SINGER 6136 User Manual

Copyright © 1979 THE SINGER COMPANY

All rights reserved throughout the world

CONTENTS

Page

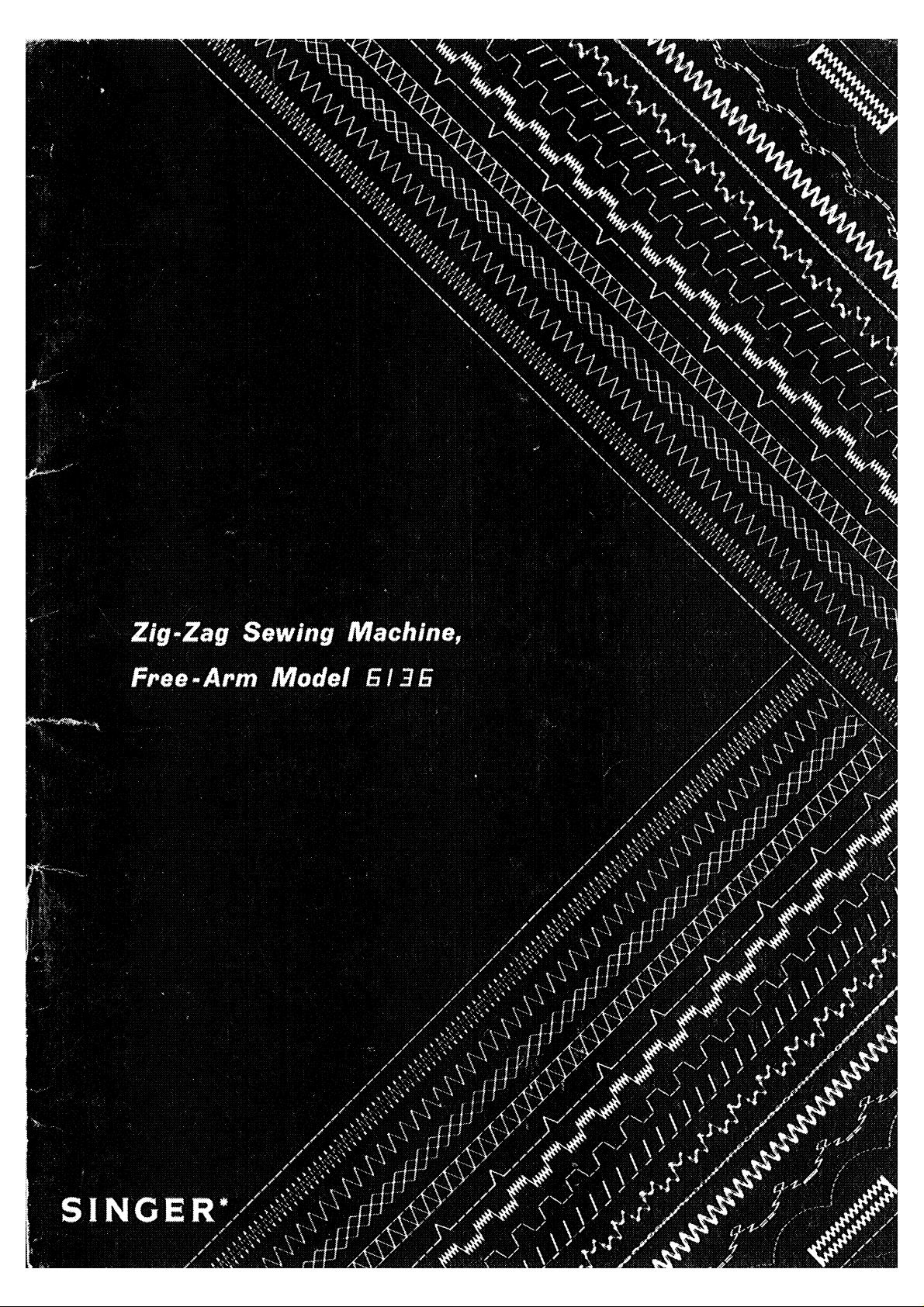

Chapter 1. Getting to Know Your Machine ............................................................................................................................ 2

Principal Parts....................................................................................................................................................2

Accessories....................................................................................................................................................... 3

Chapter 2. Getting Ready to Sew............................................................................................................................................ 4

Choosing and Changing Accessories............................................................................................................ 4

Fabric Weight Table..................................................................................................................................6

Fabric Thread and Needle Table..............................................................................................................8

Needle-Fabric Combinations..........................................................................................................................10

Operating the Machine....................................................................................................................................10

The Bobbin Thread........................................................................................................................................ 11

Winding the Bobbin • Threading the Bobbin Case

Threading the Machine....................................................................................................................................13

Raising the Bobbin Thread

Chapter 3. Straight Stitching............................................................................................................................................15

Adjusting Machine Stitch to Suit Your Fabric

Setting Selectors • Regulating Presser Foot Pressure •

Adjusting Stitch Length • Needle-Thread Tension

Sewing a Seam.................................................................................................................................................17

Keeping the Seam Straight

Applications ....................................................................................................................................................18

Zipper Insertion • Darning

Chapter 4. Basic Zig-Zag Stitching..................................................................................................................................19

Adjusting Machine to Suit Your Fabric......................................................................................................... 19

How to Set Selectors • Pattern Group Selector •

Needle Position Selector • Stitch Width Selector • Adjusting Needle Tension •

Adjusting Stitch Length • Adjusting Presser Foot Pressure

Satin Stitching.................................................................................................................................................21

Applications .................................................................................................................................................... 22

Appliqué • Lingerie Seams • Zig-Zag Seam Finishes

.............

................................................................................15

Chapter 5. Machine Stitch Patterns.................................................................................................................................24

Setting Selectors............................................................................................................................................. 24

Selecting a Pattern Group • Adjusting Width of the Design • Adjusting Stitch

Placement • Adjusting Stitch Length • Adjusting Stitch Balance

Adjusting Stitches to Suit Stretch Fabrics .

Guiding and Supporting Fabric • Adjusting Pressure

Stitch Pattern Chart.........................................................................................................................................28

Applications ....................................................................................................................................................29

Blindstitch....................................................................................................................................................... 29

Hems

Multi Stitch Zig-Zag.........................................................................................................................................30

Bar Tacks • Mending a Tear

Honeycomb Stitch......................................................................................................................................... 31

Attaching Elastic

Chapter 6. Buttonholes and Buttons.............................................................................................................................. 32

Four-Step Buttonholing................................................................................................................................. 32

Changing Stitch Density

Buttons............................................................................................................................................................ 34

Chapter 7. Twin-Needle Stitching.................................................................................................................................... 35

Chapter 8. Free-Arm Sewing.......................................................................................................................................... 36

Chapter 9. Performance Checklist................................................................................................................................... 37

Chapter 10. Caring for Your Machine....................................................................................................................................38

Index ........................................................................................................................................................................................40

................

................................................................................27

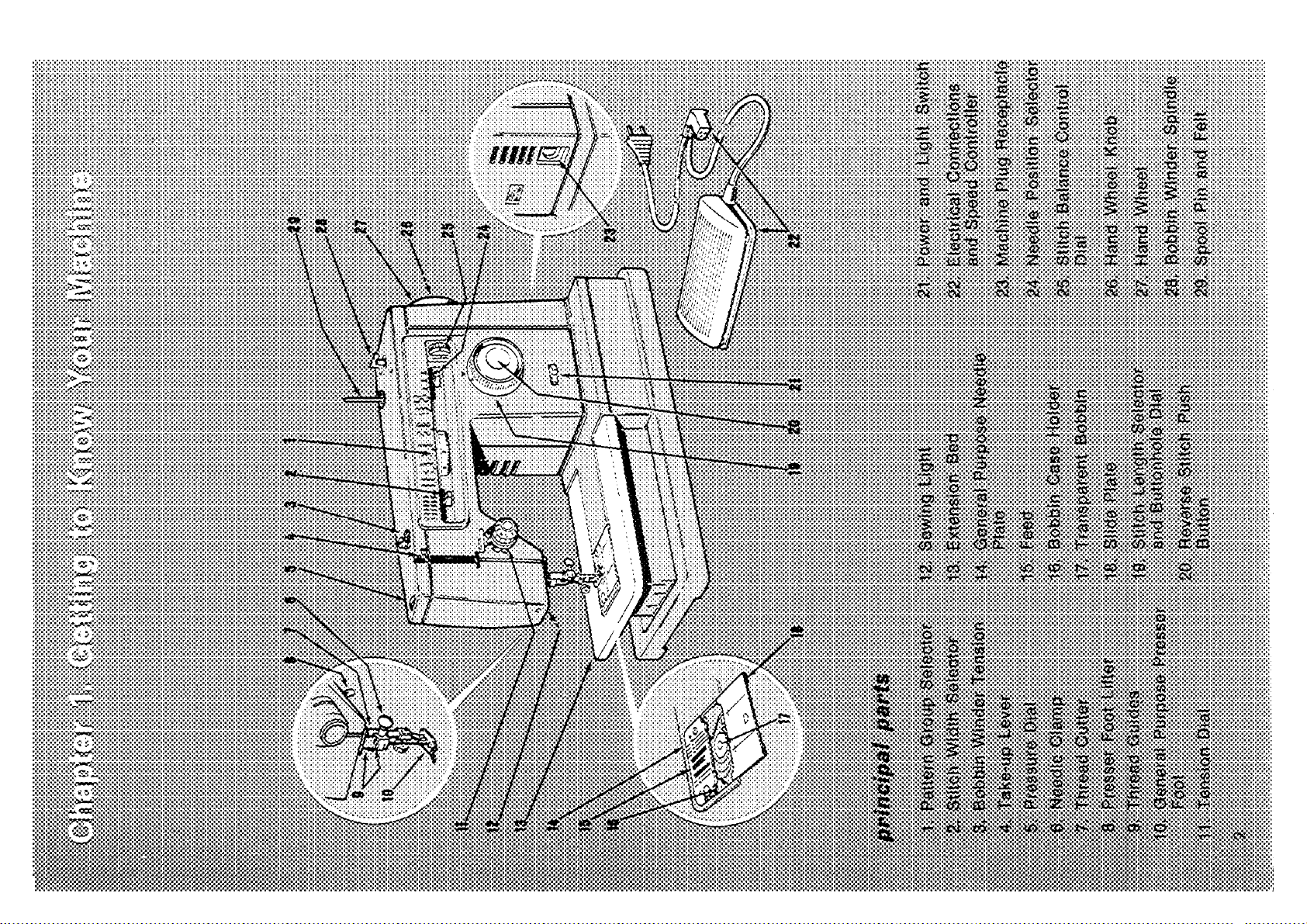

f^ccessonos

The accessories that como with your sowing

machine are designed to heip you do many

kinds of sewing easily.

1. Transparent Bobbins (No. 172336).

2. Needles

• Style 2020 for general sewing.

• Stylo 2045 is used for sewing knits»

stretch fabrics and elastic.

• Style 2025 for twin-needle decorative

stitching on woven and knit fabrics.

3. Buttonhole Foot is used to make bar tack

buttonholes of any length in four steps.

4. Special Purpose Foot, Used for all kinds

of decorative ?.ig-;iag stitching.

©

5. Zipper Foot for inserting zippers and stitch

ing corded seams.

6. General Purpose Foot on your machine

when delivered, is used for ail utility sew

ing, with either straight or z.ig-zag stitching,

7. General Purpose Needle Plate on your

machine when delivered is used with all

presser feet.

8. Snap-in Feed Cover for button sewing and

freo-motion work.

9. Spool Pin Extension used for tubes of

thread.

10. Blindstitch Hem Guido. Use this with the

genera! purpose foot to position and guide

the horn.

11. Detachable Spool Pin for decorative tv/in-

noedlo stitching and two-thread topstitching.

12. Felt to help thread unwind smoothly.

03

12

iSîmptMr Z:. Reaclÿ to kmw

choosing and changing accessories

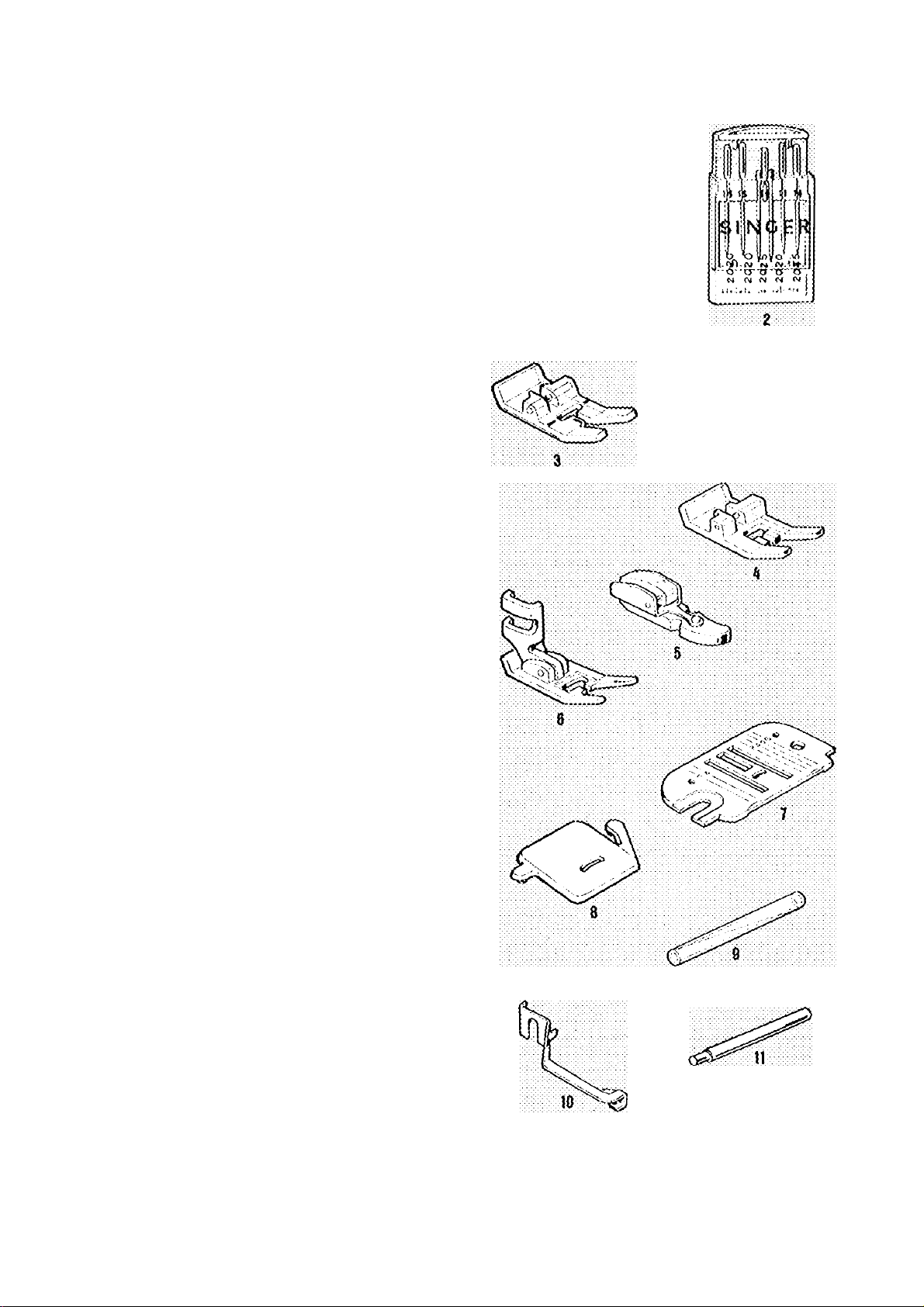

CHANGING THE NEEDLE

• Raise needle to its highest point by turning

the hand wheel toward you. Loosen needle

clamp screw A and remove the needle.

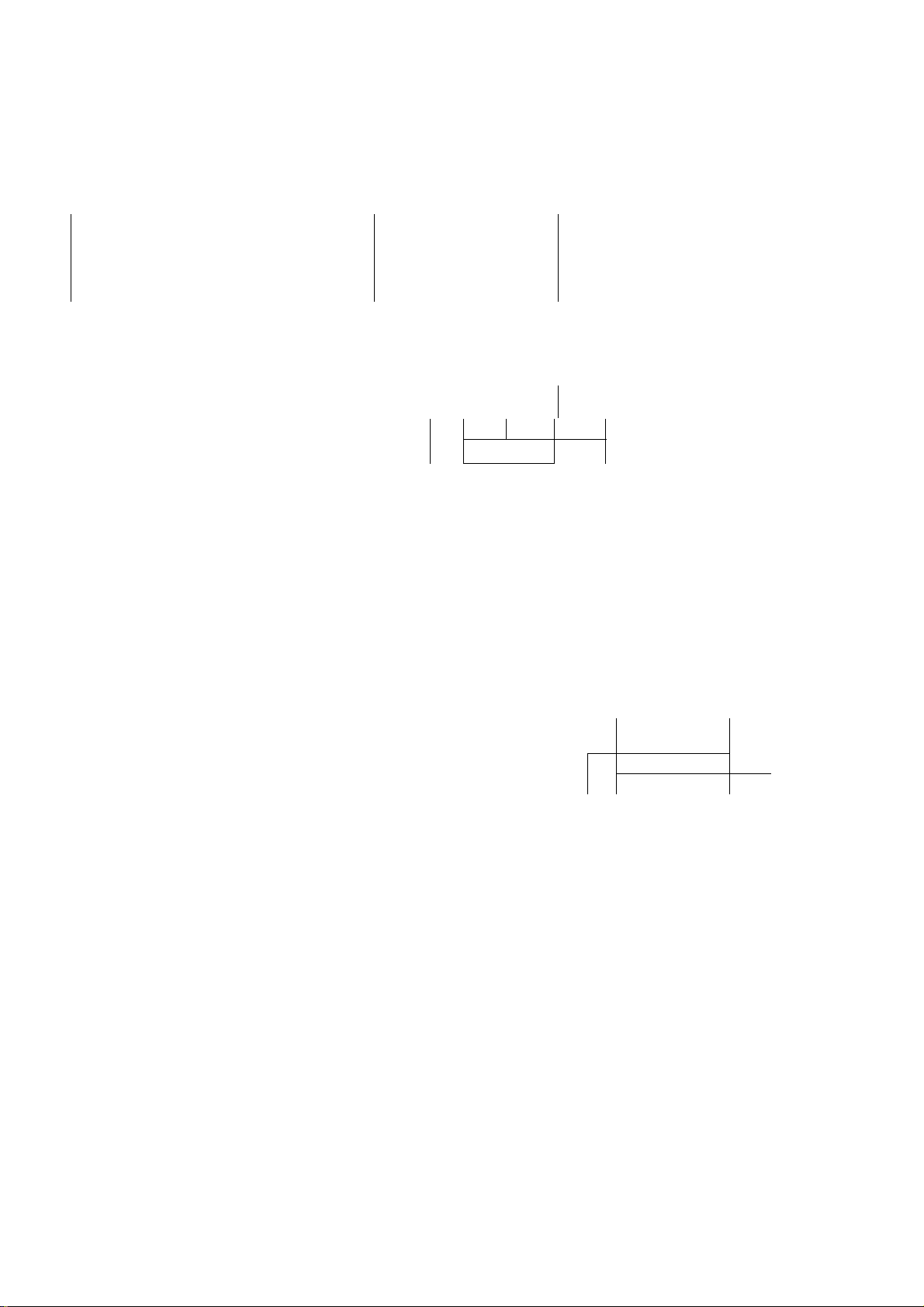

• Insert new needle up into clamp B as far

as it will go, with the flat side of the needle

to the back.

• Tighten noodle clamp screw.

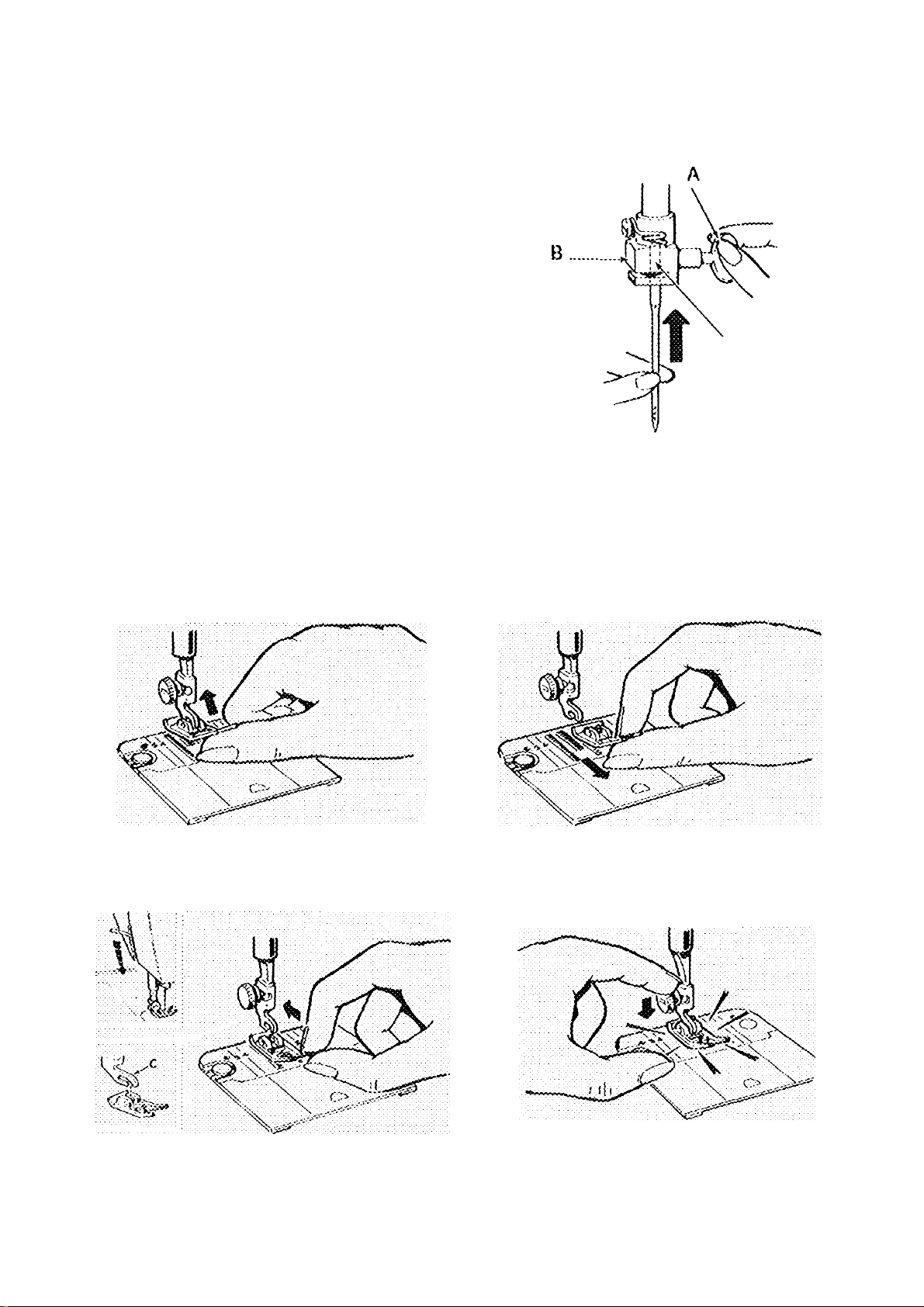

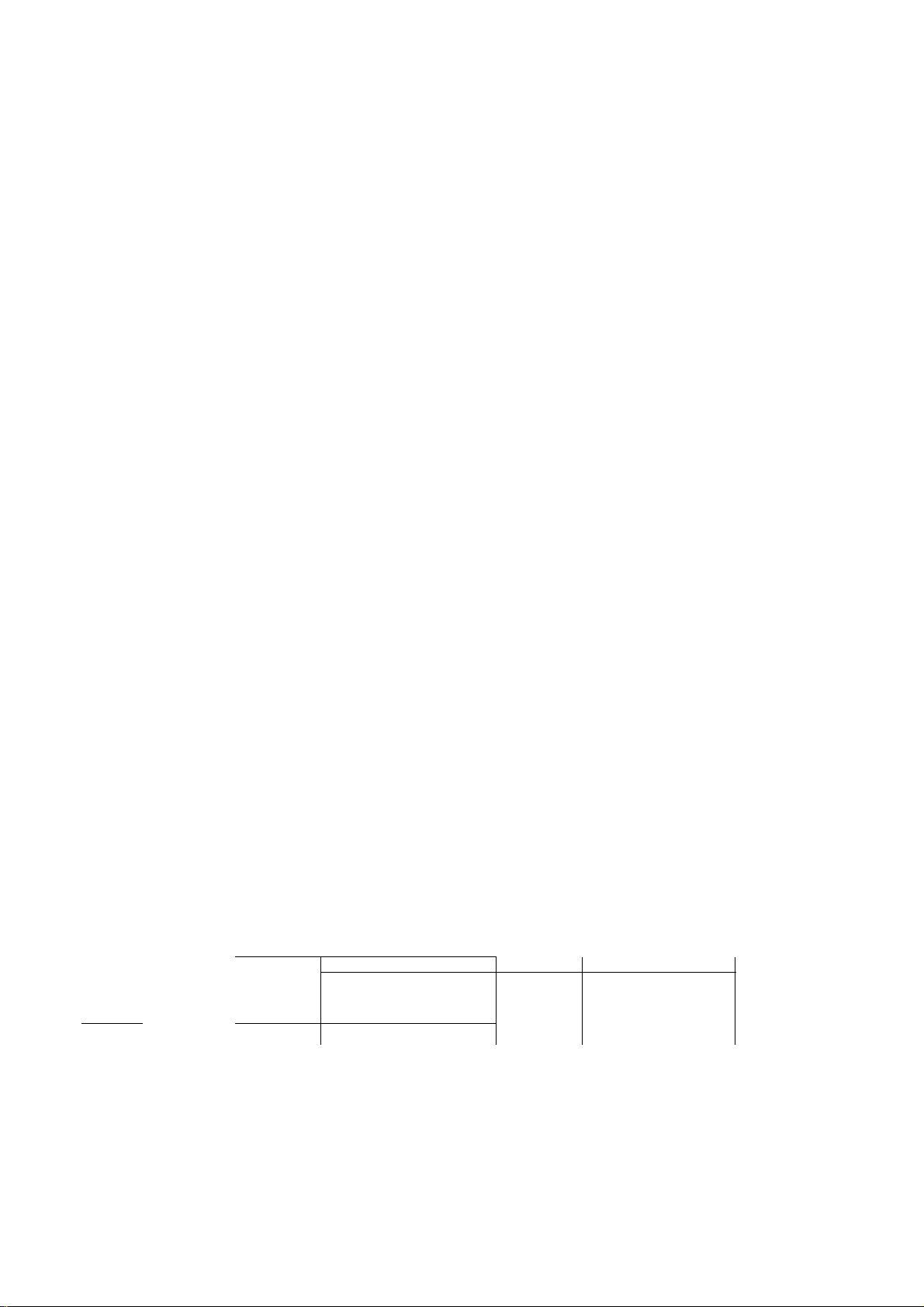

CHANGING PRESSER FEET

Snap-on Presser Feet

'ihe presser feet furnished with your machine liaise needle to highest position by turning the

snap on and off a common shank. hand wheel toward you. Raise pressor foot.

Flat Side to Back

To Remove and Replace Fool

fa. Press toe of presser foot upward as far as 1P. Then snap down to remove

it will go.

2. Centre the new pressor foot under tfie shank 3. Press pressor foot screw down firmiy until

C and towor tho proasor foot fifior so that foot snaps into placo.

the shank fits over the presser foot pin.

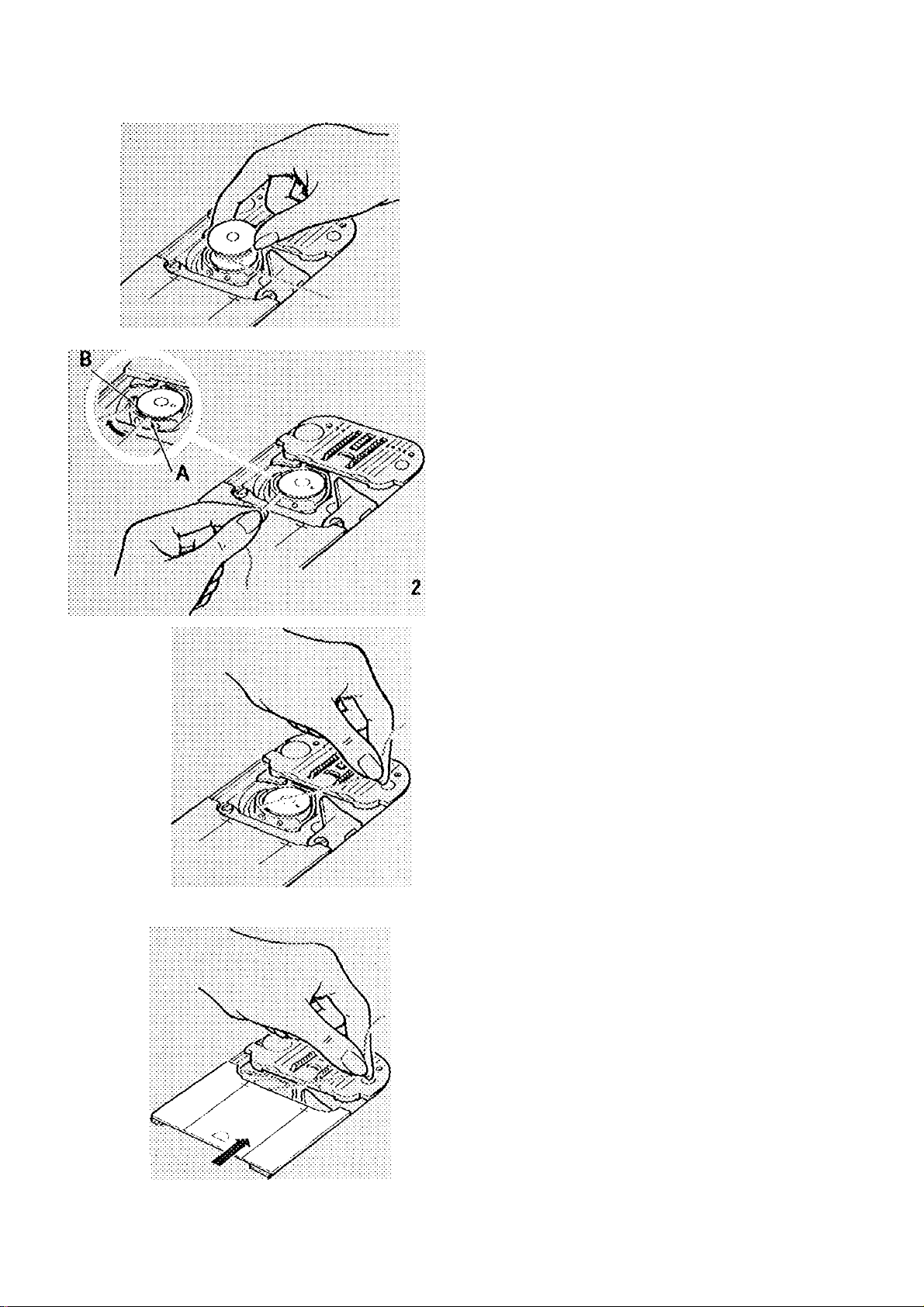

REMOVING AND REPLACING NEEDLE

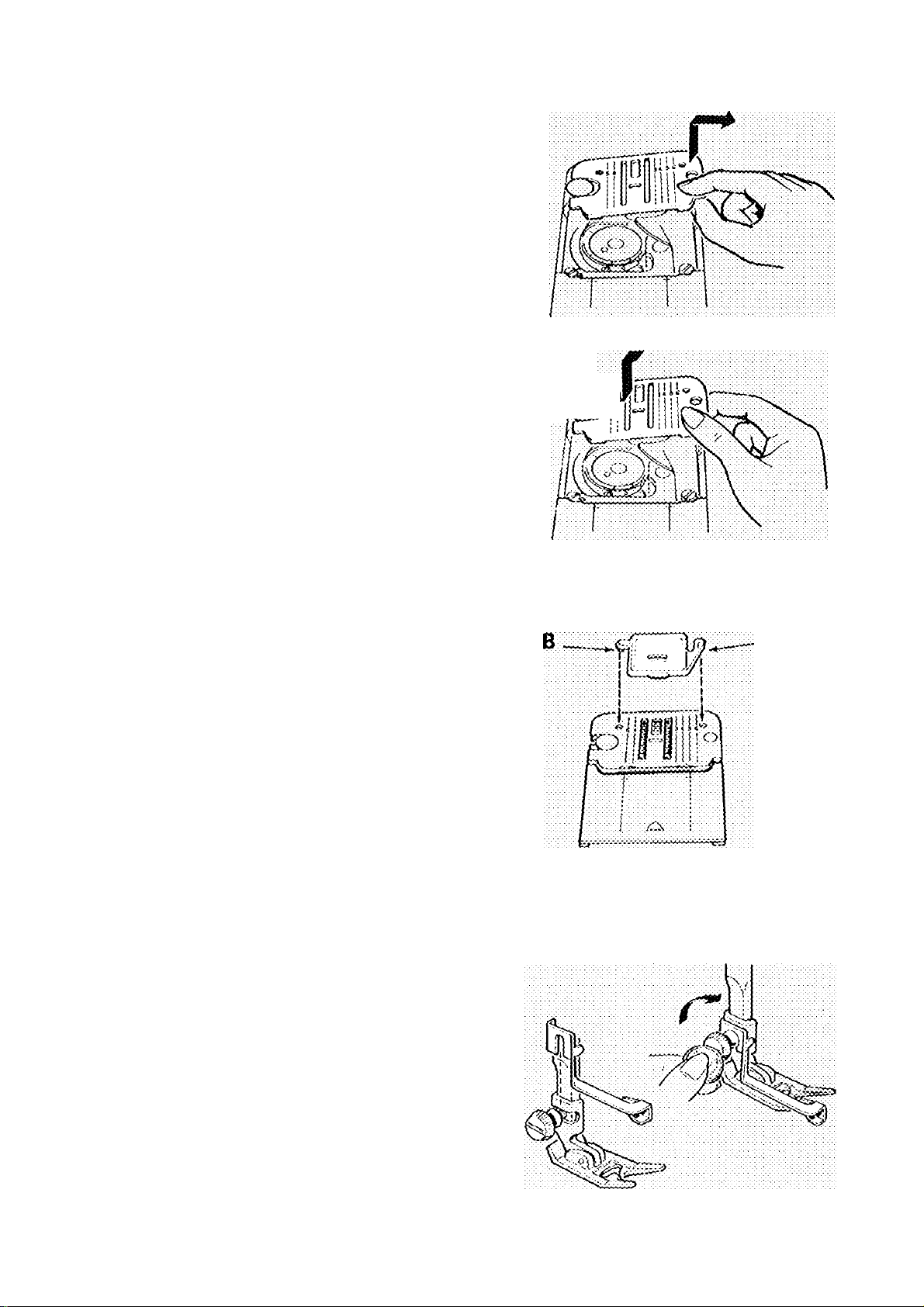

PLATE

• Raise pressor foot.

• Raise needle to highest position.

• Open slide plate. Place thumb under right

side of needle plate, lift it up and withdraw

it to right.

• Replace needle plate under clamping pin A.

push it gently to the left and press down

until it snaps Into place.

A

ATTACHING SNAP-IN FEED COVER

• Ftaise presser foot.

• Raise needle to highest position by turning

hand wheel toward you. Open slide plate.

• Slide snap-in feed cover away from you

over needle plate until points B and C are

positioned directly over holes in needle plate

as illustrated. Snap in point B. Then push

point C in toward point B until it snaps into

place. Close slide plate. To remove, open

slide plate then simply lift up front edge of

feed cover.

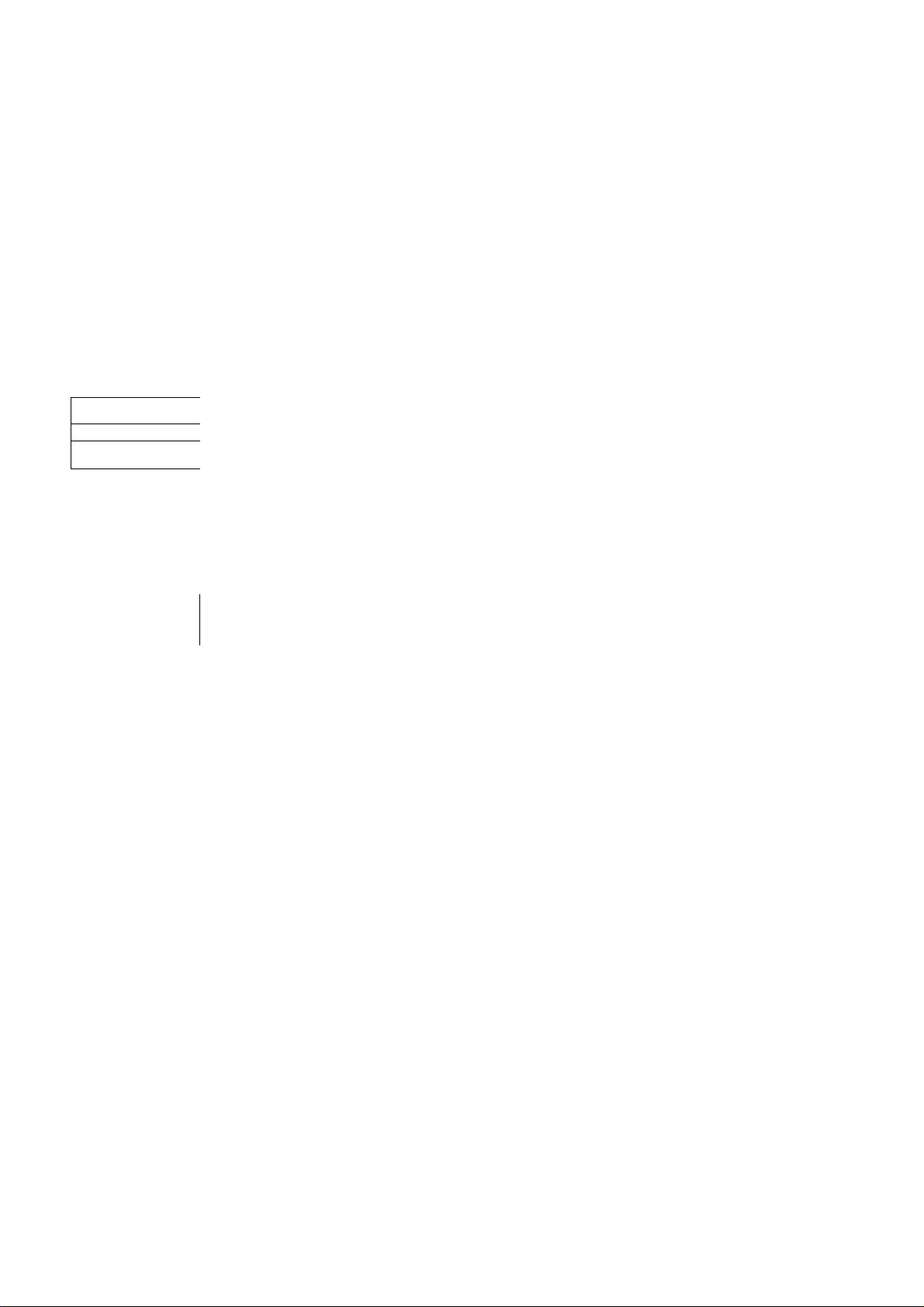

ATTACHING BLINDSTITCH HEM GUIDE

• Raise presser foot, loosen presser foot

screw with a coin and slip blindstitch hem

guide between screw and shank of the

general purpose foot.

• Be sure underside of the guide clears the

slide plate and front of foot.

•

...c

• Tighten screw with a coin.

FABRIC WEIGHT TABLE

There are many typos of fabrics around the world, each manufactured with a specific fibre and

weight. The fabric below have been classified according to weight to give a small sample of

what is available for purchase.

i Fisse ff

ANO i

FILMY

U®HT

coummenm

SILK

(Wovon)

(Knit)

RAYON

(Woven)

(Knit)

COTTON

(Woven)

(Knit)

WOOL

(Woven)

(Knit)

SYNTHGTIC

(Woven)

Chiffon,

Organza.

Tuile

Vullo

Voile,

Tullo

Chiffon,

Organza,

Tulle

Net, Lace. Ninon

Net. Lace

Net, Lnco

Net, Lace, Ninon,

Orepo de Chino

Jersey

Velvet, Taffeta, Satin

: Giré

Chailis, Orgaridy, Muslin, Batisto, Dimity,

Lawn, Percale, Eyelet, Gingham, Piqué,

Jersey

Cashmere, Piannol, Mohair, Pelt, Crepe

Jorsoy

Crepo, Velvet, Taffeta, Satin

(KnU)

SYNTHETIC

BUENOS

(Woven)

(Knit)

LEATHER

PLASTIC

VINYLS

Volfo

Plastic nim

Paschel, Singlo Knit, Sweater Knit,

Bonded Knit, Tricot, Giré

Eiroadcioth, Batiste, Eiyoiot, Gingham,

Poplin

Single Knit

Kidskin, f^atent. Chamois. ImitationLeathers & Suedes, Leather, Suede

Plastic Film

Refer to this table to determine the weight and type of fabric you will bo using in order to

select the correct needle and thread combination.

For correct neoclte and thread combinatioti for your fabric, refer to the i'abric, Thread and

Needle Table on the foiiowing page.

1 1

Velvet. Crepe dc Ctrino. Si^anumg.

Suiting. brocyOo

Velvet, Taffeta. Satin. Crepo

Voiveteen, Corduroy. VotvOt. Fleece,

Velour.'l'orry. Chintz

Stretch Velours^', Stretch Torry --

Us\uU<y coauua syoU>t-?Cc r>i)tes

Suiting. Flannel, Gabardine, Felt.

Serge, Mohair

Jersey

Volvot. Crcpo, raffeta. Satin,

Gabardine

Jacquard. Double Knit. Sweater Knit,

Bonded Knit. Tricot. Spander. Stretch

Terry, Stretci) Velour, Deep Pile. Fake

Furs

f3rocade, Taffeta, Satin, Crene

Corduroy. Denim. Ticking, Canvas,

Linen. Drapery f'ahric. durlap

Suiting. Tweed, Duffle Coating. Blanketing

Double Knit. Hoienca. Fake Furs

OerVimc Duck.

Ganvaii. Sailcloth.

Upholstery Fabric

Linen Type. Poplin. Corduroy,

Gabardine

Terry Knit

Patent. Irnltation-Leathers & Suedes,

t.eatbor. Suede, fteptile

Bonded Vinyl tKnIt Back), f’atem.

Bmbossed, t^rintod

Denim. Gabardirro, Drapery Fabric

Doublé Knit

Buckskin, Calfskin. Suede, f^eptile ; Upholstery Leather

Uptioistery Vinyl

Upholstery Vifryl

FABRIC, THREAD AND NEEDLE TABLE

Choosing ttio correct needle and thread for your fabric is of utmost importance. Correct ctioice

will make the difference in the v^ear and appearance of your new garment. The Fabric Weight

Table on the previous page, and the Fabric, Thread and Needle Table below are practical guides

to needle and thread selection. Refer to them before starting a sowing project. Be sure

to use the same size and type of thread in both needle and bobbin.

To select the correct needle and thread for your fabric, first refer to the f-abric Weight Table

to determine the weight and type of the material you arc using.

Next, refer to the Fabric Thread and Needle Table.

1 f

mm OF

НННННННН

SILK Fine Silk

RAYON Fine Silk

COTTON

WOOL

SYNTMeiTlC

SYNTHETIC

BLENDS

|[ II

: Fine

Fine

Mercerized

f-ine Mercerized

Cotton

Fine

Mercerized

Fine Synihotic : 2020-9

Fine Synthetic

2020-9 ;

2020-9

2020-0

2020^9

Ir

Fino Silk

f-ine Morcoii/od

Fine Silk

Fine Mercerized

Fine Cotton

f-ine Mercerized

Fine Silk

f-ine Mofcerizer;

Fine Synthetic

Fine Synthetic

km li?

Fino Silk

20a0-9 : f-ine Morconzod 2020-11

Fino Silk : :

2020-9 Fine Morcerized 2020-lt

Medium Cotton

2020-9 Med. Mercerized 2020-11

Fine Silk

2020-11 Fine Mercerized; 2020-11

2020-9 ; Fins Synthetic ; 20'ISdl

2020-9

Fine, Synthetic ;; 2046-11

LEATHEH

PLASTIC

VINYLS

Med. Mofcorizod

Med. Synthetic ; 2032-11

Fine Mercerized:

Fine Syntlielic 2020-11

Fine Mercenzeci

Fine Synthetic ■ 2020dl

Find the fabric you are using in Type of Fabric column at loft (silk, rayon, etc.). Thon locate

the fabric weight column (filmy, sheer, etc.) for your fabric at top of table, i^ead across from

i'ype of Fabric column to correct weight of fabric column. There, the correct thread and needle

choice for your fabric will be found.

F.xampfe: if you arc sewing a medium weight wool, find woo! in Type of Fabric column. Read

across'to Mcdiutïi (weight) column and you will see tl^at a inediurn silk or mercerized thread

and a size 2020-14 needle are to be used.

You should follow iho recommendations in this instruction book and on tho noodle packago

for correct stylo and si/.o of >->'^odlc for different typos and weights of fabric.

ii H6AVV U VERY 8EAVŸ

THîî«A0$ tHseADs ii

Medium Silk

Medium Morcurizod 2020-M Heavy Mercerized

Modiurn Synthetic

Medium Morcorized 2020-11

Modium Cotton

Medium Mercerized 2020« 1A

Medluni Silk

Medium Mercerized 2020-14

Medium Synthetic 2045*^14

Medium Synthetic 2046-14

Medium Mercerized Heavy Mercerized

Medium Syntlietic 2032-14 Heavy Synthetic

Heavy Silk

Heavy Synthetic

Henvy Mercerized

Heavy Colton

Heavy Mercerized

Heavy Mercerized

Heavy Synthetic

Heavy Synthetic

2020-14 Heavy Silk

2020-14

2020-15

2020-16

2045-16

2040-16

2032-16

Heavy Syruhetic

Heavy Mercerized

Heavy Cotton

Heavy Mercerized

Heavy Mercerized

Heavy Synthetic

Heavy Synthetic

Heavy Mercerized

Heavy Synthetic

2020-14

2020-14

2020-18

2020-16

2020-16 or 10

2020-16 or 18

2032-18

Medium Mercerized

Medium Synthetic

Medium Mofcerized

Medium Synthetic

2020-11 : ' Medium Synthetic

2020-11 Modimn Synthetic ^ 2020-14

Medium Mercerized

20^0-M

Medium Mercerized ;

Heavy Mercerized

Heavy Synthetic :

Heavy Mercerized

Heavy Synthetic

2020-16

2020-16

necdh-fabric combinations

Cor.'oct nocdio selection is closely related to

stitch quality and appearance. Damaqod fabric

is almost always caused by a needle that is

bent, burred or that is an inappropriate style

for the fabric and thread you arc using.

The three types of needles most conimonly used

are tl'o regular, bail point, and wedge. To

obtain good results, the correct si;ie and type

of needle for the fabric and thread you are

using must be chosen, ftofer to the Fabric.

Thread and Needle Table, page 8.

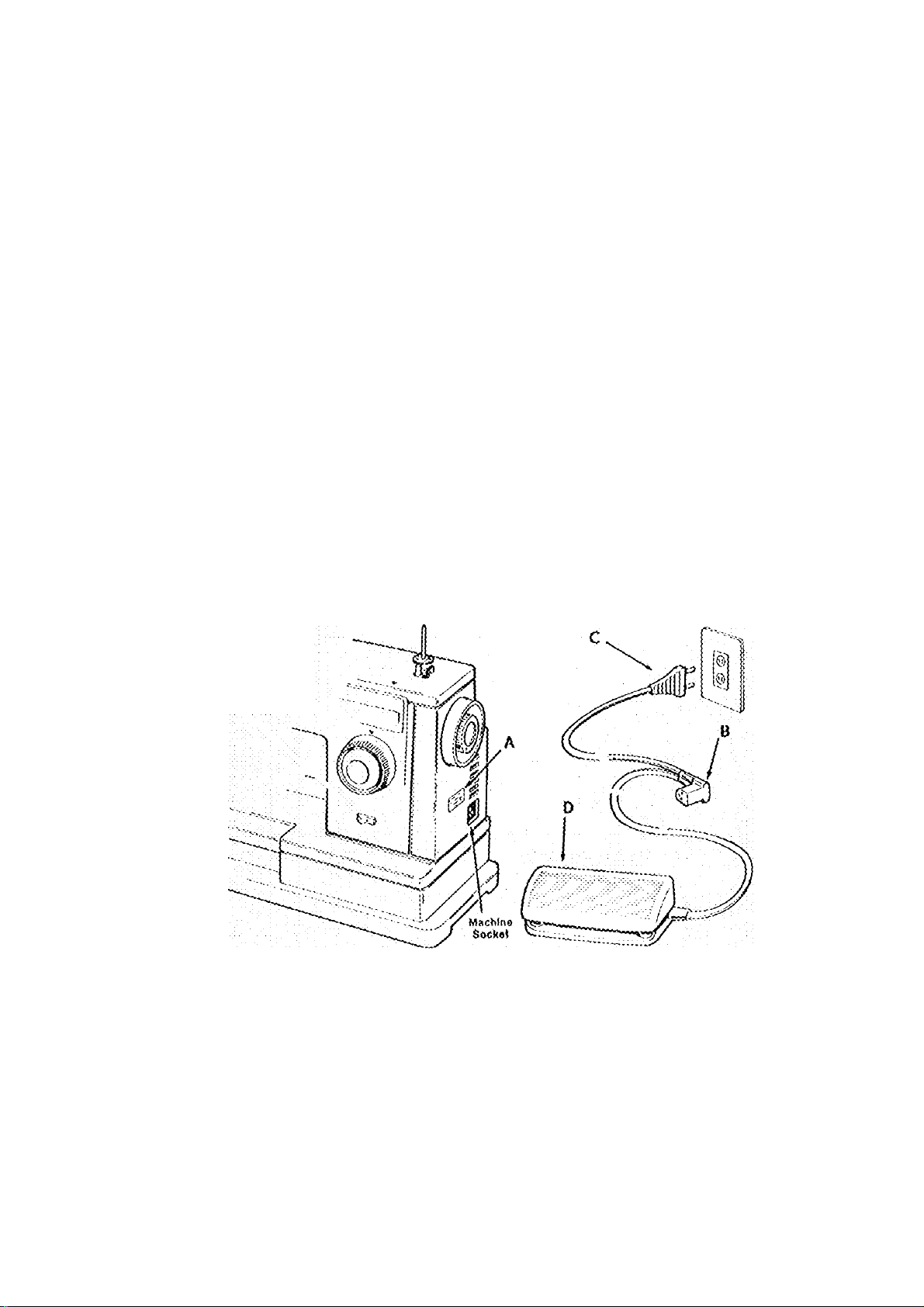

operating the machine

CONNECTING MACHINE

Result of Using a Oent Nee<llc

• fiefore plugging irt your machine, bo sure

the electrical information on the side of the

machine A. below the hand wheel agrees

with the range marked on your electrical

meter.

• Connect plug B to machine and plug C to

your socket outlet.

• To turn the machine and light on or off,

press switch as shown,

flfiOT!l

• To run the machine and control speed,

press the speed controller D with your foot.

The harder you press, the faster the ma

chine will S(iW.

CAUTION: Disconnect the power line plug from

the socket outlet when changing noodles, foot

or noodlo plates or whcf) leaving the machine

unattended. This eliminates the possibility of

starting the machine by accidentally pressing

the speed controller.

IMPOiVIANT - Mactunos for Groat t^ritam and sonro ottier countries tiaving similar wiring standards are

shipped trom the factory without a plug for connection to the mains.

■fho v/ires in tiiis mains lead are coloured in accordance with ttie ioffov/ing code:

Blue; Neutral (N)

Brown; Live (L)

As the colours of ttie wuos in the mains load of this appliance may not correspond v/iUi the colourod

in<uKmgs identifying the teimmals m your plug, proceed as follows'

i he wire which is coloured t>luo must bo connactod to Iho terminal which is marked with the

loiter N or coloured black.

Vho wire wtiich is colourod browr» must bo con.iected to the terminal which is marked with the

letter L or coloured red.

U a 13 amp (BS 13S3) plug is used a 3 arnp fuse must bo filled, or of any other typo of [)iug is tised a 6

amp h.ise must be fitted either in the plug or adaptor or at the distribution board.

tú

the bobbin thread

Your sewiag machino uses two threads to form a stitch. The upper thread comes froro the

spool and is throacied tiirough the eye of the noodle. The lower thread comes from the bob

bin. Wind the bobbin before threading the machine.

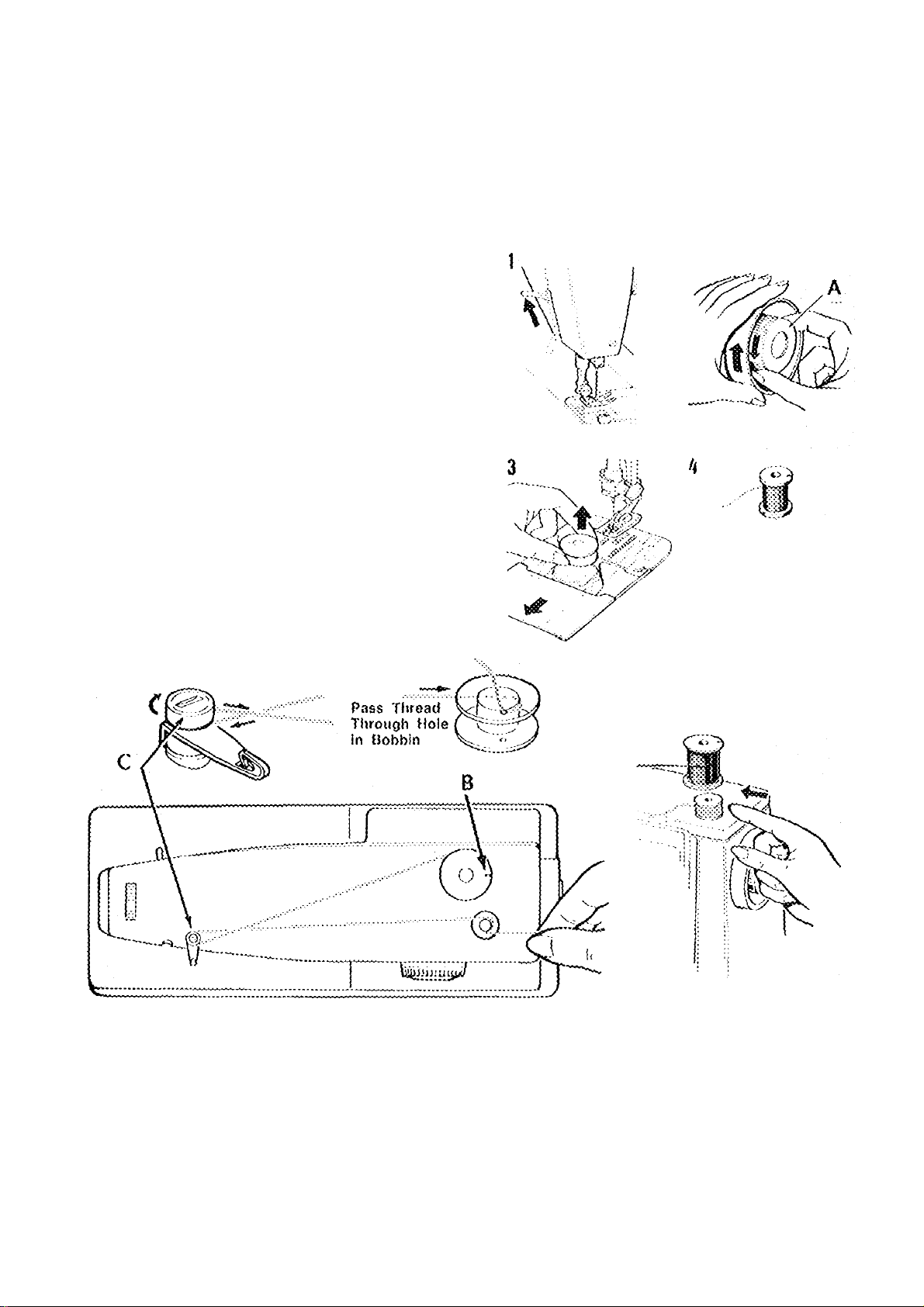

WINDING THE BOBBIN

Preparation Steps

1. Raise the presser foot and turn hand wheel

toward you until needle is in tiighest po

sition,

2. l.ooson hand wheel knob A by turning it to

ward you with the right hand while holding

hand wheel with the loft hand.

3. Open slide plate and lift out bobbin.

4- Place spool pin felt on pin.

Winding Steps

• Place thread spool on spool pin with thread

retaining slit B on top. (Break paper at the

end of spool if necessary). If you are using

a tube of thread affix spool pin extension

to spool pin to ensure even flow of thread.

• Lead thread around bobbin winder tension

disc C and through small hole in bobbin

from inside out.

• Place bobbin on spiftdie and push bobbin

to right to engage bobbin winder.

•

4

....

Hold thread end as shown and start the ma

chine. Cut off thread end after a few coils

have been wound.

When required amount of thread has been

wound (v/inding will stop when bobbin is

full), stop the machine and cut connecting

thread.

f^ush bobbin to left and remove bobbin from

spindle.

f-fold hand v/heel and tighten hand wheel

knob.

11

THREADING THE BOBBIN CASE

1. Hold bobbin so that thread unwinds in the

direction shown, and put bobbin into bobbin

case.

2. PiiW thread into notch A. draw it back under

the tension spring and back into slot B.

3. Draw approximately 10 cm (4 inches) of

thread across the bobbin.

4. Close slide plate allowing thread to enter slot

between the needle plate and slide plate.

1?

Loading...

Loading...