Page 1

Instructions for Using

SINGER“

Sewing Machine Model 631

\ \

'I'iio SINGFH Conveifibio

CHAIN ST1TC:H ieature

. . . n'jiK‘siTitK Ilio ultimali; in scwimj madii!i(> pmfurmanco. With thi*

purduiso OÍ Uk; nrw Si,AN'l'-0-.MA') 1C, you ( <in iako pride i n ovrninij

the llnc.st sev.'iiig inadhiU' cvm built. You'll imüvt'! <it its almost unbeliovablo case of opmation . . . the remai kabh' seivici's it imtfoims.

You'll deiUjht in Us ¡Kuti'ct, beautilul sütrliiiU!. In adililion to its

numerous outslandiiH! .u!v.itil<i(|es tlu’ maddne umv imoipoiatr's a

new and unique h'ature in that look stitihinq and diain sfituiiiuj can

hi' seleetivoly produeeil on tlu> s.ime maihiue.

® Only SINCFR proiiui es an .uitomafie m.uhini' that in ailtiilion (o

the fonventionat totk sUtdt also sews a single 1!iiea<i diain sliti:li

wiikli tan be nsoit ior basUiH) sinims thus replathig liaint-bastintj.

This feature will release, you fioni iiine-tonsuminij work and if

reve<ils new <t,s()ec:ls so far nnri-i;xistenl in tlie overall picture of

the applications of the modmii family sewinrj maihine, (iYu deiaited

insiructions conceininq operation and application, .see page 20.)

# SINGTR lias WOHl.D’S FIR.ST Am'OMA'nc with slant neciile ami

gear drive. Seeing is easim, sewing s!niM.)UH'St evi»r. No slipjring

i>r stallimj

O.'Jl tniiy KMmuknblf «UKÌiiiio with

Form 30-047G íRev. 176)

® SINGllR has WORI.D'S FIRST Al,iTOMAT!C

threading. Has built-in lliroading tliarl, haiuiy

f I o n t of neoiilc!

« SlNGIiR lias WORI.D'S ITRST At.iTOMA'nC wiih a buill-in eye-

level slitth diait, with push bulton seleelion lor wliatever lam y

stitch you want!

V\ Tradeitiark ol THE SINGER COMl>ANY

Copyright 1965 THE SINGER COMPANY

All Rights Reserved Throughout the World

wiih ilouble-easy

’drop-irr' bobbin in

Printed in U.S.A,

Page 2

OTHHR OUTSTANDING FJiATURliS ARE:

• CYLINDER BED simplifies sewing of articles of

a curved or cylirrdrical nature

bed with the push of a button.

• PERFECT STITCHING ... straight and zigzag.

® NEEDLE CLAMP holds one or two regular

needles

two needle stitdiing.

• NEW TYPE SPOOL HOLDER ensures a smooth

flow of the needle thread.

® THROAT PLATE with .seam guide markings.

Meld with magnets for easy removal and replace

ment.

® SUPERFINE CONTROL of stitch length ensures

perfect satin stitching.

• PRESSURE OF PHESSER FOOT can easily be

adjusted according to regulator.

TO GET THE MOST ENJOYMENT

FROM YOUR SINGER 631

Take advantage of the free sewing lessons to which you are entitled!

Skilled, SlNGER-trained teachers will give you personal guidance and

assist you in learning the iundamcntals ot home sewing.

.....

same or different .sizes for exciting

.......

converts to flat

HINGED FACE PLATE, houses threading drart

and swings open for easy access to oiling points.

BUILT-IN MOTOR with worm wheel drive, no

belts required, excellent penetrating power when

.sewing heaviest materials without.manual assis

tance.

BUILT-IN LIGHT focu.sed on sewing area, which

swings down for easy bulb replacement.

ALL MECHANISM completely enclosed.

SPECIAL PURPOSE FOOT.

FLEXIBLE SEAM GUIDE.

HINGED BED EXTENSION for increased work

area,

COMPARTMENT for attachments and accesso

ries built into dctadrable cloth plate.

SINGER SERVICE

Wherever y'ou go you will find expert, dependable SINGER' Service

close at hand, SINGER is interested in helping you keep your SINGER

Sewing Machine in top running condition. That is why you should

always call your SINGER SEWING CENTRE if your machine over

requires adjustment or repair. Only from your SINGER SEWING

CENTRE can you obtain the services of a trained SINGER repair man

and warranted SINGER* ports.

EVERYTHING FOR THE WOMAN WHO SEWS

The answer to your sewing needs is at your SINGER SEWING

CENTRE. There you will find a wide choice of sewing aids, notions,

serving instructions and services. Look for the famous red "S" and

SINGER trademarks on your SINCIER .SEWING CENTRE and the ever

ready SINGER Service car. See j)hone book for address nearest you.

Page 3

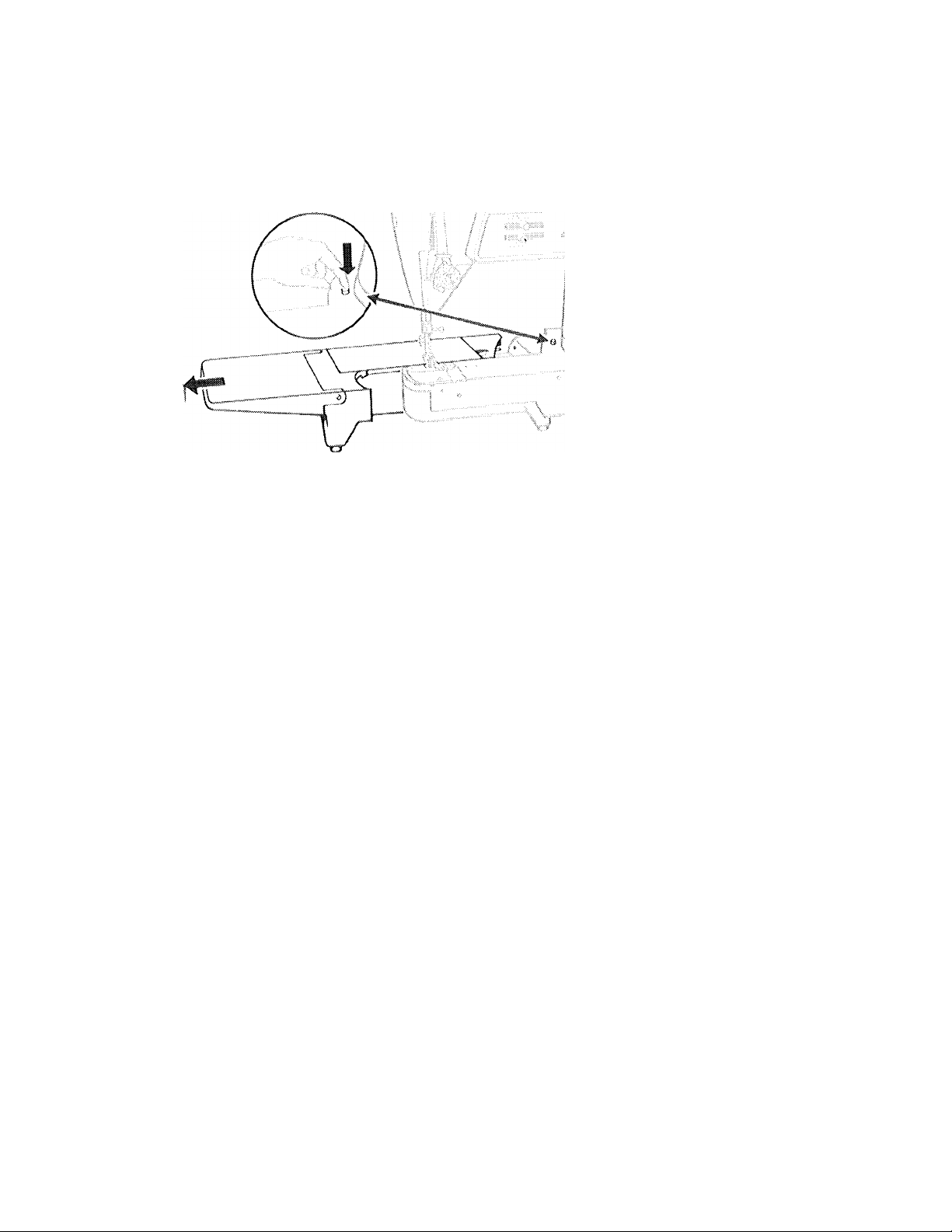

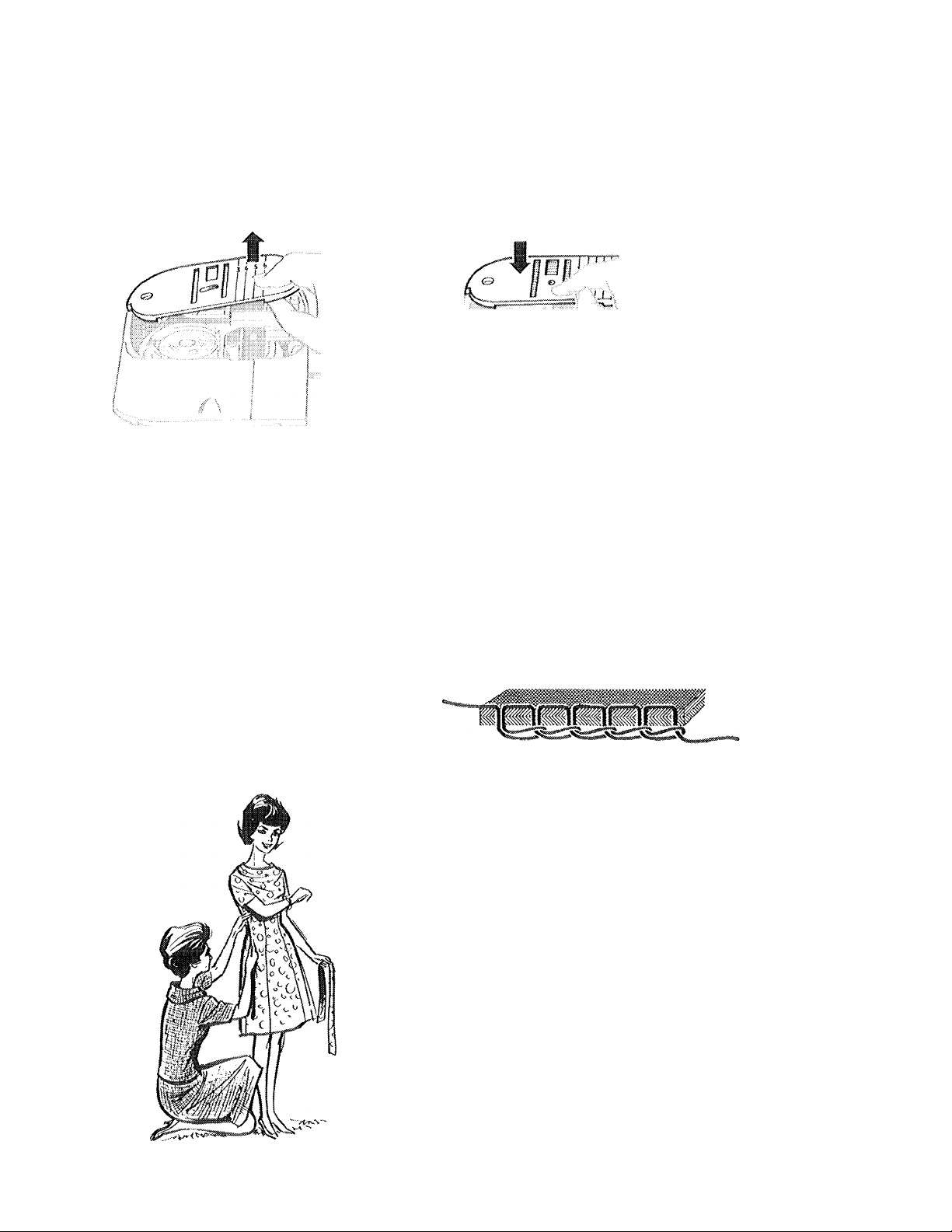

TO RliMOVn AND KI-PI-ACK DliTACHAni.E CLOTH PLATE

To dctadi cloth plate from machine, press button on machine bed and withdraw plate.

Replace cloth plate in same manner, locating two pins in plate with corre.si)ondincj holes in rnatiiinc

bed. Push cloth plate to tight until it snaps in locked position.

See pages 88 to 93 for applications of c>dinder bod feature.

NEEDLE AND THREAD SELECTION

The selection of thread should be based on the fabric to be stitched. The thread should blend with

the fabric in colour, fibre and size.

Silk and wool fabrics should be stitched with silk thread; cotton fabrics should be stitched with cotton

or cotton inorceriscd thread, etc. The thread must be of a size that will imbed itself into the texture of the

fabric. Thread that is too heavy for the fabric will remain on the surface and become weakened by fric

tion and abrasion.

The selection of the needle .should be basen on both the fabric and thread being used. The eye of the

needle must be large enough for the thread to pass freely through it. The blade of the needle must be fine

enough not to mar the fabric with too large a puncture, yet heavy enough to pierce the fabric v/ithout

binding or deflecting.

You will obtain best stitching results from your Sewing Machine if it is fitted with a SINGER* Needle.

Page 4

NEEDOiS ANJ> THREAD

This madiine uses needles

Catalogue 2020 (15X1),

Sizes 9, 11, 14, 16 and 18,

For perfect stitdiiiig, select correct needle

and thread to correspond with fabric (see

page 6),

Be sure to use similar threads for both

needle and bobbin.

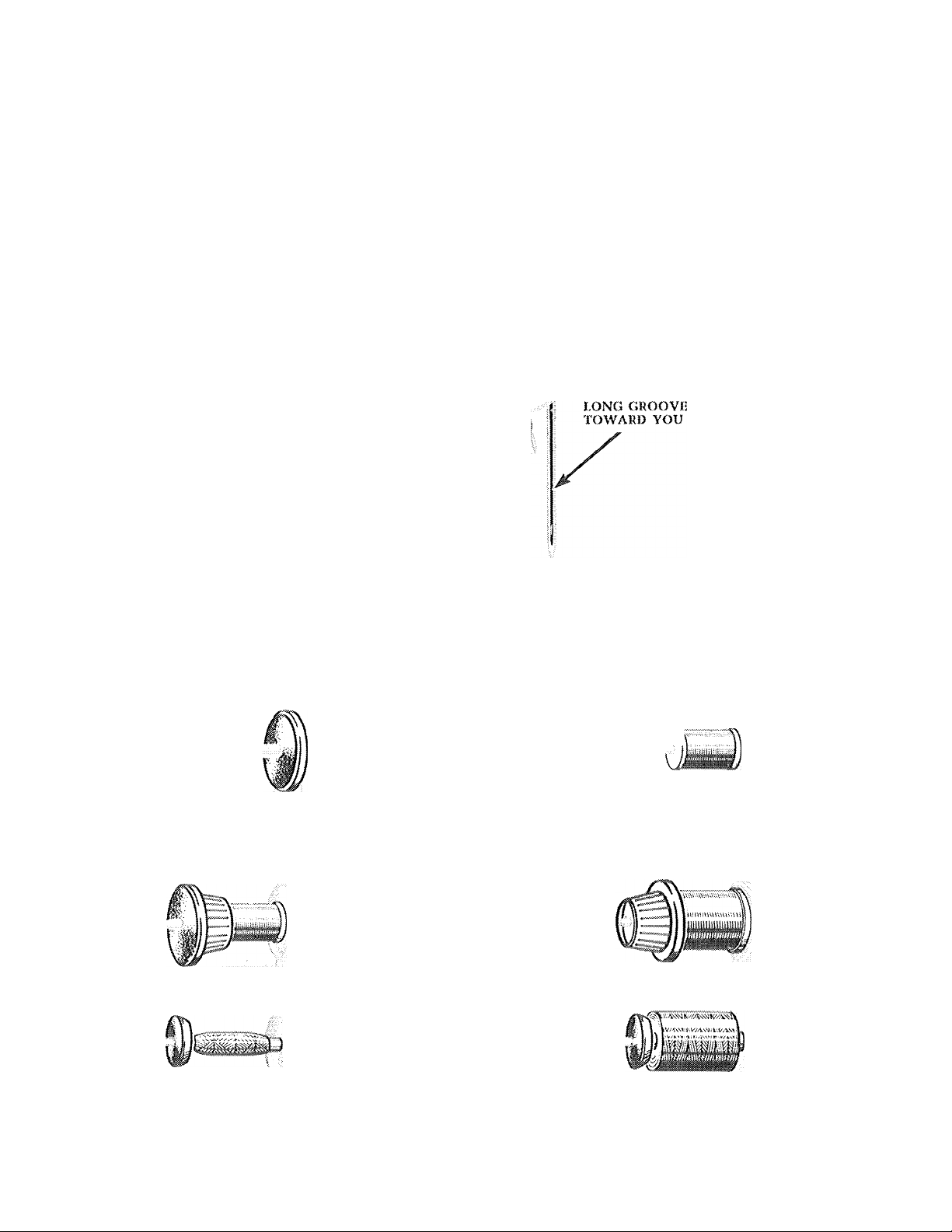

NEEDI,E INSERTION

Raise the needle bar to highest point by

turning the hand wheel toward you. Loosen

the needle clamp .screw. Insert needle upv.'ard into clamp as far as it will go, with the

flat side of the needle to the back and the

long groove toward you. Tighten needle

clamp screw.

1, Slij) spool sea! on to s])!ndle (Cushion

side i<u;ing spool of thread).

SPOOL HOLDER

n

2. Slip s])ool of thread on lo spindle.

3. Press Ihtr'ad lead-off against spool of thread. Select threarl lead-off according to the si/.e of tliread

sjroo! used, as shown.

Page 5

UPPfiR THRI-AOING-SINCU; NliKDIJi

Raise tako-up lever lo highest point. Phiee thread

on spool holder and load Ihrouyh threading points

shov.ii. Thread needle irorn front to back. Drav/

snffieient IliKidd through eye of needle v.’iUi which

to start sevring.

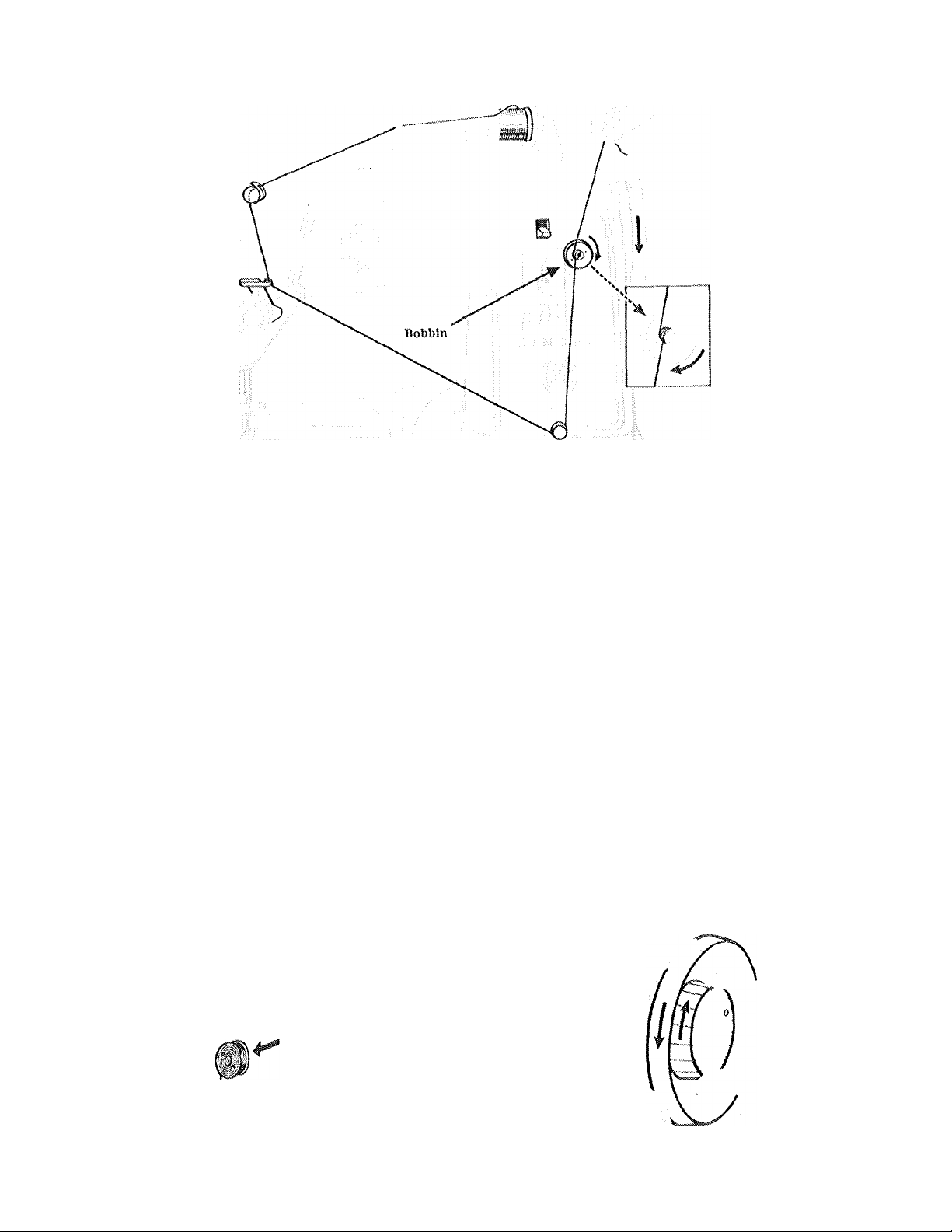

WIND THE BOBBIN

Release hand wheel, turn slop motion screw with right hand in direction shov/n by arrow. Slip bobbin

on to bobbin winder .spindle.

10

Page 6

WIND THE BOBBIN (Conftl.)

'i hreiui the madiiiie as shown. ,

Wind several coils of thread around tlie bobbin and depress bobbin winder engaging lever.

WIND THE BOBBIN (Conf'd.}

Do not wind loo riuidi thread, otherwise there

would be no free run of the bobbin in the bobbin

case.

Stop rnacliine, raise bobbin winder engaging lever

and retnove bobbin from bobbin winder .spindle.

Tighten .stop motion .screw with right hand in

direction sliown by arrow.

11

12

Page 7

REMOVE THE BOBBIN

Open slide plate and remove bobbin.

13

THREADING THE BOBBIN CASE

...

\

Hold bobbin so that thread biads off in direction shown. Place bobbin in case. Guide thread into slot

and under spriny. , .

Draw thread into notch at end of s))riny, pulling off about 3 inches of thread across the bobbin.

Closer sHd(; platci allowing thread to enter notch.

M

Page 8

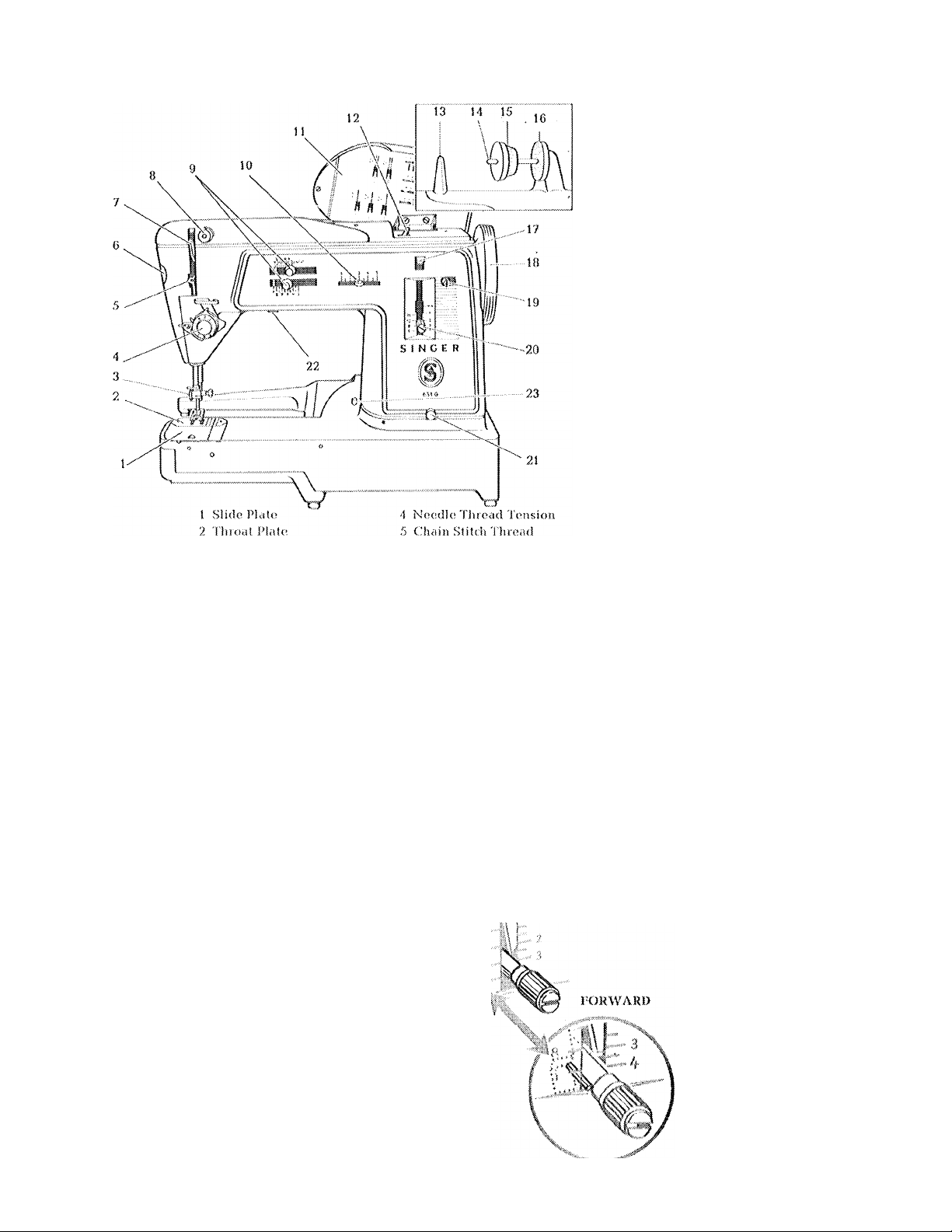

3 Piessci P'ool Screw

PKINCIPAL PARTS OP MACHINE 031

6 Pressui'« Reloiise

BuUoi)

y TJnoad T<ike-itp

I.over

8 Pre-te(!sion

9 Patteni Selector

Builoes

iO Stitch Width Lever

H Stitch Chart

12 Liyht Switch

13 Thread Guide

14 Spool Spiiuile

15 Thread Lead-off

10 Spool Stiat

17 Bobbin Winder

HngagiiKj Lever

18 Hiiud Wheel

19 Bobbin Winder

Spindle

20 Stilch Length

Regulator

21 Bobbin Winder

Pre-tension

22 Bulb Replaccnrent

Lever

23 Cloth Plate

Disenyagiiiii Ihrllon

15

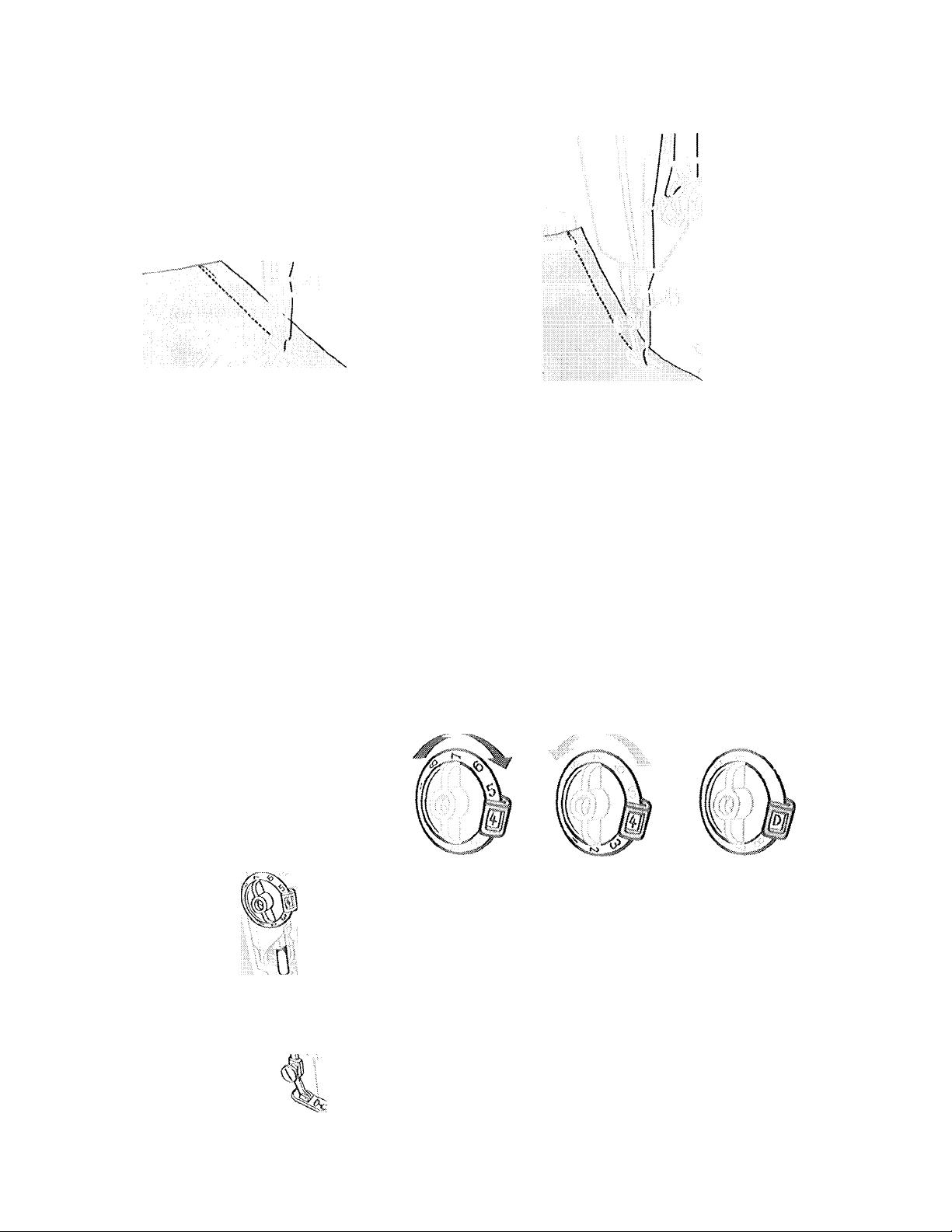

STITCH U;NGTH INDICATOR

Numerals on the left sidci of the indicartor repre

sent the mimbcu' of stitches pcrr inch. Numerals on

the right side represent stitch length in millimelcr.s,

A supertinc control can be made in case ot stitch

huKjths less than 1 mm or stitches per inch {2,0).

The greatest stitch Icmglh ol 4 nun or 0 stitches per

inch can be locked in place when slitdiing folds,

phrats or muiUph; layers of heavy fabric.

To set stitch length; Loosen by liiming tluimb nvd

to the left as shown, Position lover for desired stilch

length. Tkjlden by lutning thumb mit to the liglit.

By raising the stitch length regulator to the hig

hest point, reverse sUtdung is accomplished at the

same stitch length as forward. When in locked posi

tion, 4 inrn or stilches ¡rer inch (G) cannot be rever

sed. If reviuso stitching is ch'sired with thi.s stilch

length position, turn thumb mil to the left unlil the

stitch length regulator can bo adjusted to its highest

point al revcr.so stitching.

16

::-W )

■ IH

LJNLOCK.S

KLVliRSH

It

LOCKS

Page 9

Srn'C:H WIDTH AND NliEDI.H POSITION SEU-Cn'OR

1 2 3 4 S

I I I I,!.I I I I

A Stitdi widlh or needle position settiny is necessary for both straight and zig/.ag stitching.

When used with a straight stitdi setting, the lever ¡ilaces stitching in left, centre or right needle position

{see pages 26 and 27).

When used with a decorative stitdi settinci, the lever controls width of primaiy patterns and produces

variations of combination ¡patterns (see pages 41 and 43).

To position, depress lever and slide it left or right to desired setting. Numerals indicate five positions

but intermediate settings may also be used.

PATTERN Slil.liCTOR

Please note.': Do not make selector adjustments while the needle is in the fabric.

When make Patletn selection set stitch width lever at 3,

3

To Select Rettuired Pattern

1. Depress Push Button A and keep

depressed until selection is com

pleted.

2. ihish Pattern Selector Buttons.

,3, Select lequired Pattern.

4. Release Pattern Selector Buttons.

5. Release Push Button A.

PATT'ERN .SEUiC'I'OR

I, N P R

K|M|0|q| Special

M I I I I I I I

A 1 C I E j G I f

B D F H J

VI

Settings from K through Special are

made by the upper button.

Settings from A through J are made by

the knver buttou.

13

Page 10

THROAT RI.ATH

RliMOVAI. AND RliPLACRMENr

Removal of throat plate

Raise pressor bar. Turn hand wheel to raise needle

to its highest jjosition. (i)pen slide plate. Place thumb pins and then close slicic jriate.

under front end of throat plate and lilt plate from

machine.

Replacement of tiiroat plate

Place throat plate in position over two clampincj

19

20

CHAIN STITCH

More than any other sewing machine the new SiNGKR 631 will

eliminate a considerable amount of limc-consumincj and burden

some work previously done by hand, 'i'his machine has the unicpic feature of being capable of producing not only CMrnventional

lock stildiing but selectively single thread chain stitdung.

The main advantage of this lype of stildi is tliat the single thread

chain stildi can easily and cpiickly be removed by a single pull

on the chain stitch seam. By means of the chain stitch the, neces

sary tacking and basting operations indispensable for sewing

perfectly fitted dresses or other garments can now be produced

on a maduiie. liven a section of a chain stitch scam can be remov

ed without any effort as is frecpiently recpiired wlion fitting the

dross or garment (side and waist seam.s). Once the dress or gar

ment fits, the tinal lock stildi is stilchcd in a close parallel line

to the diain stitch. Tlien the temporary scam is removed by a

single pull without leaving remains of the thread in tlio fabric.

Thus sewing-in of the basting .seam is very unlikeiy. For basting,

regular thread or darning thread may be used.

The single thread drain stitch has a wide range of applications

and can be erniiloyed (or a variety of operations, for instance:

Page 11

Hdge basting on jackets, coats and costumes

serting — attadring collars

Basting canvasses to the fronts of costumes and jackets in

stead of sewing them with zigzag stitdres;

Sewing shrinking tucks on garments as shirts, pyjamas etc.

as well as on ready made clothes and curtains made from

fabrics which arc likely to shrink. The temporary stitdiing of

the curtains and also the final stitching can be performed on

the same madiine. Stitdiing growth tucks whidi can be open

ed on clothes for growing driklren, as desired;

Re-sev,'ing waist and leg horns on ladies' and men's under

wear of tricot or interlock fabrics wdien replacing elastics;

• Adjusting length and width of ladie.s' slips (shortening for

short persons, taking-in widtli (or slim persons) particularly

to matdi fashions when dresses have a certain degree of

transparency making a slip essential.

Another most distinctive feature of the diain stitch \cdiidi will

certainly be appreciated by the homeworker for artisan type

production is that the chain stitch is formed exclusively by the

needle thread thus freeing the operator from bobbin winding.

This, in turn, is a time saving factor. In addition to the above

mentioned applications tlie artisan worker wilt use the drain

stitdiing tor - -

l•irst contour stitdiing on shirt collars - - sewing on labels -

lieinming operations on neckties and umbrellas

all operations where the chain stitch proves to be advanta

geous with respect to convenience, C}uality and time.

...........

in .short,

.........

hems on skirts, blouses etc.;

............

- sleeve in

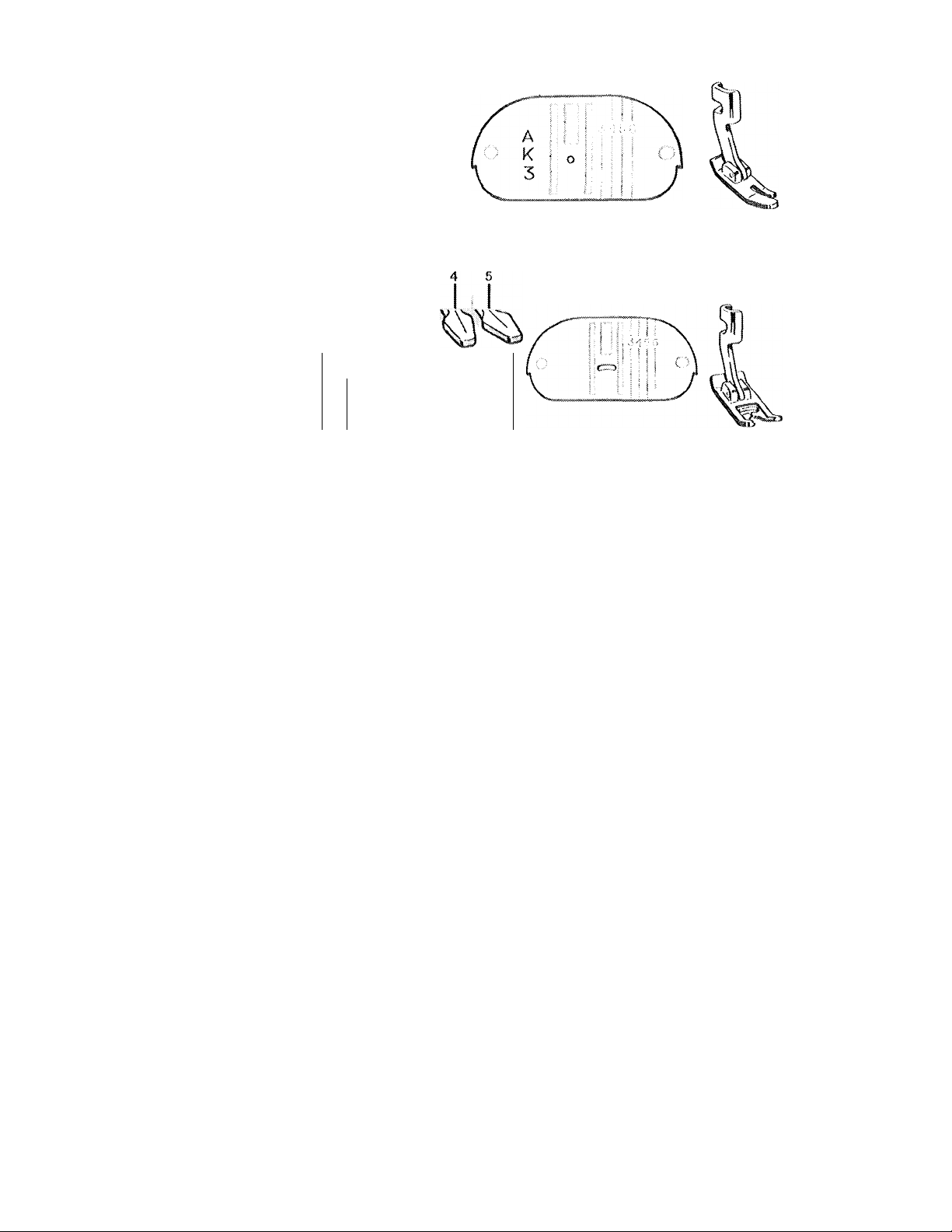

TO PUKPARE THE MACinNE EOll CHAIN STITCH SEWING

Set .Selectors at AK and stitdi width iever at .3

Idr.st remove regular throat plate and bobbin.

lii.sert chain stitdi looj) retainer into bobbin case

(lHustr<iticm 1)

Tilt latch {Illustration 2) and turn to the left against

stop (Illustration 3).

Insert chain stitdi throat plate.

22

Page 12

t!u> lu-udic thread in tlie ciiaiu stiUli Diroad yrude

lu lUldUioti io noniuil iliicudiiHj, pSuce

with llui iace ])!ale oiu-ti.

Stiktv leiiyllt; Nounallv' set for maximum lenrjth,

approx. 0 stildiirs to tiu; indi |4 mm) (ieit. tow of

mmitiers on llie sUitri indieatm jrl.ite), Лиу stiUh

ii'iMitti i)('twe(4i h and \'J. .sfitsiu's to Ih«' iu(i! {?. mm)

may ire used.

Upper fhnuHi ieiisiou: Noimiilly set between 2 and

.'i. Siiijlit adjustment ntay be lecjuittrd depemtrmt on

Itur sUtih ieufjtli and ilie iiiateiiai used.

CHAIN STirCHING

A dt<iin stiidi strain lias the, same appearauetr as a

lod; stildi .straru <)u the toj) side of the fabric,

f towevi'v, the knottimj of the slitdi doe.s not occur

in Uitr matetial as trii a propiuly ItalaiKrt'd ккк stitch

seam; instead thi> thread forms loops on tlu' imdersido of the fabiie widdi iesembh:> small arrowlteads,

Tiie.se anov.’htmds peculiar to the thaiu stitt.h poiu!

tov.xmis Uie betpunintj of the seam.

When stattintj make sute that the taktr-up lever is

in its highest ptrsiiion, ritis will prevent the needte

thread from pultintj triif of the needle И the thread

has been eut too short. Sew forward only! If the

matt'iiri! is pivoted at the needle for ojmrations

where corneitng is retpdred, m<ike certain Umt the

needle is on its upv.-artt movement (apptox, 1 cm

above its lowest iroint) to avoid skijrped .stiichos.

then cottlinne to sew,

TO KHMOVJ- 'ГПК млтешль TIIOM M'NIÎATH

тип l'IHrSSliR TOOT

'Hie easiest way of retnovinrj tlio materia! is to sew

off lilt! edge of the fabric wtiito slightly ptdiiny on

the mattnial, lliis produces a diaiir whidi sliould

ire rtU sonu' distance away ftotn the fabiic, Howev(u, if tinr scant is ended Ixrfore llu' ectge of lire

fairric, Irriug tile takc-up lever fir its liighesf posi

tion, Hum lit! (he ¡rn'ssiu loot am! pull somr; thread

thmW)li the take-UJ) lever from tllC spool pin. Nov,'

drciW the loose thread Iretv lam the pressm foot and

liie m.dtuial to tlie riglit vith the scissors <ind ttien

cni lh<> thieati. By removing the niutiuTii liie free

end of thc‘ thiead is automatically pulh'd to the

underside of the niaterial and Ifie s<Min is securely

Iruked,

2,2

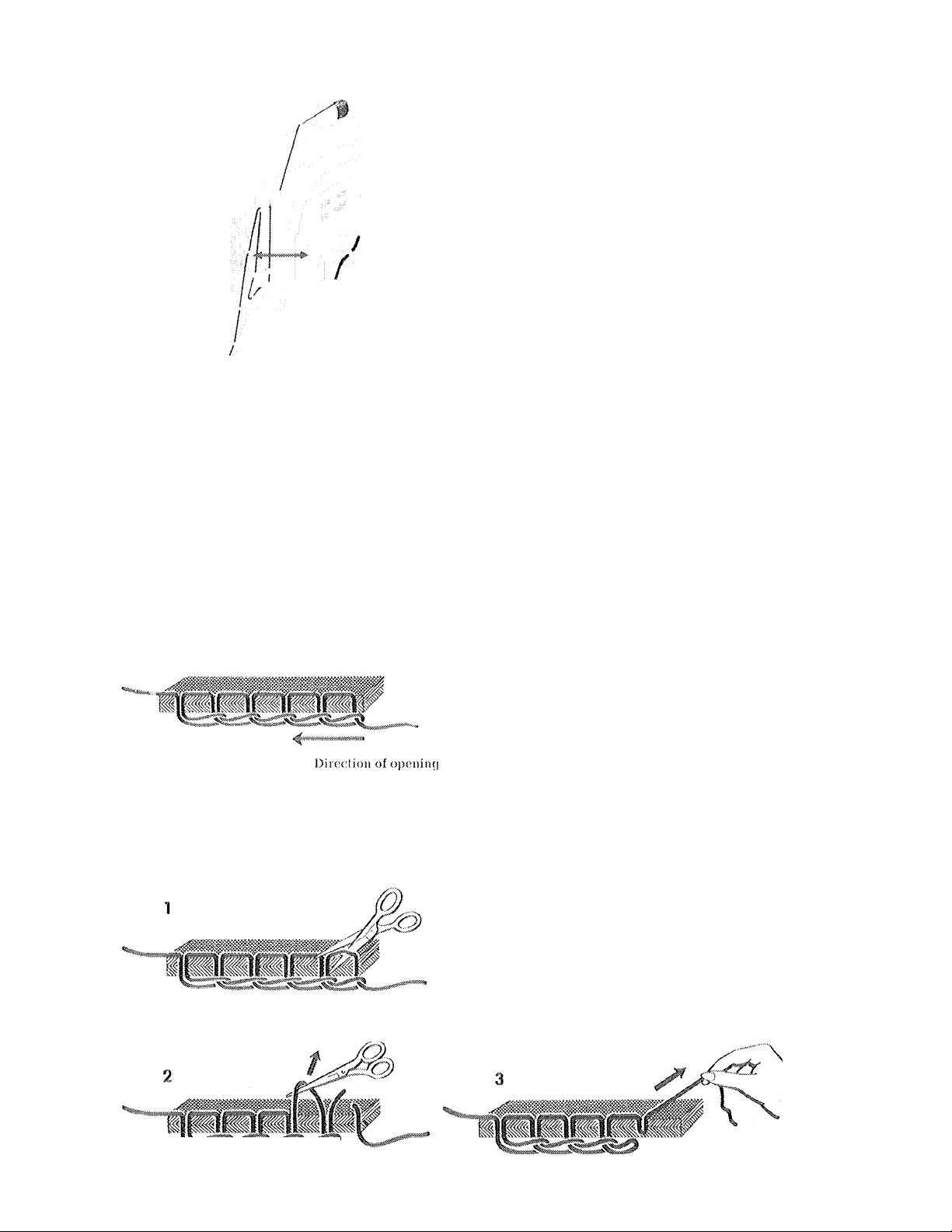

TO OPEN THI; SHAM

'i'he, diain stitdi seam can be opened in one direc

tion only, from tfio end of the seam toward.s the

start of the seam, The opening direction is distin

guished by Ihti arrov.dieads on the underside of the

fabiic which ¡roint towards fire ireginning of the

To open the seam, cut the last stitch on the top side

of the faluic and thmi pull up (he ]>ieeeding stüfi».

With ttiis free thiead end the .seam can bo removed

by a single pnil. In the same manner the scam may

bo opened and removed at any dosiroii place by

pulling the thread emt in arrowhead direction. The

remaining section to the end of the scam will be

inaiiitained.

24

Page 13

Section to ionu'tin

Section to be; opened

Section to lernain

Mowever, if the section towards tlie

beginning oi the seam is to remain and

the segment towards the end of the

seam is to be rcmoveci, cither partly

or completely, the remaining section

mnst bo locked first, inrr this purpose,

cut the scam at the desired place on

the top side and pull the loop out'of

the fabric on the uiuierddc of same.

Ttieii the desired segnrinii of the scam

can be. removed as staled above.

TO CIlANGl: PROM CHAIN STITCHING TO LOCK STirCHING

Clranging to lork stildiiirg requires only unthreading of the drain stildi llu<;ad guide (see page 2,1), repla

cing tire bobbin and inserting the desired zigzag or straight .stitch tliroat plate,

2.5

bOCK stitch

STRAIGiir SmCHING

A K 1

A

Sel Sodector at AK.

.Stitdi widlh lever al 1 To lotsile slitdiing in central position.

General purpo.se throat plate and presser foot.

lise general puiiiose throat phiie and presser foot for ali ulilify sewing, long stiaight seams, etc,, ami

wliere there is occasion to alimiiate Ixdwm'n straight and /igzag slitdiing.

25

..

Page 14

STUAICniT STITCH THROAT I’l ATii AND

PRTSSliR TOOT

Use the stiaic|hi stildi tliroal plate and ¡)rcsscr

foot where fabric anct sewing procedure require

close control. . . for precision stitching of curved

am! scalloped edges, top stitching, edge stitching,

etc.

J-'or best results, this equipment should he used

wlion stitching sheer and iiliiiy fabrics, knits and

tricots (particularly synthetics) and ail soil sirongy

materials.

STRAiGHT STTTCTHNG WITH U:TT AND RIGHT NliT.DU; ROSmON

^ i ' ! : r ; ? 1

A

1

: 1

1

^ 1 ;

: i ;

)

1

i >

i 'It

1 i 1

1 i (

* I

i j : 1

• 1

i i

i { > :■ i

Set Selector at AK.

Stitch width lever at 1, 2, 4 or S.

General purpose throat pJnte and pressor loot.

Do not make stitch width lever adjustmcnls while the needle is in the fabric.

To meet specdal recjuhemenls a line of stitching may be placed to the right or left of cenlrc.

Stitch width lever settings 1 and 2 locale siitching to the loft. Settings 4 and 5 place it to the right.

Inlcnmediote settings may also be. used,

27

PRTRARl: TO STW

V ft 1

f '/H ra

V/ \ ..

/

^ .. ]

Hold needle Ihroaci lightly with left hand. Turn hand wheel .so that needle entens plate and brings

up bobbin thread. . ,, ,, ,,

l\ ■ ' I

(U

/.

5^

/

Pull end of bobbin thread through plate and place both needle and bobbin threads diagonally under

presser foot.

28

Page 15

SHWING A SHAM

U

Sot stitch rogulator for stitch Icnytli dcsirecl. Position noocilc into fabric alront V; inch from ocicje and

lower pressor foot. Raise; stitch rccjulator to reverse.

Back stitch to c;(5c(<; of fabric for reinfmeernent, l.ov.’er reyuiator for forward slitchiny of sc;am. Raise

stitch rc(|ulalor,

4

-i

29

Back stitch to reinforce end of seam, and lower reyuiator to forward .stitching position.

With take-up lever at higJiest point, raise presser foot and remove fabric.

30

Page 16

CUiniNC AND SUPPORTING PABRIC

Most iabrics iioed only to 1)(; (juiiiod in froiit of 11k; piessei loot.

i'abiirs of umisual tt'xtuie and woavo, filmy sIkkos, CK'pos, kniis, tikots, otr., !iK|uiie supj)oit whilo

being sUldieii.

For Mich fabrics, use 11k! straight .stitch throat plate' and ¡HCSSf't foot, and ajtply gontlc tensiou to trie

seam by hoiriing tfie fabric in fioni and in b.ick of the prossei foot as iliustrated.

\

Pin-SSUiO; AOJUSTMP.N'I'S

Increase

Pressure, is tlie force tlie picsser foot exerts on fabiic

while it is Ixnng stitdred.

The presser foot inrist bo lowered prior to adjustments.

Sniootli, even haridiing of .several thicknesses of (abtic

result.s when pr<;ss«r<; is correctly regulated. Heavy pres

sure is for thick fabiic and tigiit ¡rrcssure is for thin fabric,

'I'oo light a pressure will result in itregtilar feeding which

affects both (|nality of slildi and evenness of scams.

Too heavy a pressure not crnly affects stitch and sciarn

(¡uality tnil will also rnar smooth surfaces and pile fabrics.

Surface finish, as well as the wrnghl and texture of the

fabric-, must be eousidcred iir determining the anrottnt of

prcKisurc; ncieded.

32

Decrease Position for darniric)

and cmlH'oidcny

operation.s

Page 17

NI-I-DU; THRHAB THNSION

STRAIGHT STITCHING

Needle thread tension too tight

...........

correct by setting dial to lower mimbor.

1!

'/t W//>, V/Mt Wf/it Mf/

Needle thread tension too tooso ■ ■

correct by setting dial to higher mimber.

A perfectly locked stitch results with upper and lower tensions balanced so that needle arid bobbin

threads are drawn ecjually into fabric,

33

y. y.

A perfectly locked stitch results vrilli the upper and lower tensions balanced sO that ireodio and boirbin

threads are drawn ccjually into fabric,

34

Page 18

ZIGZAG STITCHING lìQUIPMIiNT

General purpose presser fool.

STITCH I.IiNGTH ADJUSTMENT POR SATIN STTICHING

mn

Special purpose presser loot.

The upper indented area behind (he stitch indicator provides a means

of gradually shortening the stitch lengtli.

As tlie regulator knob is turned, the pointer rides deeper into this

indentation until a closed satin stitdi is obtained.

The exact stitch s(>tlin<j will vary with the texture of the fabric.

It is advisalrle to make a t<;st on a scrap of self tabric, using the

Special Purpose 1-oot, before proceeding with actual work.

30

Page 19

SATIN STJTCH

TlìNSION ADJUSTMENT

Satin stitching letjuircs a lighter needle thread

tension than straight stitching or open designs. The

wider the satin stitching the lighter the tension

reguired.

Wide satin stitching, Stitch Width at 5, requires

the least amount of tension. For narrower satin

stiIdling slightly more tension should be used.

To detonnine eoiicet tension setting, a test

sample should be made on self fabric using the

Special Purpose Foot, A properly balanced satin

stitch should lie flat across the material. Any tautncss or puckering indicates too high a needle

thread tension.

Some soft fabrics may rccpiiie the addition of a

hadcing to insure good stitching results. Crisp

organdy and lawn arc suitable for this purpose.

tension

\

LI

Correct needle thread

temsion

37

PRIMARY PATTERNS -- BUJI/MN THE MACHINE

See pages 17 and 18 for operation of stitdr width lec'cr and selector.

U N P R

I mIoI Qj Special

The operation of the upper selector button between L and Special controls the function of the primary

patterns shown below.

The setting of the lower selector button at B places the stitching in the central needle position.

The stitch width lever controls the width of primary patterns.

Do not make stitdr width lever or selector settings while the needle is in the fabric.

L

Q

s

<

s

p

38

Page 20

PRIMARY PATTERNS

SPECIAL DISCS

Those five interdiancjcable Special Discs, classified as Piimaty Patterns, are included with the ma

drine. Eadr produces an individual design.

Circled numbers {for example @) book indicate Special Disc numbers.

PRIMARY PATTERNS

REPLACEMENT OE SPECIAL DISCS

P

L N P R

kImIoIqI

A

ilihlil

39

Special

To replace any of these discs, move pointer of the upper Selector off Special.

Raise the stitch chart at top of the machine. Remove disc and place another disc onto spindle, pushing

downward untli disc .snaps in place.

Sot pointer of the upper Selector on Special to engage the. disc.

40

Page 21

PRIMARY PATTERNS

STiTCn WIDTH TEVER CONTROL OT' WIDTH

2 3

L N P R

MlOiQl Special

The width of Primary Patlcins is controlled by the stitch width lever. Settings range from a maximum

of 5 to a minimum of 2.

41

PRIMARY PATTERNS

NEEDLE POSTITONS

Selector setting of B places stitdiing in central

needle po.sition. Selector settings A and C place the

stitching in left and right needle positions at widths

less than 5,

LEFI'

CENTER B

RIGHT

Selector setting B is preferred. Settings A and C

are only used when special placement of stitching

is desired. For example: Buttonholes, button sewing.

42

L N P R

ImIoIq] Special

1- N P R

i|M|0|Q| Special

L N P

I mIoIqI Special

A I C I f. I j !

B D i- H <i

Page 22

COMBINATION PATT'ERNS AND VARIATIONS

1. ■ : r

J L 2

J I 4

J L3

A great variety of additional stitdi patterns can be created by combining any lower Selector setting

from D through J with any upper Selector setting from L through Special.

A stitch width lever setting of 3 results in a Combination Pattern. Settings of 2 and 4 produce Varia

tions.

TWO needi.es

43

The needle clamp accommodates two Cat.

2020 {ISXlj needles, generally of the same

size. However, where special effects are

desired, needles of different sizes may be

used together, with corre.sponding threads.

Loo.sen the thumb screw and insert the addi

tional needle from the right, (See page 7

for procedure.)

44

li li

Page 23

TWO NEfiDUiS

UPPI-R THREADING

Thre<id as for sinylc needle first (see parje 9).

Open top cover, insert auxiliary spool holder

(wliidi is furnished with the machine) into the hole

provided (see illustration). Slip second spool of

thread on to the auxiliary spool holder and thread

second needle as shown.

Make certain that threads are separated by tire centre truision disc. Cany only one thread through the

last guide at the needle clamp.

TWO NflEDUlS

STRAIGHT STITCHING AK 2

i I

Selector selling; AK.

Sfltdi width lever: 2 only.

General purpose loot and throal plate.

45

46

Page 24

1. N P R

¡m|0|0| Special

Seleclor setting: A - -L through speeiat

Stitch width lever: 2 or 3 maximum.

General purpose throat plate.

General purpose foot or special purpose foot

TWO NKEDtES

PRIMARY PATTKRNS

2 3

CM

Instructions for using ATTACHMENTS...

47

NO'iH: Tlio attachmemts which are not regularly furnished with your machine are avnilahie

for separate purchase at your local SINGER SEWING CliNTRE,

•18

Page 25

This liylU, il(!xibk! foot

is dosiyuod for satin-stitdiing. If provides iiuixiinuin

visibility and iiiatunivcrability while allowing

closely spaced zigzag

stitdrcs to feed freely.

It is ideal for accurate placement of satin stitdiing in buttonholes, rnonoyrains, motifs and applique

work.

The eyelet on the left side of the foot accommod

ates a filler cord.

ATPI-ICATIONS

Buttonholes

Applique

Monograms

Decorative Stitching

Cloudiing

Motifs

BUTTONIIOUiS

Selector; AL

Stitch width lever: See below

Throat plafe; General purpo.se

Special purpose foot

SUldt length; Tine

To establish the correct stitdi setting and length

of buttonhole, a sample must first be made,

'f hicc Stitch Width settings are available, b’abric

weight and buttonhole size will determine the

s(!lection,

3 5

2 3

1 1

49

BUTTON! iOUiS

Marking

lines

l.eugtli of

culting siane

Bar lacks and

.side .stildriug

The length of cutting space, the opening through whidi the button passes, is measured by the width

and thickness of the button.

The length of the finished buttonhole will bo the cutting space plus Vs inch for bar lacks

Work a sample buttonhole in the same fabric as the garment. Use a double fold, duplicating a facing,

and include interfacing if this has been used.

50

Page 26

BUTTON» tOI.ES

da)

StiUiiing Procedure. Set Selector and stitdi width lev'er. Place work under the needle, aligning the

center marking of buttonhole with center .score line of foot.

To form side stitching, turn hand wdieel toward you so the needle enters fabric at point A. Tower foot

and stitch to end of marking. I.eave needle in fabric at point B, Uaiso foot, pivot work on needle. Toever

foot. Take one stitch w'itliout changing stitch width lever setting, bringing work to point C. Adjust to

stitdi width lever setting for bar tacks and take no less than six stitches. Stop at point O. Readjust to

stitdi widtli lever setting for side stitching. Complete to point P. Move to stitdi width lever setting for bar

tacks and duplicate tack previously made, ending at point V,

ГЛ

BUTTONUOUiS

To secure stildiing move stitdi width lever to

No. 1 setting and take three stitches. Remove work,

draw thread.s to the underside, fasten and trim.

Raised or Corded Buttonholes. Both No. 8 pearl

cotton and buttonhole twist make suitable filler

cords for raised buttonholes.

Place the spool of filier cord on the second spool

pill. Cany tiie cord througli tlio first thread guide',

straight down between tlie center and back tension

discs, into the large tliread guide and then tlirough

the eyelet on tlie Special Purpose Foot. Draw tlie

cord under and in back of the foot and proceed as

for regular buttonholes.

With sharp eiiibroiciery scissors cut opening for

button.

52

Page 27

APPMQUl;

Applique iwUls beauty and iiitoresl to wearing

apparel, linens and fabric furnishings.

liither contrasting or self fabric may be u.scd

effeclively. The mo.st versatile stitch in appliqueing is a closely sid zigzag stitch (Primary Pattern

BL). The width of this stitch may be vnrioti to

accommodate weaves and textures of fabrics.

Combination Patterns and Variations present many

interesting ways to «ppligne with decorative

stitching.

Prerparation. There are two methods by which

applique work may bo done. The appropriate

method is determined by the fabric being used,

and a test sample is advisable.

Position the design properly and baste it to the

fabric. Attach the Special Purpose Foot to the pres

ser bar.

Method No. 1. Sot Selector and lever for the

desired stitch pattern, P’otlowing the shape of the

design, outline it entirely with applique stitching.

Any excess fabric on the outer edges is trimmed

away after the stitching has been completed.

53

APPLIQUI;

Method No. 2. Set Selector and Lever to AK 3

for straight stitching. Outline the entire design with

a short stitch. Trim the raw edges down to the

stitching.

Set Selector and Lever to the stitch pattern

desired, and overedge the design with this stitch

ing. A smooth, lustrous finish results, whidi requires

no additional trimming.

Corded Appli<iue. The Special Purpose Foot,

which provides for a filler cord, is perfect for cord

ed applicjiic work. Gimp, crochet thread or button

hole twist are generally used.

See page 52 for threading.

hither method of appliqueing may bo used when

cording is desired. The only change in procedure is

tl>c introduction of the cord, ov'cr which the appli

que stitching is formed.

This stitching technique results in a raised,

dimensional effect, and is an idea! finish for lace

applique.

5«i

Page 28

MONOGRAMS AND MOTIFS

Any of the many stitch patterns are perfect for

monograms and motifs.

Select a design from the many transfer patterns

available or sketch one to suit your purpose.

Some fabrics may require a badcing of lawn or

organdy.

Position the design on the right side of the

material. Trim backing away when stitdiing is

completed, if necessary.

To reproduce a specific portion of a stitdr pat

tern, first .stitdr on a scrap of material until the

desired point in the design is reached.

Remove the material from under the presser foot,

Now position motif or monogram under the needle.

Lower pres.ser foot and stitdr.

This procedure is recoirtmended for all precise

design placement. Leaves, and flower petals, for

example are created in this way.

55

SEAMING SHEERS

Selector: BL

Stitch Width: 2

Throat plate: General Purpose

Special purpo.se foot

Stitdr length: Fine (above 20)

A dainty hair-line finish is particularly desirable for tiro irrside seams of sheer collar.s, facings and

yokes. Seam allowances that ordinarily slrow tbiougir are eliminated,

Botlr heavy duty thread attd tatting thread rnak suitable filler cords (see page 52 for threading).

f-ollov.' ilu; seam outline covering the cord. Cut av.>ay seam allowance dose to line of slitdiing.

Turn and press.

Page 29

Novel effects «re obtained by concbim:) gimp,

yarn or braid with stitch patterns.

Spaced patterns are the most appropriate as

.they allow the decorative cords to show as part

of the de.sign.

COUCHING

The Sjrecial Purpose l-'oof is ideally suited to

this work (see page 52 for threading).

I,ACl:i IÌDGING AND INSIiUTION

Delicate, yet durable zigzag stitdiing is espe

cially appropriate for the application of lace

edgings and insertioiis.

Many decorative stitch patterns can bo used

effectively setving as both finish and trim.

BUTTON SEWING FOOT

A..i';A..4A .v

.57

This short, open foot

accommodates any

.size sew-through

button, and holds it

securely for sUtdring. The groove in

the foot allows for

insertion of a madrine needle, over

which a thread

shank may be form

ed.

The foot is used in connection with the Genera!

Purpose I’eed Cover Plate.

Selector setting: AT

Stitch width lever: I and 4

Feed Cover Plate

Button sewing foot

Stltdi length: above 20

Space between holes in button determines stitch width le\'er setlings. Numbers t and 4 generally

apply to standard buttons. Number 1 setting is constant, but 4 can bn increased or decreased to accom

modate buttons with unusual spacing.

Set Selector at AL and stitch width lever at 1. Attach feed cover plate to machine in place of regular

throat plate in same manner as instructed on page 19.

Position button under foot so that needle will enter into loft hole. Lower foot. Turn hand w'hcel toward

you until needle rises out of fabric and is just above fool.

58

X

Page 30

BUTTON SKWING FOOT

Sat Lavcv at 4. The needle should then enter into

the right hole ot the button. Take approximately

six zigzag stitches in this position. End at the left

side.

To fasten stitching, adjust to number 1 Stitch

Width setting and take approximately three stitciios.

THREAD SHANK

In order to form a shank, stitching is done over

a regular machine needle. Position button and lower

button foot. Place needle in the groove of the foot

so the point enters the hole.

A larger shank results when the heavy end of

the needio is utiiiitcd.

ITsed with the getiora! purpo.se throat plate this

foot provides a wide noodle slot which accommo

dates all stitch settings and cais be used for most

sewing operations.

59

a V o i? 0 9 ti » 0 o ^ o a * o » s> i t' J < s> o V -

SEAMS

ONGFRIf! SHAMS

Dainty lingerie seams are made durable! ami rij)proof witli zigzag stitching (Bh 2’/i), After straight

stitching the fitted seam on the wrong side, press

both seam ailowances in the same direction. Frocn

liie right side, top stitch wiiii a fine zigzag setting,

kitting llic! needle enter the seam line and then the

seam tiiickness. Particularly good evhere flat bias

scams are desired.

APPHICATfONS

Seams and Darts Automatic Scalloping

Mending and Maintenance Scam Ihnishes

60

Page 31

rr,AT SPAMS

Zigy.ag stitcliiug gives strength and durability to

flat felled scams.

Form the seam to the right side of the fabric,

taking full seam allowance, using a zigzag stitch

(Bl. 3).

Press the seam opeir, then fold and press the. two

edges together, keeiring the right side of the zig

zag stitch uppermost.

Trim away half the under seam edge.

Fold the upper seanr edge evenly over the trim

med seam, and top stitch.

SHAMS

KNIT TAimiC SHAMS

A fine zigzag stitch (BL V/i) is ideal for seaming

knit fabrics. Particularly desirable for underarm

seams and otluu' seams where elasticity and give

an? needed.

For neckline and waistline seams, wliero a stay

is needed to prevent undue stretching, this same

stitch can be nsert to <g)ply seam tape. To insure

a flat, smooth finish, position flie seam tape with

the edge exactly on tin; seam line, If seam is curv(;d, pre-shape tape to fit by .steaming, and Irastc

in place.

Stitch, allowing the needle alternately to enter

the seam tape and seam line.

SHAM ITNISFIHS

Seam edges support the garment and should be givxm a durable finish where fabrics have a tendency

to fray.

The zigzag slitch BL is ideal for such finishing. Place the stitching near the edge of the scam allowance,

and then trim away excess fabric.

For an overedged seam, the blind stitch BO makes a durable bulklcss finish. Good for straight grain,

lengthwise scams.

Seam edges should be trimmed evenly, and the stitch then iormed over the raw edge.

61

6?.

Page 32

»ARTS

Darts provide fit and contoru in a garmetit and

sliould bo accurately stitdied.

A straight stitch dart (AK 3) is usually formed

by stitching from the seam edge, tapering gradually

to the point, where the last 3 or 4 stitdies parallel

the fold. Stitch beyond the fabric to form a thread

chain Vr to V< inch in length. Tic the thread ends

into a single knot close to the stitdiing.

SINGLE THREAD DARTS

Darts add styling and interest when stitched with

the fold to the outside of ganneut. Thread ends

at tire point of the dart are ediminated when the

single thread principle is employed.

Unthread the needle. Use the thread leading off

the bobbin and rethread the needle from back

to front. Tie. bobbin anct upper threacLs together.

Draw bobbin thre.ad up through, threading points,

winding enough on the spool to complete a single

dart. I.osver the needle into the very edge of the

fold at thei point of tlie dart. Take any slack out of

the Ihrcacl by turning the spool. Lower the presser

foot and stitch carcfulfy toward the seam edge.

This method is also ideal for inside darts in sheer

fabrics as thread ends are eliminated at the point

of the dart. —

DARTS IN INTERLACING

Non-woven iiiterfacings c:an be shaped without

bulk v/ith '/.igzag stitching. Selector setting M. or

BQ may be us<;d.

Cut out the dart allowance on the stitdiing lino

and bring the raw edges together. Pin, over a

muslin stay, and stitch. Back stitch at both ends.

BLANKET BINDING

:j

r . i

i» «

4 i-'»« 1

ез

-

.....

<•

Л

It

<

Ч-

, II

The multiple .stitch zigzag (BQ) is an excellent

stitch for applying blanket bindings and afford,s

both a decorative and durable finish, Remove worn

binding. Baste new' binding securely in place and

stitch. Adjust pressure if necessary, to accommo

date the thickness of the blanket.

64

Page 33

MliNDING

Zigzag stitdiing is well suited for all typos of

liouschoid metsding. Selector setting BQ provides

a firm, flexible bond for the repair of rents and

tears, and is ideal lor the reinforcement and ai)))!!cation of elastie. Stitch length and width are rrigulaled according to need,

Uenl or Tear. Trim aw’ay ragged edges. Place

<m underlay to the wrong side of the tear for

n'inforcomont. Using the multiple stitch zigzag

(BQj follow the, line of the tear bringing the edges

together. Shorten the siitdi length at end.s ami

corners to give extra strength.

^(í,'^<yyyyVvrAaív^/vJtWvaгyV>ZvS'■

Application of lilastic.

Elastic, such as used in

waist bands, must be

strelrhed as it is applied,

to insure fullness requir

ed in, the garment.

65

SCAI.I.OPING

Dainty scalloped edges are used extensively as self trimming on blouses, dresses, lingerie and child

ren's wear.

Perfectly formed and evenly spaced scallops are produced automatically at Selector Settings 15R and

BS

BR results in a 12-stitdr scallop.

BS <D, a 2'1-stitdi scallop.

Stitch regulator and lever settings vary the length and depth of the scallop.

After stitdiing, trim seam allowance to less than ’A" and clip info the points between scallops.

Some fabrics may also need notching, for a smooth, evenly turned edge.

Turn, gently roll out scallops between the fingers and press.

When scalloping a shaped or bias edge it i.s best to use an interfacing.

Wlien forming scalloped tmRs, add an extra ’A" to tuck allowance for seaming.

Page 34

'!'he seam guide aids in

attaining uniformity of

seam width, it provides

for stitching to be spaced at any distance between

V»" to l'/<" from the edge of the fabric.

■ SHAMS

To guide seam stitdiing straight and iraratlel to

the edge of the fabric, adjust the attachment for

proper .seam width. Align the gnide with the pres

ser foot. {.Set Selector at AK, lover at 3.)

Pin seam edges and baste if necessary. Hand

basting can be eliminated on oasy-to-handle fabrics.

Place pins with the points toward the seam edge

•so itiey ni]) info the fabric at the stitching lino.

The tiinged presser foot will ride freely over the

points. Guide the fabric edges lightly against the

guide while stitching.

Seams Blind Stifdiing

APPLICATIONS

Top Stitching Decorative Stitching

Tlie attachment is used in connection with a

presser foot.

It is secured to the bed of the machine in either

of the threaded holes to the right of the needle.

SHAMS (Cont'd.)

Curved scams require additional treatment in

handling. A shorter stitch will provide greater

elasticity and strengtii. Set the attachment at an

angle so that the end closcist to the needle acts

as a guide.

67

TOP STITCHfNG

A simple and practical way to accent the lines

of a garment and at the same time give additional

firmness.

Hither single or multiple rows of slitching can

be ccxpcitly placed along lapels and facing edges,

around coilar.s and podccts and as a hem linish,

A subtle effect may be achieved by using straight

stitching, or a decorative touch may be added by

using any of the attractive stitch patterns accom

plished with this machine.

68

I

Page 35

m.IND STITCIIHD HHMS

Selecior: BO

Stitch width tever: 2 -5

Stitch length: 10 20

Presser foot: O'etierii! puipose

Throat piate: Geheral purpose

Scam guide

Blind stitching provides a duralrle hem finish

that is almost invisibie, and comparable to liand

sewing. It is egually suited to straight as v.'eli ns

ciicular hems. Taped, bound, tunred or unfinished

hem edges can all be blind slitchod with equal case.

Mark, (urn and ¡>rcss (lie hem in tlte usual evay.

Place a basting guide line approximately ’A" from

top horn edge.

.Set Selector at BC). 'I'his setting produces four

straight stitches, separated by a single sideward

stitch fo the left.

Stitch width level setting for width of stitch is

deteirnined by tlie v.'cigiu and texture of the fabric

used.

Place the hem edge over llie feed of the machine,

turn back the bulk of the fabric to llio lino of bast

ing, creating a soft foid.

Position the work so that tlic straiglil stitches are

made on tiie hem edge aiui the sideward stitches

piorco the fold.

The stitch length v.'ill regulate the distance bet

ween the blind stitches (10 to 20 stitches per inch).

Adjust the seam guide over the right toe of the

. foot until it rests next to the soft fold. Wliilo

stitching, fec.ti the fold against the flat of the guide.

A test sample in self fabric sliould be made to

determine correct settings.

69

THE CORDING TOOT

This foot is designed to facilitate the placing of stitdiing dose to a

raised edge. The hinged feature of tliis foot ensures even feeding over

pinS: heavy layers of fabric or cross seams. It is attached to the machtuo

in |)lace of the regular presser foot, and may be adjusted to cither the

right or left side of tlic needle. Straight stitch or zigzag settings may

be used.

APPI.ICATIONS

Zip Fastener Insertions

Corded Seams

Preparation. Secure the cording foot fo (he pres

ser bar a.s you would the regular presser foot. Set

Selector and Lover. Adjustment to the right or left

of the needle is made by loosening the thumb screw

70

ÍÍ .a a *! .> 0 o ^ <i 0 s ñ -ii 0 :■ r- >

Tubular Cording

Slip Cover Piping

at the back. Check tiie position of fhe foot by

lowering the needle into the side notch, making .sure

it dears tlie foot. Lock it into position by tightening

the thumb screw.

Page 36

ZIP FASTENlìR INSERTiON

Sfraight stiliii setting; AK 3

Throat plate; General purpose

Cording Soot

Many difforont types of zips are available for

cvoiythiiig you s(>w. Tliorc aro sovtual satisfactory

methods for insci tion. Detailed sewing instructions

aro included it! zip packet. For any method «sod,

the Cording Foot onabics you to form an even lino

of stitching close to the zip.

When the zip is to the. right of th<> needle .............-

® .A.djust the Cording Fool to the left of the needle.

When the zip is io the left of the needle

...................

0 Adjust the Cording Foot to the right of the

needle.

m.lND STITCHR» ZIP FASTflNïiR INSERTION

Selector setting: HO

Stitch Widtii: 2'A or 3

Tiiroat plate: General purpose

Stitch length: 12

Cording foot

Blind stitching the final step of a zip insertion

results in a fine linish that is almost invisible and

comjMiable to hand sewing. Parlicularly suitable

for chiffons, sheers, velvels and all delicate fabrics

where to)) stitching would be too harsh.

Allow a Vs" seam allowance. Start the insertion

in Iho regular way but omit linal .step.

VI

Work from the right side of the garment and pin

the front of the zij) tape into position.

Roll the work over finger to ease fabric and pin

through all thicknesses. Baste about Vs" from sca;n

line to provide guide for blind .stitching. Remove

pins.

Set sfildi and adjust cording foot to the right

.side ot the needle.

Turn garment inside out. Place zip tape over

feed of madiine and turn back the front section of

garment to line of basting, creating a soft fold.

Position work so that the straight line of stitching

is made through front seam allowance and zip tape,

and the sideways stitch pierces a few threads of the

fold. Lower pressor bar and stitch slowly. Remove

bastings. Press.

Page 37

C:OUl)KD PIPING

Str«i(|ht stitch setting: AK 3

riiroat plate; General purpose or straight stitch

Cording foot

Piping cord comes in a variety of sizes and, whem covered with a firmiy woven fabric, makes a piping

dial is an exeeiient seam finisli.

This piping is prepared in advance and then stitctiod into the seam. Cut a true bias strip I'A inches

wide, plus ihree limes tlio widtii of the cord, of eitliei self or contrasting fabric. Sew strips together on

the k'iigtiiwise grain to obtain desired lenytii.

Adjust corditvg foot to the iefl si(!c of the needie. Encase, (he, cord in the bias strip, raw edges even,

i.ower piosser i>ar. Stitch clo.se to the cord, applying gentle tension to bias strip in front and back of (he

cording foot. Use a stitch length sligiitly longer tlian tor regular seaming. Do not crowd (he stitching

against the, cord.

CORDED SEAMS

Straight stitch setting; AK 3

Throat plate: General purpose, or straiglit stitch

Cording foot

The corcied scam is a profe.ssional treatment for

slip covers, children's ciotiics, blou.ses and lingerie.

When cording a seam tlic cording ioot is usiudly

adjusted to the right of tire needle so that the bulk

of the work will fall to the, left.

Attach the piping to tlio rigid side of a single

scarn edge, witli the same stitch lengtl) used to

make the. piping (page ?3). Guide the edge of tlie

foot next to tire cord, but do not crowd.

Place tile attadied piping over the second seam

(>dge, and pin or baste togetlier.

Keep tlu' first stitching uppermost as a guide and

position tlu' seam under needie. Stifcii, this time,

crowding tire foot against tlie cord.

This meliiod prociuces evenly joined seam edges

and ligliUy set welting.

Curved seams are cordeci as easily as straigid

seams, e.xcept that a shorter slitcii length is used.

Since the sc-am allowance of the welting is bias,

it is not diiiicult to shape it to the seam.

Page 38

THK NARROW HEMMER

The Jiarrow hemmer forms

and stiUhes a perfc'ctiy turn

ed hem without basting or

pressing. It is attached to the

machine in place of the

regular presscr foot.

APPLICATIONS

Fine hems

Edging ruffles

Hemmed scams

Hemming with lace

Lingerie finishes

Stratghf sUfth setting: AK 3

Throat piate: Stratglil stitch

Narrow hemmer

IIEMMINO

Crease a double Vs“ fold for about 2 indies along

the edge of the fabric to be hemmed. Draw tire

Irobbin and noodle thrcad.s under the licrnmcr. Place

the fabric under the foot and stitch the creased fold

for several stitches. Hold the thread ends in the left

hand and guide the raw edge in front of the hem

mer evenly into the .scroll. .Sow .slowly, still holding

thread ends until the hem is well started.

Soft fabrics will enter the scroll best with the foot

down; firm, crisp materials v/ith the foot raised.

Even feeding is essential to good hemming. The

same width of fabric must be kept in the scroll of

the hemmer at all times, A little praclice will result

in perfectly formed hems.

75

HEMMED SEAMS

Straight sUtch setting; AK 3

Throat plate: Straight stitch

Narrow hemmer

A hemmed seam is applied where a tine narrow

seam is appropriate. Allow a scant */<" scam allo

wance. With both sides of fabric together, place

upper layer Vs" to left of lower layer. Itrserf two

fabric edges into hemmer and proceed as for plain

hem.

DECORATIVE HEMS

Selector: All settings

Stitch Widfti; 2 to 4

Throat plate: General purpose

Narrow hemmer

Narrow hem edges can ho tunred and decorated

in one operation usijig the narrow hemmer and a

stitch pattern. This time-saving fini.sh is especially

suited to ruffle edges and aprons.

76

Page 39

HfSMMlNG WITH LACK

Selector sotting: III.

Stitch Width: 3

Throat ptatc: Genera! purpose

Narrow hcminer

Lncc edgings can be applied with the Narrow

Mcmmer to trim lingerie hems, children's clothes,

etc.

I.acc Applied Over Hem. l-old and start the hem

in the usual way. Starting atront 1" down from the

end of the lace, place the selvage under the needle

and lower needle to hold lacc firmly. Raise the foot

slightly and slip the lacc under the back portion

of the foot, without disturbing the position of the

fabric. Stitch slow’ly, guiding the fabric with the

right hand, the lacc with the left. Take care not to

stretch, the lacc.

I.acc Applied Under Hem. When using lacc

underneath the fold of a hem, the procedure is the

same as when making a hemmed seam. Slip the

lace in from the left as you would the second piece

of fabric. This method is used where a neat finish

is desired on both sides of the material.

I ^

Scroll for

unfolded

binding

Selector .sotlings: All

Throat plate: General purpose

The multi-slotted binder is used to apply com

mercial binding as well as self-fabric bias to an nniini.shed edge. 'J'hi.s colourfid trimming is aUraefive

when applied to diildron's wear, aprons and house

hold linens. It is a practical Ihiish for seam edges

that fray and for making bound seams.

V8

Commercial single fold bias tape is inserted from

the rigid ink) the slot <it the wide end of the scroll,

l.infolded bias ’Vu" wide is inserted into the open

ing at the end of the scroll.

Cut binding diagonally and pnll through the

scroll until evenly loldod edges are under the

needle, I’reo length of binding is held between the

guide pins.

Insert Ihc edge to bo bound into the centre of

the scroll. Position stitrhing by moving the scroll

portion of tlx; binder to the right or left by means

of the arljusting hxj.

Page 40

MUI,Tl-SI,OTnn:) »INDEU (Cont'd.)

Cmv(!d edges require slightly different fubiie huudliug from straight edgr^s. Inside curves are straigh

tened as they are fed into the binder. If fabric is soft and has a tendency to stretch, reinforce the edge

with a single row of stitching before binding.

Outside cuivos tend to loarl away from the centre slot of the scroll and .should be guided so that a full

scam width is taken at the needle point. Do not attempt to pull or straigliten fabric into the lull length

of the scroll.

THb RUFEillR

Pork

Adjusllng

i.ever

AdjusUng

ringer

Screw

This alfadmiGiit offers a simple and effective way

to make gathered and pleated ruffles. Ruffles may

b(! made .sorparalely or made and applied at the

.same time. The ruffier i.s attached to the machine

in place of the regular presser foot and is used

with a straight slitdt setting only.

ao

ii C * is • ■ S ;s s> SS S: S t> *

Straight stitch setting: AK 3

Throat plate; Straight slitch

Ruffier

Adjusting Points

The adjusting lever sets the. niffler for gathers or

pleats. The number 1 space setting is for gathers

and plates fullness al every stitch. Numbers 6 and

12 are space settings for pleats, .spacing them 6 or

12 stitche.s apart. The star is for straight stitdiiiuj

<i!id is used when grouping gathers or pleats.

The adjusting Hnger is used only for pleating

and affects the width of the pleat. It is thrown out

of action by bringing it out of contact with the

adjusting scre,w.

The adjusting screw' regulates the fuUne.ss of

gatlters or pleats. When turned inward to its limit

with liie adjusting finger in place, tlie attadiment

is set for its deepest pleat. When turned outward

to its limit, witli file adjusting finger out of action,

¡he ruffier gives only a hint of fuliness.

Page 41

mi! RUl-I'I.ER (C:on{‘fl.)

Aftivatiiifi Parts

The ruiiliiKj blade and tlie separator blade are

of blue stool and hold the material to bo (jathered

betwoon thorn. The rnlflittg blade forms Uie yathers

or pleat.s by canyiny the fabric to the needle

according to the spacing and fullness to which the

luffler i.s ad)«sied. The separator guide is slotted to

guide .sctam edges evenly and to separate the mffle

strip from the material to which the ruffle is

attached.

Preparation

# Raise needle to it.s highest point.

0 Locale ruffler on presser bar wdlli fork, arm over

needfe clamp screw. Securely -tighten both

presser bar and needle clamp screws.

Gathering

0 Sot adjusting lover on Number I selting and

throw adjusting linger out of action.

0 Turn adjusting screw for amount of fullness

desired and sot .stitdi length to sitace fullness.

Turn screw ill for more fulluess; turn out for

less fullness.

THl; RUPTI.liR {Cont'd.)

I.cnglh of sewing machine stifdi also affects rulflo

fuliiu'ss. Since a given attadimcid setting pnls an

equal amount of fullness into each stitch legardle.ss

of its length, shortening the stitch {more stitches to

tile indi) makes ruffle fuller; lengthening the stitch

(fewer slitches to the inch) makes it less full, l-or

line, closely spaced galheving, use a .short stitch

aiui an outward adjustment of adjtisling screw, iati

deepiU', less closely spaced gathering, turn adjust

ing screw inward and use a medium stitch lengtli.

•

Materia!

• Insert material to be galhcrod between blue

blades and tbrough first separator guide.

• Draw' material to bade of needle.

0 Lower presser bar and stitch.

1-abric texttire influences peiformaiico of litfllci

as well as results. Soft tabrics, cut ou crosswise;

grain, are best adaptcul for gaiiH;re.d fulls. Always

test stitdi length and ruffler seiling on a scrap of

self-fabric before proceeding with tire aclual work.

82

AUaching fhdls

Garment

• Place strip to be gatbered between tw'o blue

bhides and tluough first separator guide,

• Idace material to which full is to bo attadied

between separator blade and feed of madiine,

• Proceeri as for plain gathering.

Right sides of fabric are placed together wdieii

the scam is to fall to the inside.

Page 42

THK UUt‘PlJ;R (Cont'd.)

PleatiiMj

# Move adjustiag lever to desired space settinej

for pleats either 6 or 12 stitches apart.

# Sot stitch length.

For deepest pleat; set adjusting finger and turn

adjustiirg screv/ inward to its maximum setting. For

smaller pioat.s, turn acijusting screw outward.

A short stitch places pleats more closely together;

a long stitch soiraratcs the pleats for a greater

distance,

® Insert fabric to be pleated between blue blades

and into first sceparator guide,

® Lower pi'csser bar and stitch.

Crisp fabrics cut on the crosswise grain form the

sharpest pleats. Glazed fabrics handle best if the

glazed side is downward and the soft backing is

next to the ruffier blade.

Group pleating

By using the star setting {straight stitching) alter

nately with 6 or 12 space .sotting, pleats are formed

in groups, Kven spacing between groui>s is accomp

lished by counting the mtmbor of stitches.

DARNING AND RMHUOlDf-RY FOOT

This attachment is an aid to

all who desire perfectioii in free

motion darning and embroidery

work.

The foot firmly holds the fabric

as lh(! necKlle enters and rises

from the work, while fully re

vealing the lin<! of design to be

followed.

Free motion evork darning

Straight stitch selling: AK 3

Jmed cover plate

Darning and embroidery foot

Stitch length: Above 20

Trim ragged cdge.s from area to be darned,

(.amtre worn section in embroidery hoops.

Attach feed cover plate to machine bed in place

of regular throat plate.

Locate darning and embroidery foot ois pressor

bar with lifting finger over needle clamp screw.

»4

• Position work underr needle and lower pressor

bar. Mold needle thread loosely with left hand,

turn hand wheel over and draw bobbin Ihrcad

up throngli fabric. Mold both thread ends and

lower needle iirto fabric,

• Outline opening with running stitches Vc" from

edge for reinfarcomont.

• Stitch across opening, moving hoops under noodfe at a slight angle, from lower left to upper right,

Keej) lines of stitching closely and evenly spaced.

® When opening is filled, turn w’ork 90'^ and con

tinue slitdiing until darn is completed.

® Run inadiine at moderate speed and control

hoops with a steady continuous movement. Slow

movement of hoops will produce a short stitch;

more rapid movement lengthens the stitch,

l-airly long stitches are best for knit and tricot

fabric.s; short stitches are l)esf for cottons and

linens a.s they appro.ximalc weave of fabric.

Page 43

FKEI; MOTION WORK

MONOGRAMS

Selector selling; )5I,

Slilth Width; 2 — 5

Peed cover plate

Darning and embroidery foot

Stitch length; Above 20

Script monograms and embroidery can bo offoc-

tively accomplished with the zigzag stitdi wlion the

free motion jHinciple is employed.

....

I;MBUOU)I:UY

• rraco or mark design on right side of fabric.

• Phice work in embroidery troops largo enougii

to encorrrpass entire desigir. Be sure fabric is

hrdd taut.

• Attach food cover plate to machine her! in place

of regular throat piate.

• Locate darning and gmbroidery foot on presser

bar with lifting finger over needie clamp senrw.

• Position work under nemilc and lower pressor

Irar. Bring bobbin ftiread up Urrough fabric at

start of desigir. Hold both thread ends to start

stitching.

DECORATIVH STITCH PAmiRNS

Examples of Stitch Patterns and their Selector SeUings

# Move haojrs slowly, following outline of design.

Maintain an rrven rate of speed so that stitdies

are uniioiiirfy irUtced.

Slow movement of hoops produces a close satin

stitch; more rapid movement lengtlrcns the stitch

and results in an open effect.

Shading stitches from wide to narrow is controll

ed by lire angle at which work is placed and moved

under needle.

A tc.st samirle should always be made before

proceding with tire actual work to determine, stitch

setting and spacing. Some fabrics may requite

(iddition of un underlay of crisp lawn or organdie.

n/ijmrmnnfirmnimimrumimrymn^^

DP4

m

DS (5) 2

DS (D 3

I;P2

F02

FR2

PS (D 3

86

Page 44

Di-COKATIVE STITCH PATTERNS

Examples of StUdfi Patterns and their Selector Settings

GM 4

Ia.^ VAwV Ia..>/ Va..,A 1a~v/ Va™v/ \y<y^ U\..A Ia™X \a>w</ Va~>¥ Va~^‘ Va-»

lJUUт^WнJAi.E'%^UJljlJUuJX^JJM)lAM^)%MAI>UJljiJUiMjXuiMi>^4Ji>.UliJ^.U/MaiuMJUM^^

^•yA...A_ ^^'i'.>Aw ■s-.Atv'-Ak ^.yN,.A- *s^vv.^fc ^oAvvA^

GP 4

GS @ 2

GS (3) 4

HS (D 4

^/SAAA/vAAA/v■SAAAA/■u-\/\A/''\AAAУ^Ar^u\/\AA.Ay'^A/vAAAA/\A7\A/

11.2

IS d) 4

8';

APPLICATIONS

OP THE

CYLINDER BED

FEATURE

1

1

t/"

I

i

/;

■ sC

llirti'^'

14 ill

\ '4 I ii.

I ;M i\S’-

it:

» „-1

/4

Page 45

89

Page 46

ч Ц ¡ù

' Í '•••I'

91

IЛ

/ /

\ »

'■ 'Л '

92

Page 47

Clean amt

93

TO CI.EAN THE MACHINE

Your sewing machine was built to exacting stand

ards of precision and workmanship. Its performance

depends on the care and treatment it rccc!vc.s when

in use and before storing it away.

When in regular use, the machine should bo

doaued periodically to remove the lint and fUiif

which may have accumulated round the working

parts. To clean the bobbin case area, see instruc

tions (or removing and replacing bobbin case on

page.s 95 and 90. Oil the machine after each clean

ing as instructed on pages 9?, 98 and 99.

If Uic machine is to be stored away for an inde-

, finite period of time, a thorough brush-cleaning

to remove all traces of lint and fluff, followed by

swabbing of all exposed parts with a lint-frcc brush

saturated with SINGER* Oil, is necessary to protect

the machine against rust damage. The areas that

should be cleaned and covered witli a protective

coat of oil arc shown in the iihisfration at tlte left.

94

Clean amt Oil

Page 48

TO RiiMOVIi AND REPLACK BOBBIN CASE

; '■

To dean hook raceway, remove bobbin case as

foliows;

1. Remove throat plate (see page 19) and open

slide plate (see page 13).

2. Unlock bobbin ease by lifting and pnlling

holder to right as shown.

3. Remove bobbin case from madiine.

4. Remove all lint, fluff, loose thread ends or any

other foreign matter which might clog the machine.

TO REMOVE AND REPLACE BOBBIN CASE

POSITIONING

STUD

95

5. Replace bobbin case so that groove under tension spring fits on hook raceway and fork of case

straddles positioning stud,

6. Push bobbin case holder to loft as shown until it .snaps down info lock position,

y. Close bod slide and replace throat plate.

96

Page 49

то LUBRICATI; TUB MACHtNB

Use SIN'GKK Oil aixl SlNGl-R Lubricant!

Both are extra quality products especially pre

pared for sewing machines, and siiould always be

used in tlu! сак; of your 631.

Clean fho machine pruiodicnlly as insinreted on

page 91,

ti Pi

У

Apply a dro)) of oil to each place indicated.

Remove screw' A and lift arm top cover slightly

and slide off toward loft and away from inacbine.

The thread take-up lover must be in its lowest

position.

Apply a small amount of lubricant to the gears

as shown.

A tube of this lubricant can be purchased at your

Singer Sewing Centre,

Never apply Oil to these gear.s.

9?

Swing face plate to left and oil flic places indi

cated.

Open slick! plate and apply a drop of oil to the

hook racciway as indicated.

Close slide plate, replace arm top cover and

close, face plate.

98

Page 50

TO UJURICATK THH MACHINE (CoiU’fl.)

Tilt machine back and remove thumb nut from screw li, being careful not to lose felt washer, and

remove cover from underside of machine.

Remove .screw C and remove cylinder cover.

Clean hook and gear area, oil each of the places indicated, and occa.sionally apply a small guantily of

lubricant lo teeth of gears as shown.

Replace bottom cover and cylinder cover.

The motor requires no lubrication.

99

ELECTRICAL INFORMATION

The SINGER* Electric Motor in the electric ma

chine is furnished for operation on an ailernathrg

or direct current. Orders must state the catalogue

number of the motor, or the voltage, and in the

case of alternating current, the number of cycles.

Before Inserting Electric Plug A, be sure, that

voltage and cycles .stamped on electrical name

plate B arc within range marked on your electric

meter installed by your power company.

Electrical Connections for Madtine. Push 3-pin

terminal plug C on 3-pin terminal block at right of

machine and connect plug A at other end of cord

to electric oullel.

Speed Controller. The speed of machine is regu

lated by amount of pressure on the pedal of the

foot controller D.

100

Page 51

SINGER LIGHT

To replace Singer Bulb.

Disconnect plug from clccliical outlet before ma- ,

king bulb replacement.

With thumb of right hand push in and down on

tab of light lens (see Illustration).

LOCKS

J-

/ li

■ /m

Do. not attempt to unscrew bulb, press it into

socket and at same time turn bulb o%'or in direction

shown to unlock bulb pin G, then withdraw’ bulb.

)-

Press new bull) into socket with bulb pin G enter

ing slot of socket and turn it over in direction shown

to lock bulb pin G in proper position.

The light is turned "on“ or "off' by the switch F.

lot

Applications of Cylinder Bed Feature

Apjrliquc ....

Attachments

Button Sewing Foot .

Darning and Embroidery Foot

Narrow Herntmu' .

General Purpose 1-oot

Multi-slotted Binder ,

Ruffle.r.................................

Seam Guide ....

Special Purpose I’oot .

Cording Foot ....

Basting......................................

Binding

Blanket Binding, Replacing of

Bobbin

Bobbin Case

Buttonholes ....

Cleaning the Machine .

Corded Ap¡)liciué .

....................................

Blind Stitching

Hems

....................................

Zip Insertion ....

Freiparing for Stitching .

Removing ....

Thread Tension ,

Winding...............................

Removal and Replacement

Tltreadiirg

Corded ....

Button Sewing .

Chain Stitch Fittings

Combination Patterns and Vari<

Illustrations .

at ions

102

INDEX

88

....

93 Corded Buttonholes

53

....

;H Cording

Scams

58 -59 Welting

84 85 Cording Foot , , , .

75 -77 Piping and Corded .Seanrs

CO 66 Zip insertion ....

78

....

79 Couching

80 -83 Cylinder Bed, Applications

67

....

69 Darning and Embroidery Foot

49 57 Darning, Free Motion \Vork

70..-74 Darts......................................

20 -25 interfacing

78

....

79 Single Thread

64 Decorative Herns

Decorative Stitch Patterns

69 Designs and MotiLs ,

72 Detachable Cloth Plate .

Elastic, Applicrations

28 Eiectrica! Information .

13 Light . . . , .

.34 Motor ....

10..12 Embroidery, Free Motion Work

95

49 52 Button Sewing

58 -59 F'ilhu' Cord, Tlireading .

20

94 96 Gathering ....

86 87 Guiding and Supporting l-abric

Features

....

96 Principal Parts of Machine

14 Feed Cover Plate

52 Free Motion Work

....

25 Ihee Motion Work .

43 Genera! Purpose Foot, Applications

54 Henuiied Seams ....

...................................

.........................................

..................................

...................................

52

74

73

70 ................-74

73

.......

57

.......

84

.......

64

63

76

55

5

65

101

100

85

15

52

.......

.......

31

76

74

93

-64

...

59

82

66

71 ................72

88

84 85

63

86 87

fOO.101

2-3

5884 85

84 85

81

60

Page 52

Hemming \vith Lace

Hems

Blind Stitched

Decorative

Knit l-'abiic Seams .

Lacc

Applicji-ic ....

Odging and ln.serlion .

Length of Stitch, Regulating

Light Bulb, Replacrcment

Lubricating ....

Mcmding ....

Monograms and Motifs .

1-ree Motion Work

Motor

................................

Multi-slotted Binder

Narrow lleminor

Decorative Hems .

Hemmed Seams .

Hemming with Lace .

Needle and Thread Selection

Needle and Thread ,

Needle Inserlion

Needle Position and Stitch

Needle Positions

Needle Thread Tension

Satin Stitching

Straight Stitching .

Needle Threading

Single ....

Two................................

Oiling

................................

Overcasting

Pattern Selector .

Piping................................

Pleating

.............................

Prepare to Sev/ .

Width electo

Pressure Adjustments .

77

Primary Patterns ....

Control of Width , , , .

69

Needle Positions ....

70

61 Special Discs...............................

Stitch Width and Stitch Pattern

Principal Parts of Machine .

54

Reverse Stitching

57

Application

10

101

97 99 Ruffler

Regulation

Attaching Ruffle , , , .

65

55 Gatherinej

Pleating

85

Satin Stiichinej

78

7,')

100

■ 77

Stitch I.englh Adjustment

79

Temsion Adjustment .

Scallopinc)......................................

76

Seam Finishes.................................

76

................................

..................................

............................................

..................................

......................................

Selector.s 38

77 Seam Guide*...................................

6

Blind Stitched Homs .

7

7 and 44

Seams .........................................

Top Stitching..............................

1 /

Seams

43

Corded........................................

Flat L’elled..................................

Guiding and Supporting .

45

97- •99

62

..

18

17

73

83

Lingerie

Sheer Idlbrics ....

9