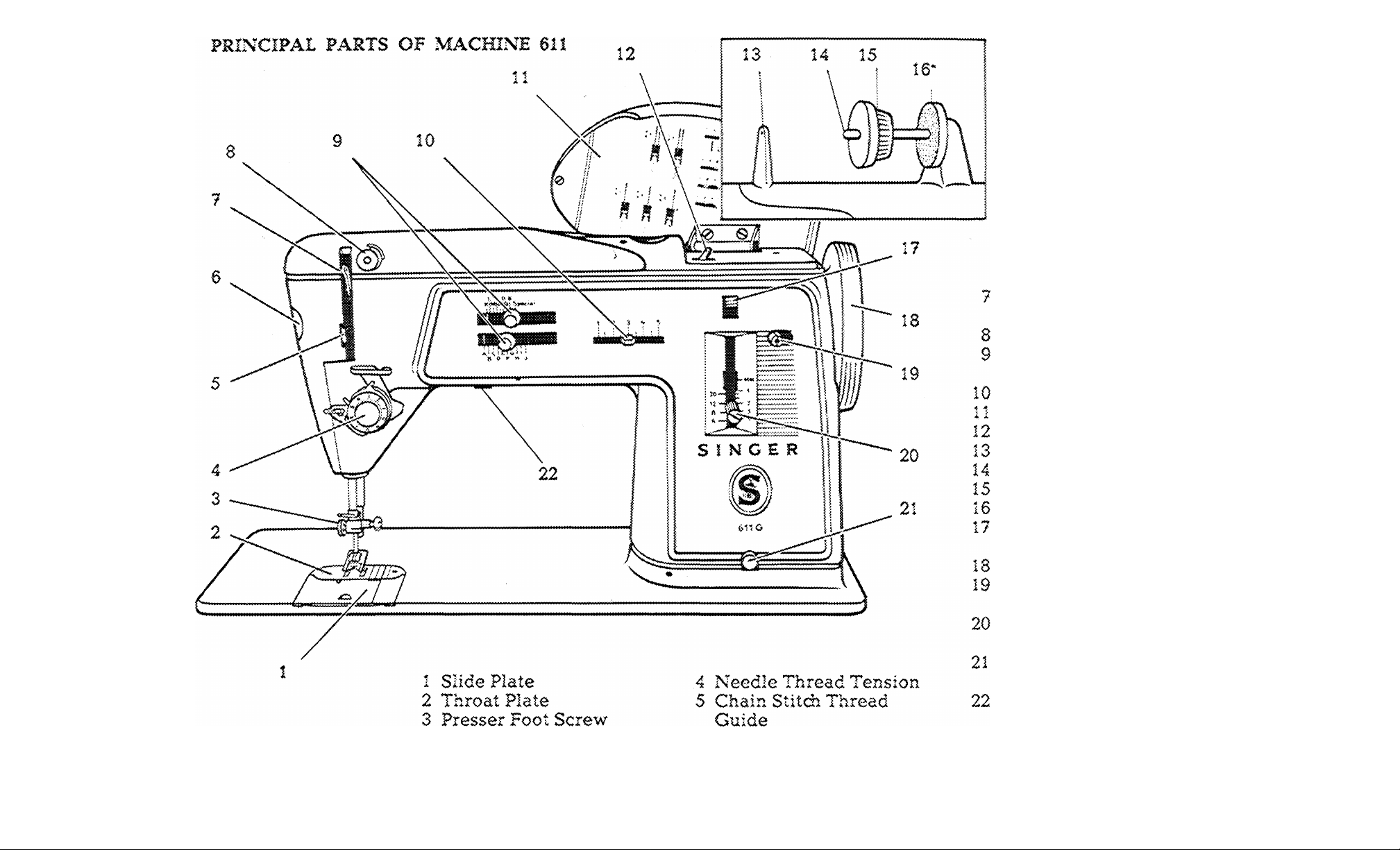

Page 1

Page 2

"V ’I T

Cl о i

/Ч A. A

• %*>Ч "• V ■ ■ •

ro

> < > vV;>045 G :12-¿'6; <;ì:’ì(':. Pruìii-c: G Wûsiôrr ОйГм'^огу

Ï» w Á.

t T

' wi

Í Ï

Wi.

•Í T^. /Nr

illy

A Trccìc-mork or THE SiNG£2 COMPANY

Page 3

the best sewing machine ever built by SINGER

Page 4

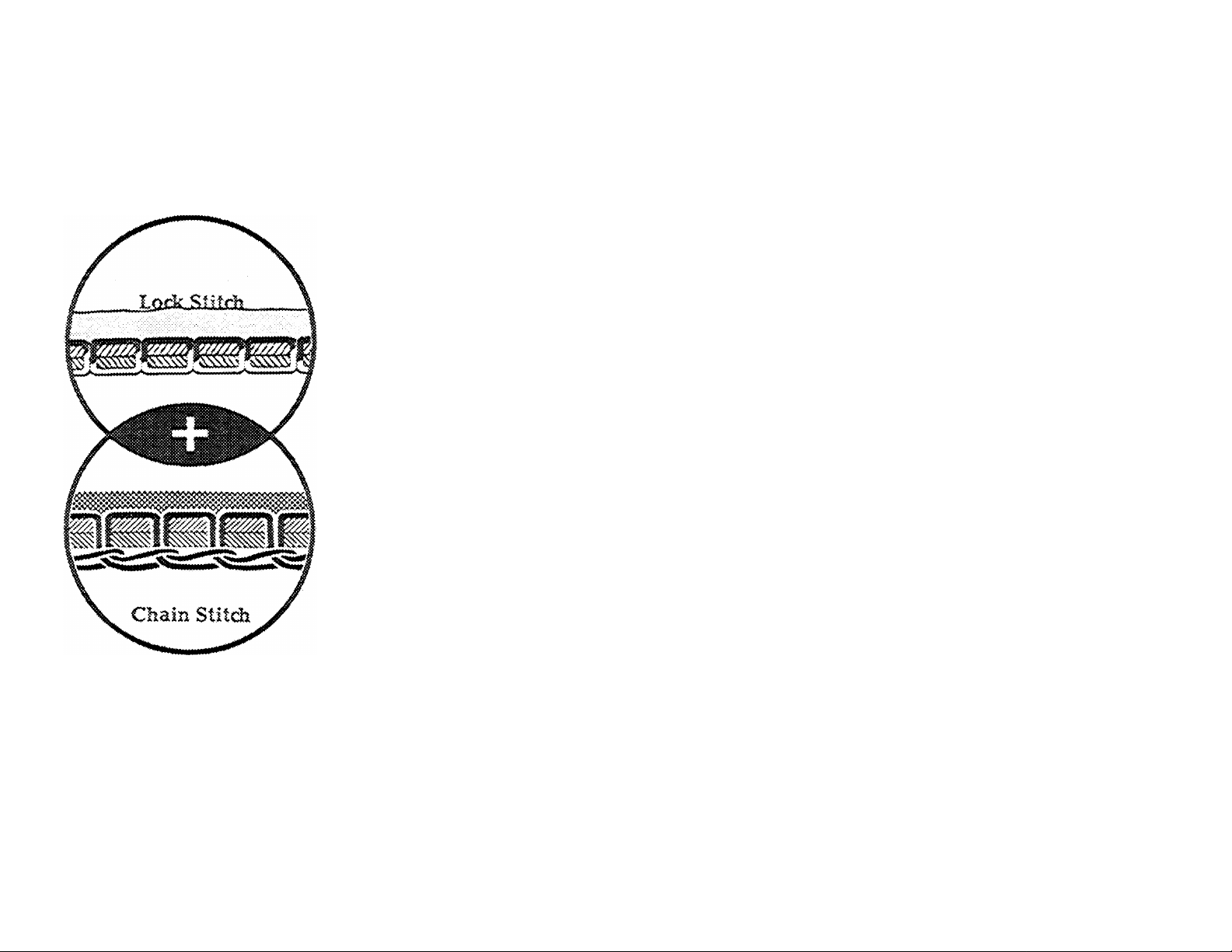

Th.6 SIMGER 611 truly remarkable macbine with CHAIN STITCH feature

The SINGER 51! represents the truly universal sewing machine that

will crreatlv contribute to nerfect domestic dressmakincn In addition

to its numerous outstanding advantages the machine now incorporates

a new and unique feature in that lock stitching and chain stitching can

be selectively produced on the same madiine.

^ Only SINGER produces an automatic machine that in addition to

the conventional lock stitch also sews a single thread chain stitch

which can be used for basting seams thus replacing hand-basting.

This feature 'whll release you from time-consuming work and

it

reveals new aspects so far non-existent in the overall picture of

the applications of the modern family sewing machine. (For detailed

instructions concerning operation and application, see page 22.)

♦ SINGER has WORLD'S FIRST AUTOMATIC with slant needle and

gear drive. Seeing is easier, sewing smoothest ever. No slipping

or stalling,

^ SINGER has WORLD'S FIRST AUTOMATIC w i t h do u b 1 e - ea s y

threading. Has built-in threading chart, handy "dropAn** bobbin in

f r o n t of needle!

♦ SINGER has WORLD'S FIRST AUTOMATIC with a built-in eye-

ievel stitch chart, with push button selection for whatever fancy

stitch you want!

0

Copyright 1965 by The Singer Compcny

Page 5

OTHER OUTSTANDING FEATURES ARE:

^ SUPERFINE CONTROL of stitdr length ensures

perfect satin stitching.

® PERFECT STITCHING ... straight and zigzag.

Ф NHBDLE CLAMP holds one or two regular need

ing — same or diiierent sizes for exciting twin

needle stitcliing*

# THItOAT FLATH with seam guide markings.

Held with magnets for easy removal and replace

ment.

# PRESSURE OF PRESSER FOOT can easily be

adjusted according to regulator.

# NEW TYPE SPOOL HOLDER ensures a smooth

how of the needle thread.

^ HINGED face plate swings open for easy access

to oiling and clc<ming points.

MOTOR with worm wheel drive, no

belts required, excellent penetrating power when

sewing heaviest materials without manual assis

tance (electric drive).

# BUILT-IN LIGHT focused on sewing area, which

swings down for easy bulb replacement.

# ALL MECHANISM completely enclosed.

# SPECIAL PURPOSE FOOT.

# FLEXIBLE SEAM GUIDE.

TO GET THE MOST ENJOYMENT

FROM YOUR SINGER 611

Take advantage of the free sewing lessons to which you are entitledl

Skilled, SINGER-trained teachers will give you personal guidance and

assist you in learning the fundamentals of home sewing.

Page 6

SINGER SERVICE

Wherever you go you will find expert, dependable SINGER* Service

close at hand. SINGER is interested in helping you keep your SINGER

Sewing Machine in top running condition. That i.s why you should

always call your SINGER SEWING CENTRE if your madrine ever

requires adjustment or repair. Only from your SINGER SEWING

CENTRE can you obtain the services of a trained SINGER repair man

and warranted SINGER'*' parts.

Пк1©Шй

risa Гб)

ШШ&

4(8У-^г==У@)

..Амм^Кмммммак. ^

EVERYTHING FOR THE WOMAN WHO SEWS

The answer to your sewing needs is at your SINGER SEWING

CENTRE. There you will find a wide choice of sewing aids, notions,

sewing instructions and services. Look for the famous red "S" and

SINGER trademarks on your SINGER SEWING CENTRE and the ever

readv SINGER Service Car. See phone book for address nearest vou.

Page 7

NEEDLE AND THREAD SELECTION

The selection of thread should be based on the fabric to be stitched,

The thread should blend with

the fabric in colour, fibre and size.

Silk and wool fabrics should be stitched with silk thread; cotton fabrics $br)uld be stitcied with cotton

or cotton mercerised thread, etc. The thread must be of a size that will imbed itself into the texture of the

fabric. Thread that is too heavy for the fabric will remain on the surface and become weakened by fric

tion and abrasion.

The selection of the needle should be based on both the fabric and thread being used. The eye of the

needle must be large enough for the thread to pass freely through it. The blade of the needle must be fine

enough not to mar the fabric with too large a puncture, yet heavy enough to pierce the fabric without

binding or deflecting.

You will obtain best stitching results from your Sewhng Machine if it is fitted wuth a SINGER* Needle.

Page 8

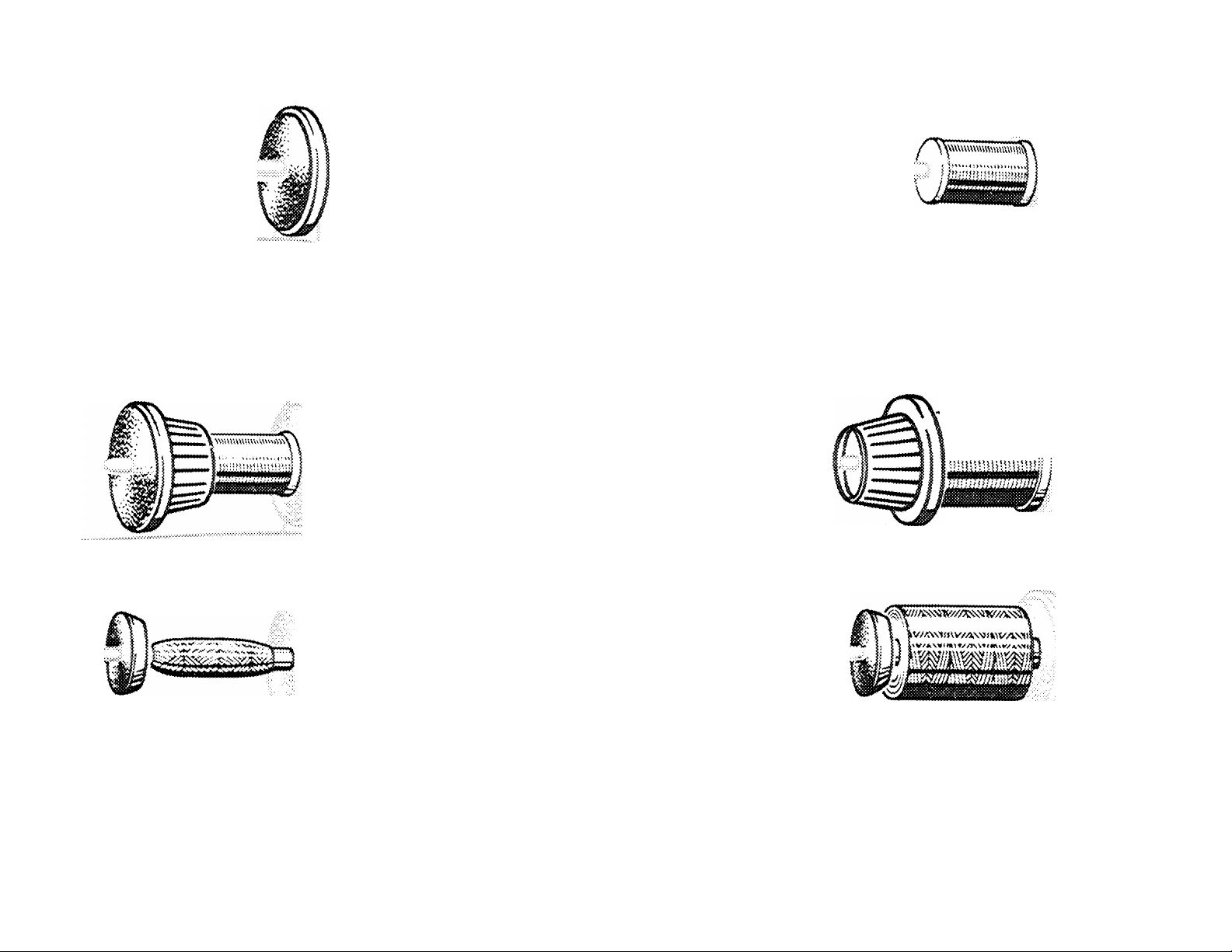

NBEDLHS AN0 THREAD

"his machine uses a Cat 2020 (15X1)

needle. Sizes 9, 11, 14, 16 and 1$.

For perfect stitching, select correct needle

and thread to correspond with fabric {see

page 5).

Be sure to use like threads for both needle

and bobbin.

NBHDIE INSERTION

Raise the needle bar to highest point by

turning the hand wheel toward you. Loosen

the needle clamp screw. Insert needle up

ward into clamp as far as it wull go, with the

flat side of the needle to the back and the

long groove toward you. Tigh.ten needle

clamp screw.

6

LOiNG GROOVE

TOWARD YOU

Page 9

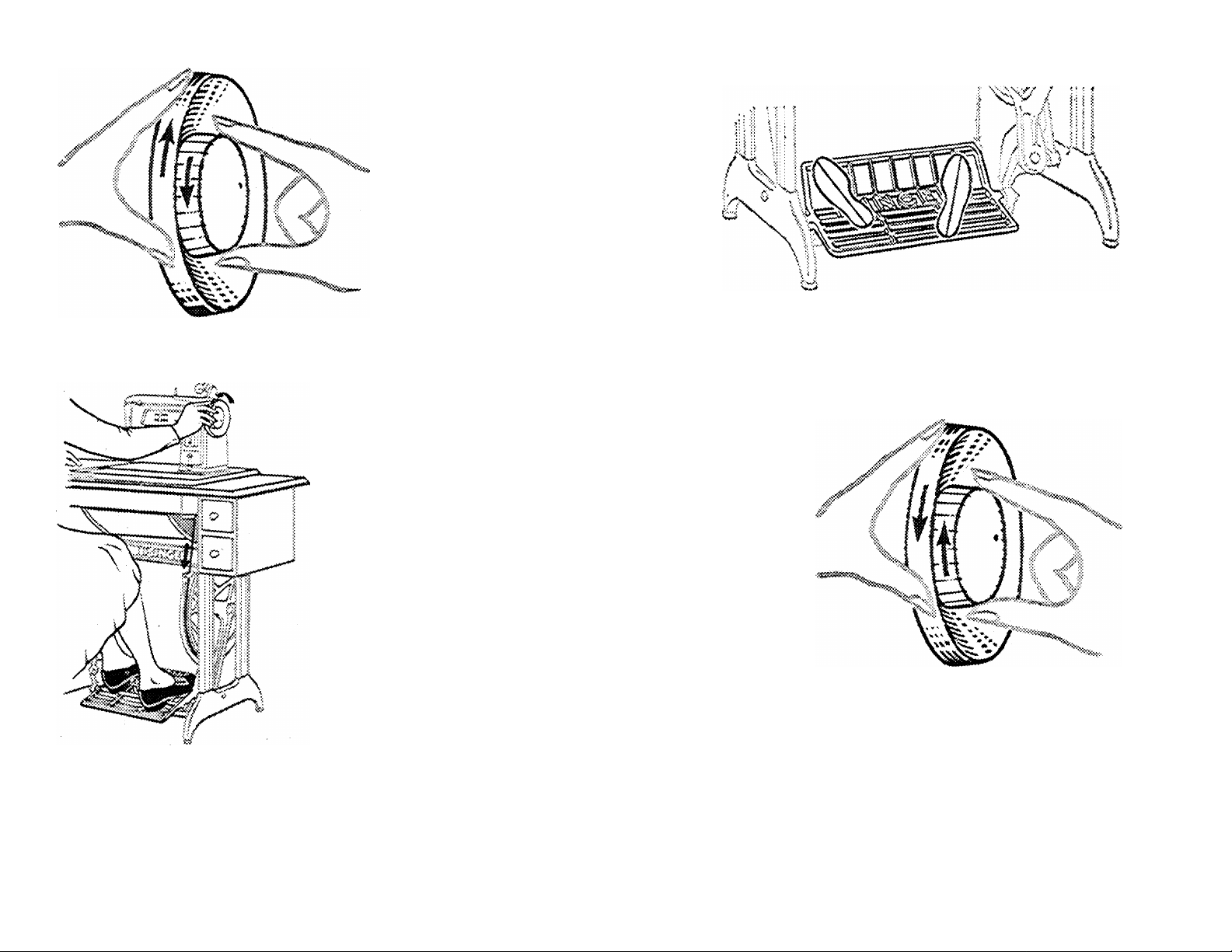

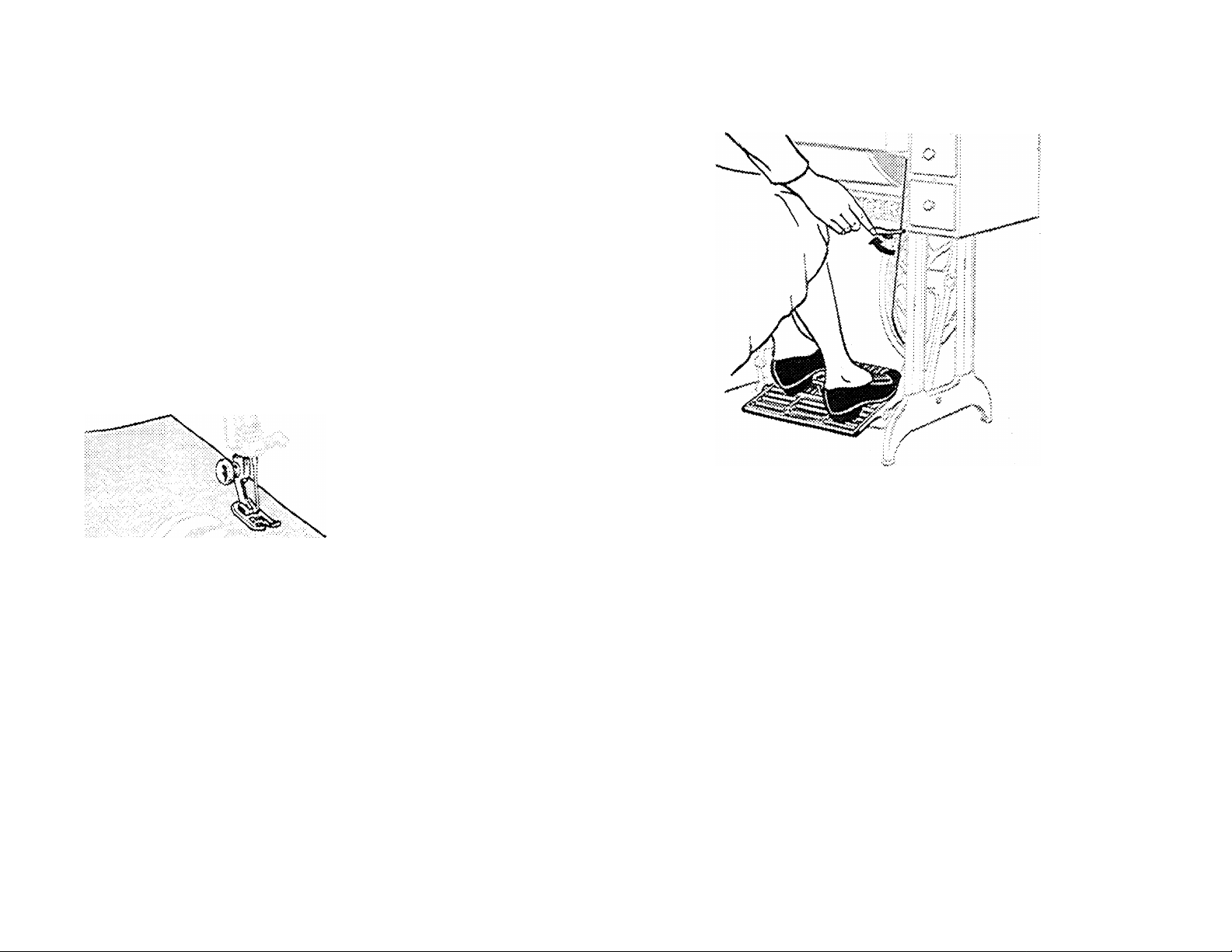

TO OFERATB MACHINE

Place material under the presser foot and

lower foot. Connect plug to electric outlet

(see page 97). Start machine by pressing con

troller.

fEIectric Drive)

The speed of the machine depends entirely

on the amount of pressure applied to the

controller.

Practice operating the machine (without

thread) until you become accustomed to

guiding material and regulating machine

sneed.

Page 10

TO OPERATE THE ?

(Treadle Drive}

Loosen stop motion screw and place both feet on treadle.

Turn hand wheel over toward you, allowing feet to move freely and lightly with motion of treadle.

Practice this motion until vou are able to re-start machine with hand wheel turning over toward you. Then

tighten stop motion screw.

8

Page 11

1RFTT «vHTFTFI?

To throw off the belt, work the treadle and move

belt shifter to position shown.

To replace belt, release belt shifter and work

Place material under presser foot and lower the

foot.

Operate machine {without thread) until you be

come accustomed to guiding the material.

treadle slowly with band wheel turning over to

ward you. One or two revolutions of band wheel

will bring belt back into place.

Note: Tension on belt should be only heavy en

ough to keep belt from slipping.

9

Page 12

spoot HOiPia

1. Slip spool seat on to spindle (Cushion

side facing spool of thread).

2, Slip spool of thread on to spindle-

3. Press thread lead-off against spool of thread. Select thread lead-off according to the size of thread

spool used^ as shown.

10

Page 13

UPPER THREADING-SINGLE NEEDLE

Raise take-up lever to highest point. Place thread

on spool holder and lead through threading points

shown. Thread needle from front to back. Draw

sufficient thread throuch eve of needle with which

to start sewing.

n

Page 14

...

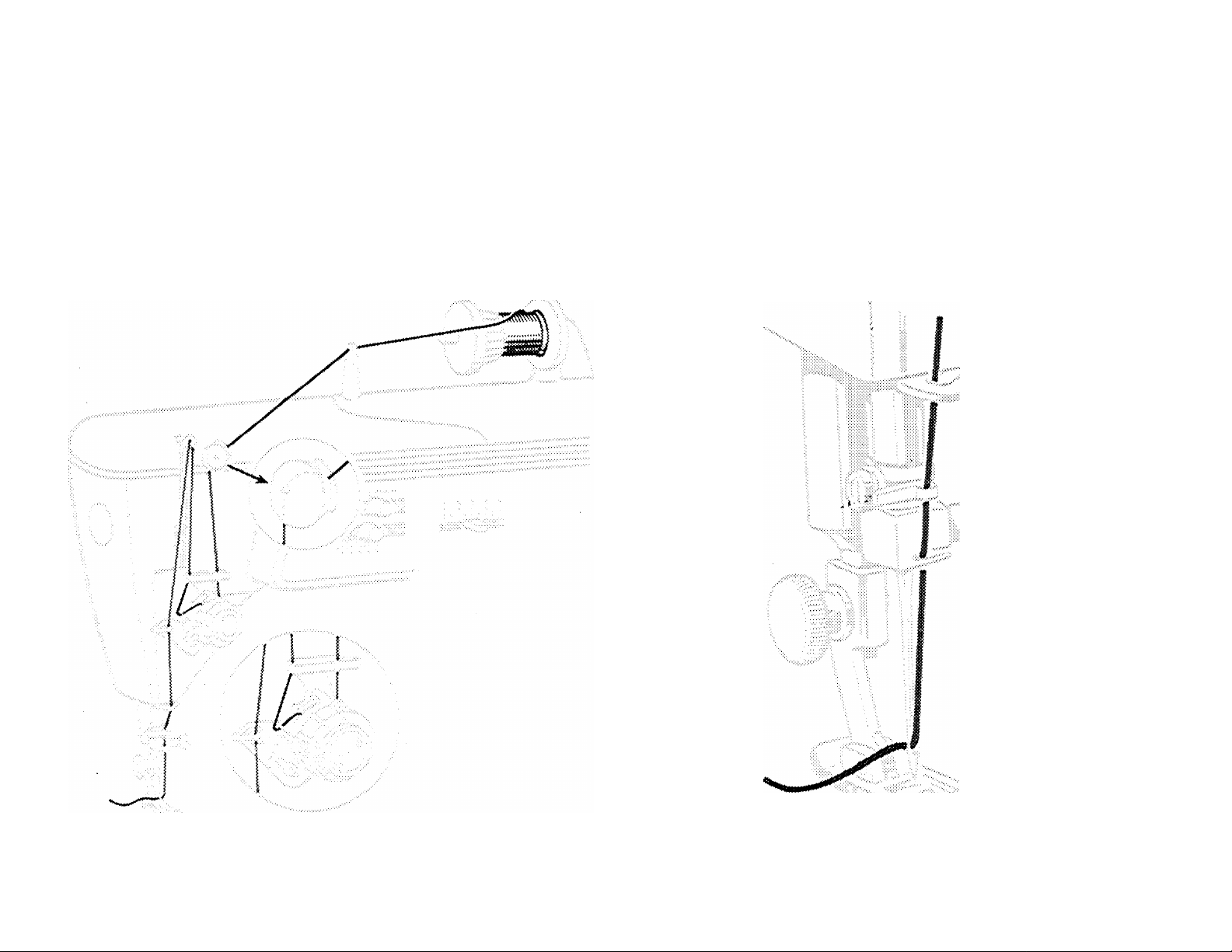

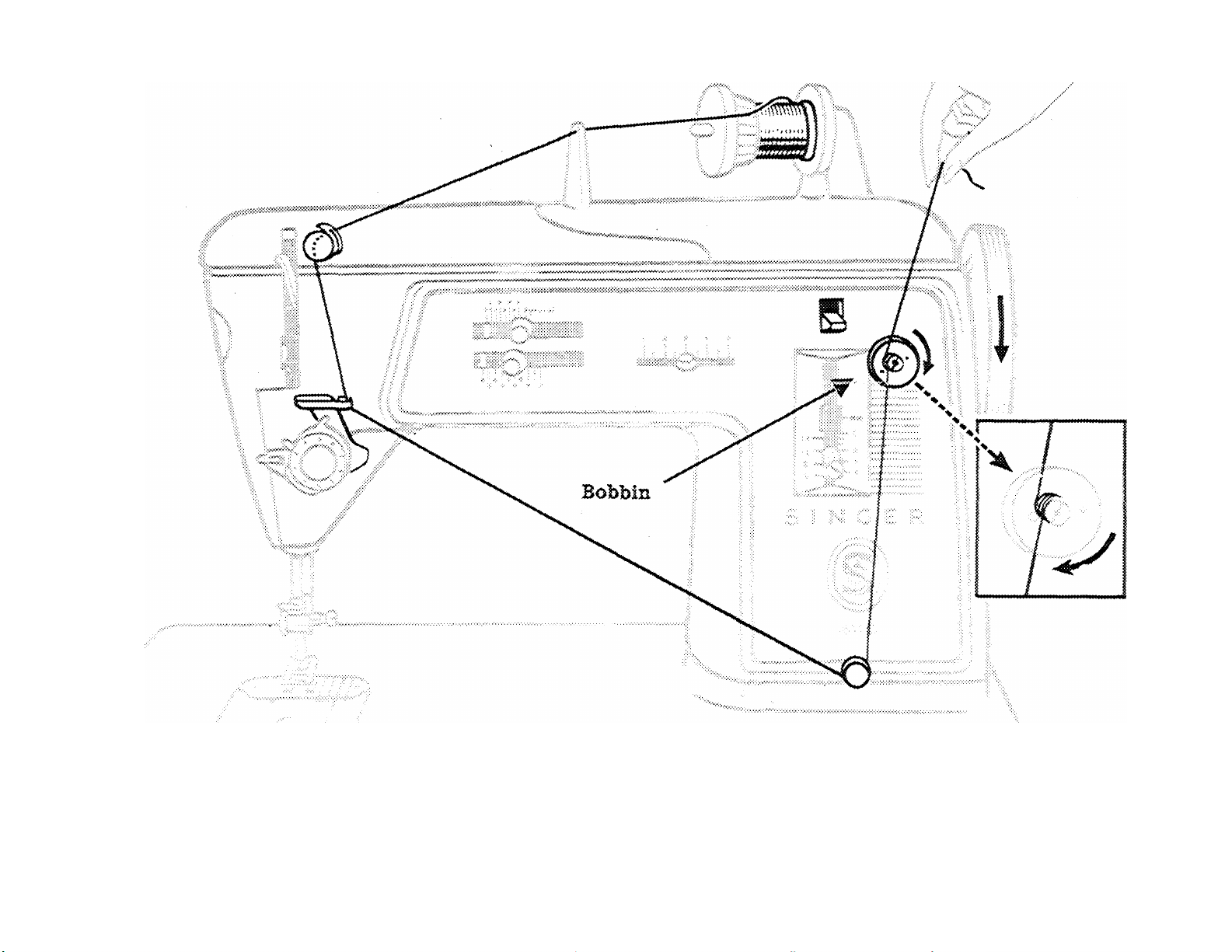

WIND THE BOBBIN

y-".

Release hand wheel turn stop motion screw with right hand in direction shown by arrow. Slip bobbin

on to bobbin winder spindle»

12

Page 15

WIND TFH BOBBIN fCoai^a.|

Thread the machine as shown.

Wind several coils of thread around the bobbin and depress bobbin winder engaging lever.

13

Page 16

WIND THB BOBBIN {ConVd,}

Do not wind too much thread, otherwise there

would be no free run of the bobbin in the bobbin

case.

Stop machine, raise bobbin winder engaging lever

and remove bobbin from bobbin winder spindle.

Tighten stop motion screw with right hand in

direction shown bv arrow.

14

Page 17

/ /■

O^ea

sU-

r0^'

! \àe

\5

Page 18

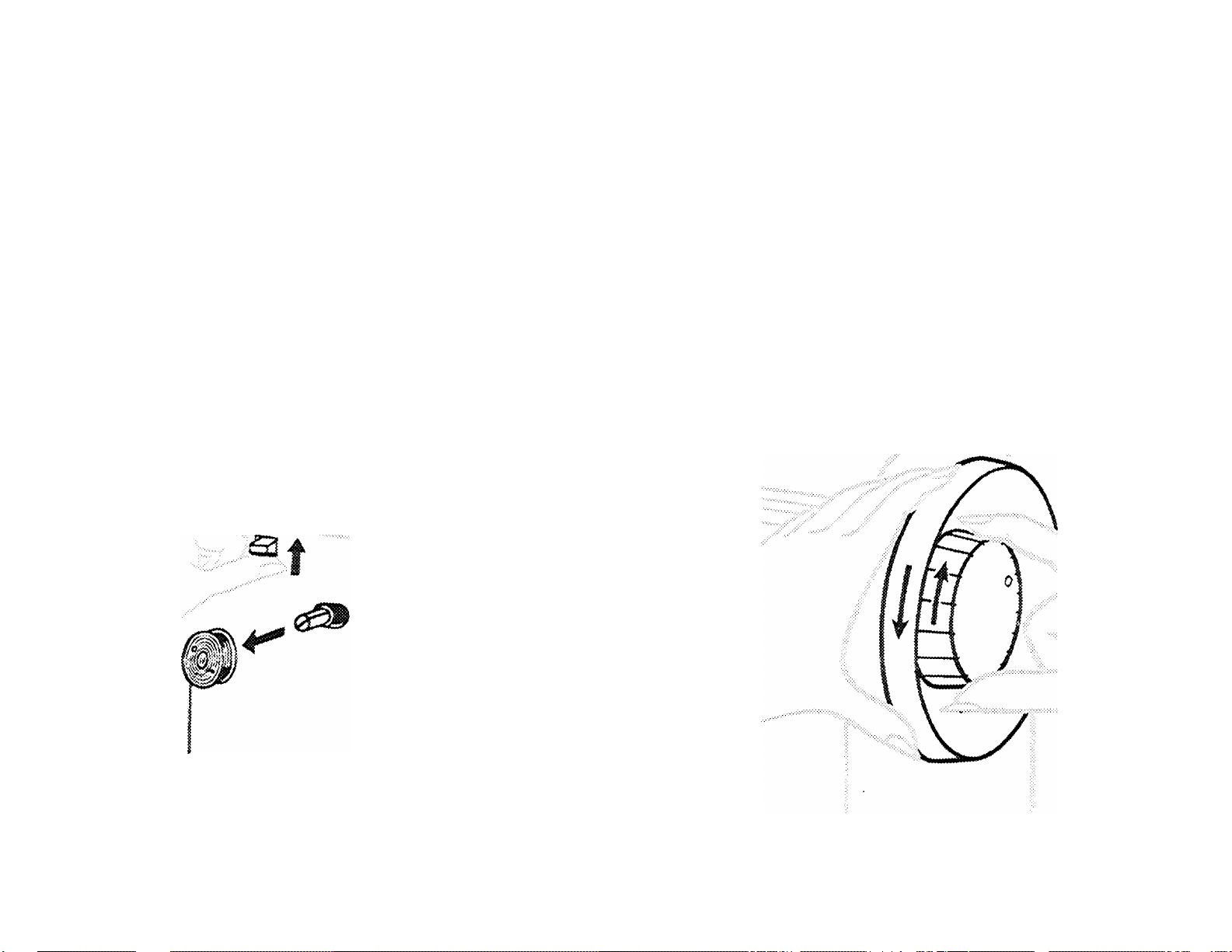

THSEA0ING THE BOBBIN CASE

'0

T-‘*s^2^*^^; v:y.‘^y.-

Hold bobbin so that thread leads off in direction shown. Place bobbin in case. Lead thread into slot

and under spring.

Draw thread into notch at end of spring, pulling off about 3 inches of thread across the bobbin.

Close slide plate allowing thread to enter notch.

16

Page 19

6 Pressure Release

Button.

Thread Take-up

Lever

Pre-tension

Pattern Selector

Buttons

Hngaging Lever

Hand Wheel

Bobbin Winder

Spindle

Stitdi Length

Regulator

Bobbin Winder

Pre-tension

Bulb Replacenre:

Lever

I?

Page 20

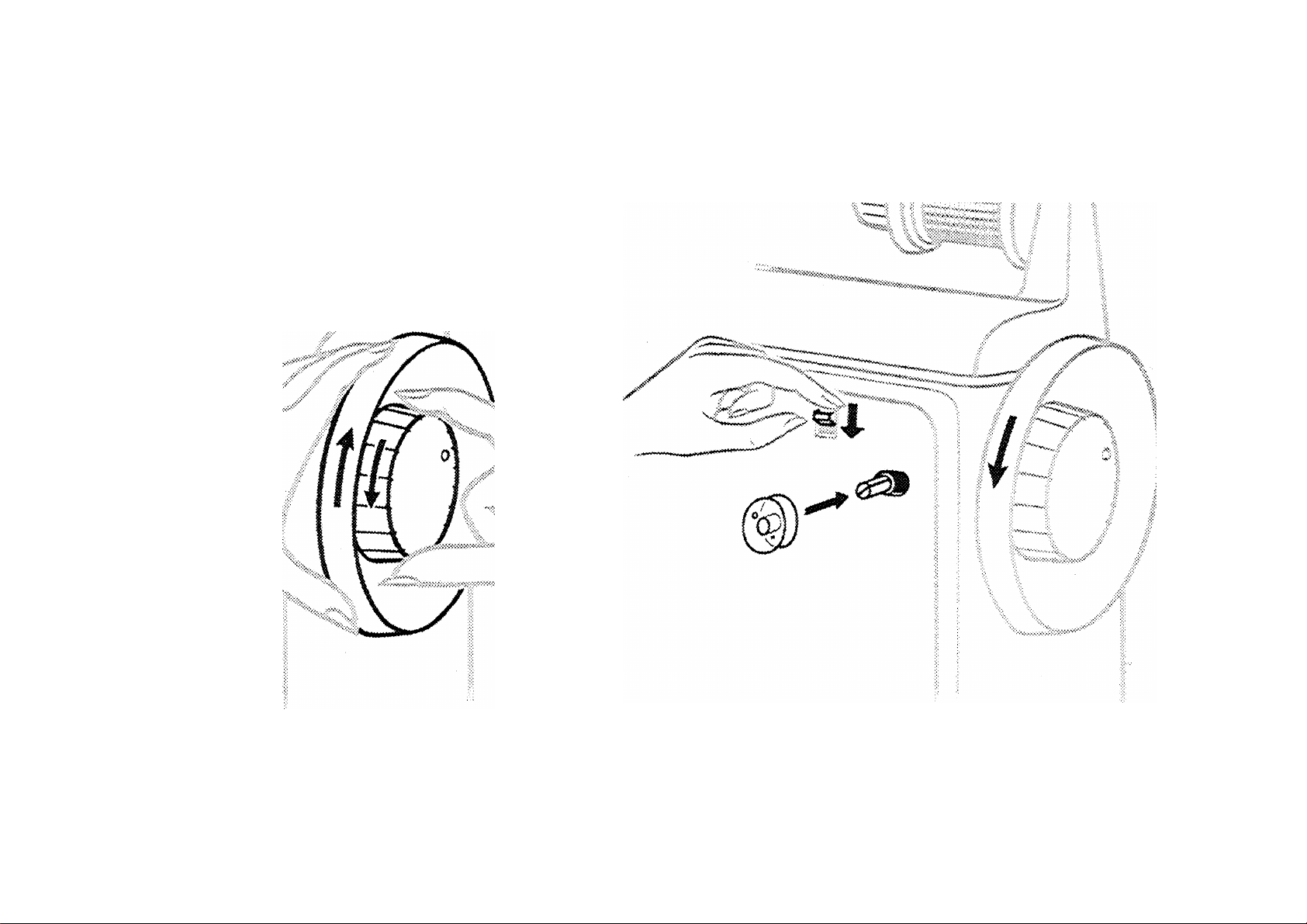

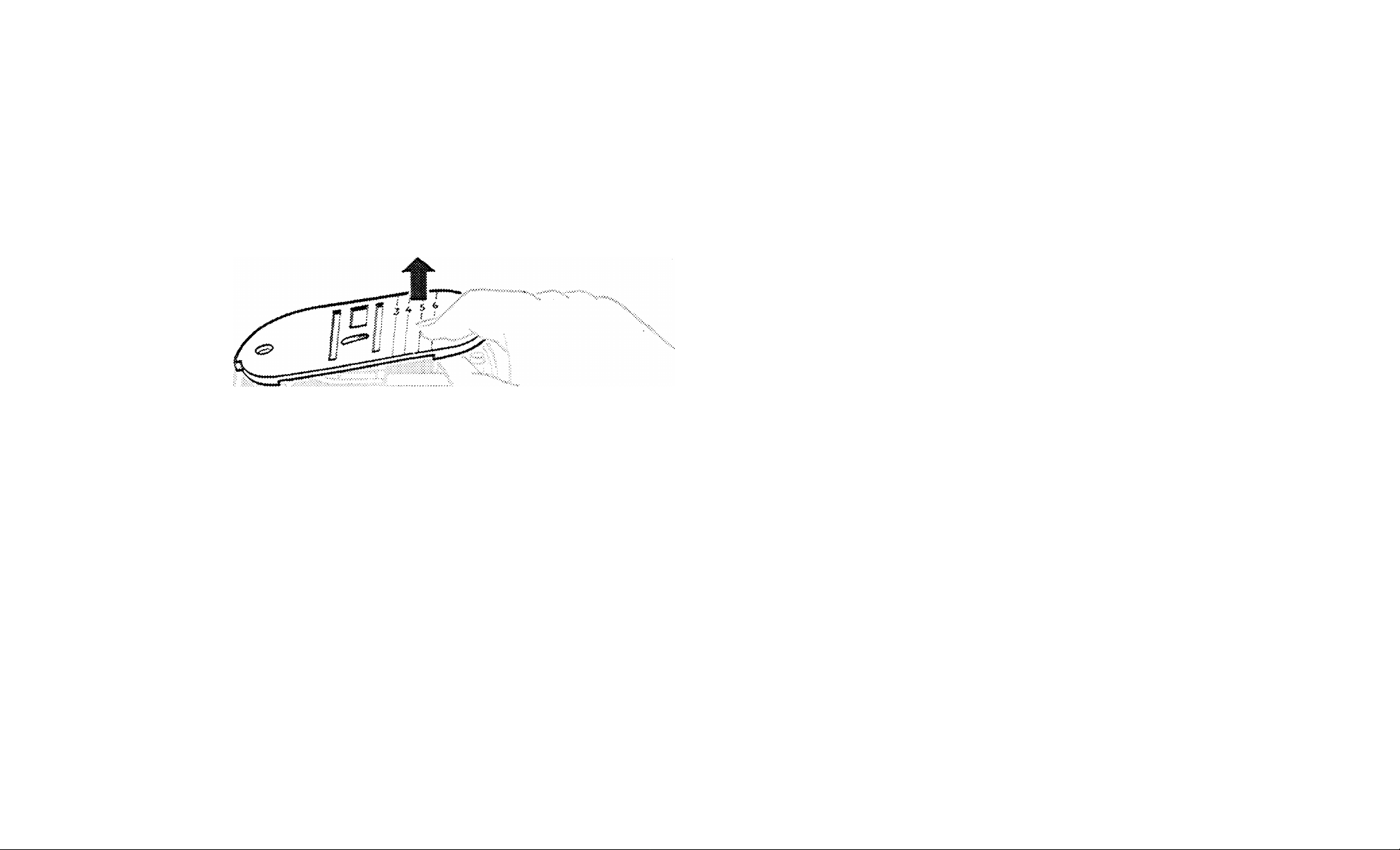

STITCH LENGTH INDICATOR

Numerals on the left side of the indicator repre

sent the number of stitches per inch. Numerals on

the right side represent stitch length in millimeters.

A superfine control cam be made in case of siitdx

lengths less than 1 mm or stitches per inch {20),

The greatest stitch length of 4 mm or 6 stitches

per inch can be locked in place when stitching folds,

pleats or multiple layers of heavy fabric.

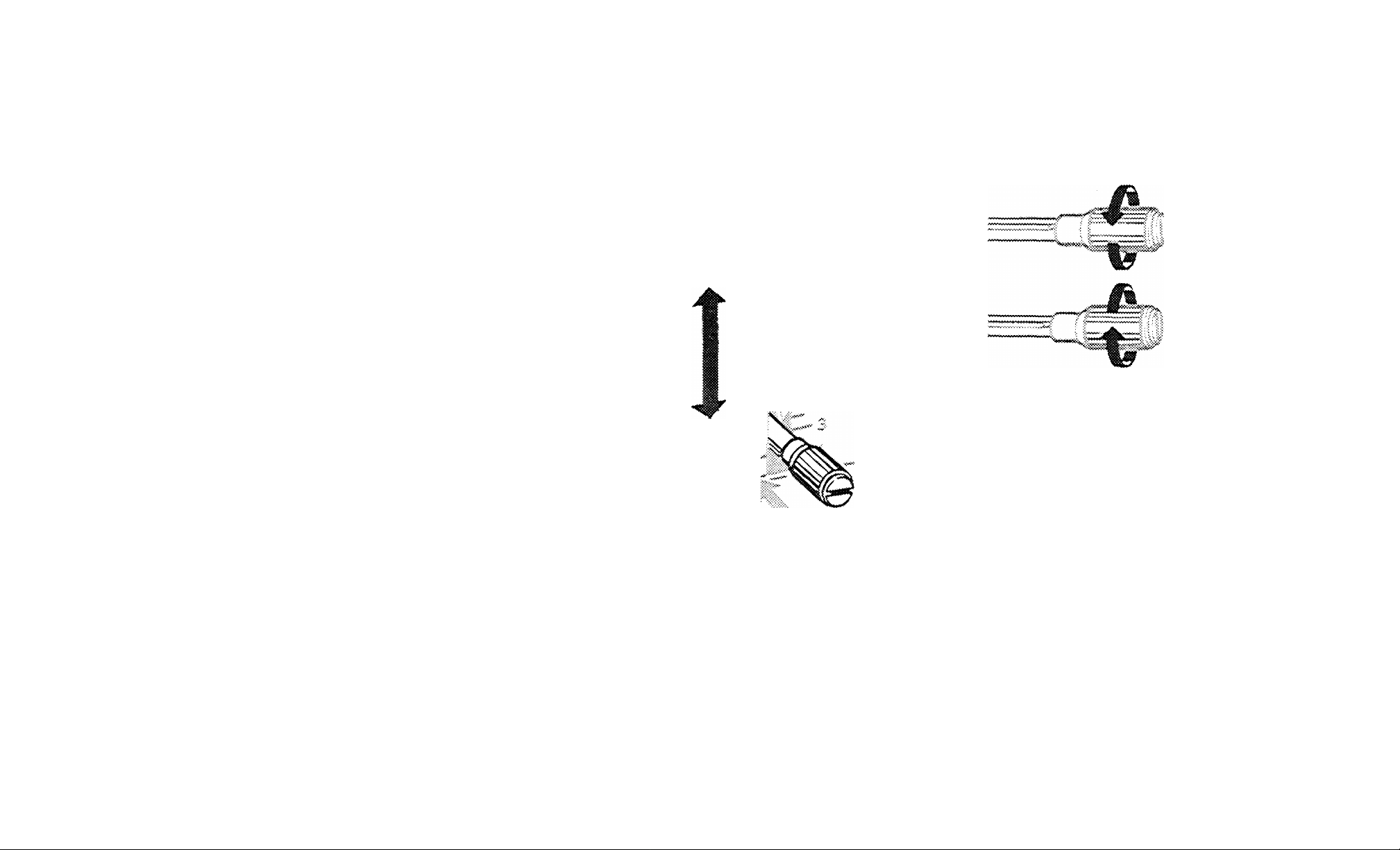

To set stitch length: Loosen by turning thumb nut

to the left as shown. Position lever for desired stitch

length. Tighten by turning thumb nut to the right.

By raising the stitch length regulator to the hig

hest point, reverse stitching is accomplished at the

UNLOCKS

REVERSE

LOCKS

FORWARD

'Nv

.2'

\

same stitch length as forward. When in locked

position, 4 mm or stitches per inch (6) cannot be

reversed. If reverse stitching is desired with this

stitch length position, turn thumb nut to the left

until the stitch

length regulator can be adjusted to

its highest point at reverse stitching.

18

V

Page 21

STITCH WIDTH IBYER

4

■:•:•:•♦ , s

.-f*

The stitch width lever is used for both straight and zigzag stitching. Numerals indicate five positions

but intermediate settings may also be used. To position, depress stitch width lever and slide it left or

right to desired setting.

Do not set stitch width lever while the needle is in the fabric.

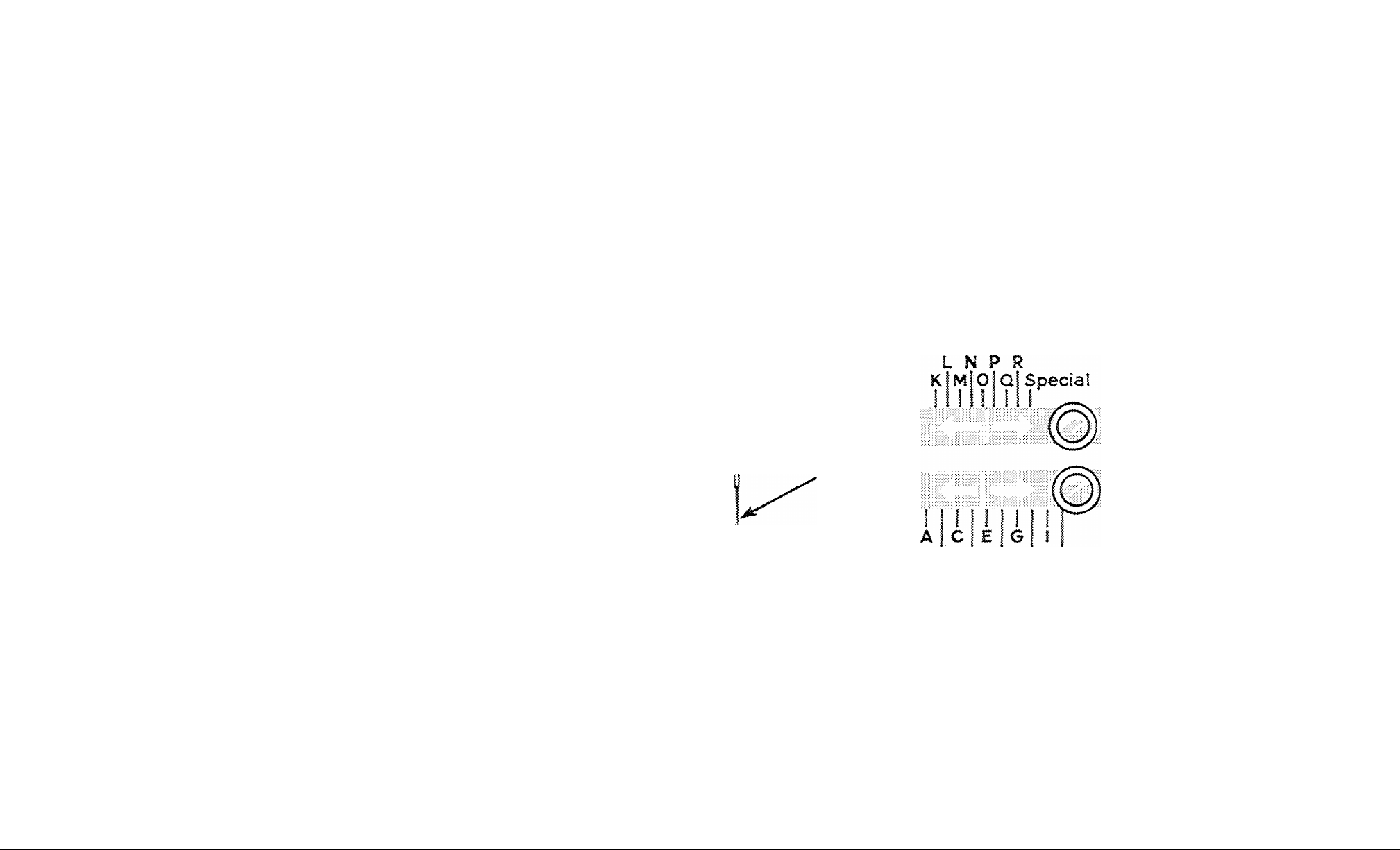

PATTEHN SEIHCTOR

Please note: Do not make selector adjustments while the needle is in the fabric.

When make Pattern selection set stitch width lever at 3.

3

19

Page 22

PATTmN SELECTOR

JStok

To Select Required Pattern

1. Depress Push Button A and keep

depressed until selection is com

pleted.

2. Push Pattern Selector Buttons.

3. Select required Pattern.

4. Release Pattern Selector Buttons.

5. Release Push Button A.

20

B D f H J

Settings from K through Special are

made by the upper button.

Settings from A through J are made by

the lower button

Page 23

THROAT PLATE

REMOVAL AND REPLACEMENT

Removal of throat plate

Replacement oi throat plate

i ! I J:

#1

©

Raise presser bar. Turn hand wheel to raise needle

to its highest position. Open slide plate. Place thumb

under front end of throat plate and lift plate from

machine.

Place throat plate in position over two clamping

pins and then close slide plate.

21

Page 24

CHAIN STITCH

More than any other sewing machine the new SINGE'R 611 will

eliminate a comidetahie amount of time-consuming and burden

some work previously done‘by hand. This machine has the uni

que feature of being capable of producing not only conventional

lock stitching but selectively single thread chain stitching,

The main advantage of this type of stitch is that the single thread

chain stitch can easily and quickly be removed by a single pull

on the dmln stitch seam. By means of the chain stitch the neces

sary tacking and basting operations indispensable for sewing

perfectly fitted cresses or other garments can now be produced

on a mmchine. Even a section of a chain stitch seam can be remov

2'>

if^

ed without any effort as is frequently required when fitting the

dress or gàTxaent (side and waist seamm). Once the dress or gar

ment fits, the final lock stitch is stitched in a close parallel line

to the chain stitch. Then the temporary seam is remioved by a

single pull without leaving remains of the thread in the fabric.

Thus sewing-in of the basting seam is very unlikely. For basting,

regular thread or darning thread may be used.

The single thread chain stitch has a wide range of applications

and can be employed for a variety of operations, for instance:

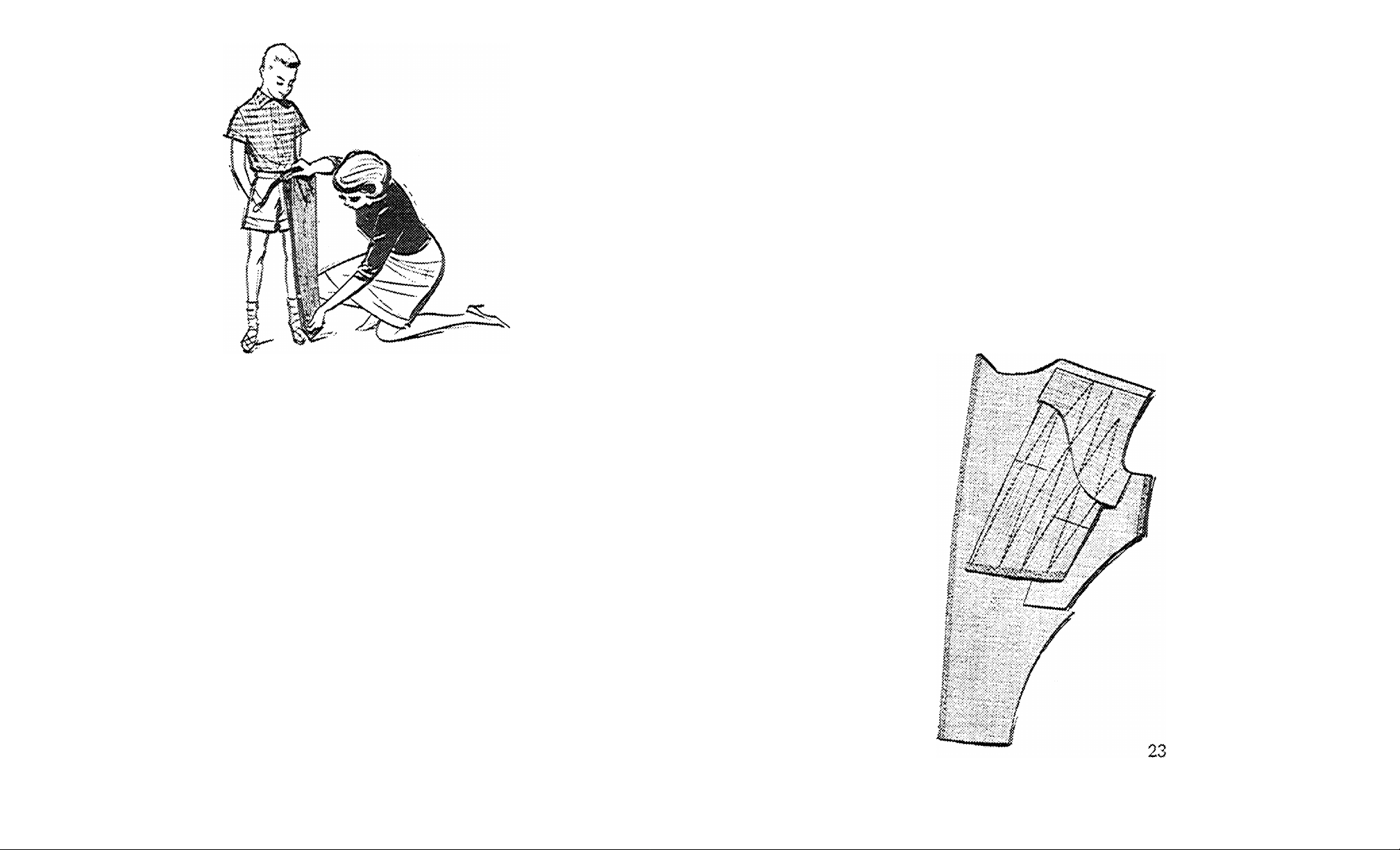

Page 25

Edge basting on jackets, coats and costumes — sleeve in

serting — attaching collars — hems on skirts, blouses etc.;

Basting canvasses to the fronts of costumes and jackets in

stead of sewing them. with, zig/^ag stitches;

Sewing shrinking tucks on garments as shirts, pyjamas etc.

as well as on ready made clothes and curtains made from

fabrics which are likely to shrink. The temporary stitching of

the curtains and also the final stit<±ing can be performed on

the same machine. Stitching growth tucks which can be open

ed on clothes for growing children, as desired;

Re-sewing waist and leg hems on ladies' and men's under

wear of tricot or interlock fabrics when replacing elastics;

# Adjusting length and width of ladies' slips (shortening for

short persons, taking-in width for slim persons) particularly

to match fashions

transparency making a slip essential.

when dresses have a certain degree of

Another most distinctive feature of the chain stitch which will

certainly be appreciated by the homeworker for artisan type

production is that the chain stitdr is formed exclusively by the

needle thread thus freeing the operator from bobbin winding.

This, in turn, is a time saving factor. In addition to the above

mentioned applications the artisan worker will use the chain

stitching for —

# First contour stitching on shirt collars — sewing on labels —

hemming operations on neckties and umbrellas — in short,

all operations where the chain stitch proves to be advanta

geous wuth respect to convenience, quality and time.

Page 26

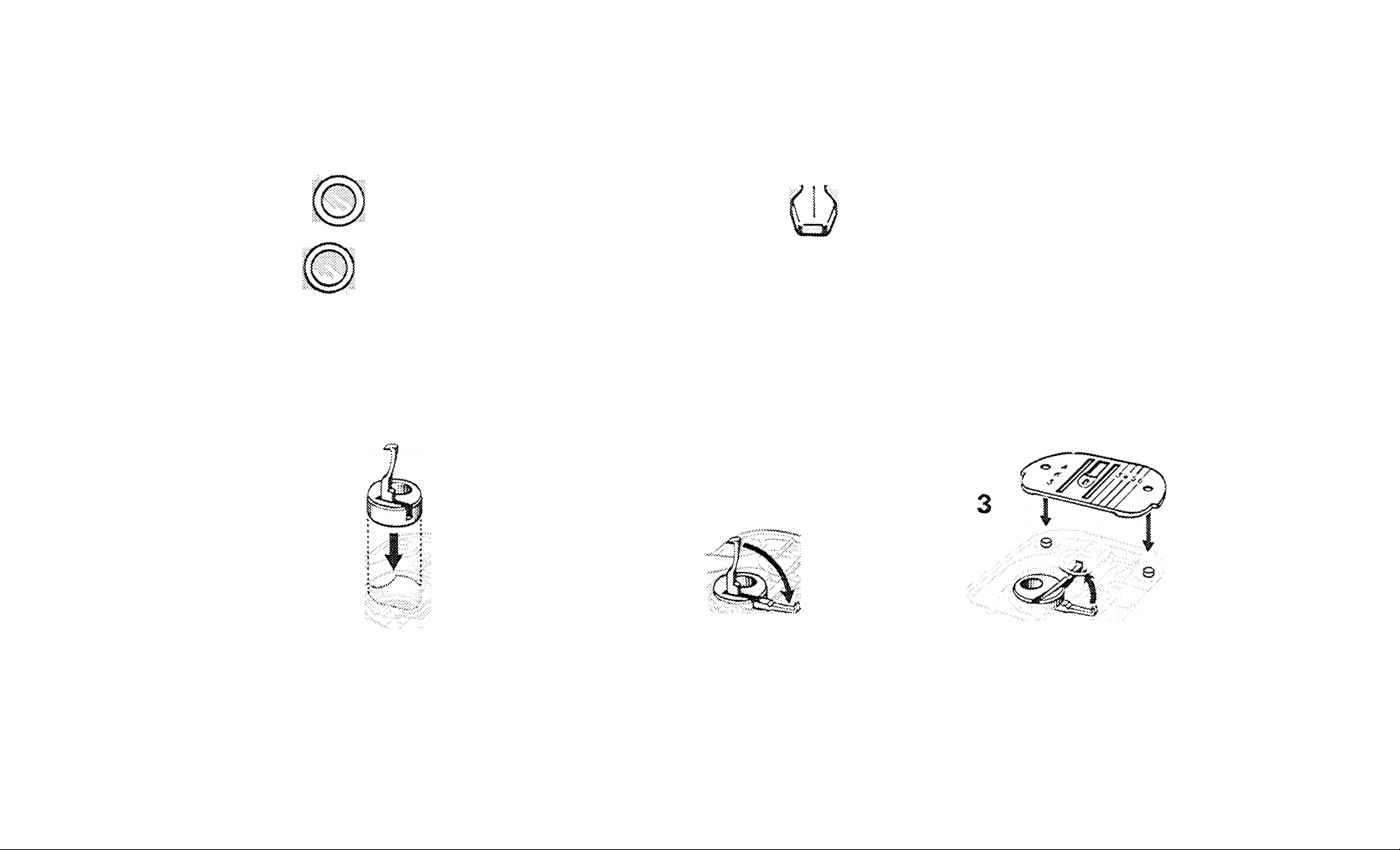

K

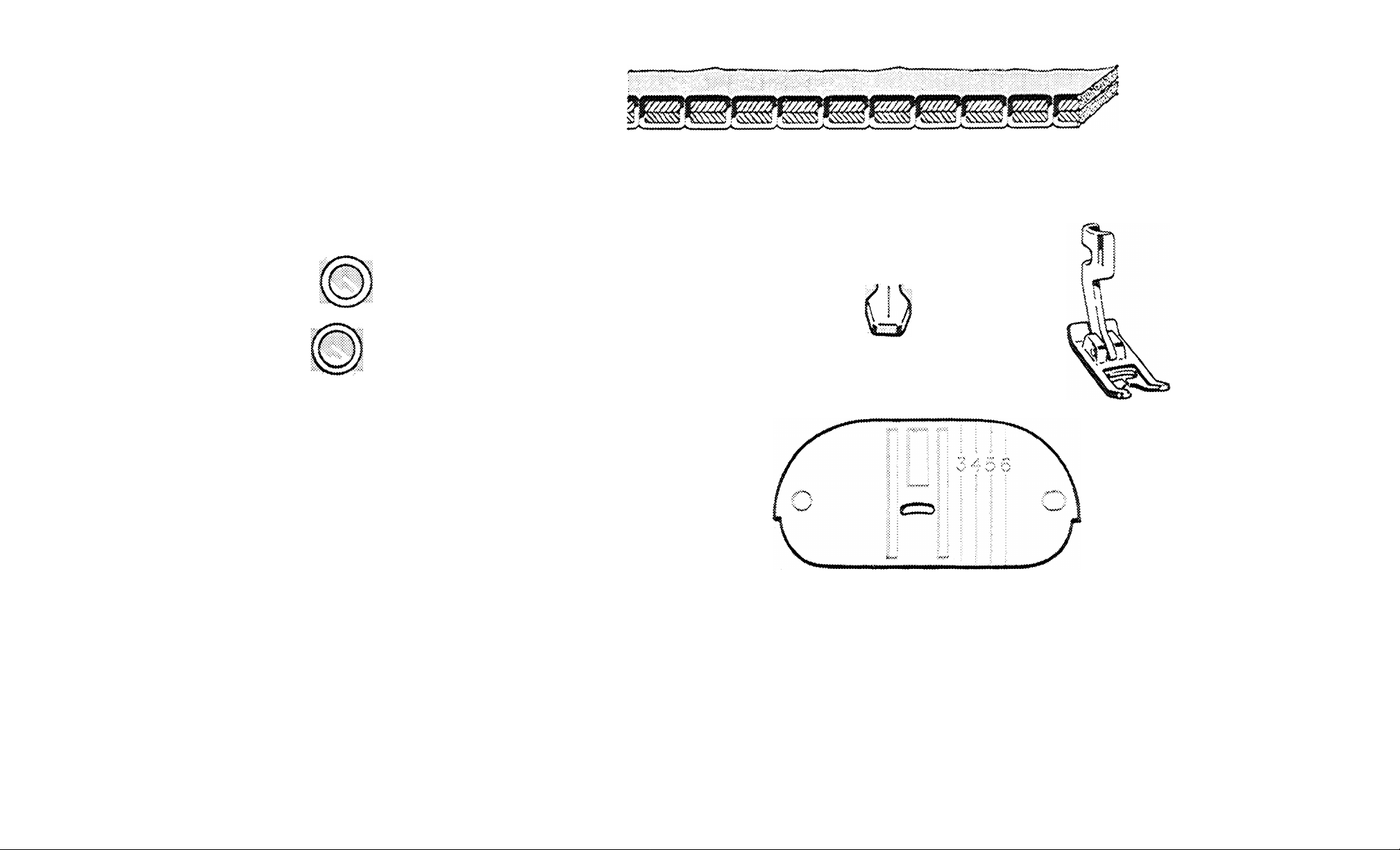

TO PREPARE THE MACHINE FOR CHAIN STITCH SEWING

Set Selectors at AK and stitch width lever at 3

First remove regular throat plate and bobbin.

A

Insert chain stitch loop retainer into bobbin, case

(Illustration 1)

Depress latch (Illustration 2) and turn to the left

against stop (Illustration 3).

Insert chain stitch throat olaie.

2

24

Page 27

J-

/

CHAIN STITCHING

A chain stitch seam has the same appearance as a

lock stitch seam on the top side of the fabric.

How^ever, the knotting of the stitch does not occur

in the m*aterial as on a nronerlv balanced lode stitch

A A A’

seam^; instead the thread forms loops on the under*

side of the fabric which resemble small arrowheads.

These arrowheads peculiar to the chain stitch point

tow^ards the beginning of the seam.

When starting make sure that the take-up lever is

in its highest position. This will prevent the needle

thread from pulling out of the needle if the thteed

has been cut too.short. Sew forward only! If the

material is

pivoted at the needle for operations

where cornering is required, make certain that the

needle is on its upward movement (approx. 1 cm

above its lowest poinX] to avoid skipped stitches.

Then continue to sew.

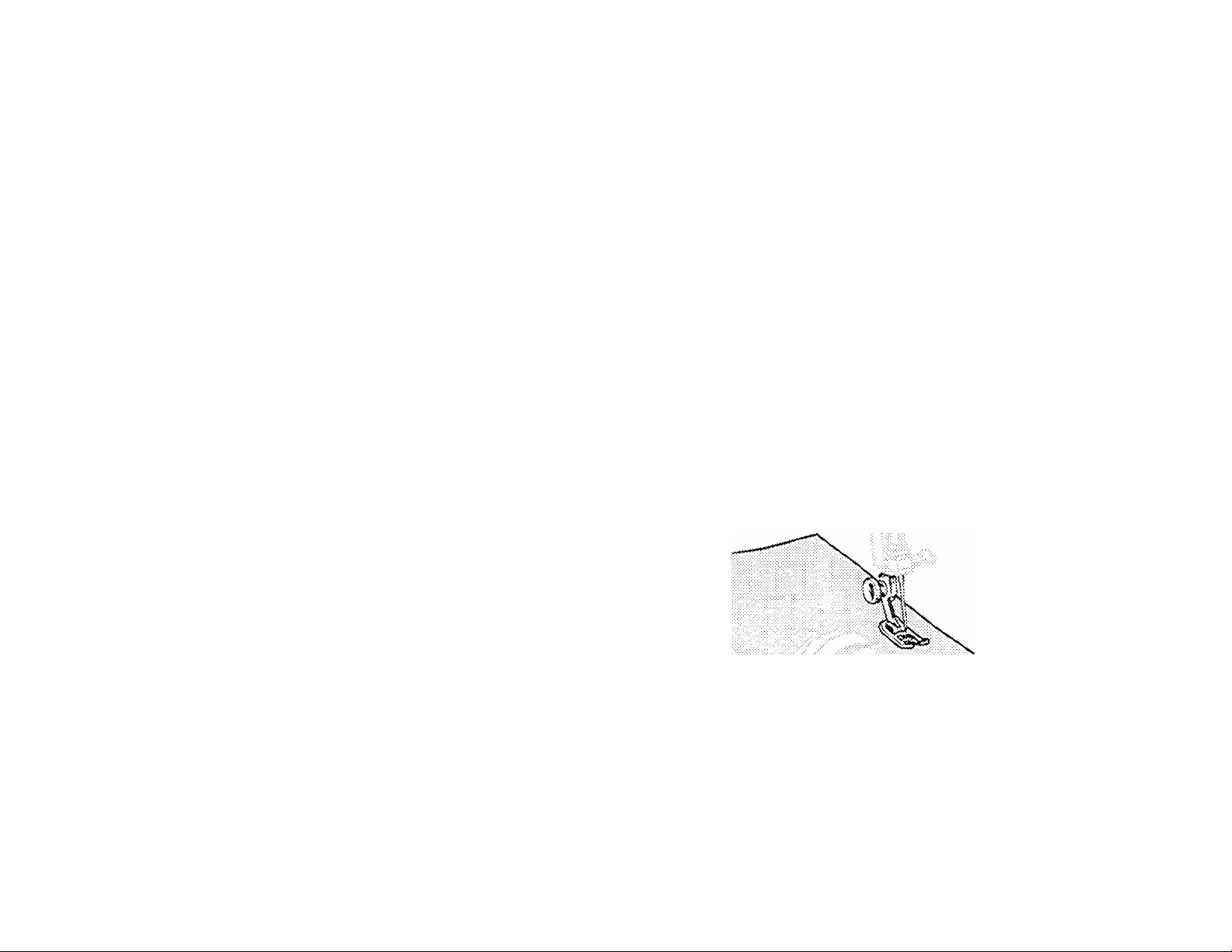

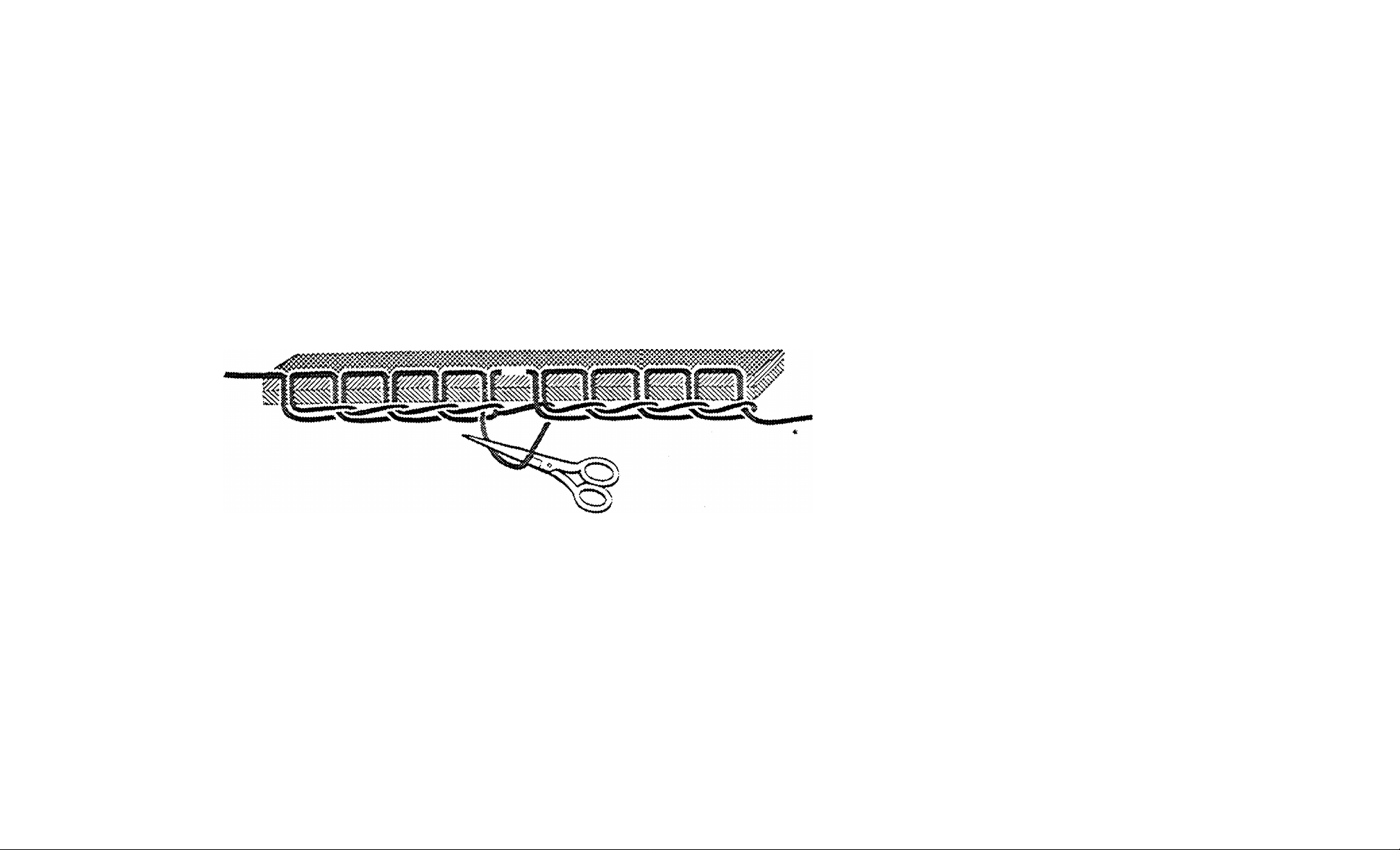

TO REMOVE THE MATERIAL FROM BENEATH

THE PRESSER FOOT

Threading: In addition to normal threading, place

the needle thread in the chain stitch thread guide

with the face plate open.

Stitch length: Normally set for mxaximum length,

approx. 6 stitches to the inch (4 mm] (left row of

numbers on the stitch indicator plate). Any stitch

length between 6 and 12 stitches to the inch (2 mm)

may be used.

Upper thread tension: Norm^ally set between 2 and

3. Slight adjustnaent may be required dependent on

the thread size and the material used.

The easiest way of removing the material is to sew

off the edge of the fabric while slightly pulling on

the material. This produces a chain which should

be cut some distance away from the fabric. How

ever, if the seam is ended before the edge of the

fabric, bring the take-up lever to its highest posi

tion, then lift the presser foot and pull some thread

through the take-up lever from the spool pin. Now

draw the loose thread between the presser foot and

the material to the right with the scissors and then

cut the thread. By removing the m^aterial the free

end of the thread is automatically pulled to the

underside of the material and the seam is securely

locked.

2o

Page 28

mmmmmmmm

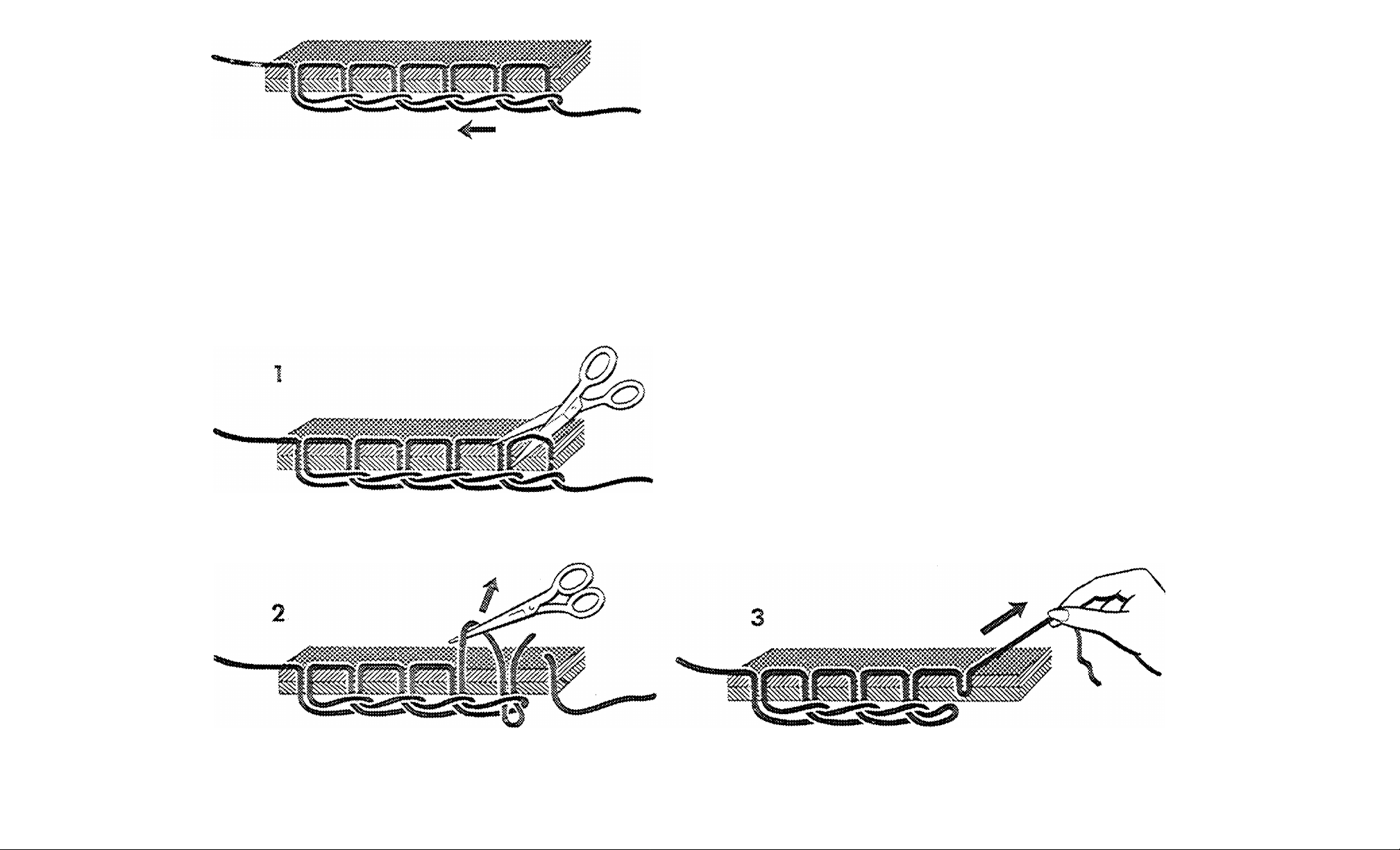

TO OPEN THE SEAM

The chain stitch seam can be opened in one direc

tion only, from the end of the seam towards the

start of the seam, The opening direction is distin-

Difeciion of oDer.incT

giiished by the arrowheads on the underside of the

fabric which point towards the beginning of the

seam.

To open the seam, cut the last stitch on the top side

of the fabric and then pull up the preceding stitch.

With this free thread end the seam can be removed

by a singie pull. In the same manner the seam may

be opened and removed at any desired place by

pulling the thread end in arrowhead direction. The

remaining section to the end of the seam will be

maintained.

28

Page 29

Section to remain

Section to remain

Section to be onened

>

However, if the section towards the

beginning of the seam is to remain and

the segment towards the end of the

seam is to be removed, either partly

or completely, the remaining section

must be locked nrst. For this purpose,

cut the seam at the desired place on

the top side and pull the loop out of

the fabric on the underside of same.

Then the desired segment of the seam

can be removed as stated above.

TO CHANGE FROM CHAIN STITCHING TO LOCK STITCHING

Cimnging to lock stitching requires only unthreading of the diain stitch thread guide (see page 25), repla

cing the bobbin and inserting the desired zigzag or straight stitch throat plate.

27

Page 30

A

LOCK STITCH

STRAIGHT STITCHING

AK 3

K

Set Selector at AK.

Stitdi width lever at 3 — To locate stitching in central position.

General purpose throat plate and presser foot.

Use general purpose throat plate and presser foot for all utility sewing, long straight seams, etc., and

where there is occasion to alternate between straight and zigzag stitching.

26

Page 31

STIiAIGHT STITCH ТНШАТ PLATE AND

PRESSER FOOT

т г.

Jse the straight stitch throat plate and presser

Ui

foot where fabric and sewing procedure require

close control.. Лог precision stitching of curved

and scalloped edges, top stitching, edge stitching,

etc.

For best results, this equipment should be used

when stitching sheer and hlmy fabrics, knits and

tricots (particularly synthetics) and all soft spongy

materials.

STRAIGHT STITCHING WITH LEFT AND RIGHT NEEDLE POSITION

12 4 5

A

Set Selector at AK.

Stitch width lever at I, 2, 4 or 5*

General purpose throat plate and presser foot.

Do not make stitch width lever adjustments while the needle is in the fabric.

To meet special requirements a line of stitching may be placed to the right or left of centre.

Stitch lever settings 1 and 2 locate stitching to the left. Settings 4 and 5 place it to the

Intermediate settings may also be used.

right.

29

Page 32

PREPASE TO SEW

Hold needle thread lightly with left hand. Turn hand wheel so that needle enters plate and brings

up bobbin thread.

-I V

i

/

Pull end of bobbin thread through plate and place both needle and bobbin threads diagonally under

presser foot.

30

Page 33

SHWING A SEAM

i ■

/

IL ‘

w

lower oresser foot. Raise stitch regulator to reverse.

/4.

U/’

i

i '

Back stitdi to

of fabric for reinforcement. Lower regulator for forward stitching of seam. Raise

stitch regulator.

from edge

anc

31

Page 34

Back stitch to reinforce end of seam, and lower regulator to forward stitching position,

With take-up lever at highest point, raise presser foot and remove fabric.

32

Page 35

GUIDING AND SUFPOETING FABRIC

Most fabrics need only to be guided in front of the presser foot.

Fabrics of unusual texture and weave, filmy sheers, crepes, knits, tricots, etc., require support while

being stitched.

For such fabrics, use the straight stitch throat plate and presser foot, and apply gentle tension to the

seara by holding the fabric in front and in back of the presser foot as illustrated.

33

Page 36

PRESSURE ADJUSTMENTS

U

Increase

Pressure is the force the presso;

while it is being stitched.

The presser foot must be lowered prior to adjustments.

Smooth, even hdj:\Qling of several thicknesses of fabric

results when pressure is correctly regulated. Heavy pressure is for thick fabric and light pressure is for thin fabric.

Too light a pressure will result in irregular feeding which

affects both quality of stitch and evenness of seams.

Too heavy a pressure not only affects stitch and seam

quality but will also mar smooth surfaces and pile fabrics.

Surface finish, as well as the weight and texture of the

fabric, must be considered in determining the amount of

oressure needed.

Position for darning

and embroidery

operations

Xy .

■oot exerts on fabric

34

Page 37

NEEDLE THREAD TENSION

STRAIGHT STITCHING

Needle thread tension too tight —

correct by setting dial to lower num

ber.

issKsse

Needle thread tension too loose

correct by setting dial to higher nm

ber.

A perfectly locked stitch results with upper and lower tensions balanced so that needle and bobbin

breads are drawn equally into fabric.

35

Page 38

BOBBIN THREAD TENSION

STRAIGHT STITCHING

Bobbin thread tension too tight —

correct by turning screw in direction

indicated.

Bobbin thread tension too loose —

correct by turning scre\v in directiO;

indicated.

A perfectly locked stitch results with the upper and lower tensions balanced so that needle and bobbin

threads are drawn equally into fabric.

36

Page 39

ZIGZAG STITCHING BQUIFMHNT

General purpose presser loot

Special purpose presser foot

37

Page 40

STITCH LENGTH ADJUSTMENT FOli SATIN STITCHING

0^

m

mSSS^H

The upper indented area behind the stitch indicator provides a means

of gradually shortening the stitch length*

As the regulator knob is turned, the pointer rides deeper into this

indentation until a closed satin stitch is obtained.

The exact stitch setting will vary with the texture of the fabric.

It is advisable to make a test on a scrap of self fabric, using the

Special Purpose Foot, before proceeding with actual work.

Page 41

SATIN STITCH

TENSION ADJUSTMENT

Satin stitdaing requires a lighter needle thread

tension than straight stit<hing or open designs. The

wider the satin stitching the lighter the tension

required.

Wide satin stitching, stitdi width lever at 5, requi

res the least amount of tension. For narrower satin

stitching slightly more tension should be used.

To determine correct tension setting, a test

sample should be made on self fabric using the

Special Purpose Foot. A properly balanced satin

stitch should lie hat across the material. Any taut

ness or puckering indicates too high a needle

thread tension.

Some soft fabrics may require the addition of a

backing to insure good stitching results. Crisp

organdy and lawn are suitable for this purpose.

Tight needle thread

tension

Correct needle

tension

Page 42

PRIMARY PATTBRNS — BUILT-IN THH MACHINH

See pages 19 and 20 for operation of stitch width lever and selector.

L N P R

S Mid 0| Special

i M h ^ ^

I i J. i 1 i.

5

The operation of the upper selector button between L and Special controls the function of the primary

patterns shown below.

The setting of the lower selector button at 3 places the stitching in the central needle position.

The stitch width lever controls the width of primary patterns.

Do not make stitch width lever or selector settings while the needle is in the fabric.

L

u

H

0

p

u

*

i

1

ylll

i

1

i

40

Q

R

'N

J

S

S

P

E

C

1

A

L

Page 43

PRIMARY PATTERNS

SPECIAL DISCS

These five interchangeable Special Discs, classihed as Primary Patterns, are included with the ma

chine. Each produces an individual design.

Circled numbers (for example in this book indicate Special Disc numbers.

41

Page 44

L N P R

: : i

M'OiOi

PltlMARY PATTERNS

REPLACEMENT OF SPECIAL DISCS

Special

To replace any of these discs, move pointer of the upper Selector off Special.

Raise the stitch chart at top of the machine. Remove disc and place another disc onto spindle, pushing

:r>vnward until disc snaps in place.

Set pointer of the upper Selector on Special to engage the disc.

Page 45

PRIMARY PATTERNS

SXrrCH WIDTH LEVER CONTROL OF WIDTH

•J*»'

58E

m|0|CI| Special

The width of Primary Patterns is controlled by the stitch width lever. Settings range from a maxi

of 0 to a minimum of 2.

Page 46

PRIMAItY PATTERNS

NEEDLE POSITIONS

Selector setting of B places stitching in central

needle position. Selector settings A and C place the

stitching in left and right needle positions at widths

less than 5.

LEFT

CENTER

L N P R

I mIoI o! Special

i i i

RIGHT

Selector setting B is preferred. Settings A and C

are only used when special placement of stitching

1$ desired. For example: Buttonholes, button sew

ing.

44

B

L N P R

¡MjO|Q| Special

\ i I

Page 47

COMBINATION PATTBRNS AND VARIATIONS

-w»

J

4

A great variety of additional stitch patterns can be created by combining any lower Selector setting

from D through J with any upper Selector setting from L through Special.

A stitch width lever setting of 3 results in a Combination Pattern. Settings of 2 and 4 produce Varia

tions.

45

Page 48

The needle clamp accommodates two Cat.

2020 (15X1) needles, generally of the same

size. However, where special effects are

desired, needles of different sizes may be

TWO NEEDLES

used together, with corresponding threads.

Loosen the thumb screw and insert the addi

tional needle from the right, (See page 6 for

procedure.)

46

Page 49

TWO NEEDLES

UFPES: THREADING

Thread as for single needle first (see page U). provided (see illustration). Slip second spool of

Open top cover, insert auxiliary spool holder thread on to the auxiliary spool holder and thread

(which is furnished with the machine) into the hole second needle as shown.

Make certain that threads are separated by the centre tension disc. Carry only one thread through last

guide at the needle clamp.

47

Page 50

A

TWO NEEDiES

STRAIGHT STITCHING AK 2

Selector setting: AK.

Siitdi width lever: 2 only.

General purpose loot and throat

4$

I I

Page 51

L N P R

. I mIoI OI Soecia’

Selector setting: A — L through special

Stitch width lever: 2 or 3 maximum.

General purpose throat plate.

General purpose foot or special purpose loot

TWO NEEDLES

miUARY PATTBItNS

40

Page 52

T A A. • ♦ A nr^ nn A T T Iftk *IW T O

mstmctions for using ATTACHMENTS..

50

NOTE: The attachments which are not regularly furnished with your machine are available

lor separate purchase at your local SINGER SHWLNG CENTRE.

Page 53

SPECIAL PURPOSE FOOT

^ •*.5' ^

BUTTONHOLES

Selector: AL

Stitch width lever: See below

Throat plate: Genera! purpose

This light, flexible foot

is designed for satin-stitching. It provides maximum

visibility and maneuver

ability while allowing

closely spaced zigzag

stitches to feed freelv.

It is ideal for accurate placement of satin stitch

ing in buttonholes, monograms, motifs and applique

work.

The eyelet on the left side of the foot accommod

ates a Mller cord.

APPLICATIONS

Special purpose foot

Stitch length: Fine

To establish the correct stitch setting and length

of buttonhole, a sample must ñrst be made.

Three stitch width lever settings are available.

Fabric weight will determine the selection.

Buttonholes

Applique

Monograms

Decorative Stitching

Couching

Motifs

51

Page 54

BUTTONHOtHS

Marking

lines

length of

cutting space

Bar tacks anci

side stitching

The length of cutting space, the opening through which the button passes, is measured by the wndth

and thickness of the hxxtton.

The length of the finished buttonhole will be the cutting space plus Vs indi for bar tacks.

Work a sample buttonhole in the same fabric as the garment. Use a double fold, duplicating a facing,

and include interfacing if this has been used.

52

Page 55

BUTTONHOLBS

Stltcbiag Procediire. Set Seiector and stitdi width lever. Place work under the needle, aligning the

center marking of buttonhole with center score line of foot.

To form side stitching, turn hand wheel toward you so the needle enters fabric at point A. Lower foot

and stitch to end of marking. Leave needle in fabric at point B. Raise foot, pivot work on needle. Lower

foot. Take one stitch without changing stitch width lever setting, bringing work to poird C. Adjust to

stitch width lever setting for bar tadcs and take no less than six stitches. Stop at point D. Readjust to

stitch width lever setting for side stitching. Complete to point B. Move to stitch width lever setting for bar

tacks and duplicate tack previously made, ending at point F.

53

Page 56

BUTTONHOIBS

Raised or Corded Buttonholes. Both No. 8 pearl

cotton and buttonhole, twist make suitable Eller

cords for raised buttonholes.

Place the spool of filler cord on the second spool

pin. Carry the cord through the first thread guide,

straight down between the center and back tension

discs, into the large thread guide and then through

the eyelet on the Special Purpose Foot. Draw the

cord under and in back of the foot and proceed as

for regular buttonholes.

To secure stitdiing move stitch width lever to

No. 1 setting and take three stitches. Remove work,

draw threads to the underside, fasten and trim.

With sharp embroidery scissors cut opening for

button.

54

Page 57

APPLIOUB

Applique adds beauty and interest to wearing

apparel, linens and fabric furnishings.

Either contrasting or self fabric may be used

effectively. The most versatile stitch in appliqueing is a closely set zigzag stitch (Primary Pattern

BL). The width of this stitch may be varied to

accommodate weaves and textures of fabrics,

Comibination Patterns and Variations present many

interesting ways to applique with decorative

stitching.

Preparation. There are two methods by which

applique work m.ay be done. The appropriate

Method No. 1. Set Selector and stitch width lever

for the desired stitch pattern. Following the shape

of the design, outline it entirely with applique stit

ching. Any excess fabric on the outer edges is

trimmed away after the stitching has been comple

ted.

method is determined by the fabric being used,

and a test sample is advisable.

Position the design properly and baste it to the

fabric. Attach the Special Purpose Foot to the pres

ser bar.

55

Page 58

APPLIQUB

Method No. 2, Set Selector and stitch width lever

to AK 3 for straight stitching. Outline the entire

design with a short stitch. Trim

le raw eages

down to the stitching.

Set Selector and stitch width lever to the stitch

pattern desired, and overedge the design with this

stitching. A

smooth, lustrous finish results, which

requires no additional trimming.

Corded Applique. The Special Purpose Foot,

which provides for a filler cord, is perfect for corded applique work. Gimp, crochet thread or button

hole twist are generally used.

See page 54 for threading.

Hither method of appliqueing may be used when

cording is desired. The only change in procedure is

the introduction of the cord, over which the appli

que stitching is formed.

This stitching technique results in a raised,

dimensional effect, and is an ideal finish for lace

applique.

56

Page 59

MONOGRAMS AND MOTIFS

Any of the many stitch patterns are perfect for

monograms and motifs.

Select a design from the mmny transfer patterns

available or sketch one to suit yoixr purpose.

Some fabrics may require a backing of lawn or

organdy.

Position the design on the right side of the

material. Trim backing away when stitching is

completed, if necessary.

To reproduce a specific portion of a stitch pattern, first stitch on a scrap of material until the

desired point in the design is reached.

Remove the material from under the presser foot.

Now position motif or monogram under the needle.

Lower presser foot and stitch.

This procedure is recommended for all precise

design placement. Leaves, and flower petals, for

example are created in this way.

57

Page 60

SEAMING SHEERS

Selector: BL

Stitdi widtE lever: 2

Throat plate: General Purpose

Special purpose foot

Stitch length: Fine (above 20)

A dainty hair-line finish is particularly desirable for the inside seams of sheer collars, facings and

yokes. Seam allowances that ordinarily show through are eliminated.

Both heavy duty thread and tatting thread make suitable filler cords (see page 54 for threading).

Follow the seam outline covering the cord. Cut away seam allowance close to line of stitdiing.

Turn and press.

Page 61

COUCHING

Novel effects are obtained by couching gimp,

yarn or braid with stiidi patterns.

Spaced patterns are the most appropriate as

they allow the decorative cords to show as part

of the design.

The Special Purpose Foot is ideally suited to

this work.

lACB EDGING AND INSERTION

Delicate and durable zigzag stitching is espe

cially appropriate for the application of lace

edgings and insertions.

Many decorative stitch patterns can be used

effectively serving as both finish and trim.

» S • /MM«,

, 'A

\

riti.

%rr ".■■■ -i

^ -

'A

' ''

V ■

• '

59

Page 62

ed.

The foot is used in connection with the Generel

Purpose reed Cover Plate.

Selector setting: AI.

Stitch width lever: 1 and 4

Feed Cover Plate

Button sewing foot

Stitdh length: above 20

Space between holes in button determines stitch width lever settings. Numbers I and 4 generally

anniv to standard buttons. Number 1 setting is constant, but 4 can be increased or decreased to accom*-

modate buttons with unusual spacing.

Set Selector at Ai and stitdi width, lever at I. Attach feed cover plate to machine in place of regular

throat plate in same manner as instmcted on page 21.

Position button under foot so that needle will enter into left hole. Lower foot. Turn hand wheel toward

you until needle rises out of fabric and is just above foot.

60

Page 63

BUTTON SEWING FOOT

Set stitch width lever at 4. The needle should then

enter into the right hole of the button. Take appro

ximately six zigzag stitches in this position. End on

the left side.

To fasten stitching, adjust to number one stitch

width lever setting and take approximately three

stitches.

THREAD SHANK

In order to form a shank, stitching is done ovpr

a regular machine needle. Position button and lower

button foot. Place needle in the groove of the foot

so the point enters the hole,

A larger shank results when the heavy end of

the needle is utilized.

61

Page 64

GENERAL PURPOSE FOOT

Used with the general purpose throat plate this

foot provides a wide needle slot which accommo

C -3 -a a it O *3 <i- ^ ■■■i ii ix ii y>

SBAMS

ONGBRIE SBAMS

Dainty lingerie seams are made durable and rip-

proof with zigzag stitching (BL 2V2), After straight

stitching the fitted seam on the wrong side, press

both seam allowances in the same direction. From

the right side, top stitch with a fine zigzag setting,

letting the needle enter the seam line and then the

seam thickness. Particularly good where fiat bias

seams are desired.

dates all stitch settings and can be used for most

sewing operations.

APPLICATIONS

Seams and Darts

Mending and Maintenance

Mi

Automatic Scalloping

Seam Finishes

62

%

%

%

%

Page 65

SBAMS

FLAT FSIIED SHAMS

Zigzag stitching gives strength and durability to

flat felled seams.

Form the seam to the right side of the fabric,

taking full seam allowance, using a zigzag stitch

(BL 3).

Press the seam open, then fold and press the two

edges together, keeping the right side of the zig

zag stitch uppermost.

Trim a wav half the under seam edge.

•A V*

Fold the upper seam edge evenly over the trim

med seam, and top stitch.

KNIT FABRIC SHAMS

A fine zigzag stitch (BL iVi) is ideal for seaming

knit fabrics. Particularly desirable for underarm

seams and other seams where elasticity and give

are needed.

For neckline and waistline seams, where a stav

is needed to prevent undue stretching, this same

stitch can be used to apply seam tape. To insure

a flat, smooth finish, position the seam tape with

the edge exactly on the seam line. If seam is cur

ved, pre-shape tape to fit by steamhng, and baste

in place.

Stitch, allowing the needle alternately to enter

the seam tape and seam line.

Page 66

SEAM FINISHES

Seam edges support the garment and should be given a durable finish where fabrics have a tendency

to ravel.

The zig/cag stitch BL is ideal for sucn finishing. Place the stitching near the edge of the seam allowance,

and then trim away excess fabric.

For an overedged seam, the blind stitch 30 makes a durable bulkless finish. Good for straight grain,

lengthwise seams.

Seam edges should be trimmed evenly, and the stitch then form^ed over the raw' edge.

Page 67

0ARTS

Darts provide fit and contour in a garment and

should be accurately stitched.

A straight stitch dart (AK 3) is usually formed

by stitching from the seam edge, tapering gradually

to the point, where the last 3 or 4 stitches parallel

the fold. Stitch beyond'the fabric to form a thread

chain V2 to V-4 inch in length. Tie the thread ends

into a single knot close to the stitching.

SINGIB THREAD DARTS ,

Darts add styling and interest when stitched with

the fold to the outside of garment. Thread ends

at the point of the dart are eliminated when the

single thread principle is employed.

Unthread the needle, use the thread leading off

the bobbin and rethread the needle from back

to front. Tie bobbin and upper threads together.

Draw bobbin thread up through, threading points,

winding enough on the spool to complete a single

dart. Lower the needle into the very edge of the

fold at the point of the dart. Take any slack out of

the thread by turning the spool. Lower the presser

foot and stitch carefullv toward the seam edae.

* V

This method is also ideal for inside darts in sheer

fabrics as thread ends are eliminated at the point

of the dart.

f 'j

h

65

Page 68

DARTS IN INTERFACING

Non-woven interfacings can be shaped withoat

bulk with гigгag stitching. Selector setting BL or

BQ may be used.

Cut out the dart allo'wance on the stitching line

and bring the raw edges together. Pin, over a

muslin stay, and stitch. Back stitch at both ends.

BLANKET BINDING

T

The multiple stitdi zigzag (BQ) is an excellent

stitch for applying blanket bindings and affords

both a decorative and durable hnish. Rem.ove worn

binding. Baste new binding securely in place and

stitch. Adjust pressure if necessary, to accommo

date the thickness <of the blanket.

66

I I »1 ■ Hw 11 i|i I in ■ I

Page 69

MINDING

Zigzag stitching is well suited for all types of

household mending. Selector setting 30 provides

a firm, flexible bond for the repair of rents and

tears, and is ideal for the reinforcement and appH*

cation of elastic. Stitch length and are regu

lated according to need.

Rent or Tear. Trim* away ragged edges. Place

an underlay to the wrong side of the tear for

reinforcement. Using the multiple stitch zigzag

(BQ) follow the line of the tear bringing the edges

together. Shorten the stitch length at ends and

corners to give extra strength.

vV\AA/>/v^AVv'^/vVVvVvWVv\A,V\A

I I

'v

i/ f

\—f

J'

r*v

W'

Application of Ilastic.

Elastic, such as used in

waist bands, must be

stretched as it is applied,

to insure fullness required in the garment.

^ 'V ■

X.

•• • ' 's •

^ -'■v'

67

Page 70

SCAIiOPING

Dainty scalloped edges are used extensively as self trimming on blouses, cresses, lingerie and child

ren’s wear.

Perfectly formed and evenly spaced scallops are produced automatically at Selector Settings BE and

BS ®

BR results in a I2-stit<m scallop.

BS a 24-stitch scallop.

Stitch regulator and stitdr width lever settings vary the length and depth of the scallop.

After stitching, trim seam allowance to less than Vs" and clip into the points between scallops.

Some fabrics may also need notching, for a smooth, evenly turned edge.

Turn, gently roll out scallops between the hngers and press.

When scalloping a shaped or bias edge it is best to use an interfacing.

When forming scalloped tucks, add an extra to tuck allowance for seaming.

Page 71

THB SHAM GUIDE

The seam guide aids in

attaining uniformity of

seam width. It provides

for stitching to be spaced at any distance between

Vs'' to IV4" from the edge of the fabric.

SEAMS

To guide seam stitching straight and parallel to

the edge of the fabric, adjust the attachment for

proper seam width. Align the guide with the pres

sor foot. (Set Selector at AK, stitch width lever at 3.)

Pin seam edges and baste if necessary. Hand

basting can be eliminated on easy-io-handle fabrics.

Place pins with the points toward the seam edge

so they nip into the fabric at the stitching line.

The hinged presser foot will ride freely over the

points. Guide the fabric edges lightly against the

guide while stitching.

APPOCATIONS

Seams

Top Stitching

Decorative Stitching

Blind Stitching

The attachment is used in connection with a

presser foot.

It is secured to the bed of the machine in either

of the threaded holes to the right of the needle.

b

i ..=i

69

Page 72

CURVED SHAMS

TOR STITCHING

Curved seams require additional treatment in

handling. A shorter stitch will provide greater

elasticity and strength. Set the attachment at an

angle so that the end closest to the needle acts

as a guide.

A simple and practical way to accent the lines

of a garment and at the same time give additional

firmness.

Hither single or multiple rows of stitching can

be expertly placed along lapels and facing e<

around collars and pockets and as a hem finish.

A subtle enect may oe acmevec oy using straight

stitching, or a decorative touch may be added by

using any of the attractive stitch patterns accom

plished with this machine.

70

Page 73

BLIND STITCHBD HBMS

Selector: BO

Stitdi width lever: 2—5

Stitch length: 10—20

Presser foot: General purpose

Throat plate: General purpose

Seam guide

Blind stitching provides a durable hem finish

that is almost invisible, and comparable to hand

sewing. It is equally suited to straight as well as

circular hems. Taped, bound, turned or unfinished

hem edges can all be blind stitched with equal ease,

Mark, turn and press the hem in the usnal way.

Place a basting guide line approximately from

top hem edge.

Set Selector at BO. This setting produces four

straight stitches, separated by a single sideward

stitch to the left.

Stitch width lever setting for width of stitch is

determined by the weight and texture of the fabric

used.

Place the hem edge over the feed of the macrine,

turn back the bulk of the fabric to the line of bast

ing, creating a soft fold.

Position the work so that the straight stitches are

made on the hem edge and the sideward stitches

pierce the fold.

The stitch length will regulate the distance bet

ween the blind stitches (10 to 20 stitches per inch).

Adjust the seam guide over the right toe of the

foot until it rests next to the soft fold. While

stitching, feed the fold against the flat of the guide.

A test sample in self fabric should be made to

determine correct settings.

Page 74

THE ZIPFER FOOT

©

^ <5

iS 1S iS

This foot is designed to facilitate the placement of stitching close

to a raised edge. The hinged feature of this foot insures even feeding

over oins, heavy lavers of fabric or cross seams. It is attached to the

machine in place of the regular presser foot, and may be adjusted to

either the right or left side of the needle. Straight stitch or zigzag

settings mav be used.

^ A

APPLICATIONS

Zipper Insertions Tabular Coidmg

Corded Seams

Preparation. Secure the zipper foot to the presser

bar as you would the regular presser foot. Set Selec

tor and stitch width lever. Adjustment to the right

or left of the needle is made by loosening the

72

Slip Cover Welting

thumb screw at the bach. Check the position of the

foot bv lowering the needle into the side notch,

making sure it clears the foot. Lock it into position

by tightening the thumb screw.

Page 75

ZIPPER INSERTION

Selector: AK

Stitch width lever: 3

Throat plate: General purpose

Zipper foot

Skirt Zipper. Machine baste the placket opening

of the skirt and press this seam open. Attach the

zipper foot to the machine and position it to the

right of the needle. Open the zipper. Place the

zipner face down on the seam allowance with the

edge of the teeth at the seam line. Turn the back

seam allowance away from the body of the skirt.

Stitch the zipper tape to the seam allowance.

Page 76

ZlWm INSERTION

Move the foot to the left. Close the zipper and

turn it face up. Smooth back the seam allowance

at the edge of the zipper. Top stitch it to the tape

close to the folded edce.

Tarn zipper face down. Turn work to right side

and pin in place. Baste. Move the foot to the right.

Stitch across the lower end of the zipper and up

to the waistline. Remove basting.

Page 77

BLIND STITCHED ZIP FASTBNBH INSERTION

Selector setting: BO

Stitch width lever: 2V2 or 3

Throat plate: General purpose

Stitch length: 12

Cording foot

Blind stitching the final step of a zip insertion

results in a fine finish that is almost invisible and

comparable to hand sewing. Particularly suitable

for chiffons, sheers, velvets and all delicate fabrics

where top stitching would be too harsh.

Allow a Vs" seam allowance. Start the insertion

in the regular way but omit final step.

Work from the right side of the garment and pin

the front of the zip tape into position.

Roll the work over hnger to ease fabric and nin

V A-

through ail thicknesses. Baste about Vs" from seam

line to provide guide for blind stitching. Remove

Dins.

Set stitch and adjust cording foot to the right

side of the needle.

Turn garment inside out. Place zip tape over

feed of machine and turn back the front section of

garm>ent to line of basting, creating a soft fold.

Position work so that the straight line of stitering

is made through front seam allowance and zip tape,

and the sicewmys stitdi pierces a few threads of the

fold. Lowmi presser bar and stitch slowly. Remove

bastings. Press.

75

Page 78

CORDED WELTING

Selector: AK

Stitdi width lever; 3

Throat plate: General purpose or

Straight stitdi

Zipper foot

Cable cord comes in a variety of sizes and when covered with a hrmly woven fabric makes a corded

welting that is an excellent seam finish.

This welting is prepared in advance and then stitched into the seam. Cut a true bias strip iV« indres

wide, plus three times the width of the cord of either self or contrasting fabric. Sew strips together on

the lengthwise grain to obtain desired length.

Set Selector. Adjust zipper foot to the left side of the needle. Encase the cord in the bias strip, raw

edges even. Lower pressar bar. Stitci close to the cord, using a stitch length slightly longer than for

seaming the weight of fabric being used. Do not crowd the stitching against ^he cord.

/6

Page 79

COR0BD SHAMS

Selector: AK

Stitdi width lever: 3

Throat plate: Genera! purpose or

Straight stitch

Zipper foot

The corded seam is a typical treatment for slip

covers, children's clothes, blouses and lingerie»

When cording a seam the zipper foot is usually

adjusted to the right of the needle so that the bulk

of the work will fall to the left.

Set Selector and stitch width lever. Attach the

corded welting to the right side of a single seam

edge, with the same stitch length used to make the

welting (page 76). Guide the edge of the foot next

to the cord, but do not crowd.

Place the attached corded welting over the

second seam edge, and pin or baste together.

Keep the Mrst stitching uppermost as a guide and

position the seam under needle. Stitch, this time

crowding the foot against the cord.

This method produces evenly joined seam edges

and tightly set welting.

Curved seams are corded as easily as straight

seams, except that a shorter stitch length is used.

Since the seam allowance of the welting is bias,

it is not difficult to shape it to the seam.

Page 80

TH£ FOOT HHMMBH

threads under the hemmer. Place the fabric under

the foot and stitch through the creased fold for seve

Fine hems

Edging ruffles

Sheer seams

Throat plate: General purpose

Foot Hemmer

The narrow hemmmr forms

and stitches a perfectly turn

ed hem without, basting or

pressing. It is attached to the

machine in place of the

regular presser foot.

APPIICATIONS

Selector: AK

Stitch width lever: 5

Hemming with lace

Lace insertion

Lingerie hnishes

ral stitches. Hold the thread ends in the left hand

and guide the raw edge in front of the hem.mer

evenly into the scroll. Sew slowly, still holding

thread ends until the hem is well started.

Soft fabrics will enter the scroll best with the foot

down; firm^, crisp materials with the foot raised.

Even feeding is essential to good hemming. The

same width of fabric must be kept in the scroll of

the hemmer at all times. A little practice will result

in perfectly formted hems.

HEMMING

Set Selector and stitdi width lever. At the very

edge of the fabric form a double Vs" fold. Crease

this fold for about 2". Draw the bobbin and needle

78

Page 81

HEMMING WITH LACB

Selector: Bi

Stitch width lever: 3

Throat plate: Genera! purpose

Foot Hemmer

Most of the popular kinds of lace edging and

insertion can be applied with the Foot Hemmer. It

is an excellent way to trim children's clothes and

to finish lingene hems,

lace Applied Over Hem. Fold and start the hem

in the msual wav. Starting about 1" dowm from the

end of the lace, place the selvage under the needle

and lower needle to hold lace firmly. Raise the foot

slightly and slip the lace under the back portion

of the foot, without disturbing the position of the

fabric. Stitch slowly, guiding the fabric with the

right hand, the lace with the left. Take care not to

stretch the lace,

lace Applied Under Hem. When using lace

underneath the fold of a hem, the procedure is the

$am*e as when making a hemmed seam. Slip the

lace in from the left as you w'ould the second piece

of fabric. This method is used where a neat finish

is desired on both sides of the material.

Page 82

DBCORATIVH HEMS

Selector: AH settings

Throat plate: Genera! purpose

Stitch width lever: 2 thru $

Foot Hemmer

Narrow hem edges can be turned and decorated

in one operation using the foot hemmer and a

stitch pattern.

This time-saving finish is especially suited to

fie edges and aprons.

Lingerie and most delicate fabrics can be attrac

tively finished with a soft shell edge. This effect

is obtained by hemming with Selector set at BO

or BQ and stitch width lever at 4.

l*‘^l

................

.........

,,|,||T> i<*n

_______

<*fwMIIII^ ^l|

..........

eo

YVry-'

V .>» y

\ V j I . i ■•■ V \ i:i VU' I ; V, '. /. iii ■' V V:'^ \ i ■ /' '■ ■' ■ ''• ^ ^ ''■■''i'’ '■ ■ \ t ■'

I-Xi!' \ I ^1 W

M i ' '■ «' . I \ ' V

Page 83

Mum-SIOTTEB BLNBBH

Slot for

folded

Adjusting

lug

bias tape

Guide

pins

Scroll for

unfolded

binding

Selector: All settings

Stitch width lever: 2 thru 5

Throat plate: General purpose

Multi-slotted binder

The multi-slotted binder is used to apply com

mercial binding as well as self fabric bias to an

unfinished edge.

Cut binding diagonally to form a long point.

Commercial binding 1$ inserted from the right into

the appropriate slot in the scroll. Unfolded bias

of an inch wide is inserted into the opening at the

end of the scroll.

Pull binding through scroll until the evenly

folded edges are under the needle. The free length

of the binding is held between the guide pins.

Set Selector and stitch width lever for either

straight or zigzag stitching.

Insert the edge to be bound into the centre of

the scroll. The stitching is positioned dose to the

edge of the binding by moving the scroll portion

of the attachment to the right or left by means of

the adjusting lug.

This colourful trim is attractive when applied to

children's wear, aprons and fabric furnishings. It is

a practical finish for seam edges that ravel and for

making bound seams.

The attadiment will accommodate both straight

and zigzag siitcfeing.

8

Page 84

MULT!>SIÒTTED BINDER

Lower the pressor bar. Allow the attachment to do the work, merely guiding the fabric into the centre

of the scroll as you stitch.

Curved edges require slightly different fabric handling than straight edges.

Inside curves are straightened as they are fed into the binder. If the fabric is soft and has a tendency

to stretdi, reinforce tlie edge with a single row of stitching before binding.

Outside curves tend to lead awmy from the centre slot of the scroll and should he guided so that a full

seam width is taken at the needle point. Do not attempt to pull or straighten fabric into the full length

of the scroll.

82

Page 85

THE RUFFLBH

Fork

Arm

presser

Bar

Separator

Blade

^uiflixig

Blade

Separator

Guide

Adjusling

Lever

Adjusting

Finger

Adjusting

Screw

Selector: AK

Stitch width lever: 3

Throat plate: Straight stitch

Ruffler

Adjusting Points. 1. The adjusting lever sets the

ruiiler lor gathers or pleats. The Number 1 space

setting Is for gathers, and places fullness at every

stitch. Numbers 6 and 12 are soace settings for

pleats, spacing them either 6 or 12 stitches apart.

The star is for straight stitching, and is used when

grouping gathers or pleats.

2. The adjusting finger is used only lor pleating

and affects the width of the pleat. It is thrown out

of action by bringing it out of contact with the

adjusting screw.

This attachment offers a simple and effective way

to make gathered and pleated raffles. Ruffles may

be made separately or mace and applied at the

same time. The ruffler is attached to the machine

m place ot tne regular presser foot anci is used

with a straight stitch setting only.

3. The adjusting screw regulates the fullness of

gathers or pleats. When turned in to its limit with

the adjusting finger in place, the attachment is set

for its deepest pleat. When turned outward to its

limit and the adjusting finger out of action, the

ruffler gives only a hint of fullness.

$3

Page 86

THE WV¥Lm

Activating Parts* The rufiling Made and the

separator blade are of blue steel and hold the

material to be gathered between them. The rnillmg

Made forms the gathers or pleats by carrying the

fabric to the needle according to the spacing and

fullness to which the rufOer is adjusted. The sepa

rator guide is slotted to guide seam edges evenly

and to separate the ruffle strip from the material to

which the ruffle is attached*

Gathering. Set the adjusting lever of the attach

ment on Number 1 setting, and throw the adjusting

hnger out of action. Turn the adjusting screw for

the amount of fullness desired and set the stitch

length to space the fullness. The attachment is

adjusted for maximum fullness by turning the

adjusting screw all the way inj for less fullness

turn it outward.

Preparation* Raise the needle to its highest point.

Locate the attachment on the machine in place

of the regular pressor foot, at the sarnie time fit the

fork arm over the needle clamp screw. Make sure

both the presser bar screw and the needle clamp

screw are tightened securely.

84

Page 87

THE RÜFFLER

The length of the sowing machine stitch also

affects ruffle fullness. Since a given attachment

setting puts an equal amount of fullness into each

stitch regardless of its length, shortening the stitch

(more studies to the inch) makes the ruffle more

full, lengthening the stitdi (few stitches to the inch)

makes it less full For fine, closely spaced gathering

use a short stitdi and an outward adjustment of

the adjusting screw. For deeper, less closely spaced

gathering, turn the adjusting screw inward and use

a medium length stitch.

Material

Attaching Ruffle. To form and attach a ruffle in

one operation, place the ruffle strip between the

two blue blades and through the first separator

guide, and the material to which it is to be attached

Ruffling

Materia!

Ganneut

between the separator blade and the feed of the

machine. Proceed as for plain gathering. Right sides

of the fabric are placed together when the seam

is to fall to the inside.

Insert the material to be gathered between thé

blue blades and through the first separator guide.

Draw to the back of the needle. Lower the presser

bar and stitch. The texture of the fabric influences

the performance of the ruffler as well as the results.

Soft fabrics, cut on the crosswise grain, are best

adapted for gathered ruffles. Always test stitch

length and ruffler setting on a scrap of self fabric

before proceeding with the actual work.

Page 88

THE RUFFIER

Pleating. Move the adjusting lever of the ruffler

to the space setting desired for pleats either 6 or

12 stitches apart.

For the deepest pleat, activate the adjusting

finger and turn the adjusting screw inward to its

maximum setting. For smaller pleats turn the

adjusting screw outward.

Set stitch length. A short stitch places the pleats

more closely together? a long stitch separates the

pleats for a greater distance.

Insert the fabric to be pleated between the blue

blades and into the first separator guide. Lower

oresser bar and stitch.

Crisp fabrics cut on the crosswise grain formA the

sharpest pleats. Glazed fabrics handle besi

if

the

glazed side is downward and the soft backing is

lext to the rum

Diaae.

Group Pleating. By using the star setting (straight

stitdiing) alternately with the 6 or 12 stitch setting,

pleats are formed in groups. Even spacing betweeli

groups is accomplished by counting the number of

stitches.

86

Page 89

DARNING AND EMBROIDERY FOOT

This attachment is an aid to

all who desire perfection in free

motion darning and embroidery

work.

The foot hrmly holds the fabric

as the needle enters and rises

from the work, while fully revealing the line of design to be

followed.

Free motion work darning

Straight stitch setting: AK 3

\

# Position work under needle and lower presser

bar. Hold needle thread loosely with left hand,

turn hand wheel over and draw bobbin thread

up through fabric. Hold both thread ends and

lower needle into fabric.

# Outline opening with running stitches Va'* from

edge for remtorcement.

Feed cover plate

Darning and embroidery foot

Stitch length: Approximately 20

Trim ragged edges from area to be darned.

Centre worn section in embroidery hoops.

Attach feed cover plate to machine bed in place

of regular throat plate.

Locate darning and embroidery foot on presser

bar with lifting finger over needle clamp screw.

# Stitch across opening, moving hoops under need

le at a slight angle, from lower left to upper right.

Keep lines of stitching closely and evenly spaced.

# When opening is hlled, turn work 90^' and con

tinue stitching until darn is completed.

# Run machine at moderate speed and control

hoops with a steady continuous movement Slow

movement of hoops will produce a short stitch;

more rapid movement lengthens the stitdi.

Fairly long stitches are best for knit and tricot

fabrics; short stitches are best for cottons and

linens as they approximate weave of fabric,

$7

Page 90

FREE MOTION WORK

Selector: BL

Stitdi width lever: 2—5

Feed cover plate

Presser Foot: None

Script monoarams, satin stitdied scalloPS and ■■ • A. л/* \ ^ '

v.4,^ ЧЛ V. с1>цста the effect of a narrower stitch

When scalloping is used as an edge finish, allow

sufficient margin of fabric beyond the desired edge

to fit the hoop. To maintain parallel stitches, scab

lops are followed without turning, the work

remaining in line with the feed at all times. The

points of the scallops are formed by lightly moving

the work to the right or left, automaticallv pro**

embroidery can be e^ectively accomplished with

the 2ig%ag stitch when the free vaoiion principle is

em* ployed.

Trace or mark the design on the right side of

the fabric. Place the work in embroidery hoops,

keeping the fabric taut.

Some fabrics may require the addition of an

underlay of crisp muslin or organdy. The darning

and embroidery foot (available separately) will

also contribute to the smmoth handling of difficult

m^aterials as it provides a close control of both

St ltd anc tannc.

Remove the pressor foot an attach feed cover

plate to machine bed in place of regular throat

plate. Set Selector at BL and stitch width lever at

desired setting.

Position the work under the needle and lower

the presser bar to activate the tension. Bring the

bobbin thread up through the fabric. Hold both

thread ends and start stitdiing after positioning

needle in fabric.

Move the hoops slowly following the outline of

the design. Maintain an even rate of speed so that

the stitches are uniformly placed. Shading the

stitches from wide to narrow is controlled by the

angle at which the work is placed and moved under

the needle.

ea

Page 91

DECORATIVE STITCH PATTERNS

Examples of Stitch Patterns and their Selector Settings

f*®? ,

«E Im» te w

DS (5) 2

DS (D 3

EP2

F02

W№r jBK

1^ w'Li

FR2

FS (D 3

Page 92

DECORATIVE STITCH PATTERNS

Examples of Stitch Patterns and their Selector Settings

GM 4

XyAwMPiP^ LpA«w*^ i*>V..wA W\p»*-.pV v*

^**A**»Afc Z**^*"'**^

GP 4

GS (2) 2

GS (3) 4

HS (3) 4

112

90

IS (D 4

Page 93

TO CLEAN THE MACHINE

Your sewing macnine was built to exacting stand

ards of precision and workmanship. Its performance

Clean and

Oil

Clean between

tension discs

depends on the care and treatment it receives when

in use and before storing it away.

When in regular use the machine should be

cleaned periodically to remove the lint and fluff

which may have accumulated around the working

parts. To clean the bobbin case area, see instruc

tions for removing and replacing bobbin case on

pages 92 and 93. Oil the machine after each cleaning

as instructed on pages 94, 95 and 95.

If the machine is to be stored away for an inde

finite period of time, a thorough brush-cleaning

to remove all traces of lint and fluff, followed by

swabbing of all exposed parts with a lint-free brush

saturated with SINGER’^ Oil, is necessary to protect

the machine against rust damage. The areas that

should be cleaned and covered with a protective

Clean and Oil

coat of oil are shown in the illustration at the left.

91

Page 94

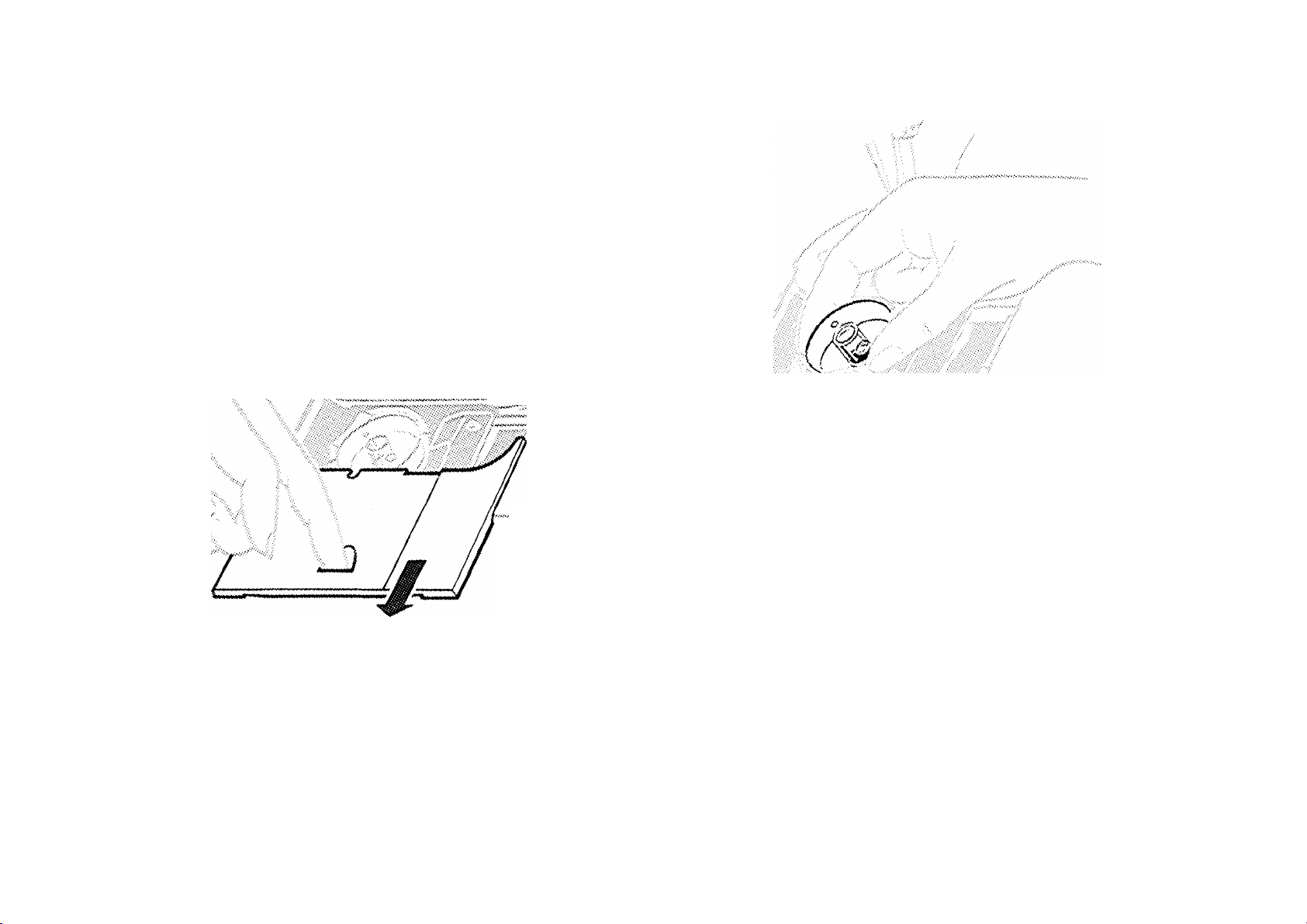

TO RBMOVH AN0 REPLACE BOBBIN CASE

To clean hook raceway, remove bobbin case as

follows:

1. Remove throat plate (see page 21] and open

slide plate (see page 15).

2. Unlock bobbin case by lifting and pulling

holder to right as shown,

3. Remove bobbin case from machine.

4- Remove all lint, fluff, loose thread ends or any

other foreign matter which might clog the miachine.

92

Page 95

POSITIONING

STUD

TO REMOVE AND REPLACE BOBBIN CASE

5. Replace bobbin case so that groove under tension spring fits on hook raceway and

straddles positioning stud.

6. Push bobbin case holder to left as shown until it snaps down into lock position.

7. Close bed slide and replace throat plate.

ot case

93

Page 96

TO tVmiCATE THE MACHINE

Use SINGER Oil and SINGER Lubricant!

Both are extra quality products especially pre

pared for sewing machines, and should always be

used in the care of vour 611.

ean the macnine periodically as instructed on

page 91.

94

!>rti

Apply a drop of oil to each place indicated.

Remove screw A and lift arm top cover slightly

and slide off toward left and away from machine.

The thread take-up lever must be in its lowest

position.

Apply a small amount of lubricant to the gears

as shown.

A tube of this lubricant can be purchased at your

Singer Sewing Centre.

Never apply Oil to these gears.

Page 97

open slide plate and apply a drop of oil to the

hook raceway as indicated.

Close slide plate, replace arm top cover and

close face plate.

95

Page 98

Oil each of places indicated by arrows and occasionally apply a small quantity of lubricant to teeth

of gears as shown.

Replace bottom cover.

THE MOTOR REQUIRES NO LUBRICATION.

96

Page 99

HIHCTRICAL INFORMATION

The SINGER* Electric Motor in the electric ma

chine is furnished for operation on an alternating

or dire« corree., Orderi =.oe. ete.e .de c.elogo’

number of the motor, or the voltage, and in the

case of alternating current, the number of cycles.

Before Inserting Electric Plug A, be sure that

voltage and cvcles stamned on electrical nameplate B are within range marked on your electric

m.eter installed by your power company.

Electrical Connections for Machine. Push 3-pin

terminal plug C on 3-pin terminal block at right of

machine and connect plug A at other end of cord

to electric outlet.

Speed Controller. The speed of machine is regu

lated by amount of pressure on the pedal of the

foot controller D.

9?

Page 100

To replace Singer Bnlb.

Disconnect plug from electrical outlet before ma

king bulb replacement.

SINGHR IIGHT

With thumb of right hand push in and down on

tab of light lens (see Illustration).

LOCKS

BULB

UNLOCKS

: :

U* :

Hi

Do not attempt to unscrew bulb, press it into

socket and at same time turn bulb over in direction

shown to unlock bulb pin G, then withdraw bulb.

Press new bulb into socket with bulb pin G enter

ing slot of socket and turn it over in direction shown

to lock bulb pin G in proper position.

The light is turned ''on" or "off" by the switch F,

Loading...

Loading...