SINGER

CONGRATULATIONS

,..on the purchase of this new Singer* electronic sewing machine. To achieve

the most enjoyment and satisfaction from this product, it is recommended

that the Instmciion manual be read through step by step while seated in

front of the machine. This will help the operator get to know all of its parts

and capabilities.

INSTRUCTION BOOK

SINGER* MODEL 2210

The manufacturer reserves the right to change the appearance, design, or

accessories of this sewing machine as considered necessary v/ithout any

notification or obligation.

* A trademark of The Singer Company

Copyright 1987, Singer Sev/ing Machine Company,

All rights reserved throughout the v/orld.

TABLE OF CONTENTS

1. GETTING TO KNOW YOUR MACHINE

Principal Parts ................................................................... 3

Accessories

Important Safeguards

2* GETTING READY TO SEW

Connecting the Controller...................................................... 6

Running the Machine

Changing Snap^on Fresser Feet

Changing Screw on Presser Feet

Changing Needles ............................................................... 8

Removing Needle Plate....................................................... 8

Replacing Needle Plate...................................................... 8

Attaching Feed Cover

Attaching Darning and Embroidery Foot ...................................... 9

Wiruling the Bobbin

Threading the Bobbin Case

Threading the Machine

Raising the Bobbin Thread

Adjusting Needle Thread Tension

Cloth Plate Removal and Replacement

.......................................................................

..........................................................

..........................................................

...

.......................................... 7

......................................

...........................................................

......................

..................................................

.......................................................

...................................................

......................................

............

................................

......................................

6

6

7

9

10

11

..13

13

14

15

A

3. STITCH SELECTION

The Basic Controls............................................................ 16

Pattern Selection ........................................................... 17

Description of Stitches......................................................... 17

Audible Signals................................................................. 20

Instant Pattern Selection.................................................. 21

Fine TunirKj Patterns

Adjusting Stitch Width

Adjusting Stitch Length ....................................................... 24

Adjusting Stitch Balance ......................................................

Reverse Stitching............................................................ 25

Left/Right Needle Position

Needle Up/Down Control ....................................................

Pattern Programming Controls

The Memory Controls ......................................................... 28

4. SEWING TIPS AND APPLICATIONS

Fabric, Thread, and Needle Table

Sewing a Seam................................................................ 32

Guiding Fabric ................................................................. 33

Basting ......................................................................... 33

Bllndstitching

Inserting a Zipper............................................................. 36

Buttonholes .................................................................... 37

Button Sewing ................................................................. 42

twin Needle Sewing

Performance Checklist

...............................................................

.......................................................

......................................................

........................................................

..........

24

24

.....................................................

...............................................

............................................

35

43

............................................ 44

25

28

27

28

31

6. CLEANING AND CARING FOR THE MACHINE

Removing Face Plate

Cleaning the Machine

F^errioving and Replacing Bobbin Case..................................... 46

Replacing Slide Plate

Removing and Replacing Light Bulb

.......................................................... 45

..........................................................

...........

................................................

..........................................

45

46

47

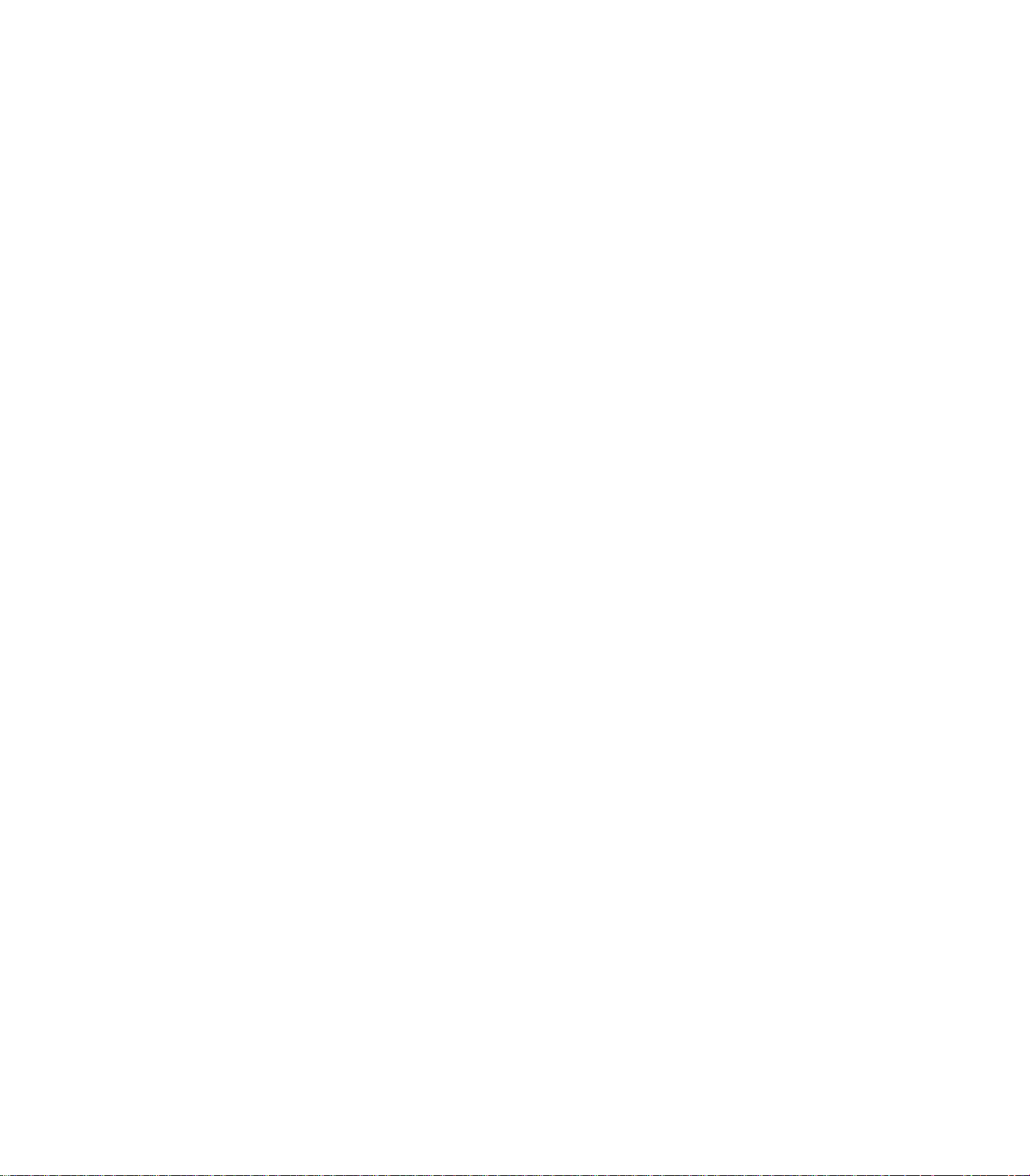

1. GETTING TO KNOW YOUR MACHINE

23 1

1

Carrying Hancllo

2.

Spool Holder

3.

Bobbin Winder

Pattern Display Panel

4.

16. Needle Clamp

17.

Cloth Plate

Prosser Foot

18.

19. Needle Plate

5. Hand Wheel

Main Control Panel

6.

Instant Pattern Buttons

1.

8. Pattern Programming Controls

Memory Buttonhole Controls

8.

Stitch length and Stitch Width Fine

10a.

Tuning Buttons

10. Stitch Ler^gth Fine Tuning Control

11. Stitch Width Fine Tuning Control

Pattern Selection Controls

12.

Pattern Preview Window

13.

20. Thread Cutter

21.

Snap«in Thread Guide

22.

Bobbin Winder Tension

23, Thread Tension Control

24.

Pressor Foot lifter

Fabric Feed (Feed Dog)

25.

26.

Slide Plate

Pov/er and Light Switch

27.

28. Stitch Balance Control

Speed Controller Connection

20.

30. Electrical Rating label

14.

Instant Reverse Button

Needle Up/Down Button

15.

Speed Controller

31.

Electrical Power Connections

32.

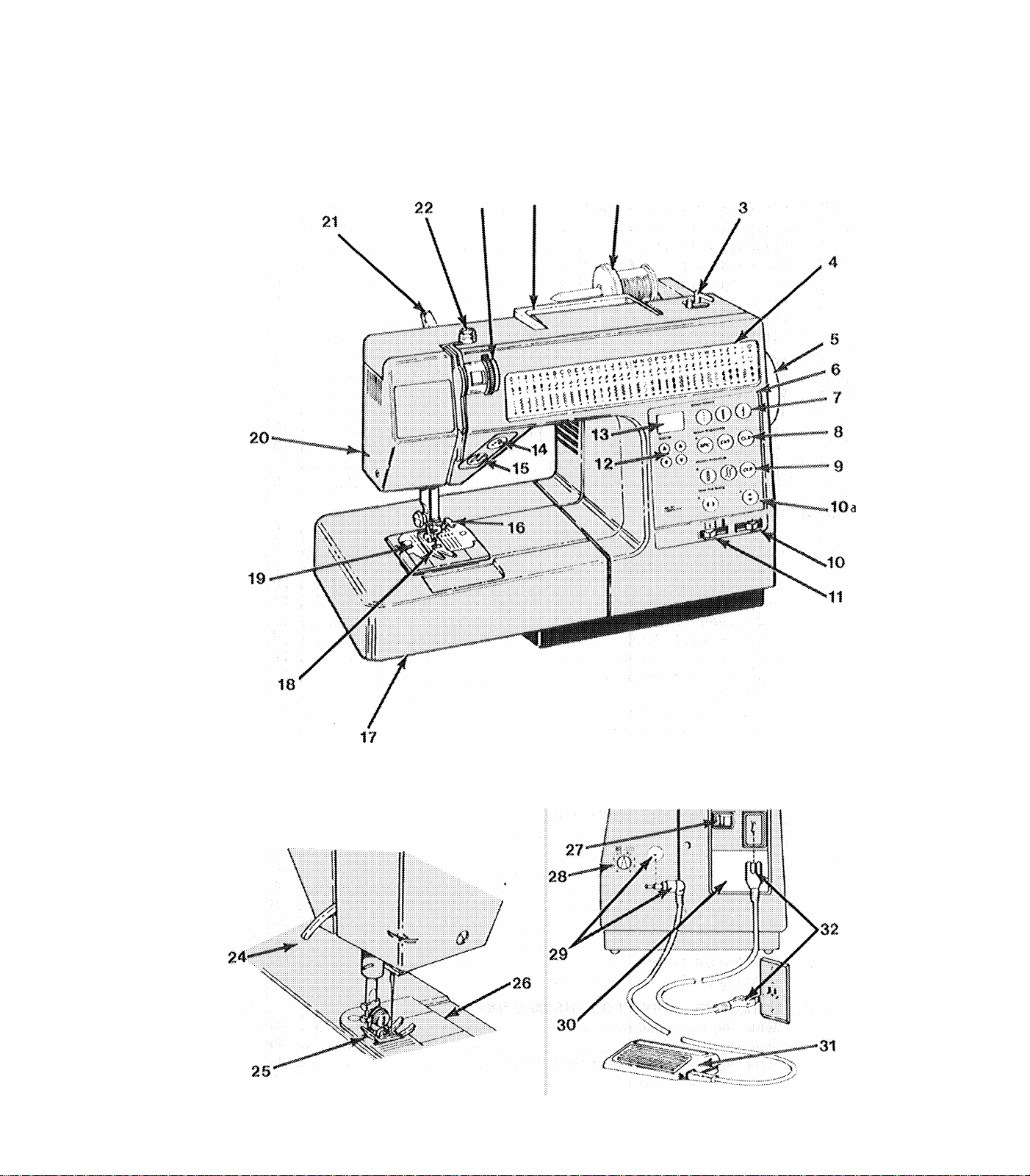

Accessories

The following accessories, except where indicated otherwise, are furnished with this

sewing machine:

t.

Qomretl

Purpose Prosser Foot and

Needle Plate are on the machine when

delivered. Use together for most sew

ing projects.

2. Special Purpose Presser Foot for

decorative stitching.

3. Buttonhole Prosser Foot.

4. Zipper Foot.

6. Blind Stitch Presser Foot.

6. Button Sewing Presser Foot.

/. Darning and Fmbroldery Foot.

6. Spoof Holder for medium and large

thread spools.

9. Small Spoof Holder for small thread

spools.

10. Needle Pack includes an assortment of

types and si/es.

11. Feed Cover for darning or embroidery.

12. Extra Bobbins.

13. Twin Needle and Extra Spool Pin v/ilh

f-elt Washer (optional) for decorative

stitching.

Important Safeguards

1. Disconnect the povveriine plug from the electrical outlet when changing

needles, feet, or needle plates, or when leaving machine unattended This

eliminates the possibility of starting the machine by accidentally pressing

the speed controller.

2. Before removing the bobbin case, disconnect the powerline plug from the

electrical outlet.

3. Because of the up and down movement of the needle, work carefully and

watch the sewing area when operating the machine.

4. Do not pull the fabric while stitching as this may deflect the needle, caus*

ing it to break.

5.

Before cleaning the machine, disconnect the powerline plug from the eleC'

trical outlet.

6. Do not attempt to adjust the motor belt. Contact the nearest service center

or an authoriiied dealer should any adjustment be required.

7. Before changing the light bulb, make sure the povveriine plug is disconnected

from the electrical outlet. Be sure to replace the face plate v/hich covers

the light bulb before operating the machine.

8. This machine is designed to use a 15 watt maximum light bulb only.

9. This machine Is double insulated. When servicing product, use only ideiv

tical replacement parts.

This product is suppressed for radio and television interference with the Interna'

tional Electrotechnical Commission requirements of the CISPR.

2. GETTING READY TO SEW

To really enjoy sewing, get to know the machine well. This chapter will be valuable

in doing just that-

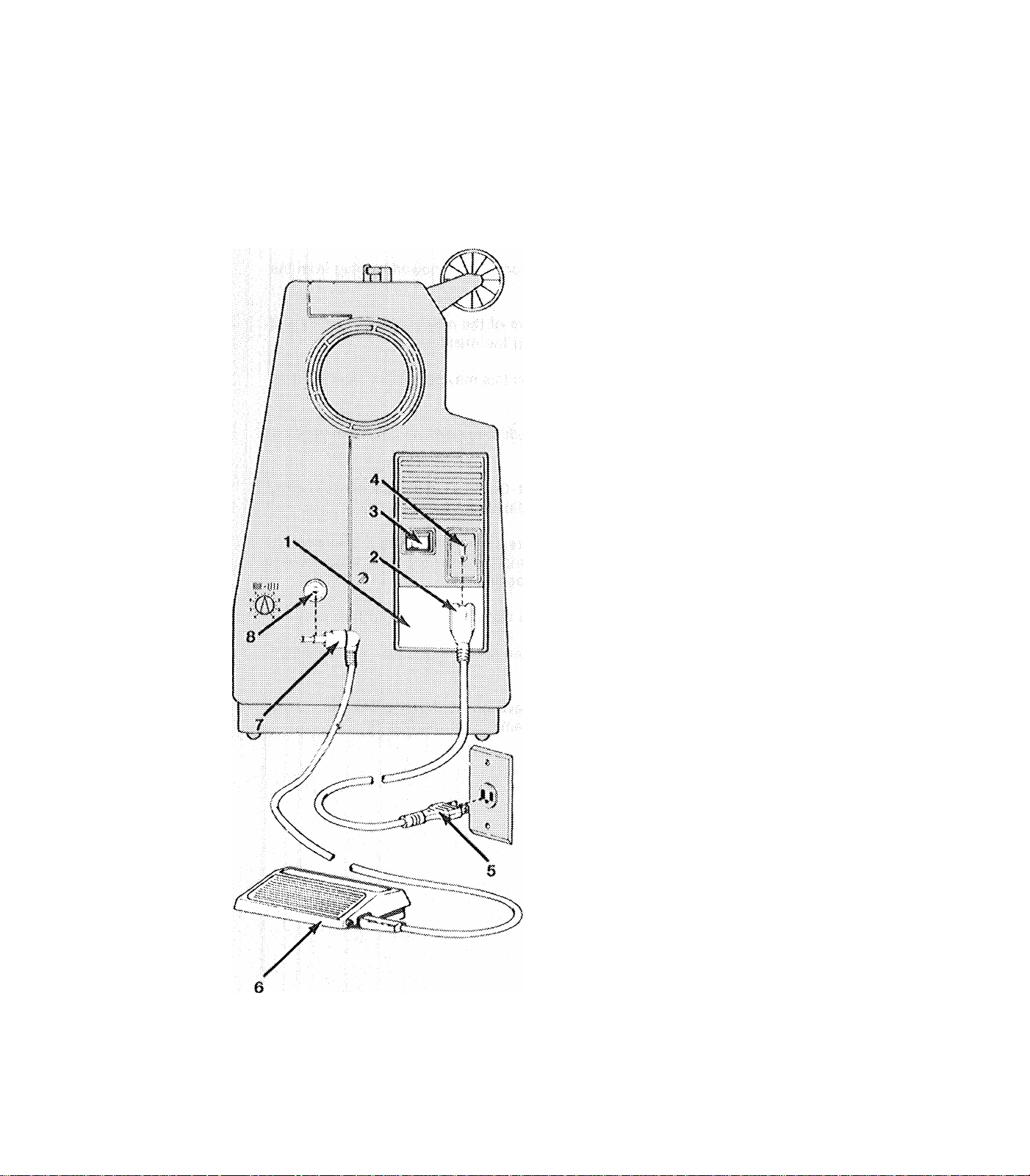

Connecting the machine

Connecting the Controller

NOTE: Before plugging in the machine, be

sure the electrical information on the label

(1) belov/ the handwheel agrees with the

local electrical supply and power switch is

in the “OFT” position.

Push plug (2) into the receptacle (4) at the

fight end of the machine. Then, connect plug

(6) to an electrical outlet.

Push speed controller plug (/) into recepta^

ele (8) also on the right end of the machine.

Runnirtg the Machine

To turn on machine and sewing light, press

portion ‘T’ of power switch (3). To turn off

machine and light, press front portion “0” of

power switch.

To run the rnactrlne and control speed, press

the speed controller (6) with foot. The tiarder

it is pressed, the faster the machine will sew.

To stop machine, remove foot from the con

troller.

NOTE: Do not operate machine without fa

bric under the pressor foot as this may da

mage the feed and the presser foot.

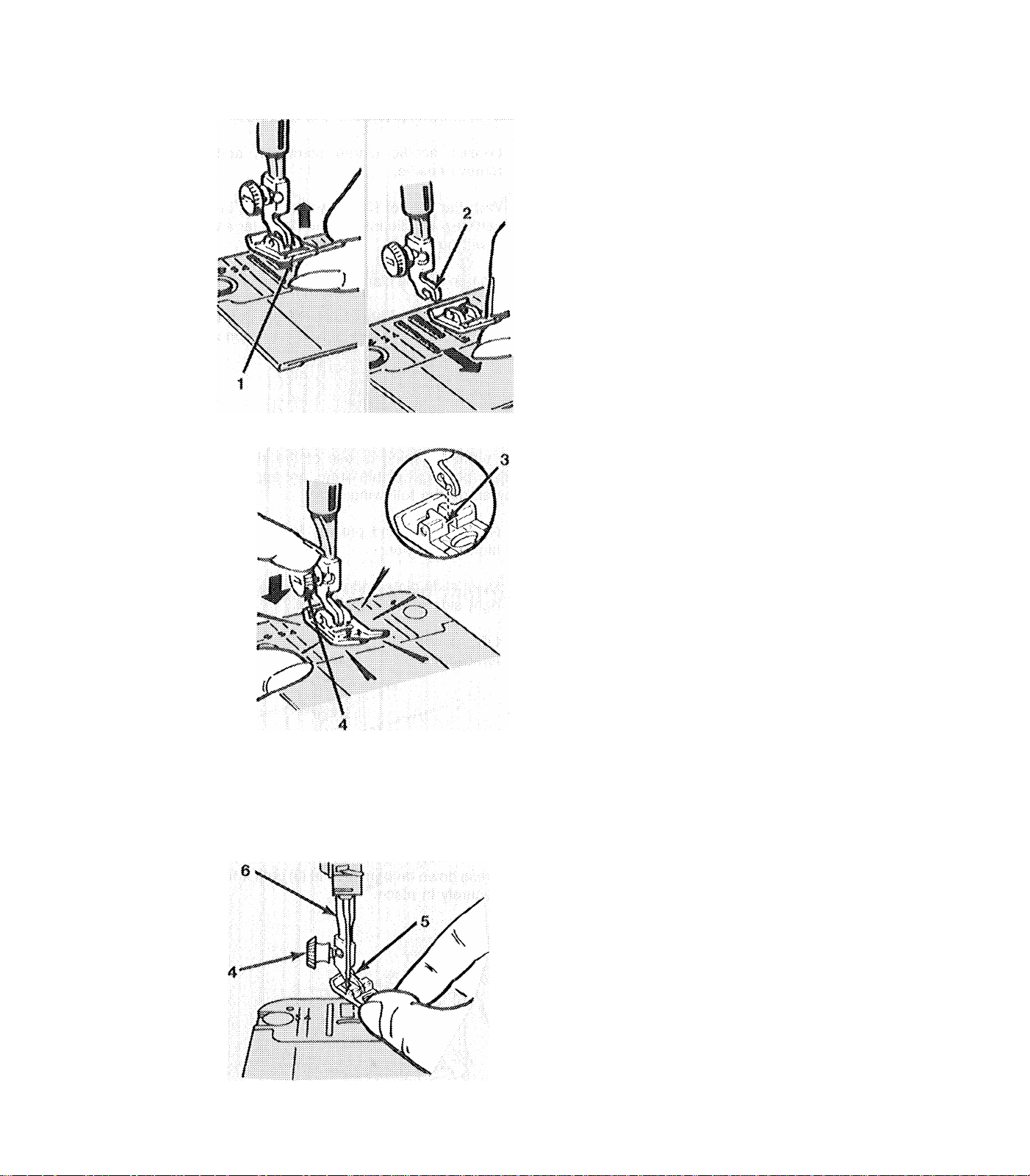

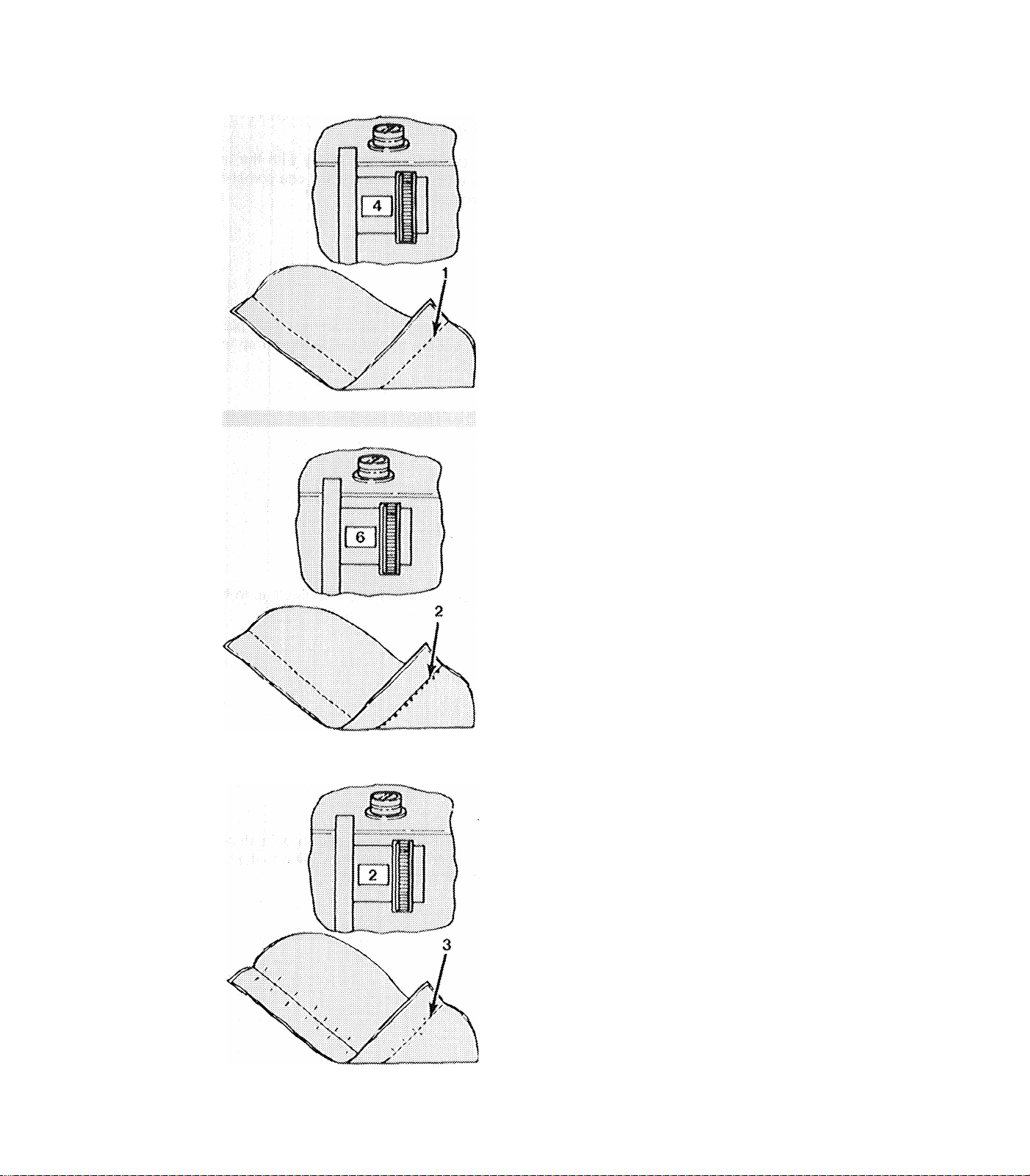

Changing Snap-on Presser Feet

The accessory feet supplied with the

machine fit onto a common shank and are

attached easily as follows:

« Raise needle to highest point by turning

the handwheel towards the operator.

^ Raise presser foot using lever on rear of

machine.

♦ Fusil up on toe of presser foot (1) until it

snaps off shank (2) and remove foot.

Place new foot on needle plate with pin

(3) under center of shank.

Changing Screw-on Presser Feet

Using presser foot lifter, lov/er siiank on

to pin (3) and push down firmly on presser

foot screw (4) until foot snaps into place

onto shank.

Special feet which have built-in shanks are

replaced as follows:

• {3aise needle and presser foot.

« l,oo$efi presser foot screw (4) with a coin

and remove presser foot with shank (5)

guiding it towards the operator and to the

*

right.

* To replace foot, fiook It around presser bar

(6) and screw (4). Tighten screw with a

coin.

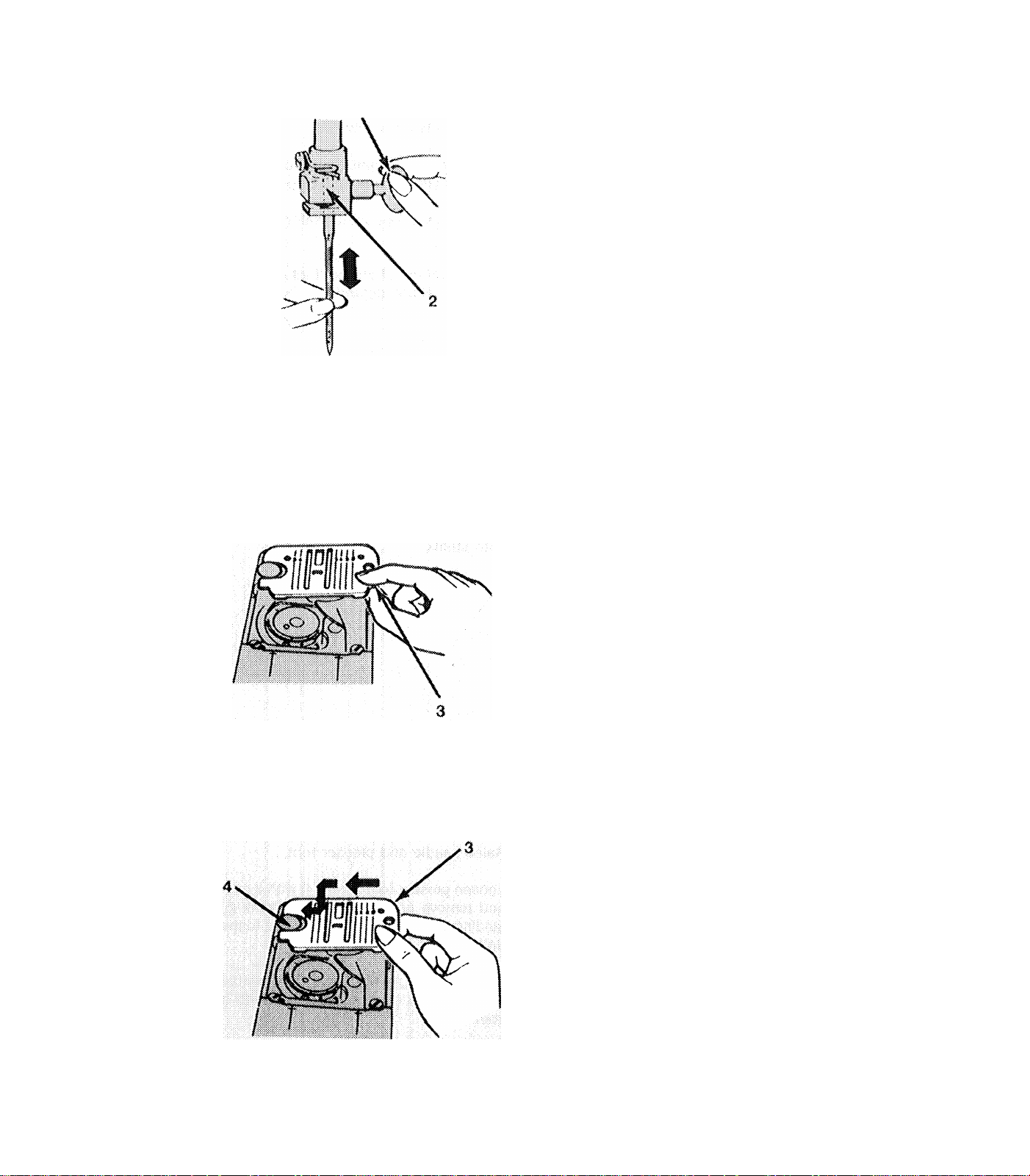

Changing Needles

Removing Needleplaie

« Raise needle to highest position by turn

ing handwheel towards the operator.

♦ Loosen needle clamp screw (1) and

remove needle.

♦ With hat side of needle to the back, in

sert new needle into damp (2) as far as

it v/lil go.

♦ Tighten needle damp screv/ (1) securely.

Check the Fabric, Thread and Needle Chad

in this book for correct needle and fabric

combinations.

For either cleaning or use of the straight

stitch plate, available from an approved

dealer, do the following:

Replacing Needleplate

♦ Raise needle and pressor foot to their

highest position.

♦ Open slide plate and place thumb under

right side of needle plate (3).

♦ Lift up and pull plate to the right to

remove it from the machine.

• Holding needle plate as shown, slide it to

the left under the head of damping pin (4).

• Press down on right side at (3) until it fits

securely in place.

•

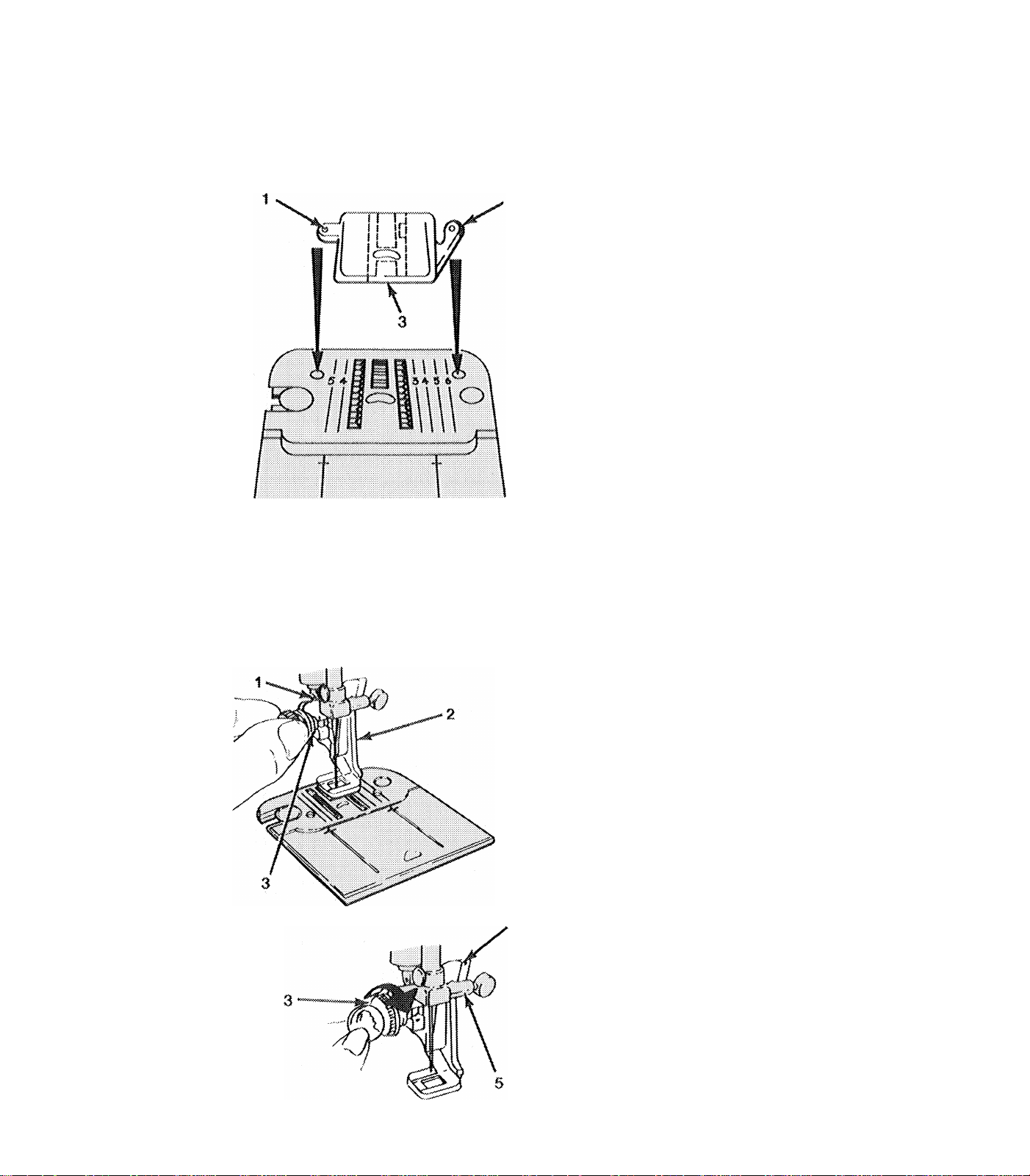

Attaching Feed Cover

I'or darning and free molion embroidery, the

feed cover prevents the feed from moving

material. Attach ft as follows:

♦ Raise needle and presser foot, and open

slide plate.

♦ Slide feed cover on top of needle plate,

pressing tabs (1) and (2) into holes in

needle plate. Then, close slide plate.

t

® To remove, open slide plate. Lift frord

edge of cover (3) and pull it away.

If operator prefers to do these operations by

removing presser foot and shank from

machine, be sure presser bar is lowered to

maintain proper thread tension.

the

Attaching Darning and Embroidery Foot

A Special presser foot is included as an accessory for use In darning, embroidery, and

machine basting. Attcich it to the machine

as follov/s:

♦ Raise presser bar (1) and remove existing

presser foot with attached shank follov/ing directions under “Changing Screw on

Presser Feet'L

♦ Wi th need I e I n t h e u p pos i t i on, g u i de dar*

ning and ernbroidety foot (2) onto presser

bar from the rear of the machine, hooking it around the bar (1) and under the

screv^ (3).

♦ Make sure tab (4) of foot is fitted on top

of the needle clamp screw (5). This pro

vides the automatic lifting of the foot for

manual positioning of the fabric when

needle is in the “up” position and out of

fabric.

♦ Tigtiten

screw

(3) snugly using a coin.

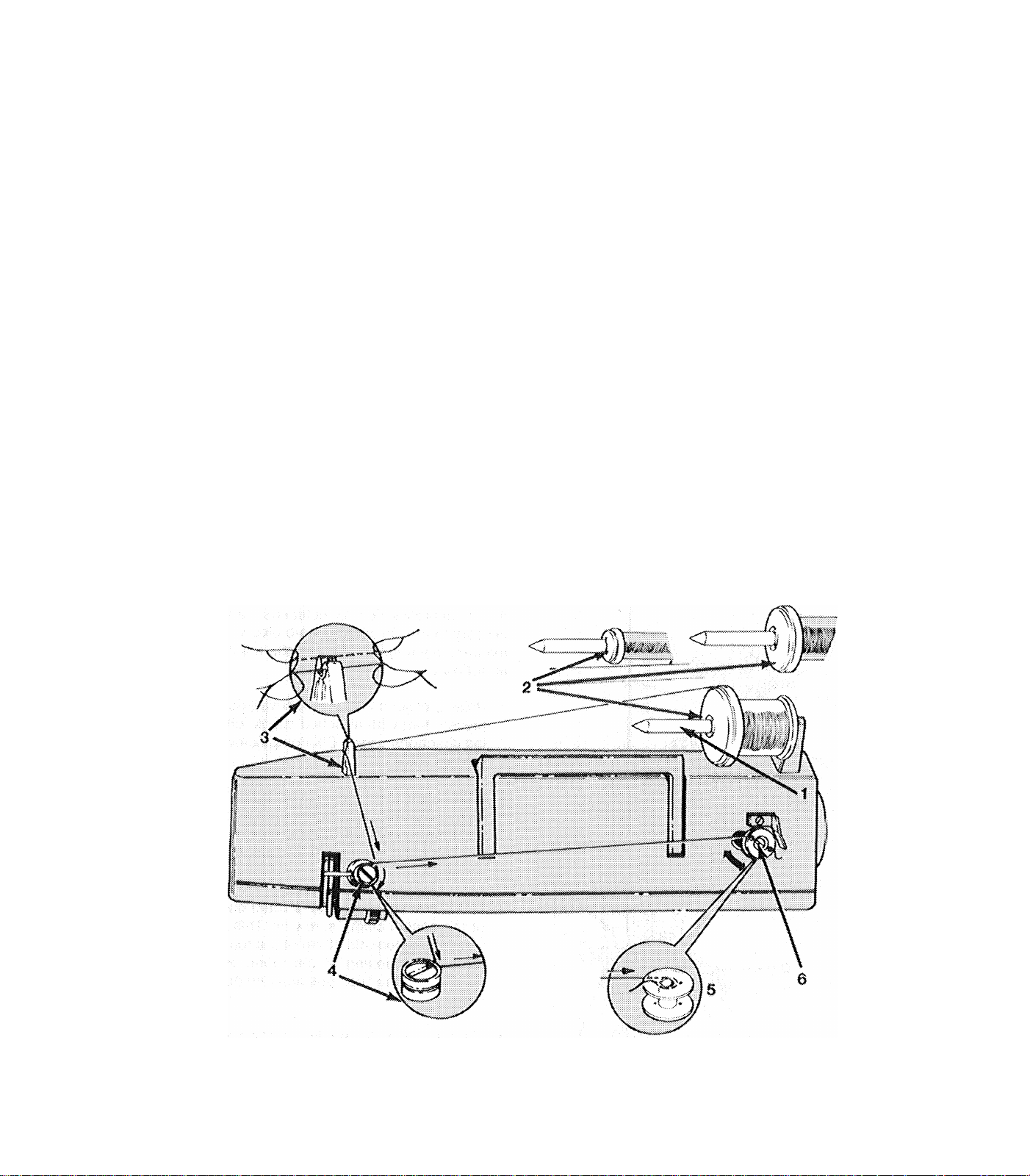

Winding the Bobbin

Winding of the bobbin is done before threading machine:

♦ Place spool of thread on spool pin (1).

* Choose size of spool holder (2) to fit spool. Slide it onto pin snugly against

spool to keep spool from turning.

♦ Lead thread into top thread guide (3) by snapping it down into lop of guide

with two hands.

♦ Proceed to thread tension (4) wrapping thread ortce around in a clockwise direc-

tion.

* Guide end of thread through small hole in top of bobbin (5) and place bobbin

onto bobbin winder (6).

* Push bobbin winder to the right to engage the drive system and to disengage

sewing mechanism for winding.

♦ Hold thread end coming through hole in bobbin and start motor. V^ind slowly.

Stop after a fev/ turns to trim end, then continue v/Inding to desired fullness.

NOTE: Bobbin will stop turnifig by itself vdien full, but sewing mechanism must

be reset by the operator.

• Release speed controller and push winder to the left to reengage sewing

mechanism.

10

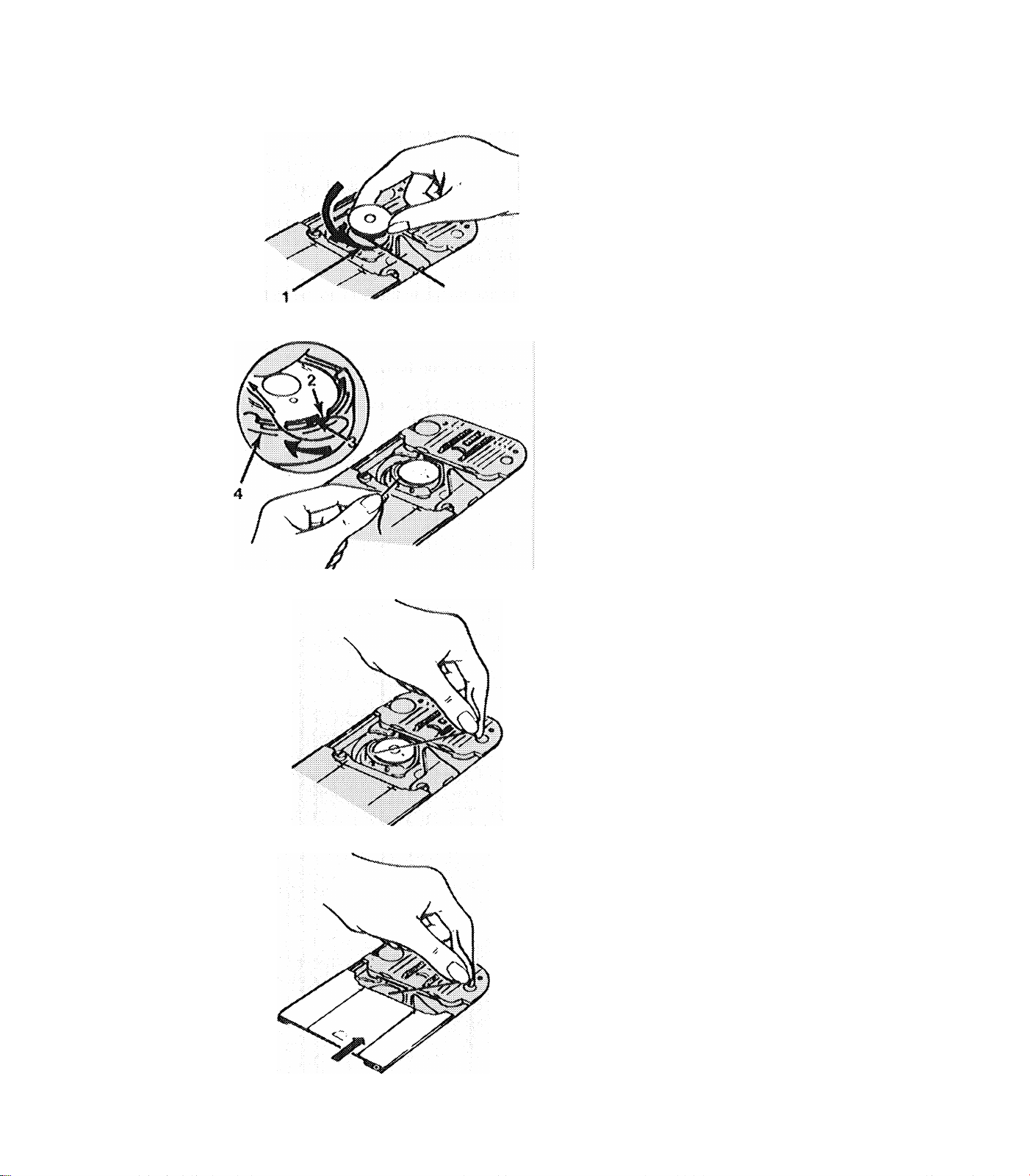

Threading the Bobbin Case

* Hold bobbin so that thread unwinds in a

counter-clockwise direction, as shown,

and place bobbin in bobbin case (1),

• Pull thread into notch (2), draw it back

under the tension spring (3), and back in

to slot (4).

Draw approximately 4 inches (10 cm) of

thread across the bobbin.

Close slide plate allowing the thread to

enter the slot between the needle plate

and slide plate.

11

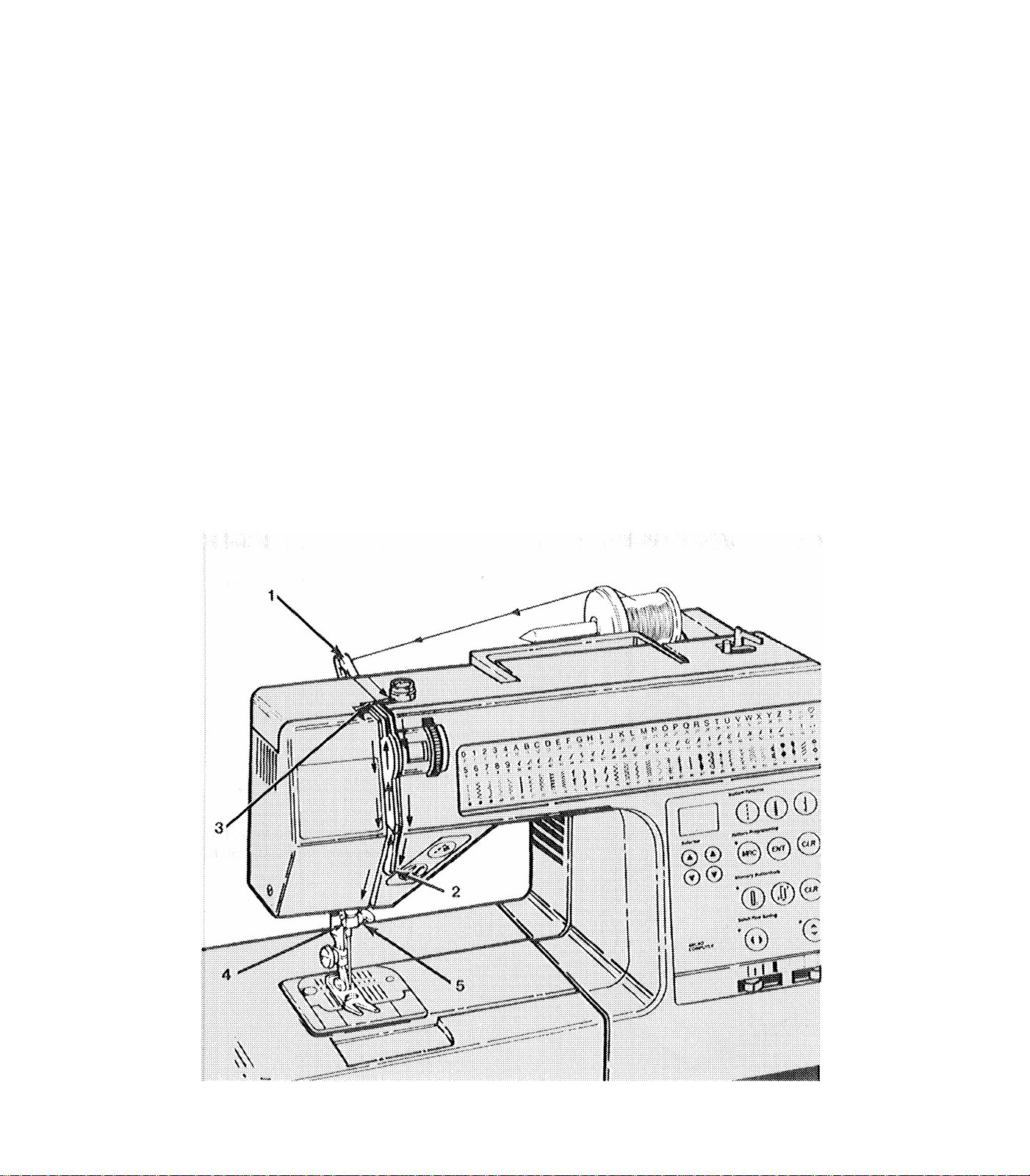

Threading the Machine

The top thread is now ready to be threaded into the machine. Proceed as foltows:

• Raise needle and presser foot to their highest positions.

*

Lead ttiread from spool on spool pin and snap into top thread guide (1) by

grasping thread with two hands and snapping it down into top of guide.

♦ Foilovving arrows in illustration, guide thread across top of machine, down the

right hand channel through the tension discs, under the bottom of the chan*

nel separator (2), and up the left hand channel.

♦ At the top of the left thread channel (3), pull the thread to the left into the self*

threadir^g take*up lever and then down to the needle going through guides (4)

and (5) on needle clamp.

NOTF: Do not thread lower guide (5) if you are using heavy thread.

• Lower the presser foot and thread the needle from front to back drawing about

4 inches (10 cm) through the eye of the needle.

12

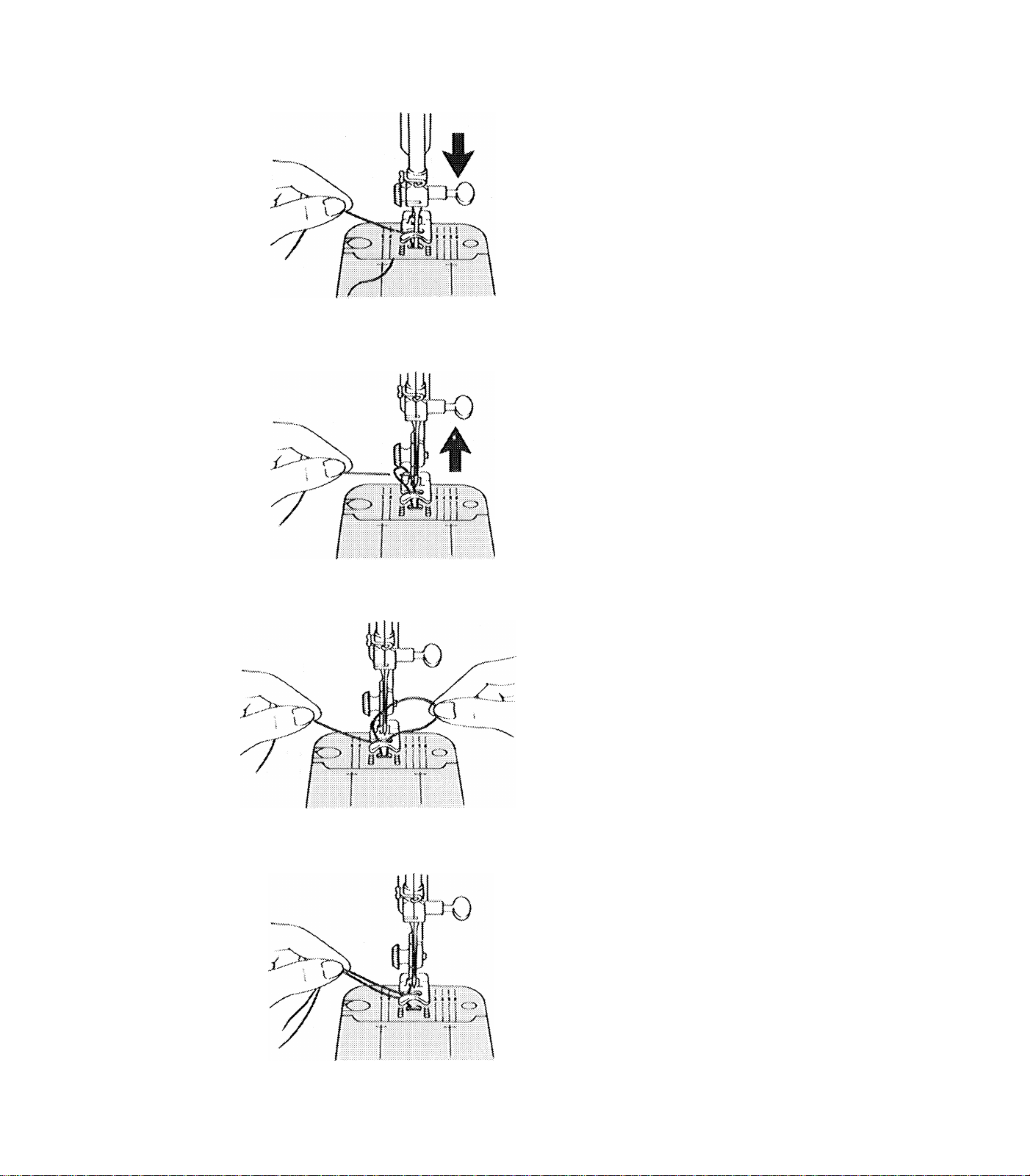

Raising the Bobbin Thread

1 he last step in tiireading the machine is to

raise the bobbin thread. Proceed as fotiows:

« Raise pressor foot.

♦ tiold needle thread lightly with the left

hand and turn handwheel one complete

revolution by hand.

• As the needle rises from the needle plate,

the bobbin thread will be drawn up in a

loop.

Grip loop with fingers and pull up to free

end of bobbin thread.

« Place both needle and bobbin threads

under the foot and draw them to the back

of the fnachine.

13

Adjusting Needle Thread Tension

Bobbin thread tension Is preset by factory

but the top thread tension can be adjusted

to suit different sewing situations.

♦ For most stitching, setting the tension

from 3 to 6 should produce satisfactory

results.

if stitching appears loose or small loops

are visible on the bottom of the seam, tiie

tension should be increased.

Turn dial upwards towards the higher

numbers until stitching is acceptable.

• If stitching appears tight and fabric

puckers, the tension should be decreased.

» Turn dial dO'Wfw^ards towards the lower

numbers until stitching is acceptable.

14

Loading...

Loading...