Page 1

SINGER

15k 66k 201k 99k 185k 327k 328k 329k 404k

A Manual of

Family

ng

ines

Page 2

PREFACE

HE great aim in education is to equip the scholar for his or her future

T

instruct her in the care and use of the family Sewing Machine so that she can

use it to the best advantage.

ability to plan and make smart, attractive clothes for herself and for her

family as well as being able to furnish her home with curtains, chair covers

and all kinds of beautiful accessories, will provide her with great satisfaction

and pleasure.

use of the modern Sewing Machine and its various attachments. Garments

can be made with a professional finish for about half the cost of a similar

ready-made garment. There are many excellent paper patterns available

featuring up-to-date styles for every age, some are specially designed for the

beginner and others fulfil the requirements of the more experienced home

dressmaker. Glossy magazines print a steady flow of ideas for making the

home beautiful, many of which are suitable for machine sewing.

career. To the girl interested in household economics the Sewing

Machine offers wonderful possibilities. The job of this booklet is to

A large part of the family income is usually spent by the woman, and her

Successful home sewing is in the reach of anyone making the fullest possible

With the introduction of the Slant-O-Matic, Zig-Zag Stitch and Automatic

Embroidery, a whole new vista of sewing skills emerge, it is not surprising,

therefore, that the woman of today is becoming interested in home sewing.

The modern electric sewing machine makes needlework a pleasure and by

using the attachments supplied, fascinating trimmings can be achieved in a

fraction of the time previously required.

The instruction contained in this booklet shows you how to use your

sewing machine and to take proper care of it, so that you may obtain the

greatest benefit.

Page 3

GENERAL INSTRUCTIONS FOR THE CARE AND OPERATION OF FAMILY SEWING MACHINES

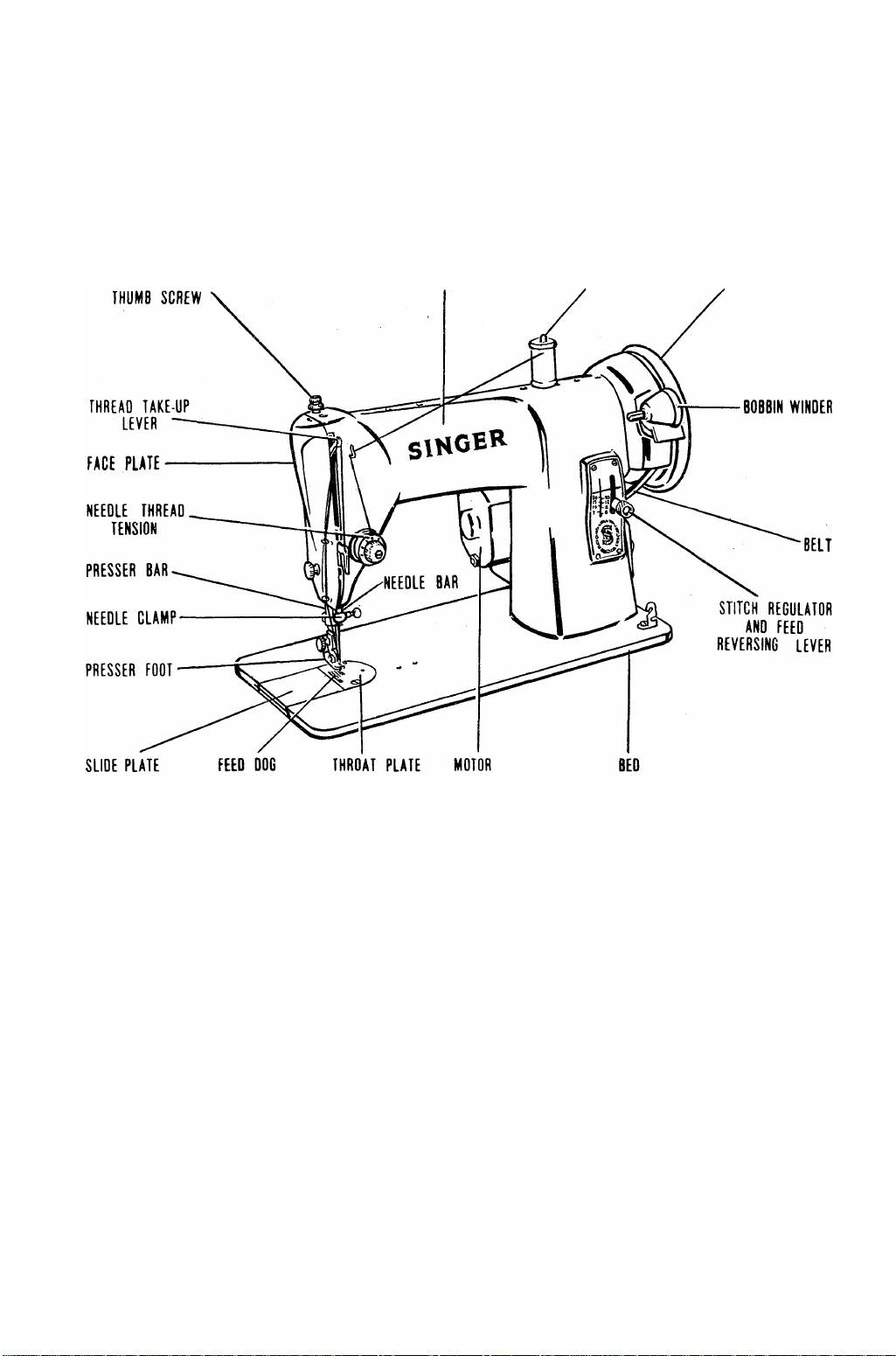

The Principal Parts of Lock Stitch Sewing Machines

and Their Uses.

PRESSURE REGULATING

ARM

SPOOL PIN

HAND WHEEL

Fig. 1. Prinxipal Parts of the Head.

Head—the part above the table (Fig. 1) containing the stitching mechanism.

Arm—the curved part of the head containing the mechanism for driving the

needle and handling the upper thread.

Bed—the flat portion of the head, under which is mounted the feeding mechan

ism and that for controlling the lower thread.

Hand Wheel—the wheel at the right of the head driven by the belt.

Bobbin Winder—the mechanism for automatically winding bobbins.

Stitch Regulator—the device which controls the length of the stitch.

Upper Tension—the means for controlling the delivery of the upper thread

from the spool.

Thread Take-up Lever—the part which pulls up the slack thread and locks

the stitch.

Needle Bar—the vertical bar in the lower end of which the needle is inserted.

Presser Bar—the vertical bar to which the presser foot is attached.

Face Plate—the vertical plate on the left of the arm, which may be removed

to give access to the needle bar, presser bar and take-up.

Page 4

Throat Plate—the plate in the bed directly below the presser foot through

which the needle passes and the feed dog moves.

Feed Dog—the toothed part which projects upward through slots in the

throat plate, carrying the fabric from the operator at each stitch. The

movement of the feed dog is controlled by the stitch regulator which

determines the desired length of stitch.

Bed Slide—the flat plate or plates at the left of the bed, which may be

opened to give access to the shuttle or bobbin case and other parts of

the lower stitch-forming mechanism.

Bobbin—the spool on which thread is wound to furnish the lower or shuttle

thread supply.

Shuttle or Bobbin Case—the container in which the bobbin is placed and

around which the loop of the needle thread is passed in forming the

lock stitch.

Rotary or Oscillating Hook—the part which enters the loop of needle

thread and carries it around the bobbin case. In the long-bobbin

machine (Singer No. 128) this function is performed by the shuttle,

which also acts as a bobbin case.

Lower Tension—the spring on the shuttle or bobbin case, which controls the

tension on the thread from the bobbin.

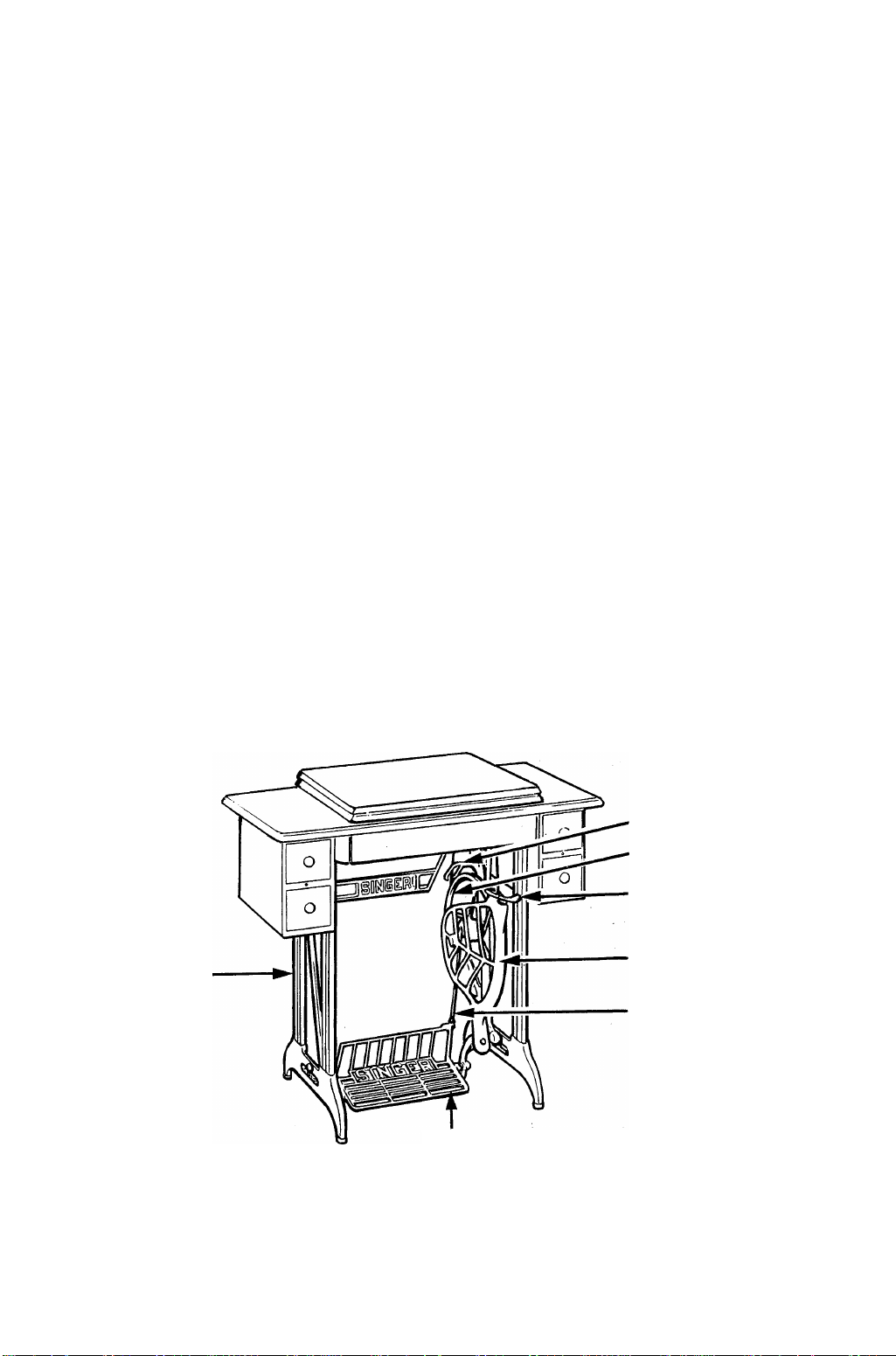

Cabinet Work—all the wood parts.

Stand—the supports and driving parts on which the cabinet work is mounted.

Treadle—the platform rocked up and down with the feet to operate the

machine.

Pitman—the rod connecting the treadle and the band wheel.

LEG

BELT GUIDE

BAND

WHEEL

BELT

SHIFTER

DRESS

GUARD

PITMAN

TREADLE

Fig. 2. Principal Parts of the Cabinet Table Stand.

4

Page 5

Band Wheel—the large wheel with a groove in which the belt runs, mounted

on the band wheel crank and rotated by the up and down motion of

the pitman.

Belt Shifter—the lever at the front of the band wheel, which may be turned

to the left to throw the belt off the wheel. The belt may be replaced

automatically by treadling, this action being accomplished by a pro

jection on the side of the band wheel, assisted by the belt guide in

the rear.

Legs—the upright members which support the table.

Dress Guard—the shield in front of the band wheel protecting the operator’s

clothing.

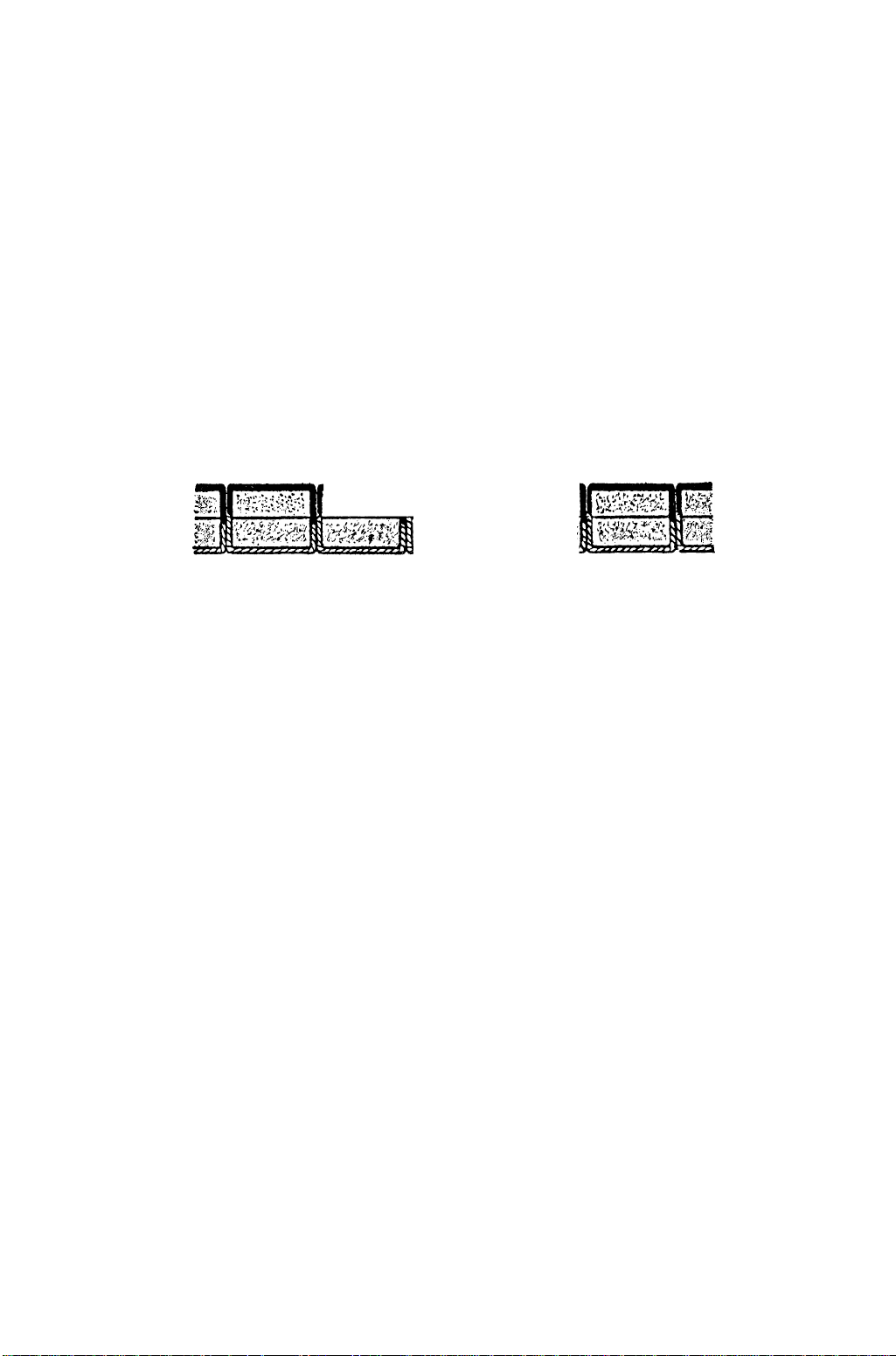

Formation of the Lock Stitch.

The lock stitch made by sewing machines consists of an upper or needle

thread and an under or bobbin thread locked together in the material which is

being stitched, the lock being formed by passing the upper around the lower

thread and tightening them together in the middle of the fabric.

^sxBBXzrea

Fig. 3.

When a stitch has been completed and before each succeeding stitch is

commenced, the fabric being stitched is carried from the needle by the feeding

mechanism, and upon the length of its movement depends the length of the

stitch.

The presser foot rests upon the fabric, prevents it from rising with the

needle and holds it in contact with the feed dog while the feeding takes place.

The section of the foot which presses on the cloth is slotted so that the view

of the stitching may not be obstructed.

PRACTICE for BEGINNERS

The beginner should acquire a knowledge of the various parts of the

sewing machine and the purpose of each, in order to give the machine proper

care and to obtain the best results from it. It is essential that practice

precede actual sewing on the machine. For this practice the upper thread and

bobbin should be removed from the machine and the presser foot raised. The

operator should be equipped with a chair high enough to allow her to sit

comfortably and squarely in front of the machine directly in line with the

needle.

Whether the machine is electric or treadle controlled it is essential that the

operator should continue practising until she is able to start smoothly and

have an easy control at varying speeds.

Electric Machine. See that the foot control is placed in such a position

on the floor that the foot can rest comfortably on it. Press lightly on the

control knob with the toe to test the amount of pressure needed for varying

speeds before threading up and starting to sew.

Treadle Machine. The operator should sit squarely in front of the

machine with the feet placed comfortably on the treadle. The right foot

should be placed forward and the left backward so that the pressure on the

treadle is with the ball of the foot.

Page 6

Practice for Beginners—(Continued)

The hand wheel should receive a start with the right hand at the same

time as pressure is applied to the treadle. In the case of family sewing

machines of the lock-stitch type, the hand wheel should turn from the top

towards the operator.

This practice should be continued until an easy method of treadling is

acquired and the operator is able to start the machine and keep it running

smoothly.

Note. During this practice and whenever a sewing machine is run with

out sewing, the needle should be unthreaded and the presser foot raised so

that it is not in contact with the feed.

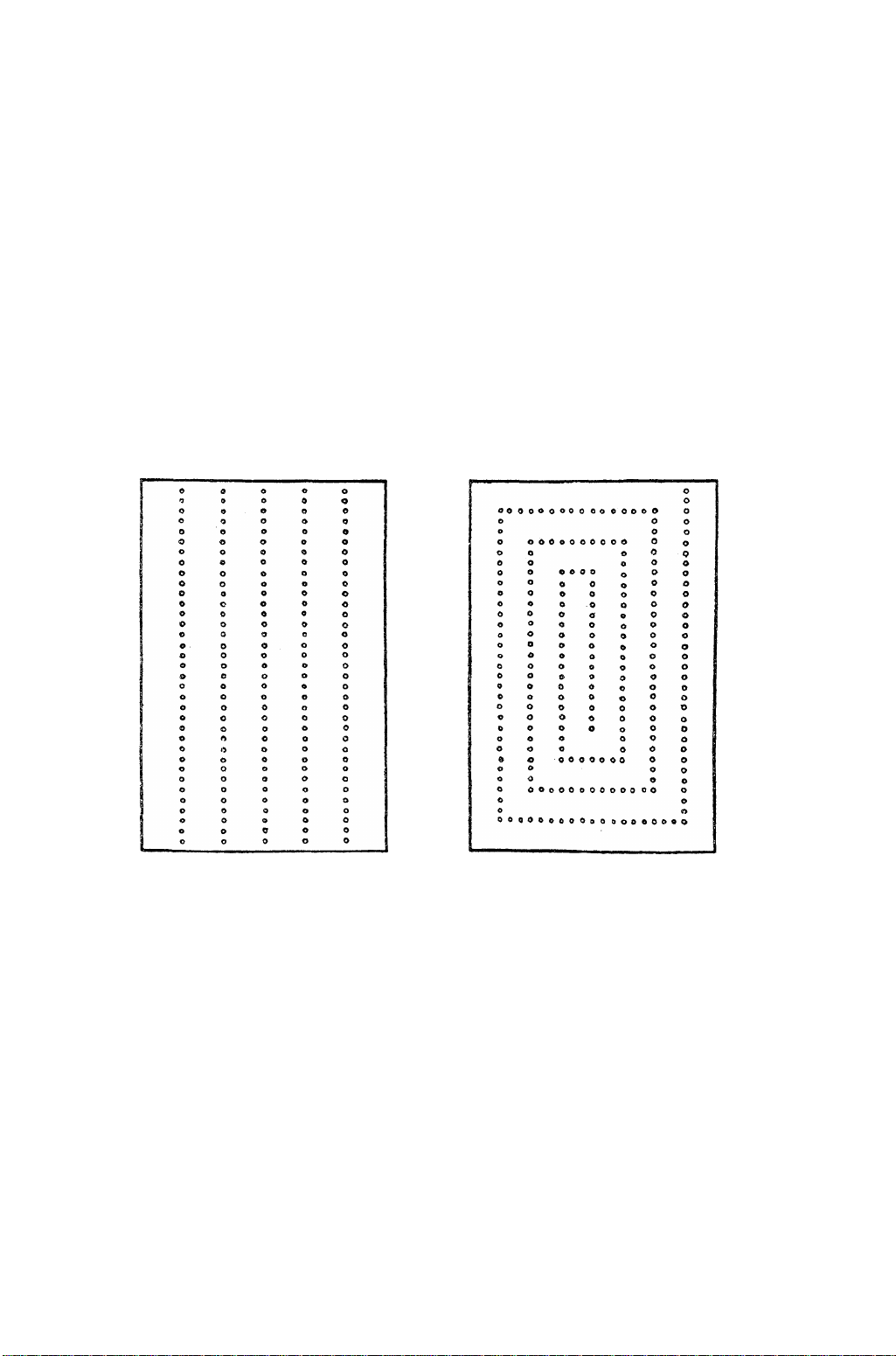

Practise Straight Stitching with Paper.

It is well to practise straight stitching with paper and without thread

until the operator can follow a line with ease before actually sewing, as crooked

Fig. 4. S.^mples of Stitching.

F'ig. 5- Pr.^ctice on Paper.

stitching will ruin a garment. Provide a few sheets of pad paper measuring

about six by nine inches, and with a pencil and ruler draw lines thereon

lengthwise about a quarter of an inch apart. Practise following these lines

with stitching until perfect results are obtained. See Fig. 4.

The next practice should be with a sheet of paper of the same size. Begin

by stitching along one edge, keeping the edge of the paper even with the

right-hand edge of the presser foot. When near the corner, stop the machine

with the needle in the paper, raise the presser bar and turn thè paper ready

to stitch along the next side ; continue along the two remaining sides of the

paper and then use the first line of stitching as a guide, making a similar

pattern to that shown in Fig. 5. This gives practice in turning corners, as

well as in making a straight line of stitching by using the edge of the presser

foot as a guide. A medium length of stitch should be used for this practice.

By following these suggestions the beginner will acquire a sufficient

knowledge of speed and control of the machine to enable her to proceed with

actual stitching.

6

Page 7

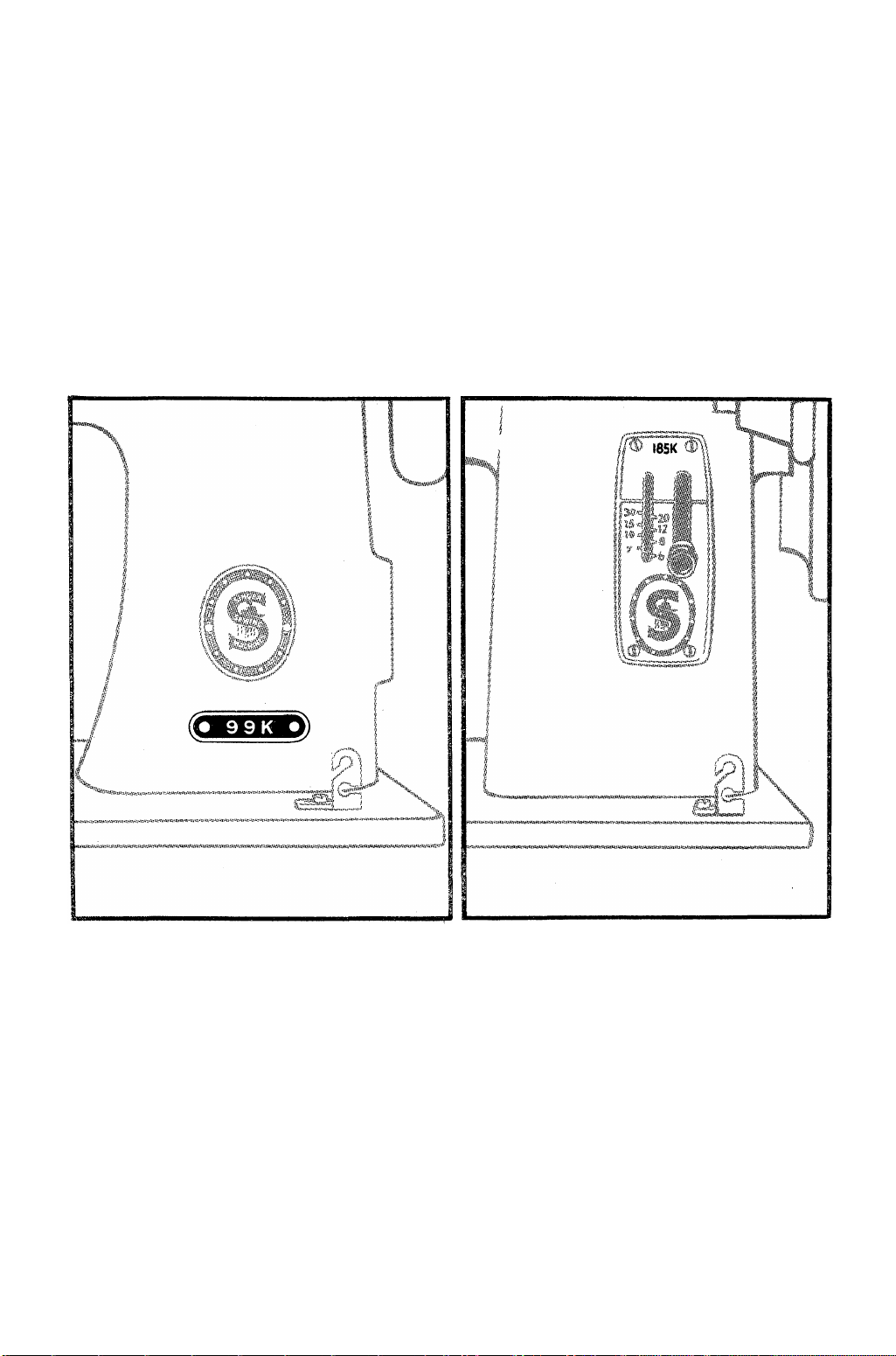

Know the Model Number of Your Machine.

To make full use of the instruction contained in this book, it will be to

your advantage to know the model number of the Sewing Machine you are

using. On all except the oldest Singer Machines, the model number will be

found printed on a small plate near the Singer trademark to the right hand

side of the machine head.

Fig. 6. Machin e Model Numbers.

Page 8

PREPARING THE MACHINE

FOR SEWING

Adjusting the Stop Motion Screw for

Winding Bobbins.

In preparing to sew with the machine,

first see that the bobbin is wound with

thread of suitable size for the material to

be sewn (see page 11).

It is necessary to understand the stop

motion of the machine by which the hand

wheel can be released when winding bobbins,

thus permitting the winder to operate with

Fig. 7. Releasing the Stop Motion.

wheel and turn the stop motion screw over towards you, as shown in Fig. 7.

out running the stitching mechanism. To

release the stop motion, hold the hand

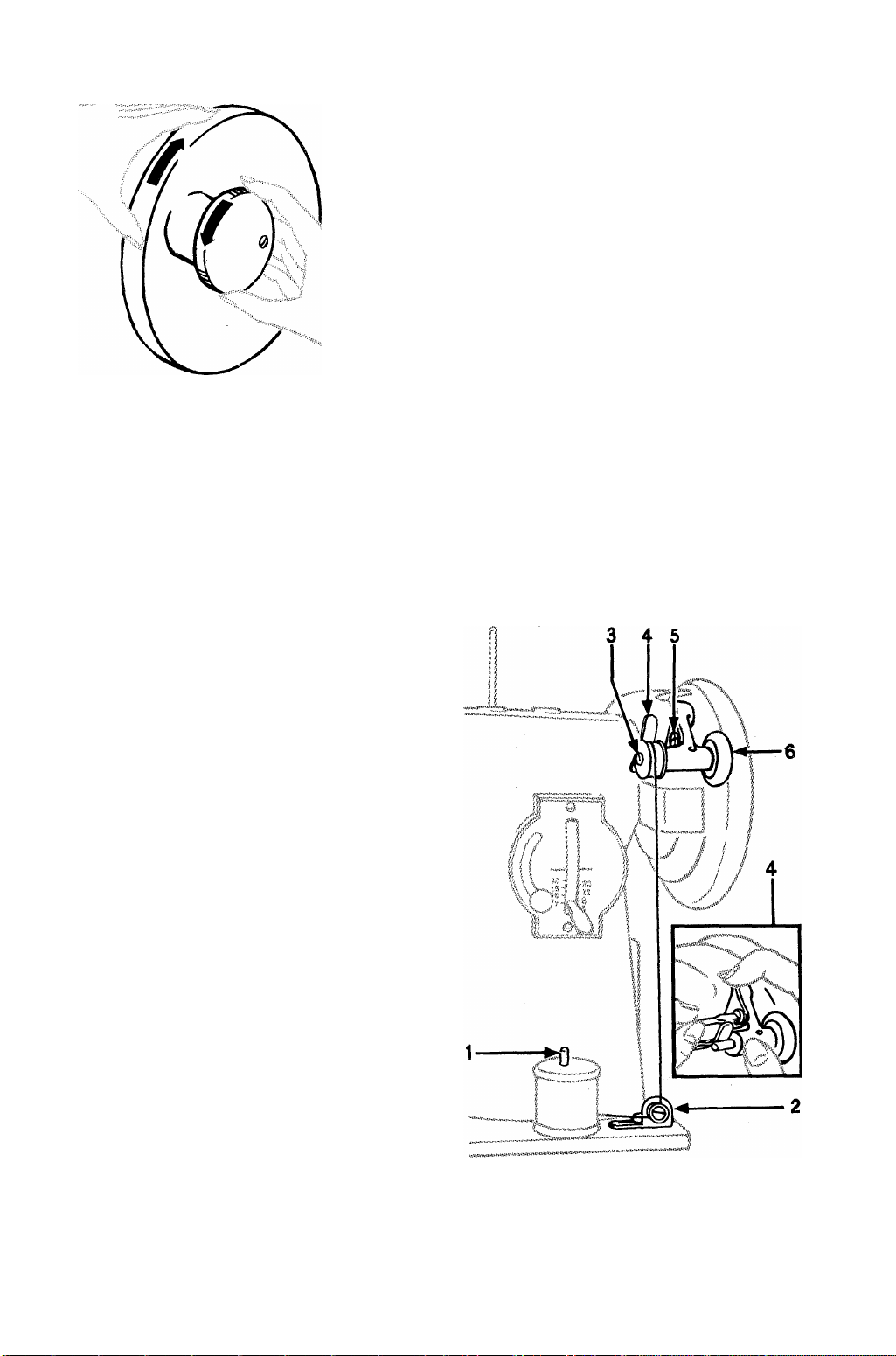

To Wind the Bobbin—Machines 15K80, 15K110 and 201K.

Loosen stop motion screw.

Place empty bobbin on

spindle.

Place spool of thread on spool

pin.

Thread machine as shown in

Fig. 8.

Hold end of thread and start

machine.

Break off end of thread after a

few coils have been wound on

bobbin and restart machine

until bobbin is filled when

winder will stop automatical-

ly-

To Increase Pressure of

Rubber Ring against hand

wheel—

# Press down winder until latch

(4) drops down and holds it.

Then loosen screw (5).

# Push back upper end of

slotted plate (see inset, Fig. 8)

as far as it will go and at same

time press winder against

hand wheel.

• Tighten screw (5).

• Raise latch to release winder.

Fig. 8.

Page 9

To Wind the Bobbin—Machine 99K (New Style),

Loosen stop motion screw.

Place empty bobbin on winder

spindle.

Turn bobbin until hole in

right side engages pin in

spindle.

Press winder down until latch

engages.

Place spool of thread on spool

pin.

I Thread machine as shown in

Fig. 9.

) Hold end of thread and start

machine. (End of thread will

break off after a few coils have

been wound on bobbin).

) When bobbin is full, winder

will stop automatically.

► Remove bobbin and retighten

stop motion screw.

Fig. 9.

To Wind the Bobbin—Machines 185K and 327K

• Loosen stop motion

screw.

• Place empty bobbin on

spindle.

• Press bobbin winder

down against hand

wheel.

• Thread machine as

shown in Fig. 10.

• Hold thread end and

start machine.

• When bobbin is full,

stop machine.

• Lift bobbin winder

away from hand wheel

and remove bobbin.

• Tighten stop motion

screw.

Fig. 10.

Page 10

To Wind the Bobbin—Machines 328K and 329K.

• Loosen stop motion screw.

• Place empty bobbin on

spindle.

• Press bobbin winder down

against hand wheel.

• Place spool of thread on

spool pin.

• Thread between tension discs

and through bobbin as shown

in Fig. 11.

• Hold end of thread and start

machine. (End of thread will

break off after a few coils have

been wound on bobbin).

When Bobbin is Full

• Stop machine.

• Lift bobbin winder away

from hand wheel and remove

bobbin.

• Tighten stop motion screw. Fig. ij.

""""""""

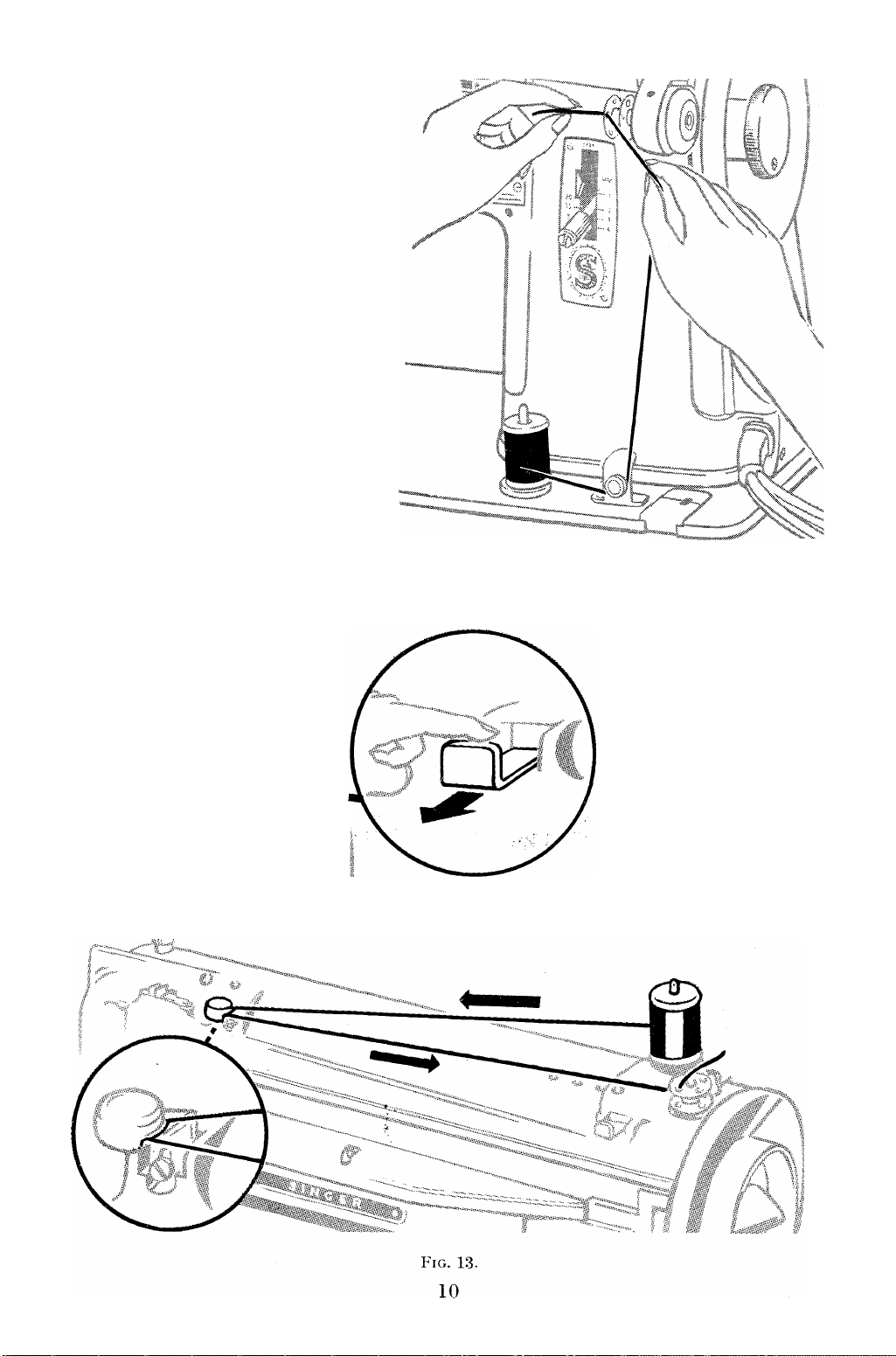

To Wind the Bobbin—Machine 404.

• Loosen stop motion

screw.

• Place bobbin on

spindle.

• Pull out bobbin

winder engaging

slide as shown in

Fig. 12.

.

Fig. ]2.

• Place spool of thread

on spool pin and

thread machine as

shown in Fig. 13.

Page 11

Wind the Bobbins Evenly.

Bobbins must be wound evenly in order that they may work properly in

the machine. In winding them, see that the thread is placed smoothly and

evenly. A correctly wound bobbin will insure the thread running smoothly

from the shuttle and prevent uneven stitching, which may occur if the bobbin

is not properly wound.

15K80,15K110, 99K (New Style), 185K, 201K, 327K, 328K and 329K.

If the thread does not wind evenly on the bobbin, loosen the screw which holds

the bobbin winder tension bracket (see 2, Fig. 8) on the machine bed and

slide the bracket to the right or left as may be required, then tighten the screw.

Always have a sufficient quantity of bobbins on hand and never wind

thread on a partly wound bobbin containing thread of another colour.

Bobbins so wound are usually uneven and cause trouble in the bobbin case.

When a rubber ring becomes worn or oil has come in contact with it, the

ring will not grip the wheel and will slip when winding a bobbin. A worn or

oily ring should be replaced.

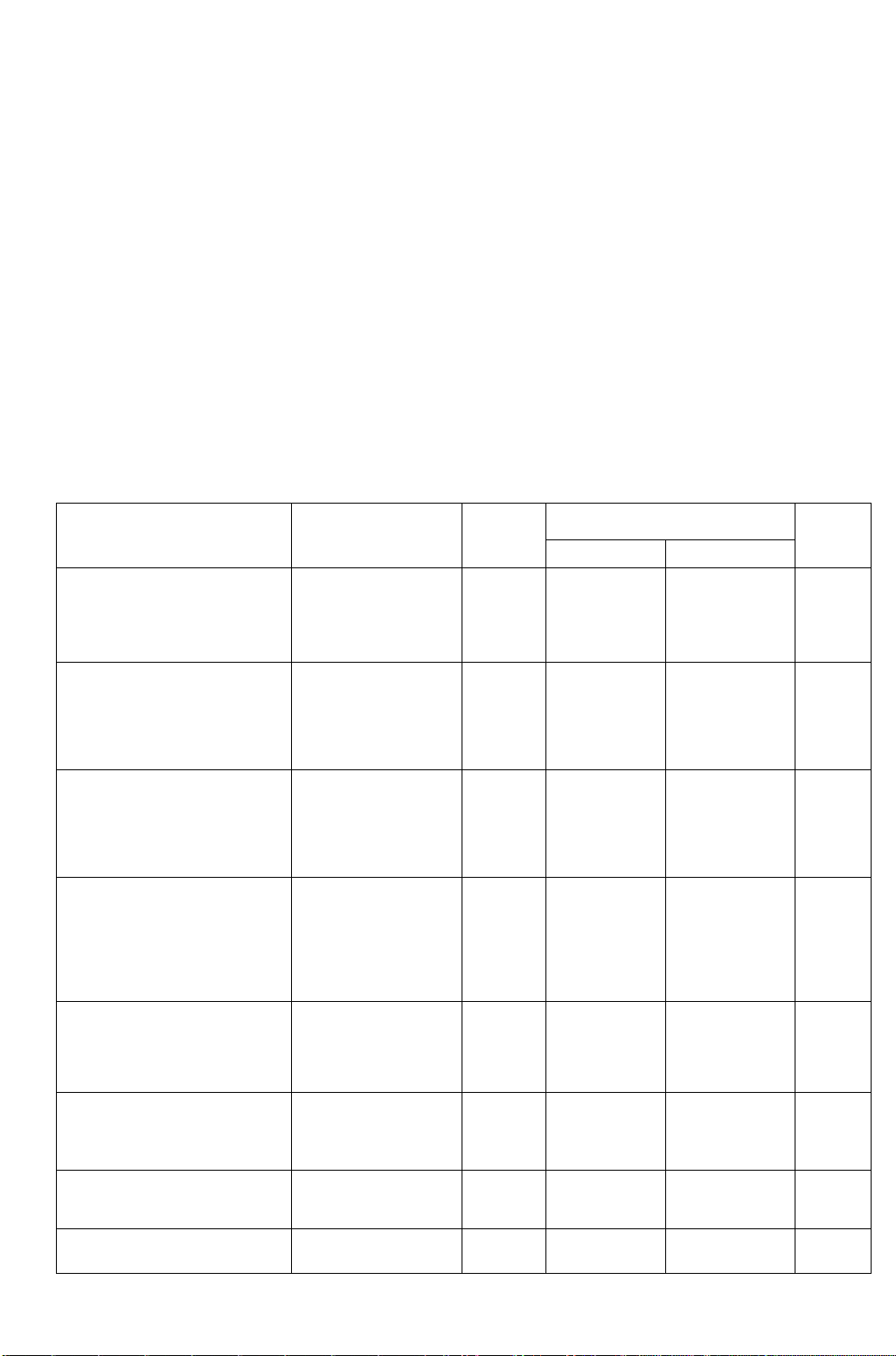

Relative Sizes of Needles and Threads.

Needles used. Catalogue 2020 (15 x 1

Types of Fabrics Thr ead Sizes

Filmy Materials

Comparable to Net—

100 Cotton

Marquisette —Chiffon—

Silk—Chiffon Velvet—

Ninon—Nylon Sheers

Sheer Materials

Comparable to Lawn—

80 to 100 Cotton

Organdie—Dimity—Batiste

—Pure Silks—Paper Taffeta

—Silk—Synthetic Tricots—

Synthetic Sheers

Lightw eight Materials

Comparable. to Gingham—

50 to 80 Cotton

Chambray Sheers—Wool

Crêpe—Taffeta—Synthetic

V el ve ts—Satin—Synthe tic

or Wool Jersey

Medium Lightweight

Materials

Comparable to Poplin—

Pique—Percale—Cretonne

50 Mercerised

60 to 80 Cotton

—Chintz—F aille—Bengaline

—Wool Flannel—Crêpe—

Lightweight Suitings

Medium Heavy Materials

Comparable to Cotton

Heavy-Duty Mercer

Vel ve teen—Corduroy—

Gabardine—Rep—Coatings

40 to 50 Cotton

and Heavy Suitings

Heavy Materials

Comparable to Sailcloth—

Heavy-Duty Mercer

Denim—T icking—

Overcoatings

Ver y Heavy Materials

Comparable to Canvas—

30-40 Cotton

40 to 60 Linen

20-24 Cotton

Duck

Plastic Materials

Nylon or

Mercerised Cotton

A Silk

Nylon

A Silk

Nylon

A Silk

Nylon

A Silk

Nylon

ised

A Silk

ised

A Silk

Machin e

Needle

Sizes

0

11 12-15 15-20

14

14

Machin e Stit ches per Inch

Inside Seams

Top Stitching

15-20 20-30

12

12

16 10

16-18

8

18-19 6

9-11

10

Hand

Needle

10

16

16 7-8

12

10

4-5

8

12

9-11

9

8

6

o

O

11

Page 12

The Importance of using Correct Needles and Thread.

A perfect stitch can be obtained only when the thread is selected to suit

the material to be stitched and the needle is of the correct size for the thread.

If the needle is too fine for the thread and material, it is likely to break when

crossing a seam. If a coarse needle is used on fine material, the perforations

made will show in the finished work. A table of correct needles for the various

sizes of silk and cotton is given on page 11. This table should be carefully follow

ed when ordering needles and wiien changing them for various classes of work.

NOTE : It is essential for good work that the needle be perfectly straight

and have a sharp point. Only SINGER needles should be used in SINGER

machines.

Needle Threaders.

No. 161307.

Fig. 14. Singer Needle Th readers.

The Singer Needle Thread

ers save time, are inexpen

sive, simple to use and

indispensable to all. They

can be used for threading

hand sewing needles as well

as sewing machine needles.

12

Page 13

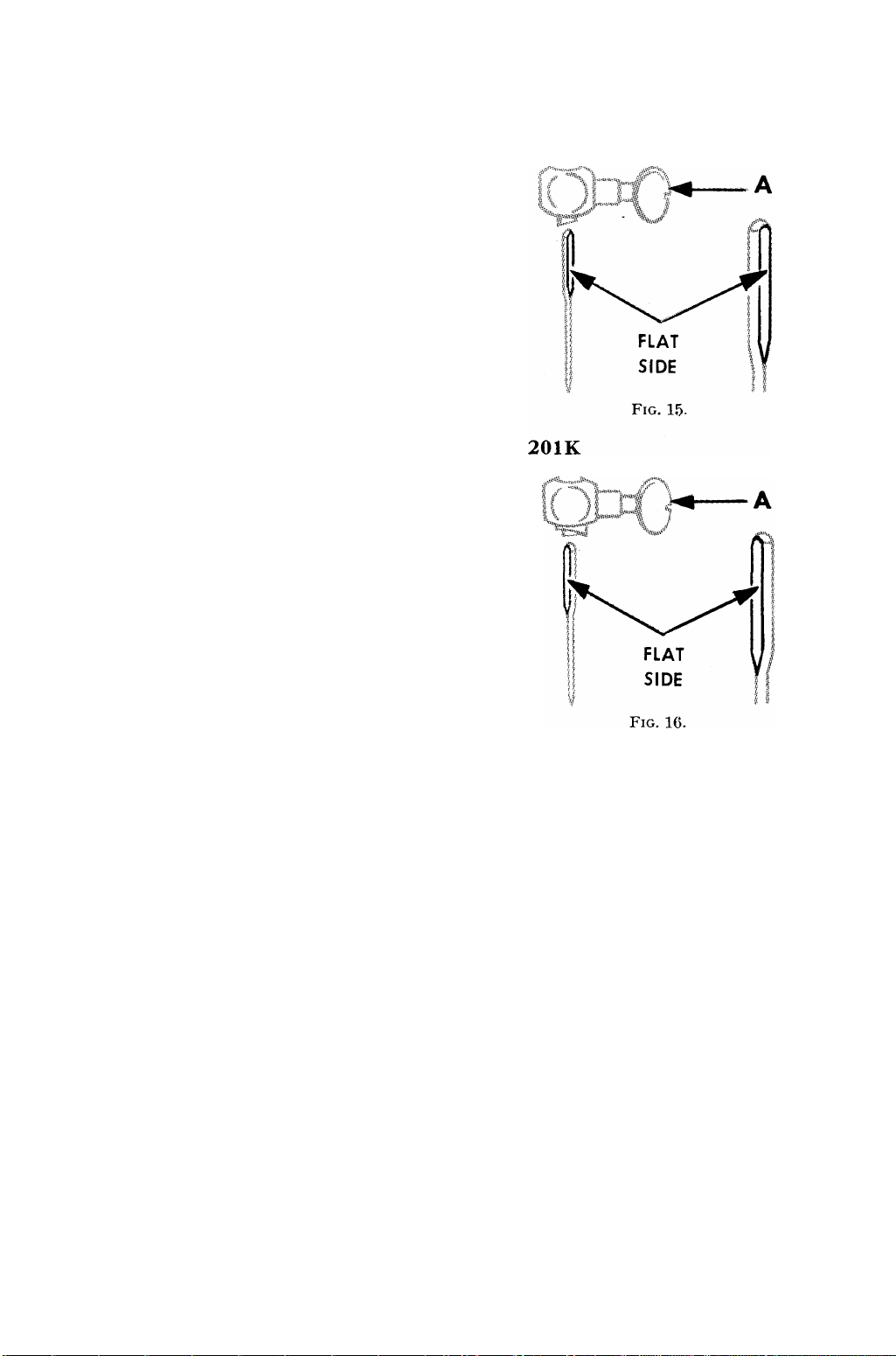

To Set the Needle in Machines 15K, 66K, 99K and

(See Fig. 15).

Raise needle bar to its highest point

by turning hand wheel toward you.

Loosen clamp screw A.

Insert needle (flat side to the right)

up into needle clamp as far as it will

go.

Tighten clamp screw A.

(See Fig. 16).

Raise needle bar to its highest point

by turning hand wheel toward you.

Loosen clamp screw A.

Insert needle (flat side to the left)

up into needle clamp as far as it will

go.

Tighten clamp screw A.

185K

To Set the Needle in Machines 327K, 328K, 329K and 404

(See Fig. 17).

Raise needle bar to highest

point by turning hand wheel

toward you.

Loosen needle clamp screw.

Insert needle upward into

clamp as far as it will go,

3?| f\ 1

f""'" 1 r“'i

MM

■L.f:!i■/

...

i

H" \j'

t\

with flat side of needle to

back and long groove to

ward you.

Tighten needle clamp screw.

f f I. 'i ]

,■0"^ i / \'|

,#'• ■ ?/■ >/ /

Fig. 17.

LONG GROOVE

TOWARD YOU

N.B.—You will note that the side of the needle with the flat on the

shank has a short groove at the eye while the other side has a long

groove. The thread must pass down this long groove when sewing. If the

needle is not placed correctly in the machine it will not sew.

Particular attention is drawn to the fact that in Machine 201K the needle is

set with the flat side of the shank to the left; on 327K, 328K and 329K Machines

the flat side is to the hack, while in the other Singer family machines referred to in

this hook the flat side must he to the right.

13

Page 14

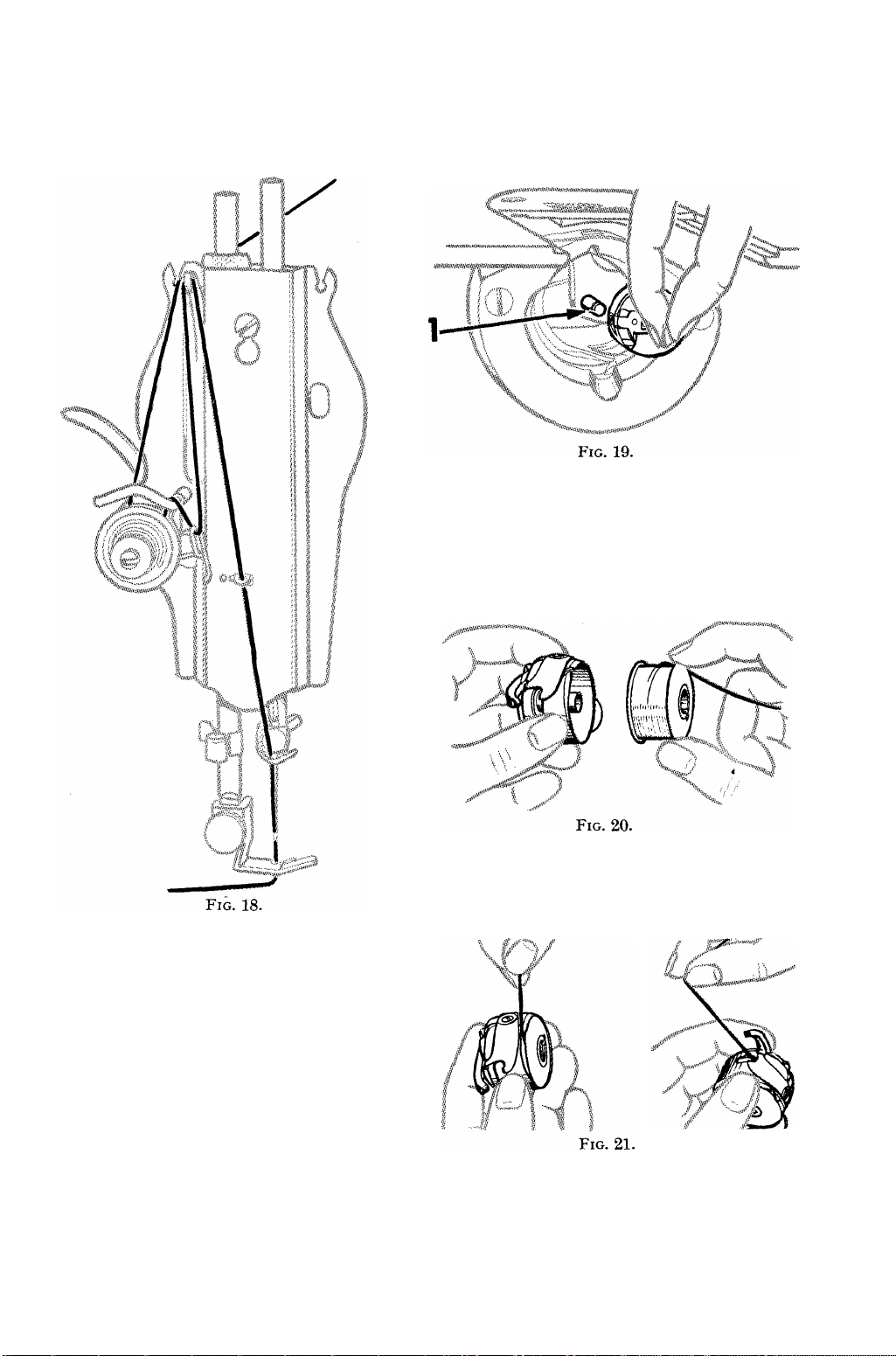

Threading Central Bobbin Machine No. 15K.

UPPER THREADING UNDER THREADING

Open bed slide.

Open bobbin case latch as shown in

Fig. 19 and withdraw bobbin.

Release the latch, turn the bobbin

case downward and bobbin will

drop out.

Raise take-up lever to its highest

point.

Place spool of thread on spool

pin.

Thread machine as shown in

Fig. 18.

Thread needle from left to right.

Hold bobbin case with slot in edge

at the top and wound bobbin with

thread leading on top towards the

right, as shown in Fig. 20.

Pull thread into slot as shown in

left hand illustration. Fig. 21.

Draw the thread down, under the

tension spring, and to the left into

the delivery eye at its end, as shown

in right hand illustration. Fig. 21.

14

Page 15

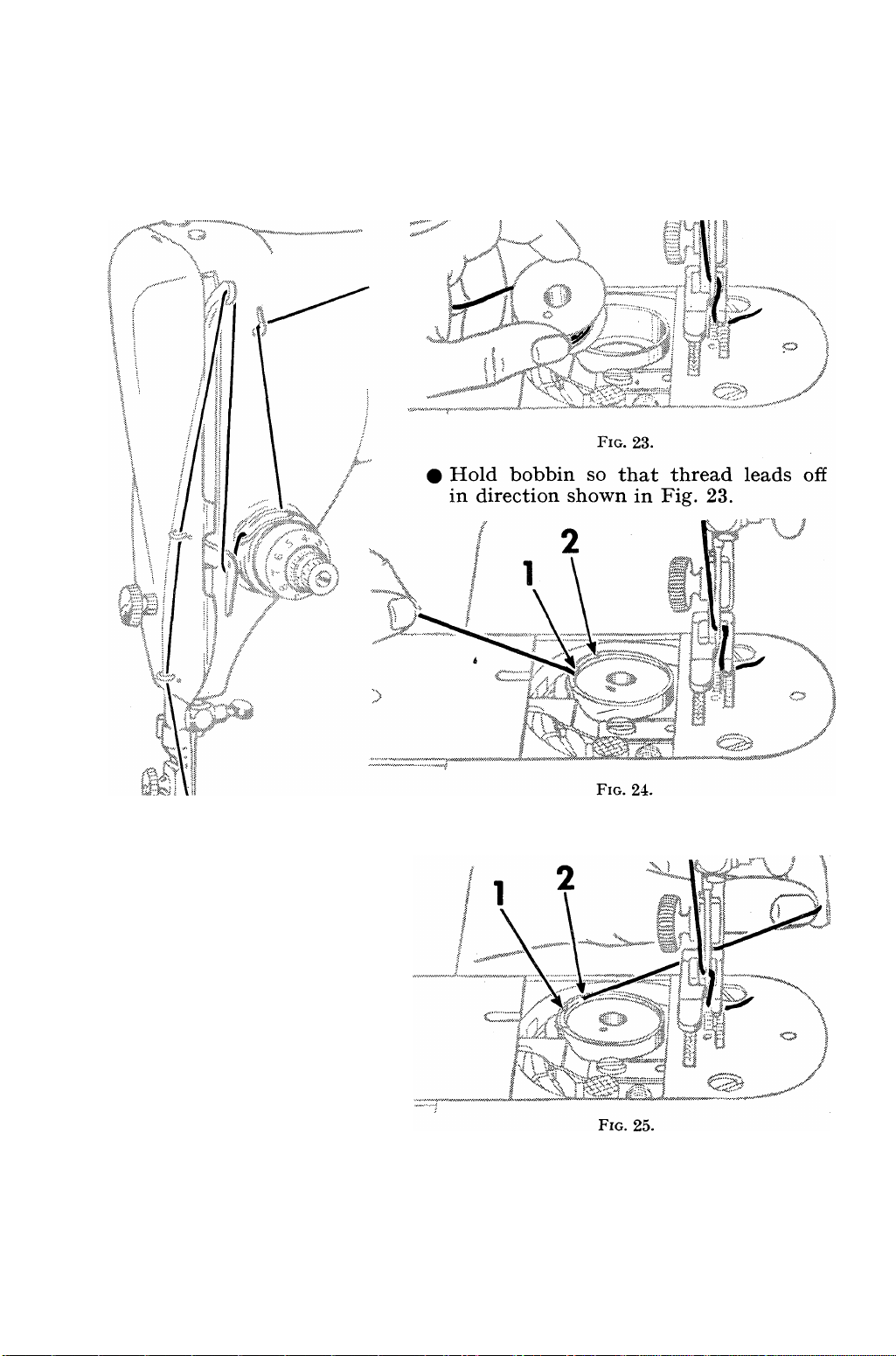

Threading Oscillating Hook Machines Nos. 66K, 99K and 185K

UPPER THREADING UNDER THREADING

Fig. 22.

# Raise take-up lever to its

highest point.

# Place spool of thread on

spool pin.

# Thread machine as shown in

Fig. 22.

# Thread needle from left to

right.

Place bobbin in case and draw thread

into slot 1, Fig. 24.

Draw thread between case and tension

spring until it reaches notch 2, Fig. 25.

Pull about 3 inches of thread across

bobbin.

Close slide plate, allowing thread to

enter notch in slide plate.

15

Page 16

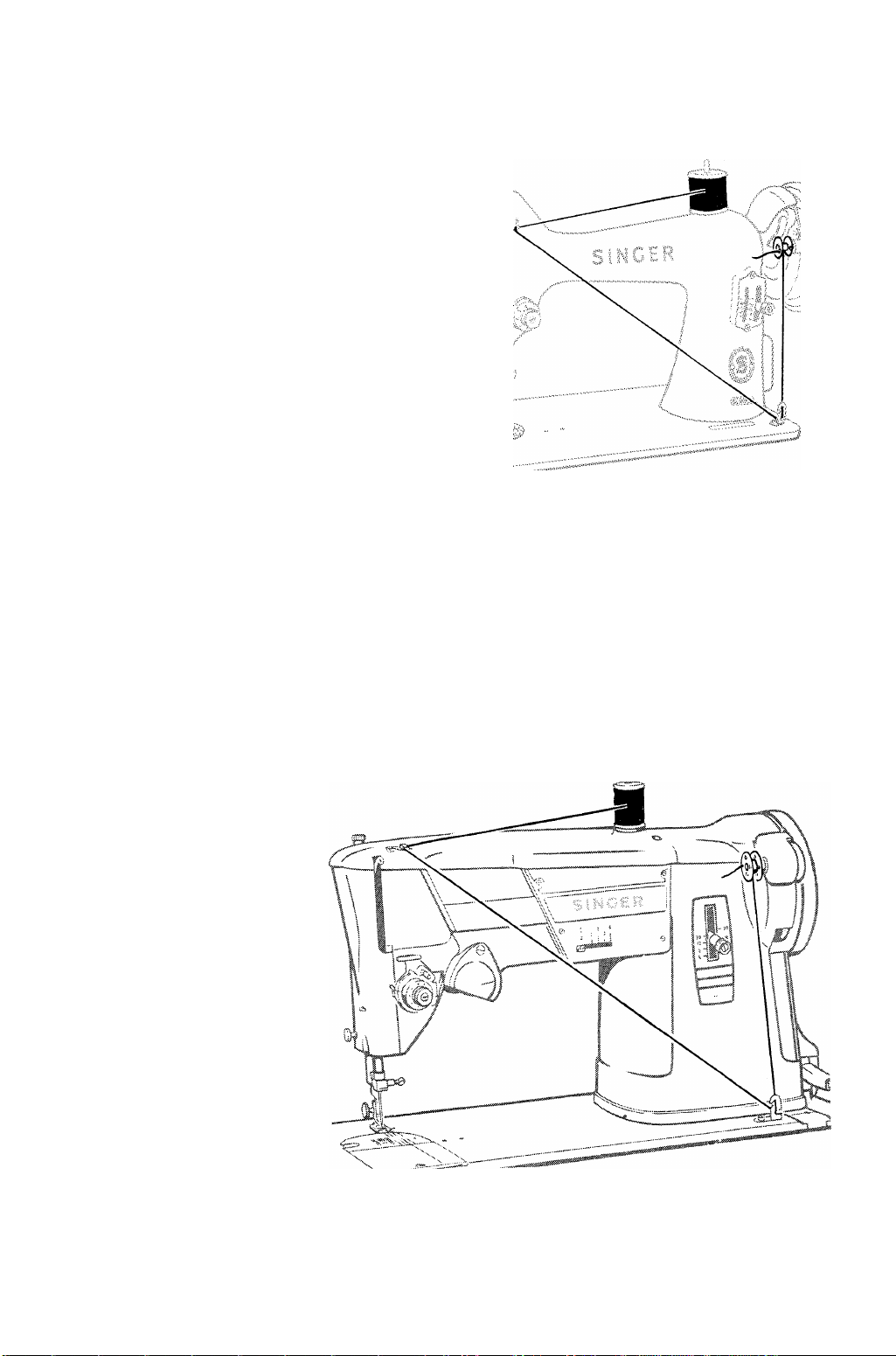

Threading Rotary Hook Machine No. 20IK.

UPPER THREADING UNDER THREADING

Hold bobbin so that thread leads

off in direction shown in Fig. 27.

/

Fig. 26.

Raise take-up lever to its highest

point.

Place spool of thread on spool

pin.

Thread machine as shown in

Fig. 26.

Thread needle from right to left.

ii'l

11

II

%■ %

Place bobbin in case and draw

thread into slot 1, Fig. 28.

Draw thread between bobbin case

and tension spring until it reaches

notch 2, Fig. 29.

Pull about 3 inches of thread

across bobbin.

Close slide plate.

Fig. 29.

16

Page 17

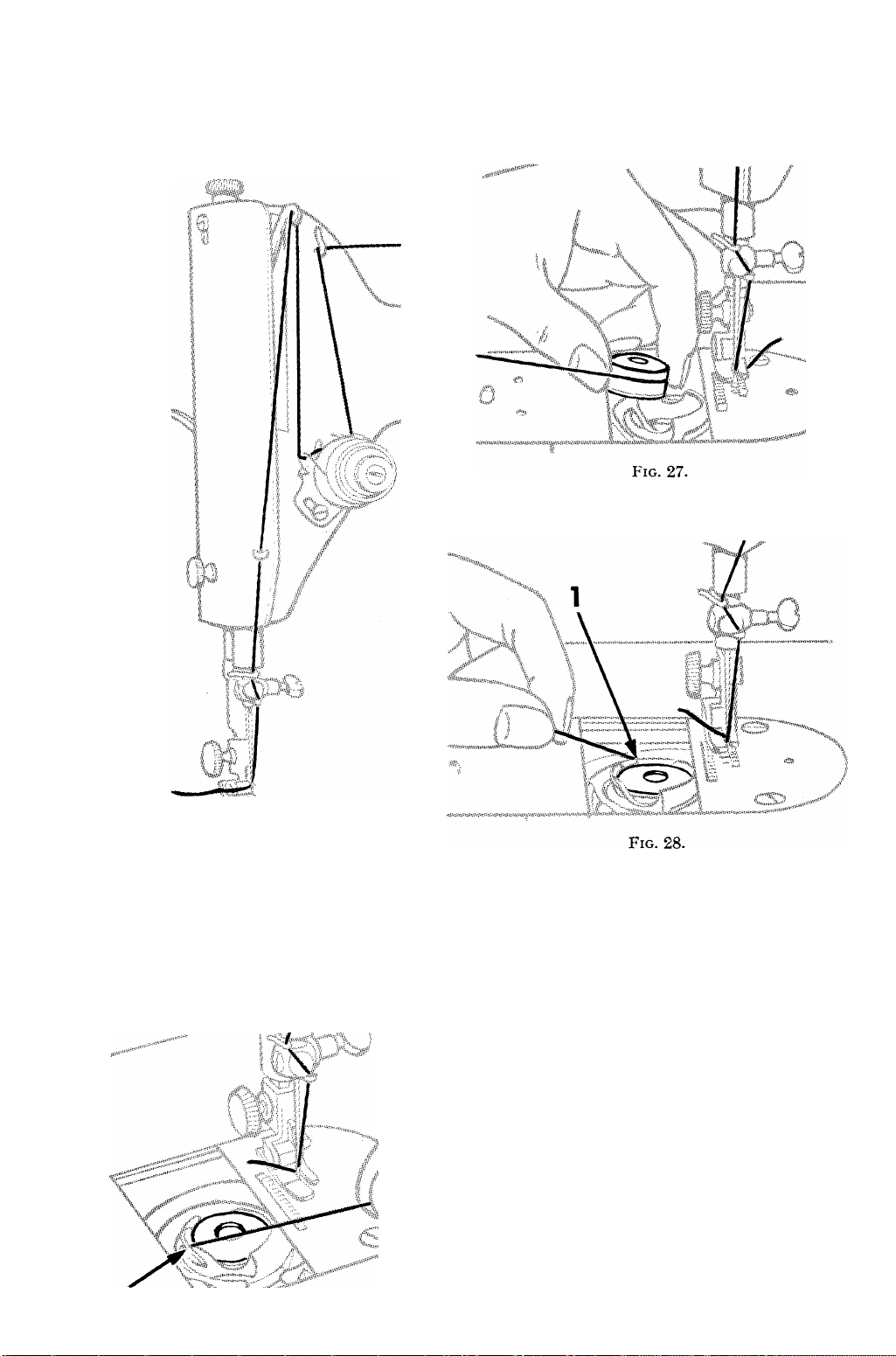

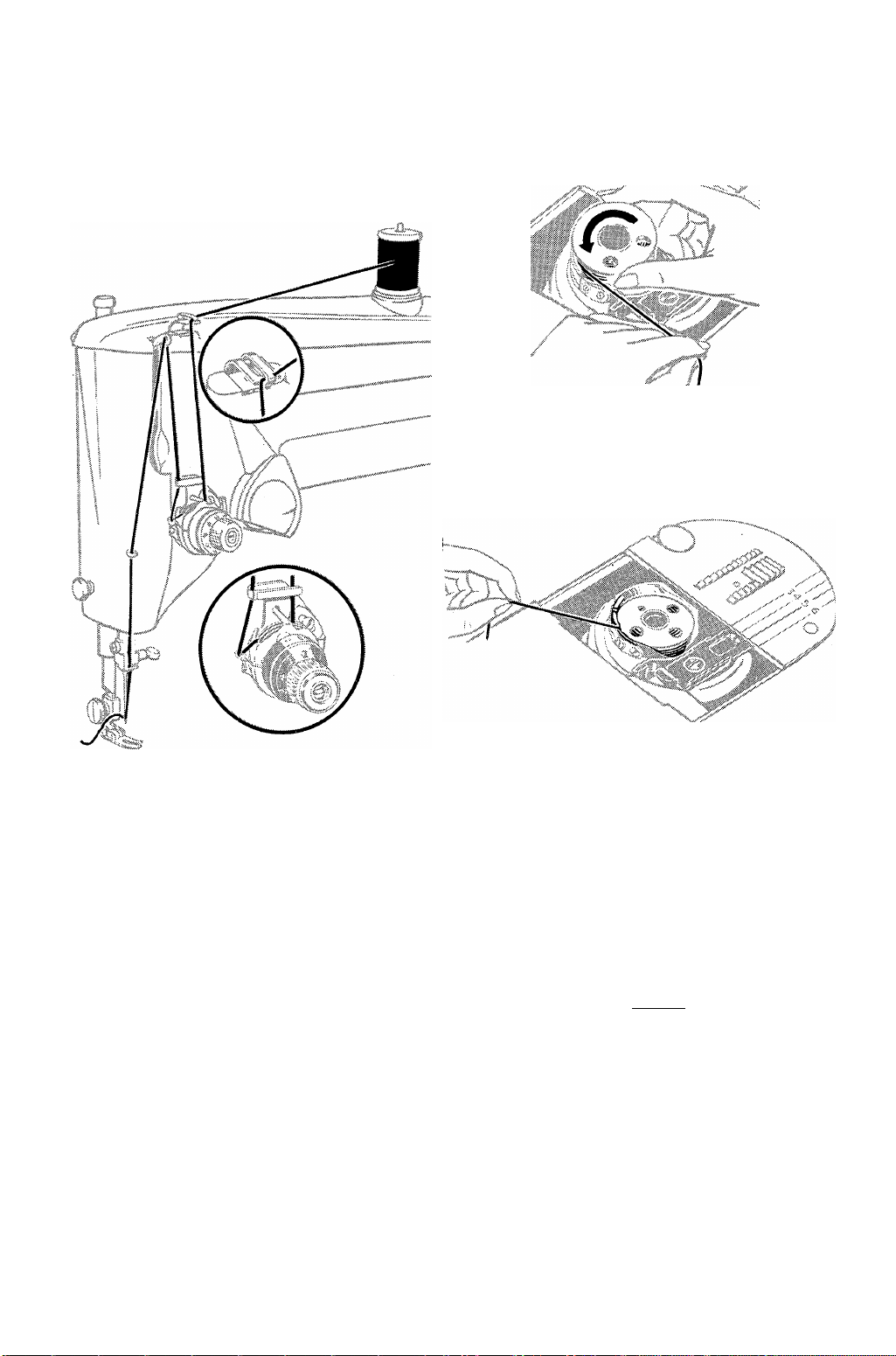

Threading Oscillating Hook Machines Nos. 327K, 328K, 329K and 404

UPPER THREADING UNDER THREADING

Fig. 31.

Open slide plate. Insert bobbin

with thread leading oil as shown in

Fig. 31.

"I

X,

Fig. 30.

Raise take-up lever to its highest

point.

Place spool of thread on spool

pin.

Thread machine as shown in

Fig. 30.

Thread needle from front to back.

Fig. 32.

Place bobbin in case.

Lead thread into slot and under

spring as shown in Fig. 32.

'X

I / %

/■

___

^ O /

Fig. 33.

Draw thread into notch at end of

spring ; pull about 3 inches of

thread across bobbin as shown in

Fig. 33.

Close slide plate.

17

Page 18

The Necessity for Proper Tensions.

The tensions on the sewing machine must be adjusted to suit various

materials. There are two tensions, the upper and the lower. The upper

tension controls the thread from the needle, while the lower tension controls

the thread from the shuttle or bobbin case.

The definition of the word tension as given in the dictionary is : “stress

by pulling.” It is the pulling of the threads together that completes a stitch

made by the sewing machine. After the needle thread passes around the

shuttle, the upper thread is pulled by the take-up lever to take up the slack

and complete the stitch by locking both threads together. If both threads

are under proper tension, the lock occurs in the centre of the material and a

perfect stitch is formed, as in Fig. 34.

To Regulate the Tensions.

Fig. 34. Co rrect Stitch.

For ordinary stitching, the tension

on the upper and under threads should

be equal and just sufficiently strong to

lock both threads in the centre of the

work as shown in Fig. 34.

If either tension is stronger than the

other, imperfect stitching will be the

result. (See Figs. 35 and 36).

Fig. 35. Needle Thread Tension.

TOO Stro ng.

~V "• V~

Fig. 36. Needle Thread Tension

TOO Weak.

A correct stitch can usually be obtained by

varying the tensions on the upper or needle

thread (see Fig. 37)—To increase the tension on

the upper thread, turn the thumb nut to the right ;

to lessen the tension turn the nut to the left.

The tension on the under thread is regulated

by the small screw holding the spring under which

the thread passes on the long shuttle or the round

bobbin case, but as all machines are correctly adjusted

before leaving the factory, it is seldom necessary to

alter this under tension. Should it become necessary,

however, to do so, tighten the tension spring screw to

Thu mb Nut

Fig. 37.

increase the tension and loosen the screw slightly to

lessen the tension, using the small screwdriver provided

for the purpose.

The tension on the upper thread should be adjusted only when

the presser foot is down, and the amount of tension should be so that

the pull on both the upper and the under threads is as nearly as

possible equal.

18

Page 19

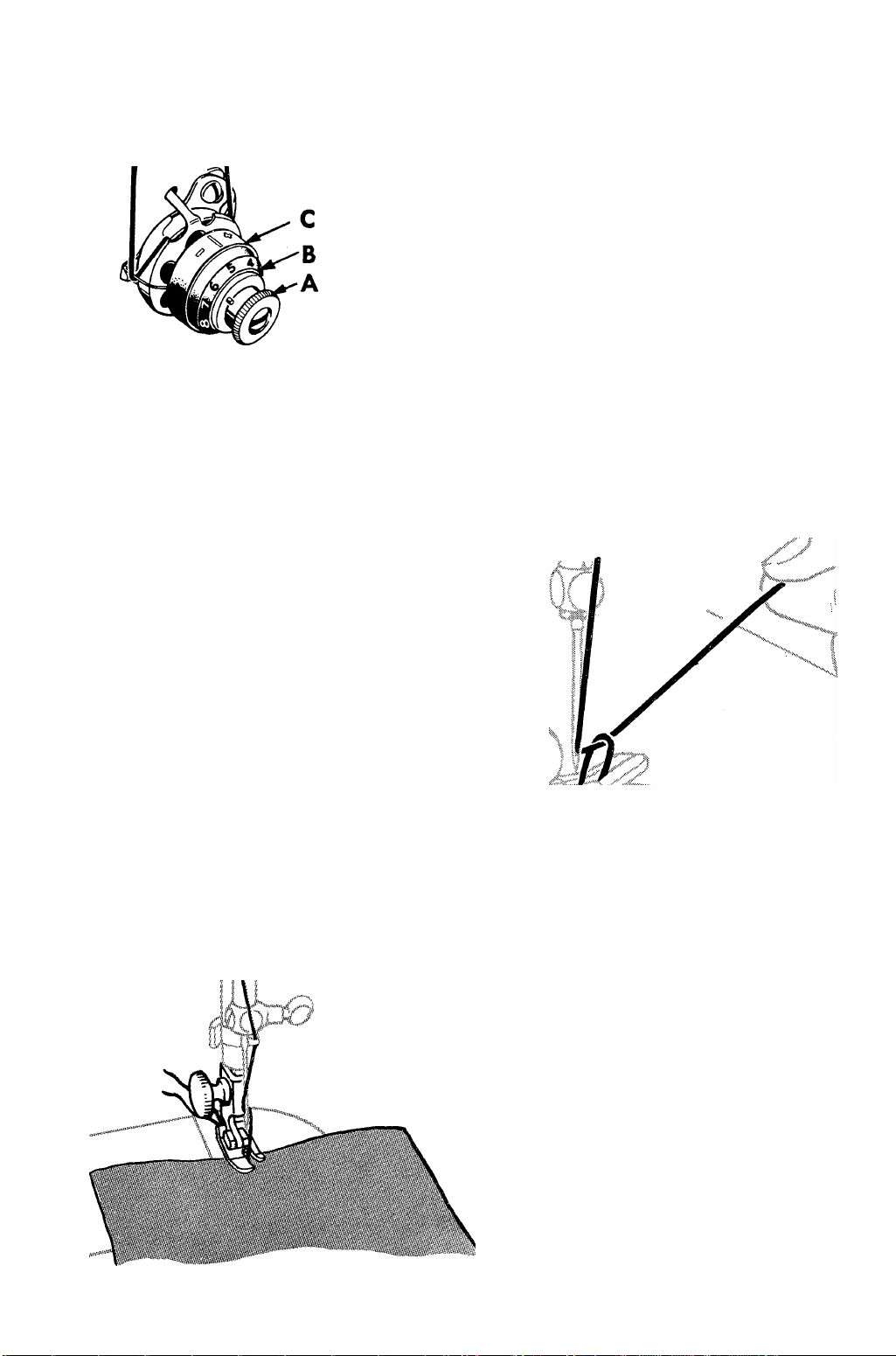

Machines 99K, 185K, 201K, 327K, 328K and 329K are furnished with a

tension indicator and flange (C and B, Fig. 38). The index flange (B) is

marked with numbers 0 to 9 indicating the

different degrees of tension that can be produced.

By noting a particular number opposite the

white line when set for a satisfactory tension on

work being stitched, this number can be readily

reverted to when changing from one class of

material to another. The higher numbers

denote increased tension and the lower numbers

less tension. Notice also that the tension

indicator (C) is marked with the signs + and —

which indicate the direction to turn the thumb

Fig. 38.

nut (A) for more or less tension.

To Prepare for Sewing.

Pull sufficient thread through the needle and with the left hand hold the

end, leaving it slack from the hand to the needle. Turn the hand wheel

towards you until the needle moves

down and up again, thus catching

the under thread ; then, when the

take-up lever is at its highest point,

pull the end of the needle thread

you are holding and the under

thread will be brought up with it

through the needle hole in the

throat plate, as shown in Fig. 39.

Lay both ends of thread under and

to the back of the presser foot, and

having inserted the material to be

stitched, lower the presser bar lifter

and commence to sew by turning

the hand wheel toward you.

1/

NOTE.—Do not try to help

the feeding of the work by pulling

\

the material, as this may deflect

the needle and cause it to break.

The machine feeds without any

Fig. 39. Pulling Up Under Thread.

assistance.

The edge of the garment to

be stitched should be placed just

far enough under the presser foot

to allow the first stitch to be taken

in the material. Never place the

material so that the first stitch

will not be taken in it, as this

would cause the thread to become

entangled in the lower mechanism.

Always lower the presser foot

before starting to sew. See Fig. 40

for the proper starting of material

under the presser foot.

Fig. 40. Beginning a Seam.

19

Page 20

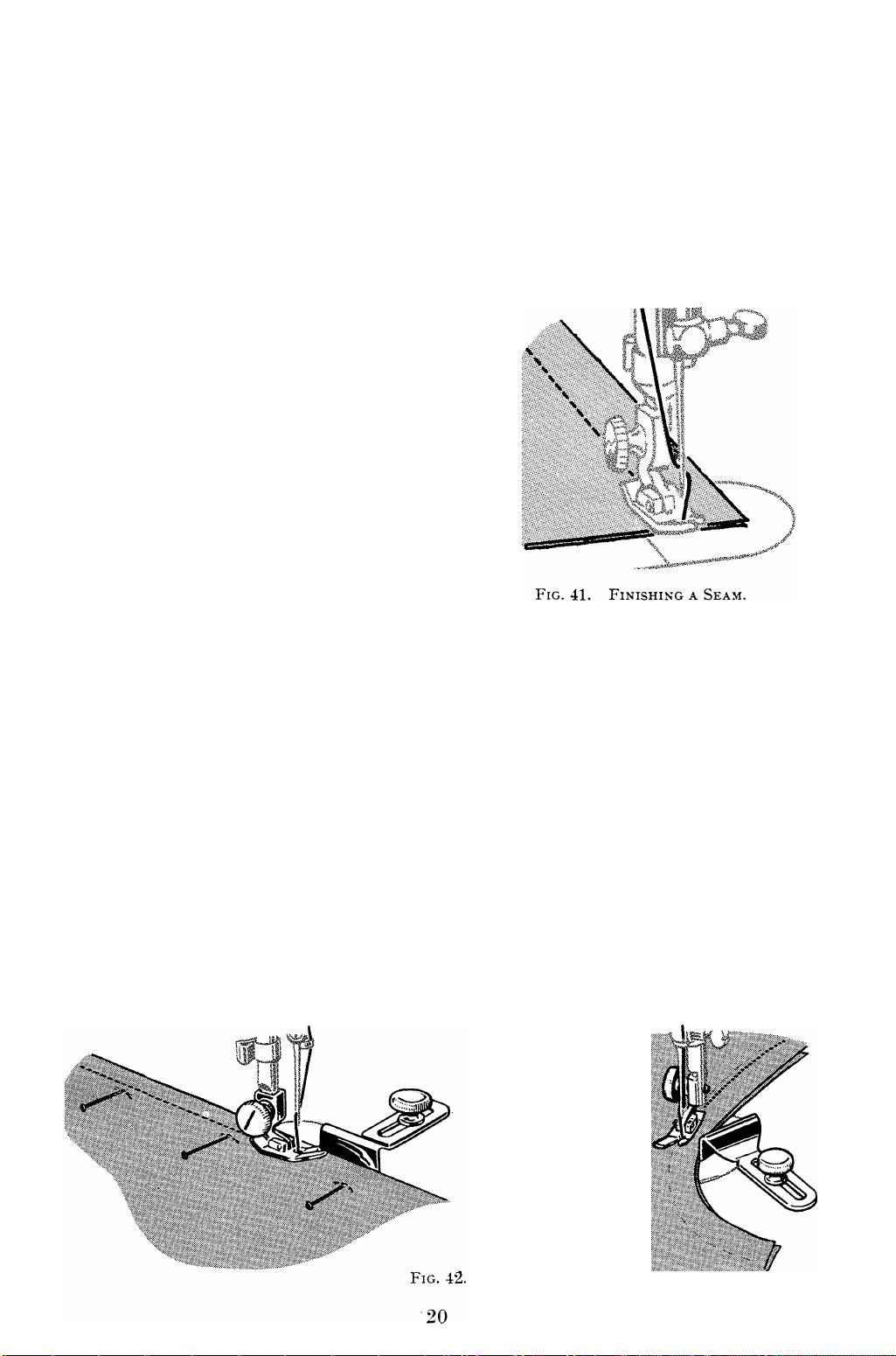

Finishing a Seam.

When finishing a seanx, never sew beyond the end of the material. Stop

the machine by placing the hand on the hand wheel shortly before the end

of the seam is reached. (See Fig. 41). This will prevent the thread from

becoming entangled in the lower mechanism.

Do not attempt to release the material from the machine until the takeup lever is at the highest point. When the take-up is in this position and the

presser foot is raised, the upper tension is released.

Always remove the material from

the machine by pulling it back and to

the left, and sever the threads by pass

ing them over the thread cutter. Hold

thread with both hands and cut with a

quick downward motion.

Always leave 3 or 4 inches of thread

to prevent it being pulled through the

needle when commencing to sew the

next seam.

On machines equipped with rever

sible feed seams can be reinforced at

the beginning and the end by back

tacking.

Hints for Sewing Various Seams.

Always keep the bulk of the material to the left of the presser foot. This

allows greater freedom of feeding than when the garment is allowed to pass

under the arm of the machine.

Stitch bias seams with the bias instead of against it. For example, when

sewing two bias seams on a skirt, start at the bottom of the garment and

stitch up. This prevents the seams from stretching. The tensions should be

sufficiently loose to prevent puckering of the seams.

When sewing a straight edge to a bias edge, place the bias piece against

the feed. This allows the feed to take care of the possible stretching of the

bias and permits the operator to guide the stitching from the warp or length

wise threads of the material.

The Cloth Guide.

The cloth guide is an aid to straight stitching, and is fastened to the

machine by means of the thumb screw, as shown in Fig. 42. It can be

adjusted to various distances from the needle, as desired.

Page 21

To Regulate the Length of Stitch.

When stitching fine material use a fine needle, fine thread, and a short

stitch. Heavy material requires a coarse needle and thread and a longer

stitch. (See chart on page 11).

The stitch on the 15K26 machine is regu

lated by the thumb screw in the slot on the

arm (see Fig. 43). To lengthen the stitch on

this machine, loosen the thumb screw and ;;

move it downwards. To shorten the stitch fV'

move the screw upwards. When the desired s , ,

length of stitch is obtained tighten the thumb

screw. The stitch on the 15K80 is regulated |

in the same way except that the thumb screw

is moved upwards to lengthen and down

wards to shorten.

About 18 stitches to the inch makes a

suitable seam for ordinary sewing. Sew on a

double thickness of material, measure off one

inch and count the stitches.

wmimirnmiimim

>:

....

! r~>vr->\

.--x MHjH

qn

I

Fig. 43. Stitch

Regulating Screw on

Singer 15K26 and 15K80

Machin es.

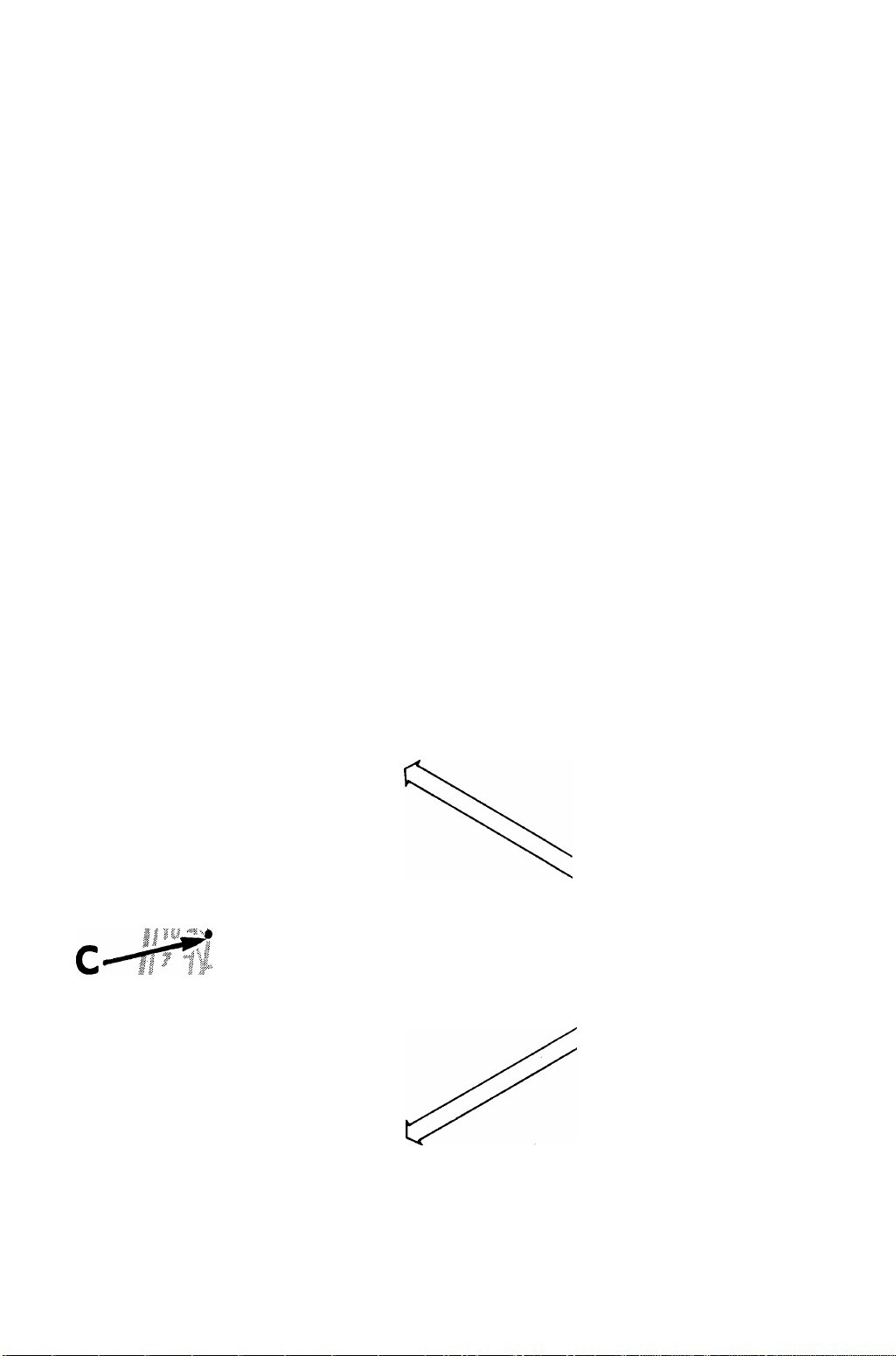

To Regulate the Length of Stitch and Direction of Feed on

Machines 99K (New Style) and 185K. (See Fig. 44).

Numerals on the indi

cator plate represent the

approximate number of

r

stitches per inch.

The “red dot” C indi

cates the stitch setting.

To set stitch length —

# Turn thumb nut to the

left.

# Move lever until “red

dot” C is at desired

stitch setting.

# Turn thumb nut to the

right until it rests

against indicator plate.

Once thumb nut is

against indicator plate,

JJJ

/

I

C

reverse stitching is ac

complished by raising

lever to its highest posi

tion.

Fig. 44.

21

Page 22

To Regulate the Length of Stitch and the Direction of Feed on

Machine 201K

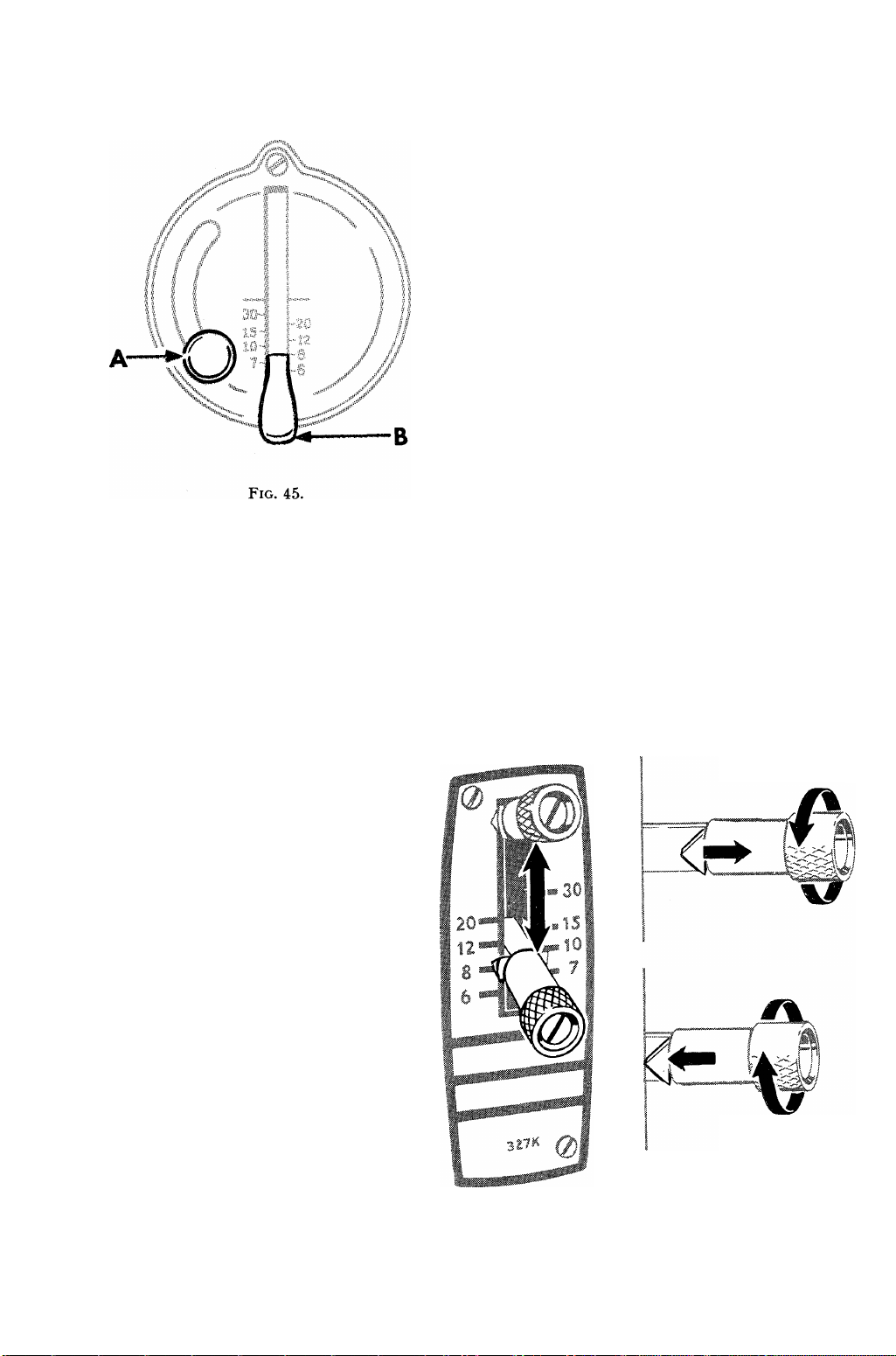

(See Fig. 45).

Numerals on the indicator plate

represent approximate number of stitches

per inch.

To set stitch length—

• Loosen thumb screw A and lower to

bottom of slot.

• Move lever B until its top edge is level

with desired stitch setting.

• Raise screw A as far as it will go and

tighten. Machine will now make the

desired number of stitches forward.

To reverse stitching—

• Set as above then raise lever B as far

as it will go.

To Regulate the Length of Stitch and Direction of Feed on

The numerals on the indi

cator represent the number of

stitches per inch.

To set stitch length—

• Release pointer by turning

thumb nut to the left.

• Position lever for desired

stitch length (the higher the

number, the shorter the

stitch length).

• Tighten pointer against indi

cator plate by turning thumb

nut to the right.

Once the pointer has been

tightened against the plate,

reverse stitching

plished by raising the lever to

its highest point.

is accom

Machine 327K

(See Fig. 46).

TO RELEASE

TO TIGHTEN

Fig. 4G.

22

Page 23

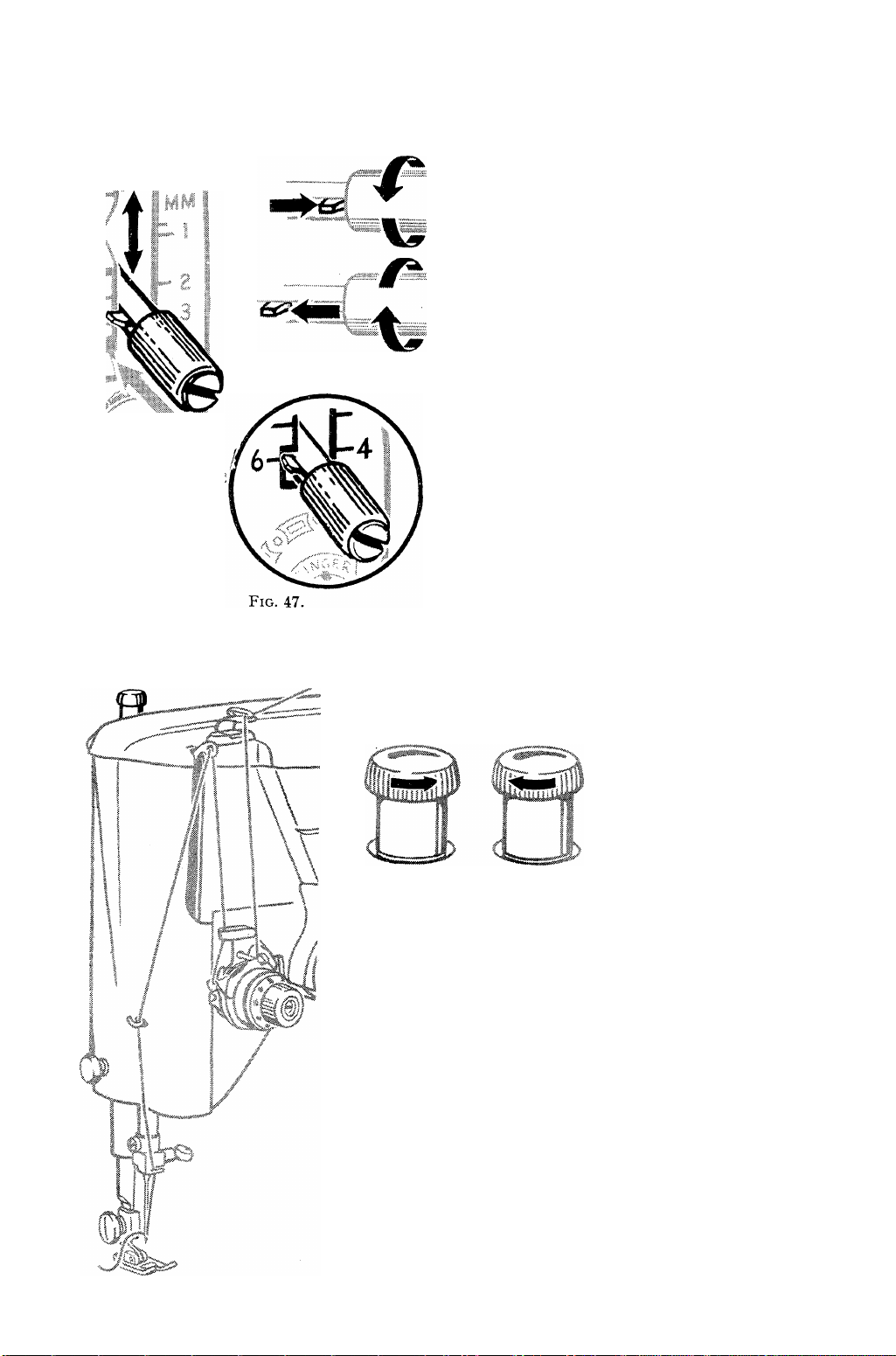

To Regulate the Length of Stitch and the Direction of Feed on

, / Machines 328K, 329K and 404. (See Fig. 47).

: i TO RELEASE

Numerals on left side of indi

cator represent number of stitches

per inch.

Numerals on right side represent

stitch length in millimeters.

Upper inclined area of the regu

lator represents stitch lengths above

20.

Lower inclined area of the regu

lator allows the No. 6 stitch length

TO TIGHTEN

setting to be “locked” in place when

stitching folds, pleats or multiple

layers of heavy fabric.

To set stitch length—

• Releasepointer by turning thumb

nut to the left.

• Position lever for desired stitch

length.

• Tighten pointer against plate by

turning thumb nut to the right.

Once the pointer has been positioned, reverse stitching is accomplished

by raising the lever to its highest point. The No. 6 “locked” position must be

unlocked for reverse stitching.

PRESSURE ADJUSTMENTS

To decrease press

ure, turn thumb

screw upward.

To increase press

ure, turn thumb

screw downward.

Decrease Increase

Smooth, even handling of several thicknesses

of fabric results when pressure is correctly

regulated.

Surface finish, as well as the weight and

texture of the fabric, must be considered in

determining the amount of pressure needed.

Adjustment of the thumb screw regulates the

amount of pressure exerted on the material while

it is being stitched.

Too light a pressure will result in irregular

feeding which affects both quality of stitch and

evenness of seams.

Too heavy a pressure not only affects stitch

and seam quality but will mar smooth surfaces

and pile fabrics.

Fig. 48. Pressure Adjustments.

23

Page 24

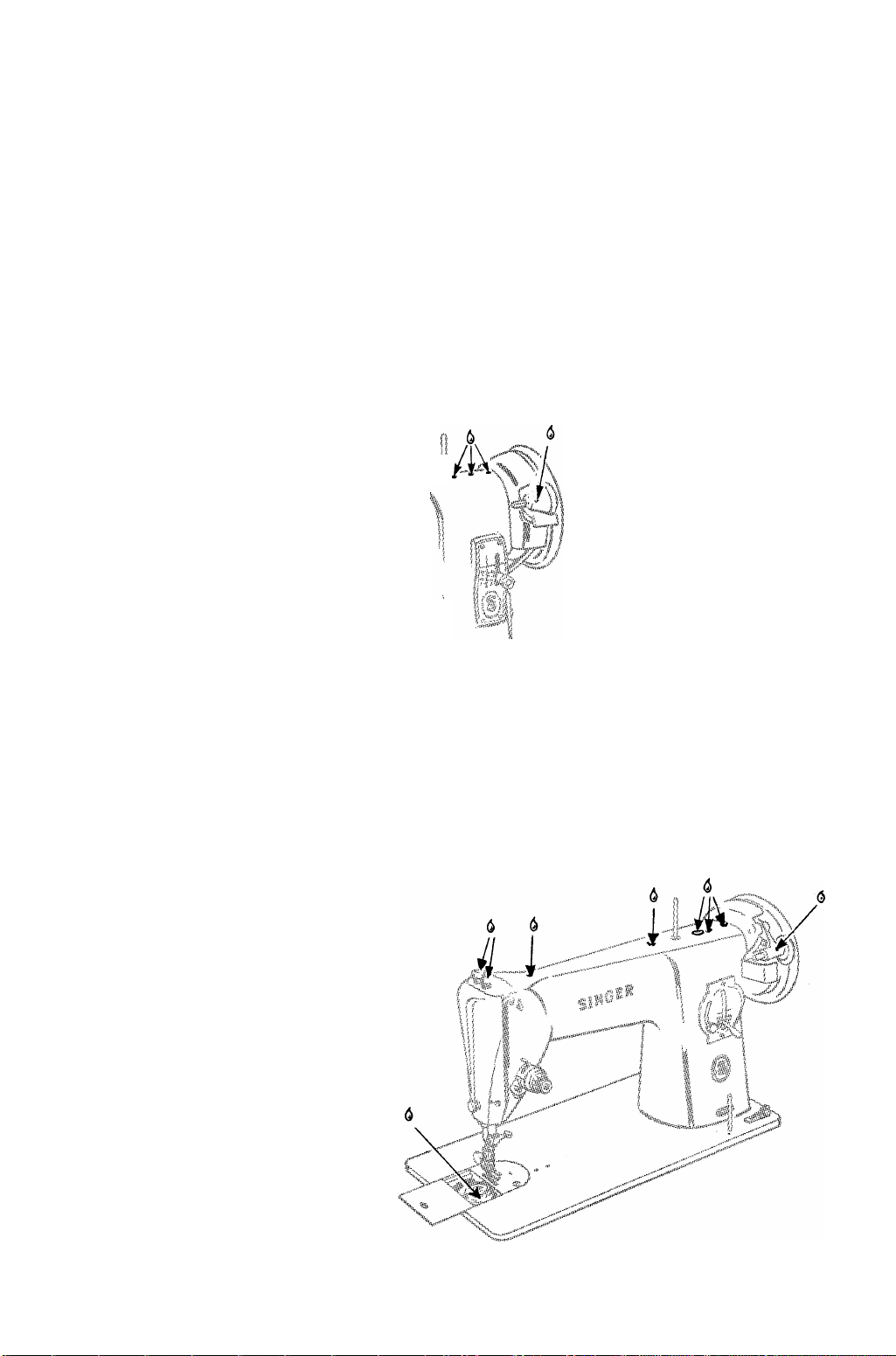

Gleaning and Oiling.

Sewing Machines require oiling and cleaning daily if they are used continu

ously. If used moderately—a few hours per day—it is sufficient to oil and

clean once or twice a week.

Like all other machinery, a sewing machine will not give satisfaction

if its working parts are allowed to become dry or gummed with a poor grade

of oil. A sewing machine that has not received proper care runs hard and

considerable energy will be wasted by using it in such a condition, besides

shortening the life of the machine. Before oiling any part of the machine or

stand, always remove all dust, lint, threads, etc., especially in and around

the Shuttle Race.

A cleaning and oiling lesson is of great value to students as emphasising

the necessity of keeping their machines in perfect running order.

The equip-

ment necessary for

thoroughly clean

ing the machine

6 6

_____

,1

C"

'"i\

I /""■ fe

i '

\\ I

V> /f!

II ;S

!i' / i

SI / I

« ¥T

■i i S /'

\

..................

.A

\

Fig. 48a.

Cleaning and Oiling the Head. working parts and

W. I

;'lt

....

I

%

1

1

1

1

\

,, ‘ffi

necessitate a complete overhaul of the machine by a competent mechanic.

Household oils are not suitable for sewing machine use. For Singer

machines use only Singer

oil, which is specially

prepared for sewing

machines and is supplied

in tins bearing the wellknown Singer Red “S."

When making a

thorough cleaning and

oiling, remove the upper

thread, slide plate, bob

bin, needle and presser

foot. Take out the screws

in the throat plate. Fig.

48b, and remove the

plate. This will enable

you to clean and oil the

shuttle race and remove

any collection of fluff.

consists of a duster

or piece of soft

material, a lint

brush, a large screw

driver and a small

screw driver.

Care should be

taken to use high-

grade machine oil

and one drop should

be applied to each

bearing or point

where there is fric

tion. It is poor

economy to use oil

of doubtful quality,

as it may gum the

Fig. 48b. Oiling Points in Head of Machine 201 K.

24

Page 25

Gleaning and Oiling—(Continued)

The face plate should also be removed

to give access to the oiling points on the

needle bar, presser bar and thread take-up.

Apply a drop of oil to each oil hole and joint.

Release the belt from the band wheel

by moving the lever of the belt shifter, Fig.

49, to the left while the machine is running.

To replace the belt, work the treadle slowly

with the band wheel turning towards you.

The belt will then be automatically brought

back into place. Do not throw the belt off

to the left side of the band wheel, as it is

difficult to replace it from that side.

Fig. 50. Oiling Points below Bed o f Machine 201K.

machine into sewing position and oil each point on top. Wipe away surplus

oil and run the machine rapidly for a few minutes so that the oil may penetrate

to the bearings. The

machine should then

be threaded and a few

stitches made in a

waste piece of material

so that any excess oil

may be removed.-

Fig. 49. The Belt Shifter.

After releasing the

^ A I belt, turn the head of

Li I the machine back on

I?

its hinges in order to

reach the oiling points

on its under side. By

it /1

turning the hand

wheel slowly you will

be able to observe all

working parts. It is

sufficient to apply a

drop of oil only at each

point of contact. After

oiling all points on the

under side, lower the

When a machine

is used and cleaned

frequently, it is not

necessary to remove

the throat plate, slide

and bobbin each time,

but this should be

done occasionally in

in order to remove

lint and dust.

'SHUilti-lIHUriiUliiliiirJttUi

Fig. 51. Oiling Points below Bed o f Machine 66K.

25

Page 26

Gleaning and Oiling—(continued)

To Glean the Stitch-Forming Mechanism

of Machines 66K, 99K and 185K.

If the stitch-forming mechanism should

become clogged with lint and interfere with the

perfect operation of the machine, remove the

bobbin case, as described in the following in

structions, and dislodge the lint accumulated in

the machine.

To Remove Bobbin Gase.

SINGER Lint Brush

Raise needle and presser foot.

Draw slide plate to the left.

• Remove bobbin from case.

• Lift edge of slide plate and draw

it to the right until it is dis

engaged from spring E, Fig. 53.

• Lift and move latch F, Fig. 54, to

position shown.

• Grasp bobbin case as shown.

• Tilt case to the left to raise the

forked end above bracket G.

• Turn forked end toward you, then

lift out bobbin case.

Fig. 54.

To Replace Bobbin Gase.

Replace bobbin case with its fork

straddling bracket G, Fig. 55.

Twist case to. the left, then gently

press down and back until edge of

sewing hook engages groove under

rim of bobbin case.

Return latch F to its original

position.

26

Page 27

Gleaning and Oiling—(Continued)

To Clean Stitch-Forming Mechanism of Machine 20IK

(See Fig. 56)

To Remove Bobbin Case

Raise needle and presser foot.

Draw slide plate to the left.

Remove bobbin from case.

Turn hand wheel over toward

you until end of hook ring E is

toward the front of machine, as

shown.

Insert blade of screwdriver into

slot C between the ring and the

edge of spring.

Press down and at same time

give screwdriver one half turn

so that it will drop into the slot

and unlock the spring.

Hold hand wheel with right

hand.

With left hand, place screw

driver against the edge of the slot

in the ring and push it around

in the opposite direction to hook

rotation until cut-out B is oppo

site spring D.

To Replace Bobbin Case

Place bobbin case in position with

finger A in the opening in the plate

under the feed dog, as shown.

Turn bobbin case back and forth

slightly to ensure proper seating.

Place ring E in position with cut-out

B opposite spring D.

Press ring into place and turn it in

direction of hook rotation until

spring locks it in position.

Replace bobbin.

Lift out ring and bobbin case.

27

Page 28

Gleaning and Oiling—(Continued).

To Glean the Stitch-Forming Mechanism on Machines 327K,

328K, 329K and 404.

To Remove the Bobbin Gase

• Raise needle bar and presser bar.

• Open slide plate.

• Remove bobbin from bobbin

case.

Remove throat plate as follows

Fig. 57.

Place thumb under right front

end of throat plate and raise

until clamping pin lifts up.

Draw toward right to disengage.

To Replace the Bobbin Gase.

POSITIONING /

STUD

Replace bobbin case so that groove

under tension spring fits on hook

raceway and fork of case straddles

positioning stud.

Push bobbin case holder to left un"

til it snaps down into lock position-

Fig. 58.

Unlock bobbin case by lifting

and pulling holder to right as

shown in Fig. 58.

Fig. 59.

Remove

bobbin

case from

machine.

Fig. 61.

Position fork of throat plate under

clamping pin as shown in Fig. 61.

Push to left and press down until

plate snaps into position.

Close slide plate.

28

Page 29

Cleaning and Oiling—(Continued).

To Oil the Bobbin Winder.

To ensure smooth running of the Bobbin

Winder, a drop of oil should be applied to its oiling

points. Care should also be taken not to allow

oil to come in contact with the rubber ring on

the Bobbin Winder, as this causes deterioration of

the rubber and also causes the ring to slip on the

hub of the hand wheel. In this case, the only

remedy is to replace the ring.

OILING THE STAND

To oil stand, apply a drop of oil to the points indicated.

Fig. 62.

Bobbin

Oiling the

Winder.

NOTE.

-The cleaning and oiling instructions given in

this manual apply in general to all Singer

sewing machines. You may find, however,

that the oiling points on your machine differ

from those illustrated. Detailed information

on cleaning and oiling each type of machine is

contained in the instruction book supplied with

the machine.

29

Page 30

To Remove Gummed Oil.

If the machine should run hard after it has been idle for some time, this

is probably due to the oil in its bearings having become gummed. A little

paraffin should then be applied at each oiling point and the machine run

rapidly for a few minutes so as to dissolve the old oil, after which the machine

should be thoroughly wiped with a duster or a piece of waste material. Singer

Oil should afterwards be applied to all working parts. Whenever paraffin

has been used, it is advisable to oil the machine a second time after a few

hours’ use.

If a machine should not run freely after treatment in this way, it should

be examined by a skilled sewing machine mechanic.

COMMON CAUSES OF MACHINE TROUBLES.

Causes of Upper Thread Breaking.

Machine incorrectly threaded. (See instruction book).

Tensions too tight. (See pages 18-19).

Needle bent or having blunt point.

Needle too fine for size of thread and material to be sewn. (See needle

table on page 11).

Burr on needle hole in throat plate (caused by needle striking the plate).

Burr on slot in presser foot (caused by sewing over pins or breaking

needle).

Needle incorrectly set. (See page 13).

Take-up spring bent or broken.

Tension discs worn so that thread works in a groove.

Causes of Lower Thread Breaking.

Tension too tight. (See pages 18-19).

Thread wound unevenly on bobbin or bobbin wound too full. (See

pages 8-10).

Spring on bobbin case or shuttle being worn.

To Avoid Breaking Needles.

Do not sew heavy seams with too fine a needle.

Use correct size of needle for thread and material to be sewn. (See

needle table on page 11).

See that the presser foot or attachments are securely fastened to the

presser bar and that the needle in its descent is central in the hole of the

attachment and throat plate.

Do not attempt to pull or remove the material until the needle is above

the work ; otherwise the needle may become bent and strike the throat plate

when re-starting to sew.

Do not use a needle of any other make. Use only Singer needles, which

are specially made for Singer Machines.

Do not leave pins in the material after basting.

Missing Stitches.

Needle not accurately set in the needle bar or being blunt or bent.

Needle too fine for thread used.

30

Page 31

Stitches Looping.

Looped stitches are usually caused by the tension being too loose. See

pages 18-19 for the regulation of tensions.

See that both the upper and lower threading are correct, that the thread

is of good quality and the correct size for the needle.

Test both tensions and stitch on a piece of the material to be sewn.

Loop stitches are sometimes caused by the placing of the bobbin in the

bobbin case or shuttle so that the thread pulls from the wrong side of the

bobbin, or by the bobbin being wound too full.

Machine Not Feeding Correctly.

This is often caused by the pressure on the work being too light for the

material. (See page 23).

The tensions may be too tight. (See pages 18-19).

The feed dog may be worn. This may be determined by running a

finger over the teeth. If they are not sharp, the feed dog should be replaced

by a competent mechanic.

The stitch regulator screw may have been adjusted too far, thus making

the feed inoperative.

Puckered Seams.

Stitch too long for material being sewn, especially on fine material.

Tension too tight.

Machine Working Heavily.

If the machine works hard after standing it is probably gummed and

needs a general cleaning. (See pages 24 to 29).

The belt may be too tight thus putting excessive pressure on the bearings.

The belt should be just long enough to grip the hand wheel without slipping.

The bobbin winder may have been inadvertently snapped down into

operative position, thus putting pressure on the hand wheel. In such case

release the winder by pressing the lever located behind the bobbin spindle.

Noisy Treadle.

If the treadle is noisy, the screws on which it is pivoted need tightening.

Release one of the screws by giving the nut one or two turns with a wrench.

Then place a screw driver in the slot of the screw and advance the screw

toward the treadle just enough to take up the play. Tighten the nut and

test the treadle. If still noisy, repeat the operation at the other side.

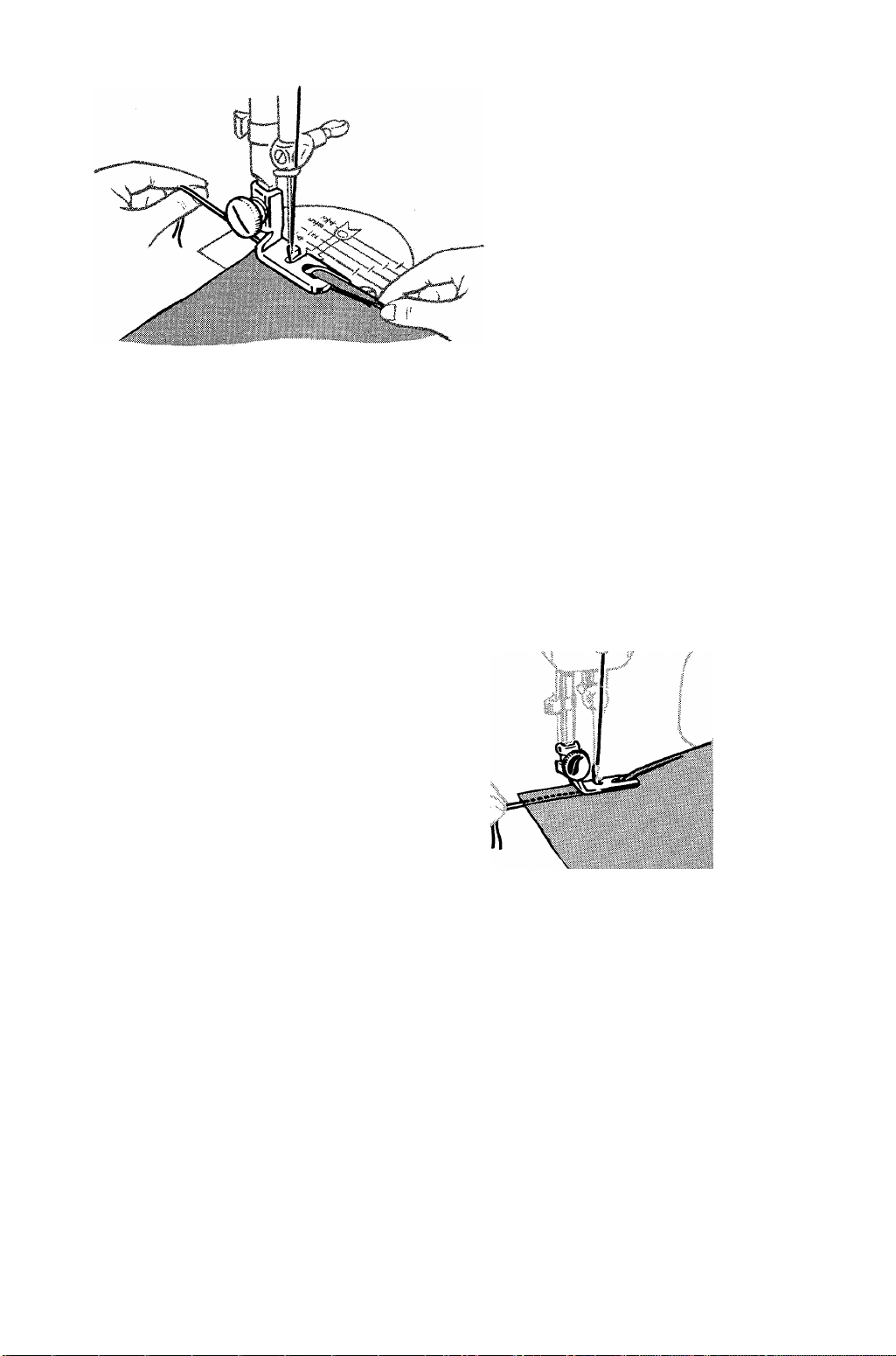

BINDING WITHOUT BASTING.

Bindings of various materials may be applied with the Binder attachment

supplied with Singer Family Sewing Machines. This attachment folds and

guides the binding and, by a simple adjustment, the stitching can be regulated

to come close to the edge of the binding.

The following pages give directions for using this time-saving attachment

and suggest many ways in which binding may be applied to curves with

perfect results.

31

Page 32

How to Cut Material for Use with the Binder.

{Material used for binding must he cut on the bias).

The bias cutting gauge, shown in Fig. 64, is very useful for cutting bias

strips to be used with the Binder attachment. Binding must be cut Y wide

if the material contains dressing, and

about I" wide for soft material. The

letter F shows the position at which to set

the blue spring or indicator for Facings,

B for Binding, and C for Cording or Piping.

The blue spring A when set at B will cut

material about Y wide. The gauge has

to be fitted to the pointed end of the

scissors, as shown in Fig. 65, and the

material is inserted up to the blue spring

when cutting, as shown in Fig. 66.

Joining Bias Strips.

One yard of material 36 inches wide is sufficient for about 30 yards of

bias strips Y wide. It is usually an economy to purchase this quantity and

to save the surplus for future use.

E 4402B

Fig. 67. The -Right Way to Join* Strips.

E4402A

Fig. 68. The Wrong Way to Join Strips.

32

Page 33

Cut the strips, lay the two diagonal ends as shown in Fig. 67, and stitch

them together. The stitching should be as close to the edge as possible so

that the seam passes through the Binder freely. When the strips are straight

ened out, as shown in Fig. 67, the edges are exactly even. Do not join the

strips as shown in Fig. 68, as the edges would be uneven when straightened

out. It is advisable to press the seams open with an iron, and if the strips

are not to be used immediately they should be wound on a piece of cardboard

to keep them from stretching.

To Attach the Binder to the

Machine.

ADJUSTING

SCREW

SLOT FOR

FOLDED BIAS

TAPE

SCROLL FOR

UNFOLDED

BINDING

highest point and remove the

presser foot from the machine by

loosening the thumb screw which

holds it in position. Then fit the

binder, Fig. 69, in its place and

turn the hand wheel slowly towards

you to make sure that the Binder is

correctly attached to the presser

bar ; also see that the needle passes

through the centre of the needle

Fig. 69. The Binder.

hole in the attachment.

To Insert the Binding in the Binder.

Fold "the binding in the centre and cut to a

point, as shown in Fig. 67. Insert the pointed end

into the binder scroll (see Fig. 71), until it comes

out at the lower end.

Raise the needle bar to the

Fig. 71. Inserting Binding

IN Binder.

Fig. 70. Cutting

Point on Binding.

Now place the edge of the material to be

bound between the scroll of the binder and

pass it and the binding under the presser foot

of the binder, then lower the presser bar and

start to sew. You will notice that as the

binding passes through the scroll of the

binder the edges are turned in.

33

Page 34

Bias binding in a variety

of colours, cut and folded

ready for use with the

Binder, may be purchased

at Singer Shops.

Fig. 72. Inserting Folded Binding in Outside Slot.

Folded binding should be inserted in the outside slot of the Binder, as

shown in Fig. 72. The Binder is adjusted and operated in the same manner

as when using unfolded binding. One-half inch braid or ribbon, having a

finished edge, may also be used in the same manner, because binding passing

through the outer slot is turned only once by the attachment.

The Adjustment and Operation of the Binder.

The edge of the material to be bound should be held well within the

centre slot of the scroll. If the material is allowed to slip away from the

scroll when near the needle, the edge will not be caught in the binding. With

a little practice it is quite easy to hold the edge in the scroll.

Various materials and conditions require different adjustments of the

Binder to bring the stitching close to the edge. A whder adjustment of the

Binder is required when binding curves than is necessary when binding a

straight edge.

Fig. 73. Adjusting the Binder.

To adjust the Binder, for the stitching to be at the desired distance from

the edge of the binding, loosen screw, as shown in Fig. 73, and move the scroll

to the right for a narrower adjustment and to the left for a wider adjustment.

Care should be taken to see that the screw is well tightened after making an

adju.stment. To become perfectly familiar with the adjustment of the Binder,

practice is necessary.

34

Page 35

Binding Outside Curves.

Practice is required to

bind a curved edge prop

erly. The edge to be

bound must be held well

within the scroll of the

Binder in order to make

a strong seam and so that

the edge will not pull out.

Fig. 72. Binding an Outside Curve.

Turn the material only as fast as the machine sews. It is not possible

to hold the material in the entire length of the scroll when binding a small

curve.

Do not push the material in too fast, as the edge will then become pucker

ed, and do not stretch the material or the curve will not be the proper shape

when finished. If the stitching does not catch the edge of the binding the

scroll should be adjusted a trifle to the left.

Never pull the binding as it feeds through the Binder, as bias material

is very easily stretched and will be too narrow when it reaches the needle.

When this occurs the edges will not be turned.

Binding Inside Curves.

It will be necessary to practise

binding an inside curve on various

kinds of material, as this curve is

found on nearly all garments which

may be finished with a bound edge.

When binding an inside curve

with the Binder, straighten out the

edge as it is being fed into the

attachment. When doing this,

care should be taken not to stretch

the edge of the material.

If the material is soft, like ba

tiste or crepe de chine, add a row

of machine stitching close to the

edge of the curve before binding.

Fig. 73. Sample of Inside Curve.

35

Page 36

A French fold

is applied by

placing the ma

terial under the

attachment and

stitching the

binding in posi

tion, as shown

in Fig. 74. A

line made by

basting or with

chalk or pencil

may be used as

a guide in apply

ing rows where

wanted.

Applying a French Fold to a Curve.

Fig. 74. Applying French Folds.

Binding a Square Corner.

To bind a square corner, apply the binding along one side to within

of the edge of the material, stopping the machine with the needle and

take-up at the highest point. Then draw the material back away from

the needle far enough to pull about two inches of the binding through the

Binder. Fold and crease the binding to a square mitred corner, turn the

Fig. 7.'). Turning .a. Square Corner, Fig. 76, Sample of Square

Corner.

material and draw it back into the Binder, bringing the needle down through

the binding close to the corner, as shown in Fig. 75. Draw the slack thread

back through the needle and tension. Be sure the new edge of the material

is properly placed in the scroll of the Binder and begin stitching slowly until

you are sure the material is feeding properly. The loop of the thread on the

underside at the corner may be tied or cut off without fear of ravelling, as the

stitch is locked.

36

Page 37

Binding Plackets.

To bind a placket, first fold the material in a straight line, as shown in

Fig. 74, placing the fullness in a flat fold on the under side of the material.

Insert the edge of the placket in the Binder and stitch the binding on as

usual. Run the machine slowly as the point is reached and take care that

Fig. 74. Binding a Placket. Fig. 75. Sample of Bound Placket

A

too much material is not allowed to feed into the Binder. As soon as you

have reached the point of the placket, fold the material to the other side of

the slit and bind to the end.

For practice, cut a slit about 5 inches deep in muslin and learn to fold

it in a straight line before starting to bind. When you have mastered the

placket you will find it quite easy to bind scallops.

Bound Scallops.

The point at the top of the scallop is bound in

exactly the same manner as the placket. Practice

the binding of a small single scallop first before

attempting to bind a row of scallops.

If the material is soft and liable to stretch, add

a row of machine stitching close to the edge of the

scallop before starting to bind the edge.

Applying Military Braid with

the Binder.

Military braid in width may be used in the

Binder by inserting it in the outside slot of the

scroll. (See directions for using folded binding

on pages 33 and 34).

Fig. 7f). Sample of Bound

Scallops.

37

Page 38

This braid makes

a suitable trimming

for serge or other

woollen material

and, when applied

with the Binder,

has a neat tailored

appearance im

possible to obtain

by hand sewing.

Both inside and

outside curves may

be bound with per

fect ease after the

Binder has been

properly adjusted.

Fig. 77. Binding with Military Braid.

Making Button Loops with the Binder.

To make button loops, first stitch together a piece of binding of the

desired material and length by using the Binder. You will then have

a quarter-inch

fold with the

edges stitched

together. Cut a

strip of binding

long enough to

make a loop of

the desired size

and fold it to a

point, as shown

in Fig. 78. Fast

en the loop at

the point with

a hand sewing

needle.

These loops

are most at

tractive when made of silk material or military braid and may be applied

in various ways to the frock or blouse.

Bound Buttonholes Made with the Binder.

Take a strip of material as wide as you wish to make your buttonholes

apart and bind each side. For example, if you wish to make your buttonholes

38

Page 39

two inches apart, take a two-

1 t:

rr*

1

t

»

1

t

1

t

1

1

1

1

1

t

<

I

♦

1

t

t

1

t

1

1

1

1

B

i

t

1

1

1

t

1

1

1

i

1

t

1

I

t

» ^

t

»

f

1

1

t

t

t

i

1

1

L.

inch strip of material, as shown

in Fig. 79, at A, and bind each

side, as shown at B.

Measure the diameter of the

button you wish to use and cut

the bound strip into pieces one-

half inch greater than the width

of the button. (See Figs. 79-B

and 80). After the strip is cut

into sections, bind them to

gether so that the bound edges

just meet, as shown in Fig. 80.

Having bound one edge, as

shown in Fig. 80, proceed to

bind the other edge, first placing

the edge of the garment even

with the strip of buttonholes, so

that both are bound at one

Fig. 79. Starting Bound Buttonholes.

stitching. (See Fig. 81). Then

open out the strip of button

holes beyond the material and

stitch down the upstanding edge of the binding to the garment.

If an extra-strong buttonhole is desired, a linen tape may be used for the

binding

This must, howev^Ki'^be one-half inch in width and be used in the

outside slot of the Binder.

39

Page 40

Making Cut-in Buttonholes with the Binder.

The cut-in buttonhole is

made in the same way as the

placket. Cut a slot in the

edge of the material to the

depth you wish to make the

buttonhole and shape it, as

shown in Fig. 82 at A. Fold

the material in the same manner

as in binding a placket. (See

Fig. 74). Trim off the edge of

the binding, as shown in Fig. 82

at B, and bind the edge with the

Binder, as shown at C.

Fig. 82. Cu t-in Buttonholes.

Fig. 83. The Blind Stitcher.

THE BLIND STITCHER.

This useful SINGER attach

ment produces invisible hem

ming with perfect blind stitches

on an almost unlimited variety

of work such as skirts, dresses,

lingerie, children's clothes,

towels, curtains, sheets, table

cloths and many other articles.

It is quickly attached to

your sewing machine in place of

the presser foot. It is easy to

use and will enable you to

accomplish superior invisible

hemming much faster and with

less effort than is possible by

hand.

40

Page 41

THE BUTTONHOLER

Fig. 84. The Buttonholer.

This attachment produces

neat and durable buttonholes

in a great variety of fabrics

without any special skill on the

part of the operator. The

buttonholes are produced in a

fraction of the time required for

hand work and they are firmer

and more even than those made

by hand.

Fig. 85.

THE FOOT HEMMER AND THE ADJUSTABLE HEMMER.

The Foot Hemmer.

Raise the needle bar to the highest point and

loosen the thumb screw which clamps the presser

foot to the presser bar. Remove the presser

foot and substitute the hemmer foot, taking

care to tighten the screw firmly so that the

Hemmer will not become loose when the machine

is running. Turn the hand wheel slowly

toward you to make sure that the needle goes

through the centre of the needle hole and that

Fig. 86. The Foot the lower thread is properly pulled up.

Hemmer.

How to Start the Hem at the Very Edge.

How to start the hem at the very edge of the material is of great im

portance in learning to use the Hemmer. If the hem is not started at the edge,

and the material is pulled bias, a perfect hem cannot be made.

There are several ways of starting the hem at the edge, but the most

practical one is as follows :

1. Fold over about of the edge of the material at the starting point

for a distance of about one inch.

41

Page 42

Fig, 87. Starting a Hem at the Edg e.

Making a Hem with the Foot Hemmer.

2. Place the material in the

Hemmer at a point just

beyond the fold, as shown in

Fig. 87.

3. Draw the material to

wards you through the Hem

mer, at the same time making

the second fold at the very

edge. Continue to draw the

material through the Hem

mer until the edge is just

under the needle. Place the

upper and lower threads

together under the Hemmer

foot and assist the starting of

the hem by slightly pulling

the threads from the back

after the first stitch has been

made.

The same width of ma

terial must be kept in the

Hemmer at all times. Guide

the material with the thumb

and forefinger of the right

hand, so that the edge lies

flat over the top of the Hem

mer, and proceed to sew,

taking care to keep the Hem

mer curl just full. Should

the edge begin to run out,

move the hand to the left ;

should too much material run

in, move to the right. (See

Fig. 88).

Fig. 88. Making a Hem with the Foot Hem mer.

Making a Hemmed Seam with the Foot Hemmer.

The hemmed seam is very practical to use on underwear, or in fact on

any garment where a straight seam is used and where a small double seam

would be suitable.

42

Page 43

When using this seam the garment must be first fitted and the edge of

the material trimmed, allowing for about one-eighth inch seam. The two

edges are placed together and in

serted in the Hemmer in the same

manner as a single hem. If the

material is bulky, the edge of the

upper piece of material may be

placed about one-eighth inch in

from the edge of the lower piece.

(See Fig.89).

The free edge of a hemmed

seam may be stitched flat to the

garment, if desired. First open

the work out flat, then place the

hem in the scroll of the Hemmer,

which acts as a guide, holding the

edge of the hem in position while

it is being stitched.

If the seam is stitched flat to

the garment one row of stitching

Fig. 8C. Making a Hemmed Seam .

is visible on the right side.

The hemmed seam may be used on muslin, lawn, organdie, or other

fine materials where a narrow seam is desirable.

Hemming and Sewing On Lace at One Operation.

Start the hem in the usual way and, with the needle holding the hem in

position, raise the piresser bar sufficiently to allow the edge of the lace to be

slipped in under the Foot Hemmer, at the same time bringing it up through

the slot at the right of the Hemmer. (See Fig. 90). Lower the bar, turn

the hand wheel and- catch the edge of the lace with the needle. Guide

the hem with the right hand and the lace with the left. Care should be taken

not to stretch the lace as it is being fed into the Hemmer.

It is not practical to sew

gathered lace on with the Foot

Hemmer, as the fulled lace

catches in the Hemmer slot.

A very attractive way of

applying lace so that the stitch

ing of the hem is not visible is

to start the hem in the usual

way, slipping the lace in from

the left as you would the

second piece of material when

making a hemmed seam.

Fig. 90. Hemm ing and Sew ing On Lace.

43

Page 44

Hemming Fine Materials with the Foot Hemmer.

When hemming fine materials, such as georgette or crepe de chine, with

the Foot Hemmer, the material will not feed through properly and the stitch

will be very much shorter than when sewing with the presser foot on the same

material.

To overcome this difficulty, and to assist in holding soft materials so that

they will be turned properly with the Foot Hemmer, insert a piece of paper

under the material between the feed and. the foot of the Hemmer and allow

it to feed through with the material. Strips of thin paper or the edges of

newspapers are very convenient for stitching. Never use tissue paper as

this will be very difficult to pull away from the material.

Hemming a Curved or Bias Edge.

A curved or bias edge may be hemmed with the Foot Hemmer by inserting

paper under the Hemmer. The paper takes up the fullness in the material

and with a little care in guiding, a curve, such as would be used on men’s

shirts or the edge of an apron, may be perfectly hemmed.

The Adjustable Hemmer.

The Adjustable Hemmer (Fig. 91) will

make a hem of any desired width up to

one inch. For making wider hems see page

46.

Remove the presser foot and attach the

Hemmer to the presser bar, taking care that

the needle descends in the centre of the

needle hole after you tighten the thumb

screw.

Fig. 91. The Adjustable Hemmer.

How to Adjust the Hemmer for Hems of Various Widths.

To adjust the Hemmer, loosen the screw and you will then be able to

move the hemmer guide to the right or to the left. Note the pointer (A, Fig.

91) which is used with the scale of figures on the Adjustable Hemmer.

The Hemmer may be adjusted as follows :

Pointer set at :

1—for Y' hem (approximate)

2— n

3— u

4— n

i"

4

8

¥'

( " ) 6— II I" II ( II )

( n ) 7—11 r " ( I, )

( II ) 8— II 1" It ( II )

After setting the Hemmer, care should be taken to see that the adjusting

screw is well tightened before starting to sew.

-for f" hem (approximate)

44

Page 45

How to Insert the Material in the Adjustable Hemmer,

Fold over the edge

at the end of the ma

terial to be hemmed,

as instructed for start

ing a hem with the

Foot Hemmer. Place

the material in the

Hemmer under the

scale and draw it back

wards and forwards

until the hem is formed.

You will then be

able to determine the

width and to fold over

the end of the hem for

the second turning.

Draw the material

back until the end

comes directly under

the needle.

Lower the presser bar and sew, guiding sufficient material in the Hemmer

to turn the hem properly. (See Fig. 92).

If the hem is not started at the edge it will run bias and not come out

even at the other end.

It is well to practise the use of this attachment with striped material.

When you are able to match each stripe exactly you are prepared to hem a

garment properly.

Fig.. 92. Hemming w ith th e Adjustable Hem mer.

Hemming Soft Material.

When hemming soft material liable to stretch, it is well to slip a piece

of paper under the Hemmer next to the feed. This will prevent the material

from stretching and assist in turning the hem.

How to Prepare a Hem on Table Linen.

Much time is spent in turning the hem of table linen to make it ready

for hand sewing. The Hemmer is very valuable for this operation. Set the

Hemmer for the desired

width of hem, take the

thread from the needle, and

run the linen through the

Hemmer.

You will find that the hem

has been evenly turned,

ready for the hand sewing

and the holes made by the

machine needle have softened

the linen, making it quite

easy to do the hand work.

(See Fig. 93).

Table linen or other ma

Fig. 93. Preparing a Hem on Table Linen.

terial may be prepared for

hemstitching in this manner.

45

Page 46

Making a Wide Hem with the Adjustable Hemmer.

To make a hem more than 1" wide, loosen the thumb screw and draw

the slide to the right as far as it will go, then turn this part towards you, as

shown in Fig. 94.

Fold and crease

down a hem of the

desired width, pass

the fold under the ex

tension at the right of

the hemmer, insert the

edge of the material

into the folder, as

shown, and proceed

to stitch.

The hemmer will

turn the edge and

stitch it flat, but the

operator must keep

the crease for the

width of the hem even

as the machine sews.

Hems may be applied

to sheets or other simi

Fig. 94. Hemm er Adjusted for Wide Hemmin g.

lar articles in this

manner.

THE PRACTICAL USE OF THE TUCKER.

Tucking is the natural trimming for fine materials, such as lawn, organdie,

batiste, etc., and, when using the Singer Tucker, may be made in any width,

without basting, from a fine pin tuck to one inch wide. The Tucker gauges

the width of the tuck and, while one tuck is being stitched, it marks the

material for the next tuck to be made.

Tucks are made so easily in this way that it is a joy to make garments

with this fascinating trimming. Then, too, such trimmings may be made

without extra cost. The fashion magazines give numerous suggestions for

tucking various garments. The following pages will explain the adjusting

and operating of this time-saving attachment.

Note the names and

uses of the various

parts of the Tucker,

Fig. 95, as follows :

The Parts of the Tucker and Their Uses.

TUCK

GUIDE

TUCK SCALE

AND

SMOOTHER

BLADES

TUCK GUIDE

ADJUSTING SCREW

SRACE

SCALE

GROOVED

BLADE

SPACE SCALE

ADJUSTING SCREW

Fig. 95. The Tucker and its Working Parts.

46

Page 47

The Tuck Guide, which is adjustable and may be set for any desired width

of tuck.

The Tuck Scale, containing figures which indicate different widths of tucks.

The tuck scale also acts as a smoothing blade, keeping the tucks of

uniform width.

The Tuck Guide Adjusting Screw, by means of which the tuck guide may

be set at any point on the tuck scale.

The Spacing Scale, contains figures on the upper blade which indicate the

width of the space between tucks. The middle or grooved blade

contains a groove into which the material is pressed by the spur at the

end of the lower or spur blade, thus marking the goods for the folding

of the next tuck.

The Spacing Scale Adjusting Screw, by means of which the space scale

may be set at any desired point.

The Marking Lever, which presses on the grooved blade, marks the material

as it passes between the grooved and spur blades.

A careful study of the Tucker parts, and their relation to each other,

before using this attachment, will make its operations quite clear.

To Attach the Tucker to the Machine.

Raise the needle bar to the highest point, remove the presser foot from

the machine and attach the Tucker in its place. Care should be taken to see

that the Tucker is securely fastened to the presser bar and that the needle

goes through the centre of the needle hole. Note the position of the marking

lever, making sure that it is in the lower position and that the needle clamp

works on it as the machine sews.

How to Adjust the Scales on the Tucker.

The width of the tucks and the space between them is determined by the

adjustment of the scales. Adjustment for width of tuck is made by loosening

the tuck guide adjusting screw, which allows you to move the tuck guide to

the desired figure on the tuck scale. The tuck guide should be set just over

the figure you wish to use. The adjusting screw should always be well

tightened.

The figures on the tuck scale indicate the width of tuck in eighths of an

inch, the marks between figures are sixteenths.

47

Page 48

To adjust for the width of space between the tucks, loosen the space

scale adjusting screw and move the space scale until the desired figure is

directly in line with the centre of the needle hole. You will find a line front

and back of the needle hole to indicate the centre.

Before starting to sew, tighten the screw well to prevent the scale shifting

when the Tucker is in operation.

The marks on the space scale are double the width of those on the tuck

scale, so that when both scales are set at the same figure, blind tucks without

spaces between them are made.

To make space between tucks, first set the tuck scale, then move the

space scale to the same number and as much further to the left as you wish

to have space. Each number on the space scale represents one-quarter of

an inch and each mark between numbers one-eighth of an inch.

Use the table below to assist you in setting the Tucker.

Tuck Guide Space Sca?e

1"

tucks with

8

1 "

8

1 "

4

1 "

4

\"

2”

1 "

Y

I I I t

I I

I I

11

I I I I

I I

I f

I f

I I

I I

no space

1"

8 "

no

I I

I "

4 "

no

I I

1"

t "

no

I I

1

1

2

2

4

4

8