SINGER 4022 User Manual

if' 'Л';

#• '5 /' ' ' '"

i-

'/ :■ Ч-

Instruction Book for

Sewing Machine Model 4012/4022

Copyright © 1984 T.S. CO.

All Rights Reserved Throughout the World

Contents

*A Trademark of

'.S.

Co.

1. Getting to Know Your

Machine

Principal Parts ...................

Accessories .........................

2. Getting Ready to Sew .

Choosing and Changing

Accessories

Operating Machine

The Bobbin

Threading the Machine

3. Straight Stitching

Adjusting Machine Stitch

Sewing a Seam

Applications

4. Basic Zig-Zag Stitching

Adjusting Machine Stitch

...........................

...................

-----------

........................

..............

..................

......................

2

2

4

5

5

12

13

16

18

18

20

21

23

OQ

¿o

5, Machine Stitch Patterns .. 29

Setting Selectors

Adjusting Stitches to

Suit Stretch Fabrics ... 31

Application

6, Buttonholes ............................

Buttonholes ...........................

Garment Preparation

Four-Step Buttonholing ,.

7. Twin-Needle Stitching .,..

8. Free-Arm Sewing

9. Performance Checklist ... 48

10. Caring for Your Machine

Index .......................................

............................

..................

............

...................

29

33

42

42

42

44

46

47

49

53

Applications

For European Territories—

This product is suppressed for radio and television interference in

accordance with the International Electrotechnical Commission require

rnents of the CISPR.

........................

25

1

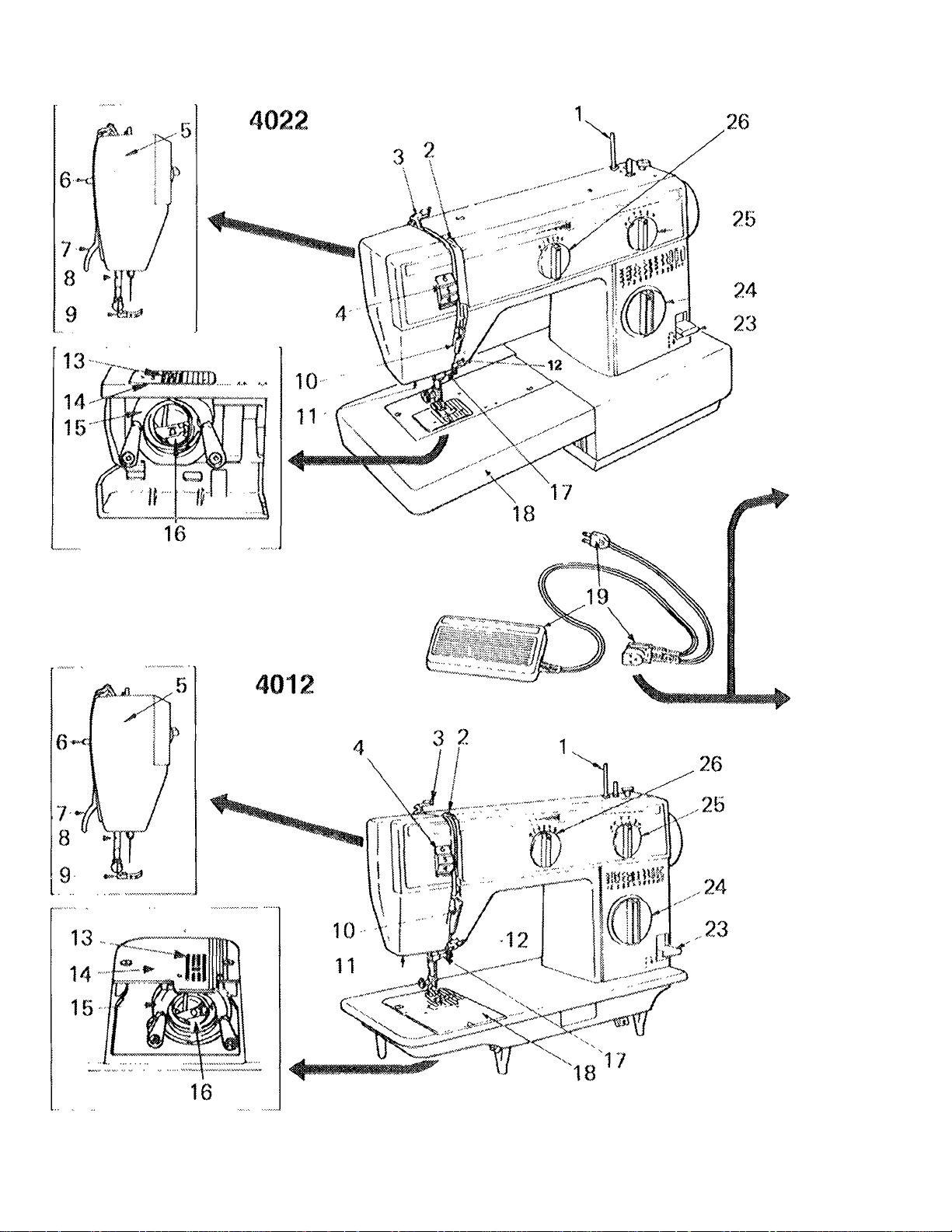

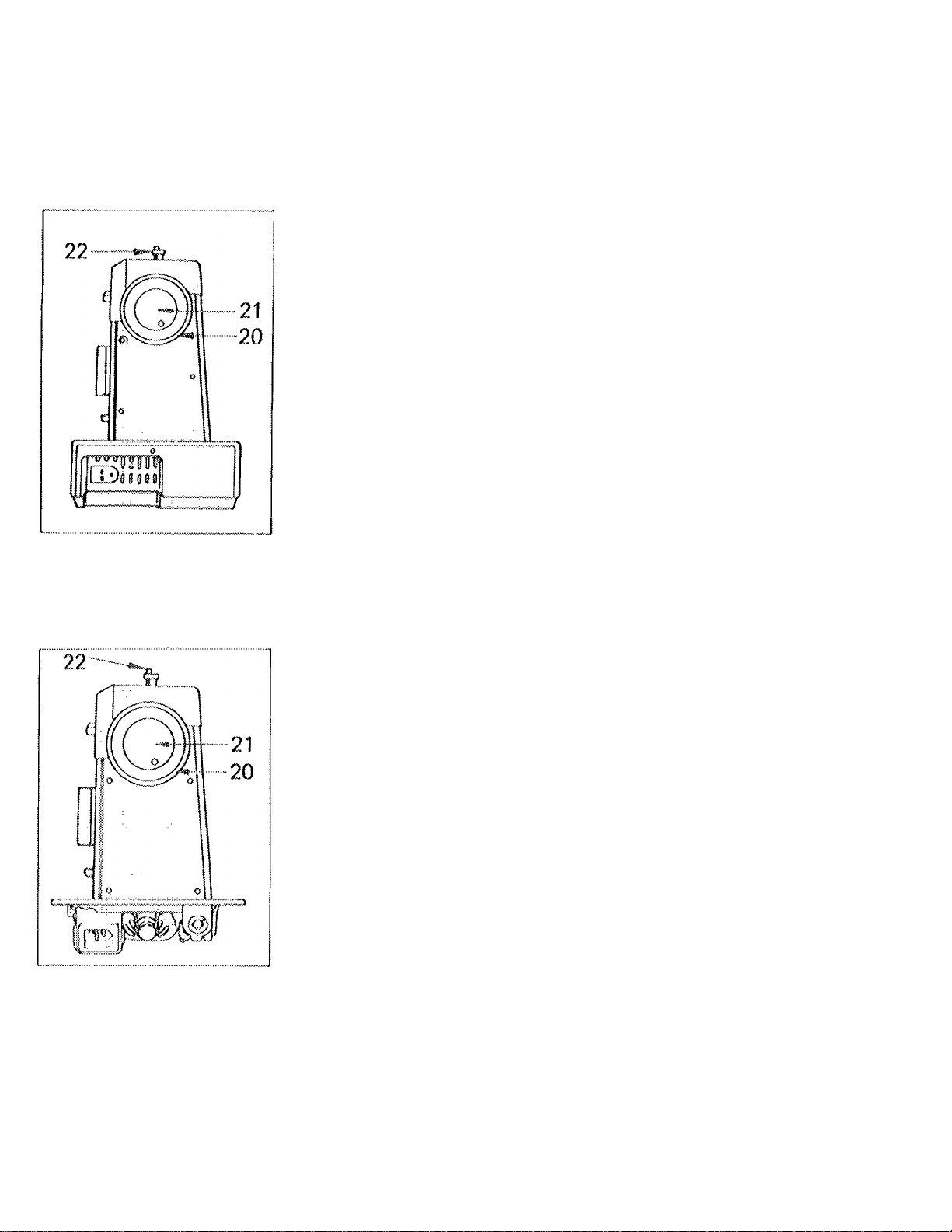

1. Getting to Know Your Machine

2

Principal Parts

1. spool Pin

2. Take-up Lever

3. Rear Thread Guide

4. Tension Dial

5. Face Plate

6. Light Switch

7. Presser Foot Lifter

8. Thread Cutter

9. General Purpose Foot

10< Thread Guard

11< Sewing Light

12. Thread Guide

13. Fabric Feed

14. Needle Plate

15. Bobbin Case Holder

16. Bobbin Case

17. Needle Clamp

18. Extension Bed (4022)

18. Slide Plate (4012)

19. Electrical Connections and

Speed Controller

20. Fland Wheel

21. Hand Wheel Knob

22. Bobbin Winder Spindle

23. Reverse Lever

24. Pattern Selector

25. Stitch Length Selector

26. Stitch Width Selector

To ensure that you are always

provided with the most modern

sewing capabilities, THE MANU

FACTURER reserves the right to

change the appearance, design or

accessories of this sewing machine

when considered necessary.

2 A

B

3

4

5

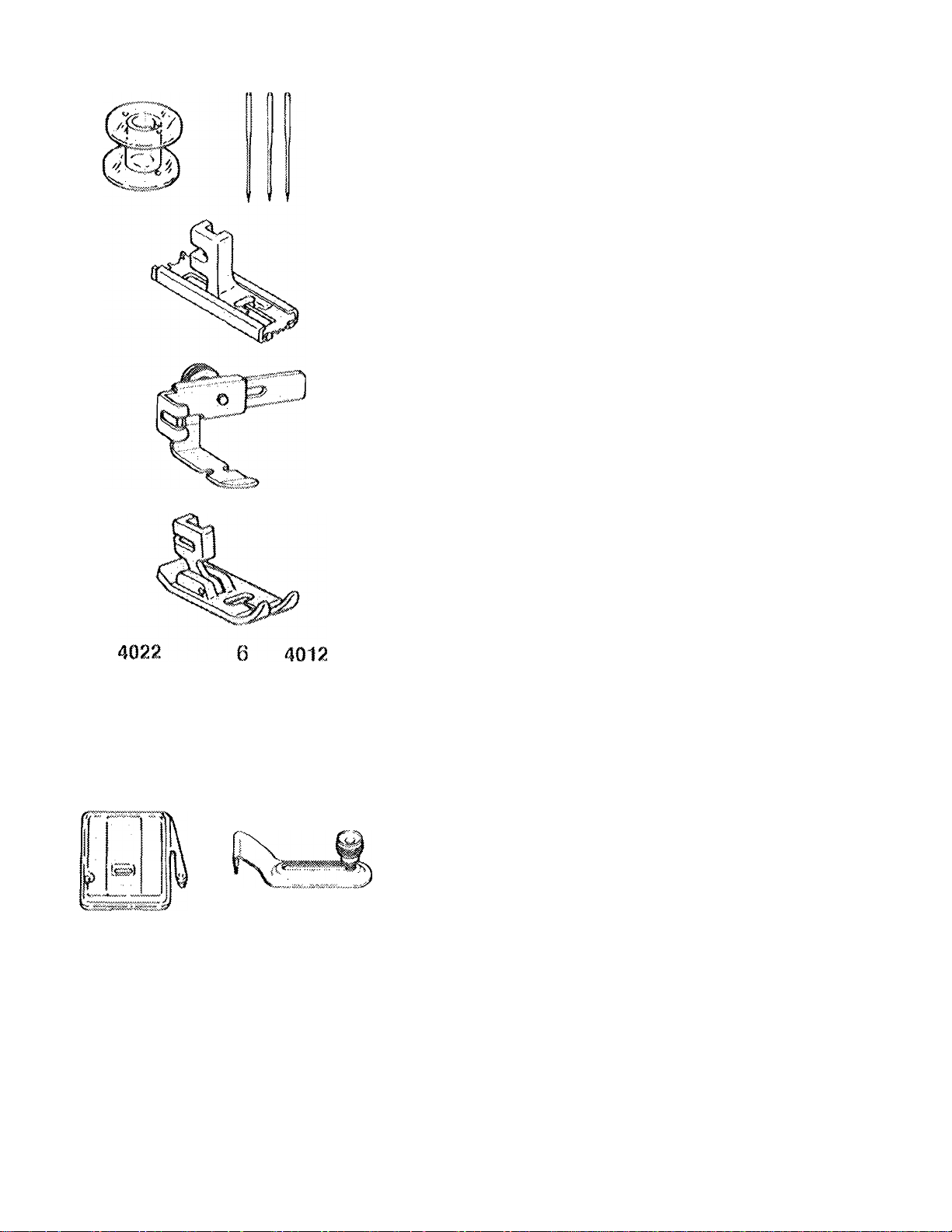

Accessories

The accessories that come with

your sewing machine are designed

to help you do many kinds of

sewing easily.

1. Transparent BobNns

(No. 541090)

2. Needles

®A Style 2020 is used for gen

eral sewing.

®B Style 2045 is used for sew

ing knits, stretch fabrics and

elastic.

®C Style 2024 is used for twin-

needle decorative stitching

on woven and knit fabrics.

CAUTION: Uso twin-needle with the

genera! purpose needle plate and

general purpose foot only. Do not

use any other accessories with this

needle as needle breakage will

occur.

6

C...

V ,

7

9

10

Cr

c

r

o

8

___

_______________

o

3. Buttonhole Foot is used to make

bar tack buttonholes in four

steps.

h

58

nr

jrj

4. Zipper Foot for inserting zippers

and stitching corded seams.

5. Gener«4 Purpose Foot, on your

machine when delivered, is used

for all utility and decorative

sewirig.

6. General Purpose Needle Plate,

on your maciiine when de

livered, is used with ail presser

feet.

7. Snaj>in Feed Cover.

8. Seam Guide helps you keep

seam allowances even,

9. Screwdriver for adjusting bob

bin-thread tension.

10. Detachable spool pin is used for

twin-needle sewing.

4

2. Getting Ready to Sew

Choosing and Changing

Accessories

CAUTION: Disconnect the power

line plug from the socket outlet

when changing needles, feet, or

needle plates, or when leaving the

machine unattended. This elimi

nates the possibility of starting the

machine by accidentally pressing

the speed controller.

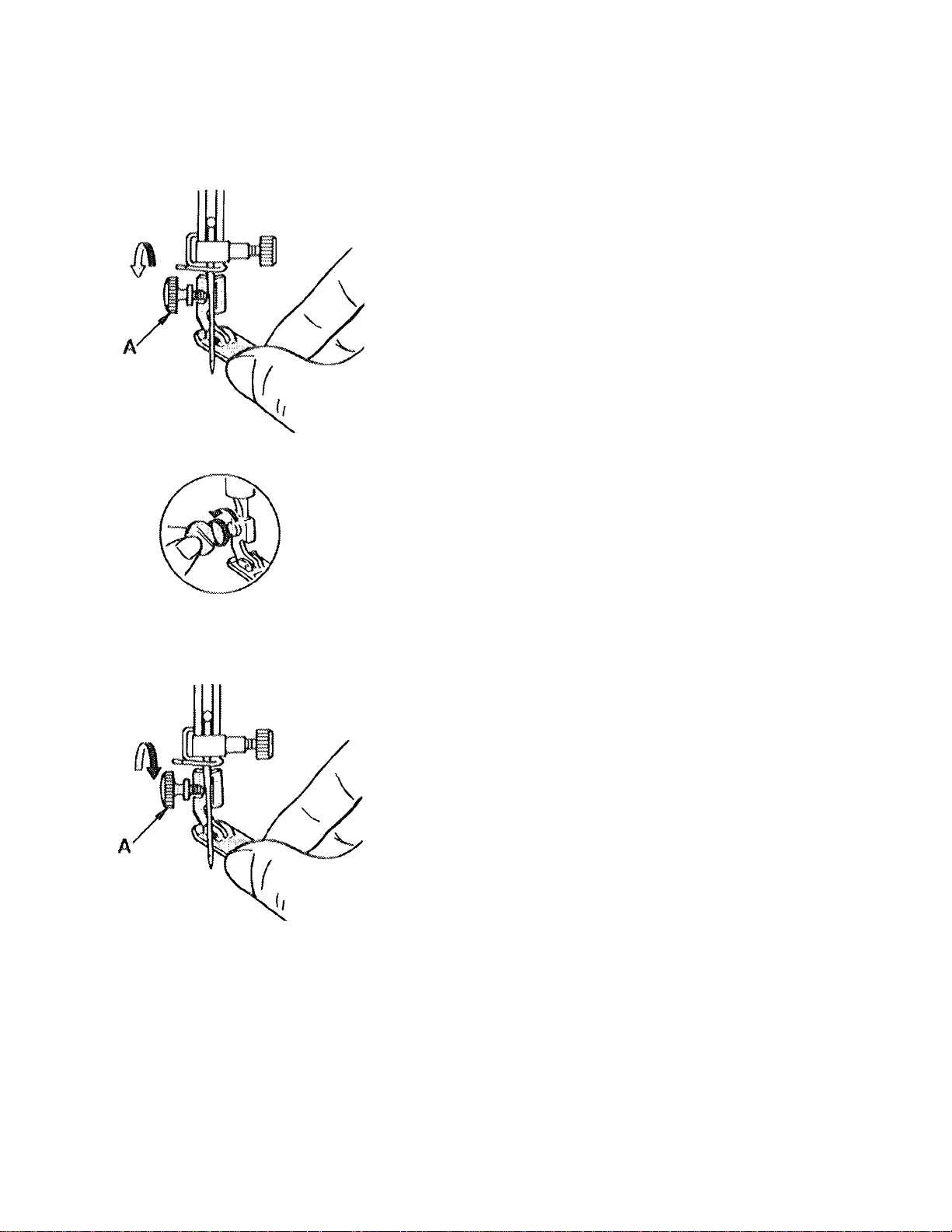

Changing Presser Feet

Removing Presser Foot with Shank

® Raise needle to highest position

by turning the hand wheel toward

you.

® Raise presser foot.

0 Loosen presser foot screw A and

remove the shank, guiding it to

the right.

Replacing Presser Foot with Shank

« Hook shank around the presser

bar, guiding it to the left and

tighten presser foot screw A.

NOTE: Insert the edge of a coin in

the slot of the presser foot screw to

loosen it and to tighten it securely.

5

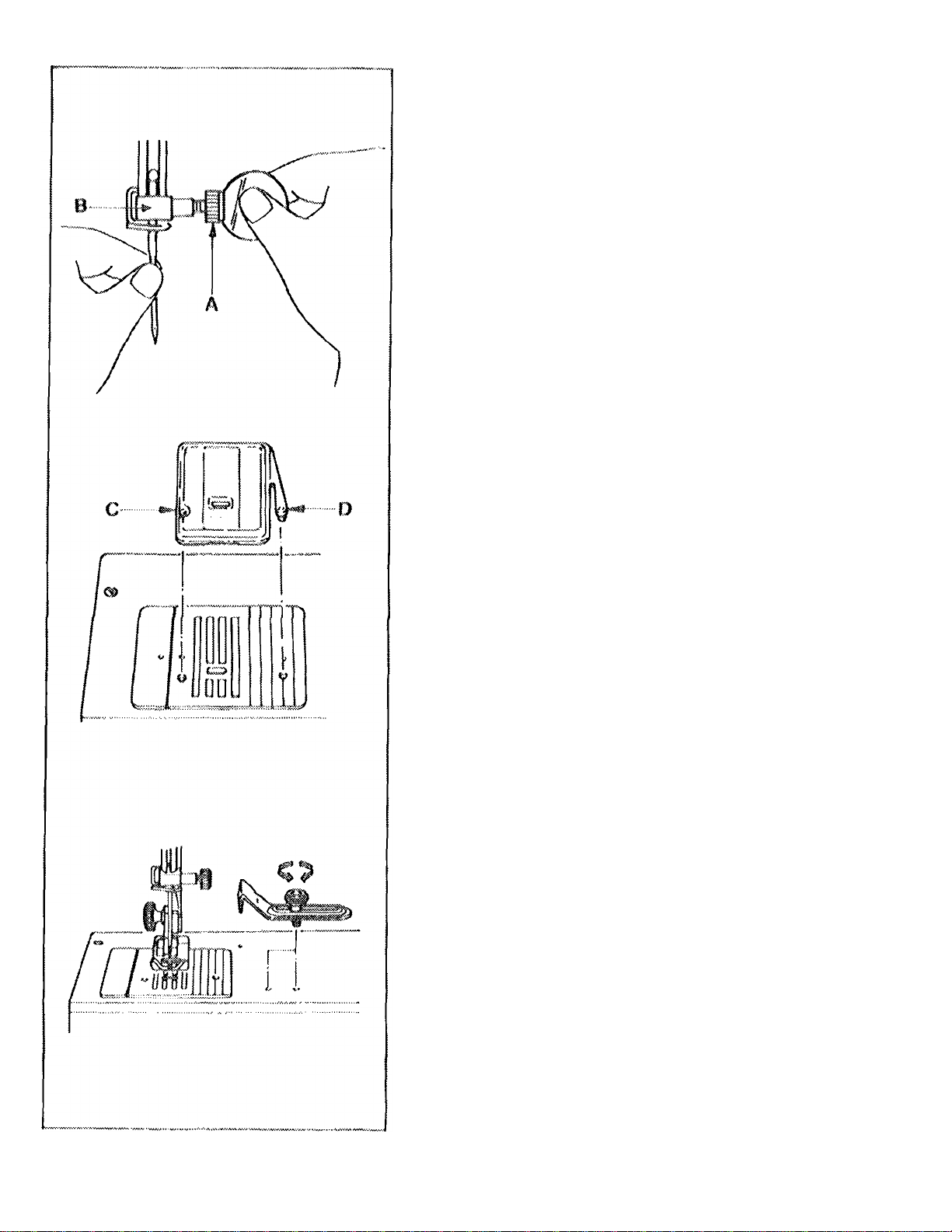

Changing the Needle

® Raise needle to its highest point

by turning the hand wheel toward

you. Loosen needle clamp screw

A and remove the needle.

« Insert new needle up into clamp

B as far as it will go, with the flat

side of the needle to the back.

® Tighten needle clamp screw.

Attaching Snap-in Feed Cover

® Raise needle to highest position

by turning fiand wheel toward

you.

® Raise presser foot.

« Slide snap-in feed cover away

from you over needle plate until

points C and D are positioned

directly over f^otes in needle plate

as illustrated. Snap in point C.

Then piish point D toward point

C until it snaps into place.

® fo remove, lift up edges of feed

cover.

Attaching the Seam Guide

Place screw in either hole to the

right of the needle plate; line up

straight edge of guide with the

needle plate guideline for desired

seam width, and tig I den screw.

6

Remove and Replacing hJeoclle

Plate

.....

4022

A

J

A

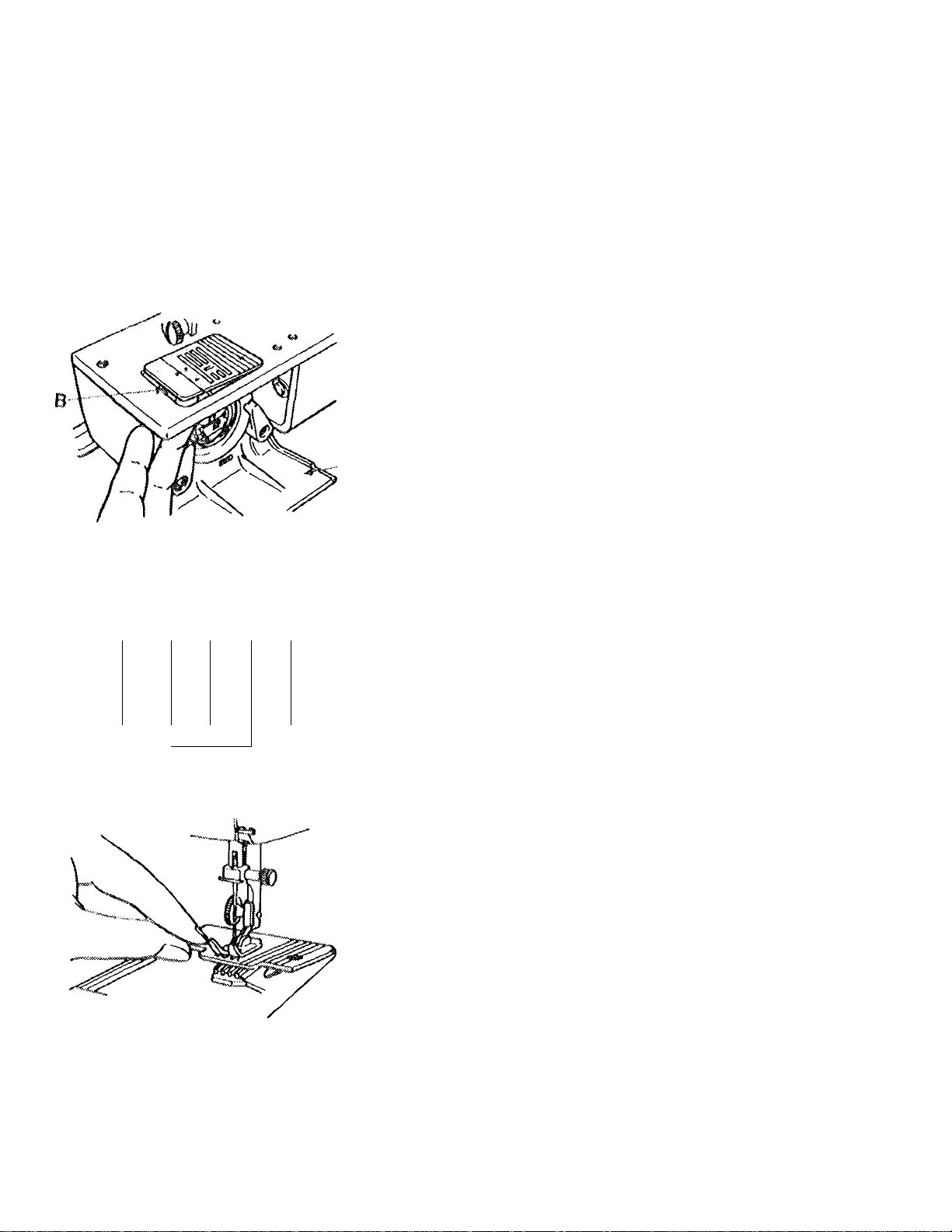

4022 Machine

e Raise needle to its higliest posi

tion.

« Raise presser foot,

® Open hook cover A.

® With your forefinger push needle

plate upward from beneath and

remove plate.

To replace needle plate, guide

needle plate into position under the

presser foot. Be sure the guide

projection B fits into the groove of

(fie free-arm. Press needle plate

down to ensure proper positioning,

Close hook cover.

o

O

4oia

000

ill I

2U

XT

4012 Machine

« Raise needle to its highest posi

tion.

o Raise presser foot.

® Draw slide plate out toward you.

® Remove the needle plate and

cover plate by simply guiding it

toward you.

To replace needle plate, guide

needle plate into position under the

presser foot.

7

Fabric Weight Table

Ttx!fe are thousands of fabrics around the world, each

manufactured with a specific fibre and weight. The

fabrics txifow trave l>een classified according to weight

to give a sniall sample of what is available lor purchase.

Refer to this table to determine the weight and type of

fabric you will be using in order to select the correct

rreedle and thread combination.

For correct needle and thread combination for your

fabric, refer to the I abric, Thread and Needle Table on

pages 10 and 11.

Jibro and

GonstrucUon

Silk

(Woven),

(Knit)_

Rayon

(Woven)

T (Knit);: :

Cotton ^

(Woven)

(Knit)

....

(Woven)

(Knit)

Synthotie

(Woven)

: PHmy

Chiffon,

Organza,

Tulle

Tulle

Voile,

Ttille

Chiffon,

Organza,

Tulle

Sheer

Net, t.ace, Ninon Velvet, Crepe de Cfiine, Shantung. Faille

Jersey

Net, Lace

Net, lace Chalte, Organdy, Muslin, Batiste, Dimity,

Net, Lace, Ninr.>n Crepe, Velvet, 1 affeta. Satin

Crepe de Cfiine

Velvet, Taffeta, Satin

Ciré

Lawn, Percale, Eyelet, Gingham, Piqué,

Poplin

Jersey

Cashmere. Flannel, Mohair, Felt, Crefxr

Jeiscy

Light

8

(Knit)

Synthetic

Blends

(Woven)

(Knit)

Leather

Plastic

Vinyls

Rasct'iet, Single Knit. Sweater Knit,

Bonded Knit. Tricot. Ciré

Voile

Plastic fulm Plastic f ilm

Broadcloth, Batiste. Eyelet, Gingham,

f^oplin

Single Knit

Kidskin, Patent, Chamois, Imitation-

Leathers and Suedes, l eather. Suede

Medium

Velvet. Crepe do Ciiine, Slvantung,

Suiting, Brocade

Velvet, Taffeta, Satin, Crepe Brocade. Taffeta, Satin.

Crepe

Heavy

Very Heavy

Veiveteen, Ciorduroy, Velvet, t-teece.

Velour, Terry, Chintz

Stretch Velours*, Stretch Terry*

‘ Usually contain some synthetic fibres also.

Suiting, Flannel, Gabardine, Felt, Serge,

Mohair

Jersey

Velvet, Crepe, Taffeta, Satin

Jacquard, Double Knit, Sweater Knit, Bonded

Knit, Tricot Spandex, Stretch Terry. Stretch

Velour, iJeep Bile. Fake Furs

Lirien type. Poplin, Corduroy, Gabardine Denim. Gabardine,

Terry Knit

Patent. Imitation-Leathers and Suedes,

Leather, Suede, Reptile

Corduroy, Denim,

Ticking, Canvas, Linen.

Drapery Fabric, Burlap

Suiting, Tweed, Duffel

Gabardine

Double Knit, Helenca,

Fake Furs

Drapery Fabric

Double Knit

Buckskin, Calfskin,

Suede, Reptile

Denim. Duck, Canvas,

Sailcloth, Upholstery

f'abric

Coating, Blanketing

Upholstery l.eather

Bonded Vinyl (Knit Back), Patent,

Embossed. Printed

Uptiolstery Vinyl

Upholstery Vinyl

9

Fabric, Thread and

Needle Table

Choosing Iho concct nccdio fHid thread for your fabric is of

utmost importance. Correct choice» will make (he rfifference in

the wear and appearance of your rrew garment The fabric

Weight Table on the previous page and the fabric, Ifiread and

Needle Table below are practical guides to needle and thread

selection, (iefer to itiorn before starting a sewing project. Be

sure to use the same siwi and typo ol thread in both trecdle and

bobbin

To select the correct needle and thread for your fabric, first

refer to the fmbric Weight lahte to determine the weight aiuf

typo ol Itie material you are using

Typo

of

Fabric

Silk

Rayon

Cotton

Woo!

Synthetic

Filmy

Threads Needles

Sheer

Threads Needles

f'ine Silk i ino Silk

l ine Cotton 2020-9/70

Fino SynUietic

Fine Silk Fine Silk

I me Cotton

Fine Synthetic

Fine Cotton I ino Cotlon

Fine Syntliotic

Fine Synthetic 2020-9/70 F ino Synthetic 2020-9/70

2020-9/70

2020-9//0 f ino Synthetic

Fine Cotton

I ino Synthetic

Fine Cotton

Fine Syntfietic

2020-9/70

2020-9/70

2020 9 70

Light

Throads

l-irie Silk

f ino Colton

Fine Synthetic

Fine Silk

t ino Colton

f ine Synthetic

Mediirjii Cottor) Woven

Medium Syntiiotic 2045-11/80

Fine Silk

t ino Colton

l-ine Syntfiefic

Needles

2020 11/80

Vv'oven

2045 11/80

Knit

202a-11./80

Woven

2045-11/80

Knit

2020 t1/80

Knit

2020-11/80

V'/ovon

2040 11/80

Knit

2020-11/80

Woven

2045-11/80

Knit

Synthetic

Biends

Leather

Plastic

Vinyls

10

I ine Synthetic

l-'ine Cotton

1 ine .Synthetic

2020 9//0

2020 9 70

2020 11/80

f'inc Synlitiitic

Medium Cotton

Mixlium Synthetic 2032-11/80

i ino Cotton

Fine Synthetic

Woven

204f>11/80

Knit

2020-11/80

Next refer to the Fabric. Thread and Neodfe Table Find the

fabric you are using iii Type of Fabric cokimri at left (silk,

rayon, etc,). Then locate the Fabric weight column (filmy,

sheer, etc.) for your Fabric at top of table. Read across from

Type of Fabric column to correct weight of Fabric column

There, the correct thread and needle clroice for your Fabric will

t)C found,

Example: If you are sewing a medium weight wool, find wool in

Type of Fabric column. Read across to Medium (weight)

column and you will see that a inodiurn silk, cotton or synthetic

thread and a size ?020'14 needle for woven fabrics or a size

2046-14 needle for knit fabrics are to be used

IMPORTANT: Your sov/ing machino has

l>8on designed to obtain best results with

SINGfrR' needles. You should lollow the

recommendations in this instruction

book and on the needle package tor

correct stylo and sine of needle tor

dillerenl types and weight ot fabric.

Medium

Threads Needles

Medium Silk

Medium Cotton 2020-11/80

Medium Syiithetic

Medium Synthetic

Medium Cotton 2020-11/80

2020-14/90

Medium

Medium

Colton Woven

Synthetic 2045-14./90

Knit

Mediiirn

Medium

Medium

Silk

Cotton

Synthetic

2020-14/90

Wovett

2045-14/90

Knit

2020-14/90

Medium Synthetic

Woven

2045-14/90

Knit

Heavy

Threads Needfes

Heavy Synttretic

Heavy Colton . 2020-16-'100

Heavy Cotton 2020-16/100

Heavy Colton 2020-16/100

202a-16/100

,, Woven

Heavy Synthct.c

Knit

Very Heavy

Threads Needles

Heavy Cotton 2020-18/110

Fleavy Cotton 2020-16/100

2020-14/90

Medium Syntliotic

W'oven

2045-14./90

Knit

Medium Cotton

Medium Syrithetic 2032-14/90

Medium Cotton

Medium Synthetic 2020-14/90

2020-16/100

Hoavy Syntholic

Wo von

KnII

Heavy Cotton

Heavy Synthetic 2032-16/100

Medium Cotton

Medium Synthetic 2020-16/100

A Trade mark of THE SINGETt COMPANY

Heavy Cotton

Heavy Synthetic 2032-18/110

Fioavy Cotton

Heavy Synthetic 2020-16/100

11

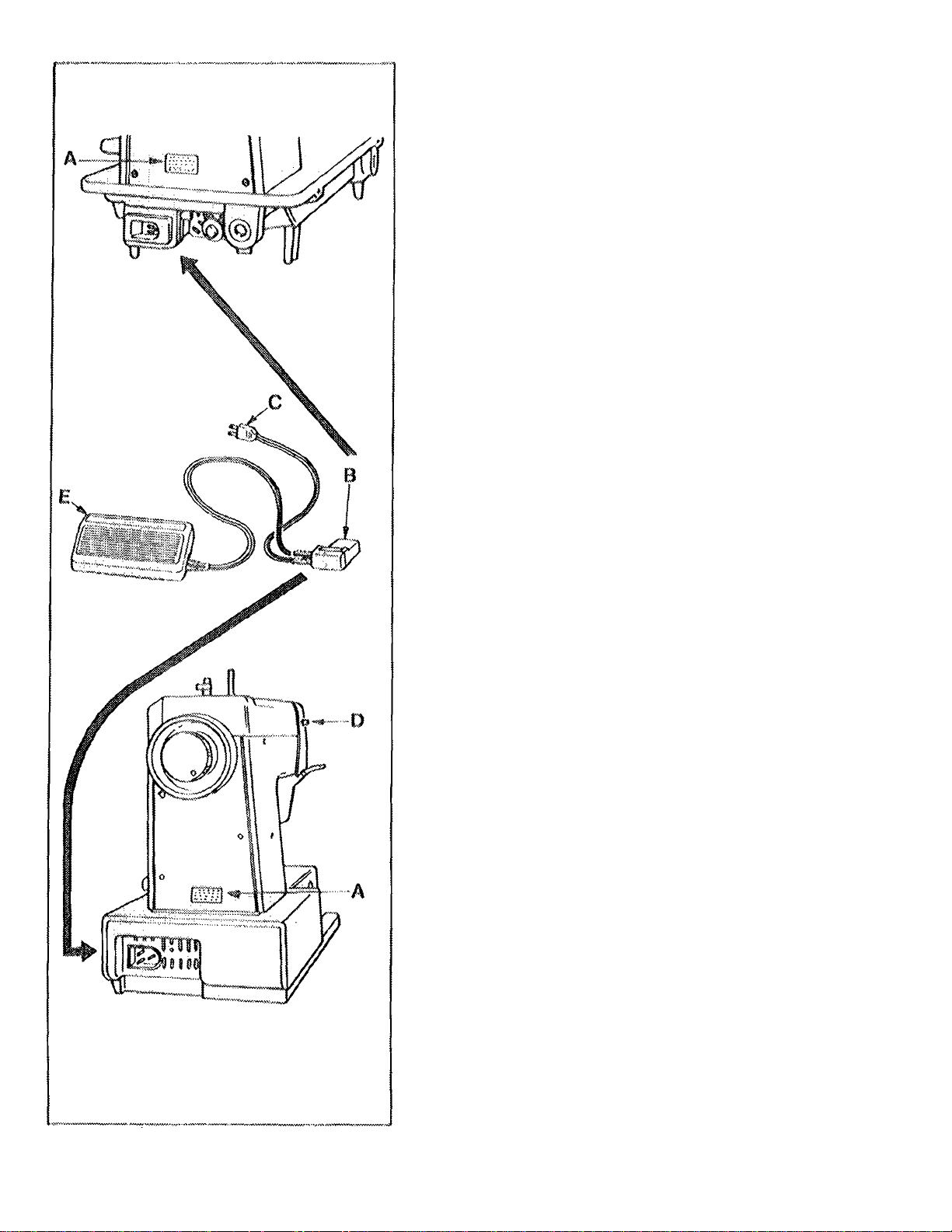

Operating the Machine

Connecting the Machine

® Before plugging in your machine, be

sure the electrical information on the

side of the machine A, below the

hand wheel, agrees with the range

marked on your electrical meter.

fMPORTANT Machines for Great

Britain and some otfier countries having

similar wiring standards are shipped

from the factory without a plug for

connection to the mains.

The wires in the main lead are coloured

according to code.

Bfue: Neutral (N)

Brown: Live (L)

As the colours of the wires in the main

lead of this appliance may not always

correspond with the coloured markings

identifying the terminals in your plug,

proceed as follows:

Tlie wire which is coloured blue must be

connected to the terminal which is

marked with the letter N or coloured

black.

The wire which is coloured brown must

be connected to the terminal which is

marked with the letter L or coloured red.

If a 13 amp (BS 1363) plug is used, a 3

amp fuse must be fitted, or if any other

type of plug is used, a 5 amp fuse must

be fitted either in the plug or adaptor or

at the distribution board,

e To turn on the machine, conrrect plug

B to machine and plug C to your

socket outlet,

9 To turn on the sewing light, press or

turn switch D as required. See

illustration.

9 To run the machine and control

speed, press the speed controller E

with your foot, i'he harder you press,

the faster the machine will sew.

CAUTION: Disconnect the powei line plug from the

socket auHot when changing needles, (cot or needle

plates or when leaving the machine imaltended.

This eliminates the possibility ol stading the

machine by accidentally pressing the speed com

Uoitor. Because ol the up and down rnovemerit of

the needle, you must work carefully and watch the

sewing area when operating the machine.

12

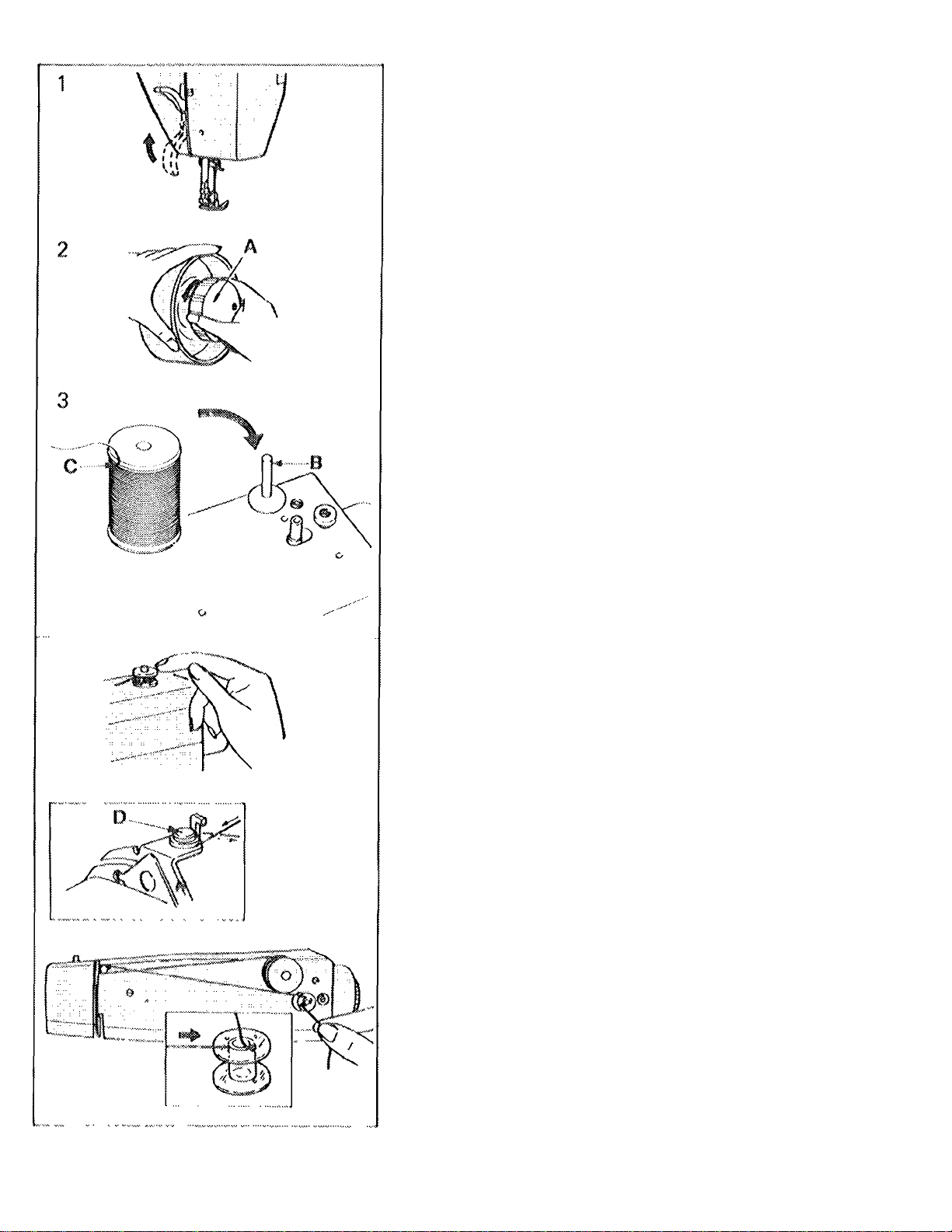

The Bobbin

Winding the Bobbin

Preparation Steps

1. Raise the pressor foot and turn

hand wheel toward you until

needle is in highest position.

2. {..oosen hand wheel ktiob A by

turning it toward you witti the

right hand while holding hand

wheel with the left hand.

3. Place thread spool on spool pin B

over the felt cushion. If spool

being used has a thread retaining

slit C, it should be placed at the

top.

Winding Steps

® Place spool of thread on spool

pin as instructed above.

® Lead thread around disc of rear

thread guide D, as illustrated, and

through small hole in l>obhin from

inside out.

® Snap bobbin onto spindle and

push bobbin to right to engage

bobbin Vv'inder.

0 Hold thread end, as shown, and

start the machine. Cut off thread

end after a few coils fiave been

wound.

0 When required amount of thread

has been wound (winding will

stop when bobbin is full), stop tfie

machine and cut cotmecting

thread.

0 Push bobbin to loft and remove

bobbin from spindle.

0 Hold hand wheel and tighten

hand wheel knob.

13

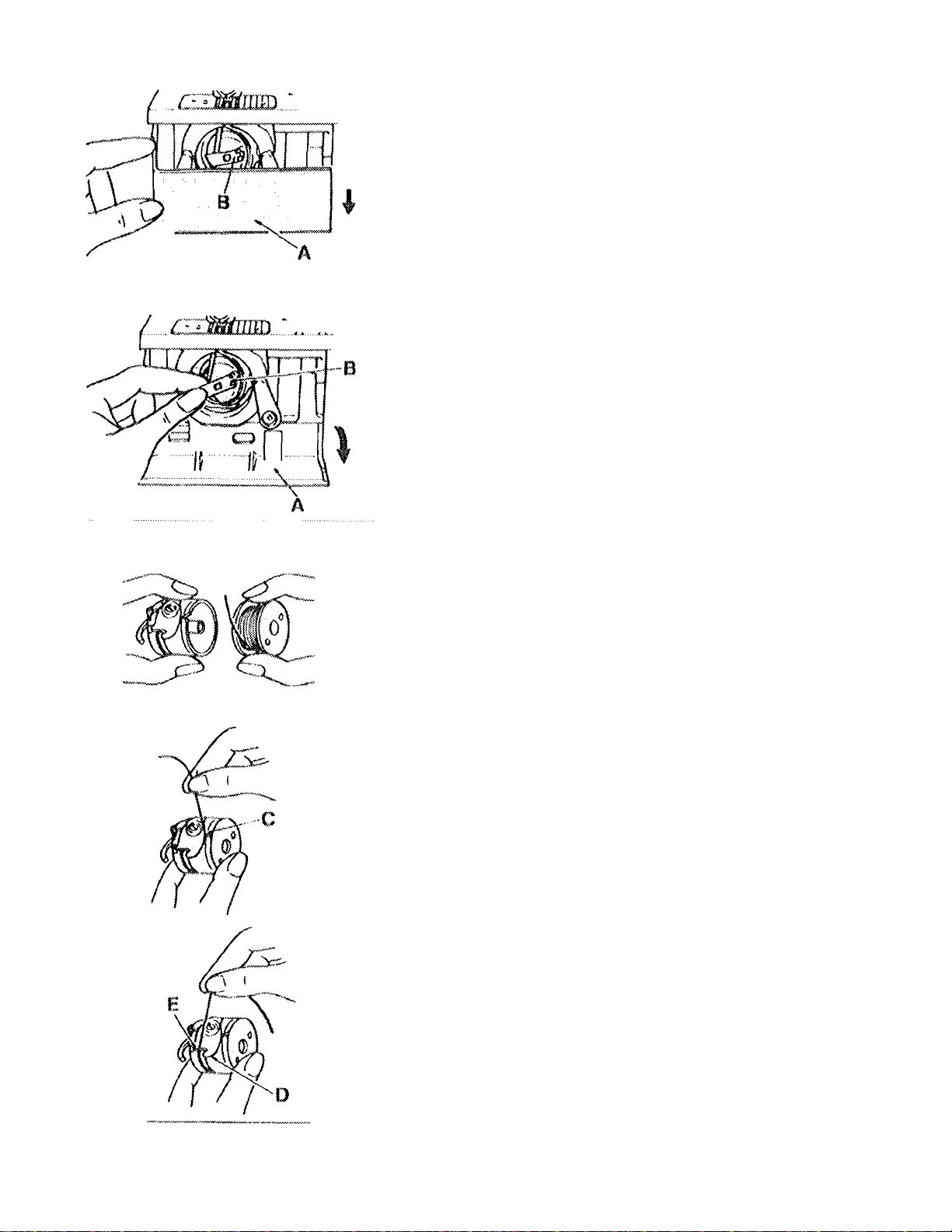

4022

Removing the Bobbin Case

When you prepare to sew, wind the

bobbin first then thread the ma

chine.

To Remove the Bobbin Case and

Bobbin.

® Turn hand wheel toward you to

raise take-up lever to its highest

position.

® 4022 Open hook cover A, as

illustrated.

e 4012 Open slide plate A by draw

ing it toward you.

® Grasp bobbin case latch B and

withdraw bobbin case.

® Release latch and bobbin will

drop out of case.

Threading the Bobbin Case

1. Hold bobbin case and bobbin so

that thread leads off in direction

shown above.

2. Place bobbin into bobbin case.

FTjII thread into slot C.

v3. Pull thread under tension spring

D and into slot E at end of spring,

as shown.

14

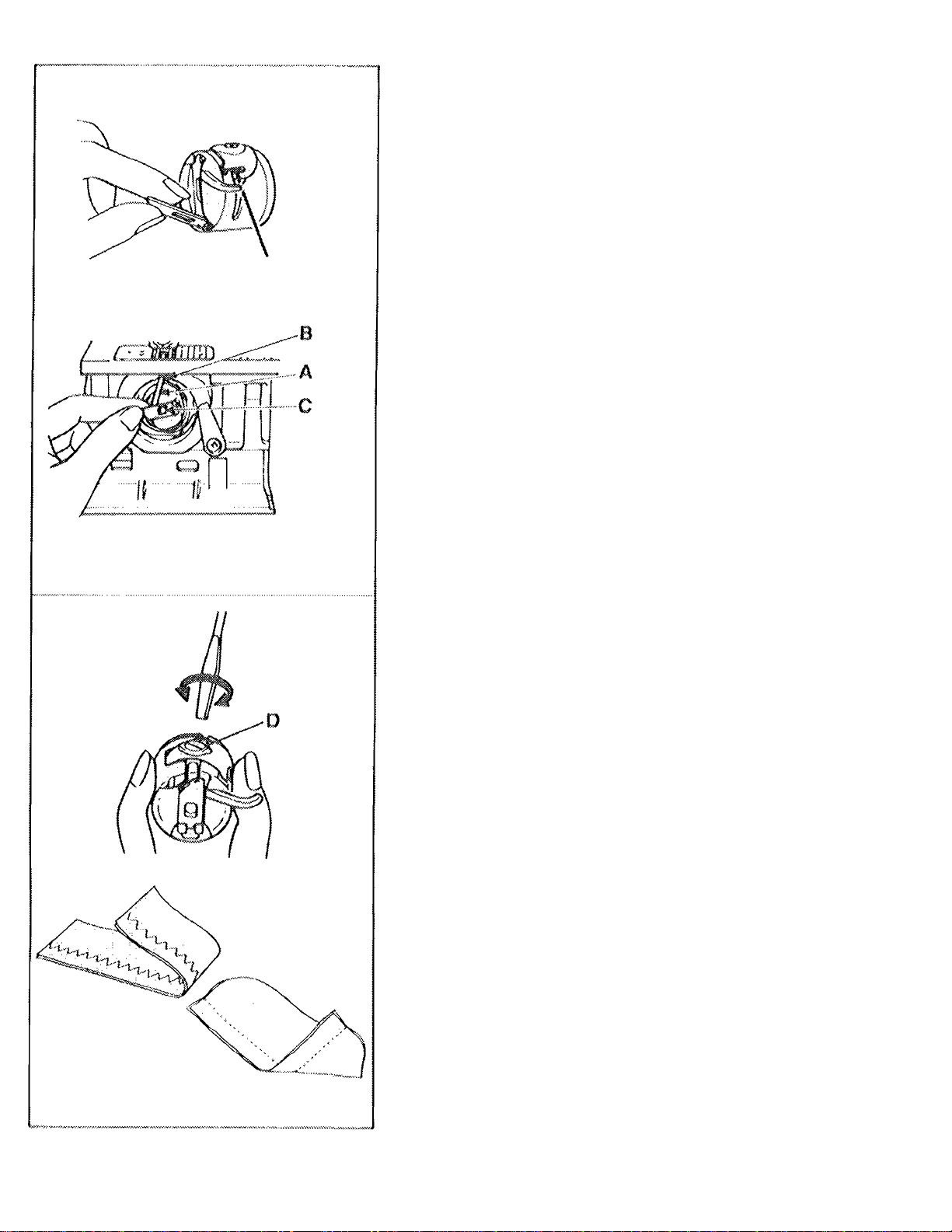

Replacing the Bobbin Case

1. Hold bobbin case by latch, with

about 7.5 cm (3 inches) of thread

leading off top of case,

2. Align protruding finger A with slot

B and slide case on the stud C.

® Release the latch and push

case until it clicks into place.

Allow 7.5 cm (3 inches) of

thread to hang free from bob

bin case.

» Close hook cover or slide

plate. Be sure thread does not

get caught when hook cover is

closed.

Adjusting Bobbin-Thread

Tension

The bobbin-thread tension has been

set at the factory for most types of

stitching. You may wish to adjust

the bobbin-thread tension when

straight stitching on fine fabrics or

to balance an open zig-zag stitch.

Bobbin and needle threads lock at

the corner of each stitch when a zig

zag stitch is balanced. To adjust the

bobbin-thread tension, follow the

procedure below using two layers of

scrap fabric.

® Raise the presser foot.

® Raise needle to highest position

by turning the hand wheel toward

you.

® Open hook cover or slide plate

and remove the bobbin case as

instructed on page 14.

® Slowly turn screw D to the left or

right, using the small screwdriver

in your accessory box, until

desired stitch appearance is

reached.

® When stitching is completed, turn

screw D to the right or left back to

original position, for all other

sewing.

15

Loading...

Loading...