SINGER 2118 User Manual

2114/

SINGER

CONGRATULATIONS

— on the purchase of this new Singer* sewing machine. To achieve the most

enjoyment and satisfaction from this product, it is recommended that the instruction

manual be read through step by step while seated in front of the machine. This will

help the operator get to know all of its parts and capabilities.

INSTRUCTION BOOK

SINGER* MODELS 2114/2118

The manufacturer reserves the right to change the appearance, design, or

accessories of this sewing machine as considered necessary without any notification

or obligation.

^ A trademark of The Singer Company

Copyright 1987, Singer Sewing Machine Company

All rights reserved throughout the world

TABLE OF CONTENTS

1. GETTING TO KNOW YOUR MACHINE...........................................................................2

Principal Parts...............................................................................................................3

Accessories.................................................................................................................... 4

Important Safeguards.................................................................................................. 5

2. GETTING READY TO SEW.................................................................................................6

Connecting the Controller............................................................................................6

Running the Machine....................................................................................................6

Changing Snap-on Presser Feet

Changing Screw-on Presser Feet................................................................................ 7

Changing Needles..........................................................................................................8

Removing Needle Plate

Replacing Needle Plate................................................................................................. 8

Attaching Feed Cover.................................................................................................. 9

Attaching Blindstitch Guide.........................................................................................9

Winding the Bobbin.....................................................................................................10

Threading the Bobbin Case........................................................................................11

Threading the Machine...............................................................................................12

Raising the Bobbin Thread.........................................................................................13

Adjusting Needle Thread Tension..............................................................................14

Cloth Plate Removal and Replacement.....................................................................15

.................................................................................................

..................................................................................

7

8

3. STITCH SELECTION...........................................................................................................16

Adjusting Stitch Width.............................................................................................. 16

Adjusting Stitch Length..............................................................................................16

Adjusting Stitch Balance............................................................................................ 17

Reverse Stitching...................................................................................................... 17

Pattern Selection..........................................................................................................17

Description of Stitches.................................................................................................18

4. SEWING TIPS AND APPLICATIONS...............................................................................19

Fabric, Thread, and Needle Ikble..............................................................................19

Sewing a Seam............................................................................................................ 20

Guiding Fabric............................................................................................................ 21

Basting..........................................................................................................................21

Blindstitching................................................................................................................22

Inserting a Zipper........................................................................................................23

Four-Step Buttonhole..................................................................................................24

TVvin Needle Sewing , ................................................................................................26

Personal Measurements..............................................................................................27

Performance Checklist................................................................................................28

5. CLEANING AND CARING FOR THE MACHINE..........................................................29

Removing Face Plate...................................................................................................29

Cleaning the Machine..................................................................................................29

Removing and Replacing Bobbin Case

Replacing Slide Plate...................................................................................................30

Removing and Replacing Light Bulb

....................................................................

........................................................................

30

31

---------------------------------- ,

1. GETTING TO KNOW YOUR MACHINE

nn rtA

13-^ \

nil li^il

in lilil

( i ? 4 i hi 9 «I 10 M 1? 13 F4 ri

16

t J 3 4 i hr « » 10 M 3? ri W ri I* 17 »• r*

L iilllaiallllHU

:5i

E] C

\ìUÌ

E:

'ipii ■

<U'

2114

2118

---------

Laj

i-9

)

I”

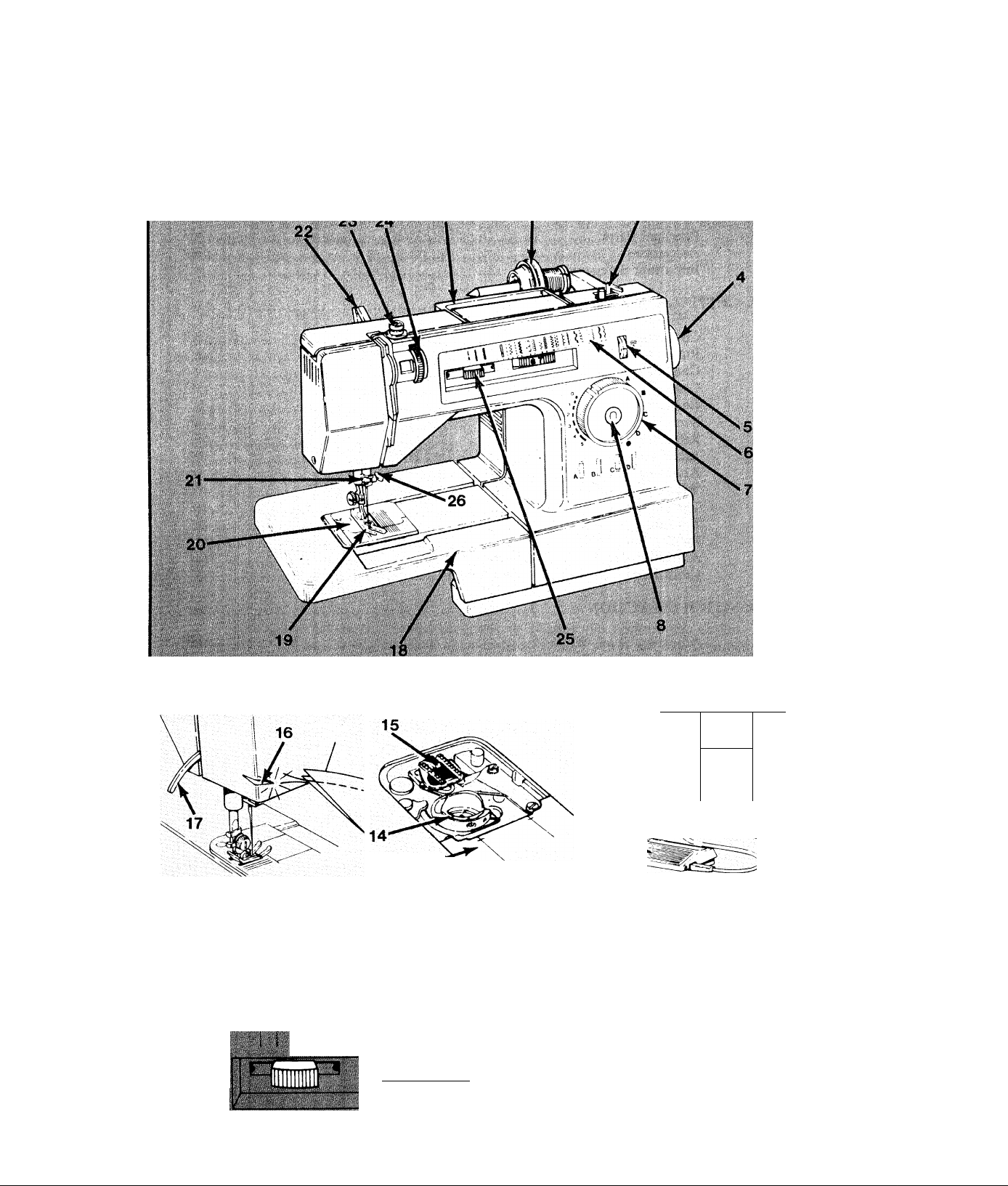

Principal Parts

1. Carrying Handle

2. Spool Holder

3. Bobbin Winder

4. Hand Wheel

■ 5. Stitch Balance Dial

6. Stitch Pattern Selector

7. Stitch Length Control

8. Reverse Stitching Button

9. Power and Light Switch

10. Electrical Connections

11. Electrical Rating Label

12. Speed Controller

13. Slide Plate

14. Bobbin Case

15. Fabric Feed (Feed Dog)

16. Thread Cutter

17. Presser Foot Lifter

18. Cloth Plate

19. Presser Foot

20. Needle Plate

21. Thread Guide

22. Snap-in Thread Guide

23. Bobbin Winder Tension

24. Top Thread Tension

25. Stitch Width Control

26. Needle Clamp

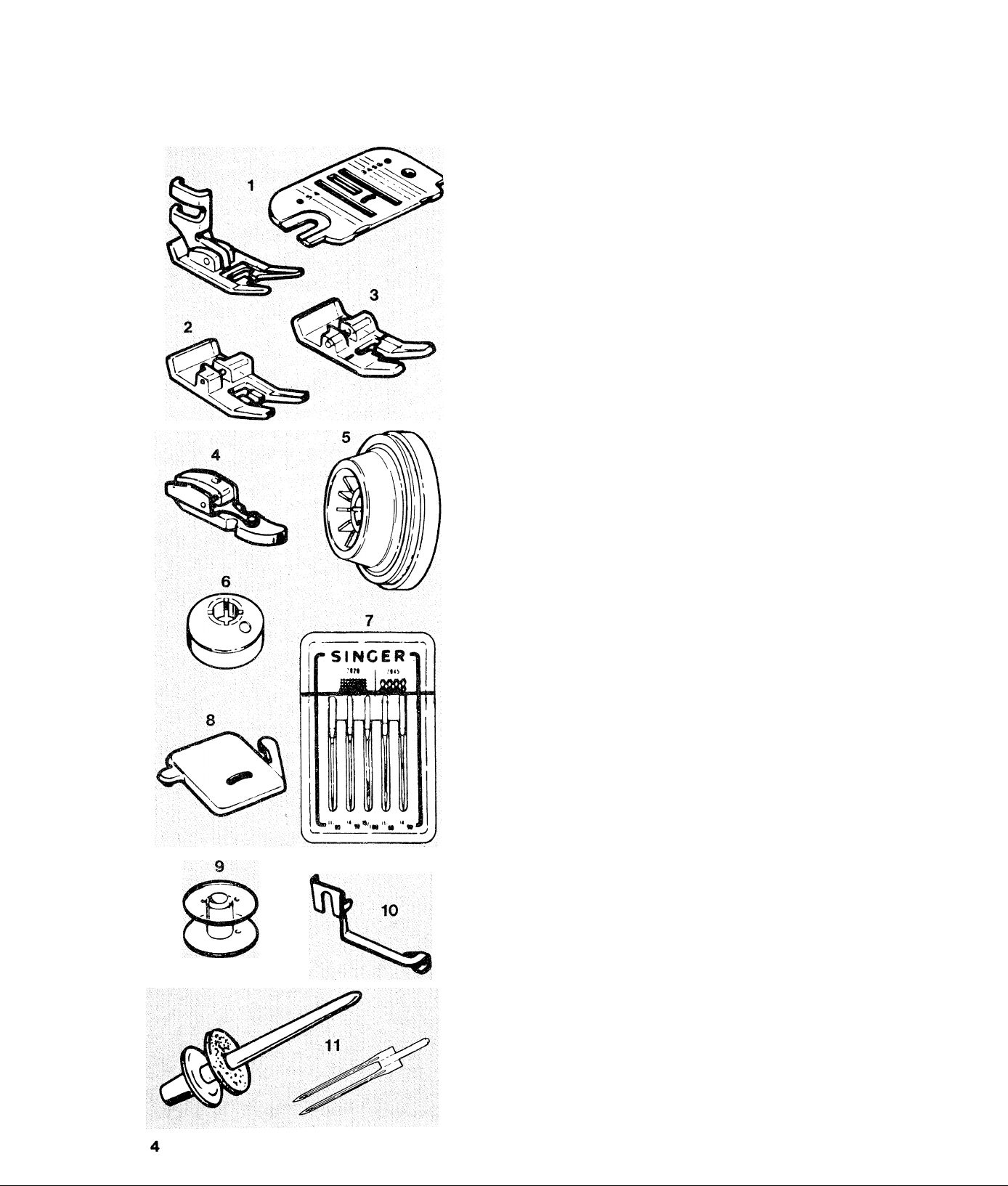

The following accessories are furnished with

this sewing machines:

1. General Purpose Presser Foot and Needle

Plate are on the machine when delivered.

Use together for most sewing projects.

2. Special Purpose Presser Foot for decorative

stitching.- -

3. Buttonhole Presser Foot

4. Zipper Foot

5. Spool Holder for medium and large thread

spools.

6. Small Spool Holder for small thread spools.

7. Needle Pack includes an assortment of types

and sizes.

8. Feed Cover for darning or embroidery.

9. Extra Bobbins

10. Bbnd Stitch Hem Guide

11. IWin Needle and Extra Spool Pin with Felt

Washer (optional) for decorative stitching.

Important Sa

1. Disconnect the powerline plug from the electrical outlet when changing needles,

feet, or needle plates, or when leaving machine unattended. This eliminates the possibili

ty of starting the machine by accidently pressing the speed controller.

2. Before removing the bobbin case, disconnect the powerline plug from the electrical

outlet.

3. Because of the up and down movement of the needle, work carefully and watch

the sewing area when operating the machine.

4. Do not pull the fabric while stitching as this may deflect the needle, causing it to

break.

5. Before cleaning the machine, disconnect the powerline plug from the electrical outlet.

6. Do not attempt to adjust the motor belt. Contact the nearest service center or an

authorized dealer should any adjustment be required.

7. Before changing the light bulb, make sure the powerline plug is disconnected from

the electrical outlet. Be sure to replace the face plate which covers the light bulb before

operating the machine.

8. This machine is designed to use a 15 watt maximum light bulb only.

9. This machine is double insulated. When servicing product, use only identical

replacement parts.

This product is suppressed for radio and television interference with the International

Electro-technical Commission requirements of the CISPR.

iî iaifînNe R

To really enjoy sewing, get to know the machine well. This chapter will be valuable in

doing just that.

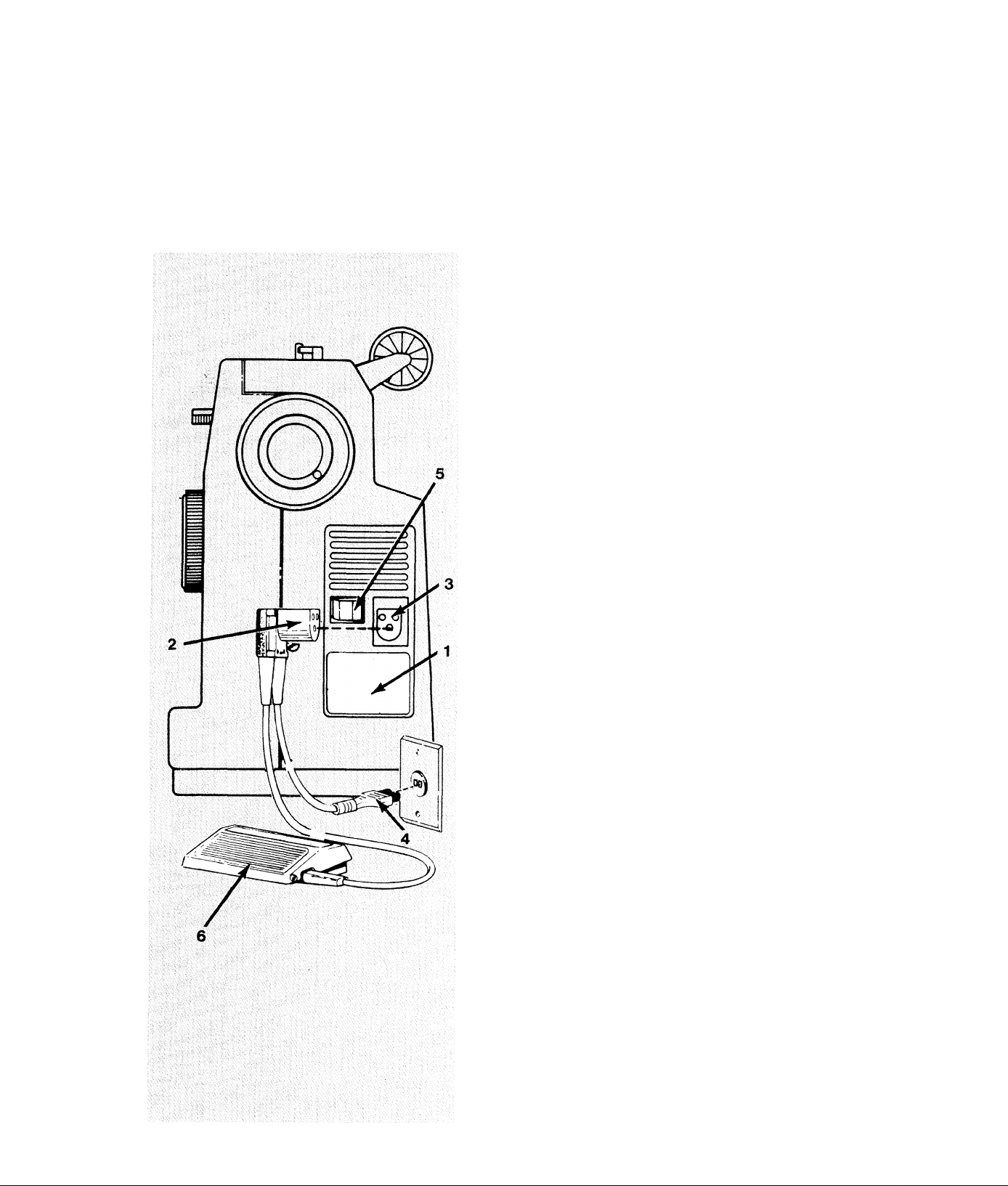

Cohnectiitg the h/lachine

Connecting the ControUer

NOTE: Before plugging in the machine, be sure

the electrical information on the label (1) below

the handwheel agrees with the local electrical

supply.

Push plug (2) into the receptacle (3) at the right

end of the machine. Then, connect plug (4) to

an electrical outlet.

Running the Machine

To turn on machine and sewing light, press rear

portion of power switch (5). To turn off machine

and light, press front portion “0” of power

switch.

To run the machine and control speed, press the

speed controller (6) with foot. The harder it is

pressed, the faster the machine will sew. To stop

machine, remove foot from the controller.

NOTE: Do not operate machine without fabric

under the presser foot as this may

damage the feed and the presser foot.

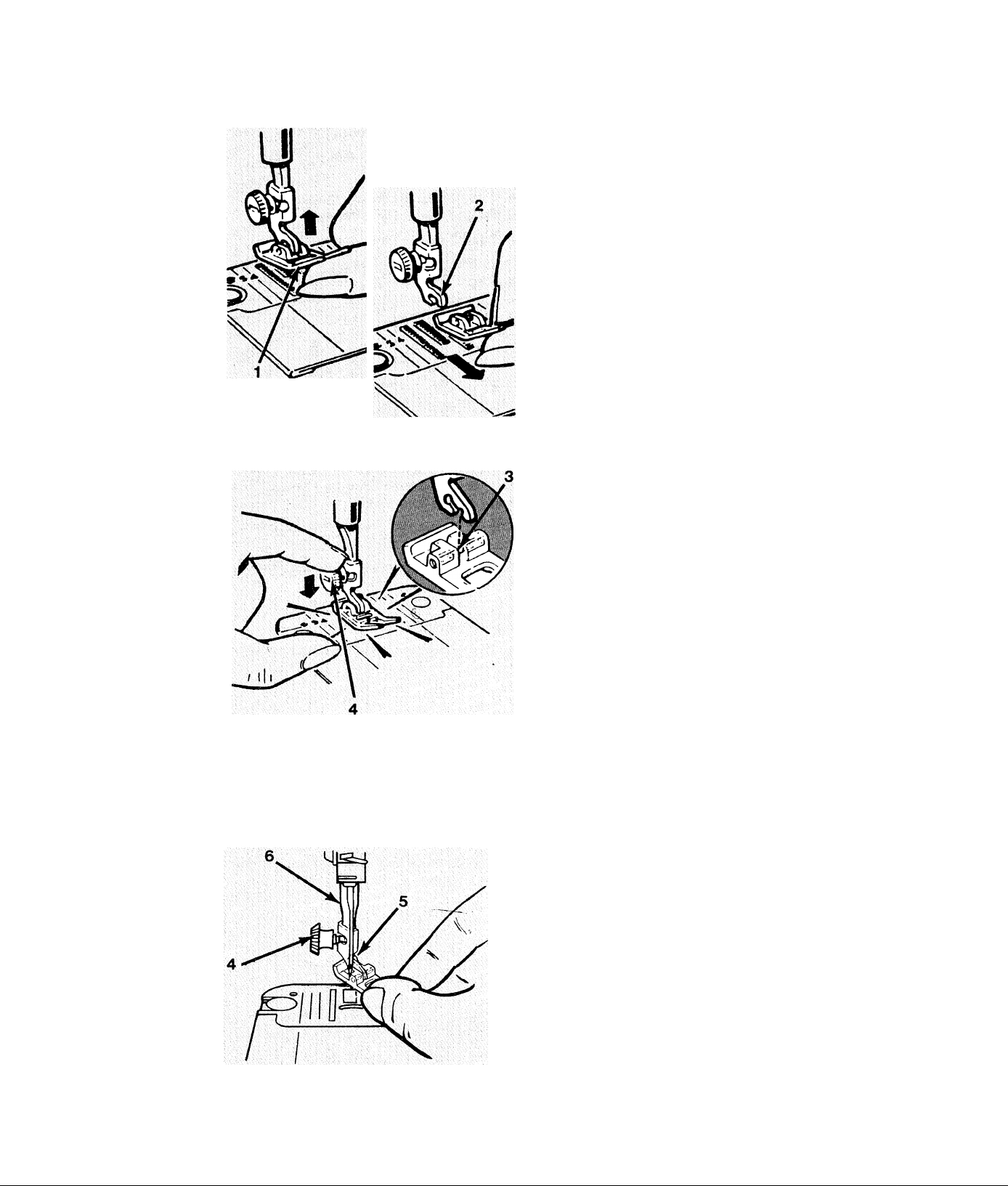

Changing Snap-on Presser Feet

The accessory feet supplied with the machine fit

onto a common shank and are attached easily

as follows:

Hi Raise needle to highest point by turning the

handwheel towards the operator.

H« Raise presser foot using lever on rear of

machine.

H< Push up on toe of presser foot (1) until it

snaps off shank (2) and remove foot.

Hi Place new foot on needle plate with pin (3)

under center of shank.

Hi Using presser foot lifter, lower shank onto pin

(3) and push down firmly on presser foot screw

(4) until foot snaps into place onto shank.

Changing Screw-on Presser Feet

special feet which have built-in shanks are

replaced as follows:

Hi Raise needle and presser foot.

Hi Loosen presser foot screw (4) with a coin and

remove presser foot with shank (5) ’guiding it

towards the operator and to the right.

Hi To replace foot, hook it around presser bar

(6) and screw (4). Tighten screw with a coin.

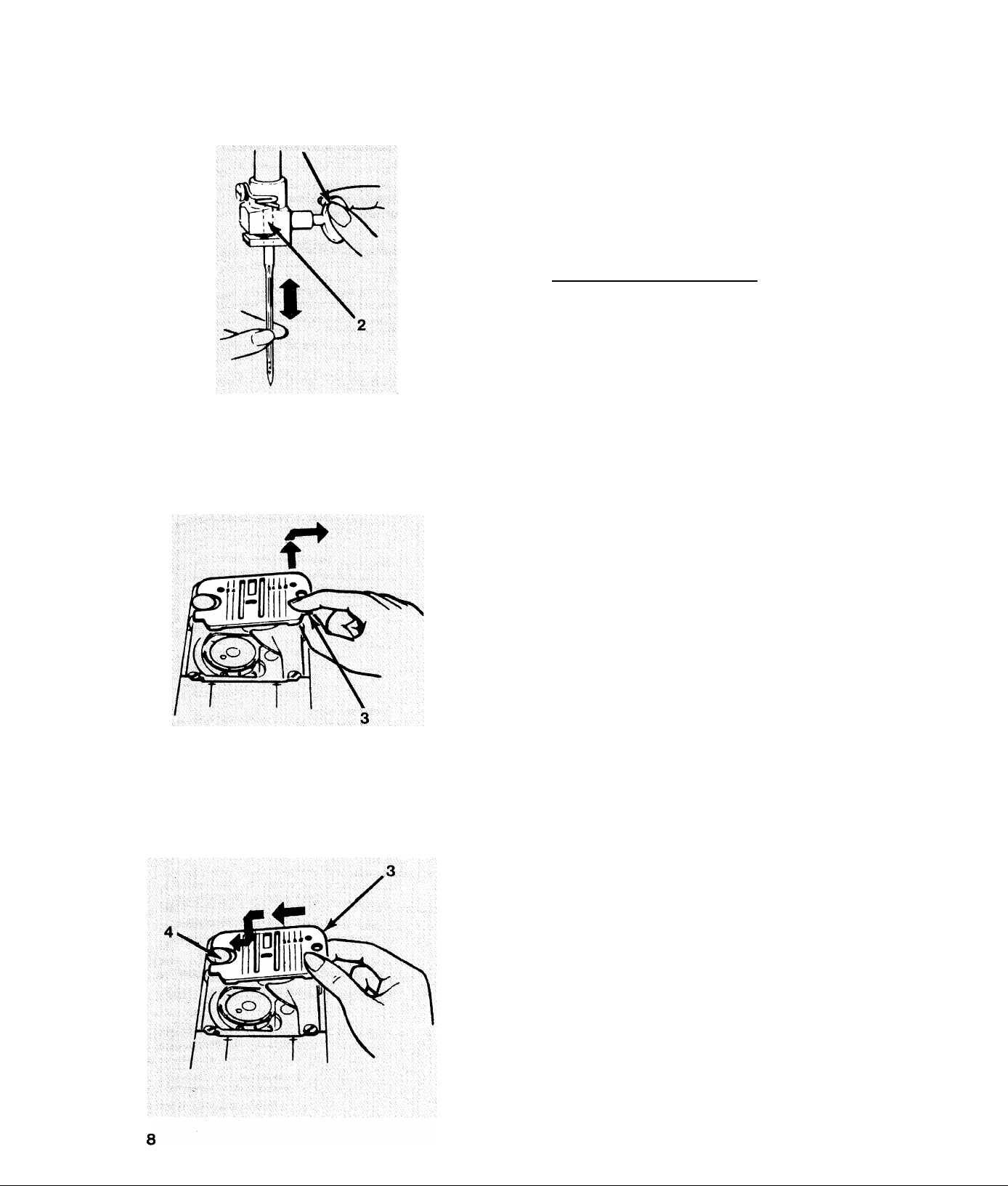

Changing Needles

Re^pvihg Niediefil^te

Raise needle to highest position by turning

handwheel towards the operator.

Loosen needle damp screw (1) and remove

needle.

* With flat side of needle to the back, insert new

needle into clamp (2) as far as it will go.

^ Tighten needle clamp screw (1) securely.

Check the Fabric. Thread and Needle Chart in

this book for correct needle and fabric

combinations.

For either cleaning or use of the straight

stitch plate, available from an approved

dealer, do the following:

Hi Raise needle and presser foot to their

highest positions.

Open slide plate and place thumb under right

side of needle plate (3).

H« Lift up and pull plate to the right to

remove it from the machine.

Replacing Necdieplate

Hi Holding needle plate as shown, slide it to the

left under the head of clamping pin (4).

Hi Press down on right side at (3) until it fits se

curely in place.

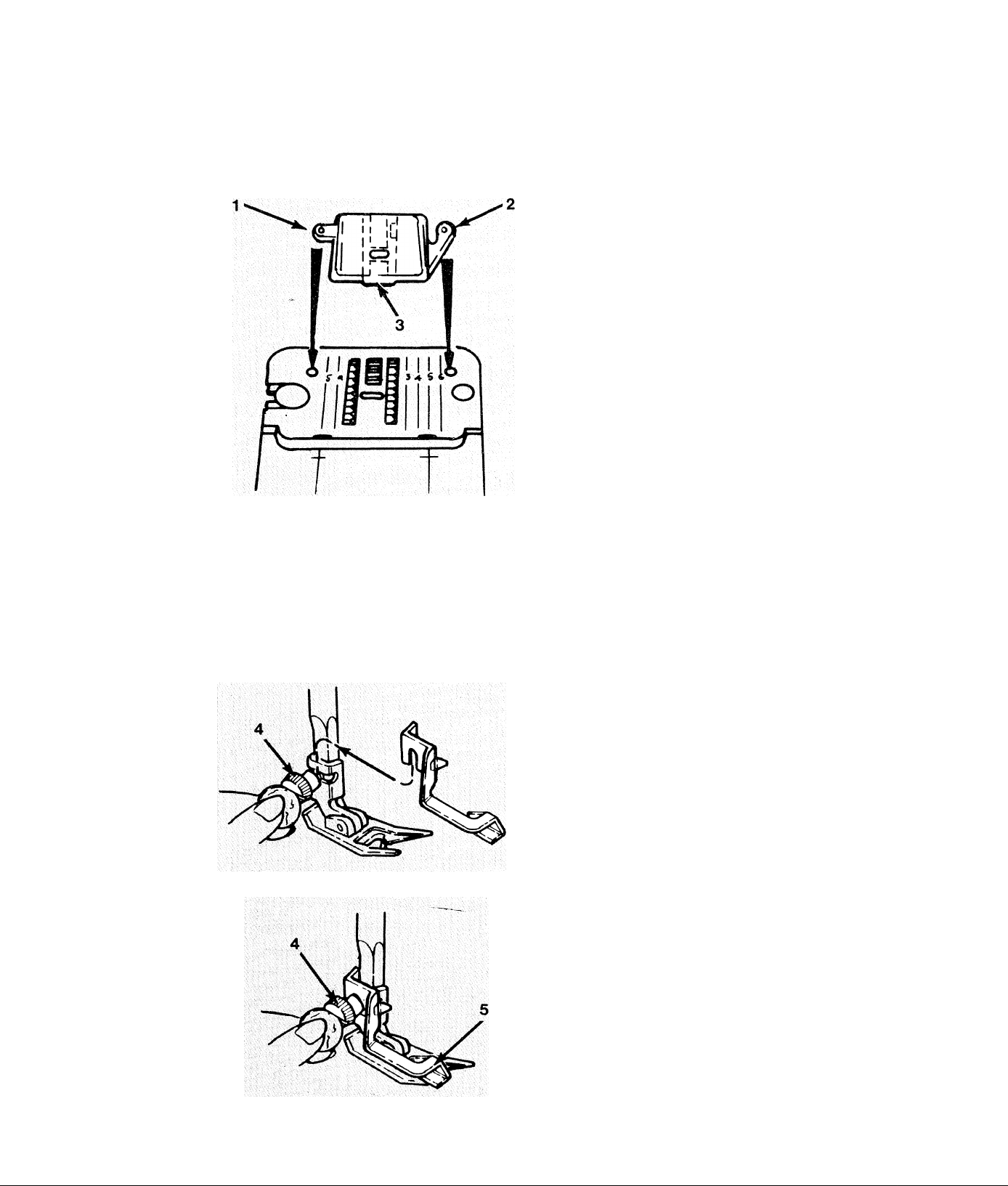

Attaching Feed Cover

For darning and free-motion embroidery, the

feed cover prevents the feed from moving the

material. Attach it as follows:

^ Raise needle and presser foot, and open slide

plate.

^ Slide feed cover on top of needle plate, press

ing tabs (1) and (2) into holes in needle plate.

Then, close slide plate.

* To remove, open slide plate. Lift front edge

of cover (3) and pull it away.

The optional darning and embroidery foot,

available from approved dealers, may be used.

If operator prefers to do these operations by

removing presser foot and shank entirely from

machine, be sure presser bar is lowered to main

tain proper thread tension.

Attaching Blindstitch Guide

5k Raise presser foot and loosen presser foot

screw with a coin.

>k Slip blindstitch hem guide between screw

and presser foot shank.

5k Be sure underside of the guide (5) clears the

slide plate and front of foot.

^ Tighten screw (4) with the coin.

Loading...

Loading...