SINGER 6105 User Manual

Copyright © 1979 THE SINGER COMPANY

All rights reserved throughout the world

CONTENTS

Page

Chapter 1. Getting to Know Your Machine.............................................................................................................................2

Principal Parts.................................................................................................................................................. 2

Accessories.......................................................................................................................................................3

Chapter 2. Getting Ready to Sew

Choosing and Changing Accessories............................................................................................................ 4

Fabric Weight Table

Fabric Thread and Needle Table.............................................................................................................8

Needle-Fabric Combinations.........................................................................................................................10

Operating the Machine...................................................................................................................................10

The Bobbin Thread.........................................................................................................................................11

Winding the Bobbin • Threading the Bobbin Case

Threading the Machine...................................................................................................................................13

Raising the Bobbin Thread

Chapter 3. Straight Stitching...........................................................................................................................................15

Adjusting Machine Stitch to Suit Your Fabric..........................................................................................15

Setting Selectors • Regulating Presser Foot Pressure •

Adjusting Stitch Length • Needle-Thread Tension

Sewing a Seam............................................................................................................................................... 17

Keeping the Seam Straight

Applications ................................................................................................................................................... 18

Zipper Insertion • Darning

Chapter 4. Basic Zig-Zag Stitching.................................................................................................................................19

Adjusting Machine to Suit Your Fabric.........................................................................................................19

How to Set Selectors • Pattern Group Selector •

Needle Position Selector • Stitch Width Selector • Adjusting Needle Tension •

Adjusting Stitch Length • Adjusting Presser Foot Pressure

Satin Stitching.......................................................

Applications ....................................................................................................................................................22

Appliqué • Lingerie Seams • Zig-Zag Seam Finishes

................................................................... ............................................................

............................................................................... ..................................................

....

.....................................................................................21

.....

. 4

6

Chapter 5. Machine Stitch Patterns............................................................................................................................... 24

Setting Selectors............................................................................................................................................ 24

Selecting a Pattern Group • Adjusting Width of the Design • Adjusting Stitch

Placement • Adjusting Stitch Length • Adjusting Stitch Balance

Adjusting Stitches to Suit Stretch Fabrics . ................................................................................................27

Guiding and Supporting Fabric • Adjusting Pressure

Stitch Pattern Chart...................................................................................................................................... 28

Applications ....................................................................................................................................................29

Blindstitch.................................................................................................................................................... 29

Hems

Multi Stitch Zig-Zag.........................................................................................................................................30

Bar Tacks • Mending a Tear

Honeycomb Stitch......................................................................................................................................... 31

Attaching Elastic

Chapter 6. Buttonholes and Buttons...............................................................................................................................32

Four-Step Buttonholing

Changing Stitch Density

Buttons............................................................................................................................................................ 34

Chapter 7. Twin-Needle Stitching.................................................................................................................................. 35

Chapter 8. Free-Arm Sewing.......................................................................................................................................... 36

Chapter 9. Performance Checklist...................................................................................................................................37

Chapter 10. Caring for Your Machine............................................................................................................................... 38

Index ................................................................................................................

...

......................................................................................................................... 32

.....

.................................................................40

,gjl

. ; ■. ■,■■■■ .

■■

bhrc^

’^^2' lixj

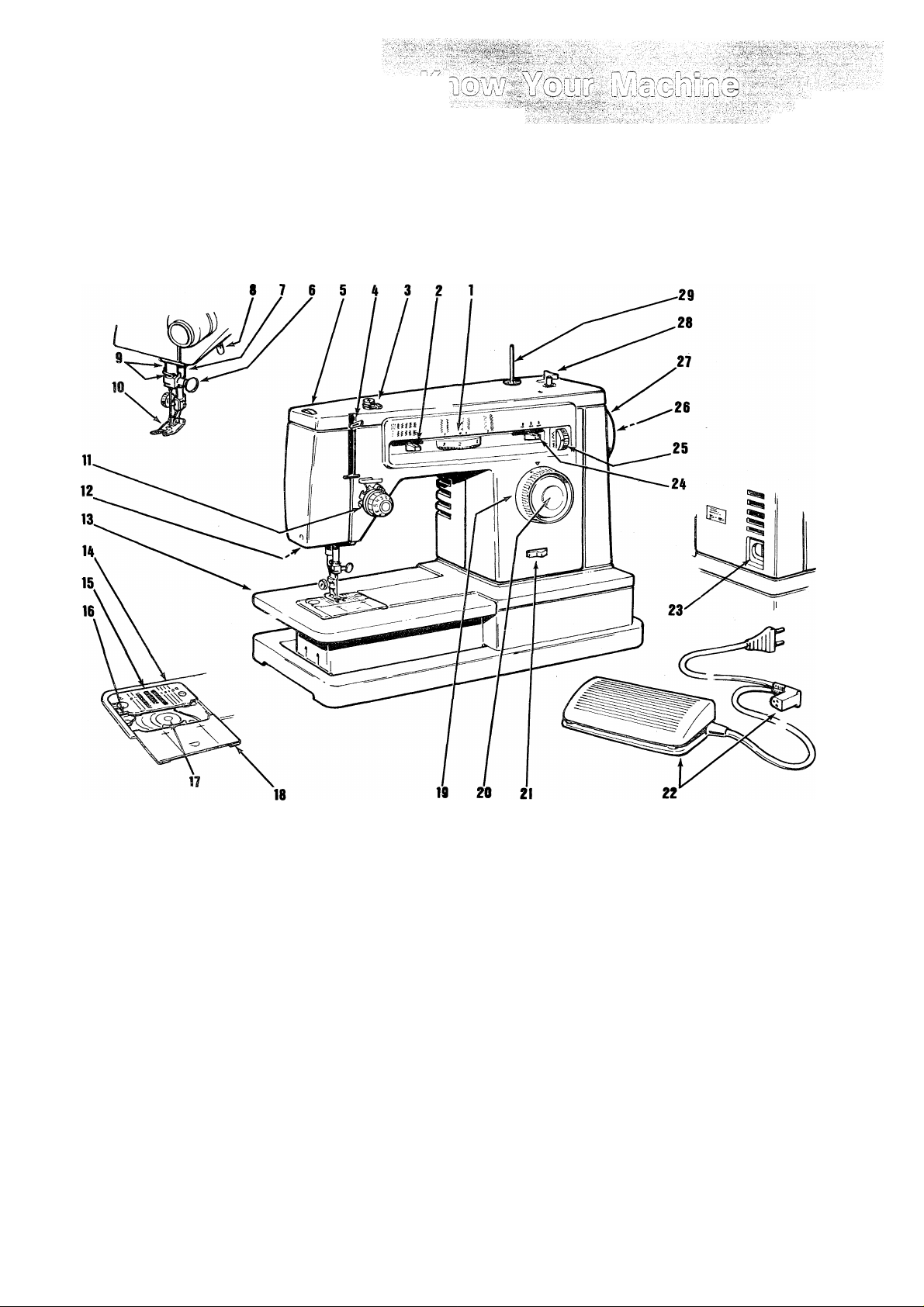

principal parts

Pattern Group Selector

1.

Stitch Width Selector

2.

Bobbin Winder Tension

3.

Take-up Lever

4.

Pressure Dial

5.

Needle Clamp

6.

7. Thread Cutter

Presser Foot Lifter

8.

9. Thread Guides

10.

General Purpose Presser

Foot

Tension Dial

11.

12. Sewing Light

13. Extension Bed

14. General Purpose Needle

Plate

15. Feed

16. Bobbin Case Flolder

17. Transparent Bobbin

18. Slide Plate

19. Stitch Length Selector

and Buttonhole Dial

20. Reverse Stitch Push

Button

21. Power and Light Switch

22. Electrical Connections

and Speed Controller

23. Machine Plug Receptacle

24. Needle Position Selector

25. Stitch Balance Control

Dial

26. Fland Wheel Knob

27. Hand Wheel

28. Bobbin Winder Spindle

29. Spool Pin and Felt

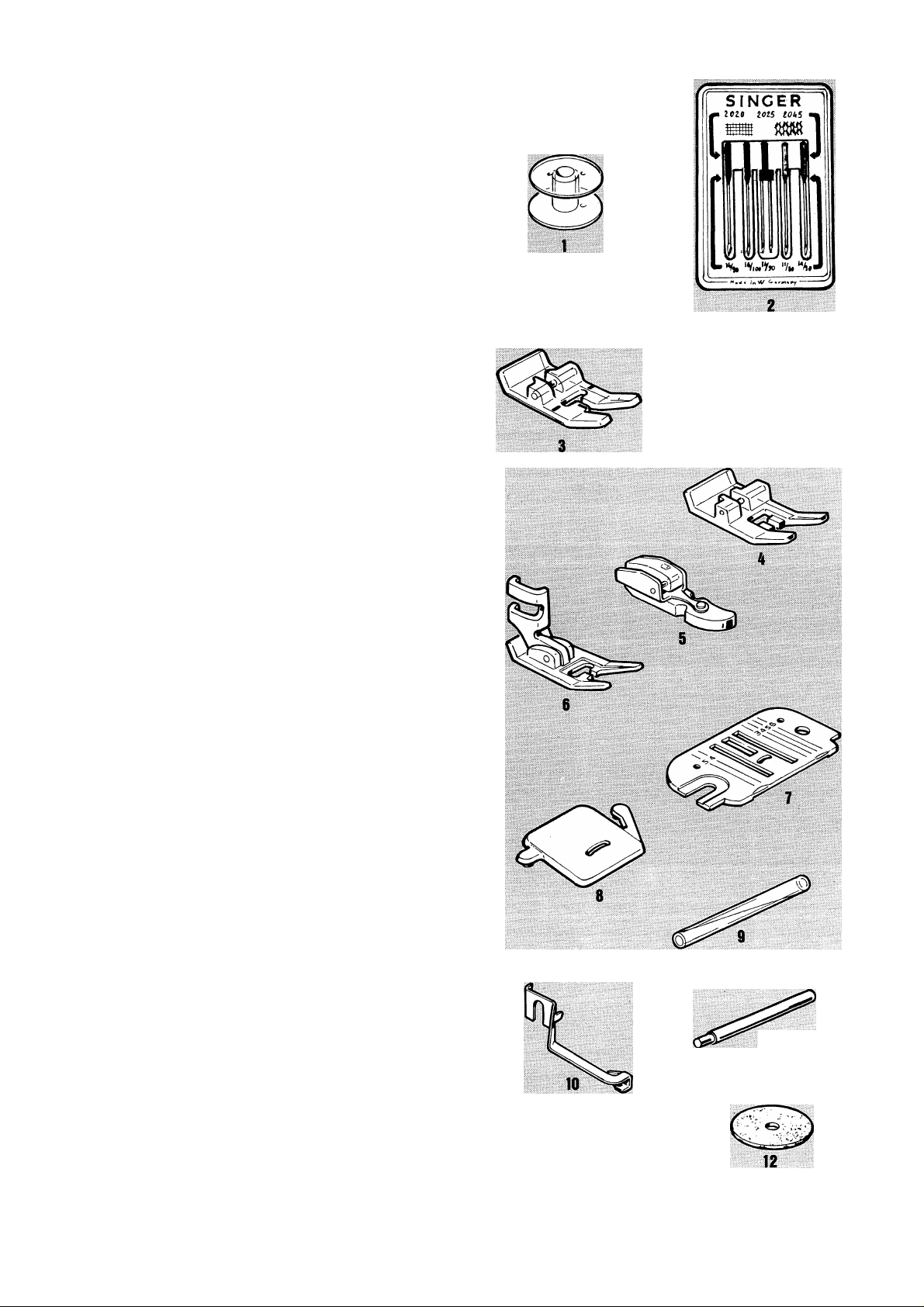

accessories

The accessories that come with your sewing

machine are designed to help you do many

kinds of sewing easily.

1. Transparent Bobbins (No. 172336).

2. Needles

• Style 2020 is for general sewing.

• Style 2045 is used for sewing knits,

stretch fabrics and elastic.

• Style 2025 for twin-needle decorative

stitching on woven and knit fabrics.

3. Buttonhole Foot is used to make bar tack

buttonholes of any length in four steps.

4. Special Purpose Foot. Used for all kinds

of decorative zig-zag stitching.

5. Zipper Foot for inserting zippers and stitch

ing corded seams.

6. General Purpose Foot on your machine

when delivered, is used for all utility sew

ing, with either straight or zig-zag stitching.

7. General Purpose Needle Plate on your

machine when delivered is used with all

presser feet.

8. Snap-in Feed Cover for button sewing and

free-motion work.

9. Spool Pin Extension used for tubes of

thread.

10. Blindstitch Hem Guide. Use this with the

general purpose foot to position and guide

the hem.

11. Detachable Spool Pin for decorative twinneedle stitching and two-thread topstitch-

ing.

12. Felt to help thread unwind smoothly.

It

Chapter 2. Getting Ready to Sew

choosing and changing accessories

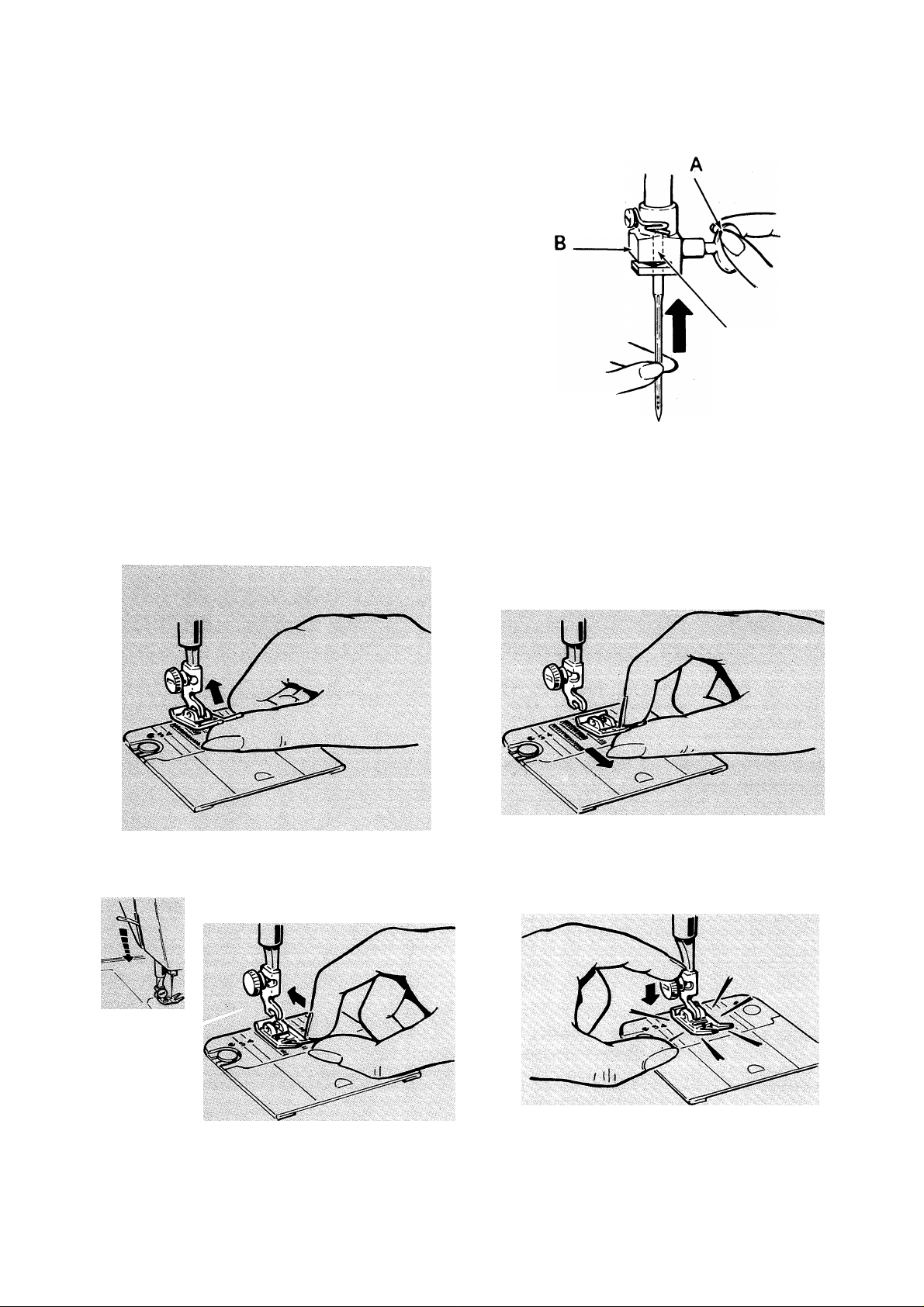

CHANGING THE NEEDLE

• Raise needle to its highest point by turning

the hand wheel toward you. Loosen needle

clamp screw A and remove the needle.

• Insert new needle up into clamp B as far

as it will go, with the flat side of the needle

to the back.

• Tighten needle clamp screw.

CHANGING PRESSER FEET

Snap-on Presser Feet

The presser feet furnished with your machine Raise needle to highest position by turning the

snap on and off a common shank. hand wheel toward you. Raise presser foot.

Flat Side to Back

it will go.

To Remove and Replace Foot

2. Centre the new presser foot under the shank 3. Press presser foot screw down firmly until

C and lower the presser foot lifter so that foot snaps into place,

the shank fits over the presser foot pin.

REMOVING AND REPLACING NEEDLE

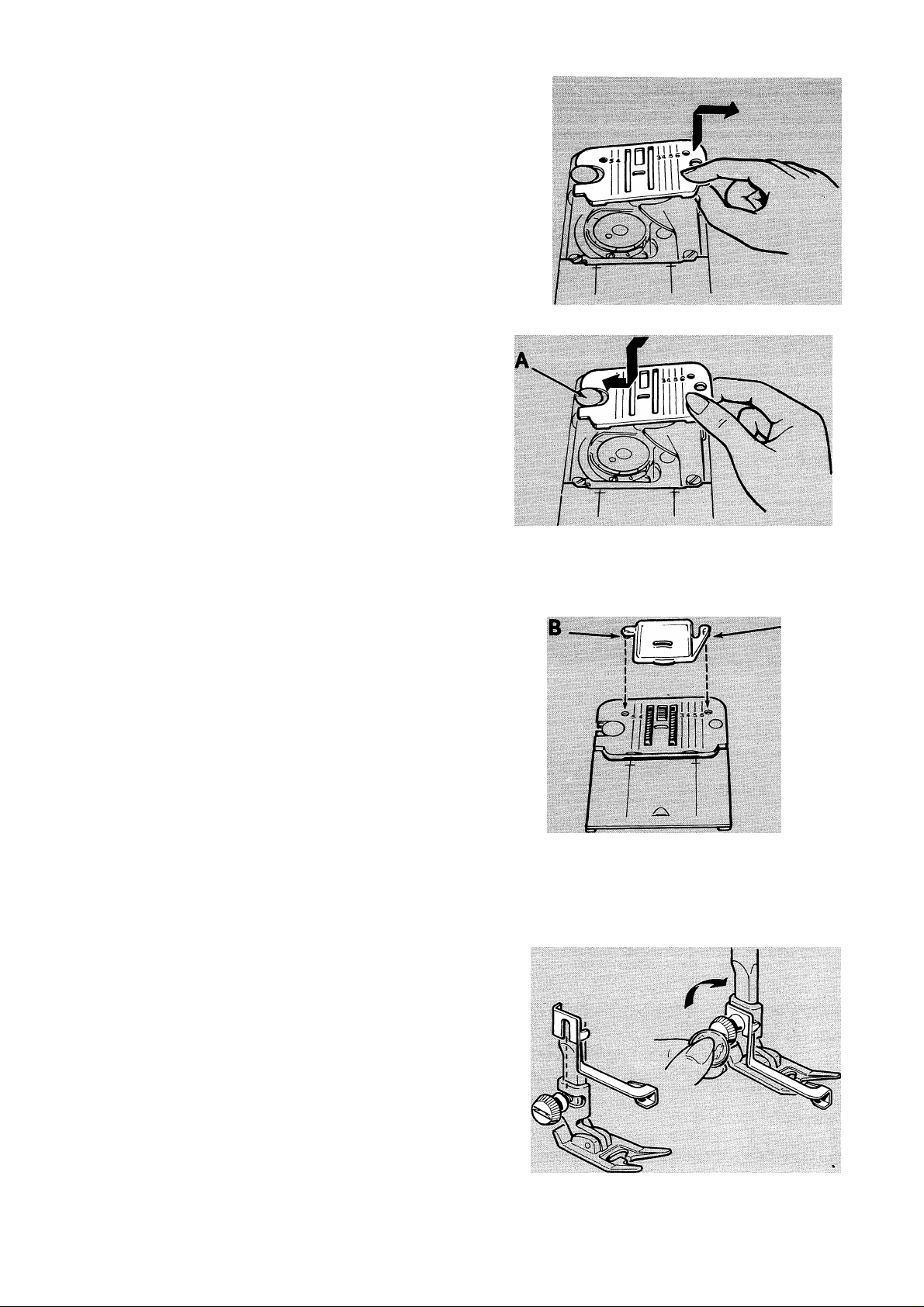

PLATE

• Raise presser foot.

• Raise needle to highest position.

• Open slide plate. Place thumb under right

side of needle plate, lift It up and withdraw

it to right.

• Replace needle plate under clamping pin A,

push it gently to the left and press down

until it snaps into place.

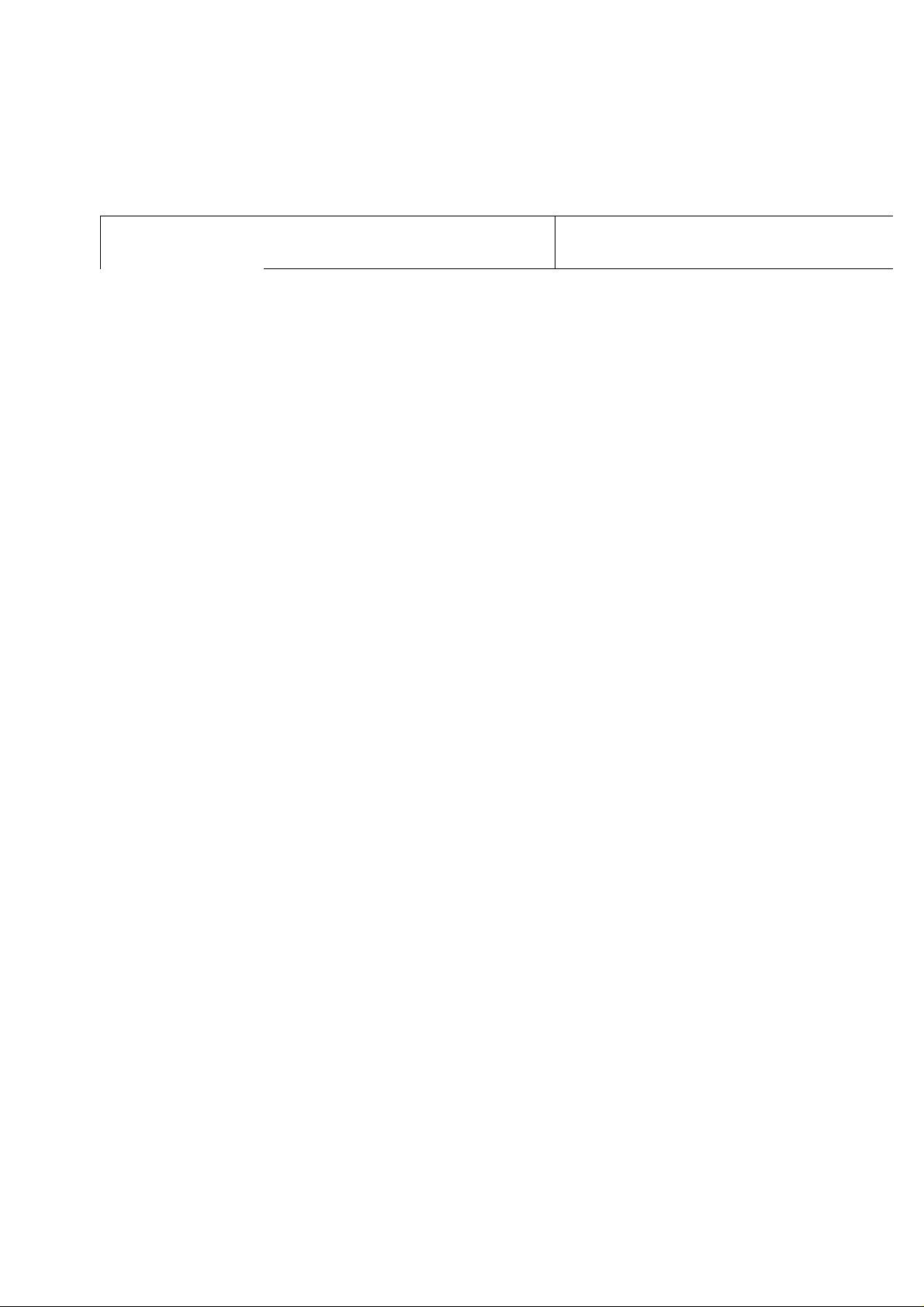

ATTACHING SNAP-IN FEED COVER

• Raise presser foot.

• Raise needle to highest position by turning

hand wheel toward you. Open slide plate.

• Slide snap-in feed cover away from you

over needle plate until points B and C are

positioned directly over holes in needle plate

as illustrated. Snap in point B. Then push

point C in toward point B until it snaps into

place. Close slide plate. To remove, open

slide plate then simply lift up front edge of

feed cover.

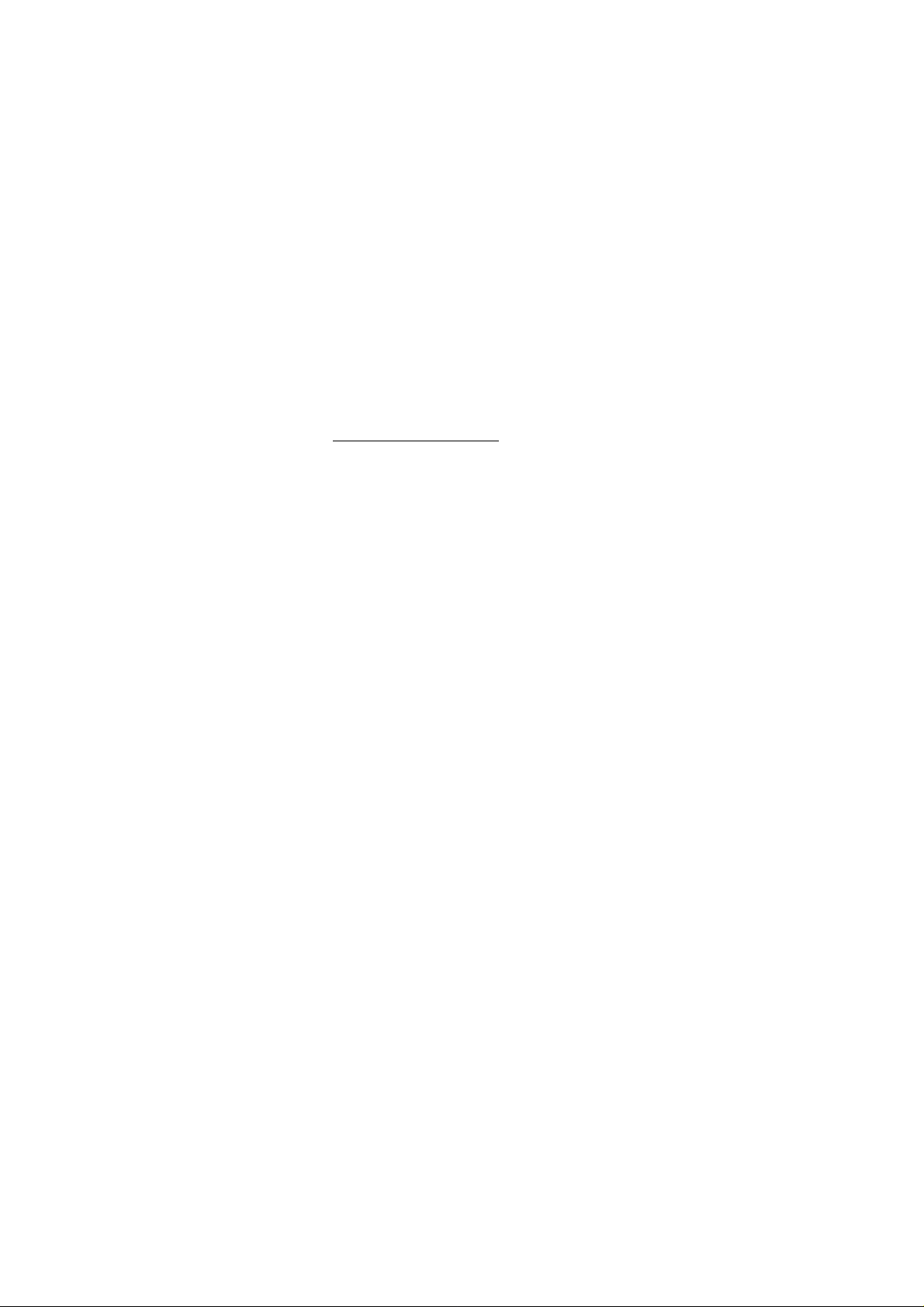

ATTACHING BLINDSTITCH HEM GUIDE

• Raise presser foot, loosen presser foot

screw with a coin and slip blindstitch hem

guide between screw and shank of the

general purpose foot.

• Be sure underside of the guide clears the

slide plate and front of foot.

• Tighten screw with a coin.

FABRIC WEIGHT TABLE

There are many types of fabrics around the world, each manufactured with a specific fibre and

weight. The fabric below have been classified according to weight to give a small sample of

what is available for purchase.

FIBRE

AND

FILMY

SHEER

CONSIBULCTfON

SILK

(Woven)

(Knit)

RAYON

Chiffon,

Organza,

Tulle

Tulle

Net, Lace, Ninon Velvet, Crepe de Chine, Shantung, Faille

Jersey

Net, Lace Velvet, Taffeta, Satin

(Woven)

(Knit)

COTTON

(Woven)

Volle,

Tulle

Net, Lace

Ciré

Challis, Organdy, Muslin, Batiste, Dimity,

Lawn, Percale, Eyelet, Gingham, Piqué,

Poplin

(Knit) Jersey

WOOL

Cashmere, Flannel, Mohair, Felt, Crepe

(Woven)

(Knit)

SYNTHETIC

(Woven)

Chiffon,

Organza,

Tulle

Net, Lace, Ninon,

Crepe de Chine

Jersey

Crepe, Velvet, Taffeta, Satin

(Knit)

SYNTHETIC

BLENDS

(Woven)

(Knit)

LEATHER

PLASTIC

VINYLS

Voile

Plastic Film

Raschel, Single Knit, Sweater Knit,

Bonded Knit, Tricot, Ciré

Broadcloth, Batiste, Eyelet, Gingham,

Poplin

Single Knit

Kidskin, Patent, Chamois, ImitationLeathers & Suedes, Leather, Suede

Plastic Film

Refer to this table to determine the weight and type of fabric you will be using in order to

select the correct needle and thread combination.

For correct needle and thread combination for your fabric, refer to the Fabric, Thread and

Needle Table on the following page.

MEDIUM HEAVY

Velvet, Crepe de Chine, Shantung,

Suiting, Brocade

Velvet, Taffeta, Satin, Crepe

Velveteen, Corduroy, Velvet, Fleece,

Velour, Terry, Chintz

Stretch Velours^, Stretch Terry^

A Usually contain some synthetic fibres also.

Suiting, Flannel, Gabardine, Felt,

Serge, Mohair

Jersey

Brocade, Taffeta, Satin, Crepe

Corduroy, Denim, Ticking, Canvas,

Linen, Drapery Fabric, Burlap

Suiting, Tweed, Duffle

VERY HEAVY

Denim, Duck,

Canvas, Sailcloth,

Upholstery Fabric

Coating, Blanketing

Velvet, Crepe, Taffeta, Satin,

Gabardine

Jacquard, Double Knit, Sweater Knit,

Bonded Knit, Tricot, Spandex, Stretch

Terry, Stretch Velour, Deep Pile, Fake

Furs

Linen Type, Poplin, Corduroy,

Gabardine

Terry Knit

Patent, Imitation-Leathers & Suedes,

Leather, Suede, Reptile

Bonded Vinyl (Knit Back), Patent,

Embossed, Printed

Double Knit, Helenca, Fake Furs

Denim, Gabardine, Drapery Fabric

Double Knit

Buckskin, Calfskin, Suede, Reptile Upholstery Leather

Upholstery Vinyl

Upholstery Vinyl

FABRIC, THREAD AND NEEDLE TABLE

Choosing the correct needle and thread for your fabric is of utmost importance. Correct choice

will make the difference in the wear and appearance of your new garment. The Fabric Weight

Table on the previous page, and the Fabric, Thread and Needle Table below are practical guides

to needle and thread selection. Refer to them before starting a sewing project. Be sure

to use the same size and type of thread in both needle and bobbin.

To select the correct needle and thread for your fabric, first refer to the Fabric Weight Table

to determine the weight and type of the material you are using.

Next, refer to the Fabric Thread and Needle Table.

TYPE

OF

FABRIC

SILK

RAYON

COTTON

WOOL

SYNTHETIC

SYNTHETIC

BLENDS

FILMY

THREADS

Fine Silk

Fine Mercerized

Fine Silk

Fine Mercerized

Fine Cotton

Fine Mercerized

Fine Synthetic

Fine Synthetic

NEEDLES

2020-9

2020-9

2020-9

2020-9

2020-9

SHEER

THREADS NEEDLES

Fine Silk

Fine Mercerized

Fine Silk

Fine Mercerized 2020-9

Fine Cotton

Fine Mercerized

Fine Silk

Fine Mercerized 2020-11

Fine Synthetic

Fine Synthetic 2020-9

2020-9

2020-9

2020-9

LIGHT

THREADS

Fine Silk

Fine Mercerized

Fine Silk

Fine Mercerized

Medium Cotton

Med. Mercerized

Fine Silk

Fine Mercerized

Fine Synthetic

Fine Synthetic

NEEDLES

2020-11

2020-11

2020-11

2020-11

2045-11

2045-11

LEATHER

PLASTIC

VINYLS

Med. Mercerized

Med. Synthetic

Fine Mercerized

Fine Synthetic 2020-11

Fine Mercerized

Fine Synthetic 2020-11

2032-11

Find the fabric you are using in Type of Fabric column at left (silk, rayon, etc.). Then locate

the fabric weight column (filmy, sheer, etc.) for your fabric at top of table. Read across from

Type of Fabric column to correct weight of fabric column. There, the correct thread and needle

choice for your fabric will be found.

Example: If you are sewing a medium weight wool, find wool in Type of Fabric column. Read

across to Medium (weight) column and you will see that a medium silk or mercerized thread

and a size 2020-14 needle are to be used.

You should follow the recommendations in this instruction book and on the needle package

for correct style and size of needle for different types and weights of fabric.

MEDIUM

THREADS

Medium Silk

Medium Mercerized

Medium Synthetic

Medium Mercerized

Medium Cotton

Medium Mercerized

Medium Silk

Medium Mercerized

Medium Synthetic

Medium Synthetic

NEEDLES

2020-11

2020-11

2020-14

2020-14

2045-14

2045-14

HEAVY

THREADS

Heavy Silk

Heavy Mercerized

Heavy Synthetic

Heavy Mercerized

Heavy Cotton

Heavy Mercerized

Heavy Mercerized

Heavy Synthetic 2045-16 Heavy Synthetic

Heavy Synthetic

NEEDLES THREADS

2020-14 Heavy Silk

Heavy Synthetic

2020-14

2020-16

2020-16 Heavy Mercerized

2045-16 Heavy Synthetic

Heavy Mercerized

Heavy Cotton

Heavy Mercerized

VERY HEAVY

NEEDLES

2020-14

2020-14

2020-18

2020-16

2020-16 or 18

2020-16 or 18

Medium Mercerized

Medium Synthetic

Medium Mercerized

Medium Synthetic

Medium Mercerized

Medium Synthetic

2032-14

2020-11

2020-11

Heavy Mercerized

Heavy Synthetic

Medium Mercerized

Medium Synthetic

Medium Mercerized

Medium Synthetic

2032-16

2020-14

2020-14

Heavy Mercerized

Heavy Synthetic

Heavy Mercerized

Heavy Synthetic

Heavy Mercerized

Heavy Synthetic

2032-18

2020-16 '

2020-16

needle-fabric combinations

Correct needle selection is closely related to

stitch quality and appearance. Damaged fabric

is almost always caused by a needle that Is

bent, burred or that Is an inappropriate style

for the fabric and thread you are using.

The three types of needles most commonly used

are the regular, ball point, and wedge. To

obtain good results, the correct size and type

of needle for the fabric and thread you are

using must be chosen. Refer to the Fabric,

Thread and Needle Table, page 8.

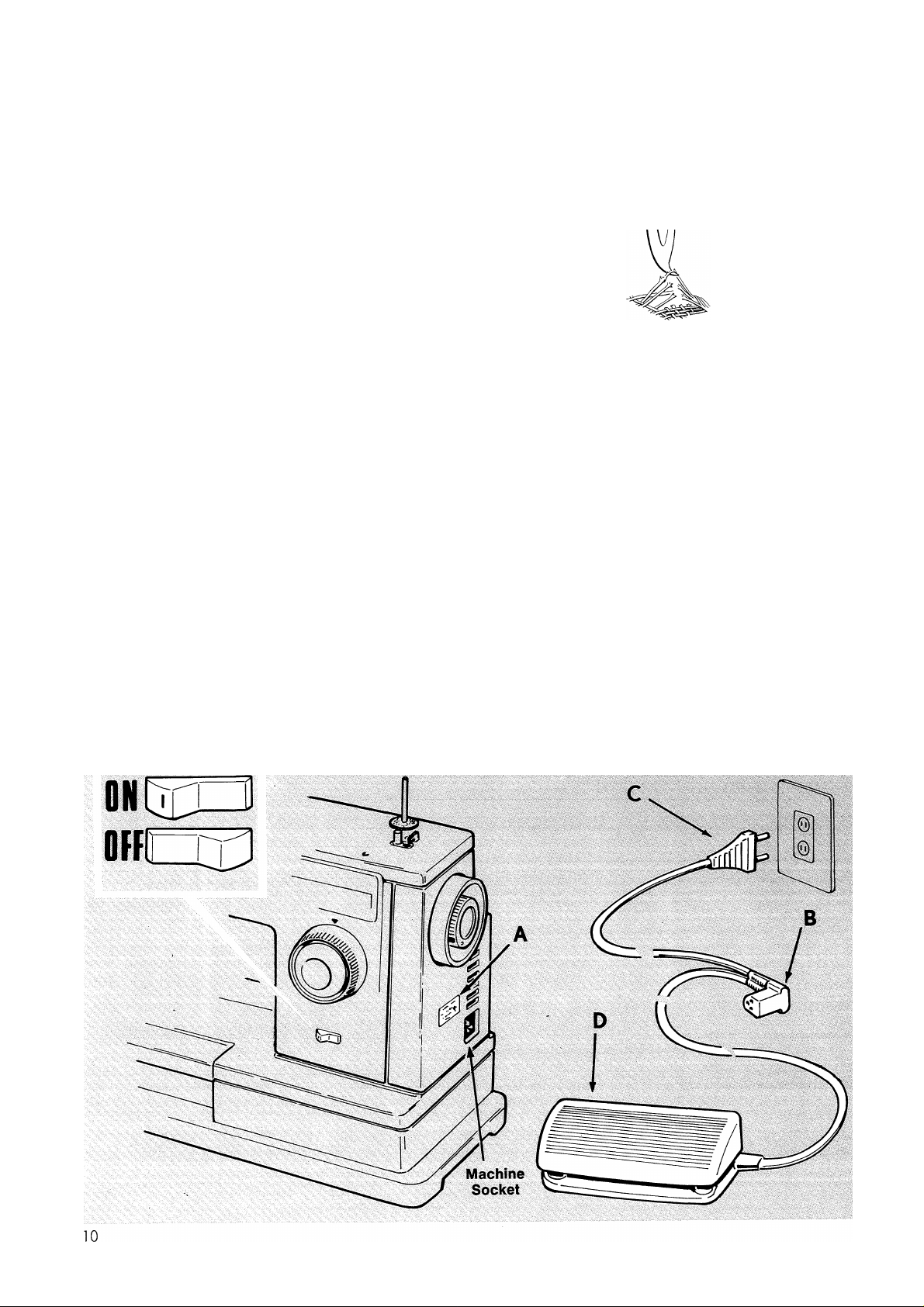

operating the machine

CONNECTING MACHINE

i

Result of Using a Bent Needle

• Before plugging in your machine, be sure

the electrical information on the side of the

machine A, below the hand wheel agrees

with the range marked on your electrical

meter.

• Connect plug B to machine and plug C to

your socket outlet.

• To turn the machine and light on or off,

press switch as shown.

• To run the machine and control speed,

press the speed controller D with your foot.

The harder you press, the faster the ma

chine will sew.

CAUTION: Disconnect the power line plug from

the socket outlet when changing needles, feet

or needle plates or when leaving the machine

unattended. This eliminates the possibility of

starting the machine by accidentaily pressing

the speed controller.

the bobbin thread

Your sewing machine uses two threads to form a stitch. The upper thread comes from the

spool and is threaded through the eye of the needle. The lower thread comes from the bob

bin. Wind the bobbin before threading the machine.

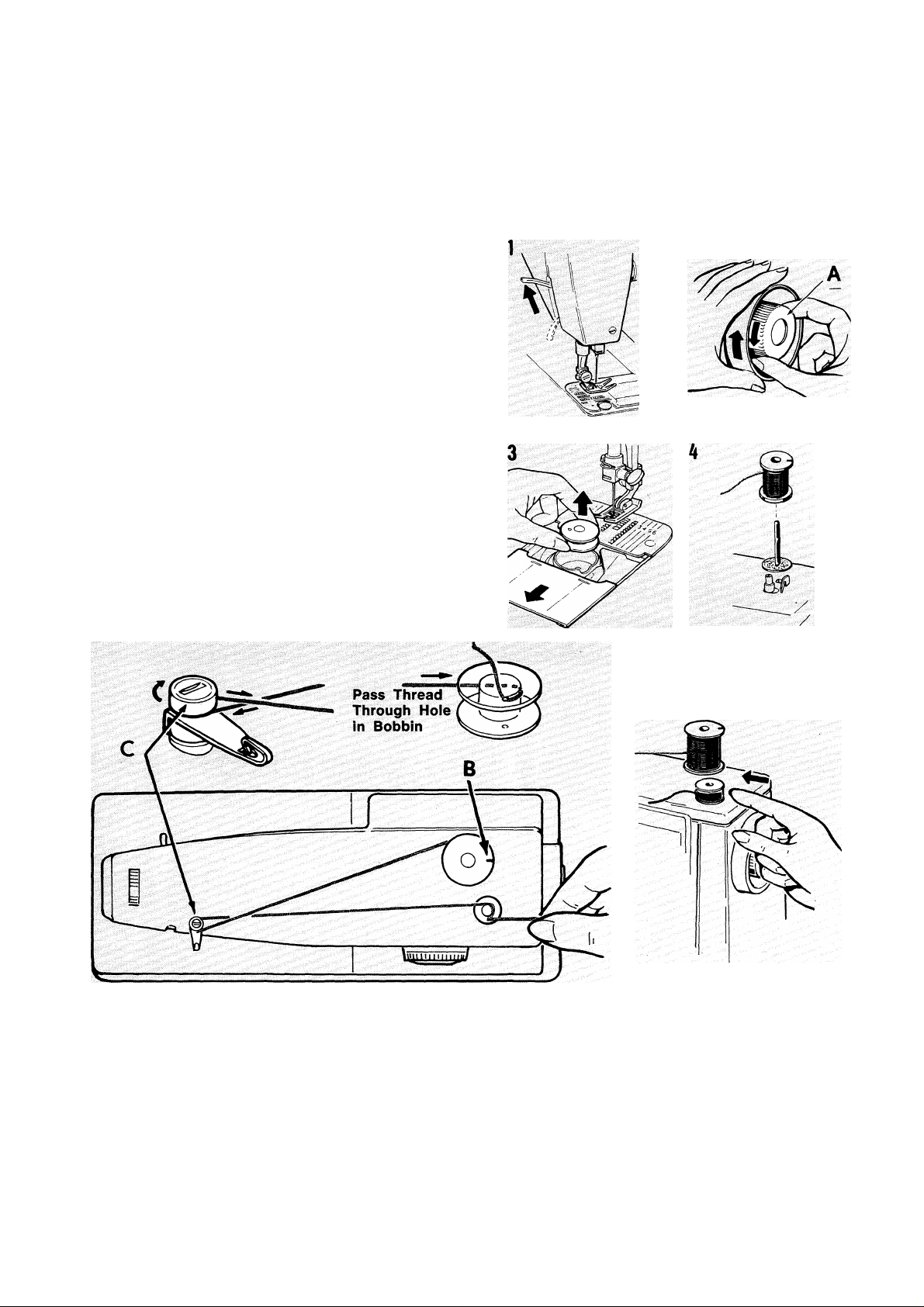

WINDING THE BOBBIN

Preparation Steps

1. Raise the presser foot and turn hand wheel

toward you until needle is in highest po

sition.

2. Loosen hand wheel knob A by turning it to

ward you with the right hand while holding

hand wheel with the left hand.

3. Open slide plate and lift out bobbin.

4. Place spool pin felt on pin.

Winding Steps

• Place thread spool on spool pin with thread

retaining slit B on top. (Break paper at the

end of spool if necessary). If you are using

a tube of thread affix spool pin extension

to spool pin to ensure even flow of thread.

• Lead thread around bobbin winder tension

disc C and through small hole in bobbin

from inside out.

• Place bobbin on spindle and push bobbin

to right to engage bobbin winder.

• Hold thread end as shown and start the ma

chine. Cut off thread end after a few coils

have been wound.

• When required amount of thread has been

wound (winding will stop when bobbin is

full), stop the machine and cut connecting

thread.

• Push bobbin to left and remove bobbin from

spindle.

• Hold hand wheel and tighten hand wheel

knob.

II

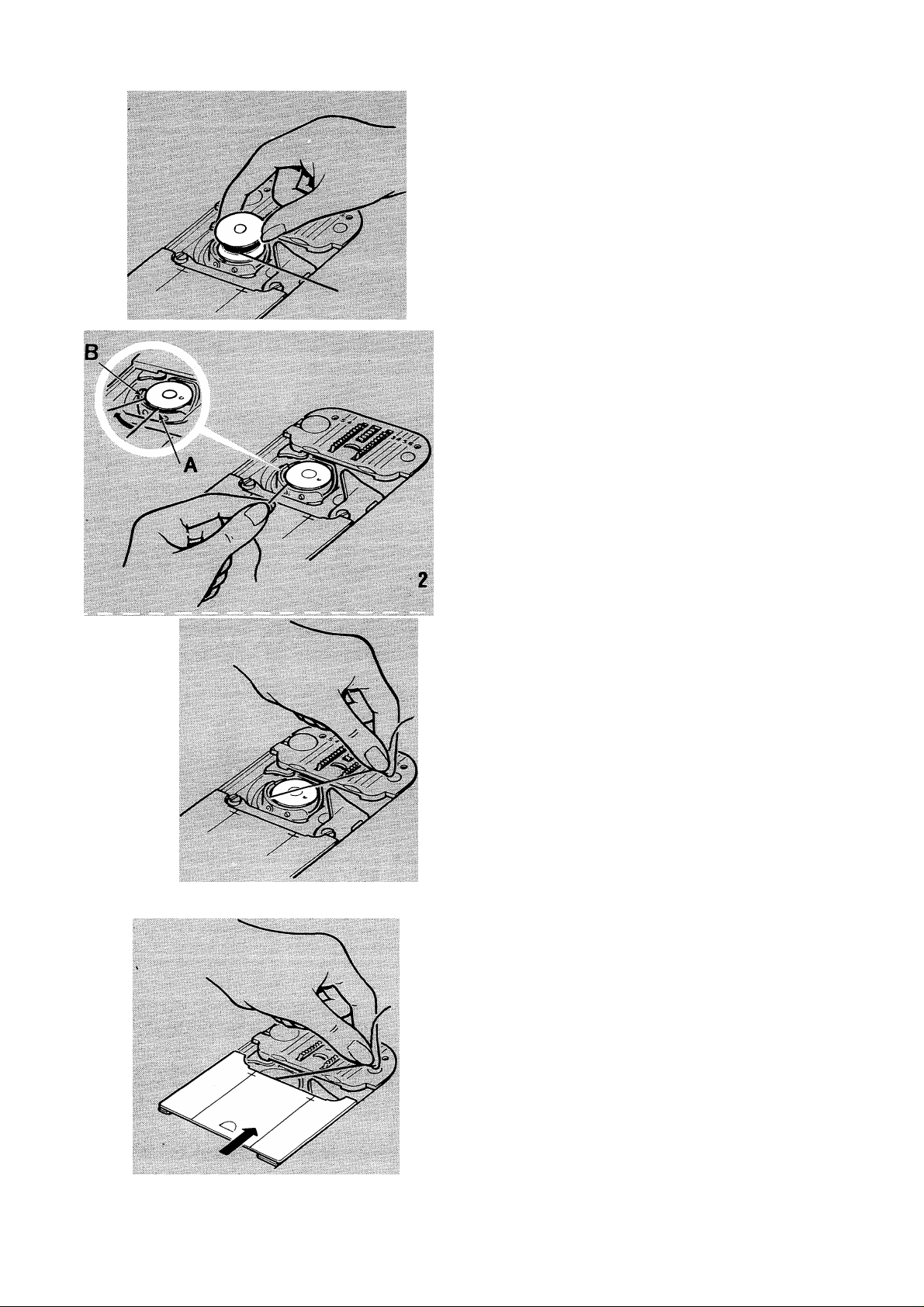

THREADING THE BOBBIN CASE

1. Hold bobbin so that thread unwinds in the

direction shown, and put bobbin into bobbin

case.

2. Pull thread into notch A, draw it back under

the tension spring and back into slot B.

3. Draw approximately 10 cm (4 inches) of

thread across the bobbin.

4. Close slide plate allowing thread to enter slot

between the needle plate and slide plate.

12

Loading...

Loading...