Singer 457G1 Service Manual

Form

(1062)

30252

G

•.,u-r,^.V;t

i-.-s

SERVICE

for

SINGER

MACHINE

Class

MANUAL

457G1

Machine

SINGER

NAHMASCHINENFABRIK

KARLSRUHE/BADEN

Class

457G1

KARLSRUHE

(GERMANY)

AKTIENGESELLSCHAFT

CONTENTS

Page

Description 3

Speed 3

Setting Up 3

Lubrication

Adjustment of the Oil

Needles

Thread

To remove the Bobbin Case

To

wind

the

Bobbin

To

thread

Toreplace the

To

set

the

the

Bobbin

Needle

Bobbin

Flow

for the Hook Lubrication . . . 4

Cap

Cose

Case 7

Upper Threading 8

Toprepare for Sewing 8

Toregulate the Tensions 8

Toregulate the

Toset the Width of the Zig-Zog

To clean the Hook

Timing

and other Adjustments 10

Length

and

of the

Stitch

Stitch

the Thread Ways 9

Toset the Thread Take-up Spring 10

4

5

5

6

6

7

7

9

9

To

set

the

Presser

Bar

Toregulate the Pressureof the Presser Bar on the Material

To

set

the

Tension

To set the Needle Bar at the correct Height . . . .

To

time

the

Hook

Reieaser

.12

To time the Feed Driving Eccentric 14

To set the Feed Dog 15

To set the Needle Vibrating Mechanism 15

To

set

the

Needle

Bar

Yoke

10

11

11

13

16

DESCRIPTION

The 457 G 1 machine is a high speed, single needle,

lock

stitch,

zig-zag sewing machine for stitching light

and medium weignt fabrics.

^

The

machine

1.

Needle

Presser

Maximum

Zig-Zag Stitch

specifications

Bar

Stroke

Bar

Lift

Width

are as

of

1-5/16

9/32

5/32

follows:

inch =

inch

inch = 4.00 mm

-

33.40

=

7.15

Space at right of Needle 8-3/16 inch = 208.00 mm

Maximum

LengthofStitch

6 stitches per

inch

= 4.20 mm per stitch

Bed 15-11/16 inches long, 7 inches wide

= 398.50 mm long, 177.80 mm wide

3/8

MachinePulley(SafetyType) for

V-Belt.

=

7.93

Outside diameter of belt groove 2.9 inches

73.65

mm.

mm

round

Effective

leather

diameter

belt

2-3/8

inch= 9.50 mm

for

5/16

inch

inches=60.30

2. Automatic lubricating system for supplying oil to

all

moving

oil

flow

3.

Transverse,

automatically pressure lubricated

justment for the oil flow.

parts

window

two

which

at

the

toone,

can be observed through an

front

of

the

machine

horizontal

axis

and

rotary

with fine

hook,

4. Single rotary take-up which controls thread at all

times to meet the requirements of the hook.

mm

mm

mm.

arm.

ad

5. Thread pretension and rotary thread tension for

proper

6. Thewidth of the zig-zag

regulation of the stitch formation.

stitch

isset by turning the

bight control knob and the corresponding setting

is

indicated

7. Thelength of the

feed driving eccentric on the bed shaft

at

the

frontofthe

machine.

stitchisadjusted by changing the

and

ting is indicated on the machine pulley.

8. Pendant

link

mechanism

with

eccentricfor adjusting

the feed dog to height and parallelism.

9. Low inertia presser

bar

mechanism.

10. The arm shaft, the needle vibrating shaft and the

belt

endofthe

bed

shaft

are

mountedindouble-

shielded ball bearings.

=

Needle bearings for the needle bar yoke connec

ting link

and

the feed driving eccentric connection;

super-oilite bushings for the feed driving eccentric

rockshaft, the needle bar yoke shaft and the needle

vibrating eccentric connection link.

11. The removable arm cover permits accessibility to

all parts in the arm.

12. Vibration absorbing location of the machine in the

machine base whioi is

and

oil

reservoir

firmly

in

the

table.

mounted as oil pan

the set

The maximum speed recommended for this machine

^

5000

R.P.M.

ons performed. It is

dependingonmaterials

advisable

to run a new machine

used

and

opera-

-or a more moderate speed until an oil flow is visible in

SETTING

The machine rests on a cork gasket in the machine

base. The machine base also serves as drip pan, oil re

servoir and as housing for the knee lifter.

When using the SINGER-table the machine base rests

on

its

four cornersandisfastened by meansof rest

(wooden) furnished

into

which

the machine base cannot be inserted pro

with

the machine.

Any

perly must be reworked or adjusted by

the

machine

base

1.

does

not rock,

2. is level in both directions,

table-cut-out

shims

pins

so that

3. prevents the inserted machine from touching

the

table,

4. raises

the

inserted machine

above

enough to open the bed slide

and

the

table,

that the

bed hinge connections support the machine

only when it is tilted back.

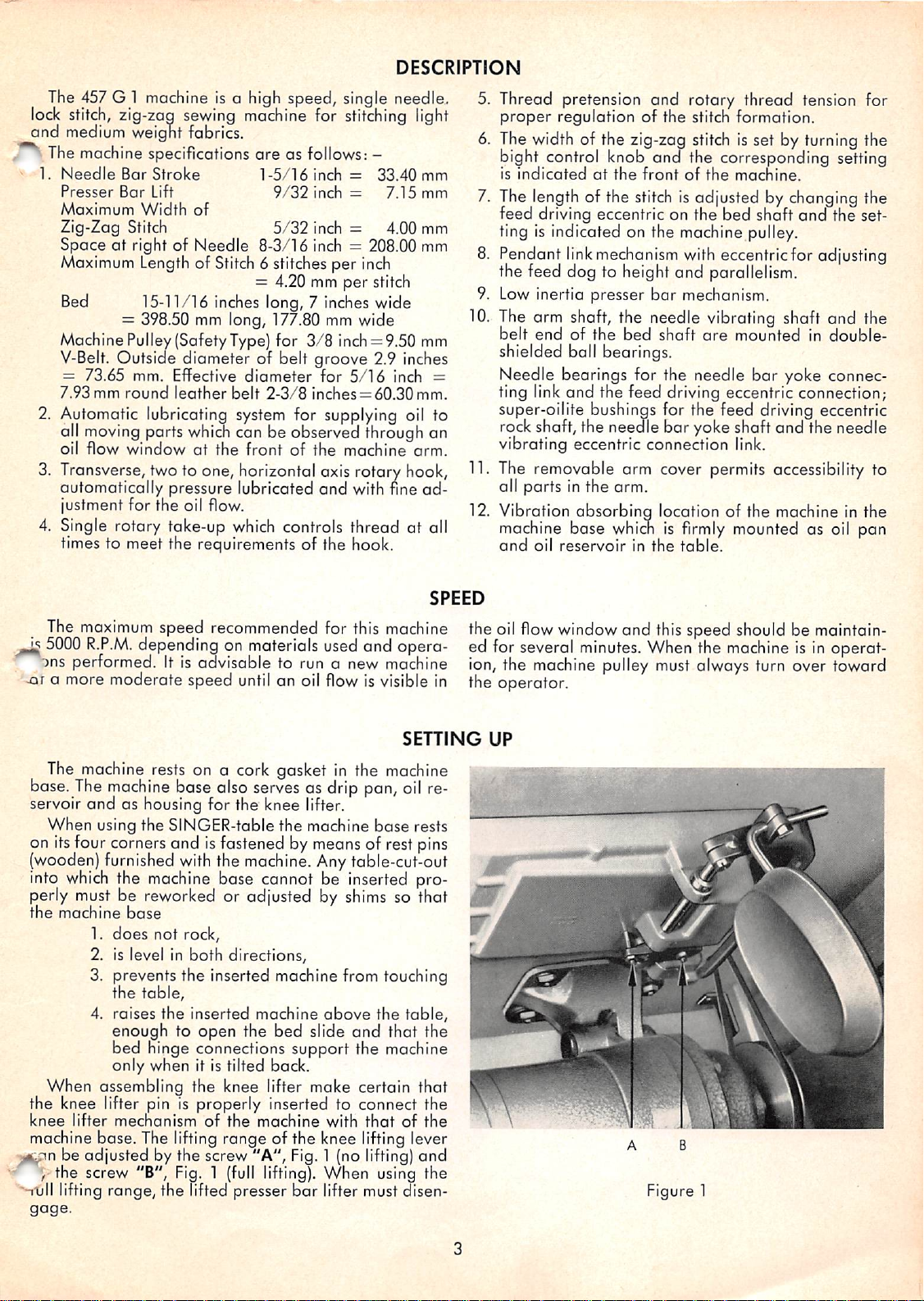

When assembling the knee lifter make certain that

the knee lifter pin is properly inserted to connect the

knee

lifter

mechanism

of

the

machine

with

that

of

the

machine base. The lifting range of the knee lifting lever

sfc^n

be adjusted bythe screw "A",

^ the screw "B", Fig. 1

~-itill

lifting range, the lifted presser

gage.

(full

Fig.

1 (no

lifting)

and

lifting). When using the

bar

lifter must disen

SPEED

the oil flow window and this speed should be maintain

ed for several minutes. When the machine isInoperat

ion, the machine pulley must always turn over toward

the operator.

UP

itufr'"-'

Figure 1

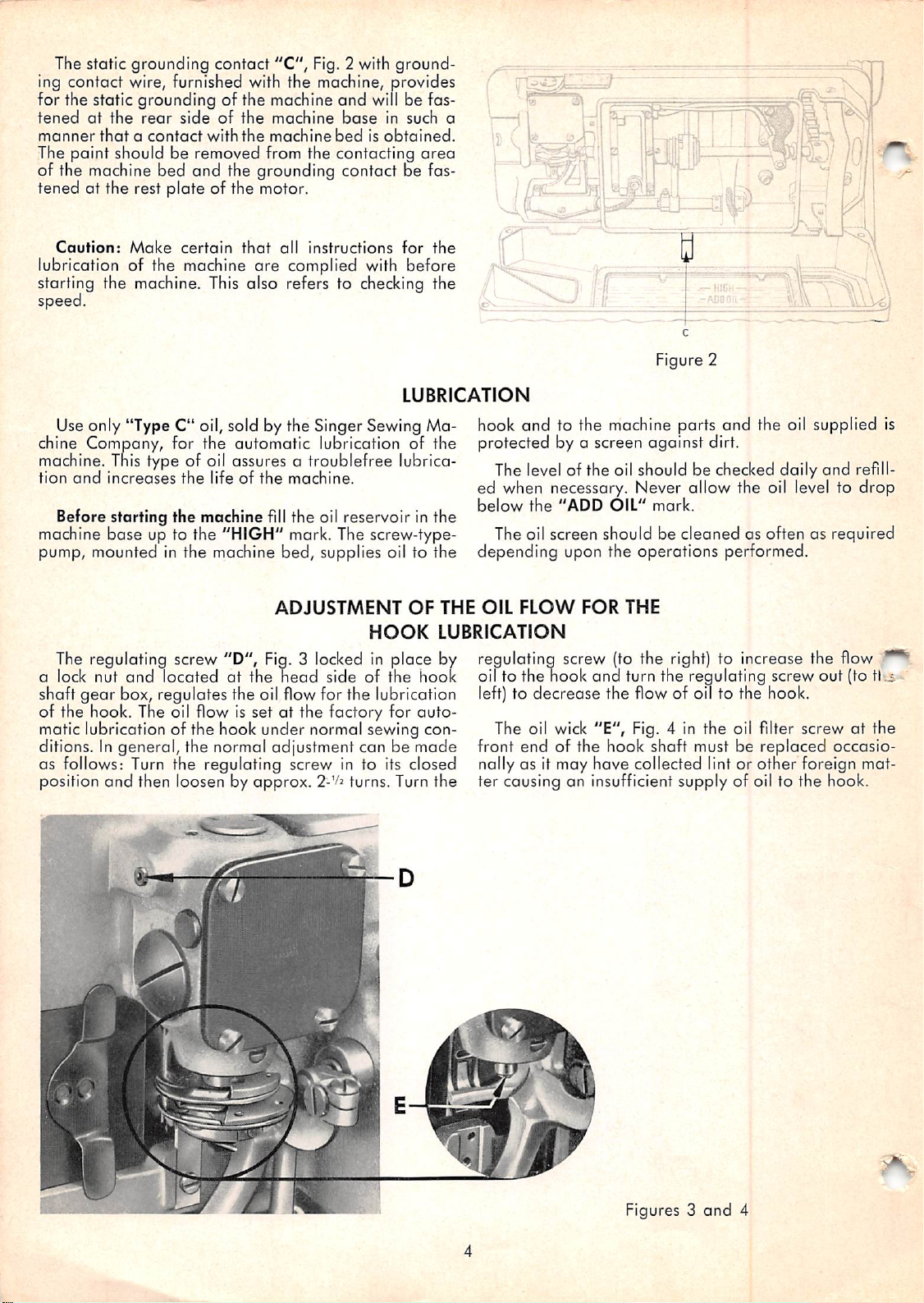

The static grounding contact

"C",

Fig. 2 with

ground

ing contact wire, furnished with the machine, provides

for the static grounding of the machine

tened

at

the

rear

side

of

the

machine

manner

The

of the machine bed

thatacontact

paint

should be removed from the contacting

with

the

machinebed

and

the grounding contact be fas

and

base

will be fas

in

such

is

obtained.

area

tened at the rest plate of the motor.

a

Caution:

Make

certain

that

all

instructions

for

the

lubrication of the machine are complied with before

starting the machine. This also refers to checking the

speed.

LUBRICATION

Use only "Type C" oil, sold by the Singer Sewing Ma

chine

Company,

for

the

automatic

lubricationofthe

machine. Tnis type of oil assures a troublefree lubrica

tion

and

increases

Before starting the machine

the

lifeofthe

machine.

fill

the oil reservoir in the

machine base up to the "HIGH" mark. The screw-typepump, mounted in the machine bed, supplies oil to the

ADJUSTMENT

HOOK

OF

THE

LUBRICATION

The regulating screw "D", Fig. 3 locked in place by

a

lock

nut

and

shaft

of the

located

gear

box, regulates the oil flow for the lubrication

hook.

The

oil

at

the

head

flowisset at the

side

factory

of

the

for auto

hook

matic lubrication of the hook under normal sewing con

ditions. Ingeneral, the normal adjustment can be made

as follows: Turn the regulating screw in to its closed

and

position

then loosen by approx.

2-^^^

turns. Turn the

0

Figure 2

hook and to the machine parts and the oil supplied is

protected by a screen against dirt.

and

The level of the oil should be checked daily

ed when necessary. Never allow the oil level to drop

below

the

"ADD

OIL"

mark.

The oil screen should be cleaned as often as required

depending upon the operations performed.

OIL

FLOW

regulating screw (to the

oil to the

left)

to decrease the flow of oil to the hook.

hook

FOR

THE

right)

to increase the

and

turn the regulating screw out (to tl.^

The oil wick "E", Fig. 4 in the oil filter screw at the

front end of the hook shaft must be replaced occasio

nally as it may have collected lint or other foreign mat

ter causing an insufficient supply of oil to the hook.

refill

flow

•*"

Figures 3

and

4

If

the

hook

receivesonexcessive

amountofoil which

cannot be reduced by the regulating screw,

sure

that

1.

the

oil wick

the filter screw,

has

not

become

detached

2. the filter screw issecurely tightened,

check

to be

from

Todetermine the proper flow of oil to the hook clean

the hookand,

rating speed, hold a small piece of white

the hook for approx. 15 seconds without

paper

streak of approx.

receives

or changing the speed. If the

with

sufficient

the

machine

runningatnormal

paper

1/32

inch = 0.8 mm width the hook

oil.

paper

moving

shows an oil

ope

under

the

3. the oil return passages

bushing or in the hook bushing housing hove

not become clogged with lint or other fo

reign

matter.

The

needles

ginal

SINGER-Needles

mium finish,

The

sizeofthe

recommended

Cat.

availableinthe

needletobe

ed by the size of the thread

through the eye of the needle.

or thread

which

ofthe needle

y

the

machine.

will

passes

interfere

with

with

In

the hook shaft, the

NEEDLES

for

this

machine

No.

1905

(Syst.

sizes

7-25.

used

shouldbedetermin

which

Rough

must

or uneven thread

are

Ori

265}

chro

pass freely

difficulty through the eye

the

successful

operation

Orders for needles mustspecifythe quantity required,

the catalogue number, the size number and the

Example: 100 - 1905 - 14 - 1

100 (Needles) 1905 (Cat. No.) 14

1 (Chromium

Finish)

SINGER-Needles and packets are stamped with the

trademark

"SINGER".

finish.

(Size)

Only left twist

thread

should be used in the

needle

(upper thread).

Either left or right twist thread can be used in the

bobbin (bobbin thread).

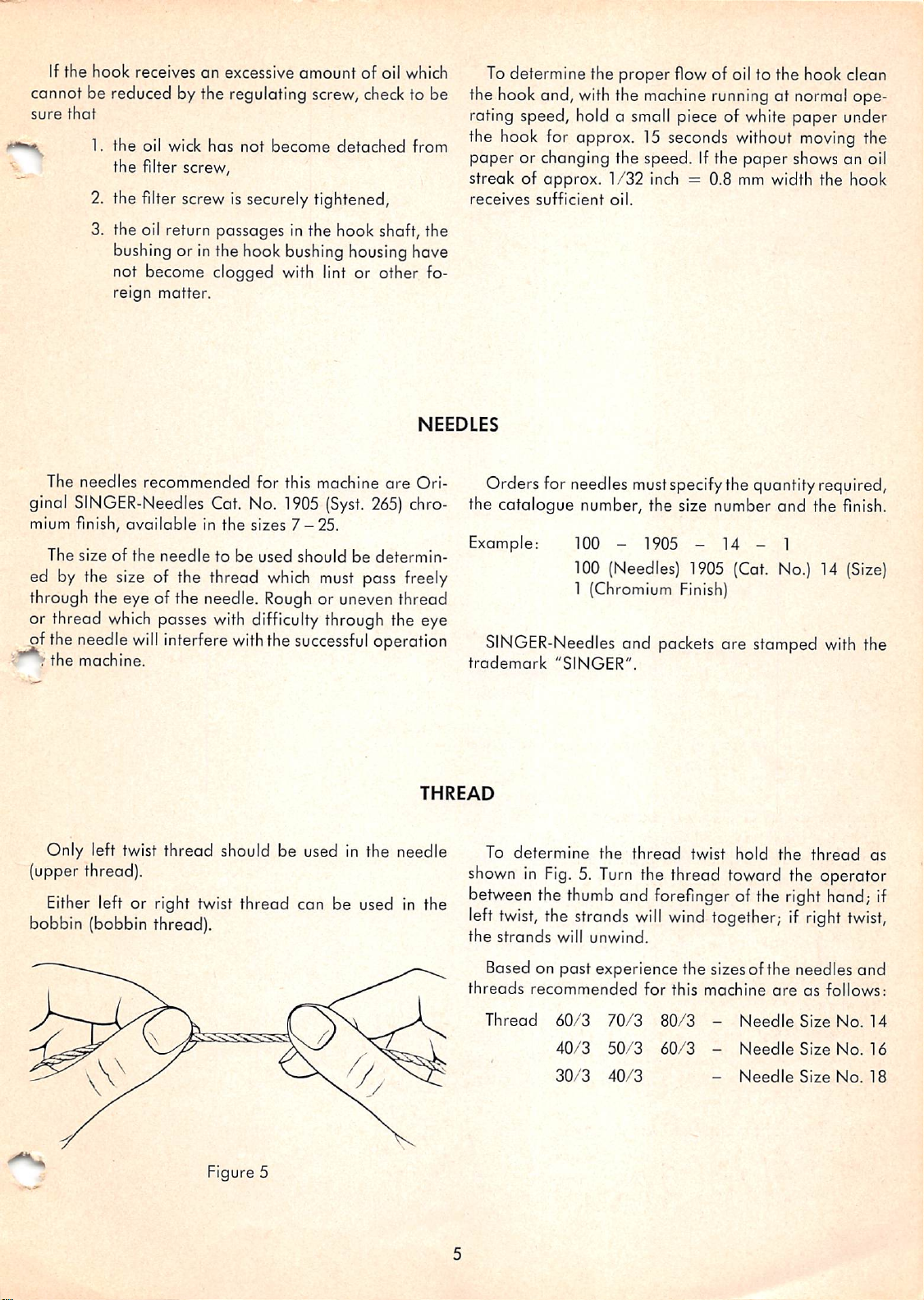

Figure 5

THREAD

showninFig.5.Turn

between

left

the

threads

To

determine

the

twist,

strands

the strands

thumb

will

the

thread

twist

the thread

and forefinger of the

will

wind

unwind.

hold

the

toward

right

together; if

thread

the operator

hand; if

right

Based on past experience the sizes of the needles

Thread

recommended

60/3

40/3

30/3

70/3

50/3

40/3

for

this

80/3

60/3

machine

-

Needle

-

Needle

-

Needle

areasfollows:

Size

No.

Size

No.

Size

No.

as

twist,

and

14

16

18

TO

REMOVE

THE

BOBBIN

CASE

CAP

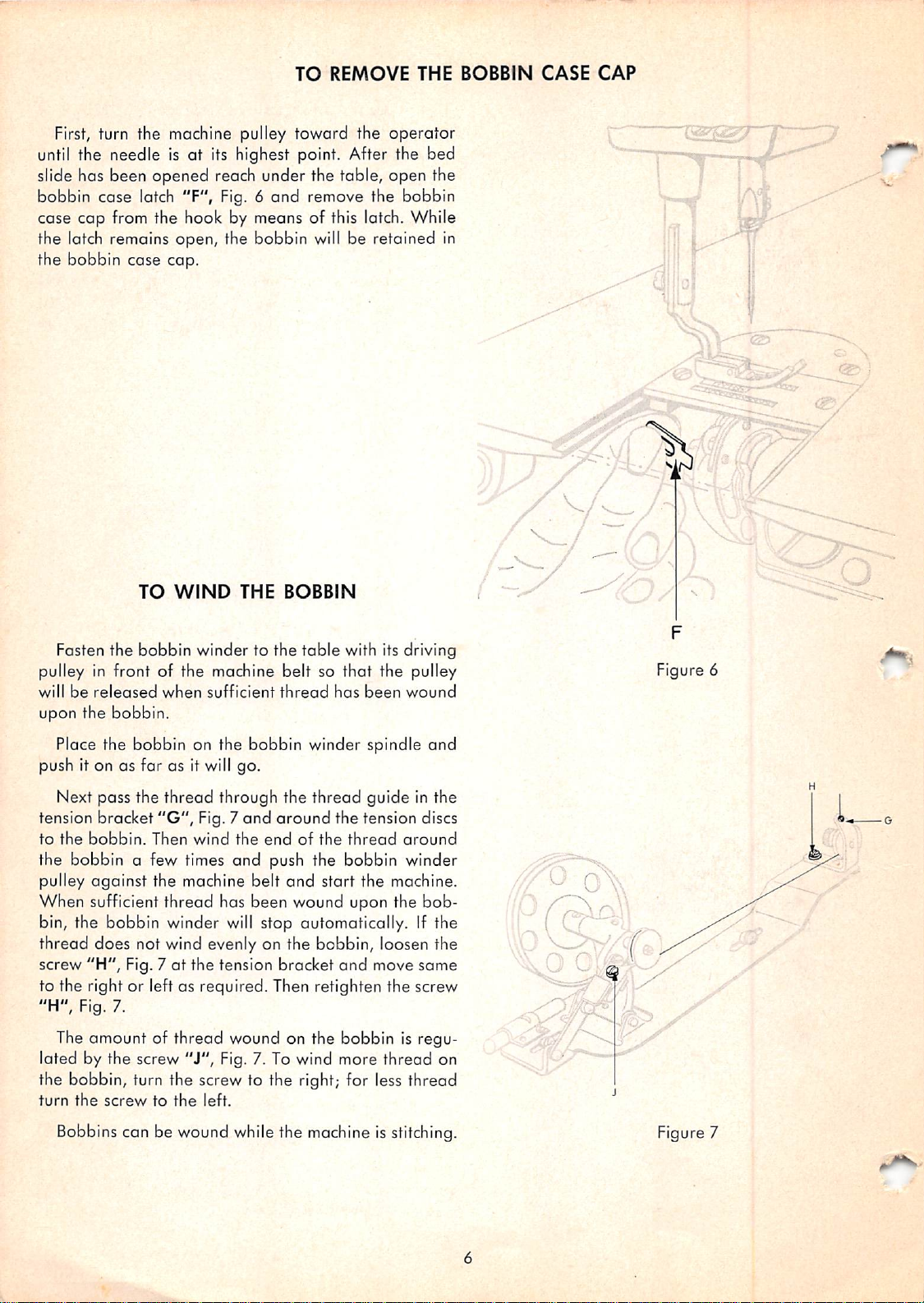

First, turn the machine pulley toward the

operator

until the needle is at its highest point. After the bed

slide has been opened reach under the table, open the

bobbin case latch Fig. 6

and

remove the bobbin

case cap from the hook by means of this latch. While

the latch remains open, the bobbin will be retained in

the bobbin case cap.

TO

WIND

THE

BOBBIN

Fasten the bobbin winder to the

pulley in front of the machine belt so

willbereleased

when

sufficient

table

thread

with its driving

that

the pulley

has

been

wound

upon the bobbin.

Place the bobbin on the bobbin winder spindle

and

push it on as far as it will go.

Next pass the

tension bracket

to

the

bobbin.

the bobbin a few times

pulley

against

When sufficient thread has been wound upon the

bin, the bobbin winder

thread

"G",

Then

through the

Fig.7

wind

the

and

endofthe

and

the machine belt

will

stop automatically. If the

thread

guideinthe

around the tension discs

thread

around

push the bobbin winder

and

start

the machine.

bob

thread does not wind evenly on the bobbin, loosen the

screw "H", Fig. 7atthe tension bracket

and

move

same

to the right or left as required. Then retighten the screw

"H",

Fig. 7.

The amount of thread wound on the bobbin is regu

lated by the screw

"J",

Fig. 7. To wind more thread on

the bobbin, turn the screw to the right; for less thread

turn

the

screwtothe

left.

Figure 6

0

Bobbins

can be wound whilethe machine is stitching.

Figure 7

Loading...

Loading...