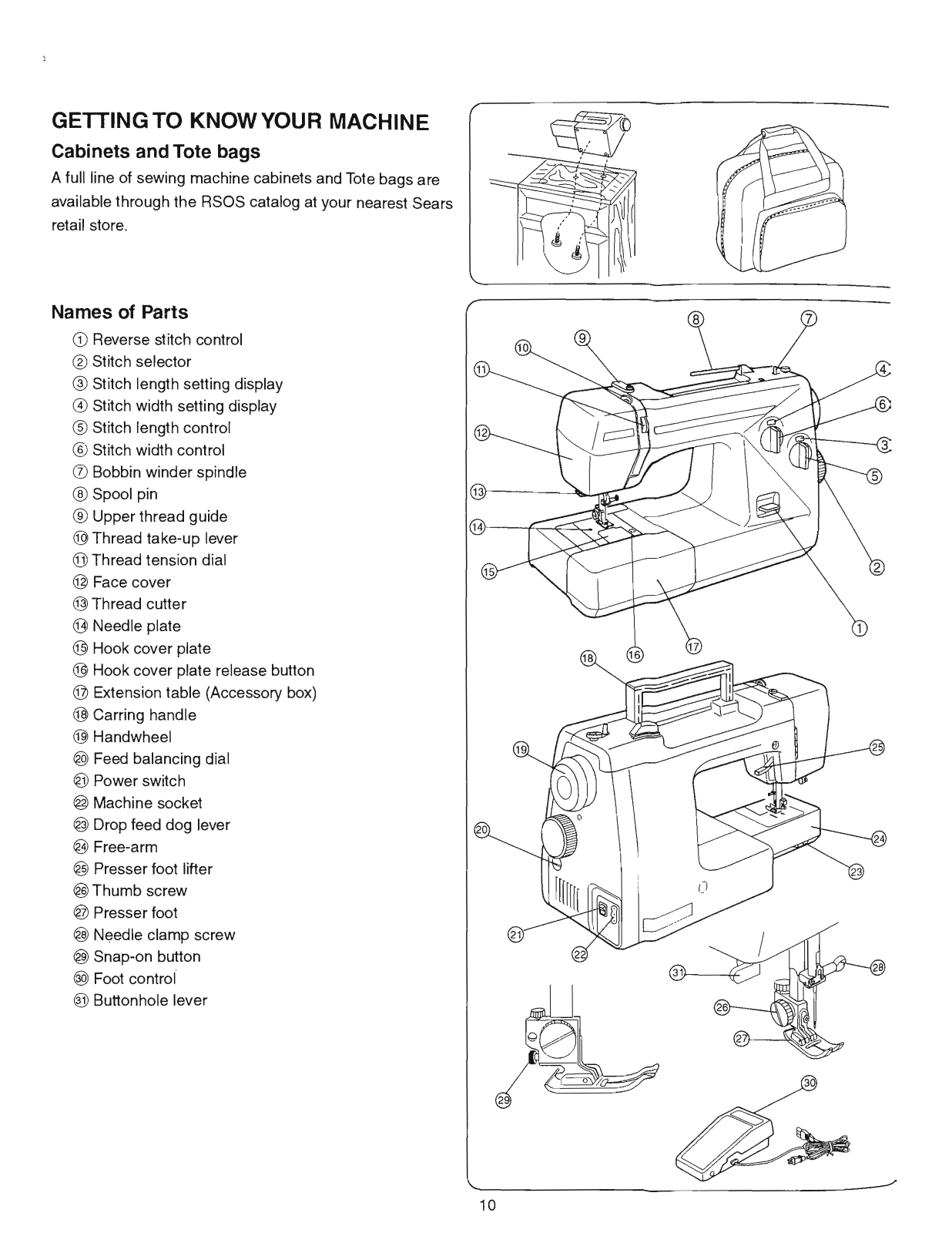

Specifications and Main Features

- Device Type: SINGER 384.18024000

- Model: Ideal domestic sewing machine.

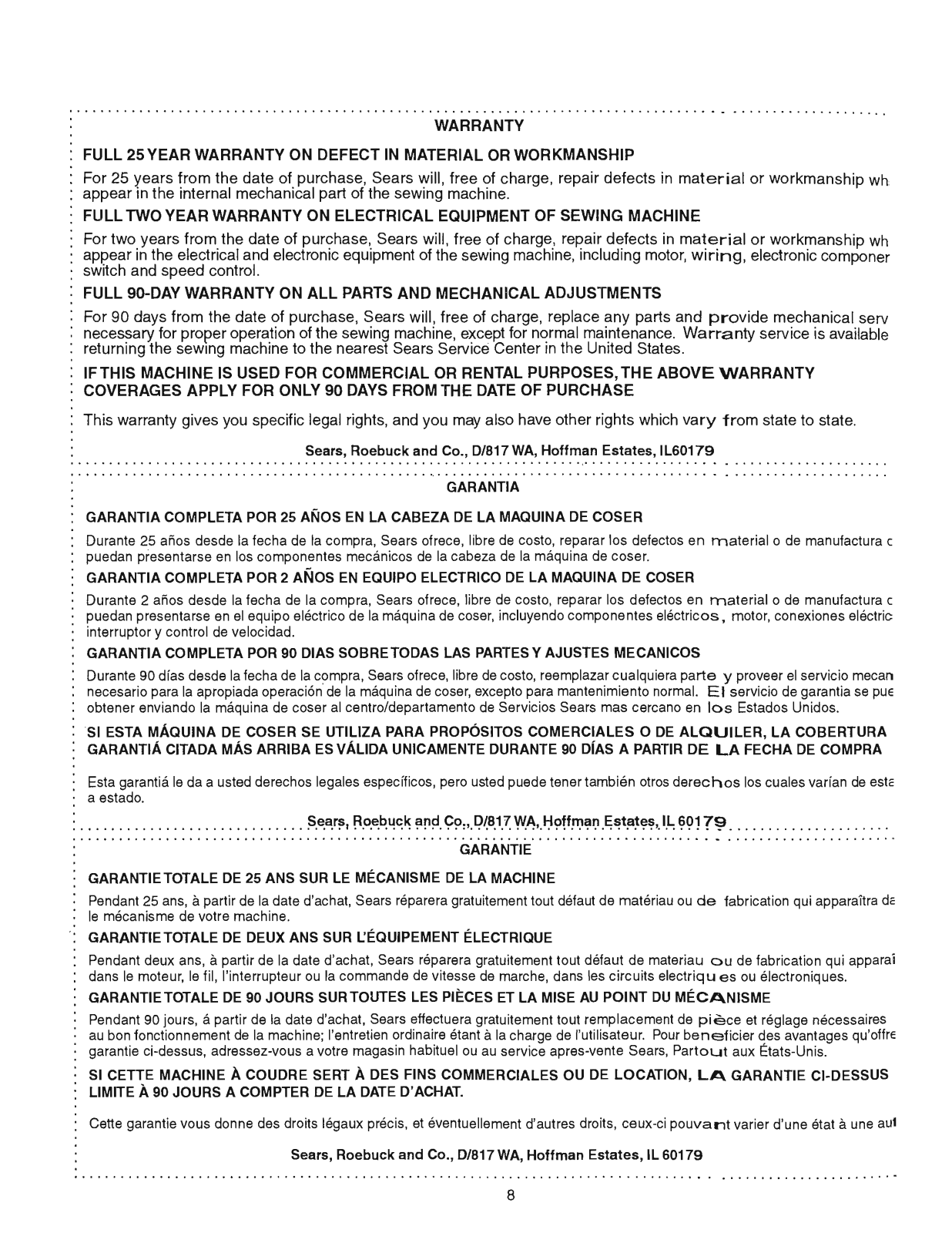

- Overall warranty of 25 years is provided against any possible manufactural defects.

- Warranty for the electrical equipment of the sewing machine for a period of two years.

- Warranty for all parts and mechanical adjustments of the sewing machine for a period of about 90 days.

- Power output: Compatible with an electrical plug socket.

- The sewing machine has the following stitch patterns: straight, zigzag, satin, buttonhole stitch.

- The device allows setting of stitch length and the stitching width.

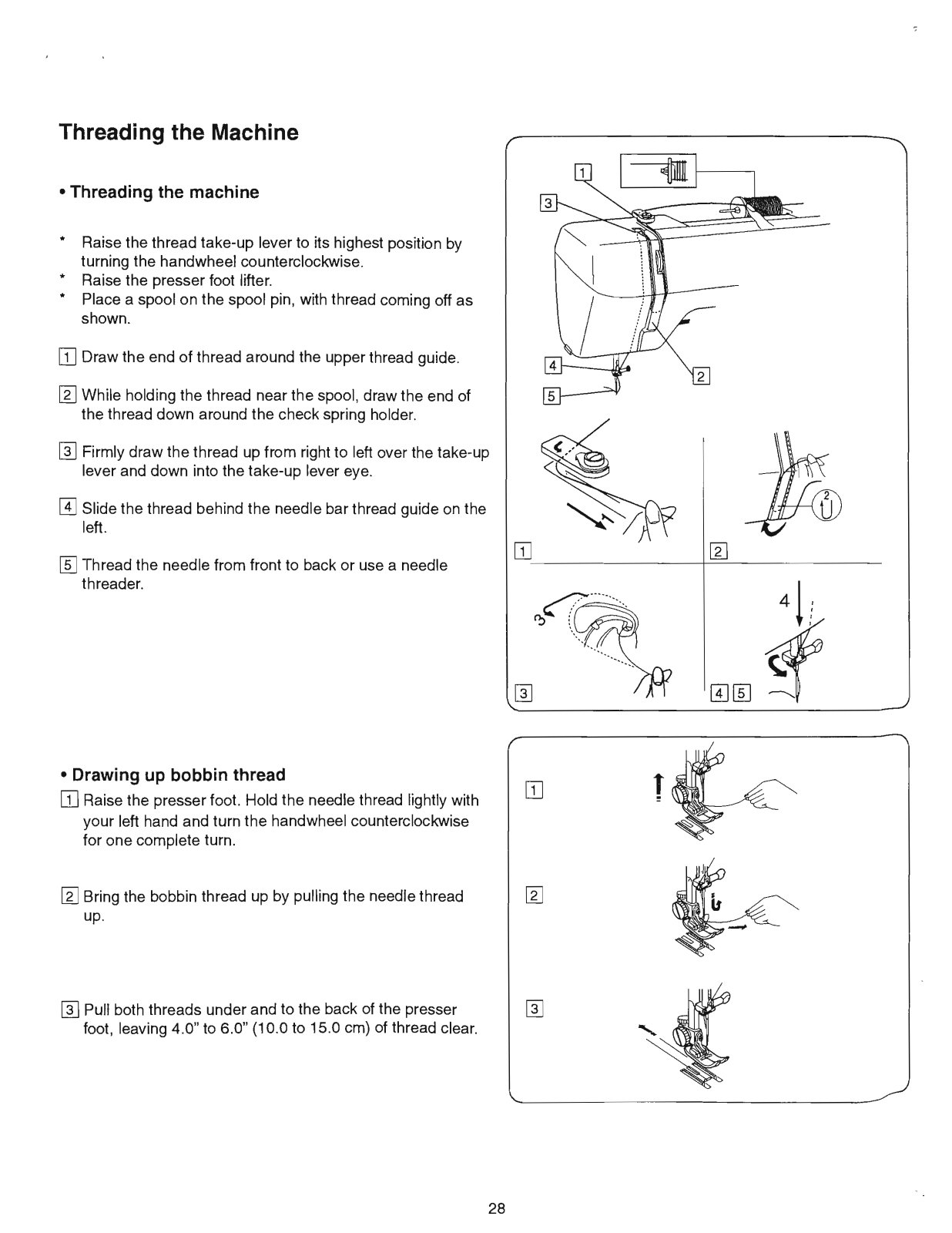

- A dial for setting needle thread tension.

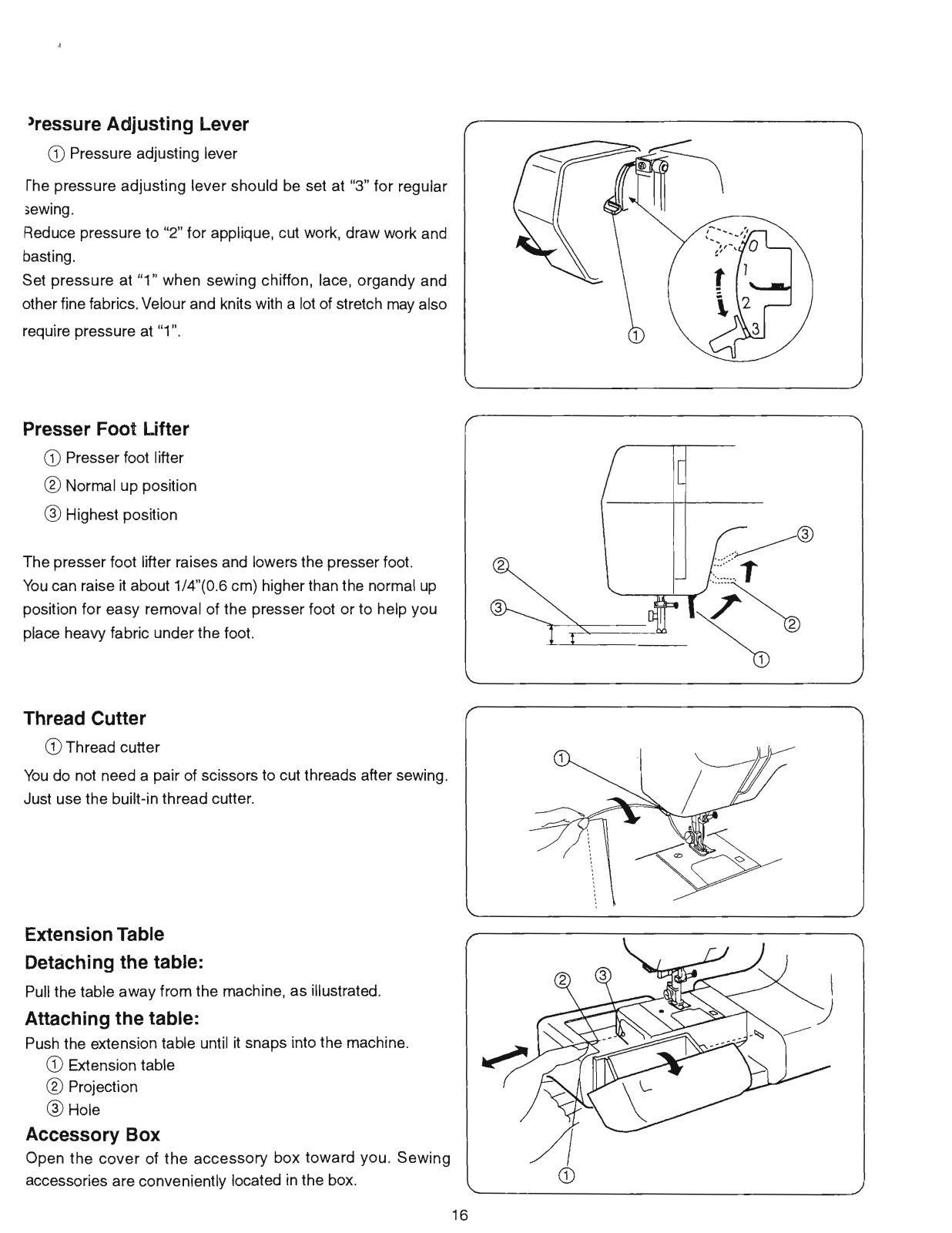

- The device contains built in thread cutter.

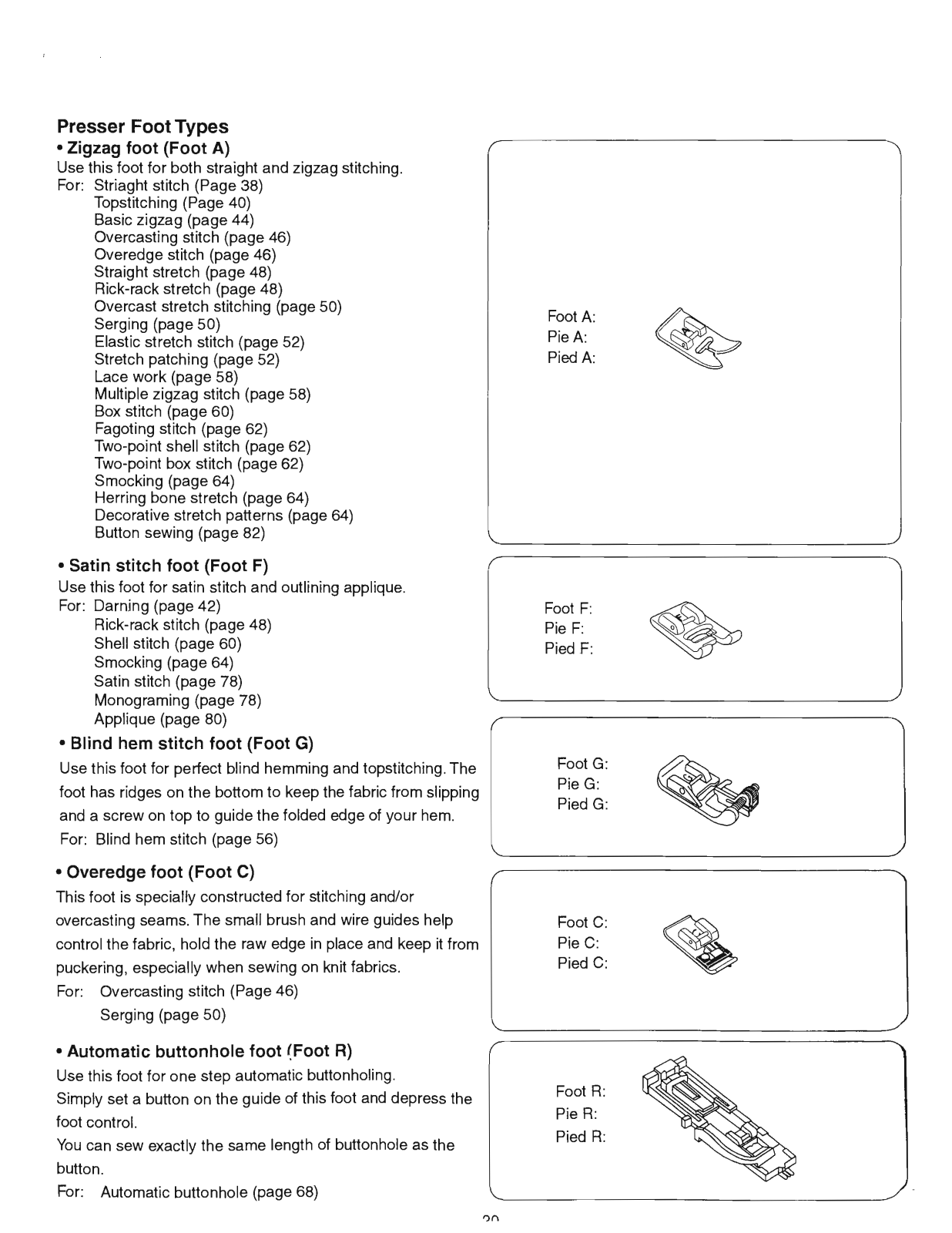

- The equipment consists of Presser foot lifter and various types of sewing Machine Presser foot.

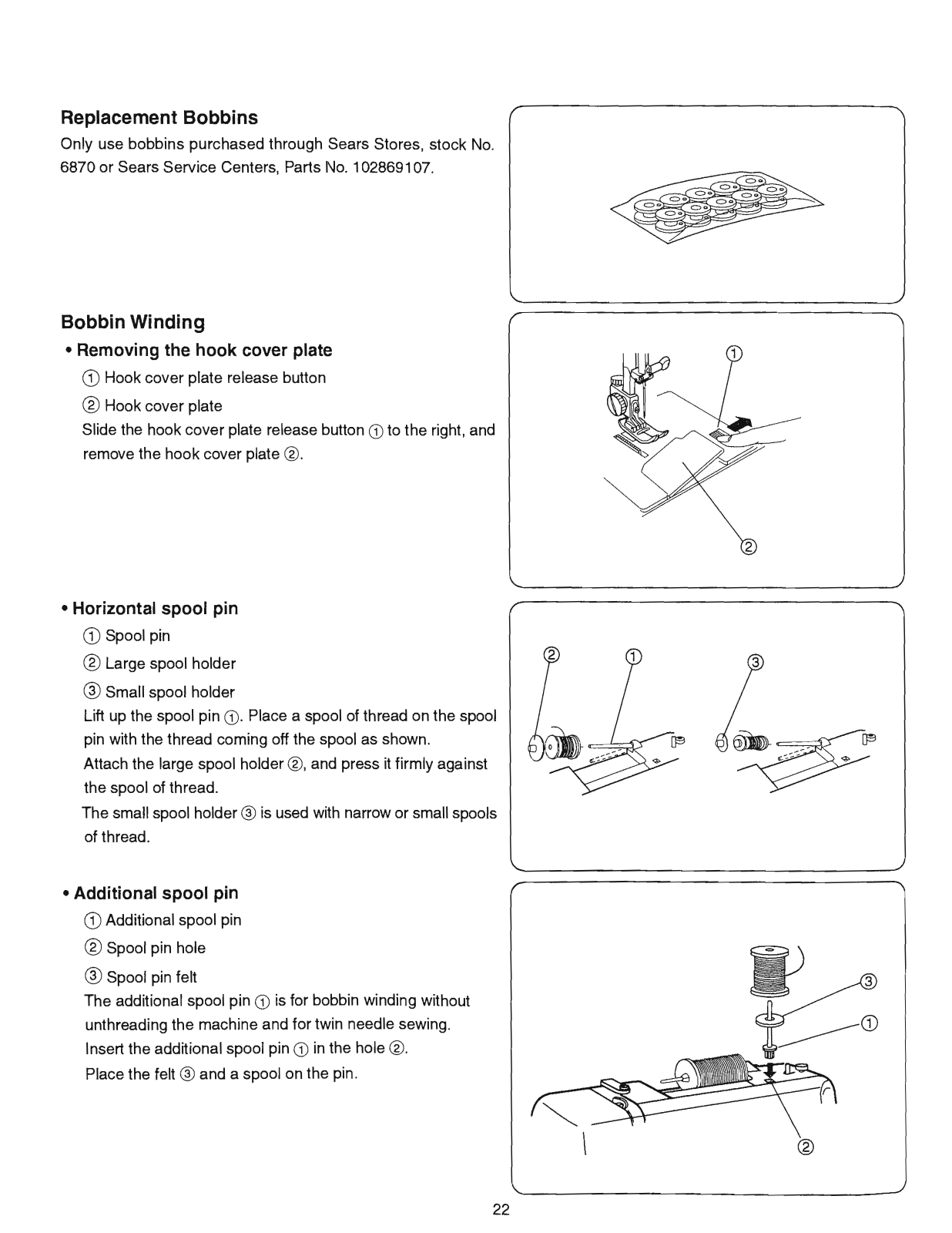

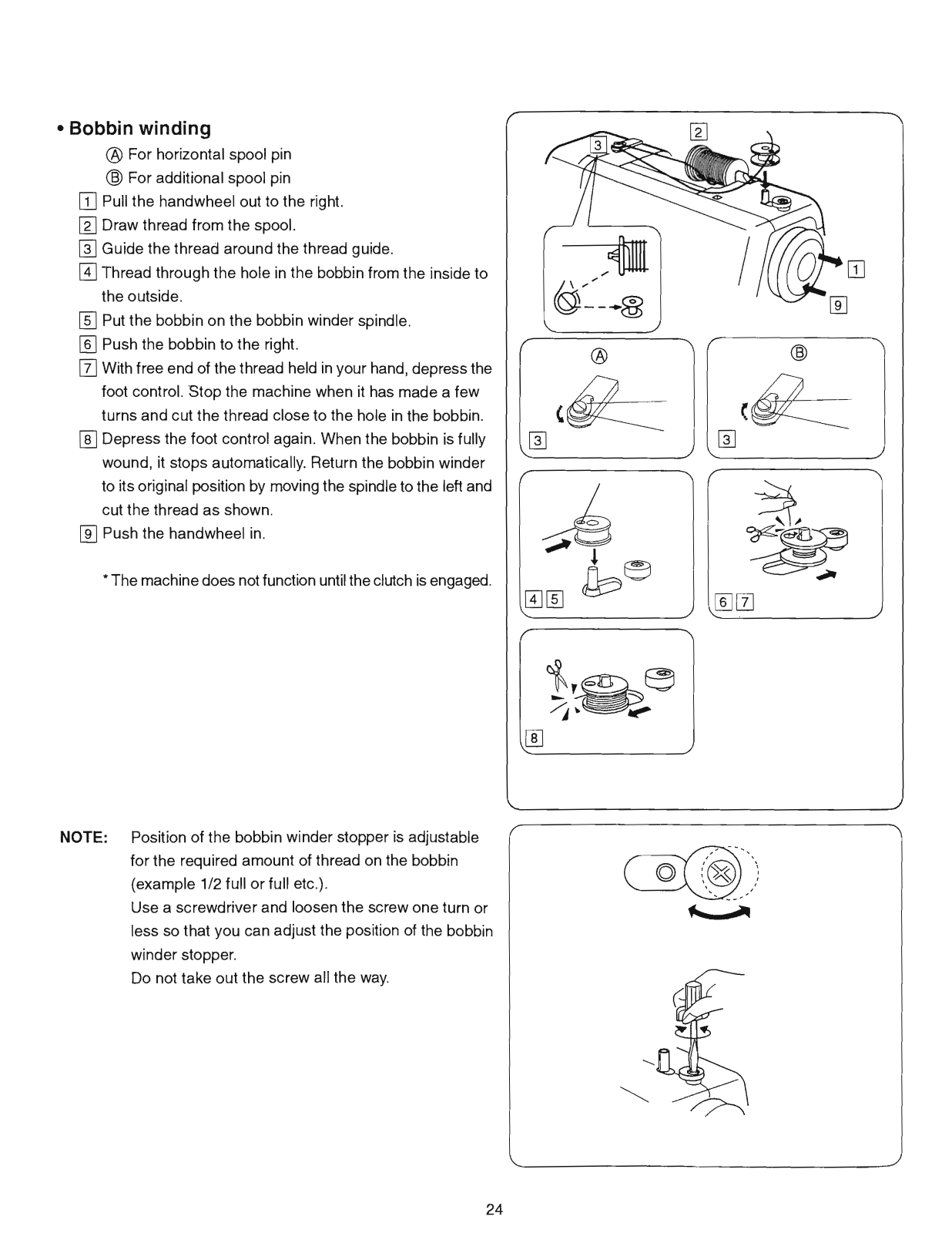

- Winding of bobbins using a horizontally mounted spool pin.

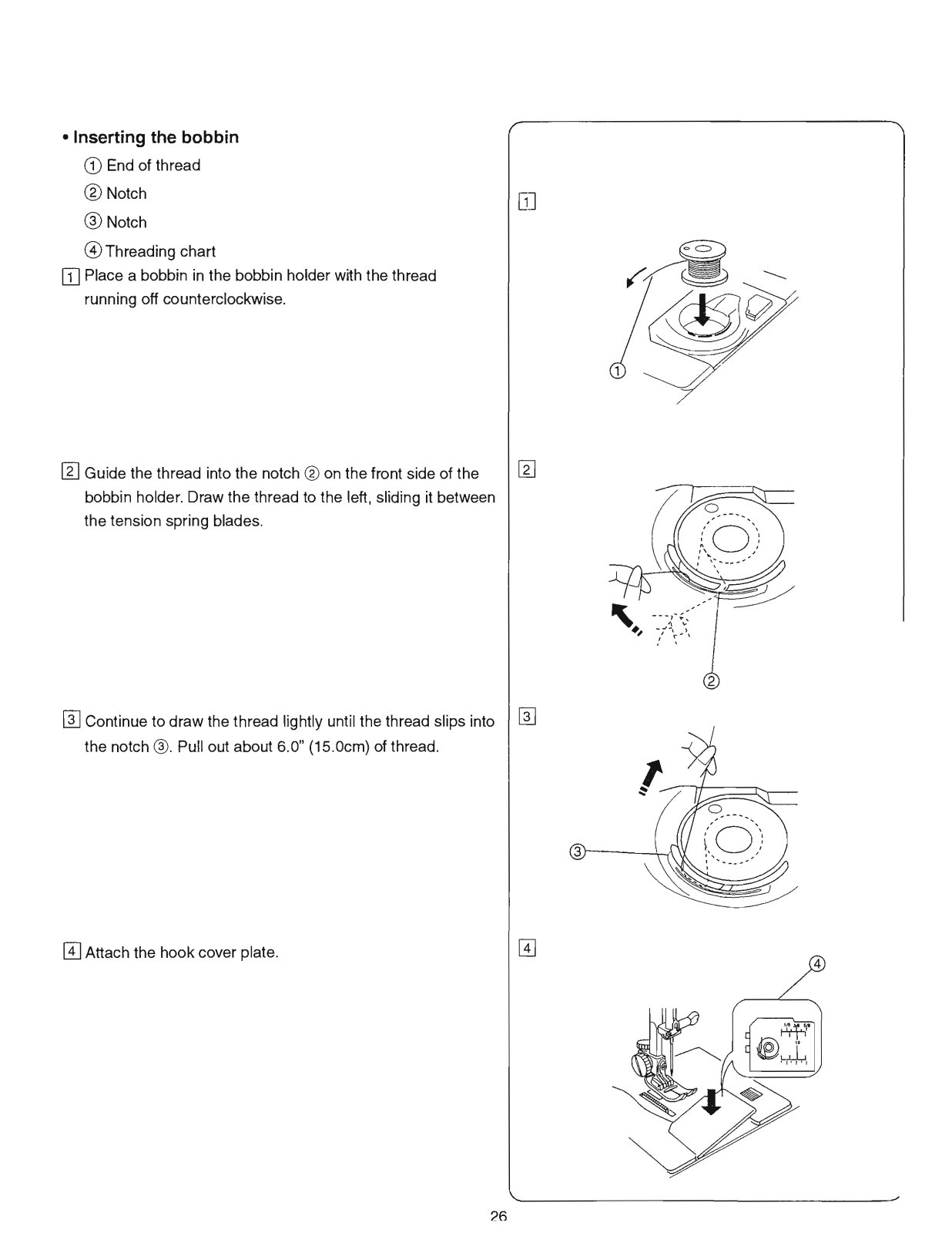

- Automatic bobbin thread- winding mechanism.

- In the sewing machine, a horizontal side lay bobbin case is used.

- Feed dog dog lever drops off for free motion sewing.

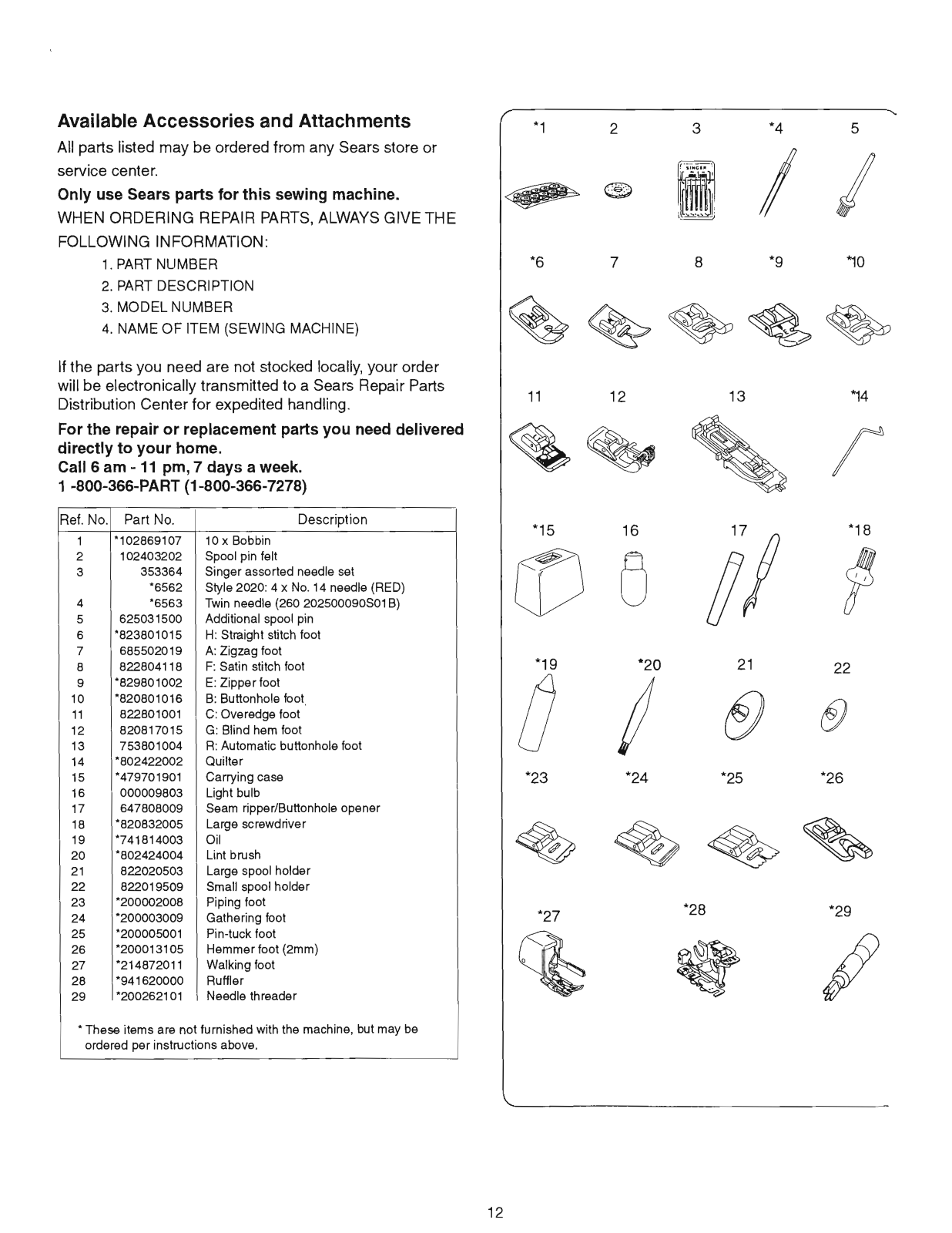

- It is possible to buy some other optional gifts and attachments to this sewing machine.

Frequently Asked Questions

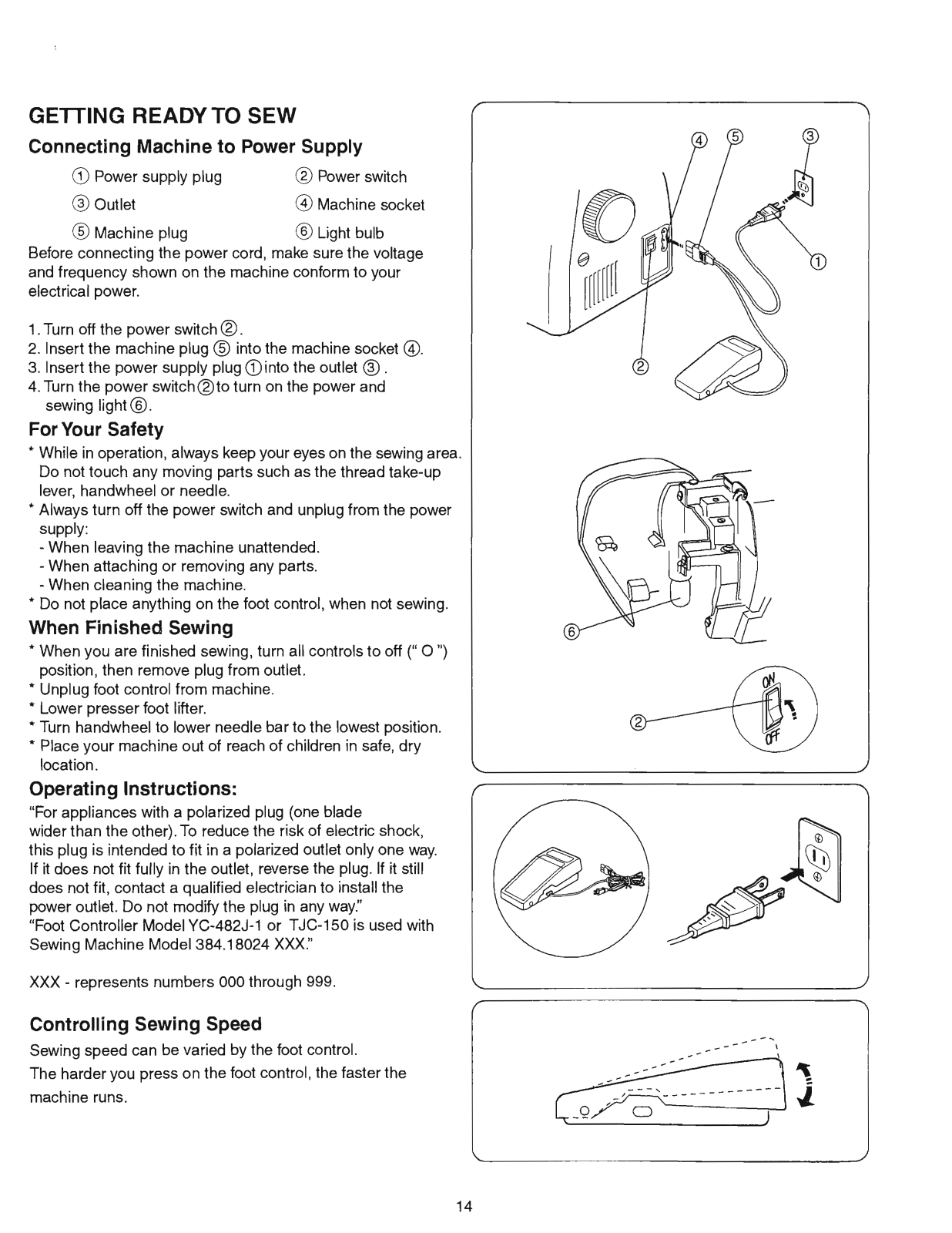

Q: What is the specified power supply connection needed for the sewing machine?

A: It is essential to connect the sewing machine to a power supply which operates on a set frequency and voltage which is compatible with the voltage requirements of the machine.

Q: Can the sewing machine be used in an industrial environment?

A: The machine is designed for household use, if used in an industrial environment only for 90 days with the machine purchased.

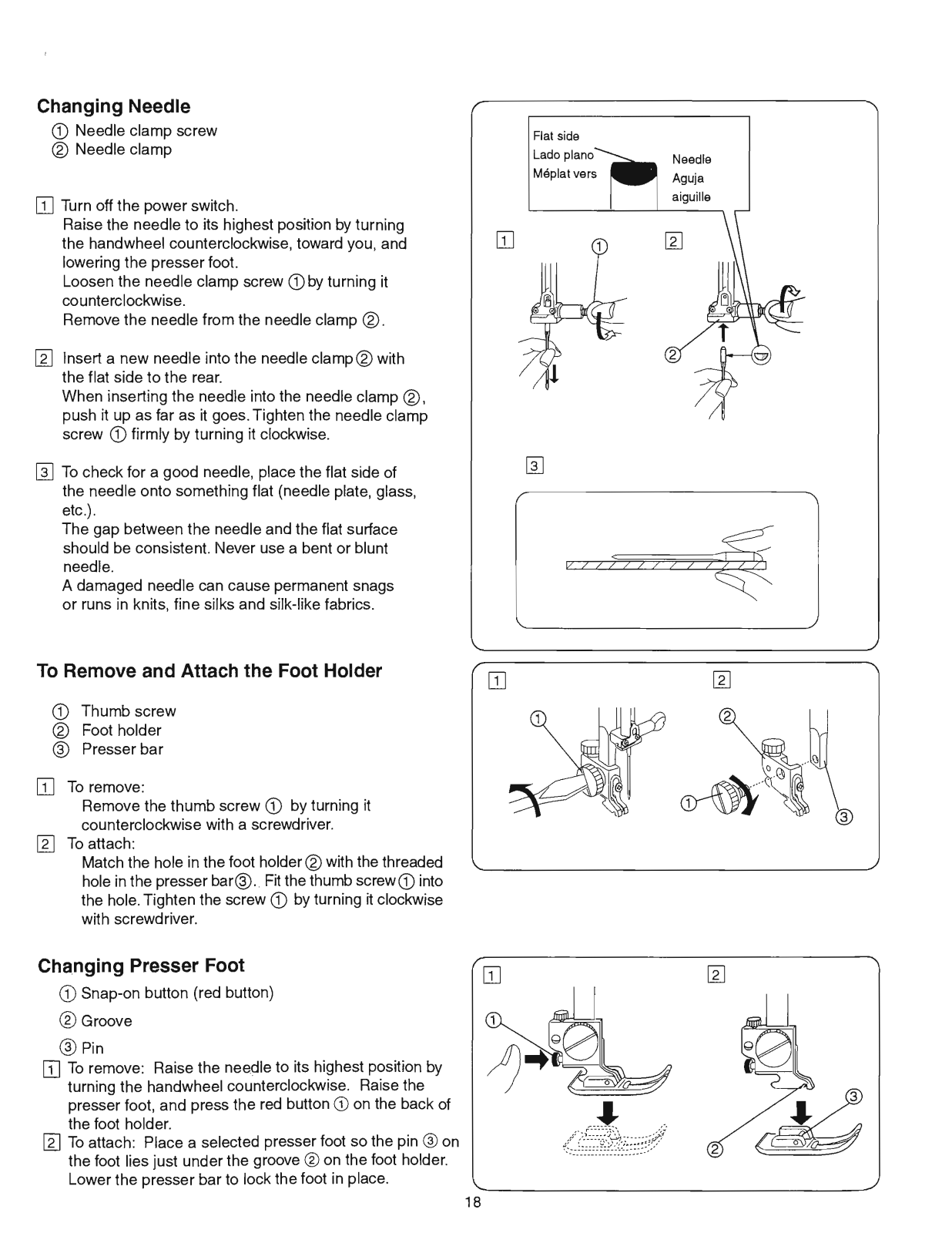

Q: What is the procedure to change the needle?

A: In order to replace the needle, first, switch off the power, then pull the needle up to the highest point, make the clamp screw of the needle loose, and take the old needle out. After that, insert a new one with the flat side towards the back, and make sure the clamp screw is tight.

Q: What do I do if the needle breaks?

A: If the needle is broken, check the “sewing needle” for insertion errors, bent or blunt nipple, or other conditions such as high or low tension. If so, it should be replaced immediately with a well sharpened needle. That will solve the problem at once.

Q: What method is followed to lengthen the stitch? Or set the stitch width?

A: The stitch length control is used to fix the length of the stitch, while the width control of the stitch is used to set the width to the needed one.

Q: Are there different kinds of presser feet? Can one use it?

A: Yes, there are numerous kinds of presser feet which can be changed depending on the type of sewing you are doing.

Q: I have a problem with thread tension. What should I do?

A: Change the setting of the needle thread tension dial. If it is too high above scale, or too much lower than it, stitch quality will be adversely affected. It is better to try the tension adjustment on a spare fabric beforehand.

User Manual

Loading...

Loading...