Singer 591V200A, 591V300A Instruction Manual

INSTRUCTION

MANUAL

A. Oil Reservoir

1.

Remove2setsofBolts

Support

2.

First

insert2Bolts@thru

andtighten withNuts © .

3.

Remove4setsofScrews®and

©

together

4.

Provisionally

Nut © and

Washer©and

and

Assembly

®.

with

hang

Washer

Nut © on

591V

Oil Reservoir, Hemmer Opening Device

Feed Roller Lift-Up Device Assembly

© ,

Shaft

® ,

Support®with2Bolts

0 on

200A/300A

Nuts

the

table

Washers

etc.

upper

underside.

sideofSupport

Machine

®,

Washers0and

bolt

holes,

© on

© ,

next

insert

Support

when

©

and

Washers0into

hanging

Spring

©

and

insert

Washers®from

Bolts

remove

Support

Washer

® ,

0 ,

Bracket

insert

Spring

©

5. Next,

the

Table

do

not

touch

6.

Next,

lower

Clamp

firmly

place

Next,

voir

Finally

place

right end of

and

left

let

Clamp@and2Brackets@assembledtoupper

Reservoir

adjust

Nuts

Reservoir

secure

Reservoir

press

(Q)

and

secure

(Q)

upper

© .

After

(Q)

with

(JJ)

Pad

@

pushtothe

Clamp®with

Reservoir

end

onthe2

.

edgeofReservoir

Cushions®assembledtoSupport

confirming,

hy 2

Brackets

Washer@and

sothat

attached

space

right.

in frontand backof

to the

This

Washer

(Q)

on the 2

@

fix

Support

@ soit

Screw

surfaceofClamp

prevents

(Q)

Cushions

parallel

©

will

© . In

longitudinal

and

Screw

with

by

not

this

table

@ .

assembled

to the

© . In

surfaceofSupport

upper

tightening

move

case,

@

surfaceofTable

Nuts

© .

forwardorbackward

care

shouldbetaken

cut-out are

against

even.

left

surfaceofReser

movementofReservoir

comers

this

case,

by 2

of

©

and

to

(Q).

B. Hemmer Opening Device Assembly

1.

Assembly

Bracket

Screws (6) .

In

has4oblong

no

2.

Next,

@

assembling,

axial

Bracket

@

playofShaft

remove

together

(8)

previously

attached)tobottom

pull

holes).

Ring

with

Bracket

Further,

@ on

Lever

(§) as far to the front as

(9)

within

front

@ .

removed

(with

surfaceofSupport

adjust

positionofRing

Bracket

(§)

endofShaft

.

Shaft

(|) ,

(9),Hub

(f)

possible

@ on

and

pull

@ ,

Lever@and

with4Washers

and

Shaft

out

secure

Hub

(9)

(Bracket

sothat

®

from

(7)

there

Shaft

and

(8)

is

3. Next, firmly

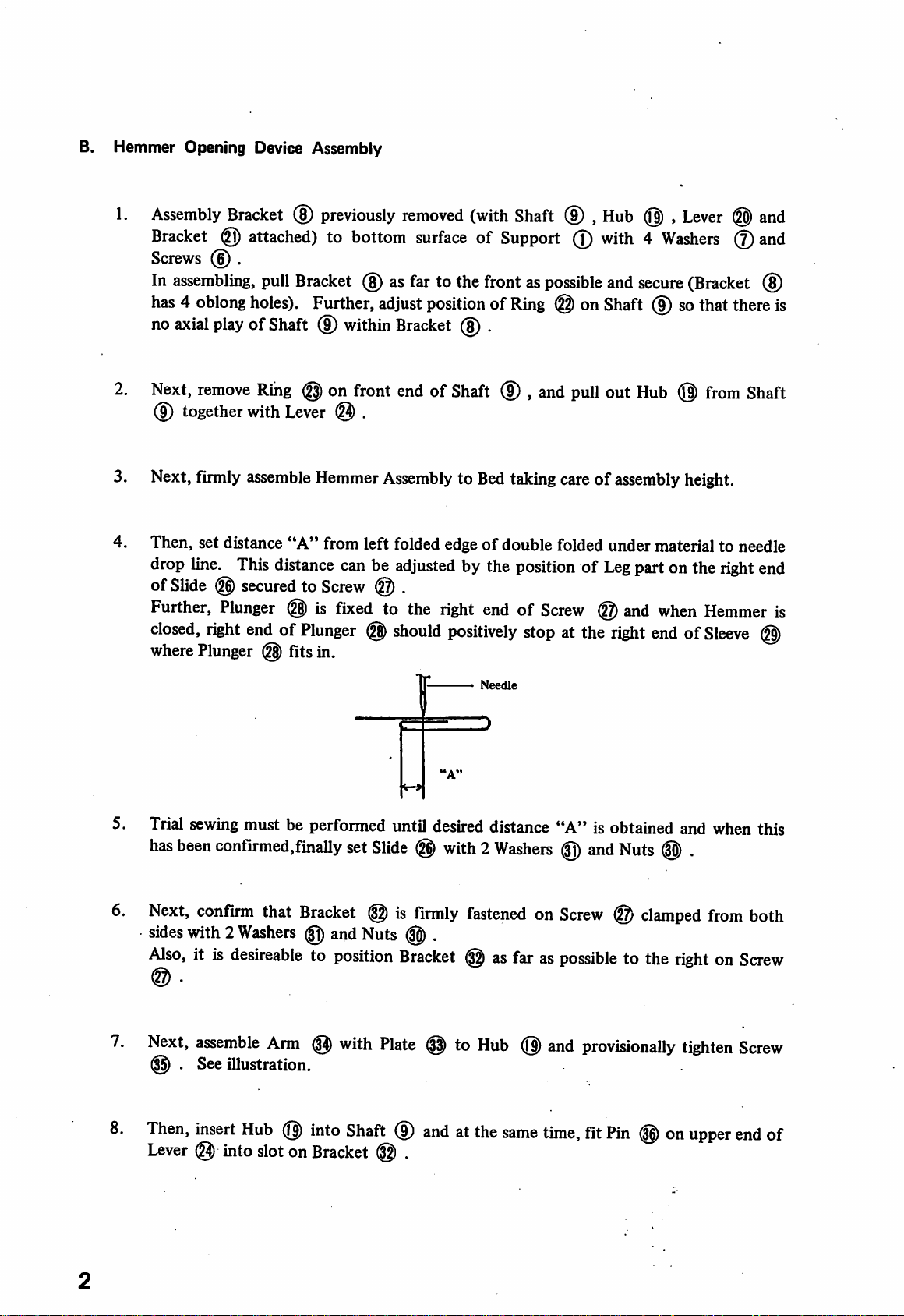

4. Then, set distance

drop

line.

of

Slide

Further,

closed,

where

5. Trial

hasbeenconfirmed,finally set Slide @ with 2

Next,

sides

Also,

Plunger @ fits in.

sewing

confirm

with2

it is

assemble

This

@

securedtoScrew

Plunger

right

endofPlunger@should

must be performed until

that

Washers

desireabletoposition

Hemmer

"A"

distance

®

is

Bracket

(Q)

from left foldededgeof double folded under material to needle

canbe

fixedtothe

and

AssemblytoBed

adjusted

@ .

is

Nuts

Bracket

J-

desired

firmly

® .

takingcareofassembly

by the position of

right

endofScrew

positively

fastenedonScrew

@asfaraspossible

Needle

distance

Washers

stopatthe

"A"

^ and Nuts ® .

height.

Leg

parton the

@

and

when

right

endofSleeve

is obtained and when this

clamped

to the

right

end

Hemmer

@

from

both

rightonScrew

is

7.

Next,

8.

Then,

Lever ® into slot on Bracket .

assemble

.

See

insert

Arm

illustration.

Hub

®

into

with

Shaft

Plate

(9)

® to

Hub

andatthe

®

same

and

provisionally

time,

fit

Pin

(g)onupper

tighten

Screw

end

of

Loading...

Loading...