SINGER 216G User Manual

The use of a good

SPECIAL OIL

gives best results, in the use of

your sewing maschine; by using

such an oil, smooth running and

satisfactory work and a long life

for the machine are guaranteed.

For this reason, use

SINGER OIL

which is available in small glass

bottles at all SINGER Shops.

Form 2760/652 Ru.

DIN A 6

INSTRUCTIO

SEWING MACHINE

CLASS 216

FOR COMBINED ZIGZAG AND

STRAIGHT STITCHING

FOR HOUSEHOLD AND

MANUFACTURING

NOTICE

The unauthorized use of the name SINGER or any similar

protected trade marks of SINGER machines will be legally pro

secuted, as will also the alteration of the SINGER name or the

ornamentation, on used machines.

Trade Mark of

SINGER SEWING MACHINE COMPANY

Reprinting Forbidden

SINGER Sewing Machine

Class 216

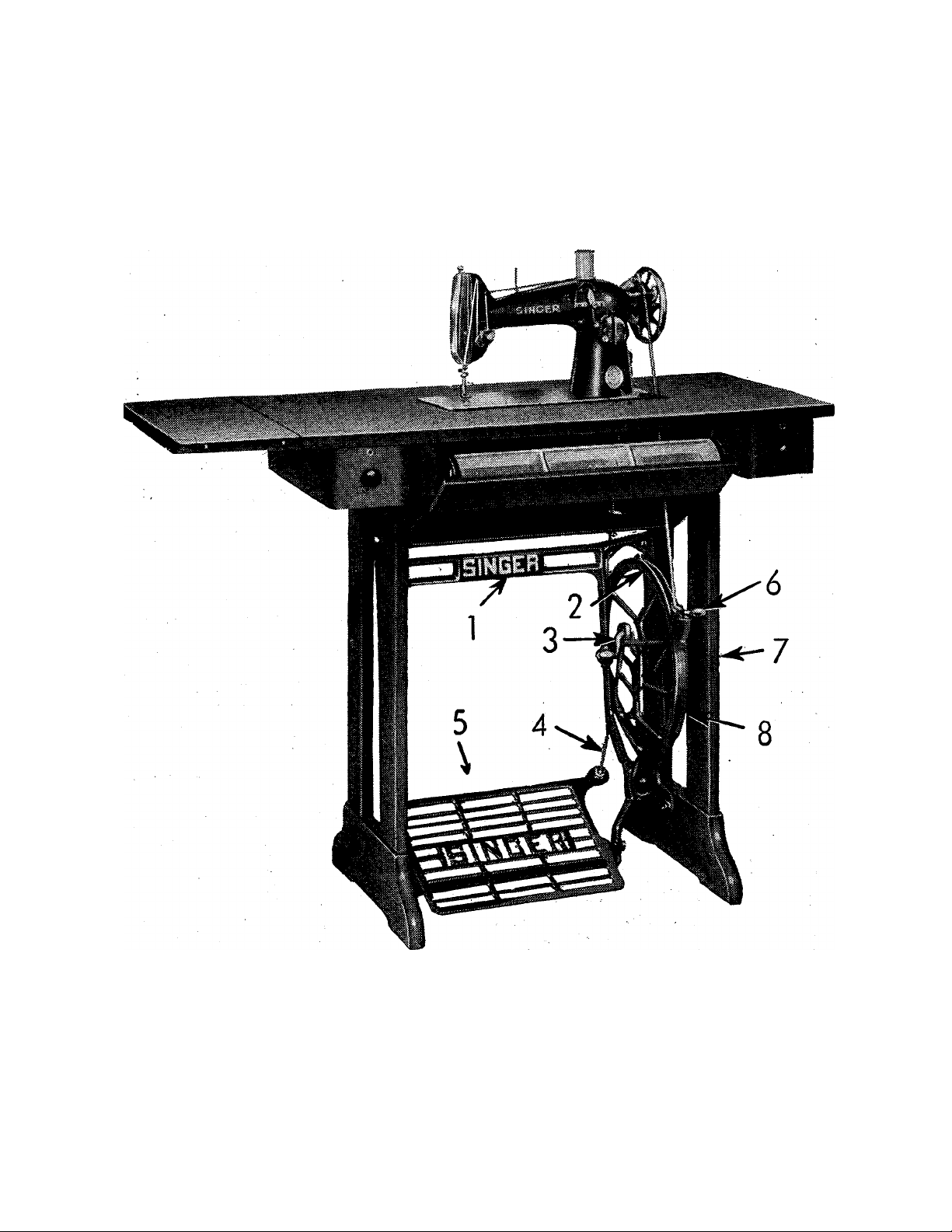

Fig. 1

Parts of the Machine Stand

1 Brace

2 Band Wheel

3 Band Wheel Crank

4 Pitman

5 Treadle

6 Bel Shifter

7 Leg

8 Dress Guard

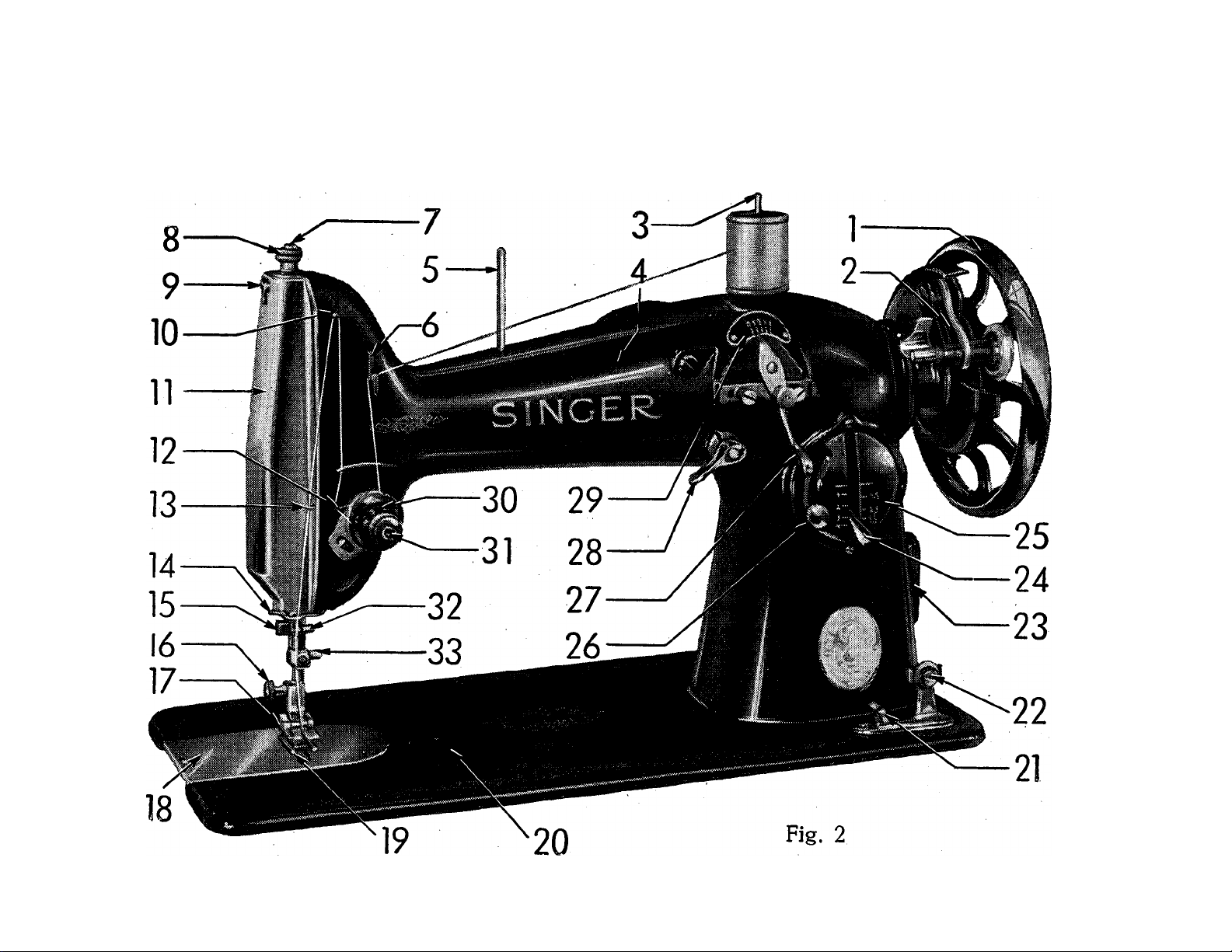

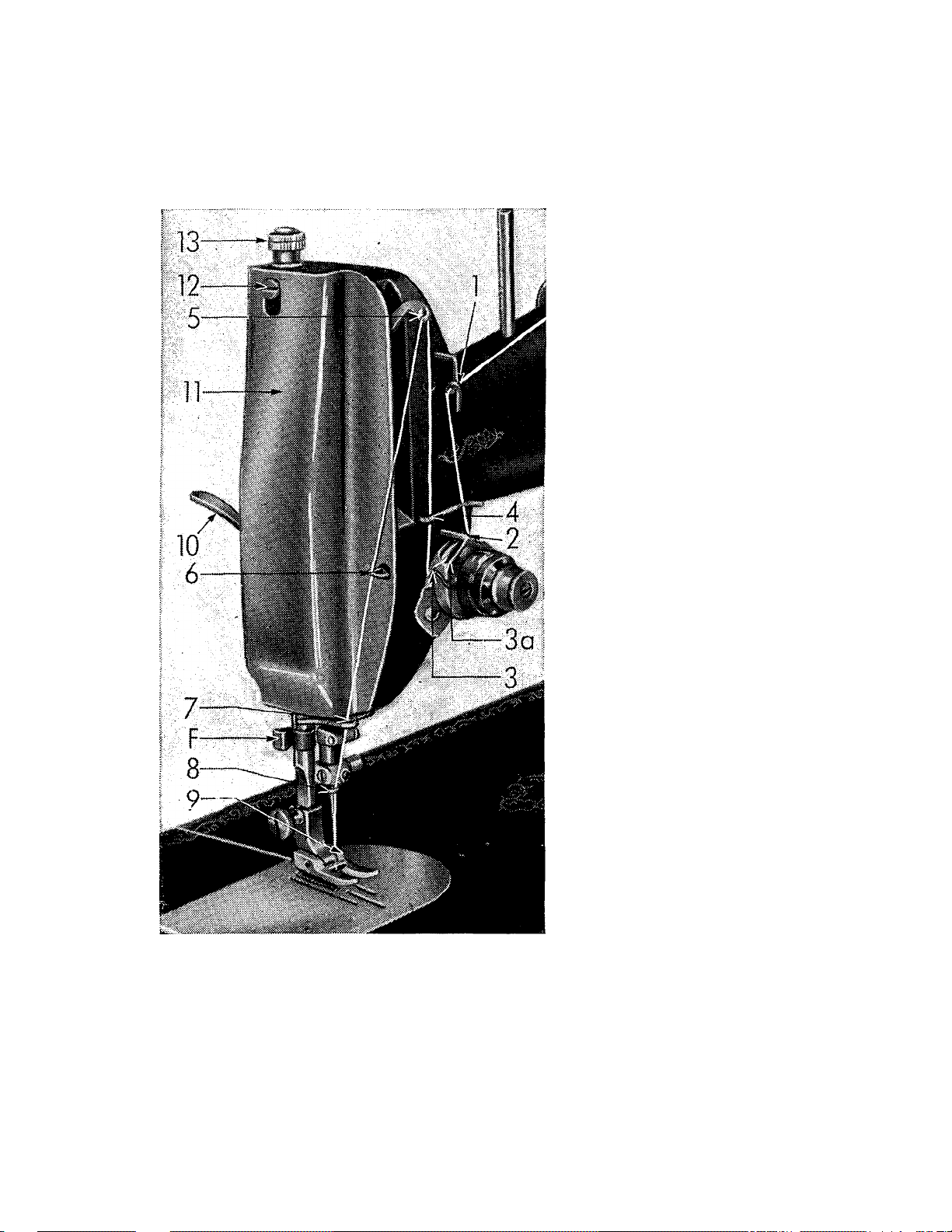

Parts of the Singer Class 216

with identifying references of those parts whidi are used in this instruction book

Description of Parts as shown

on Fig. 1 and 2

Balance Wheel

1.

Bobbin Winder 19.

2.

Right Spool Spindle 20.

3.

4. Arm

5. Left Spool Spindle 22.

6. Thread Guide

Presser Bar

7.

8. Pressure Regulating Thumb Screw

9.

Face Plate Set Screw

10.

11. Face Plate 28.

12. Thread Take-up Spring 29.

13.

Thread Take-up Lever

Face Plate Thread Guide

18.

21. Drop Feed Lever

23.

24. Stitch Length Regulator

25. Stitch Length Scale

26.

27. Bight Lever

30. Thread Tension with Scale

Throat Plate

Feed Dog

Bed Plate

Bobbin Winder Tension Discs

Motor Seat

Stitch Length Set Screw

Needle Position Lever

Bight Scale

cn

14.

15.

16.

17. Presser Foot

Thread Guide 31. Thread Tension Regulating

Thread Cutter

Presser Foot Thumb Screw

Thumb Nut

32. Needle Bar

33.

Needle Clamp

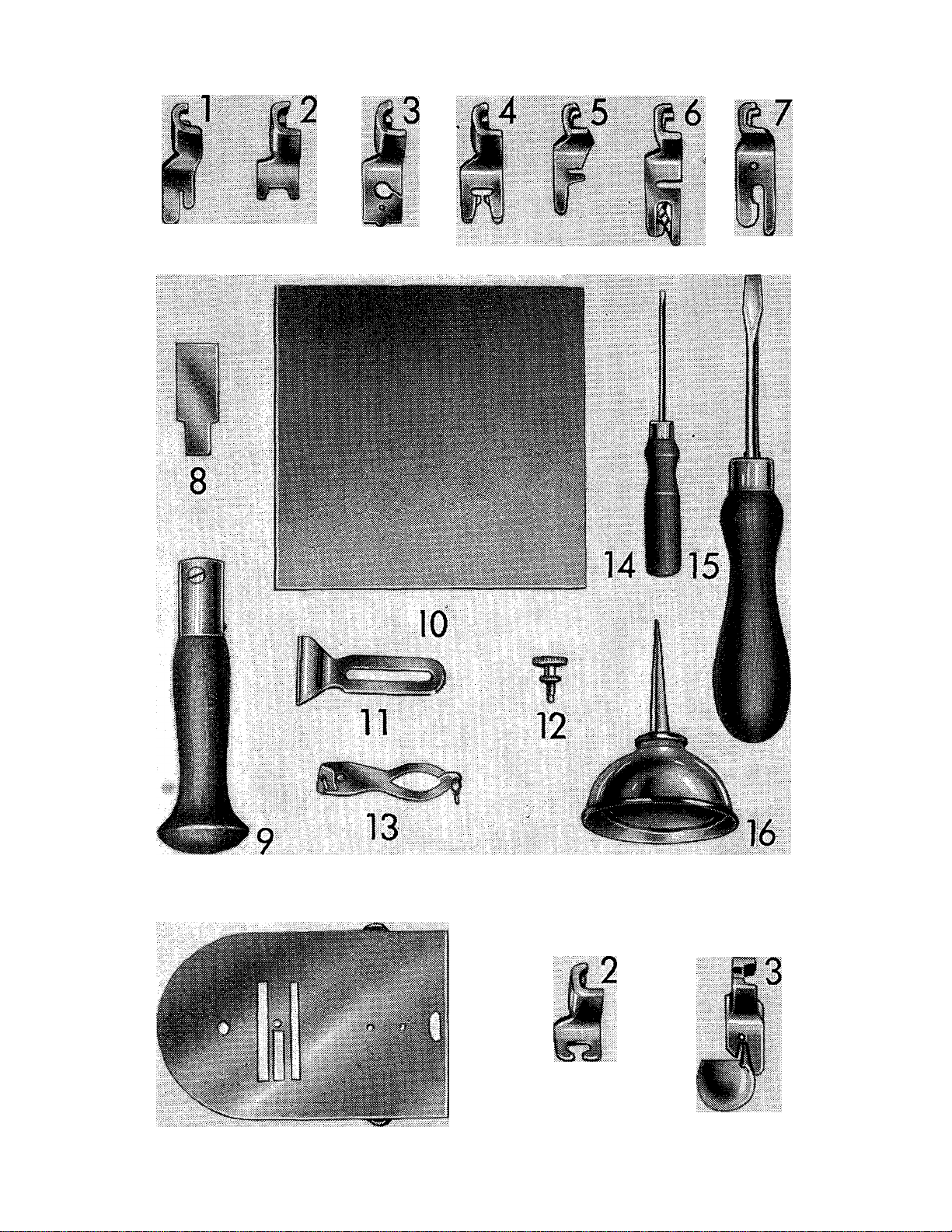

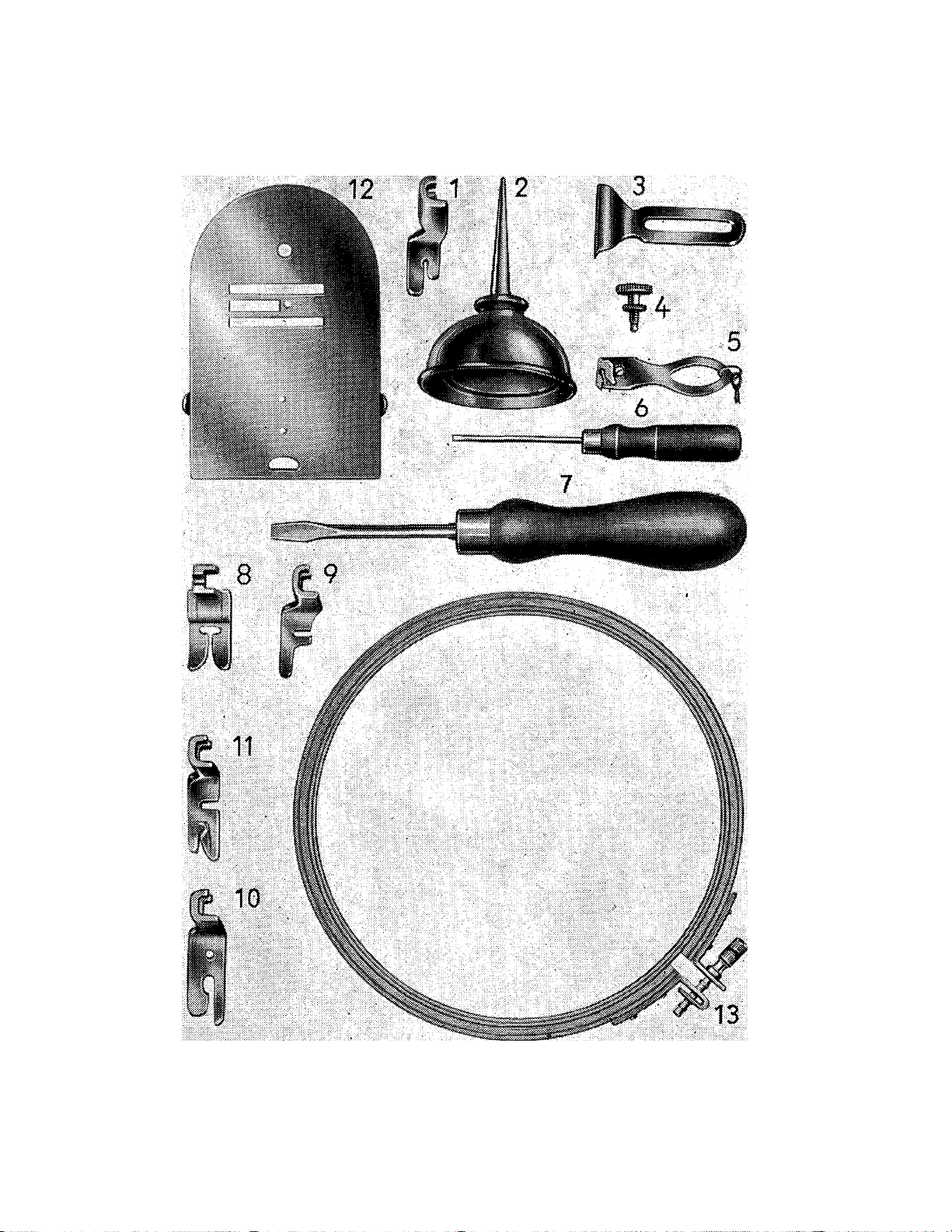

Accessory Set (Fig 3)

No.

Straight Stitching Foot

Button Sewing Foot

Buttonhole Foot ........................................................................... 3

Ornamental zigzag stitching Foot

Zigzag and straight stitch cording

and braiding Foot ..................................................................... 5

Shell Hemmer .............................................................................. 6

Felling Foot for straight stitching ................................................ 7

Buttonhole knife .......................................................................... 8

Buttonhole knife handle

Fibre Plate for cutting buttonholes

Adjustable cloth guide

................................................................

.....................................................................

......................................

...............................................................

............................................

..............................................................

10

11

1

2

4

9

Cloth guide screw ...................................................................... 12

Needle Threader ........................................................................ 13

Small Screw Driver

Large Screw Driver

Oil Can

......

.............................................................................. 16

....................................................................

...................................................................

14

15

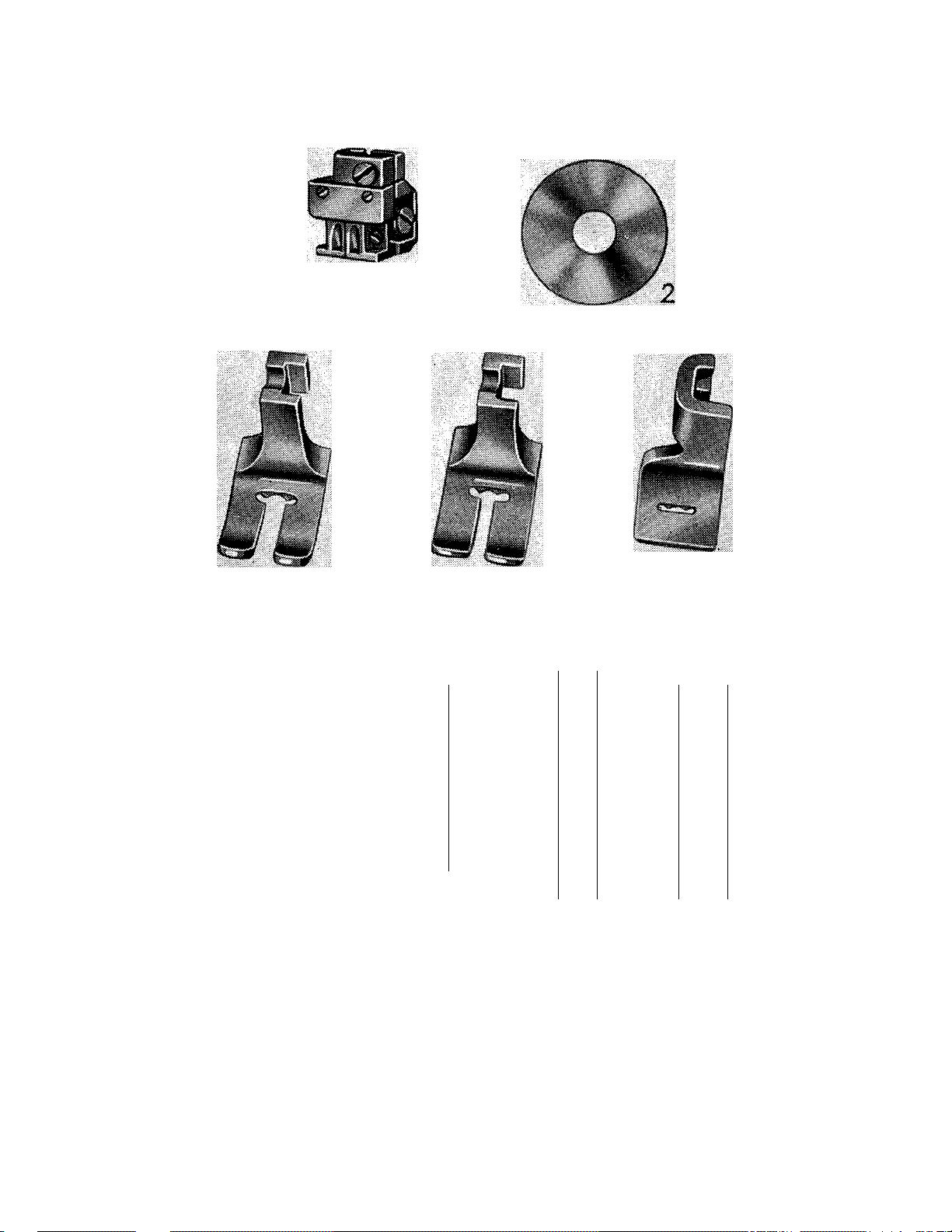

Supplied at Additional Cost (Fig. 4)

straight Stitch Plate

Curved cord covering Foot . .........................................

Roll Hemmer................................................................................ 3

.....................................................................

1

2

6

Fig. 3

1

Fig 4

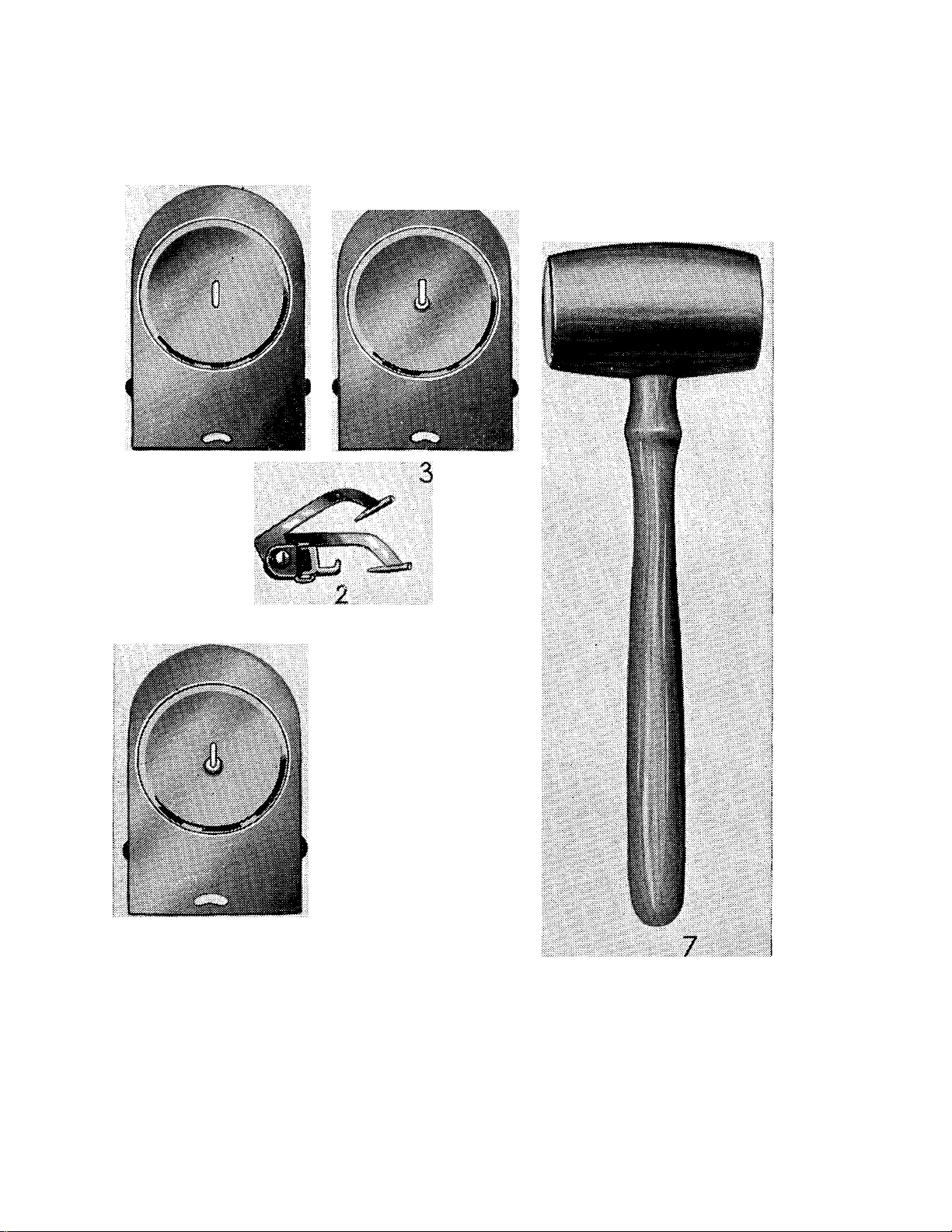

Embroidery Set (Fig. 5)

(Supplied at Additional Cost)

No.

Throat Plate ................................................................................. 1

Double cord guide for cording, embroidery,

Madeira and Richelieu work

Spur Plate with 3V4 mm. spur ............................

Spur Plate with mm. spur

Punch for 3V4 mm. spur plate

Punch for 4V4 mm. spur plate

Mallet ........................................................................................... 7

...................................................... 4

.....................................................

.....................................................

...............

.........................

.........................

2

3

5

6

8

Fig. 5

6

9

Fig. 5

9

Air Tucking Set (Fig. 6)

(Supplied at Additional Cost)

No.

Two-Needle Clamp .................................................................... 1

Middle Tension Needle Disc ...................................................... 2

Foot for wide air tucks

Foot for medium air tucks

Foot for narrow air tucks ..............................

Traverse for wide air tucks

Traverse for medium air tucks

Tubular Traverse for wide air tucks with cords .. 8

Traverse Clamp ............................................................................ 9

The needle used for the air tucking set is the round

shank needle of Class 16 x 1 No. 9 or Nr. 10 .... 11

...............

.......................................................... 4

................

..................

........................................ 6

...............

.............................

.............................

........................... 7

3

5

10

i i iiiiïiîS

И SlíiSfi;

И]

<■

/

6

^Я11

шШШМшШй

Fig. 6

iiiliili

11

Î

И

Table of contents

I. General Instructions for

Page

Using the Machine

II. Care of the Machine .

III. Hints ...................................................................... 35

IV. Hemming and Seaming with Straight

Stitches .................................................................. 36—37

V. General Zig Zag Work .......................................... 38—42

VI. Special Work with the Zig Zag Stitch . . 43—50

VII. Embroidery and Darning

VIII. Use of the Embroidery Set ................................... 52—55

IX. Work with Air Tucking

X. Sewing Very Narrow Air Tucks with the

Single Needle Clamp . .............

XI. Needles and Threads ............................................. 63—64

.......................................... 13—30

...........................................

......................................

........................................

.............................

31—34

51—52

56—61

62

12

I. GENERAL INSTRUCTIONS FOR

USING THE MACHINE

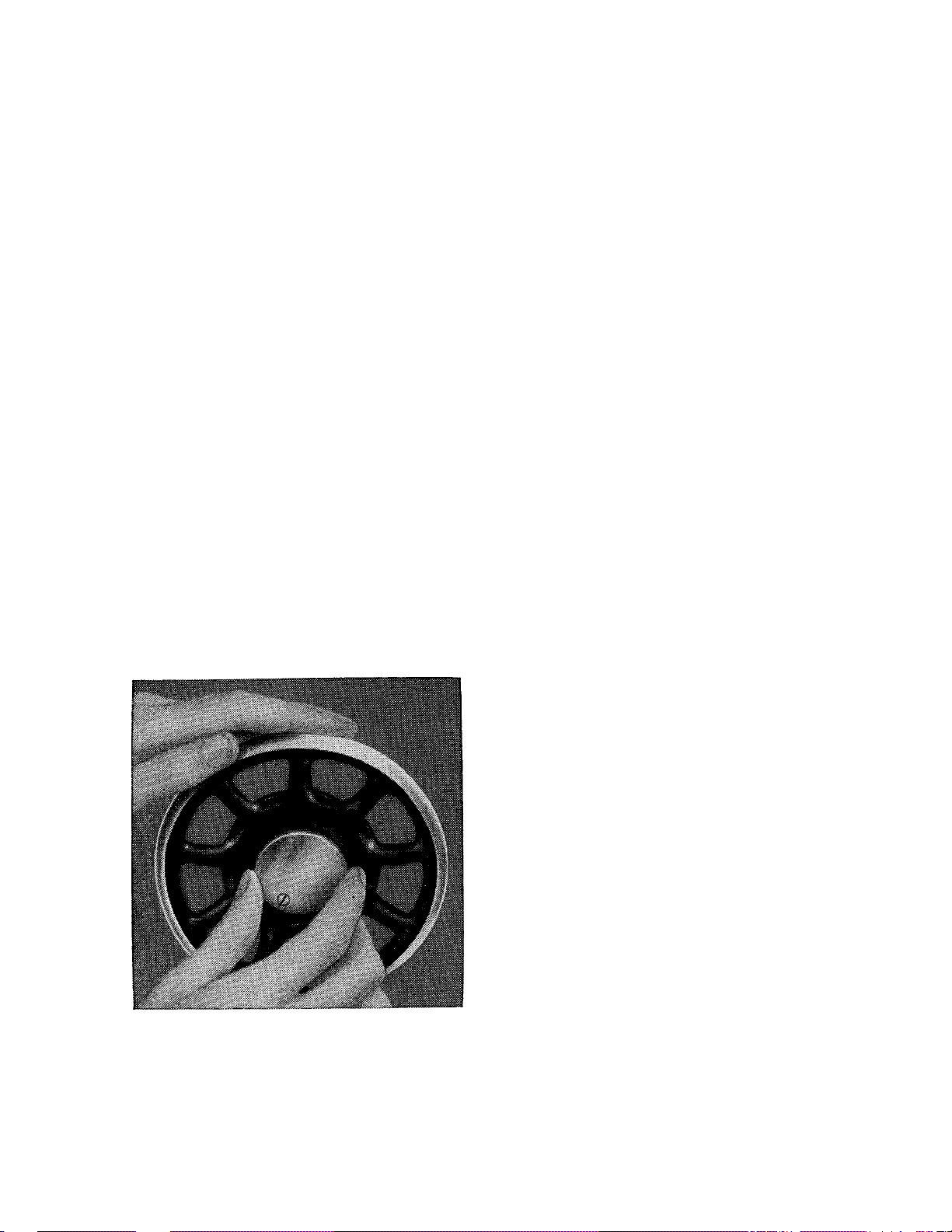

Releasing the Balance Wheel

Before setting the machine in operation, the presser

foot should be raised by means of the presser bar

lifter, to prevent injury to the presser foot and the

feed dog.

Next, one should become acquainted with the me

chanism for releasing the balance wheel. This me

chanism permits the beginner to practice using the

treadle without actually running the machine. Releas

ing the balance wheel also permits bobbin re-winding

without requiring the

Fig. 7

Releasing the Balance Wheel

sewing work to be re

moved or the thread to

be removed from the

machine. The balance

wheel is released as

shown in Fig. 7, by

holding the balance

wheel in place with the

left hand and, with the

right hand, turning stop

motion screw toward

the operator until no

ticeable resistance is

met.

13

The Treadle of the Machine

After releasing the balance wheel, place the foot

on the treadle of the machine, then turning the

balance wheel over toward you, with the right hand,

and by alternately pressing down with the heel and the

toes try to attain a uniform motion of the driving

wheel. As soon as the motion of the treadle has been

well learned, and the machine can again be set in

motion without turning the balance wheel in the

wrong direction, the releasing mechanism (Fig. 7) is

again tightened by turning the stop motion screw

toward the right (away from operator) and the ma

chine is again ready for sewing. Place a piece of

material under the presser foot, lower the presser

foot on the material and work in this manner with

the unthreaded machine until the operation of guid

ing the material through the machine has been

learned.

General Instructions

In order to obtain satisfactory work from the machine

it is necessary to observe the following:

The balance wheel must be turned only in the

direction of the operator.

When the machine is not being used the presser

foot should be raised.

As long as there is no material under the pres

ser foot the machine should not be run without

threading the needle.

In order to avoid the breaking of the needle,

do not pull on the goods while sewing. The

work will be moved by the feed without

assistance.

Kinds of Needles

The Glass 216 Machine uses SINGER needles of

14

Class 15X1 (flat shank). To choose the correct needle

size, see the charts on pages 63 and 64.

Quality of Needles (Fig. 8)

Since bad needles or needles of poor quality can

easily break the thread, skip stitches and make uneven

Fig. 8 SINGER Needles are stamped with the Company's Trade

Mark,, SIM ANCO*"

raw edges in your sewing work, be sure to purchase

you,T needles for this machine in a qualified SINGER

Shop, where the needles of the correct size, for the

type of work being done, can be purchased.

Fig. 9 To Set the Needle

To Set the Needle (Fig. 9)

Turn the balance wheel over toward you, until the

needle bar is at its highest position. Loosen screw

(A, Fig. 9) and insert the needle, as far up as it will

go, into the clamp (B, Fig. 9) with its flat side toward

the rear, and long groove of the needle towards you.

Then tighten screw (A).

Threading the Needle (Fig. 10)

Place the spool of thread on the right spool spindle.

15

With the thread take-up lever (No. 5) and the presser

foot both in their highest positions, thread the needle

as follows: 1. From right to

left through the

thread guide 1.

2. Down and from

right to left be

tween the ten

sion discs 2.

3. From there lead

the thread down

and around and

upwards into the

loop of the takeup spring (3) and

Fig. 10 Upper Threading

7. Behind the guide 7.

pull the thread

taut until it slips

behind the small

retaining fork

(3 a), (see also

Fig. 22).

4. Upwards behind

the thread guide

No. 4.

5. From right to left

through the eye

of the take-up

lever No. 5.

6. Down through the

thread guide 6.

8. Through the thread guide 8, under the needle

clamp.

9. And from front to rear through the eye of the

needle 9.

16

Leave about 8 to 10 cm. (3 to 4 inches) of thread hang

out of the eye of the needle.

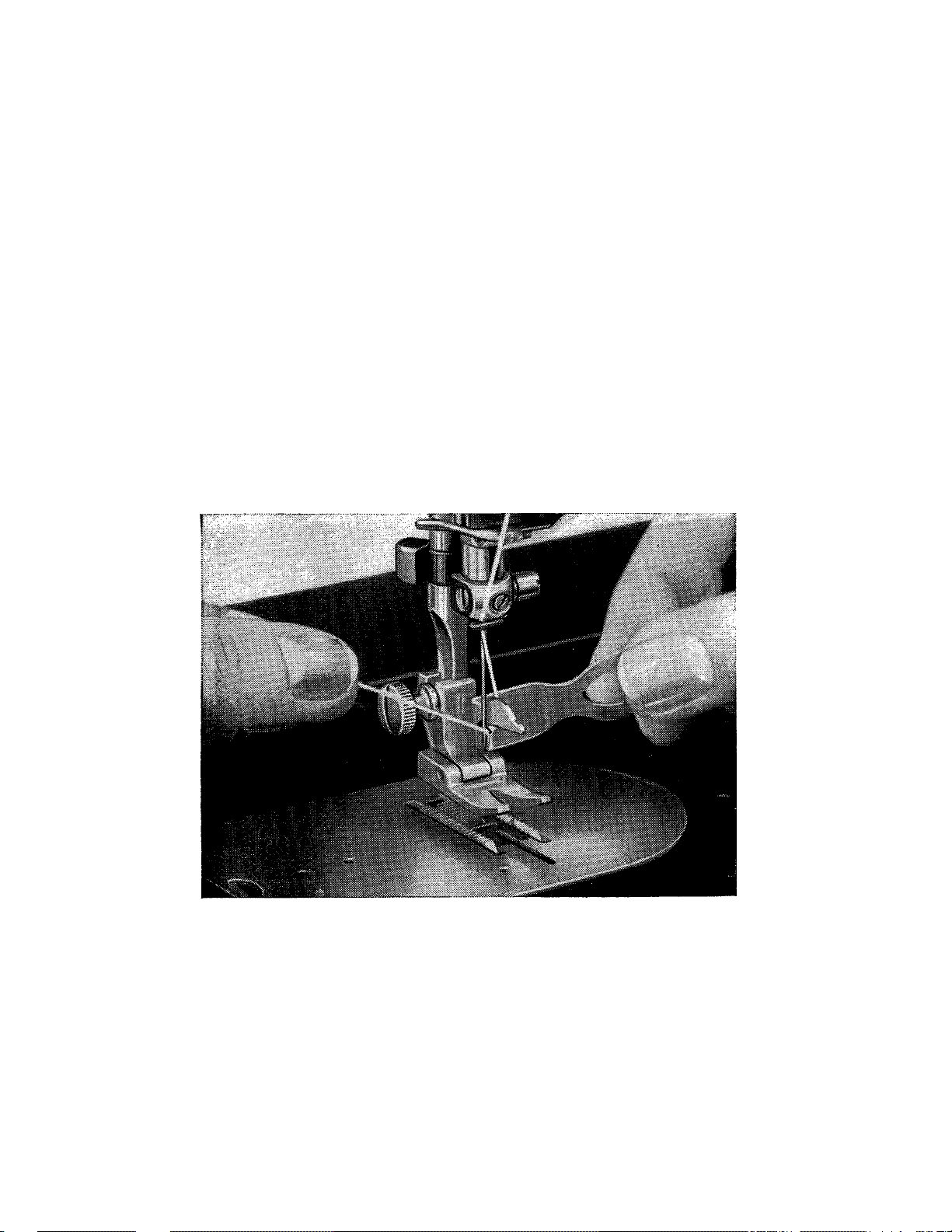

SINGER Threader (Fig. 11)

To thread the needle use the needle threader (No. 13,

Fig. 3). The presser foot is lowered and the needle bar

is raised to its highest point. Hold the needle threader

with the right hand so that it is behind the needle

and its hook is to the right of the needle and let the

hook of the threader slide down the short groove of

the needle until it slips into the eye of the needle.

Next, lead the hook as far as possible through the eye

of the needle, place the thread into the hook and hold

it as shown in Fig. 11.

Fig. 11 The Use of the SINGER Needle Threader

While holding the threader horizontally and lifting

slightly upward, draw the hook with the thread back

wards out of the needle eye until the end of the

thread is completely out of the hook. The needle is

now properly threaded.

17

Loading...

Loading...