SINGER 6215 User Manual

6215

SINGER

CONGRATULATIONS

As the owner of a new Singer sewing machine, you are about to begin an

exciting adventure in creativity. From the moment you first use your

machine, you will know you are sewing on one of the easiest to use sewing

machines ever made.

In addition to the many familiar Singer exclusives, like a removable

extension table and a friction-free spool holder, this machine offers

you these features;

• Zig-zag stitching for buttonholes, mending and decorative stitches.

• FlexI stitch patterns for sewing knits and other stretch fabrics.

• Built-in 4-step buttonholer that takes the difficulty out of making a

buttonhole.

• Blindstitching for invisible hems.

• Easy to find “Letter-Coded” Accessories.

• Drop In front bobbin for easy, quick bobbin replacement.

• Simple stitch length dial and push button reverse stitching.

• Snap-on presser feet that are quickly removed and easily replaced.

• One-way needle insertion that makes it impossible to insert the needle

incorrectly.

May we recommend that, before you start to use your sewing machine,

you discover the many advantages and the ease of operation by going

through this instruction book, step by step, seated at your machine.

To ensure that you are always provided with the most modern sewing

capabilities, the manufacturer reserves the right to change the appearance,

design or accessories of this sewing machine when considered

necessary.

*A Trademark of The Singer Company

Copyright 1984 The Singer Company All rights reserved throughout the world

TABLE OF CONTENTS

SECTION 1. Getting To Know Your Machine 2

Principal Parts....................................................................................... 2

Accessories............................................................................................. 4

SECTION 2. Getting Ready to Sew 5

SECTION 3. Straight Stitching 14

SECTION 4. Zig-Zag Stitching 20

SECTION 5. FlexI Stitch Patterns 27

SECTION 6. Four Step Buttonhole.......................................................................... 32

SECTION 7. Free-Arm Sewing................................................................................ 34

SECTION 8. Twin Needle Sewing............................................................................ 35

SECTION 9. Caring For Your Machine

ADDITIONAL ACCESSORIES....................................................................................... 40

PERFORMANCE CHECKLIST 41

PERSONAL MEASUREMENTS 42

NOTES......................................................................................................................... 43

INDEX

Important Safeguards

Operating the Machine.............................................................................6

Choosing and Changing Needles

Changing Presser Feet........................................................................... 7

Changing the Needle Plate................................................................... 8

Attaching the Feed Cover

Removing and Replacing the Extension Table

Fabric. Thread and Needle Table.......................................................... 9

Winding a Bobbin...................................................................................10

Inserting a Bobbin

Threading the Machine

Raising the Bobbin Thread :

Stitch Width Selector

Needle Position Selector

Stitch Length Selector..

Reverse Stitch Button............................................................................14

Adjusting Thread Tension

Sewing a Seam

Darning................................................................................................. 18.

Quilting................................................................................................... 18

Inserting A Zipper.............................................................................. 19

Stitch Pattern Selector...................................................................... 20

Needle Position Selector

Stitch Width Selector............................................................................. 20

Adjusting Stitch Length.........................................................................21

Needle Thread Tension....................................................................... 22

Zig-Zag Stitch........................................................................................ 22

Multi-Stitch Zig-Zag #8........................................................................ 23

Blindstitch #6....................................................................................... 24

Ladder Seams.........................................................................................25

Attaching a Button

Stitch Pattern Selector.......................................................................... 27

Adjusting Stitch Length

Stitch Width Selector............................................................................. 28

Needle Position Selector. .

Balancing Flexi Stitches..................................................................... 28

Straight Stretch Stitch #3 ...

Ric Rac Stitch #5,..... .„.

Slant Overedge Stitch #7.................................................................... .30

Honeycomb Stitch #9

Removing arid Replacing the Bobbin Case... ..

Changing th0 Light Bulb........................................................................37

Cleaning the Machine

Lubricating the Machine........................................................................39

............................. ...................

............................................................................

...........................................................

.......................................................................

............

8

.................................................................................

.....................................................................

...........................................................

............................................................................

.......................................................................

.....................................................................

.....................................................................

.....................................................................................

.......................................................................

.......

...................................................................... 26

......

...................................................................27

.................................................................

............................................................... 29

.......

...................;

.........................................................................

......

............................................................ 36

.......................................................................

.............................................................................44

................................

................................. 36

5

11

12

.13

14

14

14

15

16

20

.28

31

38

6

8

29

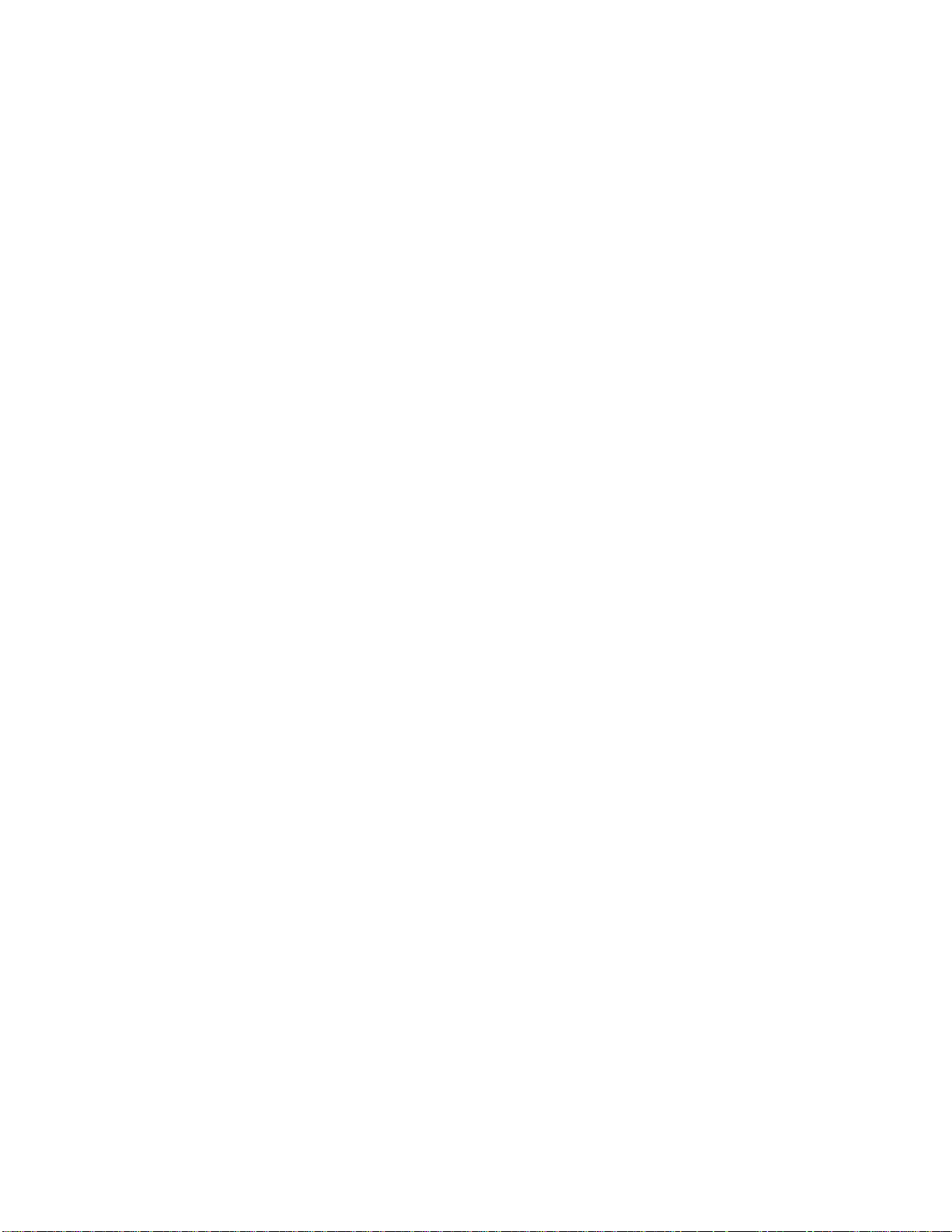

1. GETTING TO KNOW YOUR MACHINE

PRINCIPAL PARTS

............

What they are and what they do

1. HAND WHEEL provides a means

of raising or lowering needle

manually.

2. BOBBIN WINDER is for filling the

bobbin with thread.

3. PATTERN SELECTOR LEVER for

selecting different patterns.

4. FRICTION-FREE SPOOL PIN AND

CAP hold the top thread supply and

allow it to unwind smoothly.

5. NEEDLE POSITION SELECTOR

positions needle in left, center or

right position for special

applications.

6. STITCH WIDTH LEVER controls

width of patterns and sets needle

for straight stitching.

7. SNAP-IN THREAD GUIDE helps to

insure smooth flow of thread.

8. BOBBIN WINDER TENSION DISC

provides thread tension when bob

bin winding.

9. THREAD GUIDE leads thread

down into tension discs.

10. TAKE UP LEVER draws correct

amount of thread from spool for

best stitch formation.

11. FACE PLATE is a removable cover

protecting movable parts and sew

ing light.

12. NEEDLE THREAD TENSION DIAL

controls top thread tension.

13. THREAD GUIDES lead thread to

needle.

14. SNAP ON PRESSER FOOT holds

fabric against feed system teeth.

15. FEED SYSTEM moves fabric

under presser foot.

16. NEEDLE PLATE supports the

fabric during sewing.

17. ONE-WAY NEEDLE CLAMP holds

needle in machine and prevents

Incorrect insertion.

18. REMOVABLE EXTENSION TABLE

lets you change from flat bed to

free arm.

19. STITCH LENGTH DIAL allows for

a variety of stitch lengths.

20. REVERSE STITCH BUTTON,

when pushed in provides continu

ous reverse fabric movement.

When turned right or left, adjusts

balance of buttonhole.

21. PRESSER FOOT LIFTER, at the

back of machine, lets you raise

and lower presser foot.

22. THREAD CUTTER, on presser bar

is built-in for ease.

23. SLIDE PLATE opens for easy re

moval and replacement of bobbin.

24. SPEED CONTROLLER, designed

for safety, regulates the speed of

your sewing machine.

25. ELECTRICAL POWER CORD con

nects machine to your electrical

outlet.

26. MACHINE PLUG connects the

speed controller and power line to

the motor. Push the machine plug

into the machine receptacle to the

right of the power and light switch.

27. POWER AND LIGHT SWITCH

turns on machine and sewing light

at one time.

28. BOBBIN WINDING INDENT, on

hand wheel. When pressed, stops

needle movement for smooth even

bobbin winding.

29. STITCH BALANCE CONTROL

adjusts the appearance of a

flexl-stitch pattern.

J

3

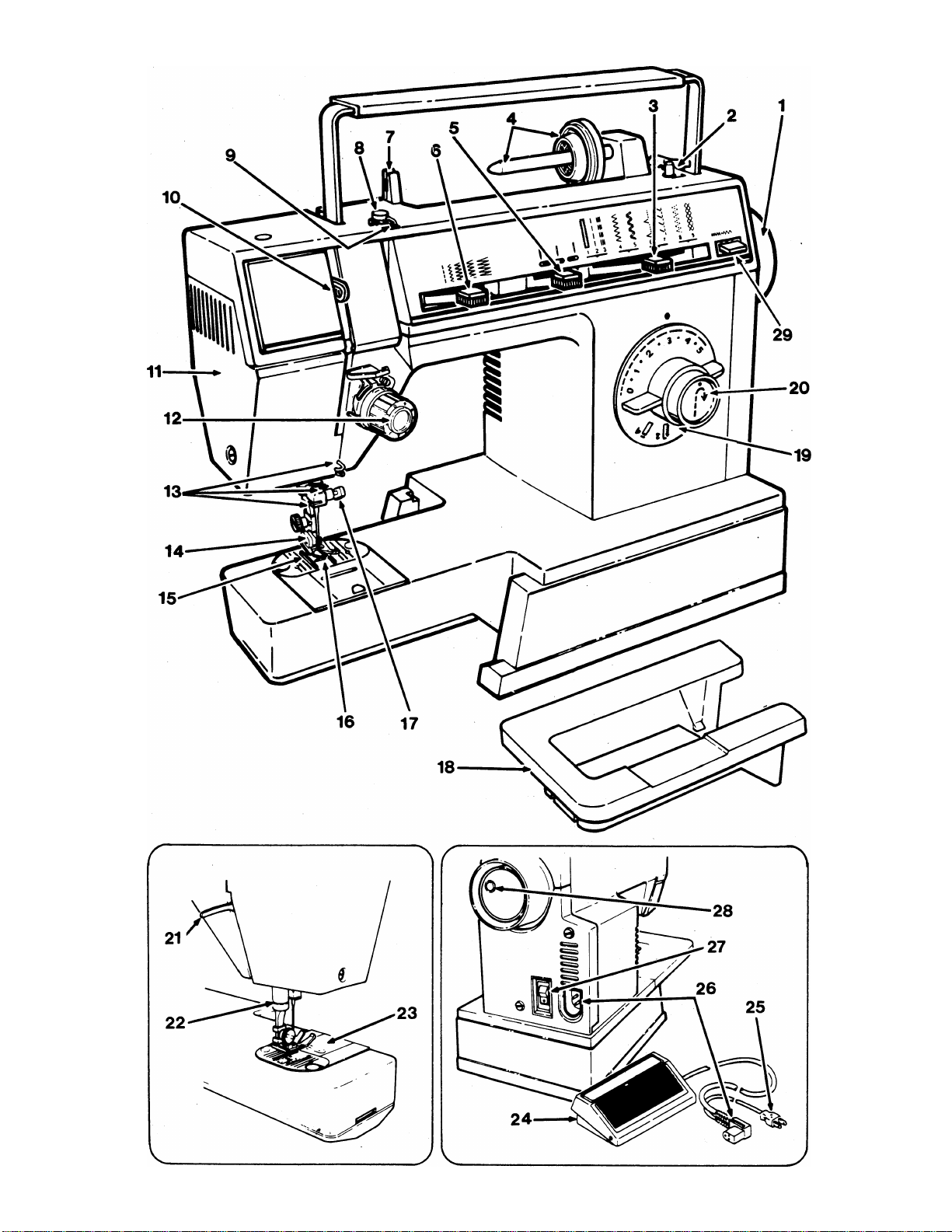

ACCCESSORIES

The following accessories furnished with your sewing machine are designed to

simplify your sewing projects and increase the versatility of your machine.

The letter you see next to the illus

trated part is actually on the part itself

and is to help you make sure your

selection is correct when sewing differ

ent applications.

1. SPECIAL PURPOSE PRESSER

FOOT (J) is used for decorative

and zig-zag sewing.

2. GENERAL PURPOSE NEEDLE

PLATE (A) and PRESSER FOOT

(B) are on your machine when

delivered. Usetogetherforalternat-

ing between straight and zig-zag

stitching.

3. BUTTONHOLE PRESSER FOOT

(L) is used with the General Pur

pose Needle Plate to make fourstep buttonholes.

4. ZIPPERFOOT(E) isusedforinserting zippers and stitching corded

seams.

5. FRICTION FREE SPOOL HOLDER

is used to hold various size spools

and allows thread to unwind

smoothly. The spool does not turn.

6. SMALL THREAD SPOOL

HOLDER (Q) for use with small

diameter spools of thread.

7. NEEDLE PACK includesan assort

ment for sewing various types of

fabrics.

8. FEED COVER (F) is used to pre

vent the feed from moving the

fabric when darning or free motion

embroidery.

9. TRANSPARENT BOBBINS for

easy viewing of thread supply.

10. BLINDSTITCH HEM GUIDE, is

used to position the hem for blindstitch hemming.

2. GETTING READY TO SEW

IMPORTANT SAFEGUARDS

1. Remove plug from the socket outlet when changing needles, feet, or

needle plates, or when leaving the machine unattended. This eliminates

the possibility of starting the machine by accidentally pressing the speed

controller.

2. Before removing the bobbin case, remove plug from the socket outlet.

3. Because of the up and down movement of the needle, you must work

carefully and watch the sewing area when operating the machine.

4. Do not pull the fabric while you are stitching as this may deflect the

needle, causing it to break.

5. Before cleaning your machine, remove plug from the socket outlet.

6. Do not attempt to adjust the motor belt. Contact your nearest Service

Center or an authorized Singer dealer should any adjustment be

required.

7. Before changing light bulb, make sure you have removed plug from

socket outlet. Be sure to replace the face plate which covers the light

bulb before operating the machine.

8. This machine is designed to use a 15-watt maximum light bulb.

This product is suppressed for radio and television interference with the

International Electro-technical Commission requirements of the CISPR.

Machines for Great Britain and some other countries having similar wiring

standards are shipped from the factory without a plug for connection to the

mains. The wires in this mains lead are coloured in accordance with the

following code:

Blue: neutral (N) Brown: live (L)

As the colours of the wires in the mains lead of this appliance may not

correspond with the coloured markings identifying the terminals in your

plug, proceed as follows:

The wire which is coloured blue must be connected to the terminal which is

marked with the letter N or coloured black. The wire which is coloured

brown must be connected to the terminal which is marked with the letter L or

coloured red. If a 13 Amp. (BS 1363) plug is used, a 3 Amp. fuse must be

fitted, or if any other type of plug is used, a 5 Amp. fuse must be fitted either in

the plug or adaptor or at the distribution board.

Neither core is to be connected to the earth terminal of a three-pin plug.

A

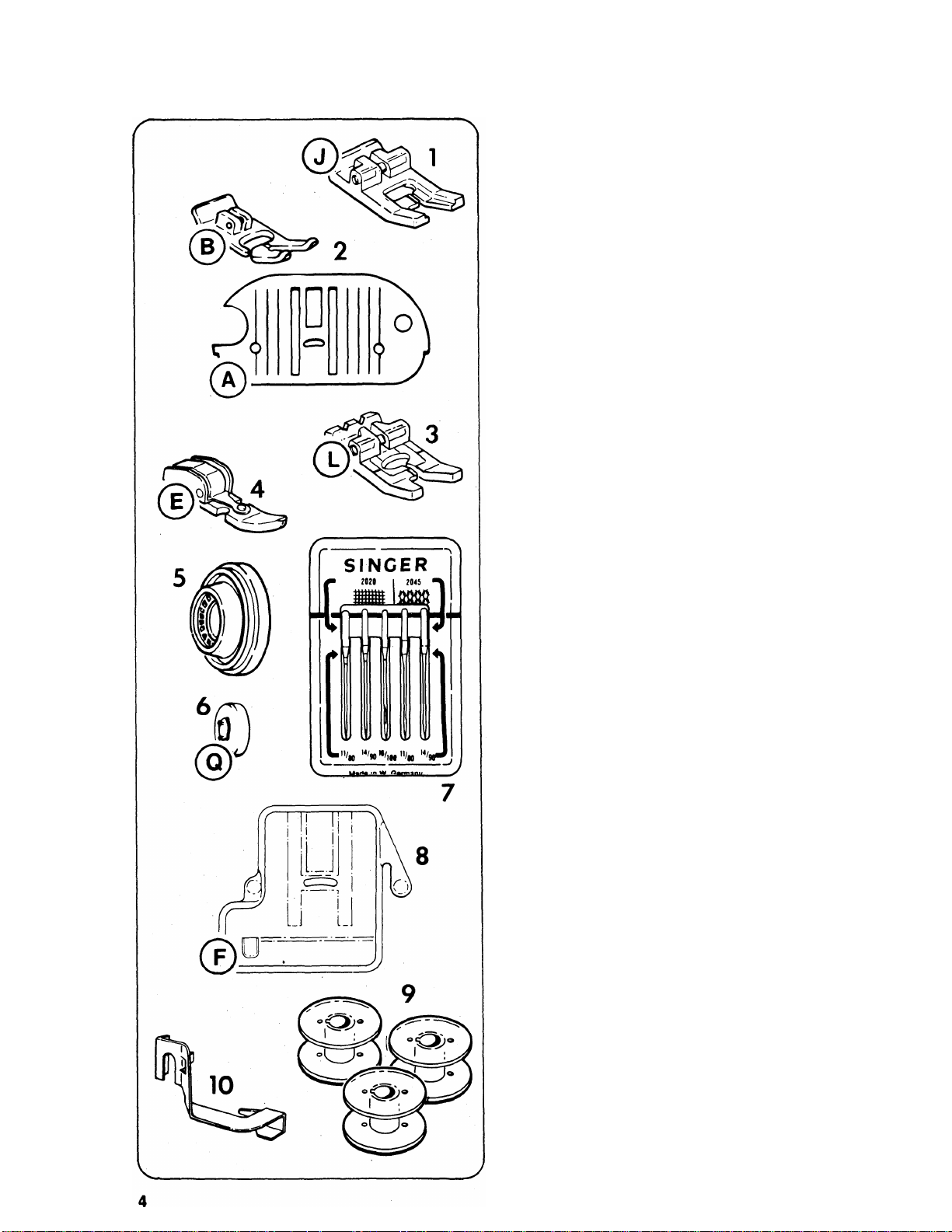

OPERATING THE MACHINE

Connecting the machine

Push plug (1) into the receptacle (2)

at the right end of the machine. Then

connect plug (3) to your socket outlet.

Running the machine

To turn on machine and sewing light,

press upper portion of power switch

(4). To turn off machine and light, press

lower portion “0” of power switch.

To run the machine and control

speed, press the speed controller (5)

with your foot. The harder you press,

the faster the machine will sew. To stop

machine, remove foot from controller.

NOTE: Do not operate machine without

fabric under the presser foot as this

may damage the feed and the presser

foot.

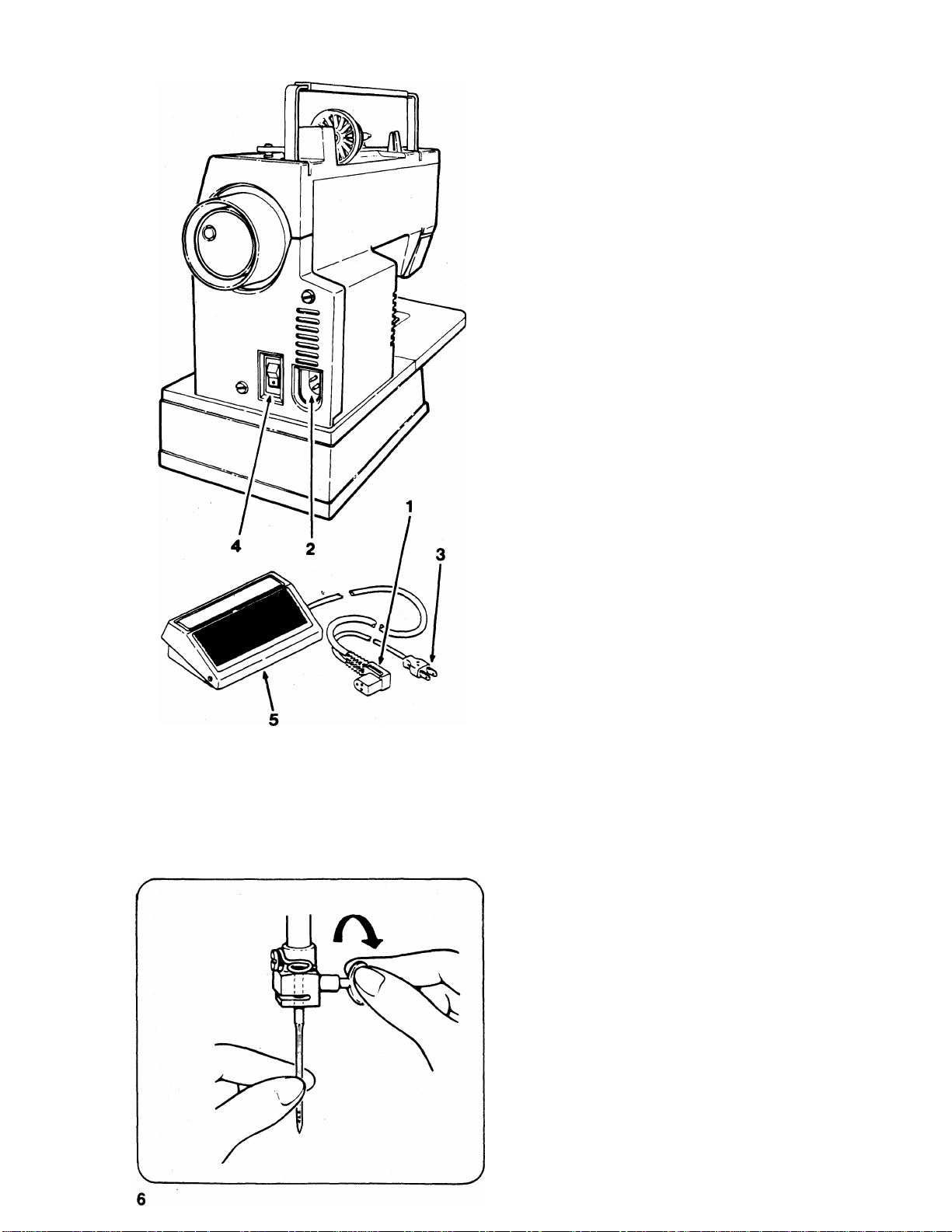

CHOOSING AND CHANGING NEEDLES

IMPORTANT:

For best results from your sewing machine, use only Singer needles. Check the

needle package, and the Fabric, Thread and Needle Table on page.9 for the correct

needle and fabric combination.

• Raise needle to its highest position.

• Loosen needle clamp screw and

remove needle.

• With flat side of needle to the back,

insert new needle up Into clamp as

far as it will go.

• Tighten needle clamp screw se

curely.

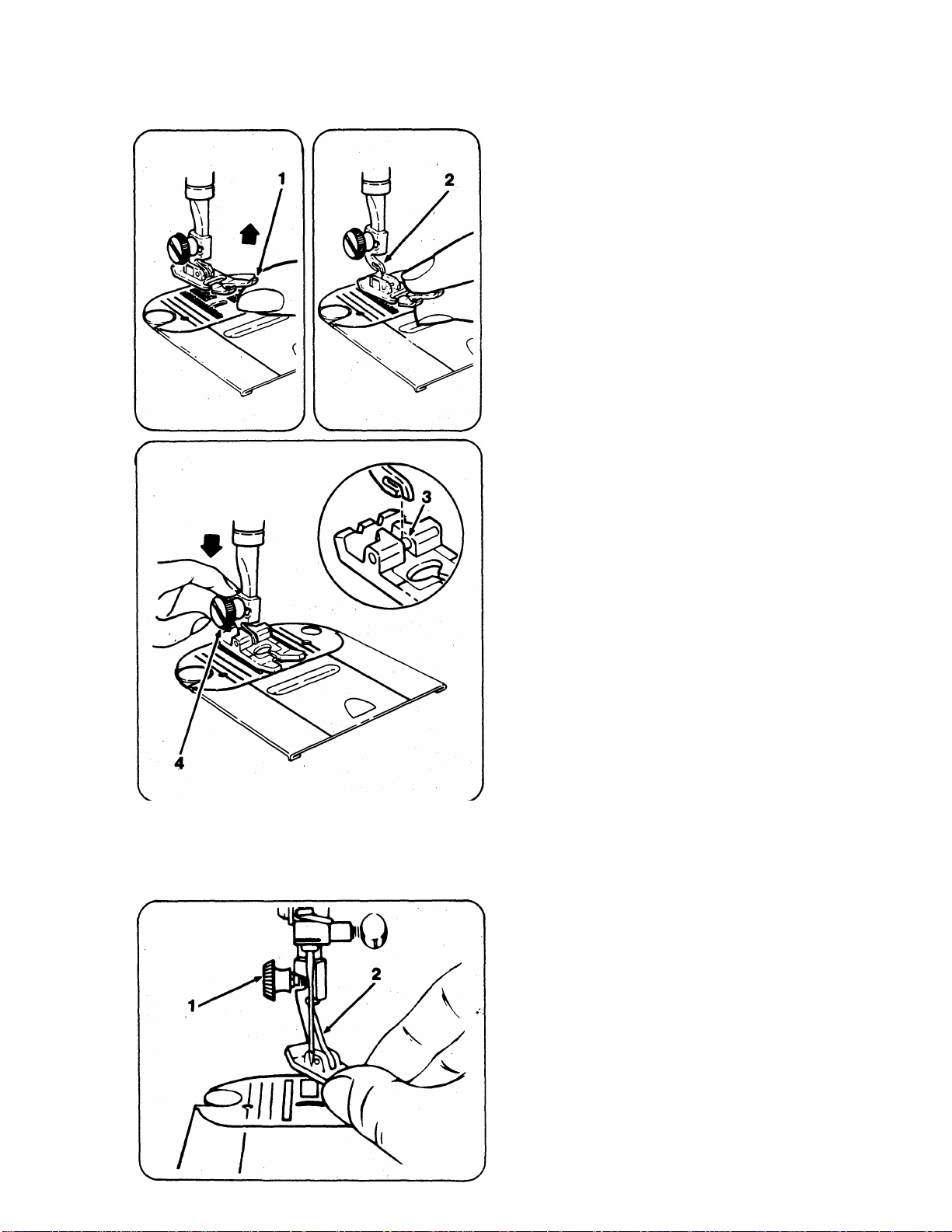

CHANGING SNAP-ON PRESSER FEET (B),(D),(J),(L)

Your machine comes with the General Purpose Presser Foot (B) already attached.

You can easily change to any one of the other presser feet which snap onto a com

mon shank by following the directions below.

Raise needle to its highest position

by turning hand wheel toward you.

Raise presser foot using presser foot

lifter at back of machine.

Push toe of presser foot (1) up, until it

snaps off the shank (2).

Remove foot from machine.

• Place new foot under center of

shank.

• Lower presser foot lifter, fitting shank

over presser foot pin (3).

• Don't turn screw. Instead, push

presser foot screw (4) down, firmly

until foot snaps into place.

CHANGING SCREW-ON PRESSER FEET (H),(G)

Some special presser feet can be purchased at your sewing center which have built-

in shanks that can be replaced as follows:

• Raise needle and presser foot.

• Loosen presser foot screw (1) and

remove presser foot with shank (2),

guiding it toward you and to the right.

• To replace presser foot with shank,

hook shank around the presser bar

and tighten presser foot screw with

the use of a coin.

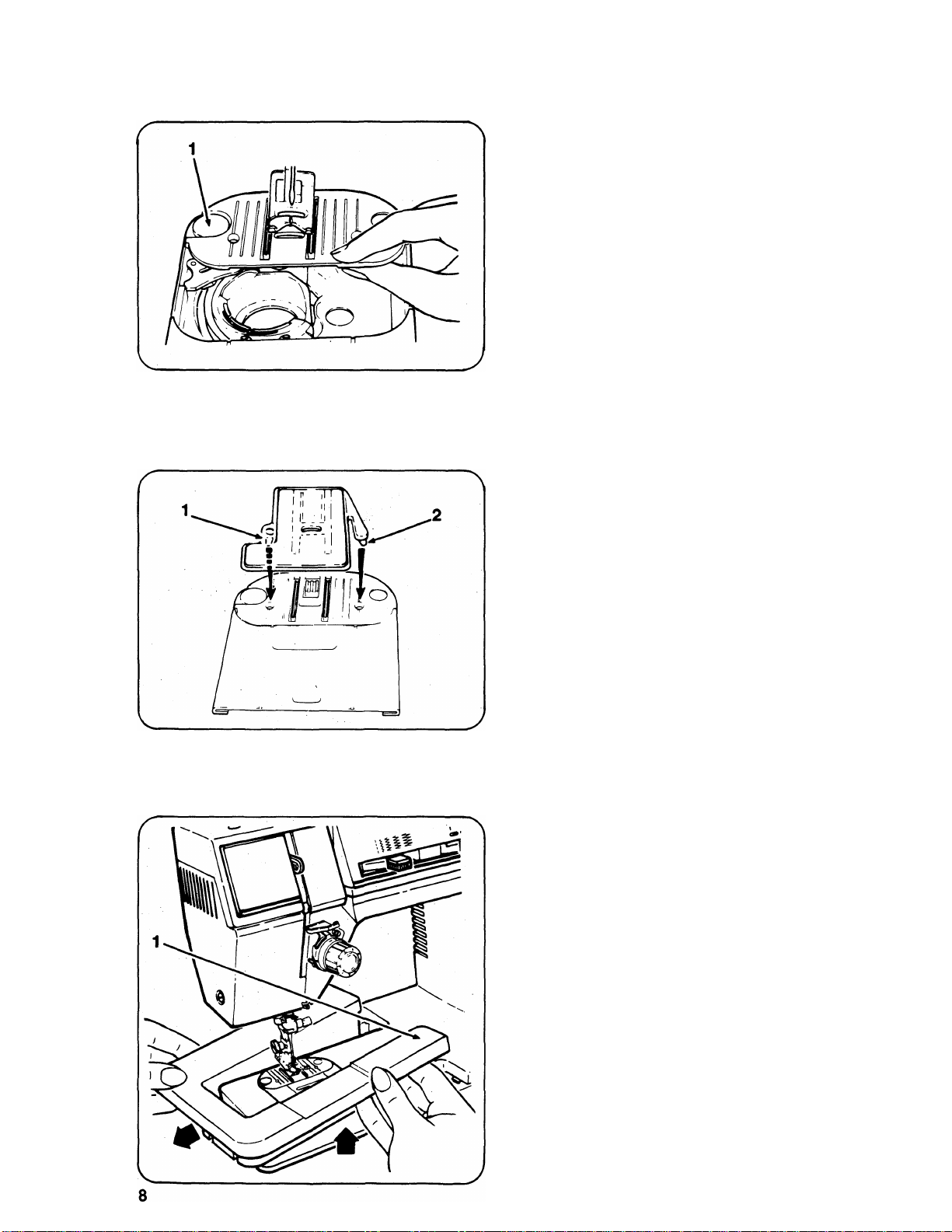

CHANGING THE NEEDLE PLATE (A),(C)

Your machine comes with the General Purpose Needle Plate (A) attached. The

Straight Stitch Needle Plate (C) may be purchased at your sewing center and can be

attached as follows:

• Raise needle and presser foot.

• Open slide plate.

• Lift up needle plate from right corner

and slide out from under foot.

• To replace needle plate, slide it

under pin (1) and push it firmly to the

left.

• Press down until It snaps Into place.

ATTACHING THE FEED COVER (F)

The feed cover is used to keep the feed from moving the fabric when attaching a

button, darning or sewing free-motion embroidery. To attach It, follow the directions

below:

• Raise needle and presser foot.

• Open slide plate.

• Slide feed cover on top of needle

plate, pressing tabs (1) and (2) into

holes.

• Close slide plate.

• To remove, open slide plate and lift

front edge of cover; pull It away.

REMOVING THE EXTENSION TABLE

Free arm sewing makes it easier to sew hard-to-reach areas.

To change machine for free arm

sewing, lift right edge (1) of extension

table, slide it to the left and off the

machine.

To replace the extension table, slide

It to the right keeping it even with the

free arm, until the tabs on the right lock

Into place.

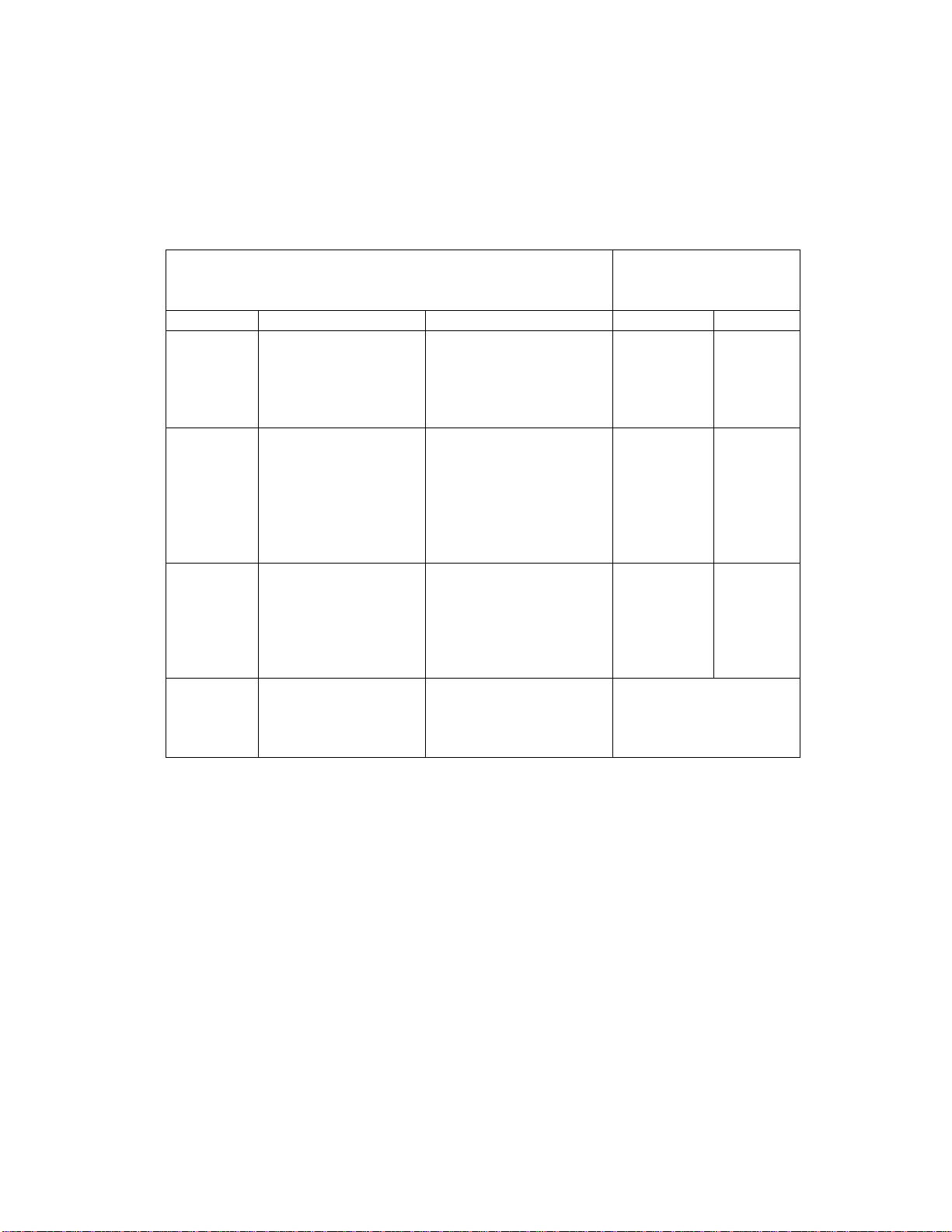

FABRIC, THREAD AND NEEDLE TABLE

The needle and thread you choose will depend upon the fabric being

sewn. The table below is a practical guide to needle and thread selection.

Always refer to It before beginning a sewing project. Be sure to use the

same size and type of thread In both needle and bobbin.

The fabrics below can be of any fiber: cotton, linen,

silk, wool, synthetic, rayon, blends. They are listed as

examples of weight.

FABRICS

LightWeight

Batiste

Chiffon

Crepe

Medium-

Weight

Corduroy

Flannel

Gabardine

' Gingham

i

Linen

Muslin

Wool Crepe

MediumHeavy

Bonded Wovens

Canvas

Coating

Denim

Duck

Sailcloth

Knits Bonded Knits

Double Knit

Jersey

Tricot

tNot recommended on stretch fabrics

THREAD TYPE

Cotton-wrapped

Polyester

100% Polyester

fMercerized Size 50

Nylon

Cotton-wrapped

Polyester

100% Polyester

fMercerized Size 50

Nylon

Cotton-wrapped

Polyester

100% Polyester

fMercerized Size 40

f"Heavy Duty"

Cotton-wrapped

Polyester

Polyester

Nylon

Ball-Point 2045

Size 11/80,14/100,

NEEDLES

SIZE

2020

2020

2020 16/100

2020

11/80

14/90

18/110

16/110

J

9

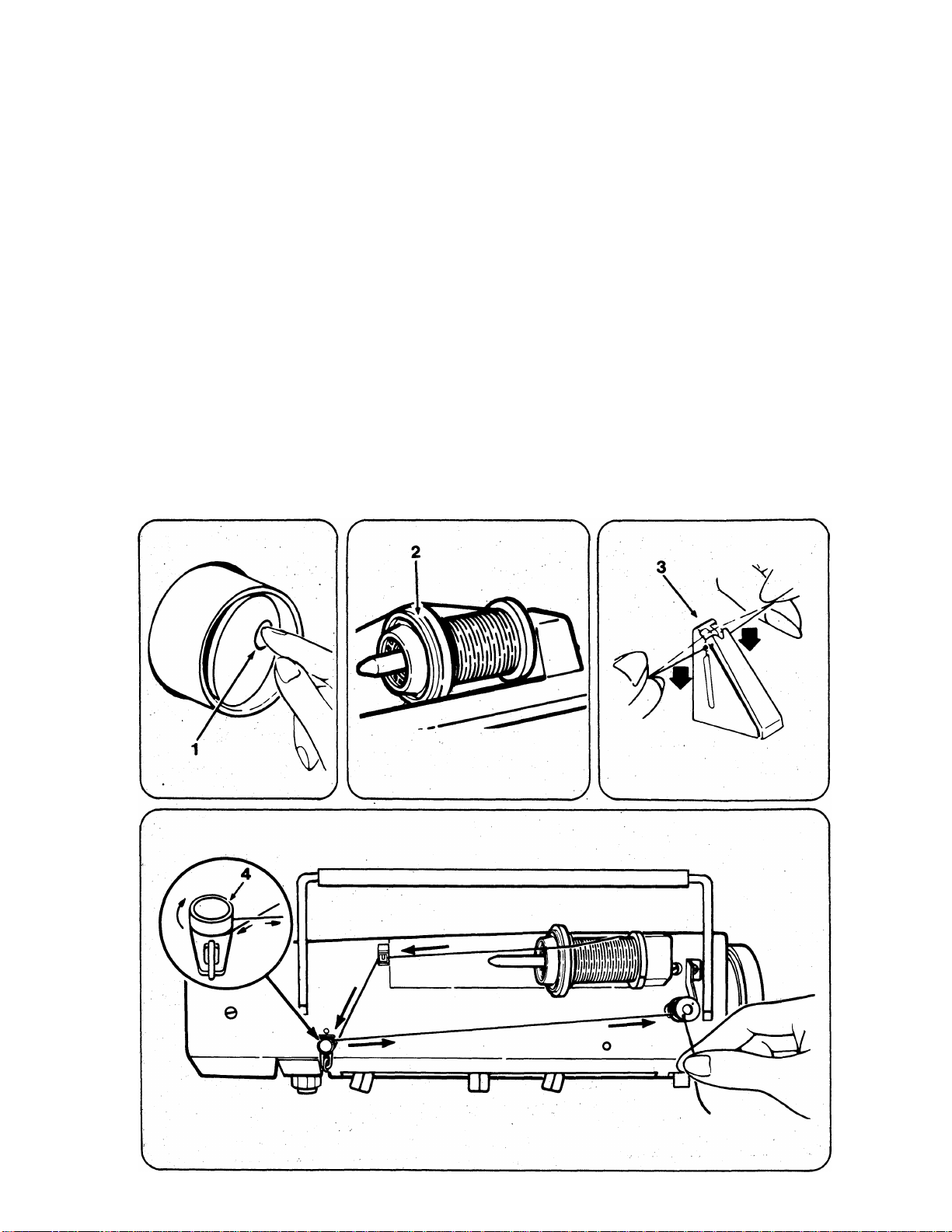

WINDING A BOBBIN

Winding a bobbin is quick and easy when you follow the directions below. Always

wind the bobbin before threading the machine and needle.

• Push in indent (1) on hand wheel disc. This will stop the needle from movmg.

• Place spool of thread on spool pin.

• Slide spool cap (2) firmly over rim of spool to prevent thread tangling.

• Lead thread from spool and snap into thread guide post (3).

• Wind thread clockwise around front of bobbin winder tension disc (4).

• Pass thread end, from inside, through small hole in rim of bobbin.

• Place bobbin on spindle and push It to the right.

• Holding thread end, step on speed controller to run machine until desired amount

of thread Is wound. (Winding stops automatically once bobbin is full.)

• Cut thread; push bobbin to the left and remove it from spindle.

• Trim thread end from top of bobbin.

• Return hand wheel disc to sewing position by pressing on side opposite indent.

10

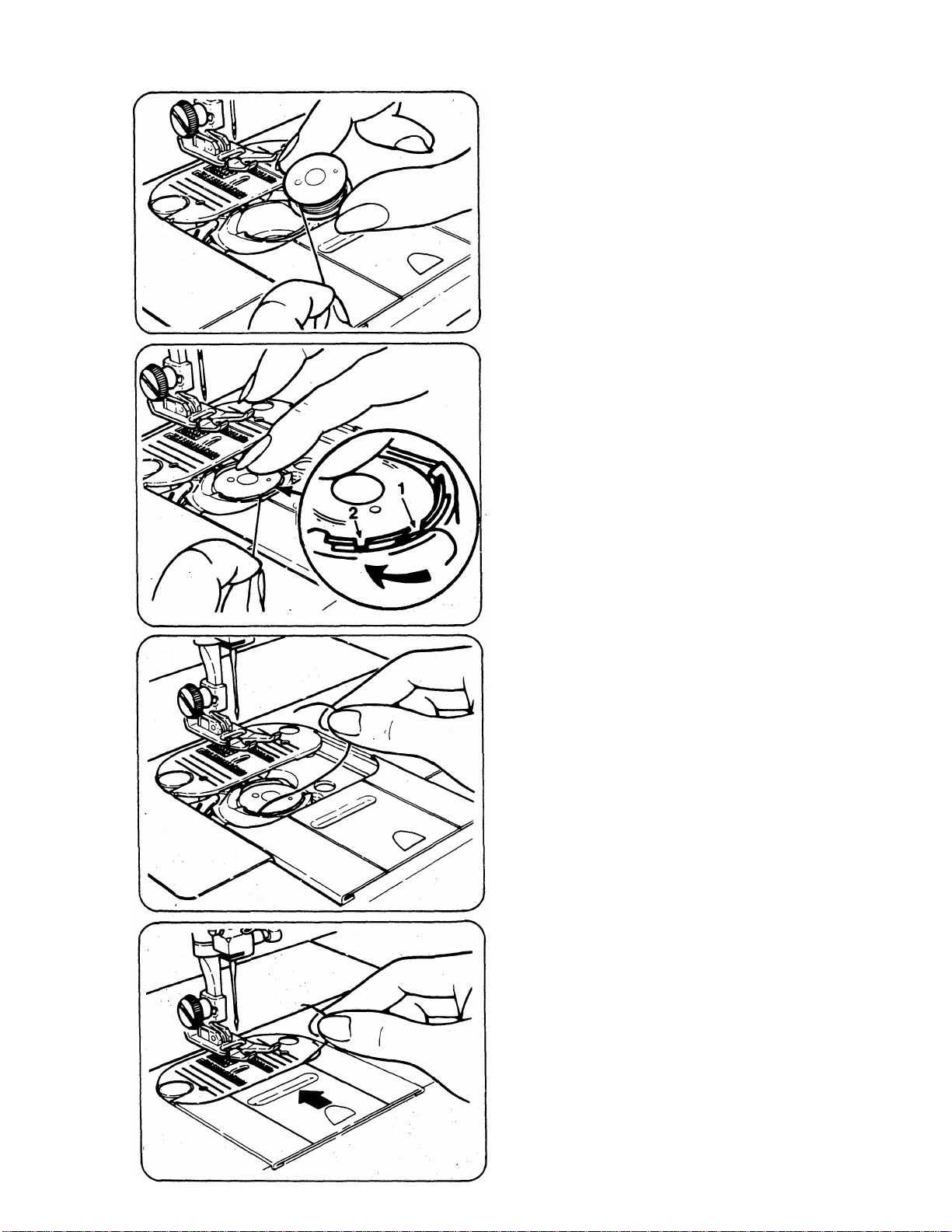

INSERTING A BOBBIN

To insert a bobbin, follow the instructions below:

> Raise presser foot.

• Turn hand wheel toward you until

needle is in its highest position.

• Open slide plate and remove empty

bobbin.

1. Pull 4" (10cm) of thread from

replacement bobbin and insert

bobbin into case, as shown.

2. Holding bobbin in place, guide

thread into notch (1) and then down

the slot to the left and guide around

Into notch (2).

3. Draw several inches of thread

diagonally across the bobbin

toward the back of the machine.

4. While holding thread on outside,

close the slide plate, allowing

thread to extend through the slot

between the slide plate and needle

plate.

• Follow directions for “Raising

Bobbin Thread” on page 13.

11

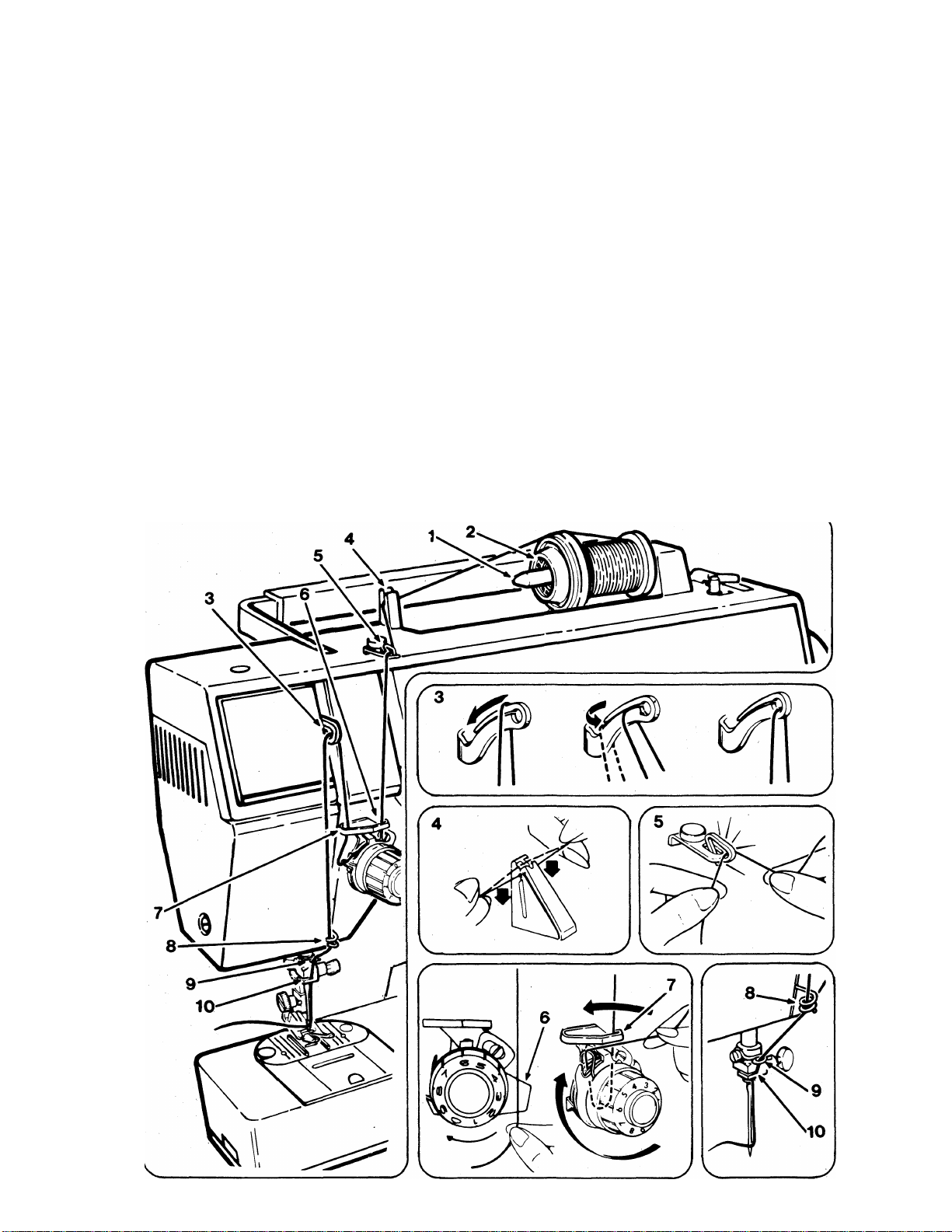

THREADING THE MACHINE

To thread your machine correctly, follow the steps below;

• Raise take-up lever (3) to highest position by turning hand wheel toward you.

• Raise presser foot to release thread tension.

• Place spool of thread on spool pin (1).

• Slide spool cap (2) firmly over rim of spool to prevent thread tangling.

• Lead thread from spool and snap into thread guides (4) and (5).

• Thread the tension discs by leading thread down against the tab (6), as shown,

around the tension discs and up under the spring on the left side. Hold the

spool lightly with finger, pull thread gently up and to the right, lifting the spring

and allowing thread to slip into thread guard. Then, lead thread up behind

thread guide (7).

• Slip thread into take-up lever as Illustrated (3).

• Pass thread through guides (8) and (9).

• When sewing heavier weight threads, do not thread the lower thread guide (10).

• Thread needle from front to back, pulling 4” (10cm) of thread through eye.

12

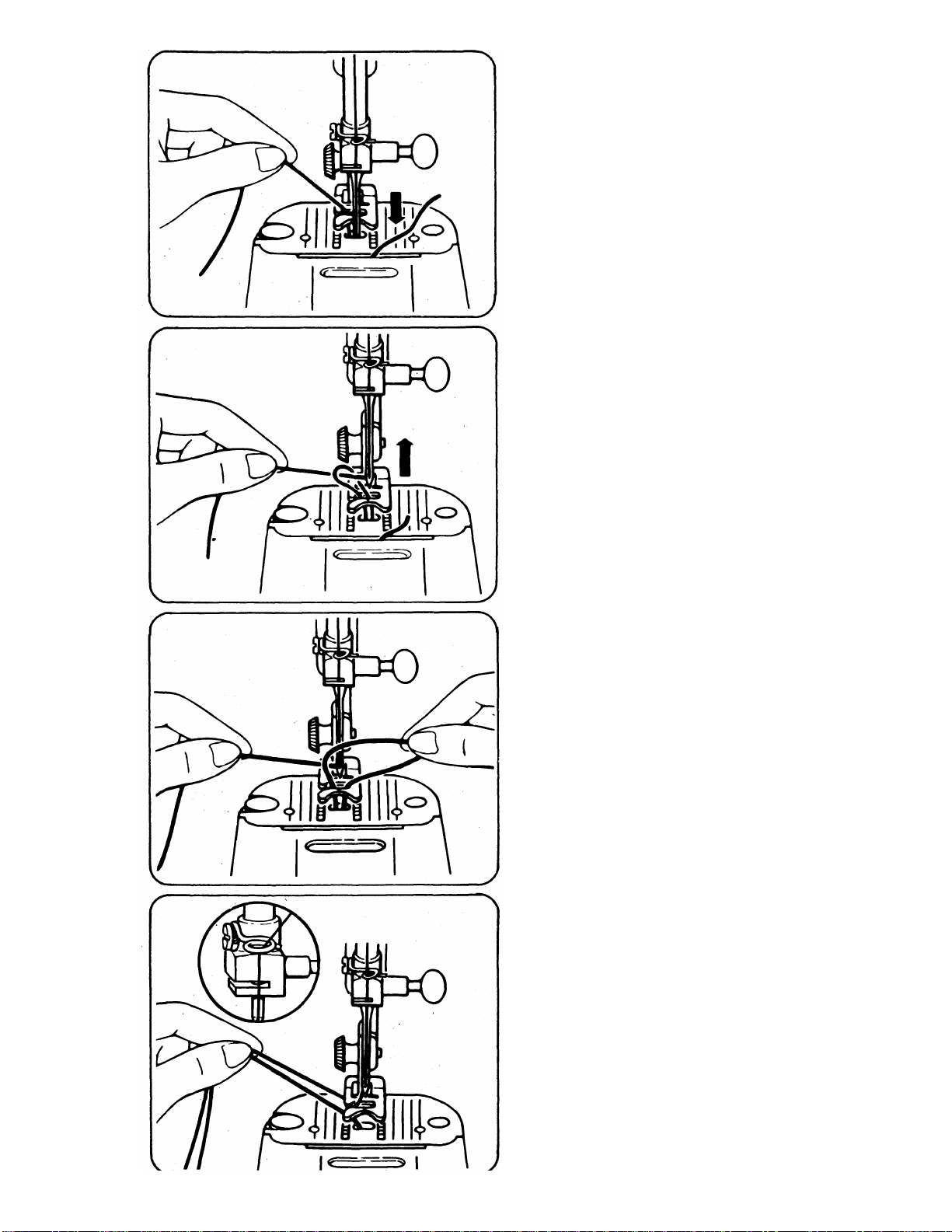

RAISING THE BOBBIN THREAD

Once the needle has been threaded

and the bobbin placed in the bobbin

case, the bobbin thread must be brought

up through the hole in the needle plate.

1. Hold needle thread loosely with left

hand.

• Turn hand wheel slowly toward

you, lowering needle into hole in

plate.

2. Continue to do this until needle

rises above needle plate.

• Pull gently on needle thread and

bring up bobbin thread in a loop.

3. Open loop with fingers to find end

of bobbin thread.

4. Draw needle thread through left

side opening in presser foot.

• Pull both threads to back of ma

chine.

• When sewing with heavier weight

thread, do not thread the lower

thread guide no. 10.

13

Loading...

Loading...