SINGER 401A User Manual

SINGER

SIANT-O-MAT/C

Instructions for using-

SINGER

SIANT-O-MAT/C

The SLAAiT~0~MAT/C-the greatest sewing machine ever built!

*A Trademark of THE SINGER COMPANY

The SXHGER Slj^Aír-O-MAr/C the greatest sewing machine ever built.. .

From the moment you see the new slant-o-mat/c, you’ll know it’s

excitingly different. You’ll marvel at its automatic sewing... its al

most unbelievable ease of operation ... the remarkable services it

performs. You’ll delight in its sure, beautiful stitching. The only auto

matic zigzag machine for home use made entirely in America, it out-

sews all other machines in both straight and fancy stitching.

# World’s first automatic with a slant needle and gear drive. Seeing

is easier, sewing smoothest e\er. No slipping or stalling.

# World’s first automatic with double easy threading. Has built-in

threading chart, handy "'drop-in” bobbin in Jront of needle!

# World’s first automatic with a built-in eye-level stitch chart, that

lets you "tune” the knob for whatever fancy stitch you want!

Add to these major developments in sewing machine design the

following ADVANCED features, and you have a machine far ahead in

design, unequalled in performance.

Copyright © 1958 by The Singer Company

ELEVATOR TYPE multi-purpose calibrated

throat plate, lever operated, simplifies

darning.

NEW NEEDLE CLAMP holds one or two

regular needles —same or different sizes

for exciting twin needle stitching.

HINGED face plate swings open for easy

cleaning.

SUPERFINE CONTROL of stitch length en

sures perfect satin stitching.

PERFECT Straight Stitching.

BUILT-IN LIGHT focused on sewing area.

TO GET THE MOST ENJOYMENT

FROM YOUR SINGER

ALL MECHANISM completely enclosed.

NEW ADJUSTABLE HINGED zipper and cord

ing foot.

NEW SPECIAL PURPOSE FOOT.

NEW SEAM GUIDE.

Take advantage of the free sewing lessons to which you are entitled!

Skilled, SiNGER-trained teachers will give you personal guidance and

assist you in learning the fundamentals of home sewing.

SINGER SERVICE

Wherever you go you will find expert, dependable singer*

Service close at hand, singer is interested in helping you

keep your singer Sewing Machine in top running condition.

That is why you should always call your singer center if your

machine ever requires adjustment or repair. Only from your

SINGER CENTER

Can you obtain the services of a trained singer

repair man and warranted singer* parts.

EVERYTHING FOR THE WOMAN WHO SEWS

The answer to your sewing needs is at your singer center.

There you will find a wide choice of sewing aids, notions, sew

ing instructions and services. Look for the famous red and

SINGER trademarks on your singer center and the ever ready

QKI(§liia

SINGER Service Car. See phone book under the singer company

for address nearest you.

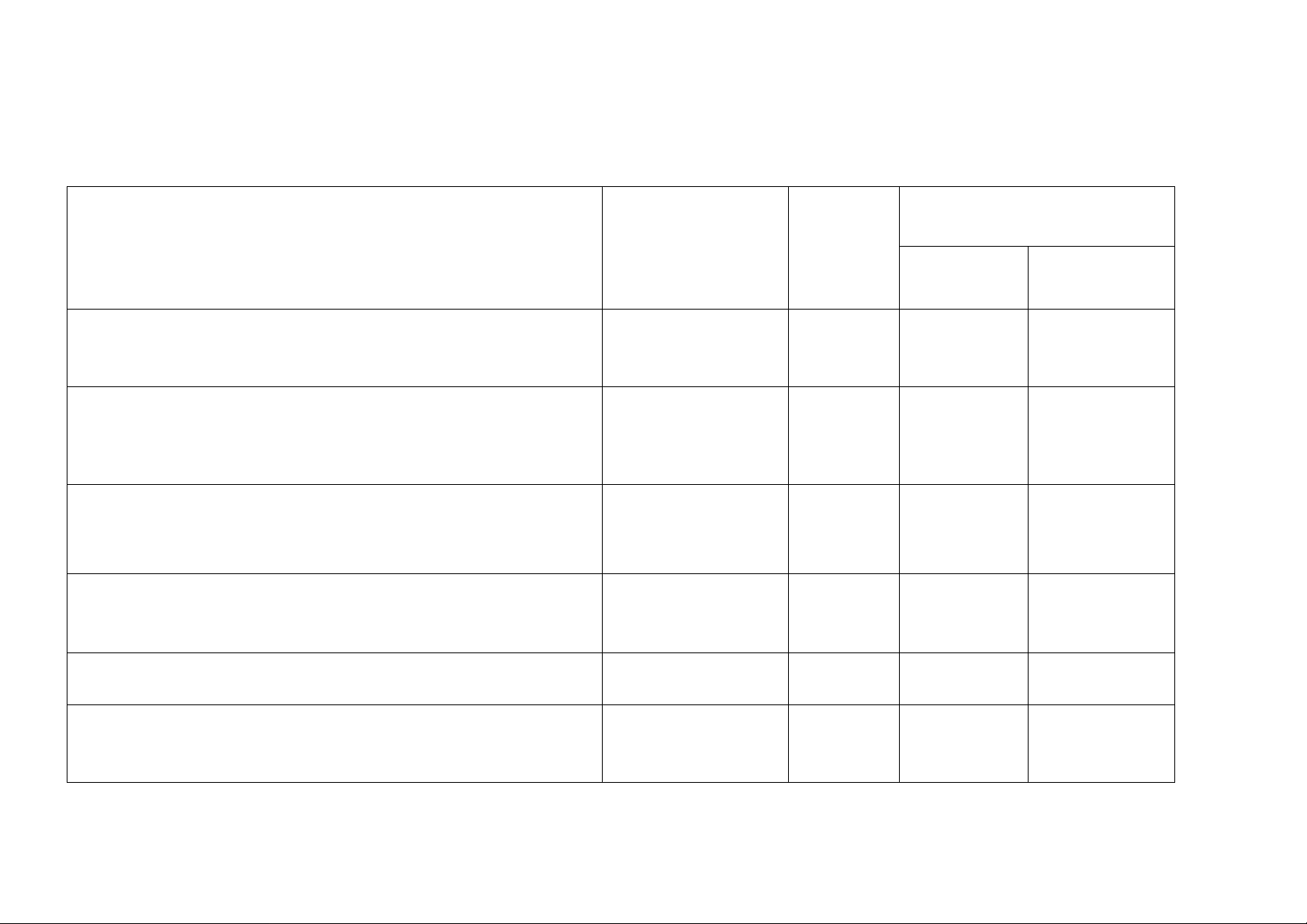

FABRIC, THREAD, NEEDLE AND STITCH LENGTH CHART

TYPES OF FABRICS

THREAD

SIZES

NEEDLE

SIZES

MACHINE STITCH SETTINGS

FOR STRAIGHT SEWING

INSIDE

SEAMS

TOP

STITCHING

Filmy materials comparable to Net, Marquisette, Chiffon,

Silk and Chiffon Velvets, Voiles, Ninon

Sheer materials comparable to Lawn, Dimity, Synthetic

Sheers, Paper Taffetas, Pure Silks, Gossamer Silks, Silk or

Synthetic Tricots, Synthetic Velvets, Satins

Lightweight materials comparable to Gingham, Chambray. Pique, Poplin, Percale, Cretonne, Chintz, Faille,

Bengaline, Wool Flannel, Wool Jersey, Wool Crepe,

Cotton Velvets and Velveteens, Lightweight Suitings

Medium heavy materials comparable to Corduroy, Crash,

Gabardine, Rep, Heavy Suitings and Coatings

Heavy materials comparable to Sailcloth, Denim, Ticking,

Overcoatings

Plastic Materials

50 Embroidery

100 Cotton

Synthetic Thread

50 Embroidery

80 to 100 Cotton

Synthetic Thread

50 Mercerized

60 to 80 Cotton

A Silk

Heavy Duty Mer.

40 to 60 Cotton

Synthetic Thread

30 to 40 Cotton

Thread

50 Embroidery

Synthetic Thread

50 Mercerized

9

11

14

or

16

16

18

11 or 14

15 to 20 15 to 20

12 to 15

12 15 to 18

10 12

8

10

15 to 20

10

12

When ordering needles, always specify ''Class and Variety 15 x 1" and state the size and quantity required.

NEEDLES AND THREAD

This machine uses a 15 x 1 needle.

Si2es 9, llj 14, 16 and 18.

For perfect stitching, select correct needle and

thread to correspond with fabric according to

table on page 5. Be sure to use like threads for

both needle and bobbin.

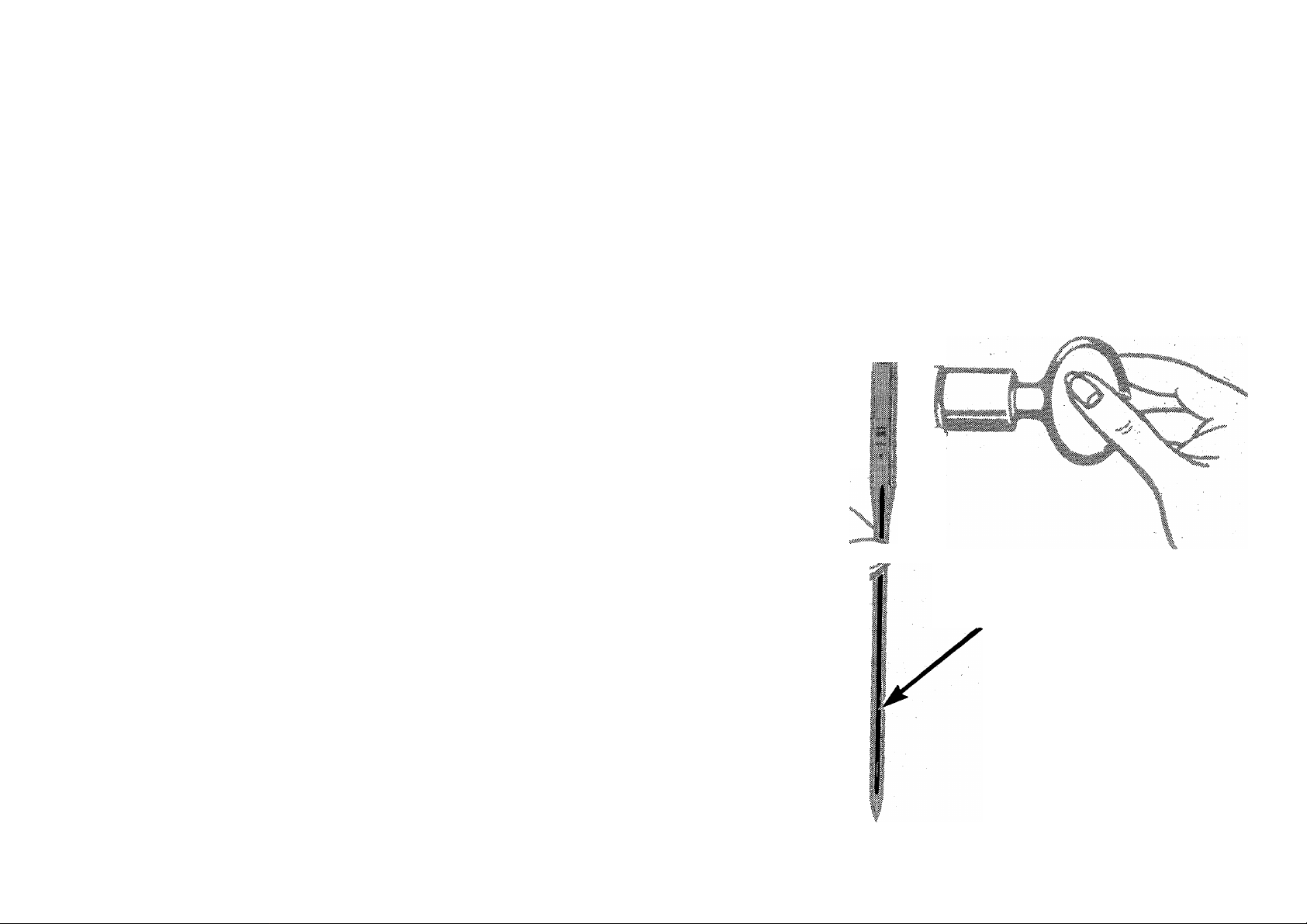

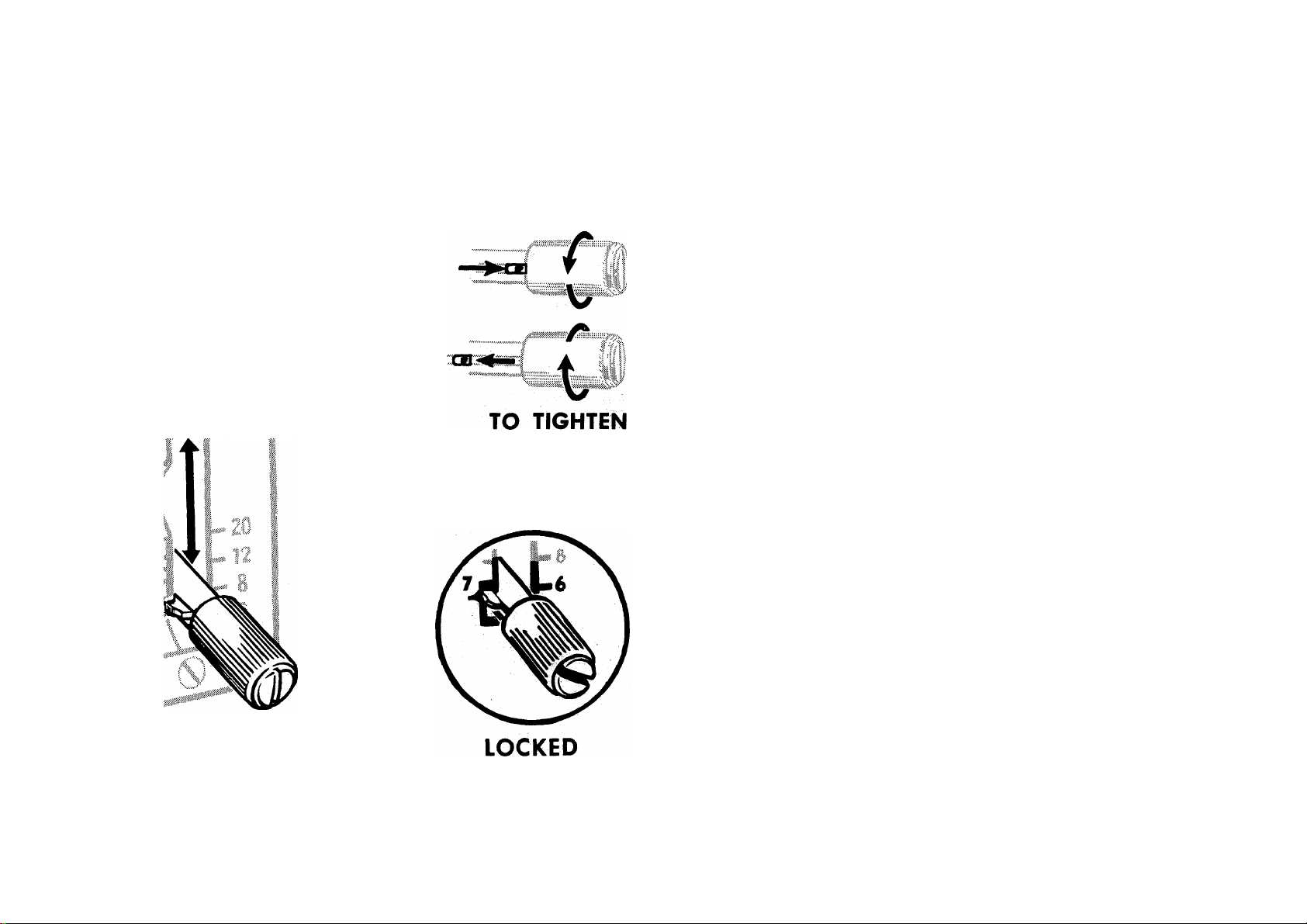

NEEDLE INSERTION

Raise the needle bar to highest point by turn

ing the hand wheel toward you. Loosen the needle

I \ 'v

i mk

m №

p t ^

mn

i PI 1 i ^'1

9 iSS» SSSKWiiSSWii

clamp screw. Insert needle upward into clamp

ias far as it will go, with the flat side of the needle

to the back and the long groove toward you.

Tighten needle clamp screw.

LONG GROOVE

TOWARD YOU

UPPER THREADING-SINGLE NEEDLE

Raise take-up lever to highest point. Place

thread on spool pin and lead through threading

points shown. Thread needle from front to back.

Draw sufficient thread through eye of needle with

which to start sewing.

I

s

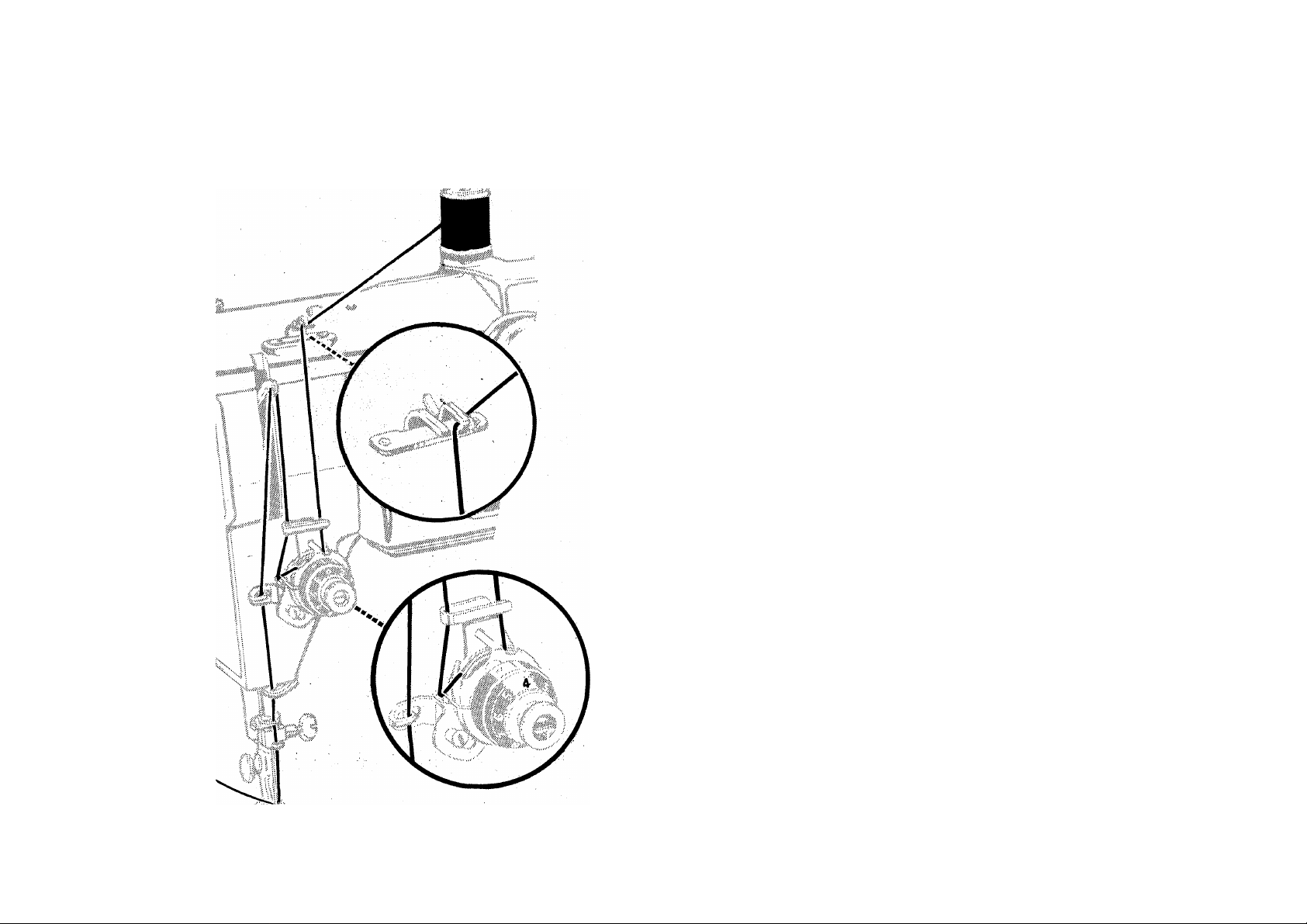

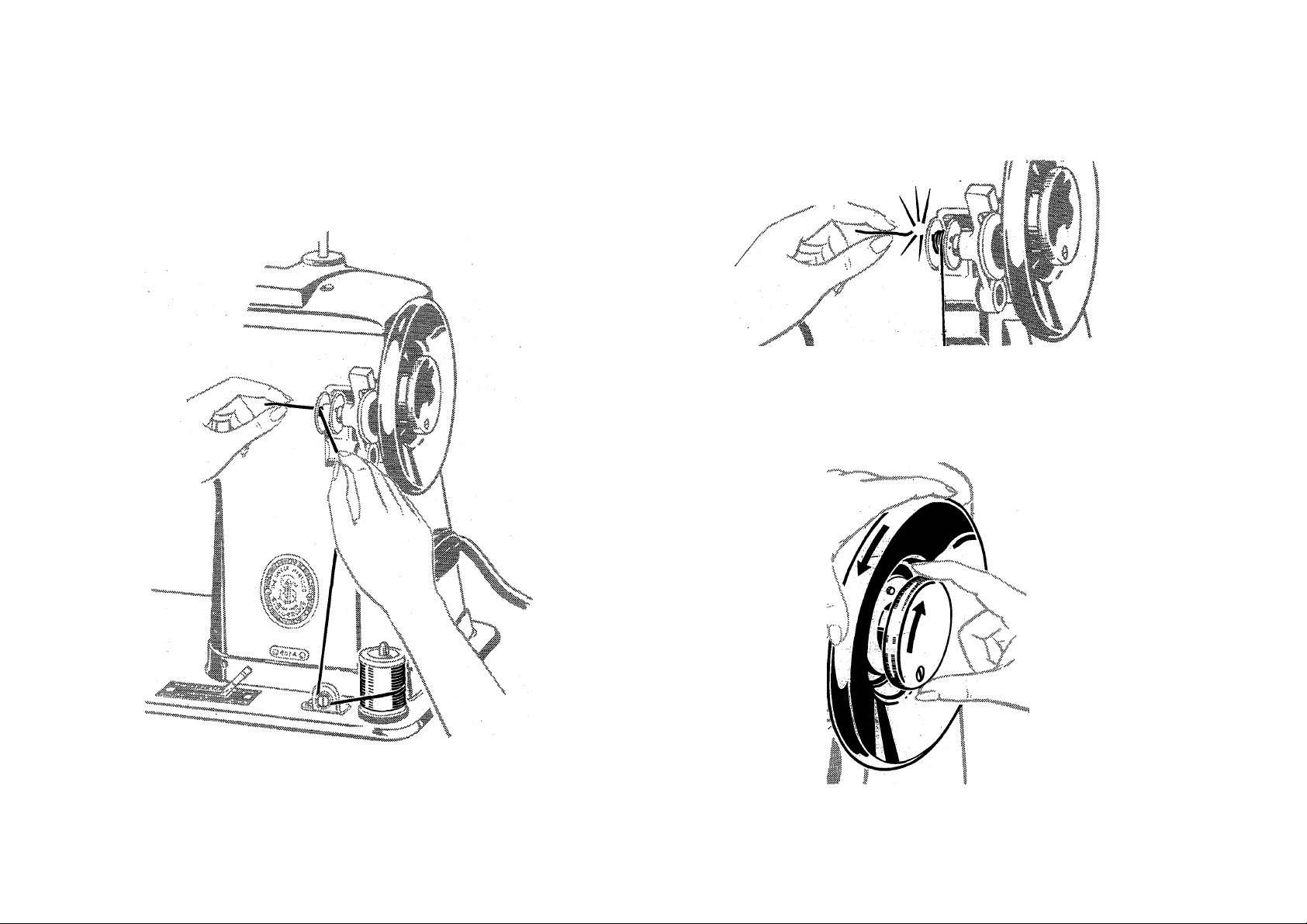

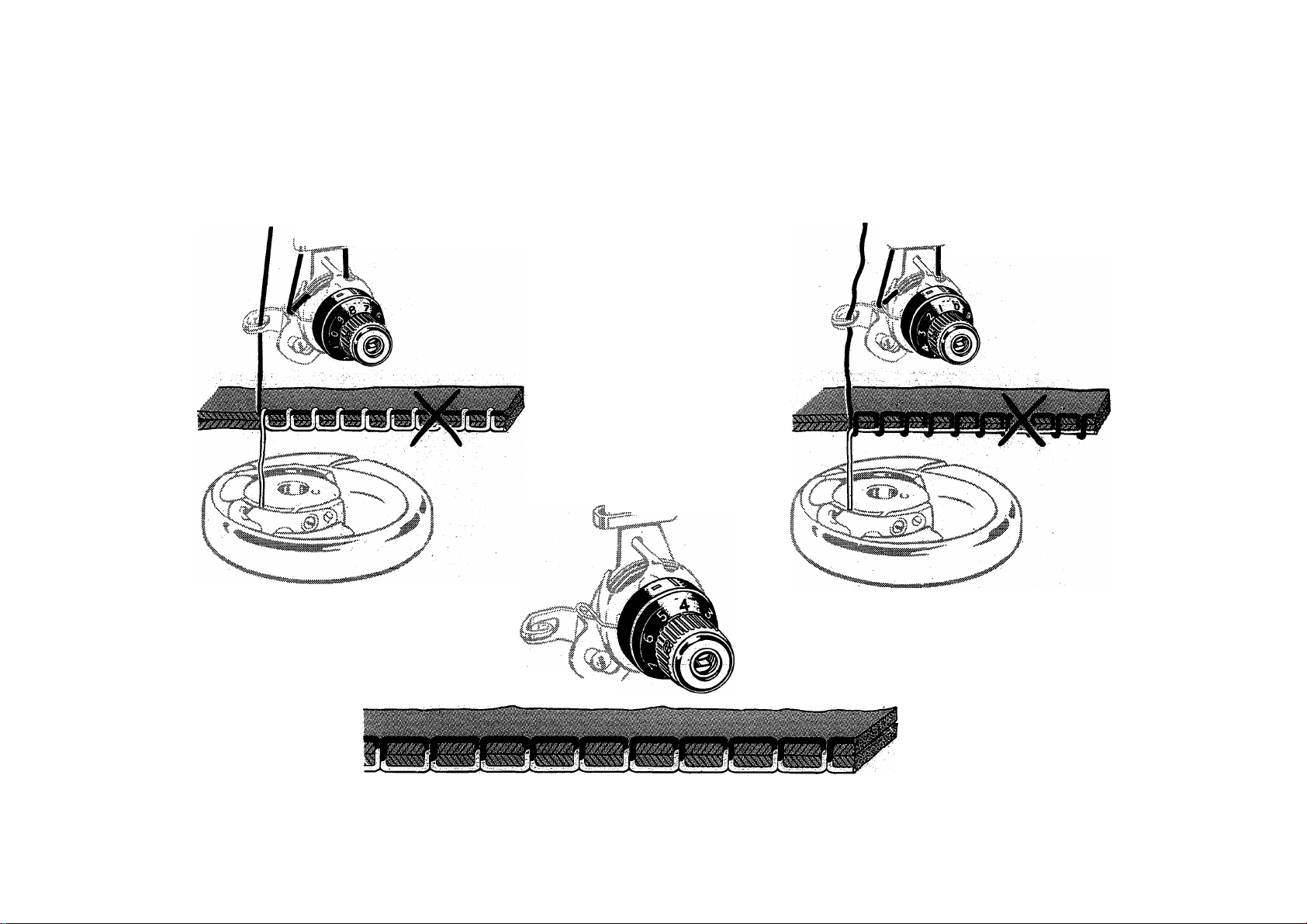

WIND THE BOBBIN

Loosen Stop motion screw with right hand. Raise bobbin winder and position

bobbin on spindle. Press winder against hand wheel.

WIND THE BOBBIN (Confd.)

Hold thread end to start winding. Activate

machine.

I-...,.

Place thread on spool pin and lead between

bobbin winder tension discs. Thread through

hole in left side of bobbin as shown.

jlllll

■'■••v.-Wiv

Full bobbin will automatically release.

Tighten stop motion screw.

I

Wk^A

«.«'■^C I 'V*^ 'Ц

'■• Ч. г .^■

n

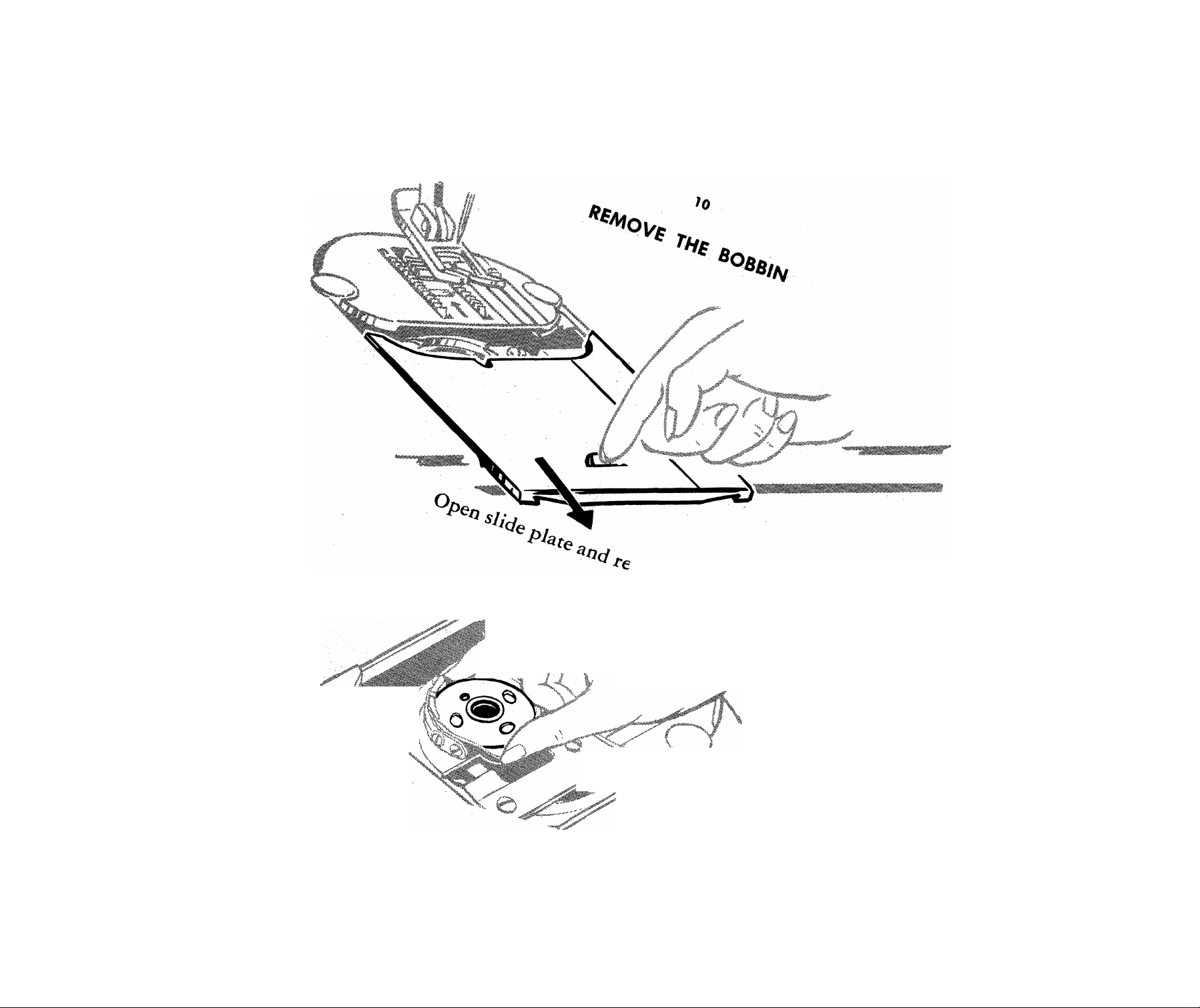

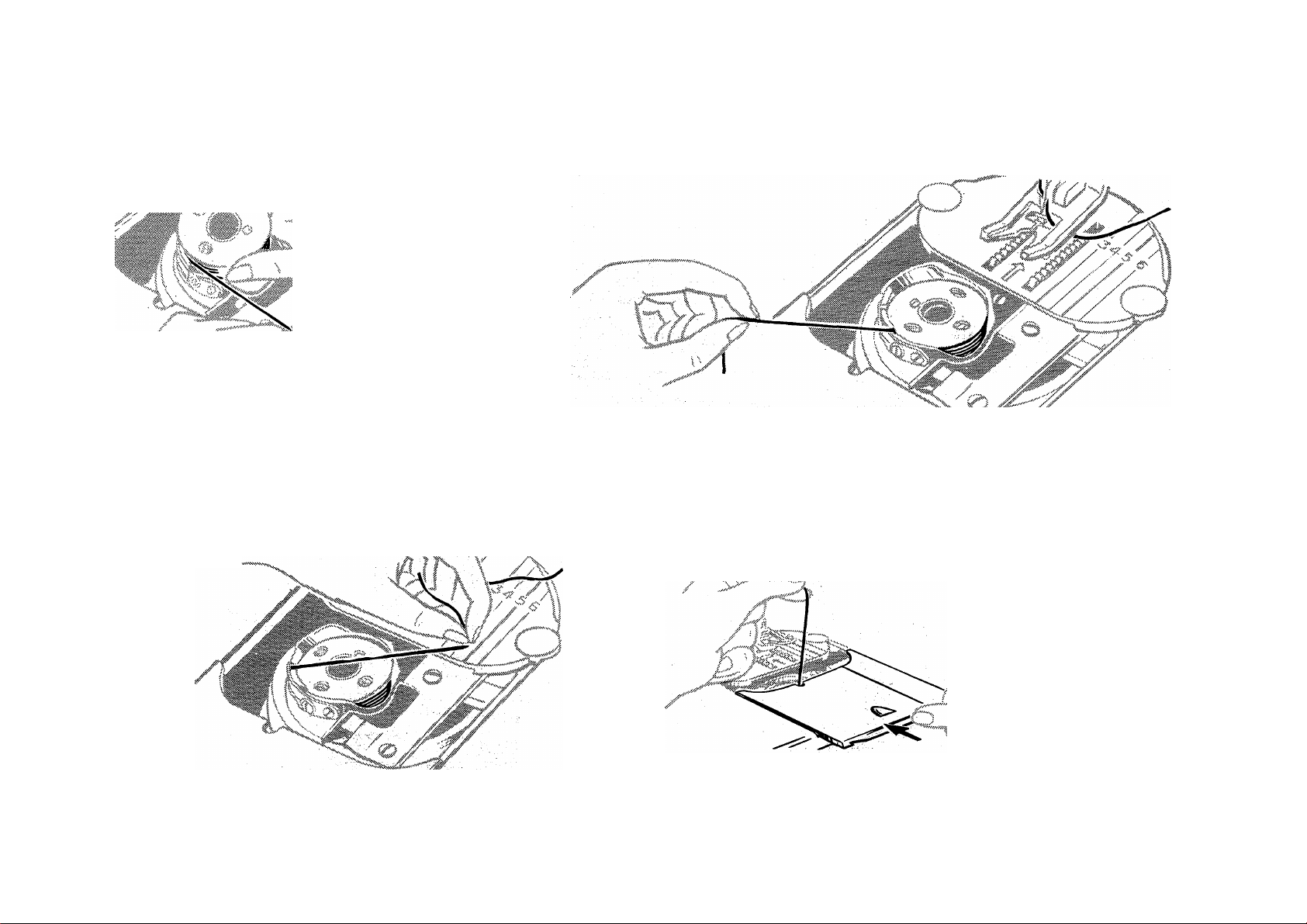

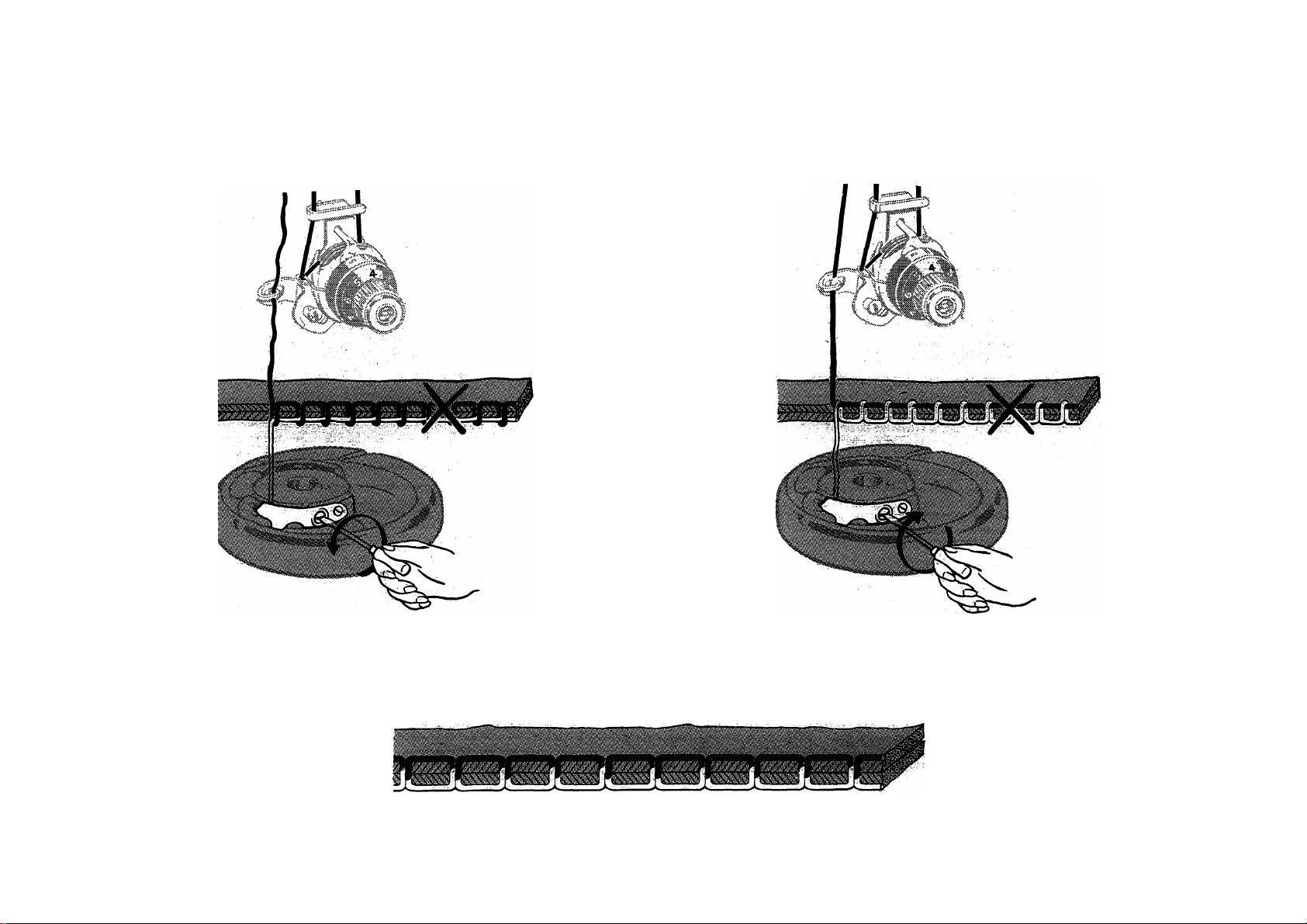

THREADING THE BOBBIN CASE

V

(

Hold bobbin so that thread leads off, in direGtion shown. Place bobbin in case.

Lead thread into slot and under spring. ^

' 1

J

it- i Si \

WSSM«hy«Wi«<sw.»5

Draw thread into notch at end of spring, pulling off about 3 inches of thread

across the bpbbin.

Close slide plate allowing thread to enter notch.

12

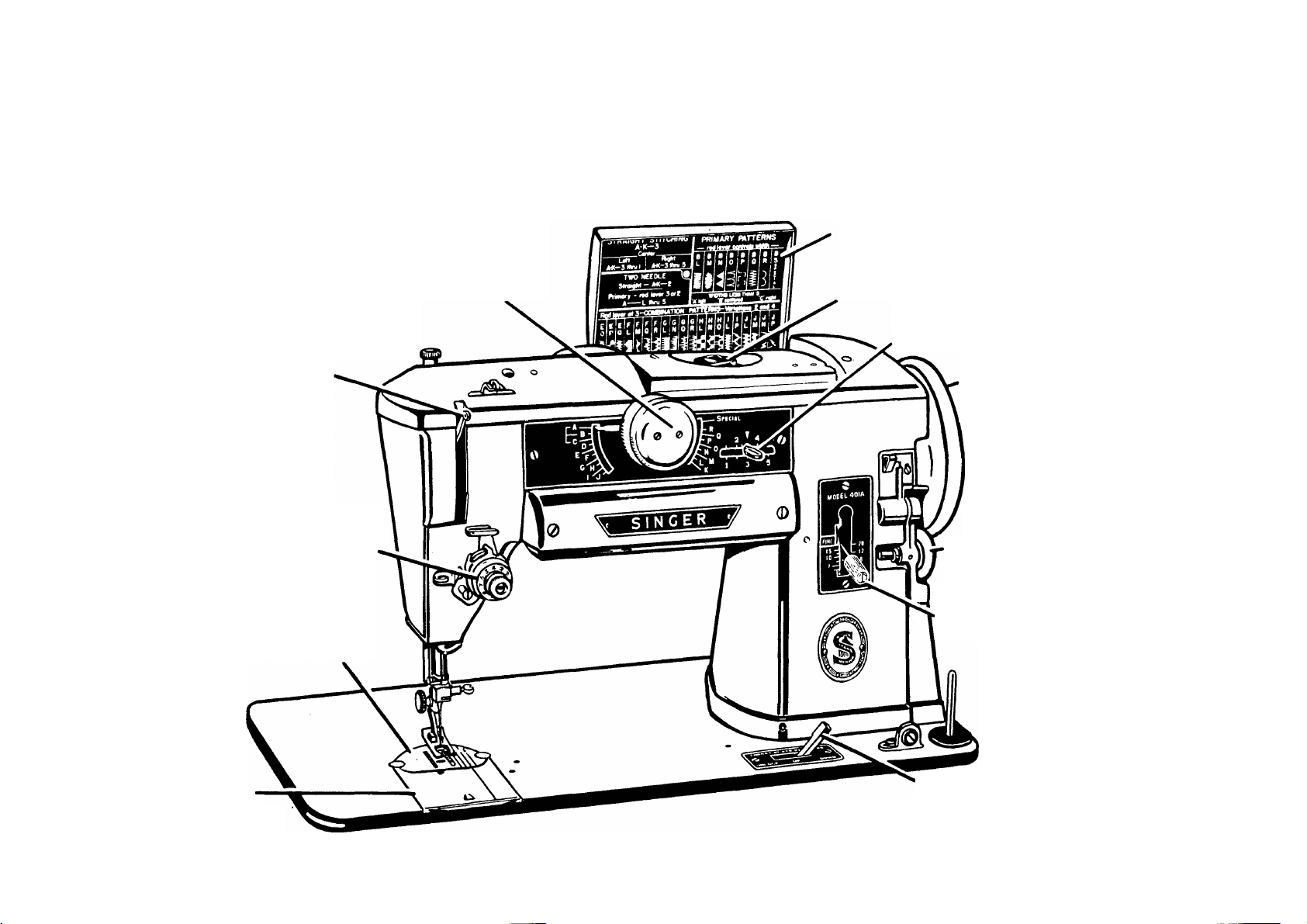

PRINCIPAL PARTS OF MACHINE 401

STITCH CHART

STITCH SELECTOR

TAKE-UP

LEVER

NEEDLE THREAD

TENSION

THROAT PLATE

SPECIAL DISC

RED LEVER

HAND WHEEL

BOBBIN WINDER

STITCH REGULATOR

SLIDE

PLATE

THROAT PLATE

POSITIONING LEVER

13

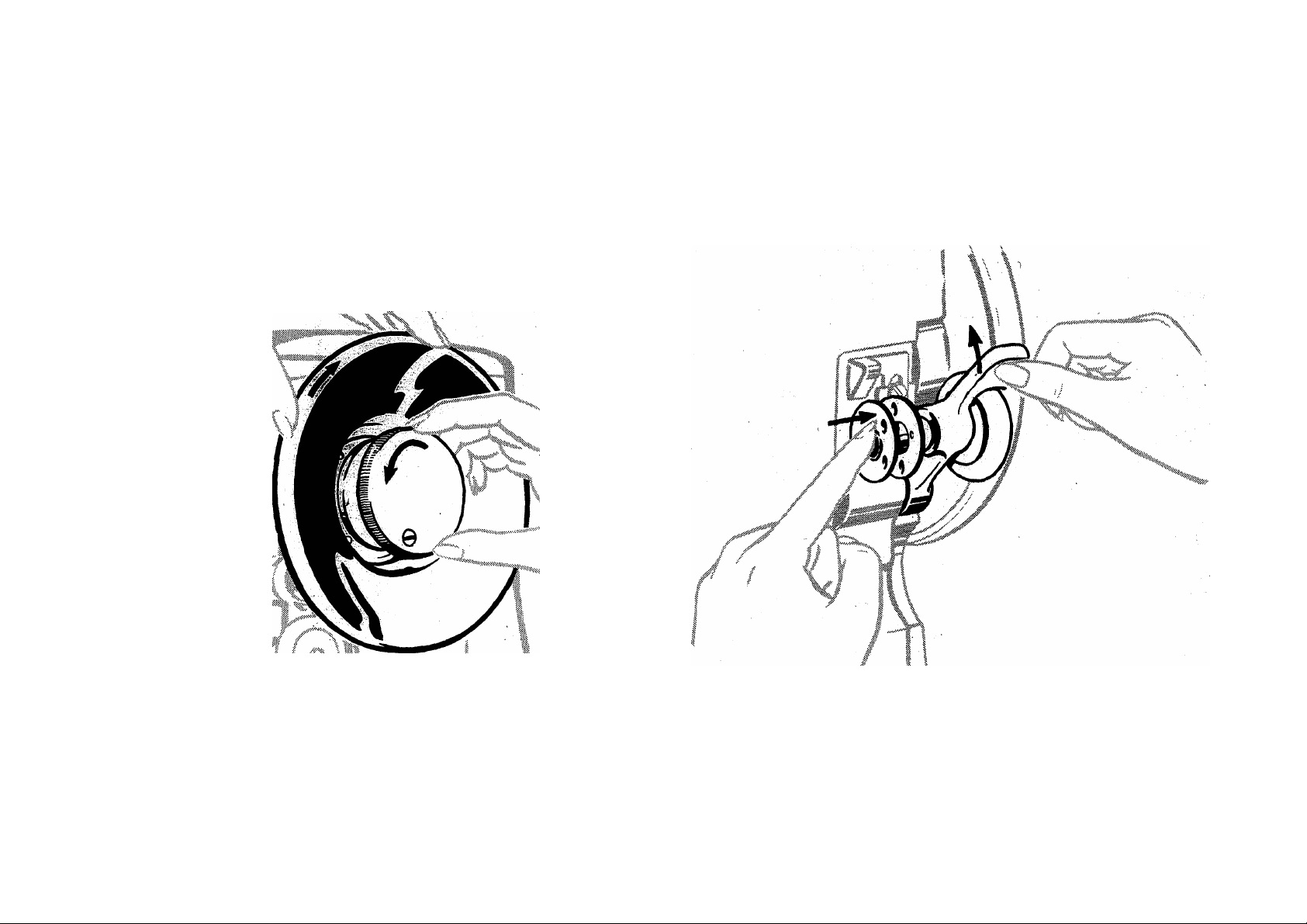

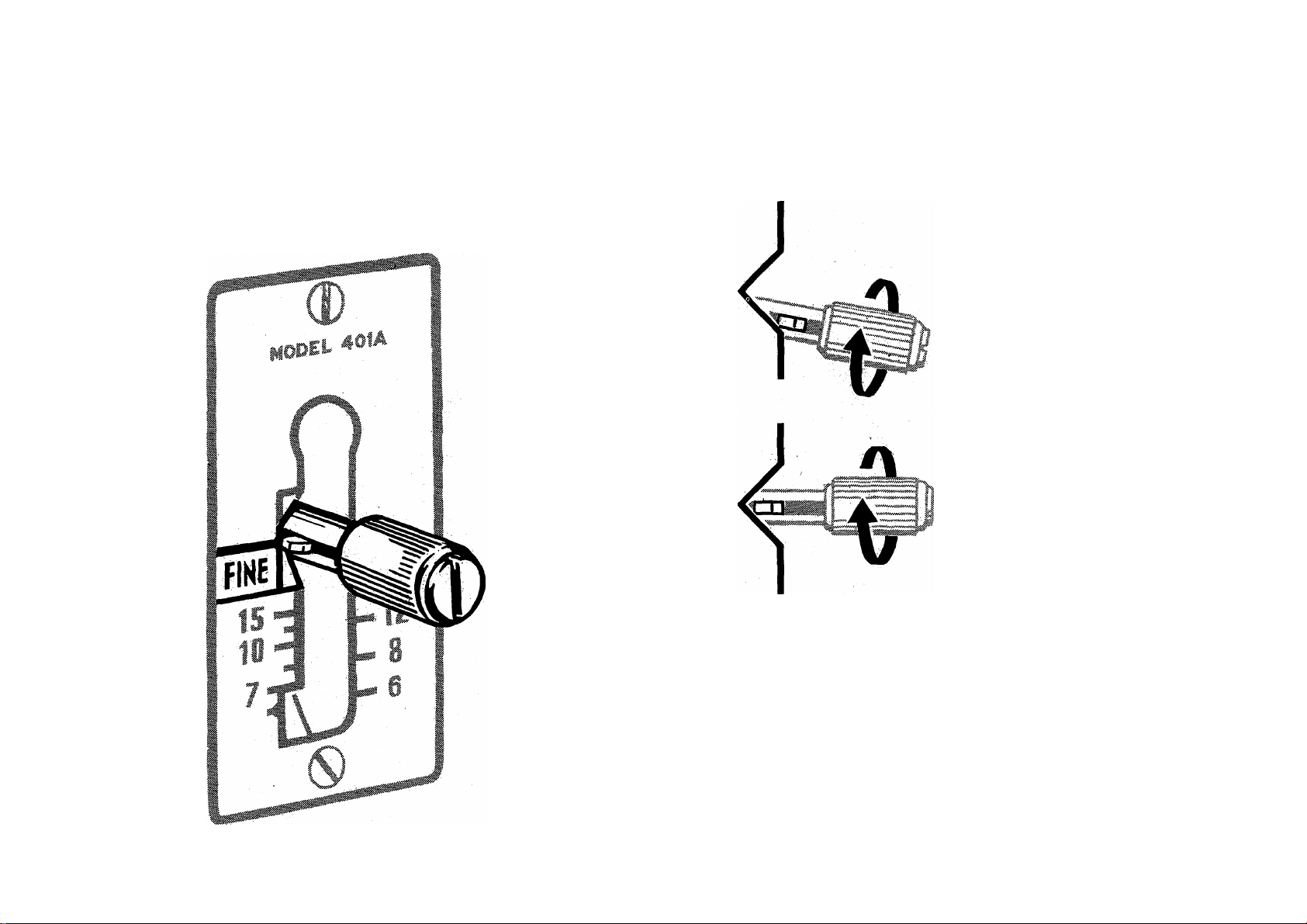

STITCH LENGTH REGULATOR

REVERSE

TO RELEASE

Numerals on the indicator represent the number

of stitches per inch.

The upper indented area of the indicator

represents **fine'' stitch lengths above 20.

The lower indented area of the indicator allows

the #6 stitch length setting to be “locked’’ in place

when stitching folds, pleats or multiple layers of

heavy fabric.

To set stitch length: Release pointer by turning

thumb nut to the left, as shown. Position lever for

desired stitch length. Tighten pointer against the

plate by turning thumb nut to the right.

Once the pointer has been positioned, reverse

FORWARD

stitching is accomplished by raising the lever to

its highest point. The #6 “locked” position cannot

be reversed.

SETTING

14

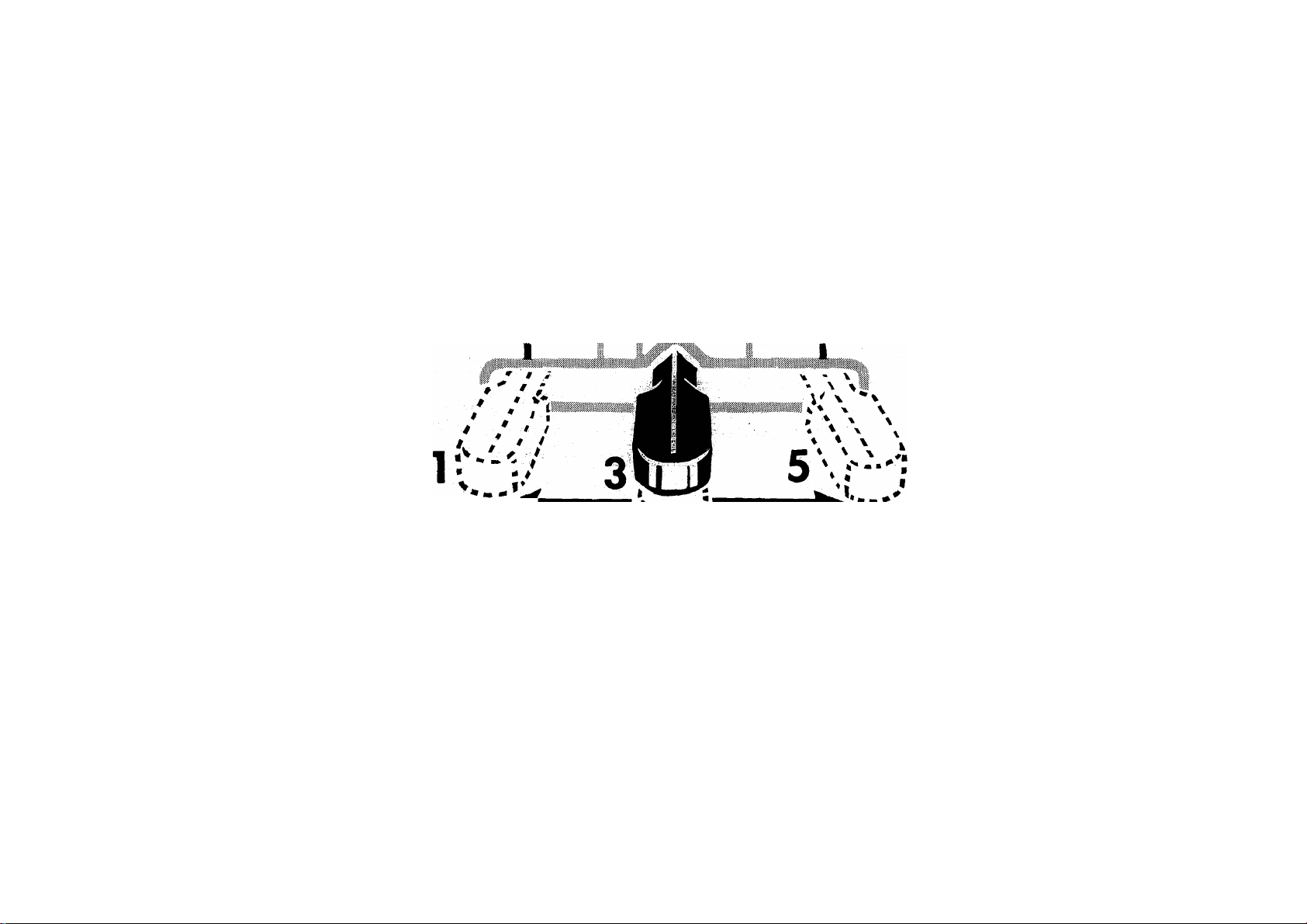

RED LEVER

T

I

A Red Lever setting is necessary for both straight and zigzag stitching.

Numerals indicate five positions, but intermediate settings may also be used.

To position, depress lever and slide it left or right to desired setting.

15

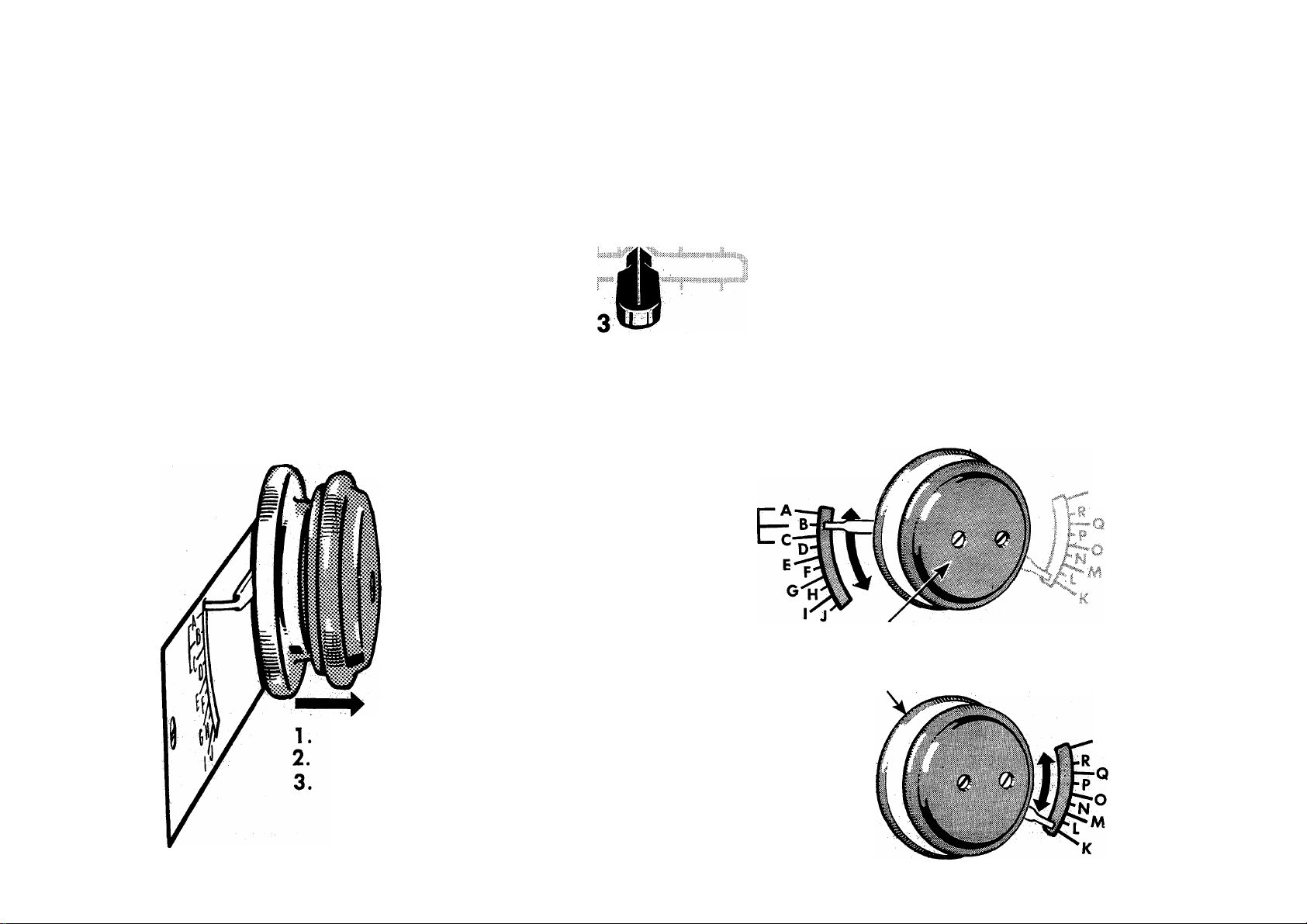

STITCH SELECTOR

Set Red Lever at 3

?

All settings on the left of the plate are controlled by the outer knob.

Push (using right hand)—^seleet desired setting and release.

All settings on the right of the plate are controlled by the inner knob.

Pull (using left hand)—select desired setting and release.

Do not make selector adjustments while the

needle is in the fabric.

1. PUSH

2. SELEGT (A THRU J)

3. RELEASE

PULL

SELECT (K THRU S)

RELEASE

PUSH AND SELECT

PULL AND SELECT

Special

16

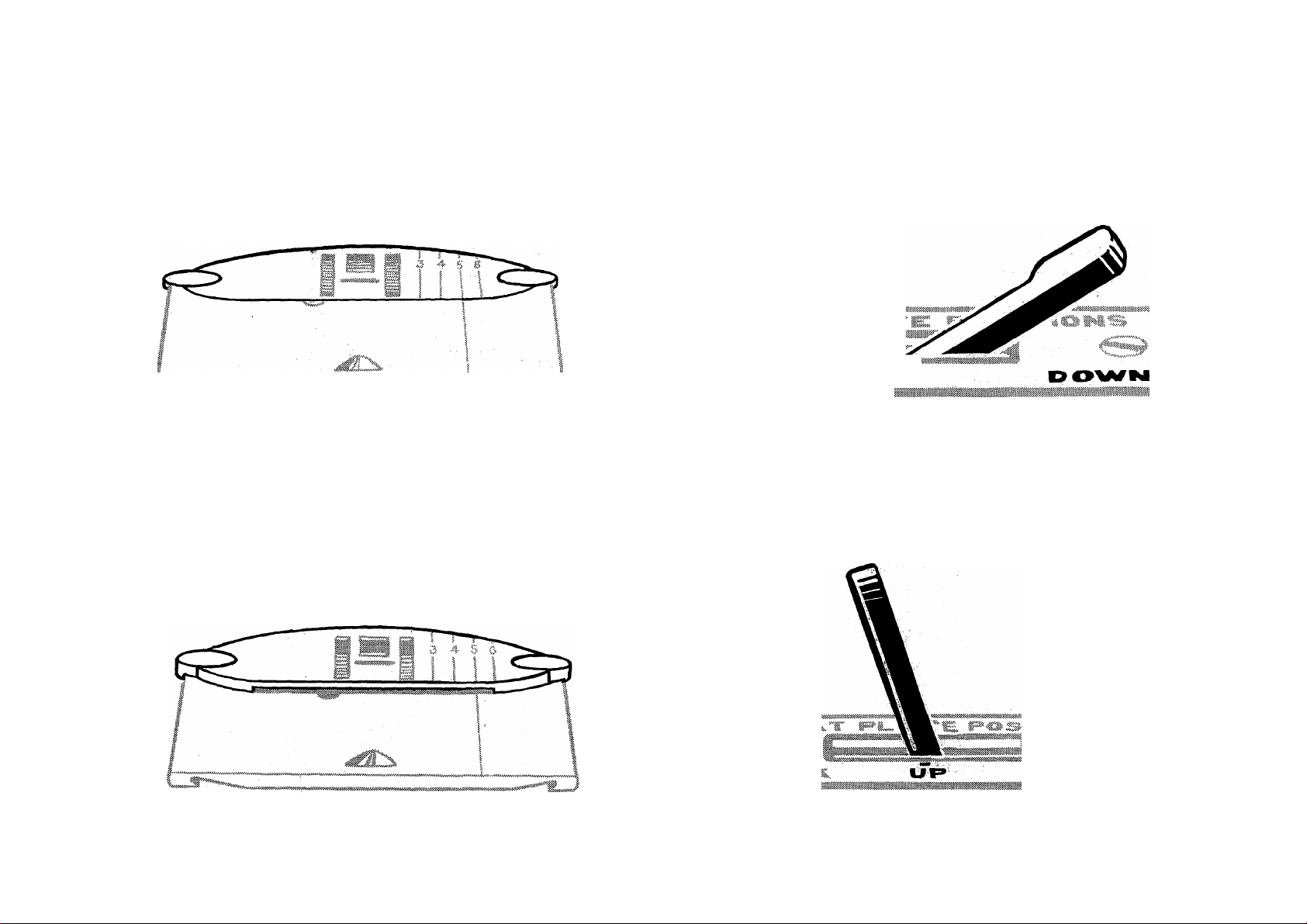

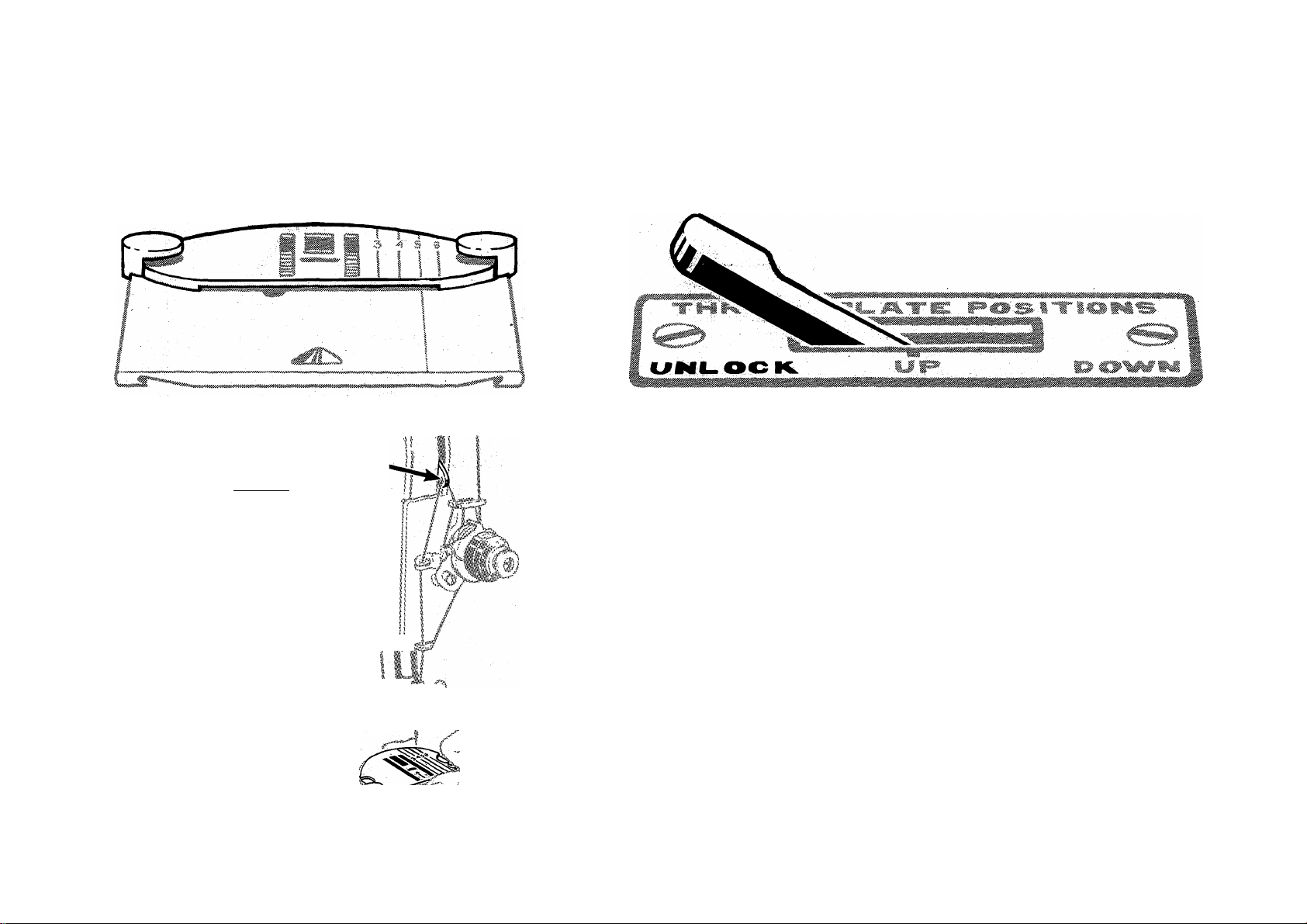

THROAT PLATE POSITIONS

- • >• -i< --V. ; , /'

' // i^i> '|S2^

Throat plate in ''Down’' position for general sewing.

Throat plate in "Up” position for darning, embroidering and button sewing.

^ a'

Throat plate in "Unlock” position for removaPand replacement.

TAKE-UP LEVER

MUST BE IN

LOWEST POSITION

I V

17

THROAT PLATE

REMOVAL AND REPLACEMENT

Raise pressler bar. Turn hand wheel to drop

take-up lever to its lowest point. Set throat plate

lever to "'Unlock’’ position. This preparation

applies to both removal and replacement.

Remove throat plate by sliding it back.

Replace throat plate by sliding it on from the

rear.

Lock in position.

Presser foot need not be removed for this

operation.

r-A

18

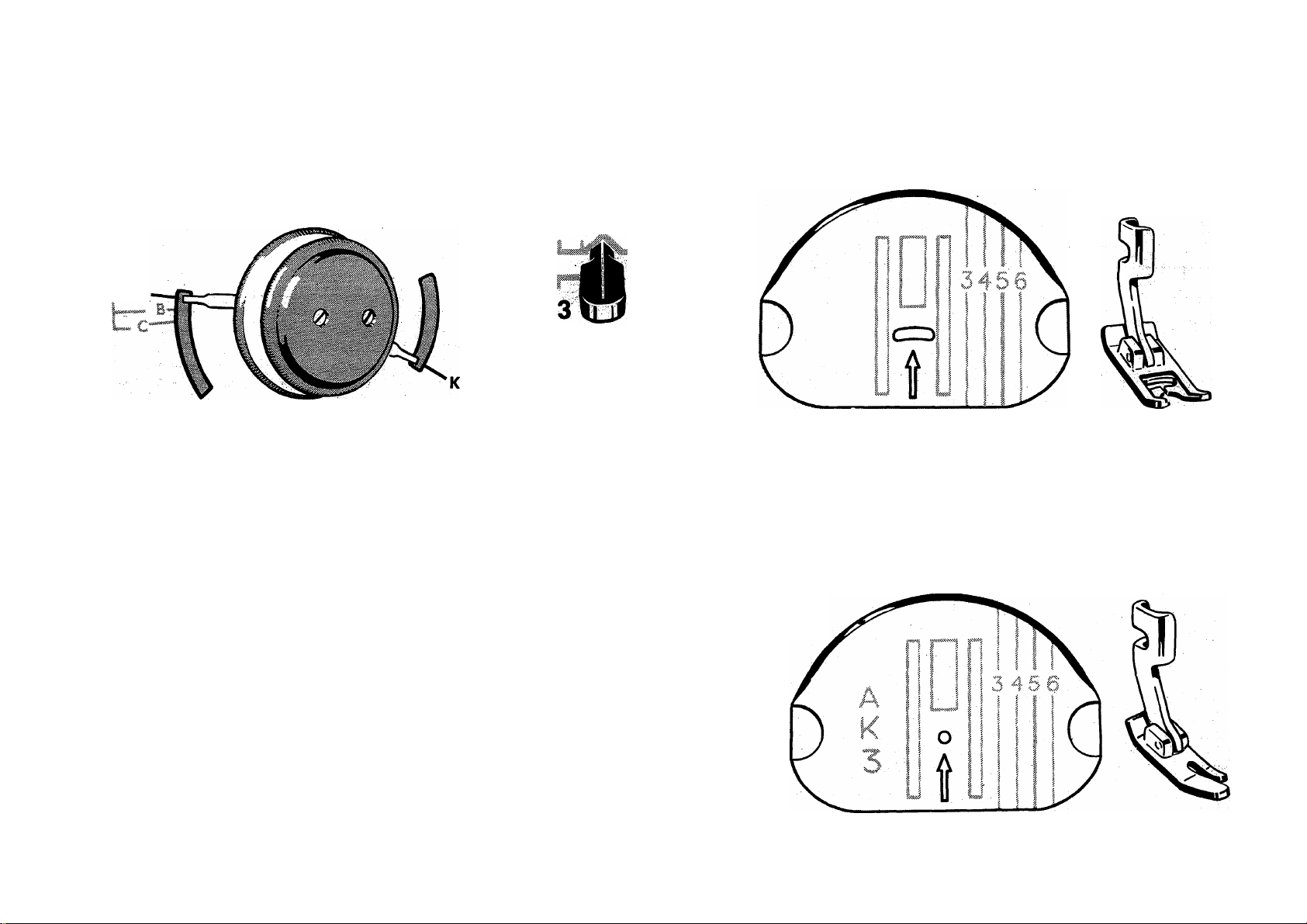

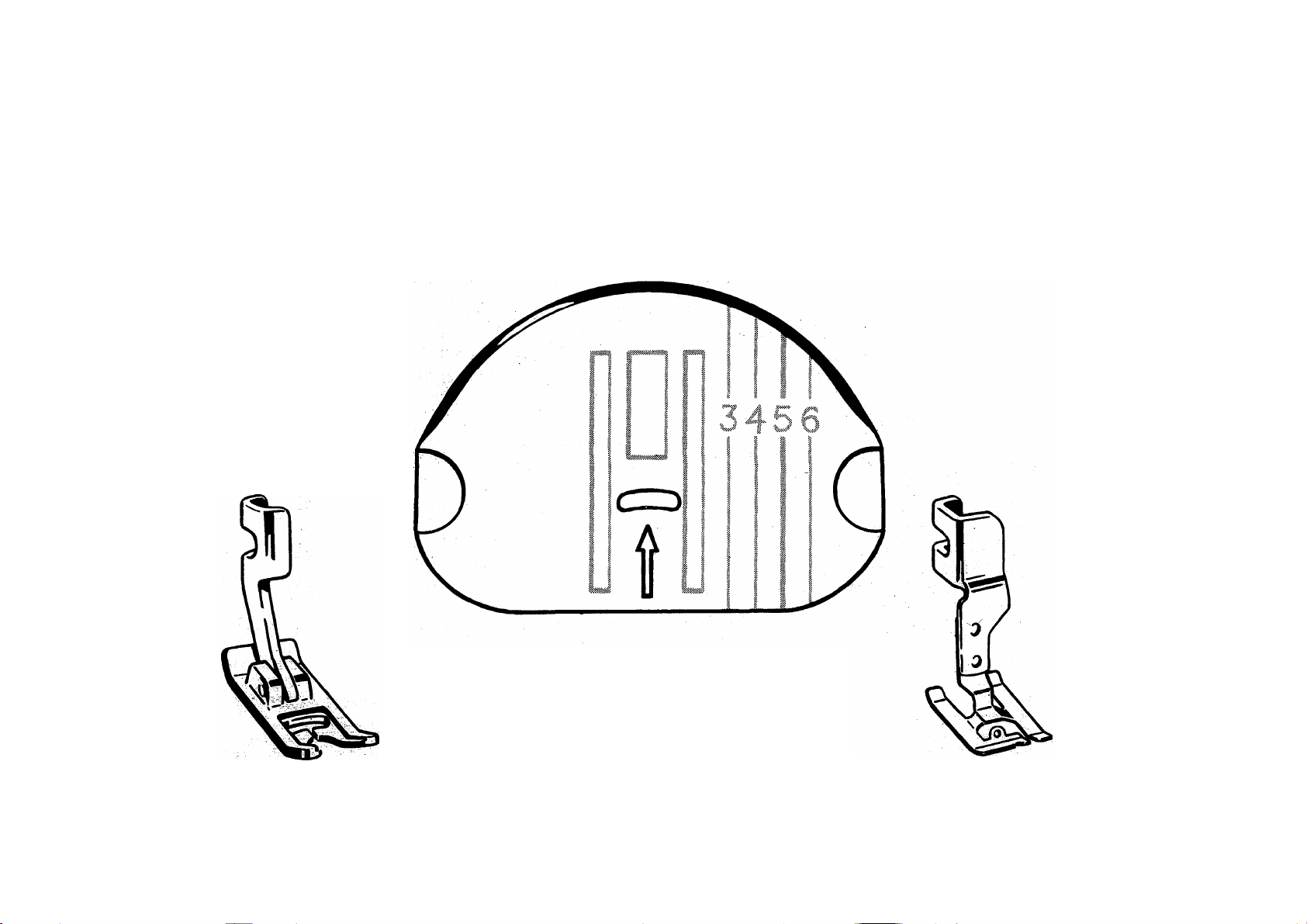

STRAIGHT STITCHING

A K 3

SET SELECTOR AT A K.

RK) LEVER AT 3-K) LOCATE STITCHING IN CENTRAL POSITION.

GENERAL PURPOSE THROAT PLATE AND PRESSER FOOT.

Use general purpose throat plate and presser foot for all utility sewing, long

straight seams, etc., and where there is occasion to alternate between straight and

zigzag stitching.

STRAÍGHT STITCH THROAT PLATE AND PRESSER FOOT

Use the straight stitch throat plate and presser

foot where fabric and sewing procedure require

close control ... for precision stitching of curved

and scalloped edges, top stitching, edge stitching,

etc.

For best results, this equipment should be used

when stitching sheer and filmy fabrics, knits

and tricots (particularly synthetics) and all soft

spongy materials.

K I

19

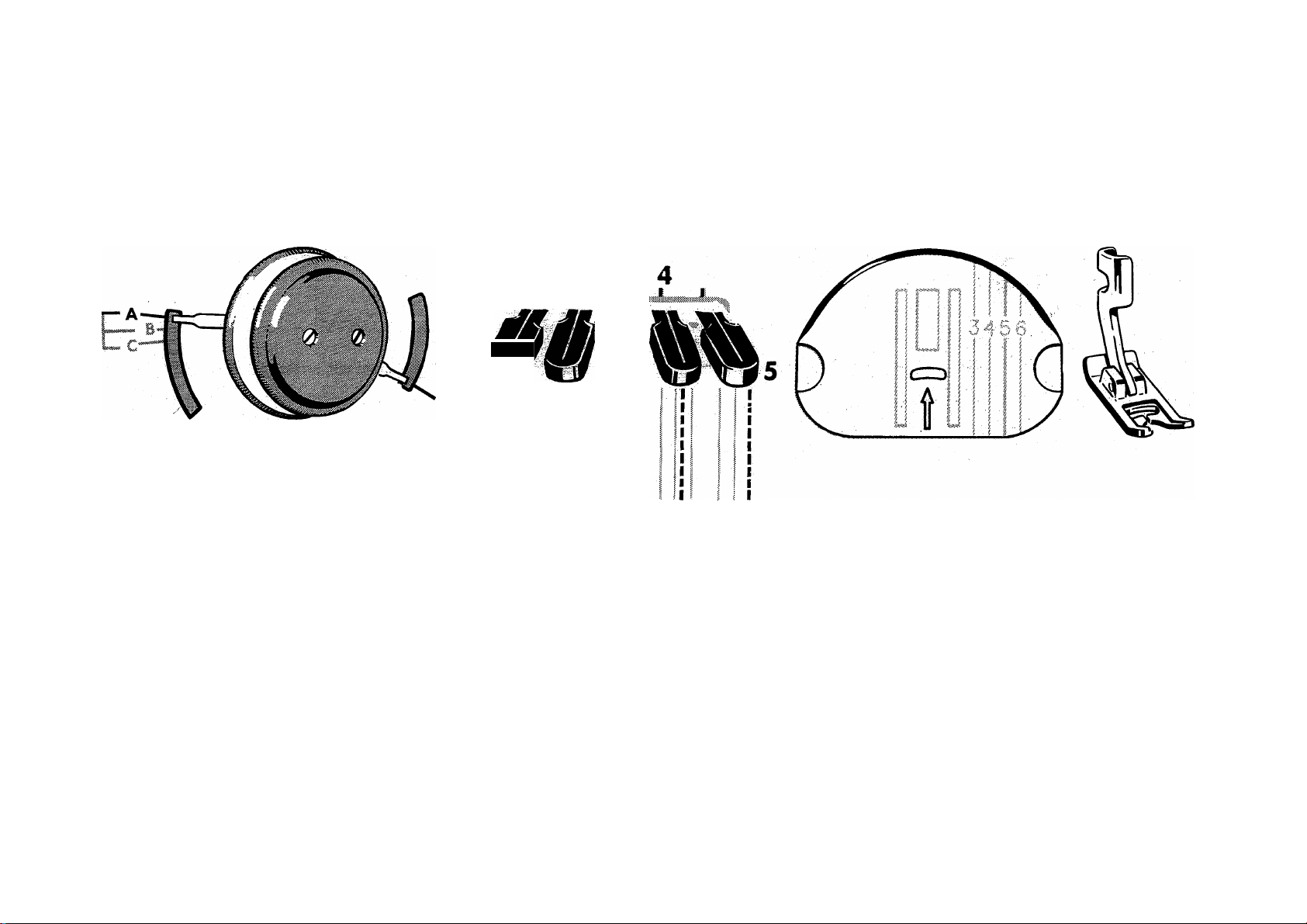

STRAIGHT STITCHING

SECONDARY POSITIONS

I i

SET SELECTOR AT A K.

RED LEVER AT 1, 2, 4 OR 5.

GENERAL PURPOSE THROAT PLATE AND PRESSER FOOT.

Do not make red lever adjustments while the needle is in the fabric.

To meet special requirements a line of stitching may be placed to the right or

left of center.

Red Lever settings 1 and 2 locate stitching to the left. Settings 4 and 5 place

it to the right. Intermediate settings may also be us^d.

20

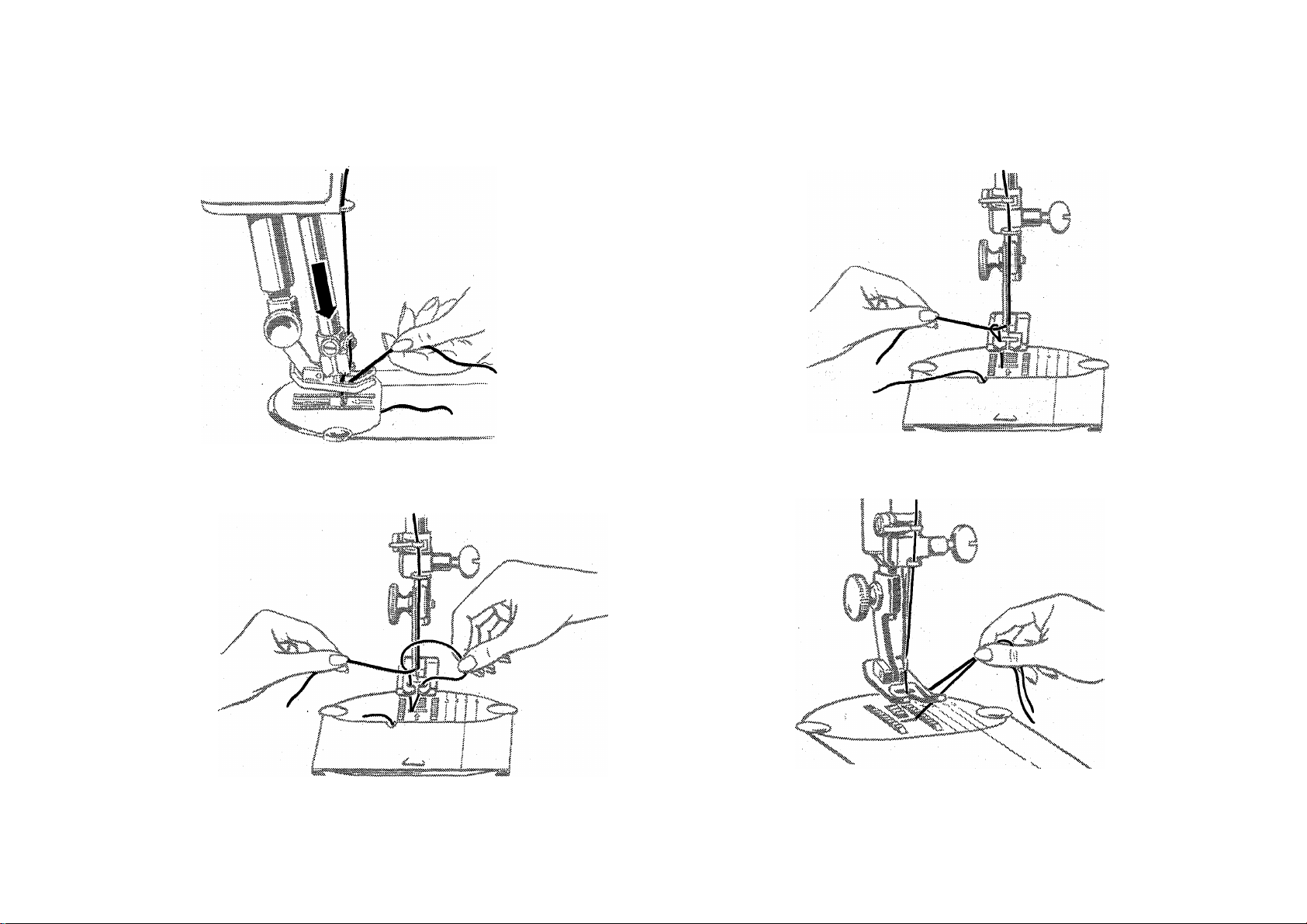

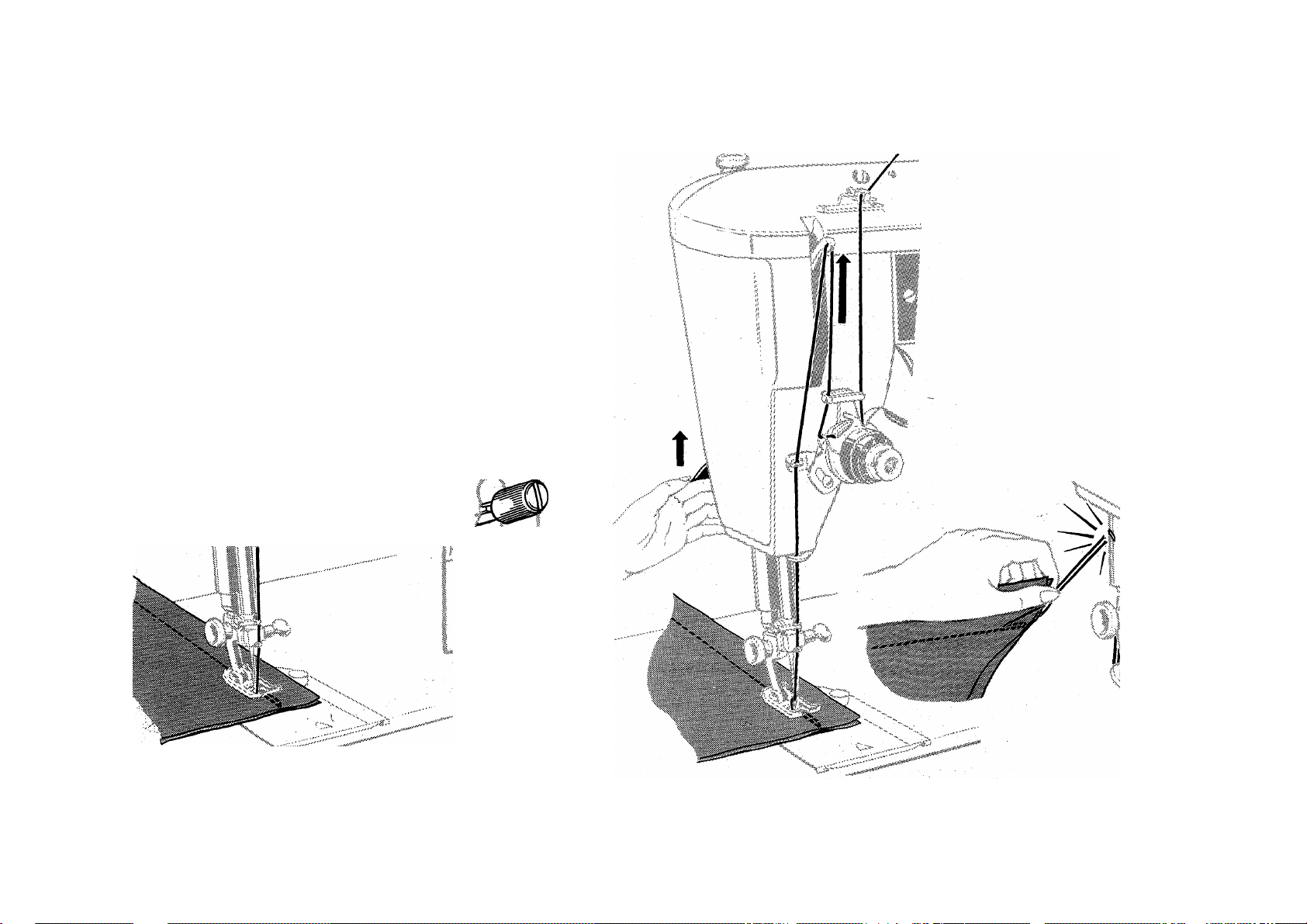

PREPARE TO SEW

Hold needle thread lightly with left hand. Turn hand wheel so that needle

enters plate and brings up bobbin thread.

Pull end pf bobbin thread through plate and place both needle and bobbin

threads diagonally under presser foot.

21

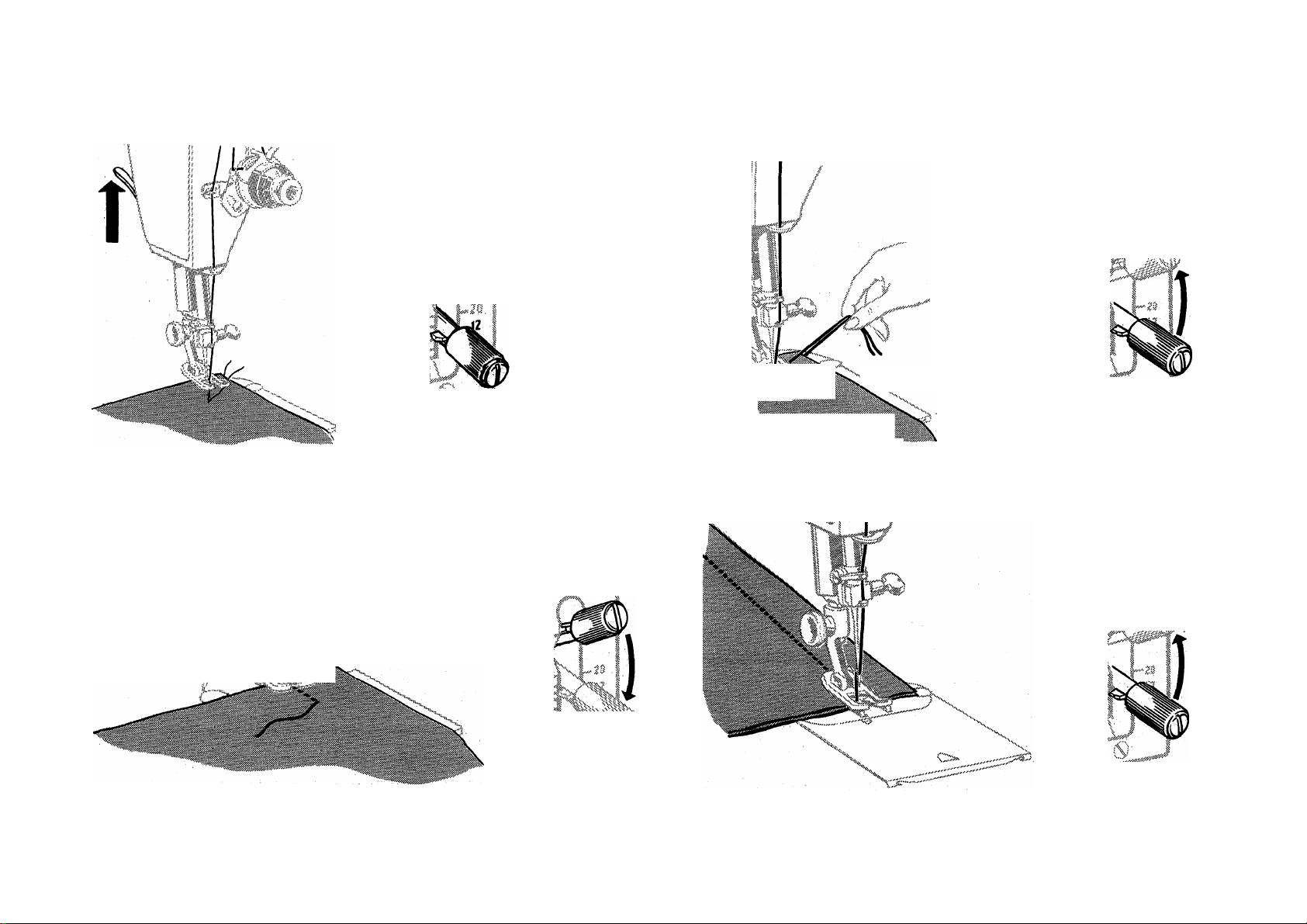

SEWING A SEAM

V. -

i

Set stitch regulator for stitch length desired. Position needle into fabric about

1/2 inch from edge and lower presser foot. Raise stitch regulator to reverse.

1.1

i,,

.. .. .. .. ...

,|.| ;| I I

I'li

5 W' V--U III

.

^

••hA'K- ■-. ■•..*••/»,...

Back stitch to edge of fabric for reinforcement. Lower regulator for forward

stitching of seam. Raise stitch regulator.

Im

i»*- <•,

22

■

i W#

]

Back stitch to reinforce end of seam, and lower regulator to forward stitching

jposition.

With take-up lever at highest point, raise presser foot and remove fabric.

23

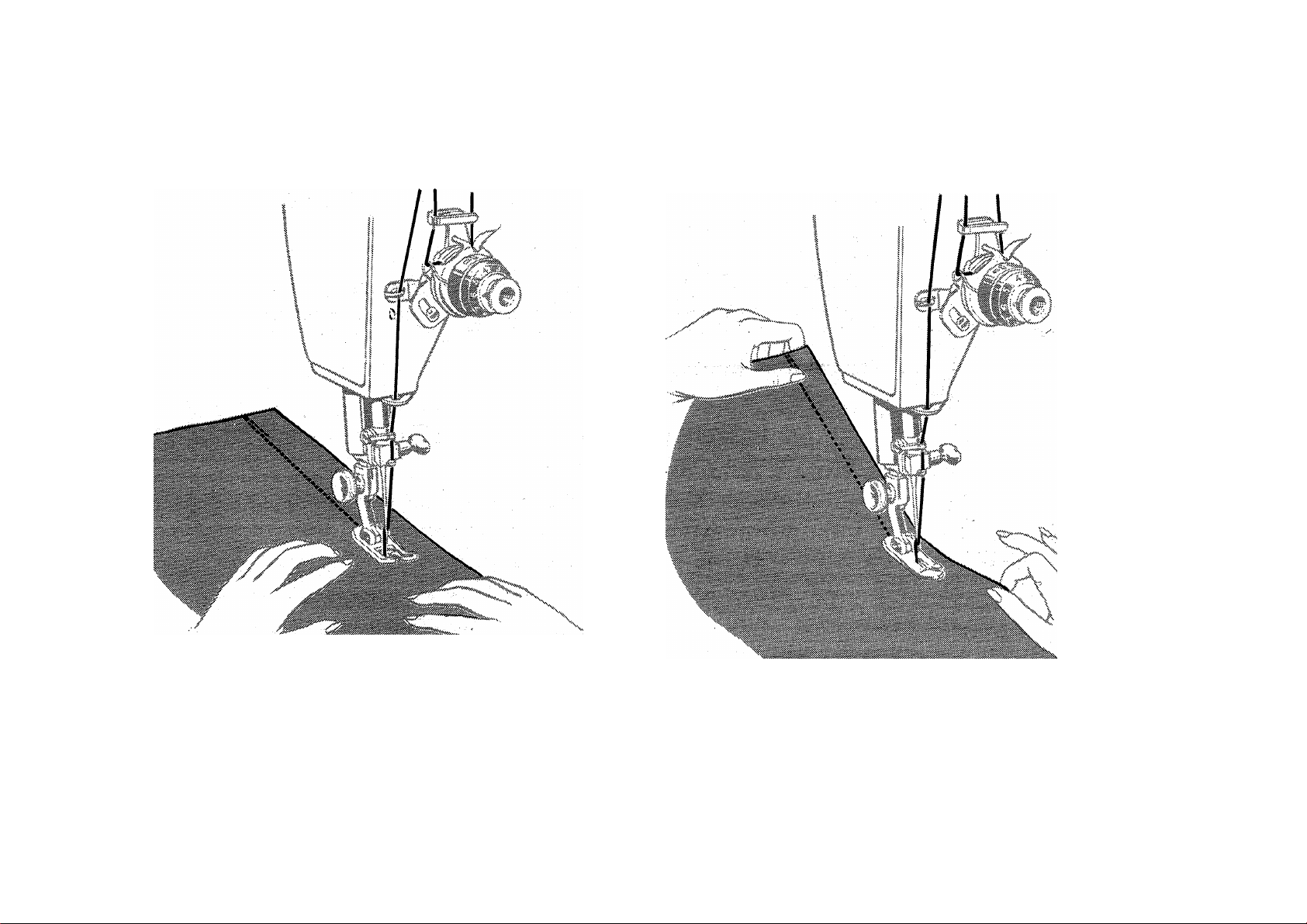

GUIDING AND SUPPORTING FABRIC

Most fabrics need only to be guided in front of the presser foot.

Fabrics of unusual texture and weave, filmy sheers, crepes, knits, tricots, etc., require

support while being stitched.

For such fabrics, use the straight stitch throat plate and presser foot, and apply gentle

tension to the seam by holding the fabric in front and in back of the presser foot as

illustrated.

24

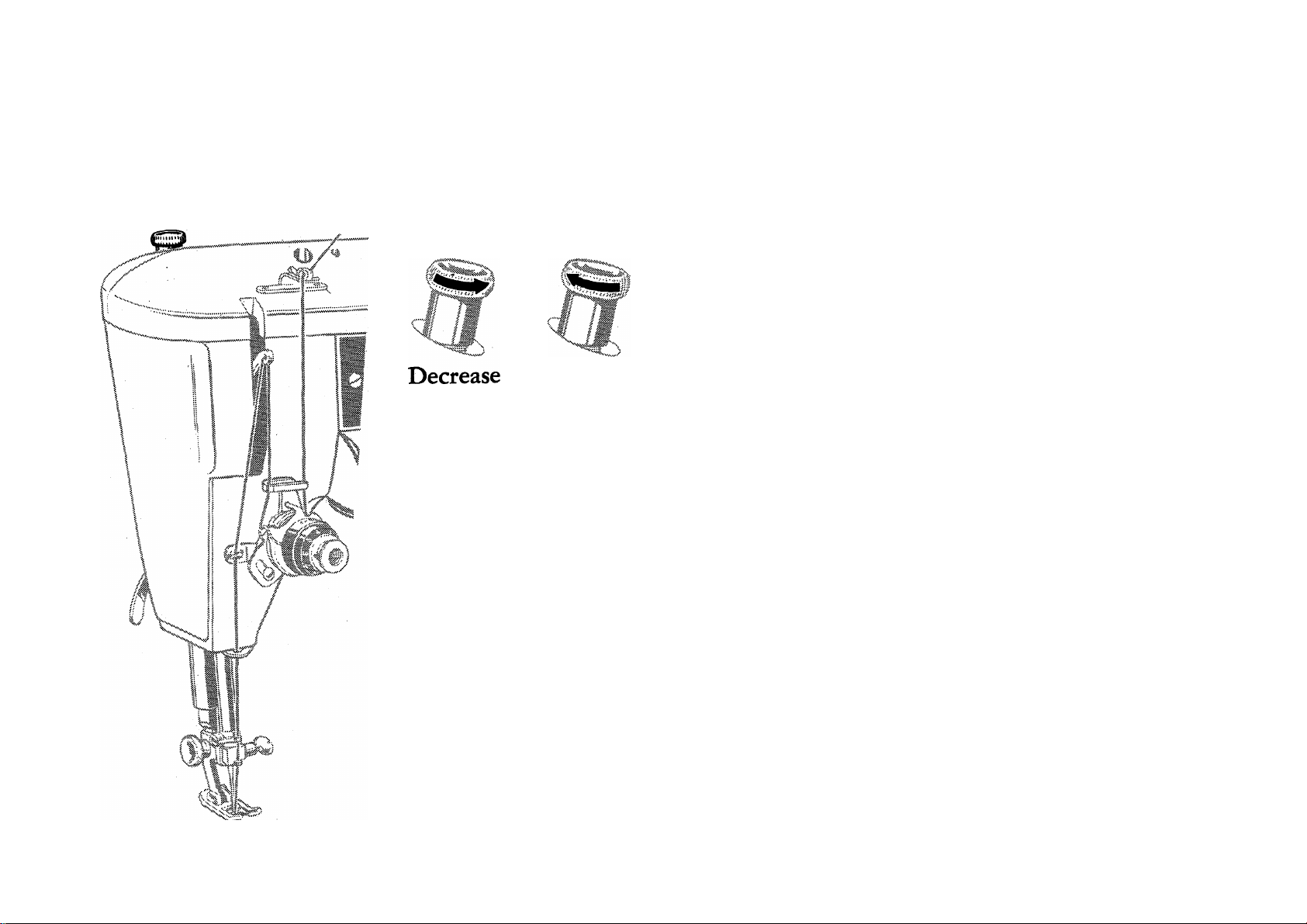

PRESSURE ADJUSTMENTS

To decrease pressure, turn thumb screw upward.

To increase pressure, turn screw downward.

Increase

Pressure is the force the presser foot exerts on fabric while it

is being stitched.

Smooth, even handling of several thicknesses of fabric results

when pressure is correctly regulated.

Too light a pressure will result in irregular feeding which

affects both quality of stitch and evenness of seams.

Too heavy a pressure not only affects stitch and seam quality

but will mar smooth surfaces and pile fabrics.

Surface finish, as well as the weight and texture of the fabric,

must be considered in determining the amount of pressure needed.

25

NEEDLE THREAD TENSION

STRAIGHT STITCHING

i ■

Needle thread tension too

tight — correct by setting

dial to lower number.

,fca

Needle thread tension too

loose -— correct by setting

dial to higher number.

A perfectly locked stitch results with upper and lower tensions balanced so that

needle and bobbin threads are dr^n equally into fiibric.

26

BOBBIN THREAD TENSION

STRAIGHT STITCHING

Bobbin thread tension too

tight—correct by turning screw

counterclockwise.

that needle and bobbin threads are drawn equally into fabric.

Bobbin thread tension too

loose—correct by turning screw

clockwise.

lower tensions balanced so

27

ZIGZAG STITCHING EQUIPMENT

GENERAL PURPOSE THROAT PLATE.

GENERAL PURPOSE PRESSER FOOT.

SPECIAL PURPOSE PRESSER FOOT.

28

STITCH LENGTH ADJUSTMENT FOR SATIN STITCHING

The area of the stitch regulator with its inclined

surface provides a means of gradually shortening the stitch

length.

As the knob is turned, the pointer rides up the incline

until a closed satin stitch is obtained.

The exact stitch setting will vary with the texture of

the fabric. It is advisable to make a test on a scrap of self

fabric, using the Special Purpose Foot, before proceeding

with the actual work.

Loading...

Loading...