Singer 591UTT Service Manual

SINGER

591

UTT

Service

Manual

CONTENTS

Page

No.

Description

UnderbedThread Trimmer

Principal

Descriptionof TrimmingOperation

Timing and Setting

Parts

DriveSystem of Thread Trimmer 2

Pullingand TrimmingUnit 2

Tension Releaseand MovableSlack Thread Regulator 3

Adjustment of Needle Stop Positions

Timing—ActuationofTrimmer Solenoid 8

Timing —CompletionofActuationofTrinuner Solenoid

SettingofTrimmer Solenoid 9

SettingofStationary Knife 9

SettingofThread Puller

AdjustmentofPressureofThread Puller Against Stationary Knife

Timing and Setting of Thread Puller Action Cam

TimingofTension Release ActionCam 12

SettingofThread PuUerAction Cam Adjusting Plate 13

AdjustmentofGap Between Tension Discs

TimingofTension Release 14

Adjusting the LengthofNeedle Thread End

AdjustmentofThread Wiper 15

1

2-15

2-3

3-6

6-15

6-8

8-9

9-10

10-11

11-12

13-14

14-15

Back

Tack

Device

Principal Parts

Description of BackTacking Operation 18

Setting and Adjustment

of

BackTack Device

SettingofBack Tack Solenoid 18

SettingofFeed Rock Shaft DrivingFrame 19

Setting

of

Feed Rock Shaft DrivingFrame Action Shaft and Collar 19

SettingofFeed Rock Shaft DrivingFrame Action Lever

Feed Rock Shaft Driving Frame Spring Tension 20

Setting of Feed Rock Shaft Driving Frame Stopper Spring 20

SettingofPush

Button

Switch 20

AdjustmentofPush Button Spring Tension 21

Cords

and

Connections

* A

Trademark

Copyright©

All

Rights

of

THE

1981 THE SINGER COMPANY

Reserved

SINGER

Throughout

COMPANY

the

World

16-21

16-17

18-21

19-20

21

DESCRIPTION

An

electro-mechanical

variety machines.

The

machineisdriven

built-in

The needle and bobbin threads are trimmed below the throat plate after the sewing operation.

solenoidsofthe

underbed

by a

needle

machine.

thread

trimming

unit,

positioner motor, and its

which

is an

integral

sensor

and controlbox

part of the

machine,isincorporated

relay

the electronic

in the "B"

commands

to the

A thread wiper

In addition to the under bed thread trimming unit, a back tackingsystem is incorporatedin the "G"

automatic back tack switch and control box relay the electronic commandsto the built-insolenoid for automatic back tacking

at start and at end of stitching. The push button switch

of

the sewing operation.

This manual should be used in connection with the Service Manual Form U3208 for the regular 591 machine. It informs

especially regarding the operation and maintenanceofthe underbed thread trimmer and back tacking

systems.

"Wipes"

the

needle

thread to properpositionfor startingthe next

provided

adjacentto the

sewing

needle

operation.

barpermitsback

variety

tacking

device

machines. The

in themidst

and their

drive

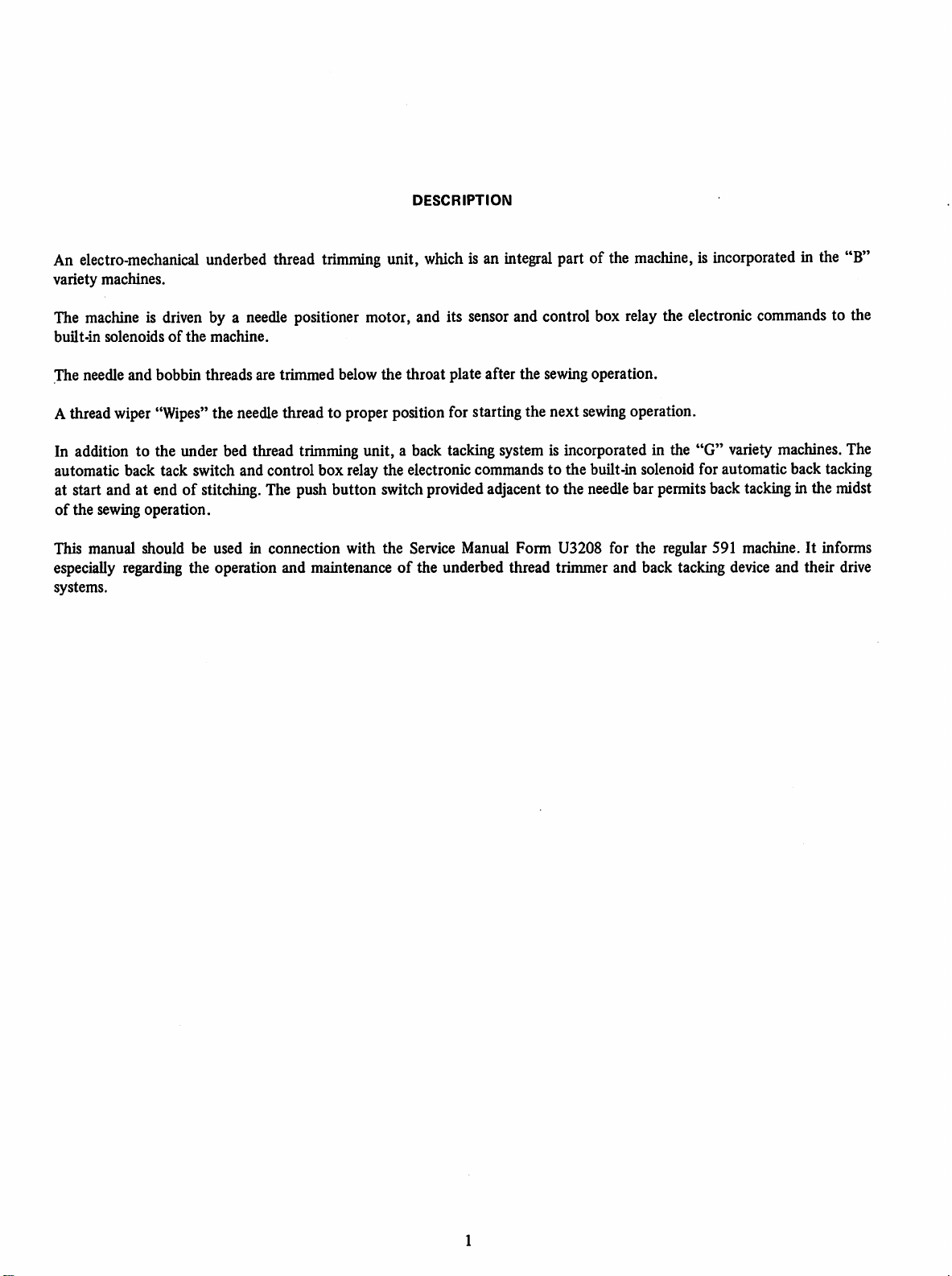

UNDERBED

THREAD

TRIMMER

PRINCIPAL

Drive

SystemofThread

THREAD

THREAD

STATIONARY

KNIFE

PARTS

THREAD

THREAD

PULLER

PULLER

PULLER

ACTION

PULLER

THREAD

CAM

Trimmer

ACTION

BRACKET

FOLLOWER

LEVER

LEVER

ROTATING

HOOK

PULLER

LINK

/WVW/

SHAFT

ACTION

THREAD

PULLER

TENSION

ACTION

THREAD

PULLER

ACTION

CAM

RELEASE

CAM

ACTION

ADJUSTING

TENSION

TENSION

CAM

PLATE

RELEASE

ACTION

RELEASING

PLATE

WIRE

Fig. 1

Pulling and

Trimming

Fig. 2

THREAD

Unit

PULLER

STATIONARY

ACTION

KNIFE

PLATE

THREAD

PULLER

TRIMMER

THREAD

SOLENOID

PULLER

ADJUSTING

BLOCK

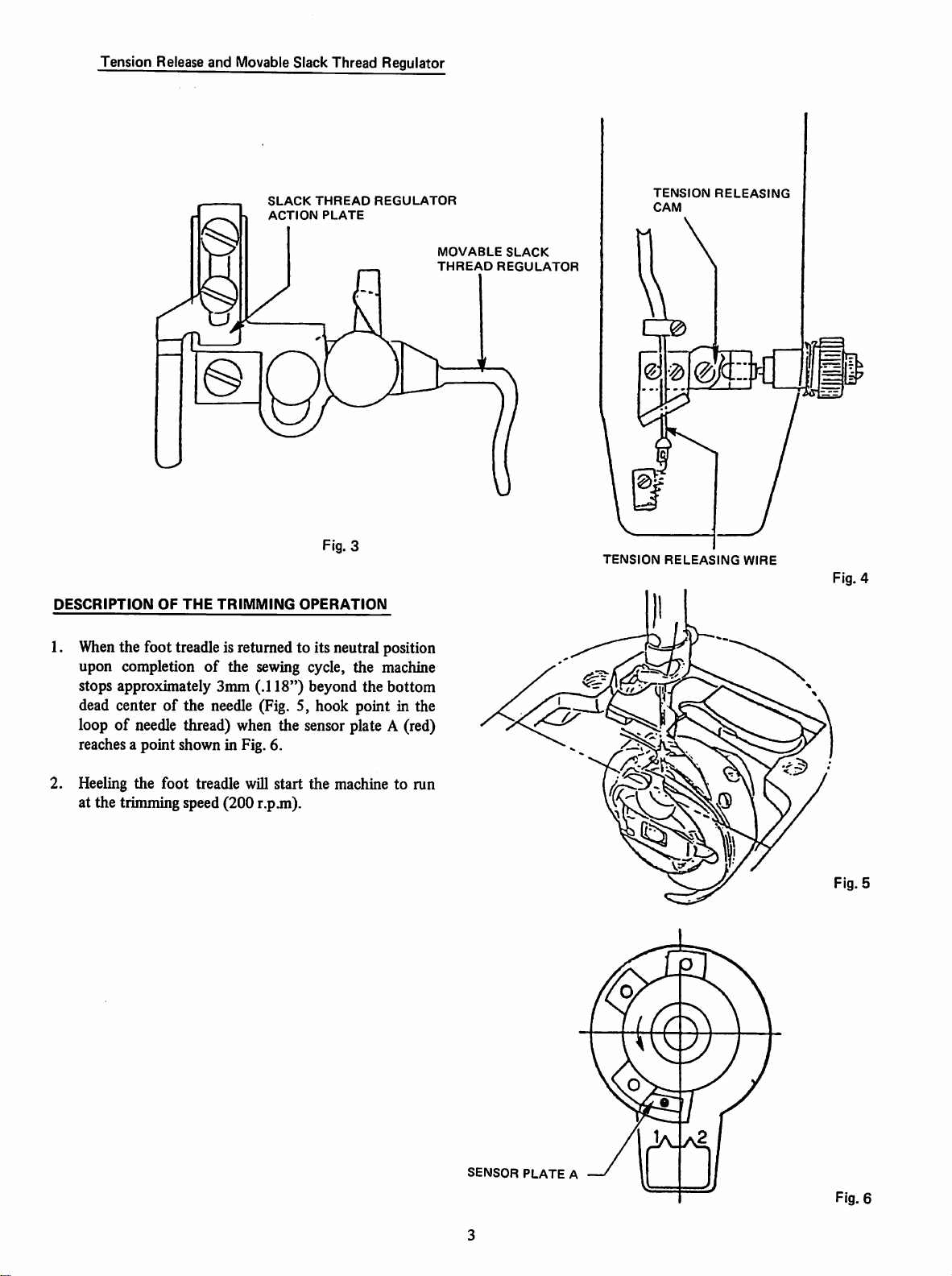

Tension Release and Movable Slack Thread Regulator

SLACK

THREAD

ACTION

PLATE

Fig. 3

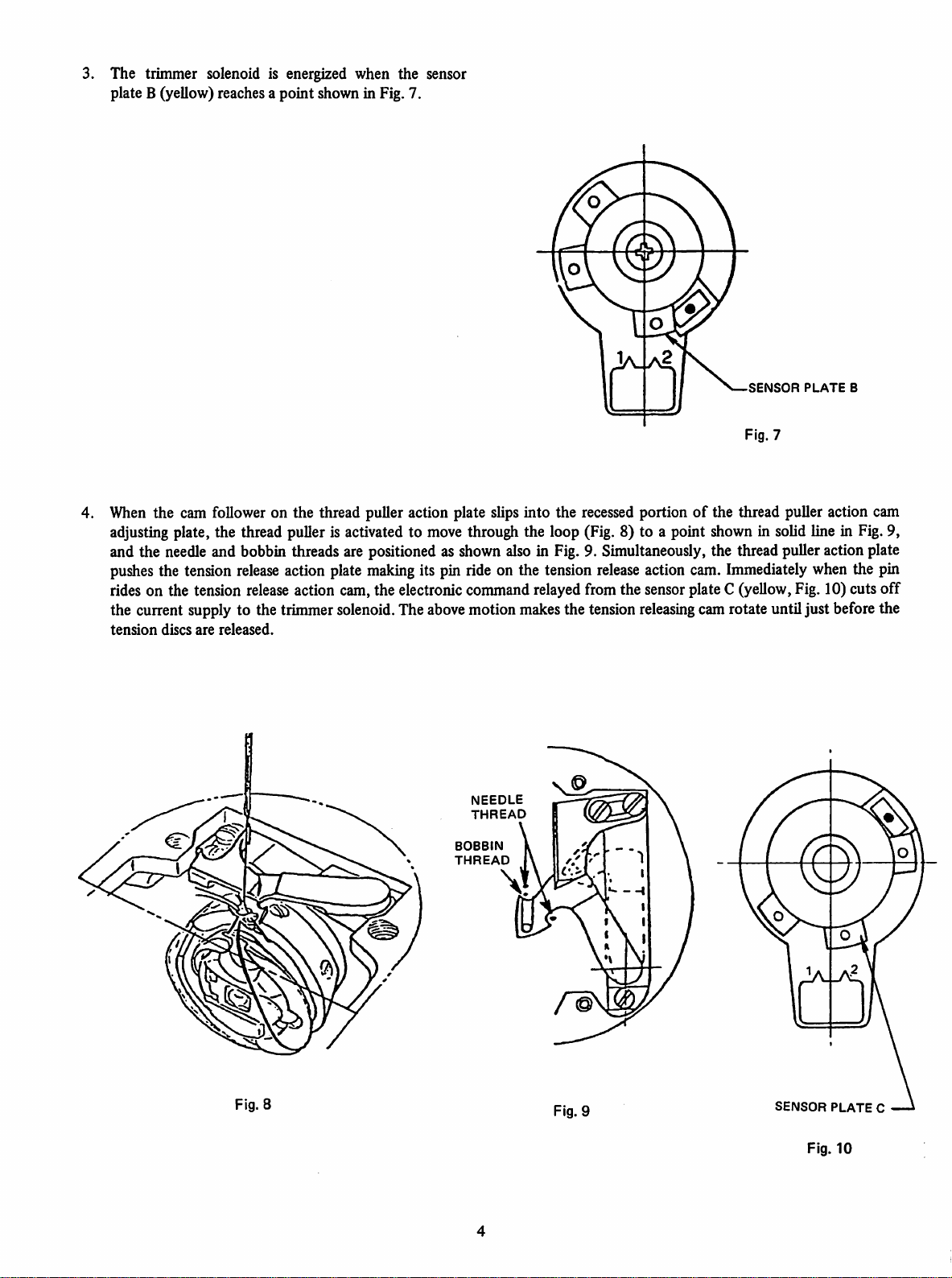

DESCRIPTION

1.

When

upon completion

OF

THE

TRIMMING

OPERATION

the foot treadle is returned to its neutral position

of

the sewing cycle, the machine

stops approximately Smm (.118") beyond the bottom

dead center of the needle (Fig. 5, hook point in the

loop of needle thread) when the sensor plate A (red)

reaches a point shown in Fig. 6.

REGULATOR

MOVABLE

THREAD

SLACK

REGULATOR

TENSION

TENSION

CAM

RELEASING

RELEASING

WIRE

Fig. 4

2. Heeling the foot treadle will start the machine to run

at the trimming speed (200 r.p.m).

SENSOR

PLATE

Fig. 5

A

Fig. 6

The trimmer solenoid is energized when the sensor

plate B (yellow) reaches a point shown in Fig, 7.

SENSOR

Fig. 7

PLATE

B

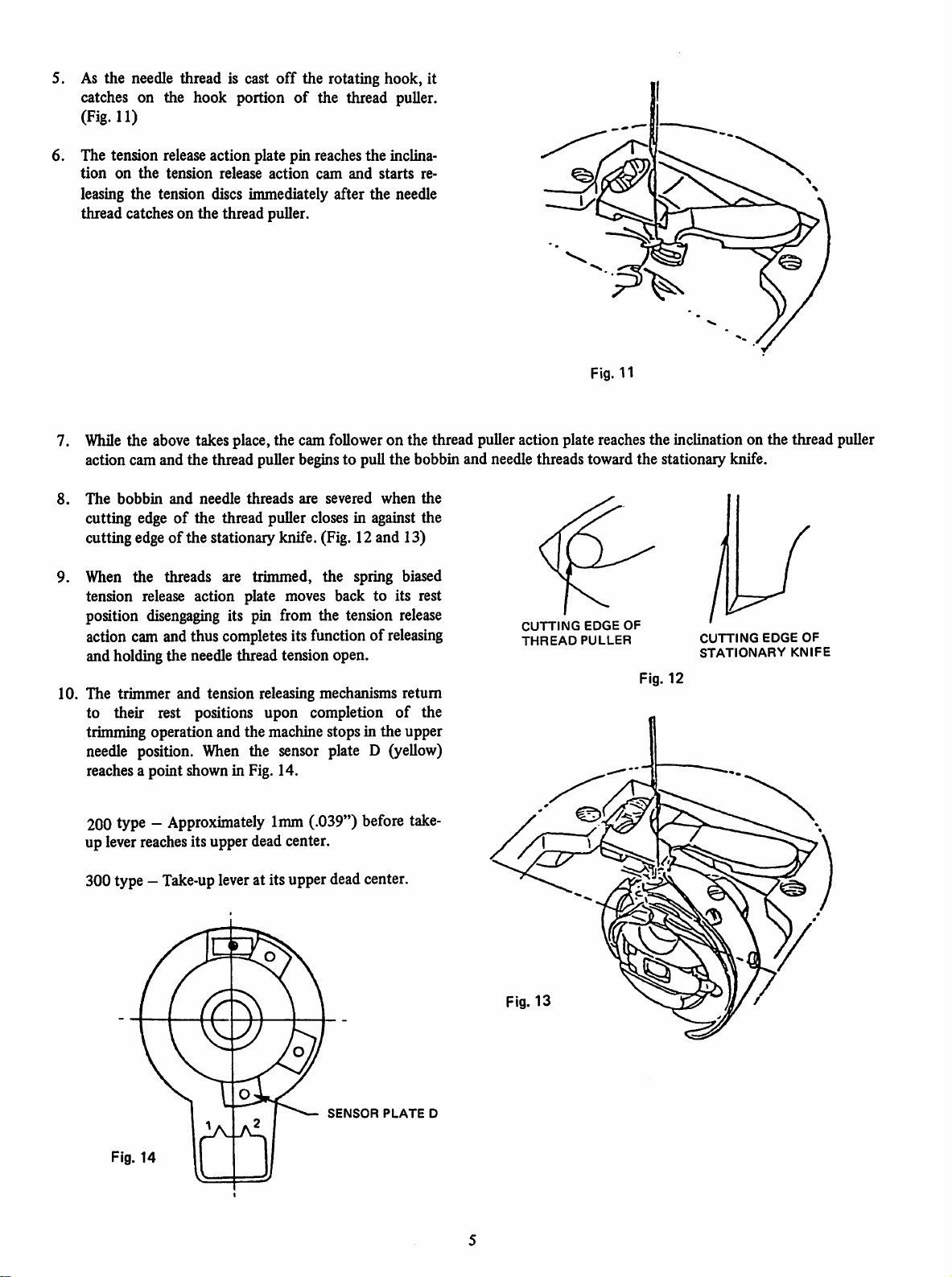

When the cam follower on the thread puller action plate slips into the recessed portionofthe thread puller action cam

adjustingplate, the thread puller is activated to move through the loop (Fig. 8) to a point shownin solid line in Fig.9,

and the needleand bobbin threads are positioned as shown also in Fig. 9. Simultaneously, the thread pulleraction plate

pushes

rides on the tension

the current supply to the trimmersolenoid. The

tension

the tension

discs

are

released.

release

release

action plate

making

its pin ride on the tension

release

action cam.Immediately when the pin

action cam,the electroniccommandrelayedfrom the sensorplate C (yellow,Fig. 10) cuts

above

motion

THREAD

BOBBIN

THREAD

NEEDLE

makes

the tension

releasing

camrotate untiljust beforethe

off

©

Fig. 8

Fig. 9

n

SENSOR

Fig.

PLATE

10

C

5. As the needle thread is cast

catches on the hook portion

off

the rotating hook, it

of

the thread puller.

(Fig. 11)

6. The tension release action plate pin reaches the inclina

tion

on

the

tension

release

action

cam

and

starts

re

leasing the tension discs immediately after the needle

the

thread catches on

thread puller.

Fig. 11

7.

While

the above takesplace,the cam followeron the thread puller action plate reachesthe inclinationon the thread puller

action camand the thread puller beginsto pull the bobbin and needle threads toward the stationary knife.

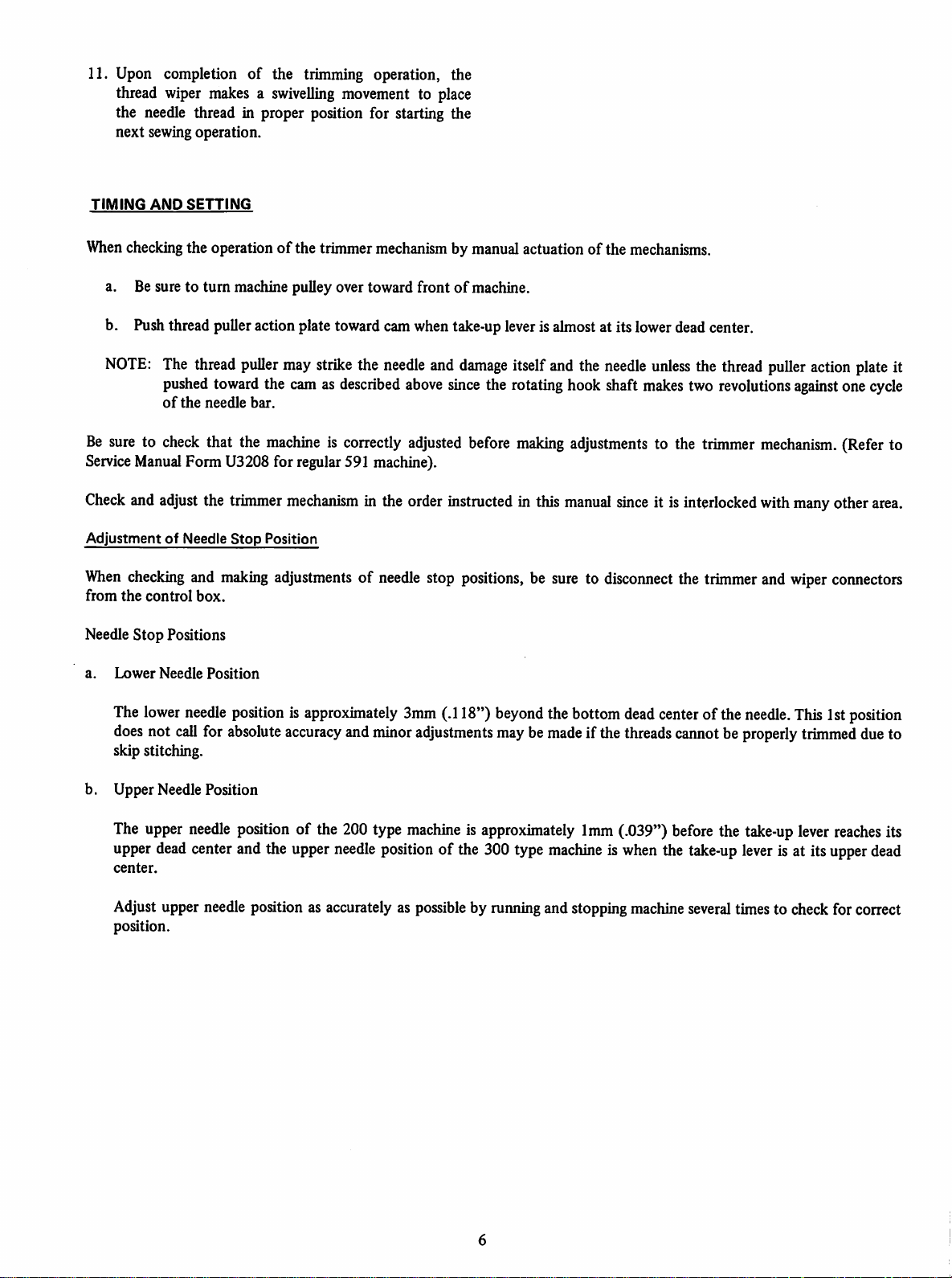

8.

The

bobbin

and

needle

threads

are

severed

when

the

cutting edgeofthe thread puller closes in against the

cutting edgeofthe stationary knife. (Fig. 12 and 13)

9. When the threads are trimmed, the spring biased

tension release action plate moves back to its rest

position

action cam and thus completesits function of

disengaging

its pin from the tension release

releasing

and holding the needle thread tension open.

10. The trimmer and tension releasing mechanisms return

to their rest positions upon completion

of

the

trimming operation and the machine stops in the upper

needle position. When the sensor plate D (yellow)

reaches a point shown in Fig. 14.

200 type -

Approximately

1mm

(.039") before

take-

up leverreachesits upper dead center.

300 type —

Take-up

leverat its upperdeadcenter.

CUTTING

THREAD

EDGE

PULLER

OF

Fig. 12

CUTTING

STATIONARY

EDGE

OF

KNIFE

SENSOR

Fig. 14

PLATE

D

11. Upon completion of the trimming operation, the

thread wiper makes a

the needle thread in proper position for starting the

next

sewing operation.

swivelling

movement to place

TIMING

When

Be

ServiceManualForm U3208 for regular 591 machine).

Check

AdjustmentofNeedle

When

from

Needle Stop Positions

AND

SETTING

checking the operationofthe trimmer mechanism by manualactuation of the mechanisms.

a. Be sure to

b. Push thread puller action plate toward camwhen take-upleverisalmost at its lower dead center.

NOTE:

suretocheck

and

checking

the

control

The

pushed

of

the

adjust

tum

machine pulley over toward frontofmachine.

thread

puller

may

strike

the

needle

towardthe cam as

needle

bar.

that the

the

and

box.

machineiscorrectly

trimmer

Stop

Position

making

adjustmentsofneedle

mechanism

described

in the

above

adjusted

order

stop

and

damage

since

instructedinthis

itself

and

the

the rotating hook shaft

before

making

adjustments

manual

positions,besuretodisconnect

needle

since

unless

makes

to the

it is

interlocked

the

the

two revolutions

thread

trimmer

trimmer

puller

action

against

mechanism.

with

many

and

wiper

plate

onecycle

(Refer

to

other

area.

connectors

it

a.

Lower

Needle

Position

The

lower

needle

positionisapproximately

does

not

call

for

absolute

skip stitching.

b. Upper NeedlePosition

The

upper

needle

position

upper

dead

centerandthe upper

center.

Adjust

upper

needle

position.

accuracy

of the

positionas accurately as

and

200

needle

minor

type

position

3mm

(.118")

adjustments

beyond

the

maybemade

machineisapproximately

of the 300 type

possiblebyrunning

machineiswhen

andstopping

bottom

ifthe

1mm

dead

threads

(.039")

machine

center

ofthe

needle.

cannotbeproperly

before

the

take-up

the

take-up

several

lever

times

This

1st

position

trimmed

lever

is at itsupper

to checkfor correct

dueto

reaches

its

dead

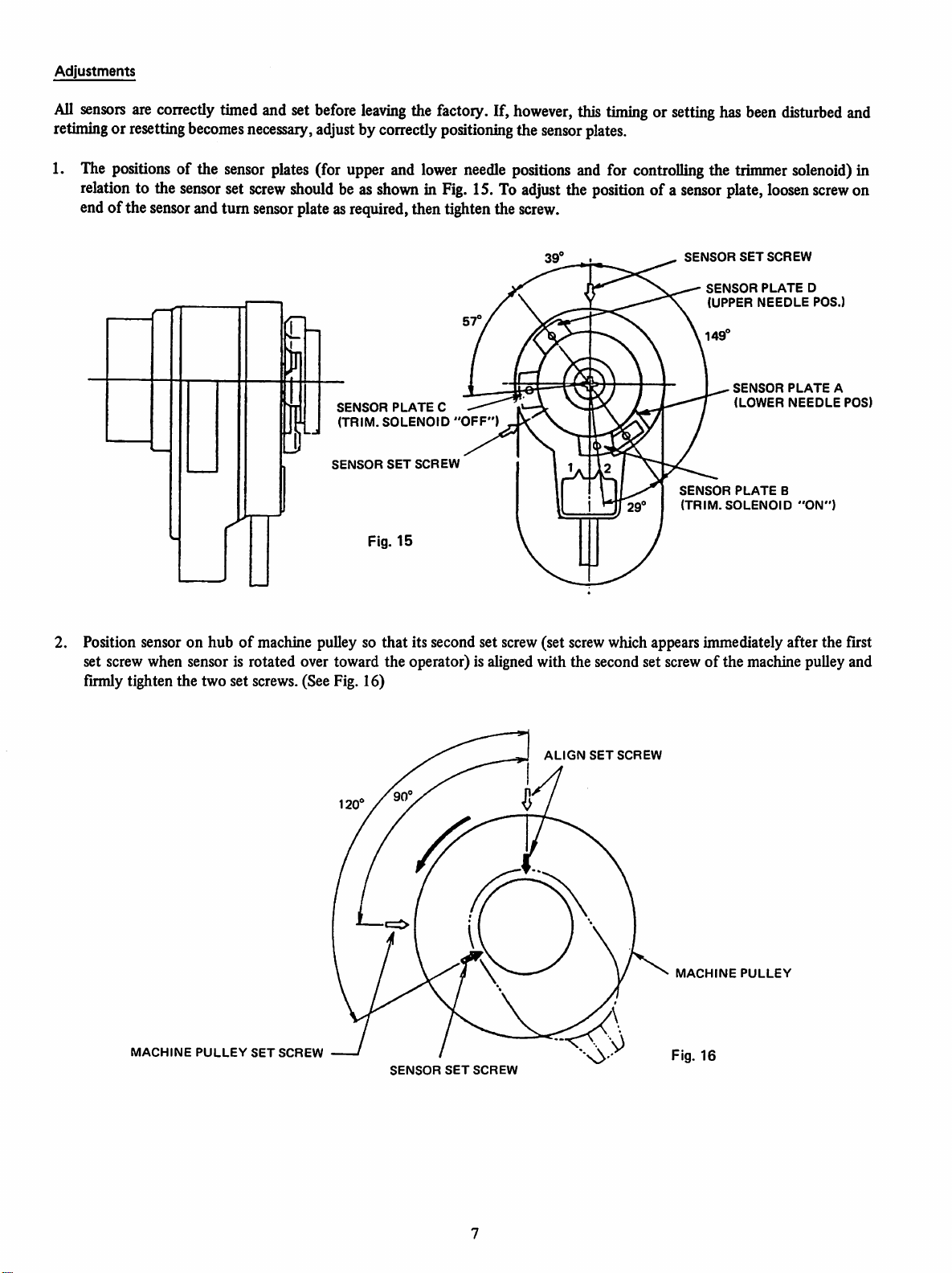

Adjustments

AH

sensors

are

correctly

retimingorresetting

timed

becomes

andset

necessary,

before

adjust

leaving

the

bycorrectly

factory.

positioning

If,

however,

the

sensor

this

timingorsetting

plates.

has

been

disturbed

and

1. The positions of the

relation

to the

sensor

endof the sensorand turn

sensor

set

screw

plates

(for upper and

should

sensor

be as

showninFig.

plateasrequired,then tighten the

SENSOR

(TRIM.

SENSOR

PLATE

SOLENOID

SET

Fig.

15

lower

C —

SCREW

needle

15. To

"OFF")

positions and for controlling the

adjust

the

position

of a

sensor

screw.

39'

SENSOR

SENSOR

(UPPER

149'

SENSOR

(TRIM.SOLENOID

trimmer

plate,

SET

SENSOR

(LOWER

PLATE

solenoid)

loosen

SCREW

PLATE

NEEDLE

PLATE

NEEDLE

B

screw

D

POS.)

"ON")

in

on

A

POS)

Position sensor on hubofmachine pulley so that its second set screw (set screw which appears immediately after the first

set screw when sensor is rotated over toward the operator) is alignedwith the second set screwofthe machine pulley and

firmly tighten the two set screws. (See Fig. 16)

ALIGN

SET

SCREW

MACHINE

PULLEY

SET

SCREW

SENSOR

SET

MACHINE

Fig.

SCREW

PULLEY

16

Loading...

Loading...