Singer 300W103, 300W203 Instruction Manual

Fofm

3066W

INSTRUCTIONS

FOR

USING

AND

ADJUSTING

SINGER

SEWING

300wl03

Machine

MACHINES

and

300w203

300w203

"A

Trademark

THE

of THE SINGER

Special atlenlion is

SINGER

called

to the lubricolinQ itistructions on

MANUFACTURING

MANUFACTURING

COMPANY

pages6and

7

COMPANY

Copyright © 1958 by The Singer Manufacturing Company

DESCRIPTION

Machine 300w103

single row of two-thread chain stitching.

has

one

needle

and one

looper

and

makes

a

Machine 300w203

ously

making

two

parallel

are set abreast and the distance

to 1

inch,instepsof 1/32

5/16",

work pants, automobile

similar

in

foot and lifting presser foot, carry the work forward in unison with the

3/8",

These

machines

work in

A

compound

combination

1/2"

medium

feed,

with

needle in the material,

two or more plies of material.

The maximum length of stitch is 3 to the inch. The

is

1-1/4

inches and the presser

An automatic oiling

principal bearings.

has

two

rowsoftwo-thread

inch,

and

3/4".

needles

between

as ordered.

and

two

loopers

chain

stitching.

them

may be

The

standard gaugesare 1/4",

for

The

from

simultane

needles

3/16

are especially adapted for seaming overalls and

trim,

stitching tarpaulins, tents, seat covers and

and heavy fabrics.

consisting

alternating

insuring

system

of needle feed and drop feed,

pressers,

powerful,

bar

lift is

delivers the required amount of oil to all

comprising

positive

3/8

inch.

on upper feeding

and even feeding of

needle

working

bar

Inch

stroke

SPEED

The

maximum

depending upon the nature of the

machines

of the

driven at their

toward the operator.

CAUTION:

oughly

oiled,asinstructed

speed recommended for these machines is 4000

work.

For

the

first

few days, the speed

should

maximum

not exceed 3500

speed. The top of the balance wheel turns over

Before

starting

on

R.P.M.,

the

machine,itmust

pages6and

after

7.

which

they can be

be

R.P.M.,

thor

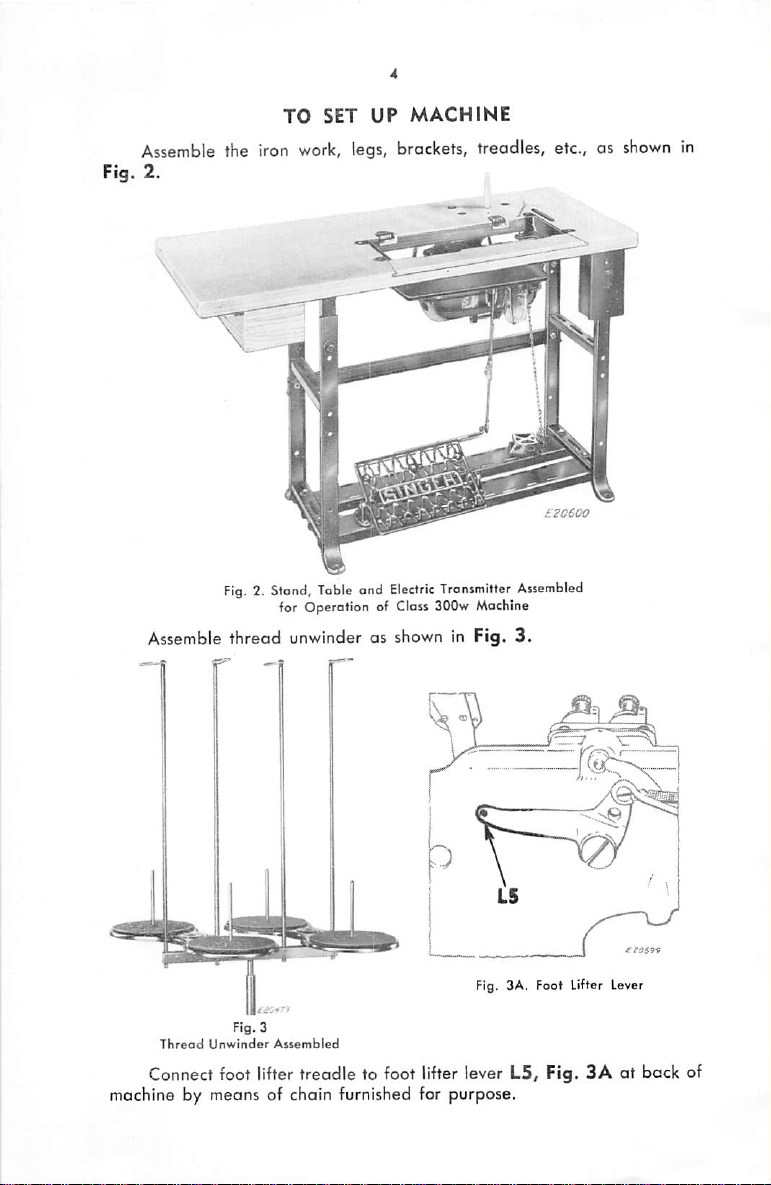

TO

SET

UP

MACHINE

Assemble the iron work, legs, brackets, treadles, etc., as shown it

Fig.

2. Stand, Table end

for Operation of Class 300w Machine

Assemble thread unwinder as shown in Fig.

Electric

Transmitter

Assembled

3.

Fig, 3A, Foot Lifter Lever

Thread

Connect foot litter treadle to foot lifter lever L5, Fig.

Fig. 3

Unwinder

Assembled

3A

machine by means of chain furnished for purpose.

at back of

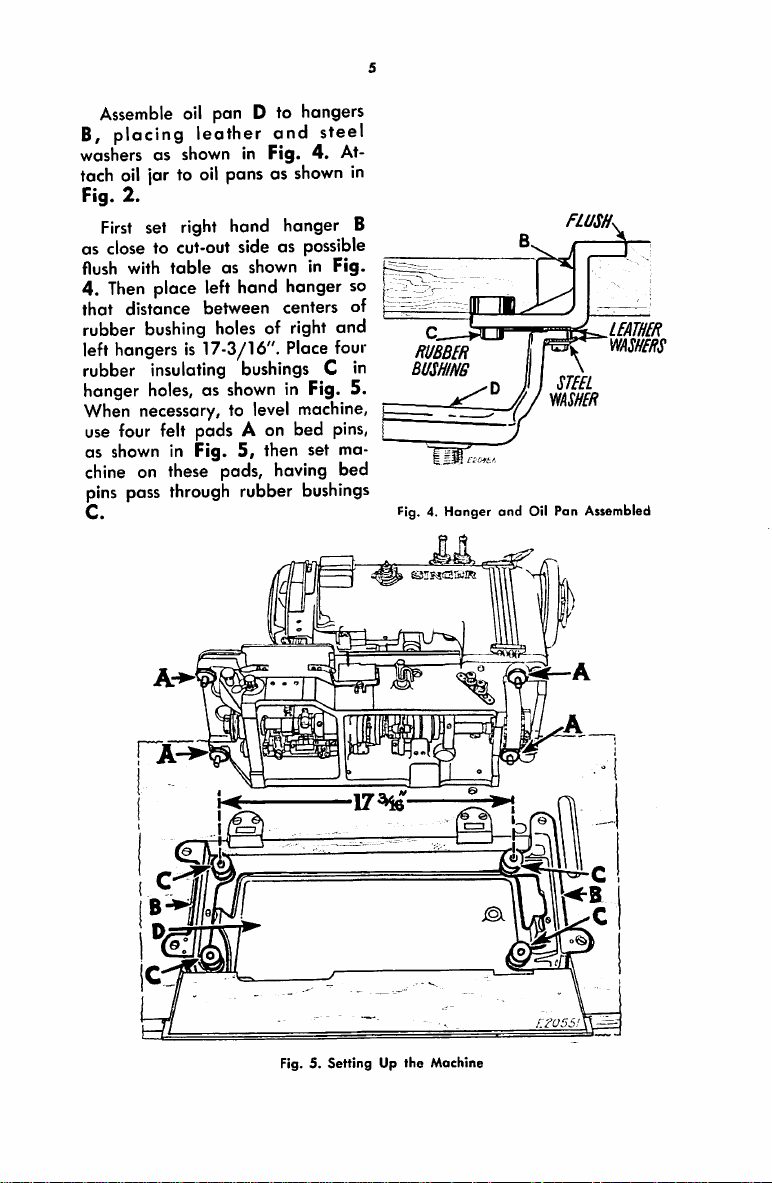

Assemble

oil pan D to hangers

B, placing leather and steel

washers as

tach oil jar to oil pans as

Fig. 2.

First

as close to cut-out side as possible

flush with table as shown in Fig.

4.

Then

that

rubber bushing holes of right and

left

hangersis17-3/16".

rubber insulating bushings C in

hanger

When necessary, to level

use four felt pods A on bed

OS

shown in Fig. 5, then set ma

chine

pins

C.

shown

in Fig. 4. At

shown

set right hand hanger B

place left hand hanger so

distance

between

centers of

Place

holes,asshown

in Fig. 5.

machine,

on these pods, having bed

pass

through

rubber

bushings

in

four

pins,

FLUSHs.

mWER

mmRS

Fig. 4. Hanger and Oil Pan Assembled

f.?05b

Fig. 5. Setting Up the Machine

TO

The

machine

hollow

arm shaft and o

deliver

the

by

oil

of parts in movable contact

the

machineisin

centrifugal

reaches

required

operation.

force

the

bearing

hasanefficient

hollow

amountofoiltoallofthe

through

surfaces.

OfL

THE

MACHINE

automatic

bed shaft

The

oilisdistributedtothe

small

jetsinthe

Oil

holes

which

are not oiled from the reservoirs.

citing

which

act as oil

principal

shaftssothat

ore

provided

system

various

for

comprising

reservoirs

bearings

bearings

only

hand

a

and

when

clean

oiling

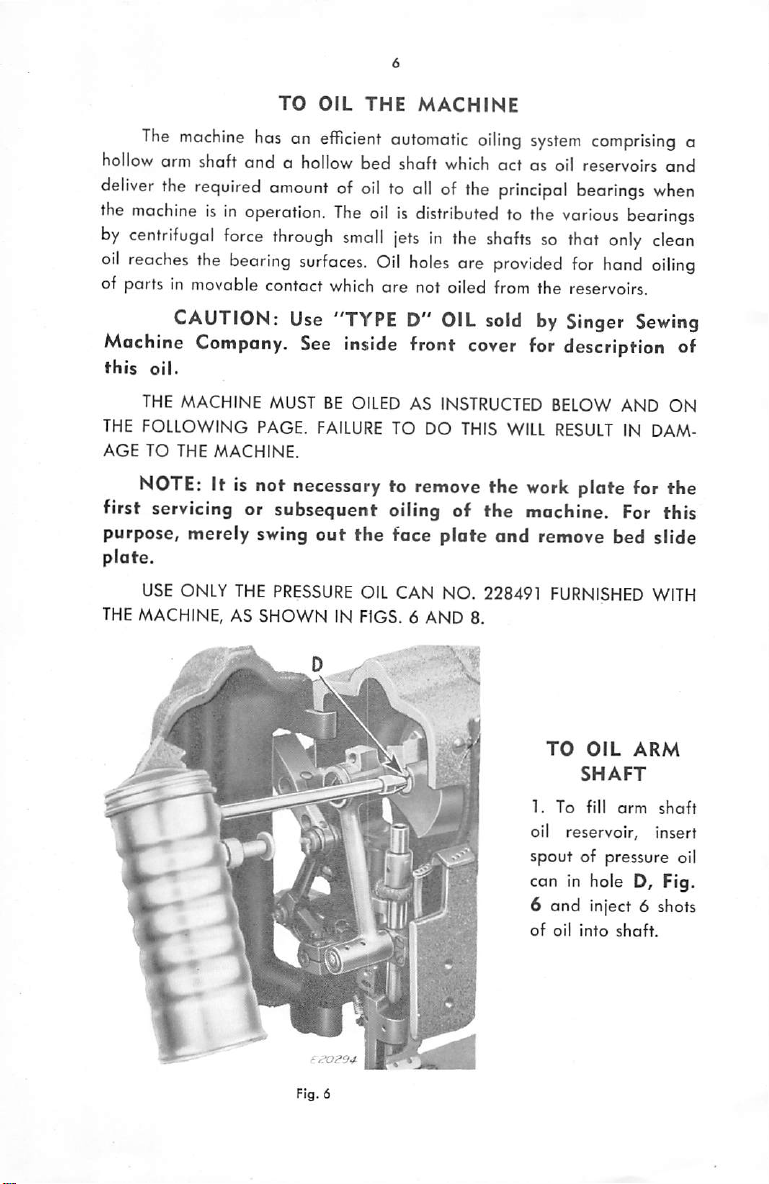

CAUTION:

Machine

this

THE

AGE

Company.

oil-

THE

MACHINE

FOLLOWING PAGE.

TO

THE

NOTE:

It is not necessary to remove the work plate for the

MACHINE.

Use

"TYPE

See

inside

MUSTBEOILEDASINSTRUCTED

FAILURE

D"

front

TO DO

OIL

THIS

sold

cover

for

WILL

by

Singer

description

BELOW

RESULT

Sewing

of

AND ON

IN DAM

first servicing or subsequent oiling of the machine. For this

purpose, merely swing

plate.

USE

ONLY

THE

THE

MACHINE, AS

PRESSURE

SHOWN

out

the

face

OIL CAN NO. 228491

IN FIGS. 6 AND 8.

plate

and

remove bed slide

FURNISHED

TO

OIL

SHAFT

1.

To

fill

oil reservoir, insert

spout of pressure oil

can in hole D, Fig.

6 and inject 6 shots

of

oil

into

ARM

arm

shaft.

WITH

shaft

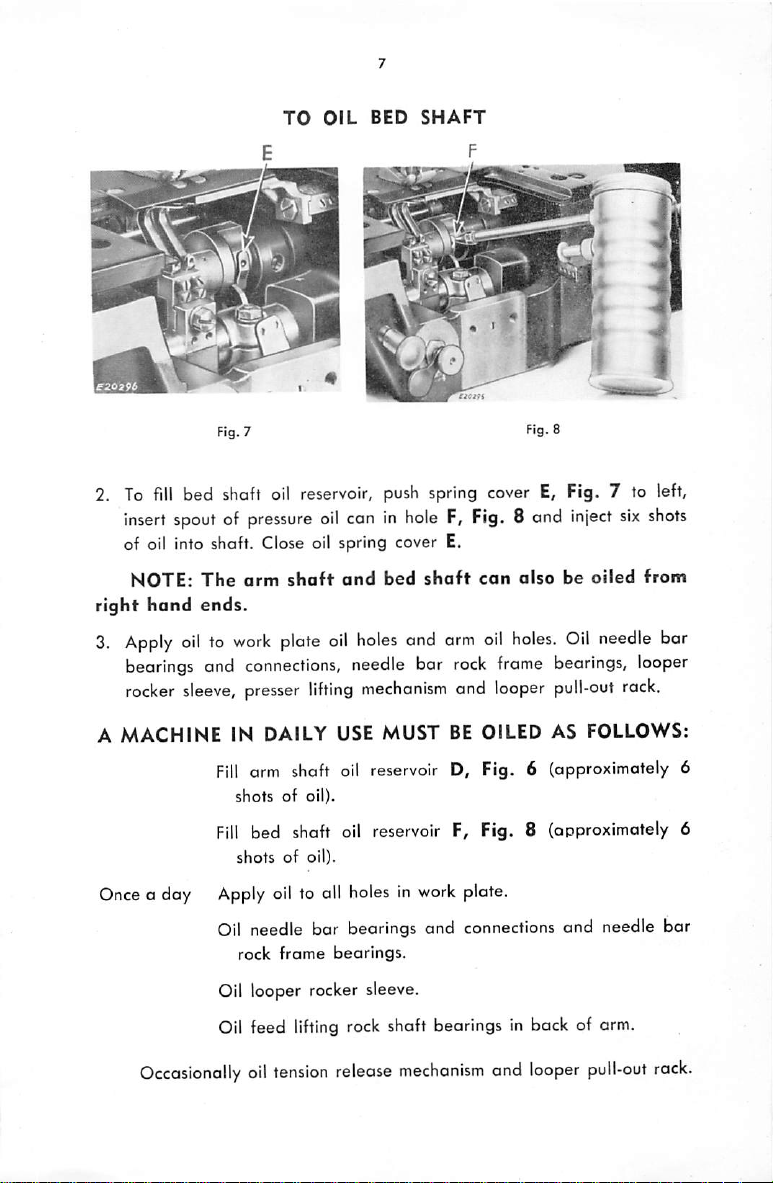

2.

To

fill

bed shaft oil reservoir,

insert

spoutofpressure

of oil into shaft. Close oil spring cover E.

oil

push

caninhole

spring cover E, Fig. 7 to left,

F, Fig. 8 and

inject

six

shots

NOTE:

right

3.

Apply

bearings and

rocker

A MACHINE IN DAILY

Once

Occasionally

hand

oiltowork

sleeve,

a day

The

arm

shaft

ends.

plate

connections,

presser

Fill

shots of oil).

Fill

shots of oil).

Apply

Oil needle bar bearings and connections and needle bar

rock

Oil looper

Oil feed

oil

lifting

arm shaft oil reservoir D, Fig. 6 (approximately 6

bed shaft oil

oil

to all

frame

rocker

lifting

tension

and

bed

shaft

con

alsobeoiled

oil

holes

and

arm

oil

holes.

Oil

needle

USE

holesinwork

bearings.

rock shaft bearings in back of arm.

release

bar

mechanism

MUST

reservoir

sleeve.

mechanism

rock

frame

bearings,

and

looper

BE

OILED AS FOLLOWS:

F, Fig. 8

pull-out

(opproximately

plate.

and

looper

needle

rack.

pull-out

from

bar

looper

6

rack.

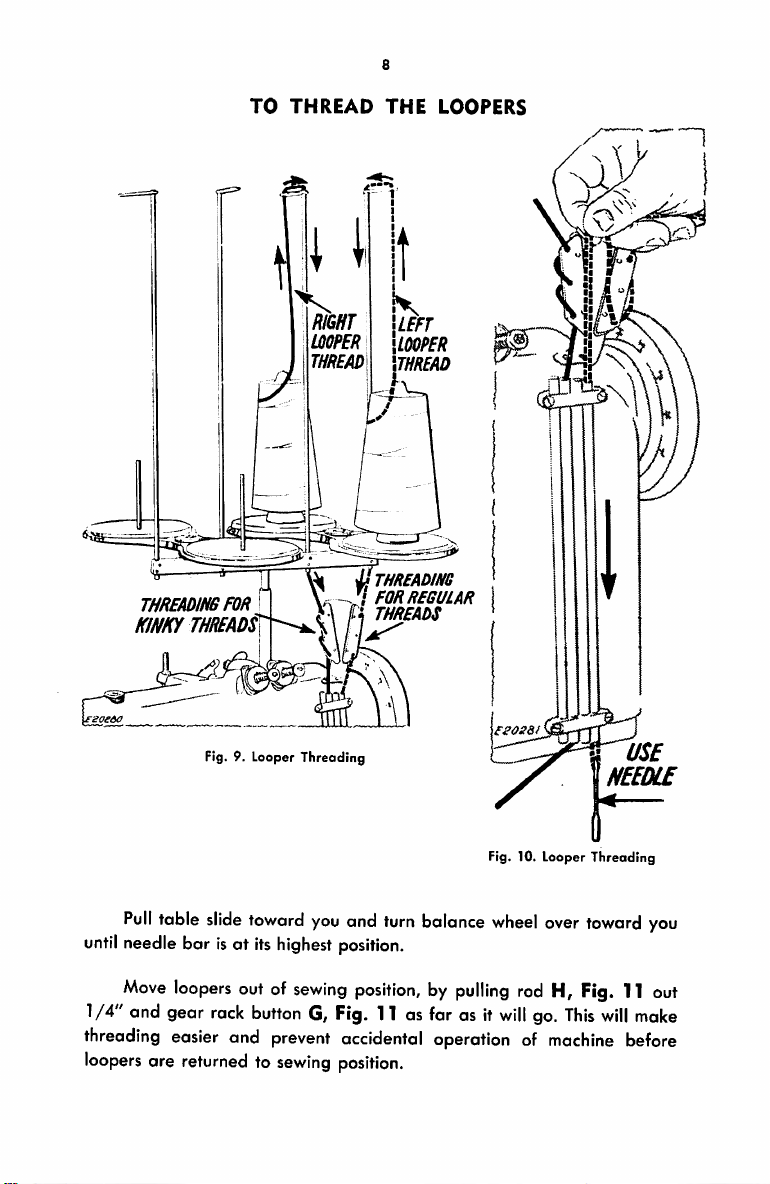

TO

THREAD

THE

LOOPERS

THREADING

Kim

THREADS

RIGHT

IQOPER

THREAD

FOR

Fig. 9. Looper Threading

\LEFT

\LmER

MHREAD

I

THREADING

FOR REGULAR

THREADS

eeosd!

NEEDtl

Fig. 10. Looper Threading

Pull

table

slide

until

needle bar is at

Move

loopers

1/4" and gear

threading

loopers

easier

are

returnedtosewing

toward

outofsewing

rack

and

you

and

turn

its

highest

position.

position,bypulling

button

G, Fig. 11 as far asItwill

prevent

accidental

position.

balance

wheel

rod

over

H, Fig. 11

go.

This

operationofmachine

toward

will

you

out

make

before

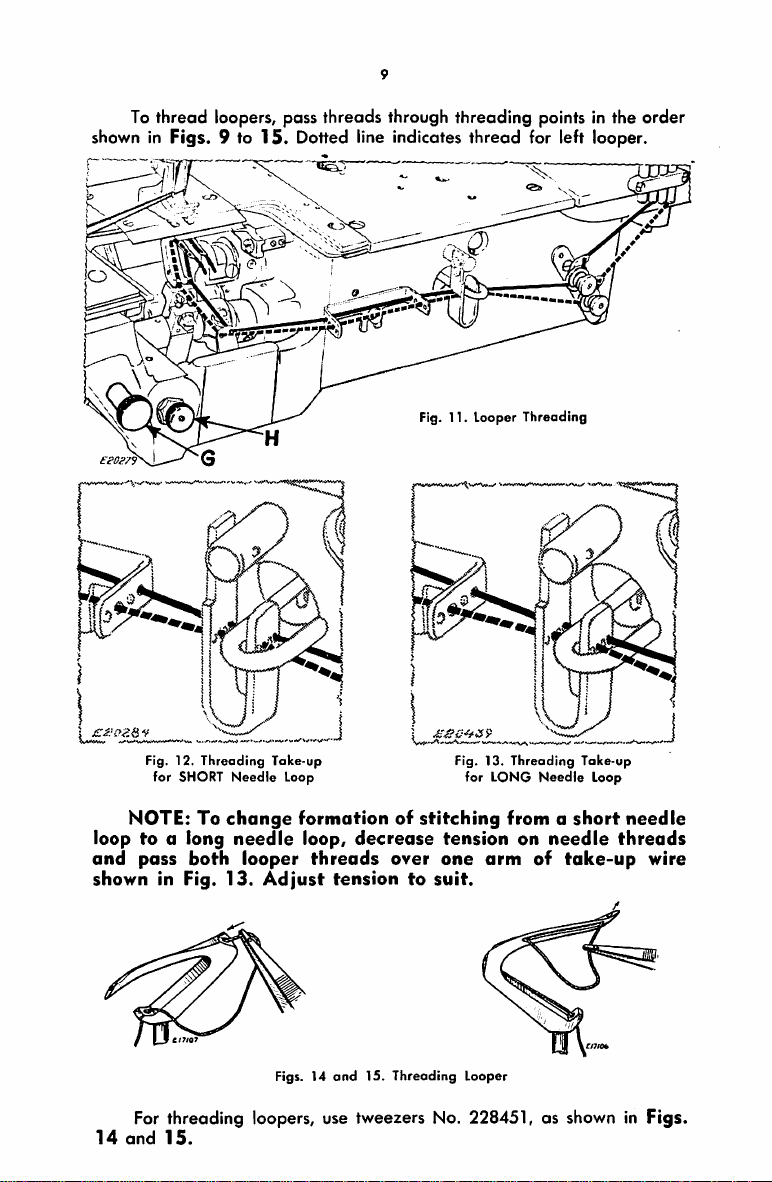

To thread loopers, pass threads through threading points in the order

shown in Figs. 9 to

15.

Dotted line indicates thread for left looper.

Fig. 11. Looper Threading

Fig. 12.

Threading

for SHORT

NOTE: To

looptoa long

and

pass

both

shown

in Fig.

Needle

change

needle

looper

13.

Adjust

Take-up

Loop

formationofstitching

loop,

decrease

threads

over

tensiontosuit.

Figs. 14

and

15.

Threoding

Fig. 13.

for LONG

tension

one

arm

Looper

Threading

Needle

Take-up

Loop

fromashort

on

needle

of

take-up

threads

For threading loopers, use tweezers No. 228451, as shown in Figs.

14

and

15.

needle

wire

TO

THREAD

10

THE

NEEDLES

mBHT

HmiB

jHfm

Fig. 16.

LEFT

fmif

rm/iD

Needle

Threading

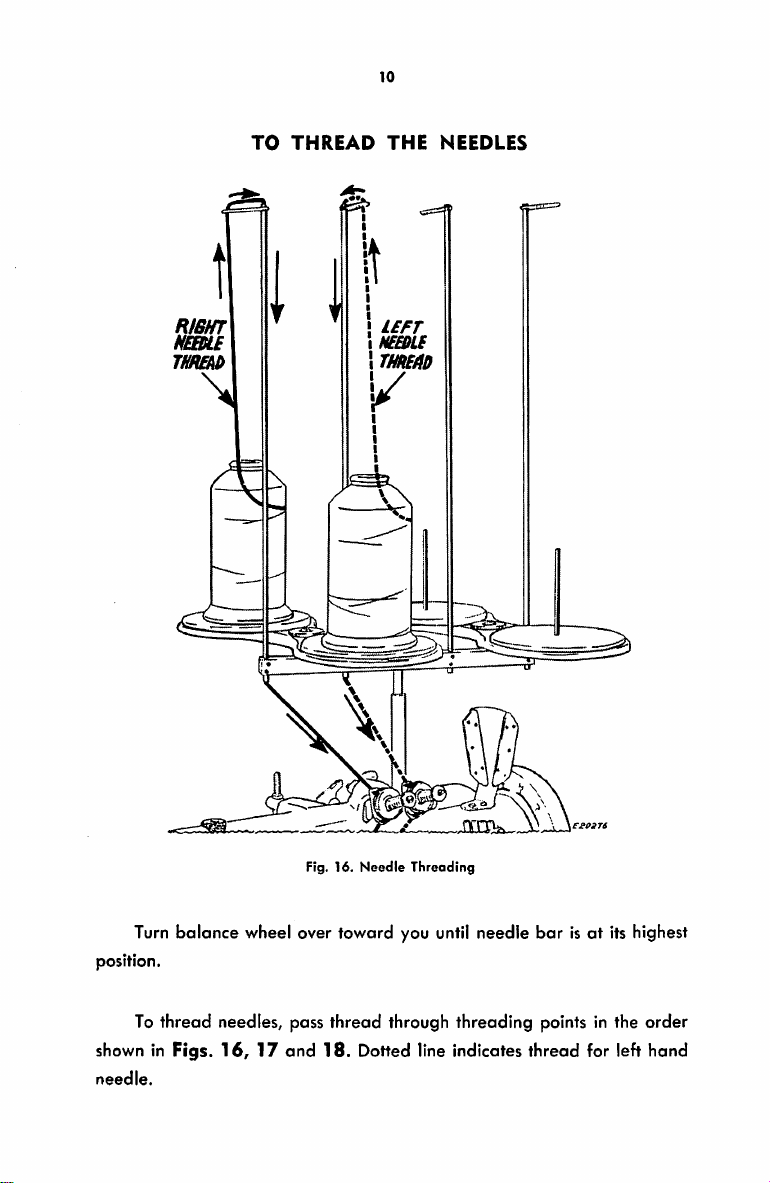

Turn balance wheel over toward you until needle

barIsat its highest

position.

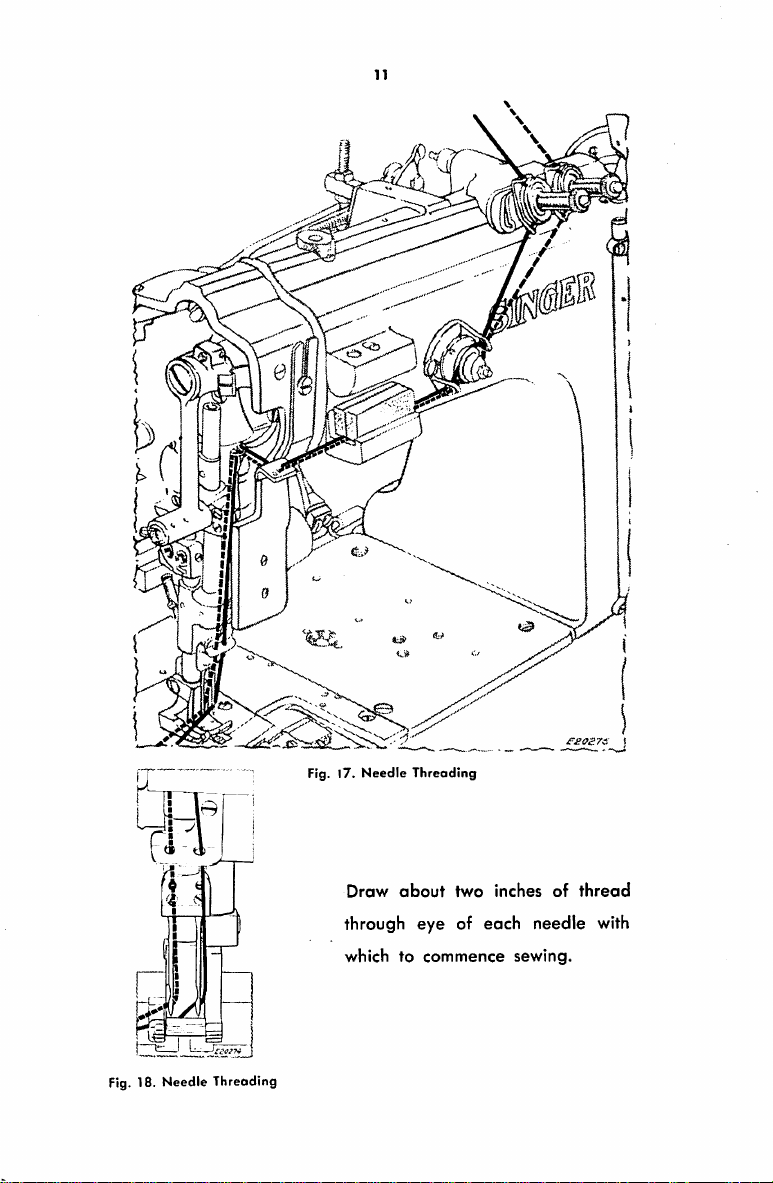

To thread needles, pass thread through threading points in the order

shown in Figs.

needle.

16,17and

18.

Dotted line indicates thread for left hand

11

eaosrs

Fig.

l7.

Needle

Threading

Draw

about

two

inches

of

thread

through eye of each needle with

which to

Fig. 18. Needle Threoding

commence

sewing.

i

12

TO

SET

THE

NEEDLES

@ ©

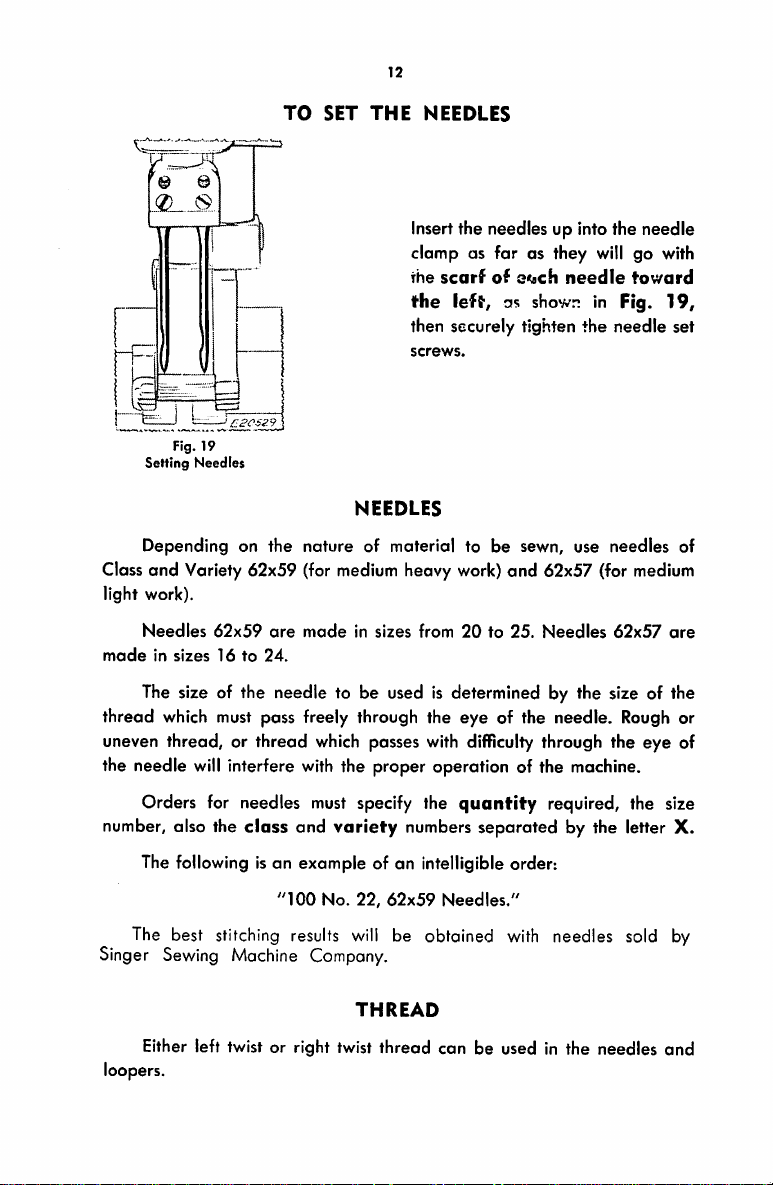

Insertthe needles up Intothe needle

clamp as far as they

the

scarf

of

8<bch

the

left/

as

shown

will

needle

in Fig.

then securely tighten the needle set

screws.

Fig. 19

Setting Needles

NEEDLES

Depending on the nature of material to be sewn, use needles of

Classand Variety 62x59 (for

light work).

medium

heavy

work)

and 62x57 (for

go with

toward

19,

medium

Needles

modeinsizes16to

62x59

are

madeinsizes

24.

from20to

25.

Needles

62x57

The size of the needle to be used is determined by the size of the

thread

uneven thread, or thread

the needle

number, also the

which

must

pass freely through the eye of the needle.

will

interfere

Orders for needles

class

which

passes

with

difficulty

with

the proper operation of the machine.

must

and

specify the

variety

quantity

numbers separated by the letter X.

through the eye of

required, the size

The following is an example of an intelligible order:

"100

No.

22,

62x59

Needles."

The best stitching

Singer

Sewing

results

will

Machine Company.

THREAD

be obtained

with

needles sold by

Either left twist or right twist thread can be used in the needles

loopers.

Rough

ore

or

and

Loading...

Loading...