Page 1

SINGER

Sewing nVCacliine

201k

Page 2

SINGER

Form K6053

(1266)

All Rights Reserved

Printed in Great Britain

Page 3

Sewing Machine 2 OIK

The SINGER 201K is another in a long line of products

resulting from the skill and ability of SINGER

craftsmen.

*A Trademark of THE SINGER COMPANY

K4d$8

Page 4

WHEN YOU OWN A SINGER 201K MACHINE

you have a beautifully styled, smooth running

machine which offers you a new world of sewing

enjoyment. Exclusive dresses for yourself, clothing

for your family, and numerous items for the home—

all will be yours at a fraction of their ready-made cost.

TO GET THE MOST ENJOYMENT FROM YOUR

You are entitled to sewing lessons when you

SINGER

become the owner of a new SINGER. A skilled,

SINGER-trained teacher personally guides you

and assists you in learning the fundamentals of

home sewing. Other courses embracing all phases

of home sewing are available at low cost.

2

Page 5

SINGER SERVICE

WHerever you go you will find expert, depend

able SINGER* Service nearby. SINGER is

interested in helping you keep your SINGER

Sewing Machine in top condition. That is why

you should always call your SINGER SEWING

CENTRE if your machine ever requires adjust

ment or repair. When you call your SINGER

SEWING CENTRE you can be sure of obtain

ing the service of a trained SINGER repair man

and can be assured of warranted SINGER* parts

when needed ! Look for the familiar red “S” Trade Mark on your SINGER SEWING

CENTRE and the ever ready SINGER Service Car.

EVERYTHING FOR THE WOMAN WHO SEWS

The answer to your sewing needs is at your SINGER

SEWING CENTRE. There you will find a wide

choice of sewing necessities and notions, sewing

instructions and guidance and services for covering

buttons, hemstitching, making belts and buckles, to

mention a few. Look in your telephone directory

under SINGER SEWING MACHINE COMPANY

for the SINGER SEWING CENTRE nearest you.

3

SINGER

Page 6

ELECTRICAL INFORMATION

The SINGER* Electric Motor

is located at the back of the machine,

and can be supplied for operation on

alternating or direct current. Orders

must state the catalogue number of the

motor, or the voltage, and in the case of

alternating current, the number of cycles.

Before Inserting Electric Plug—

be sure that voltage and number of

cycles stamped on motor nameplate

are within range marked on electric

meter installed by electric power company.

Electrical Connections for Machine

Push three-pin safety plug into three-

pin terminal block at right of machine

and connect plug at othei end of cord

to electric supply point.

Speed Controller

The speed of machine is regulated by

amount of pressure on foot controller

or knee controller.

CAUTION

When you have finished your sewing always dis

connect the plug from the electric supply point.

■fe

Page 7

r-

LIGHT

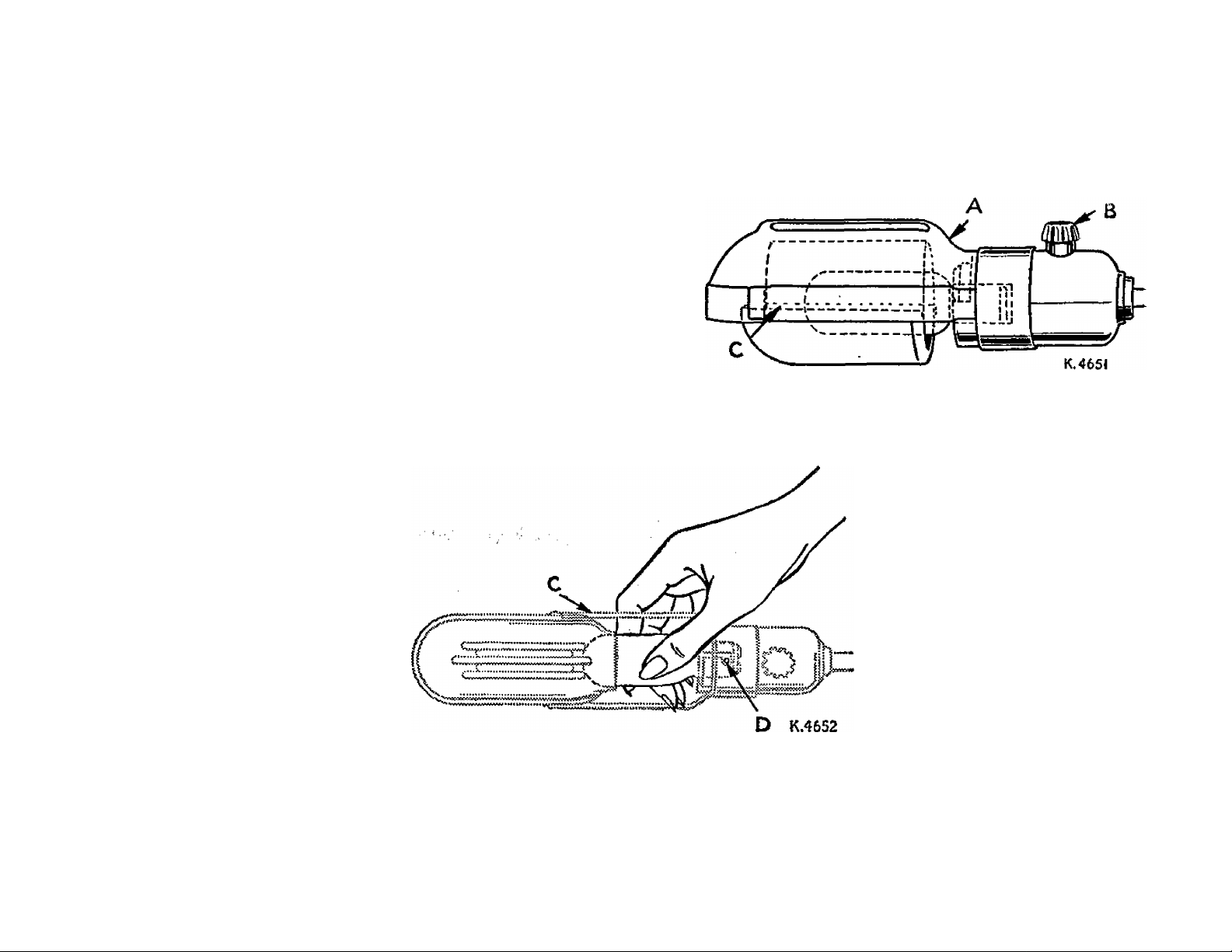

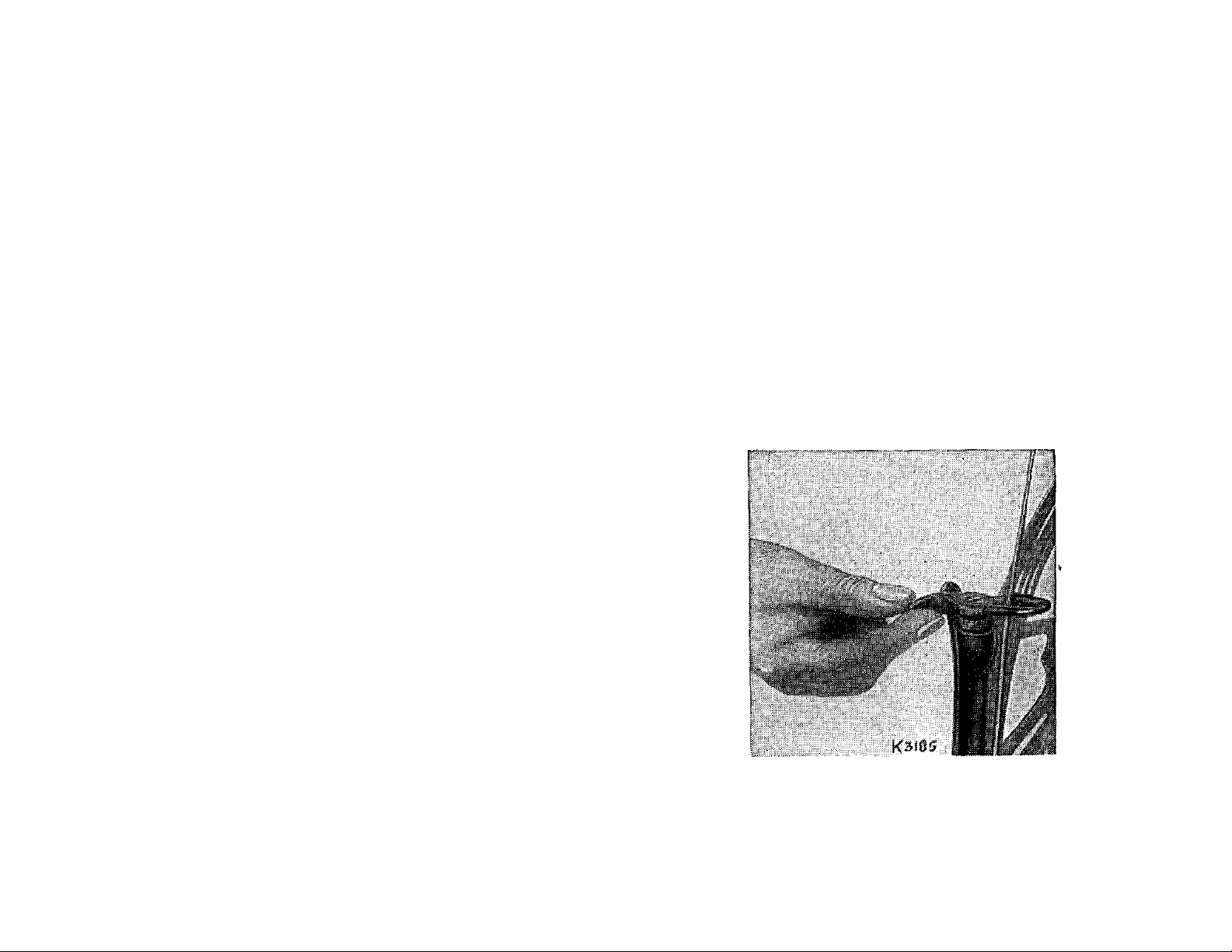

To Turn Light ‘Sn” or “off.”

To turn on light, reach over

machine arm and turn switch

B, Fig. 1 clockwise. To exting

uish light turn switch anti

clockwise.

Fig, 1. Light,

Fig, 2, Removing and replacing bulb,

5

Page 8

To Remoye Bulb

Grasp light socket so that thumb extends

over switch B. Press shade with thumb

at A to release shade from two catches,

and slide it halfway out of shade holder

C. Press bulb into socket and at same

time turn bulb over from machine as far

as it will go to unlock pin D (see Figs* 3

and 4). Withdraw the bulb.

To Insert New Bulb

Press bulb into socket and turn it over

toward machine until pin D enters notch

in socket (see Fig. 3). Return shade to

its normal position as shown in Fig. 1.

Fig. 5. Locking or unlocking hutb pin.

j..

“““VESSKS»,

K.465i

Fig. 4. Inserting bulb in socket.

Page 9

IF MACHINE IS ELECTRICALLY

OPERATED

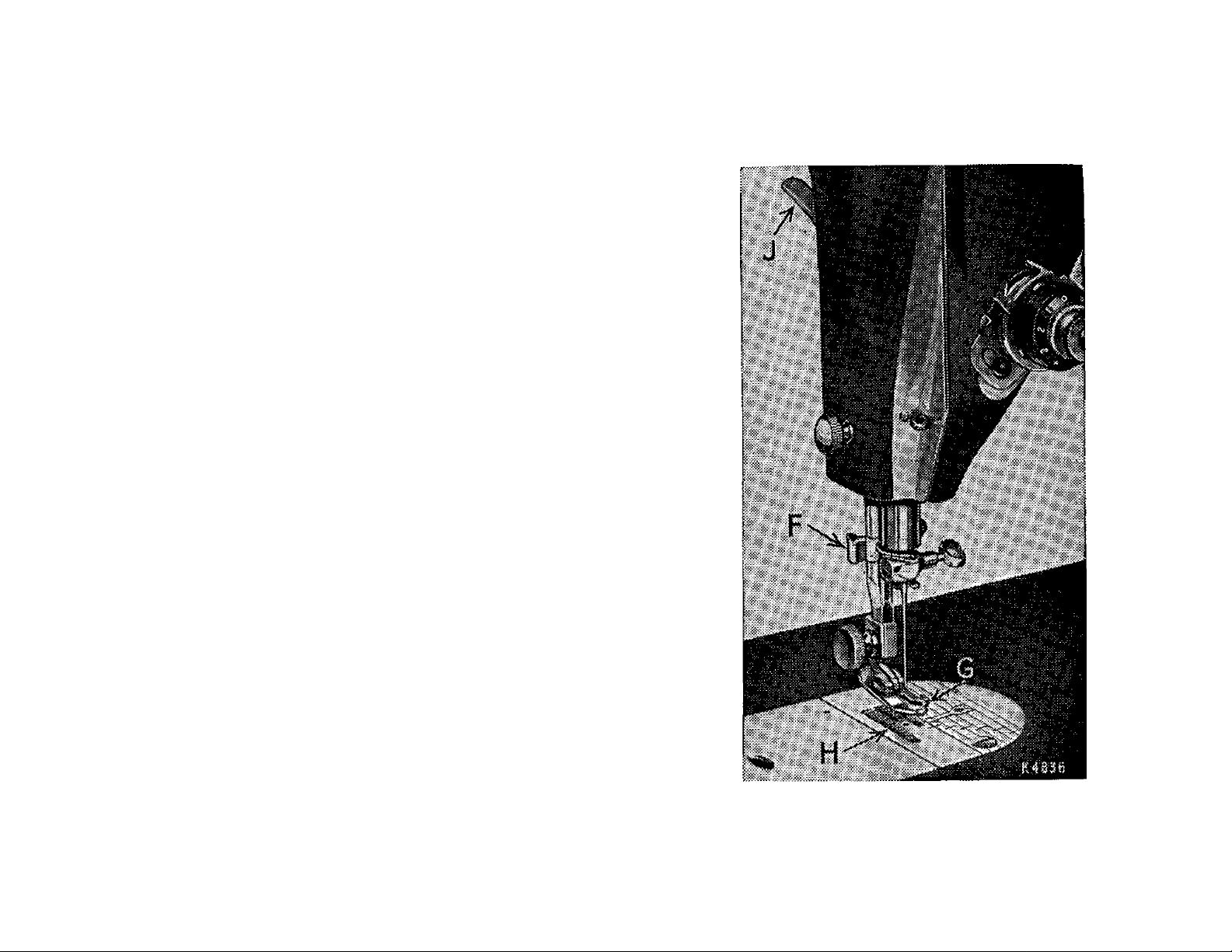

Raise presser foot G by means of presser bar

lifter J to prevent injury to the foot G and

feed H.

Place a piece of material under presser foot

and let the foot down upon it. Turn on

electric current and, if the combination knee

and foot controller is installed as a knee con

troller, press knee lever to the right. If

controller is placed on the floor to be used as

a foot controller, press down oh pedal of

controller. The speed of the machine is

controlled entirely by the amount of pressure

applied to the controller. Operate machine

in this way, without being threaded, until

you have become accustomed to guiding the

material and operating the controller.

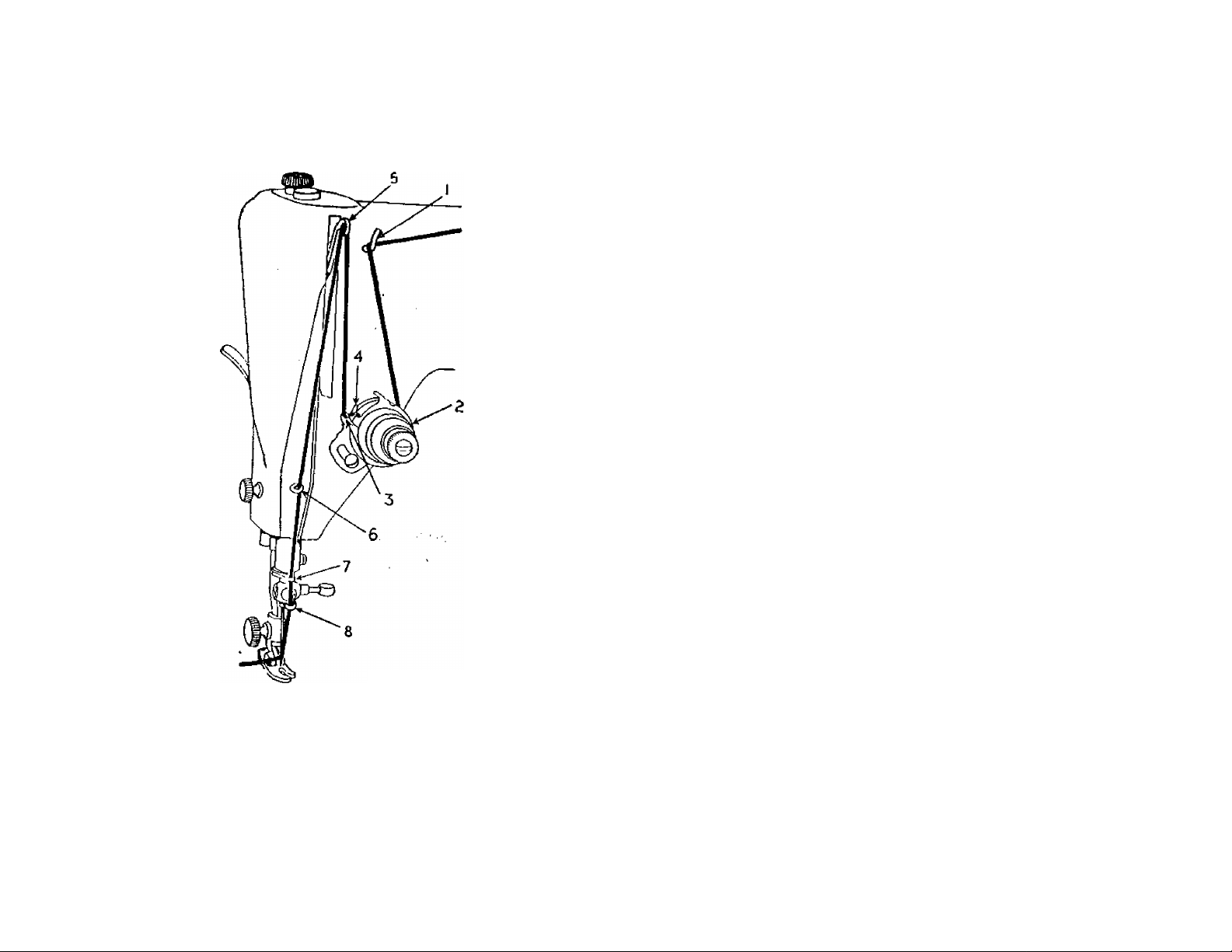

Fig, 5, Front view of machine.

Page 10

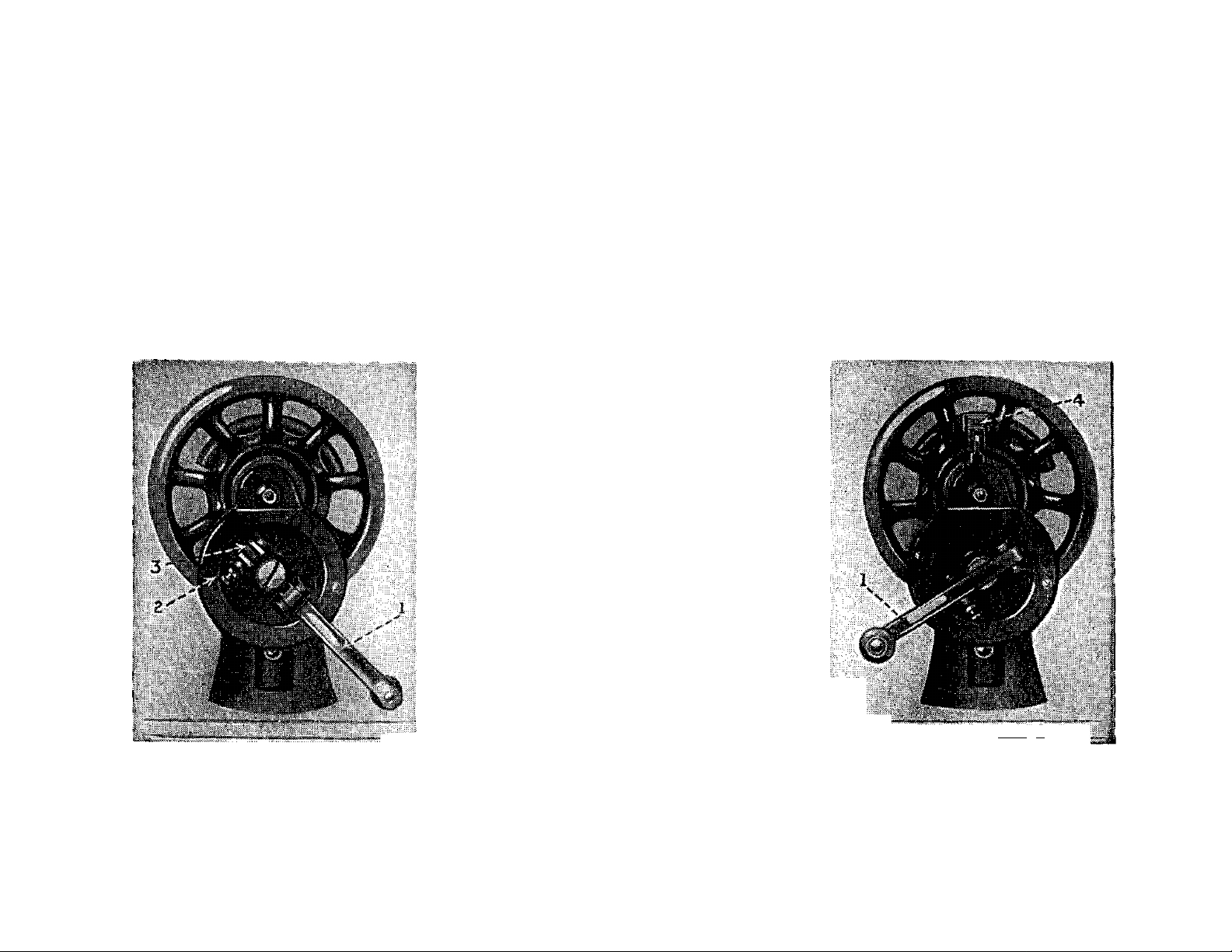

IF MACHINE IS HAND OPERATED

When the machine is uncovered, the hand attachment will be found to be out of working

position as shown in Fig. 6, Pull the small spring stud 2, and turn the handle back

until the lever 1, enters the socket 3. Press back the hinged finger 4, Fig. 7 between the

spokes of the wheel. The machine is now ready for working, as shown in Fig. 7.

NOTE. Before replacing the

cover or the machine in its

case, the lever should be dis

engaged and the handle placed

in the position shown in Fig. 6.

TO OPERATE THE HAND

MACHINE

Place a piece of material under

the presser foot G, Fig. 5, and

lower the latter by means of

the lifter J.

Now turn the handle over

from you to work the machine,

without being threaded, until

you are accustomed to guiding

g the material with the left hand. Fig. 7

... K3975

8

Page 11

IF MACHINE IS TREADLE OPERATED

BELT SHIFTER

Loosen the hand wheel by turning stop

motion screw 17, Fig. 12, oyer toward you,

place both feet upon the treadle and turn

the hand wheel over toward you, at the

same time allowing the feet to move

freely and lightly with the motion of the

treadle. Continue to do this until a

regular and easy movement is acquired

and you are able to work the treadle so

that you can re-start the machine with

the wheel turning toward you,

When familiar with the working move

ment, tighten the hand wheel by turning

the stop motion screw over from you, and

place a piece of material under the presser

foot G, Fig. 5. Lower the latter by means

This device simplifies throwing off and

replacing the belt. To throw off the

belt, move the belt shifter to the left

(see Fig, 8), working the treadle at the

same time. To replace the belt, work

the treadle slowly with the band wheel

turning toward you, when a revolution

or two of the wheel will bring the belt back

into its place.

of the lifter and again work the machine,

without being threaded, until you are

accustomed to guiding the material.

The belt should be only just tight enough

not to slip. If too loose, shorten and

rejoin.

Fig. 8.

Page 12

NEEDLES AND THREAD

This machine uses a 15x1 Needle—available

in sizes 9, 11, 14, 16, 18, 19 and 21.

For perfect stitching, the thread should be selected

according to the fabric to be stitched and the

needle must be of the correct size for the thread

which must pass freely through eye of needle.

Select the correct needle according to the chart

on page 11. Be sure that the needle is not blunt

or bent.

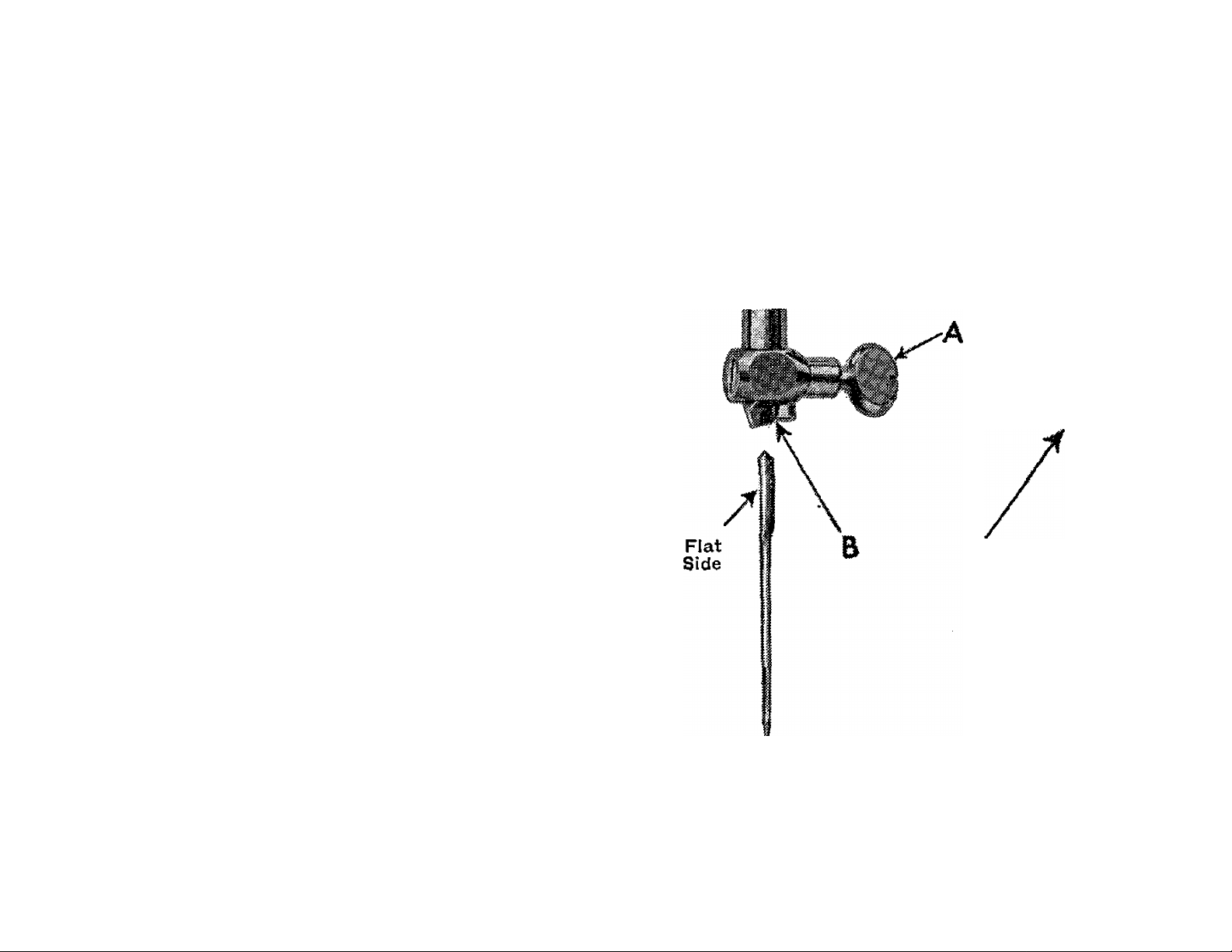

TO SET THE NEEDLE

Raise needle bar to its highest position and loosen

thumb screw A in needle clamp. Insert needle

with its flat side to the left up into the needle

clamp B as far as it will go, then tighten thumb

screw A.

10

Flat

Side

Fig, 9, Setting the Needle,

Page 13

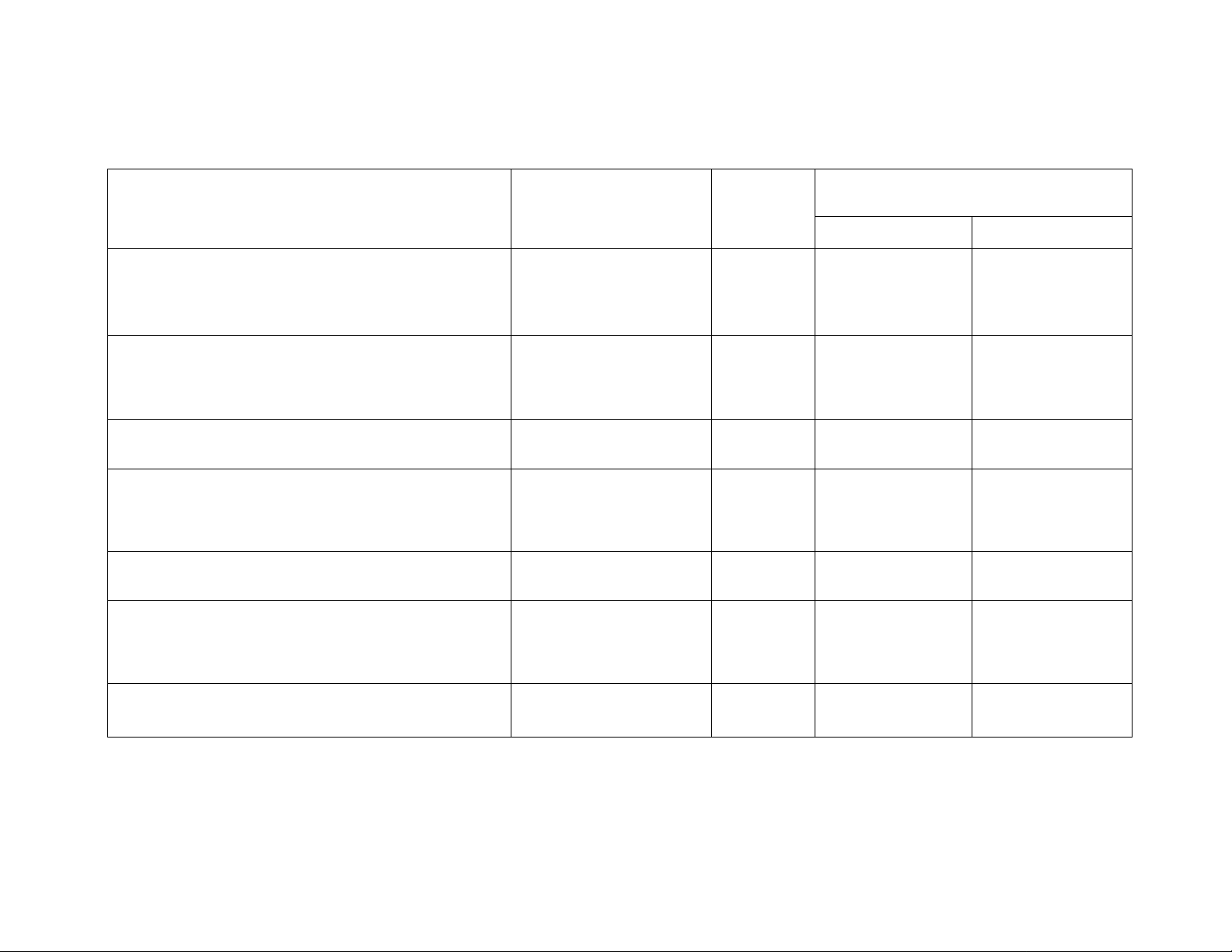

CHART SHOWING THE RELATIONSHIP OF TYPES OF FABRICS, THREAD

AND NEEDLE SIZES AND MACHINE STITCHES TO THE INCH

Types of Fabrics

Very thin Silk, Muslin, Cambric, Light

weight Delicate Fabrics, etc.

Fine Calicoes, Linens, Shirtings, Fine

Silk Goods, etc.

Plastic Materials 50 to 80

Shirtings, Sheetings, Bleached Calicoes,

Silk and General Domestic Goods,

Light Woollen Goods and all classes

of general work

All kinds of heavy Calicoes, Drill, Wool

len Goods, etc.

Tickings, Heavy Woollens, Trousers,

Boys’ Clothing, Corsets, Cloaks,

Mantles, Heavy Coats, and Heavy

Clothing generally

Thread Sizes

100 to 150 Cotton,

50 Silk,

80 Mercerised

Darning Cotton

80 to 100 Cotton,

50 Silk,

50 Mercerised

Darning Cotton

Mercerised Cotton

60 to 80 Cotton,

50 Silk,

50 Syifko

40 to 60 Cotton 16

24 to 40 Cotton,

60 to 80 Linen

Needle

Sizes

9

11

11

14

18 or 19

Machine Stitches per Inch

Inside Seams

20

16

10

12

10

8

Top Stitching

25 to 30

20

12

18

12

10

Bags, Coarse Cloths, Canvas, Duck,

Heavy Goods of any texture

When ordering needles,^always specify *'Class and Variety 15x1 ’* and state the size and quantity required.

You will obtain the best stitching results from your Sewing Machine if it is fitted with t SINGER* Needle.

40 to 60 Linen, or

very coarse cotton

19 OP 21

6

8

11

Page 14

UPPER THREADING

See Fig. 10.

Raise take-up lever 5 to its highest point.

Place spool of thread on spool pin.

Lead thread into thread guide 1.

Down and from right to left between

tension discs 2.

Into the loop of the take-up spring 3 and

to the right until it enters the fork 4.

Up and from right to left through hole

in take-up lever 5.

Down through guide 6 on face plate.

Down through guide 7 into guide 8.

From right to left through the eye of the

Fig. 10.

K4SQ6

needle.

Draw about two inches of thread through

the eye of the needle with which to

begin sewing.

12

Page 15

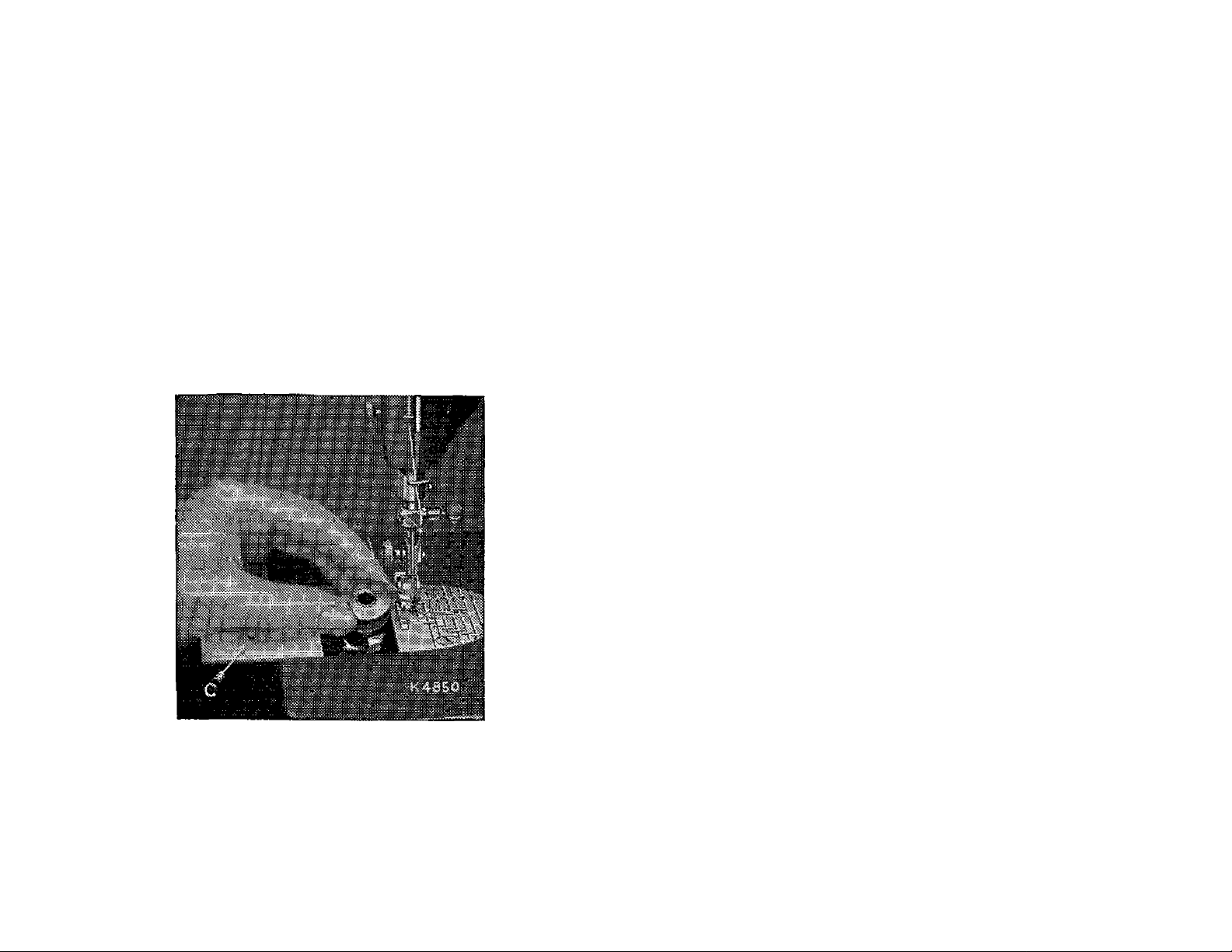

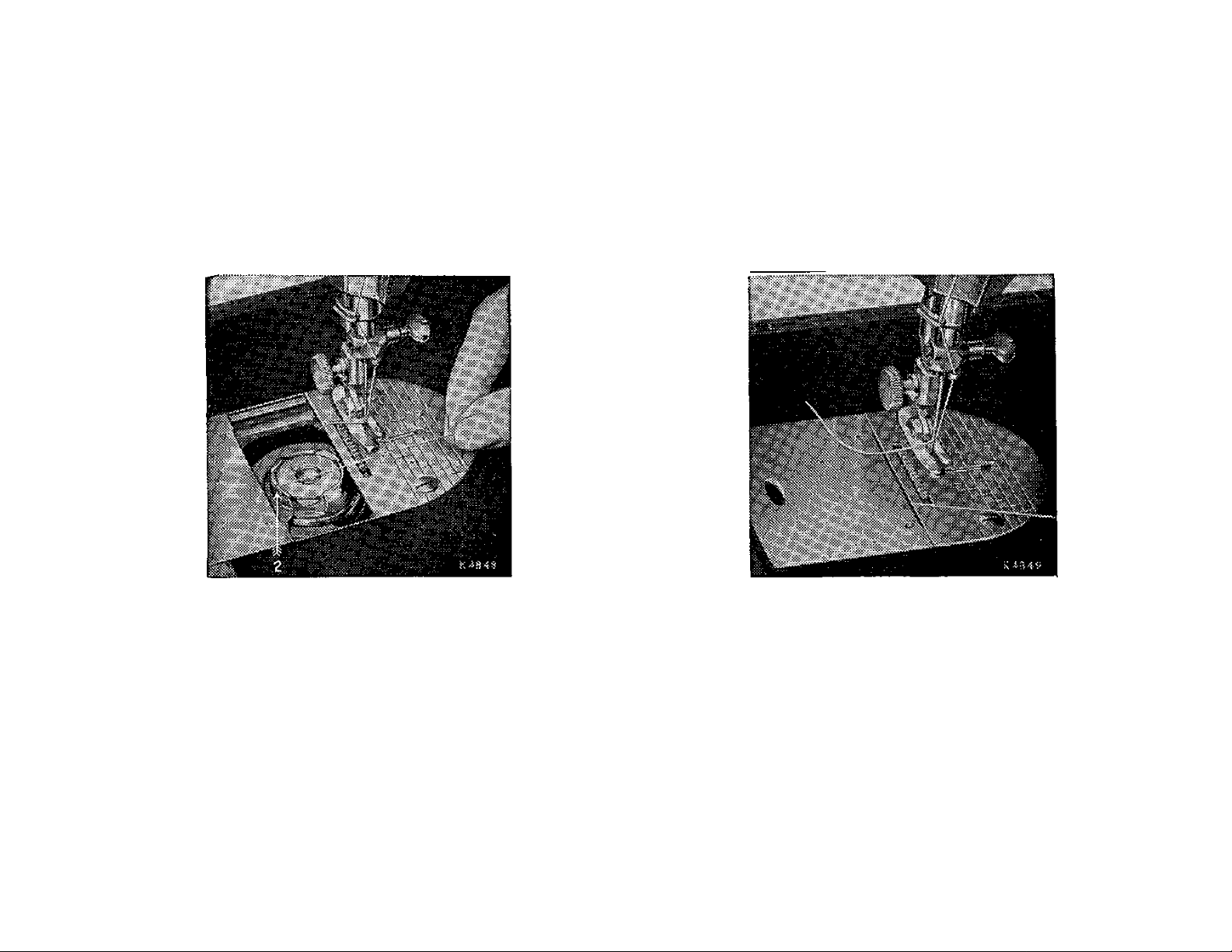

TO REMOVE BOBBIN

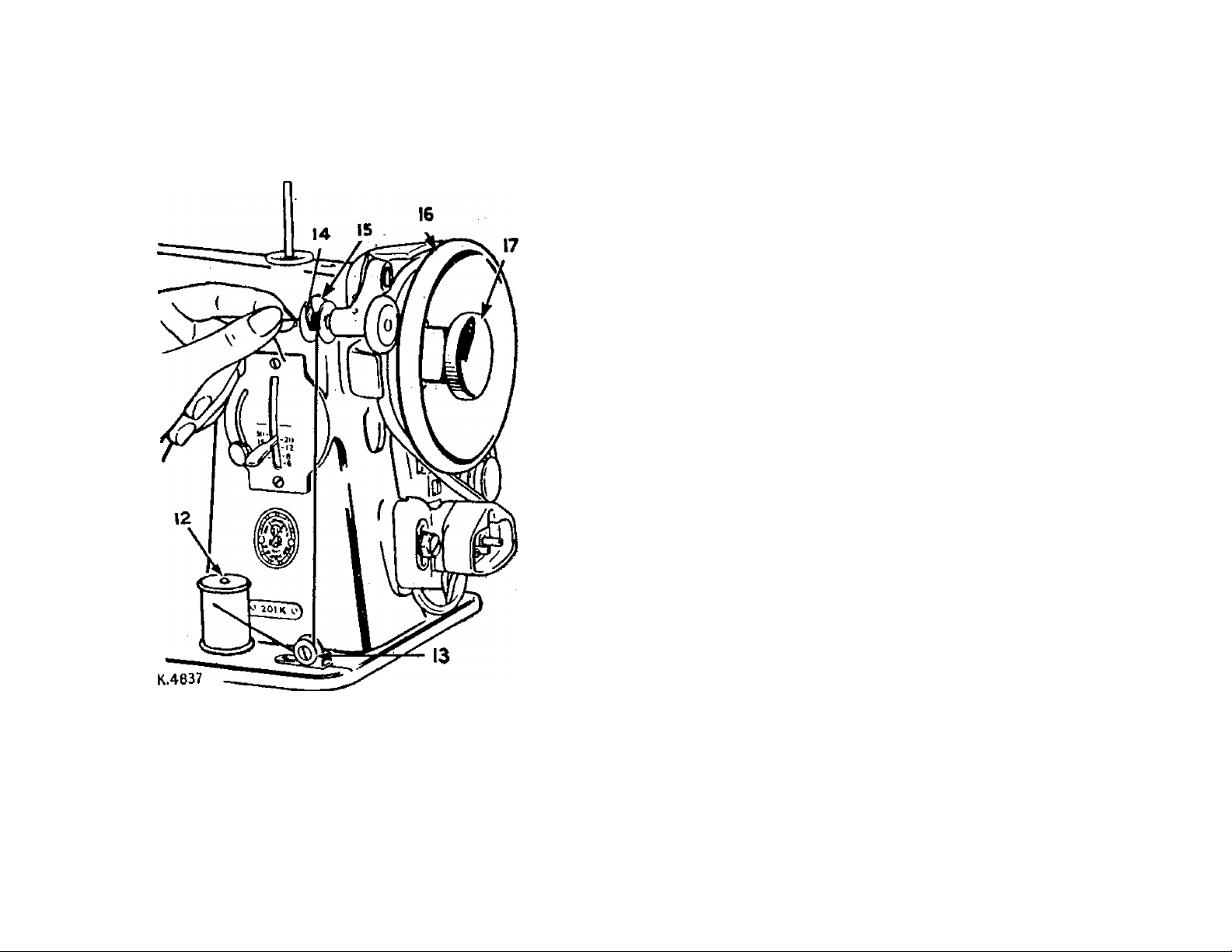

TO WIND BOBBIN. Fig. 12.

Raise the needle to its highest point.

Draw to the left the slide (C) in the bed

of the machine and remove the bobbin

with the thumb and forefinger of the

left hand, as shown in Fig. 11.

1. Place bobbin on spindle with pin of

spindle entering hole in right side of

bobbin.

2. Lock bobbin in place by pressing bob

bin winder down until latch 15, Fig. 12

engages.

3. Place spool of thread on spool pin 12.

Draw thread under and between

tension discs 13. Lead thread up

through hole in bobbin 14 from the

inside.

4. Hold hand wheel 16 and loosen

knurled screw 17 by turning it over

toward you.

5. Hold end of thread and operate

machine as for sewing. Continue to

Fig. 11. Removing the Bobbin,

hold end of thread until it breaks off.

Allow tension discs to control flow of

thread. Do not guide or hold thread

when winding bobbin.

The bobbin winder will stop automatically

when the bobbin is filled.

13

Page 16

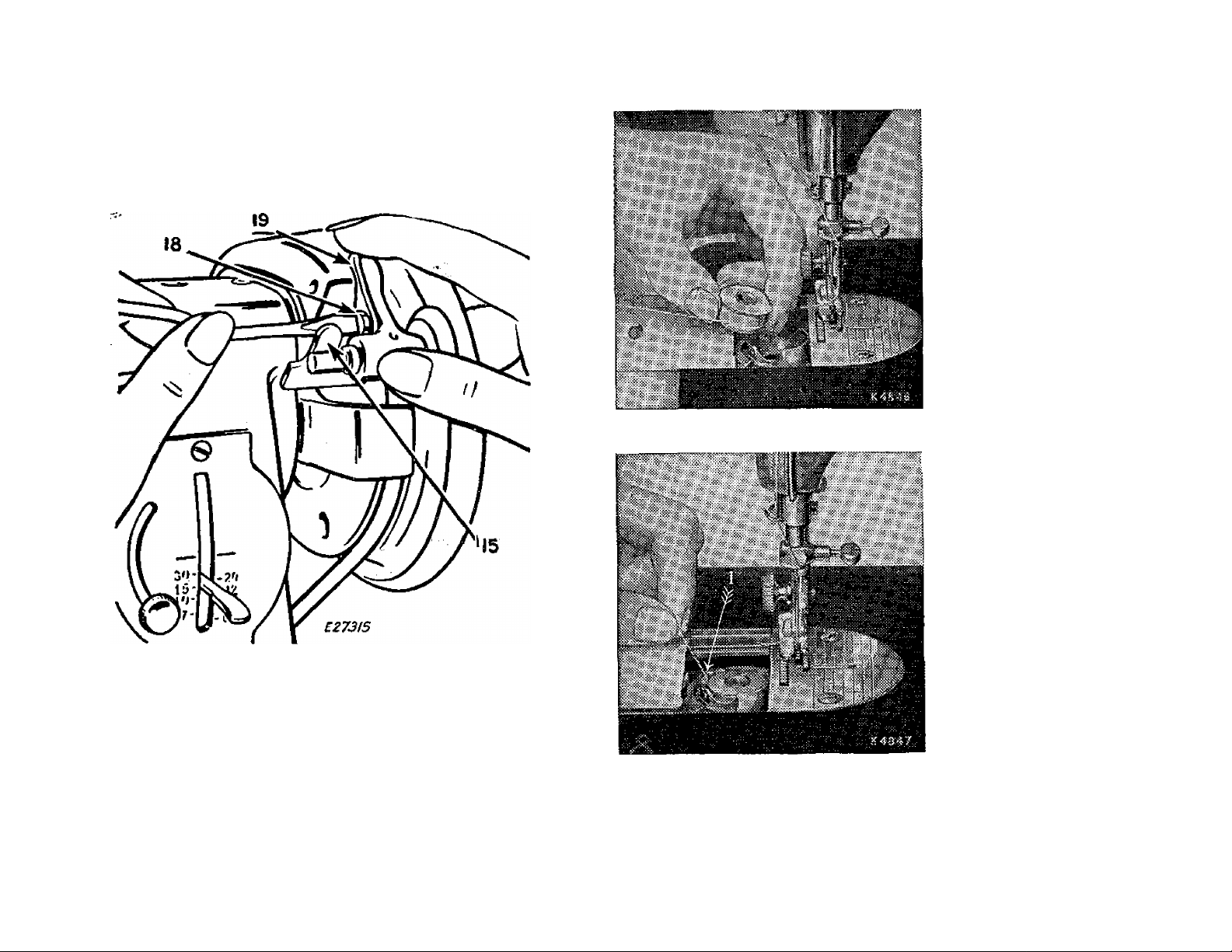

Remove bobbin from spindle and tighten

knurled screw 17.

If pressure of bobbin winder pulley

against bub of hand wheel is insufficient

for winding the bobbin, press down bobbin

winder until latch 15, Fig. 13 drops and

holds it in position. Loosen adjusting

screw 18, Fig. 13. With forefinger, push

back upper end of slotted plate 19 as far

as it will go, as shown in Fig. 13, and at

the same time, press bobbin winder

pulley against hub of hand wheel. Tight

en adjusting screw 18. If thread does

not wind evenly on bobbin, loosen screw

which holds tension bracket 13, Fig. 12

in position. Move bracket to the left if

Fig. 12* Winding the Bobbin.

bobbin winds high on right; move

bracket to the right if bobbin winds high

on left. When bracket is properly

centred, thread will wind evenly across

bobbin.

Bobbins can be wound while machine is

sewing. Follow instructions on page 13

omitting item 4.

14

Page 17

TO REPLACE BOBBIN

Hold the bob

bin between

the thumb and

forefinger of

the left band,

Fig, 13, Adjustment of Bobbin Windet,

Fig, 14, Replacing the Bobbin,

the

drawing from

right to left, as

shown in Fig.

14.

Place the bob

bin into the

bobbin case

and draw the

thread into the

slot 1, Fig. 15

in the bobbin

case, as shown.

Draw the

threadback-

thread

15

ward between

Fig, 15. Threading the

Bobbin Case.

Page 18

the bobbin case and the tension spring

until it reaches the notch 2, Fig, 16, then

pull the thread toward the right, as shown

in Fig. 16. Close the slide, as shown in

Fig. 17.

Fig. 16, Bobbin Case Threaded^

Fig, 17m Under Threading Completed,

16

Page 19

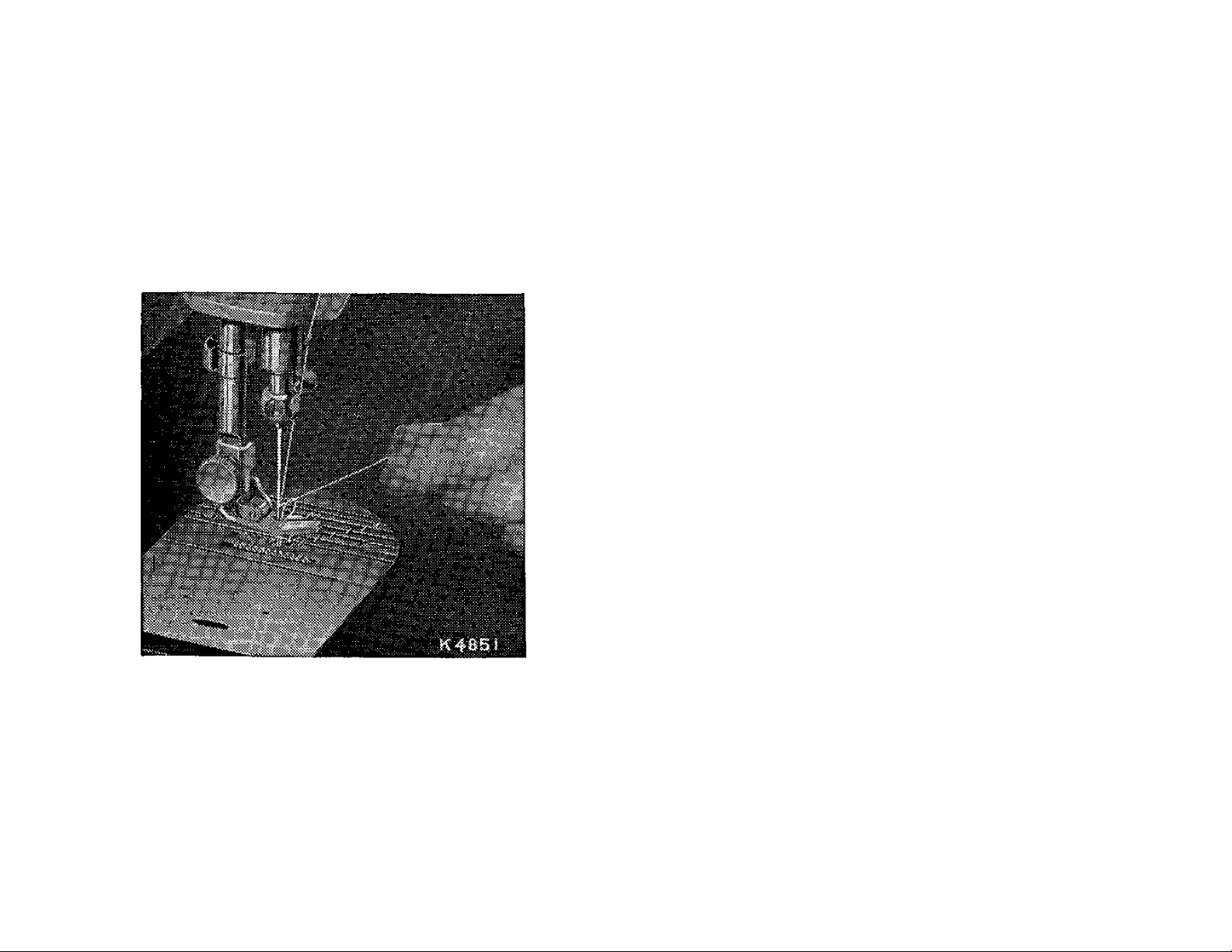

TO PREPARE FOR SEWING

Have the thread take-up lever at its

highest position, then, with the left

hand, hold the end of the needle thread,

leaving it slack from the hand to the

needle. Turn the hand wheel over

toward you until the needle moves down

and up again to its highest position, thus

catching the bobbin thread. Draw up

the needle thread and the bobbin thread

will come up with it through the hole in

the throat plate as shown in Fig. 18.

Lay both threads back under the presser

foot diagonally across the feed, to the

right or left, depending upon which side

of the needle the material is to be located

so that when the presser foot is lowered,

the threads will be firmly held between

Fig. 18. Drawing Up the Under Thread.

the feed and the presser foot, *

17

Page 20

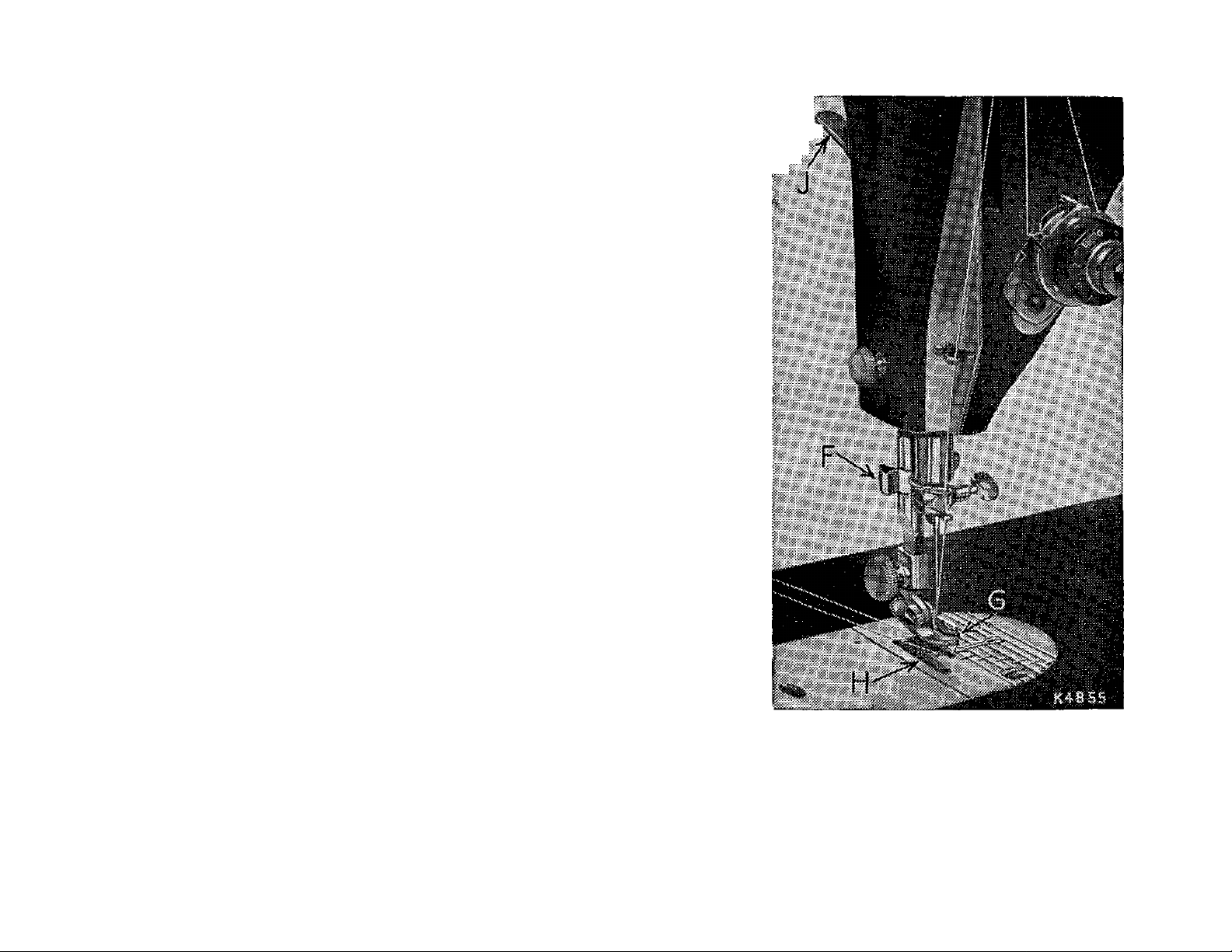

TO START SEWING

See Fig. 19.

Be sure to have thread take-up lever 5, Fig. 10 in

its highest position.

The throat plate has guide lines for seam width gauged

from centre of needle hole, and cross lines for gauging

square corners.

Pla ce material beneath the presser foot G, turn the

hand wheel to bring the point of the needle into the

material, then lower the presser foot by means of

presser bar lifter J, and start to sew.

Some materials, such as soft finished sheers, nylons,

jerseys, tricots and other elastic and spongy textiles,

require a slight amount of assistance in feeding during

sewing operations.

I*'"'

1^: "

However, too much pull will stretch the seam, create

irregular stitching and bend the needle. Most

materials require only guiding for best sewing results,

«

Fig. 19. To Start Sewing.

18

Page 21

TO TURN A CORNER

TO SEW BIAS SEAMS

Stop the machine when the needle eye,

making its upward stroke, is still in the

fabric. Raise the presser foot and turn

the work as desired, using the needle as

a pivot, then lower the presser foot.

BASTING

The longest stitch, No. 6 on the stitch

indicator, is satisfactory for basting and

is easily removed by clipping every sixth

stitch and withdrawing the long continuous

thread.

Use a short stitch and as light a tension

as possible on the needle thread so that

the thread is loose enough in the seam

to allow the goods, to stretch if necessary.

Machine basting is firmer ^ and more

even than that done by hand in addition

to being much quicker.

Fig. 20. To Regulate Stitch Length.

19

Page 22

TO REMOVE THE WORK

TO REGULATE LENGTH OF

STITCH AND DIRECTION OF

Stop the machine with the thread takeup lever 5, Fig, 10 at its highest point.

Raise the presser foot by means of presser

bar lifter J, Fig. 19, draw the fabric back

and to the left and sever the threads on

thread cutter F, Fig, 19. Place ends of

threads under presser foot.

CAUTION :

FEED. See Fig. 20.

The machine can be adjusted to make

from 6 to 30 stitches to the inch, as

indicated by the numerals on the stitch

indicator plate.

Loosen screw A and lower it to the

bottom of the slot, then move lever B

until its top edge is level with the figure

denoting the number of stitches desired

per inch. Raise screw A as far as possible,

and tighten it. Thus set, the machine

will make the indicated number of

stitches in a forward direction. If it is

desired to reverse the direction of the

When the machine is not in use, raise

the presser foot by means of presser bar

lifter J to prevent injury to the presser

foot G and the feed H, Fig. 19,

stitching, raise lever B as far as possible,

and the machine will make the same

number of stitches in a backward

direction.

20

Page 23

TO REGULATE PRESSURE ON

MATERIAL

For ordinary sewing, the pressure of

the presser foot on the material seldom

requires changing. Heavy materials re

quire more pressure than light weight

materials. The pressure should be only

heavy enough to prevent the material

from rising with the needle and to enable

the feed to move the work along evenly^

To increase the pressure, turn the thumb

screw W, Fig. 21 clockwise or downward.

To lighten the pressure, turn the thumb

screw upward.

THREAD TENSIONS

For perfect stitching, the tension on

the needle and bobbin threads must

be heavy enough to pull the threads

to the centre of the thickness of the

material and make a firm stitch, as

shown in Fig, 22.

Fig, Thumb Screw for Regulating

Pressure on Presser Foot,

E754

Fig. 22. Perfect Stitching.

If the needle thread lies straight along

the top side of the material, the tension

21

Page 24

Y?

---

{?-

Fig. 23. Imperfect Stitching.

TO REGULATE NEEDLE

THREAD TENSION

E U3fa

See Fig. 25.

on the needle thread is too heavy or the

tension on the bobbin thread is too light,

as shown in Fig. 23.

If the bobbin thread lies straight along

the underside of the material, the tension

on the needle thread is too light or the

tension on the bobbin thread is too

heavy, as shown in Fig. 24.

V

VP77PPPP/

____

^

Fig. 24, Imperfect Stitching,

£1/319

The tension on the needle thread can

be tested only when the presser foot is

down.

The numerals “0” to on dial B,

indicate the different degrees of tension

that can be obtained.

When the tension has been correctly

set note the number at the indicator

line C, so that this setting may be regained

should the tension be altered for special

work.

To increase tension, turn the thumb nut

A gradually to the right (clockwise)

until the required tension is obtained.

Each higher number denotes increased

tension.

22

Page 25

decrease tension, turn the thumb

xxiit A gradually to the left (counter

clockwise) until the required tension

TO REGULATE BOBBIN

THREAD TENSION

is obtained. Each lower number denotes

less tension.

The tension indicator C is marked with

the signs + and —which indicate the

direction in which to turn the thumb nut

A for more or less tension.

The tension on the bobbin thread is

regulated by screw F, Fig. 32, which is

nearest the centre of the tension spring

on the outside of the bobbin case. To

increase the tension, turn screw F over

to the right. To decrease the tension,

turn this screw to the left.

When the tension on the bobbin thread

has been once properly adjusted, it is

seldom necessary to change it, as a

correct stitch can usually be obtained by

varying the tension on the needle thread.

Fig, 25. To Regulate Needle

Thread Tension.

23

Page 26

DARNING (See Fig. 26).

Raise needle to its highest point, turn machine

back on its hinges, unscrew knurled screw A,

as far as it will go, and move crank B down so

that the screw A will enter the upper hole C.

The screw should then be securely tightened. The

feed is now inactive and wOl not impede free

movement of the work. Restore machine to its

working position and raise the presser bar. Remove

the presser foot and fit Spring Darning Foot No.

121094, but do not tighten the thumb screw.

Stretch tightly the article to be repaired in an

embroidery hoop and place below the needle by

tilting the edge of the hoop. Then lower the presser

bar by means of its lifter, and adjust the height of

the darning foot to allow just sufficient space for the

free movement of the work in hand. After ad

justment, tighten the thumb screw securely. Now

move the hoop backward and forward by the hands

until the hole or damaged part is completely

covered with stitching in one direction. Then

turn the work and stitch across to complete the

darn. After darning, reinsert and firmly tighten

the screw A in the lower hole, and replace the

presser foot for ordinary sewing.

Fig. 26.

EMBROIDERY

For surface embroidery, remove the

presser foot to give a clear view of the

stitching. For lace embroidery, i.e.

open work, remove the ordinary

presser foot and fit Spring Foot No,

121094. For embroidery the feed

should be lowered and the work

handled as advised in the preceding

paragraph.

24

Page 27

SEWING SUGGESTIONS

Breaking of needles might be caused by

1. Improper size of needle for thread

and material—See page 11*

2. Bent needle.

3. Pulling ©f material when stitching.

4. Needle striking improperly fastened

presser foot or attachment.

5. Crossing thick seams with too small a

needle.

Breaking of needle thread might be caused

by ;

1. A knot in thread.

2. Improper threading—See page 12.

7. Roughened hole in throat plate,

8. Improper arrangement of threads to

start sewing—See page 18,

Breaking of bobbin thread might be

caused by :

1. Improper threading of bobbin case—

See page 15.

2. Bobbin thread tension too tight—See

page 23.

3. Bobbin wound unevenly.

Skipping of stitches might be caused by :

3. Upper tension too tight—See pages 22

and 23.

4. Needle set incorrectly—See page 10.

5. Needle blunt or bent,

6. Thread too coarse for needle—^See

page 11,

1, Improper setting of needle—See page

10.

2, Needle blunt or bent.

3. Needle too small for thread—See

page 11.

4. Needle rubbing presser foot.

25

Page 28

PROTECTION AGAINST RUST DAMAGE

Lint and fluff, if not removed prior to storage will, during humid periods, absorb and

hold moisture, and thus accelerate rust damage to highly polished thread handling and

other exposed parts. The extent of rust damage would depend upon the length of time

the machine remained in idle storage where there is no ventilation. Sudden drops in

temperature will cause moisture to form on parts which, if not protected by a film of oil,

would rust and damage while in storage.

Proper storage care suggests thorough brush-cleaning to remove all traces of lint and

fluff, followed by swabbing of all the exposed parts in Figs. 28 and 29 with a lint-free

brush saturated with SINGER Oil.

SINGER Lint Brush may he purchased at

your local SINGER SEWING CENTRE,

26

Page 29

TO OIL MACHINE and STAND

The Arm Spool Pin C is screwed for

insertion in the left plugged hole and it

is also provided with a screw driver slot.

If the machine is used continuously, it

should be oiled daily. If moderately

used, an occasional oiling is sufficient.

Apply one drop of oil to each of the

places indicated in Figs. 27, 28, 29, 30 and

31 and carefully clean the machin e to

insure smooth and satisfactory perform

ance. Oil holes are provided in the

machine for bearings which cannot be

Fig, 27, Front View, Showing

Oiling Points,

K4S3d

27

directly reached.

Remove face plate A, Fig. 27, by taking

out screw B and slipping plate over screw

D, Fig. 28. After oiling replace face plate.

Draw to the left the slide in the bed of the

machine, as shown in Fig. 27, while the

Page 30

thread take-up lever (5, Fig, 10) is at its

highest position, and, after removing the

lint and dust which may have accumu

lated (see instructions on page 26), apply

one drop of oil to the sewing hook race

in the bobbin case, as indicated by arrow

in Fig, 29, and a few drops to the

oil hole in Fig. 29, Then close the

slide.

Fi^. 28. Face Plate Removed,

Showing Oiling Points.

B A

Fig. 29. Oiling the Sewing Hook,

28

Page 31

Fig* 30* Oiling Points in Bed of Machine.

Fig. 31.

To oil the parts underneath the bed of the machine, turn the machine back on its hinges and

apply oil to the oil holes and bearings indicated in Fig* 30* The gears concealed by the gear

cover (E2, Fig. 30) are oiled through the oil hole (E, Fig. 27), The gears concealed by gear cover

(D, Fig* 30) are oiled through the space just above this cover, as indicated hy arrow (D2, Fig. 31).

After oiling at D2, rotate the hand wheel toward you to distribute the oil on these gears. To

oil the stand, apply a drop of oil to the centres upon which the treadle works, and to the lower

end of the pitman rod. Run the machine rapidly for a few minutes so that the oU may reach

the bearings. Neglect to oil the machine will shorten its life and cause you trouble and annoyance.

Always use SINGER* oil. Inferior oil clogs the bearings, prevents efficient working, and causes

rapid wear of the mechanism.

29

Page 32

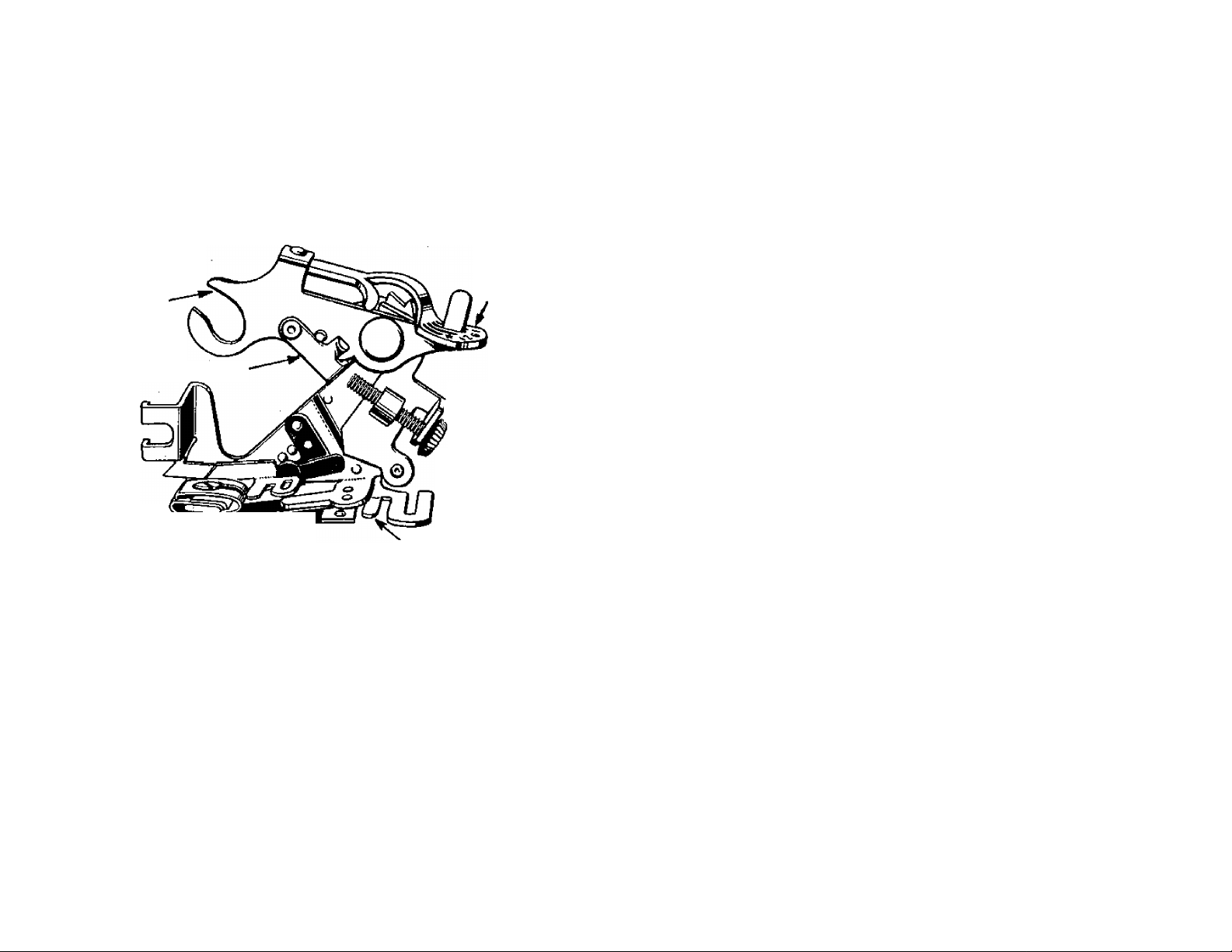

TO CLEAN STITCH

FORMING MECHANISM

After considerable use, the stitch forming

mechanism may become clogged with

lint and this may interfere with the perfect

operation of the machine.

Occasionally remove the bobbin case

according to the following instructions,

and remove any lint, etc., which has

accumulated.

TO REMOVE BOBBIN CASE

See Fig» 32.

The bobbin case may be easily removed

without taking off the throat plate,

Fig. 32. Bobbin Case in Position.

{Throat Plate broken away to show correct

location of Finger A).

although for the purpose of illustration

the throat plate and feed dog are shown

broken away.

Remove bobbin from the bobbin case.

Turn hand wheel over toward you until

the end of hook ring E is toward the

front of machine, as shown. Insert the

blade of the small screw driver into slot

C between the ring and the edge of spring,

as shown. With a downward pressure.

30

Page 33

dve the screwdriver one half turn to the

right so that it will drop into the slot and

unlock the spring.

TO REPLACE BOBBIN CASE

See Fig, 32.

With the right hand hold the hand

wheel to prevent its turning and» with

the left, place the screwdriver against

the edge of the slot in the ring and push

it around in the direction opposite to the

hook rotation until the circular cut-out

B is opposite the spring D. The ring and

bobbin case may then be lifted out.

Free instruction for using the machine is gladly given at any

When replacing the parts, first place

the bobbin case into position with

the finger A in the opening in the plate

under the feed dog, as shown. Turn the

bobbin case back and forth slightly to

make sure that it is properly seated, then

place the hook ring E in position with the

cut-out B opposite the spring D. Press

the ring into place and turn it in the

direction of hook rotation until the

spring locks it in position. Then replace

the bobbin.

SINGER SEWING CENTRE

31

Page 34

Page 35

33

Page 36

THE FOOT HEMMER

• Place the creased hem edge under the

foot and take several stitches through

The foot hemmer

forms and stitches a

perfectly turned hem

without basting or

pressing. It is at

tached to the ma

chine in place of the

presser foot.

Applications

Fine hems Hemming with lace

Edging ruffles Lace insertion

Sheer seams Lingerie finishes

Hemming

the fold.

• Grasp the thread ends and the single

fold in front of the hemmer and lift

the single fold into the hemmer

scroll.

Soft fabrics will enter the scroll best

with the foot down, firm crisp fabrics

with the foot raised.

• Form a double Yq" fold at the very edge

of the fabric.

• Crease this fold for about

0 Draw the needle and bobbin threads

under the hemmer.

34

Page 37

# Stitch slowly for several inches until

hem is well started. Hold thread

Hemmed Seams

Hemmed seams are often substituted

ends in back of foot with the left hand

and guide the raw fabric edge into

the mouth of the scroll with the right

hand.

Even feeding is essential to good

hemming. The same width of fabric

must be kept in the scroll of the hemmer

at all times.

for French seams where a fine narrow

seam is appropriate.

• Allow a scant seam allowance.

• With right sides of the fabric together,

place the upper layer a scant

the left of the lower layer.

• Insert the two fabric edges into the

hemmer and proceed as for a plain

hem.

Page 38

Hemming With Lace

Most of the popular kinds of lace edging

and insertion can be applied with the foot

hemmer. It is an excellent way to trim

children’s clothes and to finish lingerie

hems.

Lace Applied Over Hem

• Fold and start hem in usual way.

• Starting about 1 inch down from end of

lace, place selvage under the needle,

then lower the needle to hold lace

firmly,

• Raise hemmer foot slightly and slip lace

under back part of foot.

• Stitch slowly, guiding fabric with right

hand and lace with left hand. Take

care not to stretch the lace.

Lace Applied Under Hem

When using lace underneath the fold

of a hem, the procedure is the same as

when making a hemmed seam (page 39).

Slip the lace in from the left as you would

the second piece of fabric.

This method is used where a neat finish

is desired on both sides of the material.

36

Page 39

THE BINDER

Inserting the Binding

Pre-folded commercial bias binding is

inserted from the right into the outside

slot of the binder scroll,

• Cut the binding diagonally to

ADIUSTING

SCREW

BINDER

SCROLL

OUTSIDE

SLOT OF

SCROLL

CENTRE

SLOT

The binder is used to apply commercial

binding as well as self-fabric bias to an

unfinished edge.

form a long point.

• Insert the pointed

end into the slot

and pull through

the scroll until

the evenly fold

ed edges are

under the needle.

Self-fabric bias binding should be cut

wide on the true bias.

• Insert the unfolded

binding directly

into the two

folds at the end

of the scroll and

draw it back

This colourful trim is attractive when

applied to children’s wear, aprons and

fabric furnishings. It is a practical finish

for seam edges that ravel and for making

bound seams.

37

under the needle.

As the binding

passes through the

scroll the raw edges

are turned in.

Page 40

Adjustment and Operation of the Binder

The edge to be bound is guided into the

centre of the scroll. Stitching is positioned

close to the edge of the binding by adjust

ing the scroll portion of the attachment,

• Loosen the adjusting screw and move

the scroll to the right to bring the

stitching closer to the binding edge.

For a wider adjustment, move the

scroll to the left.

Be sure that the screw is well tightened

after making an adjustment.

Never pull the binding as it feeds

through the scroll. Allow the attachment

to do the work. Merely guide thé edge to

be bound well into the centre of the scroll

as you stitch.

38

Page 41

Binding Curved Edges

Curved edges can be bound as easily as

straight edges, but require slightly differ

ent fabric handling.

Outside Curves^

Outside curves tend to lead away from

the centre slot of the scroll and should be

guided so that a full seam width is taken

Inside Curves

Inside curves are straightened as they

are fed into the binder. If the fabric is

soft and has a tendency to stretch rein

force the edge with a single row of

stitching before binding.

at the needle point. Do not attempt to

pull or straighten the fabric into the full

length of the scroll.

Page 42

THE GATHERING FOOT

rows of shirring can

be quickly and ex

pertly placed with

the gathering foot.

Evenly spaced shirr

ing is insured as this

foot is designed to

Single or multiple

lock fullness into

every stitch.

Applications

Plain shirring Waffle shirring

Elastic shirring Machine smocking

Slurring

Shirring is usually done on the crosswise

grain of the fabric. Soft fabrics lend them

selves to shirring better than firm fabrics.

The amount of fullness is very simply

controlled by stitch length and degree of

tension.

A long stitch produces more fullness

than a short stitch. Balanced tensions are

always required, but heavy tensions, hoth

upper and lower, produce more fullness

Many lovely effects are accomplished

with simple rows of evenly spaced shirr

ing. A yoke section, insert or trimming

band of self-fabric affords an interesting

contrast of texture when stitched with

the gathering foot in rows apart.

than light tensions.

40

Page 43

THE RÜFFLER

Adjusting Points

Occasionally apply a drop of oil to parts

in movable contact.

DRIVING

LEVER

ADJUSTING FINGER

SEPARATOR RUFFLING

BLADE BLADE

SEPARATOR

GUIDE

ADJUSTING

LEVER

ADJUSTING

SCREW

This attachment offers a simple and

effective way to make gathered and

pleated ruffles.

Ruffles may be made separately or

made and applied at the same time.

The ruffler is attached to the machine

in place of the presser foot.

1. The adjusting lever sets the ruffler for

gathers or pleats. The number 1 space

setting is for gathers, and places fullness

at every stitch. Numbers 6 and 12 are

space settings for pleats, spacing them

either 6 or 12 stitches apart. The star is

for plain stitching, and is used when

grouping gathers or pleats.

2. The adjusting finger is used only for

pleating and affects the width of the pleat.

It is thrown out of action by bringing it

out of contact with the adjusting screw

located at the right of the ruffler,

3. The adjusting screw regulates the

fullness of gathers or pleats. When turned

in (clockwise) to its limit with jhe adjust

ing finger in place, the attachment is set

for its deepest pleat. When turned out

(anti-clockwise) to its limit and the

adjusting finger out of action, the ruffler

gives only a hint of fullness.

Activating Parts

The ruffling blade and the separator

blade are of blue steel and hold the

material to be gathered between them.

41

Page 44

The ruffling blade forms the gathers or

pleats by carrying the fabric to the needle

according to the spacing and fullness to

which the ruffler is adjusted. The separa

tor guide is slotted to guide seam edges

evenly and to separate the ruffle strip

from the material to which the ruffle is

attached.

0

Set stitch length to space the fullness.

A short stitch gives more fullness than

a long stitch.

MATeRtAL

Preparation

Raise the needle to its highest point.

Locate the attachment on the machine

in place of the regular presser foot, and at

the same time fit the fork of the driving

lever over the needle clamp screw. Make

sure both the presser bar screw and the

needle clamp screw are tightened securely.

Gathering

0 Set adjusting lever on No. 1 setting,

• Throw adjusting finger out of action.

0 Turn adjusting screw for amount of

fullness desired.

The attachment is set for maximum

fullness by turning adjusting screw in

(clockwise) as far as possible ; for less

fullness, turn adjusting screw out (anti

clockwise).

Insert material to be gathered between

the blue blades and through the first

separator guide.

Lower presser bar and stitch. Always

test the stitch length and ruffler

setting on a scrap of self fabric before

proceeding with the actual work.

42

Page 45

Forming and Attaching a Ruffle in one

operation—

• Place ruffle strip between the two blue

blades and through the first separator

guide.

• Place fabric to which ruffle is to be

attached between the separator blade

and the feed of the machine.

Right sides of the fabric are placed

together when the seam is to fall to the

inside.

• Proceed as for plain gathering.

Pleating

• Move adjusting lever to space setting

desired for pleats of either 6 or 12

stitches apart.

• Activate adjusting finger.

• For deepest pleat, turn adjusting screw

in (clockwise) to its maximum. For

shallower pleats, turn adjusting

screw out (anti-clockwise).

• Set stitch length. A short stitch places

pleats close together, A longer stitch

separates the pleats for a greater

distance.

43

• Insert fabric to be pleated between the

blue blades and through the separa

tor guide.

# Lower presser bar and stitch.

Group Pleating

By using the star setting (plain stitch

ing) alternately with the 6 or 12 setting,

pleats are formed in groups. Even spacing

between groups is easily accomplished by

counting the number of stitches^

Page 46

THE SEAM GUIDE

For pinned seams, place the pins with

the points toward the seam edge so

The seam guide is

adjustable for spacing

stitching at any dis

tance between and

lYs" from a fabric

edge. It is used in

connection with the

presser foot.

Applications

Seams Stay stitching

Top stitching—single and multiple rows

• Attach the guide to the machine with

the thumb screw in either of the

threaded holes at the right of the

needle.

• Adjust for width desired.

that they nip into the fabric at the

stitching line. The hinged foot will

then ride freely over the points.

• For straight edges, align guide with the

presser foot.

• For curved edges, set the guide at an

angle so that the end closest to the

needle acts as a guide.

44

Page 47

HE ZIPPER FOOT

The zipper foot is designed for accurate placement of

stitches close to a raised edge. The hinged feature of this

foot insures even feeding over pins, heavy layers of fabric

or cross seams. It is attached to the machine in place of

the presser foot, and may be adjusted to either side of the

needle.

Applications

Zipper insertions

Corded seams

Preparation

• Attach zipper foot to machine in place

of presser foot.

0 Loosen zipper foot thumb screw and

adjust foot to right or left of needle,

as desired.

Tubular cording

Slip cover welting

Align the notch in the toe with the

needle hole in the throat plate.

Check adjustment by lowering needle

into side notch, making sure it clears

the foot.

Lock foot in position by tightening

thumb screw.

45

Page 48

Skirt Zipper

Machine baste placket

opening of skirt and press

this seam open-

Attach zipper foot to ma

chine in place of presser

foot.

Position zipper foot to

right of needle.

Open zipper.

Place zipper face down on

seam allowance with edge

of teeth at seam line.

Turn the back seam allow

ance away from body of

skirt.

Stitch zipper tape to the

seam allowance.

46

Page 49

Move foot to the left of needle.

Turn skirt to right side.

Close zipper and turn it face up.

Smooth back the seam allowance at the

edge of the zipper.

Top stitch the seam allowance to the

tape close to the folded edge.

Fold zipper to front of skirt.

Pin in place from right side.

Baste.

Move foot to right of needle.

Stitch across lower end of zipper and up

to waistline.

Remove basting.

47

Page 50

Corded Welting

Cable cord comes in a variety of sizes and wben covered with a firmly woven fabric

makes a corded welting that is an excellent seam finish.

This welting is prepared in advance and then stitched into the seam. Cut a true bias

strip 154 inches wide, plus three times the width of the cord of either self or contrasting

fabric. Sew strips together on the lengthwise grain to obtain desired length.

^-Adjust zipper foot to left side of needle. .

Encase cord in bias strip,

raw edges

even.

Lower presser bar.

Stitch close to cord, using a stitch

length slightly longer than for plain

seaming of same fabric.

Do not crowd stitching against cord.

48

Page 51

Corded Seams

• Place attached corded welting over

The corded seam is a typical treatment

for slip covers, children’s clothes, blouses

and lingerie.

When cording a seam the zipper foot is

usually adjusted to the right of the needle

so that the bulk of the work will fall to the

left.

• Attach corded welting to right side of a

single seam edge, using same length

stitch as used for welting (page 40).

Guide edge of foot next to cord, but

do not crowd.

second seam edge, and pin or baste

together,

0 Keep the first stitching uppermost as a

guide and position the seam under

the needle.

• Stitch, this time crowding the foot

against the cord.

This method produces evenly joined

seam edges and tightly set welting.

Curved seams are corded as easily as

straight seams, except that a shorter

stitch is used. Since the seam allowance

of the welting is bias, it is easy to shape

it to the seam.

49

Page 52

available for separate purchase at your local SINGER SEWING CENTRE.

THE BUTTONHOLER

FASHION AIDS

This attachment produces neat

and durable buttonholes in a great

variety of fabrics without any

special skill on the part of the oper

ator. The buttonholes are produced

in a fraction of the time required for

hand work and they are firmer and

more even than those made by hand.

50

Page 53

THE BLIND STITCHER

This useful SINGER attach

ment produces invisible hemming

with perfect blind stitches on an

almost unlimited variety of work

such as skirts, dresses, lingerie,

children’s clothes, towels, curtains,

sheets, table cloths and many other

articles.

It is quickly attached to your

sewing machine in place of the

presser foot. It is easy to use and

K 4430

will enable you to accomplish

superior invisible hemming much

faster and with less effort than is

possible by hand.

51

Page 54

THE ZIGZAGGER

^/VV^/S^V'^X\|'VSíy«V*V''v^VV\í

Some of the designs made by SINGER Zigzagger

This wonderful SINGER fashion aid will enable you to produce an infinite variety of

attractive ornamental designs merely through the interchange of the different Stitch

Patterns and the adjustment of the bight and stitch length. Such decorative effects as

applique, scalloped edges, border designs, as well as blind stitched hems and simple

mending can be produced with this attachment on women’s and children’s clothing,

lingerie, linens, draperies and an unlimited array of other garments and household items.

With the flick of a lever, plain sewing may be done without removing the zigzagger

from the sewing machine.

52

Page 55

THE BIAS GAUGE

The Bias Gauge is very useful (especial

ly in the case of soft materials) when

THE EDGE-STITCHER

The edge stitcher pro

cutting bias strips from inch to 1%

inches in width. This is done by placing

the bias gauge upon the point of the

scissors and setting the blued indicator

to the width desired. The line F is the

point at which to set the blued indicator

for facings, the line B for binding, and the

line C for cording or piping.

vides a series of slotted

guides which regulate

the placement of stitches

in relation to a fabric

edge.

It is attached to the machine in place

of the presser foot.

Applications

Joining lace and insertion, French seams.

Tucking with lace. Straight and pin tucks.

Facing and seam finishes. Seam piping.

Joining Lace and Insertion

Lovely lingerie detail is simple to

accomplish with the edge stitcher by

Insert the material in the gauge with

the edge against the blued indicator, and

hold as shown above.

Bias binding should be cut -Jl inch wide,

and to do this the indicator should be set

midway between the lines F and B.

joining lace insertion or alternate bands

of fabric and lace. Slots 1 and 4 are used

for this work. Since slot 1 overlaps

slot 4, the edge inserted into slot 1 will be

the top stitched edge,

• Place the first band (the fabric band

53

where used) into slot 1.

Page 56

Adjust lug A to position tlie stitcMng

French Seams

close to the edge of this baud.

Place the second band (lace) into slot 4.

Adjust pressure to correct degree of

lightness for even feeding.

Use a short stitch length and balanced

tensions.

Hold both band edges against the ends

of the slots while stitching.

The edge stitcher makes very fine

French seams, so well adapted to sheer

fabrics where raw seam edges must be

concealed.

• Trim away seam allowances to

• Lay seam edges together, right sides of

fabric outward, and insert into slot 1.

0 Move lug A to the left to position stitch

ing Yq" from the edge.

0 Stitch and press,

0 Fold with right sides of fabric together

and insert into slot 1,

• Move lug A to extreme left, allowing

just enough margin to conceal raw

edges.

• Stitch,

Tucking

Dainty tucks from “pin” width to Y^"

may be produced with the edge stitcher.

Tucks are usually made on the lengthwise

grain of the fabric.

O Draw a single thread from the fabric,

or measure from the selvage to locate

the first tuck on the straight grain of

54

the fabric.

Page 57

# For succeeding tucks, crease fabric or

THE QUIETER

draw a thread at distance desired

from previous tuck.

• Press tuck folds before stitching,

# To make “pin” tucks, insert the tuck

fold in slot 1 and adjust lug A to

locate stitching a pin width from the

fold.

• To make tucks, insert the tuck fold

into slot 5, and move lug A to its

extreme left position.

Use a short stitch length and perfectly

balanced tensions.

The Quilter, designed with a short, open

foot and an adjustable and removable

space guide, is especially well adapted to

stitching lightly padded materials. The

light padding is basted to the underside

of the fabric and may be of outing flannel,

canton flannel, sheet wadding or light

wool interlining.

Replace the presser foot with the

Quilter, Adjust the space guide for the

width between stitching lines. The space

guide may be used to the right or left of

55

the needle.

Page 58

THE ADJUSTABLE HEMMER

To Make Hems

from 3/16 to 15/16 Inch Wide

1. Attach adjustable hemmer to presser

bar in place of presser foot,

2. Pull up bobbin thread as instructed

on page 19.

3. Loosen thumb screw on hemmer and

move scale until pointer registers

with number of desired width of hem.

(No. 1 indicates the narrowest hem

and No. 8, the widest.) Then tighten

thumb screw.

4. Place cloth in hemmer and draw it

back and forth until hem is formed

as shown.

5. Draw end of hem back under needle,

lower presser bar and start to sew.

6. Guide sufficient cloth into hemmer ta>

turn hem properly.

56

Page 59

THE ADJUSTABLE HEMMER

WIDE HEMMING

To make a hem more than ^ inch wide,

loo&en thumb screw in hemmer and move

scale to right as far as it will go, then

swing it toward you as shown and tighten

thumb screw. Fold and crease down a

hem of the desired width, pass fold under

extension at right of hemmer, and the

edge into folder as shown and proceed to

atitch the hem.

57

Page 60

THE TUCKER

The Tucker is a time-saver for

making tucks up to one inch in

width. Two adjustable scales are

provided, the smaller near the

needle is numbered from 1 to 8, ex

pressing in eighths of an inch the

width of the tuck. The larger scale

expresses in quarter inches the

spacing between tucks.

Set the tuck scale first for the

width of tuck. The space scale is

then adjusted using the needle as an

indicator for the spacing between

tucks. When both scales are set at the same number, blind tucks result. That is, the

fold of one tuck just touches the stitching line of the next. When additional space

between tucks is desired, adjust the space scale to a point beyond the tuck scale reading

equal to the spacing desired, expressed in quarters of an inch. Thus half-inch tucks spaced

a half inch apart require a tuck scale setting of 4, and a space scale setting of 6,

58

Page 61

IND

EX

Page

Attachments

Binder..................................................37

Foot Hemmer......................................34

Gathering Foot ...................................40

Ruffler

Seam Guide

Zipper Foot

Belt Shifter ............................................ 9

Bobbin

Removing ...........................................13

Replacing

Winding

Bobbin Case

Removing

...........................................

............................................—41

........................................

........................................

...........................................

..........................................

...........................................

33

44

45

15

13

30

Page

Fashion Aids ...........................................50

Bias Gauge

Blind Stitcher......................................51

Buttonholer

Edge Stitcher ......................................53

Hemmer, Adjustable ..........................56

Quilter ................................................55

Tucker

Zigzagger, Automatic

Hand Attachment ................................... 8

Light ....................................................... 5

Lubrication

To Oil the Machine and Stand

To Oil the Sewing Hook

...........................................

........................................

................................................

........................

..........

....................

53

50

58

52

27

28

Replacing

Threading ...........................................15

Bobbin Winder

Darning and Embroidery

Electrical Information

...........................................

......................................

......................

............................

31

13

24

4

59

Needles and Thread

Needle Setting

Presser Foot, to Regulate Pressure

Rust damage, prevention of.................26

Service, SINGER ...................................... 3

........................................

...............................

.........

11

10

21

Page 62

INDEX— continued.

Sewing

To Operate Electric Machine

To Operate Hand Machine

To Operate Treadle Machine

To Prepare for Sewing

To Start Sewing

To Turn a Corner

..................................

...............................

.......................

.............

...............

.............

Basting ................................................19

To Sew Bias Seams

To Remove the Work

.............................

........................

To Regulate Length of Stitch and

Direction of Feed

............................

Sewing Suggestions.............................25

Page

7

8

9

17

18

19

19

20

20

Stitch Forming Mechanism

Cleaning

..........................

Stop Motion

Threading

Upper Threading

...........

Bobbin Case Threading

Thread Tensions

..................

Bobbin Thread Tension,

to Regulate ...................

Needle Thread Tension,

to Regulate ...................

Page

....30

.... 9

12

15

21

23

22

60

Page 63

Page 64

For your protection

SINGER Sewing Machines are sold and serviced wherever you

see the famous SINGER and Red “S” Trademarks. When your

machine needs servicing call your SINGER SEWING CENTRE to be

sure of warranted SINGER parts and service. See address in the

classified telephone directory.

SINGE

SEWING

MACHINE

COMPANY

Loading...

Loading...