Singer 451K41, 451K45, 451K145 Service Manual

Form

(562)

K6S06

SERVICE

451k41,

SINGLE

PARTS

SINGER

451k45

HIGH

NEEDLE

MANUAL

LIST

and

SPEED

LOCK

451k145

STITCH

MACHINES

Machine

451K41

*A

Trademork

THE

of THE

SINGER

SINGER

MANUFACTURING

MANUFACTURING

Copyright Under International Copyright

COMPANY

COMPANY

Union

PrintedinGreat

Britain

CONTENTS

DESCRIPTION

SETTING

LUBRICATION

INFORMATION

Alignment

Arm

Arm

Arm

Arm

Automatic

Ball

UP 4

Shaft

Shaft

Shaft

Connection

Shaft

Connection Belt Pulley 22, 23

Lubrication

Bearings

FOR

with

Hook Driving

and

OPERATOR

Shaft

Belt 3,

Needle

Bearings

Page

6-11

12,

22,

12,22,23

4-6

Bobbin 7, 8

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Bobbin

Broken

Carefree

CentralizationofFeed

Change

Case

Case

Case

Cose

Holder

Holder

Slide

Needle

Guard

13,

7-9,

15,

13, 15

Thread

Thread

Tension

Winder

Thread

Operation

Hints 11

7, 11

Dog 18

of Stitch Length 10, 19

7, 8

5, 8

Check-Spring 15, 16

Cleaning

Connection Belt, Arm

Common

Cover

Daily

Damaged

Damaged

DimensionsofMachine

Drawing

Drip

CausesofStitching

Guard

(Take-up)

Care

Needles

Parts

Up Bobbin

Pan,

Installation

Face Plate, Removal

Shaft

Troubles

Thread

and

Replacement 16

5, 11, 17, 21

3, 22

11,13

11

Feed Dog 12, 18, 19

Feed Driving Eccentric

Feed Driving

and

Gib

19

Reversing Mechanism 19

Feed Driving Eccentric 19

Feed Lifting Eccentric

Feed Mechanism (Pendant

Cam

Link)

19

3, 13, 18, 19

Feed Movement, Description 18

Feed Reversing Lever Stop Pin 19

Formation

Fraying

of

Stitch 9

of

Material

Gib (Feed Driving Eccentric) 19

Hints for Carefree Operation 11

Hook

Clearance

to

Needle

14

Description 3

Lubrication

Removal

and

Replacement 20

5^

Stringing

Timing

Hook

Driving Shaft 12, 22

Hook Oil Shield, Installation 6

Hook Oil Wick 5

Hook Section 20

Knee

Lifter

4^

11

Knee Lifter Rod Spring 19

Length

Light Fixture Mounting

of Stitch 3, 10, 19

Seat

Locking Feed Driving Eccentric 19

Loop Lift 12

Machine Pulley 3, 4, 22

3

INDEX

12

23

22

5

11

20

11

9

6

4

6

3

9

4

6

6

3

Page

TIMING

REMOVAL

PARTS

Machine

Machine

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Needle

Oil

Oil

Oil

Pendant

Perfect

Position

AND

PRINCIPAL

LIST

Rest

Storage

Bar

Bar

BartoPresser

Clearance

Bearings

Breakage,

to

Guard

Threading

Thread

Thread

Reservoir

Shield

Wick

(Hook)

Link

Stitch

Finger

ADJUSTING

AND

REPLACEMENT

ASSEMBLIES

Pin

and

Bushing

Connection

and

OF

Link

Foot,

Alignment

12-19

20-23

4,

12-14,23

3, 12

Prevention

Hook

Clearance

Tension

Tension

(Hook) 6

Feed

Releoser

Mechanism

6,11,15

13,

9,

15,

9,

3,5,22

6,

14

Preliminary Inspection 12

Preparation

Presser

Presser

Pressure

Prevention

Change

Puckering

Pulley (Arm

Pulley,

Removing

for

Sewing

Bar

and

Bushing 17

Foot

of

Presser

of

Unauthorized

of Stitch Length

Shaft

Machine

Broken

Thread

Foot

Connection

Belt)

10,

11,

12, 16,

3, 4, 11, 22

10,

22,

17

19

19

18

23

11

Rest Pin 4, 11

Reverse

Feed

3,

10,

16,

19

Reversing Lever Stop Pin 19

Rock

Shafts

21

Rotary Take-up (See "Take-up")

Sewing

Speed

Setting

Specifications

Spillage

StartingtoSew

Stitch

Hook

the

Needle

of

Bobbin

Formation

(See

"Hook")

3, 11

12

Thread

11

Stitch Length 3, 10, 19

Stitch Regulator

Stitching

Stringing

Troubles,

the

Needle

Superfinish

Causes

Guard

(Hook) 15

3,10,11

n

Tacking 3, 10, 16

Take-up 3, 12, 16

Take-up Cover Guard 11, 13

Tension

Tension Releoser

Devices

(Needle

Thread)

17

Threading 7, 8

Thread Breakage 6, 11

Thread Cutters 3, 11

Thread Tensions 9, 16

TurningaCorner

V-Belt 3

11

Wearing Checks 6, 12, 17, 18

Winding

the

Bobbin 8

24

11

5

6

23

17

14

15

7

16

17

6

3

9

9

6

8

9

6

3

DESCRIPTION

Machine 451K41 produces top quality, high speed,

lockstitching on

sieres, lingerie, ladies' overalls, children's

wear,

rainwear,

many

other

Particularly

rials,

this

Lock stitch (Stitch Type

Single

needle.

Socket-type

Short

arm,

Drop

feed.

reinforced

uniform stitch

Hinged

Feed

Dog

•I

Throat

Throat

lifter

It

Plate

Plate

Enclosed

228710.

similar

designed

machine

needle

flat

Pendant

feed

lengthatall

presser

149031

149057

52033

147150

knee

dresses,

uniforms,

light

has

the

Catalogue

bar

bed

bar

insures

foot

161066

(19

teeth)

(21

for

for

lifter

skirts, shirts,

aprons,

and

medium

for

"wash

following

#301)

1361 (88x9)

link

feeding

level

speeds.

(22

teethtothe

II

) (

II II

149031

149057

rod

and

blouses,

wear,

caps

and

weight

and

garments.

wear"

characteristics:

mechanism with

feed

motion

Inch)

11

II II

connections

sports

ties

)

to

bras

and

mate

and

knee

Modified, single rotary take-up maintains constant

thread

thread.

(belt

holes

control

Simple to

Long

point

rotary

driven);

One

serve

automatic

oil reservoir

all principal

Rotary tension

to

meet

hook

adjust.

sewing

lubrication

and

three

bearings

and

pre-tension devices

requirements.

hook

on

can

easily

in machine.

Easy to

horizontal

be

regulated.

accessible oil

achieve

axis

pre

cise thread control throughout speed range of stitching

with

all

typesofnatural

materials

lightest

Tension

tary

hazards.

Two

wrapping

The

broken

Durable,

270926,

readily

Large rim,

3/8

eterofbelt

5/16

Tapped

mounting

Compact

and

Maximum

Needle

Presser

inch.

Bed

of light

tensions

guard,

tension

thread

of broken

other,

on

thread

steel-reinforced,

from

accessible

aluminium

inch V-belt, is

groove,

inch

round

hole

a light

stitch

to

set.

lengthofstitch, 6 to

bar

bar

dimensions:

inches. Working

Double

shaft

Needle

connections

Nylon

and

shielded

andatpulley

bearings

and

insert

feed

lifting rock

Controlled

shaft.

for

mountedonface

from

cutters; One, on face plate, prevents

rear

of

from

arm

when

designed

leather

and

fixture.

length

stroke,

lift (capacity of machine),

Length,

spaceatrightofneedle,

ball

for

bearings

pressure

and

synthetic

and

perfect

medium

"wash

weight—permitting

and

wear"

plate,

broken

thread

thread

threads,

around

guard,

lint

rotary take-up.

removes

take-up.

rubber

shaft

to

hook

driving

rear

arm

coverisremoved.

machine pulley

for

2.9

inches.

belt,

safety.

Effective

2-3/8

Outside

inches.

seatinrearofarm

mechanismiseasytoread

the

inch.

1-9/64

(1.140)

15-11/16

inches.

inches.

bearingsatboth

end

of hook driving shaft.

for

feed

needle

for

driving

bar

feed

and

connecting

driving rock

shaft.

lubricated

bearings

threads

and

sewing.

protects

and

other

excess

driving

shaft,

272227,

diam

diameter

provided

9/32

(.281)

Width

8 inches.

endsofarm

feed

lifting

link.

shaft

on hook

ro

belt

for

for

for

cept

to

seam

and7to

ley

groove

leather

451K45

fabrics.

18-3/4

rightofneedle,

oiled,

is

minute,

the

of time, should be run slower

for

the moving ports. Check principal bearing points for

freedomofmovement

fore

7

woven

nature of the operation, the ability of the

the type of

speed for the work being accomplished. Disregard of

this precaution could result in considerable

to

Machine

• Reverse

forward

•

•

•

for

451K45

these

special

feed,

is

hand

similar

features

operated,

stitch. Performs precise tacking

reinforcing

Maximum

the

Feed

dog

Throat

inch

149031

plate

with

stitch

in

52033

minimum

length,

reverse.

to

. . .

6 to

Machine

with

thread

the

451K41

spring

and

breakage.

inch

forward

ex

return

strong

• Machine pulley 276530: Large rim aluminium pul

designed

2.9

Machine

• Designed for light,

• Long

•

Single

•

Feed

•

Throat

•

Needle

•

Presser

Do

not

OS

Maximum speed recommended is

• Run a

first

• A

machine

the

first

running

• Reduce

or

Maximum efficient

for

safety.

inches. Effective

belt,

2-3/8

inches.

451K145issimilartoReverse

except

for

these

Outside

diameter

special

medium

arm

and

bed.

Bed

inches.

Width,

7 inches.

11 inches.

needle.

dog

plate

bar

bar

start

instructed on

with

new

few

few

speed

treated

Catalogue

149366

270326

stroke,

lift,

machine

1-5/16

5/16

CAUTION

until it

pages

SPEED

these

exceptions

machineata

days.

that

has

been

minutestoallow

and

machineattop

of machine

material.

inches.

adequate

speed.

speedisdependent

thread

and

material in use.

diameter

features

and

dimensions:

Working

1969

inches

has

been

4, 5

and

5000

. . .

more

idle,

for

than

maximum

time

when

of

for

5/16

round

Feed

Machine

. . .

medium-heavy

Length,

space

(135x39).

thoroughly

6.

stitches per

moderate

a long

speed

period

speed

for

oiltoreach

lubrication be

sewing closely

upon

operator

belt

the

and

Never force machine beyond its maximum efficient

damage

machine.

at

SEHING

DRIP

PAN

Position

in Fig. 2,

edge

Using four

enough

rock

KNEE

Using

Fig. 2)

table.

and

out

striking

Locate

equidistant

pan.

will be directly

in

machine;

Raise rock

below

certain

curely tighten

Knee

suit

clamping

moved

rear,

drip

pan

with

its

right

of

lever

LIFTER

Locate

fall

machine

in

rod

three

fasten

through

cut-outintable.

3/4

inch

table

cut-out

(shown

7/8

rock

bracket2so

hole

edgeofhole.

rock

lever

extension

from

front

Make

certain

that

under

then

securely

lever

rod 5 to bring its

knee

lifting

rodinmachine,

platformisturnedasshown

clamping

plate7may

the

requirementsofthe

screw 8. Knee

toward

as

required

the

leftorright

after

Tighten both screws 8

position is

Set

as soon

to trip

ing

screw

MACHINE

Machine

four

obtained.

stop

stud 11 to stop

as

knee

hand

12.

HEAD

head

corners

lifter

lifter on

should rest

of

cut-out

on

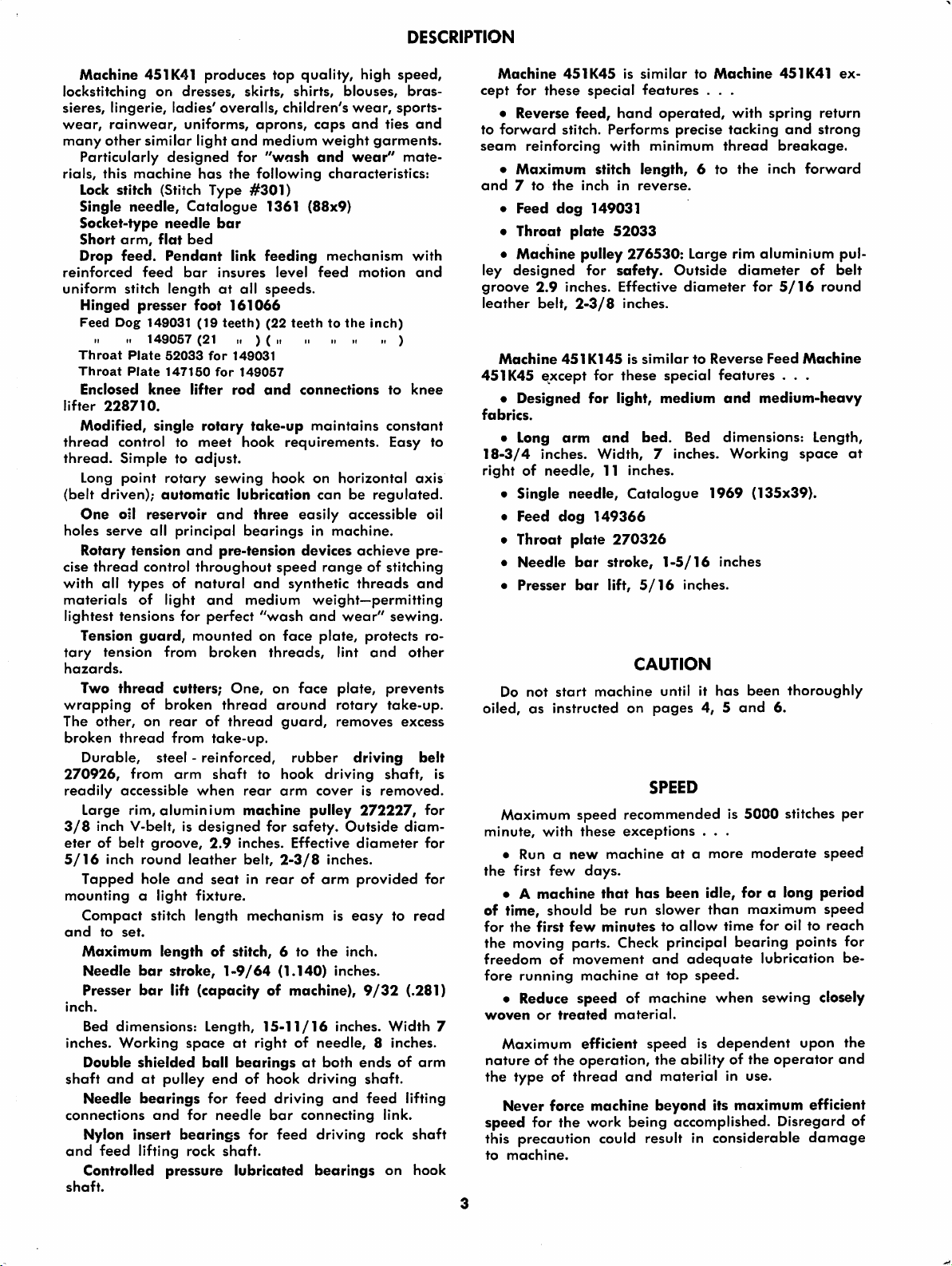

undersideoftable,asshown

wire

in Fig. 2).

inch

lever

provided

and

knee lifting rod A, Fig. 5,

be

loosening

and

raises

machine.

in

end

nails,

to

ovoid

wood

bracket

that

rear

platform

tighten

screw

raised,

operator,

plate

10 securely

the

presser

upon

table.

UP

even

rock

for it in

3tohold

6.

action of

Securely

tened. Machine hinges must not be

head

chine

except

rest pin on

when

machine is tilted back upon ma

table.

with

right

fasten

drip

pan

interference

screws

edges

2 to

lever

of hole in

at

top

(shown

underside

rod

drip

pan

rock

lever

end

can

of

page

clamp

screw

platform

whenatrest.

in Fig. 2

and

loweredorturned

after

loosening

arm9may

and

toward

clamping

foot

cushioning

Machine

screw

when

the

knee

high

tighten

is

also

front

correct

enough

clamp

pads

not

requiredtosupport

inside

low

with

at

of

rise

with

rod

drip

rod

4.

just

Make

se

be

or

10.

lifter

fas

FRONT

t

LEVER

EDGEOFTABLE

\N

ROD—

t

1,

12 11

PLATFORM

5,

ROCK

t

is

to

Fig. 2. Drip Pan

beneath

and

the

Knee Lifter

Table

it

. ^

in

Fig. 3. Direction of Rotation

DIRECTION

OF

ROTATION

MACHINE

When

ways

shown

Use

must

in Fig.

SINGER*

machine

turn

is in

over

3.

LUBRICATION

OIL

"TYPE

front cover of this book

Keep

machine

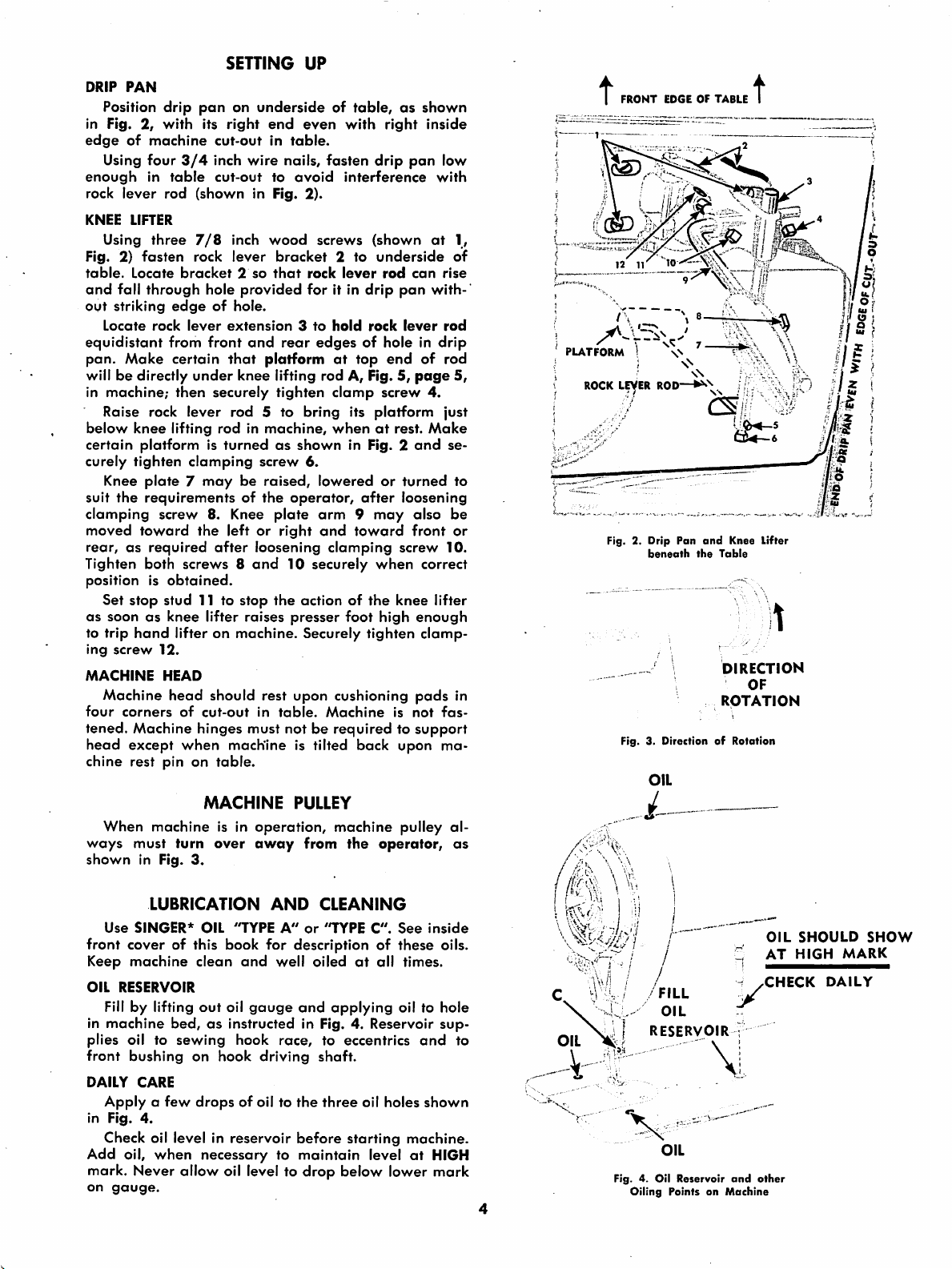

OIL

RESERVOIR

Fill

by lifting

in

machine

plies oil to

front

bushing

DAILY

CARE

Applyafew

in Fig.

4.

clean

and

out

oil

bed,asinstructed in Fig. 4. Reservoir

sewing

hook race, to eccentrics

on

hook

dropsofoil to

Check oil level in reservoir

Add oil,

when

necessary to

mark. Never allow oil level to

on

gauge.

PULLEY

operation,

away

AND

A"or'TYPE

for

well

gauge

driving

machine

from

the

CLEANING

description of these oils.

oiledatall times.

and

applying oil to hole

shaft.

the

three

oil

before

starting

maintain

drop

below lower

pulley al

operator,

C".

See

holes

machine.

level

and

at

as

inside

sup

shown

HIGH

mark

;

<TV

v<-

//)7

' -

to

'I

- t

FILL

RESERVOIR

OIL

Fig. 4. Oil

Oiling Points on

Reservoir

and

Machine

OIL

AT

CHECK

other

SHOULD

HIGH

DAILY

SHOW

MARK

LUBRICATION

AND

CLEANING

(Cont'd)

1 ! i p

/W\\

'•

///

/•///

/ •!; a

ii

,^ir'

J

{r-

) \l

I \

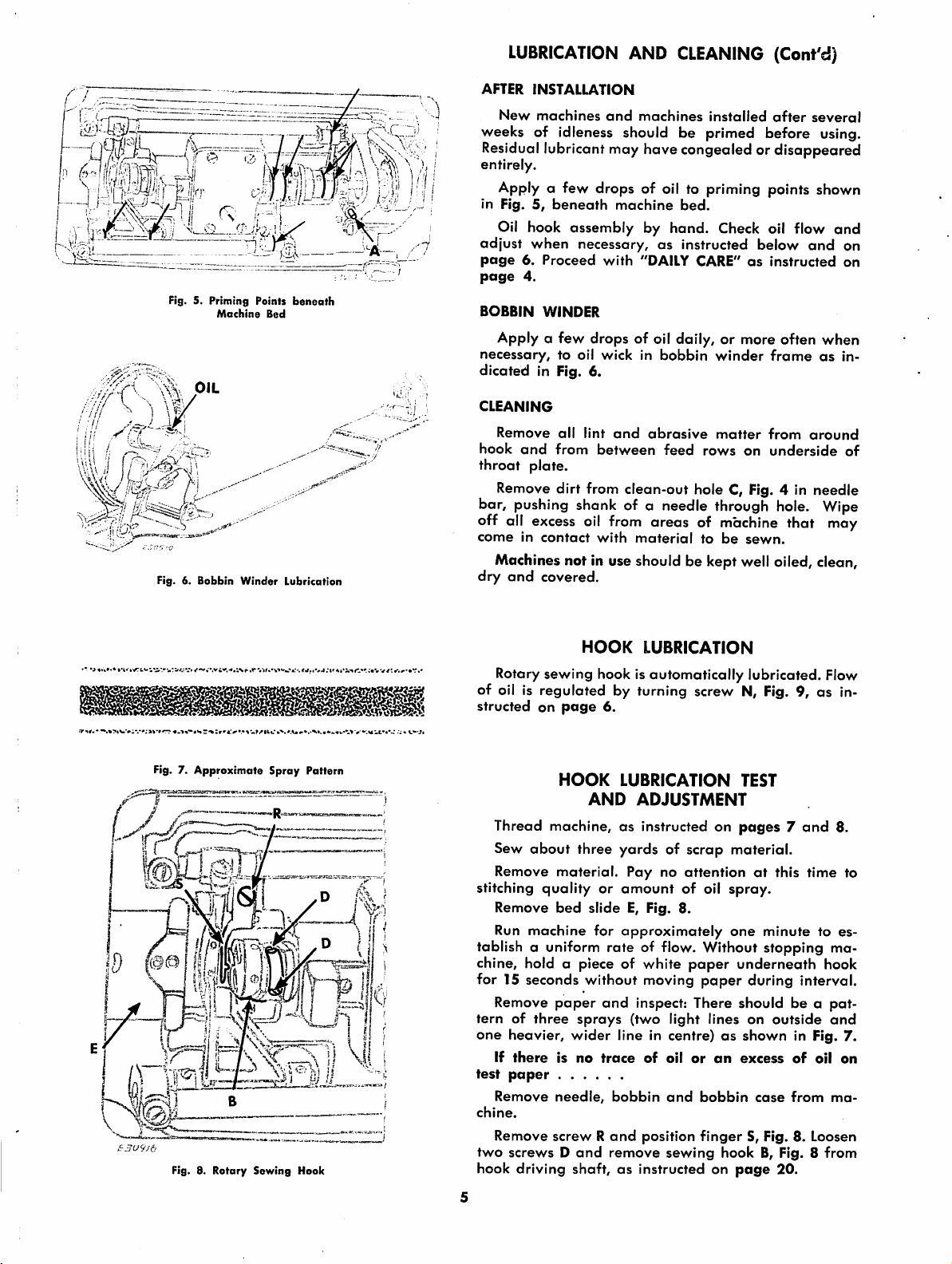

Fig. 6.

Fig. 5.

llirr

OIL

Bobbin

Priming

Machine

Points

Winder

Bed

Lubrication

IrrtK-cc-c

beneath

AFTER

INSTALLATION

New

machines

and

machines

installed

after

several

weeks of idleness should be primed before using.

Residuallubricant may have congealed or disappeared

entirely.

Apply a few drops of oil to priming points shown

in Fig.5,beneath

Oil hook assembly by

adjust

page

page

BOBBIN

when necessary, as instructed below

6.

Proceed

4.

WINDER

machine

with

hand.

"DAILY

bed.

Check oil flow

CARE"asinstructed

and

and

on

on

Apply a few drops of oil daily, or more often when

necessary,

to oil

wickinbobbin

winder

frame

as

in

dicated in Fig. 6.

CLEANING

Remove

hook

throat

Remove dirt from clean-out hole C, Fig. 4 in

and

plate.

all

from

lint

between

and

abrasive

feed

matter

rows

on

from

around

underside

of

needle

bar, pushing shank of a needle through hole. Wipe

off all excess oil from areas of machine that may

come

in

contact

Machines not in use should be kept well oiled, clean,

dry

and

covered.

with

material

to

be

sewn.

Fig. 7. Approximate Spray Pattern

p) I

Id

-•''—^^.-^^11

j ^

)7^

TTW-A11 \ti I

ir\¥4^zl±^Hi

''SU9/6

Fig. 8.

Rotary

W Y y ^j

Sewing

Hook

fX'

HOOK

LUBRICATION

Rotary sewing hook is automatically lubricated. Flow

of oil is regulated by turning screw N, Fig. 9, as in

structedonpage

Thread machine, as instructed on

about

Sew

Remove

stitching quality or

Remove

Run

machine

tablish a uniform

chine, hold a piece of white

for 15 seconds without moving

Cy

i

Remove

tern of

one

heavier,

If

test

paper

Remove

chine.

paper

three

there

needle,

Remove screw R

two

screwsDand

hook driving shaft,asinstructed on

HOOK

AND

three

material.

bed

slide

for

and

sprays

wider

is

no

trace

6.

LUBRICATION

ADJUSTMENT

TEST

pages7and

yards

of scrap material.

Paynoattention

amount

E, Fig. 8.

of oil spray.

approximately

rate

of flow. Without stopping ma

paper

paper

at

one

underneath hook

during interval.

inspect: There should be a

(two light lines on

line in centre)asshown

of

oil

or

an

excess

bobbin

and

remove

and

position

sewing

bobbin

finger

S, Fig. 8. Loosen

hook

case

B, Fig. 8

page

8.

this

time

minute to es

pat

outside

and

in Fig. 7.

of

oil

from

ma

from

20.

to

on

HOOK

LUBRICATION

(Cont'd)

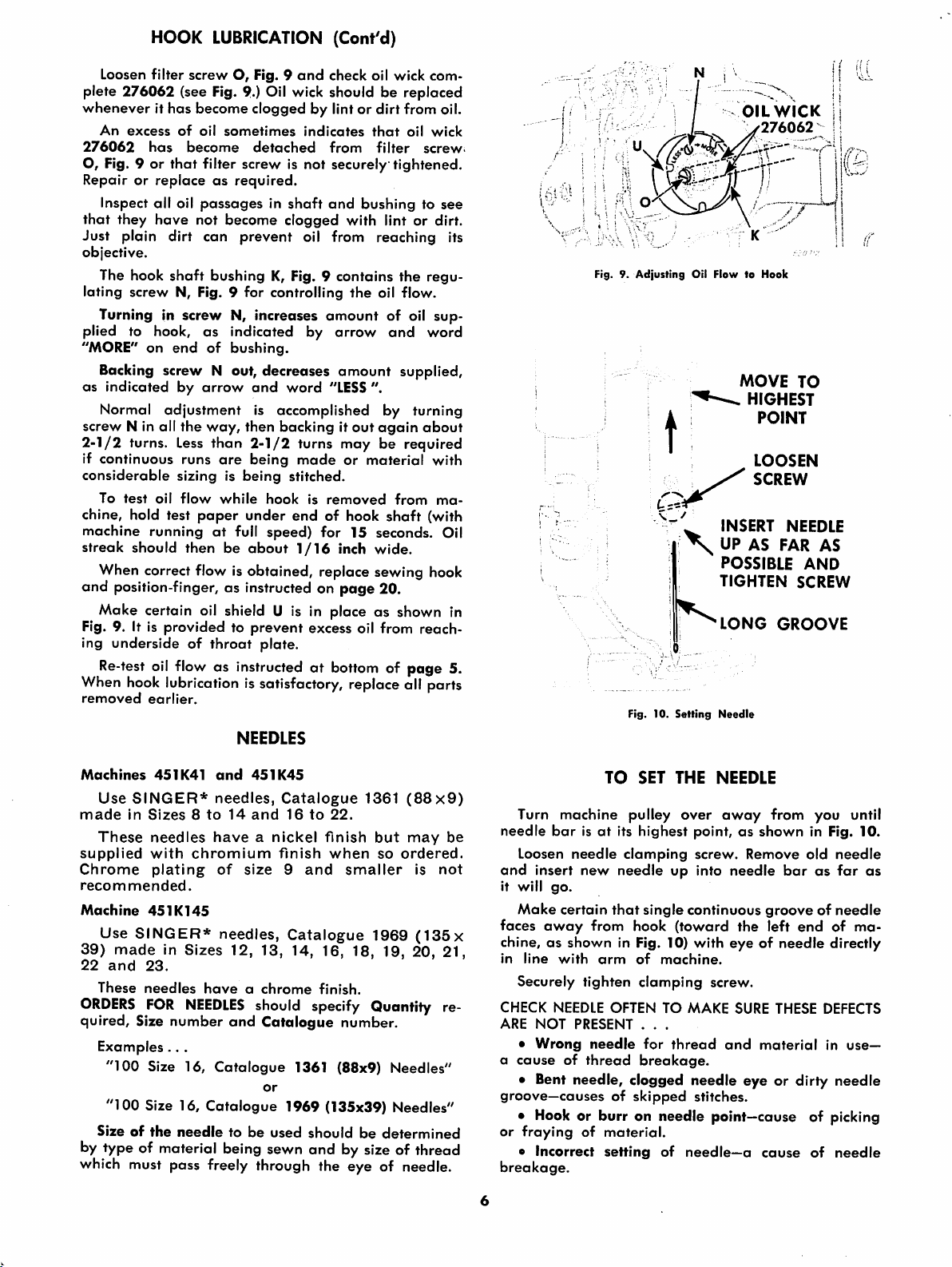

Loosen

filter

screw

O, Fig. 9

and

check oil wick

com

plete 276062 (see Fig. 90 Oil wick should be replaced

whenever

An

276062

O, Fig. 9 or

Repairorreplaceasrequired.

Inspect

that

it has become clogged by lint or dirt from oil.

excess

they

has

all

have

of

oil

sometimes

become

that

filter screw is not

oil

passagesinshaft

not

become

detached

clogged

indicates

from

securely

and

that

bushingtosee

with

oil

wick

filter

screw.

tightened.

lintordirt.

Just plain dirt can prevent oil from reaching its

objective.

The hook

lating

Turning in screw N, increases

plied to hook,

"MORE" on

shaft

bushing K, Fig. 9 contains

screw

N, Fig. 9 for controlling

OS

indicated by

end

of

bushing.

the

amount

arrow

the

oil flow.

of oil

and

regu

sup

word

Backing screw N out, decreases amount supplied,

OS

indicated

by

arrow

and

word

"LESS

".

Normal adjustment is accomplished by turning

screw

N in all

2-1/2

turns.

if continuous runs

considerable

To

test

chine, hold test

machine running

streak

should

Less

sizing is

oil

the

flow

then

way,

then

backingitout

than

2-1/2

are

being

while

paper

under

at

full speed) for 15 seconds. Oil

be

about

turns may be required

being

made

or

stitched.

hook

is

removed

end

of hook

1/16

inch

material

again

from

shaft

wide.

about

with

ma

(with

When correct flow is obtained, replace sewing hook

and position-finger, as instructed on page 20.

Moke certain oil shield U is in place as shown in

Fig. 9. It is provided to prevent excess oil from reach

ing

undersideofthroat

plate.

Re-test oil flow as instructed at bottom of page 5.

When hook lubrication issatisfactory, replace all parts

removed

earlier.

NEEDLES

OILWICK

• I 1

Fig. 9.

Adjusting

Fig. 10.

t

Setting

Oil Flow to

MOVE

.

INSERT

UP

POSSIBLE

TIGHTEN

LONG

Needle

HIGHEST

POINT

LOOSEN

SCREW

AS

276062

Hook

NEEDLE

FAR

GROOVE

1"'^

TO

AS

AND

SCREW

Machines

LJse

made

These

supplied

Chrome

recommended.

Machine

Use

39)

22

These

ORDERS

quired, Size number

Examples...

"ICQ Size 16,

"100

Sizeofthe

SINGER*

in

SINGER*

made

and

451K41

Sizes8to

needles

with

plating

451K145

and

451K45

needles,

14

and

haveanickel

chromium

of

size

needles,

Catalogue

16to22.

finish

finish

when

9

and

Catalogue

1361

but

so

smaller

1969

(88x9)

may

ordered.

in Sizes 12, 13, 14, 16, 18, 19, 20, 21,

23.

needles

FOR

Size 16,

haveachrome

NEEDLES

and

Catalogue

Catalogue

needletobe

finish.

should specify Quantity re

Catalogue number.

1361 (88x9)

or

1969 (135x39) Needles"

used

shouldbedetermined

Needles"

is

not

(135x

by type of material being sewn and by size of thread

which

must pass freely through the eye of needle.

be

TO

SET

THE

NEEDLE

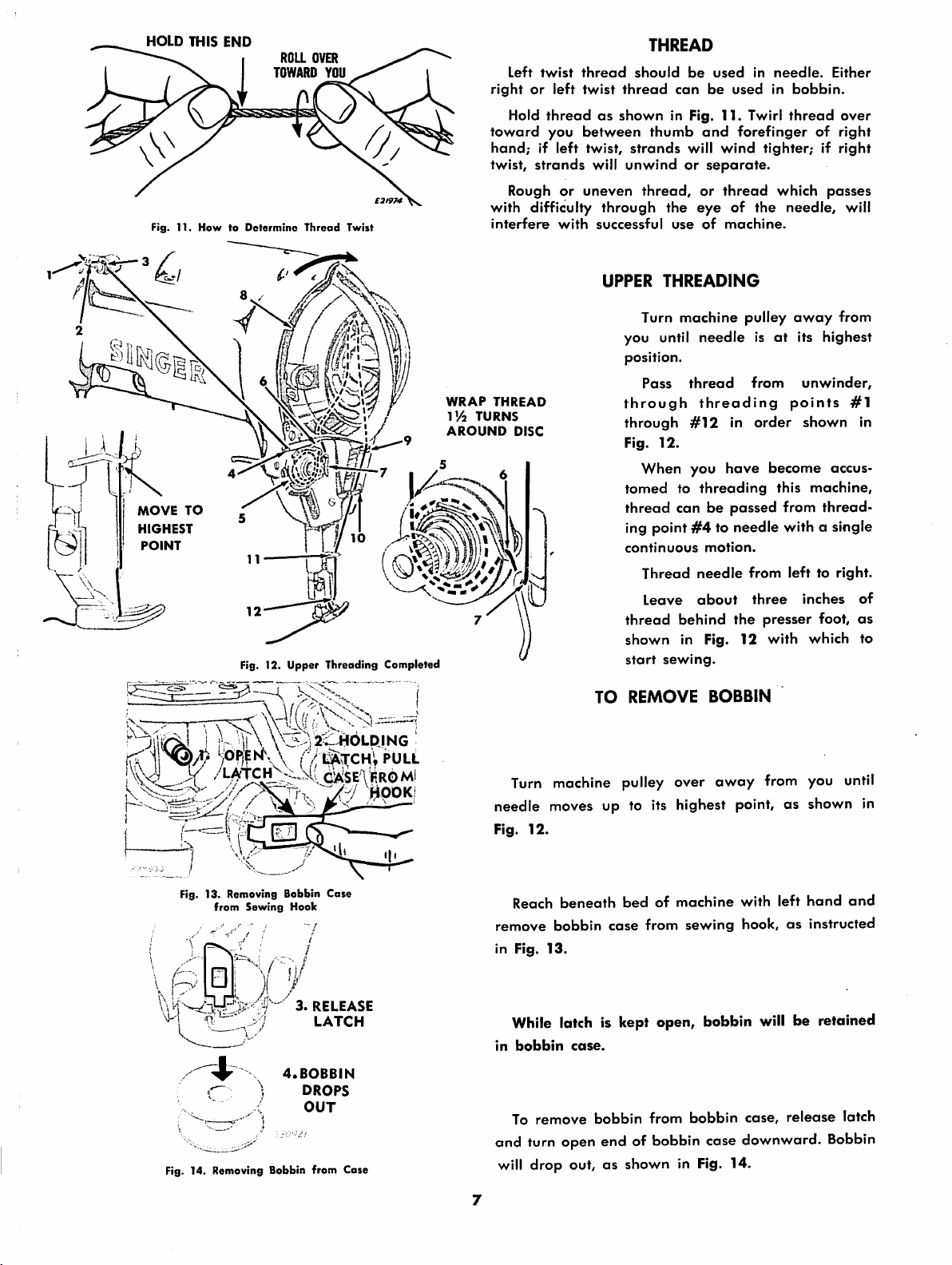

Turn machine pulley

needle

and

it will

faces

Loosen

insert

Moke

away

barisat

needle

new

go.

certain

from hook

its

clamping

needle

that

chine, as shown in Fig. 10) with eye of

in

line

with

arm

Securely

CHECK

ARE

•

a

cause

Wrong

NEEDLE

NOT

tighten

PRESENT

needle

of

thread

OFTEN

• Bent needle, clogged needle

groove—causesofskipped

over

highest

up into

single

(toward

of

machine.

clamping

TO

. . .

for

thread

breakage.

away

from you until

point,asshown

screw.

Remove

needle

continuous

grooveofneedle

the left

screw.

MAKE

SURE

THESE

and

material

eye

or dirty needle

stitches.

in Fig.

old

barasfar

end

needle

DEFECTS

in use—

• Hook or burr on needle point—cause of picking

or

fraying

•

breakage.

Incorrect

of

material.

setting

of

needle—a

cause

of

10.

needle

as

of ma

directly

needle

HOLD

Fig. 11.

THIS

END

HowtoDetermine

ROLL

TOWARD

Thread

OVER

YOU

Twist

Left

twist

rightorleft

Hold

thread

toward

you

hand;ifleft

twist,

strands

Rough

or

with difficulty

interfere

with

THREAD

thread

twist

between

twist,

uneven

should

thread

as

shown

thumb

strands

will

unwindorseparate.

thread,

through

successful

the

be

can

in Fig.

will

eye

use

used

in

be

usedinbobbin.

11.

Twirl

and

forefinger

wind

or

thread

of

the

of

machine.

needle.

thread

of

Either

over

right

tighter;ifright

which

needle,

passes

will

MOVE

HIGHEST

POINT

TO

yn

>1

Fig. 12. Upper Threading Completed

i

WRAP

1*/2

TURNS

AROUND

THREAD

Disc

UPPER

THREADING

Turn

you until

position.

Pass

through

through

Fig.

12.

When you

tomed

thread

machine

needleisat

thread

threading

#12

hove

to

threading

can be

pulley

from

in

order

passed

away

points

become

this

from

ing point#4to needle with a single

TO

continuous

Thread

Leave

thread

shown

start

REMOVE

motion.

needle

about

from

three

lefttoright.

behind the presser foot,

in Fig. 12

sewing.

with

BOBBIN

from

its

highest

unwinder,

shown

accus

machine,

thread

inches

which to

#1

in

of

as

Sf/y

X

Fig. 13. Removing Bobbin Cose

from

A]

Fig. 14. Removing Bobbin from Cose

Sewing

\

A

A-A

Hook

1/

3.

RELEASE

LATCH

4.BOBBiN

DROPS

OUT

PULL

mo

M:

Turn

machine pulley over away from you until

needle moves up to its highest point, as shown in

Fig.

12.

Reach

remove

in Fig.

beneath

bobbin

13.

bedofmachine

cose from

sewing

with

left

hand

and

hook,asinstructed

While latch is kept open, bobbin will be retained

in

bobbin

To

and turn open end of bobbin case downward.

will

case.

remove

drop

bobbin

from

out, as shown in Fig. 14.

bobbin

case,

release

latch

Bobbin

Loading...

Loading...