Page 1

Form K6542

(365)

SINGER

SERVICE MANUAL

331K1 and 331K4

*A Trademark of THE SINGER COMPANY

THE SINGER COMPANY

© 1962 by The Singer Company

Copyright Under International Copyright Union

All Rights Reserved under Inter-American Copyright Union

Printed in Great Britain

Page 2

CONTENTS

PAGE

DESCRIPTION...............................................................3

LUBRICATION AND CLEANING...................................4

INFORMATION FOR OPERATION

Bed Slide (Slide Plate)

Belt Guard......................................................................3

Bobbin and Bobbin Case

Bobbin Winder..................................................

Capacity of Machine...................................................3, 12

Centralizing Feed Dog

Common Causes of Stitching Troubles

Description of Oil..........................................................4

Dimensions of Machine..................................................3

Drawing Up Bobbin Thread............................................8

Feed Dog

Feed, Reverse......................................................... 3, 10

Feed Timing

Graduated Stitch Indicator

Knee Lifter..................................................................... 3

Length of Stitch

Light Fixture....................................................................3

Link Take-up ..............................................................3, 6

Lint, Removal of Excess.................................................4

Machine Dimensions.................................................... 3

Machine Pulley...........................................................3, 11

Needles

Needle Bar.........................................................3, 12, 13

Needle Setting............................................................... 5

Needle to Shuttle, Clearance.

Perfect Stitch..................................................................8

Preparation for Sewing...................................................8

Presser Bar

Presser Bar Guide Bracket

Presser Foot

Pressure of Presser Foot

Pulley........................................................................ 3, 11

.................................................................

................................................................

..........................................................................

.................................................................

......................................................

...................................................

...........................................

.................................................

...........................................

........................................................

..........................................

.........

.........................

..........

.........................

....

............................13, 16

3, 12, 15

................................

4-11

7-9

4, 7

16

15, 16

15

10

3, 10

12

12

9, 15

INDEX

8

5

5

PAGE

ADJUSTMENTS

PARTS LIST

Reverse Feed

Rotary Tension................................................................3, 9

Setting Up Machine....................................................... 3

Shuttle

.....................................................................

Shuttle to Needle Clearance

Specifications............................................................3,12

Speed.............................................................................3

Starting to Sew...........................................................8, 11

Spillage, to Avoid............................................................7

Stand..............................................................................3

Stitch Indicator..............................................................10

Stitch Length

Stitch Type

Stitching Troubles, Causes of

Stop Motion...................................................................11

Table...............................................................................3

Tacking.........................................................................10

Take-up Lever

Take-up Lever Guard

Tension, Check Spring

Tension, Threads.............................................................8, 9

Thread

............................................................................

Threading, Bobbin Case.................................................7

Threading, Upper (Needle).............................................6

Throat Plate................................................................3, 16

Treated Material, Speed when Sewing

Treadling Procedure

Turning a Corner

Twist of Thread............................................................. 5

Unwinder

Upper Threading.............................................................6

Winder (Bobbin)...............................................................4, 7

.....................................................

.................................................................

..........................................................

...................................

................................................................

.....................................................................

........................................

.................................................................

.....................................................

.................................................

..........................

....................................................

........................................................

.........................................................................

12-16

3, 10

13, 14

13, 16

.8

17

10

3

5

3, 6

3

14

5

3

11

3, 6

Page 3

DESCRIPTION MACHINE 331K4:

Machines 331K1 and 331K4 produce top quality,

single-needle, straight-line lock stitching in suits, shirts,

skirts and other clothing.

MACHINE 331K1:

Stitch Type #301.

Central bobbin.

Short beak, oscillating shuttle on horizontal axis.

Link take-up.

Thread take-up lever guard.

Drop feed.

Hinged presser foot 161066.

Feed dog 149603.

Similar to Machine 331K1, with the following

exceptions;

Spring-biased, quick reversible feed mechanism

permits operator to feed work backward or forward

at will.

Solid presser foot 12144.

Feed dog 149304. Throat plate 12414.

INSTALLATION

Before placing the machine in its cut-out on table,

see that the four cushioning pads are at the four cor

ners of the cut-out. Place the machine on these pads.

SPEED

Throat plate 26606.

Length of stitch controlled by regulator thumb screw

on front of machine arm.

Maximum stitch length—5-1 /3 to the inch.

Front, intermediate and rear plain bearings.

Clamp type needle bar.

Tapped hole and seat in rear of arm provided for

mounting light fixture independently of presser bar

lifting lever hinge screw.

Needle bar stroke is 1.472 inches.

Clearance under presser foot is 5/16 inch.

Machine dimensions; Bed length 18-3/4 inches,

width 7 inches.

Belt guard 174112 available on order.

Knee lifter 139625 regularly supplied.

The maximum speed for these machines is 2200

stitches per minute, according to the material sewn

and the type of work being done.

It is advisable to operate these machines at a more

moderate speed the first few days, after which they

can be operated at maximum speed.

Reduce speed of machine when sewing closely

woven fabrics or treated materials.

MACHINE PULLEY

Machine pulley 139724 (solid discs, balanced) has

an outside diameter of belt groove of 2.90 inches

for 3/8 inch V-belt. Effective diameter for 5/16 inch

round leather belt is 2-5/16 inches.

When in operation, the top of the machine pulley

must always turn over toward the operator.

Page 4

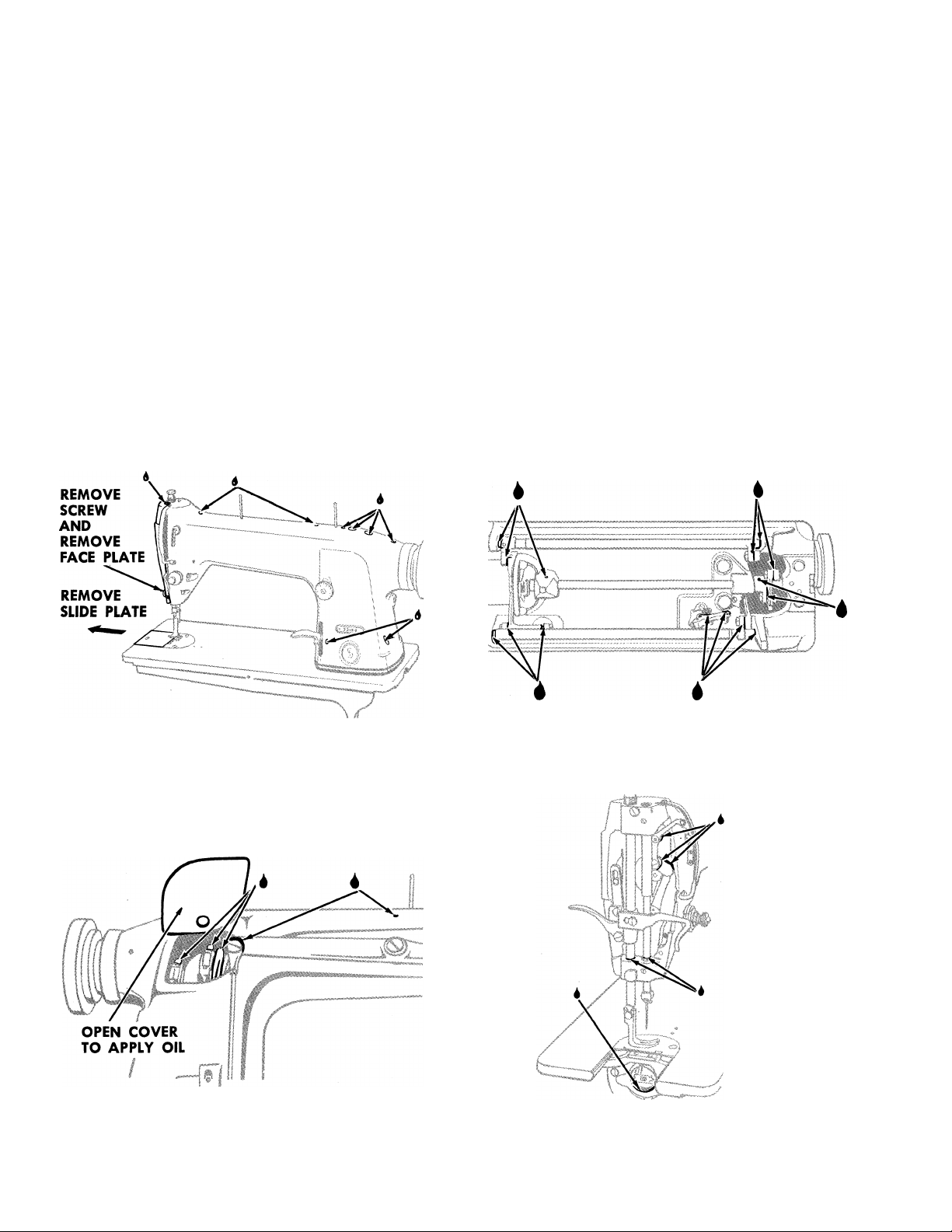

LUBRICATION AND CLEANING

Use SINGER* OIL, “TYPE B” or “TYPE D”. Use

“TYPE D” OIL when an oil is desired which will

produce minimum stain on fabrics.

A machine in continuous use should be oiled fre

quently. Frequency is dependent upon the speed at

which the machine is operated and the type of work

being done. Basically the machine needs oiling at

least twice each working day.

Before starting the machine, at the beginning of the

day and again after the midday recess, apply a few

drops of oil at each of the oiling points on the machine.

Arrows indicate oiling points in Figs. 2 through 5.

Never attempt to oil shuttle race (See Fig. 5) through

holes in throat plate.

BOBBIN WINDER LUBRICATION

Oil bobbin winder occasionally by applying a few

drops of oil to oil wick in bobbin winder frame, as

instructed in

Fig. 11, page 7.

CLEANING

Clean out all lint and abrasive matter from around

the shuttle and between the feed rows on the under

side of the throat plate.

Close all covers after oiling and cleaning. Wipe off

excess oil from surfaces of machine that may come in

contact with material.

Fig. 2. Oiling Points—Front View

Fig. 3. Oiling Points—Rear View

Fig. 4. Oiling beneath Machine Bed

Fig. 5. Oiling Points behind Face Plate and in Shuttle Race

Page 5

THREAD

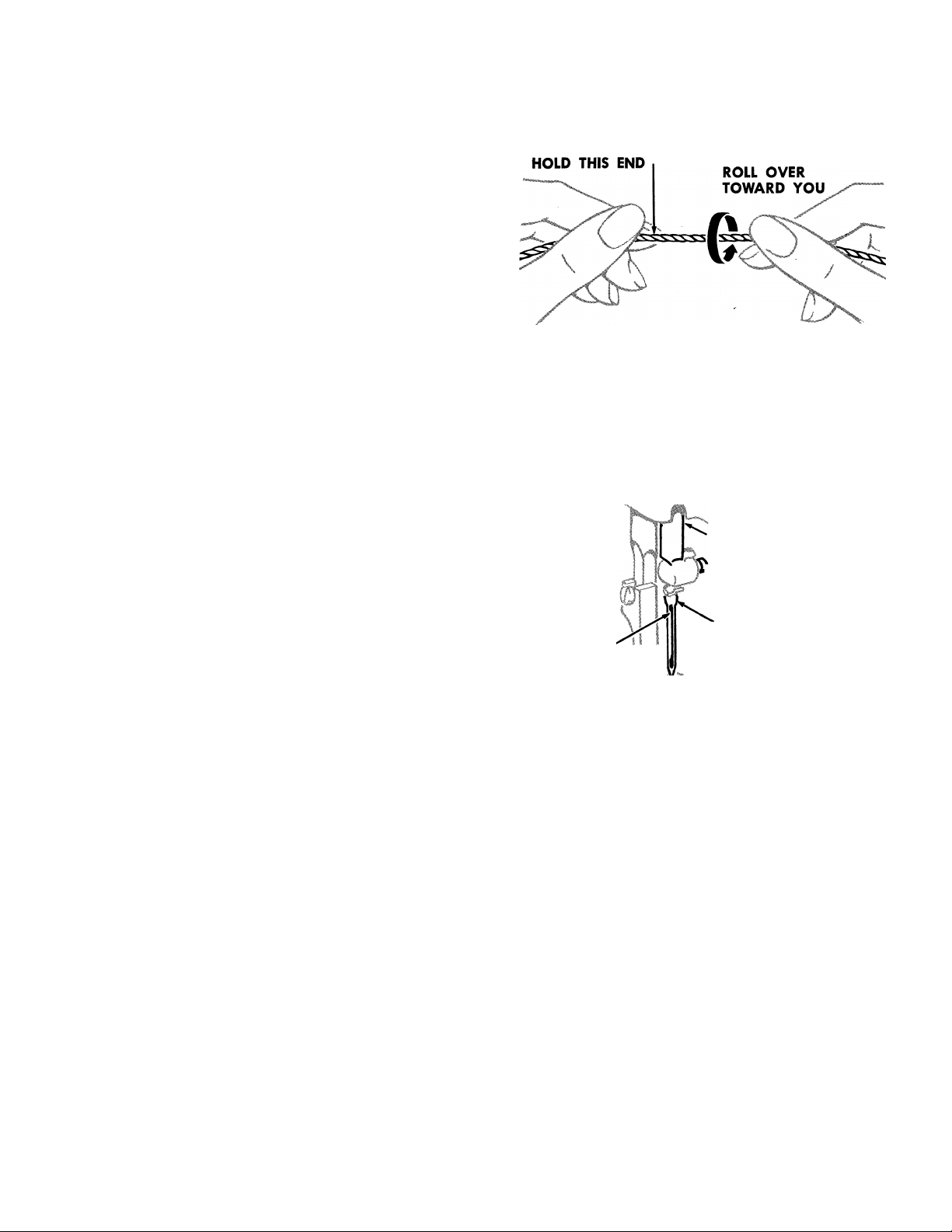

On Machines of Class 331K, use only left twist

thread in the needle. Either right or left twist thread

can be used in the bobbin.

To determine the thread twist, hold the thread as

shown in Fig. 6. Then twirl the thread over toward you.

If the strands of the thread wind tighter, the thread is

left twist, if the strands unwind or separate, the thread

is right twist. Rough or uneven thread, or thread which

passes with difficulty through the eye of the needle,

will interfere with the successful use of the machine.

NEEDLES

The needle you select will have a very direct effect

on the quality, strength and appearance of the stitch

produced by the machine.

In selecting a needle size . . . the eye must be large

enough to allow the thread you are using to pass

through freely without binding or chafing. A simple

test is to thread a short length of thread through the

eye of the needle selected; hold the thread taut in a

vertical position and twirl the needle about the thread.

If the size is correct, the needle should slip down the

thread easily.

Needles for this machine are of Catalog #2055

(16 X 87) in Sizes 8 to 14, 16 to 19 and 21 to 25.

Fig. 6. How to Determine the Twist

MOVE TO

HIGHEST POINT

N

LOOSEN SCREW

INSERT NEEDLE UP

LONG

GROOVE It

AS FAR AS POSSIBLE

AND TIGHTEN SCREW

Orders for needles must specify the Quantity

required, the Size number, also the Catalog number.

For example:

‘nOO Size 16, Catalog #2055

(16x87) Needles’’

For best results always use SINGER needles.

TO SET THE NEEDLE

Turn the machine pulley over toward you until the

needle bar moves to its highest point.

After loosening needle clamping screw, remove old

needle and insert new needle UP into needle bar AS

FAR AS IT WILL GO, as instructed in Fig. 7.

The single continuous groove of the needle MUST

face away from the shuttle point (toward the left end

of the machine, as shown in Fig. 7) with eye of needle

directly in line with arm of machine.

Securely tighten needle clamping screw.

Fig. 7. Setting the Needle

COMMON CAUSES OF STITCHING TROUBLES

Check needles often to make sure these defects are

not present...

^ Wrong needle for thread and material in use.

• Bent needle, clogged needle eye, or dirty

needle grooves may cause skipped stitches.

• Hook or burr on needle point may cause picking

or fraying of the material.

• Incorrect setting of needle.

Page 6

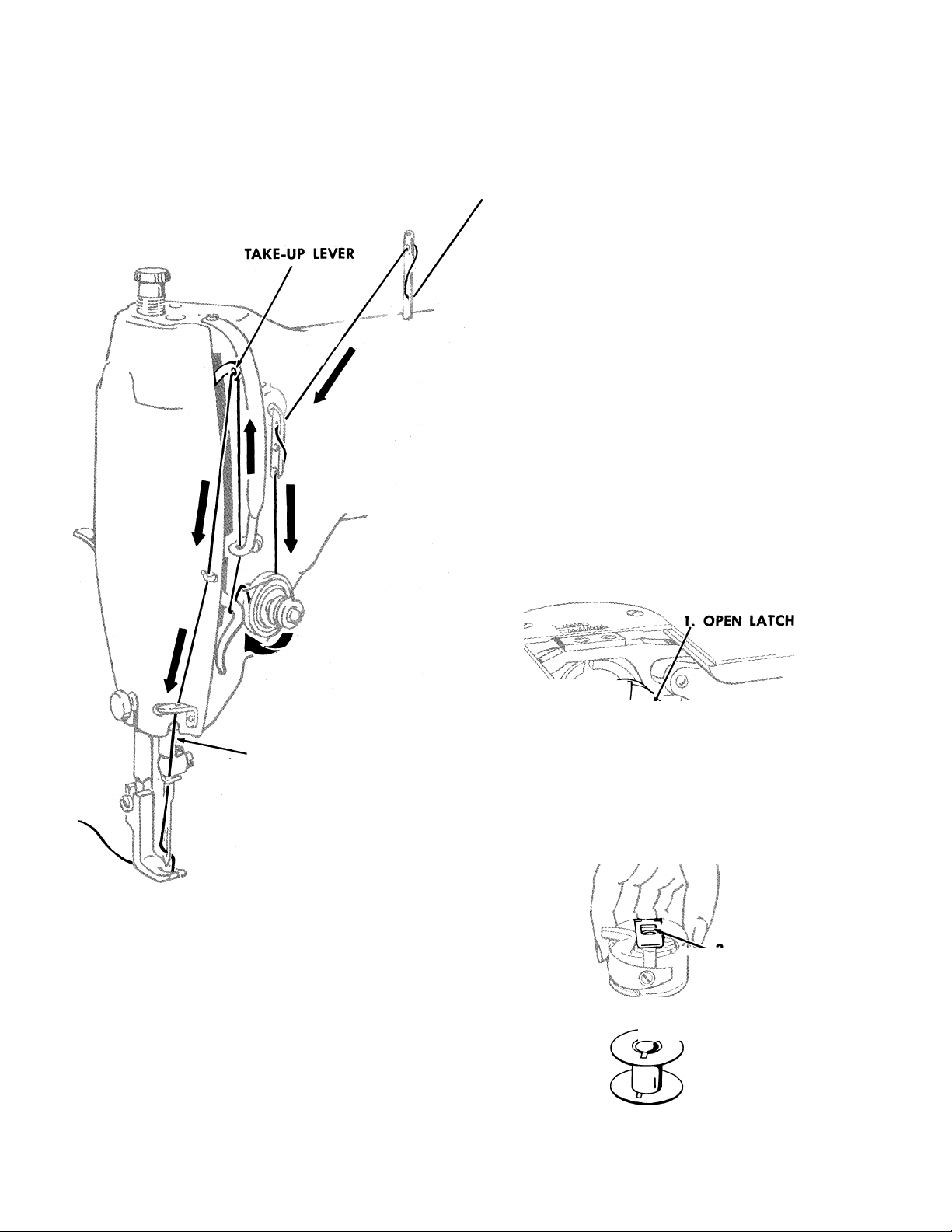

UPPER THREADING

NOTE: Thread unwinder 225258 is recommended for

use with these machines.

First, turn the machine pulley over toward you until

needle is at its highest point, then pass the needle

thread from the unwinder through the threading points

in the order shown in Fig. 8.

Pass the thread from left to right through needle eye.

Draw about two inches of thread through the eye of

the needle with which to start sewing.

TO REMOVE THE BOBBIN

Turn machine pulley over toward you until needle

thread take-up lever is at highest point, as shown in

Fig. 8.

Reach beneath bed of machine with left hand and

remove bobbin from shuttle body, as instructed in

Fig. 9.

While latch is kept open, bobbin will be retained

in bobbin case.

To remove bobbin from bobbin case, release latch

and turn the open end of bobbin case downward.

Bobbin will drop out, as shown in Fig. 10.

MOVE NEEDLE BAR

TO HIGHEST POINT

Fig. 8. Upper Threading

HOLD LATCH AND

\r PULL CASE FROM

A SHUTTLE

""/A.)

Fig. 9. Removing Bobbin Case and Bobbin from Machine

I —o. RELEASE

LATCH

4. BOBBIN

DROPS OUT

Fig. 10. Removing Bobbin from Bobbin Case

Page 7

TO WIND THE BOBBIN

(See “STOP MOTION DEVICE” for

treadle machines on page 11)

Bobbin winder should be fastened to table with its

driving pulley approximately 1 /4 inch in front of the

machine belt. Bobbin winder driving pulley will then

make firm contact with machine belt when thumb latch

is pressed down. Bobbin winder pulley will be released

from contact with belt when sufficient thread has been

wound upon the bobbin.

Place bobbin on spindle, pushing it on as far as it

will go and pass thread through threading points, as

shown in Fig. 11.

Wind end of thread around the bobbin a few times

in the direction shown in Fig. 11. Press down on thumb

latch, pushing driving pulley over against belt.

OIL

LOOSEN TO ADJUST^

FOR EVEN WINDING ^

NOTE—TIGHTEN FOR

MORE THREAD ON BOBBIN

Fig. 11. Winding the Bobbin

SLOTn

TENSION /

CONTROL ^

1. PLACE BOBBIN

ON SPINDLE

2. WIND THREAD

3. PRESS DOWN

Start the machine.

Bobbins can be wound while the machine is stitching.

TO AVOID SPILLAGE: Regulate bobbin winder to

stop automatically when bobbin is wound approx

imately

1/16 inch short of bobbin rim.

TO THREAD THE BOBBIN CASE

Hold the bobbin so that the thread will unwind in the

direction shown in Fig. 12.

Hold the bobbin case as shown in Fig. 12 and place

thé bobbin into it.

Pull the thread into the slot 1, Fig. 13 and under the

tension spring 2, Fig. 13.

Draw the thread into the delivery eye at the end of

the tension spring, as shown at 3, Fig. 14.

TO REPLACE THE BOBBIN CASE

r--

Fig. 12. Placing Bobbin in Bobbin Case

1. PULL THREAD

INTO SLOT

2. DRAW THREAD

DOWN AND

UNDER SPRING

Fig. 13. Pulling the Thread into the Slot

3. TURN BOBBIN

CASE OVER

AND DRAW

.THREAD UP INTO

DELIVERY EYE

Fig. 14. Drawing the Thread Under the Tension Spring

After threading, take bobbin case by latch in the

left hand.

Place bobbin case on centre stud of shuttle body

with position finger pointing upward, in front of notch

in upper plate over shuttle race, as shown in Fig. 15.

Release latch.

Press bobbin case back until latch catches groove

near end of stud.

Allow about two inches of thread to hang free.

Fig. 15. Bobbin Case Threaded and Replaced

Page 8

Fig. 17. Perfect Stitch

TO PREPARE FOR SEWING

Hold slack end of needle thread loosely and turn

machine pulley over toward you until needle moves

down and up again to its highest point, catching bobbin

thread.

• Draw up needle thread; bobbin thread will come

up with it through hole in throat plate, as shown in

Fig. 16.

• Lay both threads back under presser foot.

• Close the bed slide.

• Always keep the bed slide closed when the

machine is in operation.

TO START SEWING

• Move take-up lever to top of its stroke as shown

in Fig. 8, page 6.

• Place material beneath the presser foot. Lower

the presser foot. Start to sew, turning the machine pulley

over toward you.

TO TURN A CORNER

• Stop the machine when needle is rising but before

it is out of the material.

• Raise the presser foot.

• Turn material for next line of stitching, using needle

as a pivot.

• Lower the presser foot.

• Resume sewing.

• Avoid aiding the machine by pulling the fabric,

lest you damage the needle. The machine feeds the

work without assistance.

Fig. 18. Too Tight Needle Thread Tension

TO REMOVE THE WORK

• Stop the machine with the take-up lever at top of

its stroke.

• Raise the presser foot.

• Draw the work toward the rear until it is clear of

the needle.

• Cut the threads close to the goods.

• Lay the threads back under the presser foot.

THREAD TENSION

For ordinary stitching, tension on needle and bob

bin threads should be balanced with needle and

bobbin threads locked in centre of thickness of

material as shown in Fig. 17.

When there is too much tension on needle thread and

not enough on bobbin thread, needle thread cannot be

pulled down into material, as required. Poor stitching

results.

Needle thread will lie on top of material as

shown in Fig. 18.

When there is too much tension on bobbin thread and

not enough on needle thread, you get the reverse of

the condition shown in Fig. 18. The stitching is just as

poor. The bobbin thread will lie on bottom of mate

rial as shown in Fig. 19.

Page 9

REGULATION

BOBBIN THREAD TENSION:

For average sewing, tension on bobbin thread should

be very light.

To regulate tension on bobbin thread, remove the

bobbin case and turn screw in tension spring, as in

structed in Fig. 20.

^When tension on bobbin thread has been correctly

adjusted for ordinary stitching, the required stitch

can usually be obtained thereafter to suit the work in

process by varying the tension on needle thread

only.

NEEDLE THREAD TENSION:

To avoid accumulating excessive tension on needle

thread, first obtain correct tension on bobbin thread, as

instructed above.

Regulate needle thread tension only when

presser foot is down (since needle thread tension is

automatically released when presser foot is raised).

Fig. 20. Regulating Bobbin Thread Tension

Tension on needle thread should be just enough to

set stitch correctly in material.

Having lowered presser foot, turn thumb nut at the

front of tension discs either over toward right or left, as

required. See instructions in Fig. 21.

PRESSURE OF PRESSER FOOT

ON THE MATERIAL:

The correct presser foot pressure helps feed the

work efficiently. You can regulate the amount of pres

sure exerted by the presser foot on the material by

means of the thumb screw, as shown in

Fig. 22.

The pressure on the material should be as light as

possible, while sufficient to insure correct feeding.

To increase the pressure turn the thumb screw down

ward.

To reduce the pressure turn this screw upward.

The pressure is correct when the work moves steadily

and smoothly without stalling.

Fig. 21. Regulating Needle Thread Tension

MORE PRESSURE

Fig. 22. Regulating the Pressure on the Material

Page 10

1. LOOSEN

THUMB SCREW—

TO CHANGE

STITCH SETTING

2. RAISE OR

LOWER

AS DESIRED.

3. TIGHTEN—

WHEN DESIRED

STITCH SETTING

IS OBTAINED

Fig. 23. Regulating Length of Stitch on Machine 331K1

SHORTER

LONGER

10

REGULATION

LENGTH OF STITCH, ON MACHINE 331K1:

The length of stitch is regulated by moving the

pointer in the stitch indicator plate on the front of the

machine as instructed in Fig. 23.

When pointer is set at 0 there can be no feeding

motion.

Maximum length of stitch is 5Vb stitches per inch.

Move pointer to desired length of stitch and firmly

tighten thumb screw.

LENGTH OF STITCH, ON MACHINE 331K4:

Depress the feed-reversing lever slightly and turn

thumb screw over to the left to lengthen the stitch or over

to the right to shorten the stitch, as instructed in Fig. 24.

2. TURN

THUMB i

SCRiW I for longer

•STITCH

1. DEPRESS

LEVER STITCH

^ 3. RELEASE

LEVER

Fig. 24. Regulating Length of Stitch on Machine 331K4

Thumb screw is marked with numerals from “0” to

“5”.

When thumb screw is set at “0” feed reversing lever

is fixed at central position and there can be no forward

or reverse feeding.

When thumb screw is set at “5”, machine will feed at

maximum stitch length.

REVERSE FEED, ON MACHINE 331K4:

(See instructions in Fig. 25)

Simply depress the feed-reversing lever as far as it

will go.

Feeding in reverse continues only as long as lever is

held in depressed position.

Forward feeding is resumed upon release of lever.

Direction of feed can be reversed at any point in a

seam while machine is in operation, without disturbing

the work. Back tacking is therefore readily accom

plished and ends of seams are easily fastened.

The range of movement of feed reversing lever is

limited by the setting of thumb screw as instructed

above under stitch length regulation.

When lever is released it will rise to highest point

permitted by setting of thumb screw and machine will

stitch forward at the set stitch length.

Fig. 25. Reversing the Feeding Movement

on Machine 331K4

When lever is depressed as far as permitted by the

thumb screw setting, machine will feed in reverse at the

set stitch length.

Page 11

THE STOP MOTION DEVICE

Machine 331K1 and 331K4 are regularly fitted

with solid disc (balanced) machine pulley 139724^

without stop motion device.

When required for treadle operation a machine may

be obtained, on specific order, with machine pulley

139725, including a stop motion device, as shown in

Fig. 26.

This device allows machine pulley to turn without

turning arm shaft so that bobbins ma/ be wound and

correct treadling acquired without disturbing the

stitching mechanism.

To loosen the machine pulley, hold pulley with left

hand and, with right hand, turn the stop motion screw

over toward you, as shown in Fig. 26.

11

Fig. 26. Loosening Machine Pulley

TREADLING

To acquire correct treadling habits, loosen the

machine pulley, as instructed in Fig. 26 and place both

feet squarely but comfortable upon treadle, as instruct

ed in Fig. 27.

Turn machine pulley over toward you by hand and

at the same time, allow your feet to move freely and

lightly with motion of the treadle.

Continue to do this until a regular, easy movement is

acquired and you are able to stop and restart the

machine without the machine pulley turning in

the wrong direction.

Tighten the stop motion screw and practice sewing

until you have become accustomed to the necessary

motion of hands and feet during the actual operation.

Fig. 27. Position of Feet Upon Treadle

NOTE: The instructions on the following pages are for Service Representatives.

To insure correct timing and avoid unnecessary repetition, these instructions should

be followed in the order given.

Page 12

12

SPECIFICATIONS

The following gauge distances should be of help to

adjusters of these machines:

• Height of presser foot above throat plate 5/16

inch.

• Distance from throat plate seat to needle stop in

needle bar (needle bar at lowest point), 1.004 inches.

• Needle bar stroke 1.472 inches

• Rise of needle bar when point of shuttle is at

center of needle (loop lift), .100 inch.

VARIATIONS: Certain conditions of sewing may

necessitate slight variations from thèse settings.

TO SET THE PRESSER BAR

AT THE CORRECT HEIGHT

PREPARATION:

Remove face plate and slide plate.

Accumulation of lint, oil and dirt on presser foot seat

on presser bar may prevent proper seating of foot.

Clean this area before checking and setting the

presser bar.

CHECK:

1. When presser foot is raised with presser bar lifting

lever there should be a 5/16 inch clearance between

presser foot and throat plate.

2. When presser foot rests firmly upon throat plate

(with feed dog below throat plate) there should still be

some clearance between guide bracket A, Fig. 28 and

lifting bracket B, as shown in Fig. 28.

Fig. 28. Checking Height of Presser Bar

3. When presser foot is at its highest point and needle

bar is at its lowest, top of presser foot should clear the

needle thread eyelet C, Fig. 28 at the lower end of

needle bar.

SETTING:

• Release the presser bar lifting lever D, Fig. 28,

lowering the presser foot.

• Loosen clamping screw E, Fig. 28.

• Raise or lower guide bracket A, as required.

• Make certain presser bar is positioned correctly

so that needle will locate centrally between the two

toes of the presser foot.

• Securely tighten screw E.

Whenever guide bracket A, Fig. 28 has been

moved on presser bar, check the setting of check

spring as instructed on page 14.

Page 13

TO SET THE NEEDLE BAR AT THE

CORRECT HEIGHT

PREPARATION:

Remove face plate, slide plate and throat plate. See

that needle is correctly set in needle bar, as instructed

on page 5.

CHECK:

When shuttle point passes centre of needle, top of

needle eye should be approximately 1/16 inch below

point of shuttle. See Fig. 29.

13

A 4 SHUTTLE POINT

CENTER

VW

I

ALTERNATE CHECK:

The gauge distance from throat plate seat to needle

stop in needle bar (at lowest point) should be 1.004

inches, as indicated in Fig. 30.

SETTING:

Loosen clamping screw F, Fig. 30. Raise or lower

needle bar, as required. Then securely tighten screw F.

Replace throat plate, slide plate and face plate.

TO TIME THE SHUTTLE

EXPLANATION:

Timing of shuttle is fixed at the factory for normal

sewing conditions at a 1/10 inch loop lift.

This is accomplished by pinning the shuttle driver at

one end of the oscillating shaft and then pinning crank

G, Fig. 31

at the other end of the shaft at the specified

timing location.

TO CHECK THE TIMING:

Turn the machine pulley over toward you until needle

bar descends to lowest point and then rises approxi

mately 1/10 inch.

At this setting, for normal sewing, the point of the

shuttle should be at the centre of the needle as shown

in Fig. 29.

Fig. 29. Relationship of Shuttle Point to Needle Eye

Fig. 30. Setting Needle Bar Height

TO RE-SET THE TIMING:

When it becomes necessary to replace one or more

of the shuttle driving parts or to alter the timing to suit

a particular sewing condition, remove pin H, Fig. 31.

Loosen set screw J, Fig. 31.

Move point of shuttle to desired timing position and

securely tighten set screw J in crank G.

Plug pin hole in shaft and drill new hole to receive

pin in desired location.

Insert pin H.

Fig. 31. Setting the Oscillating Shaft Crank

to Time of Shuttle

Page 14

Fig. 32. Setting Height of Check Spring

14

HEIGHT SETTING

PREPARATION:

Thread the machine.

CHECK:

Turn machine pulley over toward you slowly. When

take-up lever begins to rise^ spring K, Fig. 32 “checks”,

showing a slight dip and a return to its highest position.

Later, as take-up lever approaches top of stroke,

setting the stitch, this “check” spring K should be drawn

all the way down. As lever descends, check spring K

returns to rest.

TO SET THE CHECK SPRING

SETTING:

To obtain the slight dip in check spring when take-up

begins to rise, loosen screw L, Fig. 32. Turn stud M,

Fig. 32 (at the same time turning entire tension as

sembly) either over toward left to lower the spring’s

resting position and decrease its movement, or

over toward right to raise the spring’s resting

position and increase its movement. Securely tighten

set screw L.

Fig. 33. Adjusting Tension on Check Spring

VARIATIONS (FOR MACHINE 331K4):

Under certain conditions of tacking, it may be neces

sary to set the check spring higher than it is otherwise

normally set.

TENSION SETTING

PREPARATION:

Thread the machine. Securely tighten set screw L,

Fig. 33. Make certain thumb nut is on stud M, Fig. 33.

CHECK:

Tension on check spring K, Fig. 33, should be suffi

cient to ensure action at top speed; but still light

enough to permit itself to be drawn all the way down

before any thread is drawn through the tension discs,

as take-up lever approaches height of stroke.

Check spring setting should be reviewed each time a

different foot is applied to machine.

SETTING:

Using a large screwdriver in slot of stud M, turn stud

either over toward left to decrease tension or over

toward right in increase it, as shown in Fig. 33.

VARIATIONS:

The tension on the check spring may require a

different setting, depending upon the thread and

material used. Heavier thread or bulkier material re

quires more tension to ensure correct thread control.

Page 15

TO TIME THE FEED

CHECK:

Test feed assembly linkage for freedom of move

ment. Action of feed dog must be regular and smooth

for maximum efficiency

15

When the feeding movement is correctly timed

• The feed dog stops moving toward the rear

just as the take-up lever reaches the top of its stroke.

• The feed dog drops below surface of throat

plate just as needle is about to enter material.

TIMING:

• Set the machine for longest stitch as instructed on

page 10.

• Turn up the cover plate at the rear of the machine

arm.

• Loosen set screw N in feed eccentric P, Fig. 34.

• Rotate feed eccentric P as required to obtain

desired timing.

• Securely tighten set screw N.

• Close cover plate at rear of arm.

----------

Fig. 34. Timing the Feed

FULL DEPTH

OF REAR TEETH

TO SET THE FEED DOG AT THE

CORRECT HEIGHT

Before checking height of feed dog, set the machine

for longest stitch, as instructed on page 10.

When the feed dog is at its highest position, ap

proximately the full depth of the rear teeth of the

feed dog should project above the top surface of

throat plate, as shown in Fig. 35.

Variations of feed dog height may be necessary to

balance the height with the presser foot pressure.

To adjust the height of the feed dog, loosen screw

O, Fig. 35 and raise or lower the feed bar R, Fig. 35,

as required.

When the feed dog is set to the desired height,

securely tighten screw O.

/

Fig. 35. Adjusting Height of Feed Dog

Page 16

16

TO CENTRALIZE FEED DOG IN THROAT

PLATE SLOTS

CHECK:

Feed dog should not contact edges of throat plate

slots.

SIDEWISE SETTING:

Feed dog should travel on a line midway between

sides of throat plate slots.

Feed dog can be moved toward left or right, as

required, after loosening two nuts S and screw U, Fig.

36, on screw centres T.

To move feed dog toward left, loosen screw centre

T at left end of shaft V, as required, and tighten the

other screw centre an equal amount.

Make certain that screw centres hold feed rock shaft

V snugly in place without binding. Then securely tighten

both nuts S and screw U.

Fig. 36. Centralizing Feed Dog

LENGTHWISE SETTING:

Set machine for longest stitch as instructed on page

10.

Feed dog should be set so that its movement is

equidistant from front and rear edges of throat plate

slots.

Loosen clamping screw U and move feed bar R and

rock shaft V, as required.

Securely tighten screw U.

TO REMOVE AND REPLACE THE

SHUTTLE RACE

REMOVAL (With needle at highest position):

Remove the two screws W, Fig. 37.

Remove the shuttle race X, Fig. 37, from machine.

Shuttle Y may now be slipped in or out of shuttle race

X without difficulty.

REPLACEMENT (With needle at highest position):

Slip shuttle Y into shuttle race X, Fig. 37. Turn shuttle

in shuttle race so that shuttle will correctly engage

shuttle driver Z, Fig. 37.

Install shuttle race with shuttle in machine.

Fasten with two screws W, Fig. 37.

Tighten two screws W.

Page 17

The Some !

To get replacements

that are the same

as parts in new

machines...

BUY PARTS AND

NEEDLES MADE BY

TO BE DOUBLY SURE...

SINGERS

of new machine performance, make sure that all

replacement parts and needles are precisely

identical to those in new SINGER machines.

Look for the trademark

SINGER

or SIMANCO

O on every package or container

& on the needle or numbered part

TO ALL WHOM IT MAY CONCERN: The improper placing or renewal

of the trademark “SINGER” or any other of the trademarks of The

Singer Company (all of which are duly Registered Trademarks) on any

machine that has been repaired, rebuilt, reconditioned, or altered in

any way whatsoever outside a SINGER factory or an authorised

SINGER agency is forbidden.

Needles in containers marked “For Singer Machines” are NOT made by SINGER.

Page 18

Loading...

Loading...