Page 1

Instructions

SINGER

Zig-Zag Sewing Machine

Model 177

Page 2

I ?

enjoy carefree sewingi

Congratulations...

You are about to discover the wonderful pleas

ure of sewing with your new SINGER sewing

machine. We know you are eager to get started

on a sewing project... but we urge you to be

come familiar with this book before you begin.

It is designed to help you get the benefit of all

the capabilities of this machine. Especially, we

recommend that you keep the following points

in mind:

/

DO choose the correct needle and thread for

your fabric — if either is the wrong size or type,

you may encounter broken or knotted thread, or

faulty stitching. The Fabric, Thread and Needle

Table on page 9 Wift help you make a perfect

choice. - .

DON’T sew with a bent or blunt needle. If the

needle is damaged — or improperly inserted in

the machine — It can cause skipped stitches.

See page 8 for instructions.

DO folio# the instructions on page 16 for

threading the machine. Note particularly the

directions for threading the tension discs.

Form 21577 (572)

Printed in U.S.A.

Page 3

\ 'SiJiiiSsi

....................

"jiwi'fJ'i.i.;i.ói;À:

''liSliiSÌii.'.

'■liiilifl',

DON’T forget to hold the bobbin properly

when you thread the bobbin case. Page 14 tells

you how to do this correctly.

DO become familiar with the instructions for

regulating stitch length (page 22), presser-foot

iislfe.

mim

'■mM

"■Ri

pressure (page 22), and thread tension (page

24). Take advantage of the capability of your

sewing machine!

DONT allow lint or thread ends to accumu

late in the lower thread area — they can cause

jamming or excessive noise. Clean and lubricate

machine regularly, as instructed on page 52.

DO remember that expert, dependable SINGER

Service is always available. If your sewing ma

chine should require maintenance or repair, be

sure to call your Singer Sewing Center or Au

thorized Singer Dealer. You will find the number

listed under “Singer Company” in your tele

phone book.

Above all, do enjoy sewing!

....

....■■"iSÌ'ìsyyfKiÌii

'¿ ■ i-M

Page 4

*A Trademark of THE SINGER COMPANY

Copyright © 1972 by The Singer Company

Page 5

Contents

Page

1. Getting to Know Your Machine

Principal Parts

Getting Ready to Sew

Preliminary Steps

.................................

..........................................................

......................................................

. 4,5

6

6

Choosing Needle and Thread........................................ 8

Threading the Machine................................................ 10

The Bobbin Thread

..................................................

10

The Needle Thread.................................................. 16

3. Straight Stitching.......................................................... 20

Preparation.................................................................. 20

Starting to Sew

Adjusting Selectors for Your Fabric

Sewing a Seam

............................................................

.............................

...........................................................

20

22

26

4. Zig-Zag Stitching.......................................................... 32

Adjusting Selectors...................................................... 32

Adjusting Needle-Thread Tension

...............................

34

Adjusting Presser-Foot Pressure................................. 34

4

5. Sewing the Professional Way

Construction Details

....................................................

......................................

36

36

Lingerie Seams........................................................ 36

Seams in Knit Fabrics.............................................. 36

Flat-Felled Seams

...................................................

38

Seam Finishes......................................................... 38

Darts........................................................................ 40

Buttonholes

Keeping Up Appearances

.............................................................

...........................................

42

48

Mending................................................................... 48

Blanket Binding........................................................ 50

Darning.................................................................... 50

6. Caring for Your Machine.............................................. 52

Cleaning and Lubricating............................................. 52

Adjusting Motor Belt Tension....................................... 58

Replacing Slide Plate

Removing Machine from Cabinet

7. Fashion* Aids

..............................................................

..................................................

................................

58

60

62

Index.............................................................................. 63

Page 6

^^■ ■ MBilBlllilllli

(ij|||^i||i|(i^i||i|p|i|||j^^

jjj|§j|g^|||||il||g||i|||||i^

lilllttiiiiiiliiiiiiSiiiiJiiSi^^

the right tension for your fabric, stitch, and

thread. The numbers eliminate guesswork

llttiiiiiiiKiiiSSiiiiiiWiSiMiSiSii

15 14 13

Page 7

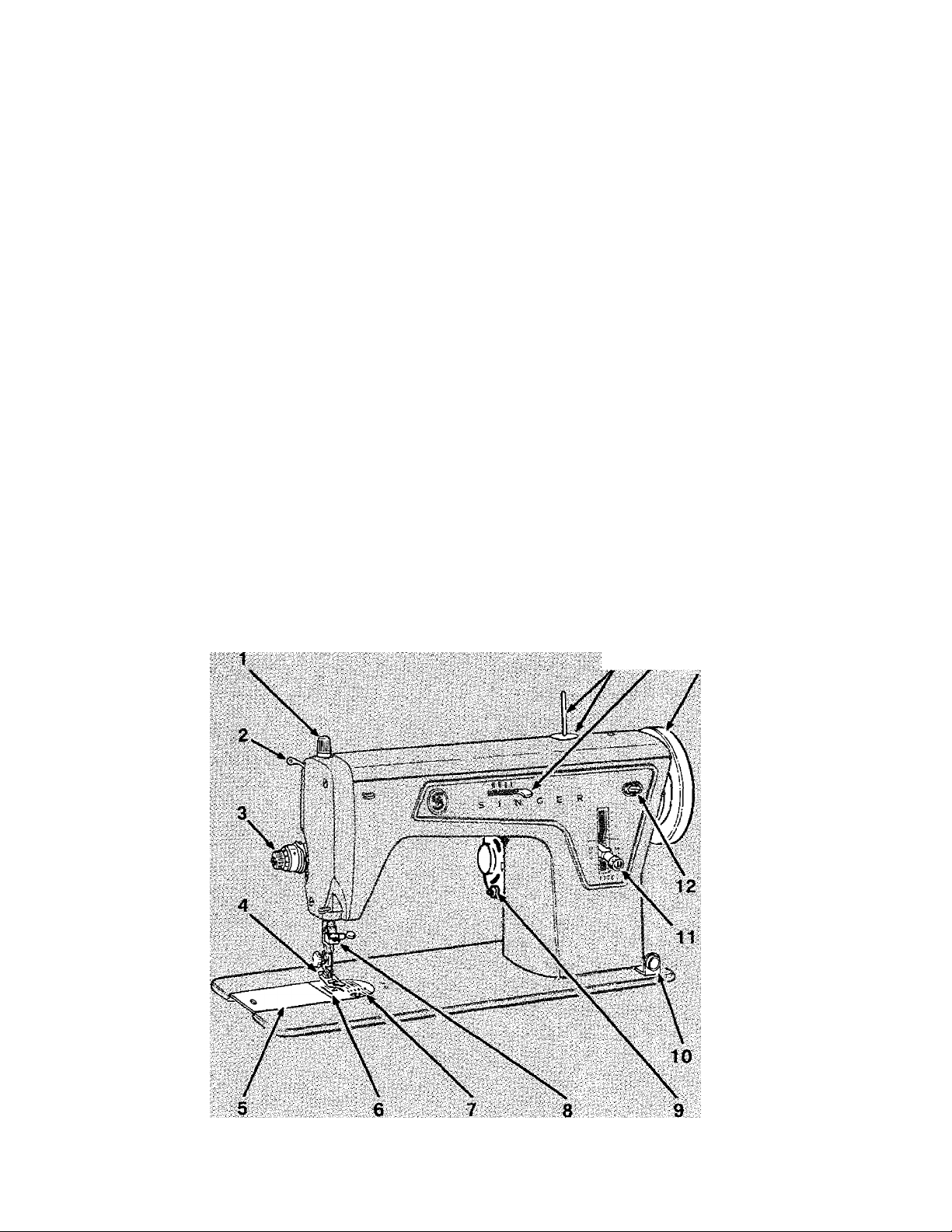

4. Presser Foot holds fabric against feed.

Presser-foot lifter at rear of machine (not

shown] raises and lowers the presser foot.

6. Slide Plate opens easily, provides access

to bobbin case latch for removal and re

placement of the bobbin.

6. Feed moves fabric under the presser foot.

7. Needle Plate provides working surface

around the needle. Guidelines on plate

help you keep seams straight.

8. Needle Clamp holds needle and is designed

to eliminate the possibility of inserting the

needle backwards.

9. Electric Motor supplies power to machine

through a belt to the hand wheel. Motor is

activated by a speed controller.

10. Bobbin-Winder Tension Discs regulate

thread tension for winding bobbins.

11. Stitch Length Selector allows you to

choose from a variety of stitch lengths, in

cluding fine adjustments for close zig-zag

stitching. Raising the lever permits reverse

stitching.

12. Bobbin Winder Spindle lets you wind the

bobbin quickly and easily.

13. Hand Wheel controls movement of take-up

lever and needle. Always turn it toward you.

14. Stitch Width Selector controls the width of

zig-zag stitching and positions the needle

for straight stitching.

15. Spool Pin and Felt. Pin holds thread spools

of various sizes. Felt helps thread unwind

smoothly.

Page 8

2. Getting Ready to Sew

preliminary steps

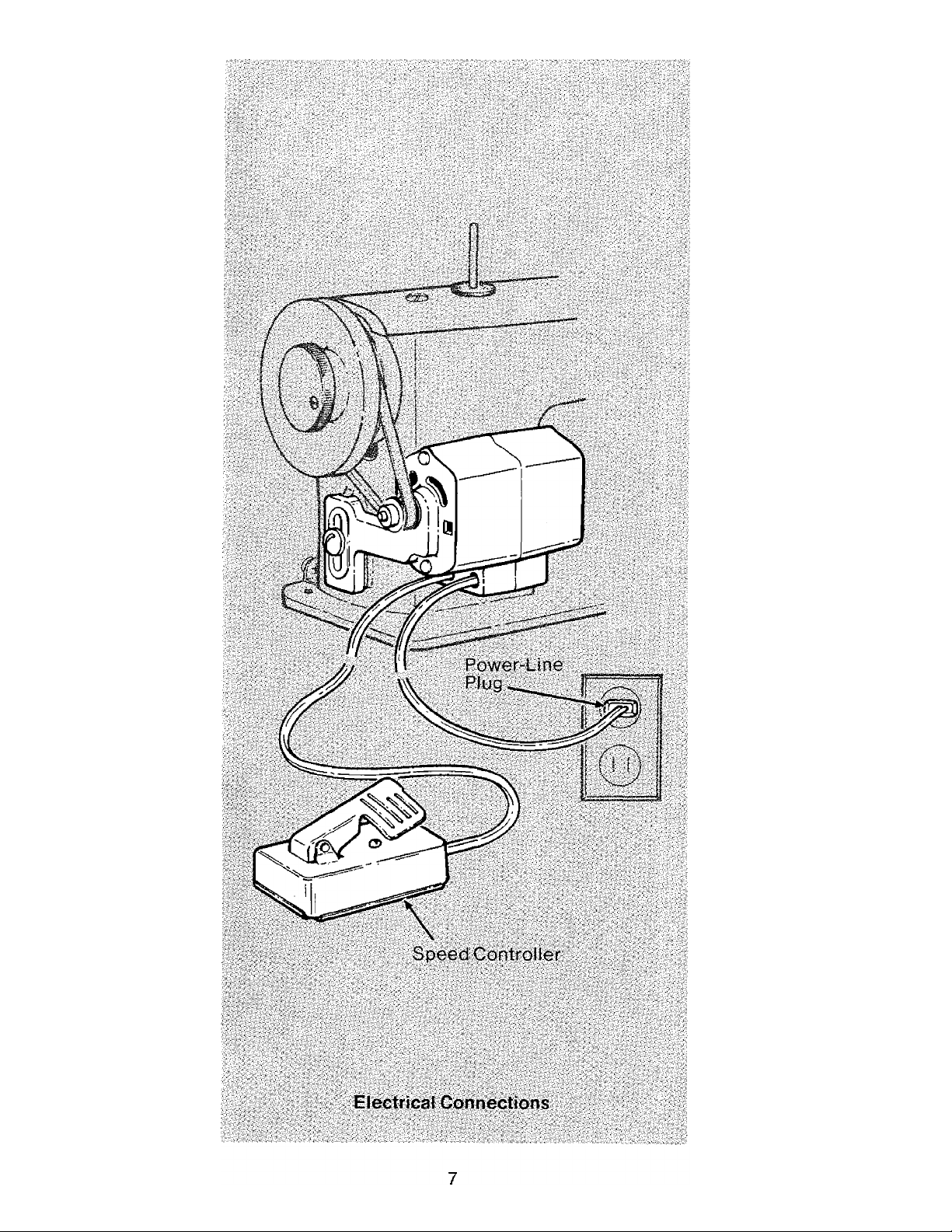

CONNECTING MACHINE

Before plugging in your machine, be sure that

the electrical information on the motor bracket

conforms to your electrical power supply.

To connect the machine, insert the power-line

plug into your electrical outlet.

OPERATING MACHINE AND

CONTROLLER

The speed controller controls the speed of the

machine.

To run the machine, press the speed controller.

The harder you press, the faster the machine

will sew.

CAUTION: IVe recommend that you unplug

your machine from the electrical outlet before

changing needles, removing presser foot or

needle plate and when leaving the machine un

attended. This eliminates the possibility of start

ing the machine by accidentally pressing the

speed controller.

Page 9

Page 10

choosing needle

and thread

The needle and thread you choose will depend

upon the fabric being stitched. The table on the

following page is a practical guide to thread and

needle selection. Refer to it before starting a

sewing project. Be sure to use the same size

thread in both the needle and bobbin.

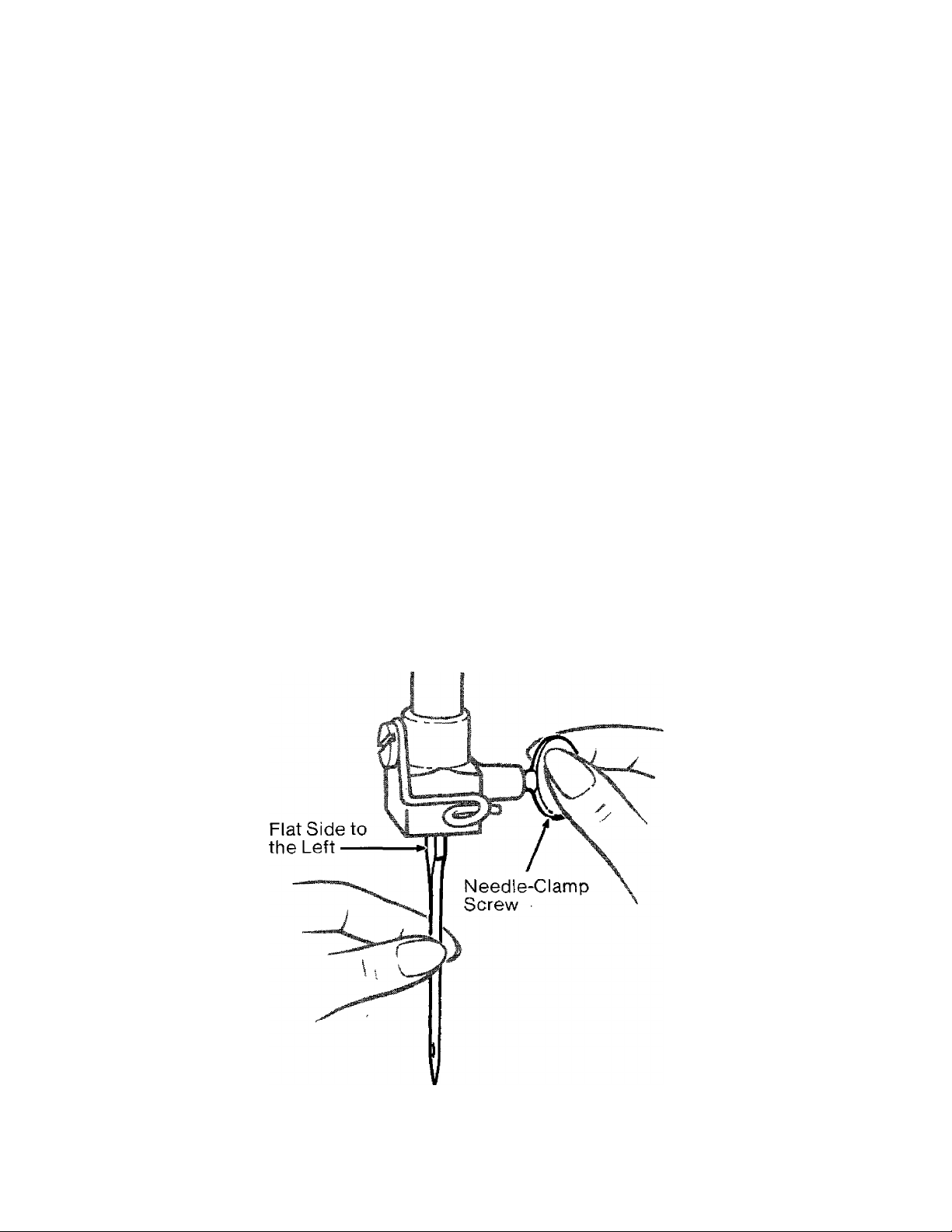

CHANGING THE NEEDLE

The needle clamp has been designed so that

the needle can only be inserted with the flat

side of the shank toward the left.

1. Raise needle bar to its highest position,

loosen needle-clamp screw, and remove

needle.

2. Insert new needle in clamp, with flat side to

the left, and push it up as far as it will go.

3. Tighten needle-clamp screw.

Changing the Needle

8

Page 11

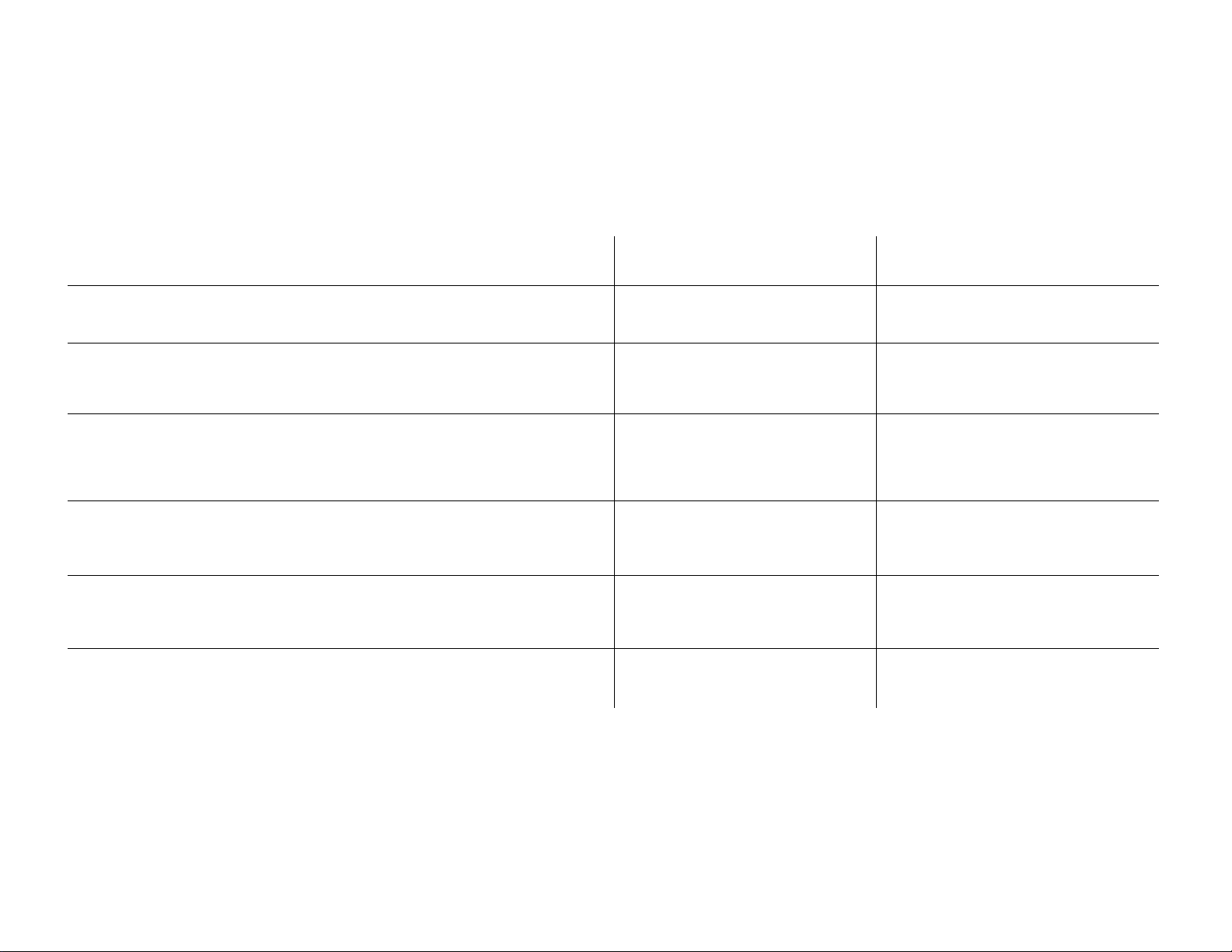

FABRIC, THREAD AND NEEDLE TABLE

..3/' Needles '

liiliiiiSiliilSi

batiste, organdy, jersey, voile, taffeta, crepe, chiffon

<£>

gingham, percale, pique, linen, chintz, faille, satin, fine :

: corduroy, velvet, suitings, knits, deep-pile fabrics, vinyl

gabardine, tweed, sail-cloth, denim, coatings, drapery

fabrics, vinyl, deep-pile fabrics

overcoatings, dungaree, upholstery fabrics, canvas

tUse with 50 mercerized cotton or "A" silk in bobbin.

iiiffiiilSIttilSSiBisliliSifiSW

50 mercerized cotton

iliiiiiliilllliiiiiliM

A. Synthetic thread ;

i; Polyester core/cotton

iiiiliiiiiiiiiliiSiiiiM

mercerized potton

lllif iiilliiiiiiliil

ilMiiiililiiiiiPffiliiiil

2020 . . . 11 ■

(15x1)

Style -

Page 12

threading the machine

THE BOBBIN THREAD

Winding the Bobbin

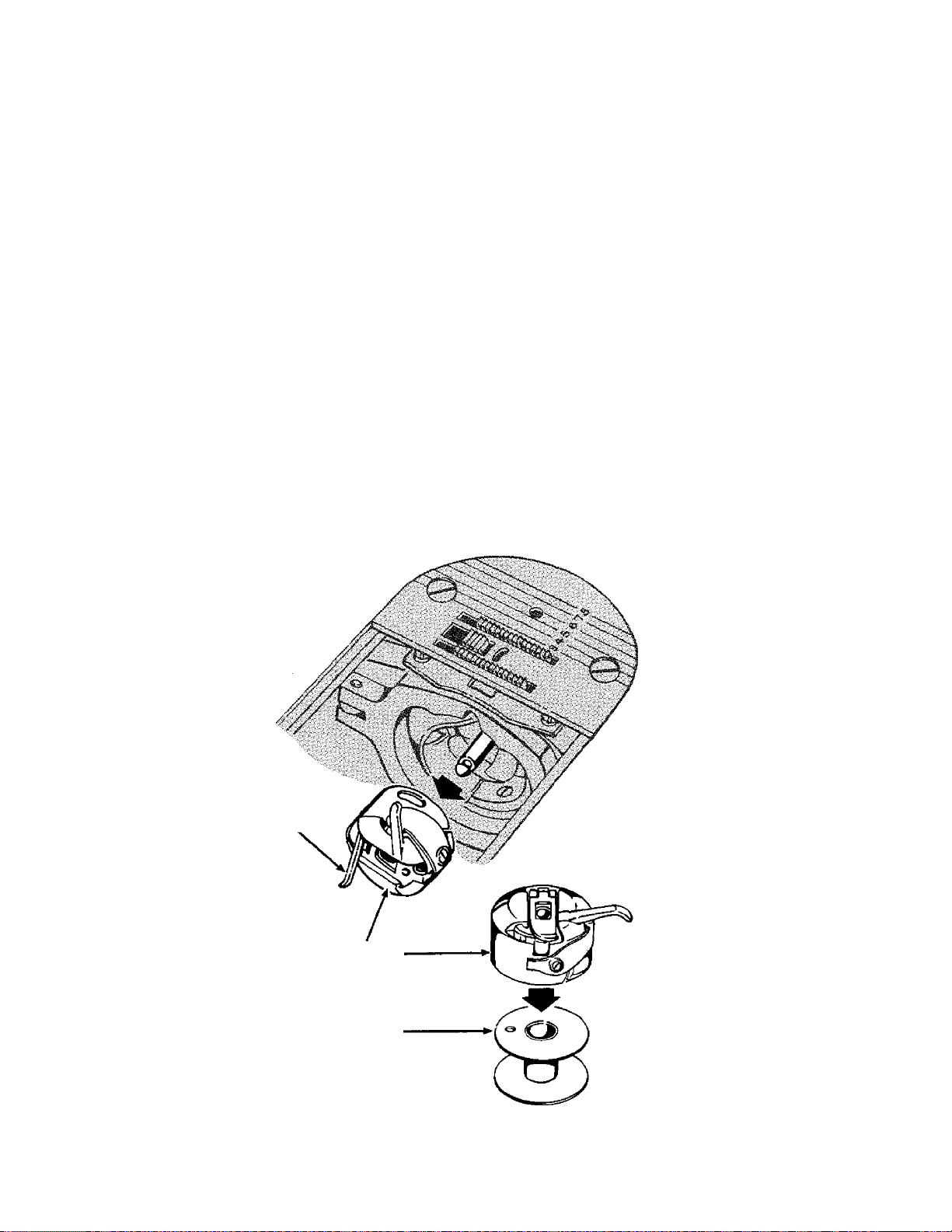

Removing bobbin case

1. Raise the presser foot and turn hand wheel

toward you until needle is at its highest

position.

2. Open the slide plate.

3. Reach down with your left hand and open

the bobbin case latch.

4. Withdraw bobbin case from machine.

5. Release the latch and bobbin will drop from

bobbin case.

Latch

Bobbin

Case

Bobbin

Removing Bobbin Case

10

Page 13

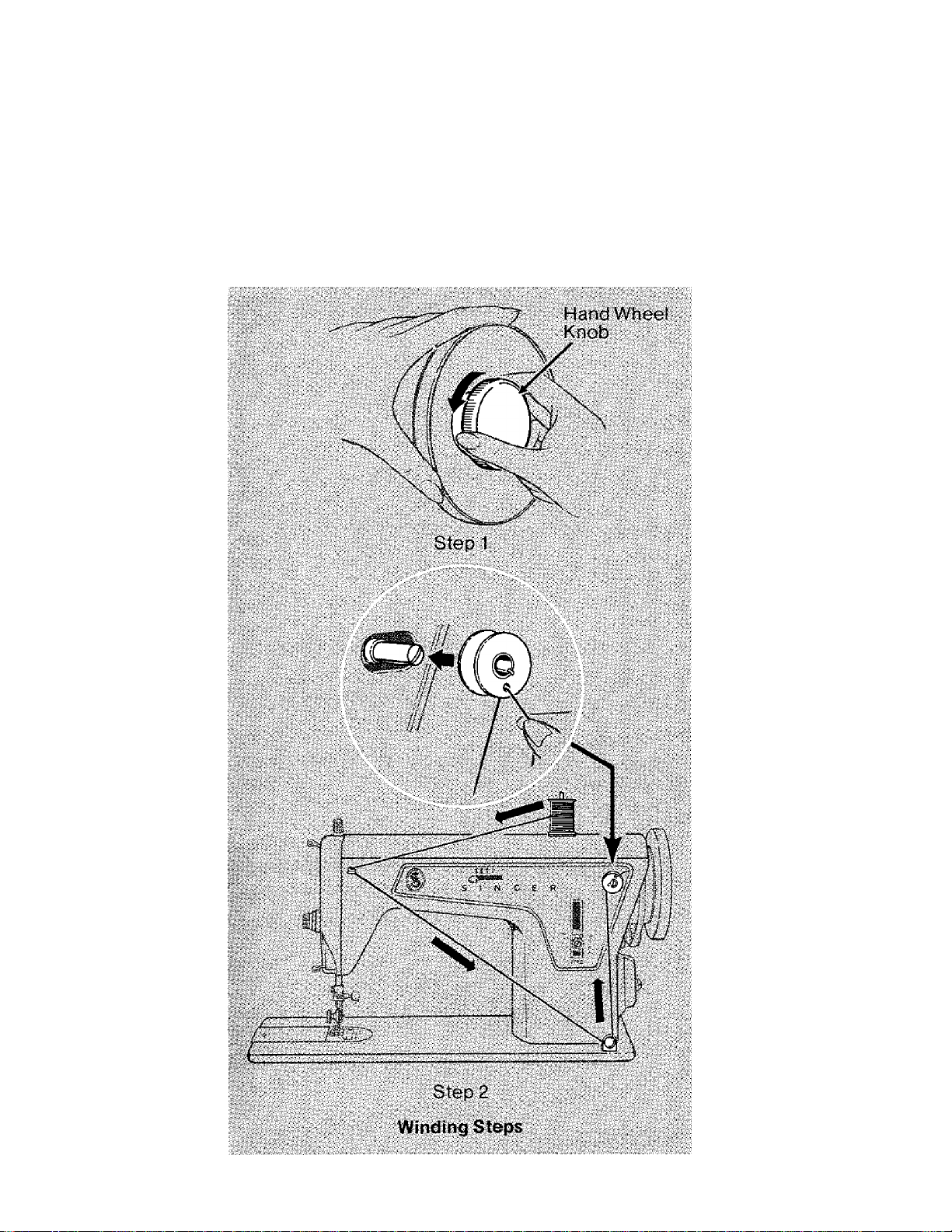

Winding steps

1. Hold hand wheel with left hand and loosen

hand wheel knob by turning it toward you.

2. Place spool of thread on spool pin over the

felt. Pass thread from spool through thread

guide, between bobbin-winder tension discs

and through hole in bobbin {from inside

out).

11

Page 14

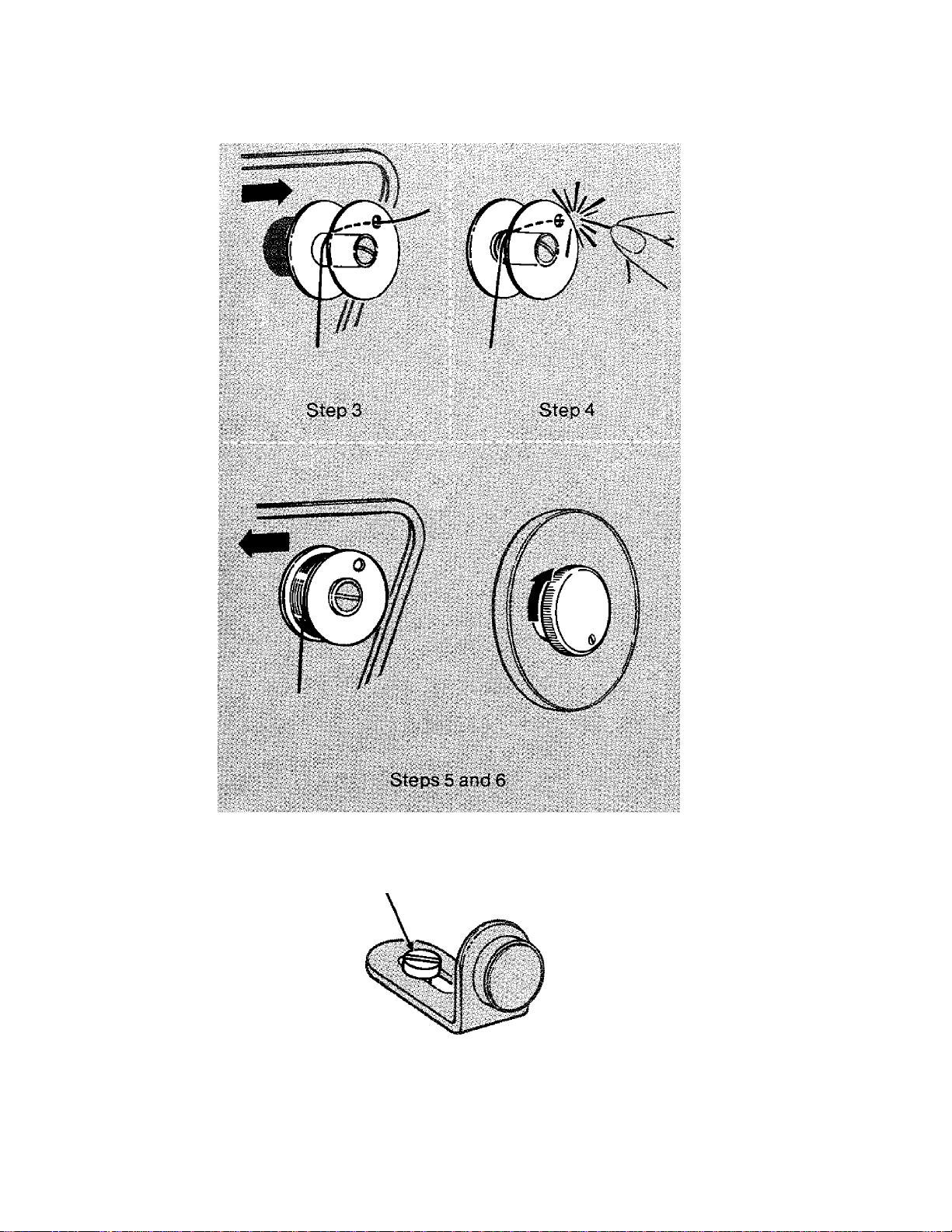

Winding steps (continued)

3. Place bobbin on spindle and slide bobbin

and spindle to the right.

4. Hold thread end and start the machine.

(Thread end will break off after a few coils

have been wound.)

5. When bobbin is slightly less than full, stop

the machine and slide bobbin and spindle

to the left. Cut thread about four inches from

the bobbin and remove bobbin from spindle.

6. Hold the hand wheel from turning and tighten

hand wheel knob.

The bobbin-winding tension has been pre-set

at the factory and should need no adjusting.

However, if adjustment is required, loosen the

screw that holds the bobbin-winder tension

bracket to the machine and slide the bracket

forward if bobbin winds high to the rear; slide

bracket back if bobbin winds high to the front.

12

Page 15

Bracket

Screw

Bobbin-Winding Tension Discs

13

Page 16

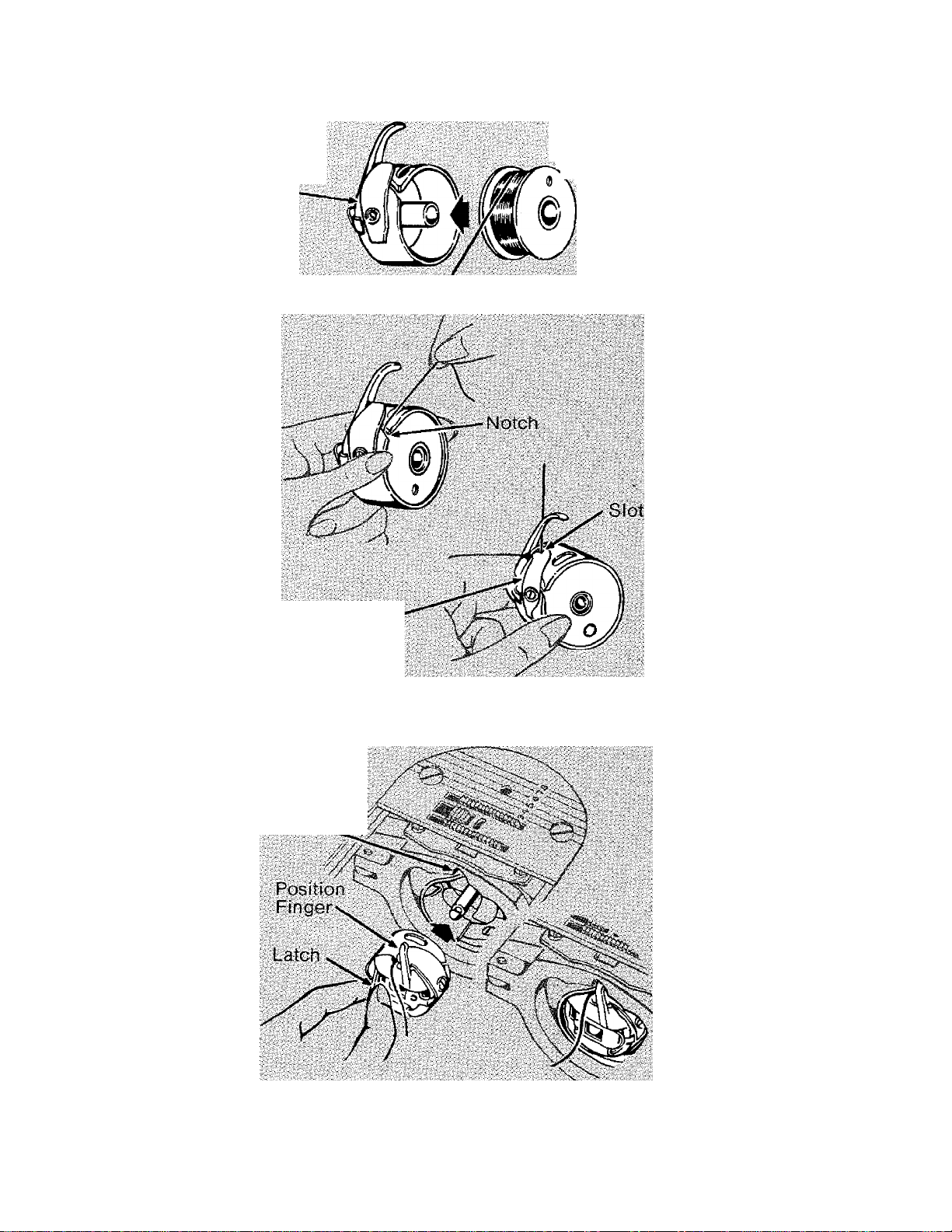

Threading bobbin case

1. Hold the bobbin so that the thread will

unwind in the direction shown.

2. Place bobbin into the bobbin case.

3. Pull thread into notch, under the tension

spring and into the slot at the end of the

tension spring. Allow about three or four

inches of thread to hang from the bobbin

case.

Replacing bobbin case

1. Raise needle to its highest position.

2. Hold bobbin case by latch and place it on the

stud of the shuttle allowing position finger

to enter notch at top of shuttle body.

3. Release latch and press bobbin case in until

it clicks into place. Then close slide plate.

14

Page 17

Bobbin

Case

Threading Bobbin Case

.Bobbin

Notch ./■

Tension.'

Spring

Beplacihg Bobbin Case

15

Page 18

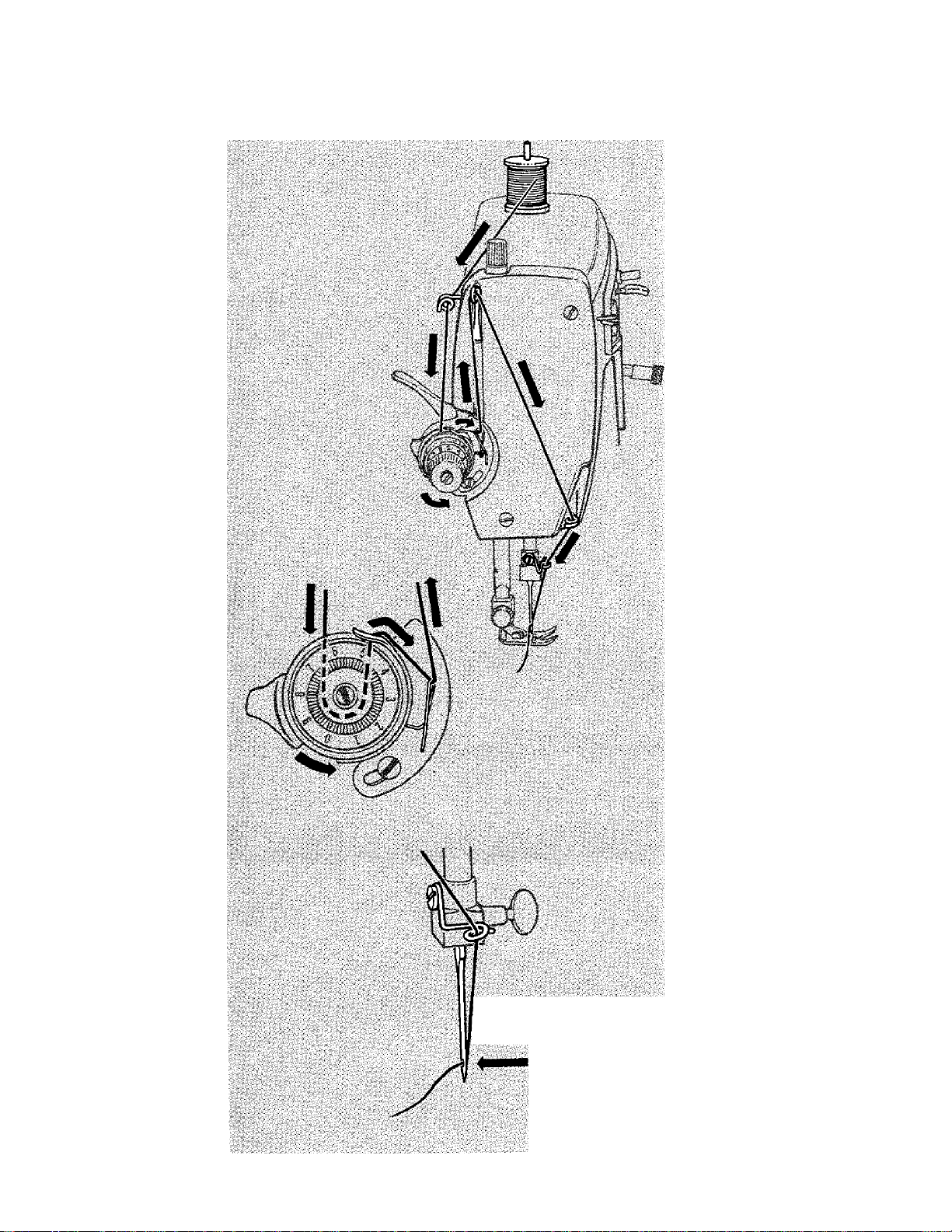

THE NEEDLE THREAD

1. Turn hand wheel toward you to raise needle

to its highest position.

2. Raise the presser foot.

3. Place spool of thread on the spool pin over

the spool pin felt.

4. Lead thread from spool through upper

thread guide, down around and between

tension discs, over tension thread guide,

under spring and up through eyelet in takeup lever.

5. Continue to lead thread through all other

threading points shown.

6. Thread the needle from right to left drawing

about four inches of thread through eye of

needle.

16

Page 19

Threading the Needle

Thread Needle

. From. Right to Left

17

Page 20

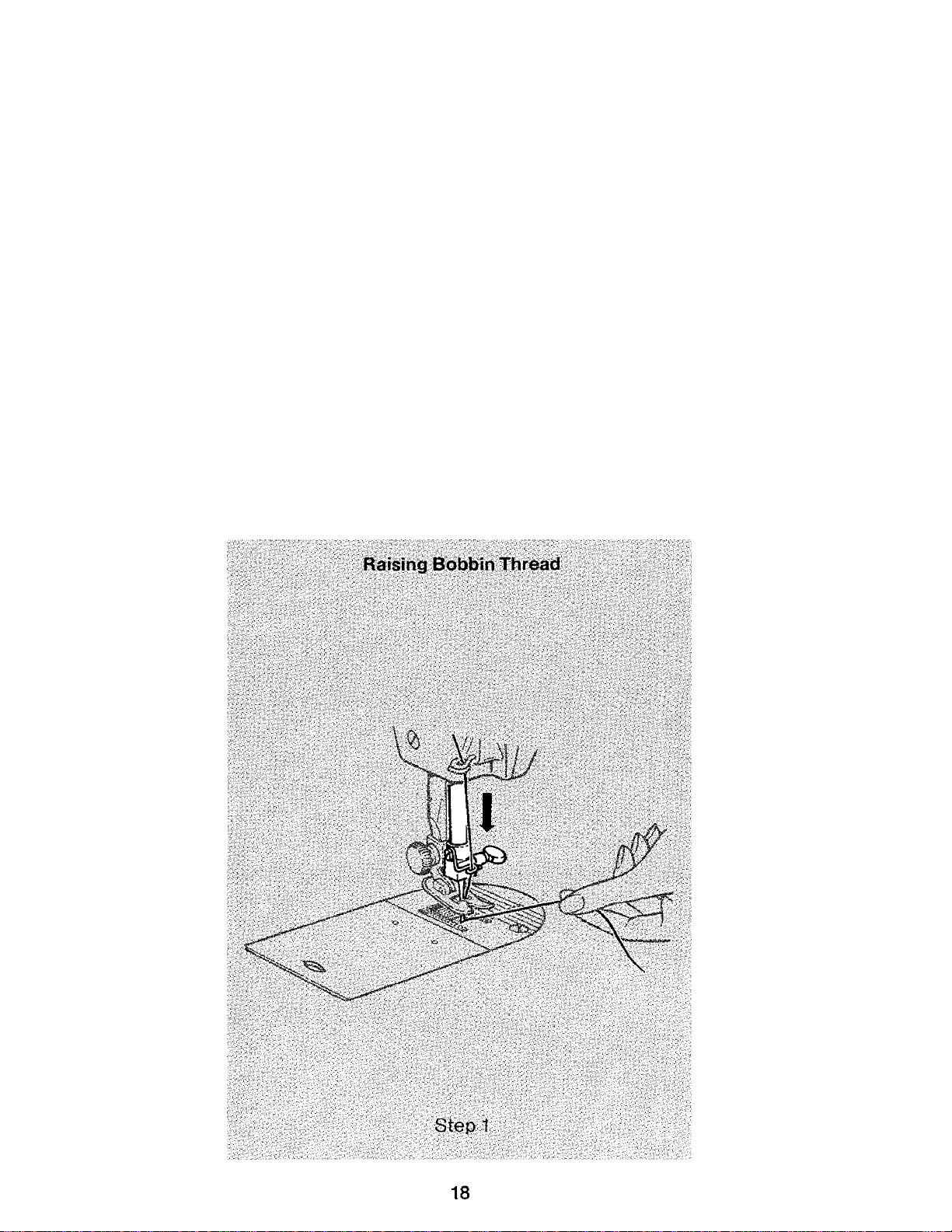

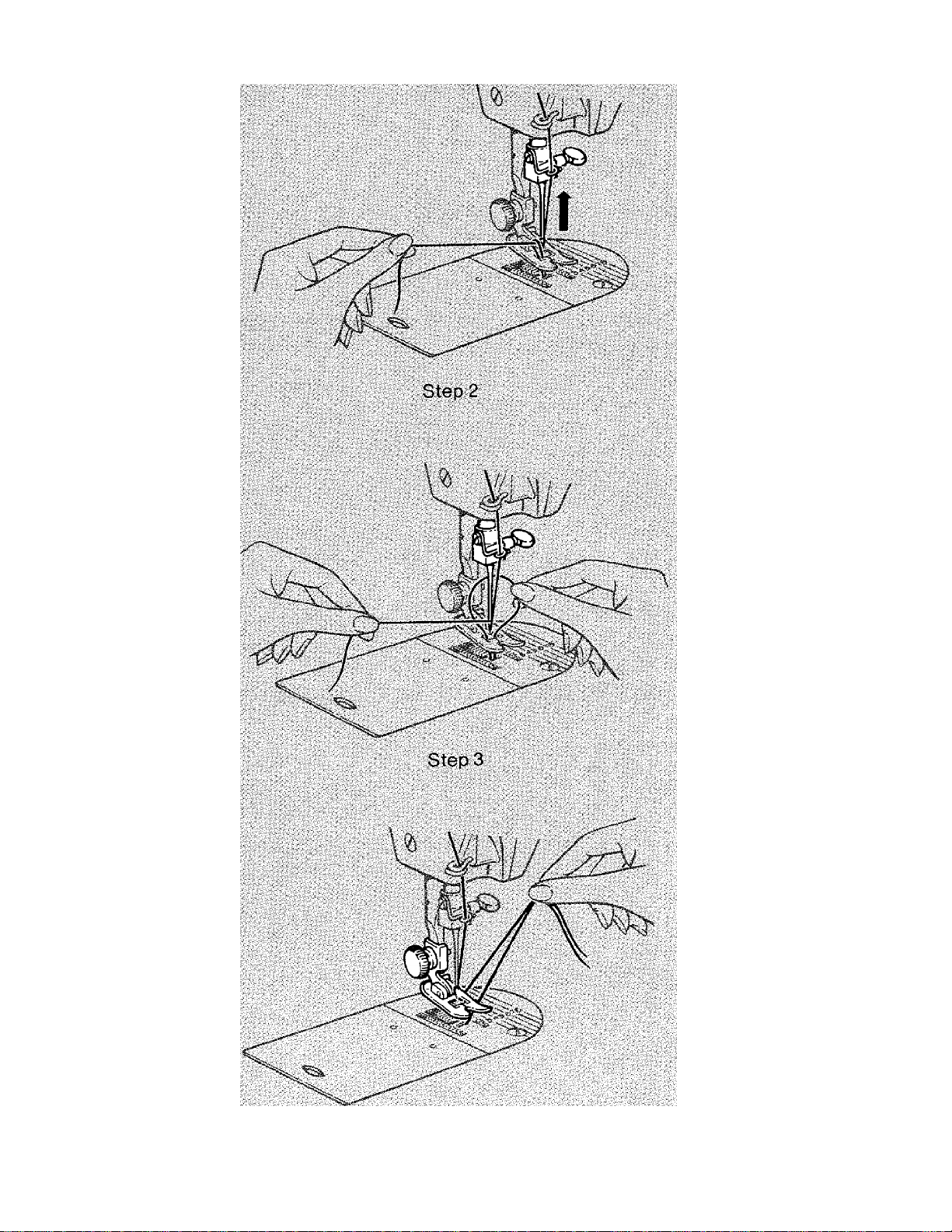

RAISING THE BOBBIN THREAD

Now that you have wound the bobbin and

threaded the needle, you will need to raise the

bobbin thread through the hole in the needle

plate.

1. Hold needle thread lightly with left hand and

turn hand wheel slowly toward you so that

needle enters needle plate.

2. Continue turning hand wheel and holding

needle thread until needle rises and brings

up bobbin thread in a loop.

3. Undo the loop with your fingers.

4. Place both needle and bobbin threads under

the presser foot, and draw them diagonally

to the back of the machine.

Page 21

step 4

19

Page 22

3. straight Stitching

preparation

Before moving the stitch width selector, make

sure the needle is above the needle plate.

SETTING THE MACHINE

1. Press down on stitch width selector lever

and slide lever to right until groove in lever

is directly under the straight-stitch symbol

(setting 0).

For your convenience, the position numbers

0,1,2,3,4 will be used throughout this book

when the instructions require stitch width

settings.

2. Set stitch length selector for desired stitch

length. (See page 22 for instructions.)

starting to sew

1. Place needle and bobbin threads under

presser foot and draw them diagonally to

the back of machine.

2. Position the needle in the fabric where de

sired for stitching start.

3. Lowerthe presser foot and start the machine.

To sew perfectly on a wide variety of fabrics

adjust stitch length, pressure and thread ten

sion as instructed on following pages.

20

Page 23

Starting to Sew

21

Page 24

adjusting selectors

for your fabric

SETTING STITCH LENGTH

The stitch length selector regulates the length

of both straight and zig-zag stitches. The num

bers at the right and left of the lever represent

the number of stitches per inch: the higher the

number, the shorter the stitch. Generally,

shorter stitches are best for lightweight fabric;

longer ones for heavy fabric.

Setting Selector

1. Loosen thumb nut by turning to left

2. Position lever for desired stitch length.

3. Tighten thumb nut by turning to right.

For reverse stitching, simply raise the selector

lever as far as it will go. Do not loosen thumb

nut to reverse.

REGULATING PRESSURE

The pressure screw regulates the pressure that

the presser foot exerts on the fabric. Correct

pressure is important to ensure smooth and

even feeding of the fabric. Generally, heavy

fabric requires heavy pressure; lightweight

fabric, light pressure. But fabric texture must

also be considered. Soft fabrics, for example,

require less pressure than crisp fabrics.

Lower the presser foot before setting pressure.

• To decrease pressure, turn screw upward

(counterclockwise).

• To increase pressure, turn screw downward

(clockwise).

22

Page 25

Loosen

Setting Stitch Length

20 ;Tighten

Regulating Pressure

To Reverse

: Stitching :,

To Decrease To Increase

23

Page 26

REGULATING THREAD TENSION

Correct tension is important because too much

or too little will weaken your seams or cause

the fabric to pucker. Make a test sample with

the fabric and thread you plan to use. A perfect

stitch will have the needle and bobbin threads

locked between the two layers of fabric with

no loops on top or bottom and no puckers.

Needle-Thread Tension

The tension dial regulates the degree of tension

on your needle thread. Set it according to the

type of thread and fabric you use. The numbers

on the dial eliminate guesswork in duplicating

settings.

If the stitches in your sample look loose,

increase needle-thread tension. If the fabric

puckers, decrease tension.

• To increase tension, turn dial to a higher

number.

• To decrease tension, turn dial to a lower

number.

Bobbin-Thread Tension

Bobbin-thread tension is controlled by a screw

located on the bobbin case. You will seldom

need to adjust it since it is usually possible to

obtain the correct balance by adjusting needle-

thread tension alone.

Should it become necessary to adjust bobbinthread tension, use the small screwdriver that

comes with your machine. A very slight turn will

produce a noticeable change in bobbin-thread

tension.

• To increase tension, turn screw clockwise.

• To decrease tension, turn screw counter

clockwise.

24

Page 27

isleedle-Thread Tension

i ! \

i /

‘ /

To Increase

To Decrease

Bobbin-Thread Tension

25

Page 28

sewing a seam

PIN BASTING

Pin basting is a time-saver and can be used in

place of hand basting when you are straight

stitching seams in easy-to-handle fabric.

Use fine pins and place them so that:

• They are at right angles to the presser foot

and just nip into the fabric at the stitching

line.

• They do not extend under both sides of the

presser foot. Never place pins on the under

side of the fabric in contact with the feed.

STARTING A SEAM

1. With presser foot raised, turn hand wheel

toward you to position the needle in fabric

about 1/2 inch from starting edge. Lower

the presser foot.

2. Set stitch length selector for desired number

of stitches per inch.

3. Raise stitch length selector to reverse and

backstitch to edge of fabric for reinforce

ment.

4. Lower stitch length selector for forward

stitching and stitch.

26

Page 29

stitching a Seaitt

27

Page 30

Keeping Seams Straight

KEEPING SEAMS STRAIGHT

To keep the seam straight, use one of the num

bered guidelines on the needle plate. The

numbers indicate distance, in eighths of an

inch, from the needle. If you want a 5/8-inch

seam, for example, line up your fabric with the

number 5 guideline.

GUIDING AND SUPPORTING FABRIC

Most fabrics need only to be guided in front

of the presser foot as shown. Some fabrics,

however, require support while being stitched:

• For filmy sheers, knits, tricots, etc., apply

gentle tension by holding fabric in front and

back of the presser foot.

• For stretch fabrics, apply firm tension front

and back when stitching in the same direc

tion as the stretch. For seams not on the

stretch direction, stitch in the conventional

manner, guiding fabric in front of the presser

foot.

28

Page 31

Supporting Fabric

29

Page 32

REINFORCING END OF SEAM

1. Stitch to the edge of the fabric.

2. Raise stitch length selector as far as it will

go and backstitch to reinforce end of seam.

Then lower stitch length selector for forward

stitching.

3. Raise needle to its highest position, raise

the presser foot, and remove the fabric by

drawing it to the back and left.

4. Cut threads on thread cutter at rear of

presser bar.

CURVED SEAMS

When sewing armhole and neckline seams, you

usually will be sewing on a curve. To do this,

follow the same procedure as for sewing a

straight seam except:

• Use a short stitch length for elasticity and

strength. For example, if you use 12 stitches

to the inch for straight seams, select 15 to 20

per inch for curved seams in the same fabric.

30

Page 33

Ending la Seam

Reinforcing End of Seam

Cutting Threads , :

Sewing a Curved Seam

31

Page 34

4. Zig-Zag Stitching

You will find the zig-zag stitch that is built into

your machine ideal for many of your sewing

applications. To use this stitch, simply follow

the instructions below and on following pages.

adjusting selectors

ADJUSTING STITCH WIDTH

Before moving selector, make sure the needle

is above fabric.

To produce a zig-zag pattern, depress and slide

stitch width selector lever to any zig-zag set

ting between I (narrow-position 1) and ^(wide-

position 4).

For your convenience, the position numbers 0,

1,2,3,4 will be used throughout this book when

instructions require stitch width settings.

ADJUSTING STITCH LENGTH

For open zig-zag stitching, choose any stitch

length from 6 to 30, depending on how open

you wish the stitching to be. If you wish a

closely spaced zig-zag stitch:

1. Move stitch length selector to 30.

2. Run the machine at slow speed and gradu

ally tighten thumb nut by turning it clockwise,

until stitches are closely spaced and form

a smooth surface.

NOTE: For best results in producing a smooth,

satiny surface, use the special-purpose foot

which is available at your local Singer Sewing

Center (see page 62).

32

Page 35

4 3 2 1 0

Hi

Adjusting $titc h Length

As Selector is Raised,

Stitches Close Up

33

Page 36

adjusting needle-thread

tension

Zig-zag stitching requires less needle-thread

tension than straight stitching; and closed zig

zag stitching requires even less tension than

open zig-zag stitching. Furthermore, the wider

the stitch, the lighter the tension on the thread

must be. Thus, stitch width 4 requires the least

tension; narrower stitching requires more.

Make a test sample with the fabric and thread

you plan to use and notice the stitching. If the

stitching looks too taut, or if the fabric is pucker

ing, lower the needle-thread tension by turning

the tension dial to a lower number.

adjusting presser-foot

pressure

Turn to page 22 under “Straight^ Stitching” for

instructions on adjusting pressure.

34

Page 37

Increase

Decrease

Too Tight

Correct

Adjusting Needle^Thread Tension

35

Page 38

5. Sewing the Professional Way

construction details

LINGERIE SEAMS

• Stitch Width: 2 to 3

• Stitch length; 15 to 20, depending on fabric

To make seams in lingerie both durable and

flexible, use the zig-zag stitch. This treatment

is particularly suitable for bias seams.

1. Straight-stitch the seam (with stitch width at

0) on wrong side of fabric.

2. Press both seam allowances in the same

direction.

3. Set stitch width at 2 or 3 and, from the right

side, top stitch with zig-zag stitching, letting

the needle alternately enter the seam line

and seam thickness.

SEAMS IN KNIT FABRICS

• Stitch Width: 1 to 2

• Stitch Length; About 20

The zig-zag stitch is ideal for seaming knit

fabrics. It is particularly desirable for underarm

seams where elasticity and give are needed.

For neckline and waistline seams, where a stay

is needed to prevent undue stretching, this

same stitch can be used to apply seam tape.

For a flat, smooth finish:

1. If seam is curved, pre-shape tape to fit by

steam pressing.

2. Baste tape in place.

3. Stitch, allowing needle to alternatively enter

the seam tape and seam allowance.

36

Page 39

Page 40

FLAT-FELLED SEAMS

• Stitch Width: 2

• Stitch Length: 15 to 20, depending on fabric

Zig-zag stitching gives strength and durability

to flat-felled seams.

1. Stitch the seam on the right side of the

fabric, taking full seam allowance.

2. Press seam allowance to one side, keeping

the right side of the stitch on top.

3. Trim the under-seam allowance to one-half

its width.

4. Turn the upper-seam allowance edge evenly

over the trimmed edge and top stitch.

SEAM FINISHES

• Stitch Width: 3 or 4

• Stitch Length: 8 to 20, depending on fabric

Seam edges support the garment and should

be given a durable finish if the fabric is likely

to ravel.

1. Adjust stitch width and stitch length settings

to suit the fabric. Choose the settings that

will give you the most “open” stitch that will

secure the fabric edges; avoid harsh, over

stitched edges.

2. Trim seam edges evenly.

3. Place stitching near the edge of the seam

allowance or over the raw edge as illustrated.

4. If stitching is placed near the edge of the

seam allowance, trim away excess fabric

after stitching.

38

Page 41

Page 42

DARTS

Darts can be made in the usual way on your

sewing machine. That is, you begin stitching at

the wide end of the dart, stitch to the point, and

then fasten the two thread ends.

Regular Darts

• stitch Width: 0

• Stitch Length: About 12 or to suit fabric

1. Stitch from the seam edge, tapering gradu

ally to the point.

2. Stitch beyond the fabric to form a thread

chain 1/2 to 3/4 inch long.

3. Tie the thread ends into a single knot close

to the stitching.

Darts in Interfacing

• stitch Width: 4

• stitch Length: About 20 or to suit fabric

With zig-zag stitching, darts in interfacings can

be shaped without bulk.

1. Cut out the dart allowance on the stitching

line.

2. Bring raw edges together and pin or baste

over a muslin stay.

3. Stitch, backstitching at both ends.

40

Page 43

Regular Dart

apragna

II iJIiII

41

Page 44

BUTTONHOLES

• Stitch Width: 2 and 4

• Stitch Length: Above 30

Make a test buttonhole on a sample of your

fabric so you can adjust stitch length to produce

a closely spaced, freely-feeding zig-zag stitch.

Be sure to duplicate the thickness of the gar

ment and include interfacing if appropriate.

NOTE: For best results, use the special purpose

foot which is available at your local Singer

Sewing Center (see page 62).

Stitch Width Settings

You will use two stitch width settings: for side

stitching, stitch width 2, and for bar tacks (clos

ings at ends of buttonhole), stitch width 4.

Buttonhole Length

The length of the buttonhole depends on the

diameter and thickness of the button. To find

the correct length:

1. Cut a small slit in a scrap of fabric and

gradually enlarge it until the button slips

through easily.

2. Add approximately 1/8 inch at each end for

bar tacks, and mark the fabric as shown.

This bar-tack measurement is approximate; on

some buttonholes, you may need to increase it

or decrease it to arrive at pleasing proportions.

42

Page 45

Side: Stitching

Stitch Vyidth iSettings

Marking Lines

Length of

Cutting Space

Bar Tacks and

Side Stitching

43

Page 46

Buttonholes (Continued)

Procedure

Place work under the presser foot, aligning

center marking of buttonhole with the needle.

Side stitching

Set stitch width selector at 2. Position the

needle in the fabric at point A. Lower the pres

ser foot and stitch down left side to end of

buttonhole marking, stopping at point B. Leave

needle in fabric. Raise presser foot and pivot

work on needle. Lower the foot and take one

stitch at same stitch width setting bringing

needle to point C. Leave needle in fabric.

Bar tack

With needle in fabric, raise presser foot and set

stitch width selector at 4. Lower presser foot

and take approximately 6 stitches ending at

point D. Leave needle in fabric.

44

Page 47

iSislEiiSiiiÄ

Side Stitching

Bar Tack

45

Page 48

Buttonholes (Continued)

Side stitching

With needle in fabric, raise presser foot and

reset stitch width selector to 2. Lower presser

foot and stitch, stopping at point E. Leave

needle in fabric.

Final bar tack

With needle in fabric, raise presser foot and set

stitch width selector at 4. Lower presser foot

and take approximately 6 stitches ending at

point F. Leave needle in fabric.

Fastening stitch

With needle in fabric, raise presser foot and

set stitch width selector at 0. Lower the presser

foot and take approximately 3 stitches.

Remove work, draw threads to underside,

fasten and trim. Cut opening for button with

sharp scissors.

46

Page 49

Side Stitching

Final Bar Tack

Fastening Stitch

47

Page 50

keeping up appearances

MENDING

The zig-zag stitch is just as useful for mending

as it is for creative sewing. It forms a firm,

flexible bond for repairing tears, replacing

elastic and for making bar tacks to repair lin

gerie and to reinforce points of strain.

Mending a Tear

• stitch Width: 2 to 4

• Stitch Length: About 20

1. Trim ragged edges.

2. Place underlay on the wrong side of tear for

reinforcement. (It is best not to baste or pin

the underlay, since you will be bringing the

edges together in the next step.)

3. Stitch on the right side, bringing the edges

of the tear together. Shorten stitch length

at ends and corners to give extra strength.

Trim underlay.

48

Page 51

Replacing Elastic

When replacing elastic, use the same settings

as for “Mending a Tear.”

1. Fit elastic for desired snugness at waistline,

allowing one inch for joining. Lap the ends

and join with zig-zag stitching.

2. Divide elastic band and garment waistline

into quarters. Lap elastic over fabric and pin

the two together at these intervals. Place

pins at right angles to stitching line.

3. Take a few stitches to anchor elastic to

fabric, then hold the elastic taut as you stitch

so that it will remain stretchable after stitch

ing is completed.

Bar Tacks

Bar tacks, to repair lingerie and attach belt

loops, are made with the zig-zag stitch at a

closed stitch length.

Bar-Tacked Beit Loops

49

Page 52

BLANKET BINDING

Often you can make an old blanket look almost

new by replacing the binding.

• Stitch Width: 4

• Stitch Length: 15 to 20

1. Remove worn binding and baste new binding

in place.

2. Reduce pressure on fabric by turning pres

sure thumb screw counterclockwise and

increase stitch length, if necessary, so that

blanket feeds freely.

3. Stitch, and remove basting.

DARNING

Worn or torn spots on children’s clothes and

household linens can be darned effortlessly

and quickly with little practice.

• Stitch Width: 0

• Stitch Length: 10 to 15

• Pressure: Very light

1. If area to be darned is open, baste an under

lay in place.

2. Place area to be darned under presser foot;

lower presser foot and start stitching, al

ternately drawing fabric toward you and

pulling it gently away from you.

3. Continue this back and forth motion until

you fill the area with parallel lines of stitch

ing. For additional strength, cover area with

crosswise lines of stitching.

50

Page 53

Blanket Binding

barning

51

Page 54

6. Caring for Your Machine

cleaning and lubricating

Your machine will serve you perfectly for many

years if you keep it clean and lubricated. How

often you will need to clean and lubricate the

machine will depend on how often you use it.

CAUTION: Before cleaning and lubricating the

machine, disconnect the power-line plug from

electrical supply.

EVERY WEEK OR SO...

Remove lint or fluff from exposed parts. With

a soft cloth, clean:

• Tension discs, presser bar and needle bar

• Take-up lever and thread guides

• Bobbin case, needle plate and slide plate

• Machine surface (If necessary, dampen the

cloth and use a mild soap)

Remove needle plate by removing screws

fastening it to machine bed and remove shuttle

as instructed on page 54.

Using a brush, clean:

• Feed

• Shuttle area

After cleaning, apply a drop of SINGER* oil at

points indicated on pages 55, 56, and 57.

52

Page 55

Clean Between

tension Discs ;

53

■ Briisti

Page 56

Removing and Replacing Shuttle

1. Raise take-up lever to its highest position.

2. Open slide plate, remove needle plate (see

page 52), and remove bobbin case.

3. Push latch down, swing shuttle gate open,

and remove shuttle from raceway.

4. Clean shuttle and raceway. Apply a drop of

oil to raceway.

5. Replace shuttle in raceway and close and

lock gate. Replace bobbin case and needle

plate; close slide plate.

Shuttle

Gate

Shuttle

Bobbin

Case

54

Page 57

Cleaning and Lubricating

Behind Face Plate

1. Remove the two screws from the face plate.

2. Using a brush, clean out lint and fluff which

may have accumulated. Apply one drop of

oil to all points indicated.

3. Replace face plate and sew a few lines of

stitching on a scrap of material to remove

excess oil.

Page 58

EVERY FEW WEEKS...

Lubricate Top and Bottom of Machine

• Remove two screws from top cover and lift

cover from machine.

• Apply a drop of oil to points indicated (three

drops to points indicated by t).

• Apply a small amount of SINGER* gear

lubricant to gears. Never apply oil to

gears.

• Replace top cover.

Lubricating Top of Machine

56

Page 59

Oilt

Oil

Oil

Oi

Oi!

Lubricating Bottom of Machine

• Tilt machine back and apply a drop of oil to

ail points indicated.

IF MACHINE IS TO BE STORED

Before storing, thoroughly clean the machine

to remove all traces of lint and fluff. Then swab

all exposed metal parts and parts behind the

face plate with a brush saturated with SINGER

oil to protect against rust.

57

Page 60

adjusting

motor belt tension

Tension on the motor belt should be just suf

ficient to keep the belt from slipping. If the

motor belt needs adjustment:

• Loosen motor bracket screw a full turn.

• To increase belt tension, lower the motor

bracket.

• To decrease belt tension, raise the motor

bracket.

• Securely tighten motor bracket screw.

replacing the slide plate

You will not have any occasion to remove the

slide plate. If it should accidentally become

disengaged from the machine, it is easily re

placed.

• Align back edge of slide plate with front end

of slide way.

• Push slide plate back until retaining spring

snaps into place.

58

Page 61

Page 62

removing machine

from cabinet

IMPORTANT:

• Do not attempt to remove hinges from cabinet

as this may result in damage to cabinet.

• Puil cabinet away from wall to avoid damage

to wall or machine.

• Remove power-line plug from electrical

supply.

TO REMOVE MACHINE FROM CABINET

1. Tilt machine back until it rests on hinges.

2. Loosen set screws that hold machine on

hinge pins by turning them counterclockwise.

3. Lift machine straight up and off pins. For

ease of removal, stand behind cabinet when

lifting machine.

TO REPLACE MACHINE IN CABINET

Reverse the procedure used for removal of

machine.

• Be sure set screws in machine are unscrewed

far enough to clear openings for hinge pins.

• To keep hinge pins pointing up, slip an elastic

rubber band around both pins, making sure

the elastic band is over the shoulder of each

hinge as illustrated.

• Be sure set screws are firmly tightened

against hinge pins before lowering machine

into cabinet.

60

Page 63

iBasticBartd^'

Replacing Machine in Cabinet

61

Page 64

7. FASHION Aids

Fashion Aids increase the versatility of your

sewing machine. The ones described below are

just a few of the selection available at your

local Singer Sewing Center.

SPECIAL PURPOSE FOOT-No. 161455

This light, flexible foot is designed for zig-zag

satin stitching, buttonholing and applique. The

raised center section allows very closely spaced

zig-zag stitches to feed smoothly and evenly.

The small eyelets at the front of the foot hold

filler cord when desired.

SEAM GUIDE-No. 161172

The seam guide helps keep seam width uniform

when extra control is needed, especially on

unusually wide or narrow seams.

ZIPPER FOOT-No. 161127

This foot makes it easy to place stitching close

to a raised edge. Thus, it is useful for corded

seams and zipper insertions. The zipper foot

can be adjusted to either the left or right side

of the needle. The hinged foot easily rides over

pins, heavy layers of fabric, or across seams.

62

Page 65

Index

Adjusting Motor Belt Tension

Blanket Binding

Bobbin Case

Removing

...........................................

..........................................

..................................................

....................

10,14

58

50

10

Replacing................................................... 14

Threading

Bobbin Winding

Buttonholes

Caring for Your Machine

Changing the Needle

Choosing Needle and Thread

Cleaning and Lubricating

..................................................

...................................

10,11

.................................................

............................

....................................

............

8

...........................

14

42

52

8

52

Curved Seams............................................... 30

Darning

........................................................

50

Darts............................................................. 40

In Interfacing

...........................................

40

Regular...................................................... 40

Ending a Seam

.............................................

30

Fabric, Thread and Needle Table .... 9

Fashion Aids................................................... 62

Guiding and Supporting Fabric

.........

28

Keeping Seams Straight.............................. 28

Mending....................................................... 48

Bar Tacks

..................................................

49

Mending aTear......................................... 48

Replacing Elastic...................................... 49

Needle Thread.............................................. 16

Operating Machine and Controller ... 6

Pin Basting................................................... 26

Presser-Foot Pressure............................. 22,34

Principal Parts

Raising the Bobbin Thread

Removing Bobbin Case

...............................................

.........................

...............................

4

18

10

Removing Machine from Cabinet .... 60

Removing and Replacing Shuttle .... 54

Replacing Bobbin Case

................................

14

Replacing Slide Plate................................... 58

Reverse Stitching......................................... 22

Seams.................................................. 26,30,36

Curved....................................................... 30

Flat-Felled................................................. 38

In Knit Fabrics.......................................... 36

Lingerie

.....................................................

36

Seam Finishes........................................... 38

Straight

.....................................................

26

63

Page 66

Index

Sewing a Seam

..............................................

26

Starting a Seam............................................ 26

Stitch Length Selector

.................................

22

Straight Stitching......................................... 20

Thread Tension............................................ 24

Bobbin Thread

Needle Thread

Threading Bobbin Case

Threading the Machine

Zig-Zag Stitching

Stitch Length

Stitch Width

Thread Tension

.........................................

.....................................

24,34

...............................

...............................

.........................................

............................................

.............................................

........................................

24

14

10

32

32

32

34

64

Page 67

Page 68

Let SINGER help you enjoy sewing...

with products that make sewing easy!

The Professional* buttonholer by SINGER en

ables you to sew buttonholes in five different

styles plus eyelets. You choose the style and

length—even adjust the stitch width and cutting

space—to sew perfect buttonholes every time.

Fabrics for any

season or occasion,

for the fashion

conscious and the

penny-conscious

woman, for the home

or wardrobe, are

available at most

Singer Sewing

Centers. And color-

coordinated notions

and trims are there,

too, along with

helpful, friendly

sewing advice.

*A Trademark of

THE SINGER COMPANY

Loading...

Loading...