Page 1

SINGER*

SLANT NEEDLE SEWING MACHINE

...........

represents the ultimate in sewing machine

design and styling. A product of the matchless skill

Form 20542

(Rev. 7-76)

and engineering ability of

SINGER

line of unexcelled Sewing Machines.

301 is an outstanding addition to our long

SINGER

craftsmen, the

Printed in U.S.A.

AS THE OWNER OF THIS ENTIRELY NEW

SINGER SEWING MACHINE:

You have a machine revolutionary in design, but made with

the same care and craftsmanship that have been the hallmark

of SINGER Machines for more than a century. We are acutely

aware that SINGER Sewing Machines have become an Ameri

can tradition and are intensely proud of, and determined to

continue, this heritage.

Your SINGER “301” is the product of this pride, determination

and the unsurpassed technical skill of SINGER. This smooth

running machine-of-tomorrow will amaze and thrill you with

its versatility and ease of operation.

Utilize all the advanced features, combine them with your own

skill and discover a new world of sewing enjoyment. Exclusive

dresses for yourself, clothing for your

family and a multitude of items for your

home will be yours — all at a fraction

of their ready-made cost.

*A Trademark of THE SINGER COMPANY

Copyright ® 1956 by The Singer Co.

All Rights Reserved Throughout the World

m

/f

Page 2

WHAT SINGER SERVICE MEANS TO YOU

Over 1400 SINGER SEWING CENTERS in the United States

alone are fully equipped to serve women who sew.

There you’ll find a wide selection of PATTERNS, BUTTONS,

THREAD, and FINISHING SiRVICES which include COV

ERING BUTTONS, BELTS AND BUCKLES, making BUTTONHOLES, HEMSTITCHING, etc., plus:

You are entitled to sewing lessons when you become the owner

of a new SINGER. A skilled, SINGER-trained teacher per

sonally guides you and assists you in learning the fundamentals

of home sewing. Other courses embracing all phases of home

sewing are available at low cost.

REPAIR SERVICE is as convenient as your telephone. When

ever your machine needs adjustments, a trained, courteous

SINGER representative will gladly call at your home. SINGER*

Service assures excellent workmanship,» guaranteed repairs, and

SINGER* parts. A written estimate is given you in advance

for approval.

And remember, your SINGER SEWING CENTER and the ever

ready SINGER Service Car can be easily identified by the

famous SINGER red “S” Trade Mark.

SINGER 301 FEATURES “AT YOUR SERVICE”

• SMOOTHER STITCHING than ever before

is possible with this new, gear-driven, lock

stitch machine.

• QUIET, fast and efficient — it whispers at

high speeds.

• FULL-VIEW work area. Inclined Needle Bar

places work in your direct line of vision.

• PERFECT CONTROL — even at “hand-

stitch” speeds.

•BALANCED MOTION of the new SINGER

301 prevents vibration.

• EASY STARTING — No coaxing necessary

— lightly press the knee or foot control and

your 301 starts to sew.

• SIMPLE THREADING — no complicated

diagrams are needed.

• REVERSIBLE FEED for sewing either in a

forward or backward direction — easy to back

tack and to fasten ends of seams.

• PREFOCUSED LIGHT illuminates work

ing area—prevents eye strain.

• CALIBRATED STITCH REGULATOR per

mits finger-tip control of stitch length.

• STITCHING GUIDES, with graduated

markings to guide seam width and turn square

corners.

• VERSATILE — use it as a portable or cab

inet machine.

• EASY TO CARRY — convenient handle is

concealed in top of head.

• LIGHT WEIGHT — full-sized aluminum

head weighs only 16 pounds.

Page 3

• SELF-SETTING NEEDLE makes it impos

sible to insert needle incorrectly in clamp.

• FEED THROW-OUT DEVICE permits darn

ing and embroidering without attachments.

• RECESSED BOBBIN WINDER—equipped

with automatic stop — it can’t break or tangle

your thread.

• HINGED BED EXTENSION permits quick

and easy removal of bobbin.

ELECTRICAL INFORMATION

• HINGED FACE PLATE—Simplifies clean

ing and oiling.

• DIAL TENSION takes the guess work out

of upper tension setting.

• FLEXIBLE SPOOL PINS — bend but do

not break—thread unreels smoothly and easily.

•COMPLETELY ENCLOSED motor and

principal working parts insure maximum

safety.

The SINGER"^ electric motor

in your sewing machine is furnished for oper

ation on an alternating current of 110-120

volts, 25 to 75 cycles, or on 110-120 volts

direct current. Special motors can be provided

through your SINGER SEWING CENTER

for direct or alternating current for any volt

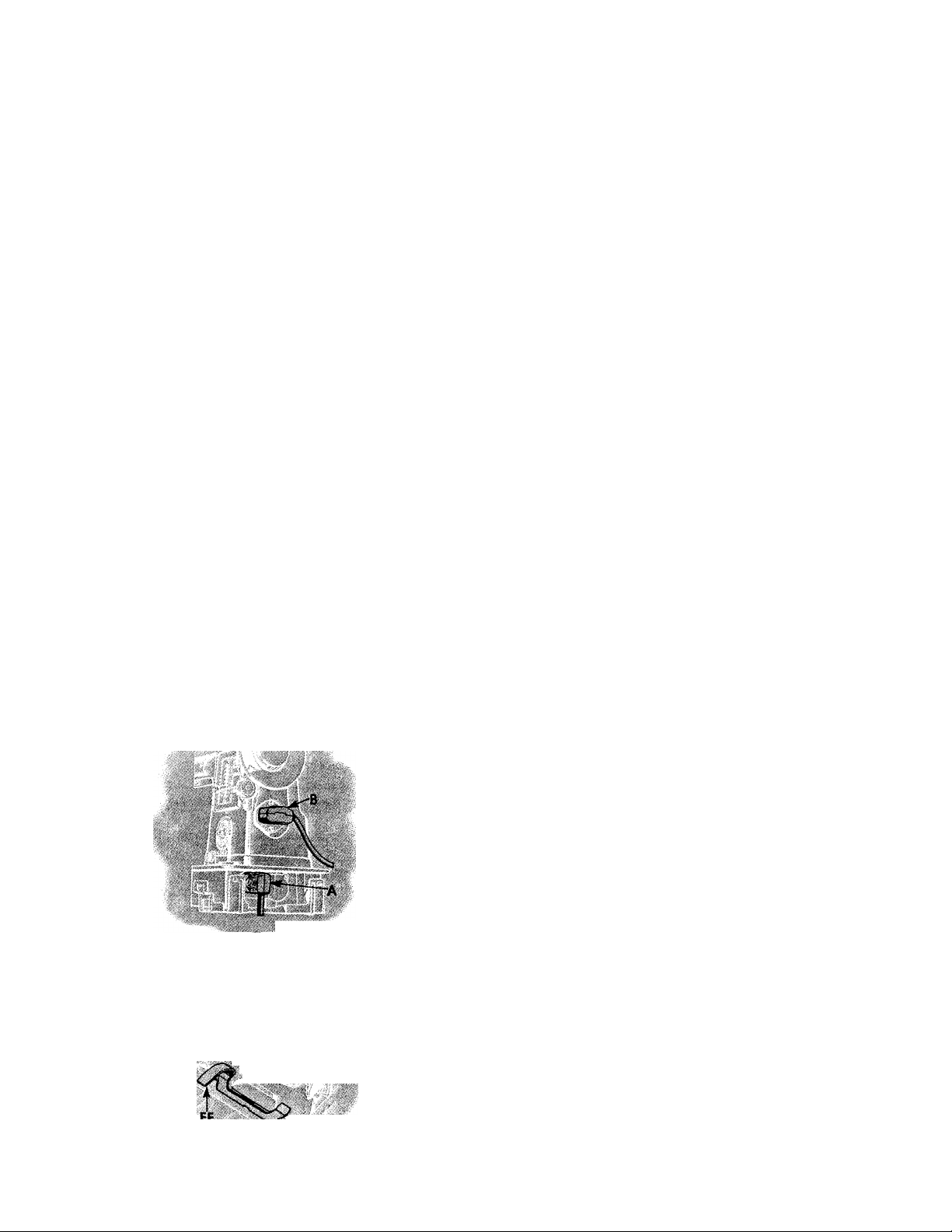

ELECTRICAL CONNECTIONS FOR MACHINE

Push 2-pin terminal plug A, Fig. 1 on 2-pin terminal block at

right end of bed.

Push 3-pin terminal plug B, Fig. 1 on 3-pin terminal block at

right of machine and connect plug at other end of cord to

electrical outlet.

age between 20 and 250, and for 32 volts

direct current.

Before Inserting Electric Plug—

be sure that the voltage and the number of

cycles stamped on the motor nameplate are

within the range marked on your electric

meter installed by your power company.

Fig, 1, Electrical Connections

for Machine

Fig. 2. Showing Latch for Releasing

Machine fron\ Cabinet

Speed Controller

The speed of machine is regulated by amount of pressure on

the pedal of the foot controller or the knee lever.

TO USE THE 301 as a portable machine

To remove the machine from the cabinet, disconnect the 3-pin

terminal plug B, Fig. 1, lift handle C, Fig. 3, raise bed ex

tension at left, depress latch FF, Fig. 2, and lift out machine.

Disconnect 2-pin terminal plug A, Fig. 1 and set machine

aside. Then remove controller from its holder in cabinet by

pulling it downward. With machine set on a suitable surface

near an electrical outlet, reconnect 2-pin and 3-pin terminals

and place foot controller on floor.

Page 4

HANDLE FOR CARRYING MACHINE

To use handle C, turn it up, as shown in Fig.

3, When not in use, turn handle down.

CAUTION: When you have finished your

sewing, always disconnect plug from electrical

outlet.

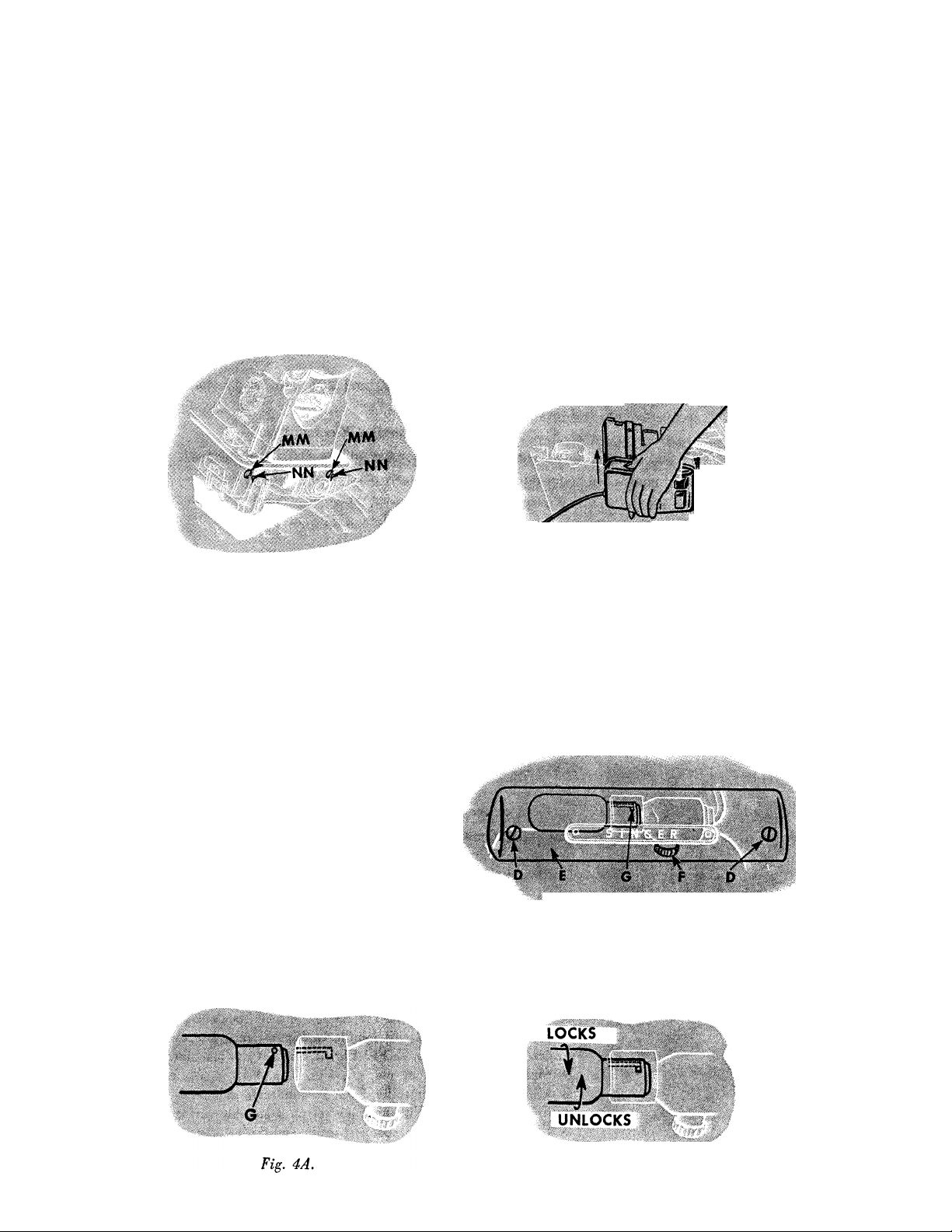

TO REPLACE MACHINE IN CABINET

Disconnect both terminal plugs. Grasping han

dle C, Fig. 3, place machine in cabinet so

that holes MM, Fig. 3A, fit over studs NN in

machine cradle. Press down on left end of ma

chine until latch

FF, Fig. 2, snaps into posi

tion to hold machine in place. Tilt back ma-

Fig. 3. Showing Handle for Carrying Machine

chine with cradle, install controller in side of

cabinet as shown in Fig. 3B, then connect

2-pin terminal. Lower machine to sewing posi

tion and connect 3-pin terminal.

Fig. 3A.To Replace Machine in Cabinet

LIGHT

The Light is turned, “on” or “off” by the

switch F, Fig. 4.

To Remove Bulb. Remove two screws D and

lamp cover E. Do not attempt to unscrew bulb.

Press it into socket and at same time turn bulb

over in direction shown in Fig. 4B to unlock

bulb pin G, then withdraw bulb.

To Replace Bulb. Press new bulb into socket

with bulb pin G, Fig. 4A entering slo jf

socket and turn it over in direction show in

Fig. 4B to lock bulb pin G in position. Replace

lamp cover E and securely fasten it in position

with two screws D.

Fig. SB. Replacing Controller in Cabinet

Fig. 4. Replacing the Bulb

Fig. 4B.

Page 5

NEEDLES AND THREAD

For perfect stitching, thread should be selected

according to fabric to be stitched and needle

must be correct size for thread which must

pass freely through eye of needle.

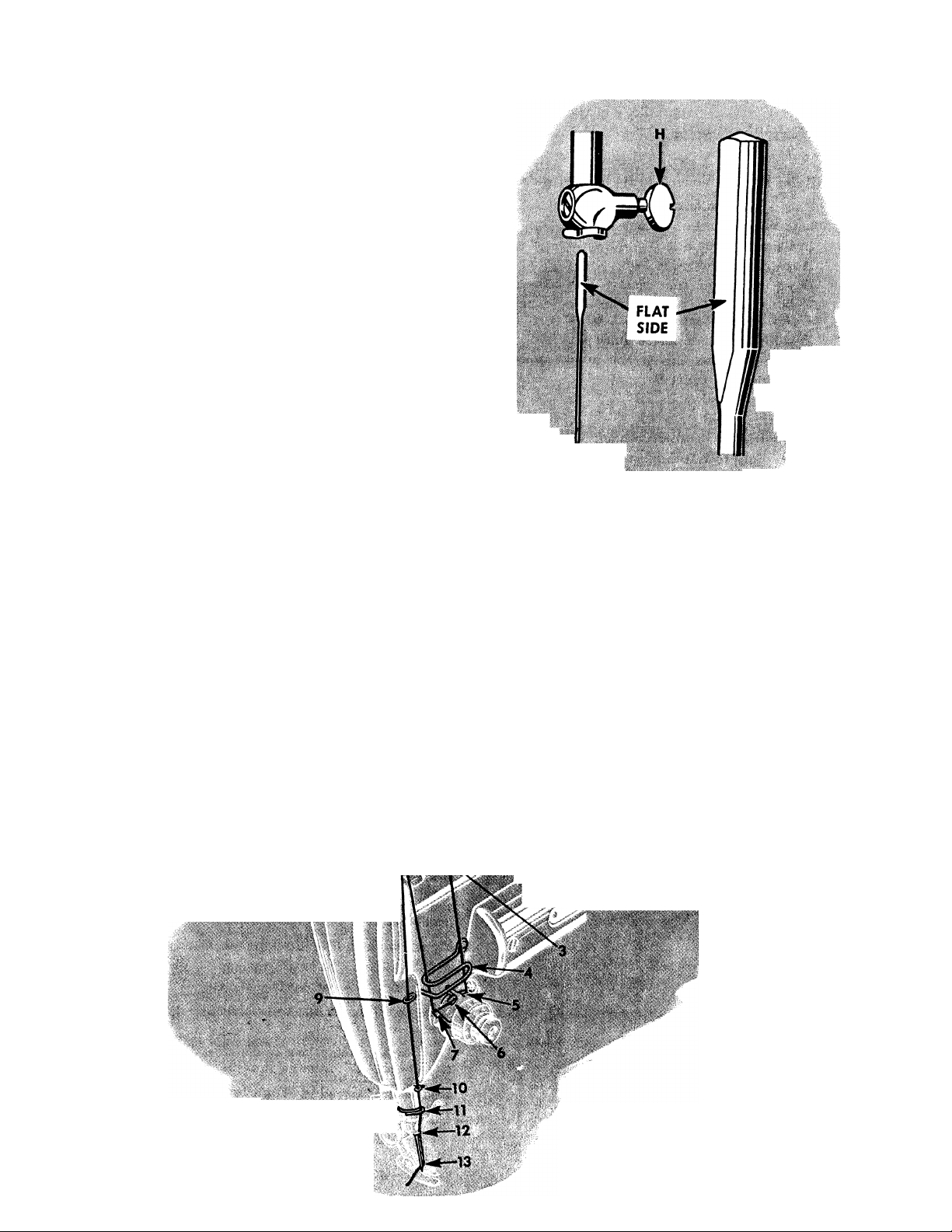

TO SET THE NEEDLE

Select correct needle according to table on

page 70. Be sure that needle is not blunt or

bent. Raise needle bar to its highest position

and loosen thumb screw H in needle clamp.

Push needle with its flat side to left up into

needle clamp as far as it will go, then tighten

thumb screw. As the needle is self-setting, it

cannot be inserted incorrectly in the needle

clamp.

Fig, 5. Setting the Needle

V

V

r '

iO

7‘" d ‘ '

s-' '-/I /1 'f • .

-t V ^ . I.f ,

Fig. 6. Upper Threading

Page 6

11

UP1»ER THREADING

See Figs. 6 and 7

Raise take-up lever 8 to its highest point.

Place spool of thread on spool pin 1

Lead thread into thread guide 2

Into thread guide 3

Down into thread guide 4

Down, under and from right to left between tension discs 5

Hold spool tightly and pull thread up against take-up spring

7 until it enters retaining fork 6

Pass thread up into thread guide 4

From right to left through hole in take-up lever 8

Down through eyelet 9

Into wire thread guide 10

Into wire thread guide 11

Into guide 12 on needle clamp

From right to left through eye of needle 13.

Draw about two inches of thread through eye of needle.

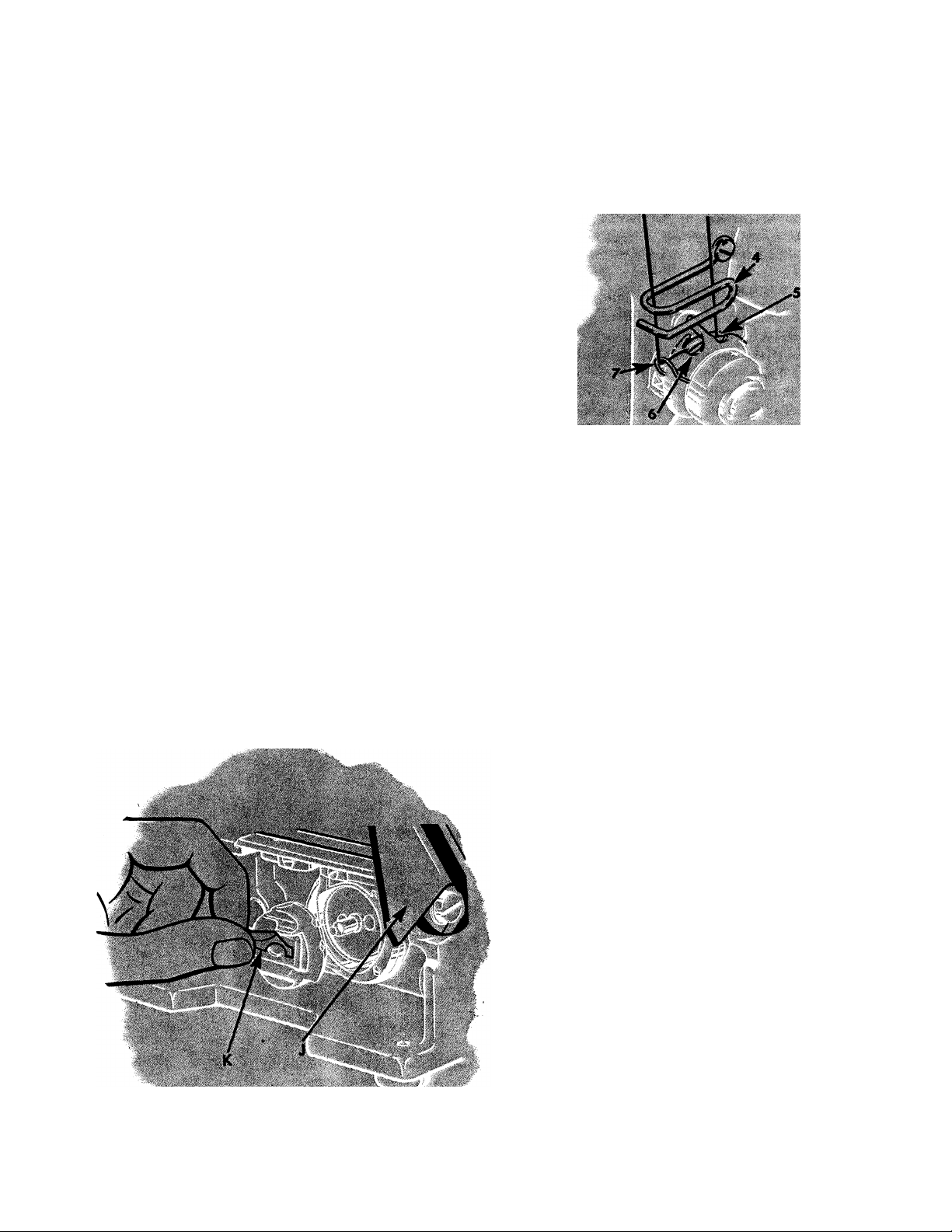

Fig. 8. Removing the Bobbin Case

12

TO REMOVE THE BOBBIN

Raise needle to its highest point.

Raise bed extension J. Grasp bobbin case latch

K and lift out bobbin case. Release latch and

remove bobbin.

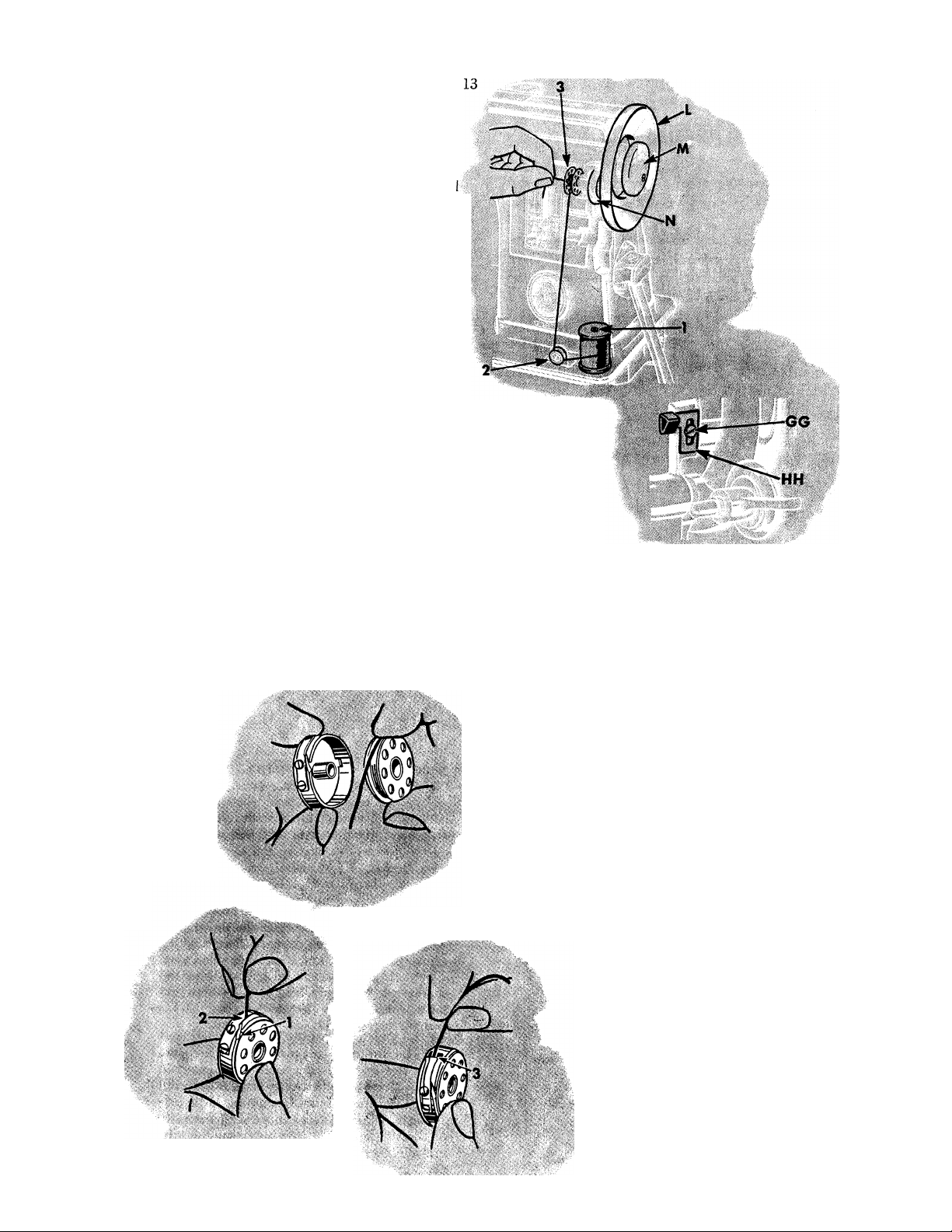

TO WIND THE BOBBIN

See Fig. 9 on the following page

To stop motion of needle, hold hand wheel L

and loosen knurled screw M by turning it over

toward you. Lift bobbin winder out of recess

and bring its pulley N into contact with hub of

hand wheel.

Place bobbin on bobbin winder spindle as far

as it will go.

Place spool of thread on spool pin 1.

Draw thread under and between tension discs

Pass thread through one of the holes in left

side of bobbin 3, from the inside.

Hold end of thread as shown in Fig. 9 and

press controller pedal as for sewing. End of

thread must be held until it is broken off.

Page 7

Allow tension discs to control flow of thread

so that it winds on bobbin in uniform, level

rows.

The bobbin winder will stop automatically

when the bobbin is filled. ^

Remove bobbin from spindle and return bob'

bin winder to its recessed position. Tighten

knurled screw M,

If bobbin does not wind evenly, loosen screw

which holds tension bracket 2 in position and

move bracket to the left if bobbin winds high

on the right; move bracket to the right if

bobbin winds high on the left. When bracket

is properly centered, thread will wind evenly

across bobbin.

If bobbin winds too fully, loosen screw GG,

Fig. 10 and move plate HH, downward,

slightly. To wind more thread on bobbin, move

plate HH, upward, slightly. Tighten screw

GG.

Bobbin can be wound while machine is sewing.

Fig, 9.

Winding the Bobbin

Fig, 10,

Adjustment for

Regulating

Amount of Thread

Wound on Bobbin

Fig. 12

14

Fig.11

TO THREAD BOBBIN CASE

Hold bobbin so that thread will unwind in

direction shown in Fig. 11.

Hold bobbin case as shown in Fig. 11, and

place bobbin into it.

Fig. 13

Pull thread into slot 1, under

tension spring 2 and into slot

3 at end of spring. Allow

about three inches of thread to

hang free from bobbin case.

Page 8

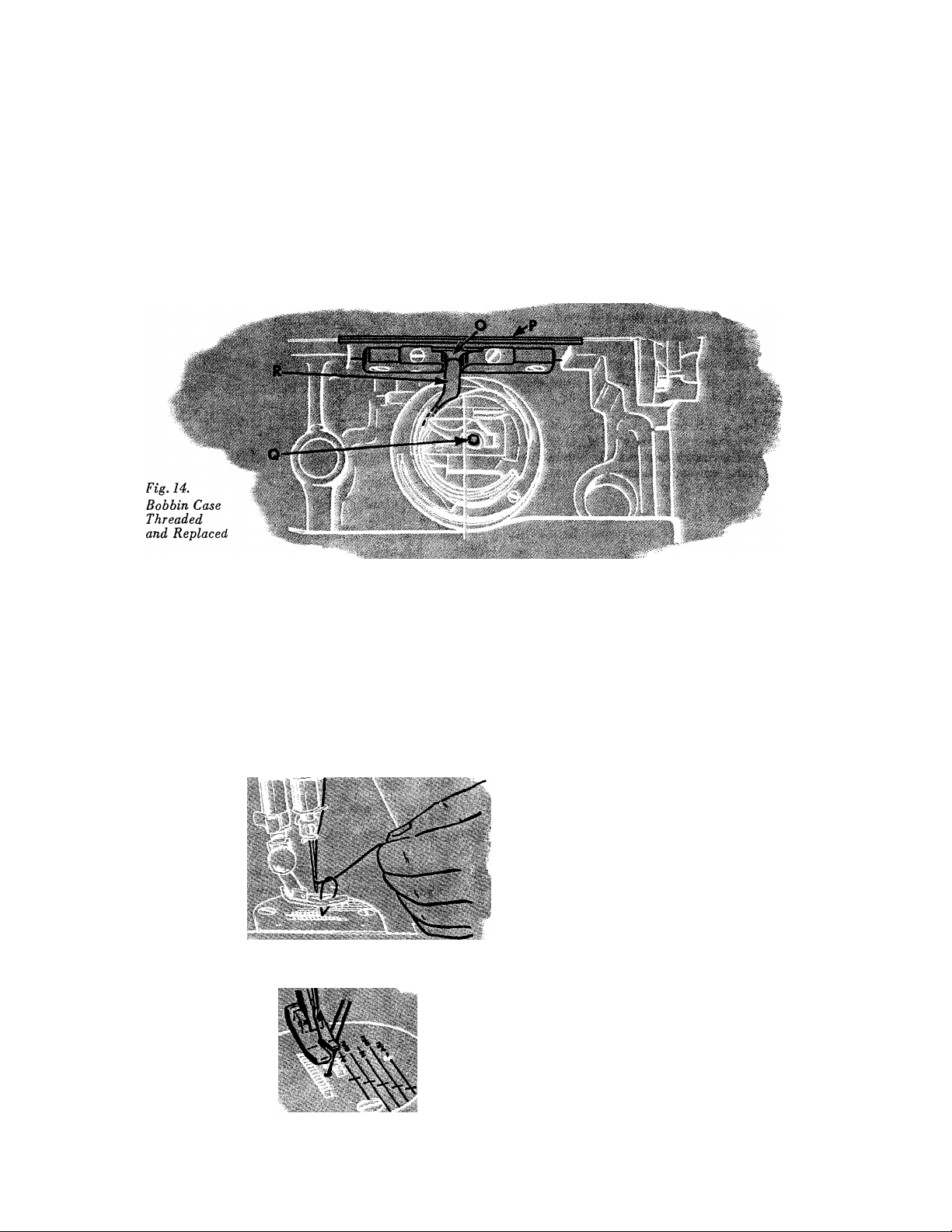

TO REPLACE BOBBIN CASE

15

Hold bobbin case by latch and place it on stud

Q, having thread draw from top of bobbin

case.

Release latch and press bobbin case back until

latch enters groove in stud. Allow about three

inches of thread to hang free from bobbin case

and turn down bed extension.

CAUTION:

If throat plate P is removed for cleaning stitch

forming mechanism, etc., make certain,

when replacing throat plate, that position

finger R, Fig. 14 of bobbin case base enters

notch O, Fig. 14 of position plate attached

to underside of throat plate.

Fig. 15, Drawing Up Bobbin Thread

Fig. 16. Threads in Position to Start Seiving

16

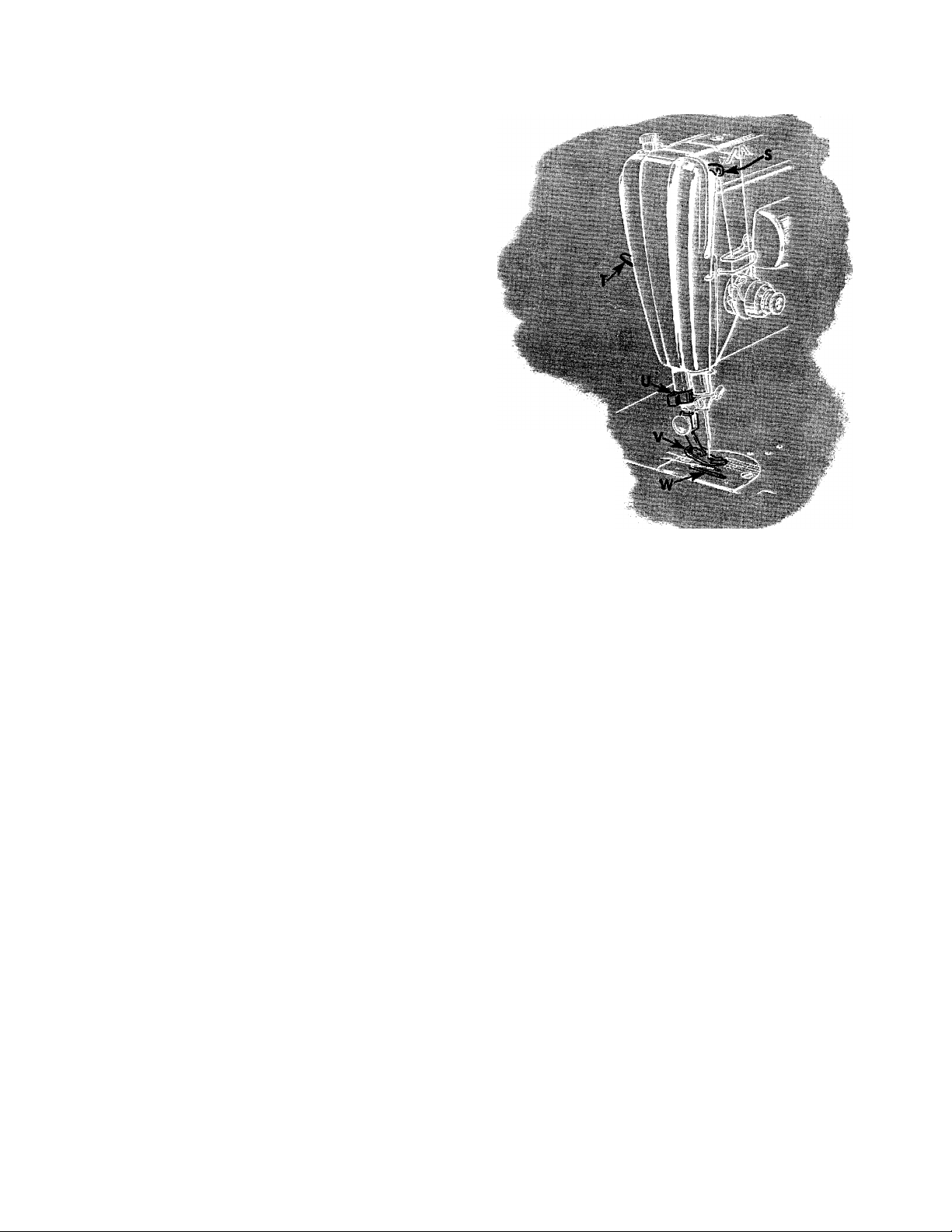

TO PREPARE FOR SEWINO

Hold end of needle thread with left hand and

turn hand wheel over toward you until needle

goes down and up again and thread take-up

lever S, Fig. 17 is at its highest point. Pull

up needle thread and bobbin thread will come

with it, as shown in Fig. 15.

Lay both threads back under the presser foot,

diagonally across the feed, as shown in Fig.

16, to the right or left, depending upon which

side of the needle the material is to be located,

so that when the presser foot is lowered, the

threads will be firmly held between the feed

and the presser foot.

NOTE: On the throat plate, there are distinct

markings to guide the edges of seams and

hems. These markings are at 1/8" intervals

from 1/4" to 3/4" in distance from the right

of the needle, and assist in guiding the fabric

uniformly. The crosslines on the throat plate

indicate the point at which to pivot on the

needle when turning square corners.

Page 9

TO START SEWING

Be sure to have thread take-up lever S

at its highest point.

Place material beneath presser foot V, turn

hand wheel to bring point of needle into fab

ric, then lower presser foot by means of

presser bar lifter T and start to sew. Press con

troller pedal to start machine. The speed de

pends upon amount of pressure on controller

pedal.

Most materials require only guiding for best

sewing results. However, the miracle fabrics

such as nylons, dacrons, orlons, blends with

various rayons, puffed weaves, sheers, jerseys

and tricots, which, by their nature, require light

pressure, also require support in the form of

holding the material taut at the back and front

of the needle as the needle enters the fabric.

This support assures a smooth, even seam.

Never pull the material when sewing.

The machine will sew its own thread when

sewing from one piece of material to another.

However, avoid operating a threaded machine

with presser foot up and without fabric under

the foot.

17

Fig, 17

S. Thread Take-up

Lever

T. Presser Bar Lifter

U. Thread Cutter

V. Presser Foot

W. Feed Dog

TO TURN A CORNER

Pivot on the eye of the needle. Stop machine

when needle is in this position. Raise presser

foot and turn work as desired, then lower

presser foot and resume sewing.

BASTING

The longest stitch, No. 6 on stitch regulator,

adjusted by lever Y, Fig. 18 is found satis

factory for basting. These basting stitches are

easily removed by clipping every sixth stitch

and withdrawing the long continuous thread.

Machine basting is firmer, more even and

much quicker than hand basting.

18

TO SEW BIAS SEAMS

Use a shorter stitch when sewing bias or

curved seams to increase the elasticity of the

seam and to prevent seam failure under strain.

No change in tensions is required.

TO REMOVE THE WORK

Stop machine with thread take-up lever

S, Fig. 17 at its highest point.

Raise presser foot, draw fabric back and to left

and sever threads on thread cutter U, Fig. 17.

Place ends of threads under presser foot, as

shown in Fig. 16.

Page 10

19

TO REGULATE LEtIGTH OF STITCH

The machine is adjustable to make from 6 to

30 stitches per inch, as indicated by numerals

on stitch indicator plate X.

To change length of stitch, turn thumb screw

on stitch regulator lever Y, away from the

stitch indicator plate X, as far as necessary.

Then move the stitch regulator lever until it

is in line with the desired number of stitches

Fig. 18.

Showing Lever for

Regulating Length

of Stitch and

Reversing Direction

of Feed

to the inch and turn the thumb screw inward

only until it touches the stitch indicator plate.

The machine will now make the indicated num

ber of stitches to the inch in either a forward

or reverse direction, depending on whether the

lever Y is at its lowest or highest position.

TO REGULATE DIRECTION OF FEED

To feed the material from you, push down

the stitch regulator lever Y, as far as it will go.

To feed the material toward you, raise the

stitch regulator lever Y, as high as it will go.

The direction of feed can be reversed at any

point of a seam without removing work from

machine.

The reverse feed makes it easy to “back stitch”

and to fasten ends of seams.

Fig. 19. Thumb Screw for Regulating

Pressure on Presser Foot

i Fig. 20. Perfect Stitching

sfig. 21. Imperfect Stitching

Fig. 22. Imperfect Stitching

20

TO REGULATE PRESSURE ON PRESSER FOOT

For average materials, the pressure of the presser foot seldom

requires changing. Heavy materials require more pressure than

lightweight fabrics. The pressure should be only heavy enough

to prevent side creeping of material and still obtain a uniform

length of stitch. To increase pressure, turn thumb screw Z clock

wise or downward. To lighten pressure, turn thumb screw so

that it screws upward.

THREAD TENSIONS

For perfect stitching, the tension on needle and bobbin threads

must be heavy enough to pull threads to center of thickness of

material and make a firm stitch, as shown in Fig. 20.

Needle Thread lies straight along top side of material, caused

by too heavy tension on needle thread or too light tension on

bobbin thread, as shown in Fig. 21.

Bobbin Thread lies straight along underside of material, caused

by too light tension on needle thread or too heavy tension on

bobbin thread, as shown in Fig. 22.

Page 11

21

TO REGULATE NEEDLE THREAD TENSION

The tension on needle thread can be tested

only when presser foot is down.

The numerals “0 to 9”

on dial D, Fig. 23 in

dicate different degrees

;y| of tension that can be

3o b t a i n e d.

The num

bers do not denote size

of thread or ounces of

tension.

NeedLe I firead 1 ension ,

J 'T • When tension has been

correctly set as de

scribed on pages 23 and 24, note number at

indicator line G so that this setting may be

regained should the tension be altered for

special work.

To increase tension, turn thumb nut B

gradually to right (clockwise) until required

tension is obtained. Each higher number de

notes increased tension.

To decrease tension, turn thumb nut B

gradually to left (counter-clockwise) until re

quired tension is obtained. Each lower num

ber denotes less tension.

The tension indicator G is marked with the

signs -f- and —, which indicate the direction

in which to turn the thumb nut B for more

or less tension.

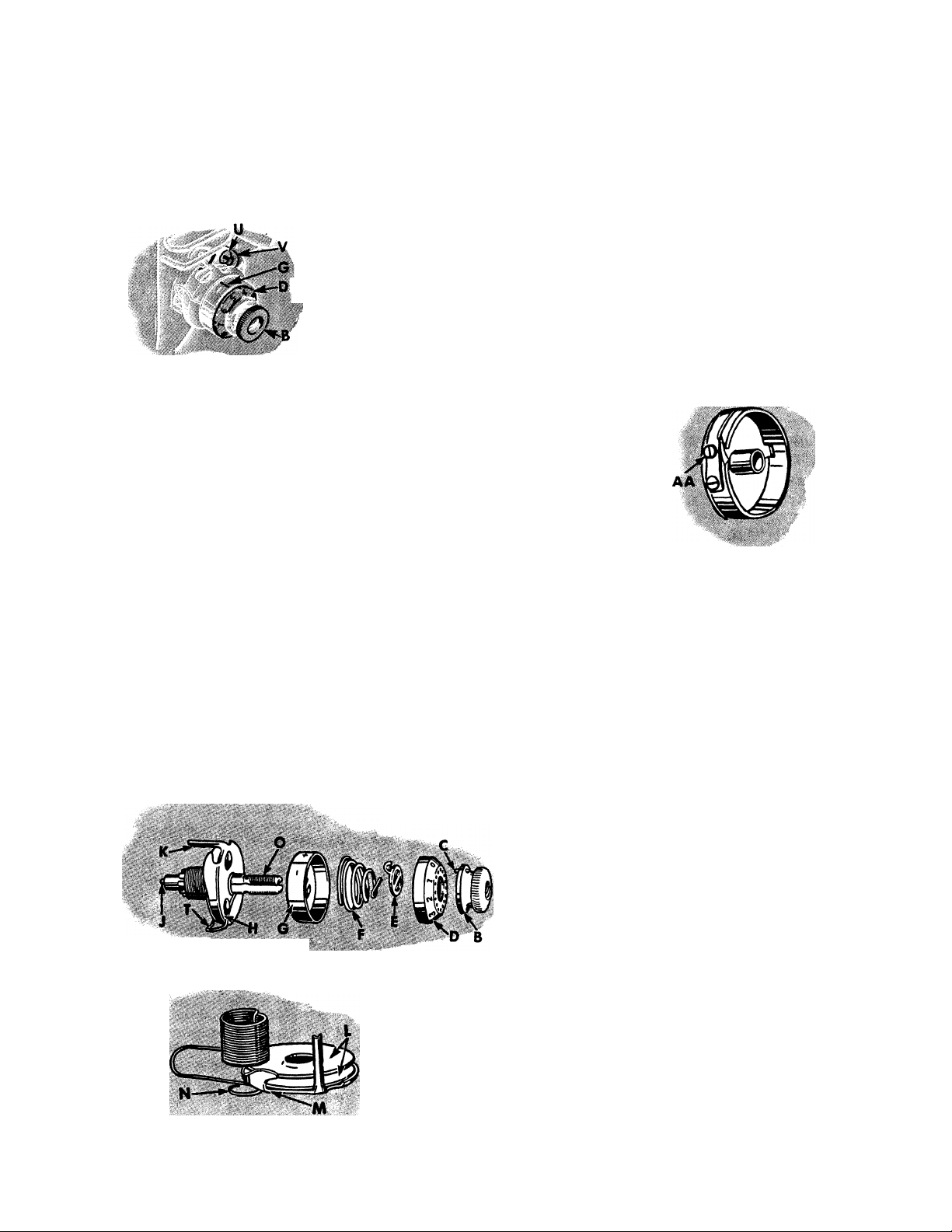

TO REGULATE BOBBIN THREAD TENSION

The tension on bobbin thread is regulated by

screw AA, Fig. 24 which is nearest center of

tension spring on outside of bobbin case. To

increase tension, turn screw AA over to right.

To decrease tension, turn

this screw over to left. ^

When tension on bobbin

thread has been once prop

erly adjusted, it is seldom

necessary to change it, as a

correct stitch can usually be

obtained by varying tension

on needle thread.

Fig. 24. Bobbin Thread Tension

TO REMOVE AND DISASSEMBLE NE 4.E THREAD TENSION

Turn thumb nut B to left (counter-clockwise) until ‘‘O” on

numbered dial stops at cente** bne on indicator G.

Fig. 25. Needle Thread Tension Disassembled

TO REASSEMBLE AND REPLACE NEEDLE THREAD TENSION

Make sure that tension releasing pin J is in place in stud O.

Place two tension discs L with their convex faces together on

tension thread guide M, then pass eyelet N of thread take-up

spring under thread guide, having coils of spring above ten

Fig. 26. Tension Disc Assembly

sion discs, as shown in Fig. 26.

22

To separate pin C in thumb nut B from dial

D, press in dial, unscrew thumb nut and re

move it. Then remove dial, stop washer E,

tension spring F, indicator G and tension

assembly H.

NOTE: It is not necessary to remove stud O

from machine to disassemble the thread ten

sion. It is shown removed in Fig. 25, only

to illustrate the complete assembly.

Page 12

23

Place tension disc assembly on stud O so that extension K

enters hole in machine and tail (inside the coil) of thread takeup spring enters one of grooves in the stud. Next replace indica

tor G, open side out, on stud with plus and minus signs at top

and hold parts, thus assembled, against shoulder of stud. Then

insert tension spring

F in indicator with first (half) coil of

spring straddling lower half of stud. Place stop washer E on

stud with extension S above stud. If spring and stop washer are

in correct position, extension S will clear first (half) of tension

spring, as shown in Fig. 28.

Next, place dial D on stud with No. 2 opposite stop washer ex

tension S, then push dial to compress tension spring and at the

same time screw thumb nut B on stud, inserting pin C on nut

in one of the holes in dial D. Then lower presser bar and turn

thumb nut B to left until on dial D stops at centerline on

indicator G. Thread the tension and pull thread through tension

discs to test amount of tension on thread at the position.

At this point there should be a slight pull on the thread to in

dicate that there is a minimum tension which gradually in

creases with the turning of thumb nut B to the right, provid

ing a full range of tensions with one revolution of the thumb nut.

Fig. 27. Reassembling

Needle Thread Tension

Fig. 28. Stop Washer and Tension Spring

If the pull is too strong for a minimum ten

sion, press in dial D to disengage pin C on

nut from dial, and reset pin in one of holes at

left of previous setting. This resetting will pro

duce less tension at ^^O.” Repeat this process

until minimum desired tension is obtained.

If there is no tension at press in dial D

and reset pin C on nut in one of holes at right

of previous setting, repeating this process until

a slight minimum tension is obtained.

The tension on thread take-up spring T and

stroke of this spring should be just sufficient

to take up slack of needle thread until eye of

needle reaches goods in its descent.

To adjust tension on thread take-up spring T,

remove tension disc assembly, disengage end

of spring from groove in tension stud, revolve

spring and place its end in the groove which

produces correct tension.

For average weights of materials, the stroke of

thread take-up spring T should release the

thread after the needle point has entered the

24

fabric, i.e., halfway between the point and eye

of the needle. To regulate stroke, loosen screw

U, Fig. 23 and turn the thread take-up spring

regulator V, Fig. 23 until correct stroke is ob

tained, then tighten screw U.

IF CORRECT STITCHING IS NOT OBTAINED

If bobbin thread tension has been disturbed,

or a correct stitch cannot be obtained without

a very heavy or very light needle thread ten

sion, the following procedure is recommended.

Using Size 50 Mercerized thread in needle and

on bobbin, adjust needle thread tension as in-

' striicted on page 23. Then turn tension thumb

nut until No. 4 on dial is opposite centerline

on indicator and, with two thicknesses of thin

material in machine, adjust bobbin thread ten

sion, as instructed on page 21, until stitch is

correctly locked in material, as shown in

Fig. 20.

A wide range of materials and threads can now

be accommodated without further adjustment

of bobbin thread tension.

Page 13

25

Page 14

Page 15

26

TO OIL THE MACHINE

If the machine is used continuously, it should

be oiled daily. If moderately used, an occa

sional oiling is sufficient.

Apply one drop of oil at each of the places inindicated by arrows in Figs. 29, 31, 32 and 33.

To Lubricate Spiral Gears

About once a year, take out two screws W,

Fig. 29, remove cover X, Fig. 29 and apply

a small quantity of lubricant to spiral gears Y

and EE, Fig. 30, then replace cover X and

fasten as before with screws W.

Never apply oil to these gears.

Fig, 30, Lubricating Points for Spiral Gears

JJJ 7* nn / ]\/I rt 1 rt rt

Swing face plate to left and oil the places in

dicated by arrows in Fig. 31, then close face

plate.

To Oil Sewing Hook

Occasionally apply a drop of oil to bobbin

case base bearing in sewing hook indicated in

Fig. 32.

27

OIL

Fig. 32. Oiling Point in Sewing Hook

Fig. 31. Face Plate Opened Shoiving Oiling Points

Page 16

28

Remove machine from cabinet as instructed on

Page 6, and then turn machine over on its rear

side. Remove thumb nut from screw BB, Fig.

33 being careful not to lose felt washer, and

remove large cover from underside of bed. Oil

each of places indicated by arrows in Fig. 33,

SEWING SUGGESTIONS

Breaking of Needles Might be Caused by:

1. Improper Size of Needle for Thread and

Material—See Page 70.

2. Needle Bent.

3. Pulling of Material when Stitching.

4. Needle Striking Improperly Fastened

Presser Foot or Attachments.

5. Crossing Too Thick Seams with Too Small

a Needle.

and occasionally apply a small quantity of

lubricant to teeth of gears CC, then replace

cover and felt washer and fasten as before

with thumb nut (not too tightly).

CAUTION:

The motor requires no lubrication.

29

7. Roughened Hole in Throat Plate.

8. Improper Arrangement of Thread to Com

mence Sewing—See Page 16.

Breaking of Bobbin Thread Might be

Caused by:

1. Improper Threading of Bobbin Case—See

Page 14.

2. Bobbin Thread Tension Too Tight—See

Page 21.

Breaking of Needle Thread Might be

Caused by:

1. A Knot in Thread.

2. Improper Threading—See Page 11.

3. Upper Tension Too Tight—See Page 21.

4. Needle not pushed up as far as it will go

into needle clamp—See Page 9.

5. Needle Blunt or Bent.

6. Thread Too Coarse for Needle—See

Page 70.

Skipping of Stitches Might be Caused by:

1. Needle not pushed up as far as it will go

into needle clamp—See Page 9.

2. Needle Blunt or Bent.

3. Needle Too Small for Thread—See

Page 70.

If Machine Runs Heavily after standing

idle for a long period, apply a few drops of

kerosene at all oiling places, run machine for

a few minutes, then wipe clean and oil—See

Pages 26, 27 and 28.

Page 17

30

FASHION STITCHES MADE

Remove the presser foot of your sewing ma

chine, and lower the feed. The design to be

followed may be stamped or marked on the

right or wrong side of the fabric, according

s.

CORDONNET STITCH

Threads:

Bobbin—“Cordonnet,” a fine silk gimp

thread.

Needle—Size A, silk of matching color.

Tensions:

Bobbin—Loosen H to M turn of screw

from normal.

Needle Thread—Tighten 1 to 2 points.

Needle:

Size 14 to accommodate size A silk.

Trace design on wrong side of fabric. Work

from center to edge of each circular motif.

WITHOUT ATTACHMENTS

to the stitch chosen. Place the work in em

broidery hoops, lower the presser bar, and

follow the design with the sewing machine

needle. Visit your local SINGER SEWING

CENTER for further help and advice.

Threads:

Both Needle and Bobbin carry regular

Tensions:

Bobbin—Loosen И to И turn of screw

Needle Thread—Tighten 3 to 4 points.

Needle:

Size 11 or 14 to accommodate needle

Trace design on right side of fabric. Hoops

are moved in circles resulting in bobbin

thread being drawn through the fabric in

radiating sparks for outlining or filling a

design.

SPARK STITCH

sewing thread; size A silk or mercerized

thread in sizes 50, 00 or 000.

from normal.

thread.

31

Threads:

Tensions:

Needle;

Trace design on wrong side of fabric, or

follow free hand heel and toe pattern.

METALLIC STITCH

Bobbin—Fine metallic gimp thread.

Needle—Size A, silk of matching color.

Bobbin—Loosen slightly from normal.

Needle Thread—Tighten one to two

points.

Size 14 to accommodate Size A silk.

i'hreads:

Tensions:

Needle:

Trace design on right side of fabric. 0|)erate

machine at moderate speed while moving

hoops very slowly so that the bobbin ilnead

completely covers the nSedle thread in a

gimp-like fashion.

SIGNATURE ^STITCH

Both Bobbin and Needle carry regular

sewing thread ; size A silk or mercerized

thread in sizes 50, 00 or 000.

Bobbin—Loosen И to И turn of screw

from normal.

Needle Thread—Tighten 2 to 3 points.

Size 11 or 14 to accommodate needle

thread.

Threads:

Tensions;

Needle:

Trace design on right side of fabric. Operate

the machine at a moderate and uniform

speed, while coordinating with it the even

movement of the hoops to produce short,

regular stitching.

ETCHING STITCH

Both Bobbin and Needle carry regular

sewing threads.

Regulate to form an evenly locked stitch

as in regular sewing.

Selected to accommodate the needle

thread.

Threads:

Bobbin—Pearl Cotton ,^8, single and

Needle—Size A, silk, or size 50 mercerized

Tensions:

Bobbin—Loosen Yi to M turn of screw

Needle Thread—Tighten 1 to 2 points.

Needle;

Size 14 to accommodate needle thread.

Trace design on wrong side of fabric. The

Bouclé Stitch is always a series of small

circles placed closely together to produce a

nubby textured solid design. An underlay of

organdy is often used on jersey or crepe

fabrics.

BOUCLE STITCH

2-ply yarns and similar threads.

thread.

from normal.

Page 18

32

PRESSURE REGULATING

THUMB SCREW-

THREAD TAKE-UP LEVER

FACE PLATE

PRESSER BAR LlFTER-^v'

THREAD TAKE-UP SPRING

NEEDLE THREAD TENSION

PRESSER BAR.

THREAD CUHER

PRESSER FOOT THUMB SCREW

PRESSER FOOT

BED EXTENSION

SPOOL PIN

THROAT PLATE

Fig. 34. Names of Principal Parts of Machine 301

HAND WHEa

liU-BOBBIN WINDER

STITCH INDICATOR

STITCH REGULATOR AND

FEED REVERSING LEVER

m BOBBIN WINDER

SPOOL PIN

BOBBIN WINDER

THREAD TENSION

33

.' -re'--

INSTRUCTIONS FOR USING ATTACHMENTS

..Jÿ-V-V;

man«

‘ -V ■

Page 19

THE FOOT HEMMER

The foot hemmer may be used for hemming

edge of material, making hemmed and felled

seams and for hemming and sewing on lace in

one operation.

To Attach Foot Hemmer

Raise needle to its highest point, remove

presser foot and attach foot hemmer to presser

bar in place of presser foot.

34

Fig. 35. Foot Hemmer

Pull up bobbin thread as instructed on page

16.

1. Fold edge of material twice, about 1/8 inch

each time, for a distance of about two inches.

Crease folds.

2. Lay about three inches of needle and bob

bin threads back under hemmer. Place creased

edge of material under hemmer with end of

hem directly under needle. Lower hemmer and

tack end of hem with two machine stitches.

3. Raise hemmer. Pull threads and hem

slightly from you with left hand, then while

holding threads, draw material toward you

with right hand into scroll of hemmer until

tacked end is caught in hemmer, as shown in

Fig. 36.

4. Lower hemmer and commence to sew,

slightly pulling threads back while sewing.

Keep mouth of hemmer full to produce a

smooth, even hem, as shown in Fig. 37.

35

Fig. 36. Starting Hem at Very End of Material

Fig. 37. Hemming Edge of Material and

Pulling Back Threads While Sewing

Page 20

Fig. 38. Making a Hemmed Seam (First Operation)

Fig. 39. Making a Hemmed Seam (Second Operation)

36

TO MAKE A HEMMED SEAM WITH FOOT HEMMER

1. When making this seam, the garment must

first be fitted and edge of material trimmed,

allowing for about 1/8 inch seam. Insert the

two edges of material, right sides together, in

hemmer in same manner as a single hem as

shown in Fig, 38. If material is bulky, place

edge of upper piece of material about 1/8 inch

to left of edge of under piece.

2. The free edge of hemmed seam may be

stitched flat to garment, if desired. To do this,

open work out flat, wrong side up, then insert

hem in scroll of hemmer, holding edge of hem

in position while it is being stitched. If seam

is stitched flat to garment, one row of stitching

is visible on the right side.

TO MAKE A FELLED SEAM WITH FOOT HEMMER

1. Place right sides of material together, hav

ing edge of upper piece about 1/8 inch to left

of edge of under piece. Stitch the two pieces

together, using hemmer as a presser foot.

Guide both pieces by the projecting toe of

hemmer, as shown in Fig. 40.

2. Open work out flat, wrong side up, and

hem free edge of seam, stitching it flat to gar

ment as shown in Fig. 41.

Fig. 41. Making a Felled Seam (Second Operation)

37

Fig. 40. Making a Felled Seam (First Operation)

Page 21

38

TO НЕМ AND SEW ON LACE IN ONE OPERATION

1. Start hem in the regular way.

2. Hold hem in position with needle.

3. Raise presser bar and insert edge of lace in

slot of hemmer and back under hemmer.

4. Lower presser bar and commence sewing,

catching edge of lace with needle.

5. Guide hem with right hand and lace with

the left, being careful not to stretch lace as it

enters hemmer.

.. .............

Fig, 42, Hemming and Sewing on Lace

...............

................

adjustable hemmer

To Make Hems from 3/16 to 15/16

Inch Wide

1. Attach adjustable hemmer to presser bar

in place of presser foot,

2. Pull up bobbin thread, as instructed on

page 16.

3. Loosen thumb screw on hemmer and move

scale until pointer registers with number of

desired width of hem, No. 1 indicating nar

rowest hem and No. 8, the widest, then tighten

thumb screw.

4. Place cloth in hemmer and draw it back

and forth until hem is formed, as shown in

Fig. 43.

5. Draw end of hem back under needle, lower

presser bar and commence to sew.

6. Guide sufficient cloth into hemmer to turn

hem properly.

Fig. 43. Showing How Adjustable Hemmer is Used for

Making Hems up to 15/16 Inch ¡Fide

Page 22

Fig, 44. Showing How Adjustable Hemmer is Used for

Making Hems Wider than 15/16 Inch

40

ADJUSTABLE HEMMER

To Make Hems Wider than 15/16 Inch

1. Loosen thumb screw on hemmer, move

scale to right as far as it will go, then swing

it toward you, as shown in Fig. 44, and

tighten thumb screw.

2. Fold and crease desired width of hem.

3. Place fold under extension at right of hem

mer and edge into folder, as shown in Fig. 44.

4. Draw end of hem back under needle, lower

presser bar and commence to sew.

5. Guide cloth to keep hem flat.

MULTI-SLOTTED BINDER

The multi-slotted binder will apply unfolded

bias binding 15/16 inch in width and com

mercial folded binding in sizes 1, 2, 3, 4

and 5 to the seams or to the edges of garments.

These sizes of folded binding are 1/4, 5/16,

3/8, 7/16 and 1/2 inch in width, respective

ly, and are fed through slots of corresponding

sizes in the binder scroll. See Fig. 45. Bind

ing may be purchased in a variety of materials

and colors.

For convenience in determining the correct

width of unfolded binding (15/16 inch),

this measurement is marked on the binder, as

shown in Fig. 45. .

The two upright guide pins shown in Fig. 45

eliminate manual guiding of the binding.

The wide range of bindings that can be applied

with this binder makes it useful for a large

41

ADJUSTING

LUG

OUTSIDE

SLOTS FOR

DIFFERENT

WIDTHS OF

FOLDED

BINDING

Fig. 45. Multi-Slotted Binder 160624

7Z

EDGE GUIDE

FOR PIPING

SCROLL FOR

UNFOLDED

BINDING

ONLY

variety of work. It will be found particularly

advantageous for making children’s wear, lin

gerie, summer dresses, and other dainty

articles which call for the narrower bindings.

CENTER SLOT

OF SCROLL

GUIDE

PINS

Page 23

As two different widths of bindh-g of contrast

ing color can be fed through the binder at

the same time, attractive binding and piping

effects can be produced in one operation.

TO ATTACH THE BINDER

Raise needle to its highest position, then attach

binder to presser bar in place of presser foot.

See that needle enters center of needle hole.

CAUTION: When this binder is used, do not

raise hinged extension of cloth plate high

enough to strike binder, as this would tend

to distort and damage binder. Before storing

machine, binder must be removed to avoid

damage.

TO INSERT BINDING IN BINDER

Cut all binding to a long point to the left, as

shown in Fig. 46.

Folded Bias Binding must be inserted in

slot or slots of corresponding sizes. See Fig.

49.

42

Unfolded or Raw Edge Bias Binding

must be inserted in open end of scroll. See

Fig. 47.

After inserting pointed end of binding in

binder, push it through until full width of

binding is under needle.

Guide binding by means of two upright pins,

as shown in Figs. 47 and 49.

TO INSERT GARMENT IN BINDER

Place edge to be bound as far to the right as

it will go in center slot of scroll, as shown in

Fig. 47, and draw it back under binder foot.

Lower binder by means of presser foot lifter

and commence to sew. Keep material well

within center slot of scroll so that edge will .

be caught in binding.

TO ADJUST BINDER

To bring the inner edge of the binding closer

to stitching, move scroll C2, Fig. 47 to right

by means of lug B2, Fig. 47. This is the usual

adjustment when binding straight edges.

When binding curves, move scroll to left to

bring inner edge of binding farther from

stitching and allow for sweep of curve.

43

Fig. 47. Binding with Unfolded Bias Binding

Page 24

44

PIPED EDGE

To produce a piped edge on garments, move

lug B2, Fig. 48 to left to bring stitching

about midway of folded binding.

Fig. 48. Positions of Garment and Binding when Piping Edges

Crease raw edges of

garment toward wrong

side about 1/8 inch,

and insert folded edge,

/v raw edges uppermost,

into edge guide on

binder and

beneath

binding.

When stitched, both

sides of garment will

be finished, and right

side will show piped

edge.

PIPING AND BINDING IN ONE OPERATION

A garment can be piped and bound in one

operation, as shown in Fig. 49.

IMPORTANT : When piping and binding at

the same time, as shown above, insert nar

rower width of binding first in its slot, then

insert wider width in its slot. Two consecu

tive widths should not be used at the

same time. That is, if No. 1 is used, the wider

binding should not be smaller than No. 3. If

No. 2 is used, the wider binding should not

be less than No. 4. Never use Nos. 1 and 2,

or 2 and 3, etc., together.

Use upright guide pins to guide the wider of

the two widths of binding as shown in Fig.

49.

Fig. 49. Piping and Binding in One Operation

45

Page 25

Fig. 50. Binding on Outside Curve

46

TO BIND OUTSIDE CURVES

Allow edge to be bound to pass freely through

scroll without crowding against scroll wall.

The material must be guided from back of

binder and to left, permitting unfinished edges

to swing naturally into scroll of binder.

Never pull binding while it is being fed

through binder, as this may stretch binding,

making it too narrow to stitch or to turn in

edges.

When binding curves, turn material only as

fast as machine sews.

Do not push material in too fast as this will

pucker the edge.

Do not stretch material as this will distort

edge so that curve will not have proper shape

when finished.

If stitching does not catch edge of binding,

adjust scroll slightly to left.

TO BIND INSIDE CURVES

When binding an inside curve, straighten out

inside edge of material while feeding it into

binder, being careful not to stretch material.

Soft materials like batiste or crepe de chine

require a row of stitching added close to edge

of curve before binding.

TO APPLY FRENCH FOLDS TO CURVES

Place material under binder and stitch binding

onto face of material, as shown in Fig. 51.

For guidance in applying rows of French

folds, mark material with a line of basting

stitches or with chalk or pencil.

47

Fig. 51. Applying a French Fold

Page 26

48

THE EDGE STITCHER

This attachment should be used when the stitching must be

kept accurately on extreme edge of material. It is also useful

for sewing together laces, insertions and embroideries, sewing

in position hemmed or folded edges, piping or sewing flat

braid to a garment.

To Adjust the Edge Stitcher

Fasten this attachment to presser bar in place of presser foot.

See that needle enters center of needle hole.

The distance from line of stitching to edge of material in slots

is regulated by moving lug D2, Fig, 52 to right or left.

w

To Insert Lace or Ribbon

1. Fold edge of material to which lace or ribbon is to be sewn

and insert it in slot 1 of edge stitcher.

2. Insert lace or ribbon in slot 4 of edge stitcher and proceed

to sew.

3. Cut away surplus folded material close to stitching.

To Pipe with Edge Stitcher

1. Cut piping bias and twice width of slot 3 so that it can be

folded once.

2. Insert piping with its folded edge to left in slot 3 and edge

to be piped in slot 4, Fig. 52.

To Apply Folded Bias Tape or Military Braid

1. Place garment under edge stitcher and tape in slot 1 or 4,

Fig. 52.

2. To make square corners, sew to turning point, remove tape

from attachment, form corner by hand, replace tape and con

tinue stitching.

3. To space two or more parallel rows, mark material with a

guide line, using a crease,^ chalk or basting thread.

To Sew Lace Together

!• Insert one of laces in slot 1 of edge stitcher and the other

in slot 4, Fig. 52.

2. Adjust lug D2 until edges to be joined are caught by stitch

ing.

3. Slightly overlap edges of lace while stitching to keep them

against ends of slots.

4. Loosen both thread tensions to avoid puckering of fine lace.

Fig. 53. Sewing Lace Together

49

Fig. 54. Setting in lerfitiwi

Fig. 55, Piping

with the

Edge Stitcher

Fig. 56. Applying Bias Folded Tape

Page 27

50

To Stitch a Wide Hem

1. A wide hem may be stitched evenly on

sheets, pillow slips, etc., with edge stitcher

after hem has been measured and the edge

turned.

2. Insert the edge in slot 5, Fig. 52, and

adjust lug D2 to stitch as close to the edge as

desired.

Tо Make a French Seam

1. To make a uniform width French seam,

insert two edges to be joined, wrong sides to

gether, in slot 1 or 2 and stitch close to edge.

2. Fold both right sides together and insert

back of seam in slot 1 and stitch, allowing

just enough margin to conceal raw edges.

Fig. 58. Making a French Seam

To Tuck with Edge Stitcher

The maximum width of tuck that can be made

with edge stitcher is 1/8 inch.

1. Fold and crease material for desired width

of tuck.

2. For succeeding tucks, fold material desired

distance from previous tuck, running fold

lengthwise over a straight edge, then crease

folds.

3. Insert creased folds in slot 1 and adjust

edge stitcher to right or left for desired width

of tuck. Use a light tension, short stitch and

fine thread and needle.

Fig. 59. Tucking ivith Edge Stitcher

51

Page 28

52

GATHERING FOOT

To Shirr with Gathering Foot

1. Fasten gathering foot to presser bar in

place of presser foot.

2. Place material under gathering foot and

stitch in usual way.

3. The fullness of shirring or amount of

gathering is regulated bv length of stitch. A

longer stitch increases fullness of gathers.

Fig. 60. Shirring with Gathering Foot

PRINCIPAL PARTS OF RUFFLER

A—Foot—attaches ruffler to presser bar.

B—Fork Arm—straddles needle clamp.

C—Adjusting Screw—regulates fullness of

gathers.

D—Projection—engages slots in adjusting

lever.

E—Adjusting Lever—sets ruffler for gath

ering or for ihaking a plait once at every six

stitches or once every twelve stitches, as de

sired; also for disengaging ruffler, when either

plaiting or gathering is not desired.

F—Adjusting Finger—regulates width or

size of plaits.

G—Separator Guide—contains slots into

which edge of material is placed to keep head

ing of ruffle even; also for separating material

to be ruffled from material to which ruffle is

to be attached.

H—Ruffling Blade—^pushes material in

plaits up to the needle.

J —Separator Blade—^prevents teeth of

ruffling blade coming into contact with feed

of machine or material to which ruffle or plait

ing is to be applied.

53

Fig. 61. Principal Parts of Ruffler

Page 29

54

To Attach Ruffler

1. Raise needle to its highest point.

2. Loosen presser foot thumb screw and at

tach ruffler to presser bar in place of presser

foot, at the same time placing fork arm B

astride needle clamp.

3. See that needle enters center of needle hole

in ruffler.

To Adjust Ruffler for Gathering

1. Swing adjusting finger F away from needle.

2. Raise adjusting lever E and move it until

projection D can be entered in slot marked

Fig. 62. Gathering with Ruffler

MATERIAL

Fig. 63. Correct Position for Material to he Ruffled

To Make a Ruffle and Sew it to a

Garment in One Operation

1. Insert material to be ruffled between two

blue blades and under separator guide (Line

2, Fig. 64).

3. Insert material to be ruffled between two

blue blades and under separator guide (Line

2, Fig. 63).

4. Draw material slightly back of needle,

lower presser bar and commence to sew.

5. For fine gathering, turn adjusting screw C

upward to shorten stroke. Set the machine for

a shorter stitch.

6. For full gathering, turn adjusting screw C

downward to lengthen stroke. Set the machine

for a longer stitch.

55

2. Place material to which ruffle is to be at

tached under separator blade and under sepa

rator guide (Line 1, Fig. 64).

3. Proceed the same as for plain gathering.

Fig. 64. Correct Positions for Materials

Fig. 65. Making a Ruffle and Attaching it

in One Operation

Page 30

56

To Make a Ruffle and Attach it with a

Facing in One Operation

1. Insert material to be ruffled between two

blue blades and under separator guide (Line

2, Fig. 66).

2. Place material to which ruffle is to be at

tached under separator blade and under sepa

rator guide (Line 1, Fig. 66).

3. Place facing material over upper blue blade

(Line 4, Fig. 66).

4. If facing is to be on right side of garment,

place wrong sides of garment and ruffle to

gether.

5. If facing is to be on wrong side, place

right sides of garment and ruffle together.

To Pipe a Ruffle

1. Insert material to be ruffled between two

blue blades from the right (Line 3, Fig. 68).

This material must not exceed 1-1/4 inches in

width.

2. The piping material is usually cut on the

bias and it should be about 1/4 inch wide

when folded in center. Place piping material

in ruffler, following (Line 5, Fig. 68) with

folded edge of piping to right.

3. Fold edge of material to which piping and

ruffling are to be attached and insert it in

ruffler, from the left following (Line 6, Fig.

68).

Fig, 67, Making a Ruffle and Attaching it

ivith a Facing in One Operation

57

Fig, 69, Piping a Ruffle

Page 31

Fig, 70, Plaiting with Raßler

58

To Adjust Ruffler for Plaiting

1. Raise adjusting lever E and move it until

projection D can be entered in slot marked

^^6.” The ruffler will then plait once every six

stitches. To plait once every 12 stitches, have

projection D enter slot “12” in adjusting lever

E.

2. Insert material to be plaited between two

blue blades and under the separator guide

(Line 2, Fig. 71).

3. To increase width of plait, move adjusting

finger F back toward needle and turn adjust

ing screw C downward. To make a smaller

plait, turn adjusting screw C upward. The dis

tance between plaits is regulated by length of

stitch.

Fig. 71. Correct Position for Material

To Adjust Ruffler for Group Plaiting

1. To make the space between the groups of

plaits, raise adjusting lever E and move it

until projection D can be entered in small slot

indicated by star on adjusting lever E. The

ruffler will then stop plaiting and plain stitch

ing will be made.

2. When desired space is made, set projection

D in either of slots 6 or 12.

3. Insert material to be plaited between two

blue blades and under the separator guide

(Line 2, Fig. 73).

TO OIL THE RUFFLER

Occasionally apply a drop of oil to working

parts of ruffler at places indicated in Fig. 72.

Fig. 73. Correct Position for Material

59

Fig. 72. Group Plaiting with Ruffler

Page 32

60

DARNING OR EMBROIDERING

Raise bed extension. Using a screwdriver, turn

thumb screw JJ over from you as far as it

will go. The feed is thus rendered inoperative

and will not interfere with the free movement

of the work.

Move stitch regulating lever Y, Fig. 18 to its

neutral position in center of slot at front of

machine.

Remove presser foot and let down presser bar

lifter T, Fig. 17 to restore tension on needle

thread which is released when lifter is raised.

Draw up bobbin thread as instructed on page

16.

Fig, 74, Adjustment for Darning or Embroidering

When darning flat work, it is advisable to use

embroidery hoops to hold the work.

Place work with unworn part near hole under

needle. Commence darning by making a line

of stitches across hole a little longer than width

of hole. Continue making parallel lines of

stitches across hole, moving work backward

and forward and at the same time gradually

moving work sidewise until hole is covered

with lines of stitches running across hole. Then

commence as before and move work length

wise of hole until stitches across hole are com

pletely covered and darn is finished.

When darning or embroidering is completed,

turn thumb screw JJ, Fig. 74 over toward

you as far as it will go, using a screwdriver.

Raise presser bar lifter T, Fig. 17, replace

presser foot and reset stitch regulating lever

Y, Fig. 18 for desired length of stitch.

61

Fig. 75. Darning in Process

Fig, 76. Darning Finished

Page 33

62

AUTOMATIC ZIGZAGGER

Zigzag stitching, decorative pattern stitching,

applique—all of these and more may be done

automatically on vour Slant-Needle SINGER

with the Automatic Zigzag Attachment.

You can blindstitch hems, mend rips and tears,

reinforce seams, overedge seam edges and

stitch scallop facing easily and quickly.

Merely insert one of the many Stitch Patterns

into the Automatic Zigzagger and sew.

ZIGZAG

BLIND

STITCH

DOMINO

ARROW-

HEAD

SCALLOP

MULTIPLE

WALLS

OF TROY

ICICLE

STITCH PATTERNS

\mi\i\immm

WM\

/ V

. A A

N/VH/VH/**

ffffff

KEY

BALL

BLOCK

SHINGLE

CURVED

MENDING

OPEN

SCALLOP

THREESTEP

SOLID

SCALLOP

'rrrrn

MWfM-

AV

63

Border Desiseli in Domino Pattern

j Blouse with Blind Stitch Border Design

Girls Dress with

Page 34

THE BUTTONHOLER

Beautiful, evenly stitched buttonholes may be

made on your Slant Needle SINGER with the

Buttonholer, as easily as you do straight

stitching.

Merely slip the template, for the size button

hole you require, into the attachment and

replace the presser foot with the Buttonholer.

Every buttonhole will be identical. The But

tonholer does the work for you — straight but

tonholes in seven lengths: YY•>

keyhole, in two lengths;

and m"-

64

Samples of Work Produced by SINGER Buttonholer

Page 35

DARNING AND EMBROIDERY ATTACHMENT

The Web Lace Stitch

The Darning and Embroidery Attach

ment contributes to the ease with which

free-motion sewing is accomplished.

Lovely embroidered effects are possible

on a wide range of fabrics.

The foot merely holds the fabric taut

while the stitch is being formed and re

leases the fabric when the needle has

risen to allow free movement of the work

for variety of embroidered effects.

66

The Darning Stitch

The Tracing Stitch

The Granite Stitch

SEAM GUIDE

The Seam Guide is helpful in stitching seams

an exact width, and for stitching a uniform

distance from a finished edge.

Especially help'ful for those just learning to

sew and an aid to those demanding greater

uniformity in seam width than the eye might

give, the seam guide is a useful addition to your

sewing equipment.

The scoring on the throat plate of your Slant

Needle SINGER makes it easy for you to set

the Seam Guide to an exact distance from the

needle.

67

GAUGE PRESSER FOOT

Expert and beautiful stitching is accomplished

with a minimum of skill and preparation

through the use of the SINGER Gauge Presser

Foot. Single or multiple rows of stitching may

be gauged evenly along lapel and facing edges,

welt seams, or hems.

An accurate set of gauges (lined at and

numbered at intervals)—one for use at the

left of needle and three for use at right of the

needle, accompany the Gauge Presser Foot.

The side walls of the gauges vary in depth to

accommodate fabrics and constructions of

different thickness. Smart, even stitching

accents are effectively placed with the Gauge

Presser Foot.

Page 36

68

Attachments

Adjustable Hemmer

Binder................................................................ 41

Buttonholer.......................................................... 64

Darning and Embroidery........................................... 66

Edge Stitcher........................................................ 48

Foot Hemmer........................................................ 34

Gathering Foot...................................................... 52

Gauge Presser Foot................................................. 67

Ruffler................................................................ 53

Seam Guide....................................................... 67

Zigzagger, Automatic.............................................. 62

Bobbin

Removing

Replacing

Winding

..............................................................

Darning or Embroidering............................................ 60

Electricai information................................................. 5

Electrical Connections

Features of 301 Machine

Light................................................................... 8

Lubrication

To Oil the Machine

Names of Principai Parts of 301 Machine

..............................................

............................................................

............................................................

..............................................

...........................................

................................................

......................

Page

39

12

15

12

26

32

CON

ENTS

Needies and Threads to Use

Needie Setting

Portabie Machine..................................................... 6

Handle for Carrying Machine

Presser Foot, to Reguiate Pressure on Moteriai. 20

Service

Sewing

Basting

Sewing Suggestions................................................ 29

To Prepare for Sewing............................................ 16

To Reguiate Direction of Feed

To Reguiate Length of Stitch.................................... 19

To Remove the Work

To Sew Bias Seams

To Start Sewing.................................................... 17

To Turn a Corner

Threading

6

4

Bobbin Case Threading........................................... 14

Upper Threading

Thread Tensions...................................................... 20

To Reassemble and Replace Needle Thread Tension.. 22

To Regulate Bobbin Thread Tension

To Reguiate Needle Thread Tension

To Remove and Disassemble Needle Thread Tension.. 22

........................................................

.................................................................

..............................................................

........................................

....................................

..................................

........................................ 18

................................................

..................................................

..................................................

...........................

...........................

Page

70

9

7

3

18

19

18

18

11

21

21

69

9

1 1

14

14

16

18

11

THREAD AND

INCH

MACHINE STITCHES

PER INCH

INSIDE

SEAMS

20

16

12 18

12 16

10

8

10

TOP

STITCHING

30

20

12

10

12

CHART SHOWING RELATIONSHIP OF TYPES OF FABRICS,

NEEDLE SIZES AND MACHINE STITCHES TO THE

THREAD

TYPES OF FABRICS

Filmy materials comparable to Net, Marquisette,

Organdie, Ninon.

Sheer materials comparable to Lawn, Dimity,

Voile, Batiste, Chiffon, Rayon Sheer, Rayon Crepe.

Lightweight materials comparable to Gingham,

Chambray, Sheer Wool Crepe, Taffeta.

Medium lightweight materials comparable to

Pique, Poplin, Percale, Cretonne, Chintz, Faille, Bengaline. Wool Flannel, Wool Jersey, Wool Crepe.

Medium heavy materials comparable to Corduroy,

Crash, Gabardine, Velveteen, Rep.

Heavy materials,comparable to Sailcloth, Denim,

Ticking.

Plastic materials

SIZES

100 Cotton

00 and 000 Silk

80 to 100 Cotton

0 Silk

60 to 80 Cotton

A and B Silk

50 to 70 Cotton

B Silk

40 to 50 Cotton

C Silk

30 to 40 Cotton

D Silk

Mercerized

Cotton

W h en o rdering need les, a lways specify '‘Class and Variety 15 x1“ and sta te the size and quantity re quired.

NEEDLE

SIZES

Loading...

Loading...