Page 1

SINGER

COMPACT FREE-ARM SEWING MACHINE

MODEL 212

INSTRUCTION

MANUAL

Page 2

Dear Customer:

We recommend that for future reference you record the Serial Number of your

Sewing Machine in the space provided.

Refer to illustration

at right for location

Serial No.

Page 3

Know your machine ...,.*.2-3

Set up your machine.................................,......*......................4

Remov?n9 the extension table/accessory box

Prepare the bobbin

Remove the bobbin case from the machine . *

Wind the bobbin...

I nsert the bobbin into the bobbin casé.*.................................... 8

Insertthebobbin case into the shuttle........................... 8

Thread the top thread

Pick up the bobbin thread

Strai^htsdtch..................

Fas^ning seams...............

Keeping seam line straight....

Turning a square corner S/8 inch (16 mm} from the

fabric edge..

Adjusting thread tension............................................ ..........1$

Needle, thread and fabric chart........................................................14

Changing needie...................................................................... .........14

.........................................

....

..................................................................... 9

....

...............................................................

...................................................................

..........................................................

...........................................................

....

....................................................................... ...........12

.................................... S

........................ 6

..................................

7

10

...11

.......12

12

Zigzagstitch

Free-armsewing

.............................................

....

.......................

.

Overcasting.....................................

Mendiinga tear.................................

Attaching zippers, cording..................

Blind hem .....______............................

Buttonholemaking............................

Button sewing

Appliqu^.

Embroidery...,.

.............

.

...............................

............

.

.

Caring for your machine .....................

Check chan for performance problems...

.

.15

.16

.17

.17

.18

.19

.20

.21

.22

.22

.23

.24

Page 4

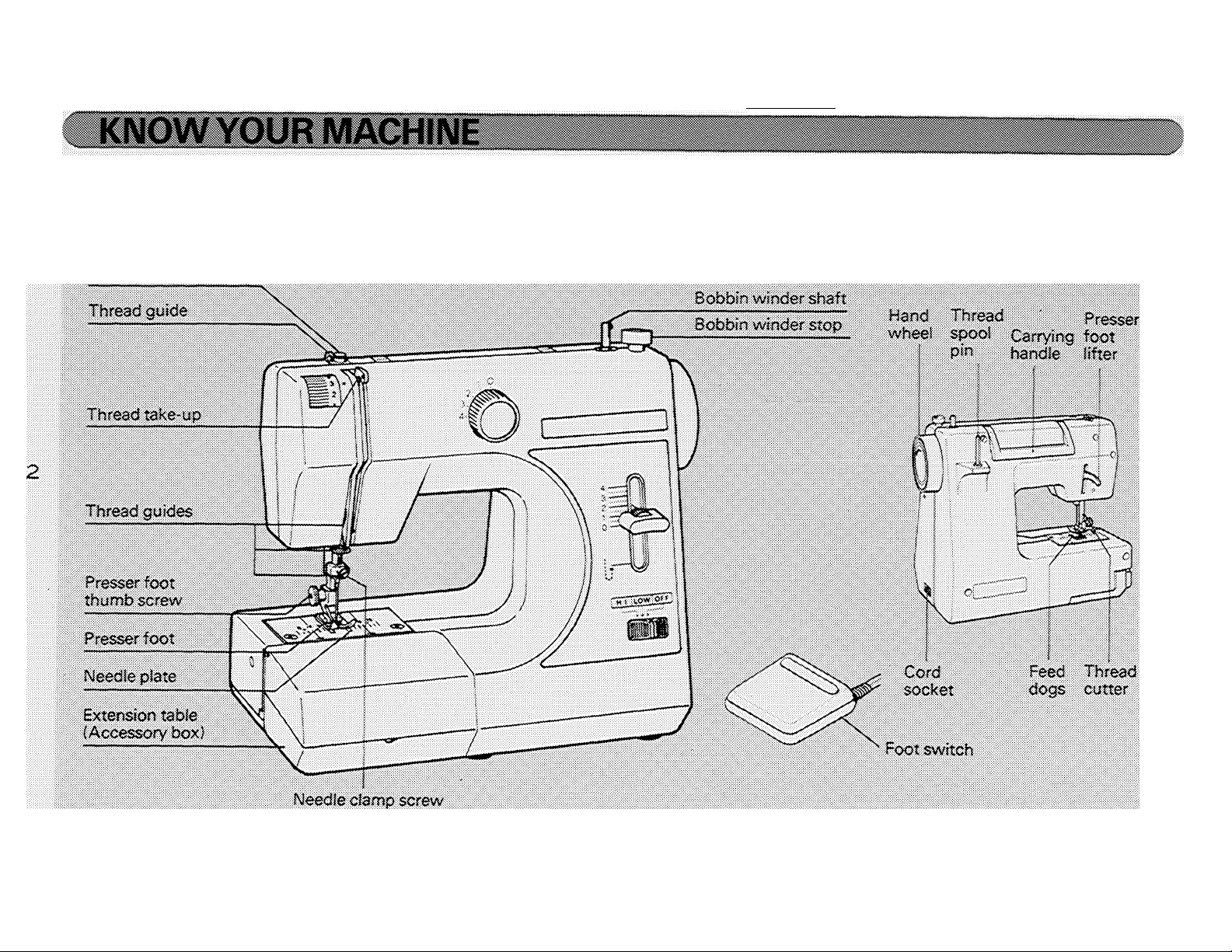

Principa! parts of your machine

Bobbin winder

tension disc

iS¡MiiiassMi!ai8MiMwwmwww^^

Page 5

::^S^^^gS333SSSSSS8SSSS88S3S8iiiiiaiiiiSiiiiiiiii^^

Top thread tension control

Decrease or Increase the tension of the

top thread by using this controL The

higher the number, the tighter the

tension<

Presser foot lifter

There are three positions for your

presser foot>

1 * Lower the presser foot to sewv

2. Raise the lifter to the middle position

to insert or remove fabric.

3. Lift it to its highest positioii to

change the presser foot or to remove

thick fabric*

Power/speed range switch

Your machine has two ranges of speeda low range for slower, intricate work

and a high one for faster, general work*

Stitch width dial

This dial regulates the stitch vyidth

when zigzag stitching* The higher the

number, the wider the stitch*

Set it at ''0'' when straight stitching

and the needle bar will be firmly locked

to achieve uniform stitches*

Stitch length/reverse stitch lever

Loosen the knob in the center by

turning it counter clockwise* Move the

lever between 4 and 0 and retighten the

knob< The lower the number, the

shorter the stitch <

Lower the lever below "'0"' to stitch in

reverse for back tacking*

Knob

Page 6

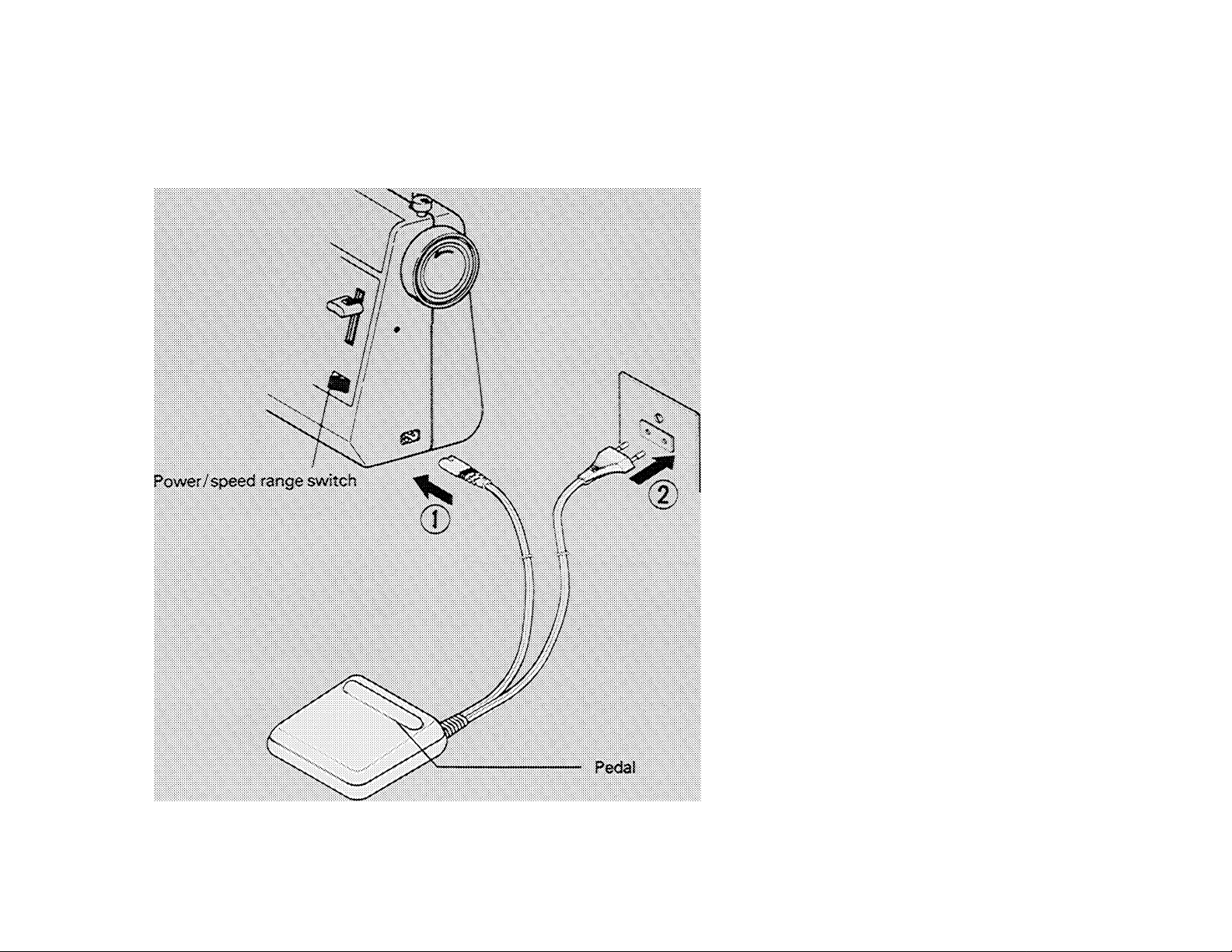

(t) How to set Foot Switch

MAKE SURE THAT THE POWER/SPEED

RANGE SWITCH IS AT POSITION

8EFORE CONNECTING FOOT SWITCH.

Connect the plugs of the foot switch Into

the machine socket i^} and your wall

outlet (2) as Illustrated,

(2} How to operate

T Set the power/speed range switch at

'XOW^^ or ^^HIGH'^ position.

2. Depress the pedal of the foot switch

with your foot to run the machine.

Remove your foot from the pedal to

stop.

4

CAUTION:

If you are Interrupted, or stop sewing or leave

the machine unattended, the plug {2) must be

removed from the outlet.

*THIS FOOT SWITCH has only ON--OFF

function, not for speed control.

Page 7

mmmm

o

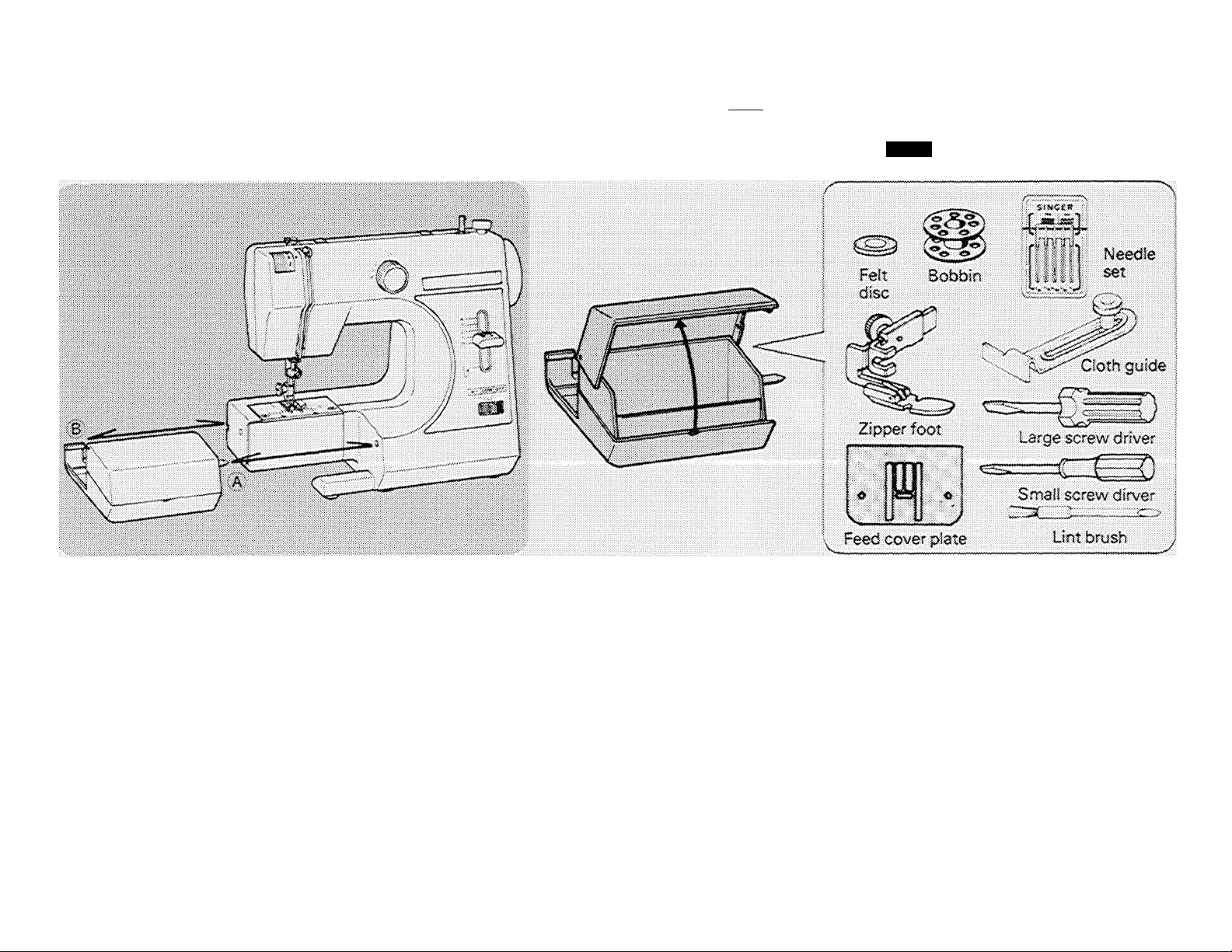

Remove the extension table by pulling it to the left.

To attach, slide the table back to position until the pins

(A and S) fit into the holes on the machine.

Open the accessory box by lifting the lid up

and backward and you will find a variety of

accessories inside.

Page 8

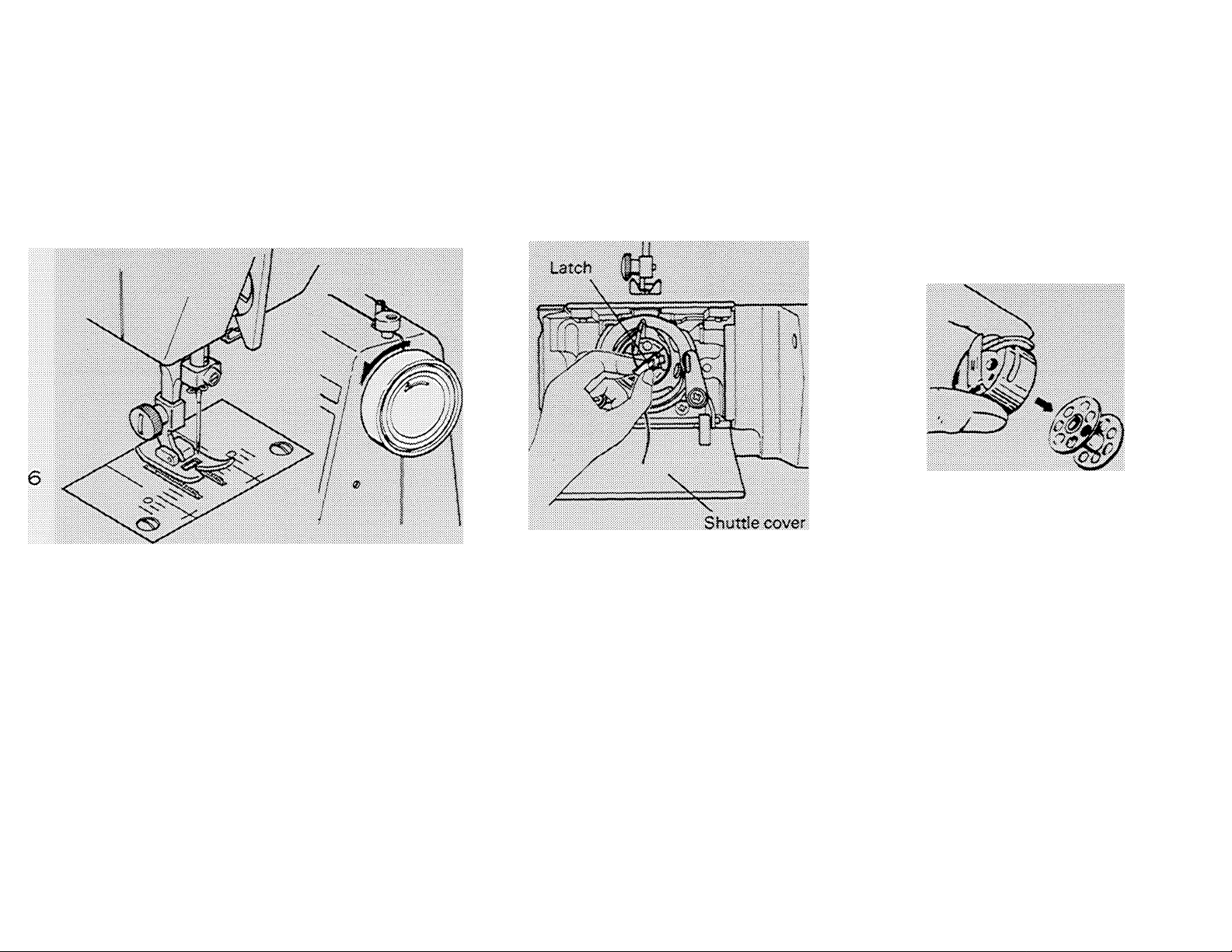

Remove the Bobbin Case from the Machine

1* Raise the needle to its highest position by turning

the hand wheel toward you.

2. Locate the notch at the left end and

open the shuttle cover by pulling

forward and down*

3. Use your forefinger and thumb to pull

open the latch on the bobbin case.

4. Pull the bobbin case straight out.

5. Release the latch and the bobbin will

drop out of the case.

Page 9

Wind the Bobbin

7

1, Fit the felt disc over the spool pm and put a spool of thread on the

spool pin.

2. Draw the thread through from the spool through the bobbin

winder tension disc.

3. a. Pull the end of the thread through the hole in the bobbin,

b. Place the bobbin onto the bobbin winder shaft with the end of

the thread coming from the top of the bobbin.

4, a. Push the bobbin winder shaft to the right until it clicks.

b. Hold onto the end of the thread.

c> Start the machine by shifting the power switch to ''LOW" or

"HIGH" position. After several rotations of the bobbin release

the thread.

NOTE: Keep away from the needle while the machine is running.

5, a. Turn off the powerswitch when the bobbin stops turning with

the thread filled.

b. Push the shaft to the left to remove the bobbin.

Page 10

Insert the Bobbin into the Bobbin Case

8

Insert the Bobbin Case into the Shuttie

1. Hold the bobbm in your right hand with the thread ruîinirjg clockwise.

2. insert the bobbin into the case with about 4 inchs (10 cm} of thread showing outside

the case.

3. Puli the thread through the slit in the case and then underneath the flat tension spring.

It will click when it is in place.

1, Hold the latch open, with the locating pin straight

up.

2, Slide the bobbin case onto the center spindle of the

shuttle, keeping the thread toward you.

NOTE: Be sure the locating pin fits into the locating

groove at the top of the shuttle.

3, Release the latch to lock the bobbin case in place.

Page 11

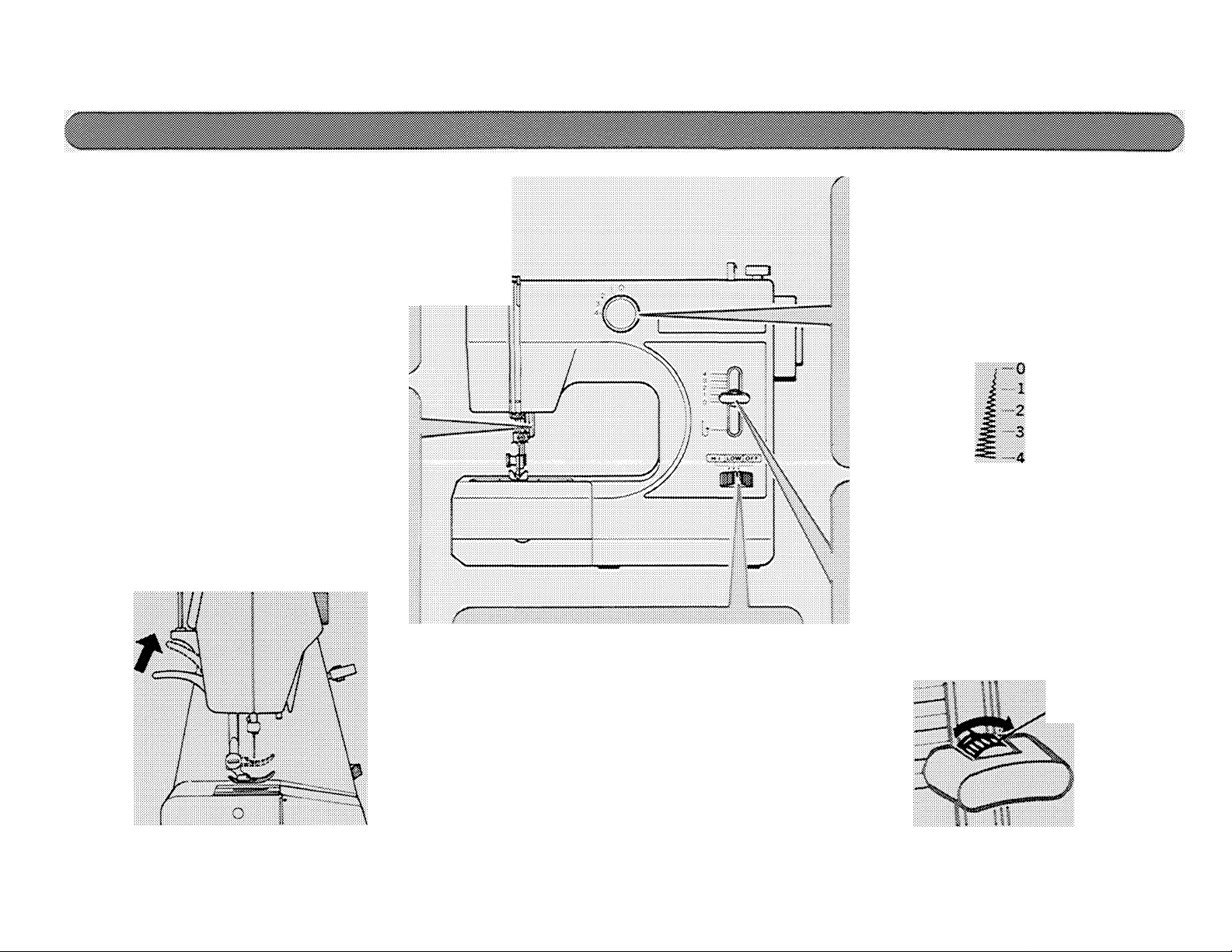

Rarse the presser foot lever to allow the

thread to pass between the tension control

discs.

* Raise the thread take-up lever to its highest

position by rotating the hand wheel toward

you.

Holding the thread taut with your right

hand, draw the thread through the thread

guides as illustrated.

* Thread the take-up lever from left to right,

* Thread the needle from front to back,

drawing 4 inches (10 cm) of thread through

the eve of the needle.

9

Page 12

1, Raise the presser foot lifter,

2* a. Hold the top thread loosely in your left hand.

b. With your right hand, rotate the hand wheel

toward you until the take-up lever has come to

the top again,

MOTE: When the needle passes beneath the needle

plate, it will pick up the thread from the

bobbin.

3, a. Raise the bobbin thread by pulling

the top thread with your left hand,

b. Pull the bobbin thread until the end

comes through the opening of the

needle plate.

4. Pull the both threads under and to the

back of the presser foot, leaving 4

inches no cm) clear.

NOW YOU'RE READY TO START TO

SEW WITH YOUR SEWING MACHINE,

PLEASE TURN TO THE NEXT PAGE,

Page 13

Straight stitch is the most frequently used for every aspect of sewing. Learn the correct use of your machine following the steps below.

Top thread

I.SETTiNGS

Thread tension - 3

Raise the take-up lever to its

highest position oy turning the

hand wheel toward you*

5* a* Start to sew shifting the power

switch to the ''LOW or

"HIGH" position.

b. Guide the fabric gently with

your hand*

c* When you reach the end of the

fabric, stop the machine turn

ing off the power switch*

11

2* Pull both threads under the

presser foot toward the back of

the machine*

3> Place the fabric under the presser

foot and lower the presser foot

lifter*

4. Turn the hand wheel toward you

until the needle enters the fabric.

6* a* Turn the hand wheel to raise

the needle.

'iiii

b. Raise the presser foot by

pushing the lifter up.

c. Use the thread cutter above

the presser foot to cut off

excess threads*

d. Puli the both thread under and

to the back of the presser foot,

leaving 4 inches (10 cm) clear*

Page 14

Fastening seams

12

Keeping seam fine straight

Turning a square corner 5/8 inch (16 mm) from the fabric edge

Cornerintg

guid^

Secure your seams by taking the first few

stitches in reverse- Then allow the

machine to go forward- This is called

back tacking. Reverse the machine at the

end of your seams as well-

Lower the stitch length lever below

for back tacking.

1- Using the seam guide lines

The needle plate is rn3rke3’'With seam

guide lines to help you stitch straight

seams- The standard 5/8 inch (16 mm}

lines are emphasized for your

convenience.

2. Using the cloth guide

Secure the cloth guide in the screw

hole to the right of the foot adjusting

to the width of your seams.

1 - Stop stitching with the needle piercing the fabric,

when you reach the cornering guide-

2. Raise the presser foot.

3. Turn the fabric and the new stitching line will align

with 5/S inch 06 mm) seam guide line.

4. Lower the presser foot and begin stitching in the

new direction.

Page 15

Adjusting thread tension

STRAIGHT STITCHINCi

Top

thread

Bobbin thread

Weil balanced

Top stitch too tight

Top stitch too loose

Under

side

The good looking apperance of your stitching rs largely

determined by the balanced tension of both top and

bobbin threa6s. The tension is well balanced when

these two threads lock' in the middle of layers of the

fabric you are sewing.

Decrease tension

Threads lock on

the top side.

Increase tension

Threads lock on

the under side.

^

.....

Bobbin thread tension

S088IN THREAD TEMSION REQUIRES

ADJUSTMENT LESS FREQUENTLY THAN

THE TOP THREAD TENSION.

If the tension is well balanced, but the fabric

puckers badly, both top and bobbin thread

tensions may be too tight and have to be

adjusted.

When adjusting the tension on the bobbin

case, make slight adjustments with the screw

13

To test that the tension is correct suspend

the bobbin case by the thread {No. 50) and

jerk it once, if the tension is correct, the

thread will unwind an Inch or two (3 to 5 cm).

If too loose it will unwind continuously. If too

tight the thread will not unwind at all.

1=^

5

u.

Page 16

Needle, Thread and Fabric Chart

Changing needie

Your fabric will determine the choice of a

needle and thread. The following table is a

practical guide to needle ard thread selection.

Always refer to it before a new sewing

FABHICS

The fabrics below can be of any

fiber: cotton, linen, silk, wool,

synthetic, rayon, blends. They

are listed as examples of weight

light

weight

14

MediumWeight

|iМММММММММММММiММММММММiilММPММppМММММММiiММММММ::iММММММММММii

i

--

w -

----------

i Medium- ; Bonded Wovens

Heavy

I

I

Knits

Batiste

Chiffon

Crepe

Corduroy

Flannel

Gabardine

Gingham

Linen

.....

....

....

....

......

....................:..

I

Canvas Polyester

i Coating

i Denim

I

Duck

I Sailcloth

Bonded Knits

Double Knit Polyester

! Jersey

I Tricot j Nylon

project. And be sure to use the same size and

type of thread In the bobbin as In the top

thread supply.

THREAD

Cotton-wrapped

Polyester

100% Polyester

■’‘■Mercerized Size 60

Cotton-wrapped

Polyester

100% Polyester

* Mercerized Size SO

My Ion

................................. Í 5

Cotton-wrapped

i 100% Polyester

\ * Mercerized Size 40

i

^^^Heavy Duty^'

Cotton-wrapped

j

Polyester

NEEDLES

TYPE

2020

2020

< :■ •

I 2020 ( 18/110 I

I Ba!i-Poim 2045

Size 11/80, 14/90,

16/100

SIZE

11/80

14/90

2020 J 16/100

i

T Raise the needle bar to Its highest position

by turning the hand wheel toward you.

2. Loosen the needle clamp screw with the

screw driver.

3. Remove the needle by pulling it downward.

I

4. Insert the new needle into the needle clamp

with the flat side away from you.

5. Push the needie up as far as it can go.

6. Tighten the needle clamp screw firmly with

the screw driver.

* Do not use on stretch fabrics.

Page 17

MACHINE SETTiMGS

Satin stitch

Closely spaced zigzag stitch

5S called sation stitch. This

Is an attractive stitch which

is used for embroidery and

applique.

Set stitch length between

0,5 and 1,

Turn the stitch width dial

from 0-4-0 and decorative

patterns will be achieved <

fffffi

0—4—0—^

■4.0-

Stop the machine at

this point arid turn the

dial back to "0".

‘4—>

15

I

Page 18

Your machíne has a free arm for sewing sleeves, pants legs etc.

For free-arm sewing, remove the extension table by pulling it to the

left. Just slip the sleeve or pants leg onto the free arm.

Page 19

.

.

Si:::;:;:;:::;:;:;:::;:;:;:;:;:::;:;:;:;:;:::;:;:;:;:;:::;:;:;:;:;:::

17

SETTiNGS

Zigzag Width-* 3to4

Stitch length - 3to4

Overcasting Is simply finishing the raw edges of fabric to prevent

fraying. Place material under the presser foot so that the needle

pierces it just short of the outside edge.

SETTI IMG$

Zigzag width - 3 to 4

Stitch length * 1 to 2

Place the fabric with the beginning of the tear under the center of the

presser foot and sew ensuring stitches catch either side of tear.

When repairing a three-cornered tear, stitch down each side to the

center.

Page 20

18

lililí

|;|||||||||||||||||:;

1. а. Raise the presser foot Hfter.

b. Loosen the presser foot thumb screw,

NOTE: Use the screw driver if it is difficult to loosen

the screw with your hand,

2. Attach the zipper foot

NOTE: loosen the screw at the back of the foot and

it can be slided to sew to the right or left side

of the needle,

SETTINGS

Zigzag width - 0 (straight stitch)

Stitch length - 1 to 3

3, To sew the right side of the zipper,

slide the foot to the right so that the

needle passes through the small

opening on the left side of the foot.

To sew the left side, position the foot

to the left of the needle.

To make a cording for slipcovers, lingerie

etc,, cover a length of cord with a bias

strip of fabric.

Position the foot to the left of the needle

so that needle passes through the

opening on the right side of the foot.

Page 21

19

1, First finish the raw edge. Do

this by turning, it up on fine

fabrics and overcasting it on

medium to heavyweight ones.

Then turn the hem up the

required depth and press,

SETTiMGS

Zigzag width ~ 3 to 4

Stitch length - 4

Speed range - LOW

2, Now fold the fabric as

iilustratec.

3. With the wrong side up, place

the fabric under the foot.

Lower the presser foot. Stitch

so that the needle just pierces

the fold when the needle

swings to the left.

4, When completed, the stitch

ing is almost invisible on the

right side of the fabric.

Page 22

20

SETTINGS

Sxkch length- 0.5îo1

Speed range - LOW

Carefully mark the buttonhole

length on your garment and

insert it under the foot

Set zigzag width at

Stitch to the end of the

marking* Stop with the

needle in the fabric at

point A*

* Always make a practice buttonhole on a scrap of the

fabric you plan to use. Then try the buttonhoie with the

selected button*

* Use interfacing between the two layers of fabric>

BA

Set zigzag width at Z and

take one stitch to the left

(point SL

the presser foot and

turn the fabric with the

needle in it* Lower the presser

foot and take one stitch to

the right {point CK

Set zigzag width at 4 and

bartack at least four stitches*

Stop at point D.

Set zigzag width at t>í and

stitch to the end of marking

(point £)*

bartack at least four stitches*

Stop at point F*

Set zigzag width at 0 and

take a few stitches in reverse.

Remove the fabric and cut

the hole open.

Page 23

21

1. Insert the two pins on the feed cover plate

into the two holes on the fabric feed area.

The curved corners will be toward you

when it is in place>

2, a. Set zigzag width at 0.

b. Place the button on the fabric with two

holes centrally situated ur^der the slot In

the presser foot.

a. Pierce the fabric through the hole on the

right side of the button*

b, lower the presser foot.

4. a. Turn the hand wheel toward you until

the needle is just above the button*

b* Adjust the stitch width control so that

the needle enters the left hole of the

button.

5. Set the speed range at LOW position and

make six or more stitches ending on the

right side*

6. a. Set the zigzag width at 0*

b. Take about three stitches for fastening

off.

Page 24

lili

mmmmmmmmmsi

D

SETTING

Stitch length - 0.5 toi

To appliqué a design on a sewing project or garment:

1, Pin or tack the appliqué to the top of your fabric.

2. Then use the satin stitch to attach permarjentiy. You may want to

use a contrasting color thread.

NOTE: For best results, be sure your sation stitch covers the bottom

fabric and the top fabric.

SETTINGS

Zigzag width - 2

Stitch length - tto2

Satin stitch can be used to produce many different designs and

patterns.

A. Turn the stitch width control from 0^4-0 at a certain speed.

3. Turn the dial faster from 0 to 4 than 4 to 0.

C> Return it faster from 4 to 0 than 0 to 4.

D. Take a several stitches with zigzag width at 4 and return the dial

to 0 quickly.

Pattern A

Pattern 8

Satin stitch with

zigzag width at 1.

Combination of patterns

8 and C

Page 25

To ensure the best possible operation of your machine, it is necessary

to keep the essential parts clean at ali times.

Always disconnect the machine from power supply by removing the

plug from the socket-outlet.

Cleaning the outer surface of the machine

1. Remove the lint from

the thread guides with

the lint brush as in

dicated by the arrows,

2. Clean the outer surface

with a cloth. Dampen

the cloth with a mild

soap if necessary.

Never use thinner or

benzine.

Cleaning the feed dogs and shuttle area

23

1, Raise the needle to its highest position.

2, a. Remove the bobbin case from the shuttle,

b. Push aside the two shuttle keepers,

c. Remove the shuttle race cover and shuttle.

3, Clean the feed dogs and shuttle area with the lint brush.

NOTE: Put 3 drop of sewing machine oil on the center pin of the

shuttle and shuttle race as indicated by the arrows,

4, a. Be sure the shuttle race forms a half moon on the left side of the

machine,

b. Holding the shuttle by its center pin, replace it so as to form a

half moon on the right side.

c. Slide the shuttle race cover back into position,

d. Snap the shuttle keepers back into position.

Page 26

G£l\i£BAL PROBimS

Machine does not sew,

“Power line cord is not connected. — See

page 4.

^Power switch is turned off, — Set it at LOW

or HIGH position.

^Thread is caught in shuttle. — Clean shuttle

(see page 23)>

■^Needle is damaged. — Replace needle (see

page 14).

Fabric does not move.

^Presser foSt is riot lowered — Lower presser

foot.

^Stitch iefigth is set at 0> — Set it at 1 to 4.

* Feed cover plate Is attached. — Remove feed

cover plate.

STiTCHílNíG PROBLEMS

Machine skips stitches.

* Needle is not all the way up into needle

clamp, - See page 14.

■“^Needle is bent or blunt. — Replace needle

(see page 14),

■^Machine is rtot threaded correctly, — See

page 9.

^Thread Is caught in shuttle, — Clean shuttle

(see page 231.

^Fabric is a certain knit or synthetic. — Use

blue shank needle (see page 14).

Stitches are Irregular.

* Needle size is not correct for threed and

fabric, — See page 14,

^Machine is not threaded correctly. — See

page 9.

*Top thread tension is too loose. — See

page 13.

*Febfic is being pulled or pushed against

machine feeding action. ~ Guide it gently.

^Bobbin has rtot been wound evenly. —

Rewind bobbin.

■“Fabric is being pulled or pushed against

machine feeding action. — Guide it gently.

* Needle size is not correct for thread and

fabric. — See page 14,

■^Needle is not all the way up into the needle

clamp (see page 14).

THREAD PROBLEMS

Thread bunches.

^Top and bobbin threads are not drawn back

under presser foot before starting seam.

— Draw both threads back under presser

foot about 4 inches (10 cm) and hold until a

few stitches are formed.

Needle thread breaks.

■^Machine is not threaded correctly,

page 9.

*Top thread tension is too tight. — See

page 13,

^Needle is bent. — Replace needle (see

page 14).

*^Needle size is not correct for thread and

fabric, — See page 14.

Bobbin thread breaks.

Bobbin case is not threaded correctly. See

page $.

*Lint accumulates in bobbin case or shuttle.

— Remove lint (see page 23).

'"Top and bobbin thread tensionsare too tight,

— Adjust thread tensions (see page 13).

“"Stitch length is too long for sheer or soft

fabric. — S.horten stitch length.

See

Loading...

Loading...