering the stitch number 35. (See Page 22)

2. Set the Stitch Width to 3.5. Your machine will automatically default to stitch width 3.5 when you

select stitch # 35. (See Page 22)

SEW ALONG: Attaching a Button

3

1. Disengage (drop) the feed teeth by moving the Drop Feed Lever to the

setting. (See Page 8)

2. Remove the All Purpose Foot and attach the Button Sewing Foot. (See

Page 29).

3. Set the Mode Button to

4. It may be necessary to adjust the stitch width between 2.5 and 4.5

according to the distance between the two holes of the button. Adjust

the width by pressing the + or the - side of the Stitch Width Button.

5. Place the fabric and the button under the Button Sewing Foot and lower

the presser foot. Turn the handwheel slowly to check that the needle

goes cleanly into the left and right holes of the button. Adjust the Stitch

Width if necessary.

6. Start to sew at low speed. The sewing machine automatically stops after

sewing reinforcement stitches. To add stability to the button stitching

repeat step 6 as necessary.

7. Pull the upper thread at the end of the stitching to the wrong side of the

fabric using a hand sewing needle, and then tie off loose threads at the

back of the fabric.

Slide the Drop Feed Lever back to the position when button sewing is completed. Turn

the handwheel toward you to raise the feed teeth.

and select stitch number 35.

27

START SEWING

2

3

Inserting and Changing Needles

⚠ Turn the machine off before changing the needle.

Change the needle regularly, especially if it is showing signs of wear resulting in sewing problems.

Needles can show signs of wear when you see snags in the fabric or hear a slight popping sound

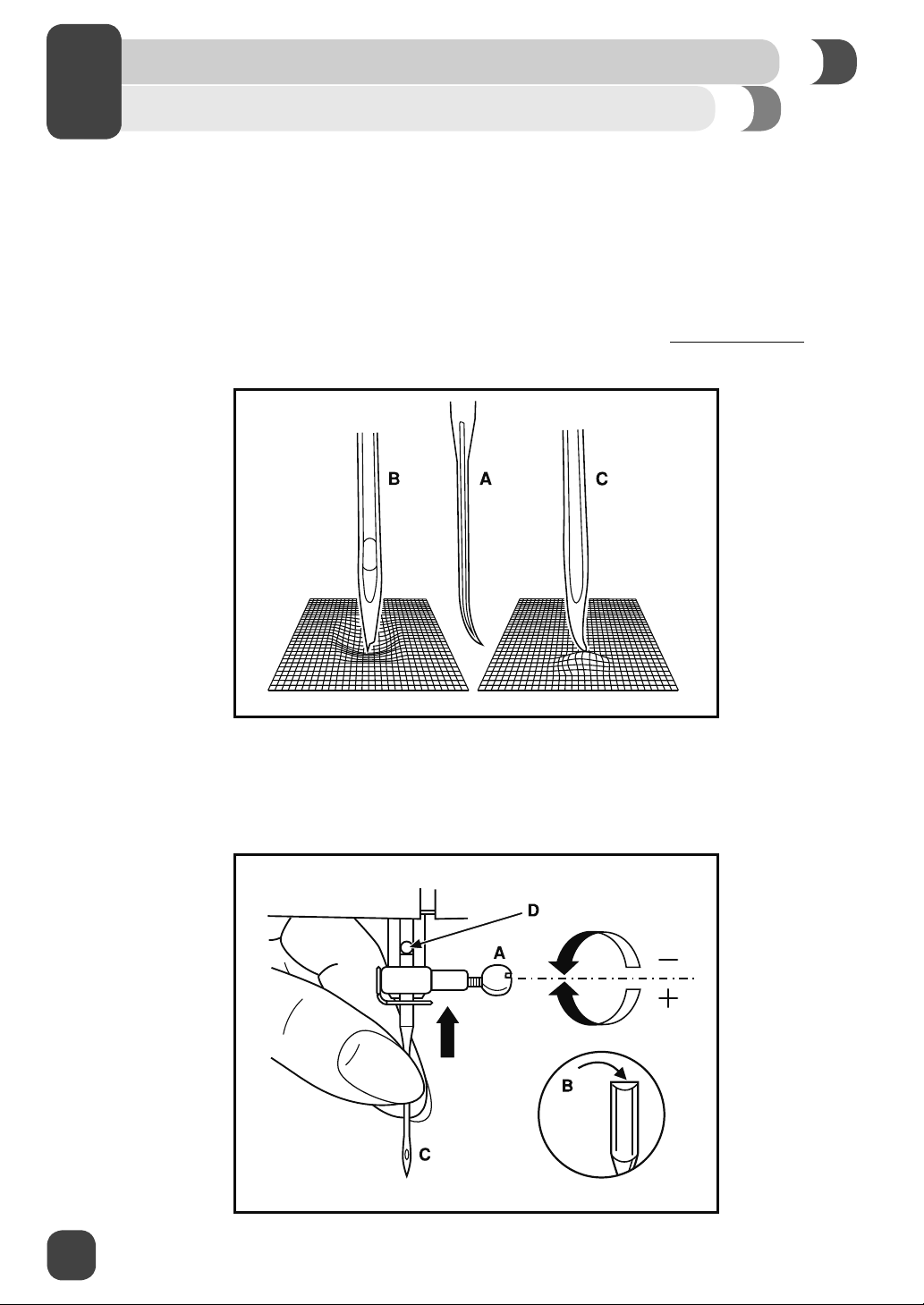

as you are sewing. If the needle becomes bent (A), the point becomes damaged (B) or the needle

becomes dull (C), you should replace it with a new needle and discard the old one.

Generally, the needle should be replaced after every 4 projects or approximately every 16 hours of

sewing time.

It is also important to use the right needle for the fabric you are sewing. (Go to www.singerco.com to

view the Stitch Reference Guide) For best results, use SINGER

sewing machine.

Loosen the needle clamp screw (A) by turning the screw toward you. Remove and discard the old

needle.

Insert the new needle, making sure that the Àat side of the top part of the needle is facing the back of

the machine (B).

Insert the new needle as far up as it will go (C and D).

Tighten the needle clamp screw (A) securely by turning it toward the back.

®

branded needles in your SINGER®

28

START SEWING

Changing the Presser Foot

⚠ For safety, turn off the power before changing the presser foot.

Before changing the presser foot, raise the presser foot lifter.

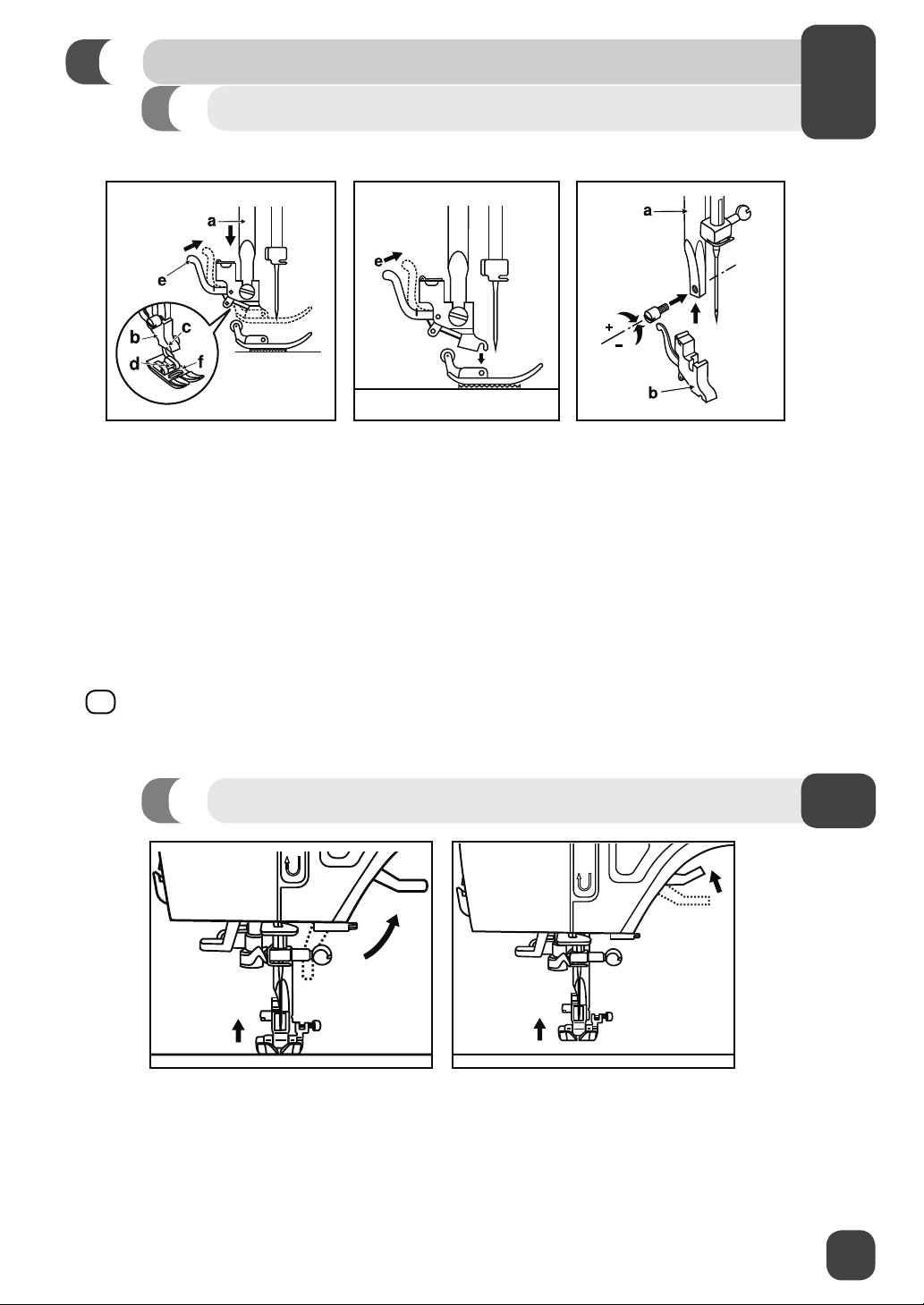

The presser foot holder (b) is attached to the presser bar (a). The presser foot (f) has a presser foot

pin (d) that connects to the presser foot holder, sometimes called a shank (b). The shank has a groove

(c) on its underside, which connects it to the presser foot.

To remove a presser foot from the shank, press the lever (e) at the back of the shank. The foot will

release. To attach a presser foot, line up the presser foot pin (d) underneath the groove (c) on the

shank (b). Lower the presser foot lifter, bringing the shank’s groove down over the pin. The foot will

snap on.

3

Some optional presser feet require you to remove the shank from the machine. To remove the shank

from the machine (see above) loosen and remove the screw that holds the presser foot onto the

presser bar (a), then remove the shank (b). To replace the shank, set the shank onto the presser bar,

then replace the screw.

¤

This machine has a low shank with snap-on presser feet. When shopping for optional presser feet

and attachments for your machine, look for low-shank, snap-on style.

Two-Step Extra Presser Foot Lift

Your machine is equipped with a two-step presser foot lifter.

1. The Presser Foot Lifter raises and lowers the presser foot.

2. When sewing several layers of fabric or heavy fabric, the presser foot can be raised to a second

level for easier positioning of the fabric.

3. When raised to the ¿rst level, the clearance is 1/4 inch (6 mm), when raised to level 2, the

clearance is 5/8 inch (9 mm).

29

2

3

START SEWING

Sew Easy Foot

Your machine may include the Sew Easy Foot.

The Sew Easy Foot has a guide to help you sew the most accurate seams

every time. The foot has an extension marked with the most popular seam

allowances and a movable fabric guide that can be set wherever you want for

the project you are making.

1. Attach the Sew Easy Foot.

2. Select Straight Stitch.

With your needle set in the center position, use the guide to select 3/8”, 1/2”,

3.

5/8”, 3/4”, and even 1” seam allowances.

4.

Place your fabric under the foot, lining up the raw edges with the guide on the

foot. Lower the presser foot lifter

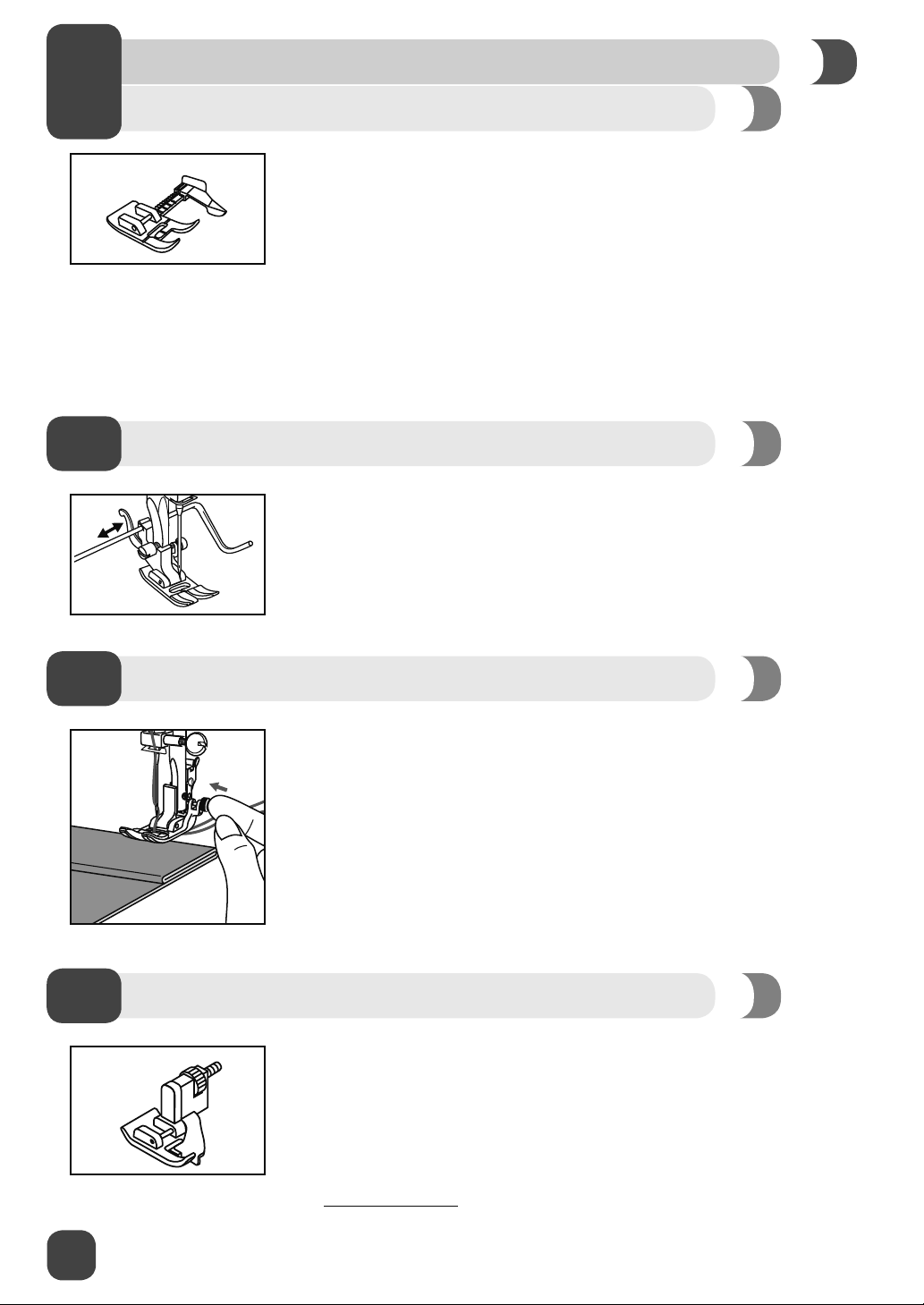

Edge/Quilting Guide

Your machine may be equipped with an Edge/Quilting Guide.

To attach the guide slip it into the slot as illustrated. Adjust the position

depending on the technique you are doing.

, then sew.

Lock in Place Button

For even feeding when sewing over thicker seams, push in the black button

located on the right hand side of the All Purpose Foot (T).

As you approach the thicker seam and the front of the presser foot begins

to raise over the thickness, lower the needle into the fabric by turning the

handwheel toward you.

Raise the presser foot, and push in the black button as you lower the presser

foot, this will lock the foot in a horizontal position.

The black button will release automatically after you sew a few stitches over the

seam.

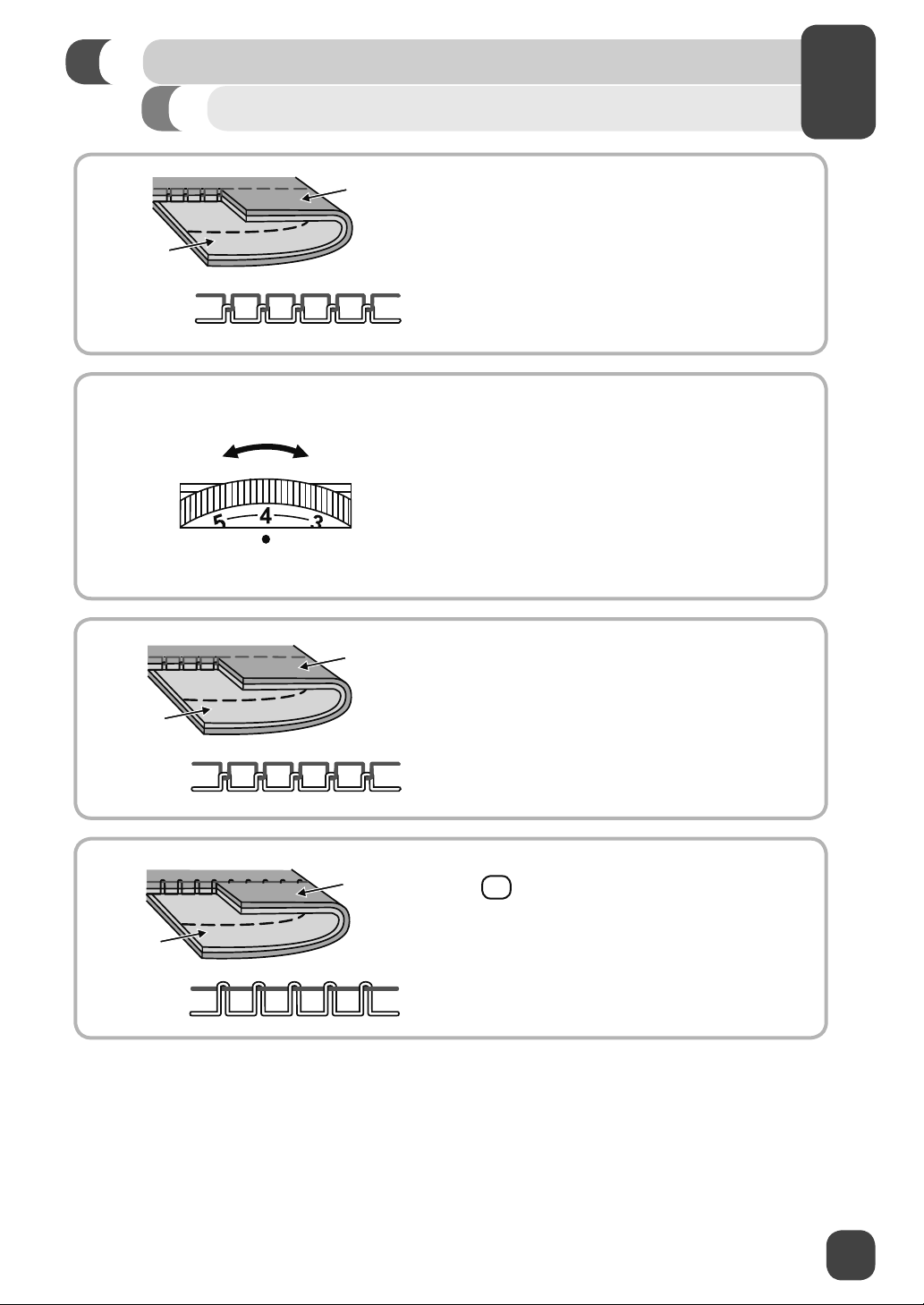

Blind Hem Foot

To sew a Blind Hem select Utility Stitch number 12 for woven fabrics and Utility

Stitch number 17 for stretch fabrics.

1.

Attach the Blind Hem Foot (F).

2. Select the Blind Hem Stitch.

3. Place your folded hem under the foot and sew the seam.

Go to www

.singerco.com

for more information on sewing a Blind hem.

30

Loading...

Loading...