Singer 591D200, 591D300, 591C200, 591C300 Operator’s Guide

SINGER

591D200A

591D240A

591D300A

591D303A

591D305A

591D308A

591C200A

591C240A

591C300A

591C308A

CONTENTS

Page

Introducingtlie NewSINGER*

Sewing

Machine

Model

591

Oiling the Machine 2

Oiling the Puller Feed 3

Needles 3

Thread

Inserting the Needle 5

Threading the Machine . 5

Removing the Bobbin Case and Bobbin 6

Winding

Threading

Replacing the Bobbin Case 8

Preparing to Sew 9

Sewing 9

the

Bobbin 7

the

Bobbin Case 8

Setting Thread Tension 10

Adjusting the Take-up Spring 11

Adjustingthe Thread Guard

Adjusting

Presser

Foot

Pressure

Adjusting Stitch Length 12

Adjusting

Adjusting

Adjusting the EdgeTrimmer

Hints for Perfect Operation I4

the

AmountofFeed

the

Pressure

of the Feed

of the Feed

Knife

Roller

Roller

Specifications 15

\

4

11

12

13

13

I4

Copyright©

All

Rights

1981

Reserved

THE

Throughout

SINGER

COMPANY

the

World

SINGER

introducing

The

most

machine will

the

New SINGER*Sewing Machine Model

dependable, lightest running machine

produce

top

quality straight-line single-needle lock

591!

of

its kind. This

stitch

ing in fabrics as fine as ladies' lingerie or as heavy as men's overcoating.

With an oil reservoir, a pump and a minimum of wicking, all parts

requiring

easily

Quiet and smooth in operation, the Model 591 was designed for

comfort,

to

you.

oil are

kept

constantly

througha"window"onarm

making sewing more pleasant,

lubricated.

top

cover.

quicker

Oil flow can be

and

more

checked

your

profitable

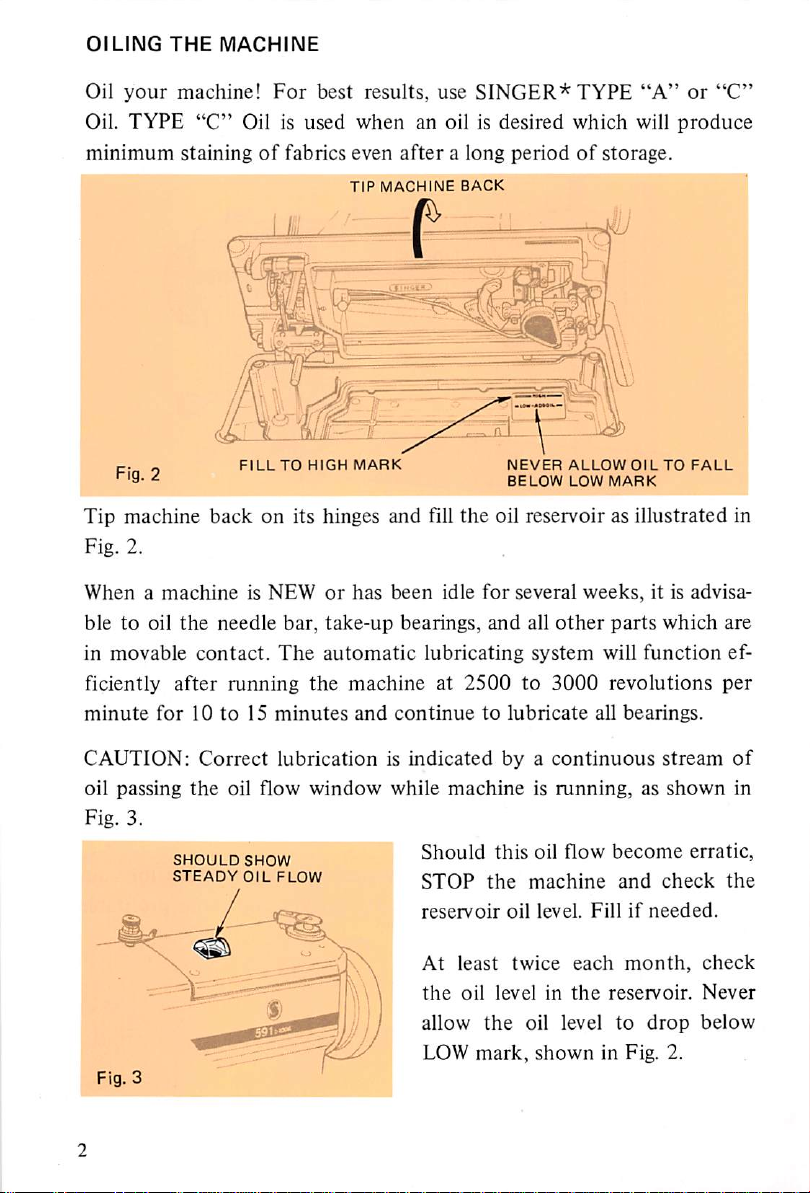

OILING

Oil

your

Oil.

TYPE

minimum

THE

MACHINE

machine!

"C"

For

Oil is

best

used

stainingoffabrics even

TIP

results,

when

MACHINE

use

SINGER*TYPE

an oil is desired

after

a long

periodofstorage.

BACK

which

"A"

will

or

"C"

produce

Fig. 2

Tip

Fig.

machine

2.

back

Whenamachine

bletooil

in

movable

ficiently

minute

CAUTION:

oil

passing

the

contact.

after

for10to15minutes

Correct

the

Fig. 3.

SHOULD

STEADY

Fig. 3

FILLTOHIGH

MARK

on its hinges

is NEWorhas

needle

The

running

bar,

the

take-up

automatic

machine

and

lubricationisindicated

oil

flow

window

SHOW

OIL

FLOW

and

fill

been

idle

bearings,

lubricating

at

continue

while

Should

STOP

reservoir

At

the

allow

LOW

NEVER

BELOW

the

oil reservoir as

for

and

2500

to

lubricate

byacontinuous

several

all

other

system

to

3000

ALLOWOILTO

LOW

MARK

illustrated

weeks,

parts

will

revolutions

all

bearings.

FALL

it is

advisa

which

function

stream

machineisrunning,asshown

this

oil

flow

the

least

oil

levelinthe

the

mark,

machine

oil

level.

twice

oil level

shown

become

and

Fillifneeded.

each

month,

reservoir.

to

in Fig. 2.

check

drop

erratic,

check

Never

below

in

are

ef

per

of

in

the

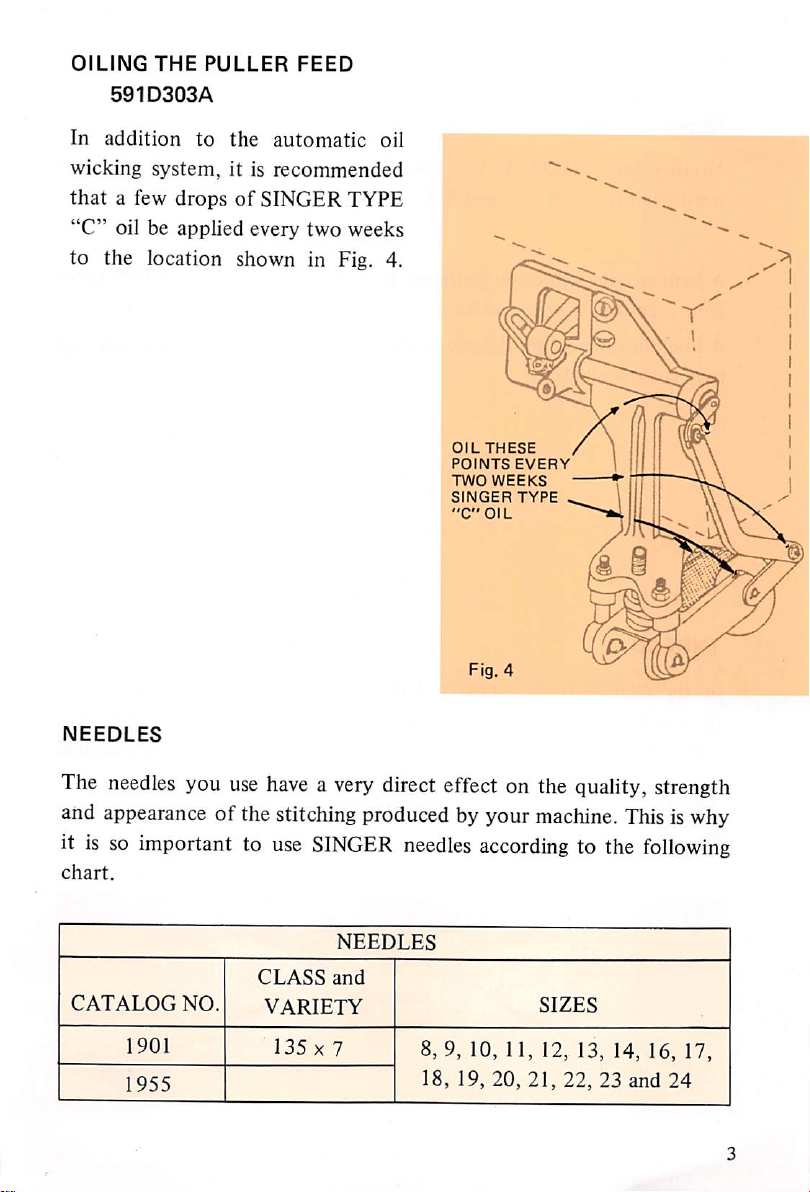

OILING

In

wicking

that

"C"

to

THE

PULLER

591D303A

addition

a few

to

the

automatic

system,itis

recommended

dropsofSINGER

oil be applied every two weeks

the

location shown in Fig. 4.

FEED

oil

TYPE

OIL

POINTS

TWO

SINGER

"COIL

THESE

WEEKS

EVERY

TYPE

NEEDLES

The

and

appearance

needles

you

use

of the stitching produced by your

it is so important to

chart.

CATALOG

NO.

1901

1955

haveavery

use

SINGER

NEEDLES

CLASS

VARIETY

135x

and

7

Fig. 4

direct effect on the quality, strength

machine.

needles

according

SIZES

8,9,

10, 11, 12, 13, 14, 16, 17,

18, 19, 20, 21, 22, 23 and

to the

This

iswhy

following

24

Note:

Needles for

needle

591D305A.

bar

for the 1/16" and

Use catalog

3/32"

trim margins.

number

1515 and corresponding

A bent needle will cause your machine to skip stitches and drift away

fromadesired

A

hookorburronthe

may

cut

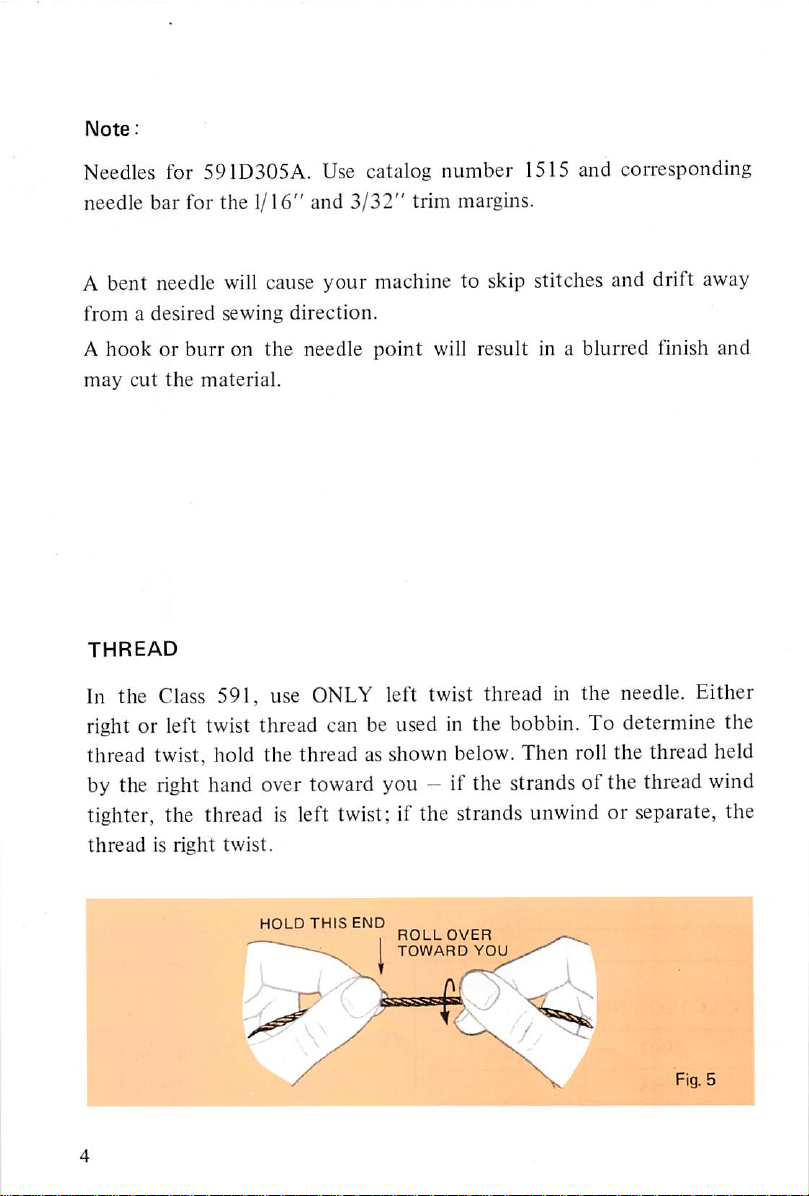

THREAD

In the Class 591, use

the

sewing

material.

direction.

needle

ONLY

point

will result in a blurred finish and

left twist thread in the needle. Either

right or left twist thread can be used in the bobbin. To determine the

thread twist, hold the thread as shown below. Then roll the thread held

by the right hand over toward you —if the strands of the thread wind

tighter, the thread is left twist; if the strands unwind or separate, the

threadisright

twist.

HOLD

THIS

END

ROLLOVER

Fig. 5

i

Loading...

Loading...