Page 1

Instructions for nsing-

SINCER

Page 2

Instructions for using

SINCER20I

ELECTRIC SEWING MACHINE

Page 3

AS THE OWNER OF THIS SINGER 201

You own a machine with a tradition of superior crafts

manship—a tradition you will recognize in the

smooth, efficient operation of this motor-driven elec

tric sewing machine. Operating either forward or

backward, it forms a lock stitch.

The machine and the foot- or knee - operated

speed control are stored in any one of a variety of

versatile and attractive sewing machine cabinets with

extra room for sewing accessories.

Copyright © 1957 by The Singer Company

2

Page 4

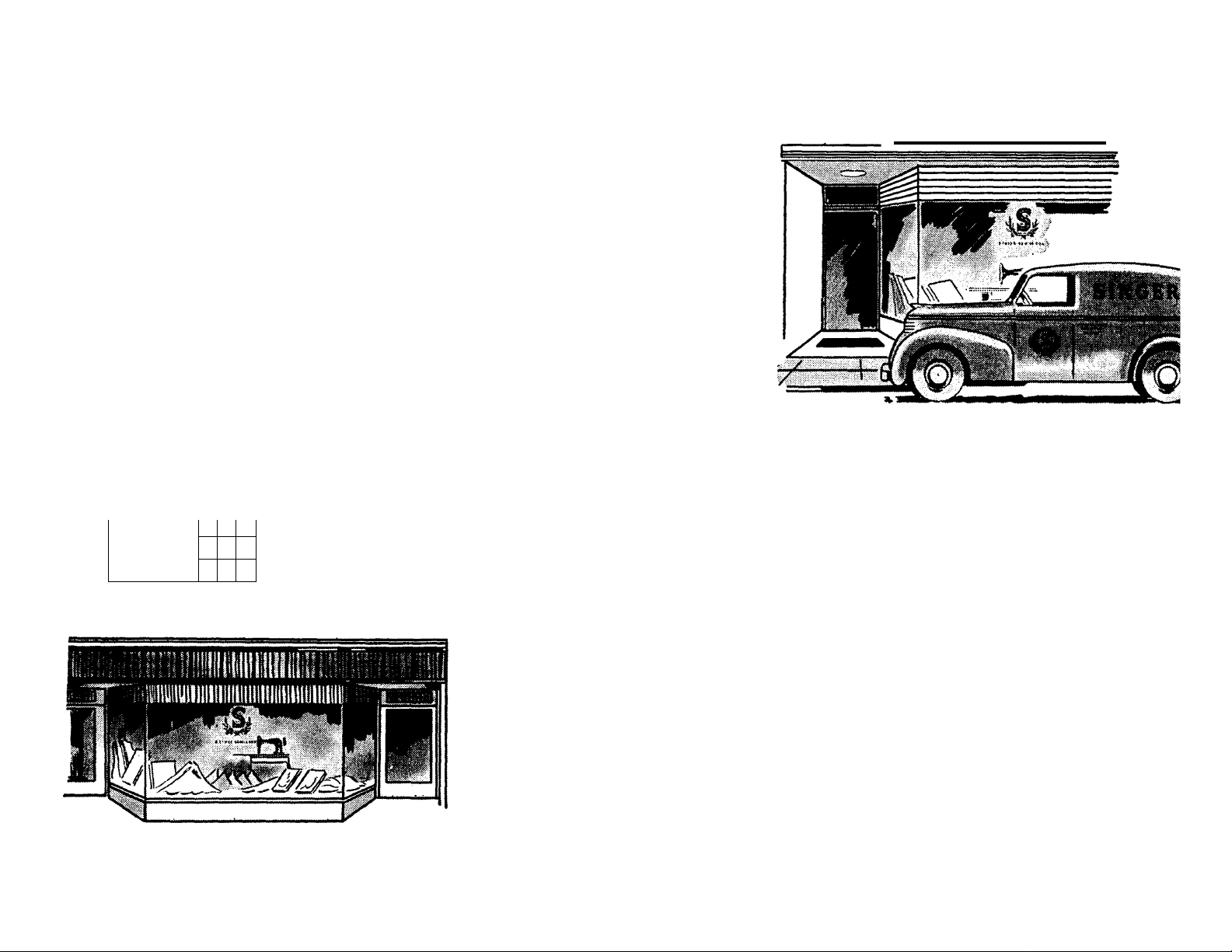

SINGER SERVICE

Wherever you go you will find expert, depend

able SINGER Service nearby. SINGER is inter

ested in helping you keep your SINGER

Sewing Machine in top condition. That’s why

it makes sense to call your SINGER Represen

tative if your machine ever requires attention.

He will submit a written estimate for your

approval. Look for the familiar red “S" on

your SINGER SEWING CENTER and the

handy SINGER Service Car.

EVERYTHING FOR THE WOMAN WHO SEWS

SINGER

' ^

SINGER

The answer to your sewing needs is at your SINGER

SEWING CENTER. There you will find a wide

choice of patterns, buttons and thread, as well as

Finishing Services such as covering buttons, hem

stitching, making belts and buckles, to mention a

few. Look in your telephone directory under

The Singer Company for the SINGER SEWING

CENTER nearest you.

3

Page 5

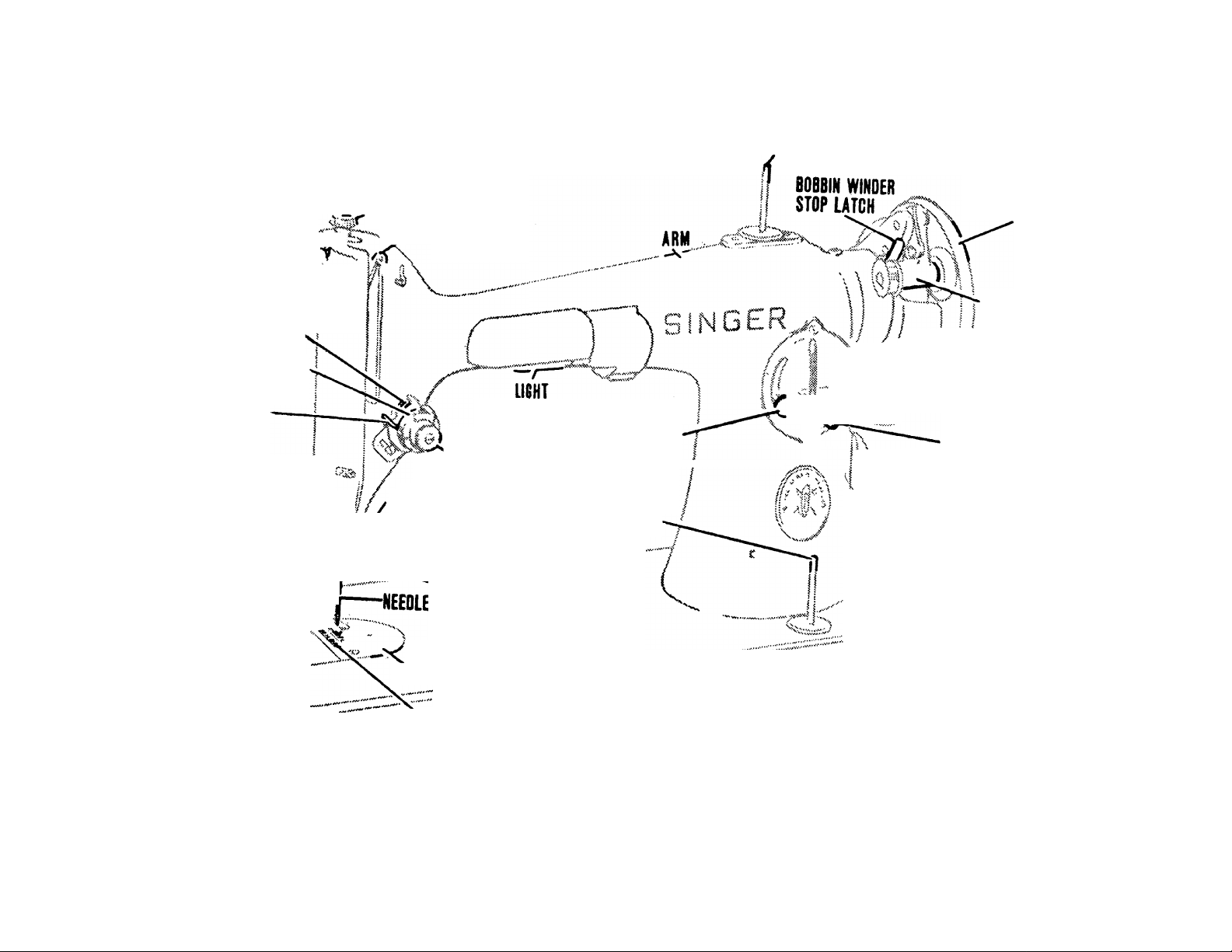

PRESSURE REGULATING

FACE PLATE SCREW^--^ ^

PRESSER BAR LIFTER J

SPOOL PIN

THUMB SCREW

HAND WHEEL

THREAD TAKE-UP

LEVER

FACE PUTE<

TENSION DISCS ^

TENSION INDICATOR DIAL

THREAD TAKE-UP

SPRING

THUMB SCREW>^^:

THREAD GUARD

THREAD CUHER

PRESSER BAR^-^,^

PRESSER FOOT

THUMB SCREW:ir>f|||

;PRESSER JO|r^f

BED SLIDE PUTE^'-

'TENSION REGULATING

THUMB NUT

NEEDLE BAR

NEEDLE CLAMP

THUMB SCREW

neeoIe clamp

THROAT PLATE

FEED DOB

STITCH REGULATOR

THUMB SCREW

BOBBIN WINDER

SPOOL PIN

BED

^1/ I i

y

,. STITCH REGULATOR

( X:'\f AND FEED

\ reversing HANDLE

I LIGHT TOGGLE SWITCH

BOBBIN WINDER

STITCH INDICATOR

----

PUTE

3-PIN TERMINAL BOOT

BOBBIN WINDER

THREAD TENSION

Fig. 2. Names of Principal Parts of Machine

4

Page 6

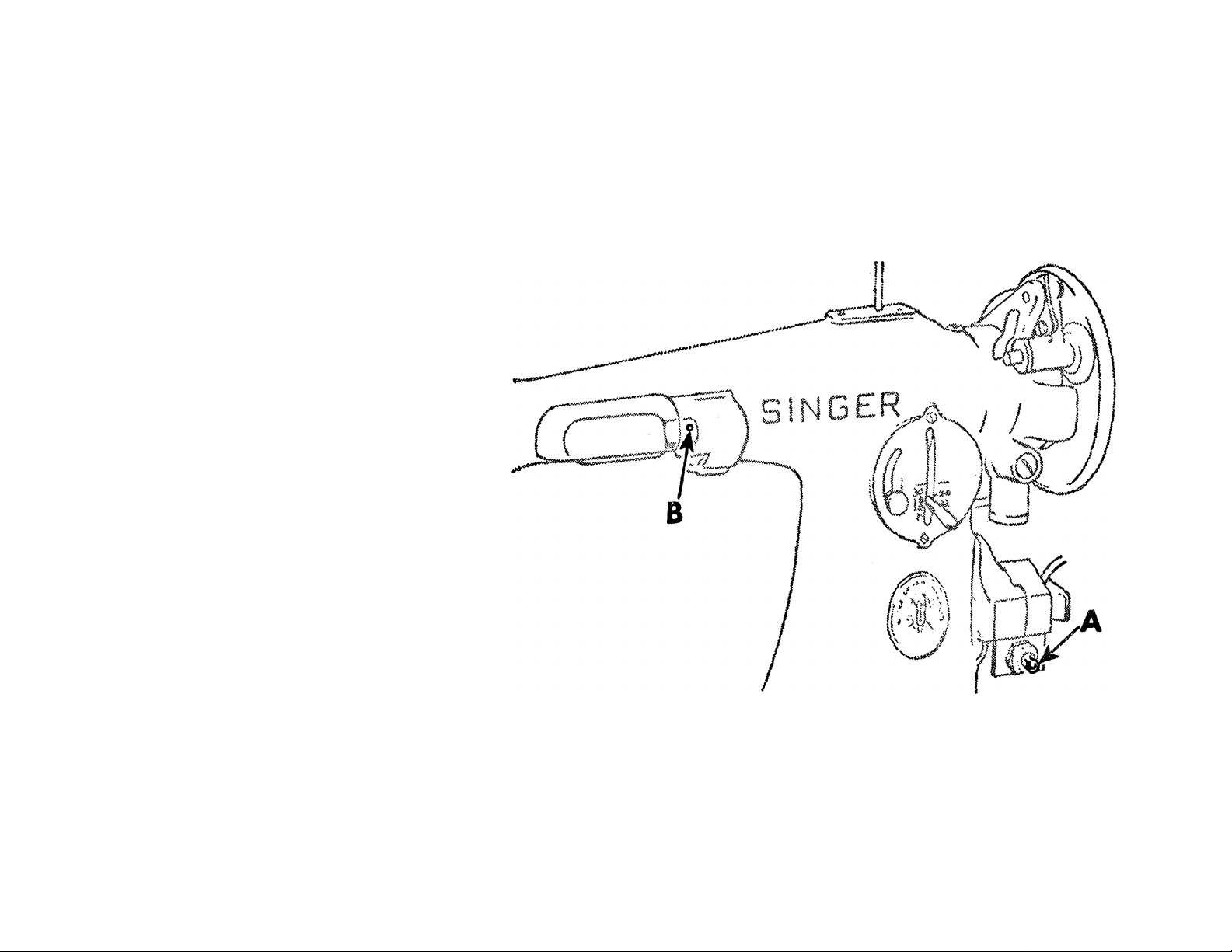

Motor

To Connect Machine to Electric Service Line

The SINGER* electric motor, located at

back of machine, is regularly furnished

for operation on a direct current of

110-120 volts or on alternating current

of 110-120 volts, 25 to 75 cycles. Special

motors can be furnished for direct or

alternating current for any voltage betvsreen 50 and 250, and for 32 volts direct

current.

CAUTION

When you have finished your sewing, always dis

Before connecting the machine to elec

tric service line, be sure that the voltage

and the number of cycles stamped on the

motor nameplate are within the range

marked on the electric meter installed

by the electric power company.

Push terminal plug into the three-pin

terminal block (see Fig. 2, page 4) at

the right of machine and connect plug at

other end of cord to an electric outlet.

connect plug from electric outlet.

5

Page 7

Turn Light “on” or “off”

A switch is conveniently lo

cated at front of three-pin

terminal block as shown at

A in Fi^. 3.

To

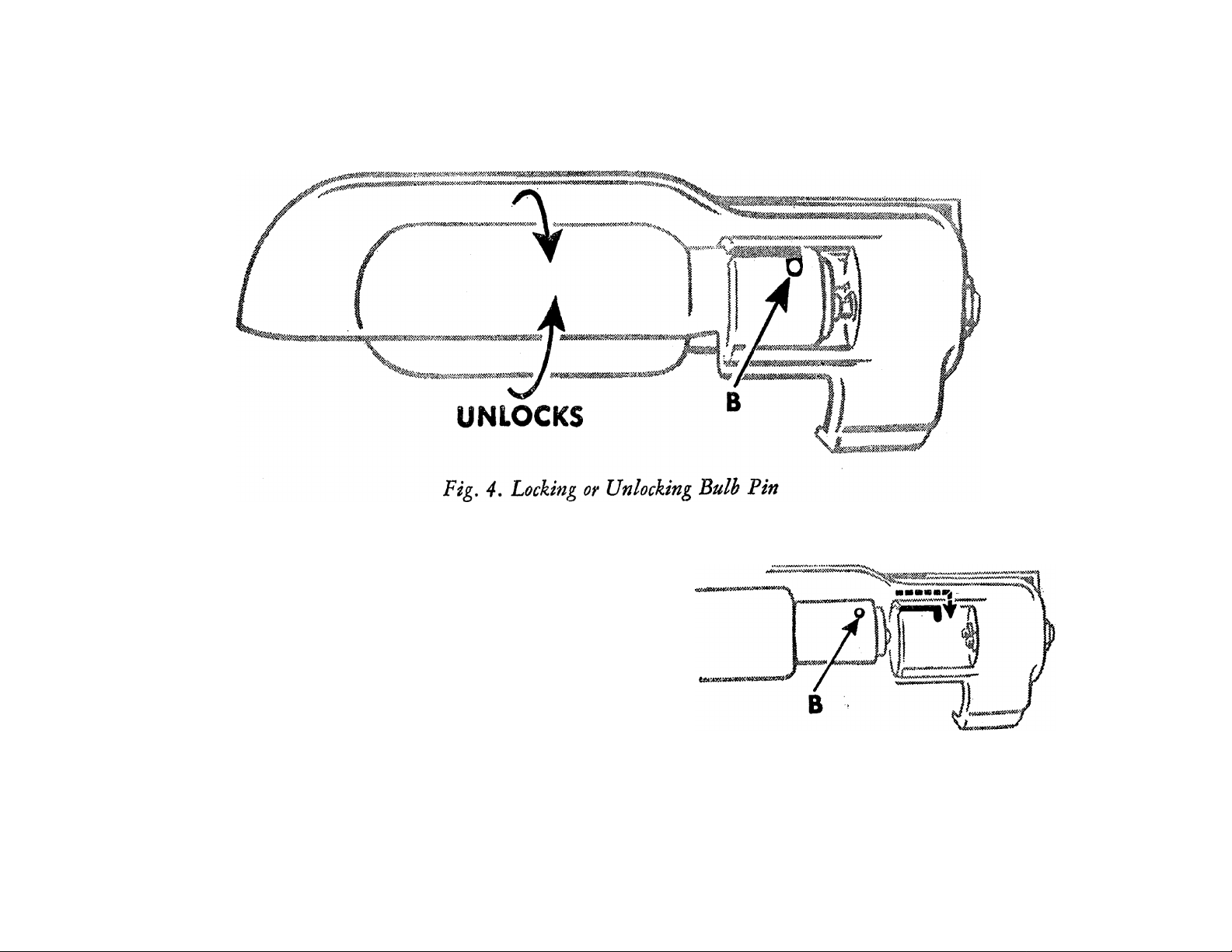

Remove the Bulb

Do not attempt to unscrew

the bulb. It is of the bayonet

and socket type and does not

unscrew. Press bulb into

light and at same time turn

bulb over toward machine

as far as it will go to unlock

bulb pin B as shown in

Fig. 4, Then withdraw bulb.

Fig. 3. Electric Light and Switch

6

Page 8

To lnsgrt a New Bulb

LOCKS

Insert a new bulb into light socket, as

shown in Fig. 5j and turn it over away

from machine, as shown in Kg. 4,

until bulb pin B enters the notch in

socket and locks into position.

Fig. 5. Inserting Bulb in Socket

7

Page 9

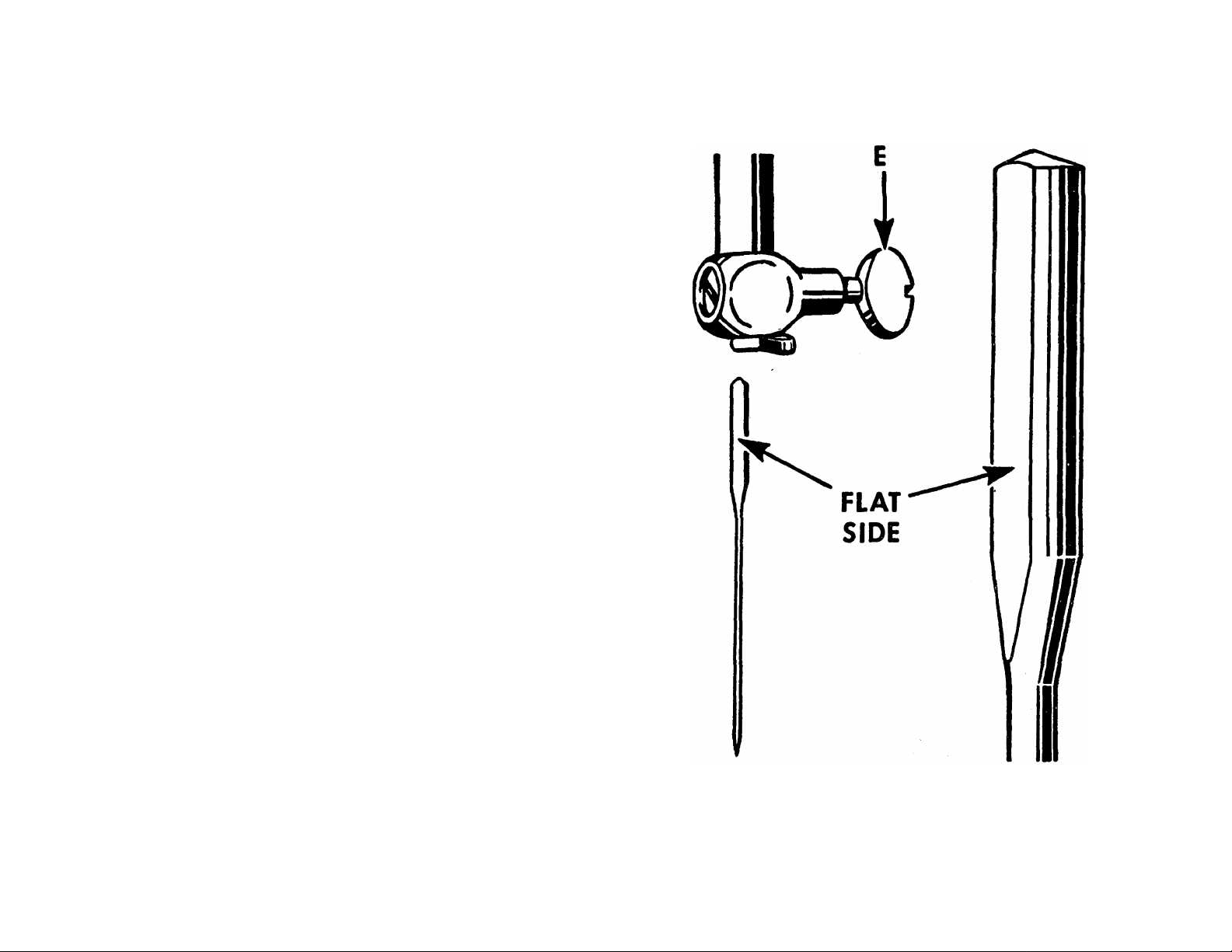

This machine uses a 15X1 Needle

—available in sizes 9, 11, 14, 16,

18, 19 and 21.

For perfect stitching, the thread should

be selected according to the fabric to be

stitched and the needle must be the

correct size for the thread which must

pass freely through eye of needle. Select

the correct needle according to the chart

on page 9. Be sure that needle is not

blunt or bent.

'■ '4;

Raise needle bar to its highest position

and loosen thumb screw E in needle

clamp. Insert needle, with its flat side

to the left, up into the needle clamp as

far as it will go, then tighten thumb

screw E.

Fig. 6. Setting the Needle

8

Page 10

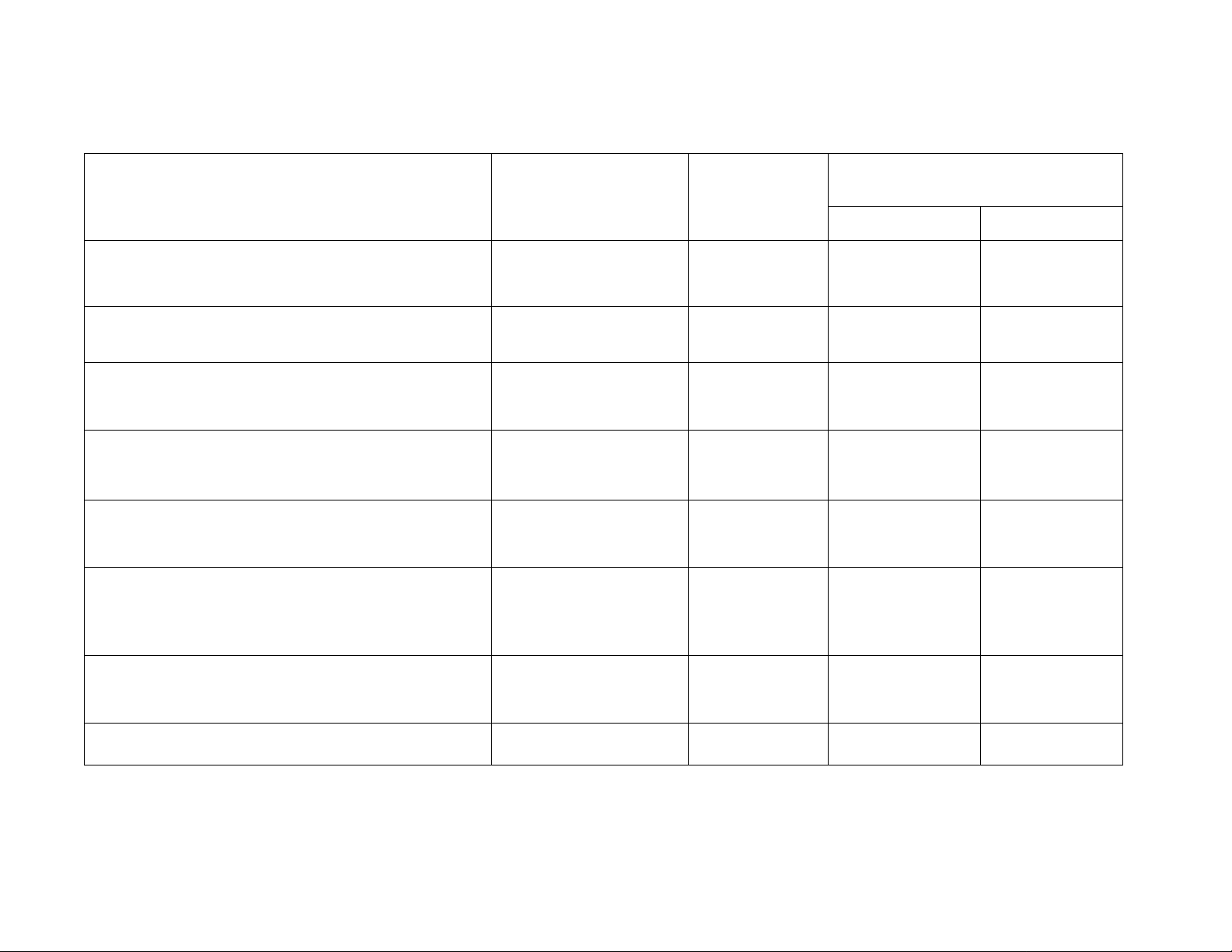

CHART SHOWING THE RELATIONSHIP OF TYPES OF FABRICS, THREAD

AND NEEDLE SIZES AND MACHINE STITCH SETTINGS

TYPES OF FABRICS

Filmy materials comparable to net, marquisette,

chifFon, silk, organdy, ninon, silk velvet, nylon

sheers.

Sheer materials comparable to lawn, dimity, voile,

batiste, rayon sheer, rayon crepe, silk crepe.

Lightweight materials comparable to gingham,

chambray, sheer wool crepe, taffeta.

Medium lightweight materials comparable to

poplin, pique, percale, chintz, faille, bengaline,

wool flannel, wool crepe, wool jersey.

Medium heavy materials comparable to crash,

gabardine, rep, corduroy, velveteen.

Heavy materials comparable to sailcloth, sturdy

denim, ticking, drill cloth.

THREAD SIZES

100 Cotton

00 and 000 Silk

80 to 100 Cotton

0 Silk

50 Mercerized

60 to 80 Cotton

A or B Silk

50 Mercerized

50 to 70 Cotton

B Silk

50 Mercerized

40 to 50 Cotton

C Silk

Heavy Duty Merc.

30 to 40 Cotton

24 to 30 Cotton

D Silk

NEEDLE

SIZES

9

11

14

14

16

18 or 19

18

19

18 or 19

MACHINE STITCH SETTINGS

Inside Seams

20

16

12 18

12

10 12

8

Top Stitching

30

20

16

10

40 to 60 Linen

Very heavy materials comparable to overcoating.

Plastic materials. Mercerized Cotton

20 to 24 Cotton

E Silk

21

11

When ordering needles, always specify "Class and Variety 15 x 1” and state the size and quantity required.

You will obtain the best stitching results from your Sewing Machine if it is fitted with a SINGER* Needle.

9

6 8

10 12

Page 11

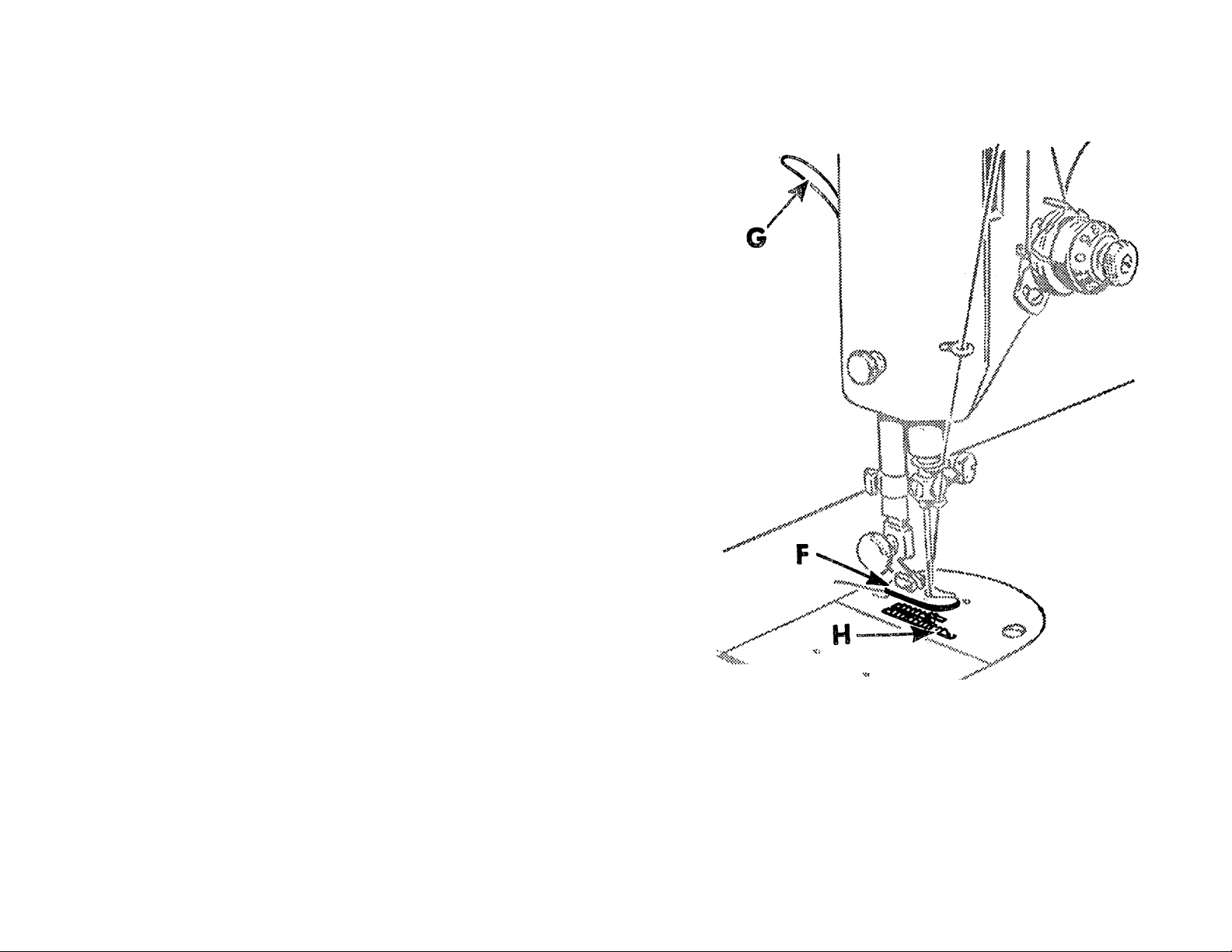

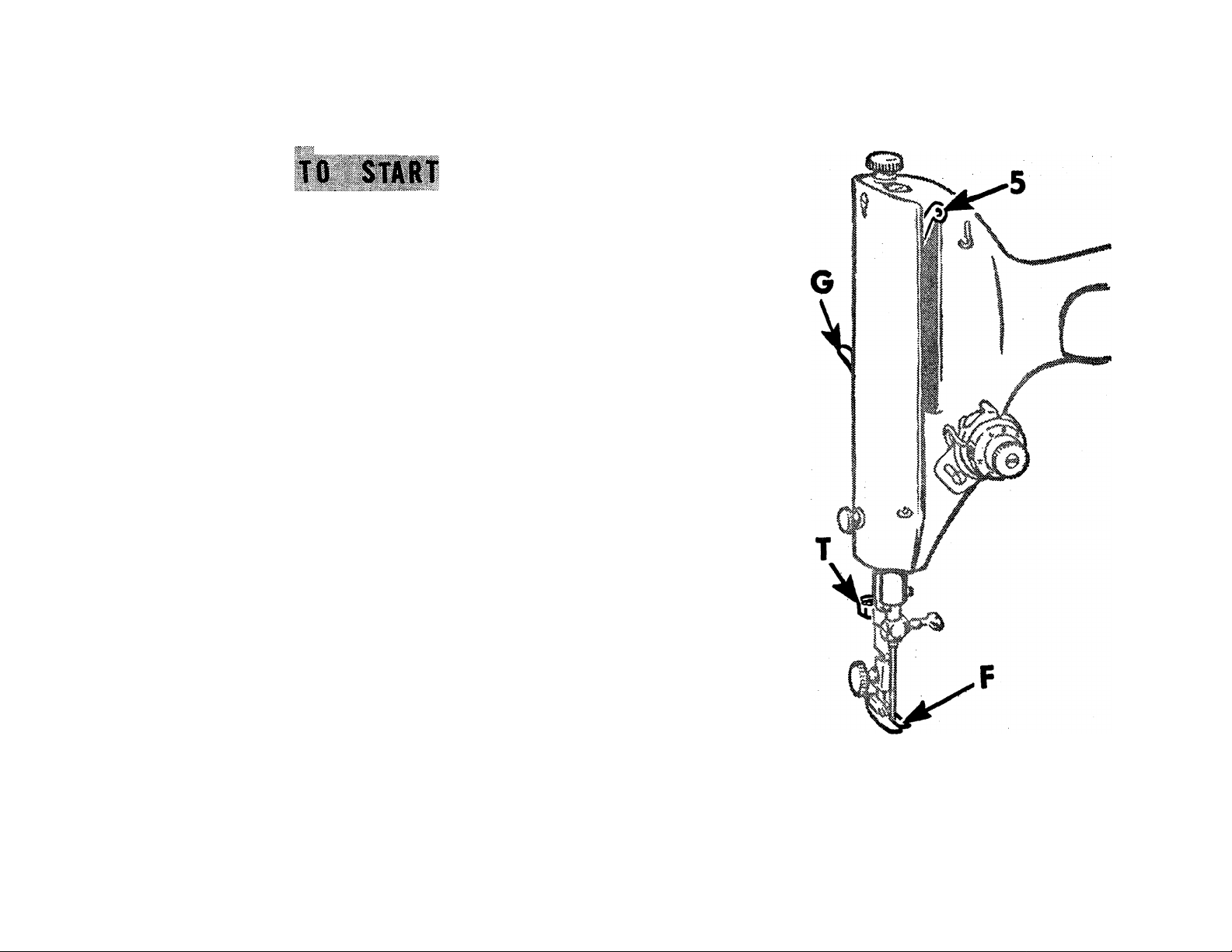

Raise presser foot F by means of presser bar lifter

G to prevent injury to the foot F and feed

Place a piece of cloth under presser foot and let

the foot down upon it.

Turn on electric current and, if the combination

knee and foot controller is installed as a knee

1

controller, press coritroller to the right,, or, if

controller is placed on the floor to be used as a

foot controller, pre?s down on pedal of con

troller. As the pressure on controller is increased,

the speed of machine is increased, the speed being

controlled entirely by amount of pressure on con

troller. Operate machine in this way, without

being threaded, until you have become accus

tomed to guiding the material and operating the

controller.

Si,,..... ,

Fig. 7. Front View of Machine

10

Page 12

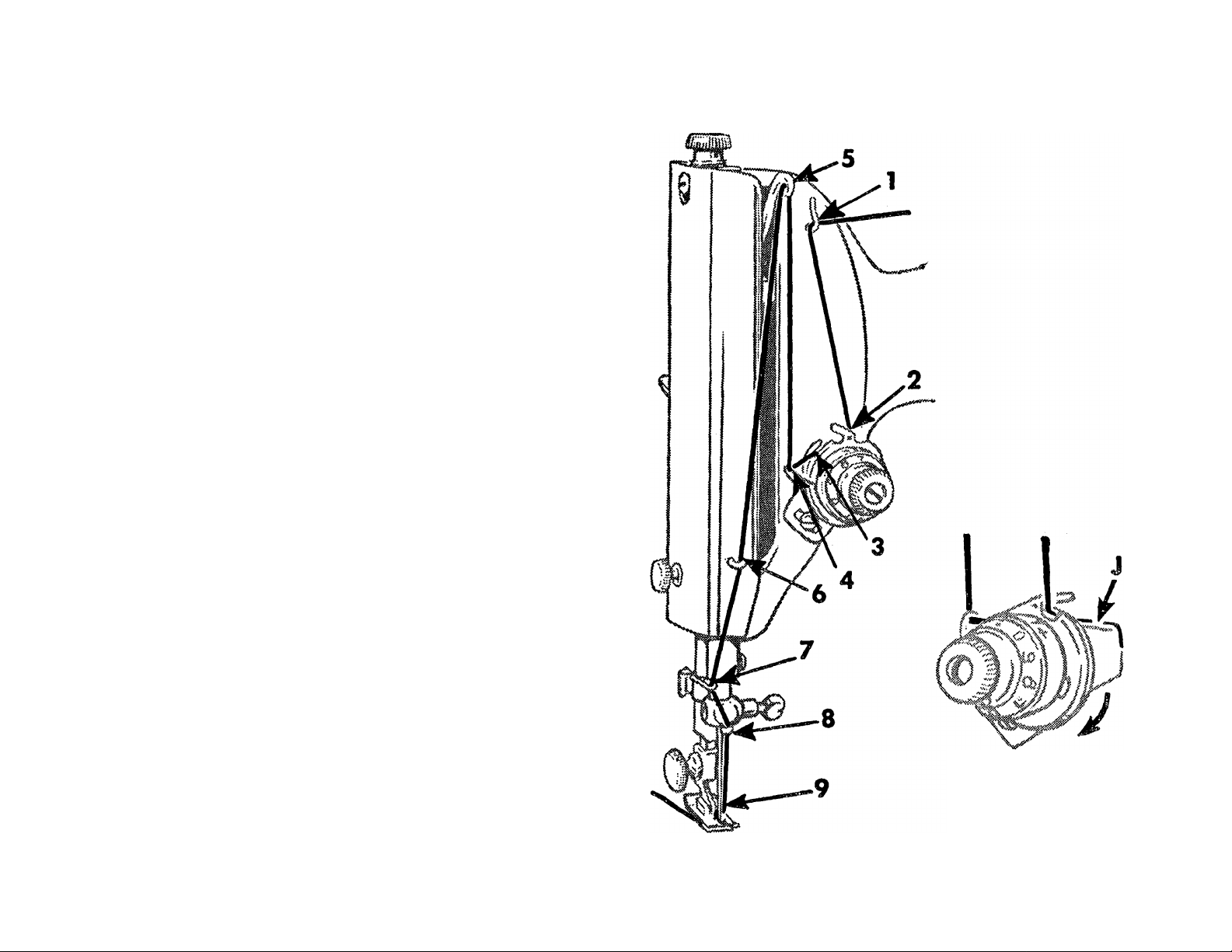

Raise take-up lever 5 to its highest point.

Place spool of thread on spool pin at top of

machine

Pass thread through thread guide 1

Down, under and from right to left be

tween tension discs 2 (thread guard J,

Fig. 9 guiding thread between discs).

Hold spool tightly and pull thread against

take-up spring 4 until it enters retaining

fork 3

Pass thread from right to left through

hole 5 in take-up lever

Down through guide 6 on face plate

Into guide 7 on needle bar bushing

Into guide 8 on needle clamp

From right to left through eye 9 of needle.

Draw about two inches of thread through

eye of needle with which to start sewing.

Fig. 8. Upper Threading

Fig. 9. Threading

Tension Discs

11

Page 13

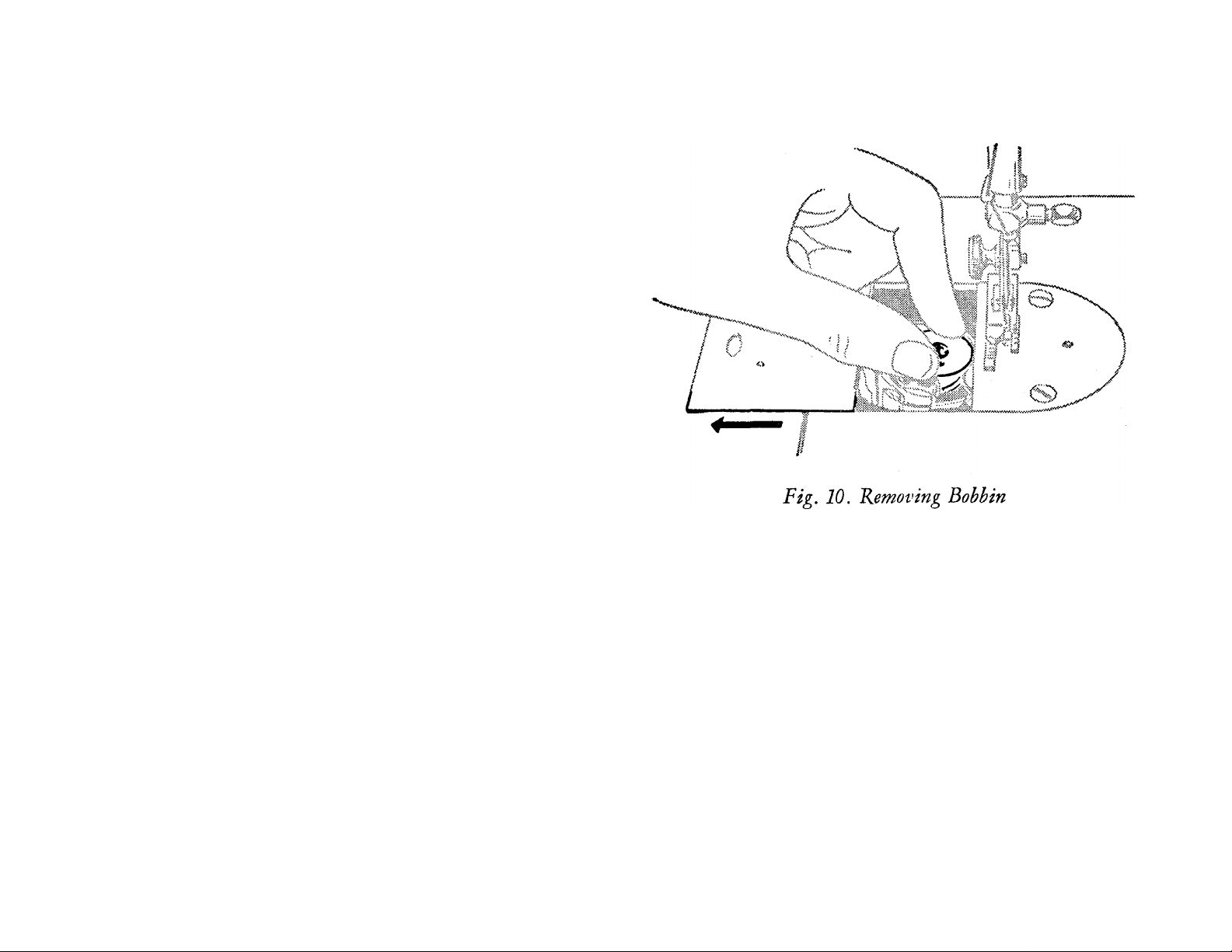

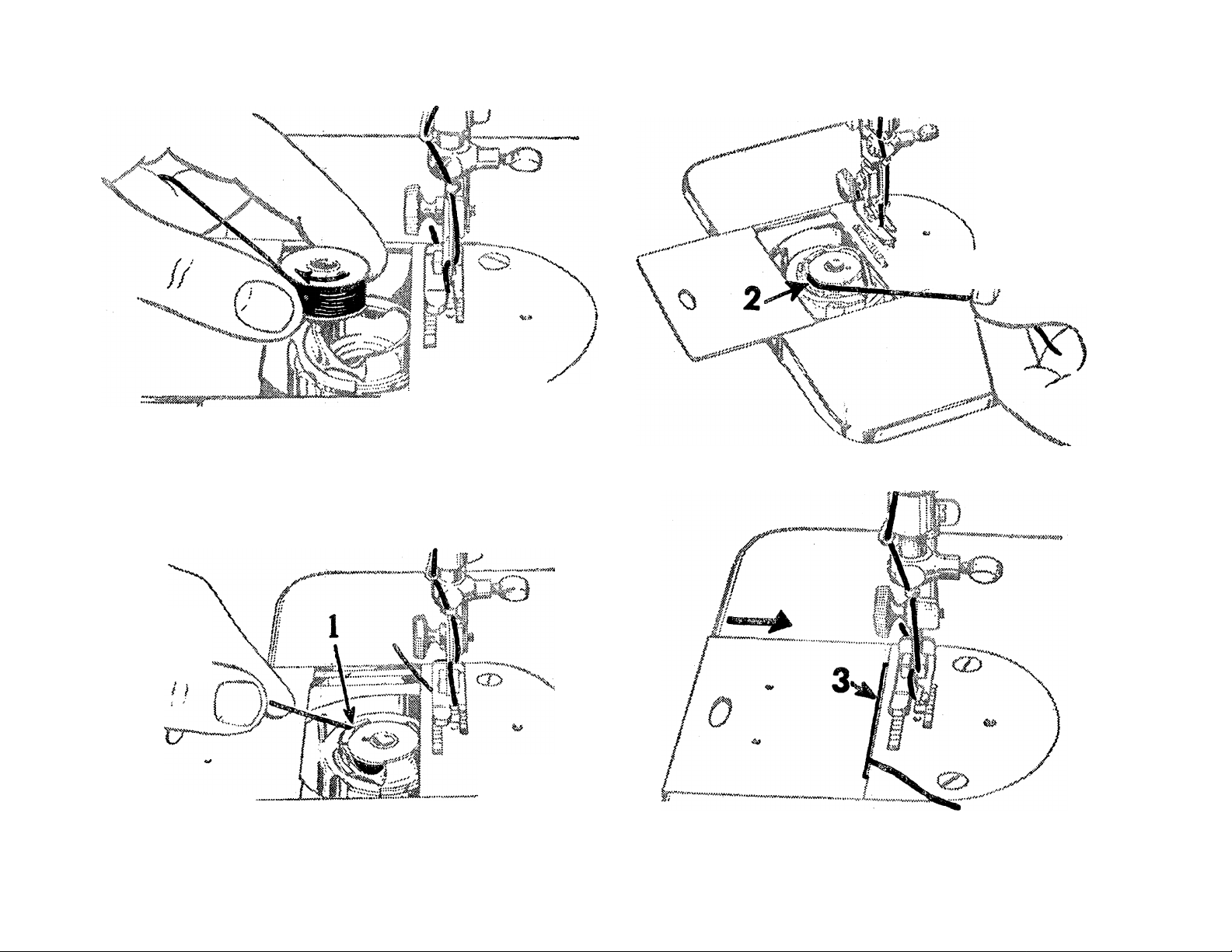

Ttf IWaVfi Tlii

Raise take-up lever 5, Fig. 8 to its

highest point. Draw the bed slide

toward the left, in the bed of machine.

Lift out bobbin with thumb and fore

finger of left hand as shown in Fig. 10.

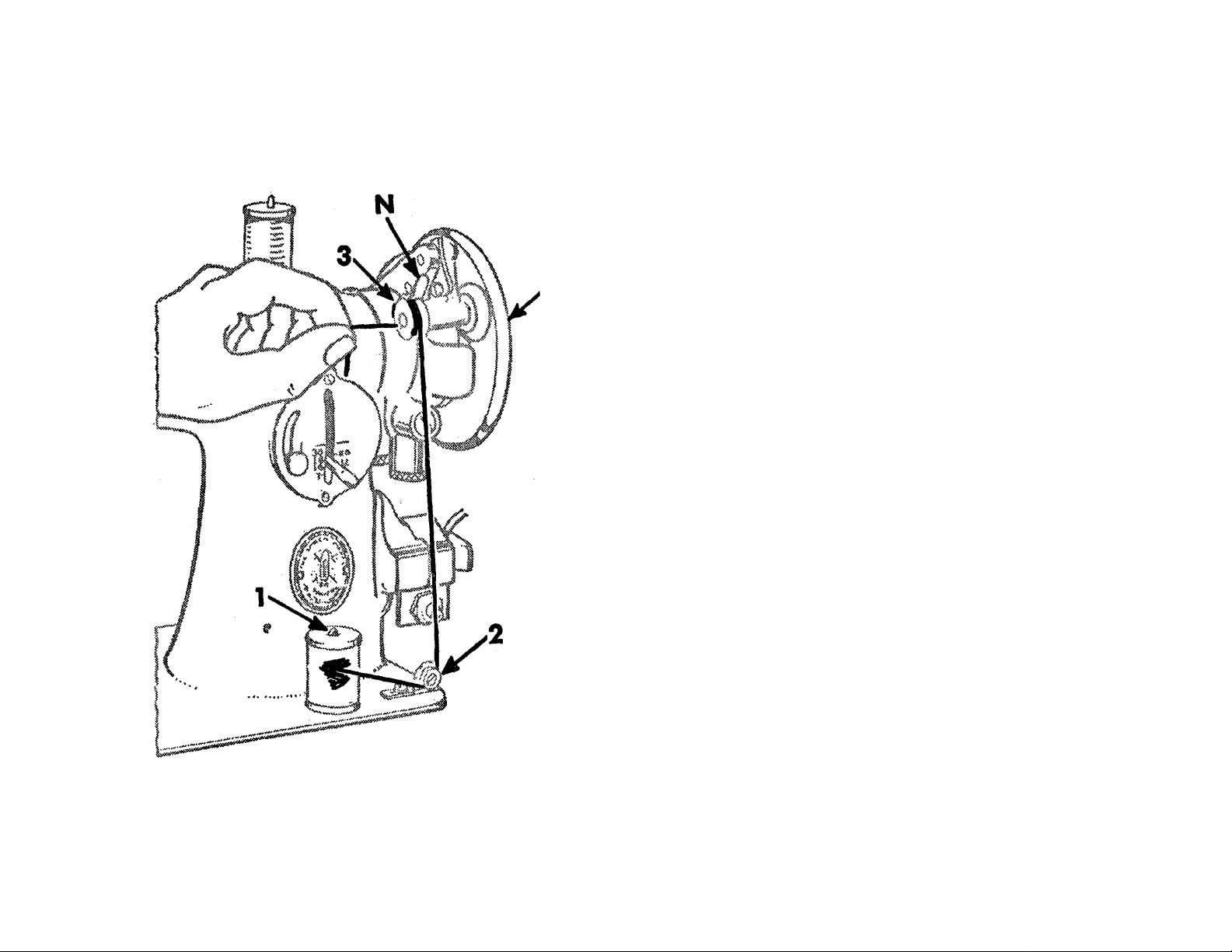

See Fig. 11

1. Place bobbin on spindle with pin of

spindle entering slot in right side of

bobbin.

2. Lock bobbin in place bv pressing

bobbin winder down until latch N,

Fig. 11 engages.

3- Hold hand wheel L and loosen large

knurled screw on hand wheel by turning

it over toward you.

4. Place spool of thread on spool pin 1.

Draw thread under and between tension

discs 2. Lead thread up through hole in

bobbin 3 from the inside.

5. Hold end of thread as shown in

Fig. 11 and press controller as for sew

ing. Continue to hold end of thread

until it breaks off.

12

Page 14

Allow tension discs to control flow of

thread. Do not guide or hold thread

when winding bobbin.

The bobbin winder will stop automati

cally when the bobbin is filled.

Remove bobbin from spindle and tighten

the large knurled screw on the hand

wheel L.

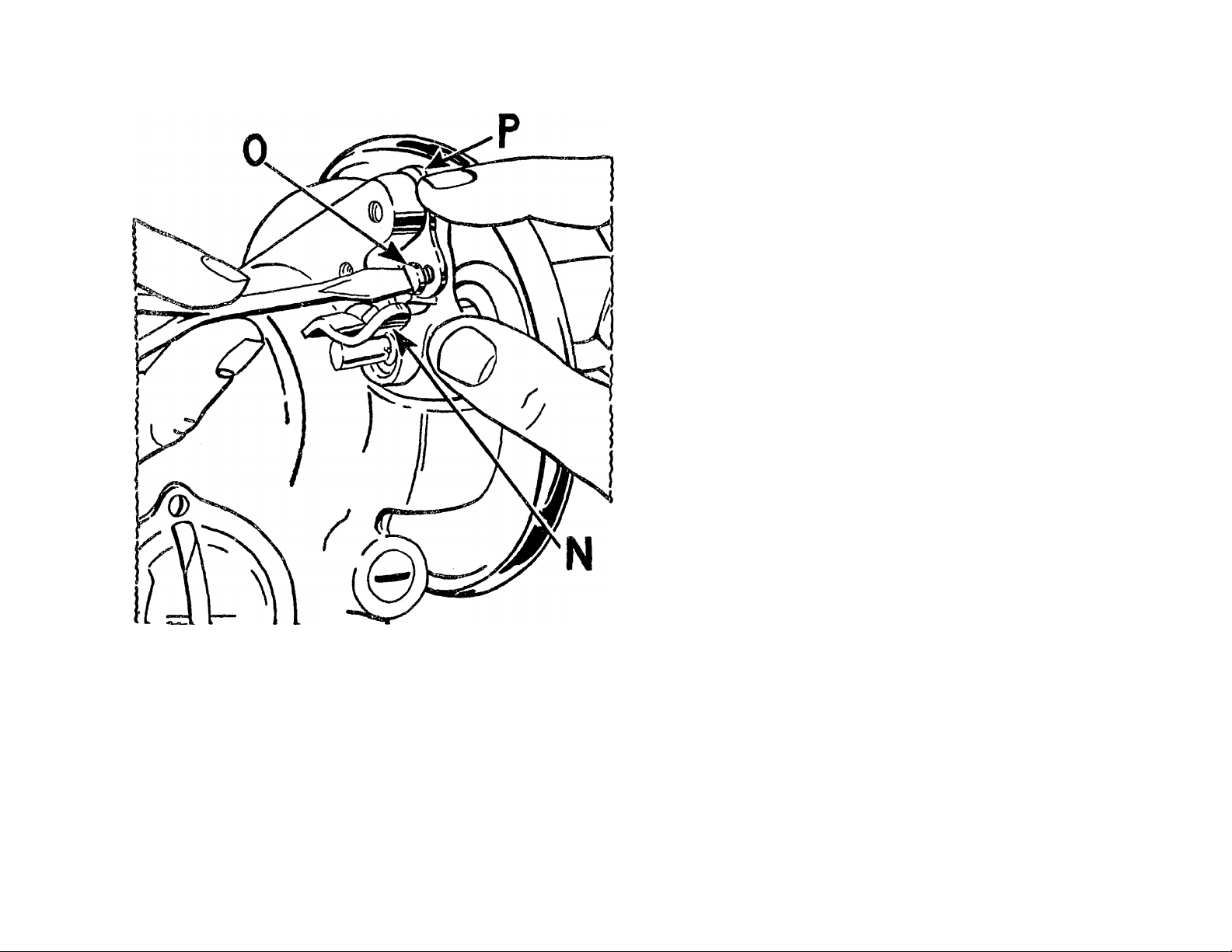

If pressure of bobbin winder pulley

Fig. 11. Winding the Bobbin

against hub of hand wheel is insufficient

for winding the bobbin, press down

bobbin winder until latch N, Figs. 11

and 12 drops and holds it in position.

13

Page 15

screw 0. If thread does not wind

evenly on bobbin, loosen screw which

holds tension bracket 2, Fig. 11 in

position.

Move bracket to the left if bobbin winds

high on right; move bracket to the right

if bobbin winds high on left. When

bracket is properly centered, thread will

wind evenly across bobbin.

Bobbins can be wound while machine is

sewing, by following instructions on

page 12, omitting item 3-

TO REPLACE THE BOBBIN AND

THREAD THE BOBBIN CASE

Fig. 12. Adjustment of Bobhm Winder

Loosen adjusting screw 0, Fig. 12.

With forefinger, push back upper end of

slotted plate P as far as it will go,

as shown in Fig. 12, and at the same

time, press bobbin winder pulley against

hub of hand wheel. Tighten adjusting

Hold bobbin between thumb and fore

finger of left hand; thread drawing from

right to left, as shown in Fig. 13.

Place bobbin in bobbin case. Draw

thread into slot 1, Fig. 14 in bobbin

case, as shown in Fig. 14.

Draw thread toward front between bob

bin case and tension spring until it

passes notch 2, Fig. 15 in bobbin case,

as shown in Fig. 15. Close slide and at

14

Page 16

Fig. 13. Replacing Bobbin

i» / —’

if

c w w •'■ v.v. *'■ '■ •’

same time draw thread into long notch

in right edge of slide, as shown at 3,

Fig. 16.

4*f

Fig. 14. Threading Bobbin Case

Fig. 15. Bobbin Case Threaded

Fig. 16. Under Threading Completed

15

Page 17

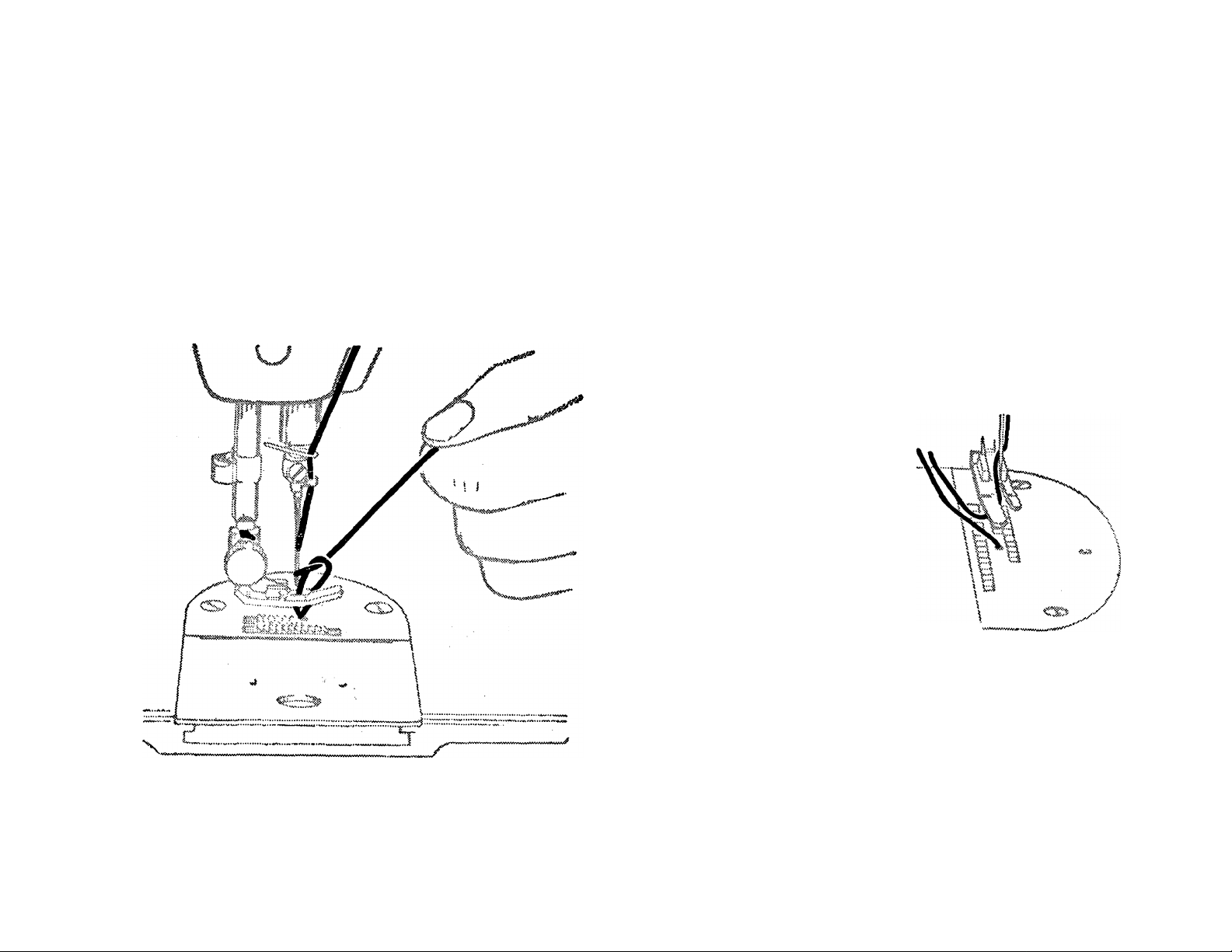

until needle goes down and up again

and thread take-up lever 5, Fig. 1 9 is

Hold end of needle thread with left hand

and turn hand wheel over toward you

at its highest point. Pull up needle

thread and bobbin thread will come

with it, as shown in Fig. 17.

Lay both threads

back under presser

foot diagonally

across the feed, as

shown in Fig. 18, to

the right or left, de

pending upon which

side of needle the

Fig. 18

material is to be lo

Fig. 17. Drawing Up Bobbin Thread

cated, so that when presser foot is low

ered, threads will be firmly held between

the feed and the presser foot.

16

Page 18

t,,, .. --s.(

■; .v%wi«v*w ^ .

■ "'I

1. Bring take-up lever 5 to its highest position.

2. Place material under presser foot F.

3. Position needle in material.

4. Lower presser foot and start to sew.

NOTE:

Most materials require only guiding for best sewing

results. However, the miracle fabrics such as nylons,

synthetic fabrics, blends with various rayons, puffed

weaves, sheers, jerseys and tricots, which, by their

nature, require light pressure, also require support in

the form of holding the material taut at the back and

front of the needle as the needle enters the fabric. This

support assures a smooth, even seam. Never ptill the

material along when stitching.

Never operate the machine without cloth under pres

ser foot.

The slide over the bobbin case should be kept closed

when the machine is in operation.

The hand wheel must always turn over toward the

operator.

17

Fig. 19

Page 19

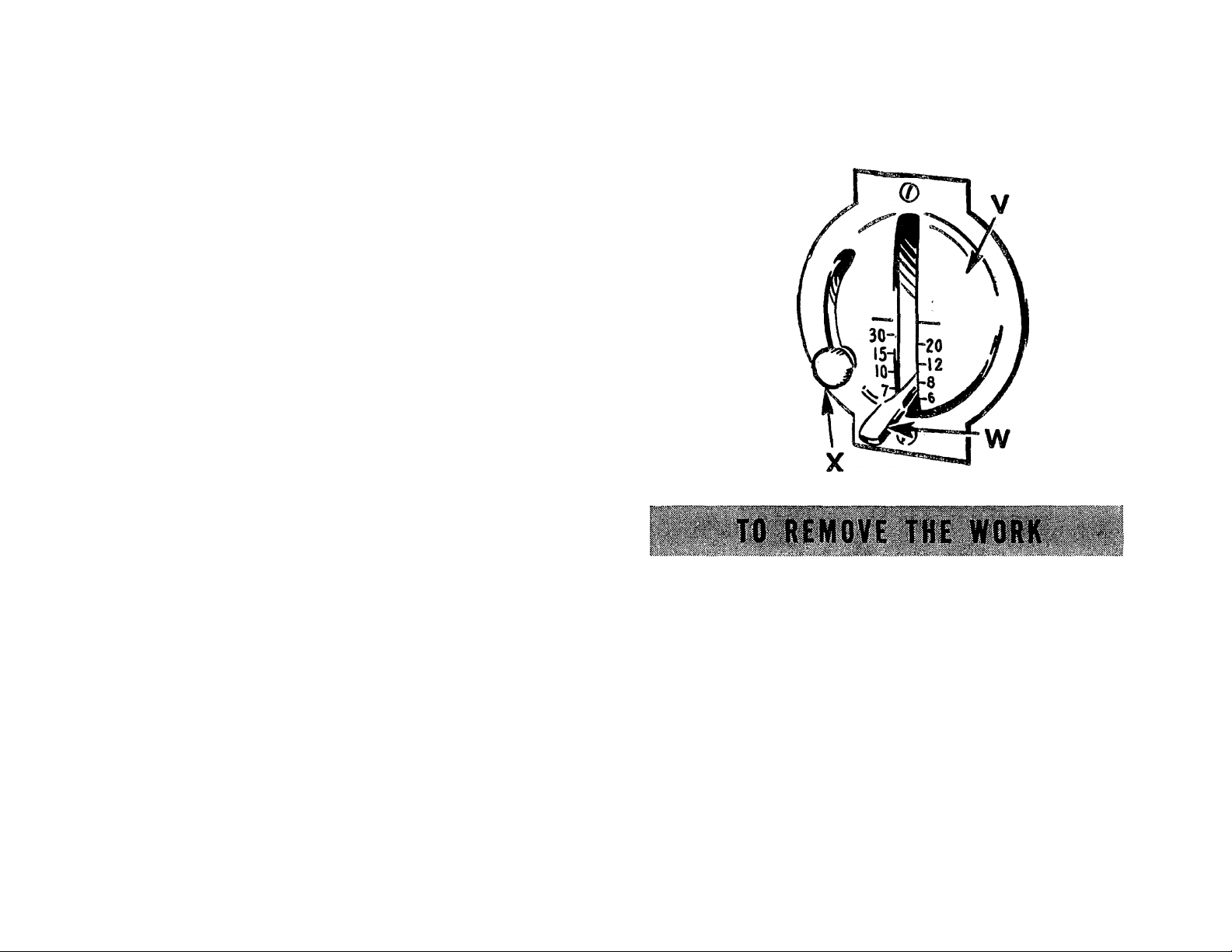

The numerals on the stitch indicator

plate V denote the approximate num~

her of stitches per inch.

To change length of stitch, loosen

thumb screw X and move it to bottom

of slot. Move stitch regulating lever W

until its upper side is in line with the

number of the desired length of stitch.

Move thumb screw X until stitch regu

lating plate (inside) touches lever W.

Tighten thumb screw X.

The machine will then make the indi

cated number of stitches to the inch in

either a forward direction (lever W at

lowest position) or a reverse direction

(lever W at highest position).

Fig. 20

Stop machine with thread take-up lever

5, Fig. 19 at its highest position. Raise

presser foot, draw the fabric back and

to the left, and sever the threads on

thread cutter T, Fig. 19* Place ends of

threads under presser foot, as shown in

Figo 18,

18

Page 20

§■

.

"y.

i-:

The longest stitch, No. 6 on the stitch

regulator, adjusted by leverW, Fig. 2 0,

is found satisfactory for basting. These

basting stitches can be easily removed

by clipping every sixth stitch and with

drawing the long, continuous thread.

Machine basting is firmer, more even

and much quicker than hand basting.

To feed the material from you, push

down stitch regulator lever W, Fig. 2 0

Stop machine when needle is in material.

Raise presser foot, turn work as desired,

lower the presser foot and resume sewing.

r'c ■ V'? '■ -'X ‘:

Use a shorter stitch when sewing bias

or curved seams to increase the elas

ticity of the seam and to prevent seami

failure under strain. No change in ten

sions is required.

PWMf: FEE

» s,' V.,

The direction of feed can be reversed at

any point of a seam without removing

to the numeral of stitch desired.

To feed the material toward you, raise

stitch regulator to the point where it

will make the desired length of stitch.

work from machine.

The reverse feed makes it easy to “back

stitch” and to fasten ends of seams.

19

Page 21

PRESSURE ON

M.edium

20

Page 22

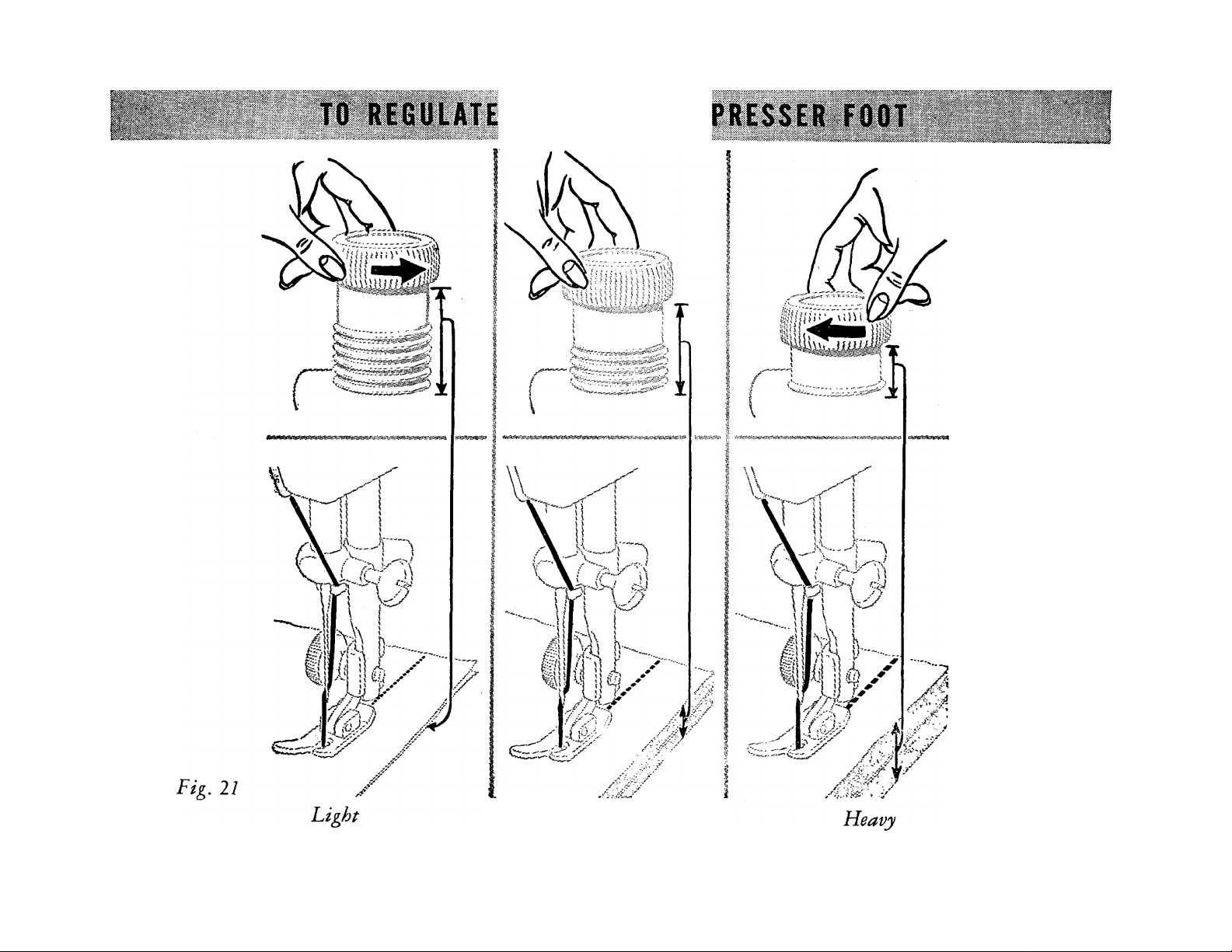

The amount of pressure influences the

ease with which you achieve a straight

seam and uniform stitching. The pres

sure should be heavy enough to prevent

side creepage of material and light

enough to carry the material without

marking.

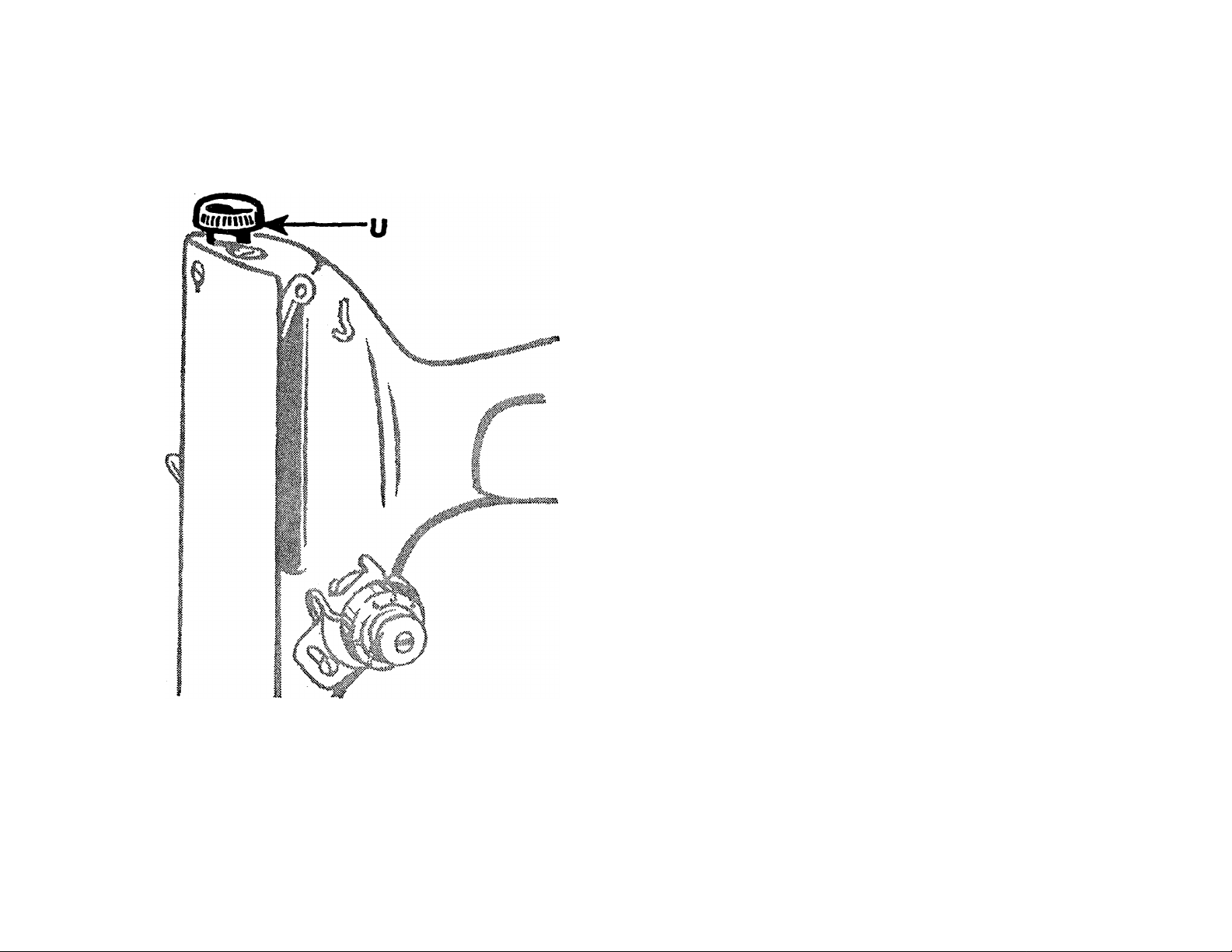

To set a light pressure, turn thumb

screw U, Fig. 2 2 upward until fabric

moves easily under presser foot without

slipping and without showing feed

marks.

Fig. 22. Thumb Screto

for Adjusting Pressure

To set a heavy pressure, turn thumb

screw U downward until the fabric

moves easily and the seam edges are car

ried evenly by the foot and the feed.

21

Page 23

L^ViV'l-^WX' ''''' \

m. mm-W Mmm>

' ' ' 1 ' "i. ' ^<i.'*%'i'Kvjw^^i'ii' ""-S-V i i\Xv'^v>l^^ 'i 'v'. ■i'S

^’1* ^ ^,\-=-^''''\

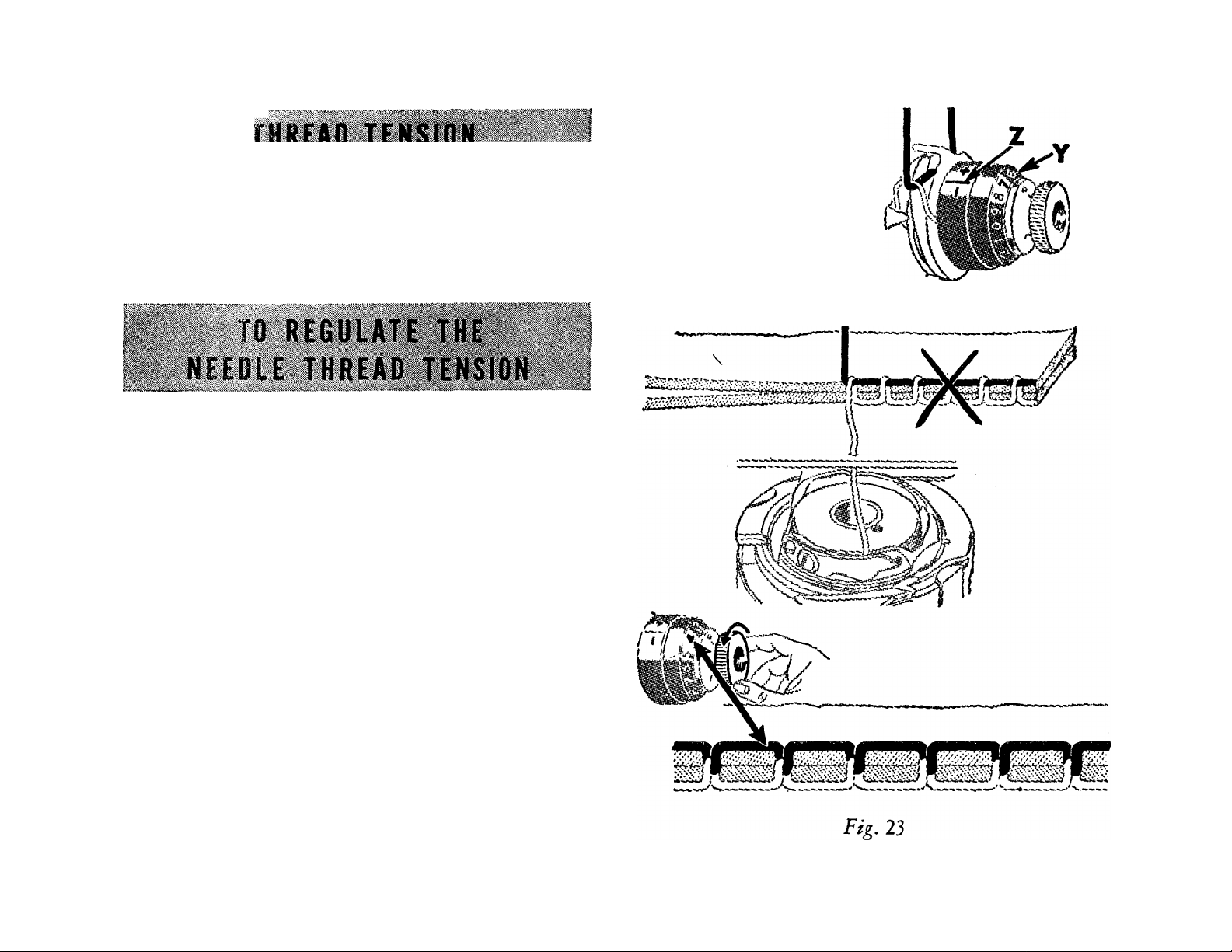

For perfect stitching, the tension on

needle and bobbin threads must be

heavy enough to pull threads to center

of material to mate a firm stitch.

NOTE: Unless the bobbin thread ten

sion has been altered, a wide range of

threads, from fine silk to heavy cottons,

can be formed into a perfect stitch by

regulating the needle thread tension

only«

The tension on needle thread can be

tested only when presser foot is down.

The numerals “0” to “9” on dial Y

indicate different degrees of tension that

can be obtained. The higher the number

the greater the tension. The numbers do

not denote size of thread or ounces of

tension.

22

Page 24

When tension has been correctly set for

average sewing, note number at indi

cator line Z. This setting may be

quickly regained should the tension be

altered for special work or a change in

size of thread.

In the unbalanced tensions shown at top

of Fig. 2 3 caused by too heavy tension

on needle thread, the needle thread lies

straight along top side of material.

In the unbalanced tensions shown at

top of Fig. 24, caused by too light ten

sion bn needle thread, the bobbin

thread lies straight along under side of

material.

If perfect stitching cannot be obtained

by regulating the needle thread tension,

check for minimum tension at “0”

position and if necessary adjust as in

structed on page 2 7. Then regulate

bobbin thread tension as instructed on

pages 24 and 2 5.

Fig. 24

23

Page 25

iiiciSi¿i5lí«jt^^'^»elx^S;»NS^¿i¿x^»»i««i»«Al«ií^;ííW:i&^;^к>4«№^'»:4:&^^

Set needle thread tension at **4**, as

shown in Figs. 2 5 and 26.

The tension on bobbin thread is regu

lated by the screw of the tension spring,

as shown in Fig. 2 5.

Fig, 25. Adjustment Kequired When

Bobbin Tension is too Loose

When adjusting bobbin tension, a

slight turn of the screw is all that is

needed to make a fine adjustment.

24

Page 26

To increase tension, turn screw gradu

ally over to the right.

Fig. 26. Adjustment Required When

Bobbin Tension is too Tight

To decrease tension, turn screw gradu

ally over to the left.

fTf

25

Page 27

Should it become necessary to remove

thumb nut. Then remove tension parts

and disassemble the tension, proceed as

follows:

Turn thumb nut A2, Fig. 2 7 over

toward the left until it stops at “0”

on numbered dial Y. Press in dial to dis

engage pin B2 in thumb nut and remove

4$- —

Fig. 27. Needle Thread Tension Disassembled

from stud J2 as shown below. To

remove pin H2 from stud J2, remove

face plate from machine and tilt ma

chine so that the pin will drop out. Do

not remove stud J2. (It is shown re

moved in Fig. 2 7, only for the purpose

of illustration.)

I

See Fig. 27 tension discs on stud, having the flat.

Replace face plate, insert tension re- thread-bearing sides of discs together,

leasing pin H2 in stud. Place the two Place thread guard plate K2 on stud,

26

Page 28

being sure that extension M 2 enters the

“0”. Thread the tension with size 50

hole provided for it in the arm of the

machine to prevent plate from turning

on stud.

Next, replace indicator Z with the

large open side facing end of stud (out

ward) so that the plus and minus signs

can be readily seen from a sewing

position. Insert tension spring D2 in

indicator so that first half turn E2 of

this spring will straddle lower half of

tension stud. Guide stop washer C2

onto stud so that extension N2 will be

above tension stud as shown in Fig. 2 7.

Next place numbered dial on stud so

that numeral 2 is opposite stop washer

mercerized cotton and pull thread

through tension discs to test amount

of tension at “0” position. At this

point there should be a barely percepti

ble pull on thread to indicate that there

is a minim.um tension, which will grad

ually increase with the turn of thumb

nut to right, providing a full range of

tensions from light to heavy within one

revolution of thumb nut. If pull is too

strong for a minimum tension, press in

numbered dial Y, to disengage pin B2

in thumb nut from dial and reset pin in

one of holes to left of previous setting.

This resetting of pin will produce less

extension N2, then push dial to com

press spring so that thumb nut can be

turned onto'stud, carefully guiding pin

in thumb nut into one of holes in num

bered dial. Lower presser bar and turn

thumb nut A2 to left until it stops at

tension at zero. On the other hand,

should there be insufficient tension at

zero, press in dial Yand reset pin B2 in

one or holes to right of previous setting.

Repeat this process until the desired

minimum tension is obtainedc

27

Page 29

ilwi

.^ :;?" '’v'o .. v.";.— ^"

. ^ ^ .c - ' \ ^ ' _ ' T'L 'J: -

^'- . \ '■ ■ ' ;V ' CCI

>»i>>VC^'Î%ÎVXwftiiX«!K'»X^%vMÎiisÎîASiriÎ^!i^TO

; ' *■■■ ' ■

Breaking of needles might be caused

by:

1. Incorrect size of needle for thread and

material. See page 9.

2. Needle bent.

3. Pulling of material when stitching.

4. Needle striking improperly fastened

presser foot or attachments.

5. Crossing thick seams with too small

a needle.

Breaking of needle thread might be

caused by:

1. A knot in the thread.

4. Needle set incorrectly. See page 8.

5. Needle blunt or bent.

6. Thread too coarse for needle. See

page 9.

7. Roughened hole in throat plate.

8. Incorrect arrangement of threads to

start sewing. See page 16.

9. Damaged sewing hook.

Breaking of bobbin thread might be

caused by:

1. Incorrect threading of the bobbin

case. See page 15.

2. Bobbin thread tension too tight. See

pages 24 and 2 5.

2. Incorrect threading. See page 11.

3. Upper tension too tight. See pages

22 and 2 3.

3. Bobbin wound unevenly. See page

14.

4. Damaged bobbin.

28

Page 30

Skipping of stitches might be caused

NOTE: If machine runs heavily after

by;

1. Incorrect setting of needle. See

page 8.

2. Needle blunt or bent.

3. Needle too small for thread. See

page 9.

4. Needle rubbing presser foot.

Gathering or Puckering of material

might be caused by:

1. Failure to use crisp lawn or organdy

backing when stitching on sheer

materials.

2. Excessive needle and bobbin thread

tensions.

standing idle for a long period, apply

a few drops of kerosene at all oil

ing points, run the machine for a few

minutes, then wipe clean and apply

SINGER* Oil as described on pages

33 to 37.

SINGER Needles should be used

in SINGER Machines.

These Needles and their Containers

are marked with the

Company’s Trade Mark“ SINGER ”1

Needles in Containers marked

“FOR SINGER MACHINES”

are NOT SINGER made Needles.

29

Page 31

' ^ \ a' '■■.'i > j’'

;. DARNIMfi

!. V '*c i;.'o'. ^ %i ^^■ ; „

Turn machine back on its hinges. Un

screw the thumb screw P2, Fig. 2 8

out of the lower hole A in the crank

Q2 until the crank Q2 is released.

Move feed lifting crank Q2 downward

so that thumb screw P2 will enter

upper hole B. Insert thumb screw P2

in this hole and tighten firmly. The

feed is thus rendered inoperative and

will not interfere with the free move

ment of the work. Bring machine for

ward into place.

Move stitch regulating lever W, Fig.

2 0, page 1 8 to its neutral position in

the center of slot at front of machine.

Remove presser foot and let down

presser bar lifter G, Fig. 19, page 17

to restore tension on needle thread

which is released when lifter is raised.

Draw up bobbin thread as instructed on

page 16.

30

Page 32

Darning:

When darning flat work, it is advisable

to use embroidery hoops to hold the

work. Place the work in machine, hav

ing the unworn part near the hole

\ under the needle. Start darning by mak

ing a line of stitches across the hole a

little longer than width of hole. Con

tinue making parallel lines of stitches

Fig. 29 Starting the Darn

across hole, moving the work backward

and forward, as shown in Fig. 2 9, and

at same time gradually moving the

work sidewise until hole is covered with

/

lines of stitches running across hole.

Then turn the work 90°, as shown in

'/V"

I

^ , Fig. 30 and continue as before moving

i'A work backward and forward, form

"'V?.

ing parallel lines of stitches until the

Av,

i

vV

i.,.„A

first group of stitches across hole are

completely covered and the darn is

finished.

When you have finished darning, raise

Fig. 30. Darning in Process

presser bar lifter and replace presser

31

Page 33

foot. Turn machine back on its hinges

and turn thumb screw P2, Fig. 28,

page 30 out of upper hole B, Fig. 28

Embroidering:

Prepare the machine the same as for

darning as instructed on page 30, with

in feed lifting crank Q2, Fig. 28, and

into lower hole A, Fig. 28. Make sure

that thumb screw is firmly tightened.

Bring machine forward into place, re

turn stitch regulating lever W, Fig. 2 0,

page IS, to its original position and

the machine is ready for regular stitch

ing. Stockings and socks, underwear,

etc., can be more conveniently darned

on the machine with the SINGER*

DARNING and Embroidery Attach

the following exceptions—

For surface embroidery, remove the

presser foot to give a clear view of the

stitching in process.

For lace embroidery remove the regular

presser foot and replace with Foot

160858 or with Darning and Embroidery

Attachment 160720, either of which

can be purchased from any SINGER

SEWING CENTER or from any

SINGER Salesman. See instructions on

ment 160720 (page 68).

page 68.

32

Page 34

../-v: ;!&'■ 5Y, '-

.........

i;*

:;v.' >V'.- .':, -

WL tHt

If machine is used continuously, it

should be oiled daily. If moderately

used, an occasional oiling is sufficient.

Preparation: Remove face plate. Draw

bed slide plate to the left. Remove dust

and lint (see instructions on page 3 8).

Swing rear cover plate up toward hand

wheel.

Fig. 31. Front Views Showing Oiling Points

33

Page 35

Oiling: Apply a drop of oil to the

places indicated by unlettered arrows in

Figs. 31, 32,33 and 34, and 3 drops of

oil to the places so indicated in Figs. 31

and 34.

After applying one drop of oil to the

places indicated by the unlettered ar

rows in Fig. 32, replace face plate and

fasten it as before.

Fig. 32. End View Showing Oiling Pointi

34

Page 36

To reach parts uridenieath

bed of machine, turn ma

chine back on its hinges.

Apply one drop of oil to the

places indicated by the un

lettered arrows in Fig. 33.

The gears concealed by gear cover E2, Fig’» 3 3 aic

D2 oiled through oil hole E, Fig. 31.

The gears concealed by gear cover D, Fig. 3 3 are

Fig. 33. Views, Showing Oiling Points in

Base of Niachine

oiled through the space just above this cover, as

indicated by arrow D2. After oiling the gears at

D2 , rotate the hand wheel toward you to distribute

the oil on these gears.

35

Page 37

Turn hand wheel over toward you until

connecting rod R2, Fig. 34 is at its

highest position. Then apply oil through

hole in top of machine to the wick

which is retained in cap of connecting

rod, as shown in Fig. 34. Also oil the

other moving parts inside and replace

cover.

Machine Working Heavily

If the machine runs hard after standing

idle for some time, use a little kerosene

in the oiling places, run the machine

rapidly, then wipe clean and oil.

36

Fig. 34. Oiling Foints At the Back

of the M.achine

Page 38

:

NEVER USE OIL OR ORDINARY

GREASE FOR LUBRICATING

MOTOR. USE the SINGER* Motor

Lubricant, supplied with the machine.

Machine is shipped from factory with

sufficient SINGER Motor Lubricant

in motor grease cups T2, Fig. 35, for

approximately one year’s use.

At least once a year thereafter, turn

machine back on its hinges and remove

the two thumb screws from the two

grease cups T2. Clean out interior of

cups. Insert tip of motor lubricant tube

into each grease cup as shown in

Fig. 35, and while holding tube firmly

against bottom of grease cup squeeze

enough grease into each cup to fill it.

Replace and tighten thumb screws.

37

Fig. 35. Lubricating the hAotor

Page 39

After considerable use, the stitch form

Occasionally remove the bobbin case

ing mechanism in bed of machine may

become clogged with lint and this may

interfere with the perfect operation of

the machine.

from machine, as instructed below, and

remove any lint, etc., which has accu

mulated in machine.

Draw bed slide plate to the left. Turn

hand wheel over toward you until

^ needle is at its highest point and end of

the hook ring E is toward the front of

the machine, as shown in Fig. 36.

Insert the blade of small tension screw

driver 120378, which is furnished with

the machine, into slot C between the

ring and the edge of the spring, as

Fig, 36. View from Left Endy Showing Position of Bobbin

Case and Hook Ring for Removal from Machine

shown in Fig. 36. With a downward

pressure, turn the screwdriver one-half

turn to the right so that the screwdriver

will drop into the slot and unlock the

spring. With the right hand, hold the

hand wheel to prevent its turning, and,

with the left, place the screwdriver

38

Page 40

against the edge of the slot in the ring

circular cutout B is opposite the spring

and push it around in the direction op

posite to the hook rotation until the

When replacing the parts,

first place the bobbin case [

into position with the finger

A, Fig. 37 in the opening in

the position plate under the

throat plate as shown in

Fig. 37. Turn the bobbin

case back and forth slightly

to make sure that it is proper

ly seated, then place the hook

D, as shown in Fig. 37. The ring E and

bobbin case may then be lifted out.

THROAT PLATE

ring E in position with the

cutout B opposite the spring

D. Press the ring into place

and turn it in the direction

of hook rotation until the

spring locks it in position.

Then replace the bobbin.

Fig. 37. View from Left End, Showing

Keflacement of Bobbin Case

39

Page 41

mitw

ATTACHMENTS

40

Page 42

The foot hemmer may

2. Lay about three inches of needle and

be used for hemming

edge of material, mak

ing hemmed and felled

seams and for hemming

and sewing on lace in

one operation.

Raise needle to its high

est point, remove pres

Fig. 38

Foot Hemmer

ser foot and attach foot

hemmer to presser bar

in place of presser foot.

Pull up bobbin thread as instructed on

page 16.

To Start Hem at Very Edge

bobbin threads back under hemmer.

Place creased edge of material under

hemmer with end of hem directly

under needle. Lower hemmer and

tack end of hem with two machine

stitches.

1. Fold edge of material twice, about

^ inch each time, for a distance of

about two inches. Crease folds.

41

Fig, 39. Starting Hem at Very End of Material

Page 43

3. Raise hemmer. Pull threads and hem

4. Lower hemmer and start to sew,

slightly from you with left hand,

then while holding threads, draw

material toward you, with right hand,

into scroll of hemmer until tacked

end is caught in hemmer, as shown in

Fig. 39.

slightly pulling threads back while

sewing. Keep mouth of hemmer

full to produce a smooth, even

hem as shown in Fig. 40.

To Make a Hemmed Seam with Foot Hemmer

Fig. 40. Hemming Edge of Material and

Fulling Back Threads While Sewing

Fig. 41. Making a

Hemmed Seam

(First Operation')

1. When making this seam, the gar

ment must first be fitted and the edge

42

Page 44

of material trimmed, allowing for

2. The free edge of hemmed seam may

about 3^ inch of seam. Insert the two

edges of material, right sides to

gether, in the hemmer in same man

ner as a single hem as shown in

Fig. 41. If the material is bulky,

place edge of upper piece of material

about inch left of edge of under

piece.

be stitched flat to garment, if de

sired. To do this, open the work out

flat, wrong side up, then insert the

hem in scroll of hemmer, holding

edge of hem in position while it is

being stitched. If seam is stitched

flat to garment, one row of stitching

is visible on the right side.

To Make a Felled Seam

with Foot Hemmer

1. Place right sides of material together,

having edge of upper piece about 3^

Fig, 41. Making a

Hemmed Seam

(^Second Operation^

43

inch to the left of edge of under

piece. Stitch the two pieces together,

using hemmer as a presser foot.

Guide both pieces by the projecting

toe of hemmer, as shown in Fig. 43.

Page 45

2. Open the work out flat, wrong side

3. Raise presser bar and insert edge of

up, and hem free edge of seam,

stitching it flat to garment as shown

in Fig. 44.

Fi£. 43. lAaking a

Felled Seam

(First Operation)

Fig. 44. Making a

Felled Seam

(Second Operation)

lace in slot of hemmer and back

under hemmer.

4. Lower presser bar and start sewing,

catching edge of lace with needle.

5. Guide hem with right hand and lace

with left hand, being careful not to

stretch lace as it enters hemmer.

To Hem and Sew on Lace

in One Operation

1. Start hem in regular way.

2. Hold hem in position with needle.

Fig. 45. Hemming and Sewing on Lace

44

Page 46

■

' ■ > . .■■ i ■ 1 /■'. „ <•

To Make Hems

from 3/16 to 15/16 Inch Wide

1. Attach adjustable hemmer to presser

bar in place of presser foot.

2. Pull up bobbin thread, as instructed

on page 16.

3. Loosen thumb screw on hemmer and

move scale until pointer registers

with number of desired width of

hem. (No. 1 indicates the narrowest

hem and No. 8, the widest.) Then

tighten thumb screw.

4. Place cloth in hemmer and draw it

6. Guide sufficient cloth into hemmer to

turn hem properly.

back and forth until hem is formed,

as shown in Fig. 46.

5. Draw end of hem back under needle,

lower presser bar and start to sew.

45

Fig 46. Mutking Hem Up to Inch Wide

With Adjustable Hemmer

Page 47

The two upright guide pins, shown in

Fig. 47 eliminate manual guiding of

the binding.

This multi-slotted binder will apply

unfolded bias binding iS/fg inch in

width and commercial folded binding

in sizes 1, 2, 3, 4 and 5 to seams or to

edges of garments. These sizes of folded

binding are M, We and ]4 inch in

width, respectively, and are fed through

slots of corresponding sizes in the binder

scroll. See Fig. 47. Binding may be

purchased in a variety of materials and

colors.

For convenience in determining the

correct width of unfolded binding

(iWe inch), this measurement is marked

The wide range of bindings that can be

applied with this binder makes it useful

for a large variety of work. It will be

ADJUSTING

LUG

SCROLL FOR

OUTSIDE

t/,"

SLOTS FOR ^16

DIFFERENT

WIDTHS OF ^8

FOLDED Vie'

BINDING

CENTER SLOT

OF SCROLL

EDGE GUIDE

FOR PIPING

ONLY

UNFOLDED

BINDING

on the binder, as shown in Fig. 47.

f/g. 47. Mulpi-Slotfed Binder 160359

46

Page 48

found particularly advantageous for

making children’s wear, lingerie, sum

mer dresses, and other dainty articles

which call for narrower bindings.

As two different widths of binding of

contrasting colors can be fed through

binder at same time, attractive binding

and piping effects can be produced in

one operation.

Folded bias binding

must be inserted in the

slot or slots of corre

sponding sizes. See

Fig. 51.

Unfolded or raw edge

bias binding must be

inserted in the open

end of the scroll. See

Fig. 49 .

To Attach the Binder

Raise needle to its highest position.

Then attach binder to presser bar in

place of presser foot.

See that needle enters center of needle

hole.

To Insert Binding In Binder

Cut all binding to a long point to the

left, as shown in 48.

After inserting pointed

end of binding in bind

er, push it through until full width of

binding is under needle.

Guide binding by means of two upright

pins, as shown in Figs. 49 to 53.

To Insert Garment in Binder

Place edge to be bound as far to right as

it will go in center slot of scroll C2, as

shown in Fig. 4 9, and draw it back

under binder foot.

Fig. 48

47

Page 49

Lower binder by means of presser foot

to the right by means of lug B2 * Fig. 49.

lifter, and start to sew. Keep material

Fig. 49. Binding with Unfolded Binding

well within center slot of scroll so that

This is the usual adjustment when

binding straight edges.

When binding curves, move scroll to

left to bring inner edge of binding

farther from stitching and allow for

sweep of curve.

Piped Edge

To produce a piped edge on garments,

move lug B2, Fig. 50 to left to bring

edge will be caught in binding.

To Adjust the Binder

To bring inner edge of binding closer to

the stitching, move scroll C2, Fig. 49

Fig. 50. Position of Garment and Binding

When Piping Edges

48

Page 50

stitching about midway of folded

time. That is, if No. 1 is used, wider

binding.

Crease raw edges of garment toward

wrong side about H inch, and insert

folded edge, raw edges uppermost, into

edge guide on binder, and beneath

binding.

When stitched, both sides of garment

will be finished, and right side will

show piped edge.

Piping and Binding in One Operation

A garment can be piped and bound in

one operation, as shown in Fig. 51.

binding should not be smaller than No.

3. If No. 2 is used, wider binding

should not be less than No. 4. Never

use Nos. 1 and 2, or 2 and 3, etc.,

together.

Use the upright guide pins to guide the

wider of the two widths of binding, as

shown in Fig. 51.

IMPORTANT: When piping and

binding at same time, as shown in Fig.

51, insert narrow width of binding

first in its slot, then insert wider

width in its slot. Two consecutive

widths should not be used at same

49

Fig, 51. Piping and Finding in One Operation

Page 51

To Bind Outside Curves

If stitching does not catch edge of bind

Allow edge to be bound to pass freely

through scroll without crowding against

scroll wall. The material must be guided

from back of binder and to left, permit

ting unfinished edges to swing naturally

into scroll of binder.

Never pull binding while it is being fed

through binder, as this may stretch

binding, making it too narrow to stitch

or to turn in the edges.

When binding curves, turn material

only as fast as machine sews.

ing, adjust scroll slightly to the left.

To Bind Inside Curves

When binding an inside curve, straighten

out edge of material while feeding it

into binder, being careful not to stretch

material.

Do not push material in too fast as this

will pucker edge.

Do not stretch material as this will dis

tort edge so that curve will not have

proper shape when finished.

Fig. 52. Binding an Outside Curve

50

Page 52

Soft materials, like batiste or crepe de

For guidance in applying, rows of

chine, require a row of stitching added

close to edge of curve before binding.

To Apply French Folds to Curves

Place material under binder and stitch

binding onto face of material, as shown

in Fig. 53.

French folds, mark material with a line

of basting stitches or with chalk or

pencil.

This useful attachment is fastened to

machine in place of presser foot, and

will be found an

indispensable aid

whenever stitch

ing must be kept

accurately on ex

treme edge of a

Fig, 53. Applying a French Fold

piece of material.

The slots, num

■ ^4

bered from 1 to 5

Fig. 54

The Edge-Stitcher

51

Page 53

in Fig. 54, serve as guides for sewing

To Sew Lace Together

together laces, insertions and embroid

eries, sewing in position hemmed or

folded edges, piping or sewing flat

braid to a garment.

To Adjust the Edge-Stitcher

Fasten this attachment to presser bar in

place of presser foot.

Turn hand wheel slowly by hand to see

that needle goes through center of

needle hole.

The distance from line of stitching to

1. Insert one of the laces in slot 1 of

edge-stitcher and the other in slot

4, Fig. 54.

edge of material in slots is regulated by

moving lug D2, Fig. 54 to right or left.

If lug moves with difficulty, place a drop

of oil under blue spring, then wipe it

dry.

Fig. 55. Sewing Lace Together

52

Page 54

2. Adjust lug D2 until edges to be

2. Insert lace or ribbon in slot 4 of

joined are caught by the stitching.

3. Slightly overlap edges of lace while

stitching to keep them against ends

of slots.

4. Loosen both thread tensions to avoid

puckering of fine lace.

To Insert Lace or Ribbon

1. Fold edge of material to which lace

or ribbon is to be sewn and insert it

in slot 1, Fig. 54 of edge-stitcher.

edge-stitcher and proceed to sew.

3. Cut away surplus folded material

close to stitching.

To Pipe with Edge-Stitcher

1. Cut piping bias and twice width of

slot 3 so that it can be folded once.

2. Insert piping

with its

folded edge

to left in slot

3 and edge

to be piped

in slot 4,

Fig. 56. Setting in Lace Insertion

Fig. 54.

Fig. 57. Piping with

Edge-Stitcher

53

Page 55

To Apply Folded Bias Tape

To Stitch a Wide Hem

or Military Braid

1. Place garment under edge-stitcher

and tape in slot 1 or 4, Fig. 54.

2. To make square corners, sew to turn

ing point, remove tape from attach

ment, form corner by hand, replace

tape and continue stitching. See

Fig. 58.

3. To space two or more parallel rows,

mark material with a guide line,

using a crease, chalk or basting

thread.

1. A wide hem may be stitched evenly

on sheets, pillow slips, etc., with

edge-stitcher after hem has been

measured and edge turned.

2. Insert edge in slot 5, Fig. 54, and

adjust lug D2 to stitch as close to

edge as desired.

Fig. 59. Making a Wide Hem

Fig. 58. Applying Bias Folded Tape

54

Page 56

To Make a French Seam

To Tuck with Edge-Stitcher

1. To make a French seam of uniform

width, insert two edges to be joined,

wrong sides together, in slot 1 or 2,

Fig. 54, and stitch close to edge.

2. Fold both right sides together and in

sert back of seam in slot 1, as shown

in Fig. 60, and stitch, allowing just

enough margin to conceal raw edges.

The maximum width of tuck that can

be made with edge-stitcher is ^ inch.

1. Fold and crease material for desired

width of tuck.

Fig. 60. Making a French Seam

(Second Operation^

Fig. 61. Tucking with Edge-Stitcher

55

Page 57

2. For succeeding tucks, fold material

3. The fullness of shirring or amount of

the desired distance from previous

tuck, running the fold lengthwise

over a straight edge, then crease

folds.

3. Insert creased folds in slot 1, Fig. 54

and adjust edge-stitcher to right or

left for the desired width of tuck.

Use a light tension, short stitch and

fine thread and needle.

To Shirr with Gathering Foot

gathering is regulated by length of

stitch. A longer stitch increases full

ness of gathers.

1. Fasten gathering foot to presser bar

in place of presser foot.

2. Place material under gathering foot

and stitch in usual way.

Fig. 62. Shirring with Gathering Foot

56

Page 58

oil. Insert scrap of material in Rufiler

and operate attachment until no oil

appears on work.

Principal Parts

-V

^€/''-S" ,;-''v-.^» .^- \rM

Fig. 63. Principal Parts of Kuffler

Lubrication

At the beginning of each working day

lubricate Ruffler to insure smooth opera

A—Foot—attaches rufiler

to presser

bar.

B—Fork Arm—straddles needle clamp.

C—Adjusting Screw—regulates full

ness of gathers.

D—Projection—engages slots in ad

justing lever.

E—Adjusting Lever—sets rufiler to

gather or pleat once every 6 stitches

or once every 12 stitches or not at

all, as desired.

F—Adjusting Finger—regulates width

or size of pleats.

G—Separator Guide—edge of ma

terial placed in slots to keep head

ing of rufile even. Separates ruffling

material from material to which

tion and to prevent jamming, rust and

wear.

Apply one drop of oil at each point

indicated in Fig. 63. Wipe off excess

57

ruffle is being attached.

H—Ruffling Blade—pushes material;

forms pleats and pushes material

toward needle.

Page 59

J—Separator Blade—prevents ruffling

blade teeth from damaging material

or feed.

MATERIAL

1. Raise needle to its highest point.

2. Loosen presser foot thumb screw and

attach ruffler to presser bar in place

of presser foot, at same time placing

fork arm B astride needle clamp.

3- See that needle enters center of needle

hole in ruffler.

To Adjust Ruffler for Gathering

1. Swing adjusting finger F away from

needle.

2. Raise adjusting lever E and move it

until projection D can be entered in

Fig, 64. Correct Position for Material

to he Pjijfled

3. Insert material to be ruffled between

two blue blades Line 2, Fig. 64.

slot marked “1”.

Fig. 65. Gathering with Ruffler

58

Page 60

4. Draw material slightly back of nee

2, Place material to which ruffle is to

dle, lower presser bar and start to

sew.

5. For fine gathering, turn adjusting

screw C upward and shorten stitch.

6. For full gathering, turn adjusting

screw C downward and lengthen

stitch.

To Make a Ruffle and Sew It to a Garment In One Operation

1. Insert material to be ruffled between

two blue blades Line 2, Fig. 66.

be attached under separator blade

Line 1, Fig. 66.

3. Proceed same as for plain gathering.

To Make a Ruffle and Attach It With a Facing in One Operation

1. Insert material to be ruffled between

two blue blades Line 2, Fig. 68.

Fig. 66. Correct Positions for Materials

RUFFLING

MATERIAL^ 2

GARMENT-^

Fig. 67. Making a Ruffle and

Attaching It In One Operation

59

Page 61

2. Place material to which ruffle is to

be attached under separator blade

Line 1, Fig. 68.

3. Place facing material over upper blue

blade Line 4, Fig* 68.

Fig. 68. Correct Positions for lAaterials

4. It facing is to be on right side of .gar

ment, place wrong sides of garment

and ruffle together.

5. If facing is to be on wrong side, place

right sides of garment and ruffle

together.

To Pipe a Ruffle

1. Insert material to be ruffled between

two blue blades Line 3, Fig. 70.

60

Fig. 69. Making a Ruffle and Attaching

It With a Facing In One Operation

This material must not exceed 1 \i

inches in width.

IQI GARMENT;,^

RUFFLING ^

MATERIAL

Fig. 70, Correct Positions for Materials

Page 62

2. Piping material is usually cut on the

and insert it in rufiler, following

bias and it should be about 3^ inch

wide when folded in center. Place

piping material in rufiler, following

Line 5, Fig. 70 with folded edge of

piping to the right.

3. Fold edge of material to which pip

ing and ruffling are to be attached

Line 6, Fig. 70.

To Adjust Ruffler for Pleating

1. Raise adjusting lever E and move it

until projection D can be entered in

slot marked “6”. The rufiler will

then pleat once every six stitches. To

pleat once every 12 stitches, have

projection D enter slot “12” in ad

justing lever E.

2. Insert material to be pleated between

two blue blades Line 2, Fig. 72.

Fig. 71, Piping a

MATERIAL

Fig. 72. Correct Position for Material

61

Page 63

3. To increase width of pleat, move ad

To Adjust Ruffler for Group Pleating

justing finger F back toward needle

and turn adjusting screw C down

ward. To make a smaller pleat, turn

adjusting screw C upward. The dis

tance between pleats is regulated by

length of stitch.

To make the space between groups of

pleats, raise adjusting lever E and

move it Until projection D can be

entered in small slot indicated by

star on adjusting lever E. The rufiler

will then stop pleating and plain

stitching will be made.

Fig. 73. Pleating with the Kuffler

Fig. 74. Group Pleating with Kuffler

62

Page 64

^r^RUFFUNG^

ArtATERJAr

Fig. 75. Correct Position for Material

1. When the desired space is made, set

projection D in either of slots 6 or 12.

3. Insert material to be Seated between

two blue blades Line 2, Fig. 75.

The following FASHION* Aids are available for sepa

rate purchase at your SINGER SEWING CENTER.

63

Page 65

Automatic Zigzagger

ziizag mmv

Blind

Stitch

Key

Domino

Arrotv

Head

Zigzag stitching, decorative pattern n .

stitching, applique—all of these and

more may be done automatically on your

SINGER with the Automatic .. ..

Attachment. V V V \/

You can blindstitch hems, mend rips

and tears, reinforce seams, overedge n

seam edges and stitch scallop facing of Troy

easily and quickly.

W/ÌA

/

i wvw 5"

J

Block

/

/ Curved

/

blending

Open

Scall op

Merely insert one of the many Stitch c i j

Patterns into the Automatic Zigzagger T T 7 r r T ^ ^

and sew.

Scallop

64

Page 66

65

Girls Dress with

Border Design in Domino Pattern

Page 67

The Buttonholer

Beautiful, evenly stitched buttonholes

may be made on your SINGER Machine

with the Buttonholer, as easily as you

do straight stitching.

Merely slip the template, for the size

buttonhole you require, into the attach

ment and replace the presser foot with

the Buttonholer. Every buttonhole will

be identical. The Buttonholer does the

work for you—'Straight buttonholes in

seven lengths: S/ie"?

and keyhole, in two lengths:

and iVie^

66

Page 68

Samples of Work Produced by SINGEK Buttonholer

67

Page 69

Darning and Embroidery Attachment

The Web Lace Stitch

The Darning and Embroidery Attach

ment contributes to the ease with which

free-motion sewing is accomplished.

Lovely embroidered effects are possible

on a wide range of fabrics.

The foot merely holds the fabric down

while the stitch is being formed and re

leases the fabric when the needle has

risen to allow free movement of the

work for variety of embroidery effects.

68

Page 70

The Tracing Stitch

The Darning Stitch

69

Page 71

Seam Guide

The Seam Guide is helpful in stitching

seams an exact width, and for stitching

a uniform distance from a finished edge.

Especially helpful for those just learn

ing to sew and an aid to those demand

ing greater uniformity in seam width

than the eye might give, the seam guide

is a useful addition to your sewing

equipment.

The scoring on the throat plate of your

The Seam Guide-

SINGER Machine makes it easy for you

to set the Seam Guide to an exact dis

tance from the needle.

70

Page 72

Gauge Presser Foot

multiple rows of stitching may be

gauged evenly along lapel and facing

edges, welt seams, or hems.

An accurate set of gauges (lined at W'

and numbered at intervals)—one for

use at the left of needle and three for use

at right of the needle, accompany the

The Gauge Presser Foot

Gauge Presser Foot.

Expert and beautiful stitching is accom

plished with a minimum of skill and

preparation through the use of the

SINGER Gauge Presser Foot. Single or

The side walls of the gauges vary in

depth to accommodate fabrics and con

structions of different thickness. Smart,

even stitching accents are effectively

placed with the Gauge Presser Foot.

71

Page 73

INDEX

Радо

Attachments................................................. 40

Adjustable hemmer.....................................45

Edge-stitcher.............................................51

Foot hemmer............................................ 41

Gathering foot

Multi-slotted binder

Ruffler

Basting

Cleaning stitch forming mechanism

Darning and Embroidering.............

Electrical information

Fashion Aids. .

Buttonholer............................................66, 67

Gauge Presser Foot.....................................71

Seam Guide.............................................. 70

Zigzagger, Automatic................................64, 65

Light. . ......................................................

Lubricating the motor...................................37, 38

Machine working heavily

Motor. ......................................................

Needle chart.................................................. 9

Needles and thread

Oiling the machine

Operating the machine

Preparing to sew............................................16

.....................................................57

.......................................................

Darning and Embroidery Attachment. . . .68, 69

...........................................

...................................

...................

.........

......................................

...

.........................................

...............................

. .

....................................

....................................

....................................

30, 31, 32

56

46

19

.38

5

63

6, 7

29, 36

5

8

33-36

10

Page

Principal parts of Machine 201-2..

Reassembling and replacing needle thread

tension............................................... 26,27

Regulating bobbin thread tension

Regulating direction of feed

Regulating needle thread tension

Regulating pressure on presser foot. .......20, 21

Regulating stitch length...................................18

Removing and disiissembling needle thread

tension................................................... 26

Removing the bobbin

Removing the bobbin case

Removing the work

Replacing the bobbin.................................... .15

Replacing the bobbin case.

Setting the needle

Sewing bias seams.

Sewing suggestions

SINGER Service

Starting to sew..............................................17

Threading the bobbin

Thread tension

Turning a corner

Upper threading........................................... 11

Winding the bobbin

..............................................

....................................

........................................

..........................................

.....................................

....................................

..........................................

.....................................

............................................

...............................

..............................

...............................38

....

.......................

...................

...................

...................... . .39

24, 25

19

22, 23

12

18

8

. .19

28, 29

3

.15

22

19

12, 13, 14

4

72

Page 74

Page 75

TO ALL WHOM IT MAY CONCERN

The improper placing or renewal of the Trademark “SINGER” or

any other of the Trademarks of The Singer Company (all of which are

duly Registered Trademarks) on any machine that has been repaired,

rebuilt, reconditioned, or altered in any way whatsoever outside a

SINGER factory or an authorized SINGER agency is forbidden.

Form 20340

(Rev. (364)

Printed in U. S. A.

Page 76

For your protection

SINGER Sewing Machines are sold and serviced wherever you

see the famous SINGER and Red “S” Trademarks. When your

machine needs servicing call your SINGER SEWING CENTER to be

sure of warranted SINGER parts and service. See address in the

classified telephone directory.

s f

•' -V‘

Loading...

Loading...