Page 1

T H E S I N G F__ R C O M P A N Y

Page 2

Form

(865)

K6644

Printed in Great Britain

Page 3

SINGER*

Sewing Machine Model 337

Page 4

2

CONGRATULATIONS !

As the Owner of_a SING[R*337 Sewing Machine... you

have a dependable, smooth running zig-zag sewing machine

that is outstanding in its simplicity of operation. You can

overcast a seam, make a buttonhole or stitch a decorative

applique. Then, switch instantly to straight stitching for

seaming, machine basting, or darning.

You will find these features especially helpful

• TRANSPARENT "DROP-IN " BOB-

BIN... located in front of the needle;

• THROAT PLATE... clamp type for

easy removal; calibrated for control of seam

width.

shows thread supply at a glance.

• BUILT-IN SEWING LIGHT... pull-

• SINGLE-TURN TENSION . . . num-

down bracket for easy bulb replacement.

bered to eliminate guesswork in duplicating

settings.

SINGER SERVICE

Wherever you go you will find expert, dependable SINGER* Service close at hand. Look

under SINGER COMPANY, in the phone book, for the address of the nearest SINGER

CENTER. Here, you can obtain the services of a trained SINGER repair man, warranted

SINGER parts, sewing information and services, sewing aids and notions.

Copyright Under International Copyright Union

*A Trademark of THE SINGER COMPANY

Page 5

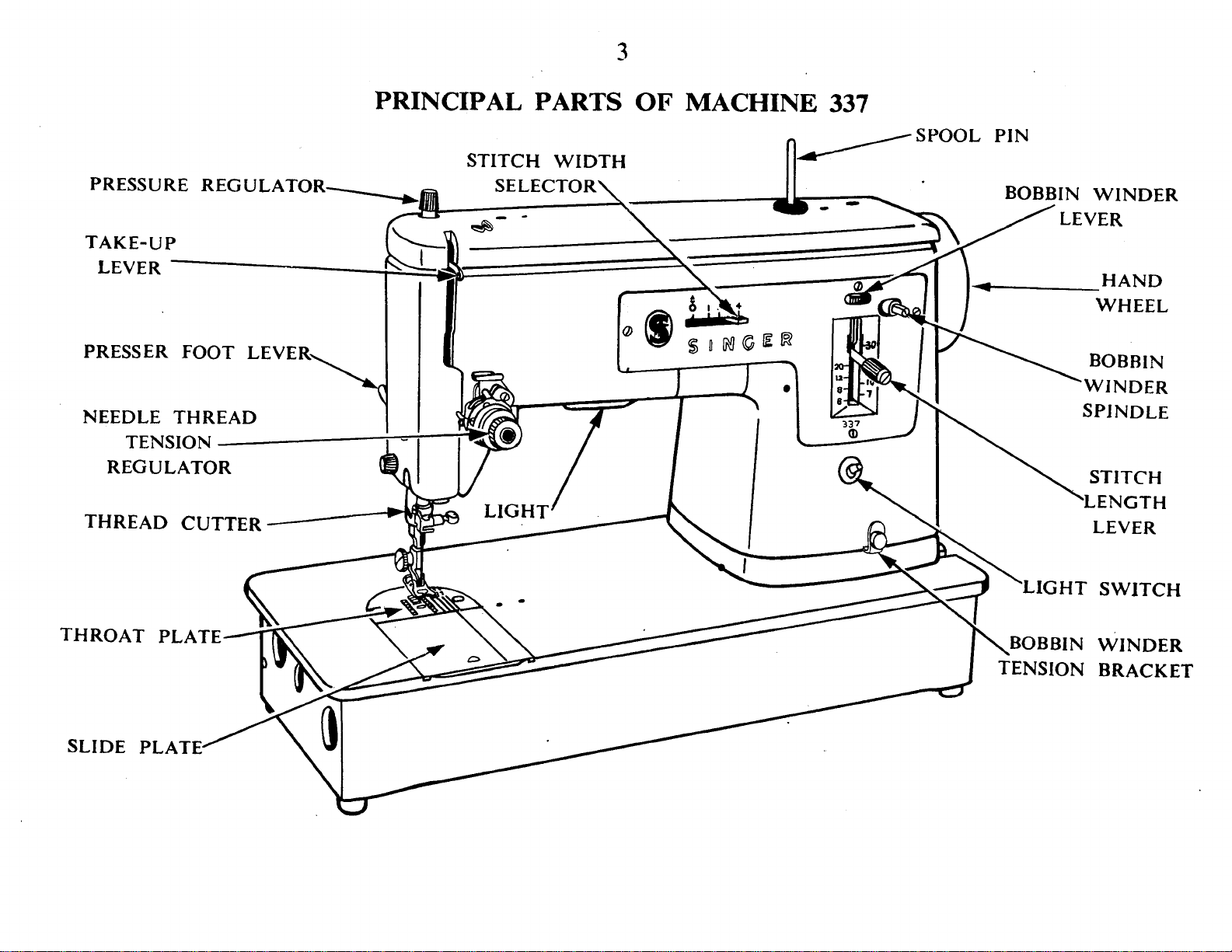

3

PRESSURE

PRESSER FOOT

NEEDLE THREAD

TENSION

REGULATOR

THREAD CUTTER

PRINCIPAL PARTS OF

STITCH WIDTH

SELE(

L1GH'[

MACHINE 337

BOBBIN WINDER

LEVER

HAND

WHEEL

BOBBIN

WINDER

SPINDLE

STITCH

H

LEVER

THROAT

SLIDE PLA

3HT SWITCH

BOBBIN WINDER

TENSION BRACKET

Page 6

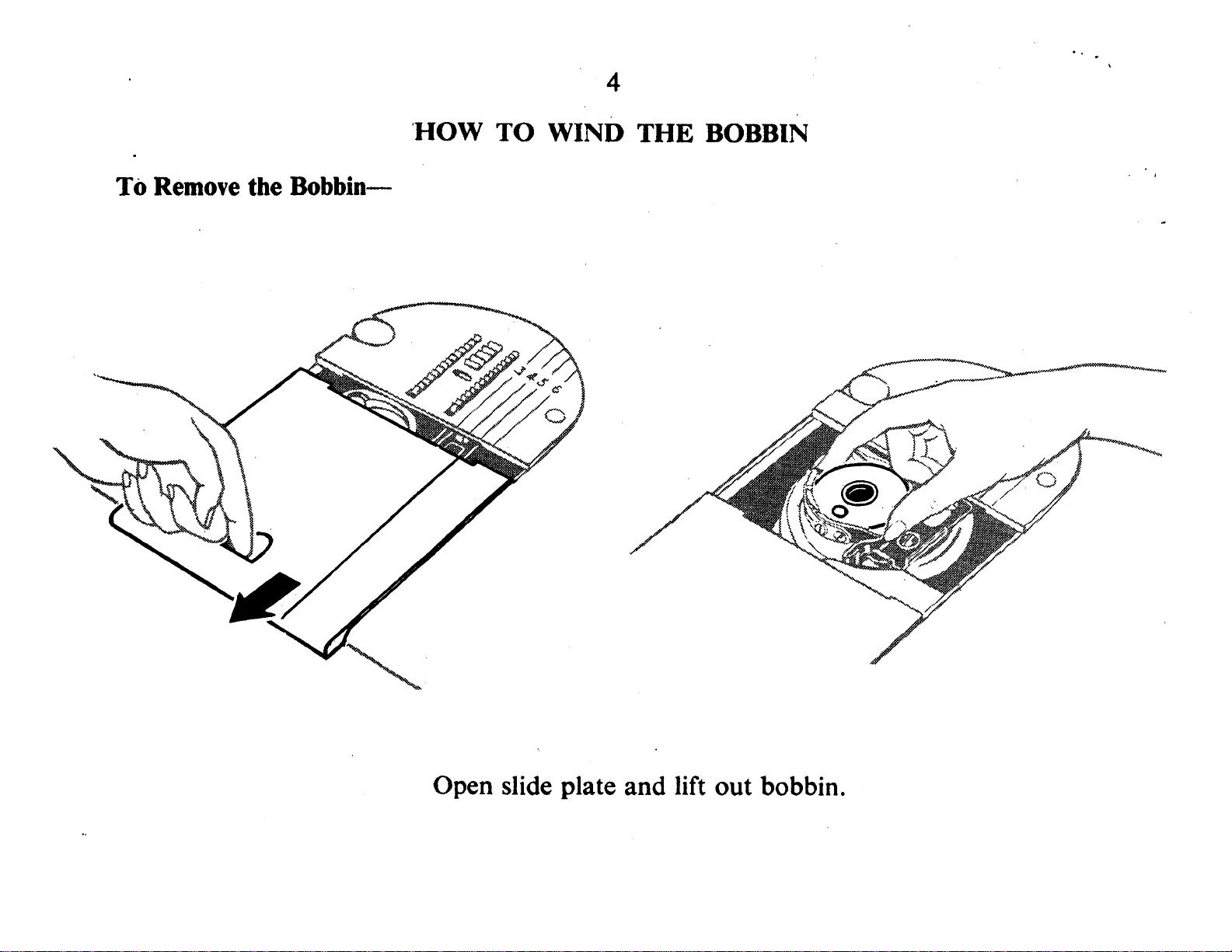

TO Remove the Bobbin--

4

'HOW TO WIND THE BOBBIN

Open slide plate and lift out bobbin.

Page 7

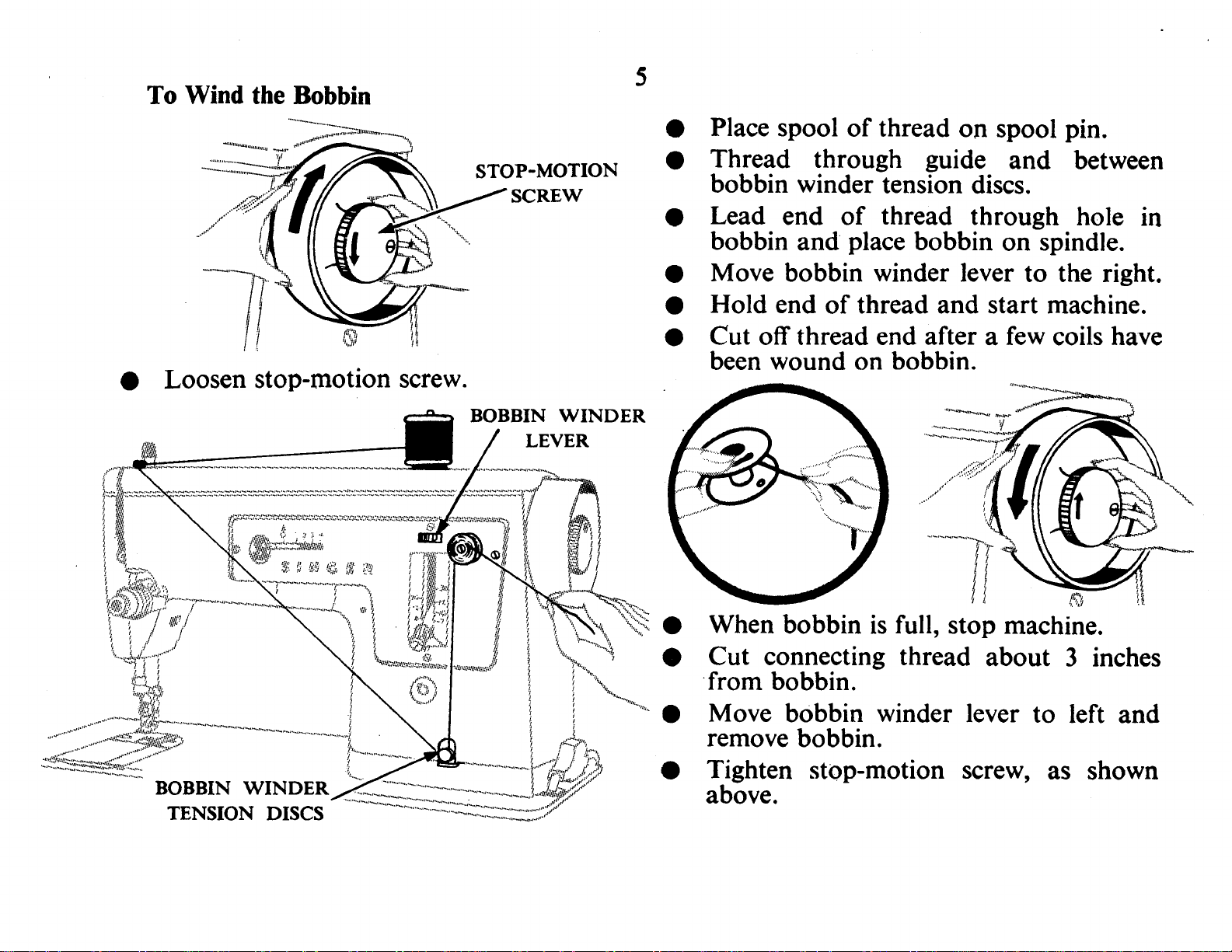

To Wind the Bobbin

5

• Place spool of thread on spool pin.

O

Loosen stop-motion screw.

STOP-MOTION

SCREW

BOBBIN WINDER

LEVER

• Thread through guide and between

bobbin winder tension discs.

• Lead end of thread through hole in

bobbin and place bobbin on spindle.

• Move bobbin winder lever to the right.

• Hold end of thread and start machine.

• Cut off thread end after a few coils have

been wound on bobbin.

.... '_'_,,_, ,,_,,,,._,,_,,_7,_-_-,,_,_%.

1 _¢_

.... i

BOBBIN WINDER

TENSION DISCS

When bobbin is full, stop machine.

Cut connecting thread about 3 inches

from bobbin.

!,

%.

D

Move bobbin winder lever to left and

remove bobbin.

Tighten stop-motion screw, as shown

above.

Page 8

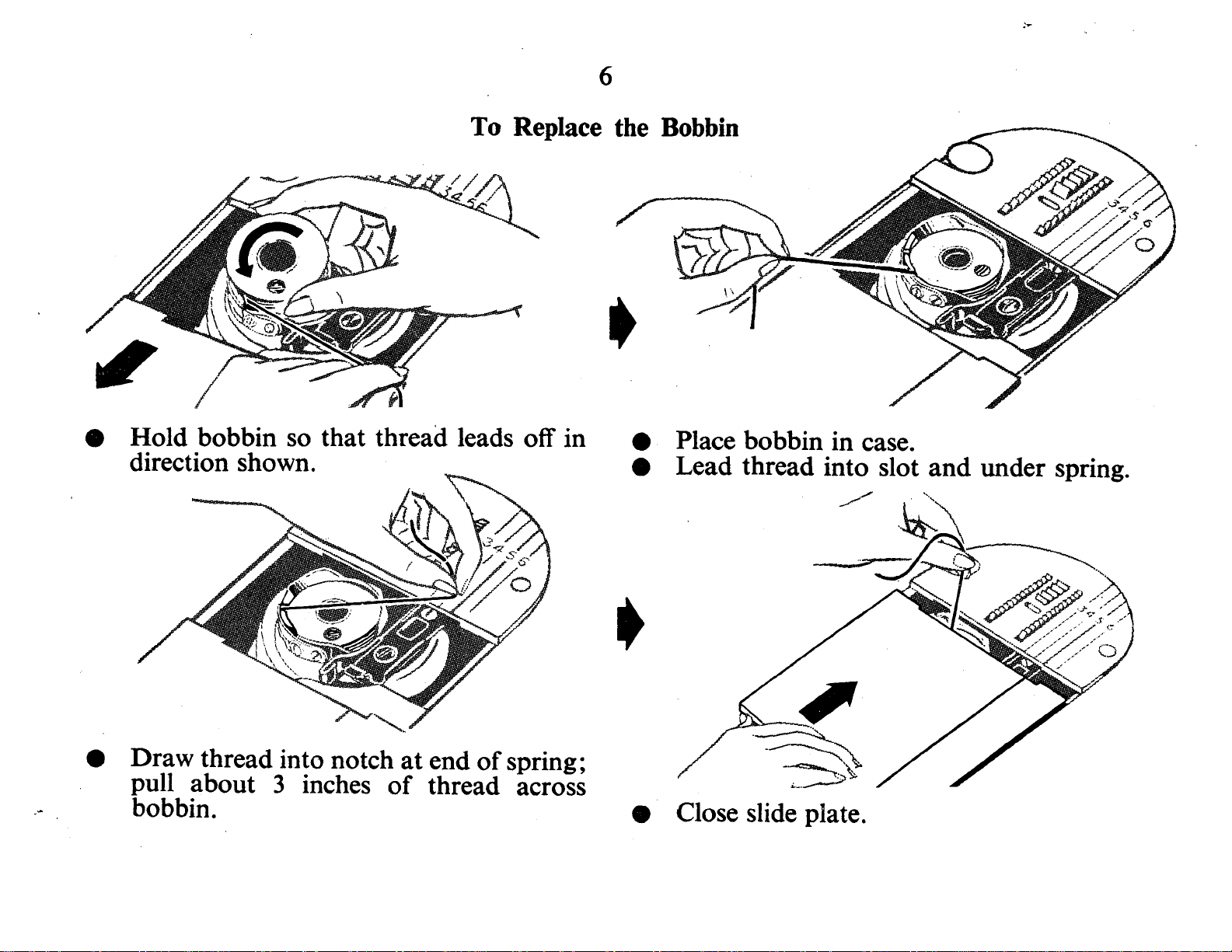

To Replace the Bobbin

/

Hold bobbin so that thread leads off in

0

direction shown.

6

• Place bobbin in case.

• Lead thread into slot and under spring.

Draw thread into notch at end of spring;

pull about 3 inches of thread across

bobbin.

• Close slide plate.

Page 9

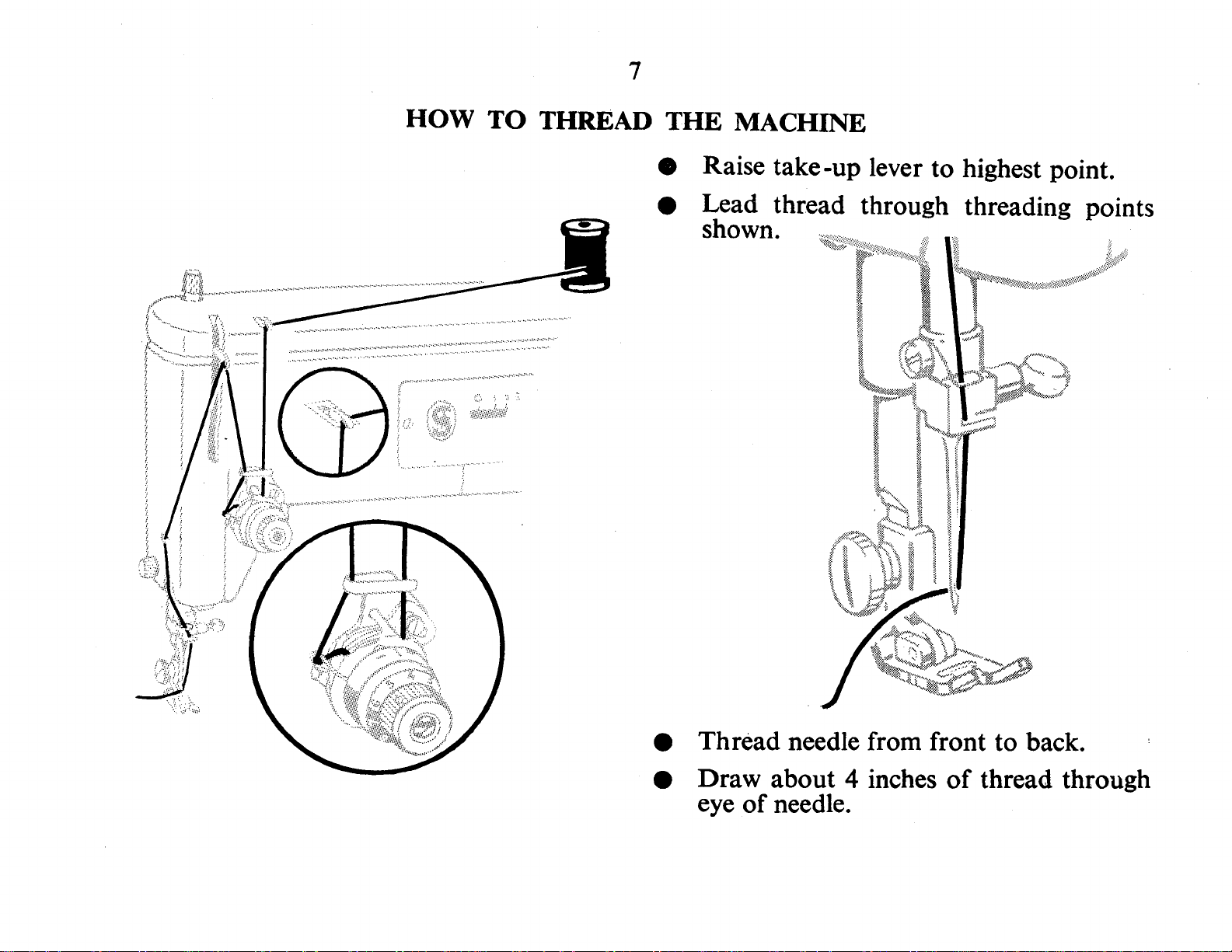

7

HOW TO THREAD THE MACHINE

Raise take-up lever to highest point.

'_:; !

?

i J

i /::

Lead thread

shown.

through threading points

._'_

• Thread needle from front to back.

• Draw about 4 inches of thread through

eye of needle.

Page 10

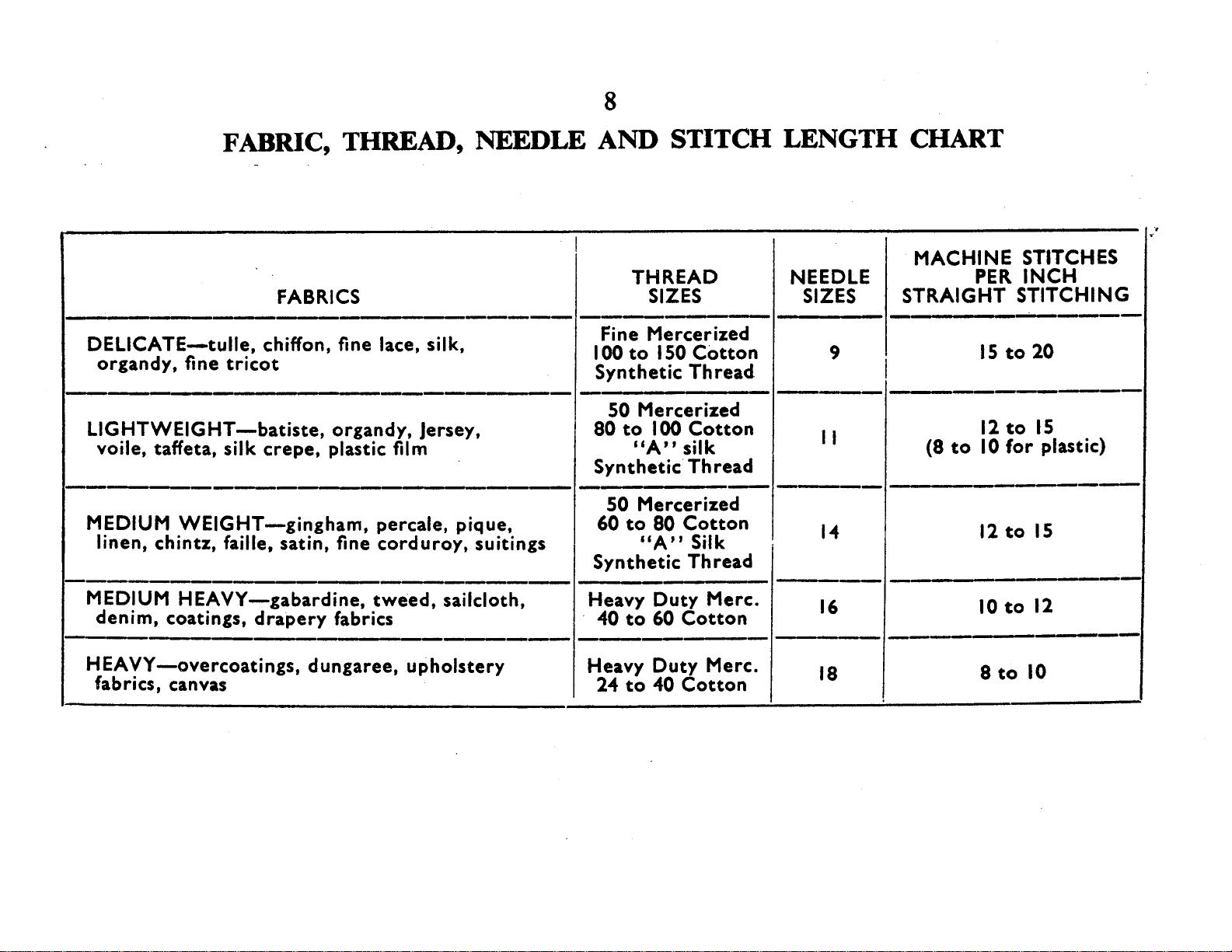

8

FABRIC, THREAD,

NEEDLE

FABRICS

__ m

DELICATE---tulle, chiffon, fine lace, silk,

organdy, fine tricot

LIGHTWEIGHTBbatiste, organdy, Jersey,

voile, taffeta, silk crepe, plastic film

MEDIUM WEIGHTBgingham, percale, pique,

linen, chintz, faille, satin, fine corduroy, suitings

MEDIUM HEAVY--gabardine, tweed, sailcloth,

denim, coatings, drapery fabrics

AND STITCH LENGTH CHART

MACHINE STITCHES

THREAD

SIZES

Fine Mercerized

100 to 150 Cotton

Synthetic Thread

50 Mercerized

80 to 100 Cotton

"A" silk

Synthetic Th read

50 Mercerized

60 to 80 Cotton

"A" Silk

Synthetic Thread

Heavy Duty Merc.

40 to 60 Cotton

NEEDLE

SIZES

9

II

14

16

STRAIGHT STITCHING

(8 to 10 for plastic)

PER INCH

15 to 20

12 to 15

12 to 15

-- w

10 to 12

HEAVYmovercoatings, dungaree, upholstery

fabrics, canvas

Heavy Duty Merc.

24 to 40 Cotton

18 8 to 10

Page 11

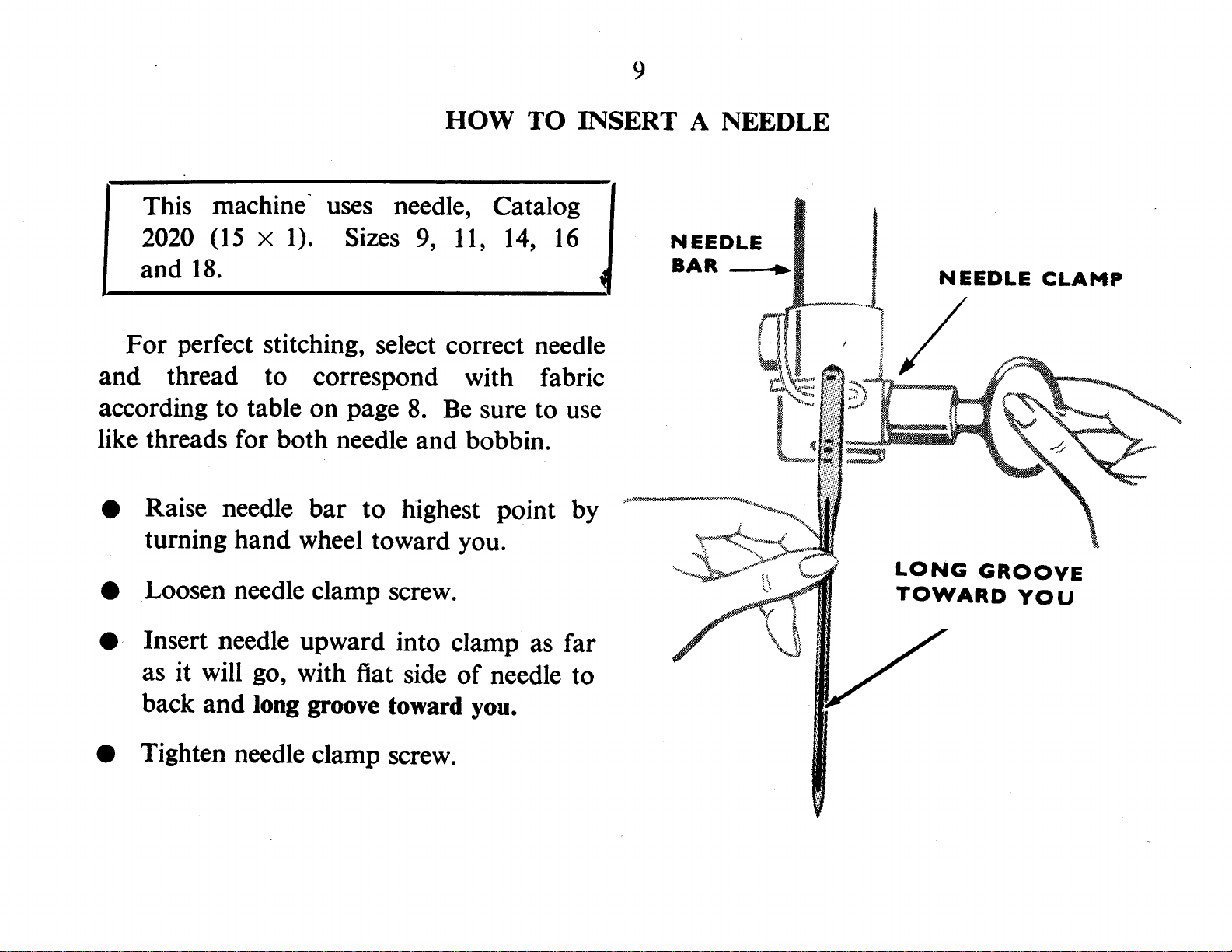

9

HOW

This machine uses needle, Catalog

2020 (15 x 1). Sizes 9, 11, 14, 16

and 18.

For perfect stitching, select correct needle

and thread to correspond with fabric

according to table on page 8. Be sure to use

like threads for both needle and bobbin.

• Raise needle bar to highest point by

turning hand wheel toward you.

• Loosen needle clamp screw.

TO INSERT A NEEDLE

NEEDLE

BAR

NEEDLE CLAMP

/

LONG GROOYE

TOWARD YO U

Insert needle upward into clamp as far

as it will go, with fiat side of needle to

back and long groove toward you.

• Tighten needle clamp screw.

Page 12

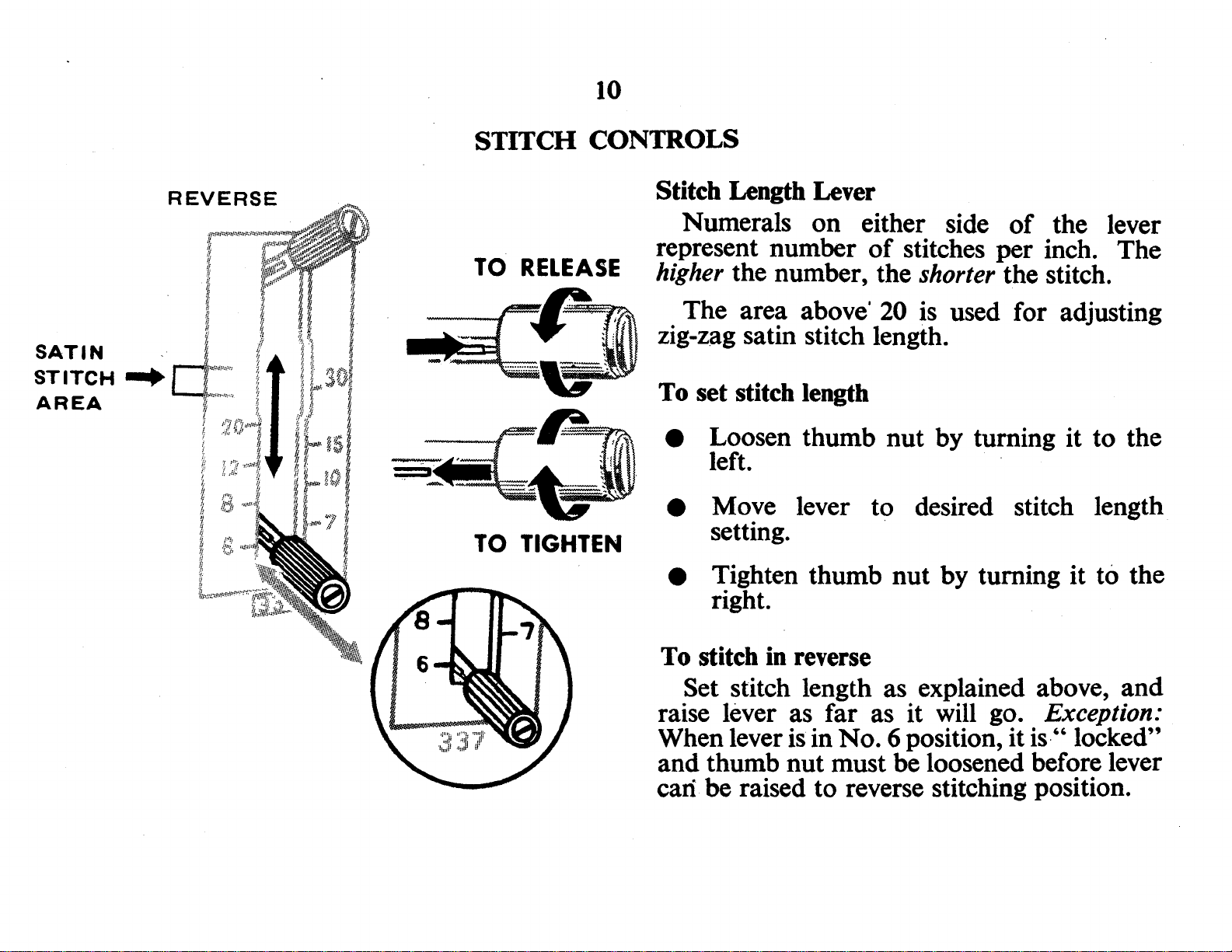

10

STITCH CONTROLS

REVERSE

TO RELEASE

TO TIGHTEN

Stitch Length Lever

Numerals on either side of the lever

represent number of stitches per inch. The

higher the number, the shorter the stitch.

The area above' 20 is used for adjusting

zig-zag satin stitch length.

To set stitch length

Loosen thumb nut by turning it to the

left.

• Move lever to desired stitch length

setting.

Tighten thumb nut by turning it tO the

right.

To stitch in reverse

Set stitch length as explained above, and

raise lever as far as it will go. Exception:

When lever is in No. 6 position, it is" locked"

and thumb nut must be loosened before lever

cari be raised to reverse stitching position.

Page 13

0

11

Stitch Width Selector

1234

T

i |

I

i [ l

STRAIGHT STITCH SETTING

0

The stitch width selector regula[es the swing of the needle from a straight

position 0 to a maximum zig-zag width 4 (5/32 inch).

To position, slide selector to desired setting. As the lever is moved to the right

the width of the zig-zag stitch is increased. Settings of I thru 4 are indicated but

intermediate settings may also be used.

To avoid damage to needle and fabric, do notmake any selector adjustments

with the needle in the fabric.

ZIG-ZAG STITCH SETTINGS

1 to4

Page 14

0 Hold needle thread lightly with left hand.

17.

Pull end of bobbin

throat plate.

thread up

through

Page 15

13

PRESSURE ADJUSTMENTS

,_,t_:_'\_'g_\ _z_%_'_

O

To decrease pressure, turn thumb

screw counterclockwise.

i!i!i

O

i!:ii. i Iti

'_,_,_'

DECREASE INCREASE

Smooth, even handling of several thicknesses of fabric results

when pressure is correctly regulated.

Surface finish, as well as the weight and texture of the fabric,

must be considered in determining the amount of pressure needed.

Adjustment of the thumb screw regulates the amount of pressure

exerted on the material while it is being stitched.

To increase pressure, turn thumb

screw clockwise.

Too light a pressure will result in irregular feeding which affects

both quality of stitch and evenness of seams.

Too heavy a pressure not only affects stitch and seam quality but

will mar smooth surfaces and pile fabrics.

Page 16

14

NEEDLE THREAD TENSION,

STRAIGHT STITCHING

_11__ - ~_.t_

Needle thread tension too Needle thread tension too

tight--correct by setting dial to loose---correct by setting dial to

lower number, higher number.

A perfectly locked straight stitch results with upper and lower tensions balanced

so that needle and bobbin threads are drawn equally into fabric.

Page 17

15

_ _:_ BOBBIN THREAD TENSION __ _._L

Bobbin thread tension too tight--

correct by turning screw counterclock-

wise.

STRAIGHT STITCHING

Bobbin thread tension too loose--

correct by turning screw clockwise.

A perfectly locked straight stitch results with upper and lower tensions balanced

so that needle and bobbin threads are drawn equally into fabric.

Page 18

16

SATIN

STITCH

AREA

STITCH

8

LENGTH ADJUSTMENT

Satin stitching, a series of closely spaced zig-zag stitches

that form a smooth satin-like surface, is useful for both utility

and decorative stitching.

FOR ZIG-ZAG SATIN STITCHING

337

STITCH LENGTH LEVER

IN SATIN STITCH AREA

To Adjust Stitch Length for Satin Stitching.

• Move stitch length lever above 20 to satin stitch area.

• Run machine at slow speed.

• Tighten indicator by turning thumb screw to the right,

until stitches form a smooth surface.

Make a test sample first before proceeding with the actual

work. The Special Purpose presser foot, described on page 26,

is recommended for decorative satin stitching, and for making

buttonholes.

Page 19

17

NEEDLE THREAD TENSION

ADJUSTMENT FOR ZIG-ZAG SATIN STITCHING

Zig-zag stitching requires less needle thread

tension than straight stitching; and closely

spaced zig-zag stitches that form a smooth

satin-like surface require less tension than

widely spaced, _pen zig-zag stitches. Further-

more, the wider the satin stitching, the lighter

the tension required.

To determine correct tension setting, a

test sample should be made on a scrap of the

fabric to be used. A properly balanced satin

stitch should lie fiat across the material.

Some soft fabrics may require the addition

of a backing to insure good stitching. Crisp

organdy and lawn are suitable for this

purpose.

The Special Purpose presser foot, described

on page 26, is recommended for decorative

satin stitch work and for making buttonholes.

Correct

incorrect

Page 20

18

ZIG-ZAG APPLICATIONS

LINGERIE SEAMS

Dainty lingerie seams are made durable

with zig-zag stitching. After straight stitching

seam on wrong side, press both seam allow-

ances in same direction. From right side,

top-stitch with a fine zig-zag setting (1½

width), letting needle alternately enter seam

line and seam thicknesses, l his finish is

particularly suitable for bias seams.

KNIT FABRIC SEAMS

A narrow zig-zag stitch is ideal for seaming

knit fabrics. It is particularly suitable for

underarm seams, or other seams where

elasticity and give are needed.

For curved or bias seams, where a stay is

needed to prevent undue stretching, this same

stitch can be used to apply seam tape.

Page 21

ZIG-ZAG APPLICATIONS

SEAM FINISHES

Seam edges support garment and should

be given a durable finish where fabrics have a

tendency to ravel.

The zig-zag stitch is ideal for seam finishing.

Place stitching near edge of seam allowance,

and then trim excess fabric.

DARTS IN INTERFACING

Interfacing can be shaped without bulk

19

with zig-zag stitching. Cut out dart allowance

on stitching line and bring raw edges together.

Pin over a muslin stay and stitch. Reinforce

both ends with reverse stitching.

Page 22

ZIG-ZAG APPLICATIONS

MENDING

Zig-zag stitching is well suited for all types

of household mending. It provides a firm,

flexible bond for repair of tears and is ideal

for reinforcement and application of elastic.

Stitch length and width are regulated according

to need.

20

Tears. Trim ragged edges and reinforce

tear with underlay. Shorten stitch length at

ends and corners for added strength.

Application of Elastic. Elastic must be

stretched as it is applied to insure fullness

required in the garment.

Page 23

21

ZIG-ZAG. APPLICATIONS

APPLIQUE

Motifs or designs, applied with a zig-zag

stitch, add beauty and interest to •wearing

appareland household textiles.

Bands, flowers, leaves or figures in con-

trasting or self fabric, may be effectively

applied to another surface by two methods.

The appropriate method is determined by the

fabric being used. A test sample is advisable.

Method _ 1

Position and baste design to fabric.

Outline entire design with a short straight

stitch. Trim raw edges close to stitching.

Set stitch width and stitch length for zig-zag

Method _ 2

Position and outline design as for Method

# 1. Follow the shape of the design, outlining

it entirely with zig-zag stitching. Trim away

excess fabric on the outer edges of the

applique after stitching has been completed.

stitch desired. Overedge design. This smooth

uniform finish requires no additional trim-

ming.

Page 24

22

BUTTONHOLES

STITCH LENGTH: ABOVE 20 STITCH WIDTH: 2 AND 4

To establish exact stitch setting and buttonhole length a test sample is advisable. Be sure

to use the same fabric and number of fabric layers as in the garment.

C ......

2

Procedure: Mark button length on garment. Allow 1/8" at each end for bar tacks.

Side Stitching: Set stitch width at 2. Stitch down left side starting at point A and stopping at

end of marking, point B. Leave needle in fabric. Raise presser foot and pivot work on needle.

Lower foot and take one stitch at same width setting.

Leave needle in fabric at point C.

Bar Tack: With needle in fabric, raise presser foot and set stitch width at 4. Lower foot and

take approximately six stitches to complete tack. Leave needle in fabric at point D.

Side Stitching: With needle in fabric, raise presser foot and re-set stitch width at 2. Lower

presser foot and stitch to point E. Leave needle in fabric at point E.

Page 25

E

23

BUTTONHOLES (Cont'd)

A

.T

O

Final Bar Tack: With needle in fabric, raise presser foot and set stitch width at 4.

presser foot and duplicate tack previously made. Leave needle in fabric at point F.

Fastening Stitch: With needle in fabric, raise presser foot and sgt stitch width at O,

foot, take approximately three stitches_

Remove work, draw threads to wrong side and trim.

Cut opening for button with a pair

of sharp embroidery scissors.

Lower

lower

Page 26

24

DARNING

With just a little practice you will be able

to darn clothing and household linens effort-

lessly and quickly.

Set Stitch Width Selector on O setting and

I •

adjust Stitch Length Lever for desired

stitch length (usually about 10 or 12).

2. Decrease pressure by turning Pressure

Regulator thumb screw to right. Pressure

should be lighter than for normal sewing

but not too light to prevent work from

feeding smoothly.

5. Lower presser foot and start stitching,

alternately letting fabric feed normally

away from you and then gently pulling

fabric toward you. Continue this forward

and backward motion until area to be

darned is filled with parallel lines of

stitching.

6. For additional strength, turn fabric and

cover area with crosswise lines of stitching•

3. If area to be darned is open, baste an

underlay in place.

4. Place area to be darned under presser foot.

Page 27

25

FASHION* AIDS AND ATTACHMENTS

Available forseparate purchase at your local SINGER CENTER

Designed to cut down your sewing time, enlarge the scope of your accomplishment and

produce "professional-looking" results, the following attachments are available for your

use on the 337 Machine.

THE AUTO-PILOT BUTTONHOLER...

automatically produces straight and eyelet-

end worked buttonholes, embroidered eyelets,

and perfectly aligned rectangles of straight

stitching for bound buttonholes. ButtOnholes

may be made in a variety of basic sizes, up

to 1½" in length, with the twelve templates

that are furnis.hed with the attachment.

Additional templates, in sets of four, are

available for separate purchase.

* A Trademark of THE SINGER COMPANY

THE RUFFLER... for gathered and

pleated ruffles. Ruffles may be made separa-

tely or made and applied in one operation.

THE STRAIGHT STITCH PRESSER

FOOT AND THROAT PLATE... for

delicate and spongy fabrics and for sewing

procedures that require close control.

THE SEAM GUIDE... aids in maintaining

uniform seam width; guides placement of

top stitching.

Page 28

26

FASHION AIDS AND ATTACHMENTS

THE ZIPPER FOOT... indispensable for

the placement of stitching close to a raised

edge. For zipper insertions, corded seams and

slip cover welting.

THE BINDER FOOT... for the application

of commercial and hand-made bias binding.

THE HEMMER FOOT... forms and

stitches a perfect narrow 1/8" hem without

pressing or basting.

THE TUCKER... a time saver for making

tucks 1/8" to 1 inch in width.. Gauges tuck

width and tuck spacing; marks and stitches

in one operation.

(Cont'd)

THE BUTTON SEWING FOOT..• holds

two- and four-hole buttons securely for

stitching and provides for formation of thread

shank.

THE GATHERING FOOT.

evenly spaced shirring with

fullness.

THE EDGE STITCHER...

•. ensures

"locked-in"

regulates the

placement of straight stitching in relation to a

fabric edge by means of a series of slotted

guides.

THE SPECIAL PURPOSE FOOT...

designed to facilitate the placement of satin

stitching. It provides maximum visibility and

allows closely spaced zig-zag stitches to feed

THE THROAT PLATE LIFTING PLATE

... fits under the regular throat plate.

Necessary for free motion darning and

embroidery work, and for button sewing.

freely.

Eyelet accommodates a filler cord.

For buttonholes, applique, and mono-

grams.

Page 29

27

HOW TO TAKE CARE OF THE MACHINE

To Clean the Machine

CLEAN

AND

OIL

BETWEEN

TENSION

CLEAN

CLEAN

DISCS

When in regular use

Machine should be cleaned periodically

with lint brush to remove lint and fluff which

may have accumulated around workirig parts.

To clean bobbin case area, removebobbin

case as instructed on page 29. Oil machine

after each cleaning as instructed on pages 30,

31 and 32.

When stored

If machine is to be stored away for an

indefinite period, a thorough brush-cleaning

to remove all traces of lint and fluff, followed

by swabbing of all exposed parts with a lint

-_._ free brush saturated with SINGER* oil is

....."_'_,..""'CLEAN necessary to protect machine against rust

AND damage.

OIL

-_"_:_ * A Trademark of THE SINGER COMPANY

Page 30

To remove the throat plate To replace the throat plate

CLAMPING PIN

28

To Remove and Replace Throat Plate

/

/

• Raise needle bar and presser foot.

$ Open slide plate.

• Place thumb under right front end of

throat plate and raise until clamping pin

lifts up.

• Draw plate toward right to disengage.

/ , H

• Position fork of plate under clamping

pin as shown above.

• Push to left and press down until plate

snaps into position.

• Close slide plate.

Page 31

To Remove and Replace Bobbin Case

• Open slide plate and remove throat plate

(see page 28).

• Unlock bobbin case by lifting and pulling

holder to right as shown.

29

POSITIONING

STUD

Remove bobbin case from machine.

Remove all lint, fluff or other foreign

matter which might clog machine.

• Replace bobbin case so that groove under

tension spring fits on hook raceway and

fork of case straddles positioning stud.

• Push bobbin case holder to left until it

snaps down into lock position.

• Replace throat plate and close slide plate_

Page 32

30

To Off the Machine

To keep_your machine in top running condition, use SINGER Oil and SINGER*

Lubricant. Both are quality products especially prepared for sewing machines, and should

always be used in the care of your 337 machine. ' i1

....:7:'::..............._..........................

o

!

• Clean machine periodically as in-

structed on page 27.

• Apply a drop of oil to each place

indicated.

• Remove screws A and lift off arm

top cover.

• Apply a small amount of lubricant

to gears as shown, A tube of this

lubricant can be purchased at your

SINGER CENTER.

NEVER APPLY 01£, TO GEARS

Disconnect Machine from electricity supply before

Top Cover or Bed Cover Plate.

* A Trademark of THE SINGER COMPANY

===========================

removing Arm ....._:_:._..,<::.:..

Page 33

31

/

• Remove face plate (see page 27) and oil the

places indicated.

• Open slide plate and apply a drop of oil to

hook raceway as indicated.

• Close side plate, replace arm top cover and

face plate.

Page 34

32

To Oil the Machine (Cont'd)

G

Tilt machine back and remove thumb nut from screw G, being careful not to lose felt

washer, and remove cover from underside of machine.

Oil each of the places indicated by arrows. Avoid getting oil on any part of the motor.

Replace bottom cover.

THE MOTOR REQUIRES NO LUBRICATION

Page 35

ARM

END

COVER

33

ELECTRICAL INFORMATION

The SINGER* Electric Motor in your

machine is furnished for operation on an

alternating current of 110-120 volts, 25 to 75

cycles, or on 110-120 volts direct current.

Special motors are available for direct or

alternating current for any voltage between

50 and 145, and for 32 volts direct current.

Before inserting Electric Plug, be sure that

voltage and cycles on arm end cover are

within range marked on electrical meter

installed by your power company.

Electrical Connections. Insert the three-

hole plug into the three-pin receptacle at the

right end of the machine. Connect the

two-pin plug into your electrical outlet and

the machine is ready to sew.

PEDAL

Speed Controller. Speed of machine is

regulated by amount of pressure on pedal

of foot controller or knee lever.

CAUTION: Do not attempt to remave the

arm end cover.

* A Trademark of THE SINGER COMPANY

Page 36

Electrical Information (Cont'd)

FINGER GRIP

34

Sewing Light

To Remove Bulb. Press bulb intosocket and

turn it in " unlock" direction, as shown, and

withdraw.

To Replace Bulb. Press bulb into socket with

bulb pin in slot and turn it in " lock"

direction, as shown.

LOCKS

The built-in sewing light is located

beneath the machine arm. It is

turned on or off by the light switch

located under the stitch length

lever.

To Change Bulb

• Switch light off.

• Pull light down by finger grip

and hold in down position.

• Release hold and light will return

to normal position.

UNLOCKS

Page 37

To all whom it may concern:

The improper placing or renewal of the trademark "S ! N G E R". or

any other of the trademarks of The Singer Company (all of which are duly

Registered Trademarks) on any machine that has been repaired, rebuilt,

reconditioned, or altered in any way whatsoever outside a SINGER factory

or an authorized SINGER agency is forbidden.

Page 38

SINGER

GUARANTEE

WE GUARANTEE that each SINGER* sewing machine has been carefully manu-

factured and is in perfect operating condition on delivery. When subject to normal

family use and care, any parts requiring replacement at any time due to defects in

material or workmanship will be replaced without charge.

THIS GUARANTEE does not apply to parts requiring replacement due to natural

wear or to abuse or negligence of the user or in the event the machine is serviced by

other than a SINGER representative or Approved Dealer or with parts other than those

supplied by The Singer Company.

IN ADDITION to the above guarantee of parts, each machine will be inspected and

adjusted whenever necessary without charge for labor for a period of one year from

date of purchase.

THIS GI_ARANTEE is effective only with respect to the person making the purchase

from The Singer Company or one of its Approved Dealers. The original Sales Agreement,

or Cash Receipt, must be presented to obtain the benefits of the guarantee.

AGREEMENTS inconsistent with the foregoing shall be void and of no effect.

THE SINGER COMPANY

Loading...

Loading...