SINAMICS G120 User Manual

Siemens D 11.1 · 2009

4

4/2 SINAMICS G120 standard inverters

4/2 Overview

4/4 Benefits

4/4 Applications

4/4 Design

4/9 Configuration

4/10 Technical specifications

4/12 CU230 Control Units

4/12 Overview

4/12 Selection and ordering data

4/12 Function

4/13 Design

4/14 Integration

4/17 Technical specifications

4/19 CU240 Control Units

4/19 Overview

4/19 Selection and ordering data

4/20 Design

4/22 Integration

4/28 Technical specifications

4/30 PM240 Power Modules

0.37 kW to 250 kW (0.5 hp to 400 hp)

4/30 Overview

4/31 Selection and ordering data

4/32 Integration

4/36 Technical specifications

4/42 Characteristic curves

4/44 Dimensional drawings

4/50 PM250 Power Modules

7.5 kW to 75 kW (10 hp to 100 hp)

4/50 Overview

4/51 Selection and ordering data

4/52 Integration

4/55 Technical specifications

4/59 Characteristic curves

4/60 Dimensional drawings

4/64 PM260 Power Modules

11 kW to 55 kW (15 hp to 75 hp)

4/64 Overview

4/65 Selection and ordering data

4/66 Integration

4/68 Technical specifications

4/71 Characteristic curves

4/72 Dimensional drawings

4/73 Compact inverters

0.37 kW to 15 kW (0.5 hp to 20 hp)

4/73 Overview

4/73 Selection and ordering data

4/74 Line-side power components

4/74 Line filters

4/77 Line reactors

4/81 Recommended line components

4/83 DC link components

4/83 Braking resistors

4/86 Braking Modules

4/88 Load-side power components

4/88 Output reactors

4/95 Sine-wave filters

4/102 Supplementary system components

4/102 Intelligent Operator Panel IOP

4/104 Basic Operator Panel BOP

4/105 MMC memory card

4/106 CM240NE chemical industry module

4/108 PC Connection Kit -2

4/108 PC Connection Kit

4/109 Brake relay

4/110 Safe Brake Relay

4/111 Adapter for mounting on DIN rails

4/111 Shield Connection Kit

4/112 Shield Connection Kit 1

for CU230P-2 Control Units

4/112 Shield Connection Kit

for CU240S Control Units

4/113 Spare parts

4/113 CU240 Spare Parts Kit

4/113 Replacement door

for PM240 frame size FSGX

4/114 Terminal Cover Kit

for frame sizes FSD and FSE

4/114 Terminal Cover Kit

for frame size FSF

4/115 Replacement connector

4/116 Replacement fan

SINAMICS G120

Standard inverters

0.37 kW to 250 kW (0.5 hp to 400 hp)

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

SINAMICS G120 standard inverters

4/2

Siemens D 11.1 · 2009

4

■

Overview

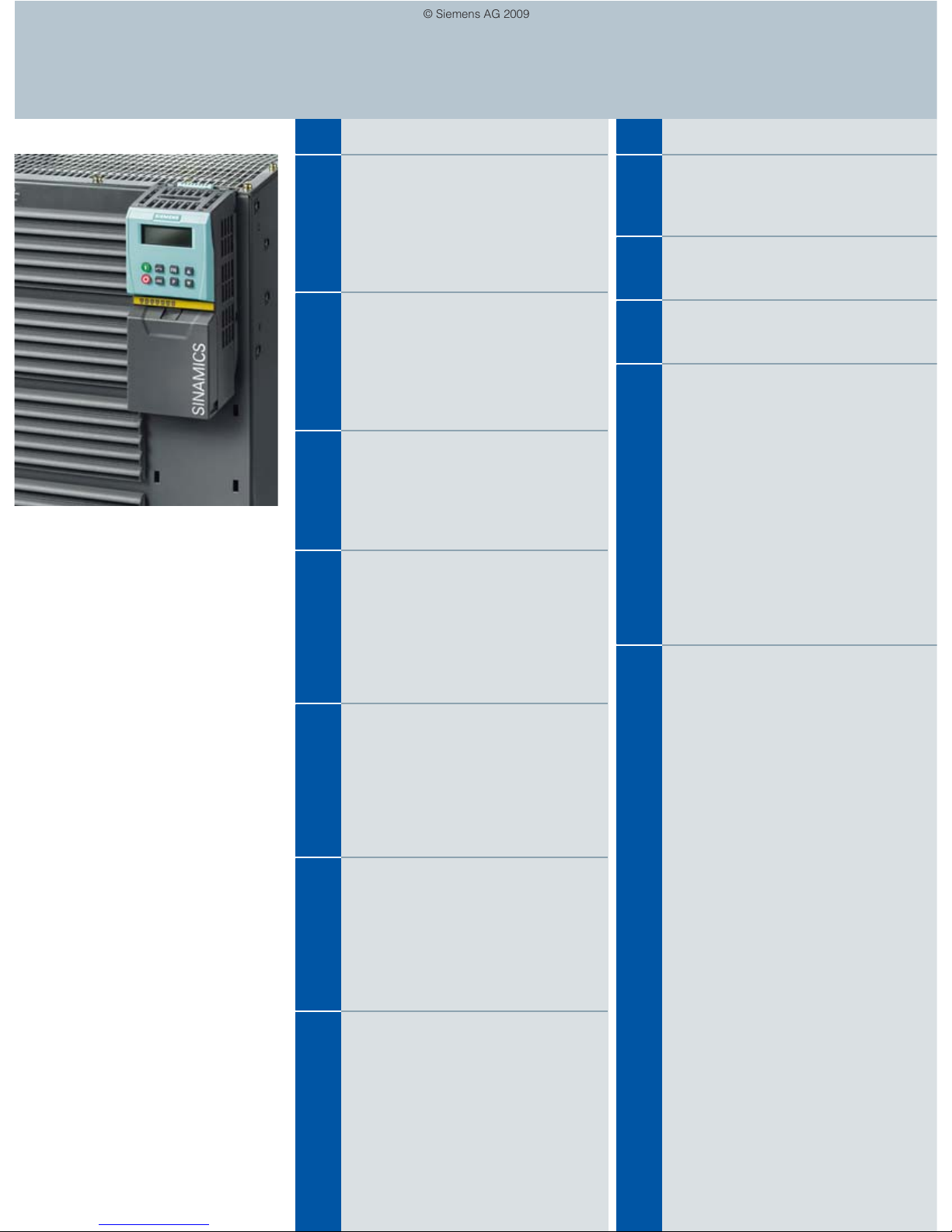

The SINAMICS G120 frequency inverter is designed to provide

precise and cost-effective speed/torque control of AC motors.

With different device versions (frame sizes FSA to FSGX) in a

power range from 0.37 kW to 250 kW (0.5 hp to 400 hp), it is suitable for a wide variety of drive solutions.

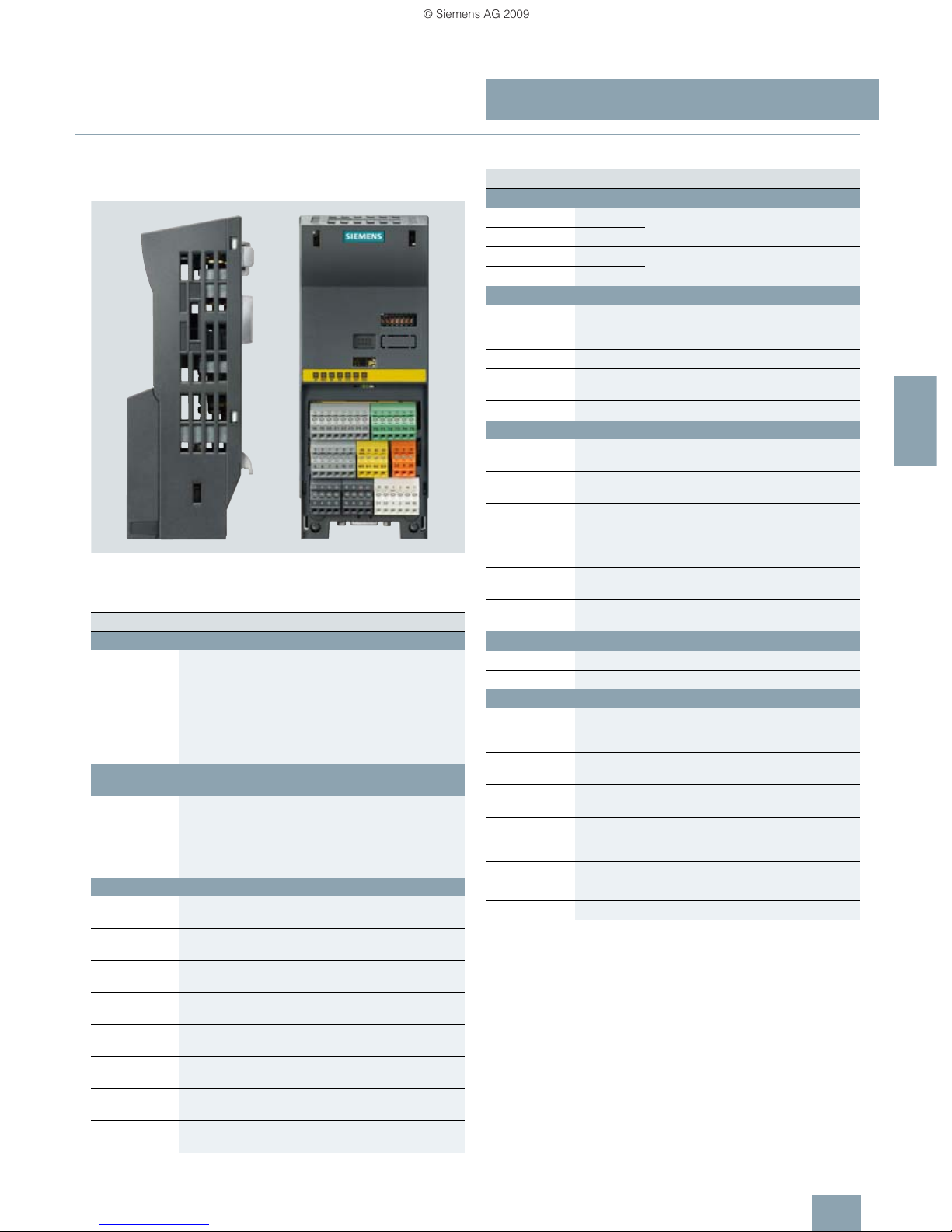

Examples of SINAMICS G120, frame sizes FSA, FSB and FSC; each with Power Module, Control Unit and Basic Operator Panel

Examples of SINAMICS G120, frame sizes FSD, FSE and FSF; each with Power Module, Control Unit and Basic Operator Panel

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

SINAMICS G120 standard inverters

4/3

Siemens D 11.1 · 2009

4

■

Overview

Examples of SINAMICS G120, frame size FSGX;

with Power Module

Modularity

SINAMICS G120 is a modular inverter system comprising a

variety of functional units. The main units are:

• the Control Unit (CU)

• the Power Module (PM)

The Control Unit

controls and monitors the Power Module and

the connected motor using several different control types that

can be selected. It supports communication with a local or

central control and monitoring devices.

The Power Module

supplies the motor in a power range 0.37 kW

to 250 kW (0.5 hp to 400 hp). The Power Module is controlled by

a microprocessor in the Control Unit. State-of-the-art IGBT technology with pulse-width modulation is used to achieve the highest degree of reliability and flexible motor operation. Comprehensive protection functions provide a high degree of protection

for the Power Module and the motor.

Furthermore, a large number of additional components

are avail-

able, such as:

• Intelligent Operator Panel (IOP) for parameterizing, diagno-

sing, controlling and copying drive parameters

• Basic Operator Panel (BOP) for parameterizing, diagnosing,

controlling and copying drive parameters

• Line filters, Classes A and B

• Line reactors

• Braking resistors

• Sine-wave filters

• Output reactors

Safety Integrated

The SINAMICS G120 standard inverters are available in a number of different versions for safety-related applications. All Power

Modules are already designed for Safety Integrated. A Safety

Integrated Drive can be created by combining a Power Module

with the appropriate Fail-safe Control Unit.

The SINAMICS G120 fail-safe frequency inverter provides four

safety functions, certified in accordance with EN 954-1,

Category 3 and IEC 61508 SIL 2:

• Safe Torque Off (STO) to protect against active movement of

the drive

• Safe Stop 1 (SS1) for continuous monitoring of a safe braking

ramp

• Safely Limited Speed (SLS) for protection against dangerous

movements when a speed limit is exceeded

• Safe Brake Control (SBC) for controlling motor brakes that are

active in the de-energized state, e.g. motor holding brakes

The functions “Safe Stop 1” and “Safely Limited Speed” can

both be implemented without having to use a motor sensor or

encoder; the implementation cost is minimal. Existing systems in

particular can be updated with safety technology without the

need to change the motor or mechanical system.

The safety functions “Safely Limited Speed” and “Safe Stop 1”

are not certified for pull-through loads as in the case of lifting

gear and winders.

Additional information is provided in the part Highlights, section

Safety Integrated.

Efficient Infeed Technology

The innovative Efficient Infeed Technology is used in PM250 and

PM260 Power Modules. This technology allows the energy produced by motors operating in generator mode connected to

standard inverters to be fed back into the supply system. Additional cooling and additional space requirement in the control

cabinet can be avoided as components such as braking resistors, brake choppers and line reactors are not required. Further,

wiring and engineering costs are significantly reduced. At the

same time, considerable savings can be achieved in terms of

energy consumption and operating costs.

Additional information is included in the part Highlights, section

Efficient Infeed Technology.

Innovative cooling concept and coated electronic modules

The innovative cooling concept and coated electronic modules

significantly increase the service life and usage time of the device. These features are based on the following principles:

• The power loss is exclusively dissipated using an external

heat sink

• Electronic modules not located in air duct

• Standardized convection cooling of Control Unit

• All cooling air from the fan is directed through the heat sink

STARTER commissioning tool

The STARTER commissioning tool simplifies the commissioning

and maintenance of SINAMICS G120 inverters. The operator

guidance combined with comprehensive, user-friendly functions

for the relevant drive solution allow you to commission the device

quickly and easily.

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

SINAMICS G120 standard inverters

4/4

Siemens D 11.1 · 2009

4

■

Benefits

7 Modularity ensures flexibility for a drive concept that is fit-for-

the-future

- Modules can be replaced under voltage (hot swapping)

- Pluggable terminals

- The modules can be easily replaced, which makes the

system extremely service friendly.

7 The safety functions make it easier to integrate drives into

safety-oriented machines or plants

7 Communications-capable via PROFINET or PROFIBUS with

PROFIdrive Profile 4.0

- Reduced number of interfaces

- Plantwide engineering

- Easy to handle

7 The innovative circuit design (bidirectional input rectifier with

“pared-down” DC link) allows the kinetic energy of a load to be

fed back into the supply system when Power Modules PM250

and PM260 are used. This feedback capability provides enormous potential for savings because generated energy no

longer has to be converted into heat in a braking resistor

7 Innovative SiC semiconductor technology ensures that when

a PM260 Power Module is used, the inverter is more compact

than a comparable standard converter with an optional sinewave filter for the same power rating

7 An innovative cooling concept and coated electronic modules

increase robustness and service life

- External heatsink

- Electronic components are not located in air duct

- Control Unit that is completely cooled by convection

- Additional coating of the most important components

7 Simple unit replacement and quick copying of parameters

using the optional Basic Operator Panel or the optional MMC

memory card

7 Quiet motor operation as a result of the high pulse frequency

7 Compact, space-saving design

7 Software parameters for simple adaptation to 50 Hz or 60 Hz

motors (IEC or NEMA motors)

7 2-/3-wire control (static/pulsed signals) for universal control

via digital inputs (only CU240 Control Units)

7 Engineering and commissioning with uniform engineering

tools such as SIZER, STARTER, and Drive ES: ensure fast engineering and easy commissioning – STARTER is integrated in

STEP 7 with Drive ES Basic with all the advantages of central

data storage and totally integrated communication

7 Certified worldwide for compliance with CE, UL, cUL, c-tick

and Safety Integrated according to IEC 61508 SIL 2

■

Applications

SINAMICS G120 is ideally suited

• as a universal drive in all industrial and commercial applications

• e.g. in the automotive, textile, printing and chemical industries

• for higher-level applications, e.g. in conveyor systems

■

Design

SINAMICS G120 standard inverters are modular frequency inverters for standard drives. Each SINAMICS G120 comprises

two operative units – the Power Module and Control Unit. Each

Control Unit can be combined with each Power Module.

Guidelines for module selection

The procedure to select a complete SINAMICS G120 frequency

inverter should be as follows:

Control Units

The Control Unit performs closed-loop control functions for the

inverter. In addition to the closed-loop control, it has additional

functions that can be adapted to the particular application

through parameterization.

Two series of Control Units are available for SINAMICS G120

corresponding to their software packages (CU230 and CU240).

Each Control Unit comprises a defined I/O quantity structure, a

special fieldbus interface and possible additional safety functions. The following Control Units and accessories are available

for standard SINAMICS G120 inverters:

CU230 Control Units

The CU230P-2 Control Units have been specifically designed for

pump, fan and compressor applications. The following three versions are available:

• CU230P-2 HVAC

• CU230P-2 DP

• CU230P-2 CAN

CU240 Control Units

Several Control Units are available in different versions:

• CU240E

• CU240S

• CU240S DP

• CU240S DP-F

• CU240S PN

• CU240S PN-F

1. Select a suitable Control Unit (depending on the required communication, hardware and software version and safety functionality)

2. Select a suitable Power Module (depending on the power and

technology required)

3. Select the optional and additional components. There are a large

number of components for expanding the system (e.g. line-side

power components, DC link components, load-side power components, and supplementary system components). However, it

should be noted that not all of the components are required for all

of the Power Modules (example: Braking resistors are not required

for the PM250 and PM260 Power Modules!). The precise data is

provided in the technical specifications tables of the particular

components.

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

SINAMICS G120 standard inverters

4/5

Siemens D 11.1 · 2009

4

■

Design

Power Modules

The following Power Modules are available for the

SINAMICS G120 standard inverters:

PM240 Power Modules

PM240 Power Modules (0.37 kW to 250 kW / 0.5 hp to 400 hp)

feature an integrated brake chopper (for frame size FSGX external) and are designed for drives without energy recovery capability. Generator energy produced during braking is converted to

heat via externally connected braking resistors.

PM250 Power Modules

PM250 Power Modules (7.5 kW to 90 kW / 10 hp to 125 hp) have

an innovative circuit design which allows line-commutated energy recovery back into the line supply. This innovative circuit

permits generator energy to be fed back into the supply system

and therefore saves energy.

PM260 Power Modules

PM260 Power Modules (11 kW to 55 kW / 15 hp to 75 hp) also

have an innovative circuit design which allows line-commutated

energy recovery back into the line supply. This innovative circuit

permits generator energy to be fed back into the supply system

and therefore saves energy. The PM260 Power Modules also have

an integrated sine-wave filter that limits the rate of rise of voltage

and the capacitive charging/discharging currents usually associated with inverter operation.

Line-side power components

The following line-side power components are available for

SINAMICS G120 standard inverters:

Line filters

With one of the additional line filters, the Power Module reaches

a higher radio interference class.

Line reactors (for PM240 Power Modules only)

A line reactor reduces the system perturbations caused by

harmonics. This particularly applies in the case of weak line

supplies (line supply short-circuit power u

K

>1%).

Recommended line components

This is a recommendation for additional line-side components,

such as fuses and circuit-breakers (line-side components must

be dimensioned in accordance with IEC standards). Additional

information about the listed fuses and circuit breakers can be

found in Catalogs LV 1 and LV 1 T.

DC link components

The following DC link components are available for the

SINAMICS G120 standard inverters:

Braking Modules (only for PM240 Power Modules, frame

size FSGX)

A Braking Module and the matching external braking resistor are

required to bring drives with a PM240 Power Module, frame

size FSGX to a controlled standstill in the event of a power failure

(e.g. emergency retraction or EMERGENCY STOP Category 1)

or limit the DC link voltage during a short period of generator

operation. The Braking Module includes the power electronics

and the associated control circuit.

Braking resistors (for PM240 Power Modules only)

Excess energy in the DC link is dissipated in the braking resistor.

The braking resistors are designed for use with PM240 Power

Modules. They are equipped with an integrated brake chopper

(electronic switch). There is an optional plug-in Braking Module

for frame size FSGX.

Load-side power components

The following load-side power components are available for the

SINAMICS G120 standard inverters. This means that during operation with output reactors or sine-wave filters, longer, shielded

motor cables are possible and the motor service life can be extended:

Output reactors (for PM240 and PM250 Power Modules only)

Output reactors reduce the voltage stress on the motor wind-

ings. At the same time, the capacitive charging/discharging currents, which place an additional load on the power unit when

long motor cables are used, are reduced.

Sine-wave filter (not for PM260 Power Modules)

The sine-wave filter limits the rate of rise of voltage and the

capacitive charging/discharging currents that usually occur with

inverter operation. An output reactor is not required.

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

SINAMICS G120 standard inverters

4/6

Siemens D 11.1 · 2009

4

■

Design

Power and DC link components which are optionally available depending on the Power Module used

The following line-side power components, DC link components

and load-side power components are optionally available in the

appropriate frames sizes for the Power Modules:

U = Base component

S = Lateral mounting

I = Integrated

– = Not possible

F = Power Modules available with and without integrated class A filter

Frame size

FSA FSB FSC FSD FSE FSF FSGX

PM240 Power Module with integrated brake chopper without inte-

grated brake

chopper

Available frame sizes ✓ ✓ ✓ ✓ ✓ ✓ ✓

Line-side power components

Line filter, class A U F F F F F/S

3)

S

3)

Line filter, class B U U U – – – –

Line reactor U U U U U S S

DC link components

Braking resistor U U S S S S S

Braking Module – – – – – – I (Option)

Load-side power components

Output reactor U U U S S S S

Sine-wave filter U U U S S S S

PM250 Power Module with line-commutated energy recovery

Available frame sizes – – ✓ ✓ ✓ ✓ –

Line-side power components

Line filter, class A – – I F F F –

Line filter, class B – – U – – – –

Line reactor

1)

– – –

1)

–

1)

–

1)

–

1)

–

DC link components

Braking resistor

2)

– – –

2)

–

2)

–

2)

–

2)

–

Load-side power components

Output reactor – – U S S S –

Sine-wave filter – – U S S S –

PM260 Power Module with line-commutated energy recovery and integrated sine-wave filter

Available frame sizes – – – ✓ – ✓ –

Line-side power components

Line filter, class A – – – F – F –

Line filter, class B – – – – – – –

Line reactor

1)

– – – –

1)

– –

1)

–

DC link components

Braking resistor

2)

– – – –

2)

– –

2)

–

Load-side power components

Output reactor – – – – – – –

Sine-wave filter – – – I – I –

1)

A line reactor is not required and must not be used in conjunction with a

PM250 or PM260 Power Module.

2)

Line-commutated energy recovery is possible in conjunction with a PM250

or PM260 Power Module. A braking resistor cannot be connected and is

not necessary.

3)

PM240 FSF Power Modules, from 110 kW (150 hp) and higher and FSGX

are only available without an integrated class A filter. An optional class A

line filter for side mounting is available instead.

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

SINAMICS G120 standard inverters

4/7

Siemens D 11.1 · 2009

4

■

Design

General design information

Frequency inverters comprising a Power Module (PM) and a Control Unit

(CU) and two base components at position 1 and position 2 (side view)

• A maximum of two base components plus inverter are possible.

• The line filter has to be mounted directly below the frequency

inverter (position 1).

• With lateral mounting, the line-side components have to be

mounted on the left side of the frequency inverter and the

load-side components on the right side.

• Braking resistors have to be mounted directly on the control

cabinet wall due to heating issues.

Recommended installation combinations of the inverter and optional power and DC link components

Inverter chassis unit

SINAMICS G120 e. g.

Filter

Base components

e. g.

Reactor

Mounting

surface or

cabinet wall

Position1Position

2

G_D011_EN_00187

CU PM

Power

Modules

Base Lateral mounting

Frame size Position 1 Position 2 left of the inverter

(for line-side power

components)

right of the inverter

(for load-side power

components and

DC link components)

FSA and FSB Line filter Line reactor – Output reactor or

sine-wave filter and/or

braking resistor

Line filter or

line reactor

Output reactor or

sine-wave filter

– Braking resistor

Line filter or

line reactor

Braking resistor – –

Line filter or

line reactor or

braking resistor

– – –

FSC

Line filter Line reactor – Output reactor or

sine-wave filter and/or

braking resistor

Line filter or

line reactor

Output reactor or

sine-wave filter

– Braking resistor

FSD and FSE Line reactor – Line filter Output reactor or

sine-wave filter and/or

braking resistor

FSF – – Line filter and/or

line reactor

Output reactor or

sine-wave filter and/or

braking resistor

FSGX – – Line filter and/or

line reactor

Output reactor or

sine-wave filter and/or

braking resistor

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

SINAMICS G120 standard inverters

4/8

Siemens D 11.1 · 2009

4

■

Design

Maximum permissible cable lengths from the motor to the

inverter when using output reactors or sine-wave filters

depending on the voltage range and the Power Module being

used

The following load-side power components in the appropriate

frame sizes are optionally available for the Power Modules and

result in the following maximum cable lengths:

Maximum permissible motor cable lengths (shielded/unshielded) in m

Frame sizes

FSA FSB FSC FSD FSE FSF FSGX

PM240 Power Module with integrated brake chopper without inte-

grated brake

chopper

Available frame sizes ✓ ✓ ✓ ✓ ✓ ✓ ✓

Without output reactor/sine-wave filter

50/100 50/100 50/100 50/100 100/100 150/150 300/450

With optional output reactor

• at 380 V (– 10 %) to 400 V 3 AC 150/225 150/225 150/225 200/300 200/300 200/300 300/450

• at 401 V to 480 V (+ 10 %) 3 AC 100/150 100/150 100/150 200/300 200/300 200/300 300/450

With optional sine-wave filter

• at 380 V (– 10 %) to 400 V 3 AC 200/300 200/300 200/300 200/300 200/300 200/300 300/450

• at 401 V to 480 V (+ 10 %) 3 AC 200/300 200/300 200/300 200/300 200/300 200/300 300/450

PM250 Power Module with line-commutated energy recovery

Available frame sizes – – ✓ ✓ ✓ ✓ –

Without output reactor/sine-wave filter – – 50/100 50/100 50/100 50/100 –

With optional output reactor

• at 380 V (– 10 %) to 400 V 3 AC – – 150/225 200/300 200/300 200/300 –

• at 401 V to 480 V (+ 10 %) 3 AC – – 100/150 200/300 200/300 200/300 –

With optional sine-wave filter

• at 380 V (– 10 %) to 400 V 3 AC – – 200/300 200/300 200/300 200/300 –

• at 401 V to 480 V (+ 10 %) 3 AC – – 200/300 200/300 200/300 200/300 –

PM260 Power Module with line-commutated energy recovery and integrated sine-wave filter

Available frame sizes – – – ✓ – ✓ –

With integrated sine-wave filter

• at 500 V to 690 V 3 AC (± 10 %) – – – 200/300 – 200/300 –

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

SINAMICS G120 standard inverters

4/9

Siemens D 11.1 · 2009

4

■

Design

Supplementary system components

The following supplementary system components are available

for the SINAMICS G120 standard inverters:

Intelligent Operator Panel IOP

The IOP supports both entry-level personnel and drive experts.

Thanks to the large plain text display, the menu prompting and

the Application Wizards, it is easy to commission, diagnose and

locally control standard drives.

Operator Panel BOP (not for CU230P-2 Control Units)

The Basic Operator Panel BOP can be plugged onto the Control

Unit and can be used to commission drives, monitor drives in

operation and input individual parameter settings. The BOP also

provides a function to quickly copy parameters.

MMC memory card (not for CU240E Control Units)

The parameter settings for an inverter can be stored on the MMC

memory card. When service is required, e.g. after the inverter

has been replaced and the data have been downloaded from

the memory card the drive system is immediately ready for use

again. The associated slot is located on the top of the Control

Unit.

CM240NE chemical industry module

Inverters for 400 V / 500 V and 690 V are required in the chemical

industry that meet the special demands and requirements of this

industry sector. The essential requirements and demands of the

chemical industry are fulfilled using the SINAMICS G120 series

of inverters supplemented by the CM240NE chemical industry

module (with ATEX-certified PTC evaluation and a NAMUR terminal strip).

PC Inverter Connection Kit

For controlling and commissioning an inverter directly from a PC

if the appropriate software (STARTER commissioning tool) has

been installed.

The STARTER commissioning tool on DVD is included in the PC

Inverter Connection Kit.

Brake Relay

The Brake Relay allows the Power Module to be connected to an

electromechanical motor brake, thereby allowing the motor

brake to be driven directly by the Control Unit.

Safe Brake Relay

The Safe Brake Relay allows the Power Module to be connected

to an electromechanical motor brake, allowing the brake to be

directly and safely controlled from the Control Unit in accordance with EN 954-1 Category 3 and IEC 61508 SIL 2.

Adapter for mounting on DIN rails

The adapter for mounting on DIN rails can be used to mount in-

verters of the sizes FSA and FSB on DIN mounting rails (2 units

with a center-to-center distance of 100 mm).

Shield Connection Kit

The Shield Connection Kit makes it easier to connect the shields

of supply and control cables, offers mechanical strain relief and

thus ensures optimum EMC performance.

Shield Connection Kit for CU240S and CU230P-2

The Shield Connection Kit offers optimum shield connection and

strain relief for all signal and communication cables. It includes

a matching shield bonding plate and all of the necessary connecting and retaining elements for mounting.

Spare parts

Spare Parts Kit for CU240

The kit includes a replacement cover for the terminals, a suitable

shield bar for the CU240E Control Unit including screws, replacement connector for the CU240S Control Unit, protective

element of the MMC card slot and screws to attach the shield

bonding plate of the CU240S Control Unit.

Term ina l Cov er K it

The kit includes a replacement cover for the terminals. The kit can

be ordered for PM240 Power Modules, frame sizes FSD, FSE and

FSF, as well as for the PM260, frame size FSF.

PM260 replacement connector

This spare part includes a connector for the input and output sides

for the PM260 Power Module, frame size FSD.

SINAMICS G120 PM240 FSGX replacement door

A complete replacement door can be ordered for the PM240

Power Module, frame size FSGX.

Replacement fan

The Power Module fans are designed for extra long service life.

Replacement fans can be ordered for special applications.

■

Configuration

The following electronic configuring and engineering tools are

available for the SINAMICS G120 standard inverters:

Selection guide, SD Configurator

More than 100000 products with approximately 5 million possible product versions from the area of drive technology are listed

in the interactive Catalog CA 01 – the Offline Mall from Siemens

IA&DT. In order to make it easier to select the optimum motor

and/or inverter from the wide range of Standard Drives, the SD

Configurator was developed, which is integrated as “Selection

guide” in this catalog on the DVD together with the selection and

engineering tools.

Online SD Configurator

In addition, the SD Configurator can be used in the Internet with-

out requiring any installation. The SD Configurator can be found

in the Siemens Mall under the following address:

http://www.siemens.com/dt-configurator

SIZER configuration tool

The SIZER PC tool makes it easy to configure the SINAMICS and

MICROMASTER 4 drive family. It provides support when selecting the hardware and firmware components necessary to implement a drive task. SIZER supports the configuration of the complete drive system, from simple single-motor drives up to

complex multi-axis applications.

STARTER commissioning tool

The STARTER commissioning tool is used to commission, optimize and diagnose drives in a menu-prompted fashion. In

addition to SINAMICS drives, STARTER is also suitable for

MICROMASTER 4 units and the frequency converters for the

distributed I/O SIMATIC ET 200S FC and

SIMATIC ET 200pro FC.

Drive ES engineering system

Drive ES is the engineering system used to integrate the communication, configuration and data management functions of

Siemens drive technology into the SIMATIC automation world

easily, efficiently and cost-effectively. The STEP 7 Manager user

interface forms the basis. Various software packages are available for SINAMICS:

Drive ES Basic, Drive ES SIMATIC and Drive ES PCS 7.

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

SINAMICS G120 standard inverters

4/10

Siemens D 11.1 · 2009

4

■

Technical specifications

Unless explicitly specified otherwise, the following technical

specifications are valid for all the following components of the

SINAMICS G120 standard inverters.

Mechanical specifications

Vibratory load

•Transport 1) acc. to EN 60721-3-2

- All units and components

except frame size FSGX

- Units with frame size FSGX

Class 2M3

Class 2M2

• Operation

Test values acc. to EN 60068-2-6 Test Fc:

10 … 58 Hz: Constant deflection

0.075 mm

58 … 150 Hz: Constant acceleration = 9.81 m/s2 (1 × g)

Shock load

•Transport 1) acc. to EN 60721-3-2

- All units and components

except frame size FSGX

- Units with frame size FSGX

Class 2M3

Class 2M2

• Operation

Test values acc. to

EN 60068-2-27

- Frame sizes FSA to FSC

- Frame sizes FSD to FSF

- Frame size FSGX

Test E a :

147 m/s2 (15 × g)/11 ms

49 m/s2 (5 × g)/30 ms

98 m/s2 (10 × g)/20 ms

Ambient conditions

Protection class

acc. to EN 61800-5-1

Class I (with protective conductor

system) and Class III (PELV)

Touch protection

acc. to EN 61800-5-1

For the intended purpose

Permissible ambient and coolant

temperature (air) during operation for line-side power components and Power Modules

• High overload

(HO)

0…50°C (32…122°F) without

derating

(for PM240, frame size FSGX:

0 … 40 °C),

> 50 … 60 °C see derating

characteristics

• Light overload

(LO)

0…40°C (32…104°F) without

derating

(for PM240, frame size FSGX:

0 … 40 °C),

> 40 … 60 °C see derating

characteristics

Permissible ambient and coolant

temperature (air) during operation for Control Units, additional

system components and DC-link

components

–10…+50°C (14…122°F)

with CU240S DP-F: 0 … 45 °C

with CU240S PN-F: 0 … 40 °C

with IOP: 0 … 50 °C

up to 2000 m above sea level

Climatic ambient conditions

•Storage1) acc. to EN 60721-3-1 Class 1K3

temperature –25 … +55 °C

•Transport1) acc. to EN 60721-3-2 Class 2K4

temperature –40 … +70 °C

max. humidity 95 % at 40 °C

• Operation acc. to EN 60721-3-3 Class 3K5 4)

Condensation, splashwater and

ice formation not permitted

(EN 60204, Part 1)

Ambient conditions (continued)

Environmental class/harmful

chemical substances

•Storage1) acc. to EN 60721-3-1 Class 1C2

•Transport1) acc. to EN 60721-3-2 Class 2C2

• Operation acc. to EN 60721-3-3 Class 3C2

Organic/biological influences

•Storage1) acc. to EN 60721-3-1 Class 1B1

•Transport1) acc. to EN 60721-3-2 Class 2B1

• Operation acc. to EN 60721-3-3 Class 3B1

Degree of pollution

acc. to EN 61800-5-1

2

Certification for fail-safe versions

Applies to CU240 DP-F and

CU240 PN-F Control Units.

The values include Control Unit,

Power Module and Safe Brake

Relay.

• Category acc. to EN 954-1 3

• SIL Cl acc. to IEC 61508 2

• PL acc. to ISO 13849 Available soon

•PFH

D

5 × 10

–8

•T1 10 Years

Standards

Standards conformance UL, cUL, CE, c-tick

CE mark According to Low-Voltage Direc-

tive 73/23/EEC and Machinery

Directive 98/37/EC

EMC Directive acc. to EN 61800-3

• Frame sizes FSA to FSGX without

integrated line filter class A

Category C3

2)

• Frame sizes FSB to FSF with

integrated line filter class A

Category C2 3)

(corresponds to class A acc. to

EN 55011 for conducted interference emission)

• Frame size FSA without integrated line filter and with additional

line filter class A

Category C2 3)

(corresponds to class A acc. to

EN 55011 for conducted interference emission)

• Frame size FSA with additional

line filter class A and with additional line filter class B

Category C2 3)

(corresponds to class B acc. to

EN 55011 for conducted interference emission)

• Frame sizes FSB and FSC with

additional line filter class A and

with additional line filter class B

Category C2 3)

(corresponds to class B acc. to

EN 55011 for conducted interference emission)

Note: The EMC product standard EN 61800-3 does not apply directly

to a frequency inverter but to a PDS (Power Drive System), which comprises the complete circuitry, motor and cables in addition to the frequency inverters. The frequency inverters on their own do not generally

require identification according to the EMC Directive.

1)

In transport packaging.

2)

Unfiltered inverters can be used in industrial environments as long as they

are part of a system that contains line filters on the higher-level infeed side.

As a consequence, a PDS (Power Drive System) can be installed according to C3.

3)

With shielded motor cable up to 25 m.

4)

For Intelligent Operator Panel IOP, class 3K3.

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

SINAMICS G120 standard inverters

4/11

Siemens D 11.1 · 2009

4

■

Technical specifications

Compliance with standards

CE mark

The SINAMICS G120 inverters meet the requirements of the

Low-Voltage Directive 73/23/EEC.

Low-Voltage Directive

The inverters comply with the following standards listed in the

official journal of the EU:

• EN 60204

Safety of Machinery, electrical equipment of machines

• EN 61800-5-1

Electrical power drive systems with variable speed – Part 5-1:

Requirements regarding safety – electrical, thermal, and energy requirements

UL listing

Inverter devices in UL category NMMS certified to UL and cUL,

in compliance with UL508C. UL list numbers E121068 and

E192450.

For use in environments with pollution degree 2.

Also see the Internet under http://www.ul.com

Machinery Directive

The inverters are suitable for installation in machines. Compliance with the Machinery Directive 98/37/EC requires a separate

certificate of conformity. This must be provided by the plant construction company or the organization marketing the machine.

EMC Directive

• EN 61800-3

Variable-speed electric drives

Part 3: EMC product standard including specific test methods

The EMC product standard EN 61800-3 has been valid for electric drive systems since 07/01/2005. The transition period for the

predecessor standard EN 61800-3/A11 from February 2001

ended on October 1, 2007. The following information applies to

SINAMICS G120 frequency inverters from Siemens:

• The EMC product standard EN 61800-3 does not apply

directly to a frequency inverter but to a PDS (Power Drive

System), which comprises the complete circuitry, motor and

cables in addition to the inverter.

• Frequency inverters are normally only supplied to experts for

installation in machines or systems. A frequency inverter must,

therefore, only be considered as a component which, on its

own, is not subject to the EMC product standard EN 61800-3.

The inverter's operating manual, however, specifies the conditions regarding compliance with the product standard if the

frequency inverter is expanded to become a PDS. For a PDS,

the EMC Directive in the EU is complied with by observing the

product standard EN 61800-3 for variable-speed electric

drive systems. The frequency inverters on their own do not

generally require identification according to the EMC Directive.

• In the Standard EN 61800-3 from July 2005, a distinction is no

longer made between “general availability” and “restricted

availability”. Instead, different categories C1 to C4 have been

defined in accordance with the environment of the PDS at the

operating location:

- Category C1: Drive systems for rated voltages < 1000 V for

use in the first environment

- Category C2: Stationary drive systems not connected by

means of a plug connector for rated voltages < 1000 V.

When used in the first environment, the system must be installed and commissioned by personnel familiar with EMC

requirements. A warning note is required.

- Category C3: Drive systems for rated voltages < 1000 V for

exclusive use in the second environment. A warning note is

required.

- Category C4: Drive systems for rated voltages ≥ 1000 V or

for rated currents ≥ 400 A or for use in complex systems in

the second environment. An EMC plan must be generated.

• The EMC product standard EN 61800-3 also defines limit values for conducted interference and radiated interference for

the so-called “second environment” (= industrial power supply systems that do not supply households). These limit values

are below the limit values of filter class A to EN 55011. Unfiltered inverters can be used in industrial environments as long

as they are part of a system that contains line filters on the

higher-level infeed side.

• With SINAMICS G120, Power Drive Systems (PDS) that fulfill

the EMC product standard EN 61800-3 can be configured

when observing the installation instructions in the product

documentation.

• A differentiation must be made between the product standards for electrical drive systems (PDS) of the range of standards EN 61800 (of which Part 3 covers EMC topics) and the

product standards for the devices/systems/machines, etc.

This will probably not result in any changes in the practical use

of frequency inverters. Since frequency inverters are always

part of a PDS and these are part of a machine, the machine

manufacturer must observe various standards depending on

their type and environment (e.g. EN 61000-3-2 for line harmonics and EN 55011 for radio interference). The product

standard for PDS on its own is, therefore, either insufficient or

irrelevant.

• With respect to the compliance with limits for line supply harmonics, the EMC product standard EN 61800-3 for PDS refers

to compliance with the EN 61000-3-2 and EN 61000-3-12

standards.

• Regardless of the configuration with SINAMICS G120 and its

components, the machine construction company (OEM) can

also apply other measures to ensure that the machine complies with the EU EMC Directive. The EU EMC Directive is generally fulfilled when the relevant EMC product standards are

observed. If they are not available, the generic standards (e.g.

DIN EN 61000-x-x) can be used instead. It is important that

the conducted and emitted interference at the line connection

point and outside the machine remain below the relevant limit

values. Any suitable technical measures can be applied to ensure this.

SEMI F47

SEMI F47 is an industry standard relating to the immunity to voltage dips. This includes the requirement that industrial equipment must be able to tolerate defined dips or drops of the line

supply voltage. As a result, industrial equipment that fulfills this

standard is more reliable and productive. In the SINAMICS G120

product family, the PM240 and PM250 Power Modules fulfill the

latest SEMI F47-0706 standard. In the case of a voltage dip, defined in accordance with SEMI F47-0706, these drives either

continue to supply a defined output current, or using an automatic restart function, continue to operate as expected.

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

CU230 Control Units

4/12

Siemens D 11.1 · 2009

4

■

Overview

Example: CU230P-2 HVAC Control Unit with Intelligent Operator Panel

IOP on the PM240 Power Module, frame size FSC

The CU230P-2 Control Units are especially suitable for drives

with integrated technological functions for pump, fan and compressor applications. The I/O interface, the fieldbus interfaces

and the additional software functions optimally support these

applications. The integration of technological functions is a significant differentiating feature to the other Control Units of the

SINAMICS G120 drive family.

■

Selection and ordering data

■

Function

Closed-loop control

• Linear and square torque characteristics for fluid flow and

positive displacement machines

• ECO mode for additional energy saving

• Vector control without encoder for sophisticated control tasks

Connections

• Two analog inputs (current/voltage can be selected) to directly

connect pressure/level sensors

• Two additional analog inputs to connect NI1000/PT1000 temperature sensors

• Direct control of valves and flaps using two 230 V relays

Interfaces

• PROFIBUS, USS, CANopen and Modbus RTU communication

Software functions

• Automatic restart function after power failure

• Flying restart

• Kinetic buffering (V

dc min

control)

• PID controller for temperature, pressure, air quality, level

• Energy saving using the “hibernation mode”

• Load check function to monitor belts and flow

• Real time clock with three time generators

IOP wizards for special applications such as e.g.

• Pumps: Positive displacement (constant load torque) and

centrifugal pumps (square load torque) with and without

PID controller

• Fans: Radial and axial fans (square load torque) with and without PID controller

• Compressors: Positive displacement (constant load torque)

and fluid flow machines (square load torque) with and without

PID controller

Communication Digital inputs Digital outputs Analog inputs Analog outputs Designation Control Unit

Order No.

Standard

RS485/USS;

Modbus RTU

6342CU230P-2HVAC6SL3243-0BA30-1HA0

PROFIBUS DP 6 3 4 2 CU230P-2 DP 6SL3243-0BA30-1PA0

CANopen 6 3 4 2 CU230P-2 CAN 6SL3243-0BA30-1CA0

new

new

new

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

CU230 Control Units

4/13

Siemens D 11.1 · 2009

4

■

Design

CU230P-2 HVAC, CU230P-2 DP, CU230P-2 CAN Control Units

Example: CU230P-2 DP Control Unit with open terminal covers

Termi nal

No.

Signal Features

Digital inputs (DI) – Standard

69 DI Com Reference potential for digital inputs

5...8,

16.17

DI0 ... DI5 Freely programmable

isolated, inputs in compliance with

IEC 61131-2

Digital outputs (DO)

18 DO0, NC Relay output 1

NC contact (2 A, 230 V AC)

19 DO0, NO Relay output 1

NO contact (2 A, 230 V AC)

20 DO0, COM Relay output 1

Common contact (2 A, 230 V AC)

21 DO1, NO Relay output 2

NO contact (0.5 A, 30 V DC)

22 DO1, COM Relay output 2

Common contact (0.5 A, 30 V DC)

23

DO2, NC Relay output 3

NC contact (2 A, 230 V AC)

24

DO2, NO Relay output 3

NO contact (2 A, 230 V AC)

25 DO2, COM Relay output 3

Common contact (2 A, 230 V AC)

Termi nal

No.

Signal Features

Analog inputs (AI)

3 AI0+ Differential input, switchable between

current, voltage

Value range: 0 ... 10 V, –10 ... +10 V,

0/2 ... 10 V, 0/4 ... 20 mA

4 AI0-

10 AI1+ Differential input, switchable between

current, voltage

Value range: 0 ... 10 V, –10 ... +10 V,

0/2 ... 10 V, 0/4 ... 20 mA

11 AI1-

50 AI2+/NI1000 Non-isolated input, switchable between

current, temperature sensors,

type PT1000, NI1000

Value range: 0/4 ... 20 mA,

PT1000 –50 ... +250 °C;

NI1000 –50 ... +150 °C

51 GND Reference potential of the AI2/internal

electronics ground

52 AI3+/NI1000 Non-isolated input for temperature sensors,

Type PT1000, NI1000

Value range: PT1000 –50 ... +250 °C;

NI1000 –50 ... +150 °C

53 GND Reference potential of the AI3/internal

electronics ground

Analog outputs (AO)

12 AO0+ Non-isolated output

Freely programmable

Value range: 0 ... 10 V; 0/4 ... 20 mA

13 AO GND Reference potential of the AO0/internal

electronics ground

26 AO1+ Non-isolated output

Freely programmable

Value range: 0 ... 10 V; 0/4 ... 20 mA

27 AO GND Reference potential of the AO1/internal

electronics ground

Motor temperature sensor interface

14 T1 motor Positive input for motor temperature sensor

Type: PTC, KTY sensor, Thermo-Click

15

T2 motor Negative input for motor temperature

sensor

Power supply

9 +24 V OUT Power supply output

24 V DC, max. 200 mA

28 GND Reference potential of the power supply/

internal electronics ground

1 +10 V OUT Power supply output

10 V DC ±0.5 V, max. 10 mA

2 GND Reference potential of the power supply/

internal electronics ground

31 +24 V IN Power supply input

18 ... 30 V DC, max. 1500 mA

32 GND IN Reference potential of the power supply

input

35

+10 V OUT Power supply output

10 V DC ±0.5 V max. 10 mA

36

GND Reference potential of the power supply/

internal electronics ground

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

CU230 Control Units

4/14

Siemens D 11.1 · 2009

4

■

Integration

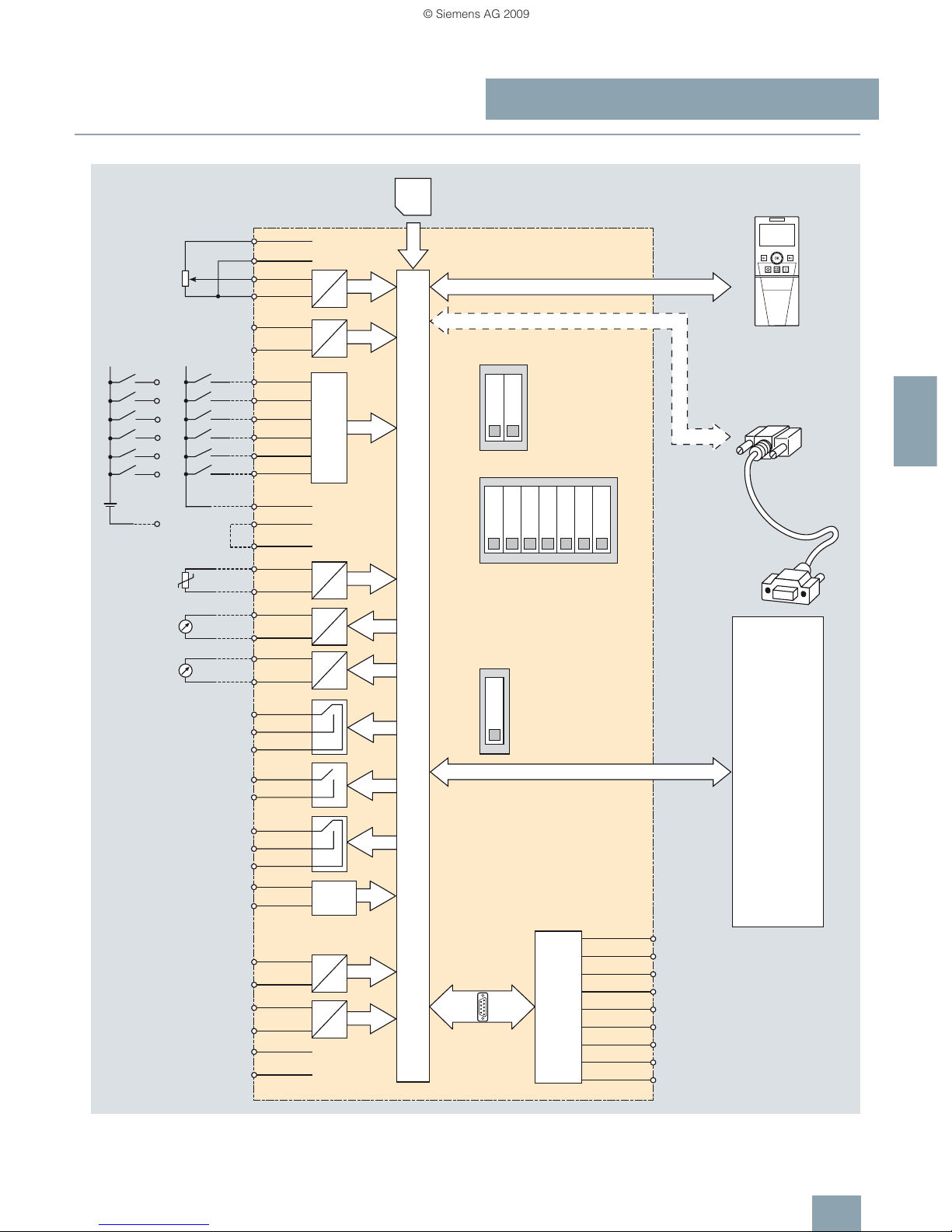

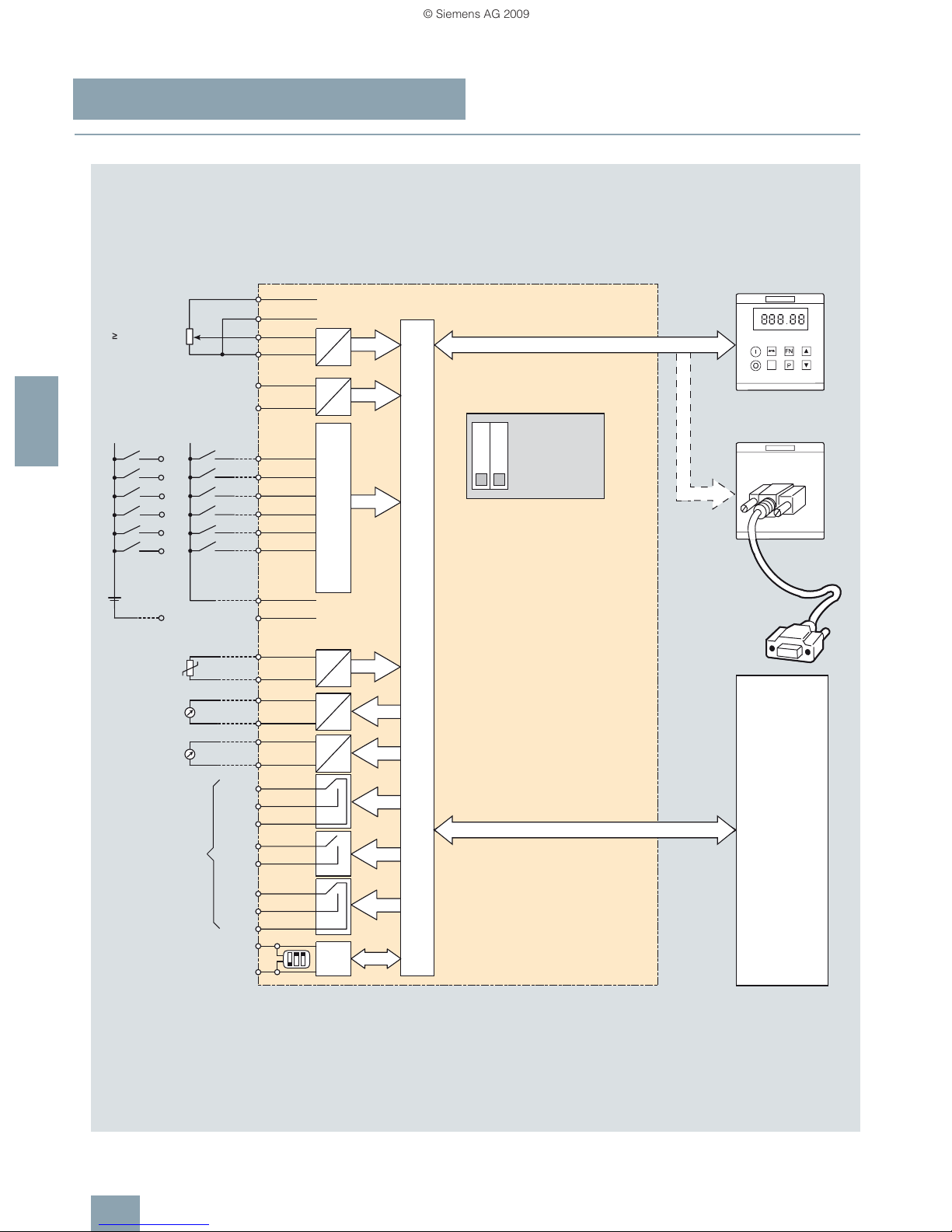

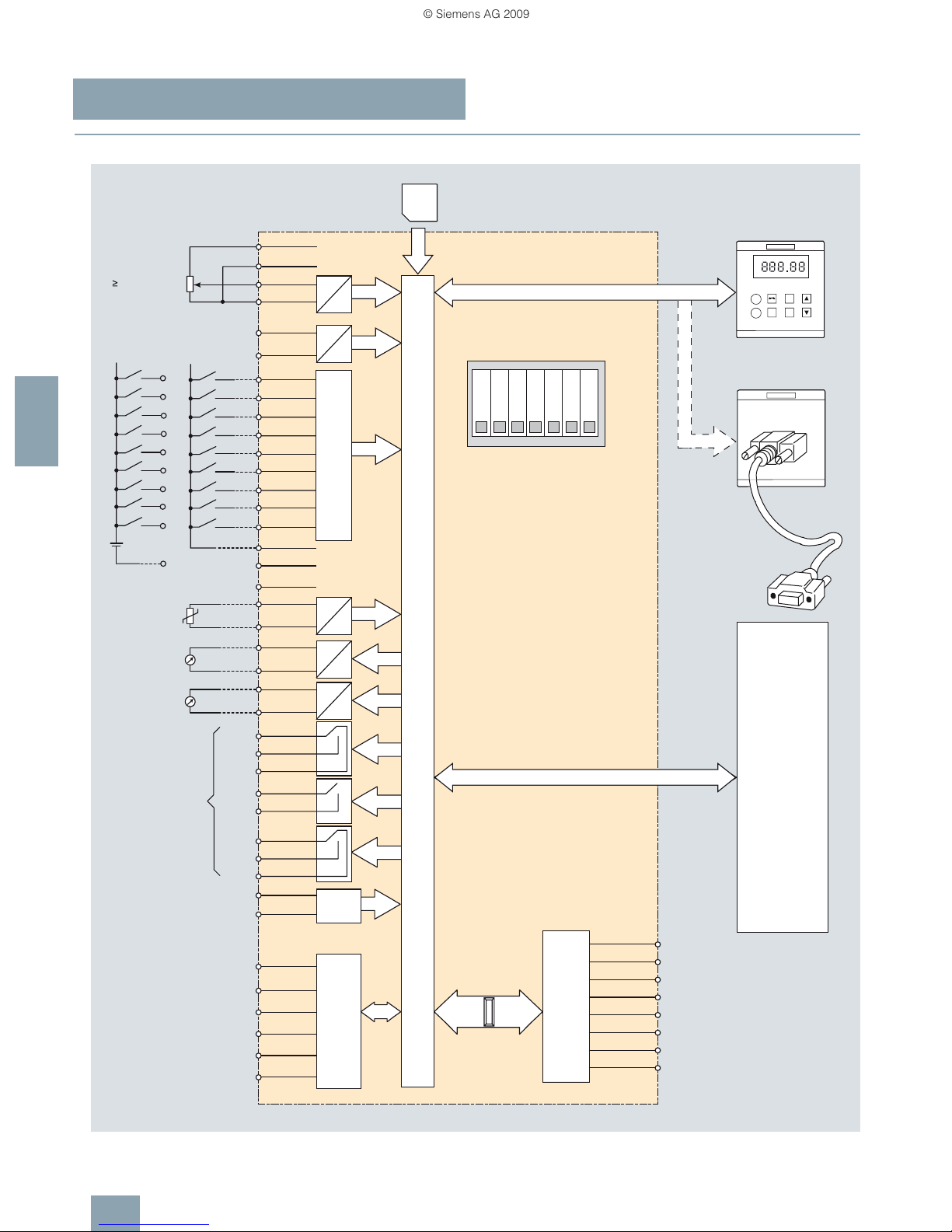

CU230P-2 HVAC Control Unit connection diagram

G_D011_EN_00210

IOP/IOP handheld

Shield

Voltage output 10 V

Temperature sensor

NI1000 or AI2+

Temperature sensor

NI1000 or AI3+

PM-IF interface

0 to 10 V

0 to 20 mA

PC to inverter

connection kit

OFF

ON

OFF

ON

0 to 20 mA

max. 500 Ohm

0 to 20 mA

max. 500 Ohm

≥ 4.7 kOhm

IOP/IOP handheld interface

USB interface for PC tools

Digital inputs

* = Not connected

RS485 connector

From

external

source

DIP switch

Bus termination

DIP switch

Analog inputs

NI1000

CURRENT

DIP switch

Temperature sensor NI1000

69

17

16

8

7

6

5

-

+

24 V

DI5

DI4

DI3

DI2

DI1

DI0

MMC

PTC/KTY

Power Module

AI1

AI0

DO0

DO2

DO1

AO1-27

AO1+26

D

A

D

A

5

4

3

2

0 V

RS485P

RS485N

*

1

0 V32

+24 V31

U0V28

NO21

COM22

NO24

NC23

COM25

NO19

NC18

COM20

AO0-13

AO0+12

15

14

69

U24V9

DI517

DI416

DI38

DI27

DI16

DI05

AI1-11

AI1+10

AI0-4

AI0+3

2

1

0 V

+ 10 V

D

A

A

D

A

D

GND

36

+ 10 V OUT

35

53

52

51

50

D

A

D

A

GND

GND

AI2+/

NI1000

AI3+/

NI1000

Control Unit

CU230P-2 HVAC

DI COM

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

CU230 Control Units

4/15

Siemens D 11.1 · 2009

4

■

Integration

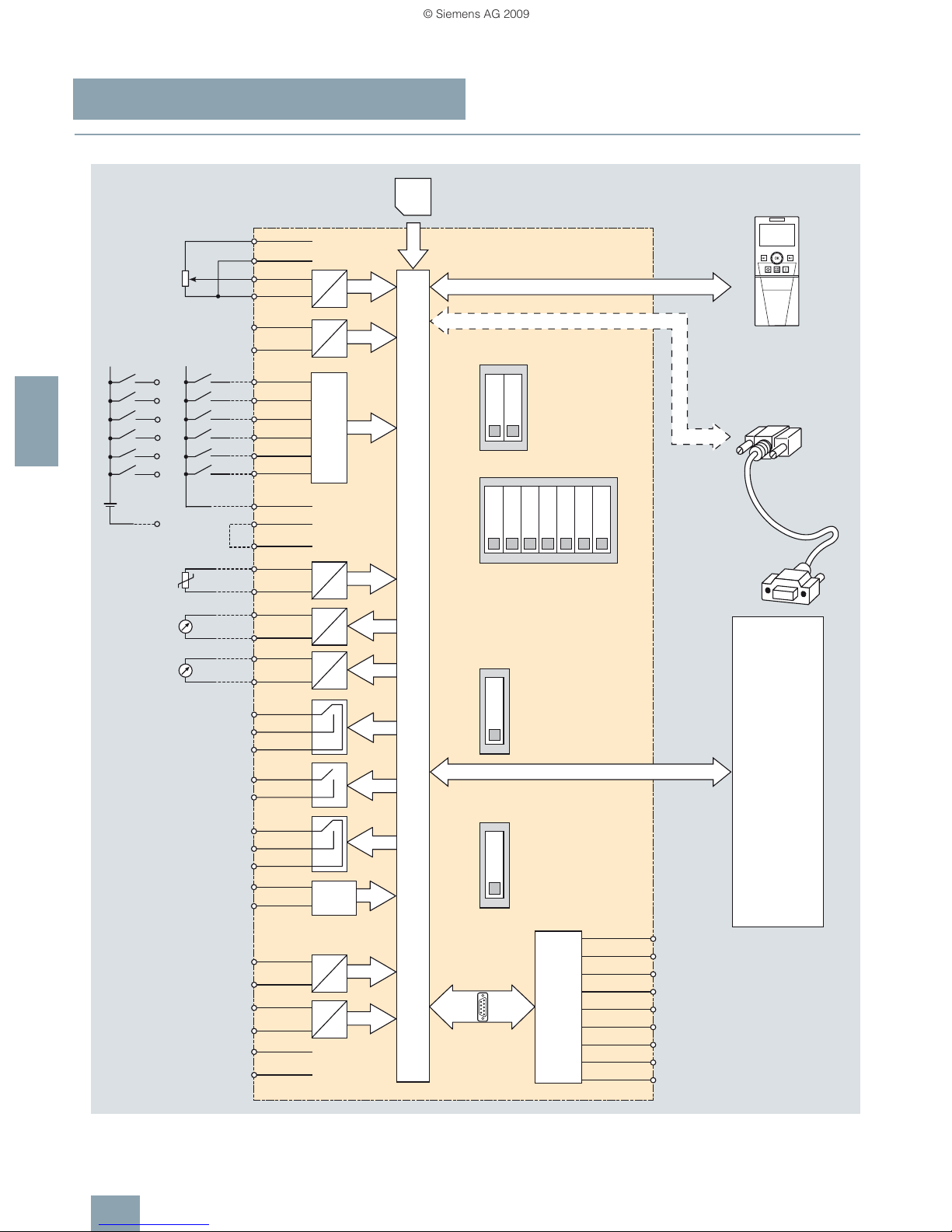

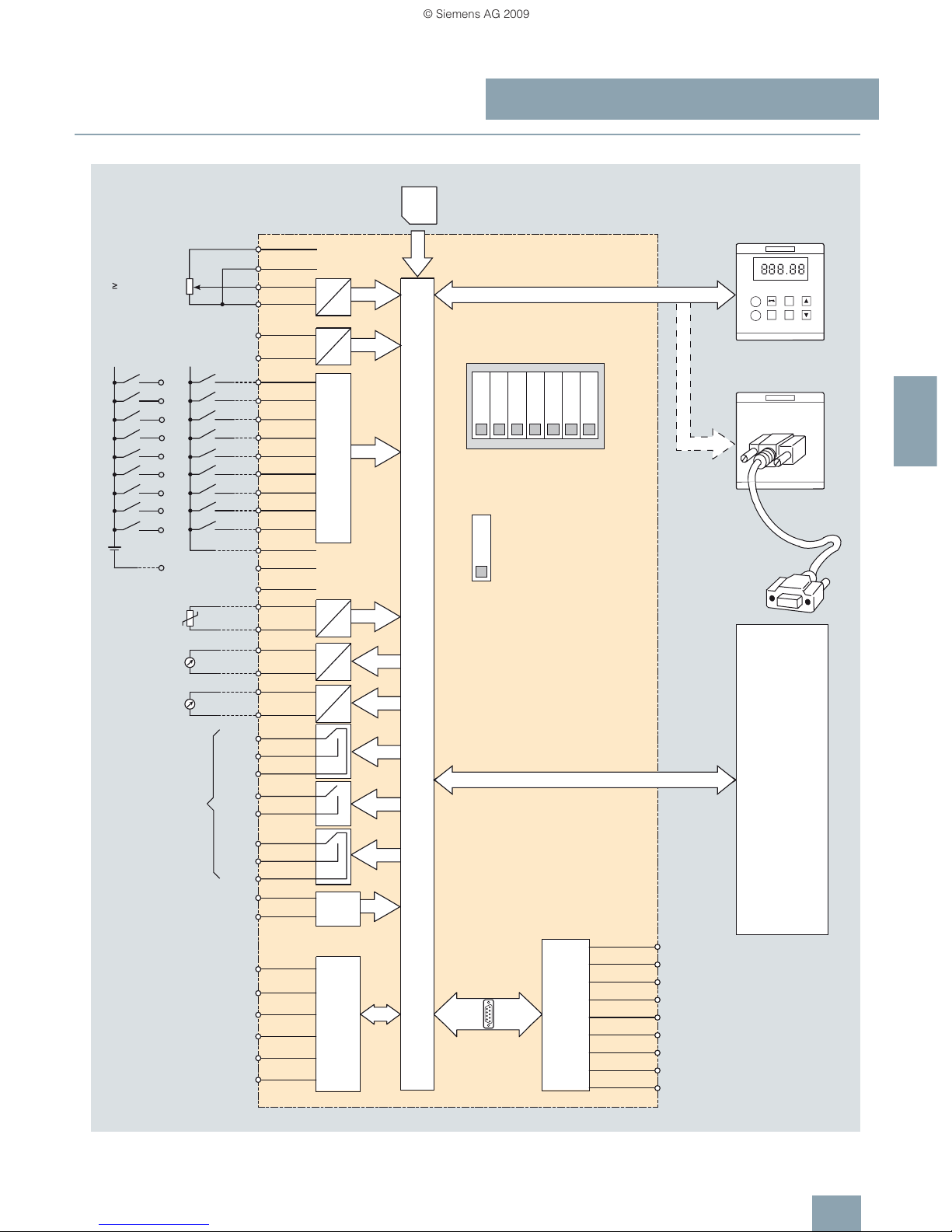

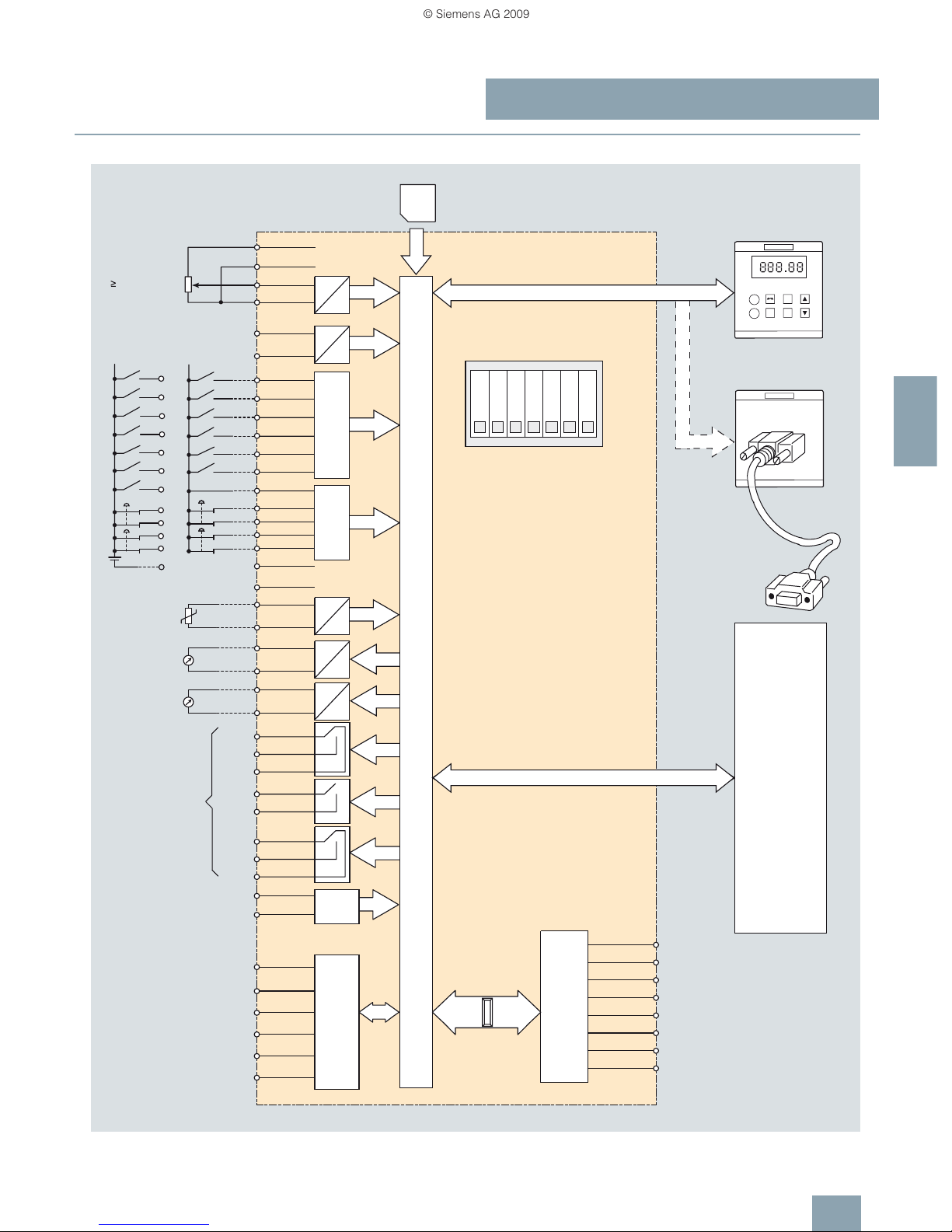

CU230P-2 DP Control Unit connection diagram

G_D011_EN_00211

IOP/IOP handheld

Shield/PE

Voltage output 10 V

Temperature sensor

NI1000 or AI2+

Temperature sensor

NI1000 or AI3+

PM-IF interface

0 to 10 V

0 to 20 mA

PC to inverter

connection kit

OFF

ON

OFF

ON

0 to 20 mA

max. 500 Ohm

0 to 20 mA

max. 500 Ohm

≥ 4.7 kOhm

IOP/IOP handheld interface

USB interface for PC tools

Digital inputs

* = Not connected

From

external

source

DIP switch

Analog inputs

NI1000

CURRENT

DIP switch

Temperature sensor NI1000

PROFIBUS address DIP switch

PROFIBUS interface

SUB-D connector

(1)

Bit 1

(64)(16) (32)(2) (4) (8)

Bit 0

Bit 3

Bit 2

Bit 5

Bit 6

Bit 4

69

17

16

8

7

6

5

-

+

24 V

DI5

DI4

DI3

DI2

DI1

DI0

MMC

PTC/KTY

Power Module

AI1

AI0

DO0

DO2

DO1

AO1-27

AO1+26

D

A

D

A

9

DPA8

7

6

5

4

DPB

RTS

0 V

5 V

*

*

*

3

2

1

0 V32

+24 V31

U0V28

NO21

COM22

NO24

NC23

COM25

NO19

NC18

COM20

AO0-13

AO0+12

15

14

69

U24V9

DI517

DI416

DI38

DI27

DI16

DI05

AI1-11

AI1+10

AI0-4

AI0+3

2

1

0 V

+ 10 V

D

A

A

D

A

D

GND

36

+ 10 V OUT

35

53

52

51

50

D

A

D

A

GND

GND

AI2+/

NI1000

AI3+/

NI1000

Control Unit

CU230P-2 DP

DI COM

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

CU230 Control Units

4/16

Siemens D 11.1 · 2009

4

■

Integration

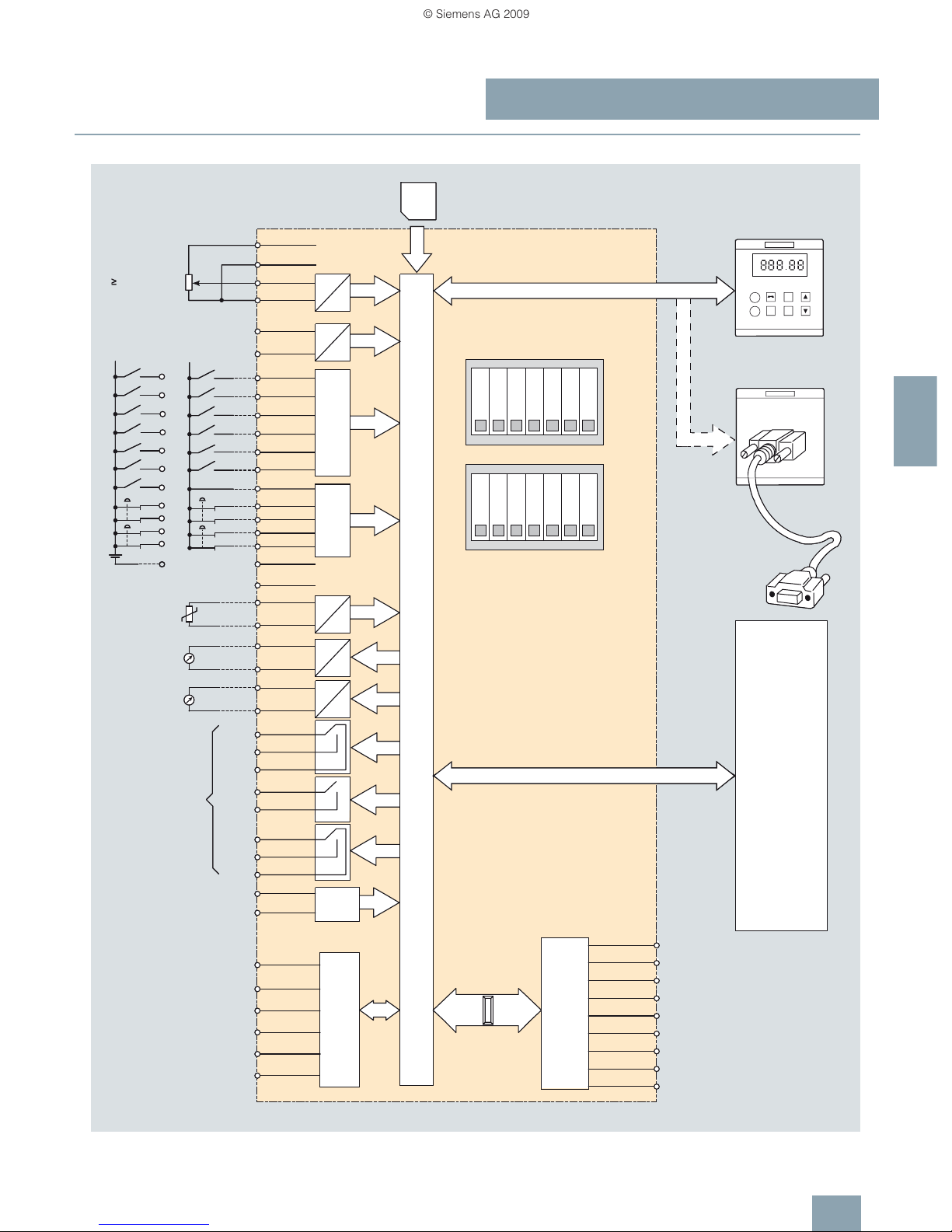

CU230P-2 CAN Control Unit connection diagram

G_D011_EN_00212

IOP/IOP handheld

Voltage output 10 V

Temperature sensor

NI1000 or AI2+

Temperature sensor

NI1000 or AI3+

PM-IF interface

0 to 10 V

0 to 20 mA

PC to inverter

connection kit

OFF

ON

OFF

ON

OFF

ON

0 to 20 mA

max. 500 Ohm

0 to 20 mA

max. 500 Ohm

≥ 4.7 kOhm

IOP/IOP handheld interface

USB interface for PC tools

Digital inputs

* = Not connected

From

external

source

DIP switch

Analog inputs

CURRENT

DIP switch

Temperature sensor NI1000

CANopen address DIP switch

CANopen interface

SUB-D-type connector

DIP switch

Bus termination

(optional shield)

(optional CAN ground)

(1)

Bit 1

(64)(16) (32)(2) (4) (8)

Bit 0

Bit 3

Bit 2

Bit 5

Bit 6

Bit 4

69

17

16

8

7

6

5

-

+

24 V

DI5

DI4

DI3

DI2

DI1

DI0

MMC

PTC/KTY

Power Module

AI1

AI0

DO0

DO2

DO1

AO1-27

AO1+26

D

A

D

A

9

*8

7

6

5

4

CAN_GND

*

(CAN_SHLD)

(GND)

CAN_L

ISO

CAN_H

3

2

1

0 V32

+24 V31

U0V28

NO21

COM22

NO24

NC23

COM25

NO19

NC18

COM20

AO0-13

AO0+12

15

14

69

U24V9

DI517

DI416

DI38

DI27

DI16

DI05

AI1-11

AI1+10

AI0-4

AI0+3

2

1

0 V

+ 10 V

D

A

A

D

A

D

GND

36

+ 10 V OUT

35

53

52

51

50

D

A

D

A

GND

GND

AI2+/

NI1000

AI3+/

NI1000

DI COM

Control Unit

CU230P-2 CAN

NI1000

*

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

CU230 Control Units

4/17

Siemens D 11.1 · 2009

4

■

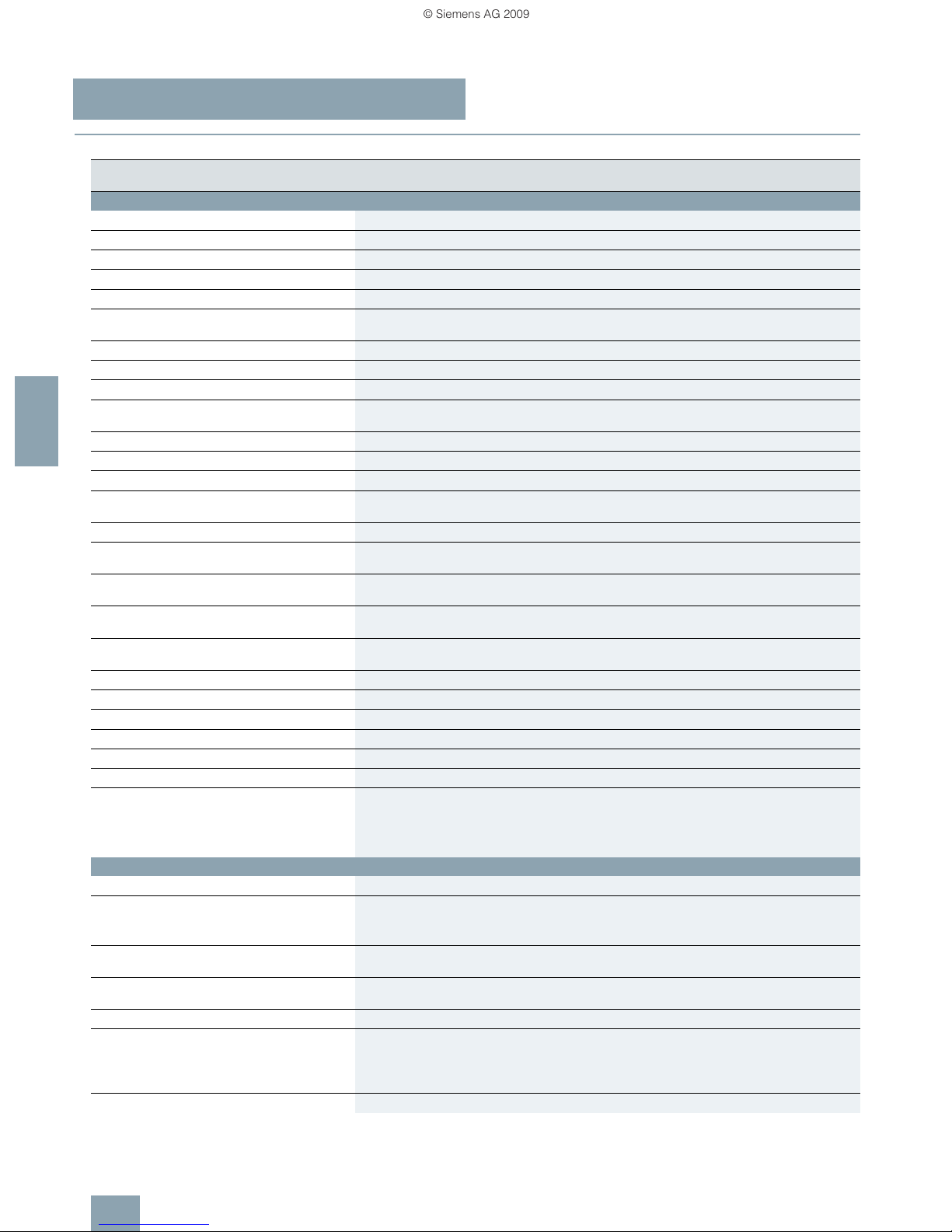

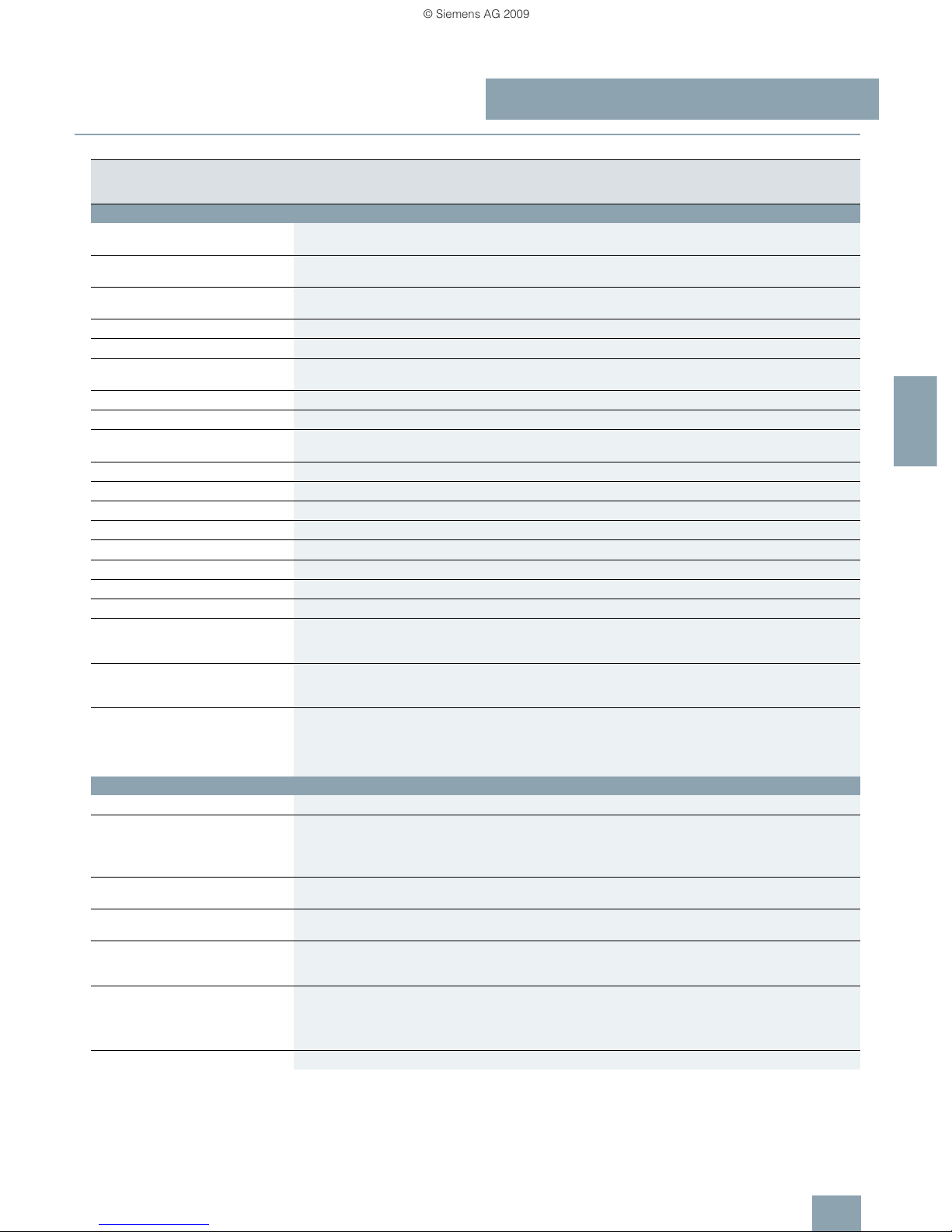

Technical specifications

Control Unit CU230P-2 HVAC

6SL3243-0BA30-1HA0

CU230P-2 DP

6SL3243-0BA30-1PA0

CU230P-2 CAN

6SL3243-0BA30-1CA0

Electrical specifications

Operating voltage 24 V DC from the Power Module or from the connection of an external power supply 18 ... 30 V DC

Current consumption Max. 0.5 A

Protective insulation PELV according to EN 50178

Protective separation from the line supply using double/reinforced insulation

Power loss <5.5 W

Interfaces

Digital inputs – Standard 6 isolated inputs, optically isolated;

free reference potential (own potential group)

NPN/PNP logic can be selected using the wiring

Switching level: 0 → 1: 11 V

Switching level: 1 → 0: 5 V

Max. input current 15 mA

Digital outputs

2 relay change-over contacts

250 V AC 2 A (inductive load), 30 V DC 5 A (ohmic load)

1 relay NO contact

30 V DC, 0.5 A (ohmic load)

Analog inputs

2 differential inputs,

switchable between voltage and current using DIP switch: –10 ... +10 V, 0/4 ... 20 mA, 10-bit resolution

1 non-isolated input,

switchable using DIP switch between current and temperature sensor, type NI1000/PT1000,

0/4 ... 20 mA; 10-bit resolution

1 non-isolated input,

temperature sensor, type NI1000/PT1000,

10-bit resolution

The two differential analog inputs can be configured as additional digital inputs.

Switching thresholds:

0 → 1: Rated voltage 4 V

1 → 0: Rated voltage 1.6 V

Analog inputs are protected against inputs in a voltage range of ±30 V and have a common-mode voltage in

the ±15 V range.

Analog outputs 2 non-isolated outputs,

switchable between voltage and current using parameter setting: 0 ... 10 V; 0/4 ... 20 mA

Voltage mode: 10 V, min. burden 10 kΩ

current mode: 20 mA, max. burden 500 Ω

The analog outputs have short circuit protection

PTC/KTY interface 1 motor temperature sensor input,

sensors that can be connected PTC, KTY and Thermo-Click,

accuracy ±5 °C

Bus interface

Type RS485 PROFIBUS DP CANopen

Protocols

USS

Modbus RTU

(switchable per software)

ProfiDrive profile V4.1 CANopen

Hardware

Te rm i na l

Insulated

USS: max. 187.5 kBaud

Modbus RTU:19.2 kBaud

bus terminating resistors can

be switched in

9-pin SUB-D connector

Insulated

Max. 12 Mbit/s

Slave address can be

set using DIP switches

9-pin SUB-D socket

Insulated

Max. 1 Mbit/s

Tool interfaces

Memory card 1 MicroMemoryCard

Operator panels IOP

supported connection options between CU230P and IOP: can be directly plugged on, door mounting or handheld

BOP not possible

PC interface USB

Open-loop/closed-loop control techniques

V/f linear/square/parameterizable ✓

V/f with flux current control (FCC) ✓

V/f ECCO linear/square ✓

Vector control, without encoder ✓

Vector control, with encoder –

Torque control, without encoder ✓

Torque control, with encoder –

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

CU230 Control Units

4/18

Siemens D 11.1 · 2009

4

■

Technical specifications

Control Unit CU230P-2 HVAC

6SL3243-0BA30-1HA0

CU230P-2 DP

6SL3243-0BA30-1PA0

CU230P-2 CAN

6SL3243-0BA30-1CA0

Software functions

Setpoint input ✓

Fixed frequencies 16, parameterizable

JOG ✓

Digital motorized potentiometer (MOP) ✓

Ramp smoothing ✓

Extended ramp-function generator

(with ramp smoothing Off3)

✓

Positioning down ramp –

Slip compensation ✓

Signal interconnection with BICO technology ✓

Free function blocks (FFB) for logic and

arithmetic operations

–

Switchable drive data sets (DDS)

✓ (4)

Switchable command data sets (CDS) ✓ (4)

Flying restart ✓

Automatic restart after line supply failure or

operating fault (AR)

✓

Technology controller (internal PID) ✓

Energy-saving function (hibernation)

with internal PID controller

✓

Energy-saving function (hibernation)

with external PID controller

✓

Belt monitoring with and without sensor

(load torque monitoring)

✓

Dry pump monitoring

(load torque monitoring)

✓

Thermal motor protection ✓ (I2t, sensor: PTC/KTY/Thermo-Click)

Thermal inverter protection ✓

Motor identification ✓

Motor holding brake –

Auto-ramping (V

dcmax

controller) ✓ (only with PM240 Power Module)

Kinetic buffering (V

dcmax

controller) ✓ (only with PM240 Power Module)

Braking functions for

•DC braking

• Compound braking

• Dynamic braking with integrated

brake chopper

✓ (only with PM240 Power Module)

Mechanical specifications and ambient conditions

Degree of protection IP20

Signal cable cross-section

•min. 0.15 mm2 (AWG28)

•max. 1.5 mm2 (AWG16)

Operating temperature –10 ... +60 °C

(14...140°F)

Storage temperature –40 ... +70 °C

(–40 ... +158 °F)

Relative humidity <95 % RH, condensation not permissible

Dimensions

• Width 73 mm

•Height 199 mm

•Depth 65.5 mm

Weight, approx. 0.61 kg

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

CU240 Control Units

4/19

Siemens D 11.1 · 2009

4

■

Overview

Example of CU240S DP-F Control Unit

The Control Unit performs closed-loop control functions for the

inverter. In addition to the closed-loop control, it has additional

functions that can be adapted to the particular application

through parameterization. Several Control Units are available in

different versions:

•CU240E

•CU240S

•CU240SDP

•CU240SDP-F

•CU240SPN

• CU240S PN-F

Safety Integrated functions

The following Safety Integrated functions are integrated in the

CU240S DP-F and CU240S PN-F Control Units and, with the exception of the “Safe Brake Control”, can be implemented without

external circuit elements:

The SINAMICS G120 fail-safe frequency inverter provides four

safety functions, certified in accordance with EN 954-1,

Category 3 and IEC 61508 SIL 2:

• Safe Torque Off (STO) to protect against active movement of

the drive

• Safe Stop 1 (SS1) for continuous monitoring of a safe braking

ramp

• Safely Limited Speed (SLS) for protection against dangerous

movements when a speed limit is exceeded

• Safe Brake Control (SBC) for controlling motor brakes that are

active in the de-energized state, e.g. motor holding brakes

The functions “Safe Stop 1” and “Safely Limited Speed” can

both be implemented without having to use a motor sensor or

encoder; the implementation cost is minimal. Existing systems in

particular can be simply updated with safety technology without

the need to change the motor or mechanical system.

The safety functions “Safely Limited Speed” and “Safe Stop 1”

are not certified for pull-through loads as in the case of lifting

gear and winders.

Safety functions have been extended with firmware V3.2.

Additional information is provided in the part Highlights, section

Safety Integrated.

■

Selection and ordering data

Communication Digital inputs

Standard

Digital inputs

Fail-safe

Digital outputs Encoder interfaces Designation Control Unit

Order No.

Standard

RS485/USS 6 – 3 – CU240E 6SL3244-0BA10-0BA0

RS485/USS 9 – 3 1 CU240S 6SL3244-0BA20-1BA0

PROFIBUS DP 9 – 3 1 CU240S DP 6SL3244-0BA20-1PA0

PROFINET 9 – 3 1 CU240S PN 6SL3244-0BA20-1FA0

Fail-safe for Safety Integrated

PROFIBUS DP 6 2 3 1 CU240S DP-F 6SL3244-0BA21-1PA0

PROFINET 6 2 3 1 CU240S PN-F 6SL3244-0BA21-1FA0

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

CU240 Control Units

4/20

Siemens D 11.1 · 2009

4

■

Design

CU240E Control Unit

CU240E Control Unit without terminal cover

Terminal No. Signal Features

Digital inputs (DI)

5…8,

16.17

DI0 … DI5 Freely programmable (isolated)

5.5 mA/24 V

Digital outputs (DO)

18 DO0, NC Relay output 1

NC contact (0.5 A, 30 V DC)

19 DO0, NO Relay output 1

NO contact (0.5 A, 30 V DC)

20 DO0, COM Relay output 1

Common contact (0.5 A, 30 V DC)

21 DO1, NO Relay output 2

NO contact (0.5 A, 30 V DC)

22 DO1, COM Relay output 2

Common contact (0.5 A, 30 V DC)

23 DO2, NC Relay output 3

NC contact (0.5 A, 30 V DC)

24 DO2, NO Relay output 3

NO contact (0.5 A, 30 V DC)

25 DO2, COM Relay output 3

Common contact (0.5 A, 30 V DC)

Analog inputs (AI)

3 AI0+ 0…10V, –10…+10V, 0/2…10V or

0/4 … 20 mA

4 AI010 AI1+ 0…10V, 0…20mA

11 AI1-

Analog outputs (AO)

12 AO0+ Freely programmable

(0/4 … 20 mA with max. 500 Ω,

0/2 … 10 V with min. 500 Ω)

13 AO0- M

26 AO1+ Freely programmable

(0/4 … 20 mA with max. 500 Ω)

27 AO1- M

PTC/KTY interface

14 PTC+ Positive PTC/KTY input

15 PTC- Negative PTC/KTY input

Serial RS485 interface

29 P+ RS485 A, USS protocol

30 N- RS485 B, USS protocol

Power supply

9 U24V Isolated user power supply

+24 V at 100 mA

28 U0V Isolated user reference voltage

1 +10 V Non-isolated, regulated

10 V power supply for I/O –

max. 10 mA

2 0V Power supply reference

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

CU240 Control Units

4/21

Siemens D 11.1 · 2009

4

■

Design

CU240S, CU240S DP, CU240S DP-F, CU240S PN and

CU240S PN-F Control Units

Example: CU240S DP-F Control Unit (right without terminal cover, with

pluggable terminals)

Terminal No. Signal Features

Digital inputs (DI) – Standard

5…8,

16.17

DI0 … DI5 Freely programmable (isolated)

5.5 mA/24 V

40 … 42

(only for

CU240S,

CU240S DP

and

CU240S PN)

DI6 … DI8 Freely programmable (isolated)

5.5 mA/24 V

Digital inputs (DI) – Fail-safe

(for CU240S DP-F and CU240S PN-F only)

60 … 63

(for

CU240S DP-F

and

CU240S PN-F

only)

FDI0A

FDI0B

FDI1A

FDI1B

Fail-safe digital inputs, 2 channels

(redundant),

freely programmable (isolated)

5.5 mA/24 V

Digital outputs (DO)

18 DO0, NC Relay output 1

NC contact (0.5 A, 30 V DC)

19 DO0, NO Relay output 1

NO contact (0.5 A, 30 V DC)

20 DO0, COM Relay output 1

Common contact (0.5 A, 30 V DC)

21 DO1, NO Relay output 2

NO contact (0.5 A, 30 V DC)

22 DO1, COM Relay output 2

Common contact (0.5 A, 30 V DC)

23 DO2, NC Relay output 3

NC contact (0.5 A, 30 V DC)

24 DO2, NO Relay output 3

NO contact (0.5 A, 30 V DC)

25 DO2, COM Relay output 3

Common contact (0.5 A, 30 V DC)

Terminal No. Signal Features

Analog inputs (AI)

3 AI0+ 0…10V, –10…+10V, 0/2…10V or

0/4 … 20 mA

4 AI0-

10 AI1+ 0…10V, 0…20mA

11 AI1-

Analog outputs (AO)

12 AO0+ Freely programmable

(0/4 … 20 mA with max. 500 Ω,

0/2 … 10 V with min. 500 Ω)

13 AO0- M

26 AO1+ Freely programmable

(0/4 … 20 mA with max. 500 Ω)

27 AO1- M

Encoder interface

70 ENC AP Encoder AP

Channel A non-inverting input

71 ENC AN Encoder AN

Channel A inverting input

72 ENC BP Encoder BP

Channel B non-inverting input

73 ENC BN Encoder BN

Channel B inverting input

74 ENC ZP Encoder ZP

Zero pulse non-inverting input

75 ENC ZN Encoder ZN

Zero pulse inverting input

PTC/KTY interface

14 PTC+ Positive PTC/KTY input

15 PTC- Negative PTC/KTY input

Power supply

33 ENC+

line supply

Isolated encoder power supply

(+24 V at 100 mA, +5 V at 300 mA),

configured using DIP switch

9

U24V Isolated user power supply

+24 V at 100 mA

28

U0V Isolated encoder power supply

and user reference voltage

1 +10 V Non-isolated, regulated

10 V power supply for I/O –

max. 10 mA

2 0V Power supply reference

31 +24 V 24 V power supply input

32 0V 24 V power supply reference

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

CU240 Control Units

4/22

Siemens D 11.1 · 2009

4

■

Integration

CU240E Control Unit connection diagram

ON

Low voltage only

(30 V, 500 mA)

Digital inputs

RS232/BOP interface

RS232 with

PC to inverter

connection kit

4.7 kOhm

0 to 20 mA

max. 500 Ohm

0 to 20 mA

max. 500 Ohm

PM-IF interface

OFF

0 to 20 mA

0 to 10 V

G_D011_EN_00183

DIP switch for

analog inputs

A

D

D

+ 10 V

0 V

1

2

3 AI0+

4 AI0-

10 AI1+

11 AI1 -

5 DI0

6 DI1

7 DI2

8 DI3

16 DI4

17 DI5

9 U24V

14 PTC+

15 PTC-

12 AO0+

13 AO0-

20 COM

18 NC

19 NO

25 COM

23 NC

24 NO

22 COM

21 NO

28 U0V

29

30

A

A

D

A

D

A

D

26 AO1+

27 AO1-

DO1

DO2

DO0

AI0

AI1

Power Module

PTC/KTY

JOG

BOP

Control Unit

CU240E

DI0

DI1

DI2

DI3

DI4

DI5

24 V

+

-

5

6

7

8

16

17

28

RS485

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

CU240 Control Units

4/23

Siemens D 11.1 · 2009

4

■

Integration

CU240S Control Unit connection diagram

A

D

A/

D

A/

D

+ 10 V

0 V

ENC+

1

2

3 AI0+

4 AI0-

10 AI1+

11 A I1-

5 DI0

6 DI1

7 DI2

8 DI3

16 DI4

17 DI5

40 DI6

41 DI7

42 DI8

9 U24V

33

14 PTC+

15 PTC-

12 AO0+

13 AO0-

20 COM

18 NC

19 NO

25 COM

23 NC

24 NO

22 COM

21 NO

28 U0V

31 +24 V

32 0V

71 ENC AN

70 ENC AP

1 *

2 *

3 RS485P

4 *

5 0 V

6 *

7 *

8 RS485N

9 *

72 ENC BP

73 ENC BN

74 ENC ZP

75 ENC ZN

A

D

A

D

A

D

A

D

26 AO1+

27 AO1-

DO1

DO2

DO0

AI0

AI1

Power Module

PTC/KTY

JOG

FN

I

P

O

BOP

Control Unit

CU240S

MMC

DI0

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

24 V

+

-

5

6

7

8

16

17

40

41

42

28

General I/O DIP switch

ON

5 V encoder

supply

24 V encoder

supply

Encoder A

termination

Encoder B

termination

Encoder Z

termination

Encoder interface

RS485

interface

SUB-D-type connector

Low voltage only

(30 V, 500 mA)

G_D011_EN_00114a

From

external

source

* = Not connected

Digital inputs

RS232/BOP interface

RS232 with

PC to inverter

connection kit

4.7 kOhm

0 to 20 mA

max. 500 Ohm

0 to 20 mA

max. 500 Ohm

Line

PM-IF interface

OFF

0 to 20 mA

0 to 10 V

Bus termination

DIP switch

ON

OFF

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

CU240 Control Units

4/24

Siemens D 11.1 · 2009

4

■

Integration

CU240S DP Control Unit connection diagram

A

D

A/

D

A/

D

+ 10 V

0 V

ENC+

1

2

3 AI0+

4 AI0-

10 AI1+

11 A I1-

5 DI0

6 DI1

7 DI2

8 DI3

16 DI4

17 DI5

40 DI6

41 DI7

42 DI8

9 U24V

33

14 PTC+

15 PTC-

12 AO0+

13 AO0-

20 COM

18 NC

19 NO

25 COM

23 NC

24 NO

22 COM

21 NO

28 U0V

31 +24 V

32 0V

71 ENC AN

70 ENC AP

1

2 U0V

3 RxD/TxD-P

4 CNTR-P

5 DGND

6 VP

7 U24V

8 RxD/TxD-N

9 *

72 ENC BP

73 ENC BN

74 ENC ZP

75 ENC ZN

A

D

A

D

A

D

A

D

26 AO1+

27 AO1-

DO1

DO2

DO0

(1) (2) (4) (8) (16) (32) (64)

AI0

AI1

Bit 0

Bit 1

Bit 2

Bit 3

Bit 4

Bit 5

Bit 6

Power Module

PTC/KTY

JOG

FN

I

P

O

BOP

Control Unit

CU240S DP

DI0

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

24 V

+

-

5

6

7

8

16

17

40

41

42

28

MMC

PROFIBUS address DIP switch

ON

General I/O DIP switch

ON

5 V encoder

supply

24 V encoder

supply

Encoder A

termination

Encoder B

termination

Encoder Z

termination

Encoder interface

PROFIBUS

interface

SUB-D-type connector

Shield

Low voltage only

(30 V, 500 mA)

G_D011_EN_00101

From

external

source

* = Not connected

Digital inputs

RS232/BOP interface

4.7 kOhm

0 to 20 mA

max. 500 Ohm

0 to 20 mA

max. 500 Ohm

Line

RS232 with

PC to inverter

connection kit

PM-IF interface

OFF

0 to 20 mA

0 to 10 V

OFF

© Siemens AG 2009

SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

CU240 Control Units

4/25

Siemens D 11.1 · 2009

4

■

Integration

CU240S DP-F Control Unit connection diagram

1

2

3

4

5

6

7

8

9*

4.7 kOhm

0 to 20 mA

max. 500 Ohm

0 to 20 mA

max. 500 Ohm

Low voltage only

(30 V, 500 mA)

Encoder interface

From

external

source

Safety

digital inputs

Standard

digital inputs

RS232/BOP interface

General I/O DIP switch

PROFIBUS address DIP switch

21

21

2))

2))

0 to 10 V

0 to 20 mA

24 V encoder

supply

5 V encoder

supply

Encoder A

termination

Encoder B

termination

Encoder Z

termination

PM-IF interface

PROFIBUS interface

SUB-D-type

connector

G_D011_EN_00102b

* = Not connected

RS232 with

PC to inverter

connection kit

Line

U0V

RxD/TxD-P

CNTR-P

DGND

VP

U24V

RxD/TxD-N

shield

60

61

62

63

+

Bit 0

Bit 1

Bit 3

Bit 4

Bit 5

Bit 6

Bit 2

(64)(32)(16)(8)(4)(2)(1)

1B

1A

FDI

62

0B

FDI61

MMC

28

40

17

16

8

7

6

5

-

24 V

DI6

DI5

DI4

DI3

DI2

DI1

DI0

Control Unit

CU240S DP-F

BOP

O

P

I

FN

JOG

PTC/KTY

Power Module

AI1

AI0

DO0

DO2

DO1

AO1-27

AO1+26

D

A

D

A

D

A

D

A

ENC ZN75

ENC ZP74

ENC BN73

ENC BP72

ENC AP70

ENC AN71

0V32

+24 V31

U0V

NO21

COM22

NO24

NC23

COM25

NO19

NC18

COM20

AO0-13

AO0+12

PTC-15

PTC+14

33

FDI

FDI 60

U24V9

DI5

17

DI416

DI38

DI27

DI16

DI05

AI1-11

AI1+

AI0-4

AI0+3

2

1

ENC+

0 V

+ 10 V

D

A

28

63

60

61

62

63

(64)(32)(16)(8)(4)(2)(1)

1B

1A

FDI

62

FDI61

MMC

28

40

17

16

8

7

6

5

-

DI6

DI5

DI4

DI3

DI2

DI1

DI0

Control Unit

CU240S DP-F