Page 1

Instruction Manual

and Parts List

Ultra High Speed Overedge

and Safety Stitch Machine

321D

131M-04

131M-04 / KS

132M-015

134M-04

241M-24

241M-24 / KS

244M-24

251M-35

251M-35 / KH

251M-55

251M-55 / KH

251M-56

251H-56 / KH

321K

131M-04

131M-04 / KS

132M-015

134M-04

241M-24

241M-24 / KS

244M-24

251M-35

251M-35 / KH

251M-55

251M-55 / KH

251M-56

251H-56 / KH

® Singer is a registered trademark of The Singer Company Limited or its affiliated companies.

© 2010 Copyright The Singer Company Limited

Page 2

Contents

1.1 1snoitcurtsnI ytefaStnatropmI

1.2 For S 2noitarepO efa

2.1 3noitpircseD tcudorP

2.2 4noitacfiicepS enihcaM

2.3 5snoitacfiicepS tleB-V dna yelluP rotoM ,rotoM

3 Mounting and Adjustment Instructions

3.1 6margaiD tuO-tuC elbaT

3.2 7noitallatsnI enihcaM

3.3 9eganiarD liO dna noitacirbuL

3.4 01riovreseR ot liO nociliS lliF

3.5 01)tnemecalpeR ro( tnemhcattA eldeeN

3.6 11efinK rewoL dna reppU gnicalpeR

3.7 21gnidaerhT enihcaM

3.8 31tnemtsujdA noisneT daerhT

3.9 41erusserp toof resserP

3.10 41etaR deeF laitnereffiD eht gnitsujdA

3.11 Stitch Length Adjustment

3.12 Parts Relation and Timing

4 Maintenance

4.1 71gninaelC daeH enihcaM

4.2 71gninaelC retliF dna egnahC liO

4.3 71noitcepsnI ytefaS

5 Troubleshooting

1snoitcurtsnI ytefaS1

3noitacfiicepS enihcaM dna noitpircseD tcudorP2

6

15

16

17

18

Page 3

Contents

6 Parts list 21

6.1 Machine Bed Frame Components 22

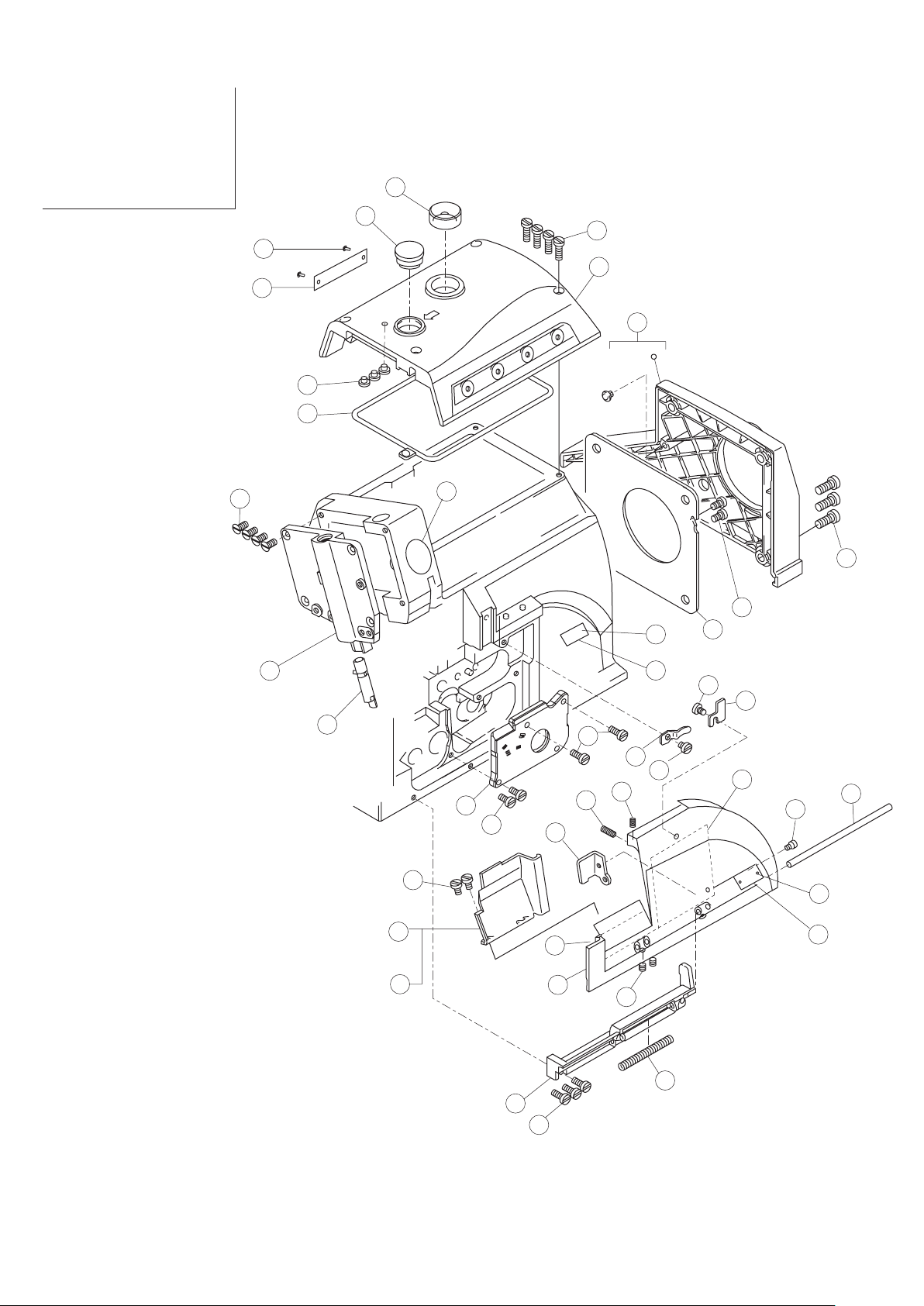

6.2 Machine Cover Components (1) 24

6.3 Machine Cover Components (2) 26

6.4 Crank Shaft Drive Components 28

6.5 Thread Tension Components 30

6.6 Thread Guide and Thread Take-up Components (1) 32

6.7 Thread Guide and Thread Take-up Components (2) 34

6.8 Thread Guide and Thread Take-up Components (3) 36

6.9 Needle Bar Components (1) 38

6.10 Needle Bar Components (2) 40

6.11 Needle Plate and Needle Guard Components 42

6.12 Upper Looper Components 44

6.13 Lower Looper Components 46

6.14 Chain Stitch Looper Components (1) 48

6.15 Chain Stitch Looper Components (2) 50

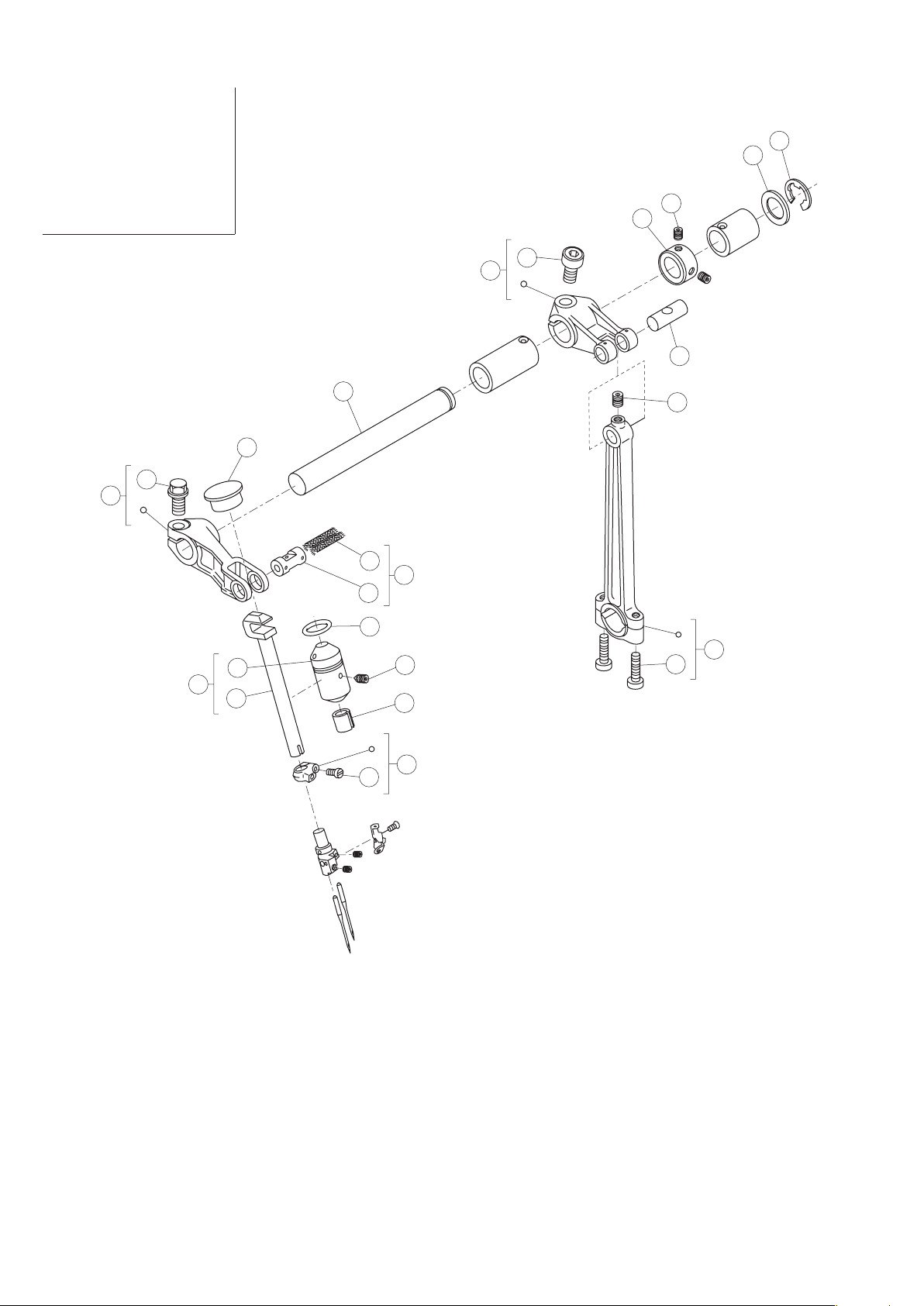

6.16 Differencial Feed Components 52

6.17 Feed Dog Components 54

6.18 Knife Drive Components 56

6.19 Presser Foot Components 58

6.20 Lubrication Components (1) 60

6.21 Lubrication Components (2) 62

6.22 Silicon Oil Reservoir Components 64

6.23 Exclusive Parts List for 321K series 66

6.24 Thread Stand Components 68

6.25 Accessories 70

6.26 Machine Support Plate For Semi-Submerged Components 72

6.27 Specific Parts for 321D-251 Hand 321K-251H 73

6.28 Optional Parts 74

6.29 Back Latch Components 76

6.30 Vacuum Suction & AFL Device (Option parts) 78

6.31 ChainCutter DeviceComponents 80

7 Gauge Parts List

81

Page 4

Safety Instructions

1.1

Important Safety

Instructions

Important

When using the

machine, basic safety

procedures must

be followed. Read

with attention all

instructions before

using the machine.

When using it,

understand that

all basic safety

instructions are

not limited to the

following items.

Read all instructions,

take care of this

manual, and use it

as reference when

necessary.

• Before running the machine, make

sure all relevant safety specifications are adequate to specifications and technical standards in

your country.

• The machine should not be run

without its safety devices.

• The machine should only be operated by properly trained personnel.

• For your safety, goggles must be

used while running the machine.

• Turn off or unplug the machine

when the following situations arise:

• Passing the thread by the needle or replacing the bobbin or

looper.

• Replacing the needle, presser

foot, throat plate, feed dog and

sliding plate.

• When the machine is in maintenance.

• When the operator is not running the machine.

• In case of lubricant oil contact

with the eyes or skin, washed the

surface with plenty of icy water

with a generous amount of cold

water. In case of ingestion, seek

medical help immediately.

• Maintenance and repair on electric equipment should only be

made by qualified personnel. If

any electric device is damaged,

the machine should be immediately stopped.

• Before starting the machine in full

running, a test must be conducted

to assure that machine and operator are able to perform the task.

• The machine should not be placed

next to a sound source as an ultrasonic welding machine and other

equipment.

• The machine should only be run

with the proper electric cable and

connectors, and also the adequate

grounding.

• The machine should only be used

to sew materials as indicated in

its instructions manual, and indications of use should be followed.

Singer will not be held responsible

for any damage caused by unauthorized changes in the product.

• Repair, fitting or maintenance

should only be performed by

properly trained personnel.

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

1

Page 5

1.2

For Safe

Operation

• To avoid the risk of electric shock,

do not open the motor wiring box

and do not touch the components

assembled inside the wiring box.

• To avoid injuries do not run the

machine without the belt cover or

in case any other safety device is

removed.

• To avoid possible injuries keep fin-

gers,

wheel, belt and motor when the machine is running. Nothing should be

placed near those parts.

• To avoid injuries never put your

fingers next to the rotating hook

and the thread take-up lever cover

when the machine is running.

• To avoid possible injuries be care-

ful when putting down or lifting

the machine head.

head and clothes far from

• If you machine is equipped with

a servomotor, it does not make

noises while being driven.To avoid

a possible accident caused by an

unexpected start, be sure the machine is turned off.

• To avoid electrical shock, do not

run the machine without proper

grounding.

• To minimize the risk of accidents

or damage in electric components

caused by electric discharge turn

the machine off before unplugging it.

• Clean the machine periodically.

• To avoid accident in case of a sudden start of the machine always

turn it off when laying it down, or

remove the belt cover and the belt.

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

2

Page 6

2.1

Product

Description

Product Description

and Machine Specification

Ultra high speed overedge and safety stitch machines

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

3

Page 7

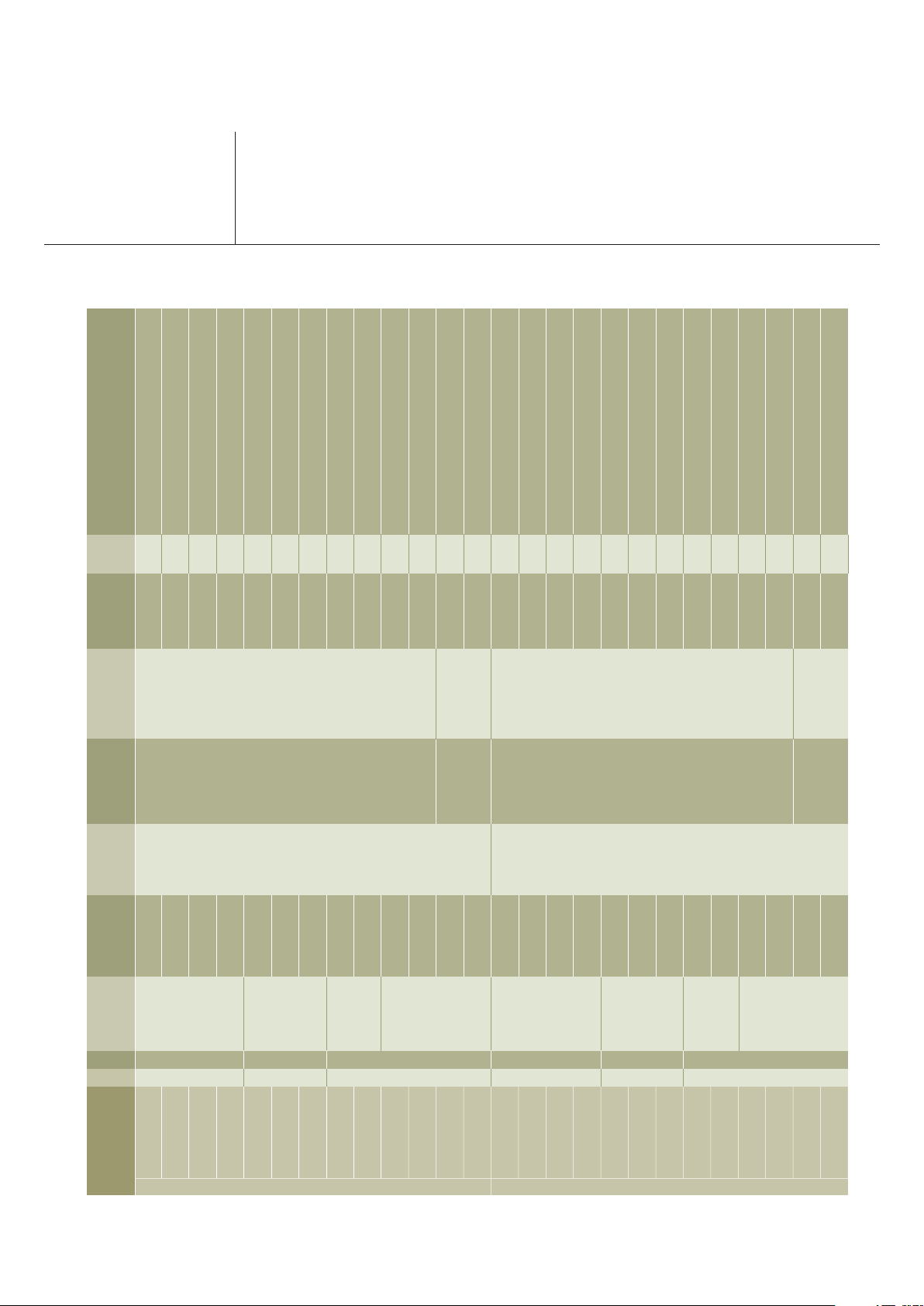

2.2

Three-thread back latch overlock machine

Four-thread back latch overlock machine

Five-thread overlock machine

Three-thread handkerchief edging (rolled hem)

overlock machine

5

-

Machine

Specification

Table 1 – Machine Specification

Application

Three-thread overlock m achine with vertical chain

cutter and AFL device

Three-thread handkerchief edging (rolled hem)

overlock machine

Four-thread overlock m achine with vertical chain

cutter and AFL device

Five-thread overlock machine with vertical chain

cutter and AFL device

Five-thread heavy duty overlock machine with

horizontal chain cutter and AFL device

Five-thread heavy duty overlock machine with

horizontal chain cutter and AFL device

Three-thread overlock m achine with vertical chain

cutter and AFL device

Four-thread overlock m achine with vertical chain

cutter and AFL device

Five-thread overlock machine with vertical chain

cutter and AFL device

Five-thread overlock machine with horizontal chain

cutter and AFL device

Five-thread heavy duty overlock machine with

horizontal chain cutter and AFL device

5

Needle Gaug e Overedge Big ht Stit ch Length Presser Foot Lift Singer Speed

0.7 ~ 2.0

Differential Rate

3.8

[mm] [mm] [mm] [mm] Needle Cat [spm]

Threads

Needles

13

2

24

3

25

0.8~1.5 7

5

13 -

0.7 ~ 2.0

24 2

3.8

3

25

0.8~1.5 7

5

Singer Model

321D-131M-04 4 6120-06 75/11 8500 Three-thread overlock m achine

321D-131M-04 / KS 4 6120-06 75/11 8500

321D-132M-015 1.5 6120-06 65/9 8500

321D-134M-04 4 6120-06 75/11 7500

321D-241M-24 4 6120-06 75/11 7500 Four-thread overlock m achine

321D-241M-24 / KS 4 6120-06 75/11 7500

321D-244M-24 4 6120-06 75/11 7500

321D-251M-35 5 612 0-06 90/14 7500

321D-251M-35 / KH 5 6120-06 90/14 7500

321D-251M-55 5 612 0-06 90/14 7500 Five-thread overlock m achine

321D-251M-55 / KH 5 6120-06 90/14 7500

321D-251H-56 6 6120-06 130/21 6500 Five-thread heavy duty overlock machine

321D-251H-56 / K H 6 6120-06 130/21 6500

321K-131M-04 4 6120-06 75/11 8500 Three-thread over lock machine

321K-131M-04 / KS 4 6120-06 75/11 8500

321K-132M-015 1.5 6120-06 65/9 8500

321K-134M-04 4 6120-06 75/11 7500 Three-thread back latch overlock machine

321K-241M-2 4 4 6120-06 75/11 7500 Four-thread over lock machine

321K-241M-2 4 / KS 4 612 0-06 75/11 7500

321K-244M -24 4 6120-06 75/11 7500 Four-thread back latch overlock machine

321K-251M-35 5 6120-06 90/14 7500 Five-thread overlock machine

321K-251M-35 / KH 5 612 0-06 90/14 7500

321K-251M-55 5 6120-06 90/14 7500 Five-thread overlock machine

With Clutch Motor

With Direct Drive Servo Motor

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

321K-251M-55 / KH 5 612 0-06 90/14 7500

321K-251H-56 6 6120-06 130/2 1 6500 Five-thread heavy duty overlock machine

321K-251H-56 / K H 6 6120-06 130/2 1 6500

4

Page 8

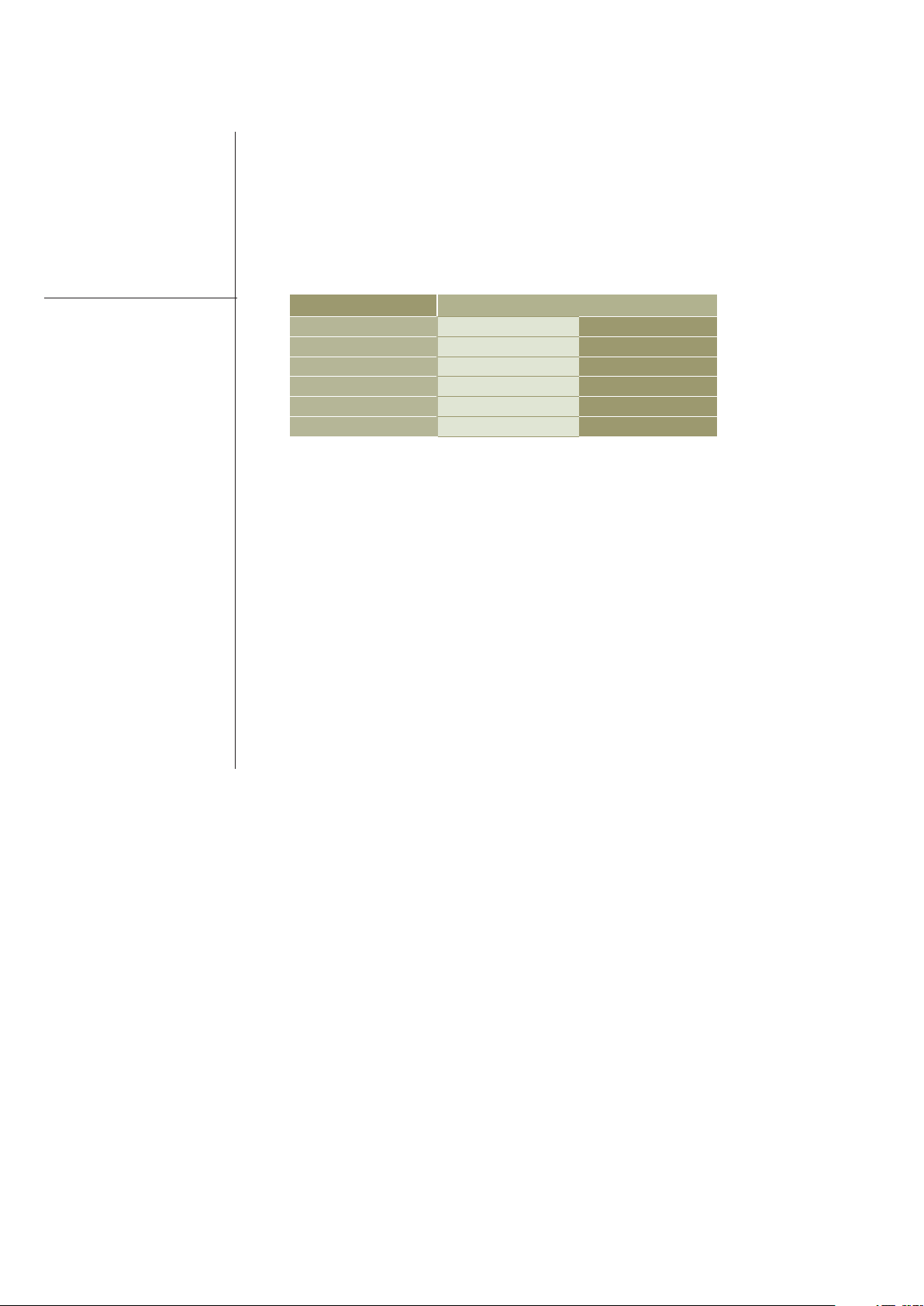

2.3

Motor,

Motor Pulley

and V-Belt

Specifications

2.3.1 For 321D series

½ HP 2-pole clutch motor

Motor pulley diameter

M type v-belt

Machine Speed

[spm] 50Hz 60Hz

5,500 110 90

6,000 115 95

6,500 130 105

7,000 140 115

7,500 150 125

2.3.2 For 321K series

Table 2

Motor Pulley Diameter [mm]

Direct drive servo motor and control system.

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

5

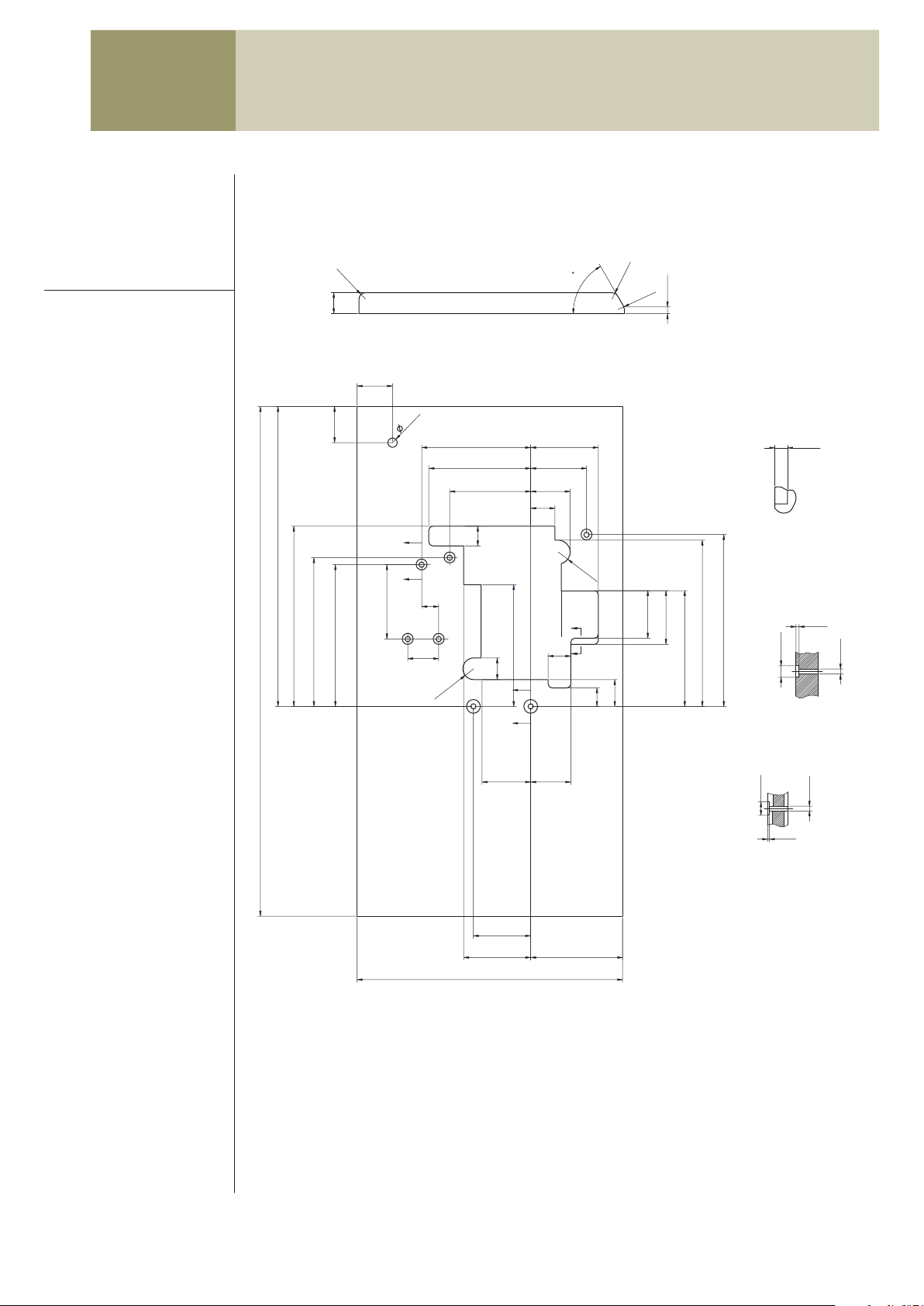

Page 9

3

3.1

Table Cut-Out

Diagram

Setup and Adjustment Instructions

RR1166

4400

65

RR2255

6600

RR2255

1133

65

662255

447755

331100

229955

11006655

20

222255

221100

118855

BBBB

3322

115555

4400

4455

4488

RR2244

111177..99559977..3311

114411

111155

9955

5500

RR2244

CCCC

4477

225500

AAAA

4400

9988

111100

5555

335588

334455

224400

AA--AA

2255

CC--CC

11..55

2255

BB--BB

2255

33

99

1133

111188..55

113388119900

555500

Figure 1

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

6

Page 10

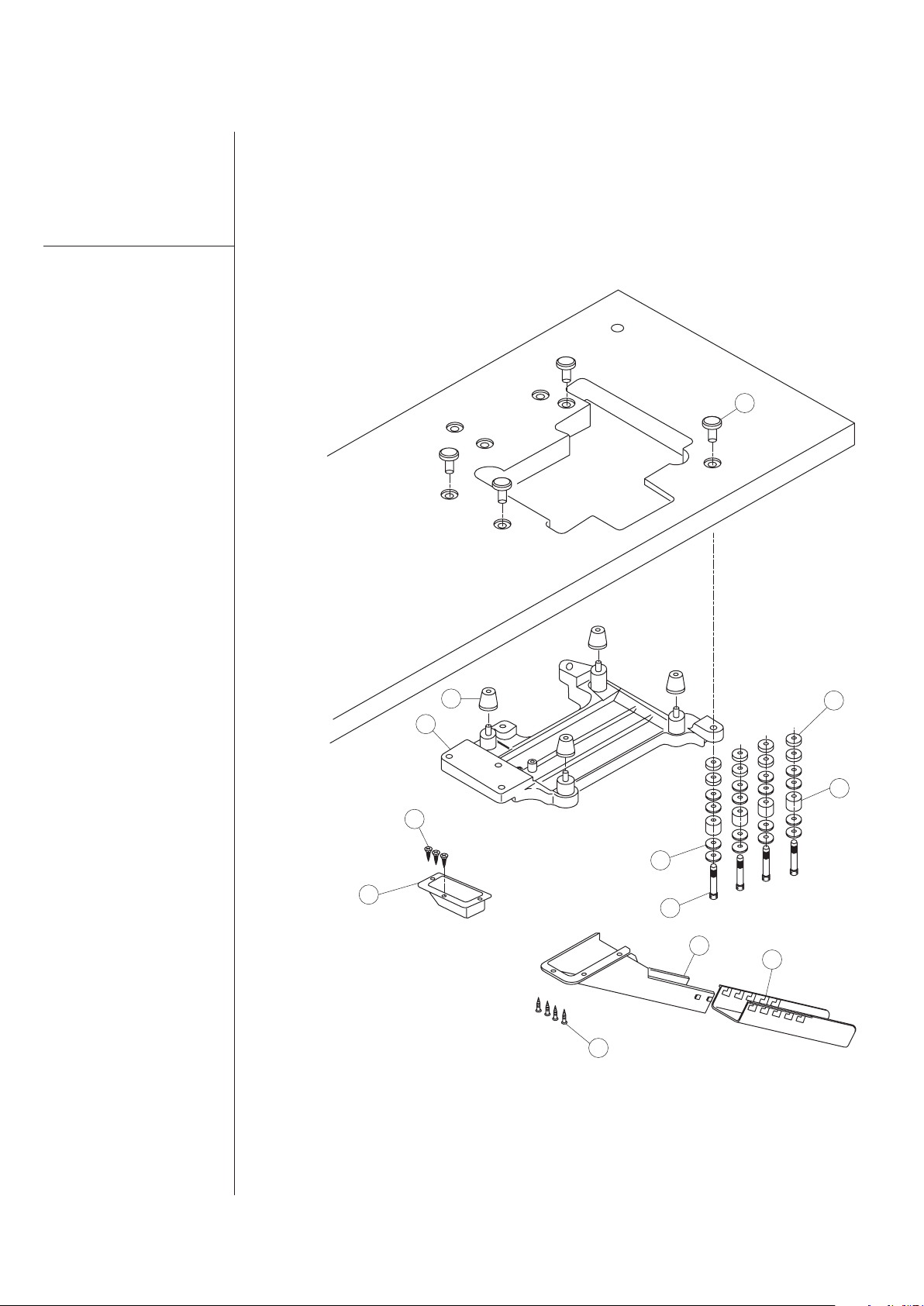

3.2

Machine

Installation

Install the machine support components and the cloth waste chute as

indicated in Figure 2. In case of

semi-submerged assembly, the

distance between the needle plate

top surface and the table top is

around 100 mm. For fullysubmerged assembly, the distance

is around 5.0 mm.

3

10

2

1

9

4

5

7

8

11

Figure 2

12

6

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

7

Page 11

3.2

Machine

Installation

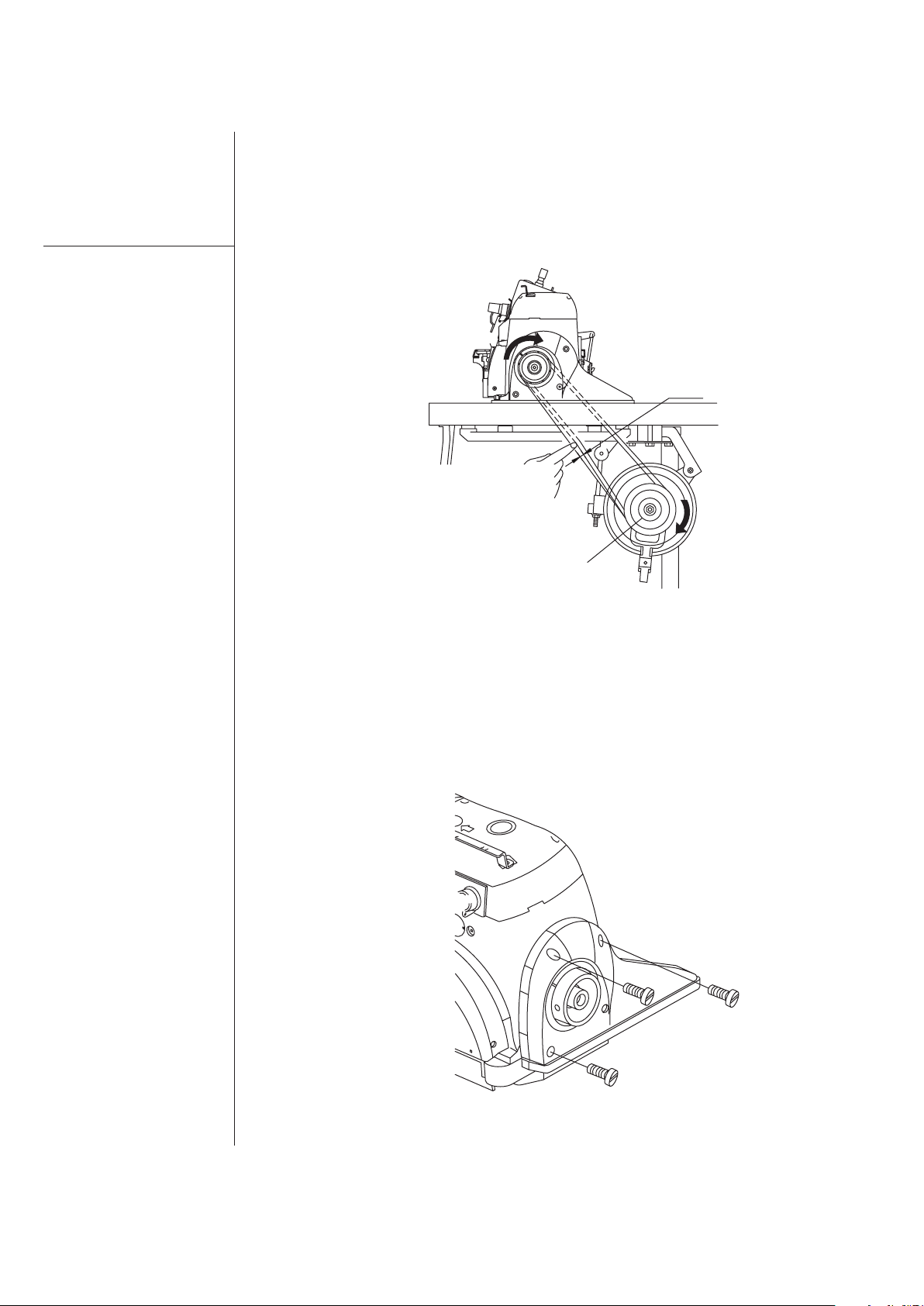

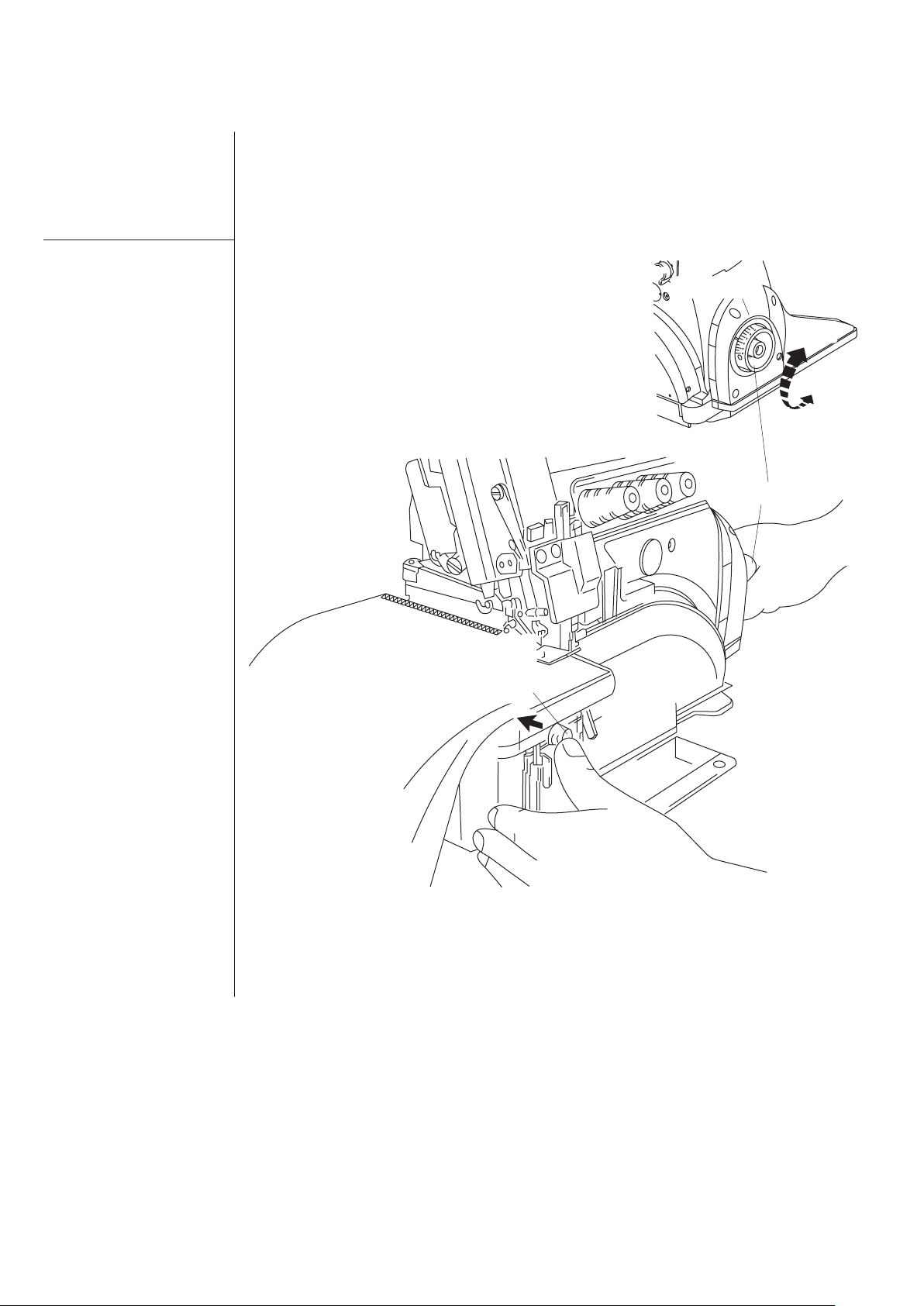

Mount the machine head over the

machine support plate.

Connect the machine handwheel to

the clutch motor with the v-belt (for

321D only)

Adjust the tension of the v-belt so

that it can be about 20 mm bent

inward when you press the middle

of it and make sure the motor turning direction is clockwise, referred

to the Figure 3.(for 321D only)

2cm

Figure 3

Set the pedal of the clutch motor to

the left side and the pedal of the

presser foot lift at right side.

Install the belt cover according to Figure 4.(for 321D only)

Install the thread stand referred to

the parts list.

Figure 4

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

8

Page 12

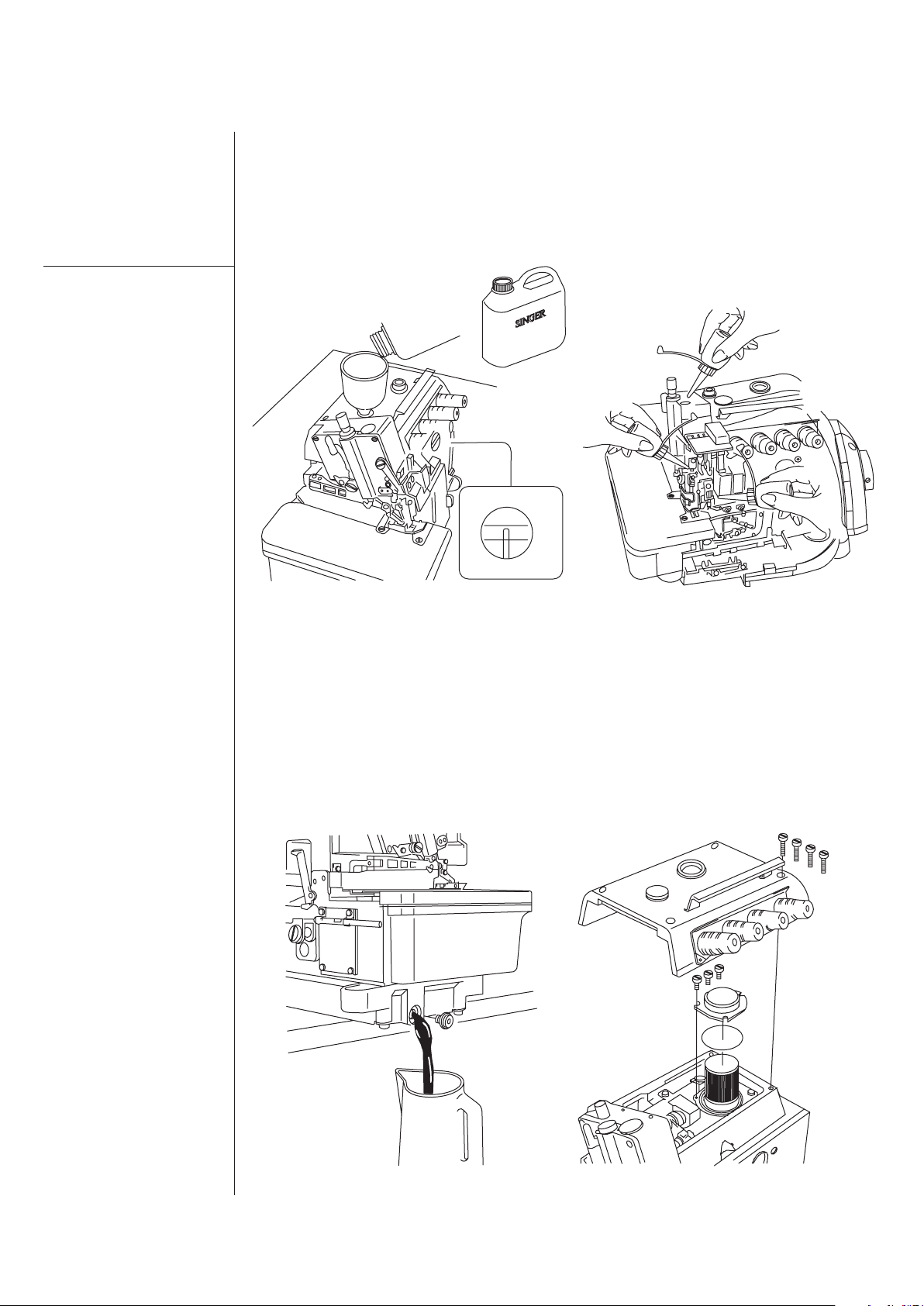

3.3

Lubrication

and Oil

Drainage

Important

As this is a ultra

high speed

machine, DO NOT

run the machine

before oiling and

assuming the

direction of the

motor rotation.

Remove the rubber plug and fill the

lubricant oil (Singer Oil) until the

indicator of the oil level between 'L'

and 'H' lines of the oil level sight

window. After that put back the

rubber plug.

H

L

When using the machine for the

first time, or a machine that has not

been used for some time, oil the

needle bar top, the guides and

looper before running it.

Figure 5a Figure 5b

To preserve the machine, change

the oil after the four weeks of use.

After that, the oil must be changed

every six months. To change the oil,

simply remove screw indicated on

Figure 6. After draining the oil,

replace the screw and fill the

machine with new oil.

This machine has an oil filter that

must be cleaned every month or

changed as needed. To replace the

oil filter, simply remove four screws

and remove the top cover indicate

on Figure 7. Then remove three

screws and remove oil filter cap.

Figure 6 Figure 7

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

9

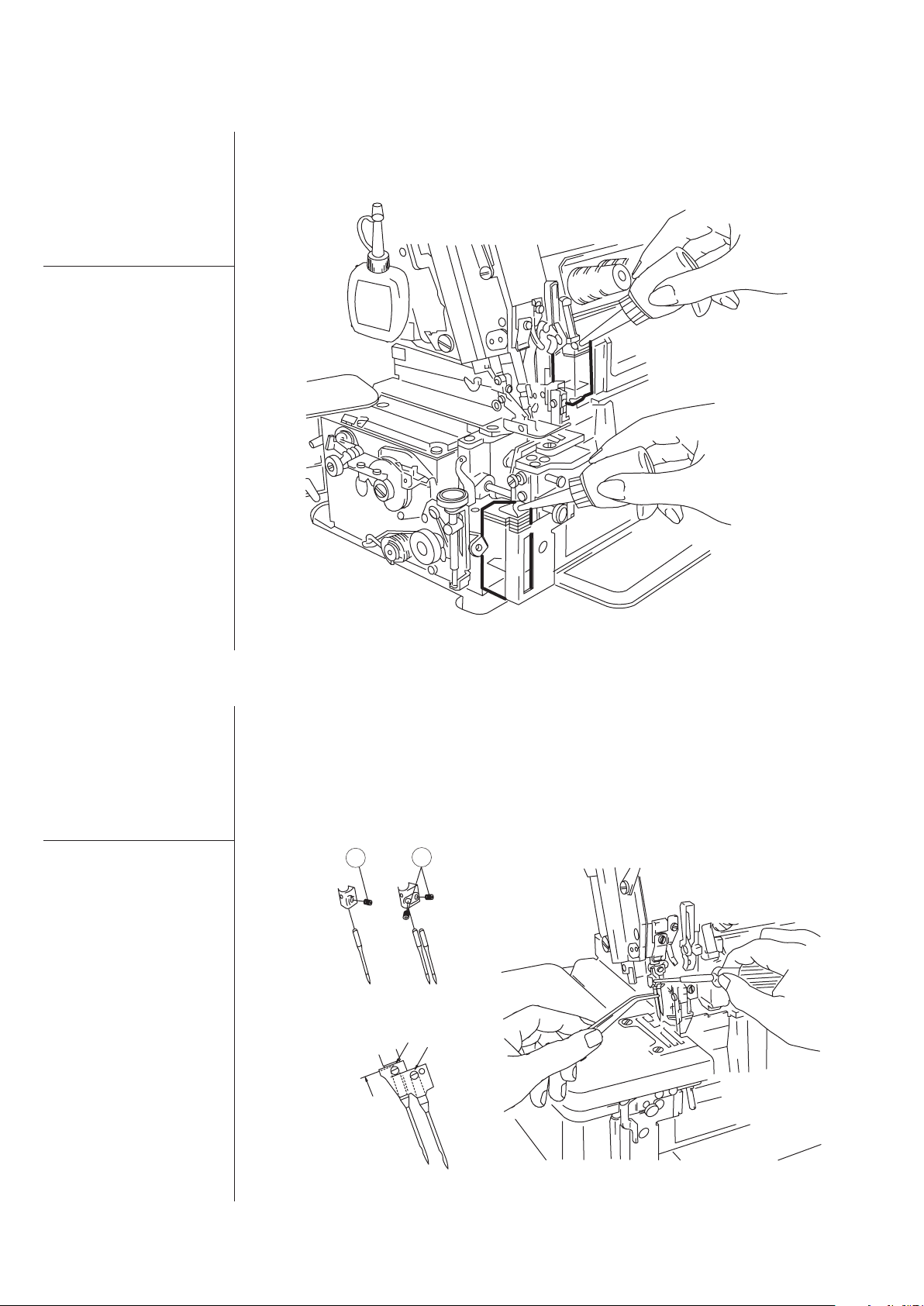

Page 13

3.4

Fill Silicon

Oil to

Reservoir

When sewing in ultra high speed,

fill the device with silicon oil in

order to prevent needle thread

breakage and fabric damage. As

show on Figure 8.

3.5

Needle

Attachment

(or Replacement)

Figure 8

Use only Singer’s Cat. 6120 needles

Loosen screw ‘1’ as indicated on

Figure 9 & 10 with the Allen key

wrench in the accessory box and

insert the needle (or remove the old

For 1 needle1For 2 needle

1

Figure 9 (a)

OK!

needle).

Insert the needle with its long

groove facing towards you and

push it up until the bar end..

Tighten screw ‘1’.

Insert the needle to

the proper depth.

Figure 9 (b)

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

Figure 10

10

Page 14

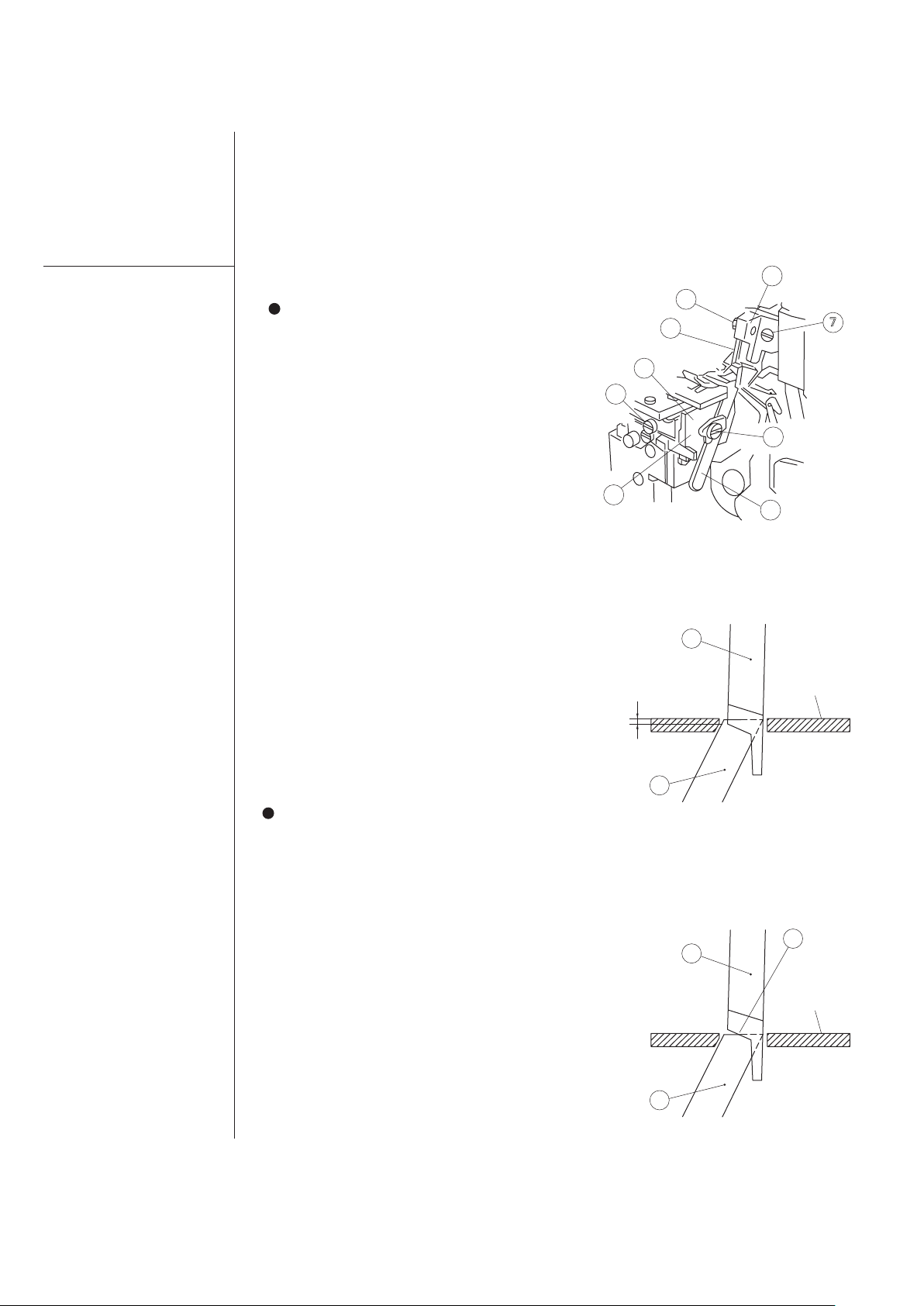

3.6

Replacing

Upper and

Lower Knife

Replacing the upper knife

1. Loosen screw ‘1’. Move lower

knife holder ‘2’ to the extreme left

position. Tighten screw ‘1’ temporarily.

2. Remove screw ‘3’ and then upper

knife ‘4’.

To install a new upper knife, turn

the handwheel until the upper knife

holder reaches the lowest position of

its stroke. Overlap the cutting edges

of the upper anb lower knives by

0.5~1.0 mm according to the overedge width (Figure 11).

3. Overlap the cutting edges of the

upper and lower knives so that midpoint ‘A’ on upper knife ‘4’ and the

midpoint of lower knife ‘6’ are

crossed (Figure 12). Loosen screw

‘1’. Make sure the upper and lower

knives mate positively. Then tighten

screw ‘1’.

4. Place a thread between the upper

and lower knives. Check the cutting by

turning the handwheel.

8

3

4

2

1

5

4

6

Figure 11

7

Replacing the lower knife

1. Loosen screw ‘1’. Move lower knife

holder ‘2’ to the extreme left position.

Tighten screw ‘1’ temporarily.

2. Loosen screw ‘5’ and remove lower

knife ‘6’. Install a new knife by referring

to "Replacing the upper knife” procedures 3 and 4.

To install a new lower knife, the

cutting edge of the lower knife should

be flush with the top surface of the

needle plate.

Adjusting overedge width

I. Loosen screw ‘1’ˈmove lower knife

holder ‘2’ all the way to the left and then

tighten the screw ‘1’ temporarily.

2. Loosen screw ‘7’ˈmove upper knife

clamp ‘8’ left or right as required. Install

upper and lower knives by referring to

"Replacing the upper knife" procedures 3

and 4.

4

0.5~1.0mm

6

4

6

Top surface

of the needle

plate

Figure 12 (a)

A

Top surface

of the needle

plate

Figure 12 (b)

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

11

Page 15

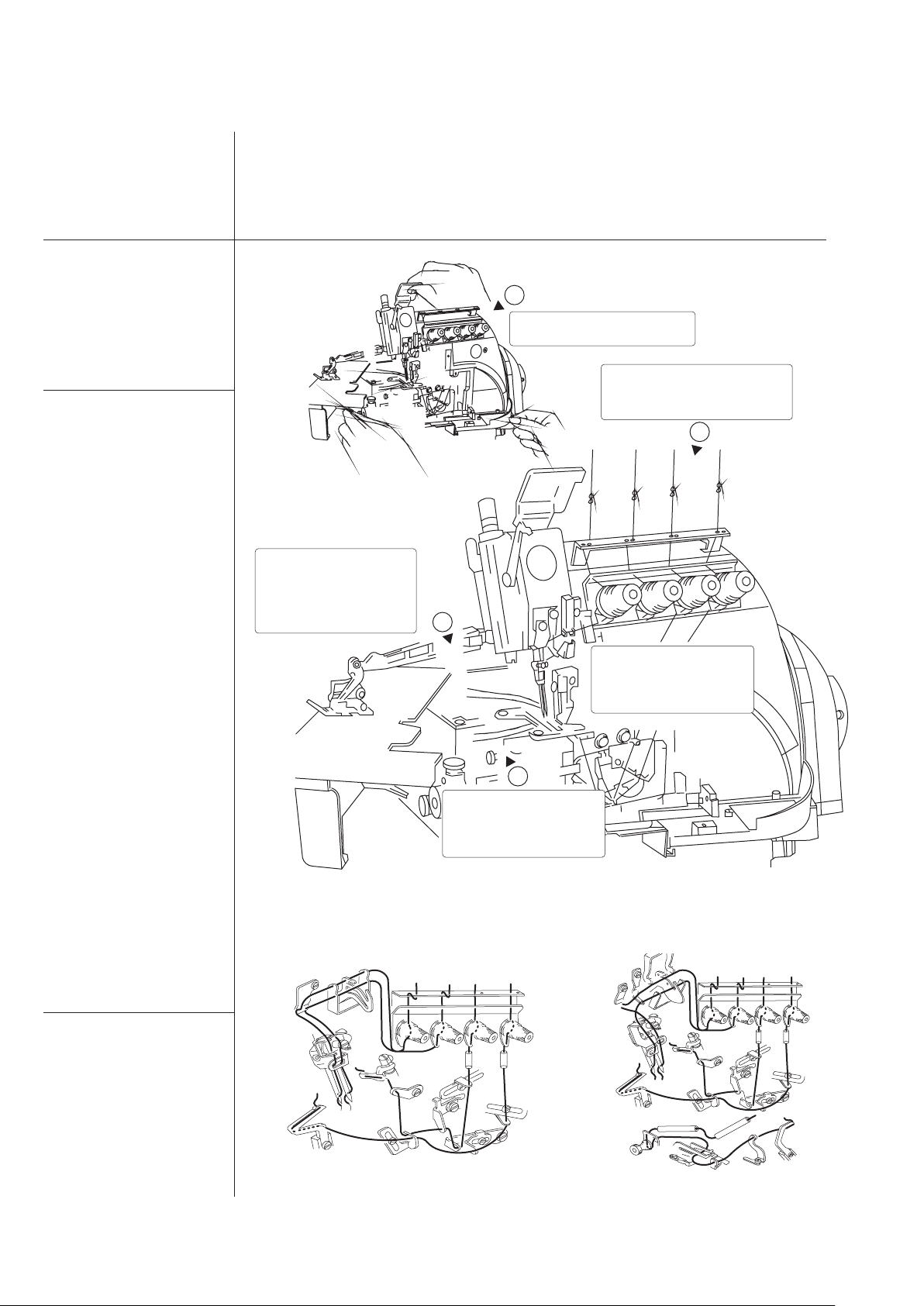

3.7

Machine

Threading

Important

Refer to the sewing type you need for correct threading.

Any incorrect threading may cause thread brake, uneven

stitches or skip stitches.

3.7.1

Easy

Threading

Method

Needle thread

Trim the knots off neatly

before passing through

the eye of the needle to

rethread.

1

Open three covers.

Move the presser foot aside.

Knot the preset thread and the

thread being used together to

thread the machine.

2

3

Make sure the machine is

threaded correctly by

referring to the threading

diagram.

3.7.2

Threading

Diagram

Looper thread

Trim the knots off neatly

after passing through the

yey of the looper.

For three / four thread machine

Figure 14 Figure 15

4

Figure 13

For five thread machine

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

12

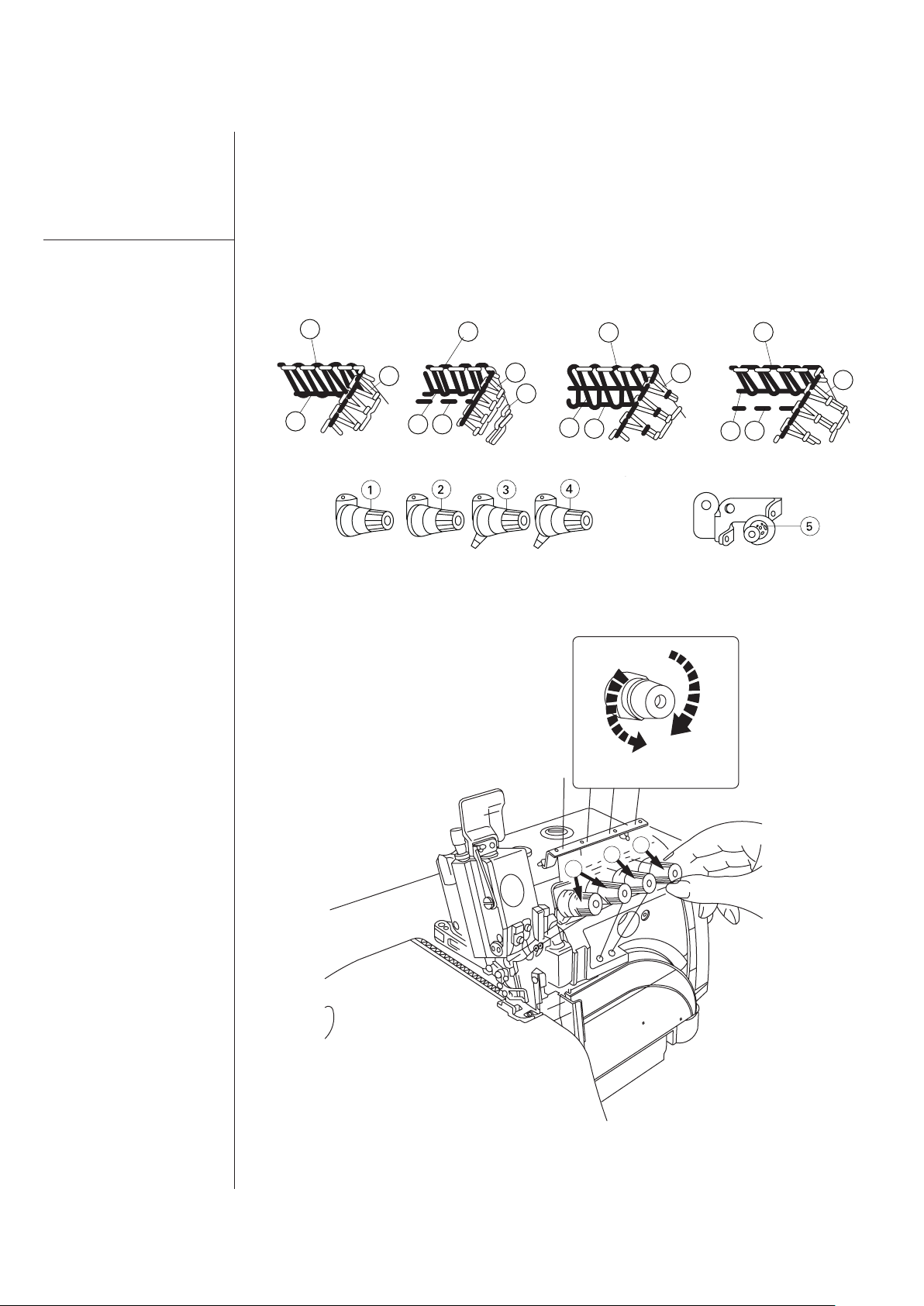

Page 16

3.8

Thread Tension

Adjustment

Important

The thread tension

should be adjusted

according to the

type and thickness

of the cloth,

sewing thread,

sewing width,

stitch length and

others. Therefore

the pressure of the

tension nuts or

thread guides

should be individu-

ally adjusted for

each case.

The following adjustments are related to Figure 16 &17.

Tension Nut 1: controls the needle thread or the left thread in

case of two needles.

Tension Nut 2: controls the thread in the right needle.

Tension Nut 3: controls the thread in the lower looper.

Tension Nut 4: controls the thread in the lower looper.

Tension Nut 5: controls the thread of the safety stitch.

3

4

2

2 1

3

4

5

Figure 16

3

4

2

1

2

3

4

1

To loosen

1

Figure 17

To tighten

3

2

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

13

Page 17

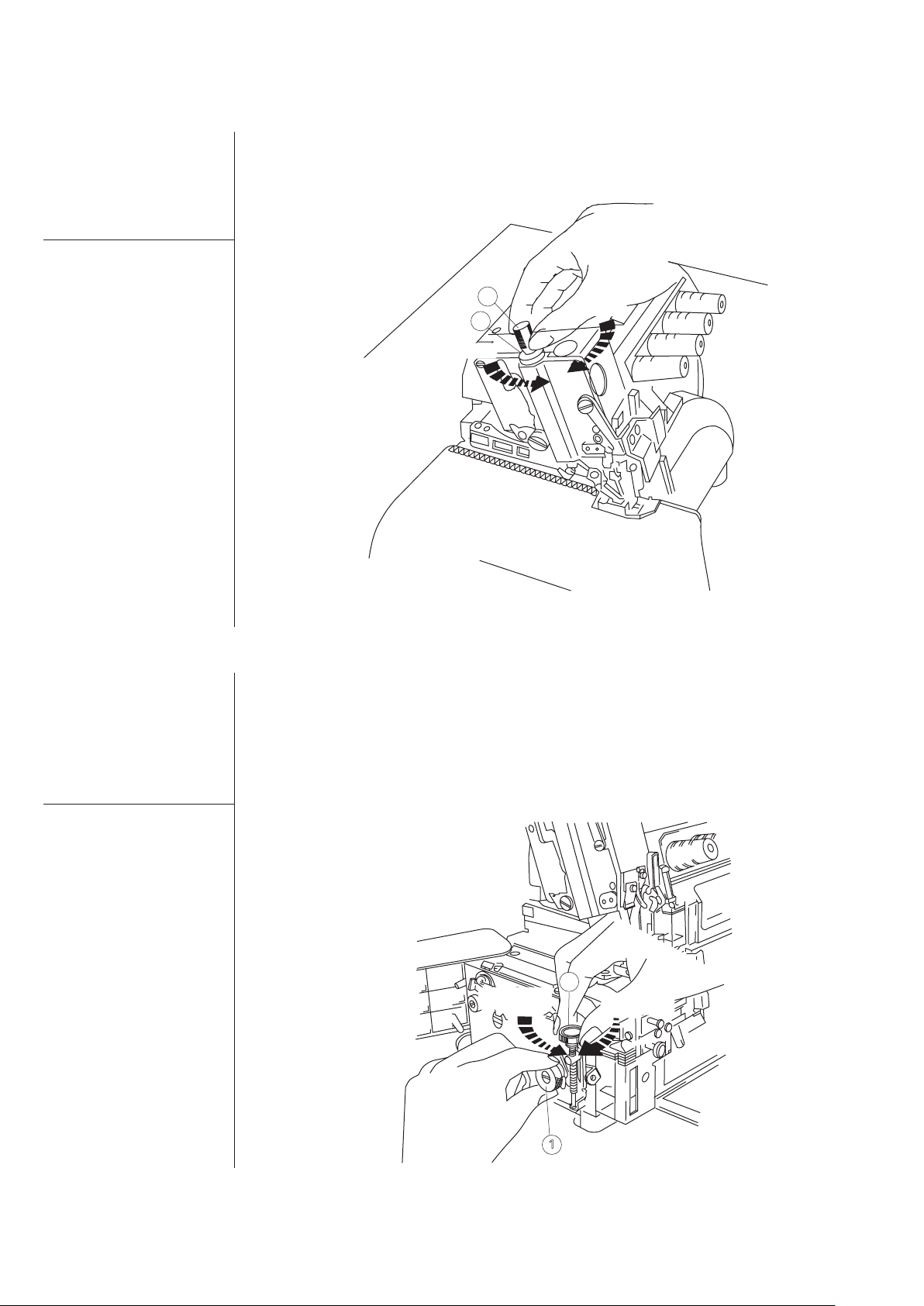

3.9

Presser foot

pressure

Loosen adjusting nut ‘1’ of Figure

18 and turn adjusting bar ‘2’ to

adjust the presser foot pressure.It

should be as light as possible to be

sufficient to obtain the proper stitch

formation.

3.10

Adjusting the

Differential

Feed Rate

2

1

Light

The differential feed ratio is the

ratio of movements between the

main feed dog and differential feed

dog. When the movement of main

feed dog is bigger than the differential feed dog, the fabric is stretched

Heavy

Figure 18

at sewing. Otherwise the fabric will

be shrunk.

Loosen the adjusting nut 1 and turn

the adjusting nut 2 to adjust the

differential feed ratio. As shown on

Figure 19.

2

To shrink

1

Figure 19

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

To stretch

14

Page 18

3.11

Stitch Length

Adjustment

Important

The stitch length

adjustment is

made according

to the sewing

fabric, differential

feed ration and

other factors.

Press button to the end and keep it

pressed as shown on Figure 20.

Turn the handwheel until we have

the desired stitch length. It is shown

on the handwheel scale.

Aligning Mark

Coarse

Fine

Handwheel

Push Button

Figure 20

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

15

Page 19

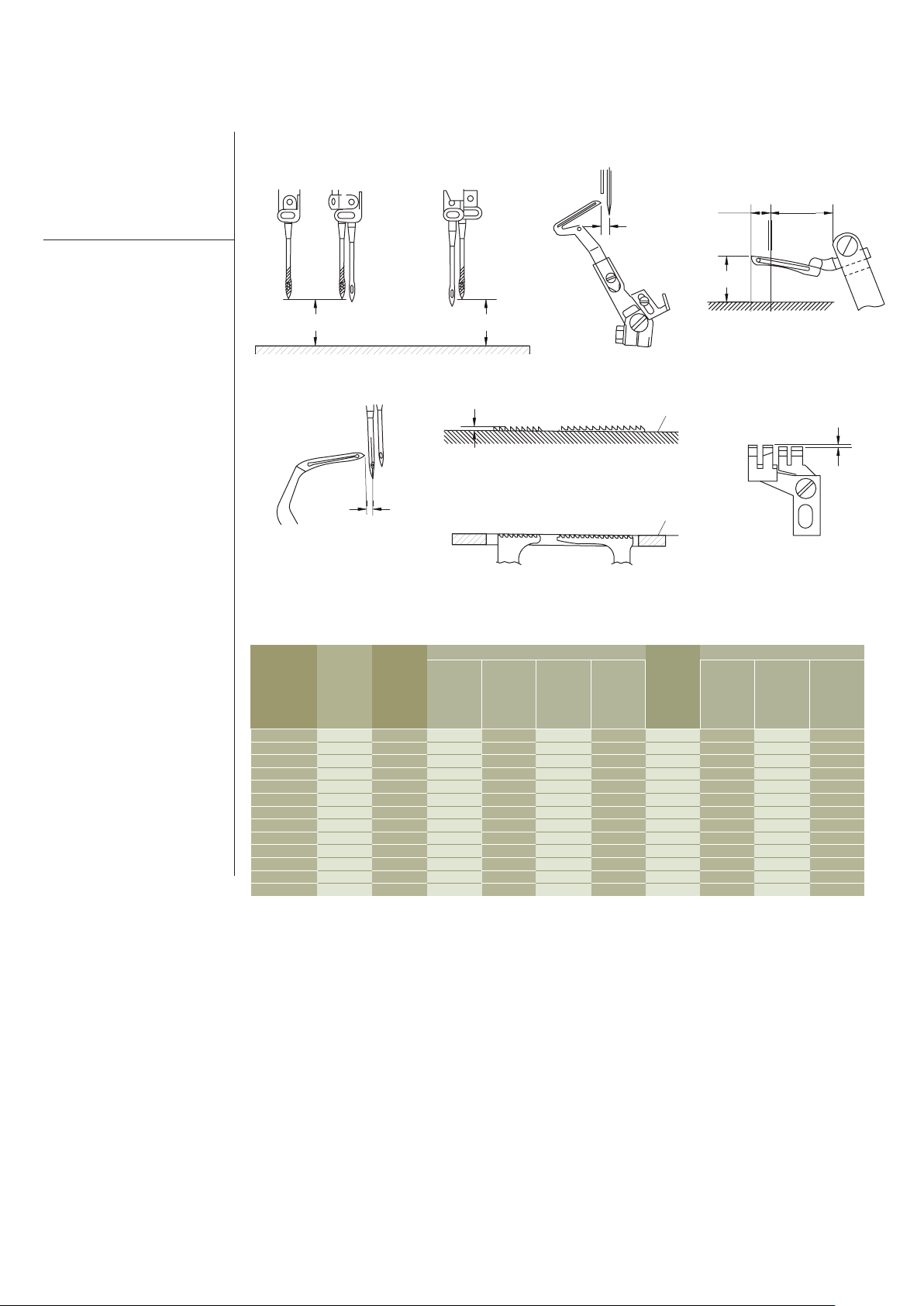

3.12

Upper looper

holder left

limit position

(e)

(Figure 23)

3,4 Thread

5 Thread

Parts Relation

and Timing

Top surface of the

(a)

needle plate

Figure 21

Figure 24

(c)

(e)

(b)

(d)

(a)

Figure 22 Figure 23

(g)

Top surface of the

needle plate

(h)

Figure 25

(f)

Top surface of the

needle plate

Figure 27

Figure 26

Upper looper

needle

Lower looper

left limit

position

(Figure 22)

Upper looper

left limit

position ( c )

(Figure 23)

Height of

upper looper

( c )

(Figure 23)

Upper looper

holder install

direction

Model

321D & 321K

-131M-04 10.5 3.8 4.4~4.7 10.8 14.5 Left - 0.8 0.5 0.35~2.0

-131M-04 / KS 10.5 3.8 4.4~4.7 10.8 14.5 Left - 0.8 0.5 0.35~2.0

-132M-015 10.5 3.8 4.4~4.7 10.8 14.5 Left 0.6~0.7 0.3 0.35~1.7

-134M-04 10.5 3.8 5.4~5.7 10.5 13.5 Right - 0.8 0.5 0.35~1.7

-241M-24 10.5 3.8 5.4~5.7 10.5 13.5 Right - 0.8 0.5 0.35~2.0

-241M-24 / KS 10.5 3.8 5.4~ 5.7 10.5 13.5 Right - 0.8 0.5 0.35~2.0

-244M-24 10.5 3.8 5.4~5.7 10.5 13.5 Right - 0.8 0.5 0.35~2.0

-251M-35 10.5 3.8 4.4~4.7 10.8 14.5 Left 1.5 0.8 0.5 0.35~2.0

-251M-35 / KH 10.5 3.8 4.4~4.7 10.8 14.5 Left 1.5 0.8 0.5 0.35~2.0

-251M-55 10.5 3.8 4.4~4.7 10.8 14.5 Left 1.5 0.8 0.5 0.35~2.0

-251H-55 / KH 10.5 3.8 4.4~4.7 10.8 14.5 Left 1.5 0.8 0.5 0.35~2.0

-251H-56 11.9 4.2 5.0~5.3 12 14.5 Left 1.7 0.8 0.5 0.35~2.0

-251H-56 / KH 11.9 4.2 5.0~5.3 12 14.5 Left 1.7 0.8 0.5 0.35~2.0

Height of

(Figure 21)

Chain looper

left limit

position (f)

(Figure 24)

Height of feed

dog (g)

(Figure 25)

Feed dog

Height of

auxiliary feed

dog (h)

(Figure 27)

Feed

eccentric

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

16

Page 20

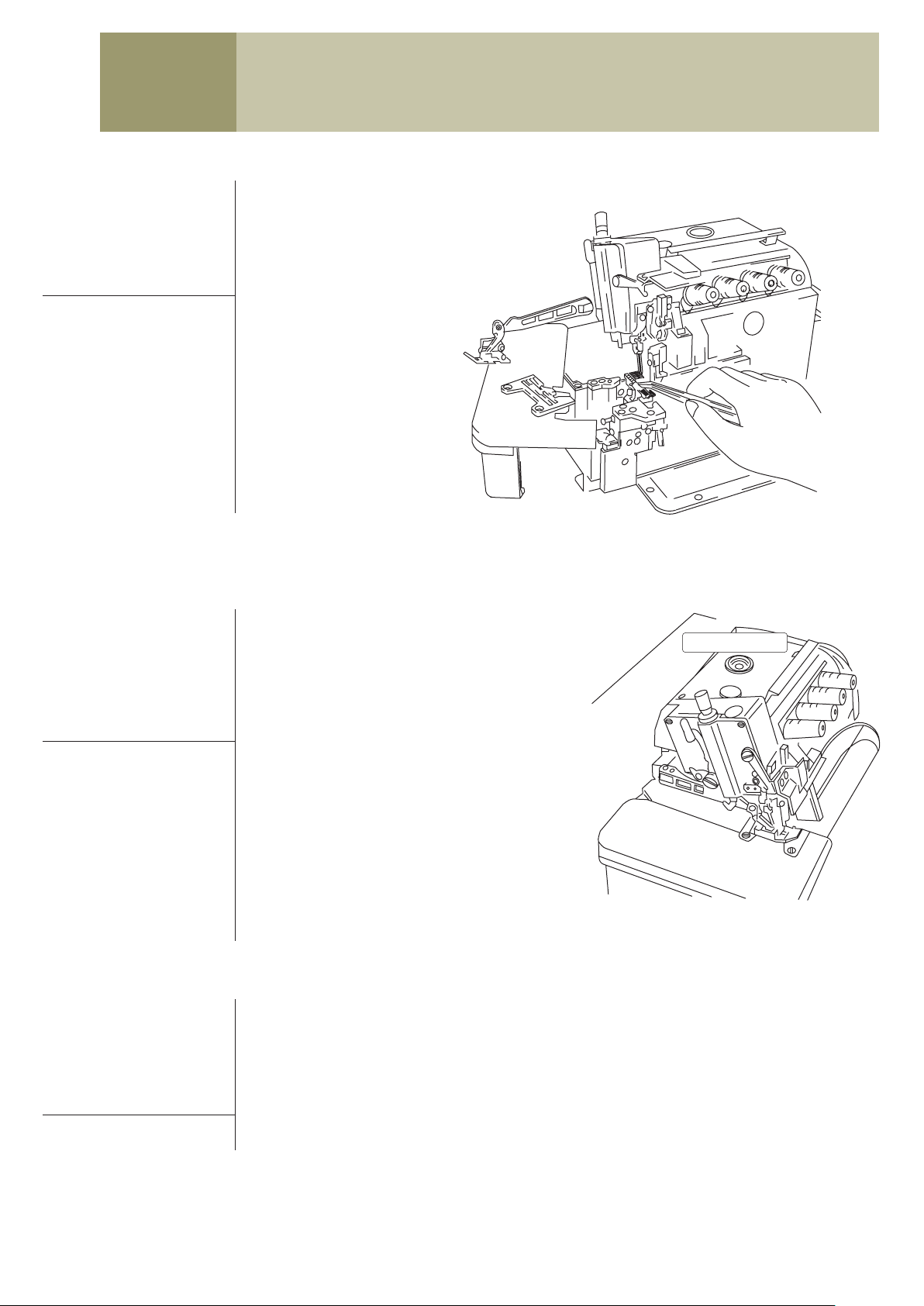

4

4.1

Machine Head

Cleaning

Maintenance

Clean the machine periodically

with a soft and dry cloth to remove

the excess of dust on the machine

head. Do not use any kind of

lacquer thinner to wipe the surface.

Figure 28

4.2

Oil Change

and Filter

Cleaning

4.3

Safety

Inspection

When Machine is running, oil will

be sprayed into the oil window. If

no oil sprayed, please check oil

level (see topic 3.3)

If the machine was idle for a long

time, oil the top of the needle

holder, guides and looper guides

before resuming the operation.

The oil should be changed every

four months. To replace the oil,

follow the instructions of topic 3.3.

The oil filter should be cleaned

every month or replaced by a new

one as necessary. To clean or

replace the oil filter, follow the

instructions of topic 3.3.

Frequently check if all safety

devices are properly installed and

adjusted.

Check all screws that fix and hold

the machine head that should be

properly tight.

(Operating)

OK!

Figure 29

Check and be sure the V-belt is not

excessively worn out and see that

it has the proper tension (Except

321K)

Check and be sure there is no

motor overheating and be sure that

the cable and electric connector are

not damaged.

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

17

Page 21

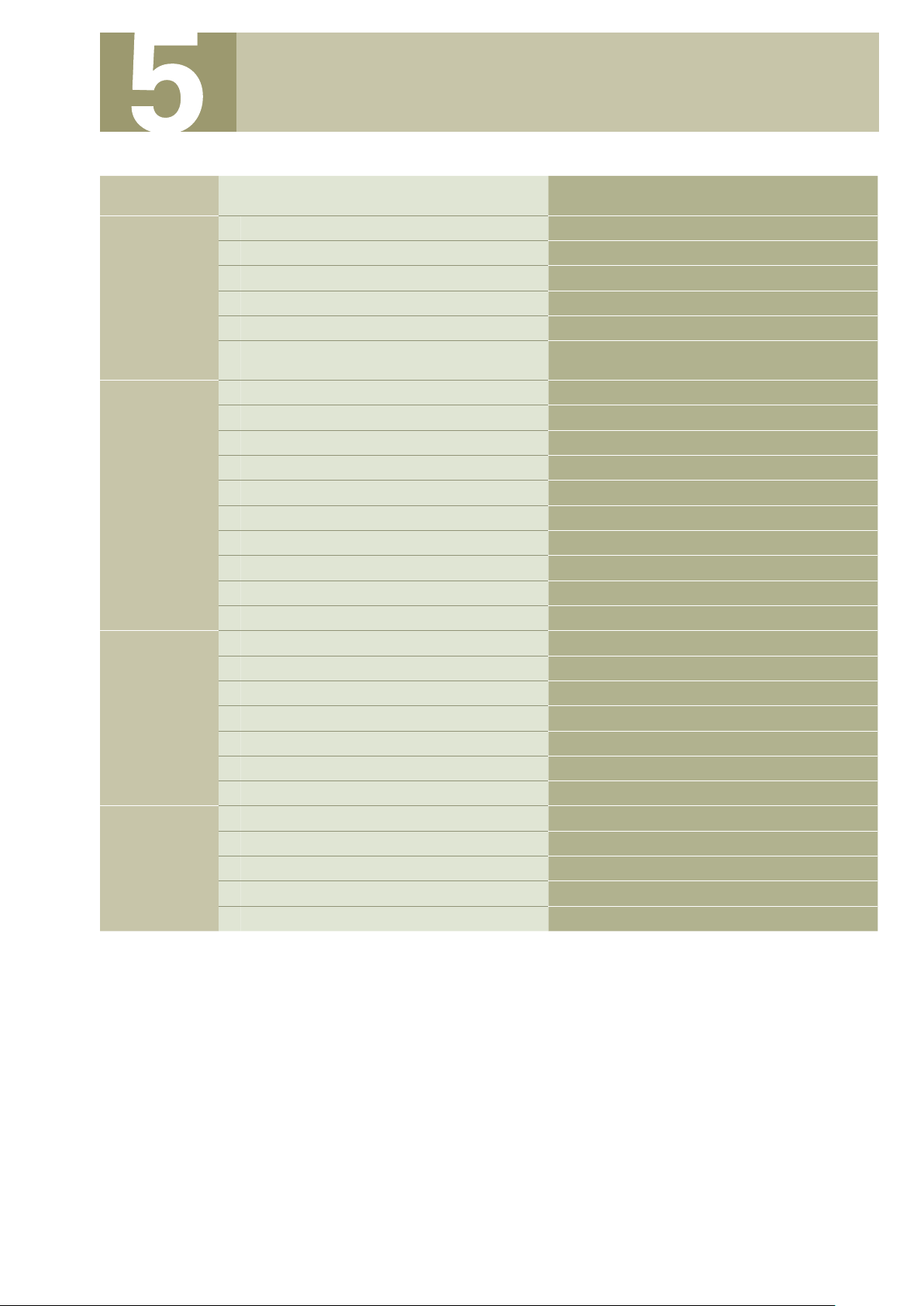

Troubleshooting

Problems Possible Causes Possible Solutions

Broken needle

Broken thread

Skip stitches

Failure in stitches

1.

Needle installed the wrong way.

2.

Wrong kind of needle.

3.

Damaged needle.

4.

Wrong relation with needle guards.

5.

Wrong relation with looper.

6.

Needle is not centralized with the hole at the needle

plate or the presser foot.

1.

Low quality thread.

2.

Thread is thicker than the eye of the needle.

3.

Wrong passage of thread.

4.

Thread tension too tight.

5.

Needle wrongly set.

6.

Thread stand wrongly set.

7.

Needle overheating.

8.

Tension disk or guides with burrs .

9.

Wrong relation of needle with looper .

10.

Needle, looper, needle plate and guides have burrs.

1.

Wrong relation of needle with looper.

2.

Wrong passage of thread.

3.

Needle installed the wrong way.

4.

Inadequate tension of thread.

5.

Point of looper damaged.

6.

Needle damaged.

7.

Wrong installation of needle guards.

1.

Wrong threading.

2.

Thread is thic

3.

Wrong thread tension.

4.

Needle thread is not lubricated.

5.

Wrong relation of needle with looper.

ker than needle hole.

1.

Install the needle correctly.

2.

Use needle adequate for cloth and thread.

3.

Replace for a new one.

4.

Adjust needle guards.

5.

Adjust the looper.

6.

Adjust the needle plate or the presser foot.

1.

Use good quality thread.

2.

Use adequate needle to cloth and thread.

3.

Pass thread correctly.

4.

Adjust the thread tension unit.

5.

Set needle correctly.

6.

Set the thread stand correctly.

7.

Fill in silicon oil or adjust needle guards.

8.

Replace the parts.

9.

Adjust the synchronism of needle and looper.

10.

Replace the part.

1.

Adjust the relation of needle with looper.

2.

Pass thread correctly.

3.

Install needle correctly.

4.

Adjust thread tension button.

5.

Replace the part.

6.

Replace for a new needle.

7.

Adjust the needle cover.

1.

Pass thread correctly.

2.

Use proper needle hole for cloth and thread.

3.

Adjust the thread tension units.

4.

Fill in the silicon oil.

5.

Adjust the needle and looper.

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

18

Page 22

Troubleshooting

Problems Possible Causes Possible Solutions

Uneven Stitches

Puckering

Poor

chain-off stitches

1.

Wrong threading.

2.

Wrong installation of thread stand.

3.

Wrong setting of lower knfe.

4.

Knives does not cut perfectly.

5.

Thread guide or tension disc with burrs.

6.

Needle point damaged.

7.

Inadequate height of feed dog.

8.

Inadequate thread tension.

1.

Thread tension is too strong.

2.

Inadequate pressure on presser foot.

3.

Inadequate height of feed dog.

4.

Knives does not cut perfectly.

5.

Differential feed is not correct.

6.

Needle is too thick.

1.

Incorrect presser foot.

2.

Inadequate synchronism of lopper cam.

3.

Chain stitch looper installed wrongly.

4.

Wrong passage of thread.

5.

Thread tension inadequate.

6.

Wrong relation of needle with looper.

7.

Needle plate or presser foot with burr.

8.

Rough thread tension disc.

1.

Threading correctly.

2.

Install thread support correctly.

3.

Adjust lower knife correctly.

4.

Adjust or replace knives.

5.

Replace the part.

6.

Replace the needle.

7.

Adjust the height of feed dog.

8.

Adjust thread tension.

1.

Adjust thread tension.

2.

Adjust pressure on presser foot.

3.

Adjust the height of feed dog.

4.

Adjust or replace knives.

5.

Adjust differential feed ratio.

6.

Use proper needle to cloth and thread.

1.

Adjust presser foot correctly.

2.

Adjust looper cam.

3.

Adjust looper correctly.

4.

Pass thread correctly.

5.

Adjust thread tension.

6.

Adjust relation of needle with looper.

7.

Replace the part.

8.

Polish thread tension disc.

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

19

Page 23

Parts list

Page 24

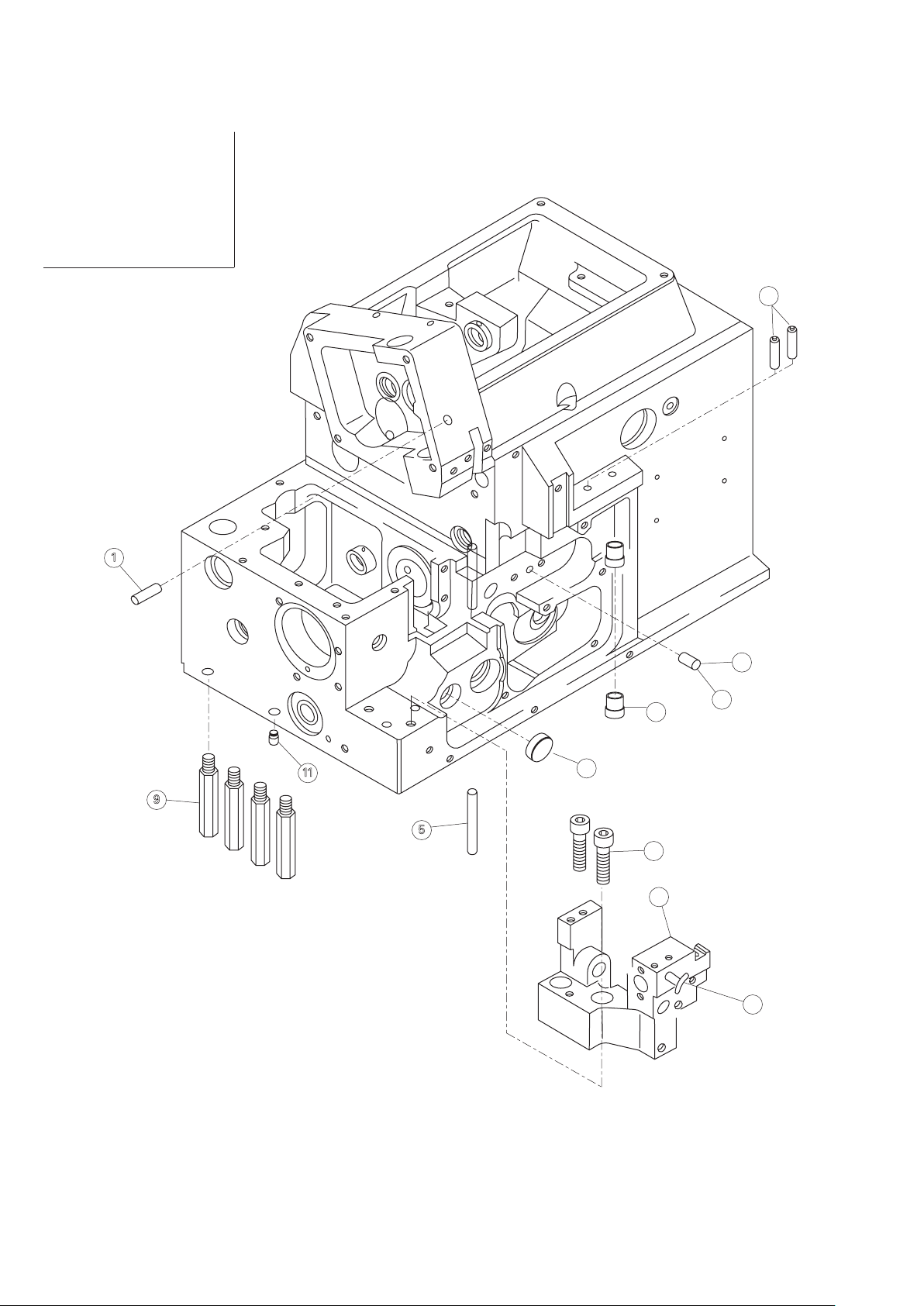

6.1

Machine

Bed Frame

Components

1

4

2

3

11

9

5

6

8

7

12

10

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

22

Page 25

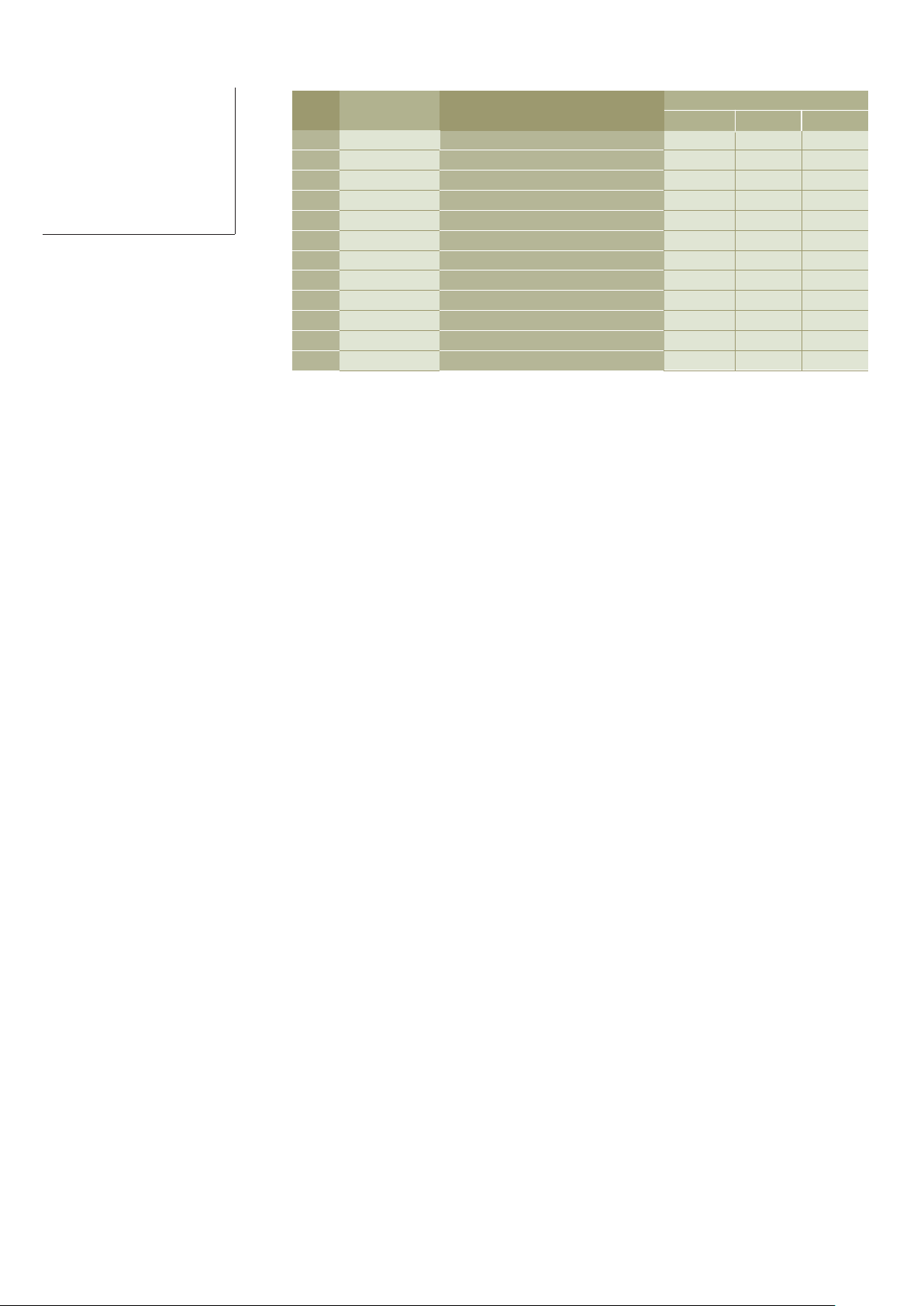

6.1

3thread 4thread 5thread

1 P03010 Pin 1 1 1

2 P03017 Pin 1 1 1

3 20711001 Indicator guide 2 2 2

4 20713027

5 P03018 Pin 1 1 1

6 20628023 Plug 1 1 0

7 20701002 Bracket Assembly 1 1 1

8 207S13003 Screw 2 2 2

9 206S30001

10 P03019 Pin 1 1 1

11 20126001 Pin 1 1 1

12 20726009 Pin (for 321D-251H only) 0 0 1

Machine

Bed Frame

Components

No. Part No. Description

Pipe

Qty

222

Bed pin

444

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

23

Page 26

6.2

Machine Cover

Components (1)

5

6

2

40

1

39

13

4

3

12

37

15

17

40

7

10

34

8

33

11

9

26

24

36

38

30

31

27

16

29

28

35

21

25

40

38

32

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

18

19

20

22

23

24

Page 27

3 thread 4 thread 5 thread

1 20701003

2 207S11012 Screw 4 4

3 20722001 Gasket 1 1

4 20622003

5 20711002 Oil sight window 1 1

6 20722002 Plug 1 1

7 20701004

8 207S11012 Screw 2 2

9 207S11008 Screw 2 2

10 2070201100

11 20712043

12 207S17001 Screw 4 4

13 20711003

15 S01013 Screw 3 3

16 20712001

17 207S11007 Screw 1 1

18 20701005

19 20701006 Hinge 1 1

20 207S11008 Screw 3 3

21 20626001 Pin 1 1

22 207S14001 Screw 2 2

23 20627001 Spring 1 1

24 20712002 Latch 1 1

25 207S11009 Screw 1 1

26 207S14002 Screw 1 1

27 207S14003 Screw 1 1

28 20712003 Latch 1 1

29 207S01031 Screw 1 1

30 20612004

31 S01031 Screw 1 1

32 20712004

33 207S11011 Screw 2 2

34 20712005

35 20737006 Threading diagram 1 1

36 20737007 Threading diagram 0 0

37 J900112-001 Singer S cameo 1 1

38 J900321-0XX Model plate 2 2

39 J900112-002 Singer resin plate 1 1

40 R03001 Revit 6 6

No. Part No. Description

Qty

6.2

Top cover

Machine Cover

Components(1)

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

Cushion rubber

Side cover

Presser bar

Front cover (left)

Belt cover assembly

Fan cover

Front cover (right)

Flat spring

Front cover (left)

Side cover

111

4

1

333

1

1

111

2

2

111

001

4

111

3

111

1

111

1

3

1

2

1

1

1

1

1

1

1

111

1

110

2

111

1

1

1

2

1

6

25

Page 28

6.3

Machine Cover

Components (2)

37

36

25

24

34

33

35

31

32

30

26

29

27

28

2

1

4

7

9

10

40

3

5

6

14

13

15

38

39

18

19

23

8

16

17

20

22

21

12

11

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

26

Page 29

6.3

Machine Cover

Components (2)

No. Part No. Description

1 2071204400 Cloth plate 0 0 1

2 2071200600 Cloth plate 1 1 0

3 20703010 Bushing 1 1 1

4 207S14001 Screw 1 1 1

5 W02004 Washer 1 1 1

6 30228008 Washer 1 1 1

7 207S11011 Screw 1 1 1

8 20622003 Cushion rubber 1 1 1

9 20711018 Side cover (Wide) 0 0 1

10 20711004 Side cover (Narrow) 1 1 0

11 207S11013 Screw 1 1 1

12 W02002 Spring washer 1 1 1

13 207S11011 Screw 2 2 2

14 20528017 Washer 2 2 2

15 20622003 Cushion rubber 1 1 1

16 20612016 Latch 1 1 1

17 207S11014 Screw 1 1 1

18 20712008 Plate 1 1 1

19 207S17003 Screw 2 2 2

20 20712009 Lever 1 1 1

21 207S20001 Screw 1 1 1

22 20727001 Spring 1 1 1

23 20709001 Bracket 1 1 1

24 20712010 Fabric guide 1 1 1

25 207S11007 Screw 2 2 2

26 20711005 Eye guide 1 1 0

27 20711019 Eye guide 0 0 1

28 207S11015 Screw 2 2 2

29 W01011 Washer 2 2 2

30 20712011 Bracket 1 1 1

31 207S20002 Screw 1 1 1

32 20628022 Washer 2 2 2

33 20701007 Bed cover plate assembly 1 1 1

34 207S12001 Screw 5 5 5

35 20722003 Gasket 1 1 1

36 2071201200 Cover plate 1 1 1

37 207S11012 Screw 4 4 4

38 207S11016 Screw 1 1 1

39 N01001 Nut 1 1 1

40 10122020 Oil Reservoir Cushion 1 1 1

3 thread 4 thread 5 thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

27

Page 30

6.4

Crank Shaft

Drive

Components

31

2930

10

12

13

11

9

8

3

1

2

28

4

5

4

5

6

7

19

18

17

16

32

33

14

15

26

27

24

25

23

20

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Man ua l and Parts List

21

22

28

Page 31

6.4

Crank Shaft

Drive

Components

No. Part No. Description

1 20702001 Crankshaft 1 1 1

2 20702050

3 20628007 Washer 4 4 4

4 20701008 Blance weight 2 2 2

5 207S11017 Screw 4 4 4

6 20726002 Pin 1 1 1

7 S10009 Screw 1 1 0

8 20712013 Cover 1 1 0

9 207S11007 Screw 3 3 0

10 001024 O Ring 1 1 1

11 B04004 Ball bearing assembly 1 1 1

12 207S11018 Screw 1 1 1

13 207S14006 Screw 1 1 1

14 20729001 Ring 1 1 1

15 B01012 Ball bearing 1 1 1

16 B04005 Ball bearing 1 1 1

17 W03003 Washer 4 4 4

18 20103002 Oil seal 1 1 1

19 001025 O ring 1 1 1

20 001028 O ring 1 1 1

21 20708002 Right cover 1 1 1

22 207S11012 Screw 3 3 3

23 20709001 Fan assembly 1 1 1

24 207350022 Machine pulley 1 1 1

25 S10009 Screw 2 2 2

26 207S13004 Screw 1 1 1

27 W02004 Spring washer 1 1 1

28 20602002 Pin 0 0 1

29 20712046 Cover 0 0 1

30 207S17001 Screw 0 0 2

31 207S11012 Screw 0 0 1

32 20708003 Spacer 1 1 1

33 20701009 Cover 1 1 1

Crankshaft (for 321D-251H / 321K-251H only)

3 thread 4 thread 5 thread

001

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

29

Page 32

6.5

Thread

Tension

Components

7

6

5

7

6

5

1

4

8

3

18

16

4

8

3

19

7

6

5

7

6

5

9

4

10

3

20

17

4

10

3

21

12

13

For 1-needle

14

11

15

1

14

12

11

17

9

For 2-needle

17

13

9

16

1

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

30

Page 33

6.5

Thread

Tension

Components

No. Part No. Description

1 2071100400 Tension spring assembly 1 1 1

3 30111006 Rachet 3 4 4

4 301110052 Cup 3 4 4

5 30128016 Tension disc 6 8 8

6 20623008 Felt 3 4 4

7 201S30016 Screw stud 3 4 4

8 20727011 Spring 1 2 2

9 2071100500 Tension spring assembly 1 1 1

10 30127013 Spring 2 2 2

11 20713001 Thread guide 1 1 1

12 207S11007 Screw 2 2 2

13 20712015 Thread guide 1 1 1

14 20612052 Tension guide 3 4 4

15 207S110014 Screw 1 0 0

16 2071100300 Tension spring assembly 0 1 1

17 2071100700 Tension spring assembly 1 1 1

18 301S160062R Knob (red dot) 1 1 1

19 301S160062Y Knob (Yellow dot) 0 1 1

20 301S160062B Knob (blue dot) 1 1 1

21 301S160062G Knob (Green dot) 1 1 1

3 thread 4 thread 5 thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

31

Page 34

6.6

Thread Guide

and Thread

Take-up

Components (1)

For 5-thread

1

9

2

8

16

13

10

12

17

18

19

20

14

15

6

5

7

3

22

21

4

11

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

32

Page 35

6.6

3thread 4thread 5thread

1 20701029 Bracket 0 0

2 207S11019 Screw 0 0

3 20713020

00

4 20713052

00

5 207S14001 Screw 0 0

6 20701030 Bracket 0 0

7 S01031 Screw 0 0

8 20713021 Thread guide 0 0

9 207S14001 Screw 0 0

10 20713022

00

11 207S11015

00

12 20713050

00

13 S01031 Screw 0 0

14 20713023

00

15 20713051

00

16 S01031 Screw 0 0

17 20713006 Bracket 0 0

18 20713007 Thread retainer 0 0

19 207S20003 Screw 0 0

20 20727002 Spring 0 0

21 20713024

00

22 207S11015

00

Thread Guide

and Thread

Take-up

Components (1)

No. Part No. Description

Thread guide (for 321D-251H / 321K-251H only)

Thread take-up (for 321D-251H / 321K-251H only)

Thread guide (except 321D-251H / 321K-251H)

Screw (for 321D-251H / 321K-251H only)

Thread guide (for 321D-251H / 321K-251H only)

Thread guide (except 321D-251H / 321K-251H)

Thread guide (for 321D-251H / 321K-251H only)

Thread take-up (except 321D-251H / 321K-251H)

Screw (except 321D-251H / 321K-251H)

Qty

1

2

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

33

Page 36

6.7

Thread Guide

and Thread

Take-up

Components (2)

10

For 3-thread and 4-thread

4

5

9

1

6

2

7

11

13

12

3

8

14

15

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

34

Page 37

6.7

3thread 4thread 5thread

1 20713002 Thread guide 1 0

2 20713003 Thread guide 0 1

3 207S14001 Screw 1 1

4 20701010 Bracket 1 1

5 207S11019 Screw 1 1

6 20713004 Thread eyelet 1 0

7 20713005 Thread eyelet 0 1

8 207S11015 Screw 2 2

9 207S11019 Screw 1 1

10 20713006 Bracket 1 1

11 20713007 Thread retainer 1 1

12 207S20003 Screw 1 1

13 20727002 Spring 1 1

14 20713008 Thread take-up 1 0

15 20713009 Thread take-up 0 1

Qty

Thread Guide

and Thread

Take-up

Components (2)

No. Part No. Description

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

35

Page 38

6.8

Thread Guide

and Thread

Take-up

Components (3)

10

9

11

15

2

4

3

12

2

1

16

5

6

14

7

8

13

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

36

Page 39

6.8

3thread 4thread 5thread

1 20712016 Bracket 1 1

2 20113015 Thread guide 2 2

3 201S11006 Screw 2 2

4 W01011 Washer 2 2

5 20713010 Thread take-up 1 1

6 207S11007 Screw 1 1

7 20713011 Thread eyelet 1 1

8 207S11020 Screw 1 1

9 20713012 Thread guide 1 1

10 20713053

00

11 20713054

00

12 20713015 Thread take-up 1 1

13 20713055

)

00

14 207S11021 Screw 1 1

15 20713013 Thread guide 1 1

Qty

Thread Guide

and Thread

Take-up

Components (3)

No. Part No. Description

Thread guide (for 321D-251H / 321K-25H only)

Thread guide (for 321D-251H / 321K-25H only)

Thread take-up (for 321D-251H / 321K-25H only

1

2

2

2

1

1

1

1

1

1

1

1

1

1

1

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

37

Page 40

6.9

Needle Bar

Components

(1)

11

10

9

8

6

5

3

12

13

17

18

7

25

16

14

15

21

19

20

22

23

24

4

1

2

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

38

Page 41

6.9

Needle Bar

Components

(1)

No. Part No. Description

1 20705001 Connection assembly 1 1 1

2 207811016 Screw 2 2 2

3 20626003 Pin 1 1 1

4 207814007 Screw 1 1 1

5 20704001 Crank assembly 1 1 1

6 S05018 Screw 1 1 1

7 20702002 Shaft 1 1 1

8 20708004 Collar 1 1 1

9 207814001 Screw 2 2 2

10 20628014 Washer 1 1 1

11 H05008 Ring 1 1 1

12 2070400200 Lever assembly 1 1 1

13 207812002 Screw 1 1 1

14 2072600300 Shaft assembly 1 1 1

15 20726003 Shaft 1 1 1

16 20523005 Oil wick 1 1 1

17 207200300 Needle bar bushing assembly 1 1 1

18 20702003 Needle Bar 1 1 1

19 20703012 Bushing 1 1 1

20 207814008 Screw 1 1 1

21 001026 O ring 1 1 1

22 20723003 Oil felt 1 1 1

23 20708005 Ring assembly 1 1 1

24 207811023 Screw 1 1 1

25 20722004 Plug 1 1 1

3 thread 4 thread 5 thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

39

Page 42

6.10

Needle Bar

Components

(2)

For 3 thread

14

13

11

12

15

For 4 thread

For 5 thread

10

9

7

8

6

4

1

2

5

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

3

40

Page 43

6.10

Needle Bar

Components

(2)

No. Part No. Description

1 XXXXXXXX Needle holder assembly 0 0 1

2 207S14009 Screw 0 0 2

3 20713017

4 207S11024 Screw 0 0 1

5 XXXXXXXX Needle 0 0 2

6 XXXXXXXX Needle 0 2 0

7 XXXXXXXX Needle holder assembly 0 1 0

8 207S14009 Screw 0 2 0

9 20713018 Thread guide 0 1 0

10 207S11024 Screw 0 1 0

11 XXXXXXXX Needle holder assembly 1 0 0

12 207S14009 Screw 1 0 0

13 20713038 Thread guide 1 0 0

14 207S11024 Screw 1 0 0

15 XXXXXXXX Needle 1 0 0

Thread guide (except 321D-251H / 321K-251H)

3 thread 4 thread 5 thread

001

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

41

Page 44

6.11

Needle

Plate and

Needle Guard

Components

For 5-thread

2

1

7

6

5

4

3

15

14

18

16

19

17

9

8

11

13

12

10

For 3-thread / 4-thread

20

26

25

21

23

22

28

27

24

30

32

31

29

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

42

Page 45

6.11

Needle

Plate and

Needle Guard

Components

No. Part No. Description

1 XXXXXXXX Needle plate 0 0 1

2 207S17003 Screw 0 0 2

3 20709002 Bracket (Front) 0 0 1

4 207S11007 Screw 0 0 2

5 20622003 Cushion rubber 0 0 2

6 20709003 Bracket (Rear) 0 0 1

7 207S11007 Screw 0 0 2

8 XXXXXXXX Needle guard (Front) 0 0 1

9 S01027 Screw 0 0 2

10 XXXXXXXX Needle guard (Rear) 0 0 1

11 207S12005 Screw 0 0 1

12 W03004 spring 0 0 1

13 207S11002 Screw 0 0 1

14 XXXXXXXX Needle guard (Front) 0 0 1

15 207S11007 Screw 0 0 1

16 XXXXXXXX Needle guard (Rear) 0 0 1

17 S01027 Screw 0 0 2

18 20701033 Bracket 0 0 1

19 207S11003 Screw 0 0 2

20 XXXXXXXX Needle plate 1 1 0

21 207S17003 Screw 2 2 0

22 20709002 Bracket (Front) 1 1 0

23 207S11007 Screw 2 2 0

24 20622003 Cushion rubber 2 2 0

25 20709003 Bracket (Rear) 1 1 0

26 207S11007 Screw 2 2 0

27 XXXXXXXX Needle guard (Front) 1 1 0

28 207S11007 Screw 1 1 0

29 XXXXXXXX Needle guard (Rear) 1 1 0

30 207S12005 Screw 1 1 0

31 W03004 spring 1 1 0

32 207S11002 Screw 1 1 0

3 thread 4 thread 5 thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

43

Page 46

6.12

Upper Looper

Components

9

10

8

7

2

1

3

11

13

30

32

31

29

27

25

26

28

20

4

6

5

22

21

19

16

18

12

15

14

17

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

44

Page 47

6.12

Upper Looper

Components

No. Part No. Description

1 20705002 Connection assembly 1 1 1

2 207S11016 Screw 2 2 2

3 207S11005 Screw 2 2 2

4 20704003 Crank assembly 1 0 0

5 20704004 Crank assembly 0 1 1

6 S05018 Screw 1 1 1

7 20702004 Shaft 1 1 1

8 20628006 Washer 1 1 1

9 207S11004 Screw 1 1 1

10 20628005 Spring washer 1 1 1

11 20708006 Spacer 0 1 0

12 20622019 Oil Seal 1 1 1

13 20708007 Spacer 1 0 1

14 20705003 Lever assembly 1 1 1

15 207S12002 Screw 1 1 1

16 20726004 Pin assembly 1 1 1

17 20523005 Oil wick 1 1 1

18 207S14010 Screw 1 1 1

19 20704005 Upper looper holder assembly 1 1 1

20 20623005 Felt 1 1 1

21 207S11025 Screw 1 1 1

22 XXXXXXXX Upper looper 1 1 1

25 207S11026 Screw 2 2 2

26 20715007 Cover 1 1 1

27 207S17004 Screw 1 1 1

28 207S11027 Screw 1 1 1

29 20123021 Oil wick 1 1 1

30 20723005 Felt 1 1 1

31 20712017 Bracket 1 1 1

32 207S11020 Screw 1 1 1

3 thread 4 thread 5 thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

45

Page 48

6.13

Lower Looper

Components

4

2

1

3

5

11

13

10

18

12

15

14

6

16

17

8

9

7

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

46

Page 49

6.13

Lower Looper

Components

No. Part No. Description

1 20705002 Connection assembly 1 1 1

2 207S11016 Screw 2 2 2

3 207S11005 Screw 2 2 2

4 20704006 Crank assembly 1 1 0

5 S05018 Screw 1 1 0

6 20702004 Shaft 1 1 1

7 20628006 Washer 1 1 1

8 207S11004 Screw 1 1 1

9 20628005 Spring washer 1 1 1

10 20622019 Oil seal 1 1 1

11 XXXXXXXX Lower looper 1 1 1

12 207S14006 Screw 0 0 1

13 207S11028 Screw 1 1 1

14 20704007 Lower looper holder assembly 1 1 1

15 207S20004 Screw 1 1 1

16 207S15001 Screw 1 1 1

17 20704013 Crank assembly 0 0 1

18 S05018 Screw 0 0 1

3 thread 4 thread 5 thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

47

Page 50

6.14

Chain

Stitch Looper

Components (1)

8

10

9

7

5

6

2

1

13

12

11

3

4

14

15

22

16

17

23

29

28

26

27

18

19

21

20

24

25

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

48

Page 51

6.14

3 thread 4 thread 5 thread

1 20705006 Connection 0 0

2 B08002 Needle bearing 0 0

3 20704014 Crank 0 0

4 20703013 Bushing 0 0

5 207S12003 Screw 0 0

6 30228008 Washer 0 0

7 20709017 Slider 0 0

8 207S13009 Screw 0 0

9 20628010 Washer 0 0

10 20628005 Spring washer 0 0

11 20710008 Pin 0 0

12 001027 O ring 0 0

13 20626017 Shaft 0 0

14 20701034 Holder assembly 0 0

15 S05018 Screw 0 0

16 20704015 Crank assembly 0 0

17 S05018 Screw 0 0

18 20705008 Link 0 0

19 20703013 Bushing 0 0

20 207S12003 Screw 0 0

21 30228008 Washer 0 0

22 20702018 Shaft 0 0

23 3052201700 Oil seal 0 0

24 XXXXXXXX Chain stitch looper 1 1

25 207Sl1028 Screw 0 0

26 20701035 Chain stitch looper holder assembly 0 0

27 207S20004 Screw 0 0

28 20728002 Spacer 0 0

29 207S15001 Screw 0 0

Qty

No. Part No. Description

Chain

Stitch Looper

Components (1)

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

49

Page 52

6.15

Chain

Stitch Looper

Components (2)

1

4

3

17

16

15

14

2

4

8

9

10

11

5

7

6

12

13

19

18

20

22

21

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

50

Page 53

6.15

3 thread 4 thread 5 thread

1 20713039 Thread guide 0 0

2 207S11007 Screw 0 0

3 20713040 Thread guide 0 0

4 20629003 Holder 0 0

5 20612057 Bracket 0 0

6 207S20002 Screw 0 0

7 20628022 Washer 0 0

8 206S30015 Screw 0 0

9 20612055 Tension disc 0 0

10 3012016 Spring 0 0

11 206S16004 Knob 0 0

12 20612056 Thread guide 0 0

13 S01031 Screw 0 0

14 20629004 Thread guide 0 0

15 207S11020 Screw 0 0

16 20613017 Thread guide 0 0

17 207S11020 Screw 0 0

18 20612058 Looper thread take-up assembly 0 0

19 207S14009 Screw 0 0

20 20629005 Spring 0 0

21 20713026 Thread guide 0 0

22 207S11007 Screw 0 0

Qty

No. Part No. Description

Chain

Stitch Looper

Components (2)

1

1

1

3

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

1

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

51

Page 54

6.16

Differencial

Feed

Components

23

14

13

12

2

8

7

1

3

4

11

16

17

18

19

15

22

21

6

10

9

5

20

27

30

26

28

29

35

34

36

24

25

41

40

33

31

32

42

43

44

37

39

38

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

52

Page 55

6.16

Differencial

Feed

Components

No. Part No. Description

1 20705004 Connection 1 1 1

2 20626003 Pin 1 1 1

3 207S14007 Screw 1 1 1

4 BO8001 Needle bearing 1 1 1

5 20710001 Eccentric 1 1 1

6 20710002 Guide (Feed eccentric) 1 1 1

7 20712018 Flat spring 1 1 1

8 207S14003 Screw 2 2 2

9 20710003 Regulator assembly 1 1 1

10 207S14006 Screw 2 2 2

11 20710004 Eccentriv assembly 1 1 1

12 20727003 Spring 1 1 1

13 207S20005 Screw 1 1 1

14 20709006 Ratchet 1 1 1

15 20702005 Push button shaft 1 1 1

16 20722005 Gaket 1 1 1

17 001027 O ring 1 1 1

18 20728001 Washer 1 1 1

19 20727004 Spring 1 1 1

20 H05018 Ring 1 1 1

21 20705005 Link 1 1 1

22 207S20006 Screw 1 1 1

23 20629002 Ring 1 1 1

24 20704008 Lever assembly 1 1 1

25 S05018 Screw 1 1 1

26 20712019 Lever 1 1 1

27 207S20007 Screw 1 1 1

28 20702006 Shaft 1 1 1

29 20622010 O ring 1 1 1

30 20627006 Spring 1 1 1

31 20712020 Regulator plate 1 1 1

32 207S11008 Screw 2 2 2

33 20711007 Spacer 2 2 2

34 2071600100 Nut 1 1 1

35 207S300011 Screw 1 1 1

36 20728003 Spring washer 1 1 1

37 207S16002 Stopper 2 2 2

38 207S11011 Screw 2 2 2

39 30228009 Washer 2 2 2

40 20702007 Adjusting shaft 1 1 1

41 20737001 Label 1 1 1

42 H05018 Ring 1 1 1

43 20727005 Spring 1 1 1

44 20709007 Pin 1 1 1

3thread 4thread 5thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

53

Page 56

6.17

Feed Dog

Components

9

5

7

6

8

10

11

13

12

17

16

15

18

2

1

3

19

22

21

32

14

4

20

21

26

24

25

23

34

33

22

35

36

37

40

38

29

28

27

30

31

42

39

41

43

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

45

44

54

Page 57

6.17

Feed Dog

Components

No. Part No. Description

1 20702008 Shaft 1 1 1

2 H05009 Ring 1 1 1

3 20628023 Plug 1 1 1

4 20628011 Washer 2 2 2

5 2070400900 Crank assembly 1 1 1

6 207S13005 Screw 1 1 1

7 207811029 Screw 2 2 2

8 20709010 Block 1 1 1

9 20704011 Crank assembly 1 1 1

10 S05018 Screw 1 1 1

11 20710005 Pin 1 1 1

12 N01004 Nut 1 1 1

13 20628010 Wsher 1 1 1

14 20710006 Pin 1 1 1

15 207S13001 Screw 1 1 1

16 20722006 Gasket 1 1 1

17 20729002 Ring 1 1 1

18 1026 O ring 1 1 1

19 20709011 Block 1 1 1

20 20708008 Collar 2 2 2

21 207S14001 Screw 2 2 2

22 20705008 Link 1 1 1

23 20703013 Bushing 1 1 1

24 207S12003 Screw 1 1 1

25 30228008 Wsher 1 1 1

26 2070600100 Main feed dog bar 1 1 1

27 XXXXXXXX Main feed dog assembly 1 1 1

28 XXXXXXXX Main feed dog 1 1 1

29 XXXXXXXX Auxiliary feed dog 1 1 1

30 207811029 Screw 1 1 1

31 801029 Screw 1 1 1

32 20706002 Differentrial feed dog bar 1 1 1

33 XXXXXXXX Differentrial feed dog 1 1 1

34 207Sl1030 Screw 1 1 1

35 20709012 Block 1 1 1

36 20701011 Feed bar guide (Right) 1 1 1

37 207S13006 Screw 2 2 2

38 20701012 Feed bar guide (Left) 1 1 1

39 207S13006 Screw 2 2 2

40 20701013 Feed bar guide oil seal 1 1 1

41 20722007 Oil seal 2 2 2

42 207S13007 Screw 2 2 2

43 20721003 Tube 1 1 1

44 20712055 Clamp 1 1 0

45 207Sl1011 Screw 1 1 1

3 thread 4 thread 5 thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

55

Page 58

6.18

Knife Drive

Components

13

16

3

4

5

6

For 321D-251H / 321K-251H

19

22

7

1

2

9

8

10

17

18

35

34

21

14

15

For 321D-251H / 321K-251H

29

33

30

31

32

27

28

23

24

26

38

37

36

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

56

Page 59

6.18

Knife Drive

Components

No. Part No. Description

1 20705007 Connection assembly 1 1 1

2 207S11016 Screw 2 2 2

3 20704012 Crank assembly 1 1 0

4 20704030 Crank assembly 0 0 1

5 S05018 Screw 1 1 1

6 20626003 Pin 1 1 1

7 207S14007 Screw 1 1 1

8 30208001 Collar assembly 1 1 1

9 S10003 Screw 1 1 1

10 20702009 Upper knife lever 1 1 1

13 20726005 Pin 1 1 1

14 20701014 Upper knife holder 1 1 0

15 20701036 Upper knife holder 0 0 1

16 207S11012 Screw 1 1 1

17 XXXXXXXXX Upper knife 1 1 1

18 S01029 Screw 1 1 1

19 20701050 Angle upper knife holder 0 0 1

21 XXXXXXXXX Angle upper knife 0 0 1

22 207S11020 Screw 0 0 1

23 20712053 Angle upper knife gib 0 0 1

24 20712051 Waste guard 0 0 1

26 S11025 Screw 0 0 1

27 W01011 Washer 0 0 1

28 20701015 Lower knife holder 1 1 0

29 20701037 Lower knife holder 0 0 1

30 207S11007 Screw 1 1 1

31 20712021 Lower knife holder guide 1 1 1

32 207S11019 Screw 2 2 2

33 20727006 Spring 1 1 1

34 20712022 Plate 1 1 1

35 207S11007 Screw 1 1 1

36 XXXXXXXXX Lower knife 1 1 1

37 20709013 Lower knife clamp 1 1 1

38

207S12004

Screw 1 1 1

3 thread 4 thread 5 thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

57

Page 60

6.19

Presser Foot

Components

5

4

6

7

17

16

8

2

1

3

15

18

14

13

12

28

29

27

10

11

9

23

22

24

36

21

35

34

32

31

19

20

26

25

33

30

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

58

Page 61

6.19

Presser Foot

Components

No. Part No. Description

1 20712023 Lever 1 1 1

2 207S20008 Screw 1 1 1

3 20727007 Spring 1 1 1

4 20712024 Stopper 1 1 1

5 207S11012 Screw 2 2 2

6 207S11031 Screw 1 1 1

7 N01004 Nut 1 1 1

8 20712025 Link 1 1 1

9 20612030 Lever 1 1 1

10 20608004 Collar assembly 1 1 1

11 S05017 Screw 1 1 1

12 20627009 Spring 1 1 1

13 20703014 Bushing 1 1 1

14 207S11016 Screw 1 1 1

15 20702010 Shaft 1 1 1

16 20701016 Presser arm 1 1 1

17 20626016 Pin 1 1 1

18 S10011 Screw 1 1 1

19 XXXXXXXX Presser foot assembly 1 1 1

20 207S11030 Screw 1 1 1

21 20712026 Finge guard 1 1 1

22 20712048 Stopper 1 1 1

23 207S11009 Screw 1 1 1

24 207S11020 Screw 1 1 1

25 20712027 Flat Spring 1 1 1

26 207S11032 Screw 1 1 1

27 20712028

28 20702012 Adjusting screw 1 1 1

29 207S16003 Nut 1 1 1

30 20612034 Lever 1 1 1

31 207 S20009 Screw 1 1 1

32 20627010 Spring 1 1 1

33 20712030 Stopper 1 1 1

34 207S11007 Screw 1 1 1

35 20619005 Chain cutter 111

36 207S11020 Screw 1 1 1

Spring (except 321D-251H / 321K-251H)

3 thread 4 thread 5 thread

111

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

59

Page 62

6.20

Lubrication

Components (1)

7

6

14

13

11

25

4

5

1

2

3

17

16

18

21

20

22

23

19

18

16

15

12

10

1

17

20

21

24

9

22

8

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

60

Page 63

6.20

Lubrication

Components (1)

No. Part No. Description

1 2072000100 Oli pump assembly 1 1 1

2 20725002 Worm wheel 1 1 1

3 207S15002 Screw 2 2 2

4 2071100900 Oil distributor assembly 1 1 1

5 20709014 Plug 2 2 2

6 207S30002 Screw 1 1 1

7 206S30009 Joint screw 1 1 1

8 20122033 Washer 10 10 10

9 207S13008 Screw 2 2 2

10 20701025 Tank 1 1 1

11 207S11005 Screw 2 2 2

12 20136001 Oli filter 1 1 1

13 20712035 Cover 1 1 1

14 207S11007 Screw 3 3 3

15 001028 O ring 1 1 1

16 20636001 Joint 2 2 2

17 206S30009 Joint screw 2 2 2

18 20629002 Clamp 2 2 2

19 30121021 Tube 1 1 1

20 20636001 Joint 2 2 2

21 206S30009 Joint screw 2 2 2

22 20629002 Clamp 2 2 2

23 30121021 Tube 1 1 1

24 20521009 Joint 2 2 2

25 20712036 Oil guide 1 1 1

3 thread 4 thread 5 thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

61

Page 64

6.21

Lubrication

Components (2)

21

18

20

25

22

17

15

16

14

23

24

19

13

2

12

1

3

4

5

11

6

8

7

10

9

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

62

Page 65

6.21

Lubrication

Components (2)

No. Part No. Description

1 2071101000 Oil sight gauge 1 1 1

2 001030 O Ring 1 1 1

3 2071101200 Indicator assembly 1 1 1

4 20711013 Indicator support 1 1 1

5 207S30002 Screw assembly 2 2 2

6 20701026 Oil reservoir assembly 1 1 1

7 207S13002 Screw 1 1 1

8 20622014 Washer 1 1 1

9 207S13009 Bolt 4 4 4

10 20628018 Washer 4 4 4

11 20722008 Gasket 1 1 1

12 20725003 Worm 1 1 1

207S14006

13

14 20626007 Pipe 1 1 1

15 20709015 Ball 1 1 1

16 207S14001 Screw 1 1 1

17 20123021 Oil wick 1 1 1

18 20721010 Pipe assembly 1 1 1

19 207S11011 Screw 1 1 1

20 20709016 Ball 2 2 2

21 207S14001 Screw 1 1 1

22 2071203800 Joint assembly 1 1 1

23 20723007 Felt 1 1 1

24 20622010 O ring 1 1 1

25 20721008 Tube 1 1 1

Screw 1 1 1

3 thread 4 thread 5 thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

63

Page 66

6.22

Silicon Oil

Reservoir

Components

8

3

4

2

1

7

5

6

12

11

25

16

15

13

16

14

17

20

21

18

9

10

22

19

23

24

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

64

Page 67

6.22

Silicon Oil

Reservoir

Components

No. Part No. Description

1 20711014 Silicone oil reservoir 1 1 1

2 20711015 Cover 1 1 1

3 20723008 Felt 1 1 0

4 20719051 Felt 0 0 1

5 20712040 Thread guide 1 1 0

6 20713019 Thread guide 0 0 1

7 207S11012 Screw 1 1 1

8 20712042 Cover 1 1 1

9 20723009 Oil felt 0 0 1

10 20726010 Pin 0 0 1

11 2071101600 Silicone oil reservoir 1 1 0

12 20711017 Cover 1 1 1

13 207S30003 Screw 1 1 1

14 40123013 Oil wick 1 1 1

15 40121002 Tube 1 1 1

16 20712041 Clamp 2 2 2

17 20701027 Needle thread lubricator 1 1 0

18 207S11008 Screw 2 2 0

19 20709014 Plug 1 1 0

20 20723009 Oil felt 1 1 0

21 20726010 Pin 1 1 0

22 20701038 Needle thread lubricator 0 0 1

23 207S11007 Screw 0 0 2

24 20709014 Plug 0 0 1

25 2070103000 Silicone oil reservoir 001

3 thread 4 thread 5 thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

65

Page 68

6.23

Exclusive

Parts List for

321K series

1

10

2

3

5

4

12

6

7

9

14

8

11

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

13

15

66

Page 69

6.23

Exclusive

Parts List for

321K series

No. Part No. Description

1 20701080 Machine Frame 1 1 1

2 20702023 Crank shaft 1 1 1

3 20723010 Washer 1 1 1

4 20725004 Worm 1 1 1

5 S10018 Screw 6 6 6

6 20708013 Helical casing 1 1 1

7 207S14006 Screw 2 2 2

8 20708014 Right cover 1 1 1

9 207S11012 Screw 3 3 3

10 2073300400 Direct drive servo motor 1 1 1

11 114S30001 Screw 4 4 4

12 20711026 Motor cover 1 1 1

13 S01013 Screw 3 3 3

14 20735015 Hand wheel 1 1 1

15 S10009 Screw 2 2 2

3 thread 4 thread 5 thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

67

Page 70

6.24

Thread Stand

Components

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

68

Page 71

6.24

Thread Stand

Components

No. Part No. Description

1 30102032 Thread bar (lower) 1 1 1

2 30128024 Washer 2 2 2

3 N02001 Nut 1 1 1

4 30101028 Bracket (3 spools) 1 0 1

5 30101029 Bracket (2 spools) 0 2 1

6 30102033 Spool pin 3 4 5

7 W02002 Washer 3 4 5

8 30101030 Thread guide bar (3 spools) 1 0 1

9 30111007 Spool tray 3 4 5

10 30123014 Cushion 3 4 5

11 30103044 Spool holder 3 4 5

12 L02004 Screw 1 2 2

13 10128006 Rubber washer 1 1 1

14 20131014 Thread stand support 1 0 1

15 30102034 Thread bar (upper) 1 1 1

16 30129005 Joint 1 1 1

17 S04002 Screw 4 4 4

18 N01004 Nut 6 6 6

19 30111008 Bracket 1 1 1

20 30113018 Thread guide bar 1 1 1

21 S04003 Screw 1 1 1

22 30101031 Thread guide bar (2 spools) 0 2 1

23 30111009 Bracket 1 1 1

24 S04004 Screw 3 3 3

25 N01005 Nut 7 8 9

26 30113019 Thread guide bar (5 holes) 1 1 1

28 30103045 Thread guide hole 3 4 5

29 30122027 Rod cap 1 1 1

30 20131023 Screw 1 1 1

31 20131024 Screw 1 1 1

32 30122027 Nut 1 1 1

3 thread 4 thread 5 thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

69

Page 72

6.25

Accessories

10

17

12

13

11

6

2

4

18

16

21

1

3

5

20

15

14 9

7

8

19

Ultra High Speed Overedge and Safety Stitch Machine | Instruct io n Manual and Parts List

70

Page 73

6.25

10131005 Dust cover

20131037 Oil bottle

2

6120-06

0131038 Small oil bottle

Needle

20619003 Lower knife

20131041 Spanner (6mm)

20131042 Spanner (7mm)

20131043 Spanner (8mm)

20131044 Allen key driver (1.5mm)

30131026 Allen key (8mm)

20131046 Allen key (2mm)

20131047 Allen key (5mm)

30131012 Allen key (4mm)

10131004 Screw driver (small)

10131003 Screw driver (middle)

20131051 Tweezers

20131056 Allen key (6mm)

20131039 Funnel

20131054 Foot controller chain

20136001 Oil filter

10131002 Screw driver (big)

Accessories

No. Part No. Description

5 111

8

3 thread 4 thread 5 thread

Qty

1111

1112

1113

3334

1116

1117

111

1119

11101

11111

11121

11131

11141

11151

11161

11171

11181

11191

11102

11112

Ultra High Speed Overedge and Safety Stitch Machine | Instruct io n Manual and Parts List

71

Page 74

6.26

Qty

Machine

Support Plate

For Semi-

Submerged

Components

3

2

1

9

4

10

11

No. Part No. Description

1 20701028 Machine support plate 1 1 1

2 20722009 Cushion rubber 4 4 4

3 301S16008 Nut 4 4 4

4 20131029 Washer 16 16 16

5 301S30017 Screw 4 4 4

6 20131030 Spacer 4 4 4

7 20131032 Waste chute (upper) 1 1 1

8 20131033 Waste chute (lower) 1 1 1

9 20131034 Screw 3 3 3

10 20131031 Waste chute inlet 1 1 1

11 20131035 Screw 4 4 4

12 30122031 Spacer 8 8 8

5

7

8

3 thread 4 thread 5 thread

12

6

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

72

Page 75

6.27

Qty

Specific Parts

for 321D-251H

and 321K-251H

1

2

3

7

8

9

10

6

5

4

12

11

No. Part No. Description

1 XXXXXXXX Presser foot assembly 0 0 1

2 207S11030 Screw 0 0 1

3 20726011 Pin 0 0 3

4 20714051 Fabric guard 0 0 1

5 W01002 Washer 0 0 1

6 206S11018 Screw 0 0 1

7 20719053 Spring 0 0 1

8 207S16050 Screw 0 0 1

9 20712052 Finger guard 0 0 1

10 207S11009 Screw 0 0 1

11 20713056 Thread eyelet 0 0 1

12 20719054 Spring 0 0 1

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

3 thread 4 thread 5 thread

73

Page 76

6.28

Optional

Parts

For

321D-131M 321K-131M

321D-241M 321K-241M

321D-251M 321K-251M

4

5

20

21

18

19

15

For

321D-132M

321K-132M

Turm down hemming

17

16

2

13

12

3

9

10

11

6

24

23

25

22

1

14

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

74

Page 77

6.28

Optional

Parts

No. Part No. Description

1 20701023 Fabric guard 1 0 0

2 20112051 Cloth plate bracket 1 1 1

3 20112052 Hinge guide bracket 1 1 1

4 201S20002 Screw 1 1 1

5 20128027 Spring washer 1 1 1

6 201S16003 Nut 1 1 1

9 20126020 Pin 1 1 1

10 20112053 Flat spring 1 1 1

11 201S11011 Screw 1 1 1

12 S01010 Screw 1 1 1

13 W02002 Spring washer 1 1 1

14 XXXXXXXXX Presser foot 1 0 0

15 20112056 Edge guide bracket 1 1 1

16 201S12001 Bolt 2 2 2

17 20128020 Washer 2 2 2

18 201S11010 Screw 1 1 1

19 20128020 Washer 1 1 1

20 20112054 Edge guide 1 1 0

21 20112055 Edge guide 0 0 1

22 207S11033 Screw 1 0 0

23 20712031 Uncurler 1 0 0

24 207S11034 Screw 1 0 0

25 XXXXXXXXX Presser foot finger 1 0 0

3 thread 4 thread 5 thread

Qty

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

75

Page 78

6.29

Back Latch

Components

1

5

For

321D-134M 321K-134M

321D-244M 321K-244M

9

2

3

4

8

10

29

30

6

7

15

14

13

16

17

18

28

19

20

21

22

23

24

25

26

52

37

50

51

9

49

38

39

9

11

12

48

48

31

32

33

27

40

36

34

35

Ultra High Speed Overedge and Safety Stitch Machine | Instruction Manual and Parts List

41

42

43

47

46

45

44

76

Page 79

6.29

Back Latch

Components

No. Part No. Description

1 205S16002 Nut 1 1 0

2 20528008 Washer 1 1 0

3 20512008 Connecting plate 1 1 0

4 205S30011 Screw 1 1 0

5 205S30012 Screw 1 1 0

6 205S16003 Nut 1 1 0

7 207S11005 Screw 2 0 0

8 20713044 Bracket 1 0 0

9 205S30013 Connecting screw 2 2 0

10 2051200900 Thread tension releasing wire assemb 1 0 0

11 205S16005 Nut 4 2 0

12 20527006 Spring 1 0 0

13 205S30009 Screw 1 0 0

14 206S11005 Screw 1 0 0

15 205S16004 Nut 1 0 0

16 20512005 Tension support 1 0 0

17 20512006 Thread tension releasing plate 1 0 0

18 205S30014 Screw 1 0 0

19 205S30007 Screw 1 1 0

20 20512002 Thread press plate 1 1 0

21 S02007 Screw 4 4 0

22 20512004 Knife supporter 1 1 0

23 205S30008 Screw 1 1 0

24 20512003 Pressing block 1 1 0

25 20519001 Small knife support 1 1 0

26 20527003 Spring 1 1 0

27 301S16007 Thread tension nut 1 1 0

28 20519002 Knife 1 1 0

29 XXXXXXXX Needle plate 1 0 0

30 XXXXXXXX Needle plate 0 1 0

31 20709021 Needle plate supporter (front) 1 1 0

32 XXXXXXXX Presser foot finger 1 0 0

33 XXXXXXXX Presser foot finger 0 1 0

34 XXXXXXXX Feed dog assembly 1 0 0

35 XXXXXXXX Feed dog assembly 0 1 0

36 2071206500 Cloth plate 1 1 0

37 20112060 Thread guide plate 0 1 0

38 20112061 Thread tension plate 0 1 0

39 201S16003 Nut 0 1 0

40 20112062 Frong frame 0 1 0

41 20112063 Thread tension releasing lever 0 1 0

42 20101039 Connector 0 1 0

43 201S20014 Connector screw 0 1 0

44 201S14003 Screw 0 2 0

45 201S20013 Screw 0 1 0

46 20127021 Spring 0 1 0

47 201S20012 Screw 0 1 0

48 20112059 Sleeve 0 1 0

49 20112058 Bracket 0 1 0

50 20103029 Collar 0 1 0

51 201S14002 Screw 0 1 0

52 201S11016 Screw 0 2 0