Page 1

Page 2

The Touch & Sew <&) Special Zig-Zag

Sewing Machine by SIN G E R*

You are about to enter the enchanted world of custom sewing. Now you can

create the elegant effects endlessly sought after by the world’s most sophisticated

women. And, it’s so easy with all of the exclusive SINGER features. Each one

is meticulously designed with ease of sewing in mind.

• Exclusive Push'Button Bobbin lets you wind and rewind your bobbin while

it stays right in the machine.

• Exclusive Set'A'Pattern makes it easy to select either straight or decorative

stitches. You can create numerous variations of patterns and designs with

one or two needles ... all without ever changing a disc.

• Exclusive Built'in Threading Chart keeps an easy-toYollow diagram at your

fingertips.

• Exclusive Friction'Free Spool Holder with horizontal pin holds spools stationary so the thread flows freely to the needle without tug or drag.

• Exclusive Singk'Thread Chainstitching holds firmly or pulls out in seconds

as needed, does away with most hand basting so you save lots of precious

time. It’s ideal for any sort of temporary stitching.

Your SINGER sewing machine is the key to your sewing success when used

properly. To achieve professional results, SINGER suggests you sit down at

your machine before you start to sew and go through this book step by step.

You’ll discover all the many advantages of sewing with your Touch & Sew

sewing machine.

SINGER* Service is always close at hand. If your sewing machine should need

servicing, call your local SINGER CENTER to be sure of warranted SINGER

Parts and Service. You will find the address under THE SINGER COMPANY

in the telephone directory.

A Trademark of The Singer Company

Form 21626 (966)

Copyright © 1966 by The Singer Company

Printed in U.S.A.

Page 3

CONTENTS

Page

1. Getting to Know Your SINGER Sewing Machine........................................................................... 2

Principal Parts — What They Are Called.................................................................................... 3

Principal Parts — How They Are Used............................................................................................ 4

To Connect Machine © To Turn On Machine and Light; Control Speed; Turn Off

Machine and Light © To Set Stitch Patterns © To Set Stitch Width © To Set Needle Posi

tion © To Set Stitch Length © To Regulate Pressure © Needle-Thread Tension © To

Thread the Needle © To Wind the Bobbin © To Position Throat Plate

Accessories ..................................................................................................................................... 13

2. Straight Stitching ................................................................................................................................ 17

Preparation ..................................................................................................................................... 17

How to Sew a Seam........................................................................................................................ 20

3» Zig-Zag Stitching................................................................................................................................ 24

To Set Pattern Selector © How to Adjust the Width of the Design © How to Adjust Stitch

Placement ® How to Adjust Stitch Length and Needle-Thread Tension

4. Two-Needle Stitching......................................................................................................................... 26

Preparation © To Thread the Needles............................................................................................ 26

Straight Stitching with Two Needles.............................................................................................. 27

Zig-Zag Stitching with Two Needles.............................................................................................. 27

Decorative Two-Needle Stitching................................................................................................... 28

5= ChainstStching ................................................................................................................................... 29

Where to Use Chainstitching © Preparation © To Sew a Chainstitch Seam © To Remove the

Stitching © To Remove the Fittings ® Garment Fitting and Construction Guides with

Chainstitching

Free-Motion Stitching ........................................................................................................................ 36

Preparation .................................................................................................................................... 36

7o Clothes and Home Decorations............................................................................................................ 37

Seams .............................................................................................................................................. 37

Lingerie Seams © Inside Seams of Sheer Collars, etc. ® Seams in Knit Fabric © Flat

Felled Seams © Seam Finishes

Darts................................................................................................................................................. 40

Regular Darts © Continuous-Thread Darts © Darts in interfacing

Hems ............................................................................................................................................... 41

Buttons ............................................................................................................................................ 42

Buttonholes ..................................................................................................................................... 43

Buttonhole Length © Stitch Width Settings © Procedure

8. Finishing Touches................................................................................................................................. 45

Top Stitching................................................................................................................................... 45

Shell Edging ................................................................................................................................... 45

Applique ........................................................................................................................................ 46

Monograms, Motifs, Script............................................................................................................. 47

Flower Embroidery ........................................................................................................................ 48

Keeping Up Appearances.................................................................................................................... 49

Mending ......................................................................................................................................... 49

Tears ® Elastic © Bar Tacks

Blanket Binding............................................................................................................................... 50

Darning .......................................................................................................................................... 51

Without Embroidery Hoop © With Embroidery Hoop

10, How to Take Care of Your Machine.....................................................................................

...........

52

Cleaning, Oiling, Lubricating ® To Remove Bobbin Case © To Replace Bobbin Case © To

Change Light Bulb © To Replace Slide Plate

11, Fashion Aids........................................................................................................................................ 58

Index ......................................................................................................................................................... bO

Page 4

1. GETTIIMG TO KNOW YOURSINGER

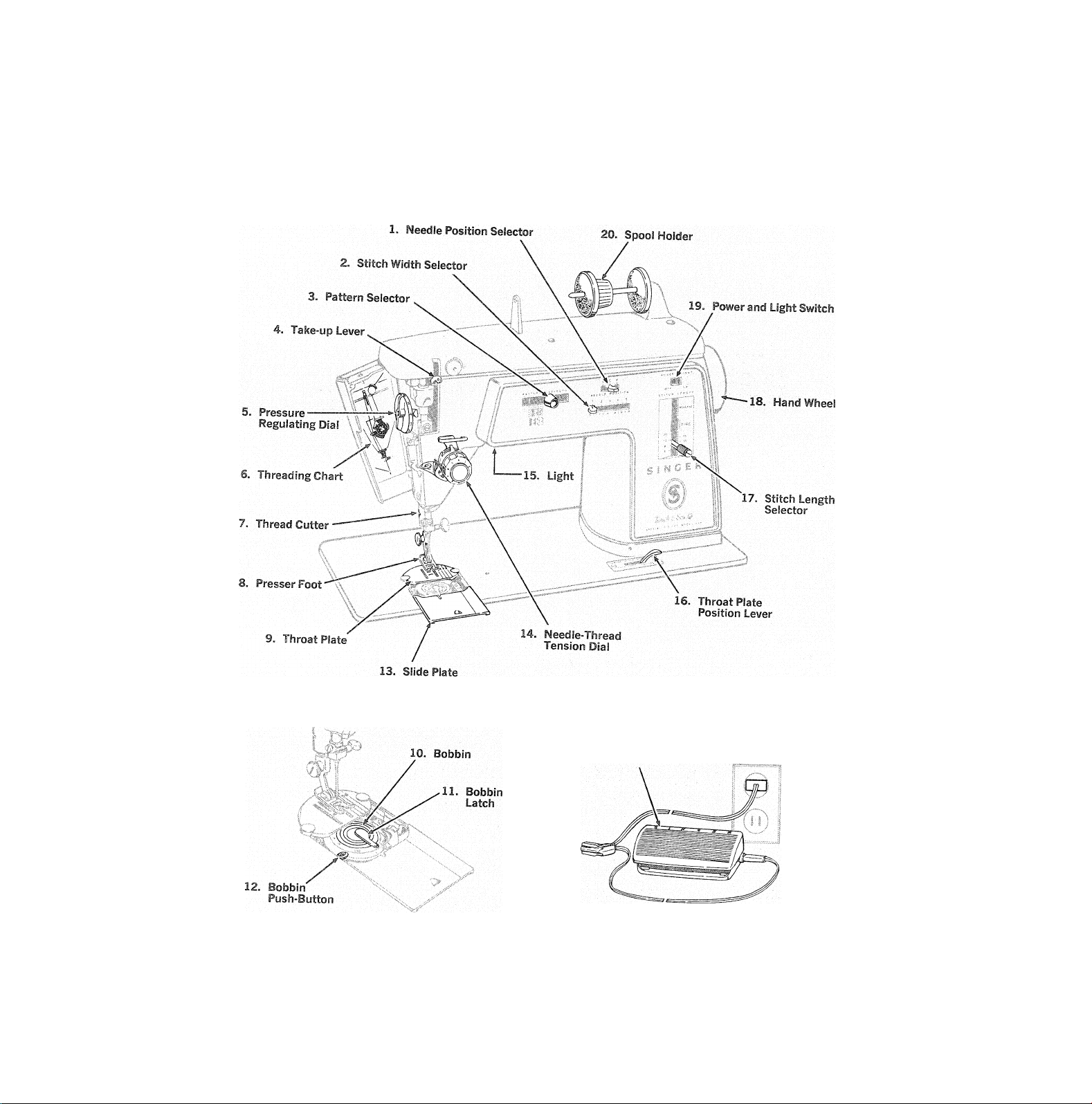

21. Foot Controller

Page 5

principa! parís—what they are called

1. Needle Position Selector allows for placement

of both straight and zig-zag stitching in either

left, center, or right needle position.

2. Stitch Width Selector allows for variety of stitch

widths, as well as straight stitching.

3. Pattern Selector with illustrated settings allows

for easy selection of seven decorative stitches,

and straight stitching.

4. Take-up Lever.

5. Pressure Regulating Dial has eight numbered

settings (from low for light pressure to high for

heavy) and special setting for darning.

6. Threading Chart on swing-open face plate is

convenient, easy to read.

7. Thread Cutler built into presser bar is designed

for safety, convenience.

8. Presser Foot holds fabric against feed dog.

(Presser Foot Lifter at back of machine, not

shown, allows you to raise and lower Presser

Foot.)

9. Elevator-Type Throat Plate is easily placed in

any of three sewing positions: REGULAR,

FINE, DARN; and UNLOCK position for easy

removal.

10. Transparent Bobbin shows thread supply. Two

halves can be unscrewed to remove unwanted

thread.

11. Bobbin Latch flips up at a touch of your finger.

12. Bobbin Push-Button allows you to switch from

sewing to bobbin winding without removing

bobbin.

13. Slide Plate opens easily, lets you see bobbin.

Automatically releases bobbin push-button

from winding to sewing position when closed.

14. Needle-Thread Tension Dial allows for exact

settings.

15. Built-in Sewing Light pours light on sewing

area.

16. Throat Plate Position Lever.

17. Stitch Length Selector allows for variety of

stitch lengths including FINE for zig-zag satin

stitching.

18. Hand Wheel controls take-up lever. Always turn

it toward you.

19. Power and Light Switch turns on machine and

sewing light simultaneously.

20. Friction-Free Spool Holder. Horizontal pin

holds spools of various sizes; holders let thread

unwind without tug or drag. The spool does not

turn.

21. Electrical Connections and Foot Controller are

designed for your convenience and safety.

Page 6

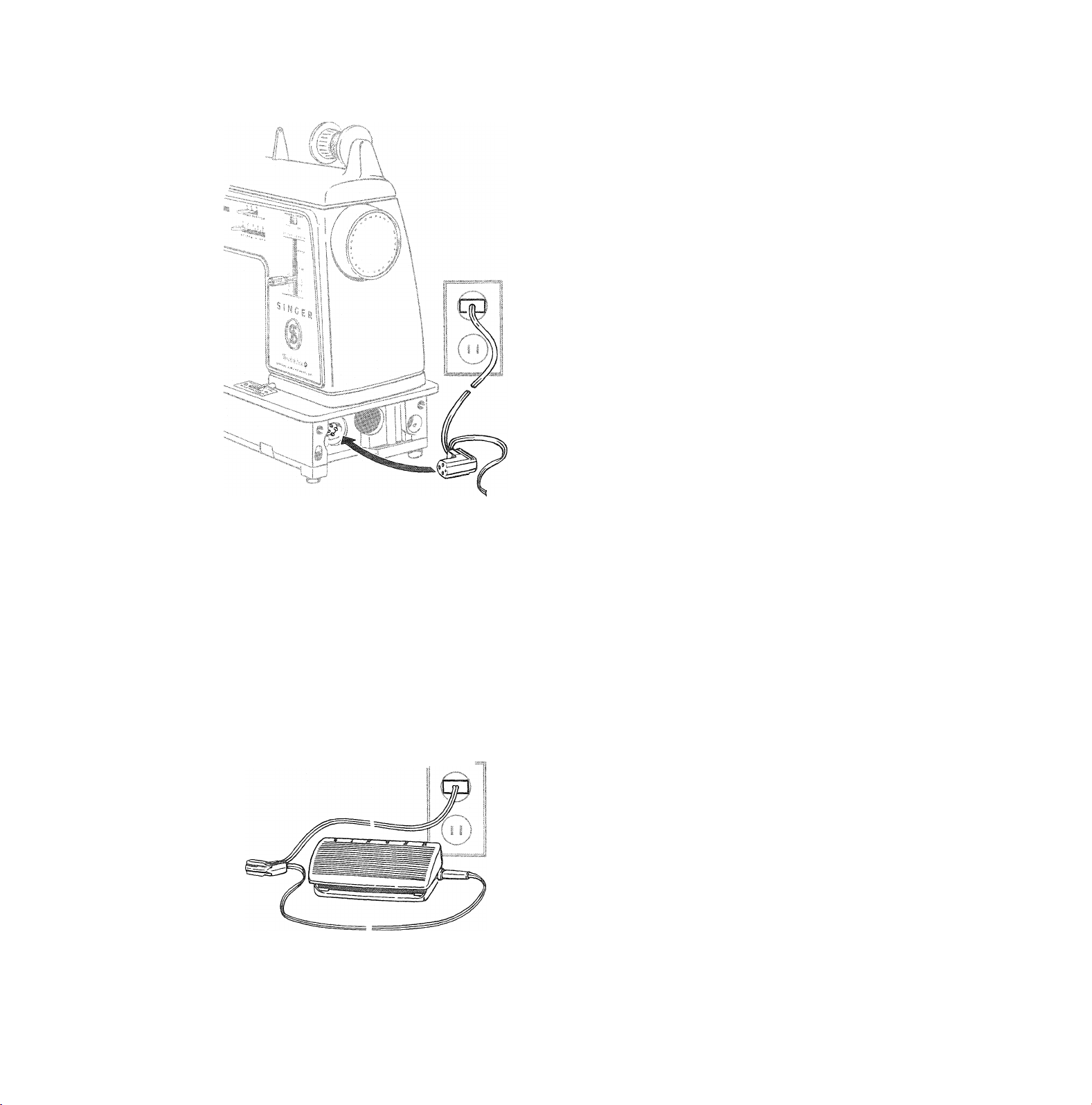

1. TO CONNECT MACHINE

Before plugging in your machine, be sure that the

voltage and number of cycles stamped on the fourpin receptacle are within the range marked on the

electric meter installed by your power company.

Push the four-hole plug onto the four pins at the

right end of the machine. Then connect the two-pin

plug to your electrical outlet.

Electrical Connections

POWER & LIGHT

OFF

Power and Light Switch

O N

rO TURN ON M

IL SPEED; TURN

OFF MACHINE

LIGHT; CC

AND LIGl

To turn on both the machine and the sewing light,

slide the Power and Light Switch to ON position.

To run the machine and control speed, press the

foot controller (or knee lever) The harder you press,

the faster the machine will sew.

To turn off both the machine and the light, return

the Power and Light Switch to the OFF position.

This unique electrical system offers several advan

tages : you see at a glance when the machine is ON

or OFF by means of the light; you can turn off the

power with the convenient switch instead of having

to unplug the machine; and since the Power and

Light Switch must be turned on before the machine

will start, there is less chance of “little hands or feet”

accidentally pressing the Foot Controller (or Knee

Lever) and starting the machine.

Foot Controller

Page 7

stitch Patterns

Straight Stitch

Zig-Zag

Bali

Pyramid

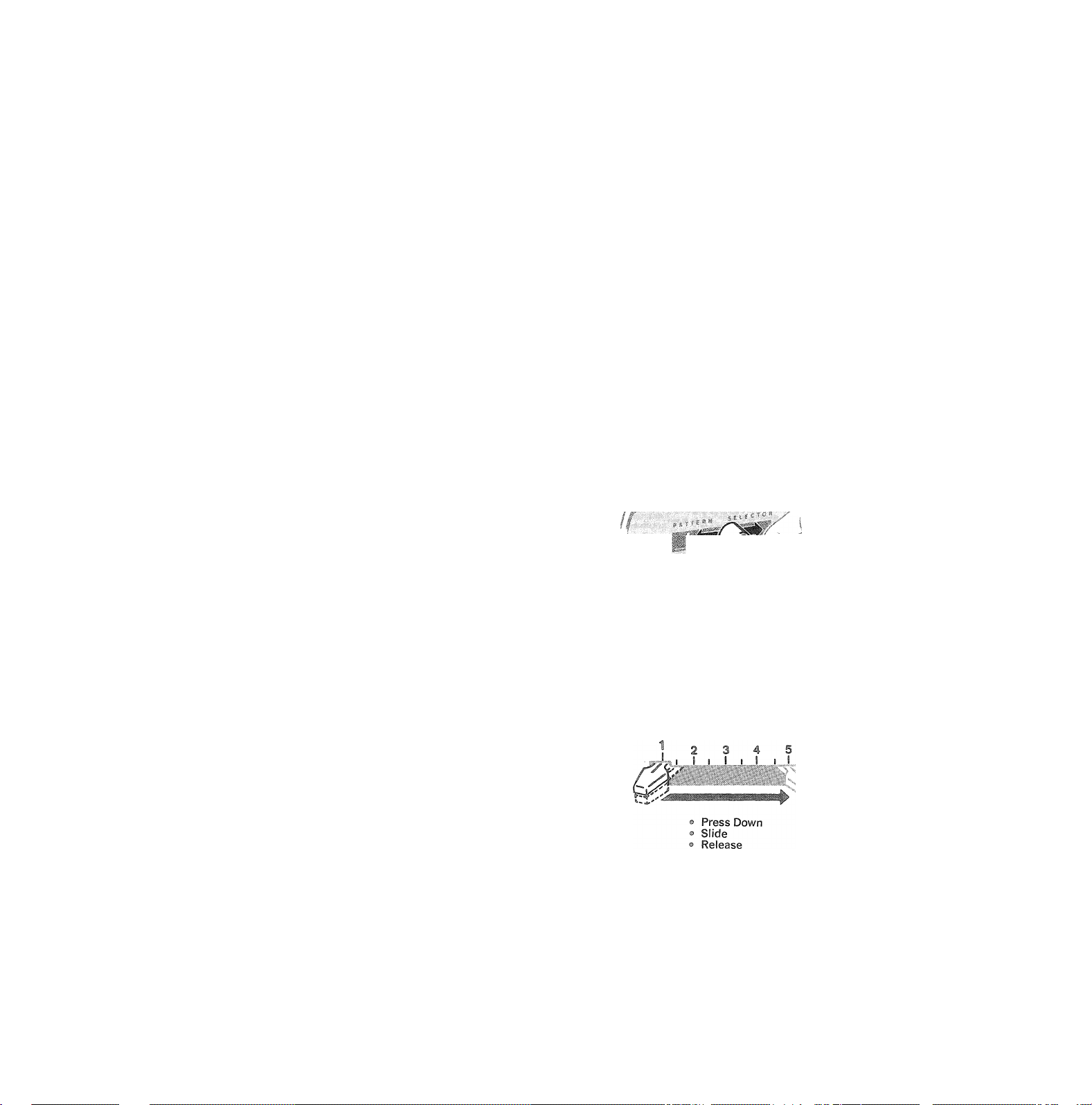

3. TO SET STITCH PATTERNS

The Pattern Selector offers you a choice among

seven decorative and practical stitch patterns in

addition to the straight stitch.

To select a pattern, push selector button in and slide

either left or right to bring indicator line to desired

setting. Release button.

4. TO SET STITCH WIDTH

The Stitch Width Selector does two jobs: it sets the

machine for bobbin winding and straight stitching,

and it controls the stitch width in zig-zag stitching.

Blindstitch

\..............1

AAAAAAAAAAA/

/\ / \ /\

/ \ / \/ \ / \ / \ / \ / \ / \ / \ / S / \ /

'VVVVVVVVVVV

...........1.............1...........1.............1...........

Box Stitch

/ \ / \ / \ / \

/ \ / \ / \ / \ /

Multi-Stitch Zig-Zag

1

V V V ? If V ? V V

Scallop

/ /1

/ ........

.....................

I i lÈMm:mrnWm

i WV?I I

.

I mmm§Mrn^

i ilmmÈimmiS

'K I ¡ ;

® Push !n

® Slide

© Release

Stitch Patterri Selector

© Straight Stitch Setting: 1

© Zig-Zag Width Setting; 2 to 5

Bobbin Winding and Straight Stitching: Set selector

at straight stitch position 1.

Zig“Zag Stitching: First be sure you set the Pattern

Selector (see instructions above). Then set selector

at any position between 2 (narrow) and 5 (wide).

Stitch Width Selector

Page 8

Meedle PosBtion Selector

Press Down

Slide

Release

Stitch Length Selector

5.

' SET N EEC

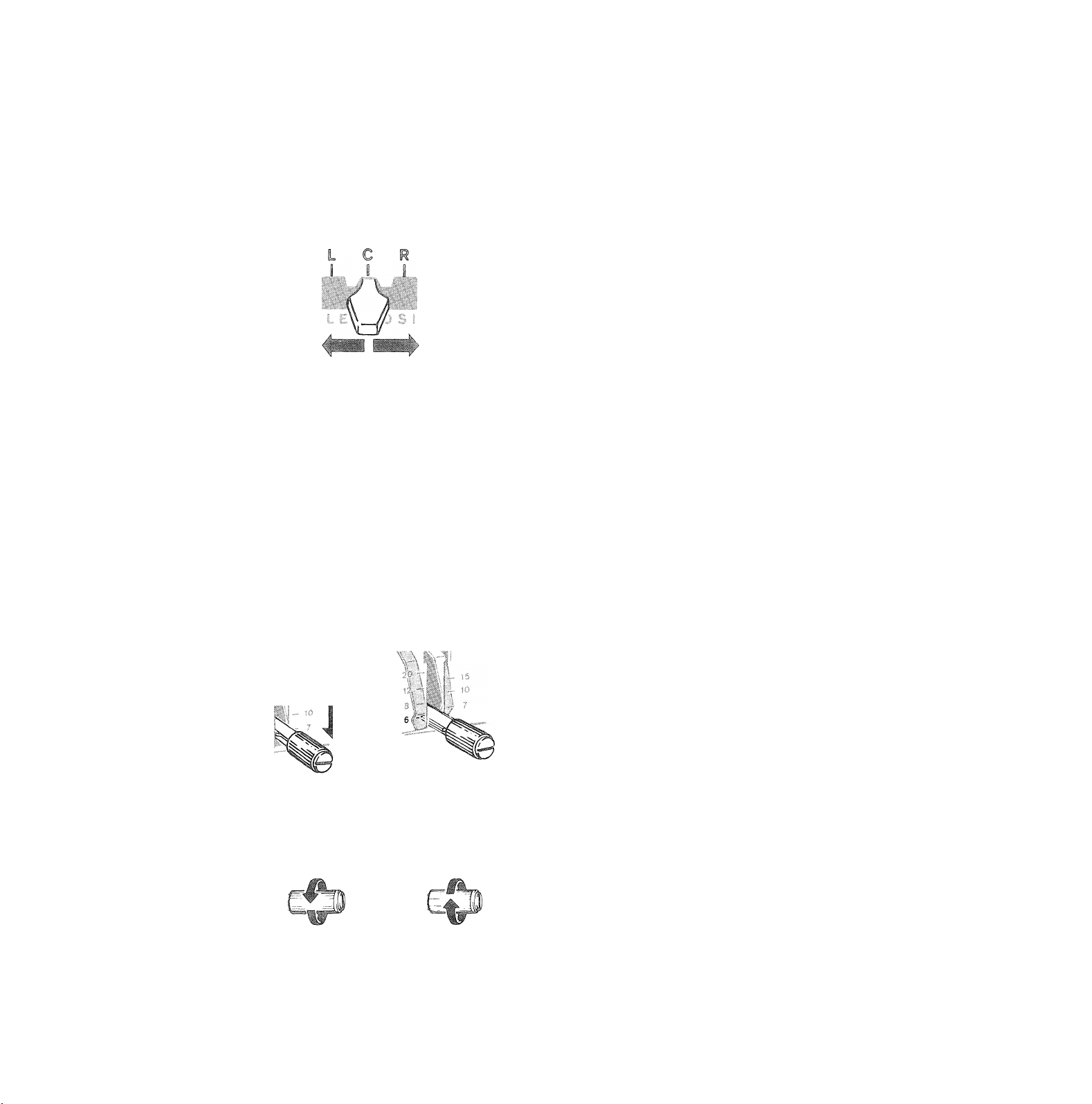

The Needle Position Selector places the needle in

either left, center, or right stitching position. Yon

will need to set it for bobbin winding as well as for

straight or zig-zag stitching.

Before moving selector, be sure that needle is out of

the fabric.

Always set selector at C.

: Set selector at C.

Zig-Zag Stitchirig: You will use C position most

often; L and R settings are for special stitch place

ment. For example: L setting is required for button

holes, button sewing, and two-needle work. L or R

setting is used to place narrow zig-zag stitching to the

left or right of center in decorative work.

Reverse

Locked Setting

Forward

Thumb Nut

To Loosen To Tighten

6. TO SET STITCH LENGTH

The Stitch Length Selector does two jobs, which in

this case are common to both straight and zig-zag

stitching: it controls the length of stitches and the

direction of stitching (either forward or reverse).

The numbers on either side of the lever represent the

number of stitches per inch: the higher the number,

the shorter the stitch. Generally, shorter stitches are

best for lightweight fabric; longer ones for heavy

fabric. The FINE area, which represents over 20

stitches per inch, is used for zig-zag stitching.

To Set Selector

® Loosen thumb nut by turning to left.

® Position lever for desired stitch length.

® Tighten thumb nut by turning to right.

For reverse stitching, simply raise lever as far as it

will go. Do not loosen the thumb nut to reverse

unless you are using the No. 6 setting, in the very

bottom position.

Page 9

1. TO REGULATE PRESSURE

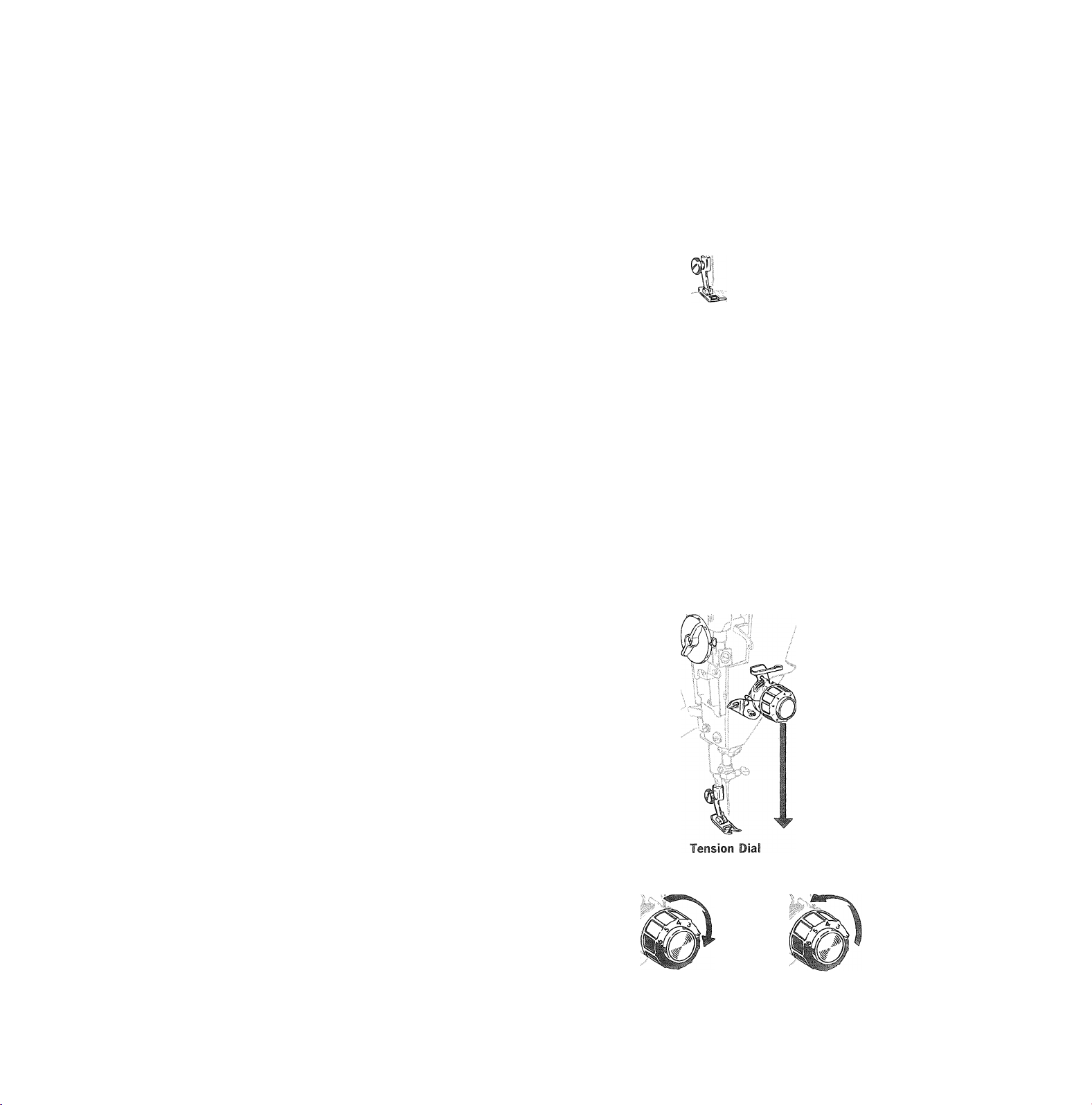

The Pressure Regulating Dial regulates the pressure

that the presser foot exerts on the fabric. Correct

pressure is important because it means fabric feeds

smoothly, evenly, without being marred. Generally,

heavy fabric requires a high number setting; light

weight fabric requires a low number setting. But

fabric texture must also be considered; soft fabrics,

for example, require less pressure than crisp fabrics.

Lower the presser foot before setting.

® T© increase pressure, turn dial to higher number.

® To decrease pressure, turn dial to lower number.

® For darning, turn dial to DARN, which releases

pressure and permits darning without an embroid

ery hoop.

c8. TO REGULATE NEEDLtTHREAD TENSION

To Lower

Presser Foot

Increase

i

Pressure Dial

Decrease

Darning

The Needle-Thread Tension Dial regulates the de

gree of tension on your needle thread and lets you

select just the right setting for your stitch pattern,

thread, and fabric. The numbers eliminate guess

work in duplicating settings.

Correct tension is important because too much or

too little will weaken your seams or mar the appear

ance of decorative work. To determine correct ten

sion setting, make a test on a sample of your fabric.

If the fabric puckers, decrease tension. If the stitches

look loose, increase tension. (For detailed instruc

tions on adjusting zig-zag stitch tension, see page 25.)

® To increase tension, turn to higher number.

® To decrease tension, turn to lower number.

Note: This dial governs needle-thread tension only.

Bobbin-thread tension has been correctly set at the

factory, and you do not need to adjust it.

Increase

Decrease

Page 10

W'5v'

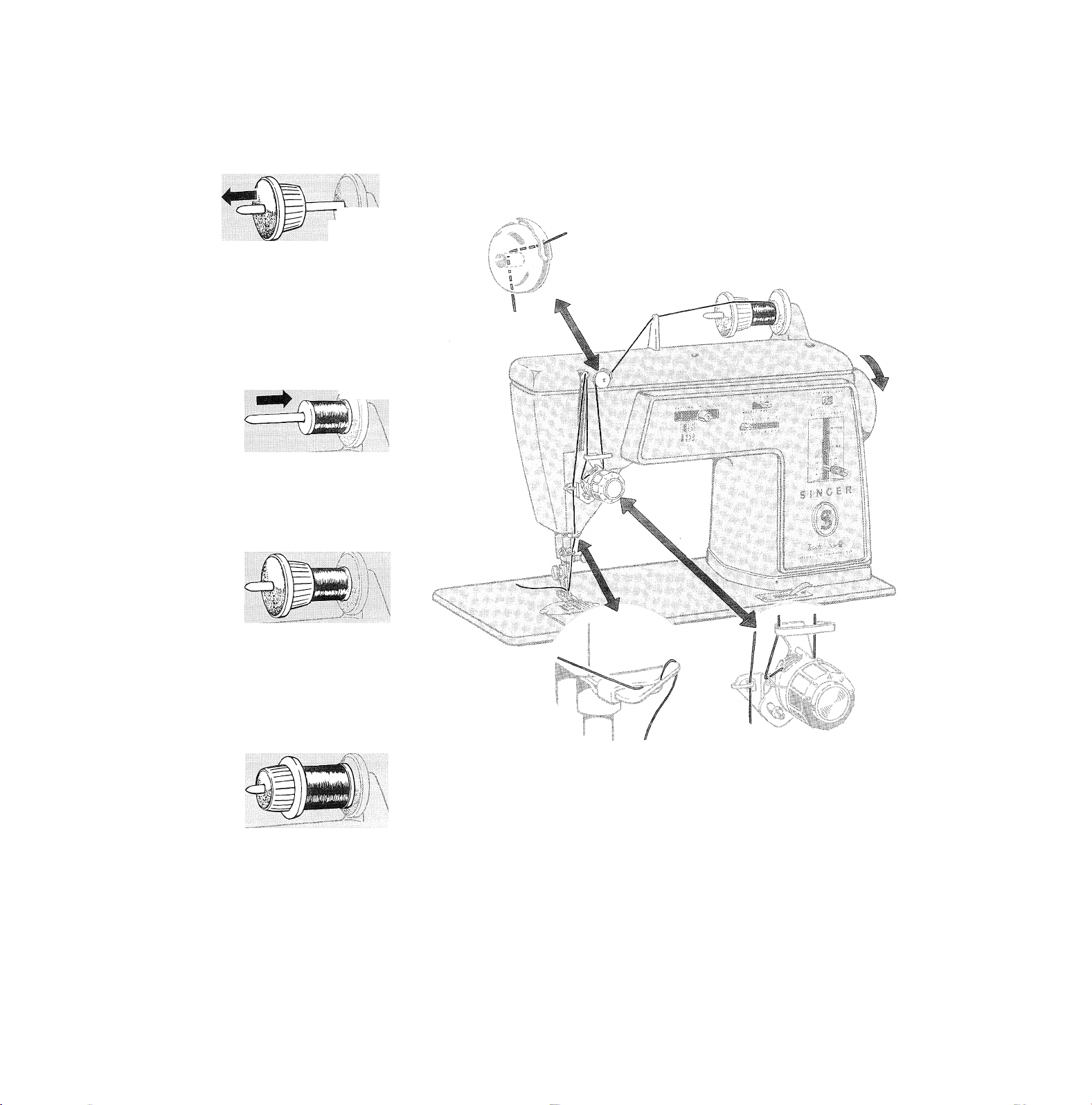

Remove spool holder

from spindle by sliding

it to the left.

rti

Slip spool of thread onto

spindle.

To hold small spools —

Turn small end of spool

holder to the right and

slide onto spindle. Press

spool holder firmly

against spool.

To hold large spools —

Turn wide end of spool

holder to the right and

slide onto spindle. Press

spool holder firmly

against spool.

1. Turn hand wheel to raise take-up lever to its highest

position.

2. Raise the presser foot.

3. Lead thread through all threading points as shown.

4. Thread needle from front to back, drawing about four

inches of thread through eye of needle.

Page 11

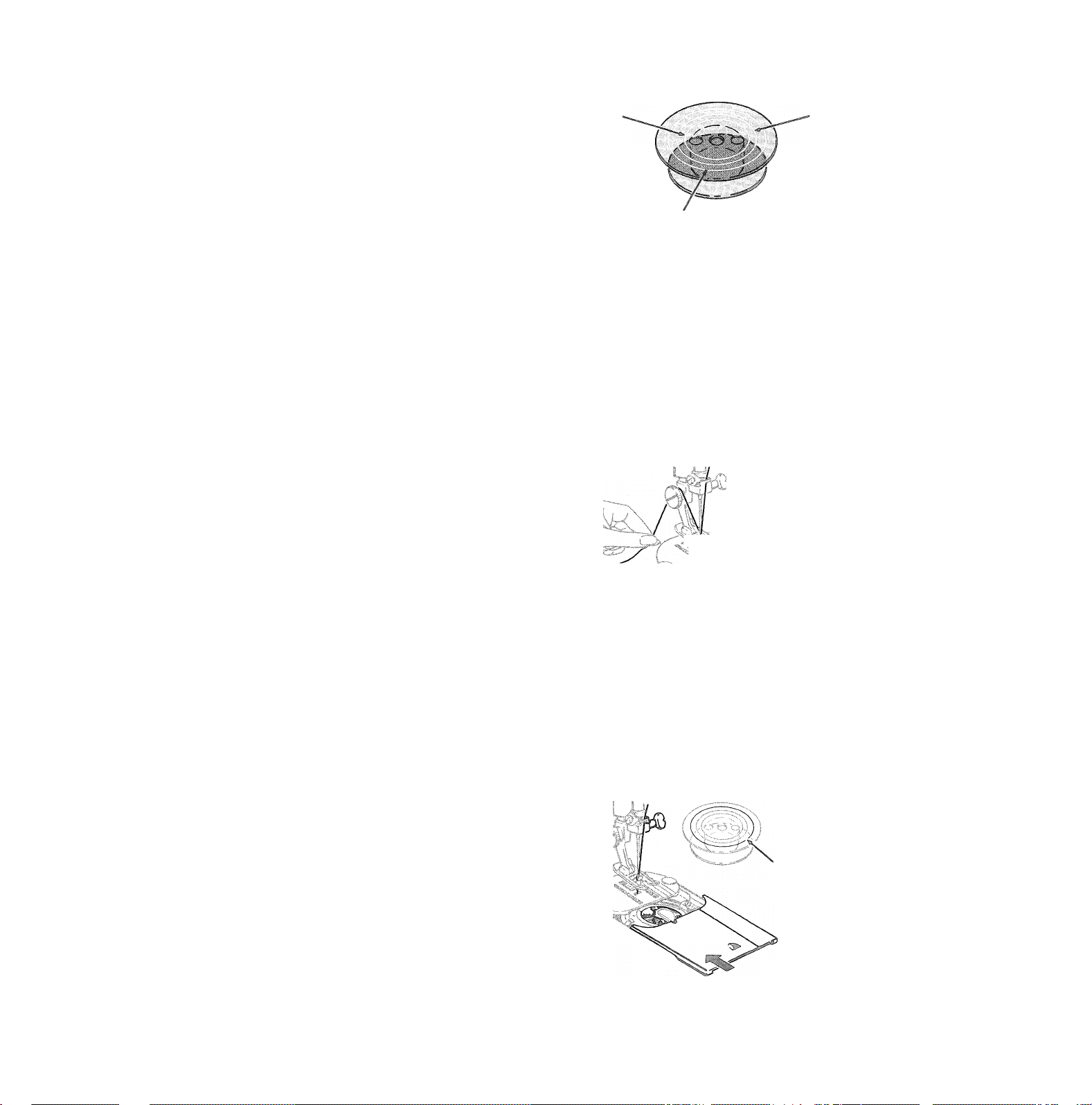

THE BOBBIN

The Push-Button Bobbin will make your sewing go

faster than ever before — whether you are using a

lot of one kind of thread or small quantities of dif

ferent threads, as you are likely to do when mending

or darning.

You will find a bobbin already in place in your ma

chine, located under the slide plate. (To open slide

plate, simply slide it gently toward you.) Notice the

white rings on the bobbin. Each ring represents an

approximate yardage of No. 50 Mercerized cotton

thread. The third, or outer ring, marks the full limit

of the bobbin and you should never wind beyond that

ring. If you are using fine thread, yardage on the

bobbin will be greater. If you use thread heavier than

No. 50, the yardage will, of course, be less.

2 Yards

Full Bobbin (approximately 20 yards)

Winding Steps

nmx

.................

10 Yards

vs

■ A .

The bobbin is ready for winding as you find it in the

machine. If the bobbin runs out of thread while you

are sewing, you can rewind it without removing it

from the machine.

Preparation Steps

1. Use General Purpose or Straight Stitch Presser

Foot. The General Purpose Foot is in place when

the machine is delivered to you.

2. Raise presser foot to release tension on thread.

3. Turn hand wheel toward you to raise take-up

lever to highest point.

4. Open slide plate.

5. Make sure bobbin is empty. (For instructions on

removing bobbin and thread, see next page.)

6. Set Pattern Selector at Straight Stitch, Stitch

Width Selector at 1, and Needle Position at C.

Winding Steps

1. Press bobbin push-button toward you.

2. Wrap thread around presser foot screw, and hold

end of thread firmly.

3. Start the machine.

® Run the machine at a moderate speed.

® Pull thread end away after a few coils have been

wound.

® Keep your eye on the bobbin and fill with desired

quantity of thread. Do not allow thread to wind

beyond FULL ring,

4. Close slide plate to release push-button, (For in

structions on starting to sew with a nev/ly wound

bobbin, see page 19.)

/ /

" step 1

/U.

/ y

Step 2

Step 3

Do Not Allow

Thread to Wind

Beyond Full Ring

Step 4

Page 12

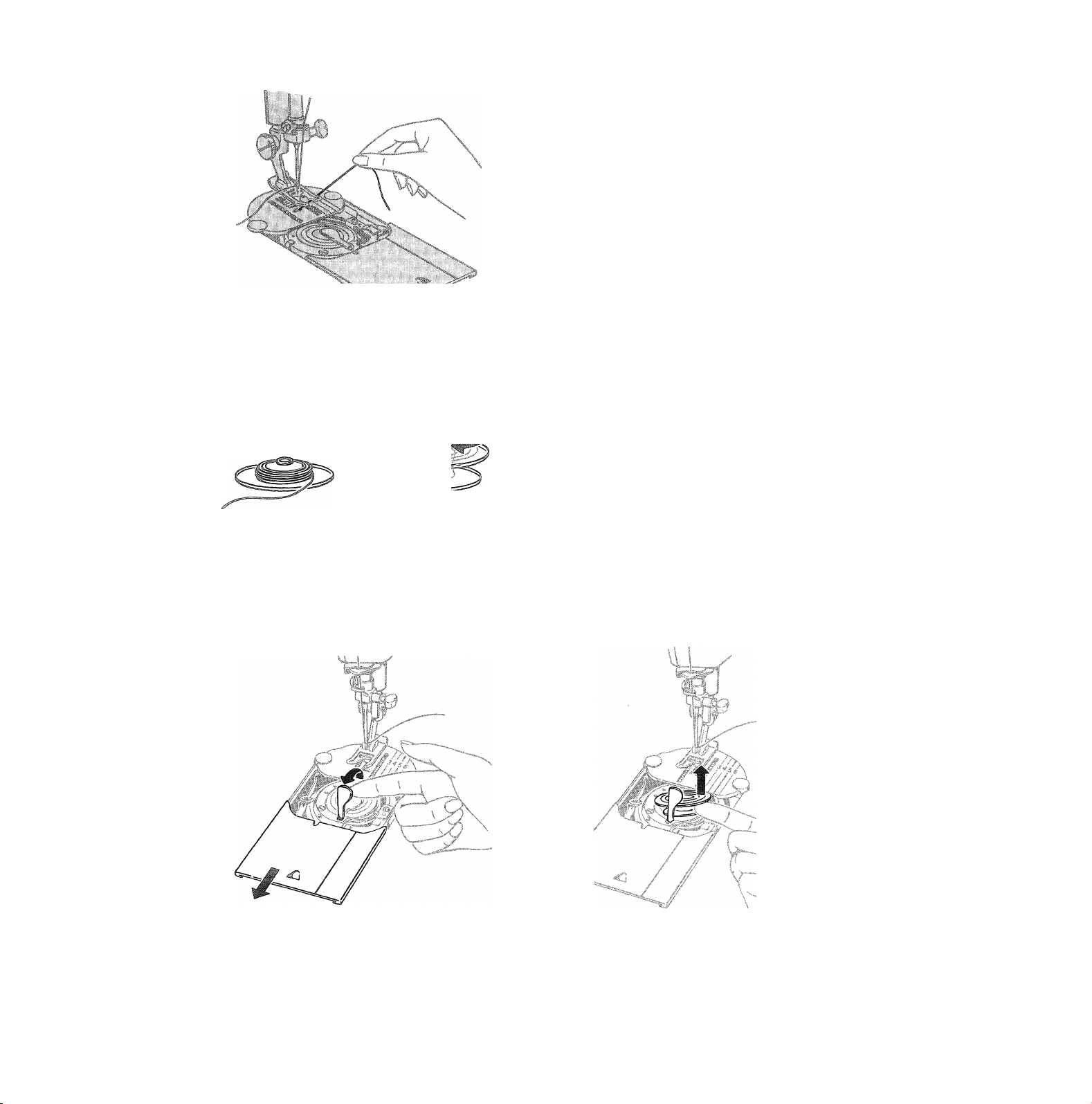

TO WtND THE BOBBIN (Continued)

To Rem©¥e Short Thread, Pull Through Throat Plate

^3-*

O

To Remove Thread

Thread can be removed from the bobbin in either of

two ways. If there is not much thread left on the bob

bin, simply pull the thread end through the throat

plate.

If there is a lot of thread left, remove the bobbin (as

illustrated below), unscrew the two halves, and re

move all the thread at once.

To Remove Bobbin

1. Turn hand wheel to raise take-up lever to its

highest position.

2. Open slide plate; leave bobbin push-button in

sewing position.

To Remove Long Thread, Unscrew Two Halves of Bobbin

U

3. Raise bobbin latch by inserting fingernail under

end of latch at center of bobbin.

4. Insert fingernail under rim of bobbin immediately

to right of latch and remove bobbin.

To Remove Bobbin

X

10

Open Slide Plate and Raise Latch

Lift Out Bobbin

Page 13

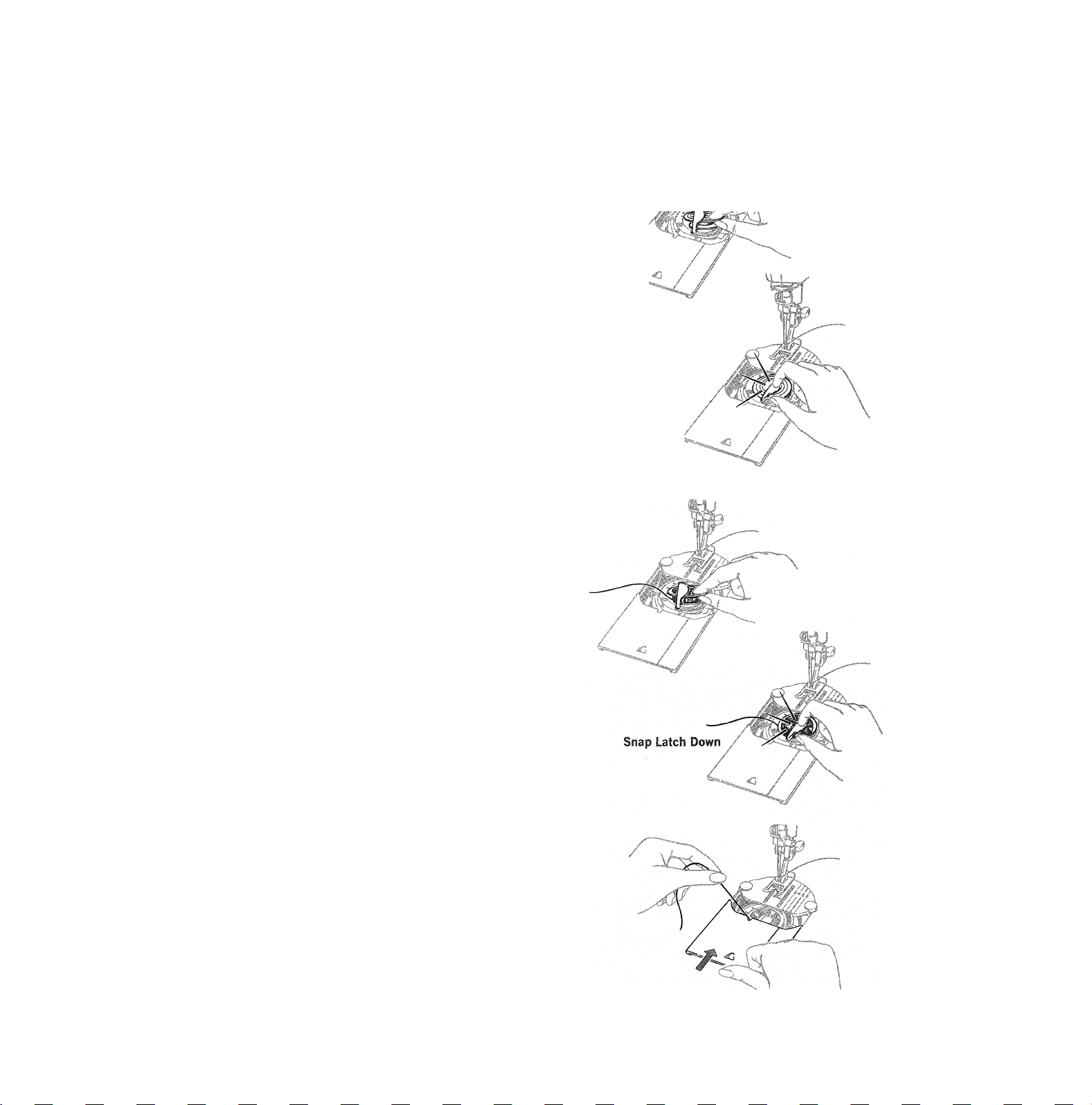

To Replace an Empty Bobbin

1. Tighten bobbin halves securely.

2. With latch raised, slip bobbin (wide side up)

into bobbin case.

3. Snap latch down to secure bobbin.

4. Leave the slide plate open until you have finished

winding.

•m,

Snap Latch Down

Slip Bobbin into Case

vr

Insert Bobbin

To insert a Previously Wound Bobbin

1. Open slide plate; leave bobbin push-button in

sewing position.

2. Turn hand wheel to raise take-up lever to its

highest position.

3. Draw three or four inches of thread from bobbin

and place bobbin in case with thread leading off

to left side of latch.

4. Snap latch down to secure bobbin.

5. Close slide plate, allowing the thread to enter the

notch. (For instructions on starting to sew with

a previously wound bobbin, see page 19.)

Close Slide Plate

11

Page 14

jgim

ig|!iT

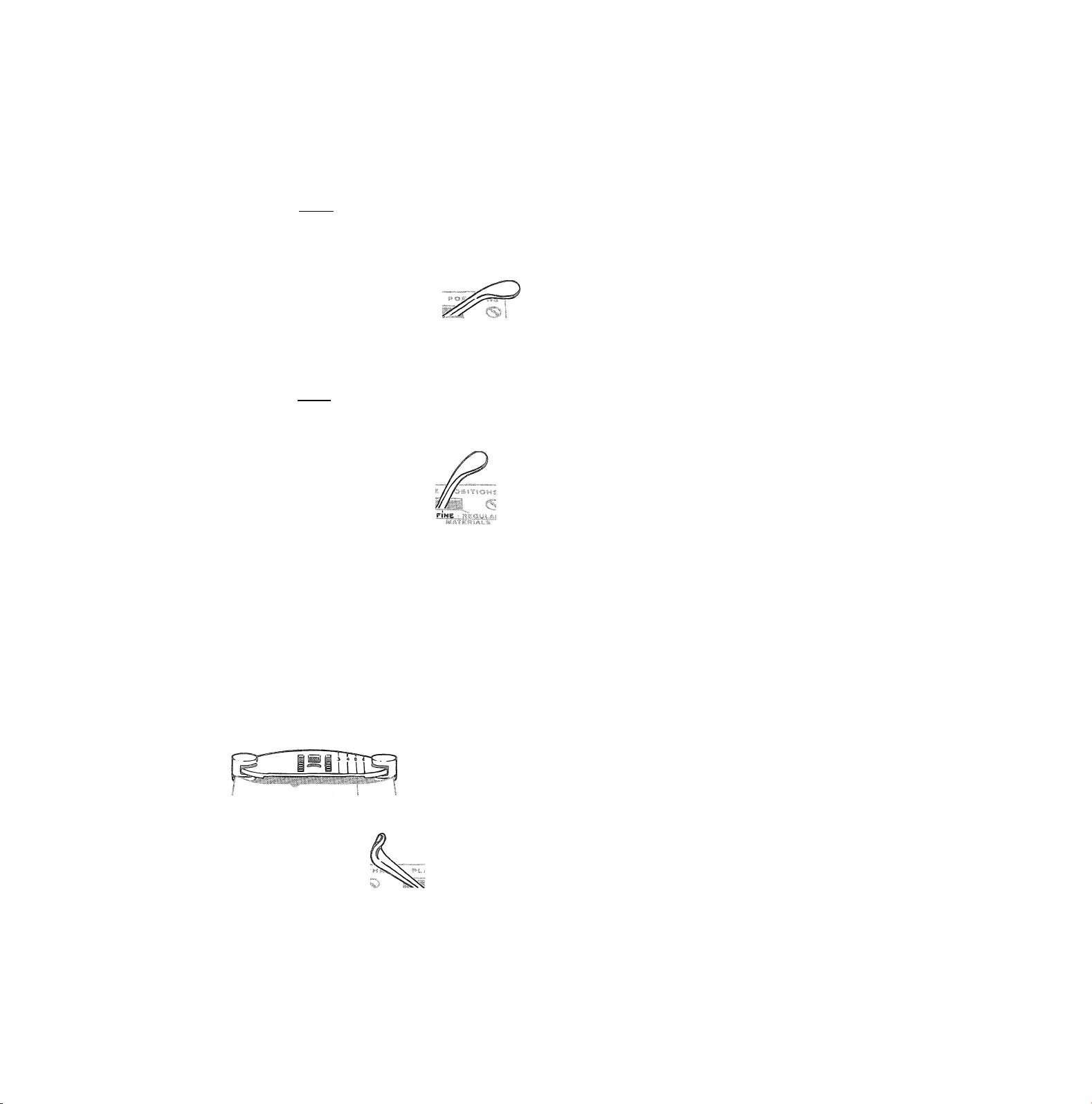

11. TO POSITION THROAT PLATE

The Throat Plate may be placed in any one of

its four positions — REGULAR, FINE, DARN,

UNLOCK — by gently moving the Throat Plate

Position Lever into place above the appropriate

designation. When each position is reached, you will

feel a slight resistance to the movement of the lever.

Throat Plate in REGULAR position for sewing on

most fabrics and for all chainstitching, no matter

what kind of fabric is used.

Throat Plate in FINE position for sewing (other than

chainstitching) on delicate or lightweight fabrics such

as silk, batiste, crepe or organdy; and on fabrics that

may mark easily.

3 4

Throat Plate in DARN position for free-motion darn

ing, embroidery and button sewing.

Throat Plate in UNLOCK position for removal and

replacement, (See page 15 for instructions on chang

ing the throat plate.

12

Page 15

'accessories

The following accessories come with your machine.

And to increase the versatility of your sewing ma

chine still further, a number of additional accessories

such as a Special Purpose Presser Foot, a Binder Foot

and a Ruffler are available at your local SINGER

CENTER. (Some of these accessories are described

at the end of this instruction book.)

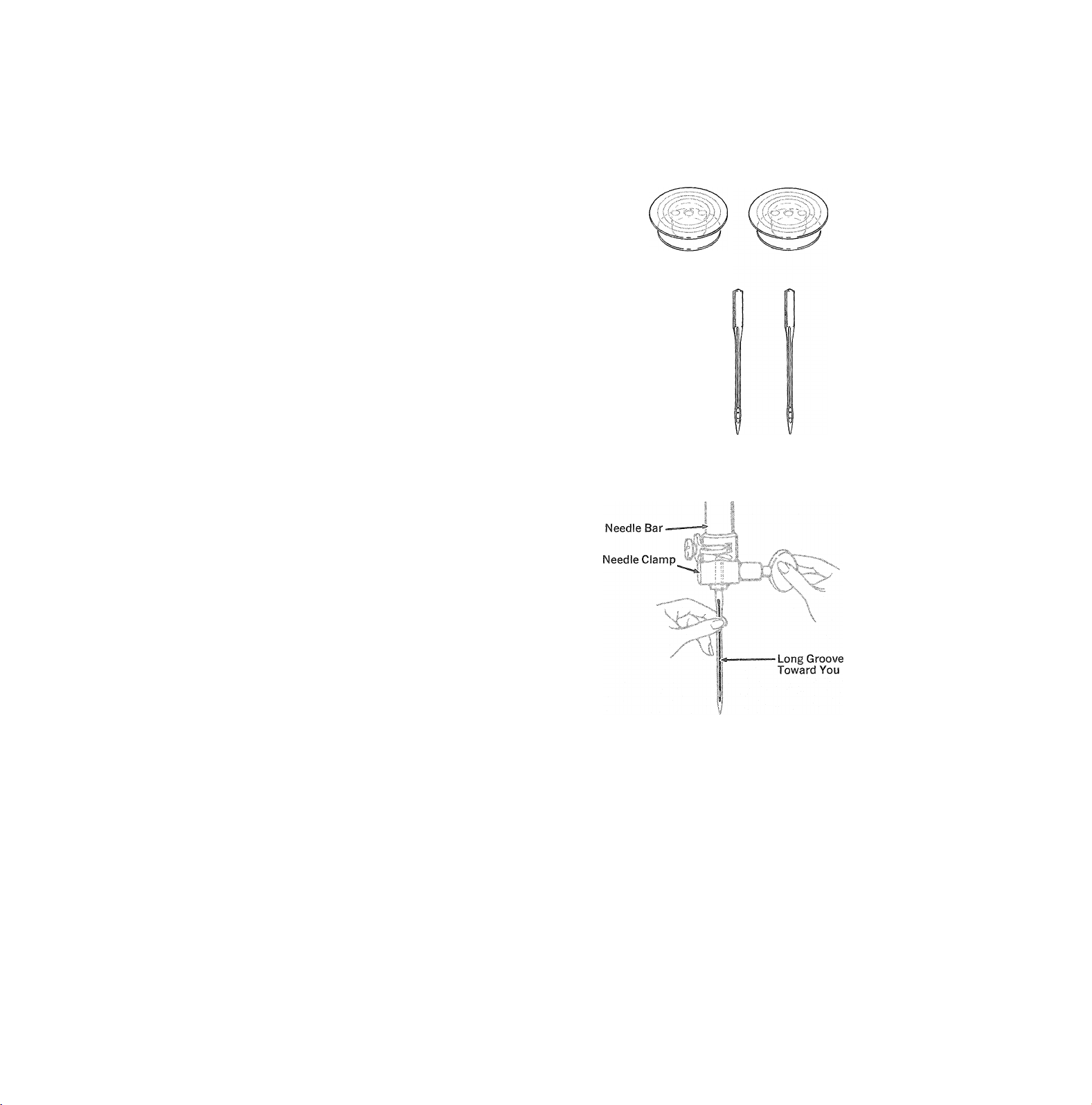

BOBBINS

® One Transparent Drop-in Bobbin in place in your

machine.

® Two extra Transparent Drop-in Bobbins,

NEEDLES

® One Needle, Catalog 2020 (15x1) Size 14, in

place in your machine.

® Three extra Needles of the same size.

To Change the Needle

1. Raise needle bar to highest position by turning

hand wheel toward you.

2. Loosen the needle-clamp screw and remove the

needle.

3. Insert new needle in clamp, with the flat side

of the needle to the back and the long groove

toward you; push it up as far as it will go.

4. Tighten needle-clamp screw.

This machiiie oses needles

Catalog 2020 (15X1)

Sizes 9p 11, 14, 16 and 18,

® One Vertical Spool Pin

The Vertical Spool Pin is used for two-needle stitch

ing (see page 26 for detailed instructions).

Vertical Spool Pin

\n

13

Page 16

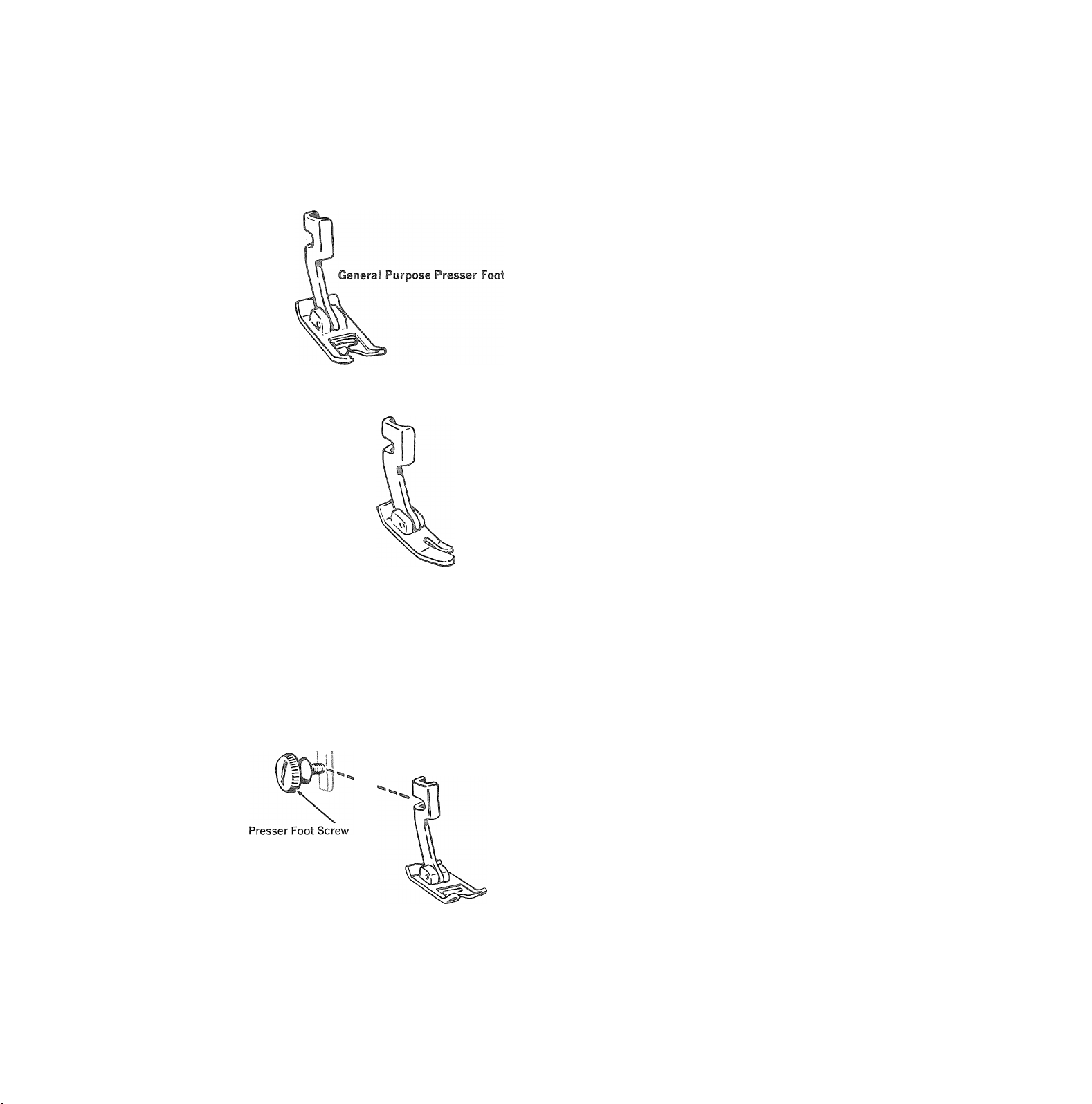

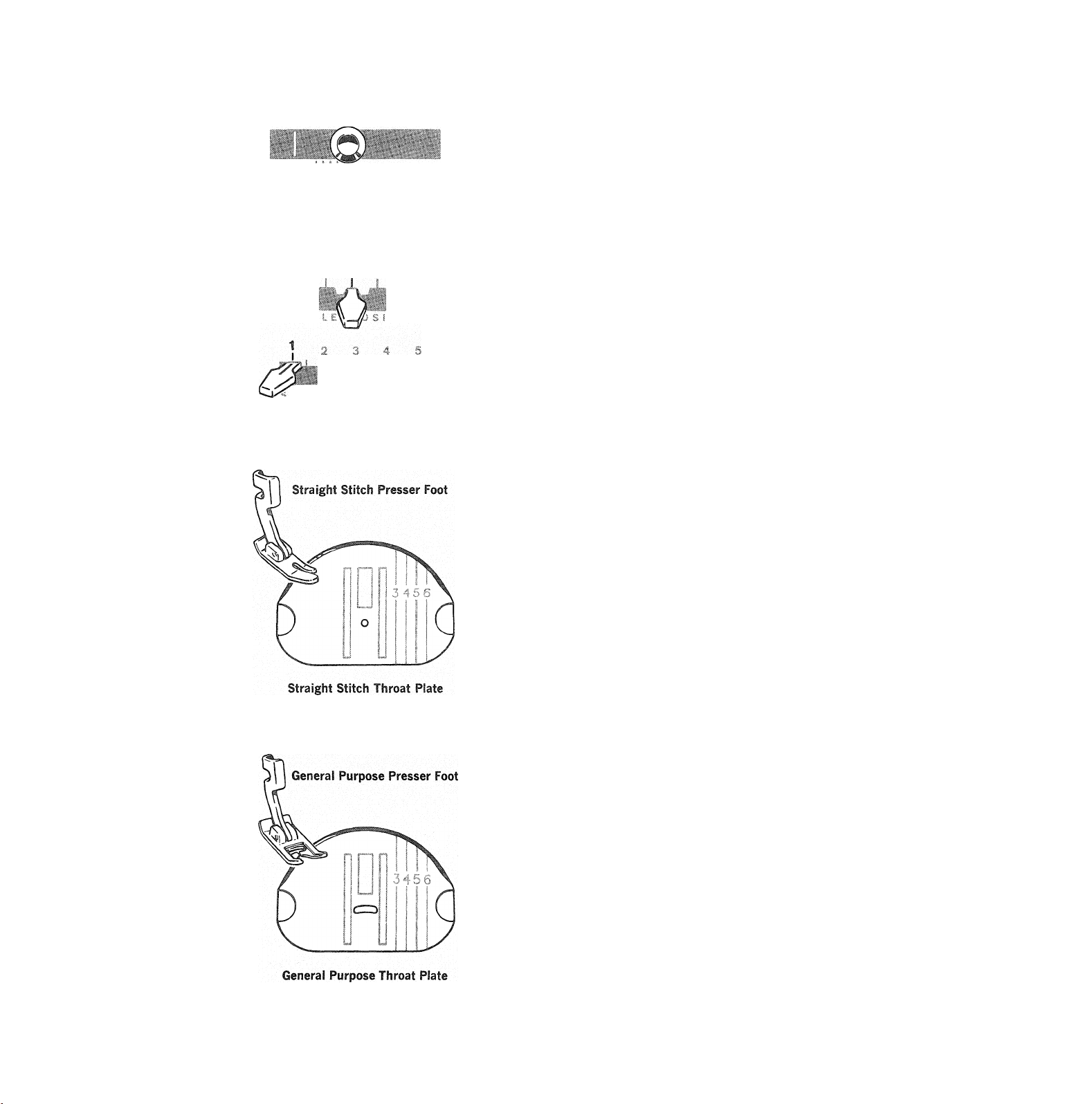

straight Stitch Presser Foot

PRESSER FEET

® General Purpose Presser Foot on your machine.

Use the General Purpose Presser Foot with the

Genera! Purpose Throat Plate for all utility sew

ing. These general purpose fittings must be used

when alternating between straight and zig-zag

stitching. (For discussion of throat plates, see page

15.)

® Straight Stitch Presser Foot,

Use the Straight Stitch Presser Foot with the

Straight Stitch Throat Plate, and pattern selector

set for straight stitching in center needle position,

when your fabric or sewing procedure requires

close control. This narrow, hinged foot rides over

pins and allows you to control the fabric easily

when stitching in a curve or close to the fabric

edge. The narrow slot prevents fabric from rising

with the needle. Use these fittings for:

® Precision stitching of curved and scalloped

edges, top stitching, edge stitching, etc.

® Stitching on delicate or spongy fabrics, synthet

ics, and knits, particularly tricot.

14

To Change Any Presser Foot

1, Raise presser foot.

2, Loosen presser foot screw. (You do not need to

remove the screw. )

3, Remove presser foot.

4, Hook new presser foot around presser bar.

5, Tighten presser foot screw.

Page 17

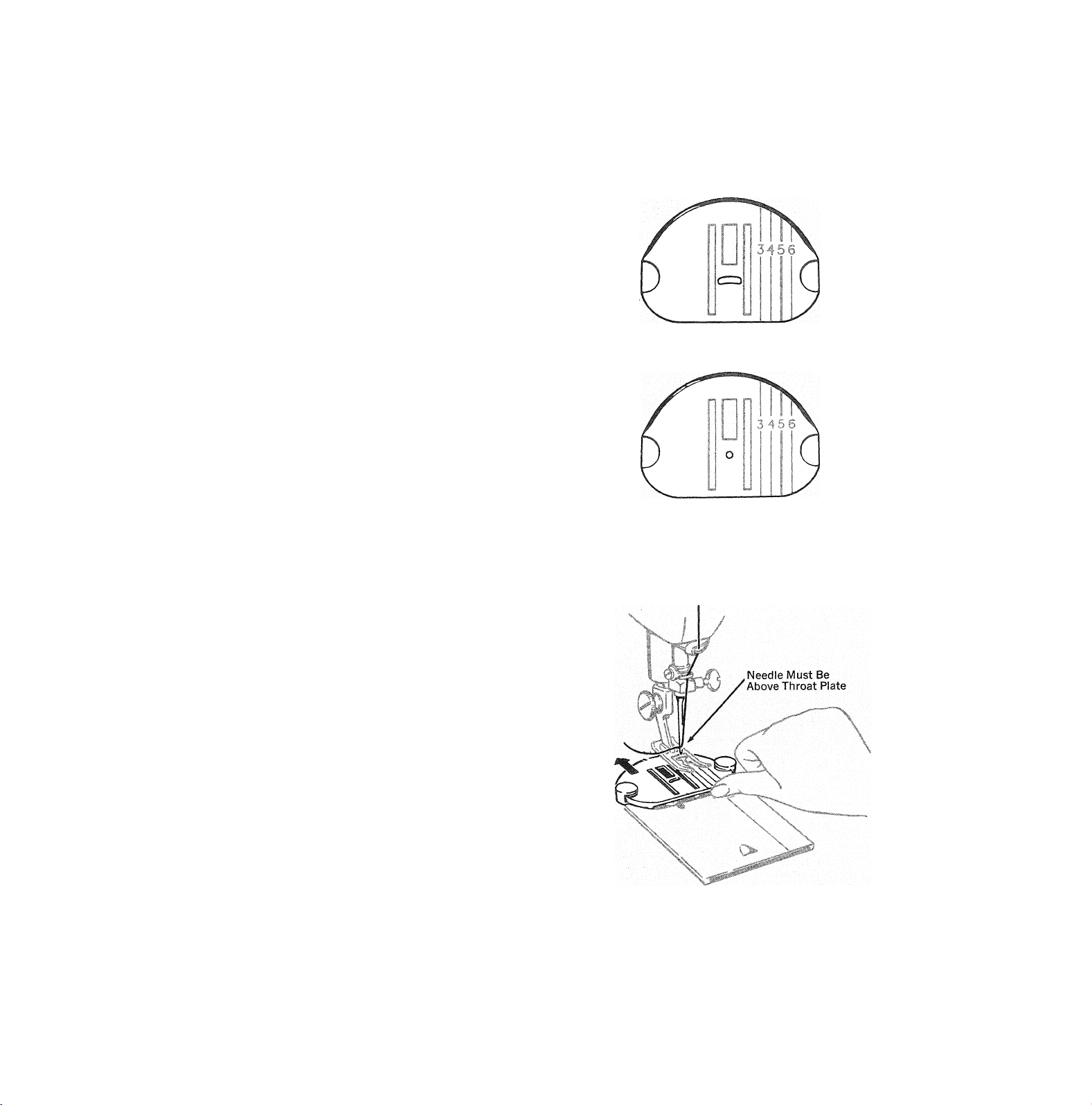

THROAT PLATES

® General Purpose Throat Plate in place on your

machine. (For use with General Purpose Presser

Foot.)

Two additional Throat Plates;

® Straight Stitch Throat Plate. (For use with Straight

Stitch Presser Foot.)

* Chainstitch Throat Plate. (This throat plate is one

of three chainstitch fittings that must be used to

gether and is discussed under the heading, “Chain

stitch Fittings” on page 16.)

To Interchange Straight Stitch and General Pur

pose Throat Plates

(For instructions on attaching and removing Chain

stitch Throat Plate, see “Chainstitching” beginning

on page 29.)

(Note: Remove bobbin if it contains thread.)

1. Raise presser foot. (You do not need to remove

the presser foot.)

2. Turn hand wheel to bring needle above throat

plate.

General Purpose Throat Plate

Straight Stitch Throat Plate

3. Move throat plate lever to UNLOCK position.

4. Remove throat plate by sliding it out.

5. Insert new throat plate by sliding it into place

between the slots in the pins.

6. Move throat plate lever toward right to lock

throat plate in place.

15

Page 18

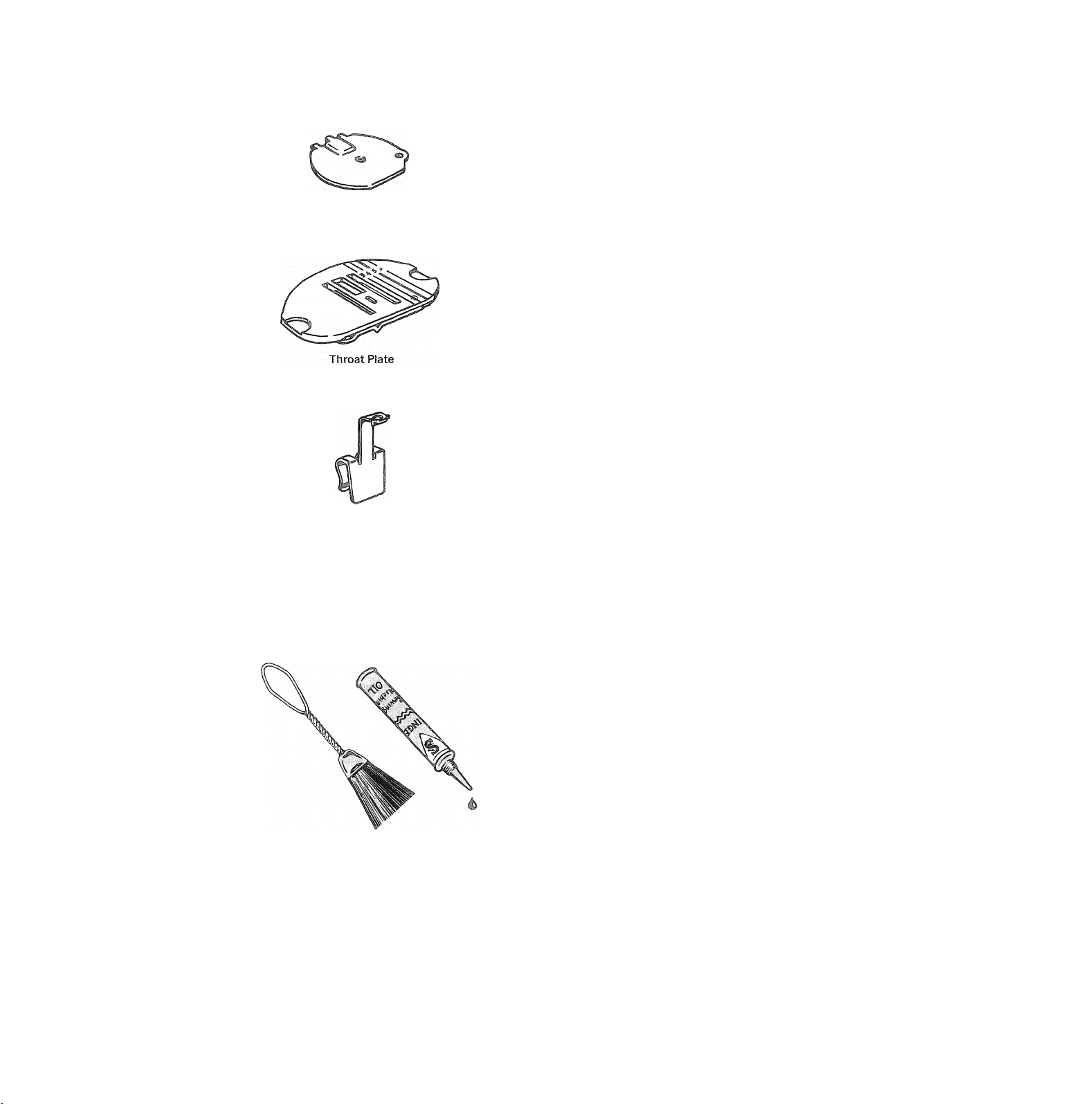

Bobbin Case Cover

Thread Guide

Chainstitch Fittings

CHAINSTiTCH FITTINGS

One Set of three fittings;

® Bobbin Case Cover

® Throat Plate

® Thread Guide

Chainstitching has many decorative as well as prac

tical uses. (See section called “Chainstitching” be

ginning on page 29 for detailed instructions on

chainstitch applications. )

16

CLEANING AND OILING TOOLS

® One Lint Brush

® One Tube SINGER* Sewing Machine Oil

Your sewing machine is a fine yet sturdy precision

instrument, and it will serve you perfectly for many

years if you take a few simple steps to keep it in good

working condition. Instructions on at-home care of

your sewing machine begin on page 52.

Page 19

Z. STMIOHT STITCHIIMG

preparation

FABRIC, THREAD, NEEDLE, AND STITCH LENGTH TABLE ^

FABRICS

DELICATE—tulle, chiffon, fine

lace, silk, organdy, fine tricot

LIGHTWEIGHT—batiste, organdy,

jersey, voile, taffeta, silk,

crepe, chiffon velvet, plastic film

MEDIUM WEIGHT—gingham,

percale, pique, linen, chintz,

faille, satin, fine corduroy, velvet,

suitings, stretch fabric

THREAD

SIZES

Fine Mercerized

100 to 150 Cotton

Synthetic Thread

50 Mercerized

80 to 100 Cotton

“A” Silk

Synthetic Thread

50 Mercerized

60 to 80 Cotton

“A” Silk

Synthetic Thread

NEEDLE

SIZES

■ 9^ 15 to 20

11

14

STITCH LENGTH

SETTING

12 to 15

(8 to 10 for plastic)

12 to 15

MEDIUM HEAVY—gabardine,

tweed, sailcloth, denim,

coatings, drapery fabrics

HEAVY—overcoatings, dungaree,

upholstery fabrics, canvas

fDoes not apply to chainstitching.

tfSIze 9 needle recommended for sewing only. For bobbin winding, use larger size needle.

Heavy Duty

Mercerized

40 to 60 Cotton

Heavy Duty

Mercerized

20 to 40 Cotton

16

18

10 to 12

6 to 10

17

Page 20

P T' T r£ n M € L J C "s i/ >

I I I

I

I

L C FI

U T I O

T I, T C H w. I 0 T H

straight Stitch Selector Settings

MACHINE SETTINGS AND ACCESSORIES

Before making any setting adjustments, turn hand

wheel until needle is out of fabric.

Your choice of accessories will depend on the fabric

and stitching requirements.

® Stitch Pattern Selector: Straight Stitch (--------------------® Stitch Width Selector: 1

® Needle Position: C

® Stitch Length: To suit fabric

® Throat Plate: Straight Stitch or General Purpose

® Presser Foot: Straight Stitch or General Purpose

18

Use the Straight Stitch Presser Foot with the

Straight Stitch Throat Plate when your fabric or

sewing procedure requires close control. This nar

row, hinged foot rides over pins and allows you to

control the fabric easily when stitching in a curve

or close to the fabric edge. The narrow slot prevents

fabric from rising with the needle.

Use the General Purpose Presser Foot with the

General Purpose Throat Plate for all utility sewing.

These general purpose fittings must be used when

alternating between straight and zig-zag stitching.

Page 21

NEEDLE AND BOBBIN THREADS

How you begin stitching depends on whether you are

using a newly wound or a previously wound bobbin.

When you have just wound a bobbin, you will have

one continuous thread leading from the needle into

the bobbin.

When you have just inserted a bobbin that was pre

viously wound, you will have two separate threads:

the upper or needle thread and the lower or bobbin

thread. Before you can start to stitch you must bring

the bobbin thread up through the throat plate needle

hole.

Instructions for both conditions are given below.

(These instructions also apply to zig-zag stitching.)

With a Newly Wound Bobbin

If you are starting to stitch at the fabric edge:

® Close Slide Plate

® Position needle in very edge of fabric

® Lower presser foot and stitch. Thread v/ill “lock”

over fabric edge.

If you are starting to stitch in from fabric edge:

® Close Slide Plate

® Pull thread back under presser foot and cut

® Position needle in from fabric edge where desired

and stitch.

NOTE: Should the bobbin run out of thread after

you have already begun a line of stitching, remove

the fabric, rewind the bobbin and follow the three

immediately preceding steps.

With a Previously Wound Bobbin

Hold needle thread

lightly with left hand

and turn hand wheel

slowly toward you so

that needle enters

throat plate.

Continue turning hand

wheel until needle

rises and brings up

bobbin thread in a

loop.

Undo the loop with

your finger.

Place both needle and

bobbin threads under

presser foot and lay

them diagonally to the

right. Position needle in

fabric where desired

and stitch.

19

Page 22

Pin Placement

Pins Nip into Fabric

at the Stitching Line

Pin basting is a time saver and can be used in place of

hand basting when you are straight stitching seams

in easy-iO"handle fabrics. The Straight Stitch Presser

Foot is recommended, but the General Purpose

Presser Foot may also be used. When sewing over

pins with either foot it is important to use fine pins

and to place them correctly in relation to the stitching

line.

Place pins so that:

® They are at right angles to the stitching line,

® They just nip into the fabric at the stitching line.

® There is minimum pin extension beyond the stitch

ing line. Pins should not extend under both sides of

the presser foot and should never be placed on the

underside of the fabric in contact with the feed dog.

STRAIGHT SEAMS

© Pattern Selector: Straight Stitch (------------------------)

® Stitch Width Selector: 1

© Needle Position: C

® Stitch Length: 6 to 20 depending on fabric

® Throat Plate: Straight Stitch or General Purpose

© Presser Foot: Straight Stitch or General Purpose

20

Starting a Seam

1. With presser foot up, position needle in fabric

about Vi inch from edge.

2. Lower presser foot and raise Stitch Length Selec

tor to RE¥ERSEo Backstitch to edge of material

for reinforcement.

3. Lower Stitch Length Selector for forward stitch

ing, and stitch.

Page 23

Gyiding and Supporting Fabric

Most fabrics need to be guided in front of the presser

foot only, as illustrated.

Some fabrics, however, require support while being

stitched. These fabrics require using the Straight

Stitch Presser Foot, as shown.

® For filmy sheers, knits, tricots, etc., apply gentle

tension by holding seam in front and back of the

presser foot.

® For stretch fabrics, apply firm tension front and

back when stitching in the same direction as the

stretch. For seams not on the stretch direction

stitch in conventional manner, guiding fabric in

front of presser foot.

To keep the seam straight as you stitch, use one of the

numbered guide lines on the throat plate. Numbers

indicate distance, in eighths of an inch, from the

needle. If you want a % inch seam, for example, line

up your fabric with line 5. Note that line 5, the one

most commonly used, is extended on the slide plate

for your convenience.

For additional guidance, you may wish to purchase

the Seam Guide. (See page 59.)

21

Page 24

Ending a Seam

1. Raise Stitch Length Selector and backstitch to re

inforce end of seam.

22

2. With take-up lever at highest, point, raise presser

foot and remove fabric.

Page 25

3. Cut threads on thread cutter at rear of presser bar.

Reset Stitch Length Selector down for forward

stitching.

Follow the same steps as for straight seams except:

1. Use a short stitch length for elasticity and strength.

For example, if you use 12 stitches per inch for

straight seams, select 15 to 20 per inch to stitch

curved seams in the same fabric.

2. Use the Straight Stitch Presser Foot for greatest

accuracy.

3. If you use the Seam Guide, attach it at an angle so

that the edge that is closer to the needle acts as a

guide. Seam Guides are available for purchase at

your local SINGER CENTER.

23

Page 26

3. ZIG-ZAG STITCHING

The seven stitch patterns that are built into your ma

chine will do a variety of jobs with a minimum of ef

fort. Some you will use for practical purposes —

buttonholes and button sewing; seaming, seam finish

ing, and blindstitching; and even mending. Others are

Q Push !n

® Slide

© Release

2 3

I s 1 a I

purely decorative and will give an individual touch to

your clothes and home. Illustrations of all seven pat

terns are shown on page 5.

The plain zig-zag (WVWWVMMM)? which is placed sec

ond from the left on your Selector, is especially useful

for many steps in sewing.

push selector button in

and slide it to right or left until indicator line is

aligned with the stitch pattern you choose. Then re

lease button.

To produce a zig-zag stitch, the Stitch Width Selector

must be moved from straight-stitch position 1 to any

setting between 2 and 5- The higher the number you

select, the wider your stitch will be.

Raise needle above fabric before moving selector.

how to adjust stitch placement

A Needle Position Selector setting of C places the

needle in center stitching position. Selector settings

L and R place the needle in left and right stitching

positions at widths less than 5.

Selector setting C is used most often. Settings L and

U are for special placement of stitching. For example,

Q

an L setting is required for buttonholes and button

sewing. An L or R setting is used to place narrow zig

zag stitching to the left or right of center In decora

tive work.

Raise needle above fabric before moving selector.

0

24

Left Needle Position

Center Needle Position

Right Needle Position

Page 27

how to adjust stitch lengi

When you are preparing to do zig-zag stitching, make

a test sample with the fabric and thread you plan to

use so that you can adjust the stitch length and needlethread tension properly. If you need to adjust pres

sure, see page 7.

For open zig-zag stitching, choose any stitch length

from 6 to 20j depending on how open you wish the

stitches to be. If you wish a closely packed zig-zag

stitch:

1, Move Stitch Length Selector to bottom of FINE

a^ea.

2, Run machine at slow speed,

3, Gradually tighten thumb nut by turning it to right,

until stitches are closely spaced and form a smooth

surface.

r :

NEEDLETHREAD TENSION

All zig-zag stitching requires less tension than straight

stitching; and closed zig-zag stitching requires even

less tension than open zig-zag stitching. Furthermore,

the wider the stitch, the lighter the tension on the

thread must be. Thus, stitch width 5 requires the least

tension; narrower stitching requires somewhat more.

Notice the stitching on your sample. If the stitching

looks too taut, or if the fabric is puckering, lower the

needle-thread tension by turning the Tension Dial to

a lower number.

As the Selector is Raised, Stitches Close Up

Tension Adlystment for Closed

Zig-Zag Stitching

Correct

Incorrect

25

Page 28

4. TWO-IMEEDLE STITCHING

By using two needles at once, you can produce two

parallel, closely spaced, decorative lines of stitching

simultaneously. You can use either one or two colors

of thread; and you can choose either a straight-stitch

or any of the seven stitch patterns built into your ma

chine.

Some of the attractive designs you can create are

shown on page 28.

1. Fill bobbin with enough thread to complete stitch

ing. (Since the bobbin cannot be filled after the

two needles are inserted, it is often wise to keep an

extra wound bobbin at hand for replacement.)

2. Close slide plate.

3. Pull out a loop of thread between the needle and

the throat plate.

4. Cut thread 4 inches from needle hole, and un

thread the machine.

5. Loosen thumb screw on needle clamp and insert

two needles, as illustrated. The two needles must

be the same size. (If the needle you used to fill

the bobbin is the correct size, simply loosen the

thumb screw and insert a second needle into the

clamp from the right.)

Note: When inserting a previously wound bobbin,

follow the instructions on page 11.

1. Place spool of thread on horizontal spool spindle.

Thread as for one-needle stitching except:

® Pass thread betvreen center and back tension

discs.

® Pass thread through eye of right needle.

2. Insert detachable spool pin into hole provided for

it, as shown below.

3. Place spool of thread on vertical spool pin. Thread

as for one-needle stitching except:

® Do not attempt to pass thread through guide

behind the spool pin.

® Pass thread between center and front tension

discs.

® Pass thread through eye of left needle.

26

Page 29

straight stitching

with two needles

® Pattern Selector: Straight Stitch (-

® Stitch Width Selector: 1

® Needle Position: C or L only

® Throat Plate: General Purpose

® Presser Foot: Genera! Purpose

I '

I

I

i 6

I i

i I

I I

i i

I

e

General Purpose Presser Foot

Pattern Selector: Any pattern

Stitch Width Selector: 2 or 3 maximum

Needle Position: L only

Throat Plate: General Purpose

Presser Foot: General Purpose

2 3

General Purpose Throat Plate

General Purpose Presser Foot

27

Page 30

Zig-Zag

Ball

Pyramid

V-“-T''T"’V‘"‘V""V"‘T’‘T'’T“'Y"'r'Y"T‘“Y‘‘T’'T'“'V"'T‘“T’'T''T”T-r"V"“V"Y‘“V"T”T"V"“V”"V-y”V

Blindstitch

28

■"\

........./..........\............/..........\............/..........\............

/.........\

............

Box

Multi-Stitch Zig-Zag

Scallop

/.........\

............

/.........\„

J

....

""1.

Page 31

i f'ii

"i£s!

Single-thread chainstitching looks like regular

straight stitching on top, but is a series of interlocking

loops on the underside of the fabric. The stitches are

produced by the needle thread alone — so you do

not need a bobbin thread or a bobbin. Because the

stitches are formed by a single thread, the interlocked

loops unravel easily. The entire line of stitching can

be removed with just a pull on the thread end. Also,

the loop formation of the stitches makes them less

taut than regular straight stitches. That’s what makes

chainstitching flexible.

Here are a few of the many sewing jobs for which you

will find chainstitching useful. Pages 34 and 35 show

you how chainstitching can save you time and work.

® Basting —

Trial seams for fitting

Construction guidelines

Zipper openings, linings and interfacings.

® Stay-stitching to preserve garment shape during

assembly

® Fastening removable trimming —

Fur collars

White collars and cuffs

® Hemming curtains and draperies that may need to

be altered

® Sewing temporary tucks to extend the life of —

Children’s clothes

Curtains and linings that might shrink

® Making welting for corded seams, tubular cording

for trimming and button loops

® Attaching hem tape

Thread Guide

Bobbin Case Cover

® Making stay chains to anchor linings, or to hold

belts or shoulder pads in place

Chainstitch Throat Plate

29

Page 32

irisert Throat Plate

Position the Bobbin Case Cover

in

1. Attach Chainstitch fittings.

® Turn hand wheel toward you to raise take-up

lever to its highest point.

® Raise presser foot, open slide plate, and remove

bobbin,

® Unlock throat plate and remove.

® Slide chainstitch throat plate into place from

front. Lock it in REGULAR position.

® Insert bobbin-case cover in bobbin case. The

finger-lift tab goes to the right. Close slide plate,

® Open face plate and slip chainstitch thread

guide into place. Close face plate.

2. Thread your machine in the usual way except

pass thread from take-up lever through self

threading eyelet in the chainstitch thread guide.

Soft, pliable threads of light and medium weight

are most suitable for chainstitching. No. 50

Mercerized cotton and “A’’ silk are recom

mended. Use these threads in a Size 14 needle.

3. Adjust thread tension. Chainstitching requires

approximately the same needle-thread tension as

regular straight stitching, provided the same kind

of thread is used. When the tension is correctly

adjusted, the chain will be flat and smooth. Puck

ers in the fabric and pinched loops indicate too

much tension; turn dial to a lower number. Large,

irregular loops indicate too little tension; turn

dial to a higher number.

30

Too Much Tension

Correct Tension

Page 33

Pattern Selector: Straight Stitch (

Stitch Width Selector: 1

Needle Position: C

Stitch Length: 8 to 12 only

Presser Foot: Straight Stitch or General Purpose

-----------------------

)

1, Be sure that throat plate is in REGULAR position,

then place needle in very edge of fabric and lower

presser foot.

2. Start the machine and stitch to end of seam. Con

tinue stitching beyond edge of fabric, making a

chain from one to two inches long,

3, Cut chain between fabric and presser foot.

4. After chaining off, start a new line of stitching by

raising the presser foot slightly and positioning

the fabric in front of needle. Lower presser foot

and stitch to end of seam,

TO RELEASE THE CHAIN FROM THE MACHINE

When you finish chainstitching, the chain can be

easily removed from the machine,

1. Raise presser foot.

2, Hold end of chain with your left hand.

3, Turn hand wheel slowly toward you with your

right hand until needle is all the way down in the

needle hole,

4. Then turn hand wheel slowly away from you,

pulling gently on chain, which will unravel as

needle raises.

7

¿A/-''A

Stitch Starting Point after Chaining Off

To Release Chain

31

Page 34

TO EWD THE STITCH I THE FABRIC

Occasionally you may need to end your stitching in

the fabric. Basted hems and temporary tucks, for ex

ample, as well as partially stitched-down pleats can

be completed in this way:

1. Stop stitching at desired point, with take-up lever

in its highest position.

2. Raise presser foot.

3. With your finger, pull the thread through the

take-up lever, forming a loop between the take-up

lever and chainstitch thread guide.

4. Pass scissors under presser foot so as to draw the

loop down to the left of the foot.

5. Hold the loop and cut the thread close to the end

of the stitching.

6. Remove fabric from machine by pulling it

straight back, away from you. This will cause the

thread end to pull through the fabric to the un

derside and form a temporary lock.

7. If you wish to secure this temporary lock, fold the

thread end back over the chain and fasten with

hand stitching.

Page 35

5

Chainstitching can be removed smoothly and cleanly

in seconds by freeing the last stitch formed in the

fabric.

1. Simply cut the last loop formed on the underside

of the fabric.

2. Then pick up the free thread end from top sur

face of fabric.

3. Pull the free thread end, removing entire line of

stitching.

1. Release chain from machine.

2. Position take-up lever at its highest point.

3. Open slide plate.

4. Remove bobbin-case cover.

5. Snap down latch.

6. Unlock throat plate and remove by sliding it

toward you.

7. Remove chainstitch thread guide.

33

Page 36

^ 3 ^ ^ a

Here are several ways in which you will find chain-

stitching preferable to either regular straight stitch

ing or hand basting.

Time and energy can be saved when chainstitching

is used to baste garment sections or muslin shells for

trial fittings. The firmness of the stitch ensures accu

racy in fitting, yet the stitching can be ripped out in

seconds if adjustments are necessary.

In many instances, construction guide lines for pock

ets, buttonholes, and other details can be advan

tageously marked with chainstitch basting. The

stitching will give a clearly defined line marking. Yet,

unlike chalk or pins, it will not rub off or become

lost as the fabric is handled. This method lends itself

particularly to use on wools and other fabrics that

do not retain needle penetrations.

STAY STITCHING

Chainstitching can be used to stay-stitch necklines,

shoulderlines, and waistlines before garment assem

bly. Flexible, yet firm, this stitching will hold the

original shape of these areas and prevent stretching.

34

Page 37

GROWTH AND SHRINKAGE TUCKS

Tucks are frequently put into curtains, linings, and

children's clothes to allow for the child's growth or

fabric shrinkage. “Letting down" is no longer a chore

when tucks are chainstitched. Simply unlock the last

loop of the chain formed on the underside of the tuck

and pull out the stitching.

Stay chains (sometimes called French tacks) and belt

loops, normally time-consuming hand-worked detail

finishes, can now be quickly chainstitched. To pro

duce a chain, place the first stitch in the fabric. Stitch

off fabric and continue stitching until a sufficient

length of chain is produced. Thread chain through an

embroidery or darning needle and tack to garment or

lining. A No. 12 stitch length setting is recommended.

Growth and Shrinkage Tucks

Belt Carriers and Stay Chains

35

Page 38

6. FREE-MOTIOIM STITCHING

In free-motion stitching, you sew without a presser

foot and instead control fabric movement (and hence

stitch length) yourself, by means of an embroidery

hoop. Either a straight or a zig-zag stitch setting can

be used. Because you can move the hoop in any di

rection — forward or backward, from side to side,

and even diagonally — free-motion stitching is ex

tremely useful for intricate embroidery designs. On

the other hand, it is equally useful for that most

humdrum but necessary task, darning.

Throat Plate ifi DARN Position

Stitch Length Selector in FINE Area

If you are embroideriiig, you can vary the length

of stitches simply by moving the hoop faster or

slower. The faster you move it, the more open the

stitches will be. A slow hoop movement will produce

closely packed stitches. You can also vary the width

of zig-zag stitches, from a hairline to the full width

of whatever stitch width setting you have chosen,

simply by moving the hoop. If you move it sideways

and stitch in a horizontal line, you will get a hairline,

if you move it forward or backward and stitch in a

vertical line, you will get a full stitch width. Thus

you can produce a ribbon-like effect in script lettering

or create delicate flower designs. This takes practice,

but you can achieve some lovely effects that look

much like hand embroidery. See pages 47 and 48

for specific directions.

For darning, the embroidery hoop used in freemotion stitching enables you to hold the fabric taut

— a real advantage when your fabric is lightweight

or soft and thus is likely to pucker. See page 51 for

directions.

36

1. Have available an embroidery hoop large enough

to encompass the entire design or area to be

darned,

2. Remove presser foot.

3. Raise throat plate to DARN position.

4. Raise Stitch Length Selector to FINE area.

Page 39

and home decorations

seams

© Pattern Selector: Zig-Zag (VW\/WW/^WAM)

® Stitch Width Selector: 2%

® Needle Position: C

® Stitch Length: 15 to 20 dependingon fabric

® Throat Plate: General Purpose

® Presser Foot: General Purpose

To make a lingerie seam both durable and flexible,

use a zig-zag stitch. This seam treatment is particu

larly suitable for bias seams.

1. Straight-stitch the seam (with Stitch Width Se

lector at 1) on wrong side.

2. Press both seam allowances in the same direction.

3. From the right side, top-stitch with zig-zag pattern

(with Stitch Width Selector at 2V2), letting the

needle alternately enter the seam line and seam

thickness.

Lingerie Seam

iSIDE SEAMS OF SHEER

® Pattern Selector: Zig-Zag (

® Stitch Width Selector: 2

® Needle Position: C

© Stitch Length: FINE (above 20)

© Throat Plate: General Purpose

© Presser Foot: General Purpose

With a delicate hairline finish, seam allowances that

ordinarily show through can be eliminated.

1. Stitch along seam outline,

2. Trim seam allowance close to line of stitching,

3. Turn and press.

inside Seam of Sheer Collar

37

Page 40

^ Pattern Selector: Zig-Zag (

® Stitch Width Selector; 2

® Needle Position: C

Stitch Length: About 20

® Throat Plate: General Purpose

® Presser Foot: Genera! Purpose

A narrow, closely spaced, zig-zag stitch is ideal for

seaming knit fabrics. It is particularly desirable

for underarm seams where elasticity and give are

needed. Stitch and press seams as when using a

straight stitch.

Where a stay is needed to prevent stretching, at neck

line and shoulder seams for example, this same fine

zig-zag stitch can be used to apply seam tape. For a

flat, smooth stayed finish:

1. If seam is curved, pre-shape tape to fit by steam

pressing.

2. Baste tape in place.

Corved Seam with Tape Stay

3. Stitch, allov/ing needle to enter seam tape and

seam allowance alternately.

® Pattern Selector: Zig-Zag (VWWWWWWWl)

® Stitch Width Selector: 3

© Needle Position: C

© Stitch Length: 15 to 20 depending on fabric

© Throat Plate: General Purpose

© Presser Foot: General Purpose

Zig-zag stitching gives strength and durability to flat

felled seams.

1. Stitch the seam on the right side of the fabric, tak

ing full seam allowance.

2. Press the seam allowance to one side, keeping the

right side of the stitch on top.

3. Trim the under seam allowance to one-half its

width.

38

Fiat Felled Seam

4. Turn the upper seam allowance edge evenly over

the trimmed edge, and top-stitch.

Page 41

SEAM FINISHES

® Pattern Selector: Zig'Zag (VWWVWMWVWA)

Biindstitch (V'”'V V ), or

Multi-Stitch Zig-Zag (/VV\A)

© Stitch Width Selector: 4 or 5

© Needle Position: C

© Stitch Length: 8 to 20, depending on choice of stitch and

fabric

® Throat Plate: General Purpose

® Presser Foot: General Purpose

Seam edges support the garment and should be given

a durable finish if the fabric is likely to raveh

1. Make a test sample first to determine whether zig

zag stitch (V\WWMWVWl)? biindstitch (

or multi-stitch zig-zag (/\^A/\y\ ) best suits your

fabric.

2. Adjust stitch length and stitch width settings to

suit fabric. Choose the setting that will give you

the most ''open” stitch that will secure the fabric

edges; avoid harsh, over-stitched edges.

3. Place stitching near the edge of the seam allow

ance or over the raw edge as illustrated.

Overedged Seam Finish

4. If stitching is placed near the edge of the seam

allowance, trim edges evenly.

39

Page 42

Darts can, of course, be made in the usual way on

your sewing machine. That is, you can begin stitch^

ing at the wide end of the dart, stitch to the point,

and then fasten the two thread ends. However,

thanks to the Push-Button Bobbin, you can avoid

the problem of fastening the thread ends by making

a “continuous-thread” dart and stitching in the op

posite direction. This method is particularly useful

for darts in sheer fabrics, where transparency re

quires a neat, clean finish. It is also useful for darts

made on the right side of a garment as a style detail.

Pattern Selector: Straight Stitch (

Stitch Width Selector: 1

Needle Position: C

Stitch Length: About 12 or to suit fabric

Throat Plate: General Purpose

Presser Foot: General Purpose

---------------

1. Stitch from the seam edge, tapering gradually to

the point.

2. Stitch beyond the fabric to form a thread chain

Ti to ^/4 inch long.

3. Tie the thread ends into a single knot close to the

stitching.

Regular Darts

Continuous-Thread Dart

CONTINUOUS^THREAD DARTS

Pattern Selector: Straight Stitch (Stitch Width Selector: 1

Needle Position: C

Throat Plate: General Purpose

Presser Foot: General Purpose

1. Wind an empty bobbin with enough thread to

make a single dart (usually less than 1 yard).

2. Close slide plate.

3. Position the needle in the very edge of the fold, at

the point of the basted or pinned dart.

4. Lower the presser foot,

5. Stitch carefully toward the wide end of the dart.

40

Page 43

DARTS IN INTERFACING

Pattern Selector: Zig-Zag (WWWWWWvVA)

or Multi-Stitch Zig-Zag (/vV\)

Stitch Width Selector: 5

Needle Position: C

Throat Plate: General Purpose

Presser Foot: General Purpose

With zig-zag stitching, interfacings can be shaped

without bulk.

1. Cut out the dart allowance on the stitching line.

2. Bring raw edges together and pin over a muslin

stay.

3. Stitch, backstitching at both ends.

BLINDSTITCH HEMS

Steps In Making a Dart in Interfacing

Pattern Selector: Blindstitch( V

Stitch Width Selector: 2 to 5

Needle Position: C

Stitch Length: 10 to 20

Throat Plate: General Purpose

Presser Foot: General Purpose

Y"T")

Blindstitching provides a durable hem finish that is

invisible and is comparable to hand sewing. It is best

suited to straight and slightly curved hems. Taped,

bound, turned, or unfinished hem edges can be blindstitched with equal ease. Blindstitching takes a little

practice, however, so make a test sample first.

1. Mark, turn, and press hem in the usual way.

2. Baste a guide line inch from the top of the hem

edge.

3. Place hem edge over the feed of the machine,

turning bulk of fabric to the left and thus creating

a soft fold.

4. Stitch so that straight stitches fall on hem edge

and sideward stitches pierce the soft fold.

Blindstitcli Hein

41

Page 44

2 a S

2 " : 3 . 4 . 5

Pattern Selector: Zig-Zag (W\WWWWWVV\)

Stitch Width Selector: 1 and 4

Needle Position: L

Throat Plate: General Purpose (DARN position)

Presser Foot: General Purpose

The space between the holes in the button determines

the stitch width settings. The 1 setting must always be

used to position the needle over the left hole and

fasten stitching. For buttons with standard hole spac

ing, use settings 1 and 4. For buttons with unusual

hole spacing, use setting 1 and increase or decrease

the width setting (4) as necessary.

S T I T C H

2 ■ 5

^ T I T ;C : h; .. :w .1: X 'X

To sew on two- or four-hole buttons, approximately

one inch in diameter or larger:

1. Set stitch width at 1 „ Position button under foot so

that the needle will enter the left hole. Lower foot.

Turn hand wheel toward you until needle rises out

of button and is just above the foot.

2. Set stitch width at 4= Then, when you begin to

stitch, the needle should enter the right hole of the

button. Take approximately six zig-zag stitches in

this position, ending on the left side.

3. To fasten stitching, return to stitch width 1 and

take approximately three stitches.

For best results with buttons smaller than one inch in

diameter, it is recommended that the Button Sewing

Presser Foot (available for separate purchase) be

used. See page 58.

42

Page 45

® Pattern Selector: Zig-Zag (WWWVWWWVl)

® Stitch Width Selector: See below

® Needle Position: L

® Stitch Length: FINE (above 20)

® Throat Plate: General Purpose

® Presser Foot: General Purpose

Always make a test buttonhole on a sample of your

fabric. Be sure to duplicate the thickness of the gar

ment and include interfacing if appropriate.

BUTTONHOLE LENGTH

First decide how long the opening needs to be. This

will depend on the diameter and thickness of the

button. To find the right length, cut a small slit in

a scrap of your fabric and gradually enlarge it until

the button slips through easily. Then add at least 1 /8

inch (1/16 inch for each bar tack), and mark the

fabric as illustrated. This bar-tack measurement is

approximate; on some buttonholes, you may need to

increase it to arrive at pleasing proportions.

STITCH WIDTH SETTINGS

Next, determine the two stitch width settings that you

will need: one for side stitching and one for the bar

tacks (closings at the ends of buttonhole). The three

possible combinations are shown below.

i

Len^h of

Cyttiiig Space

Marking Lines

Bar Tacks and

Side Stitching

1 2 3 4 5

' 1 ' ' '

Selector at 3

for Side Stitching

Selector at 5

for Bar Tacks

Selector at 2V^

for Side Stitching

Selector at 4

for Bar Tacks

Selector at 2

for Side Stitching

Selector at 3

for Bar Tacks

43

Page 46

CB

2 3

I

; '2 3

;2\

With Needle Position Selector at L, place Stitch Width

Selector on setting desired for side stitching of button

hole. Place work under needle, aligning center mark

ing of buttonhole with slot in the presser foot.

Side Stitching: Position needle in fabric at point A.

Lower foot and stitch to end of marking. Leave

needle in fabric at point B. Raise foot and pivot work

on needle. Lower foot. Take one stitch without

changing width setting, bringing work to point C.

c®

D®

Bar Tack: Adjust Stitch Width Selector for bar tacks

and take at least six stitches. Stop at point D.

I

Side Stitching: Readjust Stitch Width Selector for

side stitching. Complete work to point E. Leave

needle in fabric.

44

1 n

1 , T .. T . t

,Ul.J .

22V

5

■

Final Bar Tack: Adjust Stitch Width Selector for bar

tacks, and take at least six stitches in reverse, ending

at point F.

■2i,v

's&:

:TVvv;

'1

cVK'W

.T lv;

Fastening Stitch; To secure stitching, move Selector

to 1 and take three stitches. Remove work, draw

threads to underside, fasten and trim. Cut opening

for button with sharp scissors.

Page 47

S. FINISHING TOUCHES

top st/tciimg

A practical, simple way to accent the lines of a dress

or coat is to place one or more rows of stitching along

collars, lapels, facing edges, pockets, sleeves, etc.

For a tailored look, use lines of straight stitching.

For decorative interest, use decorative stitching.

she// edging

On soft, fine fabrics, shell edging makes an attractive

finish for narrow hems or bias folds.

® Pattern Selector: Blindstitch (V V V )

® Needle Position: C

® Throat Plate: Genera! Purpose

© Presser Foot: General Purpose

1. Make a test sample on your fabric to find the right

thread tension, stitch length, and stitch width.

2. Place folded hem (basted, if necessary) or bias

fold under presser foot, with hem or fold toward

the left.

3. Stitch slowly, guiding fabric by hand so that the

sideward stitches do not pierce the folded edge.

scalloping

Scalloping adds interest to blouses, dresses, lingerie,

and children’s clothes. Scallops will be perfect in form

and evenly spaced when you use the Scallop stitch.

® Pattern Selector: Scallop (/ V V ',)

® Stitch Width Selector: 3 to 5

© Needle Position: C

© Stitch Length: 10 to 15

® Throat Plate: General Purpose

© Presser Foot: General Purpose

1. Place right sides of fabric together. (Shaped or

bias edges should be interfaced.) Stitch scallops.

2. After stitching, and before turning, trim seam al

lowance to Vs inch or less.

3. With scissors, clip points of scallops and, if neces

sary to make fabric lie flat, clip along curves.

4. Turn and press.

Cut

Notch

45

Page 48

Applique adds beauty and interest to clothes and

household linens. Either contrasting or self fabric can

be used effectively.

The stitch most commonly used in appliqueing is a

closely spaced, plain zig-zag stitch. The width of this

stitch can be varied to accommodate fabrics of differ

ent weaves and textures. Many of the other stitch

patterns can also be used to applique with decorative

stitching.

To prepare for appliqueing, make a sample to help

you decide which of the following two methods is the

more appropriate for your fabric and design,

® Position the design.

® Baste it to the fabric.

® Attach General Purpose Presser Foot

(and General Purpose Throat Plate)

METHOD#!

Method #1 ™ Trimming after Stitching

1. Set Pattern Selector for the desired applique stitch

pattern. Set Stitch Width Selector for the desired

width, and set Stitch Length on FINE (above 20).

2. Outline the design with applique stitching.

3. Trim any excess fabric on the outer edges of

the stitching. Remove basting.

METHOD #2

1. Adjust selectors for straight stitching.

Pattern Selector: Straight Stitch (Stitch Width Selector: 1

Needle Position: C

2. Outline the entire design with a short stitch.

3. Trim raw fabric edges to the stitching.

4. Set Pattern Selector for the desired applique stitch.

5. Adjust Stitch Width Selector to desired width set

ting for applique pattern. Set Stitch Length Se

lector on FINE.

46

Method #2 — Stitching after Trimming

6. Stitch, following the straight stitch outline. This

step will produce a smooth overedged finish, with

no raw edges to be trimmed. Remove basting.

Page 49

Many of the decorative stitch patterns can be used

for monograms or motifs — for adding a personal

touch to a blouse collar, for example, or for initialing

household linens. You can buy designs — or create

them yourself.

MONOGRAMS AND MOTIFS

® Pattern Selector: for zig-zag stitching (WVWVWWVWV\)

See page 5 for decorative stitches

® Stitch Width Selector: 2 through 5

© Needle Position: C

® Stitch Length: FINE (above 20)

® Throat Plate: General Purpose

® Presser Foot: General Purpose

1. Make a sample first, to determine suitability of

stitch pattern and find the right stitch length and

width, thread tension, and pressure.

2. Transfer the design (by tracing, usually) to the

right side of the fabric.

3. If the fabric is soft or loosely woven, baste a back

ing of lawn or organdy onto the wrong side.

4. After stitching, trim the backing close to the

stitching.

To Find the Beginning of the Pattern

When you use decorative stitch patterns in a motif,

always start stitching at the beginning of a pattern

unit — that is, at the beginning of the pyramid, ball,

or whatever pattern you are using. To find the be

ginning:

1. On a scrap of material, stitch until you come to

the end of a complete pattern unit. Now you are

ready to start stitching at the beginning of the

next unit.

2. Raise presser foot and remove scrap.

3. Position motif under needle; lower presser foot;

and stitch.

SCRIPT LETTERING

® Pattern Selector: Zig-Zag (WWMWVWVW\)

® Stitch Width Selector: 2 through 5

© Needle Position: C

® Stitch Length: FINE (above 20)

® Throat Plate: General Purpose (DARN position)

® Presser Foot: None

If you wish to embroider a whole name — on a

child's dress or shirt, for example — you can do so

by free-motion stitching.

1. Always make a sample first, to find the right stitch

settings and spacing.

2. Trace or mark lettering on right side of fabric.

3. If the fabric is soft or loosely woven, add an under

lay of crisp lawn or organdy.

4. Place work in embroidery hoop large enough to

encompass the entire work design. Be sure fabric

is held taut.

5. Position work under needle and lower presser

bar to engage tension.

6. Turn hand wheel toward you to bring bobbin

thread up through fabric at start of design and

hold both threads to start stitching.

7. Stitch, following outline of lettering. Maintain an

even rate of speed so that stitches are uniformly

spaced.

To produce a close stitch, move the hoop slowly; to

produce an open stitch, move hoop more rapidly.

To shade the lettering, from wide to narrow stitching,

turn the work slightly so that you will be moving it at

an angle as you stitch.

Monogram in

Zig-Zag and

Bai! Stitch

Beginning of

Pattern Unit-

Pyramid

Pyramid Pattern

Used in Motif

47

Page 50

Flower Motif

Whether you have artistic ability or not, with your

Touch & Sew sewing machine and a little practice

you will be able to embroider flowers on table linens,

pillow covers, and other home decorations, as well as

on dresses and blouses. If you have designing skill,

you will enjoy creating your own patterns. Otherwise,

you can buy attractive transfer patterns.

Pattern Selector; Zig-Zag (WWVMWWWW)

Stitch Width Selector: 2 through 5

Needle Position: C

Stitch Length: FINE (above 20)

Throat Plate: General Purpose (DARN position)

Presser Foot: None

Prepare the machine and your fabric in the same

way as for free-motion script lettering (page 47). On

your test sample, try out different stitch width set

tings to determine the one or more best suited to your

design.

When Ailing in outlines, place stitches in parallel

lines, shifting the direction of the hoop movement as

appropriate to the design. For a smooth satin stitch

that will catch the light, place the parallel stitches

close together, moving the hoop slowly and steadily.

For an irregular texture, move the hoop more rapidly,

allowing some stitches to overlap.

48

Bar-Tack Design

A series of bar tacks can be used to form spray-like

leaves or flowers. This technique adds variety and

lightness to many designs. Leaves and petals formed

in this way may carry the thread from one bar tack

to the next. The carrying thread eliminates tying of

thread ends.

Flower, Leaf arid Bud Design

Page 51

3. ICiEPIMS yp APPEARANCES

mending

Many of the zig-zag stitch settings are just as useful

for mending as they are for creative sewing. The

multi-stitch zig-zag () forms a firm, flexi

ble bond for repairing tears, for reinforcing or for

replacing elastic. The plain zig-zag (W\WMWWW\) is

useful for making bar tacks to repair lingerie.

TEARS

® Pattern Selector: Multi-Stitch Zig-Zag (/v\r\A )

® Stitch Width Selector: 2 through 5

® Needle Position: C

3 Throat Plate: General Purpose

® Presser Foot: General Purpose

1. Trim ragged edges.

2. Place underlay on the wrong side of tear for rein

forcement. (It is best not to baste or pin the

underlay, since you will be bringing the edges

of the tear together in the next step.)

3. Stitch on the right side, bringing the edges of the

tear together.

4. Shorten stitch length at ends and corners to give

extra strength.

5. Trim underlay.

ELASTIC

1. Use the same selector settings and fittings as for

“Tears”, above.

2. Hold the elastic taut as you stitch so that it will re

main stretchable after stitching is completed.

A Tear Mended with Multi-Stitch Zig-Zag

Replacing Elastic with Multi-Stitch Zig-Zag

49

Page 52

BAR TACKS

Use a closed zig-zag (WWWWW\MWi) stitch to bar-tack

garters, pockets, zippers, shoulder straps, etc.

Bar Tack

Blanket Binding

blanket binding

Often you can make an old blanket look almost new

by replacing the binding.

® Pattern Selector: Multi-Stitch Zig-Zag (/\'\'\A)

© Stitch Width Selector: 5

© Needle Position: C

© Throat Plate: General Purpose

© Presser Foot: General Purpose

L Remove worn binding.

2. Baste new binding securely.

3. Reduce pressure (on Pressure Dial) and increase

stitch length if necessary, so that blanket feeds

freely.

4. Stitch, and remove basting.

50

Page 53

Worn or torn spots on children’s clothes, knits and

household linens can be darned effortlessly and

quickly with little practice. You may choose to darn

either with or without an embroidery hoop. When

greater control is needed, free-motion stitching, with

an embroidery hoop, is usually best.

DARNING WITHOUT EMBROIDERY HOOP

® Pattern Selector: Straight Stitch (

® Stitch Width Selector; 1

® Needle Position: C

© Stitch Length; 10 to 15

© Throat Plate: Genera! Purpose

© Presser Foot: General Purpose

© Pressure Dial: DARN

------------------------

)

1. If area to be darned is open, baste an underlay in

place,

2. Place area to be darned under presser foot.

3. Lower presser foot and start stitching, alter

nately drawing fabric toward you and pulling it

gently away from you.

4. Continue this forward and backward motion as

you fill the area with parallel lines of stitching.

5. For additional strength, cover area with crosswise

lines of stitching.

DARNING WITH EMBROIDERY HOOP

® Pattern Selector: Straight Stitch (

© Stitch Width Selector: 1

© Needle Position: C

© Stitch Length: FINE (above 20)

© Throat Plate: Straight Stitch (DARN position)

© Presser Foot: None

------------------------

)

1. Trim ragged edges from area to be darned.

2. Center worn section in embroidery hoop,

3. Position work under needle and lower presser

bar to engage tension.

4. Hold needle thread loosely with left hand, turn

hand wheel over and draw bobbin thread up

through fabric. Hold both thread ends and lower

needle into fabric,

5. Outline area to be darned with running stitches

for reinforcement.

6. Stitch across opening, moving hoop under needle

at a slight angle from lower left to upper right.

Keep lines of stitching closely spaced and even in

length.

7. When opening is filled, cover area with cross

wise lines of stitching.

Darning witfiout Embroidery Hoop

Darning with Embroidery Hoop

51

Page 54

10. HOW TO TAKE CARE OF YOUR MACHINE

Your sewing machine is a fine yet sturdy precision in

strument, and it will serve you perfectly for many

years if you take a few simple steps to keep it in good

working condition.

How often you will need to clean, oil, and lubricate

the machine will depend on how often you use it and

where you keep it. The following general guidelines

assume that you will be sewing two or three times a

week. But if you use the machine continuously, clean

and oil it daily. Or, if you keep it in a very warm or

damp place, oil and lubricate it more frequently than

the guidelines suggest.

EVERY WEEK OR SO™

Remove lint or fluff from exposed parts. (As a matter

of fact, you will be able to see the lint and fluff gather

ing on these parts, and we recommend that you re