Page 1

SINGER

THE SINGER COMPANY

Page 2

Instru-ctioiis for \xsiiig-

SINGER'

221

Page 3

Electric

Sewing Machine

Page 4

AS THE OWNER OF THE SINGER 221

You have a machine with a tradition of superior crafts

manship—a tradition you will recognize in the smooth,

efficient operation of this lightweight machine. Distinc

tive clothing for yourself and your family and numerous

items for the home—^can be yours at a fraction of their

ready-made cost.

SINGER SERVICE

T^^herever you go you will find expert, dependable

SINGER* SERVICE close at hand. SINGER is in

terested in helping you keep your SINGER SEWING

MACHINE in top running condition. That is why you

should always call your SINGER SEWING CENTER if

your machine ever requires adjustment or repair. Only

from your SINGER SEWING CENTER can you obtain

the services of a trained SINGER repair man and

warranted SINGER* parts.

EVERYTHING FOR THE WOMAN WHO SEWS

The answer to your sewing needs is at your SINGER

SEWING CENTER. There you will find a wide choice of

sewing aids, notions, sewing information and services.

Look for the famous red “S” and SINGER trademarks on

vour SINGER SEWING CENTER and the ever-ready

SINGER SERVICE CAR. Look under SINGER

COMPANY, in phone book, for address nearest you.

*A Trademark of THE SINGER COMPANY Copyright Under International Copyright Union

Page 5

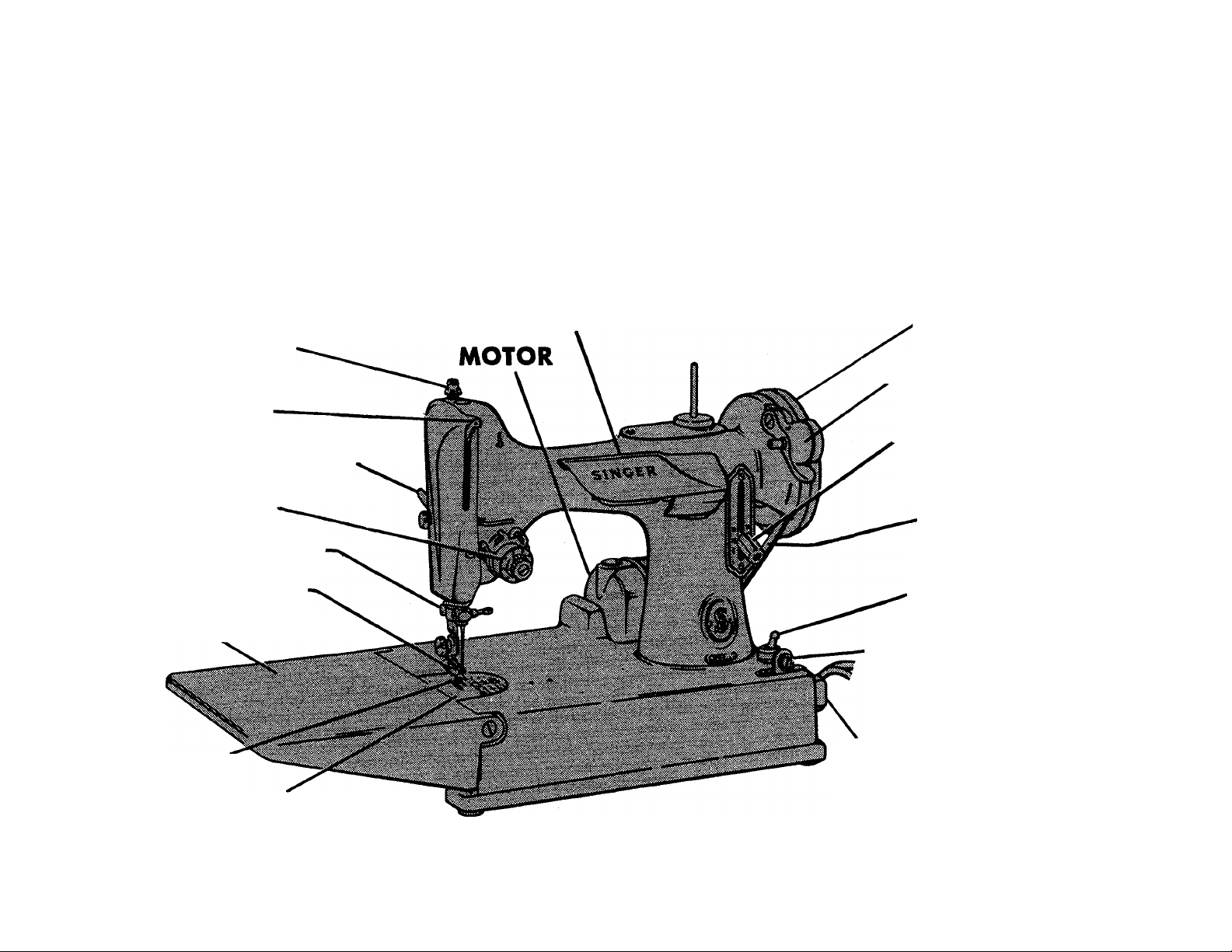

PRINCIPAL PARTS OF MACHINE 221

PRESSURE REGULATING

SCREW

THREAD TAKE-UP

LEVER

PRESSER BAR LIFTER

NEEDLE THREAD

TENSION

THREAD CUTTER

PRESSER FOOT

BED EXTENSION

FEED DOG

LIGHT

HAND WHEEL

BOBBIN WINDER

STITCH LENGTH

REGULATOR

MOTOR BELT

LIGHT SWITCH

BOBBIN WINDER

THREAD TENSION

CORD CONNECTION

THROAT PLATE

Page 6

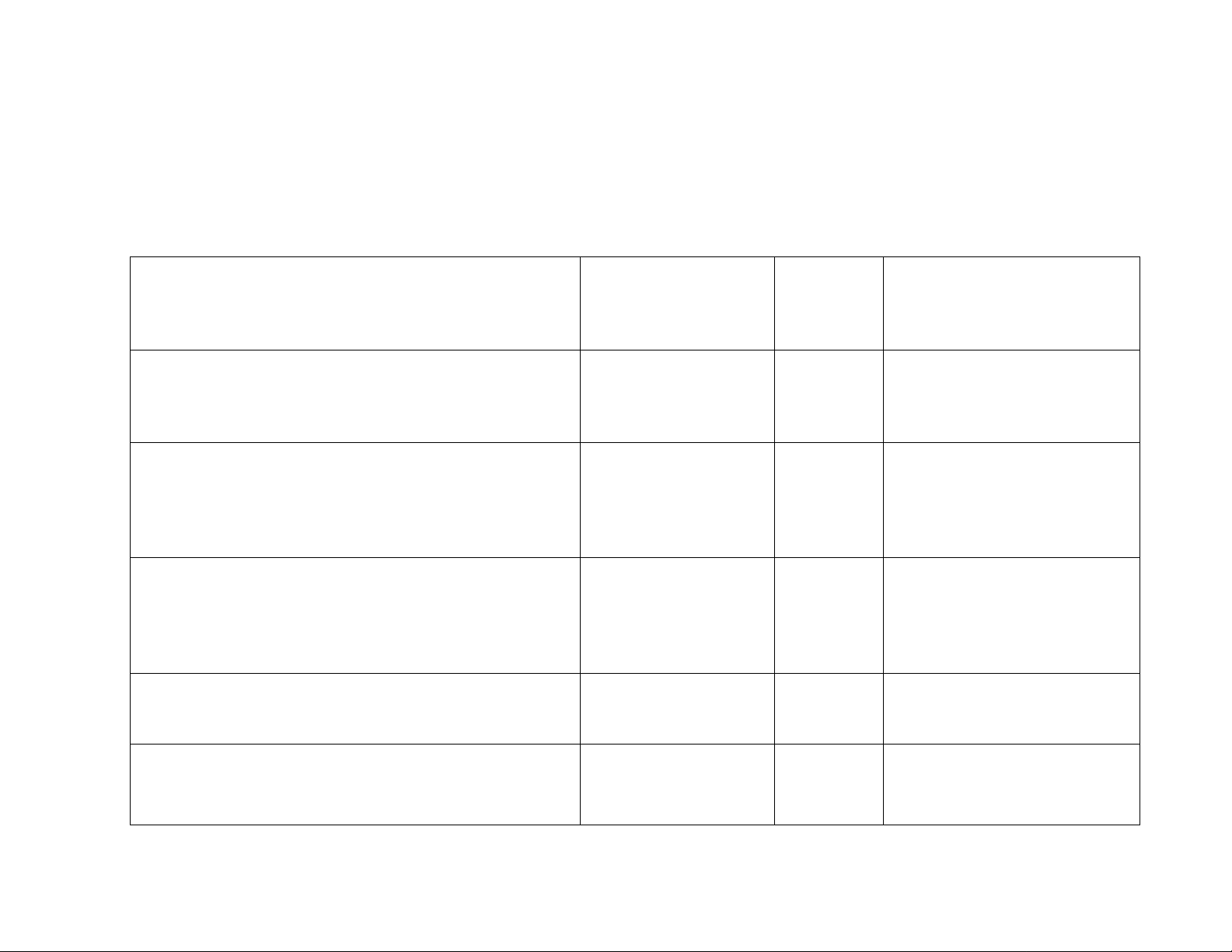

FABRIC, THREAD, NEEDLE AND STITCH LENGTH CHART

FABRICS

DELICATE—tulle, chiffon, fine lace,

silk organdy, fine tricot

LIGHTWEIGHT—batiste, organdy, jersey,

voile, taffeta, silk crepe, plastic film

MEDIUM WEIGHT—gingham, percale, pique,

linen, chintz, faille, satin, fine corduroy,

suitings

MEDIUM HEAVY—gabardine, tweed, sail

cloth, denim, coatings, drapery fabrics

THREAD

SIZES

Fine Mercerized

100 to 150 Cotton

Synthetic Thread

50 Mercerized

80 to 100 Cotton

A Silk

Synthetic Thread

50 Mercerized

60 to 80 Cotton

A Silk

Synthetic Thread

Heavy Duty Merc.

40 to 60 Cotton

NEEDLE

SIZES

9 15 to 20

11

14

16

MACHINE STITCHES

(8 to 10 for plastic)

PER INCH

12 to 15

12 to 15

10 to 12

HEAVY—overcoatings, dungaree, upholstery

fabrics, canvas

Heavy Duty Merc.

24 to 40 Cotton

18

8 to 10

Page 7

NEEDLES AND THREAD

This machine uses needle

Catalog No. 2020 (15x 1 ).

Sizes 9j llj 14, 16 and 18.

For perfect stitching, choose needle and

thread which correspond to the fabric accord

ing to the chart on page 4. Be sure to use like

threads for both needle and bobbin.

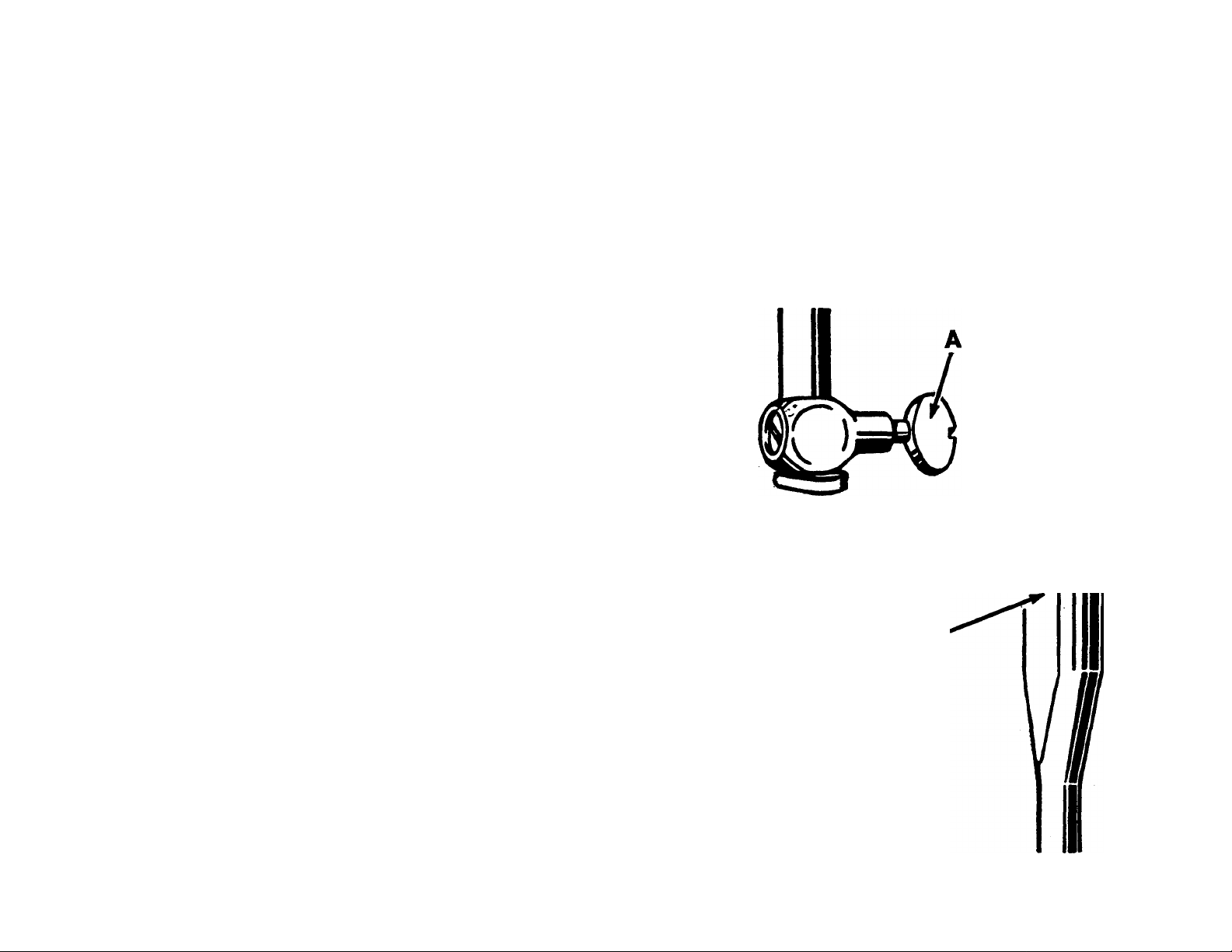

NEEDLE INSERTION

• Raise needle bar to its highest point.

• Loosen needle clamp screw A.

• Insert needle (flat side to the left) up into

needle clamp as far as it will go.

• Tighten clamp screw.

K

FLAT

SIDE

Page 8

ELECTRICAL INFORMATION

The SINGER* Electric Motor at back of ma

chine is furnished for operation on an alter

nating current of 110-120 volts, 25 to 75

cycles, or on 110-120 volts direct current.

Special motors can be provided through your

SINGER SEWING CENTER for direct or

alternating current for any voltage between 50

and 145, and for 32 volts direct current.

Before Inserting Electric Plug be sure that

voltage and number of cycles stamped on

motor nameplate are within range marked on

your electric meter installed by your power

company.

Electrical Connection. Push 3-pin terminal

plug on 3-pin terminal block at right of

machine and connect plug at other end of

cord to electrical outlet.

Speed Controller. The speed of machine is

regulated by amount of pressure on foot

controller.

Page 9

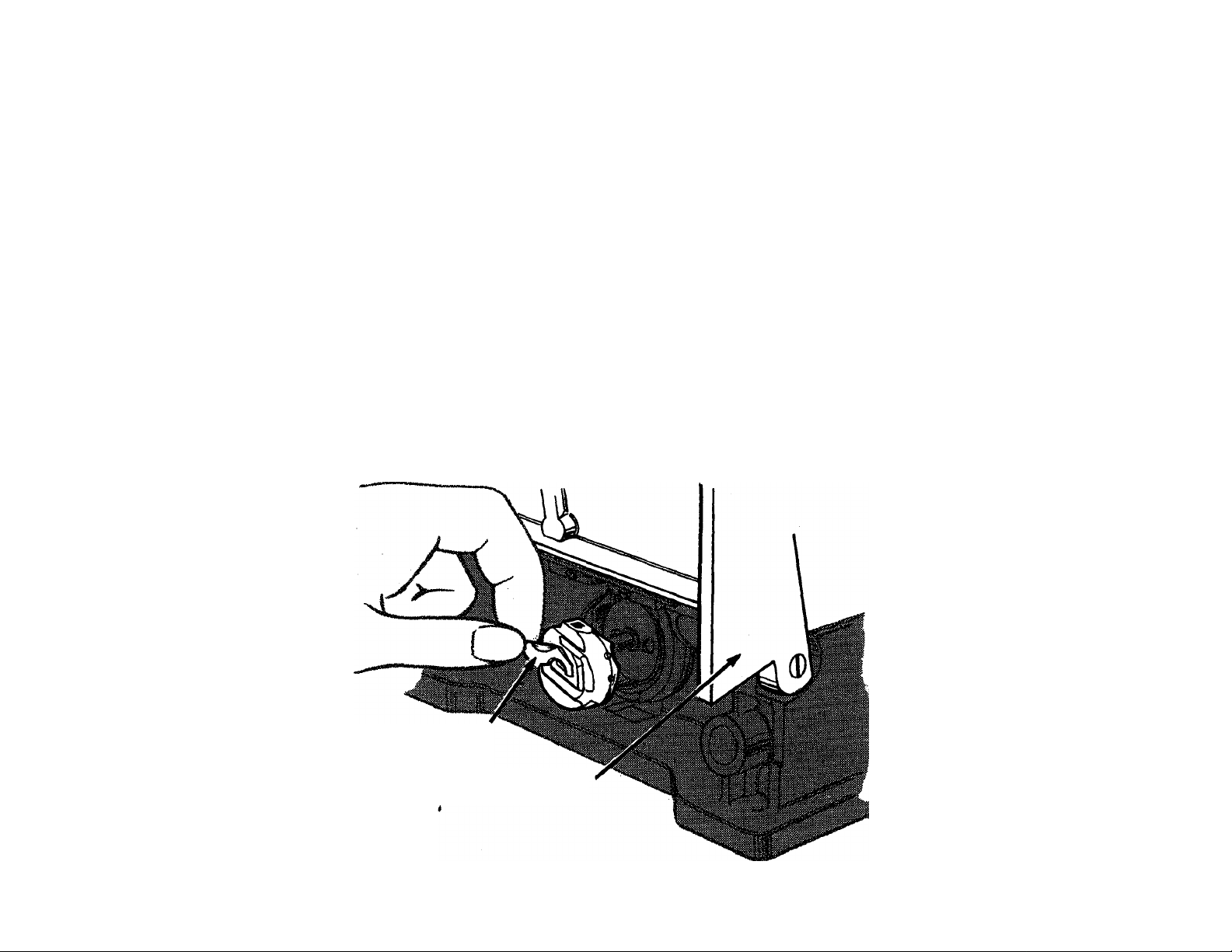

TO REMOVE BOBBIN CASE AND BOBBIN

Raise thread take-up lever to its highest position.

Raise bed extension.

Grasp bobbin case latch and withdraw bobbin case.

Release latch and bobbin will drop out.

LATCH

BED EXTENSION

Page 10

8

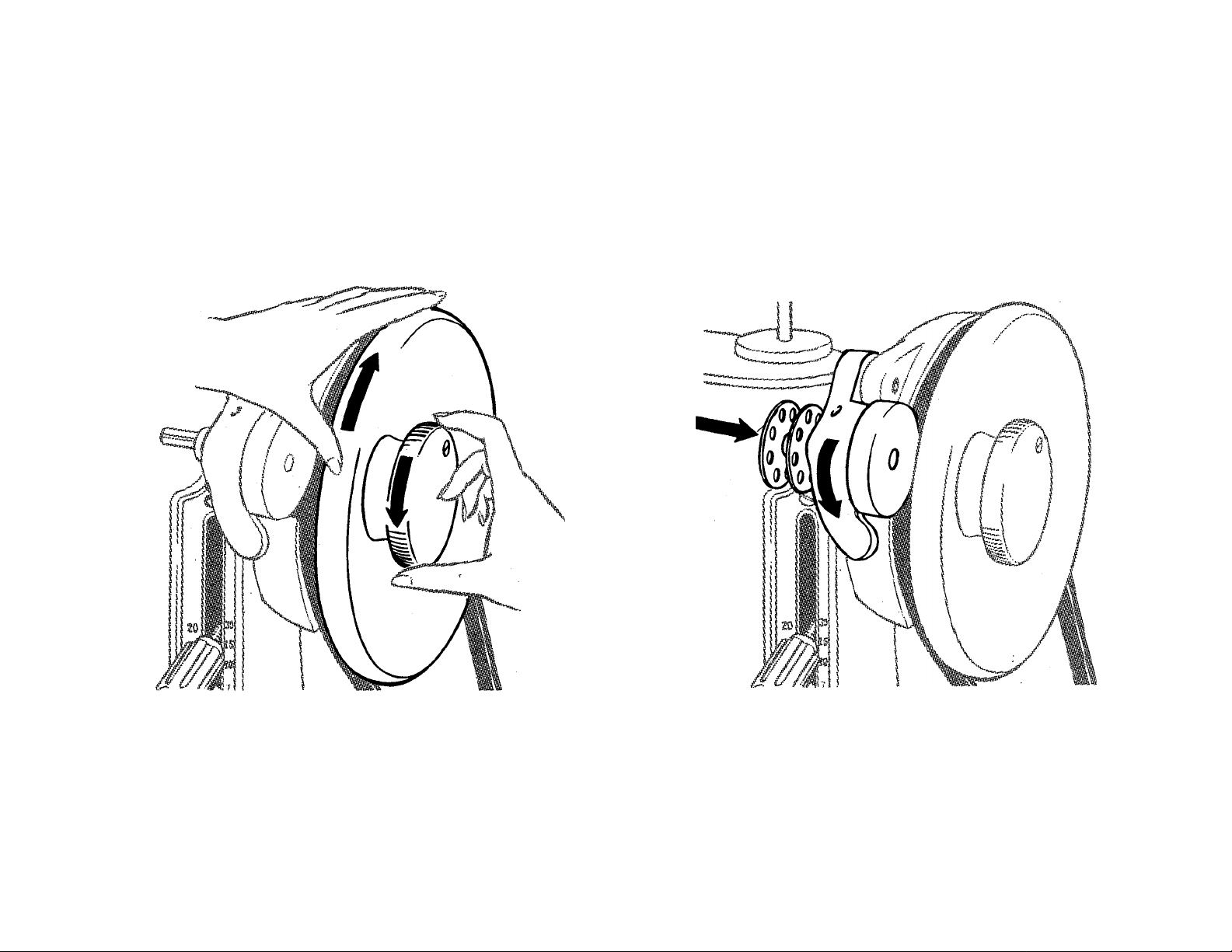

TO WIND BOBBIN

Loosen stop motion screw

with right hand.

Place empty bobbin on spindle.

Press bobbin winder down against

belt.

Page 11

TO WIND BOBBIN—Continued

If thread doesn’t wind e^venly

on bobbin—

• Loosen screw which holds bobbin

winder tension bracket to bed of

machine.

• Move bracket to left if bobbin

winds high on right.

• Move bracket to right if bobbin

winds high on left.

• Tighten tension bracket screw.

When bobbin is full—

• Stop machine.

• Lift bobbin

Place spool of thread on spool pin.

Thread machine as shown above.

Hold end of thread and start ma

chine. (End of thread will break

oflf after a few coils have been

wound on bobbin.)

winder away

from belt.

• Remove bob

bin.

• Tighten stop

motion screw.

Page 12

10

TO THREAD BOBBIN CASE

1. Hold bobbin case

and bobbin so

that thread leads

off in direction

shown above.

2. Place bobbin into

bobbin case. Pull

thread into slot 1.

3. Pull thread under

tension spring 2

and into slot 3 at

end of spring, as

shown.

Page 13

NOTCH

POSITION FINGER

STUD

11

TO REPLACE BOBBIN CASE

AmwMwiBttmAaittHunmHUiw.

nuoMUtiMUtiHsUtiimiuiuiiiMnnttxunton«

Hold bobbin case by latch and place it

on stud, having thread draw from top of

bobbin case.

Release latch apd press bobbin case

back until latch enters groove in stud.

Allow. about three inches of thread to

hang free from bobbin case and turn down

bed extension.

CAUTION: If throat plate is removed

for cleaning stitch forming mechanism,

etc., make certain, when replacing throat

plate, that position finger of bobbin case

base enters notch of position plate at

tached to underside of throat plate, as

shown above.

Page 14

12

UPPER THREADING

• Raise take-up lever to its highest point.

• Place spool of thread on spool pin.

• Lead thread through threading points shown,

• Thread needle from right to left.

• Draw sufficient thread

through eye of needle

with which to start

sewing.

Page 15

13

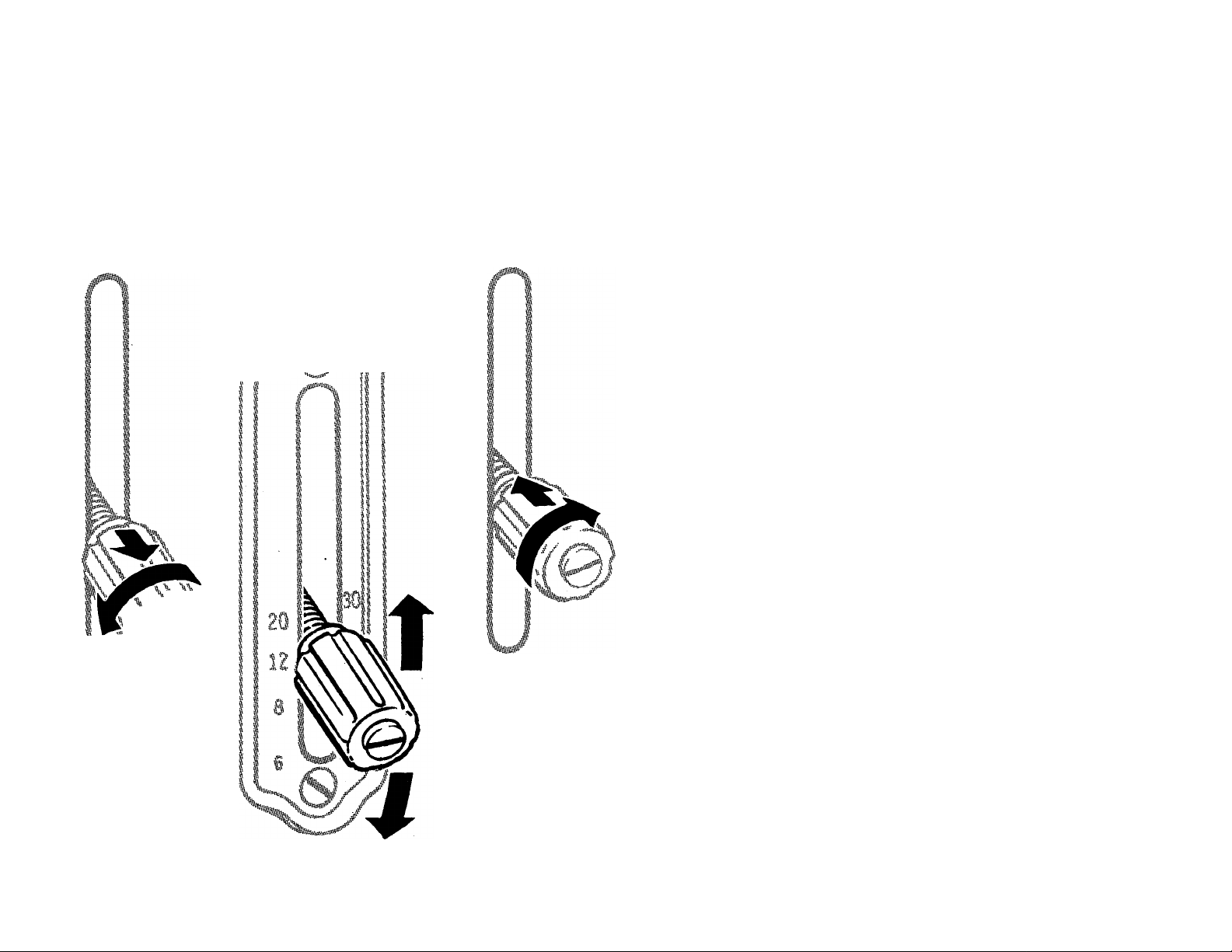

STiTCH LENGTH REGULATOR

Numerals on the indicator plate

IK K-'^x ^

>1 ia

fc.,\

represent approximate number of

stitches per inch.

I

To set stitch length—

• Turn thumb nut to the left.

• Set lever at desired stitch setting.

• Turn thumb nut to the right until

it rests against indicator plate.

Once the thumb nut has been

tightened, reverse stitching is accom

plished by raising the lever to its

highest point.

Page 16

14

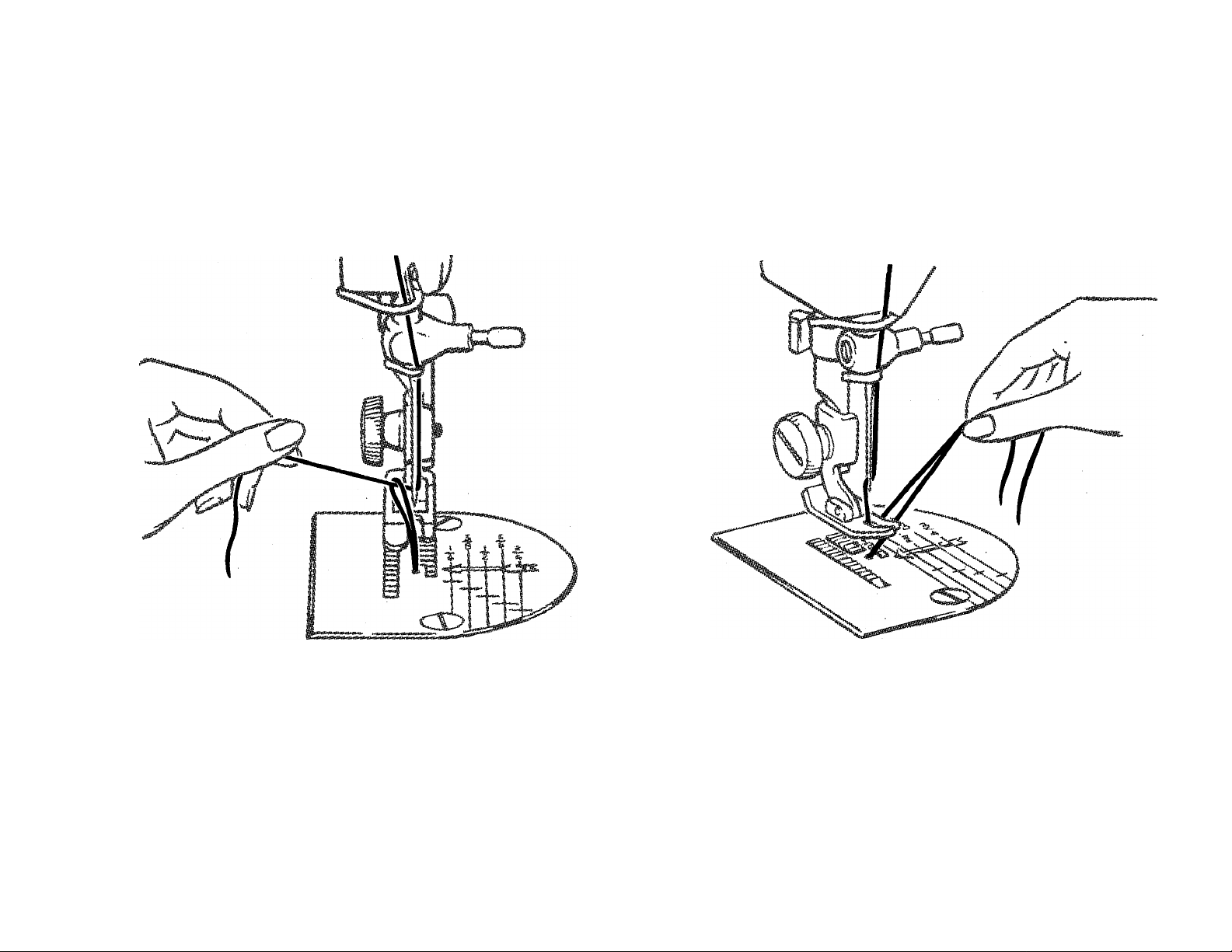

PREPARING TO SEW

Have take-up lever at its highest

point.

Hold needle thread lightly with

left hand.

Turn hand wheel so that needle

enters plate and brings up bobbin

thread.

Pull end of bobbin thread up

through oeedle hole in plate.

Lay both threads diagonally under

presser foot.

Page 17

SEWING A SEAM

Set stitch regulator for desired

stitch length.

15

Position needle in fabric about

y% inch from edge.

Raise stitch regulator to reverse.

Lower presser foot.

Page 18

76

в

act

stitch

to

of ^•з^J

^«А/и.

Co

mi,

ued

fo.

^®eao,. °^^or/o

'^^агс/

Page 19

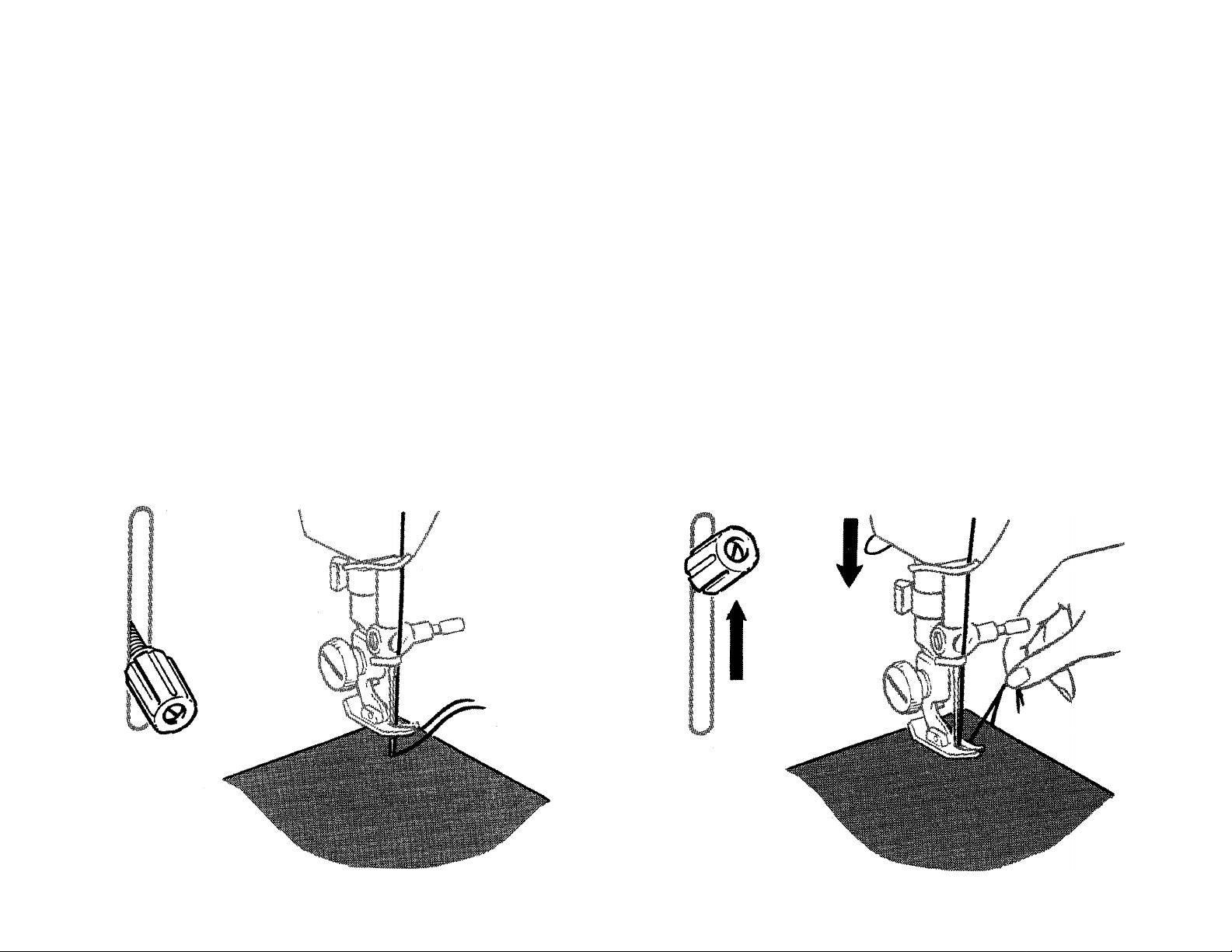

SEWING A SEAM-^Continued

Raise stitch regulator and back

stitch to reinforce end of seam.

17

With take-up lever at its highest

point, raise presser foot, draw

fabric back and cut threads on

thread cutter.

Page 20

18

GUIDING AND SUPPORTING FABRICS

Most fabrics need to be guided only in front of the presser foot.

Fabrics of unusual texture and weave, filmy sheers, crepes, knits,

tricots, etc., require support while being stitched.

For such fabrics apply gentle tension on the seam by holding

fabric in front and in back of the presser foot.

Page 21

V PRESSURE

19

PRESSURE ADJUSTMENTS

y regulating

SCREW

i /1 I 'V

//f

/1/

To decrease pressure, turn thumb

screw up.

To increase pressure, turn thumb

screw down.

Pressure is the force the presser foot exerts on

the fabric.

Too light a pressure will cause irregular feed

ing, which affects both quality of stitch and

evenness of seams.

Too heavy a pressure not only affects stitch and

seam quality, but will mar smooth surfaces and

pile fabrics.

Surface finish, as well as weight and texture of

the fabric, must be considered when determining

the amount of pressure needed.

Page 22

20

NEEDLE THREAD TENSION

Needle thread tension too

tight—correct by setting

dial to lower number.

Needle thread tension too

loose—correct by setting

dial to higher number.

I

A perfectly locked stitch results with upper and lower tensions balanced

so that needle and bobbin threads are drawn equally into fabric.

Page 23

21

BOBBIN THREAD TENSION

Bobbin thread tension

too tight—correct by turn

ing screw counterclock

Bobbin thread tension

too loose—correct by turn

ing screw clockwise.

wise.

A perfectly locked stitch results with upper and lower tensions balanced

so that needle and bobbin threads are drawn equally into fabric.

Page 24

DARNING

Worn or torn areas on household

textiles and clothing can be darned

effortlessly and quickly with little

practice. Adjust Stitch Length Reg

ulator for desired stitch length and

decrease pressure by turning thumb

screw up (see page 19). The pressure

should be lighter than for normal

sewing but not too light to prevent

work from feeding smoothly.

22

Place portion to be darned under

the presser foot. Lower presser bar

and start stitching, alternately allow

ing fabric to feed normally away

from you and then gently pulling

fabric toward you. Continue this for

ward and backward motion until area

to be darned is filled with parallel

lines of stitching. For reinforcement

or additional strength, cover area with

cross-side lines of stitching. Open

areas require an underlay. Basté

underlay in place before darning.

Page 25

23

Instructions for using

ATTACHMENTS

Those attachments which are not furnished with your machine are

available for purchase at your local SINGER SEWING CENTER.

• • •

Page 26

24

THE FOOT HEMMER

The foot hemmer

forms and stitches

a perfectly turned

hem without bast

ing or pressing. It

is attached to the

machine in place of

the presser foot.

Applications

Fine hems Hemming with lace

Edging ruffles Lace insertion

Hemmed seams Lingerie finishes

• Place the creased hem edge under

the foot and take several stitches

through the fold.

• Grasp the thread ends and the

single fold in front of the hemmer

and lift the single fold into the

hemmer scroll.

Soft fabrics will enter the scroll

best with the foot down, firm crisp

fabrics with the foot raised.

Hemming

• Form a double fold at the very

edge of the fabric.

• Crease this fold for about 2".

• Draw the needle and bobbin

threads under the hemmer.

Page 27

25

FOOT HEMMER (Confd)

• Stitch slowly for several inches until

hem is well started. Hold thread ends in

back of foot with the left hand and

guide the raw fabric edge into the mouth

of the scroll with the right hand.

Even feeding is essential to good hem

ming. The same width of fabric must be

kept in the scroll of the hemiher at all

times.

Hemmed Seams

Hemmed seams are often substituted for

French seams where a fine narrow seam is

appropriate.

• Allow a scant seam allowance.

• With right sides of the fabric together,

place the upper layer a scant to the

left of the lower layer.

• Insert the two fabric edges into the

hemmer and proceed as for a plain hem.

Page 28

FOOT HEMMER (Cont*d)

Hemming With Lace

Lace edgings can be applied with the

Foot Hemmer to trim lingerie hems, chil

dren’s clothes, etc.

Lace Applied Over Hern

• Fold and start hem in usual way.

• Starting about 1 inch down from end of

lace, place selvage under the needle,

then lower the needle to hold lace

firmly.

• Raise hemmer foot slightly and slip lace

under back part of foot.

• Stitch slowly, guiding fabric with right

hand and lace with left hand. Take care

not to stretch the lace.

26

Lace Applied Under Hem

When using lace underneath the fold of

a hem, the procedure is the same as when

making a hemmed seam (page 25). Slip

the lace in from the left as you would the

second piece of fabric.

This method is used where a neat finish

is desired on both sides of the material.'

Page 29

THE SEAM GUIDE

The seam guide is

adjustable for spac

ing stitching at any

distance between

Ys " and 1% " from a

fabric edge.

Applications

Seams Stay stitching

Top stitching—single and multiple rows

• Attach the guide to the machine with the

thumb screw in either of the threaded

holes at the right of the needle.

• Adjust for width desired.

• For straight edges, align guide with the

presser foot.

• For curved edges, set the guide at an

angle so that the end closest to the

needle acts as a guide.

• For pinned seams, place the pins with

the points toward the seam edge so that

they nip into the fabric at the stitching

line. The hinged foot will then ride

freely over the points.

•

27

Page 30

28

THE BINDER

The binder is used to apply commercial

binding as well as self-fabric bias to an

unfinished edge.

This colorful trim is attractive when

applied to children’s wear, aprons and

household textiles. It is a practical finish

for seam edges that ravel and for making

bound seams.

Inserting the Binding

Pre-folded commercial bias tape is

inserted from the right into slot of the

binder scroll.

• Cut the binding diagonally to form a

long point.

• Insert pointed end

into slot and pull

through scroll.

Self-fabric binding

should be cut

wide on the true

bias.

• Insert unfolded binding

directly into opening at end

of scroll and

pull through.

As binding passes through scroll raw

edges are turned in.

Page 31

29

BINDER-(Cont’d)

Adjustment and Operation

of the Binder

The edge to be bound is guided

into center of scroll. Stitching is

positioned close to edge of binding

by adjusting scroll portion of at

tachment.

• Loosen adjusting screw. Move

scroll to the right or left as neces

sary.

Be sure that screw is well tight

ened after making an adjustment.

Never pull binding as it feeds

through scroll. Allow attachment to

do the work. Merely guide edge to

be bound well into center of scroll

as you stitch.

Page 32

30

BINDER (Conrd)

Binding Curved Edges

Curved edges can be bound as

easily as straight edges, but require

slightly different fabric handling.

Inside Curves

Inside curves are straightened as

they are fed into the binder. If the

fabric is soft and has a tendency to

stretch, reinforce the edge with a

single row of stitching before

binding.

Outside Curves

Outside curves tend to lead away

from the center slot of the scroll and

should be guided so that a full seam

width is taken at the needle point.

Do not attempt to pull or straighten

the fabric into the full length of the

Page 33

THE ZIPPER FOOT

31

The zipper foot is designed for accurate placement of

stitches close to a raised edge. The hinged feature of this

foot insures even feeding over pins, heavy layers of

fabric or cross seams. It is attached to the machine in

place of the presser foot, and may be adjusted^ to either

side of the needle.

Applications

Zipper insertions Tubular cording

Corded seams Slip cover welting

Preparation

• Attach zipper foot to machine in

place of presser foot.

• Loosen zipper foot thumb screw

and adjust foot to right or left of

needle, as desired.

Align the notch in the toe with the

needle hole in the throat plate.

Check adjustment by lowering

needle into side notch, making

sure it clears the foot.

Lock foot in position by tighten

ing thumb screw.

Page 34

THE ZIPPER FOOT (Cont’d)

Zipper Insertion

Many diflferent types of

zippers are available for

everything you sew. There

are several satisfactory meth

ods for insertion. Detailed

sewing instructions are in

cluded in zipper packaging.

For any method used, the

Zipper Foot enables you to

form an even line of stitch

ing close to the zipper.

32

When the zipper is to the

right of the needle—

• Adjust the Zipper Foot to

the left of the needle.

When the zipper is to the

left of the needle—

• Adjust the Zipper Foot to

the right of the needle.

Page 35

THE ZIPPER FOOT (ConI’d)

Corded Welting

Cable cord comes in a variety of

sizes and when covered with a firmly

woven fabric makes a welting that is

an excellent seam finish.

This welting is prepared in advance

and then stitched into the seam. Cut a

true bias strip 1^4 inches wide, plus

three times the width of the cord of

either self or contrasting fabric. Sew

strips together on the lengthwise grain

to obtain desired length.

33

Adjust zipper foot to left side of

needle.

Encase cord in bias

strip, raw

edges even.

Lower presser bar.

Stitch close to cord, using a stitch

length slightly longer than for

regular seaming.

Do not crowd stitching against

cord.

Page 36

34

Corded Seams

The corded seam is a typical treat

ment for slip covers, children’s clothes,

blouses and lingerie.

When cording a seam the zipper foot

is usually adjusted to the right of the

needle so that the bulk of the work

will fall to the left.

• Attach corded welting to right

side of a single seam edge, using

same stitch length as used for welt-

ing (page 33). Guide edge of foot

next to cord, but do not crowd.

• Place attached corded welting over

second seam edge, and pin or baste

together.

• Keep the first stitching uppermost as

a guide and position the seam under

the needle.

• Stitch, this time crowding the foot

against the cord.

This method produces evenly joined

seam edges and tightly set welting.

Curved seams are corded as easily as

straight seams, except that a shorter

stitch is used. Since the seam allow

ance of the welting is bias, it is easy to

shape it to the seam.

Page 37

35

THE RÜFFLER

Adjusting Points

FORK

ARM>^,

SEPARATOR RUFFLING ^SEPARATOR

BLADE BLADE GUIDE

This attachment offers a simple and

effective way to make gathered and

pleated ruffles. Ruffles may be made

separately or made and applied at the

same time.

ADJUSTING

LEVER

ADJUSTING

FINGER

ADJUSTING

SCREW

1. Adjusting lever sets ruffler for gathers

or pleats. Number 1 space setting is for

gathers and places fullness at every

stitch. Numbers 6 and 12 are space

settings for pleats, spacing them 6 or

12 stitches apart. Star is for plain

stitching and is used when grouping

gathers or pleats.

2. Adjusting finger is used only for

pleating and affects width of pleat. It

is disengaged by bringing it out of

contact with adjusting screw.

3. Adjusting screw regulates fullness of

gathers or pleats. When turned in to its

limit with adjusting finger in place,

attachment is set for its deepest pleat.

When turned outward to its limit, with

adjusting finger out of action, rufiler

gives only a hint of fullness.

Page 38

36

THE RÜFFLER (Cont’d)

Activating Parts. Ruffling blade and

separator blade are of blue steel and

hold material to be gathered between

them. Ruffling blade forms gathers or

pleats by carrying fabric to needle

according to spacing and fullness to

which ruffler is adjusted. Separator

guide is slotted to guide seam edges

evenly and to separate ruffled strip

from material to which ruffle is at

tached.

Preparation

• Raise needle to highest point.

Gathering

• Set adjusting lever on Number 1

setting and throw adjusting finger

out of action.

• Turn adjusting screw for amount of

fullness desired and set stitch length

to space fullness. Turn screw in for

more fullness; turn out for less

fullness.

• Locate ruffler on presser bar with

fork arm over needle clamp screw.

Securely tighten both presser bar

and needle clamp screws.

Page 39

THE RÜFFLER (Confd)

Length of sewing machine stitch

also affects ruffle fullness. Since a given

attachment setting puts an equal

amount of fullness into each stitch

regardless of its length, shortening the

37

stitch (more stitches to inch) makes

ruffle fuller; lengthening the stitch

(fewer stitches to inch) makes it less

full. For fine, closely spaced gathering,

use a short stitch and an outward

adjustment of adjusting screw. For

deeper, less closely spaced gathering,

turn adjusting screw inward and use a

medium length stitch.

Insert material to be gathered be

tween blue blades and through first

separator guide.

MATERIAL

Draw to back of needle.

Lower presser bar and stitch.

Fabric texture influences perform

ance of ruffler as well as results. Soft

fabrics, cut on crosswise grain, are

best adapted for gathering ruffles.

Always test stitch length and ruffler

setting on a scrap of self-fabric before

proceeding with the actual work.

Page 40

THE RÜFFLER (Cont*d)

Attaching ruffle

• Place ruffle strip between two

blue blades and through first

separator guide.

• Place material to which ruffle

38

RUFFLING

MATERIAL

GARMENT

is to be attached between

separator blade and feed of

machine.

• Proceed as for plain gathering.

Right sides of fabrics are

placed together when the seam

is to fall to the inside.

Page 41

Pieciting

39

THE RÜFFLER (Confd)

• Move adjusting lever of ruffler to

desired space setting for pleats

either 6 or 12 stitches apart.

• Set stitch length.

For deepest pleat, activate adjusting

finger and turn adjusting screw inward

to its maximum setting. For smaller

pleats turn adjusting screw outward.

A short stitch places pleats more

closely together; a long stitch sepa

rates the pleats for a greater distance.

• Insert fabric to be pleated between

blue blades and into first separator

guide.

• Lower presser bar and stitch.

Page 42

40

THE RÜFFLER (Cont’d)

Crisp fabrics cut on the crosswise grain form the sharpest pleats. Glazed

fabrics handle best if the glazed side is downward and the soft backing is

next to the ruffler blade.

Group Pleating

By using star setting (plain

stitching) alternately with 6 or

12 stitch setting, pleats are

formed in groups. Even spacing

between groups is accom

plished by counting the number

of stitches.

_

______________________

Page 43

AUTOMATIC

ZIGZAGGER

41

FASHION* AIDS

Decorative stitch patterns for bor

der designs, lace applications and

applique are accomplished automat

ically with the SINGER* Zigzagger.

This time-saving attachment will

also blindstitch hems, mend rips and

tears, reinforce seams, overedge

seam edges and stitch scallop edges

easily and quickly.

Page 44

BUTTONHOLER

42

FASHION AIDS (Confd)

Beautiful, evenly stitched button

holes are quickly and easily made

with the SINGER* Buttonholer.

The attachment makes both

straight and eyelet-end styles, auto

matically guiding them to the size

and shape selected.

Nine different lengths, ranging

from to 13^", are available.

Page 45

43

FASHION AIDS (Cont’d.)

THE EDGE STITCHER

This attachment provides a series of slotted guides which

regulate the placement of stitching in relation to a fabric edge.

Among its many decorative and practical applications are

the joining and insertion of lace, tucking from pin width to

1^", French seaming, seam piping, facing and seam finishing.

THE GATHERING FOOT

Single or multiple

rows of shirring can be

quickly and expertly

placed with the gather

ing foot. Evenly spaced

shirring is insured as

this foot is designed to

lock fullness into every

Applications stitch.

Plain shirring Waffle shirring

Elastic shirring Machine smocking

Page 46

TUCKER

44

FASHION AIDS (Cont’d)

9 0

Since the beauty of tucking lies in

its explicit accuracy, use of the

Tucker will contribute greatly to the

attractiveness of the work.

With this time-saving attachment,

tucks up to one inch may be stitched

and marked in one operation.

Two adjustable scales are pro

vided to gauge tuck width and

spacing.

Page 47

X

CLEAN

BETWEEN

TENSION

DISCS

45

TO CLEAN THE MACHINE

When in regular use—

The machine should be cleaned

periodically to remove the lint and

fluff which may have accumulated

around the working parts.

To remove face plate, turn hand wheel

until take-up lever reaches its highest

point, then remove face plate thumb

screw, raise face plate and carefully pass it

toward you over end of take-up lever.

Clean the area inside. Remove bobbin

case and throat plate and clean stitch-

forming mechanism.

After each cleaning, oil the machine

as instructed on pages 46 and 47.

If the machine is to be stored for an

indefinite period, brush away all traces

of lint and fluff, then swab all exposed

CLEAN

parts with a lint free brush saturated

with SINGER* oil to protect against

rust damage.

The area in head of machine that should be cleaned

and covered with a protective coat of oil is shown at left.

Also clean stitch-forming mechanism and cover

exposed parts with a coat of oil.

Page 48

46

TO OIL THE MACHINE

To keep your machine in top condition, use SINGER Oil and SINGER*

Lubricant.

Both are quality products especially prepared for sewing machines, and

should always be used in the care of your 221.

Clean the machine periodically as

instructed on page 45.

Apply a drop of oil to each place

indicated.

Page 49

47

TO OIL THE MACHINE —(Confd)

Remove thumb nut, felt washer and cover

plate from underside of machine. Apply oil to

each place indicated below.

Apply a small amount of SINGER Motor

Lubricant to the gears.

Replace bottom cover.

NEVER APPLY OIL TO THE GEARS.

Page 50

TO LUBRICATE THE MOTOR

NEVER USE OIL OR

ORDINARY GREASE ON

THE MOTOR. FOR BEST

RESULTS, USE SINGER

MOTOR LUBRICANT fur

48

nished with the machine.

When the machine is shipped

from the factory, the two

grease tubes, indicated by

arrows, are filled with

enough lubricant for approx

imately six months’ use.

Refill grease tubes at least

once each six months by in

serting tip of lubricant con

tainer into grease tubes and

squee2ing enough lubricant

into each tube to fill it.

Page 51

49

LIGHT

The light is turned “on” or “off” by the

switch located on bed of machine at the

right.

LOCKS

▼

ammmmmm^

t

LIGHT SWITCH

%\\ft&WrAWW\iv\W»\№VS ft fli

Ir-'-'-'M

III

S '

\wAttmiHlWUlW\nWtt\vUW\i

li 8

To Remove Bulb. Press bulb into socket

and turn it in “unlock” direction, as shown,

and withdraw.

To Replace Bulb. Press bulb into socket

with bulb pin in slot and turn it in “lock”

direction, as shown.

UNLOCKS

«\AV.A\\AUV.ttWAWVAWAi\i^^.

j / i If i

|firtjwiwSK\w.MV |

^WAAHUhUH>HAb!AlWmUA»A%l

BULB PIN

Page 52

50

BELT TENSION

Tension on the belt should be only heavy

enough to keep the belt from slipping.

To adjust—

• Loosen bracket screw (A) a full turn.

• Allow weight of motor to supply correct

belt tension.

• Tighten bracket screw.

Page 53

TO PACK MACHINE

Place attachment box in its com

partment at left of carrying case, as

shown below. Turn up machine bed

extension and place machine in case

with hand wheel at right and base of

machine at right of wooden strip at

bottom of case.

51

Slide controller from right to left

into its holder in lid of case and place

electric cord at rear of machine, as

shown above.

Page 54

52

INDEX

PAGE

Attachments............................................

Foot Hemmer

Binder

Ruffler.................................................. 35-40

Seam Guide

Zipper Foot

Belt

To Regulate Belt Tension. ...... 50

Bobbin

Removing.................................................... 7

Winding

Bobbin Case

Removing

Replacing.................................................. 11

Threading

Carrying Case

To Pack Machine in Case........................ 51

Chart for Fabric, Thread, Needle

and Stitch Length....................................... 4

Darning......................................................... 22

Electrical Information

Light.....

Motor.........................................................

FASHION Aids

...................................................

...................................................

....................................................

......................................

..............................................

..........................................

.............

.................................................

......................................

23-40

24-26

28-30

27

31-34

8-9

7

10

49

6

Buttonholer............................................. 42

PAGE

Edge Stitcher

Gathering Foot

Tucker............................................... 44

Zigzagger, Automatic

Principal Parts of Machine 221. ,.. 3

Maintenance of the Machine

Oiling and Lubrication

To Clean the Machine

Needles and Thread

Needle Insertion

Pressure Adjustment

Sewing

Guiding and Supporting Fabric. . 18

Prepare to Sew

Sewing a Seam

To Regulate Length of Stitch. ... 13

SINGER Service

Threading

Bobbin Case

Needle................................................ 12

Thread Tensions

Bobbin Thread

Needle Thread

....................................

.........................................

......................

.................

.....................

.....

.................................

....................................

...................................

....

.....................................

.....................................

...................................

.....................................

........................................

..........................................

46-48

43

43

41

45

5

5

19

14

15-17

2

10

21

20

Page 55

To all whom it may concern:

The improper placing or renewal of the trademark "SINGER" or

any other of the trademarks of The Singer Company (all of which are duly

Registered Trademarks) on any machine that has been repaired, rebuilt,

reconditioned, or altered in any way whatsoever outside a SINGER factory

or an authorised SINGER agency is forbidden.

Form K6436

(364)

Printed in Great Britain

Page 56

For your protection

SINGER Sewing Machines are sold and serviced wherever you

see the famous SINGER and Red "S” Trademarks. When your

machine needs servicing call your SINGER SEWING CENTER to be

sure of warranted SINGER parts and service. See address in the

classified telephone directory.

THE

NGER COMPANY

Loading...

Loading...