Instructions For Using

SPARTAN* SEWING MACHINE 192

Needles and Thread—

Use needles 15 x 1, in sizes 11, 14, 16 and 18.

You will obtain the best stitching results from

your sewing machine if it is fitted with a

SINGER needle.

Thread should be selected according to the

fabric to be stitched. Needle must be of correct

size for thread to pass freely through eye

of needle.

To Set the Needle—

Raise needle bar to its highest position.

Loosen needle clamp thumb screw and

insert needle (flat side to the right) up into

needle clamp as far as it will go.

Tighten needle clamp screw.

Fig. 1. To Set the Needle

To Thread the Needle—

Raise take up lever 5 to highest point.

Place spool of thread on spool pin.

Lead thread into thread guide 1,

—Uown ?nd from ricrht !<^ft lv»fwee*i

♦ * ^ - <p^

tension discs 2.

—Into loop of thread take-up spring 3

—Under slack thread regulator 4 (not

through eye in thread regulator)

Fig. 2. Upper Threading

—Up and from right to left through hole

in take-up lever 5

—Down through guide 6 on face plate

—Down through lower wire guide 7.

Thread from left to right through eye of

needle 8.

Draw about two inches of thread through

eye of needle with which to begin sewing.

To Remove The Bobbin—

Raise needle to its highest point.

Open slide plate.

Press bobbin ejector J and lift

out bobbin.

Fig. 3. Removing the Bobbin

THE*SII^ER MANUFACTURING COMPANY

*A Trademark of THE SINGER MANUFACTURING COMPANY Printed in Great Britain.-^

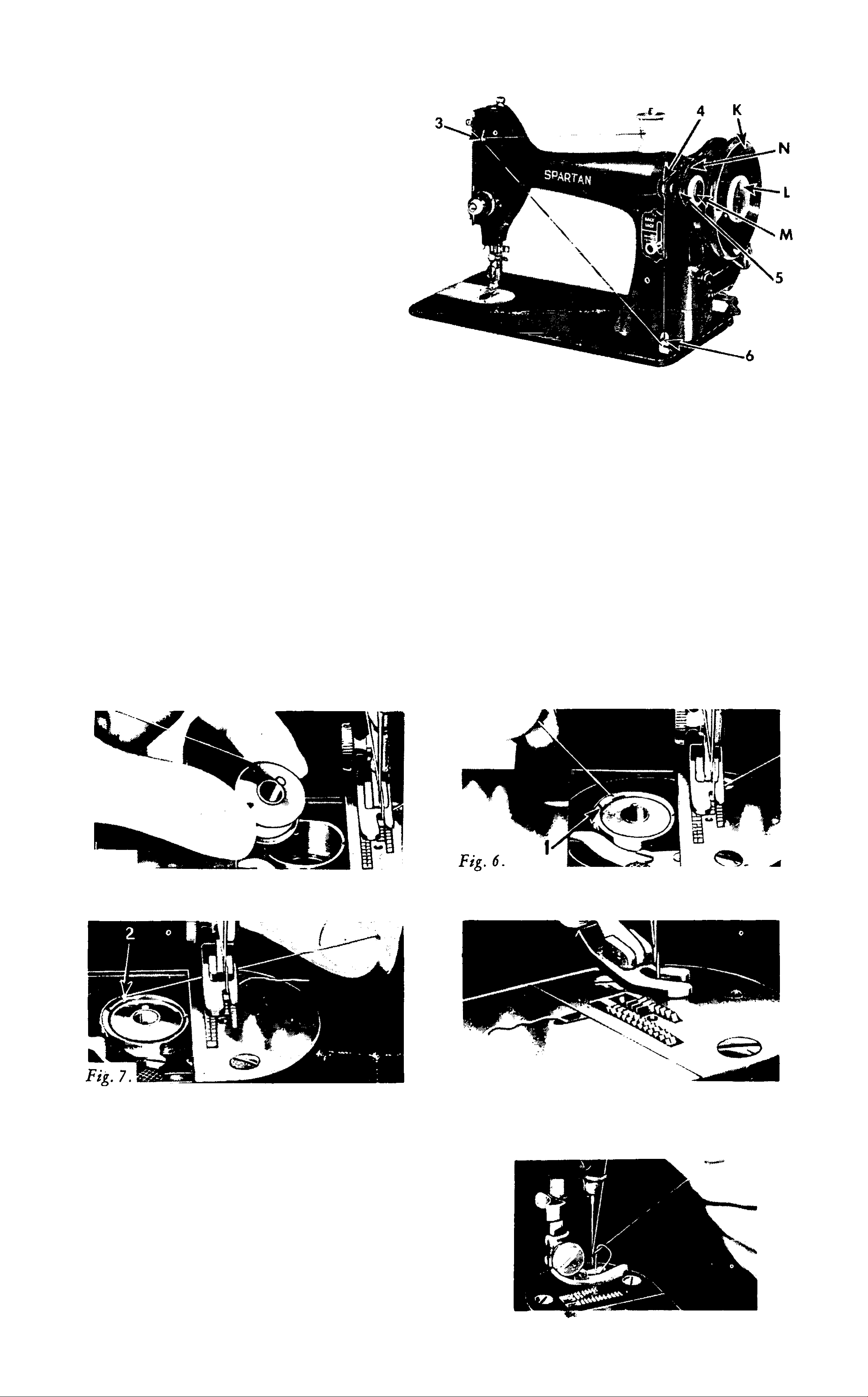

Tc Wind the Bobbin—

Hold hand wheel K with left

hand, and with right hand,

loosen stop motion screw L.

Place bobbin 4 on spindle.

Press bobbin winder 5 down

against hand wheel.

Place spool of thread on

spool pin.

Lead thread through guide 3

on arm of machine.

Pass thread through lower

notch of guide 6 from front

to back and through upper

notch from back to front.

Lead thread from right to

Fig. 4. Winding the Bobbin

left'through hole in left

side of bobbin.

Hold end of thread and start machine. (End of thread will break off

after a few coils have been wound on bobbin.)

When Bobbin is Full—

# Stop machine, lift bobbin winder away from hand wheel and remove

bobbin. Tighten stop motion screw L.

If the Bobbin Does not Wind Evenly—

Loosen screw which holds thread guide 6 to bed and move guide to right

or left as required. Then tighten screw. If pressure of bobbin winder

pulley M against hand wheel is insufficient for winding bobbin, loosen

screw N, press bobbin winder pulley against hand wheel and tighten

screw N.

To Replace the Bobbin and Thread the Bobbin Case—

Fig. 5.

Hold bobbin so that thread leads

off in direction shown.

Place bobbin in case and draw

thread into slot 1.

Fig. 8.

Draw thread between case and

tension spring until it reaches

notch 2.

Pull about 3 inches of thread

across bobbin.

To Prepare for Sewing—

Turn hand wheel over toward

you so that needle enters

throat plate and brings up the

bobbin thread.

Close slide plate, allowing

thread to enter notch in slide

plate.

Fig. 9. Drawing Up the Bobbin Thread

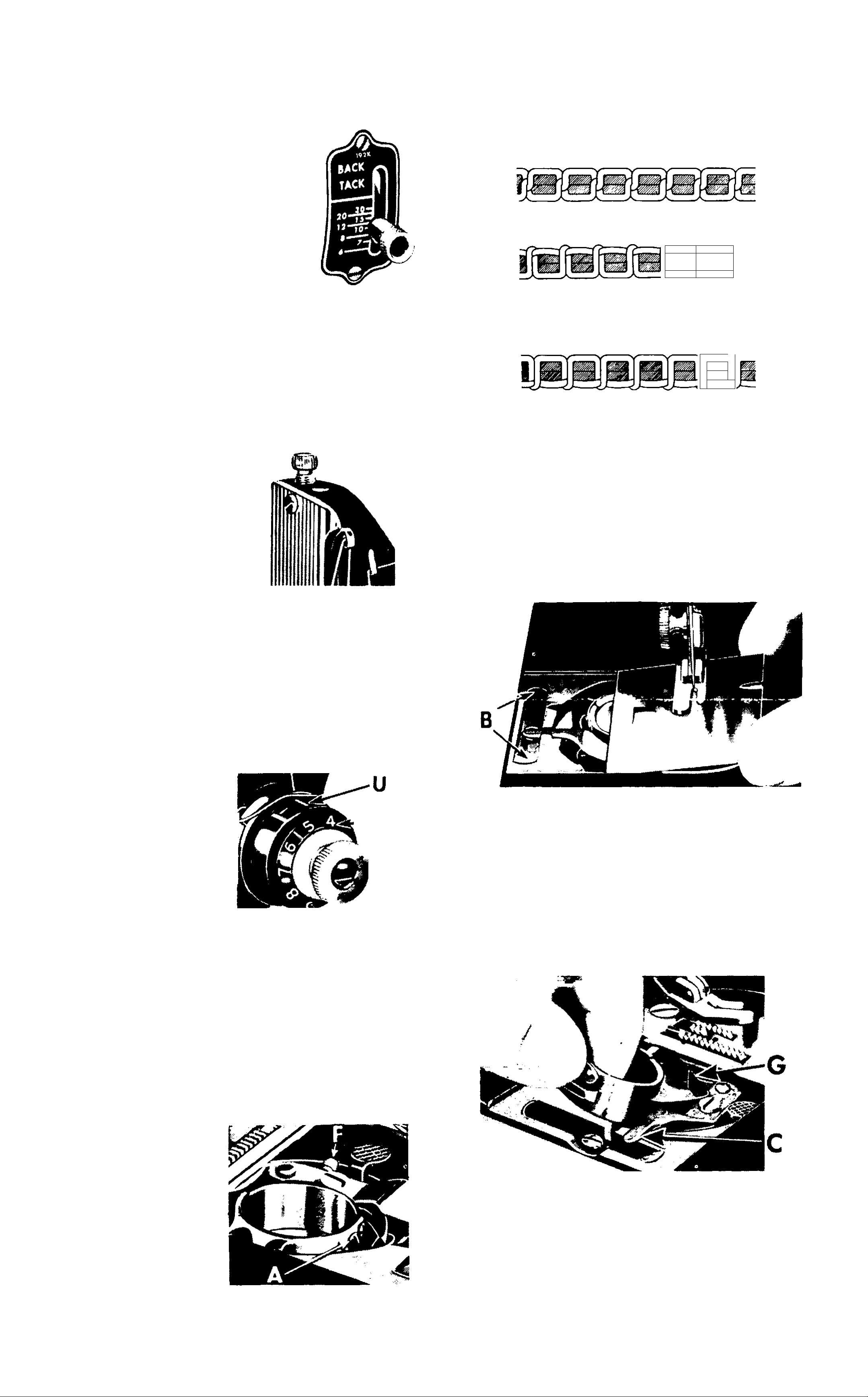

To Regulate Length of Stitch—

A perfectly formed stitch results

Numerals on the indicator

represent approximate

number of stitches per

inch.

• Turn thumb nut to left.

• Set lever at desired

stitch setting,

• Turn thumb nut to

right until it rests

against indicator

plate. F/g. W

To reinforce a seam, raise stitch

indicator lever to its highest posi

when both tensions are balanced so

that the needle and bobbin threads

are drawn equally into the fabric.

Fig. 14. Perfect Sr itching

^ -

"WT^

.

Fig. 15. Iwperject Stitching

Needle thread tension too tight or

Bobbin thread tension too loose.

tion. The machine will then stitch

in a reverse direction, making it

easy to ’*back tack”

To Regulate Pressure on Presser Foot—

• To decrease

pressure, turn

thumb screw

up.

• To increase pres

sure, turn

thumb screw

down.

F;g. II

'Mí

Fig. 16. bnperject Stitching

Bobbin thread tension too tight or

Needle thread tension too loose.

Care and Maintenance of Your

SPARTAN 192

When in regular use the machine

should be cleaned periodically.

To Remove and Replace Bobbin Case—

For ordinary sewing, pressure of

the presser foot on the material

seldom requires changing. Heavy

materials require more pressure

than light materials. Pressure

should be only heavy enough to

move the work along evenly.

To Regulate Needle Thread Tension —

Numerals on in

dicator V, Fig,

12, denote dif- \

__

y

ferent degrees of

Fig. 17. Slide Plate Removed

Raise needle and presser foot.

tension. When

tension has been f^W

correctly set,

note number at

line U so that

this setting may be regained should

the tension be altered for special

work.

• To increase tension, turn thumb

nut W to higher number.

• To decrease tension, turn thumb

nut w to lower number.

To Regulate Bobbin Thread Tension—

Draw slide plate to left.

Remove bobbin from case.

Lift edge of slide plate and draw

it to the right until it is dis

engaged from spring B.

Tension on

bobbin thread

is regulated by

screw A, Fig.

13, nearest cen

ter of tension

spring. Turn

screw A over

to right to in

crease tension;

turn screw to

left to decrease

tension.

Fig. n

Fig. 18. Removing Bobbin Case

Lift and move latch C to position

shown.

Grasp bobbin case as shown.

Tilt case to left and raise forked

end above bracket G.

Turn forked end toward you,

then lift out bobbin case.

Replace bobbin case with its fork straddling bracket G.

Twist case to the left, then gently press down and back until edge of

sewing hook engages groove under rim of bobbin case.

Return latch C to its original position.

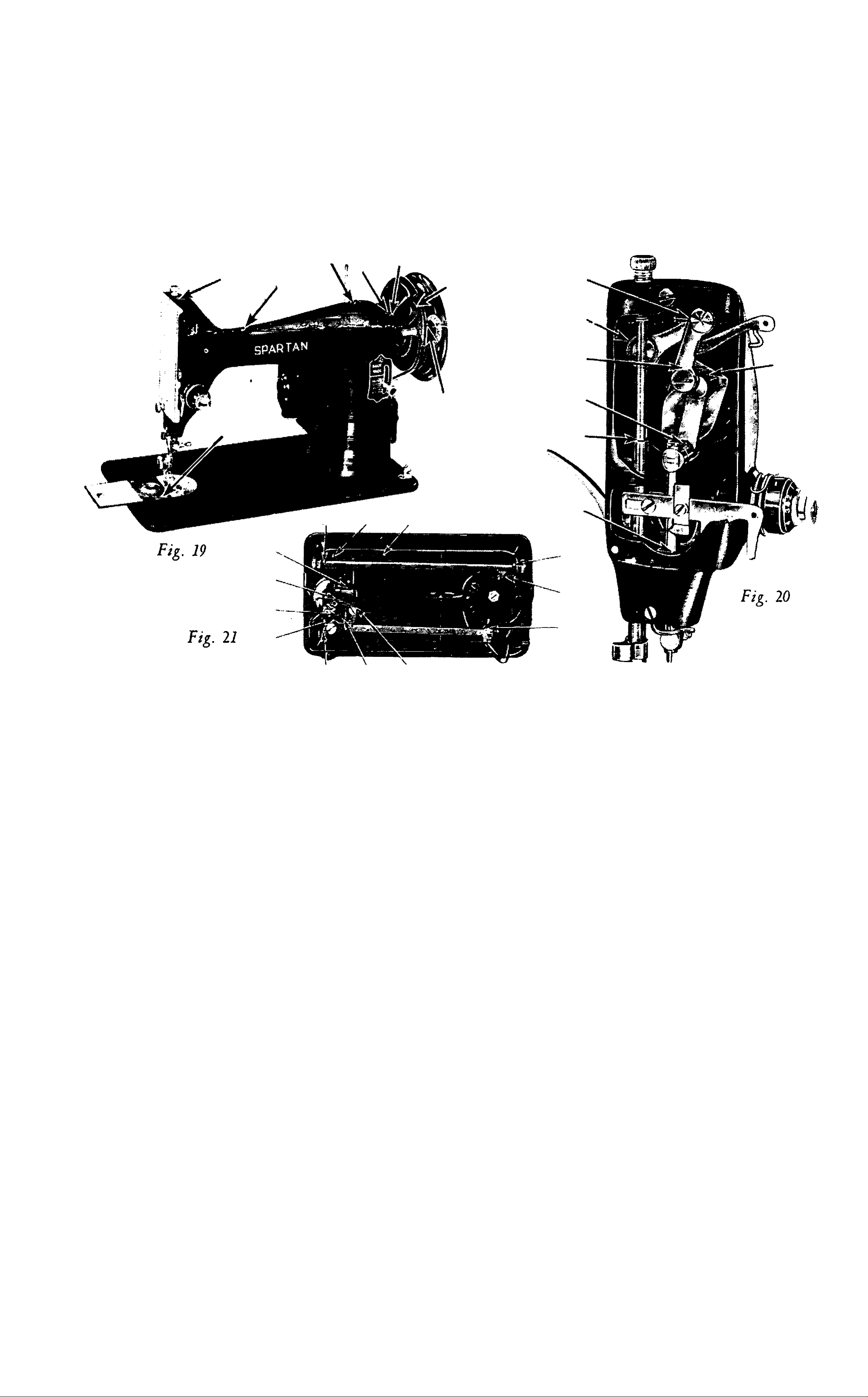

To Oil the Machine—

Apply a drop of oil to each of the places indicated in Figs. 19, 20 and 21.

Apply a few drops of oil to the felt pad F, Fig. 13.

After Cleaning—

- SPARTAN

We guarantee that each SPARTAN sewing machine, obtained

from the Singer Sewing Machine Company or one of its Approved

Dealers, is in good operating condition upon delivery to the original

purchaser.

Within a period of twelve months from original purchase, any part

delivered to a SINGER SEWING CENTER which upon examination

by us proves to have been defective in workmanship or material will

be repaired or replaced without charge.

In addition to the above guarantee of parts, free mechanical service

will be provided for a period of ninety days. Operating and mainten

ance instructions such as described in this Instruction Booklet are

available without charge only at the nearest SINGER SEWING

CENTER.

The original Sales Agreement or Cash Receipt must be presented

with this Certificate to obtain the benefit of the Guarantee.

Agreements outside of or contradictory to the foregoing shall be

void and of no effect,

SINGER SEWING MACHINE COMPANY

*A Trademark of THE SINGER MANUFACTURING CO.

Form K6349

(259)

Loading...

Loading...