Page 1

Instructions for Using

SINGER

DELUXE ZIGZAG

Sewing Machine

6I0U

* A Trademark of THE SINGER COMPANY '

Page 2

Form U 1 53

Rev. (969)

^ THE SINGER COMPANY 1969

Page 3

CONTENTS

Page

PRINCIPAL PARTS ......................................................................................................................... 2

ELEVEN CONTROLS ...................................................................................................................... 3

Electrical Controller • Sewing Light • Stitch Pattern Selectors • Stitch Width

Selector • Stitch Length Regulator ■ Feed Throw-out Lever ■ Pressure Regulat

ing Dial • Thread Tension Dial • Bobbin Thread Tension • Buttonhole Stitch

Selecting Dial • Stitch Density Control Dial

NEEDLES AND THREAD............................................................................................................... 6

To Change the Needle • To Hold Spools on Horizontal Pin • Small Spool

Holder • Vertical Spool Pin • How to Thread your Sewing Machine • Fabric,

Thread, Needle and Stitch Length Table

BOBBIN............................................................................................................................................. 8

To Wind the Bobbin • When Bobbin is Full • Threading the Bobbin Case

ATTACHMENTS ............................................................................................................................ 10

To Change Throat Plate • To Replace Slide Plate

STRAIGHT STITCHING ................................................................................................................ 12

Preparing to Sew • Sewing a Seam • To Stitch with Cloth Guide

ZIGZAG STITCHING .................................................................................................................... 14

Basic Patterns—Built-in Discs—Special Discs ■ Combination Patterns • Magic

Patterns • Satin Stitching • Blind Stitching

TWO-NEEDLE STITCHING ......................................................................................................... 22

CHAIN STITCHING....................................................................................................................... 24

FREE-MOTION STITCHING ...................................................................................................... 27

APPLIQUE ...................................................................................................................................... 28

MONOGRAMS • MOTIFS ............................................................................................................. 29

HEMS .............................................................................................................................................. 29

ZIPPERS .......................................................................................................................................... 30

BUTTONHOLES ............................................................................................................................ 31

BUTTONS ....................................................................................................................................... 35

HOW TO USE THE EDGE-STITCHER ........................................................................................ 30

CARING FOR YOUR SEWING MACHINE

Cleaning • Oiling • To Remove and Replace the Bobbin Case ■ Performance

Check List

................................................................................

33

Page 4

Presser Foot

Bobbin Winder

Actuating Slide

Light Switch

Hand Wheel

Stitch Width Selector

Buttonhole Stitch

Selecting Dial

Stitch Length Regulator

Throat Plate

Bobbin

Bobbin Case

Feed Throw-out Lever

Stitch Density Control Dial

Stitch Pattern Selectors

Slide Plate

Page 5

T. iLi€TRÍ^AI. CONTROLLER

Plug in the machine as shown at right. Before plug

ging in your machine, be sure that the voltage and

number of cycles stamped on the controller nameplate

are within the range marked on the electric meter in

stalled by your power company.

To start the machine, press the pedal of the foot

controller.

2. SEWING LIGHT

The built-in sewing light located beneath the control

panel pours light on the sewing area.

The light is turned on or off by means of the light

switch A.

To change the bulb, pull down on tab a of light

socket and lower the light bracket. Then, unscrew the

bulb by turning it counterclockwise.

3^ STITCH PATTERN SELECTORS

These buttons control the pattern of your stitches

and must be set before starting the machine.

When moving these selectors, be sure to follow the

instructions below.

(1) Raise needle to its highest point.

(2) Move disc follower releasing lever as far to the

Tight as it will go, and adjust stitch pattern selec

tor to desired position.

4. STITCH WIDTH SELECTORS

(1) This selector positions your needle for straight

stitching. Normally, you will use setting 3. But

if you wish to stitch at left or right of center, press

down on the lever and slide it to the left (1 or 2)

or right (4 or 5).

(2) This selector controls stitch width in zigzag stitch

ing. For wide stitches, slide lever to right of center

(3’/2 to 3). For narrow, slide to left (2'/3 or 2 only).

(3) This selector varies the design in combination pat

terns, (See page 16)

Page 6

ELEVEN CONTROLS (Continued)

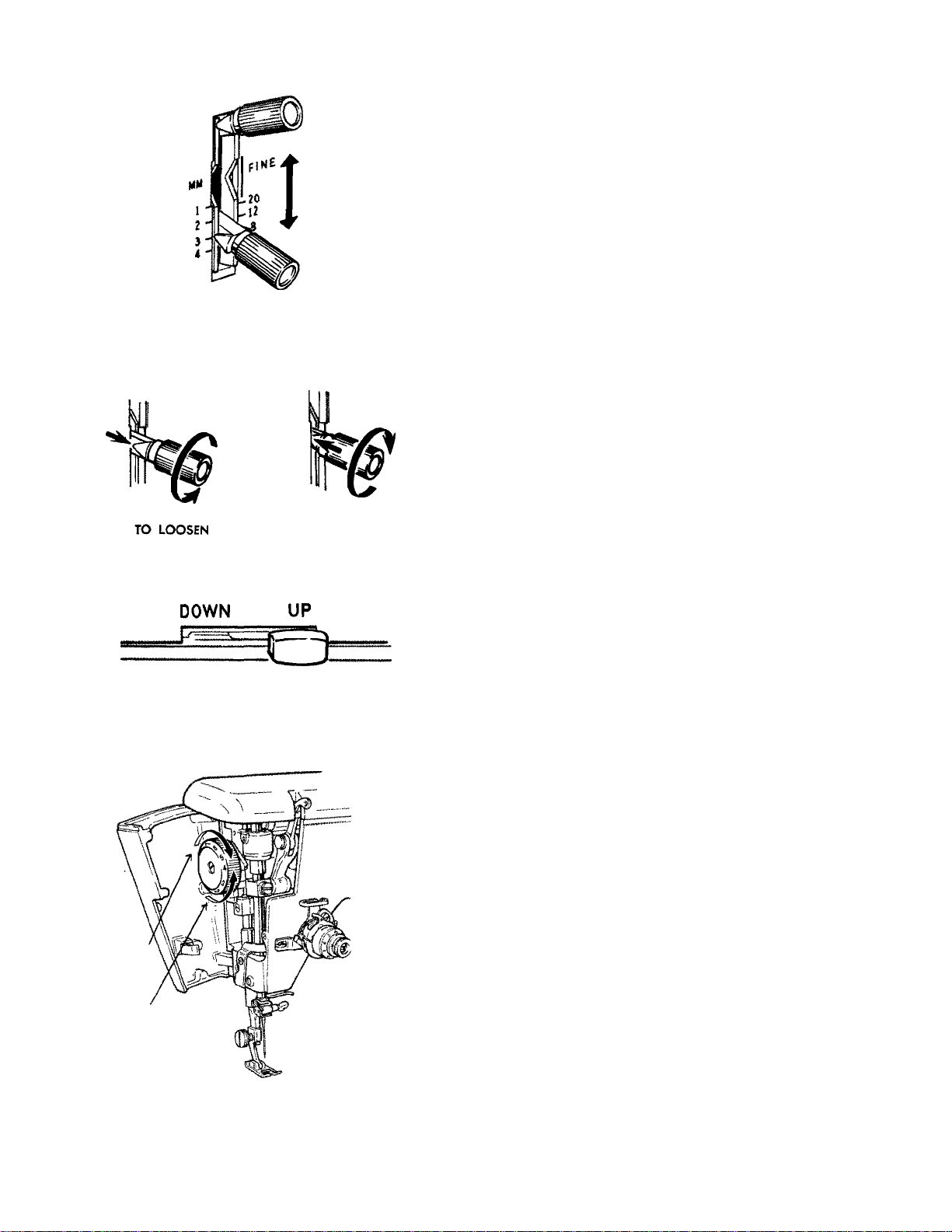

5. STITCH LENGTH REGULATOR

REVERSE

FORWARD

THUMB NUT

(1) This lever controls the number of stitches per inch.

Numerals on left side of the lever represent stitch

length in millimeters.

Numerals on right side represent number of stitches

per inch.

The FINE area, which represents over 20 stitches

per inch, is used for satin stitching (closely spaced

zigzag stitching).

To set stitch length

a. Loosen thumb nut by turning to left and posi

tion lever for desired stitch length.

b. Tighten thumb nut by turning to right.

(2) This lever controls the direction of stitching (either

forward or reverse).

For reverse stitching, raise lever as far as it will go.

Hold lever in this position by hand while stitching.

TO TIGHTEN

TO INCREASE

TO DECREASE

6. FEED THROW-OUT LEVER

Set feed throw-out lever to “UP” position at right for

normal stitching. Set feed throw-out lever to “DOWN”

position at left for embroidery, mending and button

sewing. This will lower the feed dog below throat

plate surface and will not feed the material.

7. PRESSURE REGULATING DIAL

This dial regulates the pressure that the presser foot

exerts on the fabric. Correct pressure is important

because it means fabric feeds smoothly, evenly, without

being marred. Generally, heavy fabric requires a high

number setting; lightweight fabric requires a low num

ber setting.

• To increase pressure, turn dial to higher number.

• To decrease pressure, turn dial to lower number.

• For darning, turn dial to D, vvhich releases pres

sure and permits darning without an embroidery

hoop.

Page 7

ELEVEN CONTROLS (Continued)

8. THREAD TENSION DIAL

This dial regulates the degree of tension on your

needle thread and lets you select just the right setting

for your stitch pattern, thread, and fabric.

To determine correct tension setting, make a test on

a sample of your fabric. If the fabric puckers, decrease

tension. If the stitches look loose, increase tension.

• To decrease tension, turn to lower number.

• To Increase tension, turn to higher number.

9. BOBBIN THREAD TENSION

Bobbin thread tension too tight—correct by turning

screw counterclockwise.

Bobbin thread tension too loose—correct by turning

screw clockwise.

A perfectly locked stitch results with upper and lower

tensions balanced so that needle and bobbin threads are

drawn equally into fabric.

10. BUTTONHOLE STITCH SELECTING DIAL

This dial is used when stitching buttonholes and magic

patterns.

• For buttonhole, set dial to “Bl” and “B2”.

• For magic patterns, set dial to “MAGIC”.

• For regular stitching, set dial to “OFF”.

Always push disc follower releasing lever to the right

before moving this selecting dial.

11. STITCH DENSITY CONTROL DIAL

This dial controls stitch density when making button

holes.

• For closely spaced stitches, turn dial upward.

• For open stitches, turn dial downward.

• For regular stitching, set dial to

r—«№*1

twit»!!ianii!J3agiiiiiiri

t

Page 8

^ :

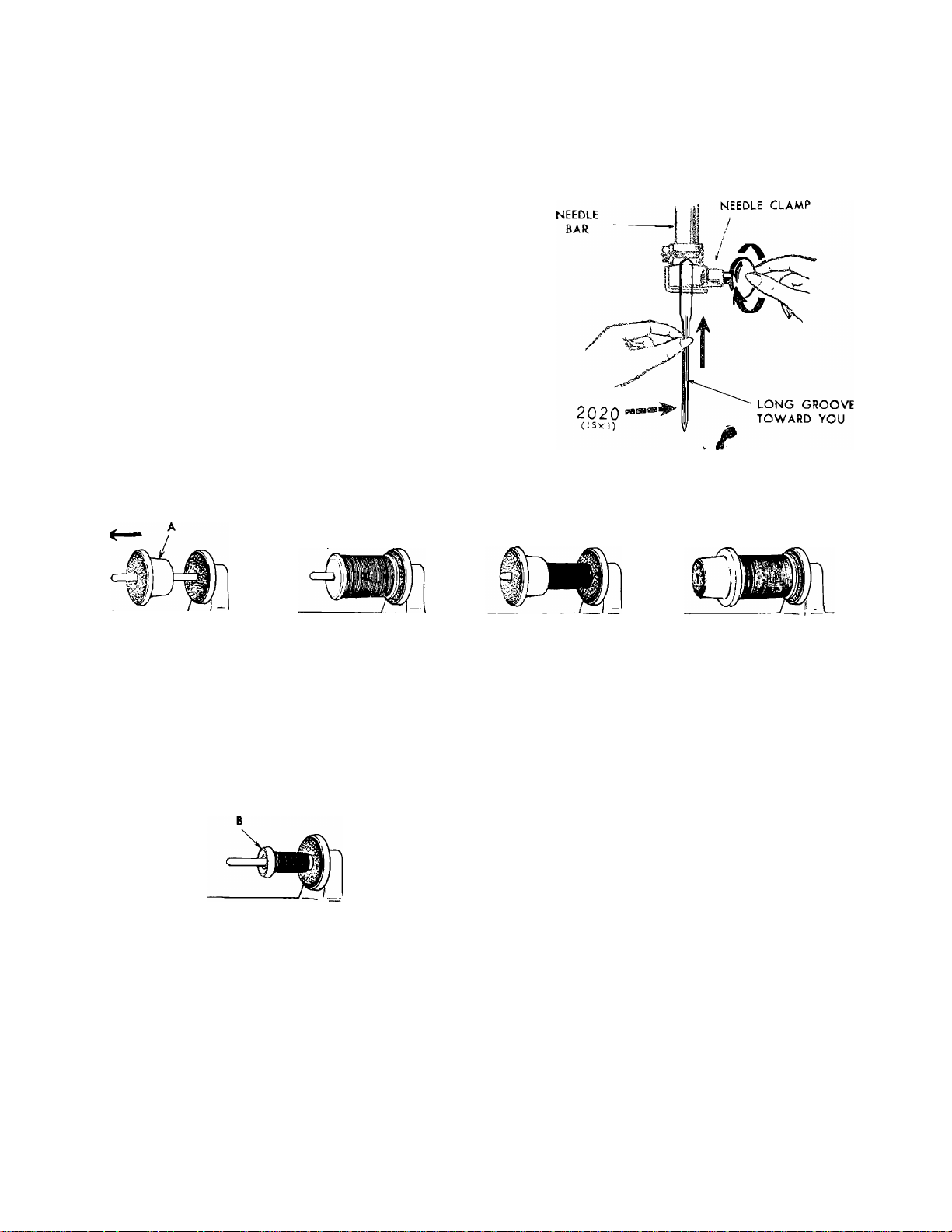

TO CHANGE THE NEEDLE

1. Raise needle bar to highest position by turning hand

wheel toward you.

2. Loosen the needle-clamp screw and remove the

needle.

3. Insert new needle in clamp, with the flat side of

the needle to the back and the long gfsova toward

you; push it up as far as it will go.

4. Tighten needle-clamp screw.

This machine uses needles

Catalog 2020 (15X 1)

Sizes 9, n, 14, 16 and 18.

TO HOLD SPOOLS ON HORBZONTAL SPOOL PIN

Remove spool holder A

from spindle by sliding

in to the left.

VERTICAL SPOOL

Slip spool

onto spindle.

This spool pin is used when two-needle stitching is

desired. For instructions, see page 22,

of thread

To hold small spools—

Turn small end of spool

holder to the right and

slide onto spindle. Press

spool holder firmly against

spool.

To hold large spools—

Turn wide end of spool

holder to the right and

slide onto spindle. Press

spool holder firmly against

spool.

SMALL SPOOL HOLDER

A small size spool holder S is furnished with the

machine. This spool holder lets thread unwind smoothly

when very small spools wound with embroidery thread,

etc. are retained on the spool pin.

Page 9

HOW TO THREAD YOUR SEWING MACHINE

1. Turn hand wheel to raise take-up lever to its highest

position.

2. Raise the presser foot.

3. Lead thread through all threading points shown.

4. Thread needle from front to back.

5. Draw about four inches of thread through eye of

needle.

FABRIC, THREAD, NEEDLE, AND STITCH LENGTH TABLE

FABRICS

DELICATE—tulle, chiffon, fine lace,

silk, organdy, fine tricot

LIGHTWEIGHT—batiste, organdy,

jersey, voile, taffeta, silk, crepe,

plastic film

MEDIUM WEIGHT—gingham,

percale, pique, linen, chintz,

faille, satin, fine corduroy,

suitings

MEDIUM HEAVY—gabardine,

tweed, sailcloth, denim,

coatings, drapery fabrics

THREAD

SIZES

Fine Mercerized

80~120 Cotton

Synthetic Thread

50 Mercerized

60~80 Cotton

“A" Silk

Synthetic Thread

50 Mercerized

50~60 Cotton

“A" Silk

Synthetic Thread

Heavy Duty

Mercerized

40 to 50 Cotton

NEEDLE STRAIGHT STITCHES

SIZES PER INCH

15 to 20

9~11

11~14

1Ó

12 to 15

(8 to TO for plastic]

12 to 15

10 to 12

HEAVY—overcoatings, dungaree,

upholstery fabrics, canvas

Heavy Duty

Mercerized

30 to 40 Cotton

18

8 to 10

Page 10

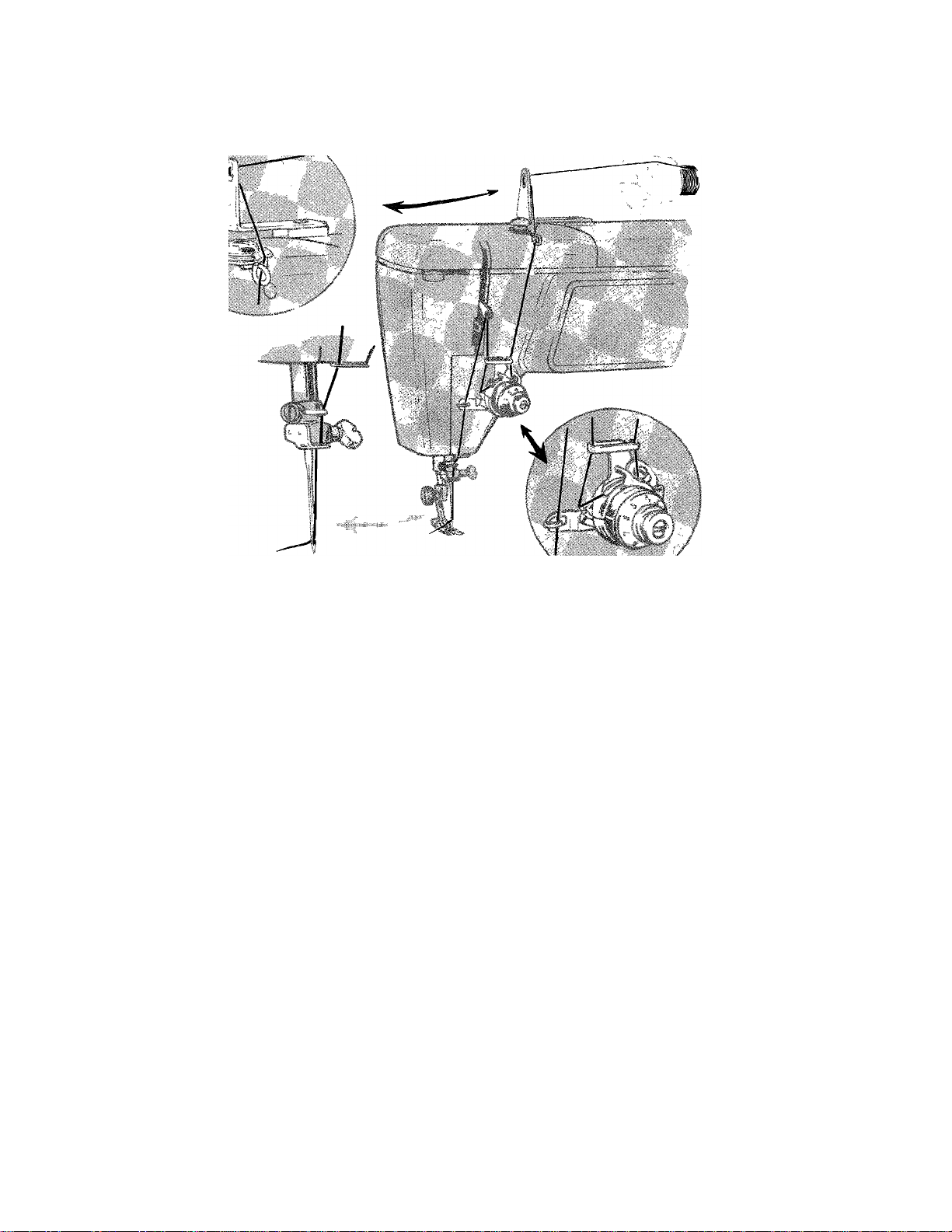

TO WIND THE BOBBIN

1. Loosen stop motion screw A with right hand in

direction shown by arrow.

Place spool of thread on Horizontal Spool Pin.

Carry the thread through the thread guide on the

arm top cover lid, between bobbin winder tension

discs and then through the hole in upper side of

bobbin as shown below.

2. Place empty bobbin on spindle with pin of spindle

entering small hole in lower side of bobbin and pull

bobbin winder actuating slide.

4, Hold end of thread until a few coils are wound and

then break off the end of thread.

L Push bobbin winder

actuating slide end

remove bobbin.

WHEN BOBBIN IS FULL

2. Tighten stop motion

screw.

Page 11

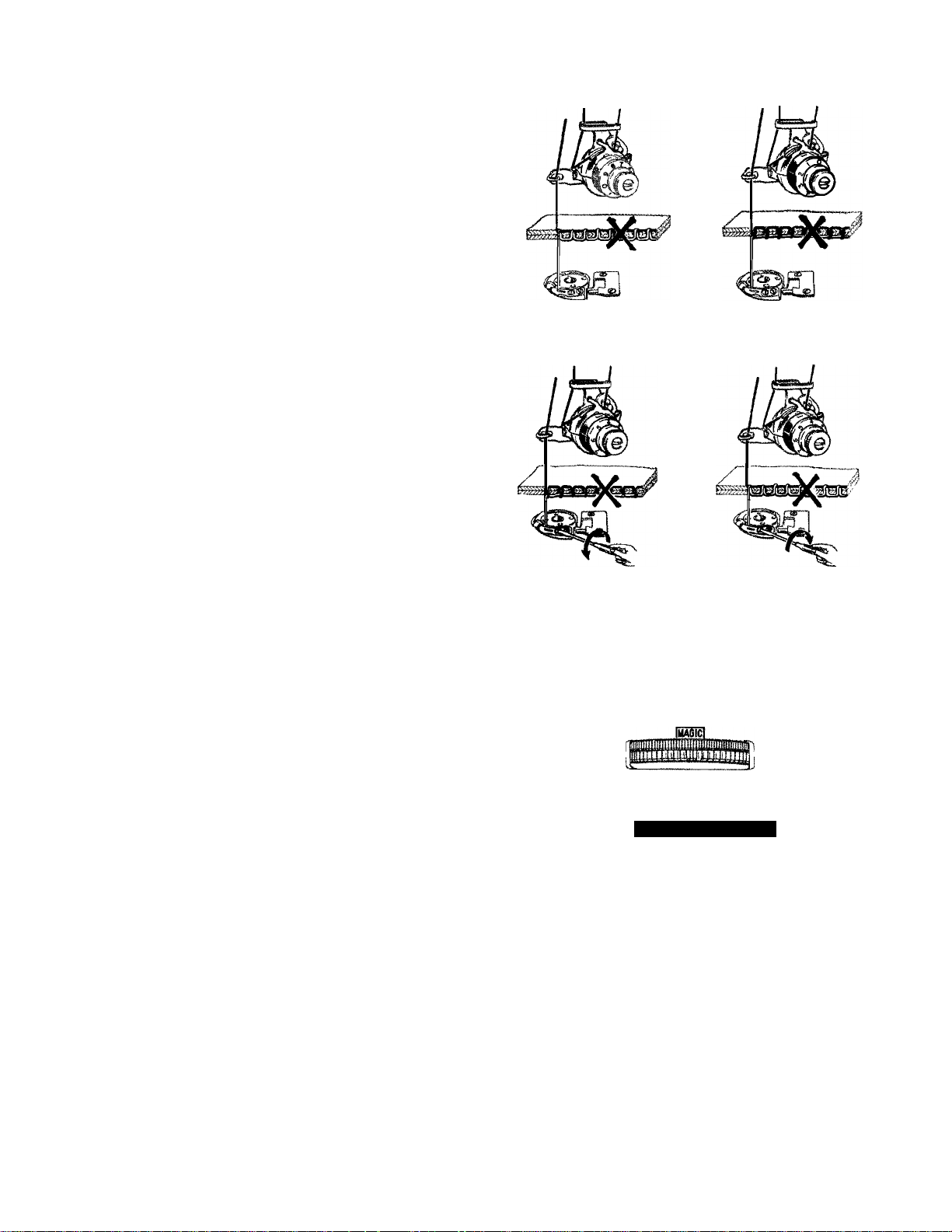

If bobbin does not

wind evenly—

Loosen screw which holds

tension brocket in posi

tion. Move bracket up

if bobbin winds towards

bottom.

Move bracket down if

bobbin winds towards

top.

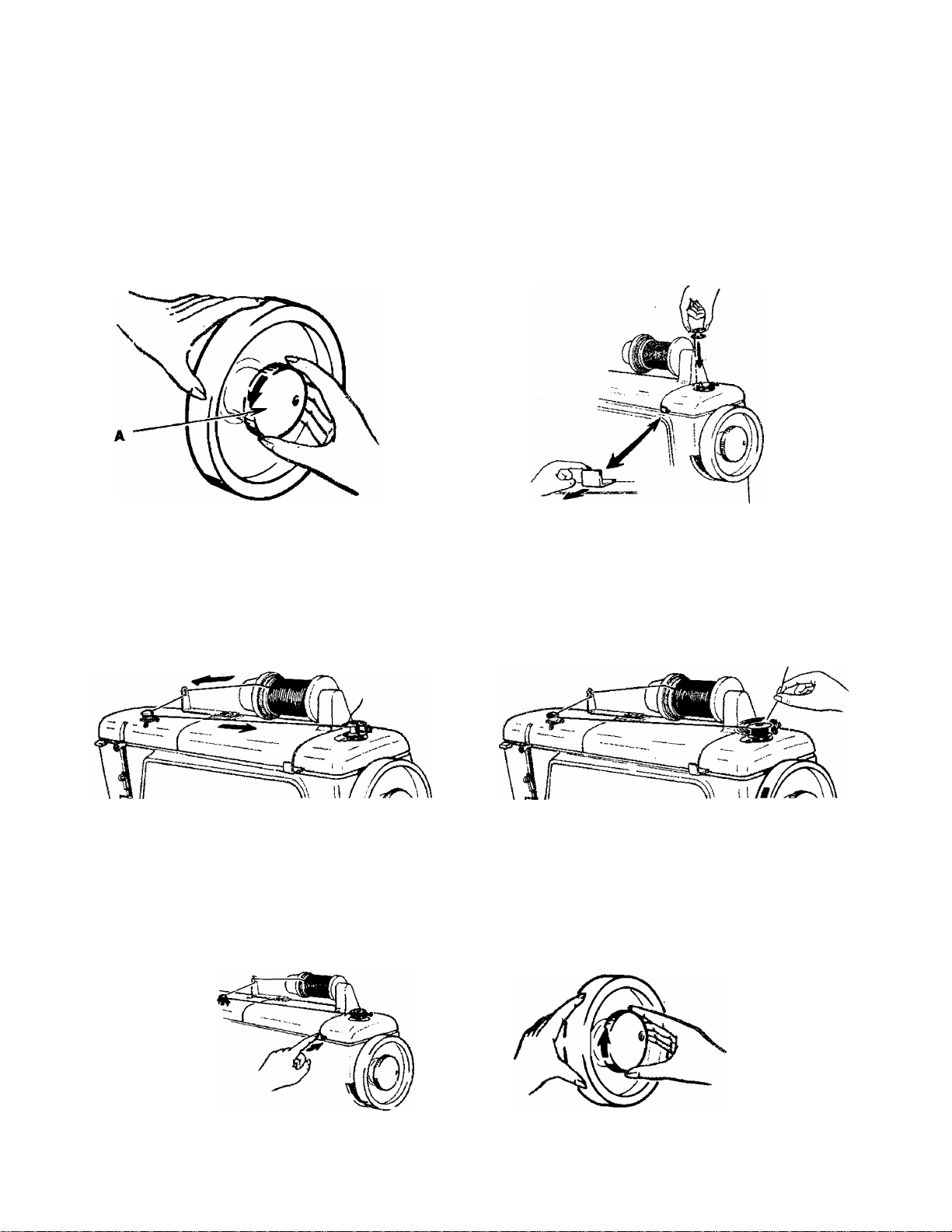

THREADING THE BOBBIN CASE

1. Hold bobbin so that thread leads

off in direction shown.

3. Draw thread into notch at end

of spring ; pull about 3 inches of

thread across bobbin.

2. Place bobbin in case.

Lead thread into slot and under

spring.

4. Close slide plate allowing thread

to enter notch.

Page 12

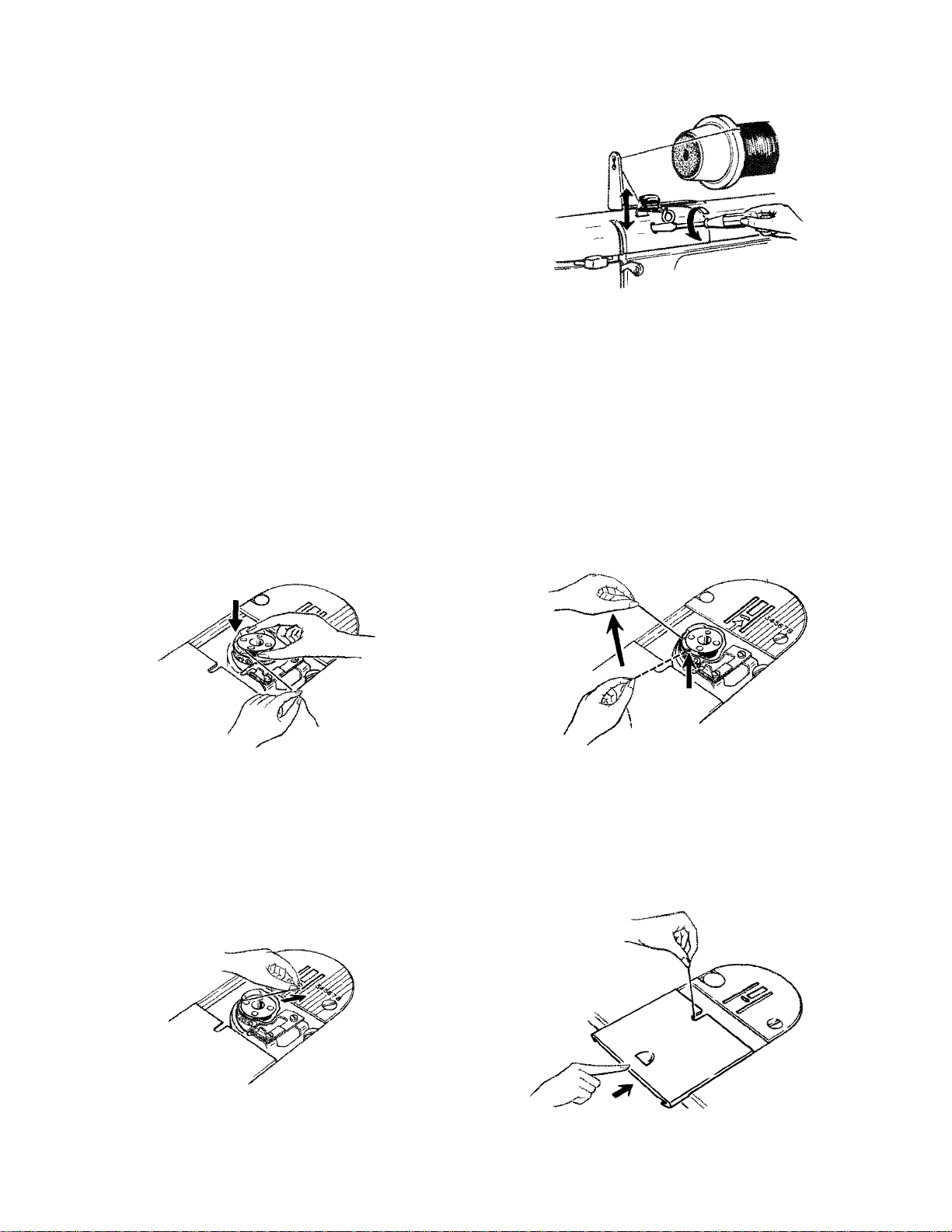

AHACHMENTS

The attachments that come with your sewing machine are designed to help you do every kind of

sewing easily and perfectly

GENERAL PURPOSE PRESSER FOOT AND GENERAL

PURPOSE THROAT PLATE

These attachments can be used for zigzag and straight

stitching.

These are used for almost all utility sewing.

STRAIGHT STITCH PRESSER FOOT AND STRAIGHT

STITCH THROAT PLATE

These attachments are used for straight stitching only,

and particularly when stitching delicate or spongy

fabrics, synthetics, etc.

SPECIAL PURPOSE PRESSER FOOT

This foot is designed especially for satin stitching

(closely spaced zigzag stitches).

APPLICATIONS :

Ornamental stitching. Monograms, Applique work,

Motifs.

CHAIN STITCH THROAT PLATE AND LOOPER

These fittings are used for chain stitching.

For instructions, see page 24.

ZIPPER FOOT

(See page 30}

HEMMER FOOT

(See page 29)

BUTTONHOLE FOOT

(See page 32)

10

(See page 35)

Page 13

ATTACHMENTS (Continued)

EDGE-STITCHER

(See page 36)

CLOTH GUIDE

(See page 1 3)

The ripper will help you to cut

opening for the button after a button

hole is completed.

It is also useful for removing seams.

In addition to the aforementioned fittings, needles, bobbins, screwdrivers, oil container and lint brush,

etc. are furnished with the machine.

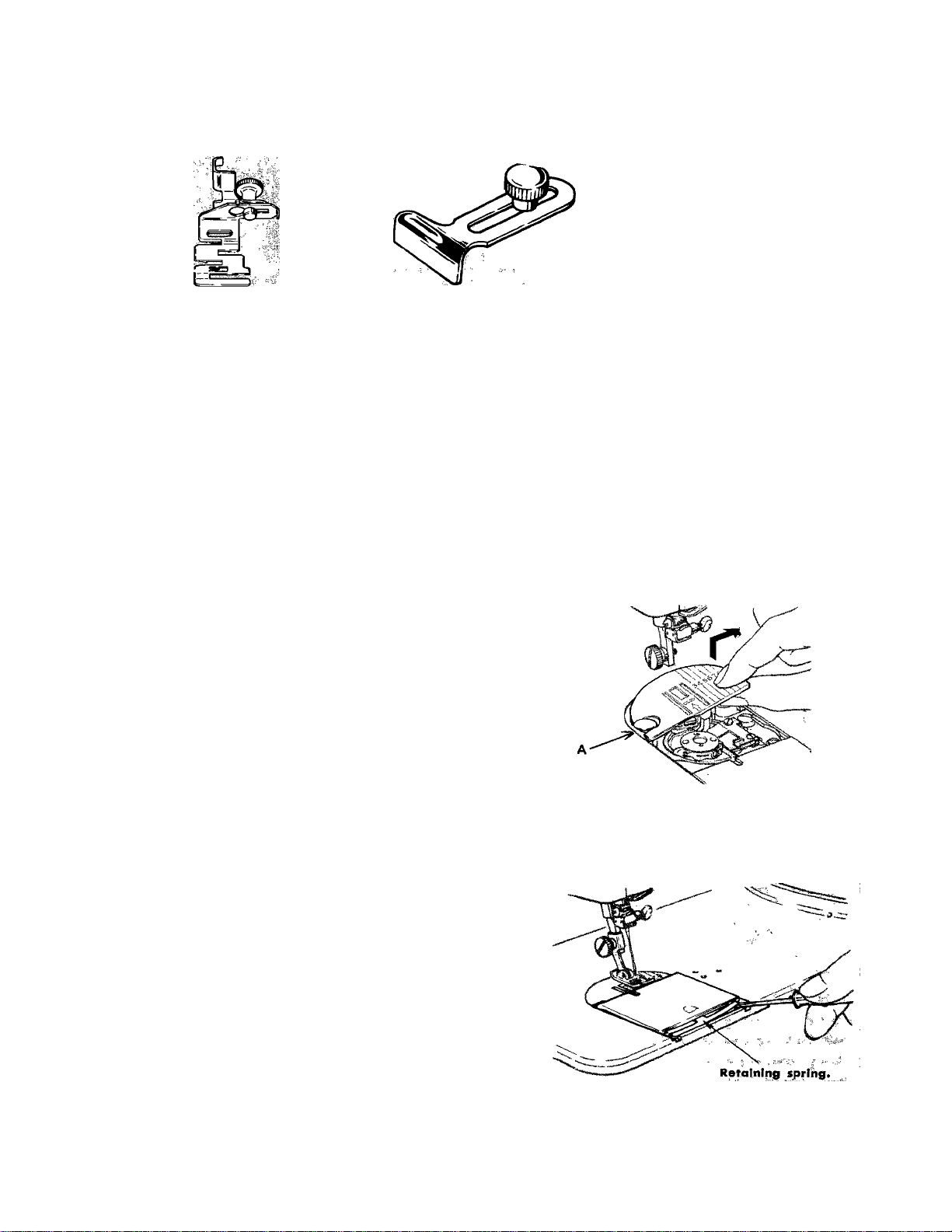

TO CHANGE THROAT PLATE

1. Raise needle bar and presser foot.

2. Open slide plate.

3. Place thumb under right front end of throat plate

and raise until clamping pin A lifts up.

4. Draw throat plate toward right to disengage.

When replacing the throat plate, fit it in the reverse

order.

NOTE: When changing the throat plate, set feed

throw-out lever to “DOWN” position.

RIPPER

TO REPLACE SLIDE PLATE

1. Raise the presser foot and the needle.

2. Place slide plate in slide way with the front edge

close to, but not covering, the retaining spring.

3. With a small screwdriver, lift each end of the spring

into each of the side grooves on the underside of

the slide plate.

4. Draw the slide plate gently toward you and fully

engage the spring.

5. Close slide plate.

11

Page 14

CENTER NEEDLE POSITION

• Stitch Pattern Selectors i AN

• Stitch Width Selector ; 3

• Throat Plate : Straight Stitch or General

Purpose

• Presser Foot; Straight Stitch or General

Purpose

J L W

1 kIm

Speci

'

2 3 4 5

- /

LEFT AND RIGHT NEEDLE POSITIONS

• Stitch Pattern Selectors: AN

• Stitch Width Selector i 1 or 2 (left)

4 or 5 (right)

• Throat Plate i General Purpose

• Presser Foot: General Purpose

J L fj

PREPARING TO SEW

3 4-5

a, i I i

12 3

4

5

Hold needle thread

lightly with left hand

and turn hand wheel

slowly toward you so

that needle enters

throat plate.

Continue turning hand

wheel until needle rises

and brings up bobbin

thread in a loop.

Undo the loop with

your finger.

12

Place both needle and

bobbin threads under

presser foot and lay

them towards the back.

Page 15

SEWING A SEAM

1. Lower presser foot.

Raise stitch regulator to reverse.

3. Lower stitch regulator.

Stitch to end of seam.

2. Back-stitch to edge of fabric for re

inforcement.

4. Raise stitch regulator.

Back-stitch to reinforce end of seam.

5. With take-up lever at highest point,

raise presser foot and remove fabric.

6. Cut threads on thread cutter at rear of

presser bar.

TO STITCH WITH CLOTH GUIDE

The cloth guide aids in attaining uniformity of seam

width.

The guide is secured to the bed of the machine in

either of the threaded holes to the right of the slide

plate. To guide seam stitching straight and parallel to

the edge of the fabric, guide the fabric edges lightly

against the guide while stitching.

13

Page 16

A WORD ABOUT HOW THE PATTERNS ARE PRODUCED

The zigzag features of your sewing machine give you an almost unlimited choice of stitch patterns. All

patterns are produced from discs. The four basic patterns as shown below come from discs that are built

into the machine. To use these, you need no special attachments—simply adjust the pattern selectors.

Also, supplied with the machine is a “Buttonhole Cam" which can easily be removed. In addition, 12

Special Discs (See page 16) and 4 Magic Cams (See page 17) are contained in the attachment box.

You can combine two basic patterns to produce a third, which will be different from either one alone.

Thus, you have an almost infinite variety of combination patterns from which to choose.

BASIC PATTERNS

BUILT-IN DISCS

Upper Stitch Pattern Selector:

Lower Stitch Pattern Selector;

B (Ord inary stitching, Buttonholes, etc.)

A (Button sewing, Two-needle stitching, etc.)

C (Occasionally)

Stitch Width Selector s

Throat Plate: General Purpose

Presser Foot: General Purpose or Special Purpose

As shown at right, the four built-in discs are re

presented by the letters J through M. If you move the

upper selector to one of these letters, and keep the

lower selector on A, B or C, you will get one of the

basic patterns.

In addition, you can use two needles if you wish

when using a basic pattern. (See page 22)

J L N

Upper Stitch Pattern Selector

K L

3

H

3

!

H

M

<

<

14

Page 17

Lower Stitch Pattern Selector

J L N

K| Sli special

J U. N

■J k ^ ■

I -_Oa

«El

B 0 F H

Left

AJ 3

BJ 3

In basic patterns, the Lower Stitch Pattern Selector controls stitch placement. Selector setting of B

places stitching in center needle position. Selector settings A and C place the stitching in left and right

needle positions at stitch widths less than 5. Selector setting B is preferred for ordinary stitching.

Control of Stitch Width Selector

A I C I E I G I

B 0 F H

Right

CJ 3

Upper Stitch Pattern Selector: Special

Lower Stitch Pattern Selector : A, B, C

Stitch Width Selector: 2—^5

Throat Plate : General Purpose

Presser Foot: General Purpose or Special Purpose

Width of zigzag stitch is controlled by the stitch width

selector. As the selector is moved to the right, the

width of zigzag stitch is increased.

To avoid damage to needle and fabric, raise needle

above fabric before moving the selector.

SPECIAL DISCS

B O F H

vJ L N

Special

15

Page 18

SPECIAL DISCS (Continued)

The interchangeable Special Discs that come with your

machine can be used to produce still other stitch patterns.

To Change Special Disc

1. Raise needle to its highest point.

2. Push disc follower releasing lever to the right and

set buttonhole stitch selecting dial to “OFF”.

3. Raise top cover lid, remove buttonhole cam and put

another disc you desire on holder; push down until

disc snaps in place.

Special Disc Patterns

®

r

• Upper Stitch Pattern Selector: J, K, L, M, Special

• Lower Stitch Pattern Selector : D through H

• Stitch Width Selector: 2 through 4

• Throat Plate : General Purpose

• Presser Foot: Special Purpose

In Combination Patterns, the Stitch Width Selector Varies the Design.

When the lower stitch pattern selector is not on A, B or C, the stitch width selector no longer controls

width.

¥

®

ww ®

COMBINATION PATTERNS

You can combine two patterns either by using two

built-in discs or by using one Special and one built-in

disc.

If you choose a setting of J, K, L, M and Special on

the upper row, and another D through H on the lower

row, you will be combining the patterns of two discs.

Thus you will have an almost infinite variety of com

bination patterns.

IUI|liyi yyuyuu /

J L N

Special

Example of Combination Pattern Varied by Stitch Width Selector

8 4

JG2

1 2 3 4 5

JG3

16

3 4

JG4

Page 19

MAGIC PATTERNS

Magic patterns are produced from magic cams sup

plied with the machine. By using these cams together

with the built-in cams, you will have an almost un

limited variety of combination patterns. Some of which

are shown below.

Magic cam is fitted to the machine in the same

method as Special Disc. (See page 16.)

Basic and Combination Patterns (Magic Cam)

BASIC PATTERN

Upper Stitch Pattern Selector;

Lower Stitch Pattern Selector:

Stitch Width Selector: 2'—5

Buttonhole Stitch Selecting Dial: MAGIC

Stitch Density Control Dial: Set dial at

Stitch Length Regulator: 6

Throat Plate : General Purpose

Presser Foot: General Purpose

* In basic patterns, selector setting at “B • Special 5” is

preferred. (See following examples.)

* Two-needle stitching can be produced if desired. (See

page 22.)

* Best Magic Patterns can be obtained by using sizes 9

or 11 needles.

No.101 No.102

Special

A, B or C

No.103

No.104

COMBINATION PATTERN

Upper Stitch Pattern Selector:

Lower Stitch Pattern Selector:

Stitch Width Selector: 2'—^5

Buttonhole Stitch Selecting Dial:

Stitch Density Control Dial: Set dial at

Stitch Length Regulator : 6

Throat Plate : General Purpose

Presser Foot: General Purpose

* The following examples show stitch patterns produced

by setting stitch width selector at 3.

* Combination patterns can not be used with two needies.

No.101

LE 3 MGS

No. 103

l~N

9~H

MAGIC

No.102

H S 3 GM 3

No.104

No. indicates Magic Cam number.

No. indicates Magic Cam number.

MGS FL 3

17

J F 3

LG 3

Page 20

MAGIC PATTERNS (Continued)

Varied Stitch Patterns

Basic patterns shown on page 17 can be produced by

setting the stitch pattern selectors at “B • Special”, the

stitch width selector at “5” and the stitch density con

trol dial at “a”. These patterns, however, can be varied

in the following manner if desired.

Patterns varied by stitch density control dial.

(A) When stitch density control dial is turned up

ward, stitch patterns will become closely spaced.

(See Fig. 1)

(B) The patterns will become compact and perfectly

balanced by making the stitch width smaller while

turning stitch density control dial upward. (See

Fig. 2)

i 4^

Fig. 1

Fig. 2

2. Patterns varied by magic pattern stitch adjusting

lever.

Magic patterns can be varied by moving the magic

pattern stitch adjusting lever toward you or away

from you. (See Fig. 3)

3. When using Magic Cam, the feed dog of the ma

chine moves forward or backward. By making the

best use of this feature, the following stitches can be

made.

(A) Threefold straight stitches can be produced by

using cam No. 101 with the selectors set at “AN3”.

(See Fig. 4) This type of stitch is most suited for

sewing crotch seams on trousers and also edge-

stitching pockets, etc. where durability is needed.

Magic Pattern Stitch

Adjusting Lever

ц

Î

0

I

u

Magic Cam No. 103 used

Fig. 3

Fig. 4

(B) Threefold zigzag stitches can also be made by

using cam No. 101 with the stitch pattern selectors

set at “BJ” and the stitch width selector at 2 through

5. (See Fig. 5)

Adjust magic pattern stitch adjusting lever when

uniform threefold stitches can not be obtained.

Fig. 5

18

Page 21

SATIN STITCHING

Satin stitching, aseries of closely spaced zigzag stitches

that form a smooth, satin-like surface, is useful for both

utility and decorative vvork.

When you wish to produce a satin stitch, make a

test sample first so that you can adjust the stitch length

and thread tension properly.

Soft fabric may require a backing to ensure firm

satin stitching. Crisp organdy or lawn is suitable for

this purpose.

Adjusting Stitch Length For Satin Stitching

1, Move Stitch Length Regulator to bottom of FINE

area.

2. Gradually tighten thumb nut by turning it to right,

until stiiches are closely spaced and form a smooth

surface.

Adjusting Tension For Satin Stitching

Satin stitching requires less tension than straight

stitching or open zigzag designs. Furthermore, the

wider the satin stitch, the lighter the tension on the

thread must be. Thus, stitch width 5 requires the least

tension; narrower satin stitching requires somewhat

more.

LINGERIE SEAMS

‘ Stitch Pattern Selectors : BJ

• Stitch Width Selector: 2^/i

• Stitch Length: 12 to 20 depending on fabric

• Throat Plate : General Purpose

• Presser Foot: General Purpose

To make a lingerie seam both durable and flexible,

use a zigzag stitch. This seam treatment is particularly

suitable for bias seams.

1. Straight-stitch the seam (with selectors at AN 3) on

wrong side.

2. Press both seam allowances in the same direction.

3. From the right side, top-stitch with zigzag setting

BJ 2V2, letting the needle alternately enter the seam

line and seam thickness.

LINGERIE SEAM

19

Page 22

FLAT FELLED SEAMS

• Stitch Pattern Selectors : BJ

• Stitch Width Selector : 3

• Stitch Length: 12 to 20 depending on fabric

• Throat Plate: General Purpose

• Presser Foot: General Purpose

Zigzag stitching gives strength and durability to flat

felled seams.

1. Stitch the seam on the right side of the fabric taking

full seam allowance.

2. Press the seam allowance to one side, keeping the

right side of the stitch on top.

3. Trim the under seam allowance to one-half its

width.

4. Turn the upper seam allowance edge evenly over

the trimmed edge, and top-stitch.

SEAMS IN KNIT FABRICS

CURVED SEAM WITH TAPE STAY

•Stitch Pattern Selectors: BM

•Stitch '^idth Selector: 2'—5’

• Throdt Plate : General Purpose

• Presser ,Foot: General Purpose

• Stitch Pattern Selectors: BJ

• Stitch Width Selector: 2

• Stitch Length : About 20

• Throat Plate: General Purpose

•.Presser Foot: General Purpose

This fine zigzag stitch is ideal for seaming knit fabrics.

It is particularly desirable for underarm seams where

elasticity and give are needed.

For neckline and waistline seams, where a stay is

needed to prevent undue stretching, this same stitch can

be used to apply seam tape. For a flat, smooth finish:

1. If seam is curved, pre-shape tape to fit by steam

pressing.

2. Baste tape in place.

3. Stitch, allowing needle to enter seam tape and seam

allowance alternately.

TEARS

1.

Trim ragged edges.

2.

Place underlay on the wrong side of tear for rein

forcement. (It is best not to baste or pin the under

lay, since you will be bringing the edges of the tear

together in the next step.)

3.

Stitch on the right side, bringing the edges of the

tear together.

4.

Shorten stitch length at ends and corners to give

extra strength.

5.

Trim underlay.

20

Page 23

BLIND STITCHING

Stitch Pattern Selectors : BK

Stitch Width Selector: 2 or 3

Throat Plate : General Purpose

Presser Foot: General Purpose

Blind stitching provides a durable hem finish that is

invisible and is best suited for curtains, draperies, table

linens and skirts, etc.

Blind Stitch Hems

1. Fold and press material as shown in sketches.

2. Place folded hem edge over the feed of the machine,

turning bulk of fabric to the left and thus creating

a soft fold.

3. Position needle into folded edge of hem at least

’/4 inch from upper fold, and stitch so that straight

stitches fall on hem edge and sideward stitches

pierce the soft fold.

Overedged Seam

For an overedged seam, the Blind Stitch makes a

durable, bulkless finish. It is particularly suitable for

lengthwise seams.

Seam edges should be trimmed evenly, and the stitch

then formed over the raw edge.

21

Page 24

By using two needles at once, you can produce two

parallel, closely spaced, decorative lines of stitching

simultaneously. You can choose either a straight-stitch

setting or decorative stitching (basic patterns). Com

bination patterns can not be used for two-needle work.

Some of the attractive designs you can create are

shown on page 23.

To Prepore for Two-Needte Stitching

1. Fill bobbin with enough thread to complete stitching.

2. Loosen thumb screw on needle clamp and insert

two needles, as illustrated.

To Thread the Machine

1. Place spool of thread on horizontal spool pin. Thread

as for one-needle stitching except:

• Pass thread between center and back tension discs.

• Pass thread through eye of left needle.

2. Raise top cover lid A and insert vertical spool pin

B into hole C provided for it, as shown below.

3. Place spool of thread on vertical spool pin. Thread

as for one-needle stitching except:

• Pass thread between center and front tension discs.

• Pass thread through eye of right needle.

• Do not attempt to pass thread through guide on

top cover lid.

Make certain that only thread from horizontal spool pin

is carried through last guide D on the needle clamp.

22

Page 25

STRAIGHT STITCHING WITH TWO NEEDLES

■ Sfitch Paitern Selectors : AN

* Stitch Width Selector : 2 (only)

♦ Throat Plate ; General Purpose

• Prosser Foot; Generol Purpose

BASIC PATTERN STITCHING WITH TWO NEEDLES

Upper Stitch Pattern Selector; J, K, L, M, Special

Lower Stitch Pattern Selector ; A

Stitch Width Selector ; 2 or 3

Throat Plate : General Purpose

Presser Foot; General Purpose (open patterns)

Special Purpose (satin stitching)

J L N

MAGIC PATTERN STITCHING WITH TWO NEEDLES

• Upper Stitch Pattern Selector ; Special

• Lower Stitch Pattern Selector t A

• Stitch Width Selector: 2 or 3

• Buttonhole Stitch Selecting Dial : MAGIC

• Throat Plate : General Purpose

• Presser Foot: General Purpose

DECORATIVE TWO-NEEDLE STITCHING

Stitch Patterns and Their Selector Settings

a

AK3 n am 3 as®s as®3

AL3

_____

____I-____

--------

___

J A— AS(i)3 ’ AS(|)3

«%SS4&

A S 3

6m)

12 3 4 6

^ A S3 “ ^

^ ¿—A l

----

X (i^

O Removable Cam Numbers

23

Page 26

A WORD ABOUT CHAIN STITCHING

This machine has the unique feature of being capable

of producing not only conventional lock stitching but also

selectively single thread chain stitching. By means of

the chain stitch, the necessary tacking and basting opera

tions indispensable for sewing prefectly fitted dresses

or other garments can now be produced.

This single thread chain stitching looks like regular

straight stitching on top, but is a series of interlocking

loops on the underside of the fabric. (See Fig, 1) The

stitches are produced by the needle thread alone, so you

do not need a bobbin thread or a bobbin.

For chain stitching, fine threads and soft fabrics are

most suitable.

WHERE TO USE CHAIN STITCHING

Here are a few of the many sewing jobs for which

you will find chain stitching useful.

- Edge basting on jackets, coat, and costumes—sleeve

inserting—attaching collars—hems on skirt, blouses etc.

“ Trial seams for fitting.

* Fastening removable trimming—

Fur collars.

White collar and cuffs.

• Hemming curtains and draperies that may need to be

altered.

• Sewing temporary tucks to extend the life of—

Children's clothes.

Curtains and linings that might shrink. (See Fig. 2)

* Sewing knit, jersey and tricot.

Fig, 2

Set feed throw-out lever to

“DOWN” position. Remove re

gular throat plate and bobbin,

and insert chain stitch loop re

tainer A into bobbin case.

TO PREPARE THE MACHINE FOR CHAIN STITCHING

Set feed throw-out lever to “UP”

position. Depress loop retainer

latch S as shown above.

24

Turn the latch to the left until

it is positioned under the feed

dog. Insert chain stitch throat

Plate C.

Page 27

CHAIN STITCHING (Continued)

TO THREAD THE MACHINE

Thread your machine in the usual way, except pass

needle thread from take-up lever through chain stitch

thread guide D with the face plate open. (See Fig. 6)

NEEDLE THREAD TENSION

Normally set between 2 and 4 on the Tension Dial,

however, slight adjustment may be required dependent

on the thread size and the material used.

When the tension is correctly adjusted, the chain will

be flat and smooth. (See Fig. 1)

Puckers in the fabric and pinched loops indicate too

much tension—turn dial to a lower number.

Large, irregular loops indicate too little tension—turn

dial to a higher number.

- T' .''1

^ t .

TO SEW AND CHAIN-OFF

• Stitch Pattern Selectors :

• Stitch Width Selector:

•Stitch Length: 6'—12

• Throat Plate:

• Presser Foot:

Chain Stitch Throat Plate

Straight Stitch or General Purpose

(When sewing soft fabric with fine

thread)

Special Purpose

(When sewing crisp fabric such as

calico with #50 cotton)

AN

3

1. Position needle in very edge of fabric and lower the

presser foot.

2.

Start the machine and stitch to end of seam. Con

tinue stitching beyond edge of fabric, making a chain

from one to two inches long.

Cut chain between fabric and presser foot. (See Fig. 9)

After chaining off, start a new line of stitching by

raising the presser foot slightly and positioning the

fabric in front of needle. Lower presser foot and

stitch to end of seam. (See Fig. 10)

Fig.

Fig. 10

25

Page 28

CHAIN STITCHING (Continued)

f

Fig. 12

TO RELEASE CHAIN FROM THE MACHINE

When you finish chain stitching, the chain can easily

be

removed from the machine.

r

1.

Raise presser foot.

2.

Hold end of chain with your left hand.

3.

Turn hand wheel slowly toward you with your right

hand until needle is all the way down in the needle

1

t

hole.

4.

Then turn hand wheel slowly away from you, pull

ing gently on chain, which will unravel as needle

rises. (See Fig. 11)

TO END THE STITCHING IN THE FABRIC

Stop stitching at desired point, with take-up lever

in its highest position.

Raise presser foot.

With your finger, pull the thread through the takeup lever, forming a loop between the take-up lever

and chain stitch thread guide. (See Fig. 12)

4.

Pass scissors under presser foot so as to' draw the

loop down to the left of the foot. (See Fig. 13)

5.

Hold the loop and cut the thread close to the end

of the stitching. (See Fig. 14)

6.

Remove fabric from the machine by pulling it straight

back, away from you. This will cause the thread

end to pull through the fabric to the underside and

form a temporary lock. (See Fig. 15)

TO REMOVE THE STITCHING

1. Cut the last loop formed on the underside

of the fabric. (See Fig. 16)

2. Pick up free thread end from top surface

of fabric.

3. Pull the free thread end, removing entire

line of stitching. (See Fig. 17)

26

Page 29

FREE-MOTION STITCHING

In. free-motion stitching, you sew without a prass»r foot and instead control fabric movement

(and hence stitch length) yourself, by means of an ombroldory hoop. Either a straight or a zigzag

stitch setting can be used. Because you can move the hoop in any direction—forward or backward,

from side to side, and even diagonally—free-motion stitching is extremely useful for intricate em

broidery designs,

SCRIPT LETTERING

1. Transfer the design (by tracing, usually) to the right

side of fabric.

2. If the fabric is soft or loosely woven, baste a back

ing of lawn or organdy onto the wrong side.

3. Place work in embroidery hoop. Be sure fabric is

held taut.

4. Position work under needle and lower presser bar

to engage tension.

5. Turn hand wheel toward you to bring bobbin thread

up through fabric at start of design and hold both

threads as you start stitching,

6. Stitch, following the outline of the lettering. Move

the hoop slowly and maintain an even rate of speed

so that stitches are uniformly spaced.

7. After stitching, trim the backing close to the

stitching.

Darning With Embroidery Hoop

♦ Stitch Pattern Selectors; AN

♦ Stitch Width

♦ Stitch Length ; FINE (above 20)

♦ Throat Plate i

* Presser Foot: None

♦ Pressure Dial t D

• Feed Throw-out Lever; DOWN

Selector: 3

Straight Stitch

ZlgTog

Stitching

BJ

* Stitch Pattern Selectors; AN

♦ Stitch Width Selector) 3

♦ Throat Plate; General Purpose

• Presser Foot: None

* Pressure Dial> D

* Feed Throw-out Lever; DOWN

Trim ragged edges from area to be darned.

1.

Center worn section in embroidery hoop.

2.

Position work under needle and lower pres;

3.

Straight

Stitchirg

to engage tension.

4.

wheel over and draw bobbin thread up through

fabric. Hold both thread ends and lower needle into

fabric.

5. Outline area to be darned with running stitches for

reinforcement.

6. Stitch across opening, moving hoop under needle at

a slight angle from lower left to upper right. Keep

lines of stitching closely spaced and even in length.

7. When opening is filled, cover area with crosswise

lines of stitching.

27

Page 30

Applique adds beauty and interest to clothes and

household linens. Either contrasting or self fabric can

be used effectively.

The stitch most commonly used in appliqueing is

basic pattern J closely spaced to form a satin stitch.

The width of this and other basic patterns can be

varied to accommodate fabrics of different weaves and

textures. Combination patterns and variations can also

be used to applique with decorative stitching.

To prepare for appliqueing, make a sample to help

you decide which of the following two methods is the

more appropriate for your fabric and design.

• Position the design.

• Baste it to the fabric.

• Attach Special Purpose Presser Foot

(and General Purpose Throat Plate).

Method

1. Set Stitch Pattern and Stitch Width Selectors for

desired applique stitch. Set Stitch Length Regula

tor on FINE (above 20).

2. Stitch, outlining the design with applique stitching.

3. Trim any excess fabric on the outer edges of the

stitching. Remove basting.

Method ^2

1. Adjust selectors for straight stitching (AN 3).

2. Outline the entire design with a short stitch.

3. Trim raw edges to the stitching.

4. Readjust selectors for stitch pattern and width desired,

and set Stitch Length Regulator on FINE.

5. Stitch, following the straight-stitch outline. This

step will produce a smooth overedged finish, with

no raw edges to be trimmed. Rernove basting.

CORDED APPLIQUE

The Special Purpose Foot, which provides for a filler

cord is most suited for corded applique work. Gimp,

crochet thread, etc. are generally used for filler cord.

Follow either Method #1 or #2, described above.

The only difference in corded applique is the introduc

tion of the cord, over which the applique stitching is

formed.

To Threod Filler Cord

1. Place the spool of filler cord on the table, floor, or

in your lap.

2. Unw’ind a suflicient amount to avoid tension or

strain on the cord.

3. Lead the end of the cord through the eyelet in front

center of the Special Purpose Foot.

4. Draw the cord under and in back of the foot.

5. Proceed with stitching as for regular applique stitch.

28

Page 31

Many of the decorative stitch patterns can be used for monograms or motifs for adding a personal

touch to a blouse collar, for example, or for initialing household linens. You can buy designs or

create them yourself.

To Stitch a Monogrom or Motif

Stitch Pattern Selectors: BJ for zigzag satin

stitching

See stitch chart for

decorative stitches

Stitch Width Selector; 2*^5 (2-^4 tor

Combination Patterns)

Stitch Length ; FINE (above 20)

Throat Plate : General Purpose

Presser Foot: Special Purpose

1. Make a sample first, to determine suitability of

stitch pattern and find the right stitch length and

width, thread tension, and pressure.

2. Transfer the design (by tracing, usually) to the

right side of the fabric, and stitch.

Hemmer Foot

Stroight Stitching

Stitch Pattern Selectors : AN

Stitch Width Selector t 3

Stitch Length: 10^20

Throat Plate: Straight Stitch

Presser Foot: Hemmer Foot

You can turn and stitch a narrow hem in a single

operation if you use the Hemmer Foot. Thus, you can

eliminate basting or pinning whenever you are making

ruffle edges, lingerie finishes, and the like.

Decorotive Stitching

• Upper Pottern Selector: Any basic pattern

» Lower Pattern Selector: B

‘ Stitch Width Selector : 3

• Throat Plate: General Purpose

‘ Presser Foot; Hemmer Foot

29

Page 32

HEMS (Continued)

GUIDING FABRIC EDGE INTO SCROLL OF FOOT

PLAIN NARROW HEM

1. Draw the bobbin and needle threads under the

Hemmer Foot.

2. Crease a double '/s ii^c-h fold for about 2 inches along

the edge of the fabric.

3. Place the creased fold under the Hemmer Foot.

4. Lower the foot and start the hem by taking two or

three stitches through the double fold.

5. Hold thread ends with the left hand and guide the

raw fabric edge in front pf the hemmer into the

scroll.

6. Sew slowly, guiding raw edge in front of Hemmer

Foot. Hold threads until hem is well started. Even

feeding is essential, so keep the same width of

fabric in the scroll of the hemmer at all times.

DECORATIVE NARROW HEM

If you use the Hemmer Foot and choose a zigzag

stitch pattern, you can turn and deearate a narrow

hem in a single operation.

DECORATIVE NARROW HEM

Stitch Pattern Selectors : AN

Stitch Width Selector : 3

Stitch Length: 10^15

Presser Foot; Zipper Foot

Throat Plate ; General Purpose or

Stroight Stitch

ZIPPER INSERTION

When the zipper is to the right of needle:

1. Loosen the thumb screw at the back of the foot

and slide the foot to the left of the needle.

2. Check the position of the foot by lowering the needle

into the right tide outer notch A of the foot, making

sure it clears the foot.

3. Lock the foot into position by tightening the thumb

screw, and the machine is ready to sew.

When the zipper is to the left of the needle, adjust

the foot to the right of the needle in the same way.

This foot makes it easy to place

stitching close to a raised edge.

Thus, it is useful for corded seams

as well as zipper insertion.

It can be adjusted to either the

right or the left side of the needle.

30

Page 33

ZIPPERS (Continued)

CORDED SEAMS

The corded seam is a professional treatment for slip

covers, children's clothes, blouses, and lingerie. To make

a corded seam, make the welting first, then stitch it

into the seam.

To make the welting

1. Cut bias strips of fabric (width: three times the

diameter of the cord plus P/< inches).

2. Sew strips together on the lengthwise grain to

obtain desired length.

3. Fold resulting strip over cord, raw edges even.

4. Adjust Zipper Foot to the left side of the needle.

5. Lower Zipper Foot.

6. Stitch close to the cord (but do not crowd stitching

against cord), pulling gently on the strip, both in

front and in back of the Zipper Foot,

To stitch welting into seam

1. Place the welting between the two fabrics.

2. Stitch, this time crowding the foot against the cord.

BUTTONHOLES

BUTTONHOLE CAM

Buttonholes can be made with the Buttonhole Cam

fitted to the machine. This cam can be easily replaced

with other interchangeable cams.

To replace the buttonhole com

1. Align slot B with hole A of the cam and place the

cam onto spindle, pushing downward until it snaps

in place.

2. Turn the cam clockwise until white mark on

the cam is aligned with red mark on top cover.

(See Fig. 1)

Viewed from underside

To remove the buttonhole cam, push disc follower re

leasing lever to the right and set buttonlmle stitch

selecting dial to "OFF”.

Fig. 1

31

Page 34

BUTTONHOLES (Continued)

Upper Stitch Pattern Selector: Special

Lower Stitch Pattern Selector : B

Stitch Width Selector: 3~5

Stitch Length Regulator :

Presser Foot: Buttonhole Foot

Pressure Regulating Dial: 2~3

Throat Plate : General Purpose

6

J L M

Special

PREPARATION

• Position buttonhole cam correctly in place as described

above.

• Attach Buttonhole Foot.

• First, decide how long the opening needs to be. This

will depend on the diameter and thickness of the

button. Then, add approximately Vb inch (about Vie

inch for each bar-tack) and mark the fabric as shown

in Fig. 2.

• Decide stitch width and stitch density according to

thickness of fabric and button. (See Fig. 3)

Always make a test buttonhole on a sample of your fabric. Be sure to duplicate the thickness of the

garment and include interfacing if appropriate.

Stitch Width and Stitch Density Table

Closely Packed Stitches

Medium Spaced Stitches

Cutting

length

1

Fig. 2

Open Stitches

Fig. 3

32

Page 35

BUTTONHOLES (Continued]

1 2 3 4. 5

PROCEDURE

1. Push disc follower releasing lever to the right and

set buttonhole stitch selecting dial to “Bl”. Posi

tion needle in fabric at point A. Lower presser

foot and stitch to point B. Stop the machine and

raise needle from fabric. (See Fig. 4)

Fig. 4

2. Push disc follower releasing lever to the right and

set buttonhole stitch selecting dial to “B2”. Start

stitching at point B and stop at point C. Raise

needle from fabric. (See Fig. 5)

Fig. 5

3. To secure stitching, move stitch width selector to

“ 1 ” and take approximately three stitches to point

D. Then, cut opening for the button with the rip

per supplied with the machine.

Fig. 6

CORDED BUTTONHOLES

Heavy cotton or buttonhole twist makes suitable filler

cords for raised buttonholes.

1. Place filler cord on the material, leaving sufficient

amount of cord for right side. (See Fig. 7)

2. Lower the foot, bringing the cord under the left

groove on the bottom side of the foot. Then, pro

ceed with stitching in the same method as stated

above except;

(1) After setting buttonhole stitch selecting dial to

“B2”, position needle in fabric at point E and

raise the foot.

(2) Lead end of cord at farther end to the right

around the needle as shown in Fig. 8.

(3) Lower the foot and continue to stitch.

3. Trim cord ends after a buttonhole is completed.

(See Fig. 9)

Leave Position

sufficient needle

amount of at point

cord* E.

Fig. 7

Fig. 8

Fig. 9

Cut cord

end.

33

Page 36

BUTTONHOLES (Continued)

To make buttonhole stitches stronger, sew over the

entire buttonholes once again. (See Fig. 10)

CAUTION

1. In case right side stitch density is not uniform with

the left side stitch density when making a test but

tonhole, move the magic pattern stitch adjusting

lever toward you or away from you as required.

• If the lever is moved toward you, stitches will

become closely spaced.

• If the lever is moved away from you, stitches will

become open. (See Fig. 11)

2. With a little practice, you will be able to sew button

holes continuously without stopping the machine as

instructed in page 33.

3. When you stop half way through the buttonhole and

wish to start over again, be sure to follow the in

structions below.

(a) Push disc follower releasing lever to the right

(b) Turn buttonhole cam clockwise and align white

(c) Set buttonhole stitch selecting dial to “Bl” and

4. Needle thread tension should be made slightly stronger

when making buttonholes. This will give neatly

finished buttonholes.

DOUBLE BUTTONHOLE STITCHES

and set buttonhole stitch selecting dial to “OFF”.

mark “0” with red mark “0” on the top cover.

continue to stitch.

Fig. 10

Open

Q stitches

t

0

Q Closely

spaced

stitches

34

Page 37

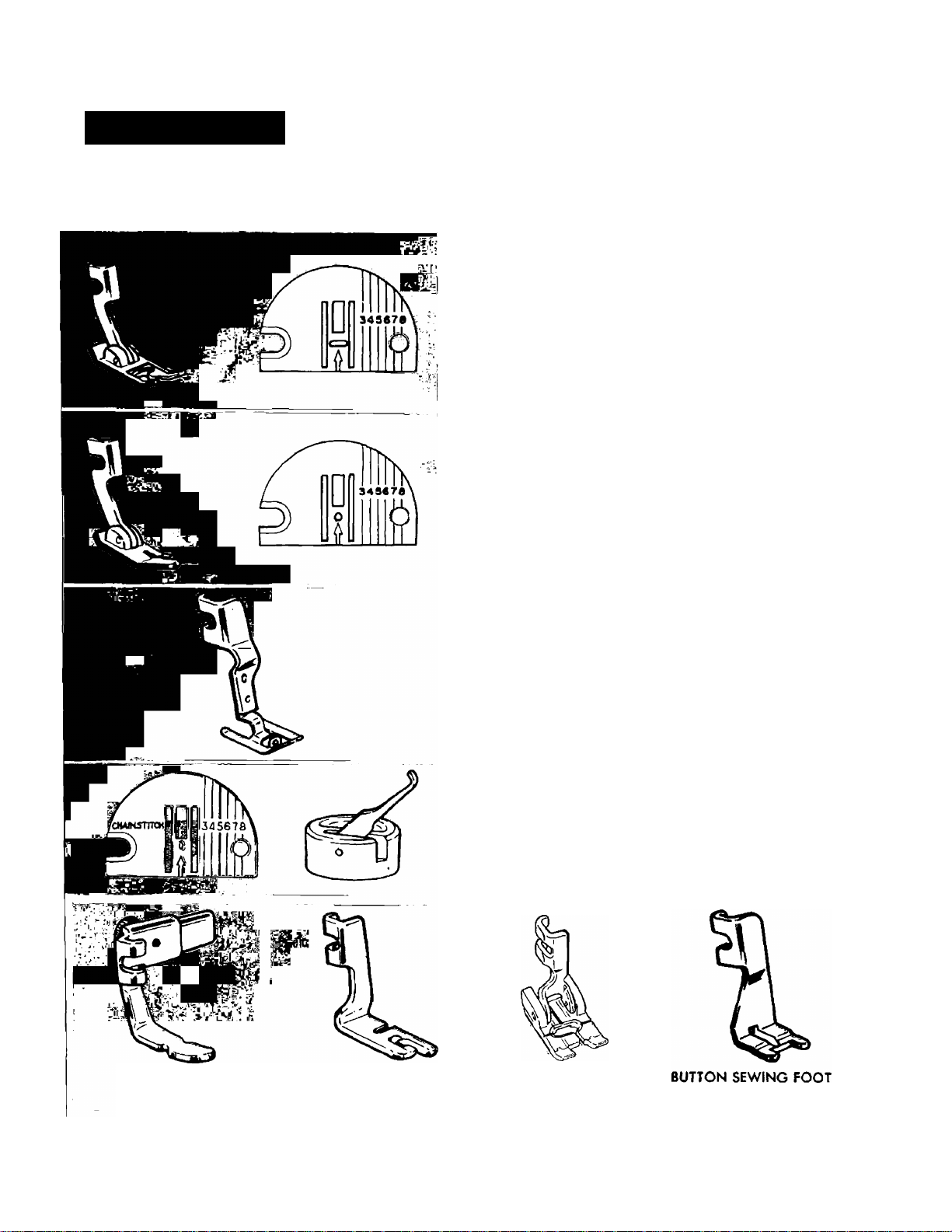

BUTTON SEWING FOOT

I

• Stitch Pattern Selectors: AJ

• Stitch Width Selector! 1 and about 4

• Throat Plate t General Purpose

• Presser Foot: Button Sewing Foot

• Lower Feed

The space between the holes in the button deter

mines the stitch width settings. The number 1 setting

must always be used to position the needle and fasten

stitching. For buttons with standard hole spacing, use

settings 1 and 4. For buttons with unusual hole spacing,

use setting 1 and increase or decrease the width setting

(4) as necessary.

'i

.

.............

Si

I ..

’ 'S

!-S; ■ S "

Set selectors at AJ and stitch width

at 1. Lower feed. Position button ;

under foot so that needle will

enter left hole. Lower foot. Turn

hand wheel toward you until

needle rises out of fabric and is

just above the foot.

Set stitch width at about 4. The

needle should then enter into the

right hole of the button. Take ap

proximately six zigzag stitches in

this position. End on the left side.

THREAD SHANK

In order to form a shank, stitch over a regular ma

chine needle. Position button and lower Button Sewing

Foot. Place needle in the groove of the foot so the

point enters the hole.

To form a long shank, stitch over the heavy end of

the needle.

%

To fasten stitching, adjust to num

ber 1 stitch width setting and

take opproximately three stitches.

35

Page 38

This attachment is fastened to machine in place of

regular presser foot, and will be found an indispensable

aid whenever stitching must be kept accurately on ex

treme edge of a piece of material.

The slots numbered from 1 to 5 in the sketch at left

serve as guides for sewing together laces, insertions

and embroideries, sewing in position hemmed or folded

edges, piping or sewing flat braid to a garment.

• Stitch Pattern Selectors : AN

• Stitch Width Selector; 3

• Stitch Length:

• Presser Foot: Edge-stitcher

• Throat Plate : Straight Stitch or

General Purpose

TO INSERT LACE OR RIBBON

terial in slots is regulated by moving thumb screw A

to the right or left.

1. Fold edge of material to which lace or ribbon is to

be sewn and insert it in slot 1 of edge-stitcher.

2. Insert lace or ribbon in slot 4 and proceed to sew.

3. Cut away surplus folded material close to stitching.

Lace or ribbon insertion can also be done with zigzag

stitching. In this case, use General Purpose Throat

Plate and set Stitch Pattern and Stitch Width Selectors

Bt BJ 2 or BJ 3.

TO ADJUST THE EDGE-STITCHER

The distance from line of stitching to edge of ma

TO PIPE WITH EDGE-STITCHER

1. Cut piping bias and twice width of slot 3 so that it

can be folded once.

2. Insert piping with its folded edge to left in slot 3

and edge to be piped in slot 4.

As in the above case, piping can be done with zigzag

stitching,

36

Page 39

HOW TO USE THE EDGE-STITCHER IContinoed)

TO MAKE A FRENCH SEAM

1. To make a French seam of uniform width, insert

two edges to be joined, wrong sides together, in slot

1 or 2, and stitch close to edge.

2. Fold both right sides together and insert back of

seam in slot 1, as shown in sketch at left and stitch,

allowing just enough margin to conceal raw edges.

TO TUCK WITH EDGE-STITCHER

1. Fold and crease material for desired width of tuck,

2. For succeeding lucks, fold material the desired dis

tance from previous tuck, running the fold length

wise over a straight edge, then crease folds.

3. Insert creased folds in slot T and 2 and adjust edgestitcher to right or left for the desired width of

tuck. Use a light tension, short stitch and fine

thread and needle.

OVERLAP SEAM

1. Fold edge of a piece of material and insert it in

slot 1.

2. Insert another piece of material in slot 5.

3. Set stitch pattern selectors at "BJ” and stitch width

selector at 2 or 3, and proceed to stitch.

37

Page 40

-i fy

Your sewing machine is a fine yet sturdy precision

instrument, and it will serve you perfectly for many

years if you take a few simple steps to keep it in

good working condition.

How often you will need to clean, oil, and lubricate

the machine will depend on how often you use it and

where you keep it.

When in regular use, the machine should be cleaned

periodically to remove lint and fluff which may have

accumulated around working parts.

With a soft doth, clean:

• Tension discs

• Take-up lever and thread guides

• Presser bar and needle bar

• Bobbin case (for instructions on removal, see page 39)

» Machine arm and bed

If necessary, dampen the cloth to clean the machine

surface. Do not use detergents.

With a lint brush, dean:

• Feed dog

• Rotating hook (area under throat plate and slide plate)

After each cleaning, apply a drop {but no more than

a drop) of SINGER oil to the areas indicated. Then

sew a line of stitching on a scrap of material to remove

excess oil.

APPLY A DROP OF OIL TO EACH SPOT SHOWN

38

Page 41

CARING FOR YOUR SEWING MACHINE (Continued)

Oil bottom of machine;

1. Disconnect plug from electrical outlet.

2. Tilt machine back and loosen screw from the center

of the machine bed to remove bottom cover.

3. Apply SINGER oil as shown.

A 6

\

If the machine is to be stored away for an indefinite period, a thorough brush-cleaning to remove all traces of

lint and fluff, followed by swabbing of all exposed parts with SINGER oil is necessary to protect the machine

against rust damage.

TO REMOVE AND REPLACE THE BOBBIN CASE

1. Remove throat plate and open slide plate.

2. -Remove the bobbin.

3. -Unlbck bobbin .ease, by lifting and twisting

bolder A to right as shown.

4. Remove bobbin case from machine.

5. Remove all lint, fluff, loose thread ends or any other

foreign matter which might clog the machine.

/

6. Replace bobbin case so that groove under tension 7_ Push bobbin case holder to left until it snaps down

spring fits on hook raceway and fork B of case into lock position.

straddles positioning stud C.

39

Close bed slide and replace throat plate.

Page 42

PERFORMANCE CHECK LIST

remember to

• Be sure to follow the instructions on page 3 when

using pattern selectors.

• Position needle out of fabric when making stitch width

and stitch pattern adjustments.

• Clear your machine of lint and fluff periodically and

apply oil.

• Use your Instruction Book. It was written to explain

the most efficient way to operate and use this remark

able new machine.

if thread breaks

• Is the machine properly threaded ?

• Is a Catalog 2020 (15 X 1) needle correctly inserted and

securely tightened in the needle clamp ?

• Is the needle straight and sharp ?

• Is the thread suitable for the size of the needle ?

• Is the thread free of twists and knots ?

• Is the thread unwinding freely from the spool?

•Is the needle-thread tension too tight?

• Is the bobbin-case area free of lint and loose thread

ends ?

• Are the thread guides and tension discs also lint-free ?

40

Page 43

FOR YOUR PROTECTION

Always look for the famous Red "S" and SINGER

tradenrark for authorized sales and service.

When your machine needs servicing, call your SINGER

SEWING CENTER and be sure of warranted SINGER

parts and service.

See address in classified telephone directory listed only

under

SINGER SEWING MACHINE COMPANY

Loading...

Loading...