SINGER 114W110 User Manual

SINGER

114W110

1595w

INSTRUCTIONS

FOR USING

SINGER BRATOING MACHINE

114 w 110

The Singer Manufacturing Co.

DESCRIPTION

Machine 114 w 110 is designed for sewing braid on waists,

cloaks, suits, dresses, skirts, robes, opera wraps, uniforms,

millinery goods and a great variety of other articles such as

curtains, table covers, mantel scarfs, etc., all of which are made

very attractive by the ornamental designs produced by the

machine. Fabrics, including fine chiffon, georgette, china silk,

net and similar sheer materials, also the heavier fabrics such as

broad cloth, velvet, etc., arc stitched with ecjual satisfaction by

the machine.

The braid can be sewn “flat on,” or it can be sewn “edge on”

for what is known as “standing” braid. When the machine is

u.scd for sewing the braid “flat on,” the invisible lock stitch is

made, the stitches being placed in the centre on the underside of

the braid. When the braid is sewn “edge on,” one of the edges of

the braid stands upward, producing artistic effects different from

those obtained when the braid is stitched on flat. (See pages 18

and 20).

The braid is taken from a s])ool located at the top of the

machine, and passed down through a tube to a suitable guide

which conducts it to the needle in the desired position for stitching.

Braid guides can be furnished for various descriptions of braids as

shown on page 15, and samples of the braid to be used should

accompany orders for guides.

The usual method for sewing on the braid is to follow a

pattern that has been stamped or traced upon the fabric. With a

little practice the operator can produce ornamental designs with

out the aid of patterns.

The machine has one needle and one oscillating shuttle.

To Oil the Machine

When the machine is received from the factory it should be

thoroughly cleaned and oiled.

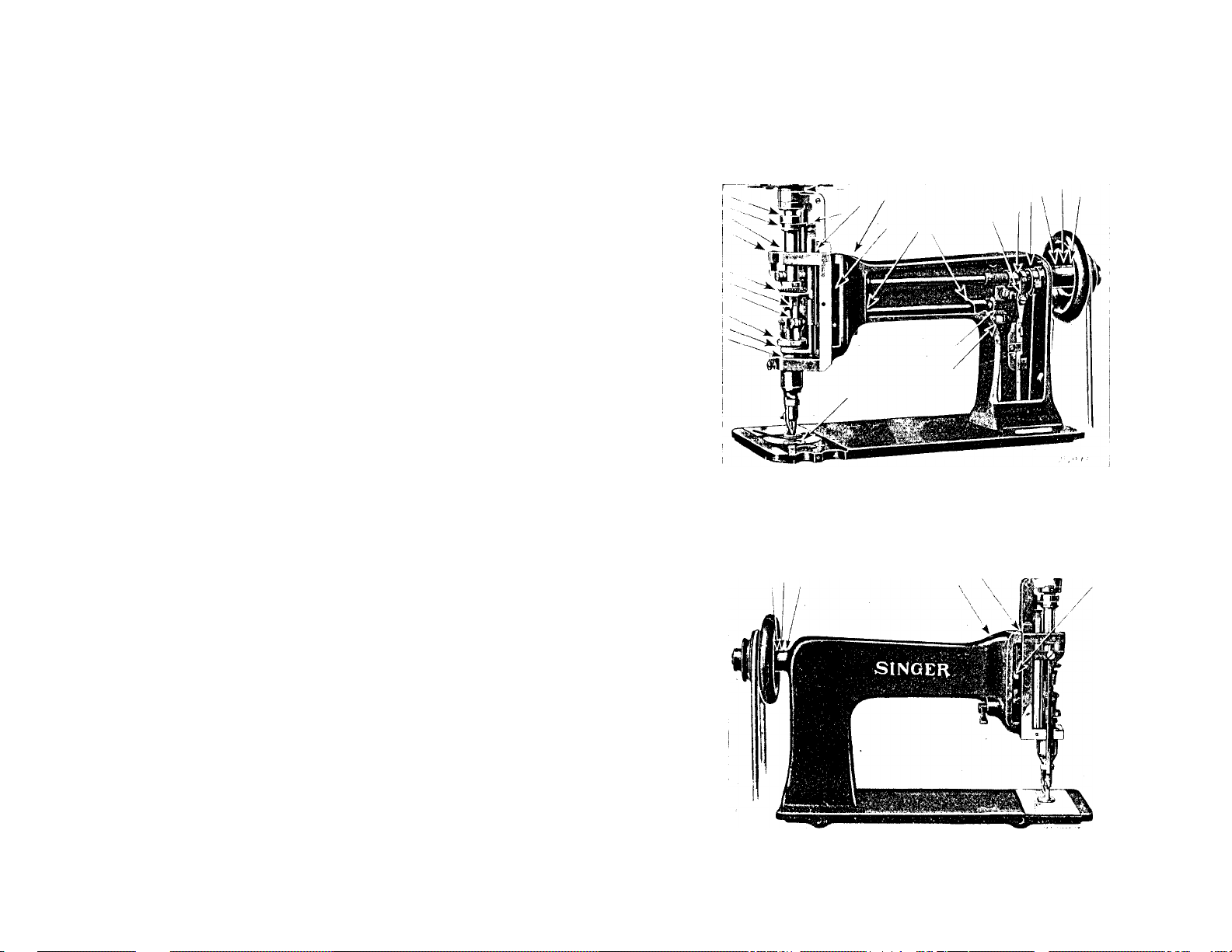

Fl(!. 2. Oir.IMi I’OIN'IS AT TMK l''lU)NT oe THIO iMachink

To clean the machine, use a little kerosene at the oiling

points shown in Figs. 2, 8, 4 and 5, run th(> machiiu' ra])idly for

one minute then wipe clean.

Speed

The speed of the machine is limited only by the skill of the

operator. The machine should be started at a speed of about 600

stitches per minute and this speed can be increased when the

operator becomes proficient and the nature of the work permits.

When the machine is in operation the balance wheel should always

turn over from the operator.

Kk;. .'i. OiLiNii I’oiNTs AT Till-: Hack ok ■niio Machine

Oil should then be applied at each of the places designated

by arrows in Figs. 2, 3, 4 and 5. When the machine is in continu

ous use it should be oiled at least once each day.

Turn the machine back on its hinges and apply oil at the

places shown by arrows in Fig. 5 and all other places where

Fig. 5. Oiling 1’oints in the Base of the Machine

there ai’e parts in movable contact, then bring the machine

forward into place.

E 36b0

Fig. 4. ]0ni) View of the Machine, Showing Oiling Points

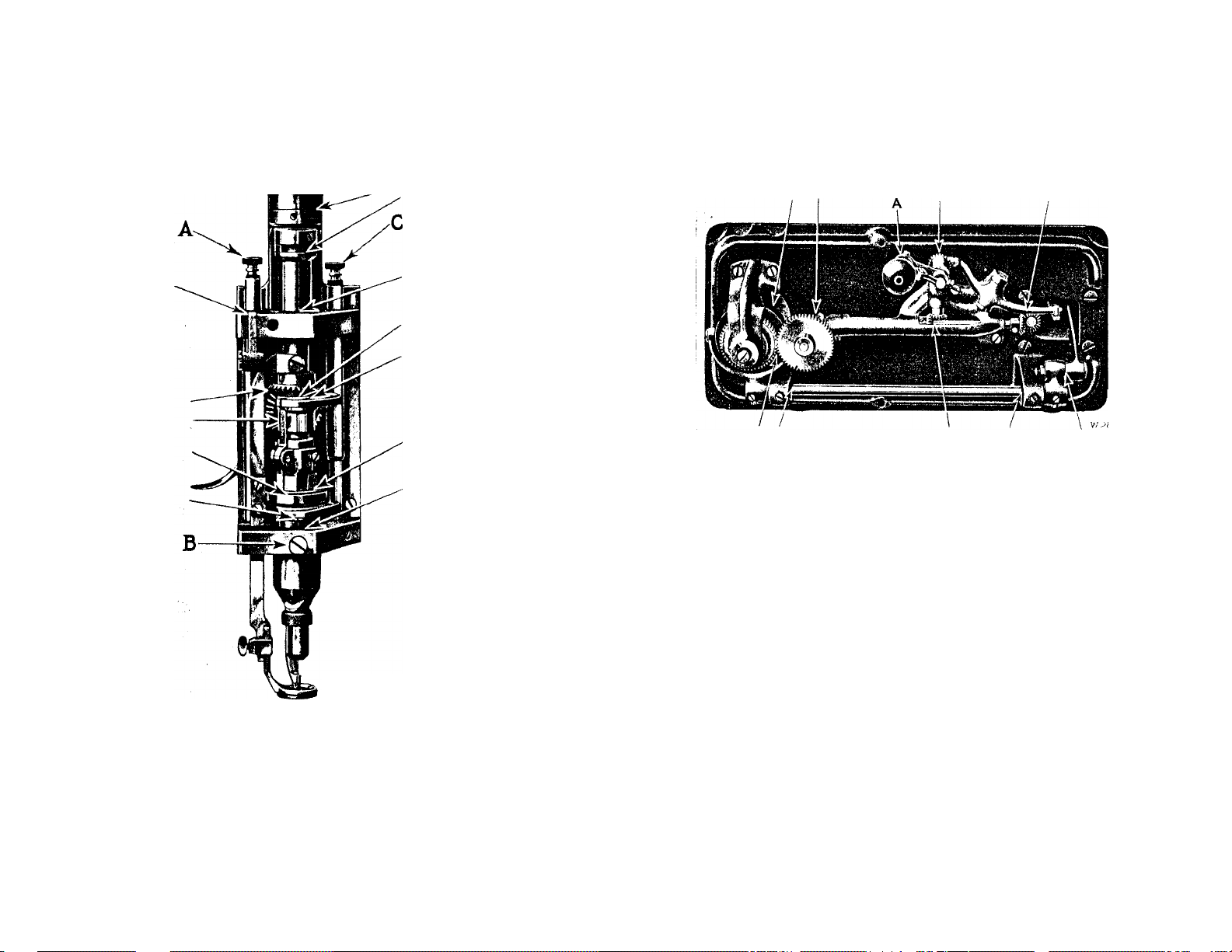

Fig. 2 shows the front plate of the machine removed for the

purpose of cleaning and oiling. The front plate can be removed

after taking out the thumb screw which holds it in position.

Fig. 4, above, shows the face plate of the machine removed

for the purpose of cleaning and oiling. The face plate can be

removed after loosening the thumb screw (B, Fig. 4).

Needles

Needles for Machine 114 w 110 are of Class and Variety

126 X 1 and are made in sizes Nos. 8, 9, 10, 12, 14, 16, 18, 20,

22, 23, 24 and 25.

The size of the needle to be used should be determined by

the size of the thread which must pass freely through the eye of

the needle. If rough or uneven thread is used the successful

operation of the machine will be interfered with.

Orders for needles must specify the quantity required, the

size number, also the class and variety numbers separated by the

letter X.

The following is an example of an intelligible order:

“100 No. 12, 126 x 1 Needles.”

The best results will be obtained in using the needles furnished

by the Singer Sewing Machine Company.

Thread

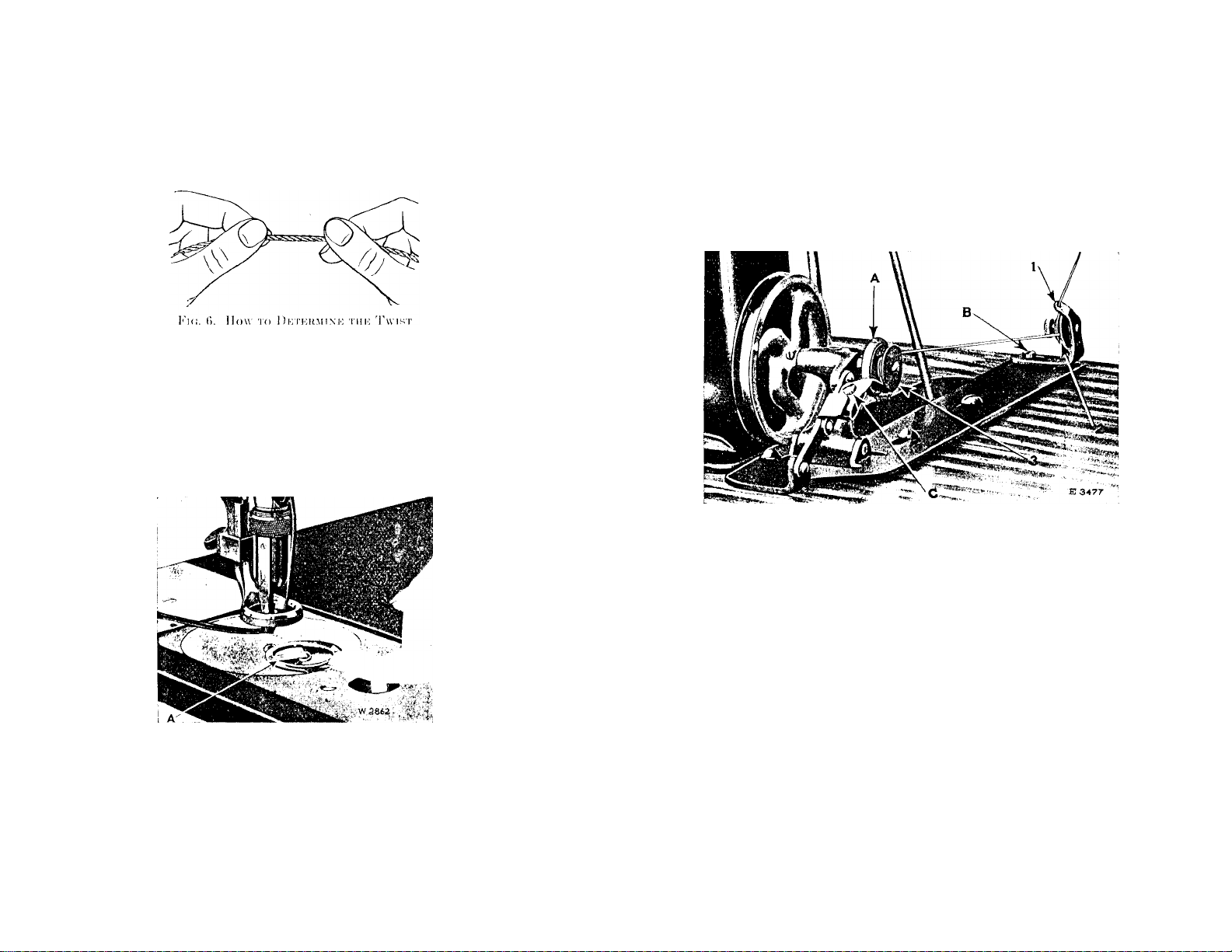

Left twist thread should be used in the needle. Either right

or left twist thread can be used in the bobbin.

Hold the thread as shown above. Turn the thread over

toward you between the thumb and forefinger of the right hand;

if right twist, the strands will unwind; if left twist, the strands

will wind tighter.

To Remove the Bobbin

(Sef, Fie. 7)

Turn the balance whei'l over from you until llu' needle bar

moves up to its highest point. Place the thumb of the left hand

Fir.. 7. Kemoving the Shu itle

under the front edge of the needle plate; raise the plate upward

and draw it toward you to remove it from the machine.

In.sert the finger nail of the forefinger of the right hand in

the notch in the side of the shuttle, as shown in Fig. 7, and lift

out the shuttle. Then raise the tension latch (A, Fig. 7) on the

shuttle, turn the open end of the shuttle downward and the

bobbin will drop out.

To Wind the Bobbin

(See Fig. Si

Fasten the bobbin winder to the table with its driving (lulley

in the front of the machine belt so that the pulley will droj) away

from the belt when sufficient thread has been wound upon the

bobbin.

Fig. S. W imhng the Hobhin

Pass the thread down through the thread guide (1) in the

tension bracket, around the back and between the tension discs (2).

Having placed the bobbin on the bobbin winder spindle, pass

the end of the thread between the bobbin (d) and tbe disc (A) on

the spindle, then push the bobbin up closely against tin' disc, and

the end of the thread will be retained between the bobbin and the

disc. With the left hand hold the bobbin winder |)ulley, and at

the same time, with the righf, hand, turn the bobbin and the disc on

the bobbin winder spindle over toward you to expand the spindle,

thus securing the bobbin. Then push the bobbin winder ¡ndley

over against the machine belt, and start the machine.

If the thread does not wind evenly on the bobbin, loosen the

screw (B) in the tension bracket ami move the bracket to the

right or left as may be reiiuired, then tighten the screw.

When sufficient thread has been wound upon the bobbin,

the bobbin winder will stop automatically. To release the bobbin,

turn the disc on the s])indle over from you, then cut the tail

thread off inside of the bobbin and the thread leading from the

spool, and remove the bobbin.

Loading...

Loading...