Page 1

....

%. #'

#

r

•>■.':■£' r ■

P

J

.//1 _. ".= -

pis

.#'■

.............

✓ ’

;-■

f

m

if

SINGER

%}>.

'1

$$

Page 2

CAUTION !

POLARIZED PLUG FOR NORTH AMERICAN TERRITORIES

To reduce the risk of electric shock, this appliance has a polarized plug

(one blade is wider than the other). This plug will fit in a polarized outlet only one

way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not

fit, contact a qualified electrician to install the proper outlet. Do not change the

plug in any way.

Dear Customer:

We recommend that for future reference you record the Serial Number

of your Sewing Machine in the space provided.

Correct foot controller for this model is model no.; 4C-316B (for North

American Territories)

To ensure that you are always provided with the most modern sewing

capabilities, the manufacturer reserves the right to change the

appearance, design or accessories of this sewing machine when

considered necessary.

SINGER® is a Registered Trademark of The Singer Company Limited

V

____________

SINGER CUSTOMER ASSISTANCE IN THE U.S.A. TOLL-FREE

NUMBER: 1-800-877-7762

^

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTION......................................................................1

PRINCIPAL PARTS.................................................................................................... 2

ACCESSORIES INCLUDED WITH MACHINE

CONNECTING AND RUNNING MACHINE................................................................4

INSTRUCTION SYMBOLS.......................................................................................... 4

WINDING BOBBIN......................................................................................................5

THREADING MACHINE..............................................................................................6

INSERTING WOUND BOBBIN...................................................................................7

RAISING BOBBIN THREAD

SELECTING A PATTERN...........................................................................................8

STRAIGHT STITCH.................................................................................................. 8

ADJUSTING THREAD TENSION................................................................................8

KEEPING SEAMS STRAIGHT....................................................................................9

TURNING SQUARE CORNER....................................................................................9

STITCHING IN REVERSE...........................................................................................9

FREE ARM SEWING.................................................................................................. 9

CHANGING PRESSER FOOT..................................................................................10

CHANGING PRESSER FOOT WITH SHANK..........................................................10

ATTACHING FEED COVER......................................................................................10

FREE MOTION EMBROIDERY................................................................................. 10

CHANGING NEEDLE

FABRIC, THREAD AND NEEDLE TABLE................................................................ 11

ADJUSTING STITCH WIDTH

ADJUSTING STITCH LENGTH.................................................................................12

BALANCING A PATTERN

INSERTING A ZIPPER..............................................................................................12

RECOMMENDED SETTINGS AND APPLICATIONS.....................................13 & 14

ONE-STEP BUTTONHOLING...................................................................................15

BLINDSTITCH...........................................................................................................16

OVEREDGING AND SEAMING ................................................................................16

REMOVING AND REPLACING BOBBIN CASE.......................................................17

REMOVING AND REPLACING LIGHT BULB........................................................... 17

CLEANING MACHINE............................................................................................... 18

BEFORE STORING YOUR MACHINE.....................................................................18

PERFORMANCE CHECKLIST

.......................................................................................

...............................................................................................

..................................................................................

........................................................................................

................................................................................

...........................................................

3

7

11

12

12

18

Page 3

IMPORTANT SAFETY INSTRUCTIONS

When using this machine, basic safety precautions should always be followed

including the following; Read all instructions before using this machine.

DANGER.

To reduce the risk of electric shock:

■ The machine should never be left unattended when plugged In. Always unplug

the machine from the electric outlet immediately after using and before cleaning.

■ Always unplug before changing light bulb. Replace bulb with the same type rated

15 watts. Be sure to replace the face plate which covers the light bulb before

operating the machine.

WARNING.

To reduce the risk of burns, fire, electric shock or injury to persons:

■ Be sure that the electrical voltage of the socket outlet (wall receptacle) is the same

as the rated voltage of the motor.

■ Use this machine only for its intended use as described in this Operator’s Guide.

Use only attachments recommended by the manufacturer as contained in the

Operator’s Guide.

■ To disconnect, turn all controls to the off (“0”) position, then remove plug from

outlet.

■ Disconnect the power-line plug from the socket outlet or switch the machine off

when making any adjustments in the needle area, such as threading needle,

changing needle, changing needle plate or changing presser foot, etc.

■ Always unplug the machine from the electrical outlet when removing covers,

lubricating, or when making any other user servicing adjustments mentioned in

the Operator’s Guide.

■ Do not attempt to adjust the motor belt. Contact your nearest Service Center

should any adjustment be required.

■ Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

■ Handle the foot controller with care and avoid dropping it on the floor. Be sure

not to place anything on top of it.

■ Always use the proper needle plate. The wrong plate can cause the needle to

break.

■ Do not use bent needles.

■ When sewing, keep, fingers away from all moving parts. Special care is required

around the sewing machine needle.

■ Do not pull or push fabric while stitching. This may deflect the needle causing

it to break .

■ Before removing the bobbin case, remove plug from the socket outlet.

■ For double insulated machines, when servicing, use only identical Singer replace

ment parts. See instructions for Servicing of Double-insulated Appliances.

■ Never operate the machine if it has a damaged cord or plug, if it is not working

properly, if it has been dropped or damaged, or dropped into water. Return the

machine to the nearest authorized dealer or Service Center for examination, repair,

electrical, or mechanical adjustment.

■ Never operate the machine with any air openings blocked. Keep ventilation open

ings of the machine and foot controller free from the accumulation of lint, dust,

and loose cloth .

■ Never drop or insert any object into any opening.

■ Do not use outdoors.

■ Do not operate where aerosol (spray) products are being used or where oxygen

is being administered.

■ Do not allow to be used as a toy. Close attention is necessary when the ma

chine is used by or near children.

■ SERVICING OF DOUBLE-INSULATED PRODUCTS. In a double-insulated prod

uct, two systems of insulation are provided instead of grounding. No grounding

means is provided on a double-insulated product, nor should a means for ground

ing be added to the product. Servicing of a double-insulated product requires

extreme care and knowledge of the system, and should be done only by quali

fied service personnel. Replacement parts for a double-insulated product must

be identical to those parts in the product. A double-insulated product is marked

with the words “DOUBLE INSULATION’’ or “DOUBLE INSULATED”.

SAVE THESE INSTRUCTIONS

Servicing should be performed by an authorized service representative.

This product is intended for household use.

FOR EUROPEAN AND SIMIAR TERRITORIES:

This product is suppressed for radio and television interference with the interna

tional Electrotechnical Commission requirements of the CISPR.

Machine for Great Britain and some other countries having similar wiring standards

are shipped from the factory with a plug for connection to the mains. The wires

in this mains lead are coloured in accordance with the following code:

Blue: neutral (N) Brown: live (L)

As the colours of the wires in the mains lead of this appliance may not correspond

with the coloured markings identifying the terminals in your plug, proceed as follows:

The wire which is coloured blue must be connected to the terminal which is marked

with the letter N or coloured black. The wire which is coloured brown must be

connected to the terminal which is marked with the letter L or coloured red. If a

13 Amp. (BS 1363) plug is used, a 3 Amp. fuse must be fitted, or if any other type

of plug is used, a 5 Amp. fuse must be fitted either in the plug or adaptor or at

the distribution board. Neither cord is to be connected to the earth terminal of a

three-pin plug.

Page 4

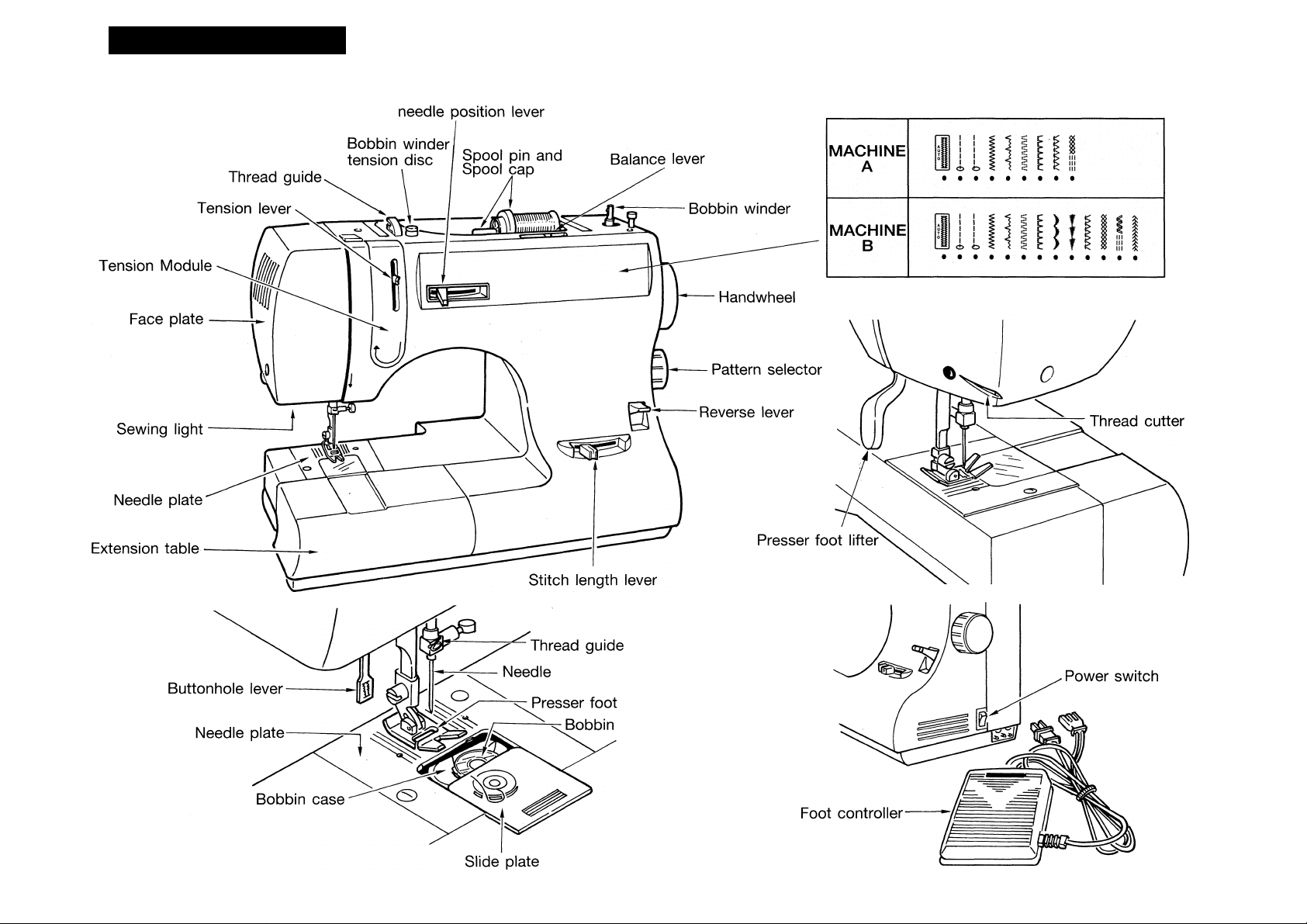

PRINCIPAL PARTS

stitch width and

PATTERN DISPLAY:

— 2 —

Page 5

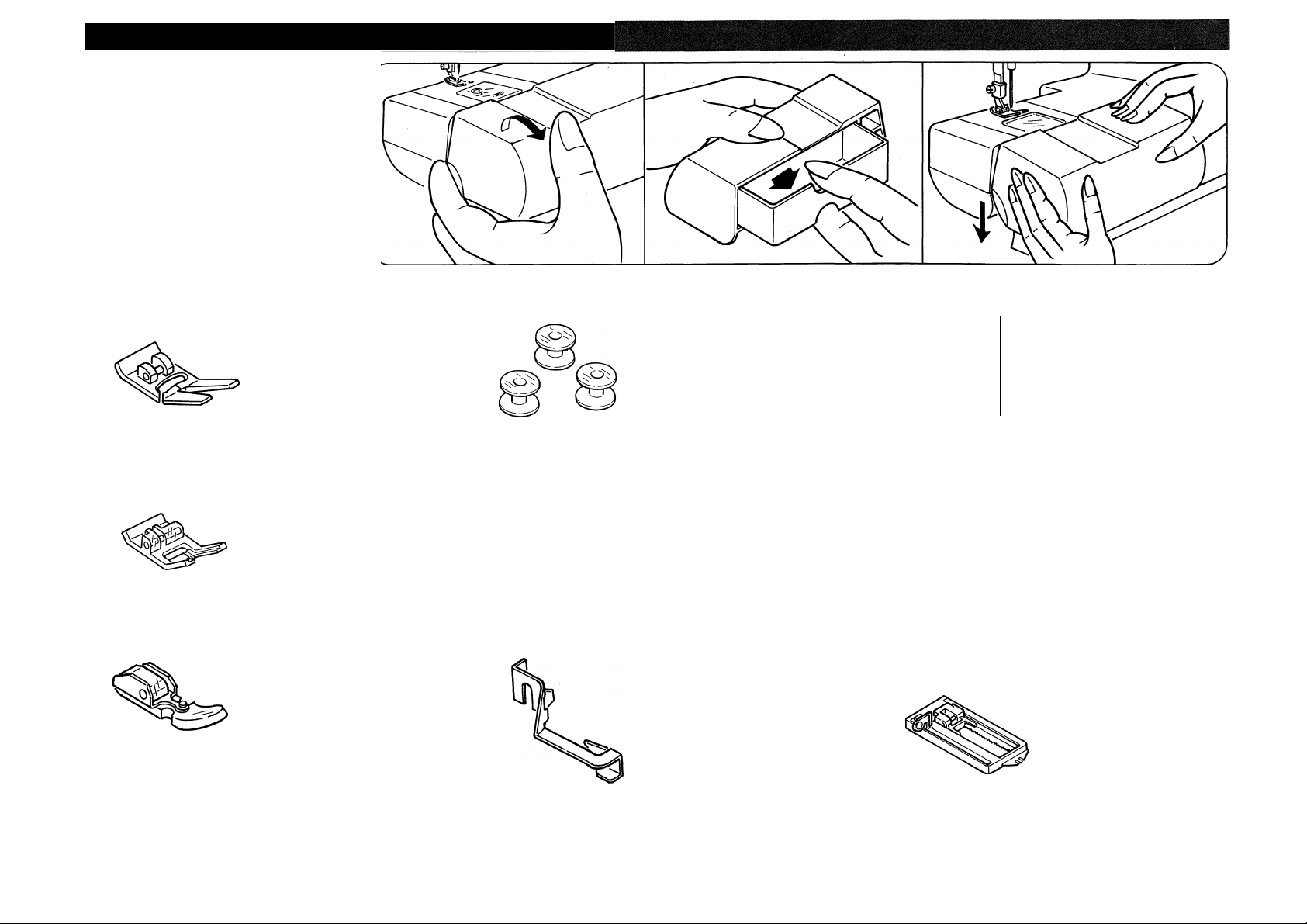

ACCESSORÊES INCLUDED WITH MACHINE

Accessories are stored

inside extension table.

General purpose

presser foot

(on machine)

#137627

Special purpose

presser foot

#137632

Zipper foot

#507836

ÍO

\ Spool cap

(on machine)

^ #137192

2021 I 204S

Needle pack

#353364

rM

f^1

Bobbins

(1 in machine)

# 81348

Feed cover

#316004

t ^ 1' Í1

SINGER

r

Blindstitch

guide

#381213

1-step buttonholing

presser foot

#137228

Lint brush

#546358

— 3 —

Page 6

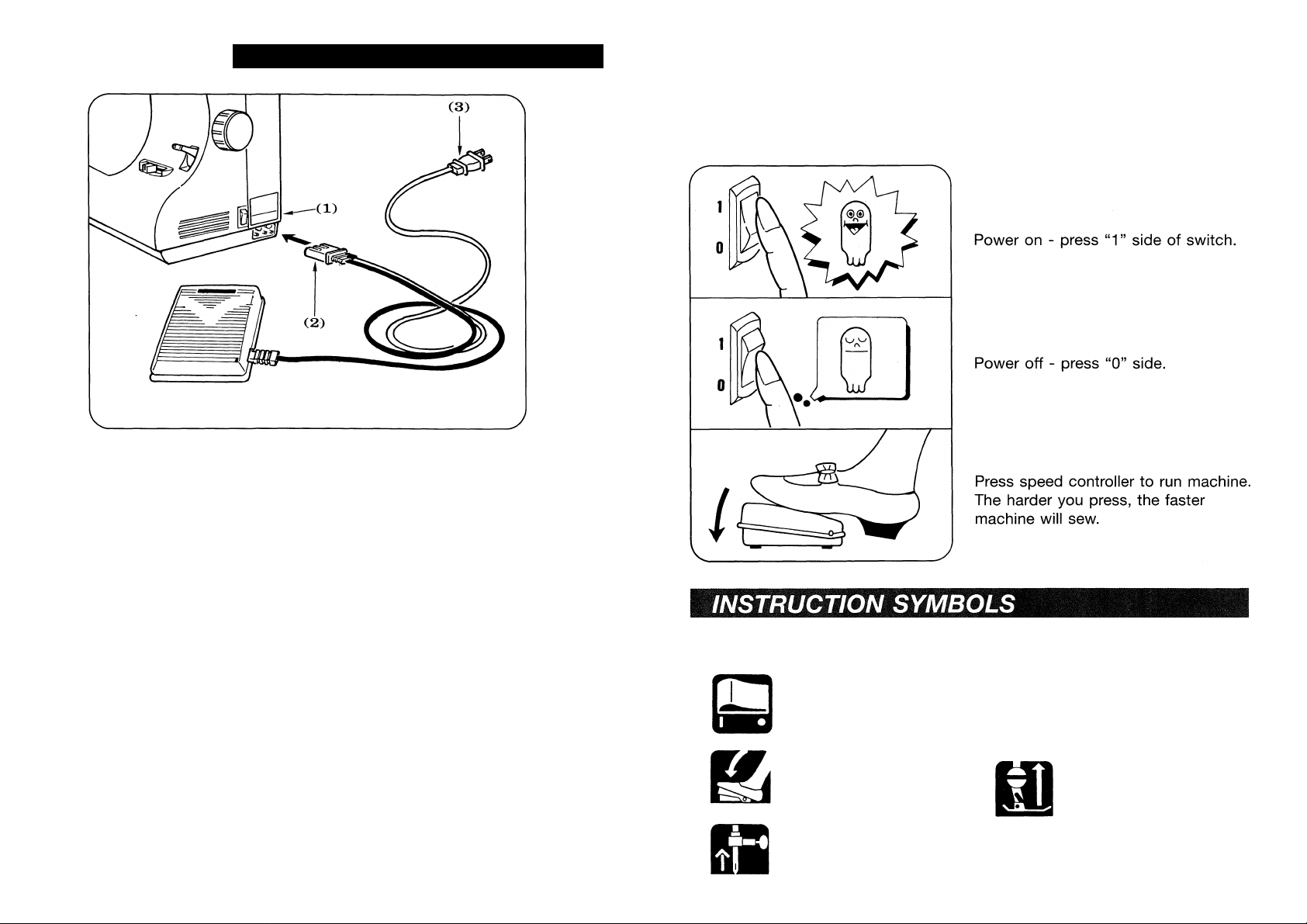

WUÜL

CONNECTING-

• Before plugging in your machine, be sure that the

voltage and number of cycles indicated on the

electrical data lable (1), conform to your electrical

outlet.

ÎNG AND RUNNING MACHINE

1

RUNNING-

• Plug controller (2), into receptacle, at the right end of

machine.

• Then connect electrical po\wer cord plug (3) to your

electrical outlet.

— 4 —

To simplify understanding, the following symbols are used throughout the

operator’s manual.

Turn power off.

Lower presser foot.

m

Press speed controller

Raise presser foot.

Use hand wheel to

raise needle.

Page 7

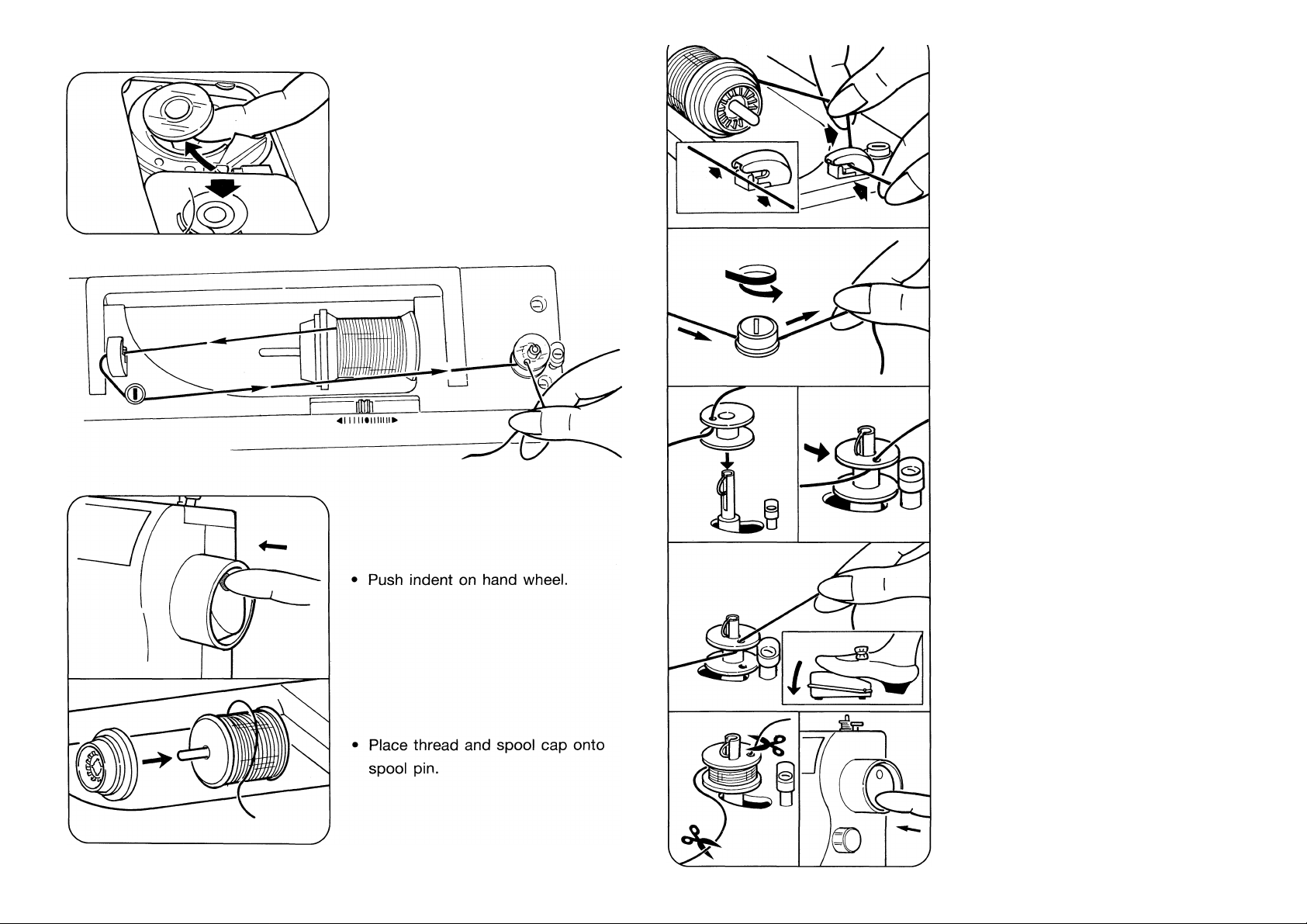

• Open slide plate.

• Take out empty bobbin.

Snap thread into thread guide.

Wind thread counterclockwise

around bobbin winder tension dies.

Thread bobbin and place on

spindle.

Push bobbin to right.

— 5 —

• Hold thread end.

• Step on speed controller.

• Cut thread.

• Push bobbin to left.

• Press side opposite indent.

Page 8

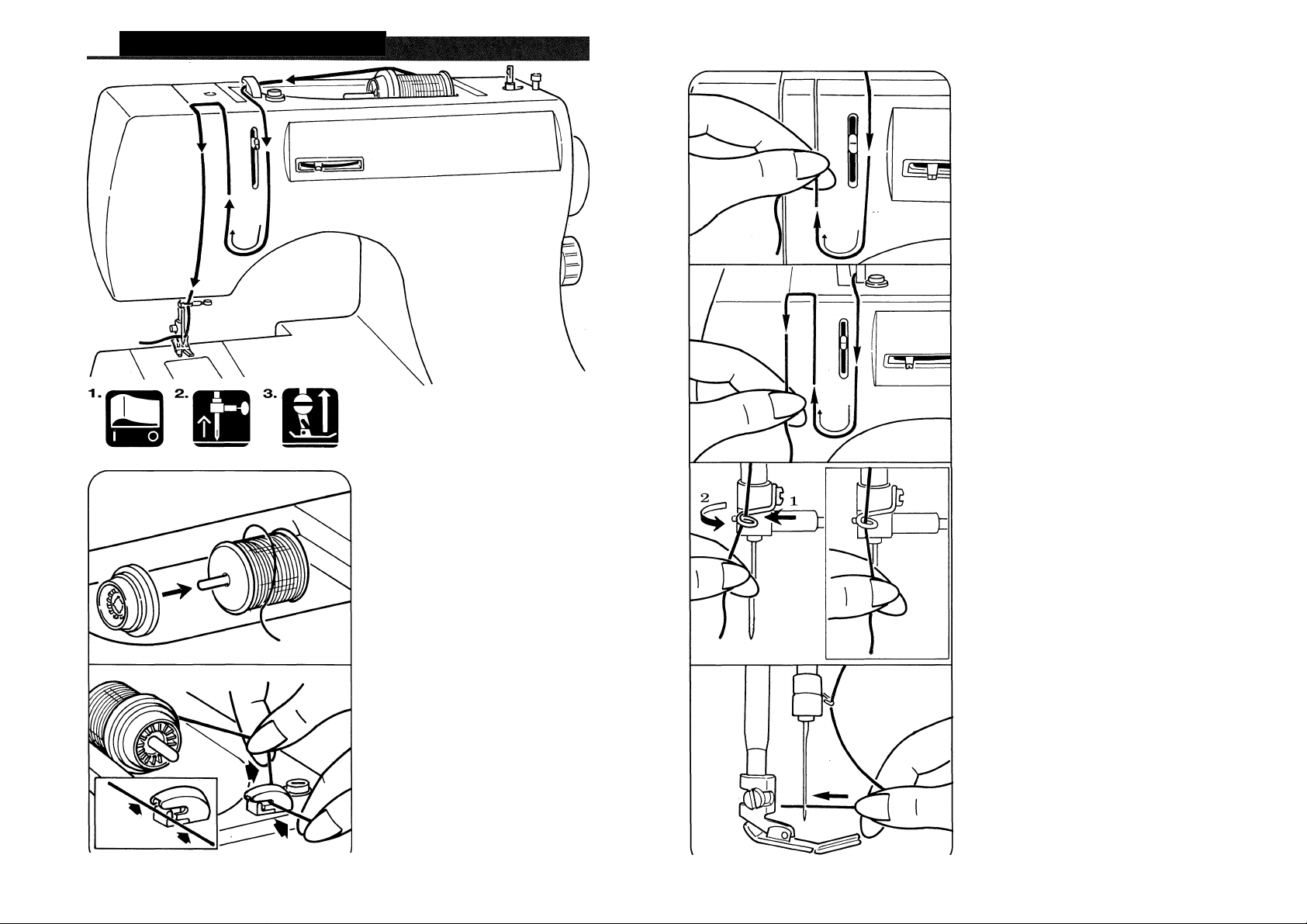

HREADING MACHINE

HHHHI

6. Thread tension module by leading

thread down right channel and up

left channel.

7. Pull down 6"~8" of thread.

1. Turn off power.

2. Raise needle.

3. Raise presser foot to allow tension

module to accept thread.

4. Place thread spool and proper

spool cap onto spool pin. ■

5. Snap thread into thread guide.

8. Wrap thread around and through

thread guide.

9. Thread needle from front to back.

Page 9

INSERTING WOUND BOBBIN

mma

RAISING BOBBIN THREAD

• Hold needle thread.

Open slide plate.

Insert bobbin into bobbin case.

• Guide thread into notch (1)

and then into notch (2).

• Turn hand wheel towards you

lowering, then raising needle.

Gently pull needle thread to raise

bobbin thread.

Open loop.

• Pull thread under and back of

presser foot.

• Close slide plate.

• Pull both threads back under

presser foot.

7 —

Page 10

SELECTING A PATTERN

Turn pattern selector dial to select

patterns.

STRAIGHT STITCH

• Preparation: refer to

“Recommended settings and

applications” on page 13.

ADJUSTING THREAD TENSION

Proper setting of tension is

important to good sewing.

There is no single tension setting

appropriate for all stitch functions,

thread or fabric.

A balanced tension (identical

stitches both top and bottom) is

usually only desireable for straight

stitch.

90% of sewing will require tension

settings between 2 and 5.

■

• Place fabric under presser foot and

lower foot.

Begin sewing.

• Guide fabric.

• At end of seam:

mm

Remove fabric.

Cut thread.

Move tension lever to lower

number.

Move tension lever to higher

number.

For zig zag sewing and decorative

stitch functions, thread tension

should be less than for straight

stitch sewing.

You will always obtain a nicer stitch

and less puckering when upper

thread appears on the bottom side

of your fabric.

8 —

Page 11

KEEPING SEAMS STRAIGHT

msEmmsim

Line up fabric with guideline (1)

on needle plate.

TURNING SQUARE CORNE

• When stitching reaches desired

pivot point, stop stitching.

• Lower needle into fabric.

Secure beginning and end of seam

as shown.

m '

• Press reverse lever for steps 1 and

3.

FREE ARM SEWING

• Roll extension table forward to

remove from machine.

• Turn fabric.

m

Continue stitching seam.

• To replace reverse process.

• Topstitch edges on sleeves, or

finish waistbands and pants legs

easily.

— 9 —

Page 12

CHANGING PRESSER FOG

TO REMOVE-

• Lift toe of presser foot

until it snaps off shank.

• Take foot off machine.

REPLACING PRESSER FOOT WITH SHANK

Loosen presser foot screw and

remove foot.

TO REPLACE-

• Center new presser foot

• Lower presser foot lifter.

• Press presser bar (2) down.

ATTACHING FEED COVER

• Press tab (1) and (2) into holes on

under shank(1).

needle plate.

— 10 —

• Hook new foot around presser bar.

• Tighten screw.

FREE MOTION EMBROIDERY

RECOMMENDED SETTINGS

Stitch Selection: Straight Stitch or Zig-Zag

Stitch Width:

Stitch Length: Feed cover

Foot:

Attach feed cover.

Control fabric with embroidery

hoop.(hoop not included).

Lower presser foot lifter.

Lengthen or shorten stitches by

moving hoop faster or slower.

D»

Remove foot with shank

Page 13

CHANGING NEBDL

For best sewing results, use

only Genuine Singer needles.

I

FABRIC, THREAD AND NEEDLE TABLE

^ Fabric

The fabrics below can be of any fiber, cotton, linen, silk, wool, synthetic,

rayon, blends. They are listed as examples of weight.

Very Lightweight-Batiste, Chiffon, Organza, Voile.

Lightweight-Challis, Chambray, Carmeuse, Crepe de Chine, Gauze,

Handkerchief Linen, Silk, Taffeta, Tissue faille.

Medium-weight-Broadcloth, Brocade, Chino, Chintz, Corduroy,

Flannel, Linen, Poplin, Satin, Synthetic, Suedes, Taffeta,’ Terry, Velvet.

Medium to Heavy-weight-Coating, Damask, Denim, Drapery Fabric,

Fake Fur, Gabardine, Ticking woolens.

Heavy-weight-Canvas, Duck, Sailcloth, Upholstery Fabric.

Leather

• Loosen screw and remove •

needle.

Thread

Cotton-Wrapped polyester core (extra fine)

Long fiber polyester (extra fine)

Cotton-Wrapped polyester core (all purpose)

Long fiber polyester (two spun)

Cotton-Wrapped polyester core (all purpose)

Long fiber polyester (two spun)

Cotton-Wrapped polyester core (all purpose)

Long fiber polyester (two spun)

Cotton-Wrapped polyester core (all purpose)

Long fiber polyester core (two spun)

Insert needle with flat away

from you.

Tighten screw.

Needle ^

Failure to use a Singer brand needle

may result in skipped stitches, poor

sewing performance or damage to

your machine.

TYPE SIZE

2020

2020 11/80

2020 14/90

2020 1 6/1 00

2020 18/110

2032 leather

9/70 or 11/80

Knits-Jersey, Tricot single Knit.

Sweatshirt-Double Knit, Swimwear Knit.

^ Twin-needle

Cotton-Wrapped polyester core (all purpose)

Long fiber polyester (two spun)

Cotton-Wrapped polyester core (all purpose)

Long fiber polyester (two spun)

11

2045 11/80

2045

2025

14/90

14/90

^

Page 14

ADJUSTING STITCH WIDTH

• Move lever to widen or narrow

stitch.

• When using twin-needle do not set

width wider than twin-needle

graphic.

ADJUSTING STITCH LENGT

• For shorter stitch move lever to

left.

INSERTING A ZIPPE

RECOMMENDED SETTINGS

Stitch Selection: Stitch

Stitch Width: i I I 11

stitch Length: 1.5-3

Foot: Zipper

• Baste zipper opening.

• Attach left side of foot to shank.

• Stitch zipper to seam allowance.

t •

J

BALANCING A PATTER

• For longer stitch move lever to

right.

mm

HH

• Machine has been balanced at

factory to optimum balance.

• Only selected patterns may be

balanced (see following pages).

• Before attempting to balance a

pattern make sure stitch length is

set at 4.

• Push lever left to open pattern or

right to close pattern.

• Attach right side of foot to shank.

• Stitch zipper to seam allowance.

12 —

Page 15

Page 16

RECOMMENDED SETTINGS AND APPLICATION

PATTERN

Crescent

Arrowhead

/WVW\

stretch overedge

Honeycomb

MACHINEAMACHINE

B

APPLICATIONS

Border, edges, smocking

and embroidering.

Decorative stitching,

decorative bartacks and

border design.

Finishing and joining

seams in one operation.

Smocking, mending,

overedging, attaching

lingerie elastic, stretch lace

and blanket binding.

Straight stretch

Ric-Rac

Feather

Stretchable straight

seams in strech fabrics

and bold topstitching.

Heavy-duty, general

purpose sewing and

bold topstitching.

Fagoting, embroidery,

patchwork, quilting and

lattice seams.

1'

14

-/ y ^ / y w / / / ;

in \ T 1 T» %C

14 1 H.I M M

Page 17

ONE-STEP BUTTONHOLING

Always make a practice buttonhole on a sample of your fabric.

WÊiamm

mm

■■¡■■■I

1

Make buttonhole position on fabric as indicated in pattern.

RECOMMENDED SETTINGS

Stitch Selection: Buttonhole Stitch

Stitch Width: | I I 11

Stitch Length: 4

Foot: Buttonhole foot

FASTENSING BUTTONHOLING

PRESSER FOOT

• Rennove presser foot from shank.

• Center pin (1) in presser foot under

shank.

¿'il'»

Press presser foot screw

down firmly until shank

snaps into place.

• Center red guidelines (4) of foot

around beginning line.

• Lower presser foot.

Start running machine.

• The entire buttonhole will be sewn

in one operation.

• Stop sewing when leg begins

overlapping bartack.

Remove fabric from

machine.

• Clip threads end; cut buttonhole

opening with scissors or seam

ripper.

• Push buttonhole lever (2) back up

into machine.

SETTING LENGTH OF BUTTONHOLE

• Pull buttonhole lever (2) straight

down as far as it will go.

• Press it toward you.

• Place button against lever (2) and

slide clamp (3) back until it

touches.

15 —

m

^1 llll•lllllll►

ADJUSTING BALANCE OF

BUTTONHOLE

• If two stitching sides of buttonhole

are unequal, move stitch balance

lever to adjust.

- If right side is too open, move

stitch balance lever slightly to right.

- If left side is too open, move stitch

balance lever slightly to left.

Page 18

BLINDSTITC

OVEREDGING AND SEAMING

be used for overcasting.

• Fold hem to wrong side.

• Pin or baste in place.

• Fold hem back as shown.

Loosen screw (1) to install

blindstitch guide.

Tighten screw.

Place folded edge against

blindstitch guide.

Sew, allowing wide stitches to

enter edge of fold.

• For overcasting edge of fabric to

prevent fraying.

For hemfinishing on fabrics to

prevent rolling.

Use with stretchy material which

tends to fray or foil.

For stitching and finishing seams in

light weight fabrics.

For overcasting edge of fabric to

prevent fraying.

Turn fabric to right side and press.

For stitching and finishing seams in

heavyweight or stretch.

— 16

Page 19

REMOVING AND REPLACING BOBBIN CASE

• Raise presser foot and needle.

• Take off presser foot.

REMOVING AND REPLACING LIGHT BULB

• Open slide plate and remove

bobbin.

• Loosen screw (1) on needle plate.

• Lift needle plate from left corner

and slide out.

• Take off slide plate.

• Lift out bobbin case.

TO REPLACE BOBBIN CASE

• Place notch (2) to rest against

cushion spring (3).

Loosen and remove screw (1).

Lift face plate slightly and remove

from machine.

TO REMOVE LIGHT BULB

• Push bulb up into socket (2) and

turn to the left to unlock bulb pin.

• Pull bulb down and out of socket.

To replace needle plate, insert

spring (4) into hole (5) and position

stud (6).

Tighten screw (1).

Insert bobbin and replace slide

plate.

TO REPLACE LIGHT BULB

• Push new bulb up into socket and

turn to right until pin lock into

position.

• Reposition face plate by sliding top

edge of plate over edge of top

cover.

• Insert screw and tighten.

— 17 —

Page 20

• Using lint brush, remove lint or dust

from:

- presser bar

BEFORE STORING YOUR MACHINE

To disconnect, turn all controls to off ("0") position, then remove plug

from outlet.

Unplug foot controller from machine.

Lower presser foot lifter.

Turn handwheel to lower needle bar to the lowest position.

Place your machine out of reach of children in safe, dry location.

PERFORMANCE

When sewing difficulties occur, look back through this manual to make

sure you are correctly following the instructions.

- needle bar

- machine surface (if necessary,

dampen a soft cloth and use a mild

soap to clean the surface).

• Remove needle plate as instructed

on page 17 and clean exposed area

with lint brush.

- bobbin case (if there is a lot of lint

in this area, remove bobbin case for

cleaning).

• Remove bobbin case and clean

with lint brush.

• With bobbin case removed clean

hook area.

Needle Does Not Move

Is machine connected to electrical supply?

Is the power and light switch on?

Is controller connected?

Needle Moves But Stitch Is Not Formed

Is needle defective?

Is needle fully inserted into needle clamp?

Are bobbin and needle corredtiy threaded?

Is bobbin correctly inserted into bobbin

case?

Needle Breaks

Is needle straight and sharp?

Is needle correct size?

Is needle fully inserted into needle clamp?

Are controls properly set?

Are accessories correct for application?

Upper Thread Breaks

Is machine properly threaded?

Is thread freely unwinding from spool?

Is proper spool cap being used?

Is needle correct size for thread?

Is upper thread tension too tight?

Is bobbin case properly inserted?

Is bobbin rim free of nicks?

Bobbin Winding Difficulties

Is thread unwinding freely from

spool?

Is bobbin winder engaged?

Is thread end securely held at

start of wind?

Lower Thread Breaks

Is bobbin correctly wound?

Is bobbin correctly inserted into

bobbin case?

Is bobbin case correctly

threaded?

Skipped Stitches

Is machine properly threaded?

Is fabric firmly held down?

Is needle correct style and

size?

Is needle straight and sharp?

Fabric Does Not Move

Property Under Presser Foot

Is presser foot correctly

attached to machine?

Is presser foot lowered?

Is stitch length correctly set?

18 —

Page 21

Page 22

Page 23

Page 24

■t-

#'✓ li

~: - - - -’v-:

,sim 9 ,#""iiife

m^’-mk a. ,4T

. ■ ‘‘

;

\ .f s

5, '■ I

#

5)’

..;e

'iJi:

,i5-

;>/■'

r\. ’I

■%„

^rvV-"'

%.

-

^mma^

,'|s. ' f ' ' " ■ ' '■' ' ','

....

■ '" ■

.....................

•■ ■

:’'f

i.

/' *

'ft

\

,,,>,'''«-:;>r,

''ft'-:, ,->-■

i i., ..

,# % f

Part No. 137030-001 Eng.

-4-ldbl C€

Printed in Taiwan

Loading...

Loading...