Page 1

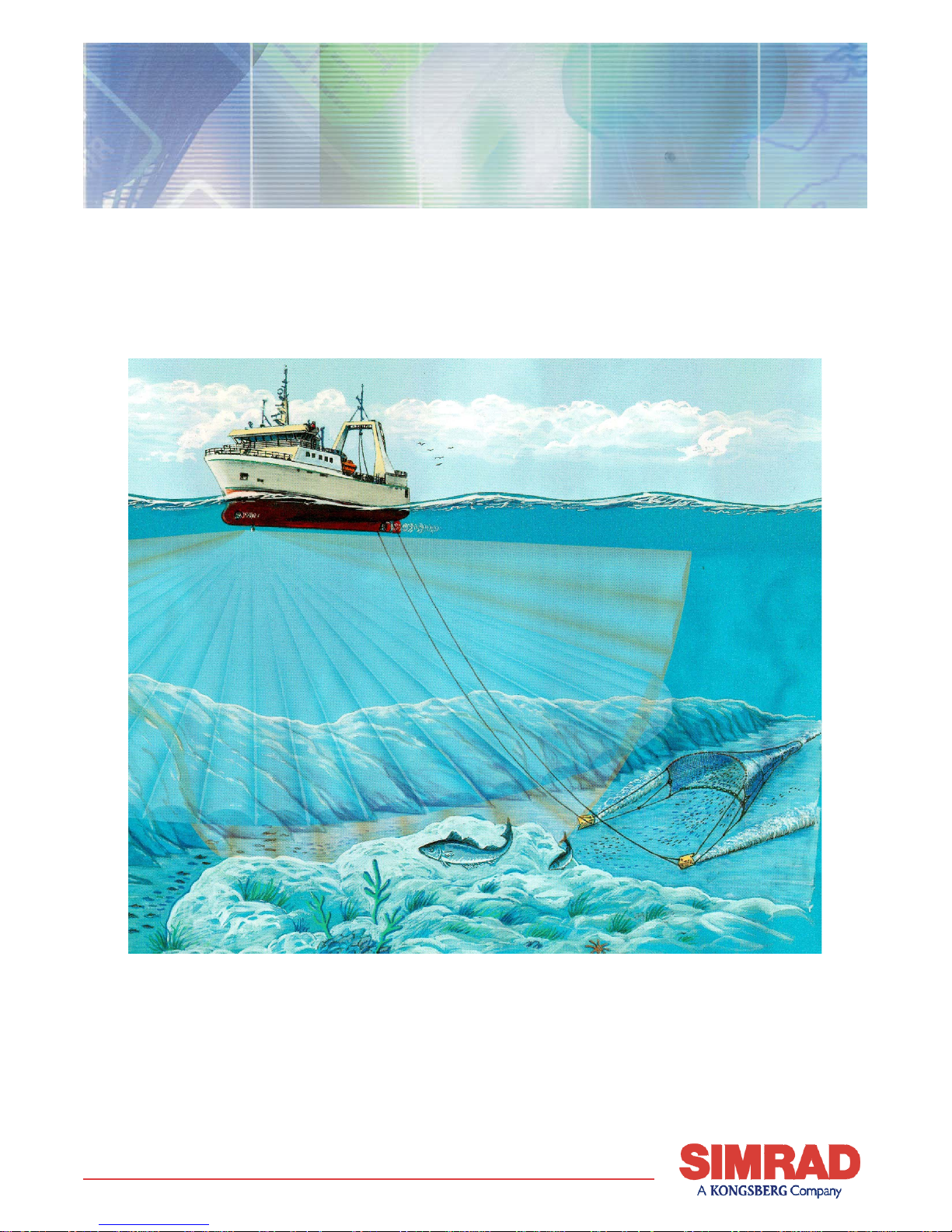

Simrad SD570

Fishery sonar

Installation manual

A L W A Y S A T T H E F O R E F R O N T O F T E C H N O L O G Y

www.simrad.com

Page 2

Page 3

Simrad SD570

Fishery sonar

Installation manual

851--160085 / Rev.B

Page 4

Note

Simrad AS makes every effort to ensure that the information contained within this

document is correct. However, our equipment is continuously being improved and

updated, so we cannot assume liability for any errors which may occur.

Warning

The equipment to which this manual applies must only be used for the purpose for

which it was designed. Improper use or maintenance may cause damage to the

equipment or injury to personnel. The user must be familiar with the contents of the

appropriate manuals before attempting to operate or work on the equipment.

Simrad AS disclaims any responsibility for damage or injury caused by improper

installation, use or maintenance of the equipment.

Copyright

E 2004 Simrad AS

ISBN 82-8066-018-6

The information contained within this document remains the sole property of Simrad

AS. No part of this document may be copied or reproduced in any form or by any

means, and the information contained within is not to be communicated to a third party,

without the prior written consent of Simrad AS.

Support

For support on your Simrad equipment, consult your local dealer, visit

www.simrad.com, or contact us directly at support.fish@simrad.com.

Simrad AS

Strandpromenaden 50

Box 111

N-3191 Horten

Telephone: +47 33 03 40 00

Facsimile: +47 33 04 29 87

M A X I M I Z I N G Y O U R P E R F O R M A N C E A T S E A

Page 5

Installation manual

1

851-160085 /B

Sections

This book is the Installation manual for the SD570 fishery sonar. It describes how to

install the various units used by the SD570 system.

1Introduction

This section gives a brief description of the SD 570/SE 570 sonars and the

installation requirements.

2 Installation procedures

Thissectionprovidesthenecessaryinformationfortheinstallationandcabling

of the complete sonar system according to Simrad’s requirements.

3 Start-up procedures

This sectioncontains the start-up procedures to be carried out after the

installation of the sonar.

4 Trunk systems

This sectiondescribes the differenttrunk systemsthat can be used with the SD

570/SE570 Hull Unit. Also described are the adapter flanges which must be

used if the Hull Unit is to be installed into alreadyinstalled SQ4, SQ, SB2 and

SK3 trunks.

5Drawings

6 Appendices

Page 6

Simrad SD570

2

851-160085 / B

Remarks

References

Further information about the SD570 system may be found in the following manuals:

• SD570 Operator manual

The reader

This Installation manual is intended for the design and installation engineers at the

shipyard performing the installation. The information is supplied as the basis for the

shipyard’s own installation drawings applicable to the vessel. On completion of the

installation, this manual must be kept on the vessel for reference purposes during

system maintenance.

Note

This manual includes sections that may be revised individually. In the event of a

revision to any part of this manual, this “Cover and Contents” section will be replaced.

Page 7

Installation manual

3

851-160085 / B

Document revisions

Rev Written by

Checked by Approved by

Date Sign Date Sign Date Sign

A Unknown CL

B 02.02.04 RBr 02.02.04 EGj 02.02.04 ESB

Sect Title Revision File

0 Cover and contents B 851--160085

1 Introduction B 851--160115

2 Installation procedures B 851--160116

3

4

5

6

Start--up procedures

Trunk syst em

Drawings

Appendices

B

B

B

B

851--160117

851--160503

851--160118

851--160675

Rev.A First edition.

Rev.B Re--issued. All sections updated to Rev.B, but product specific informa-

tion has not been changed. ISBN number issued.

Page 8

Simrad SD570

4

851-160085 / B

Blank page

Page 9

Installation manual

I

851-160085 / B

High voltage safety warning

Precautionary measures

The voltages used to power this equipment

are potentially lethal. Even 110 volts can kill.

Whenever possible, the following

precautionary measures must be taken before

any work is carried out inside the equipment:

S Switch off all high-voltage power supplies.

S Check the operation of any door interlocks

and any other safety devices.

S Completely discharge all high-voltage

capacitors.

It should be noted that interlocks and safety

devices are normally located only at regular

access points, and high voltages may be

exposed during dismantling.

Never work alone on high-voltage

equipment!

First aid in the event of

electric shock

Normally, even a high voltage electric shock

will not kill instantly. The victim can still be

revived even when his breathing and

heart-beat have ceased.

Could YOU save someone’s life?

In the event of electric shock, the correct

actions, performed quickly may well save the

victim’s life. Make sure you know what to

do!

Immediate action

While shouting for help, remove the source of

power from the victim. Switch off the supply

if possible, or using a dry, non-conductive

material (rubber gloves, broom handle etc.) to

insulate yourself, separate the victim from the

source. If the voltage exceeds 1000 volts,

switch off the supply and be ready to catch

the victim. Take care- do not become a victim

yourself.

Commence first aid on the spot. Continue to

shout for assistance till someone arrives.

1 Lay the victim flat on his back and loosen

any tight clothing (collar, tie, belt etc.).

2 Open his mouth and check for and remove

any false teeth, chewing gum etc.

3 Check if the victim is breathing. If not,

check if his heart is beating. The pulse is

normally easily found in the main arteries

of the neck, either side of the throat, up

under the chin.

If his heart is beating but he is not breathing,

commence artificial respiration. If the

victim’s heart is not beating, commence

external cardiac massage (ECM). Continue to

shout for assistance till someone arrives.

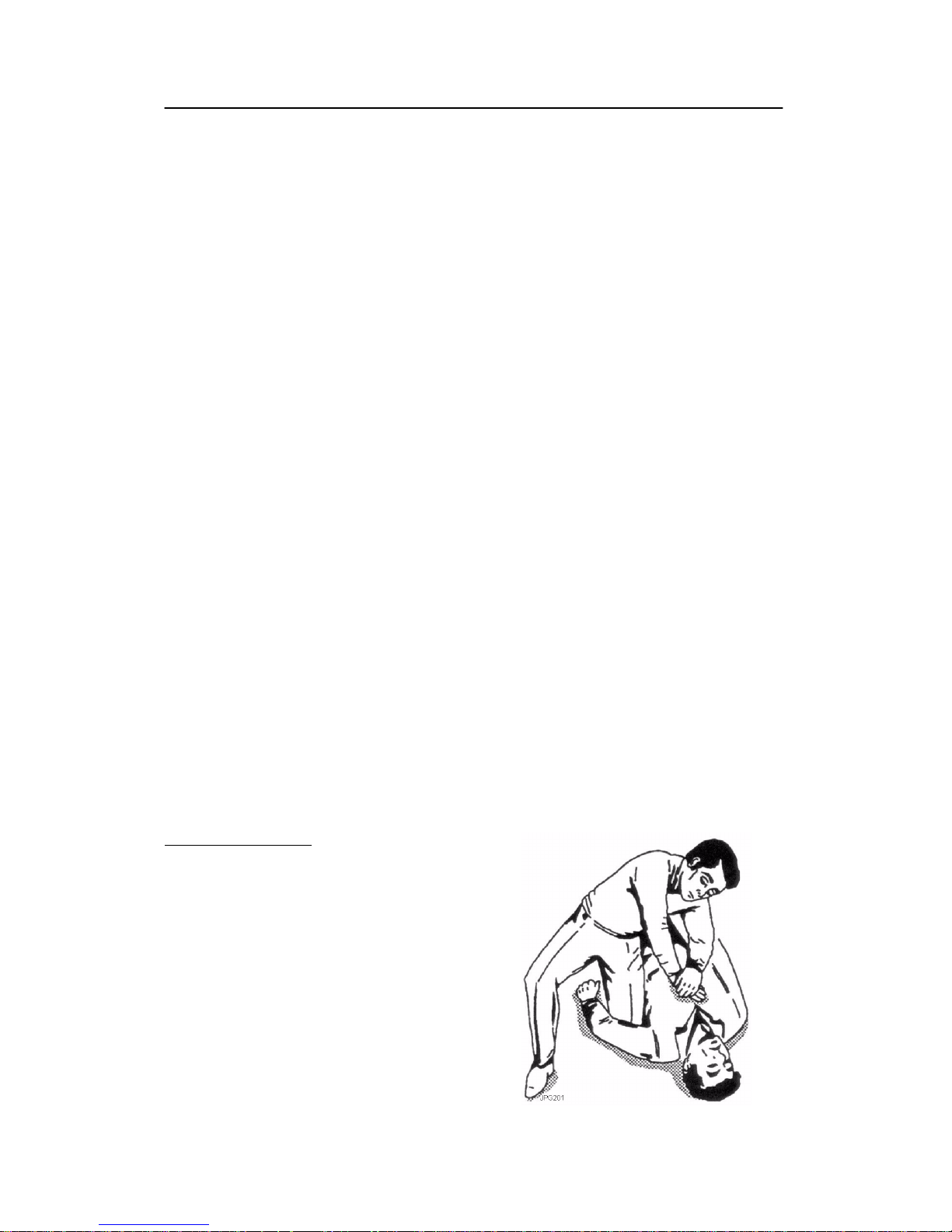

External cardiac massage

1 Kneel beside the victim. Place the heel of

one hand in the centre of his chest, at a

position half way between the notch

between the collar-bones at the top of his

chest, and the dip i n the breast-bone at the

base of his rib cage. Place the other hand

on top of the first.

2 Keeping the arms straight and using your

entire weight, press down rapidly so that

the breast bone is depressed four- five cm,

then release the pressure. Repeat

rhythmically at a rate of one cycle per

second. This will be hard work, but keep

going. His life depends on YOU. Do not

worry about breaking his ribs - these will

heal if he survives.

Page 10

Simrad SD570

II

851-160085 / B

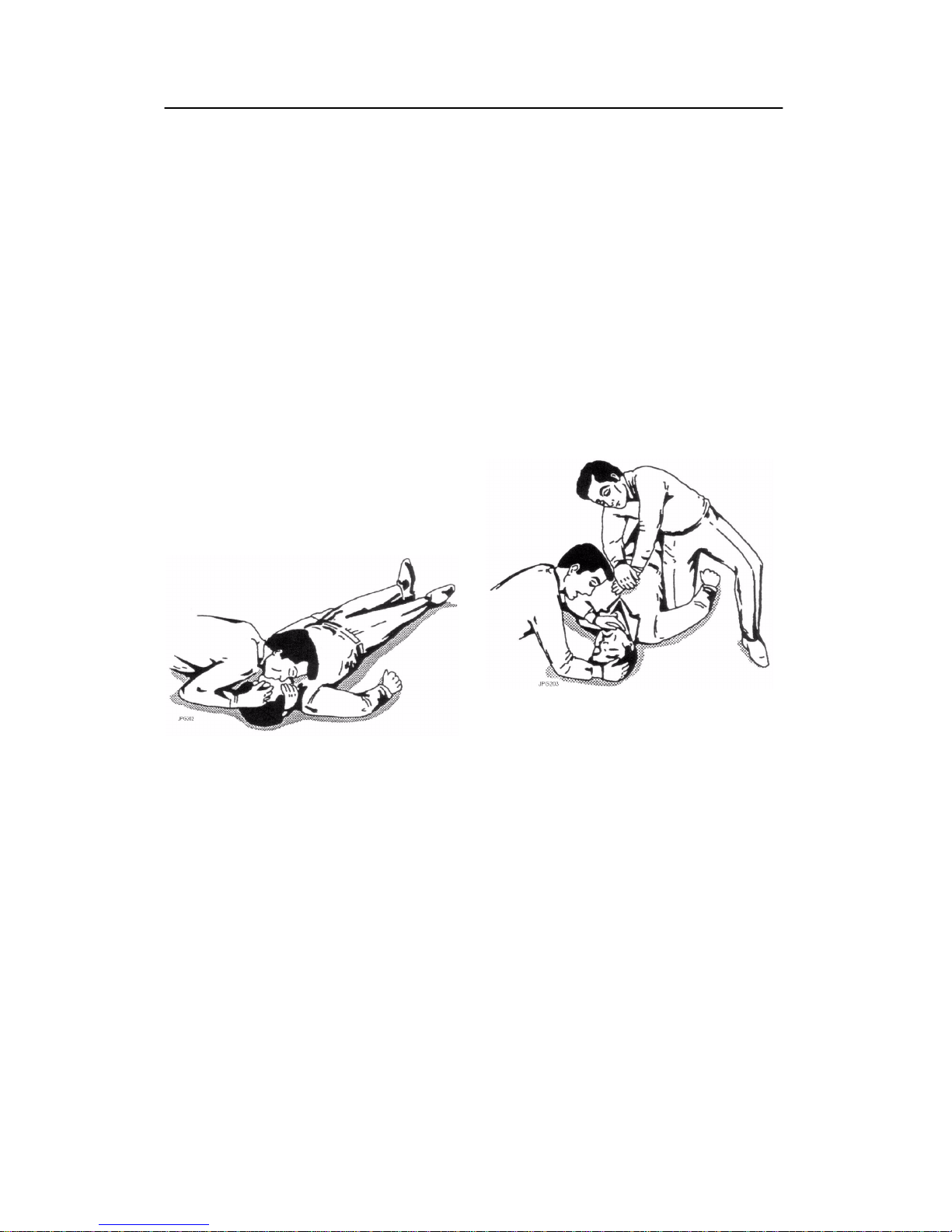

Artificial respiration

1 Kneel besides the victim’s head. Place one

hand under his neck and lift, allowing his

head to fall back. This will lift his tongue

and open the air passage in his throat.

2 Place the palm of the hand on his forehead

to maintain the ”chin-up” position.

3 Using the index finger and thumb of the

same hand, pinch the victim’s nostrils

closed. Open his mouth.

4 Take a deep breath and cover his mouth

with yours. Blow steadily into his lungs to

expand his chest. Remove your mouth

from his to allow the air t o escape from his

chest. You should be able to see his chest

deflate.

5 Repeat the ”inflation-deflation” cycle at a

rate of about 12 cycles per minute till the

victim begins to breath normally again.

Combining ECM and artificial

respiration

If you are alone, perform one cycle of

artificial respiration for every five cycles of

ECM. This will be hard work, but keep going.

His life depends on you!

If there are other people available to help, one

should perform the ECM while one performs

the artificial respiration for every five cycles

of ECM. It will be much more efficient with

two people.

Once the victim’s heart is beating and he is

breathing, roll him onto his side and support

him in that position. As consciousness returns

he may vomit, and this will allow any liquid

to drain out of his mouth.

Remove the victim to a hospital as soon as

possible, but do not interrupt the artificial

respiration and ECM cycles till his heart beat

and breathing returns.

If started quickly and performed correctly, the

resuscitation methods described will keep a

sufficient volume of oxygenated blood

flowing trough the victims body to allow full

recovery.

Proficiency i n the resuscitation methods can

only be achieved trough training. All

personnel concerned should attend courses on

a regular basis. Remember, someone’s life

could depend on you.

Do you know what to do?

Page 11

Introduction

I

851--160115 / B

851- 160115 / AA000 / 3- 11

Introduction

This section gives a brief description of the

SD 570 / SE 570 sonars and the installation

requirements.

Page 12

Simrad SD570 / Base version

II

851--160115 / B

Document revisions

Rev Date Written by Checked by Approved by

A Unknown

B 03.01.01 RBr ESB RBr

C

D

(The original signatures are recorded in the company’s logistic database)

Page 13

Introduction

III

851--160115 / B

Table of contents

1 INSTALLATION DOCUMENT 1..................................

2 SUPPLY CONDITIONS 2.......................................

2.1 General 2.....................................................

2.2 Main units 2..................................................

2.3 Options 2.....................................................

2.4 Installation procedures 5.......................................

2.5 Equipment responsibility 5.....................................

2.6 Receipt, unpacking and storage 5................................

3 GENERAL REQUIREMENTS 7..................................

3.1 Responsibility and approbation 7................................

3.2 Compass deviation 7...........................................

3.3 Noise sources 7...............................................

3.4 Docking 7....................................................

3.5 Cabling 7.....................................................

3.6 Auxiliary equipment 8.........................................

3.7 Technical specifications 9.......................................

3.8 Weights and dimensions 10......................................

Page 14

Simrad SD570 / Base version

IV

851--160115 / B

Document history

(The information on this page is for internal use)

Rev.A Original issue for Base version.

Rev.B Document transferred to Interleaf. No changes made to text or illustra-

tions.

Page 15

Introduction

1

851--160115 / B

1 INSTALLATION DOCUMENT

This installation manual will act as an installation document for

later updating and service on the sonar, and must therefore be

stored on board the vessel into which the equipment is to be

installed.

To ensure the best possible result of the installation, it is important

that each procedure is carefully followed. Each listed procedure

comprises squares for t icking off while proceeding in the

procedure. In addition to be a sign that the procedure is followed,

this will also be a good guidance for the installer.

Note that the installer becomes fully responsible for the

equipment during the installation, and that the guarantee only is

covered when the installation is made in full accordance with this

installation manual.

Page 16

Simrad SD570 / Base version

2

851--160115 / B

2 SUPPLY CONDITIONS

2.1 General

This manual describes the installation for both the SD 570 and the

SE 570 sonars. The only difference between these sonars is the

angle to which the transducer can be tilted. The SD 570

transducer can be tilted to - 90_, while the SE 570 transducer is

limited to - 45_. All units for the SD 570 and SE 570 have the same

physical size.

The Hull Unit uses an installation trunk which is equal to the old

Simrad SL and SX installation trunks. The Hull Unit can therefore

easily be mounted in an old SL or SX trunk. As an option, an

adapter flange can be delivered for mounting the Hull Unit in an

old SK, SB or SQ trunk. Note that the trunk is not included in the

standard delivery, but can be ordered as an option (see chapter 2.3

Options ).

2.2 Main units

The standard SD 570 Sonar system comprises the following main

units:

Simrad SD 570 Sonar Control Unit SD5- 112629..............

Simrad SD 570 Transceiver Unit SD5- 112630................

Simrad SD 570 Hull Unit SD5- 112631.......................

The standard SE 570 Sonar system comprises the following main

units:

Simrad SE 570 Sonar Control Unit SE5- 112898...............

Simrad SE 570 Transceiver Unit SE5- 112899.................

Simrad SE 570 Hull Unit SE5- 112900.......................

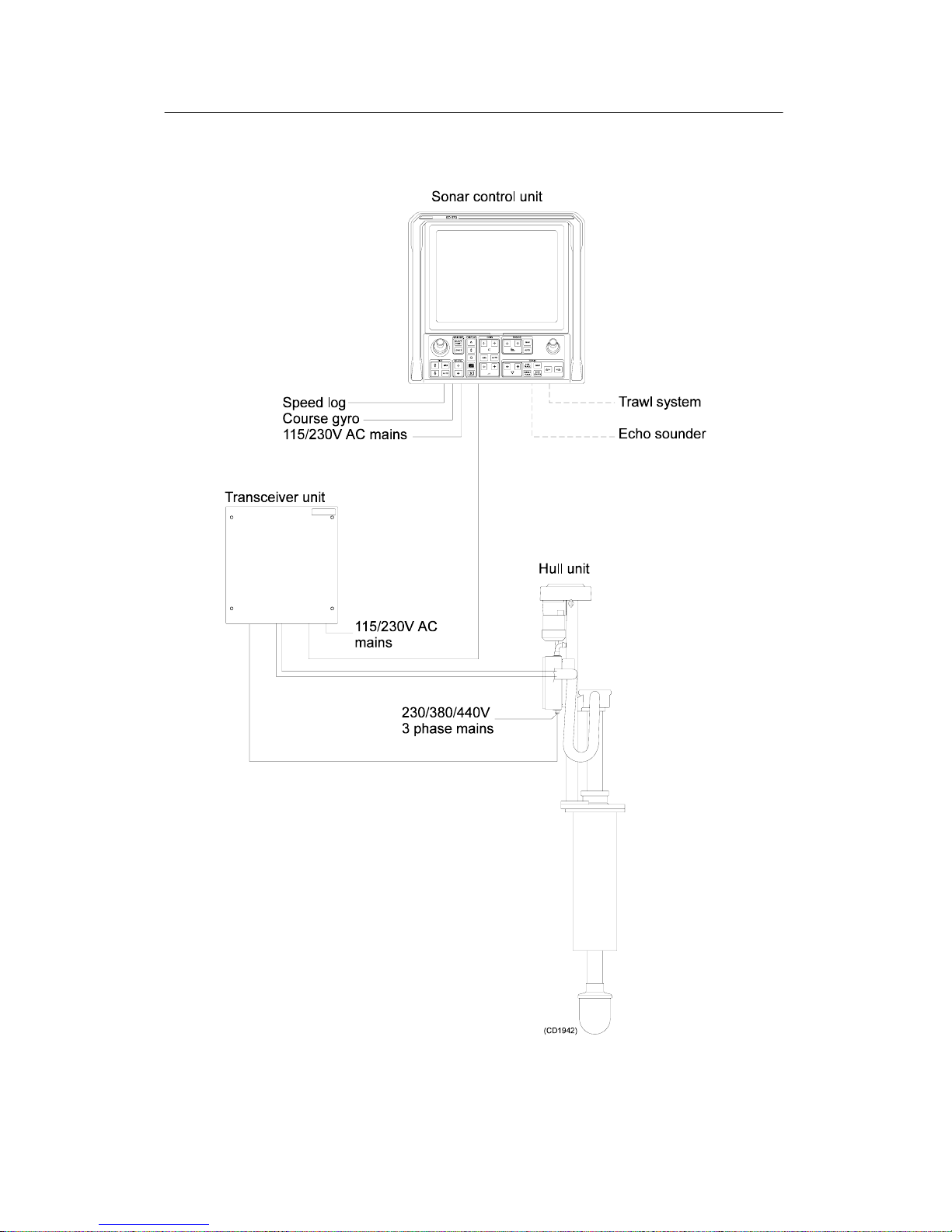

A diagram of the standard sonar system is shown in figure 1.

2.3 Options

The installation trunk can be made by the shipyard (refer to

drawing in section “Trunksystems” ) or be ordered as an optional

delivery:

Installation trunk with blind cover SD5- 112632..............

For installations in an existing SK, SB or SQ trunk, refer to the

drawings in the section Trunk systems in this manual. The

following adapters with blind covers can be ordered as options:

SQ4 Adapter flange SD5- 112641...........................

Page 17

Introduction

3

851--160115 / B

SQ & SB2 Adapter flange SD5- 112642......................

SK3 Adapter flange SD5- 112643...........................

The cable between the Sonar Control Unit in the wheelhouse and

the Transceiver Unit in the sonar room (see figure 1) can be

delivered with the following lengths:

50- meter interconnection cable 380- 112595..................

75- meter interconnection cable 380- 112596..................

100- meter interconnection cable 380- 112597.................

The interconnection cable has a preconnected connector at the

Sonar Control Unit end.

A system for electronic stabilization of the transducer may be

delivered as an option. If the stabilization system is ordered, the

kit is included in the box for the Sonar Control Unit.

Stabilization system KIT- 113200...........................

Page 18

Simrad SD570 / Base version

4

851--160115 / B

Figure 1 - SD 570 / SE 570 sonar system

Page 19

Introduction

5

851--160115 / B

2.4 Installation procedures

The installation of the standard SD 570 / SE 570 Sonar systems

includes the following stages:

The installation of the standard SP 270 Sonar system includes the

following stages:

• Mounting the Installation Trunk

• Mounting the Hull Unit

• Mounting the Transceiver Unit

• Mounting the Sonar Control Unit

• Cabling

• Start- Up

• Final Test

Refer to the cable plan, the main interconnection diagrams and the

outline dimensions drawings of the units.

2.5 Equipment responsibility

Upon receipt of the equipment, the installation shipyard and/or

the dealer automatically becomes fully responsible for the

equipment unless otherwise is stated in the contract. This

responsibility covers the storage period before the installation, the

actual installation, commissioning, and the period between the

commissioning and the acceptance of the equipment by the end

user (normally the owner of the vessel into which the equipment

is to be installed).

The guarantee period for the system (as specified in the contract)

begins as soon as acceptance documents have been signed, unless

other arrangements have been made in the contract.

2.6 Receipt, unpacking and storage

On receiving the equipment, the shipyard and/or the dealer

should ensure that the delivery is complete and inspect each

container for physical damage. If the inspection at receipt reveals

indication of crushing, dropping, immersion in water or any other

form of damage, the recipient should request a representative

from the carrier to be present during unpacking.

During unpacking, the equipment should be inspected for

physical damage, i.e. broken controls and indicators, dents,

scratches etc.

If damage to the equipment is discovered, the recipient should

notify the carrier and Simrad so that Simrad can arrange for

replacement or repair of the damaged equipment.

Page 20

Simrad SD570 / Base version

6

851--160115 / B

The equipment, once unpacked, must be stored inside in a room

with an atmosphere free from corrosive agents. In addition, the

equipment must be covered to protect it from dust and other

forms of contamination.

Page 21

Introduction

7

851--160115 / B

3 GENERAL REQUIREMENTS

3.1 Responsibility and approbation

The Hull Unit of the sonar is generally approved by The

Norwegian Veritas (Organization for classification and registry of

shipping). An approval of the installation must, however, be

applied for in each case to the local maritime authority.

The ship owner and the shipyard are responsible for the

application.

3.2 Compass deviation

When the installation is finished, the compass must be checked

both with the sonar operative and inoperative. The ship owner

and the skipper are responsible for such a check to be carried out.

3.3 Noise sources

Prior to installation, the vessel’s h ull should be thoroughly

inspected in dock. Roughness on the shell plating surface, and

protruding obstacles are examples of noise-causing elements.

These must be smoothed or removed. Also ensure that the

propeller is not chipped or corroded.

3.4 Docking

When dry docking the vessel, make sure that there is enough

room underneath for installation of the sonar trunk and

protection blister (refer to figures 4 and 5 in section Installation

procedures .

3.5 Cabling

If the cable from the wheelhouse to the sonar room passes through

hatches or places where it may be damaged, it should be run

through a pipe. Note that the cable must not be installed together

with high-power cables, antenna cables etc.

Page 22

Simrad SD570 / Base version

8

851--160115 / B

3.6 Auxiliary equipment

The SD 570/SE 570 sonars require connection of a speed log and

a course gyro. An inaccurate log or gyro input will cause

inaccurate indication of the vessel and target movements.

Speed

log:

• Pulse log: 100, 200 or 400 pulses/nm.

• Serial line, standard NMEA 0183; RS232, RS422 or Current

loop.

Course gyr

o:

• 3- phase synchro signal, 20-220V L- L, 50/60/400 Hz.

Gear ratio 1:360, 1:180, 1:90, 1:36

• 3- phase stepper signal, 20- 220V L- L.

Gear ratio 1:360, 1:180, 1:90, 1:36.

• Serial line, standard NMEA 0183; RS232, RS422 or Current

loop.

Echo

sounder:

In order to get a depth indication on the catch control page on the

sonar, one of the following Simrad echo sounders can be

connected:

• EQ50, EQ55, EQ100, ES60, ES380 series, ES500 (RS232 serial

line).

Traw l

system:

In order to get the trawl information on the sonar display, one of

the following Simrad trawl systems can be connected:

• FS 903 Trawl sonar system (RS232 serial line)

• FS 3300 Trawl sonar (RS232 serial line or 20 mA current loop)

• ITI Integrated trawl instrumentation (RS232 serial line)

Page 23

Introduction

9

851--160115 / B

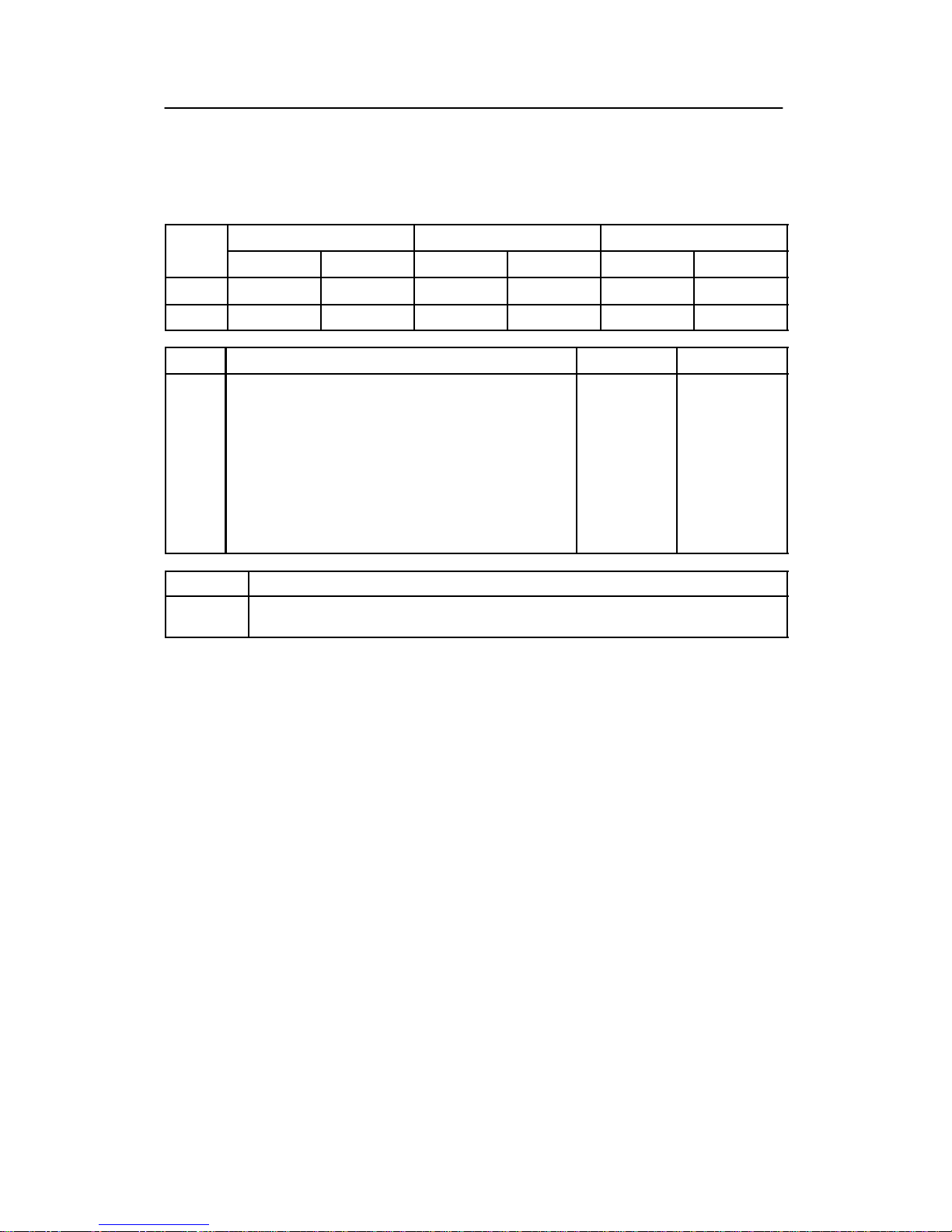

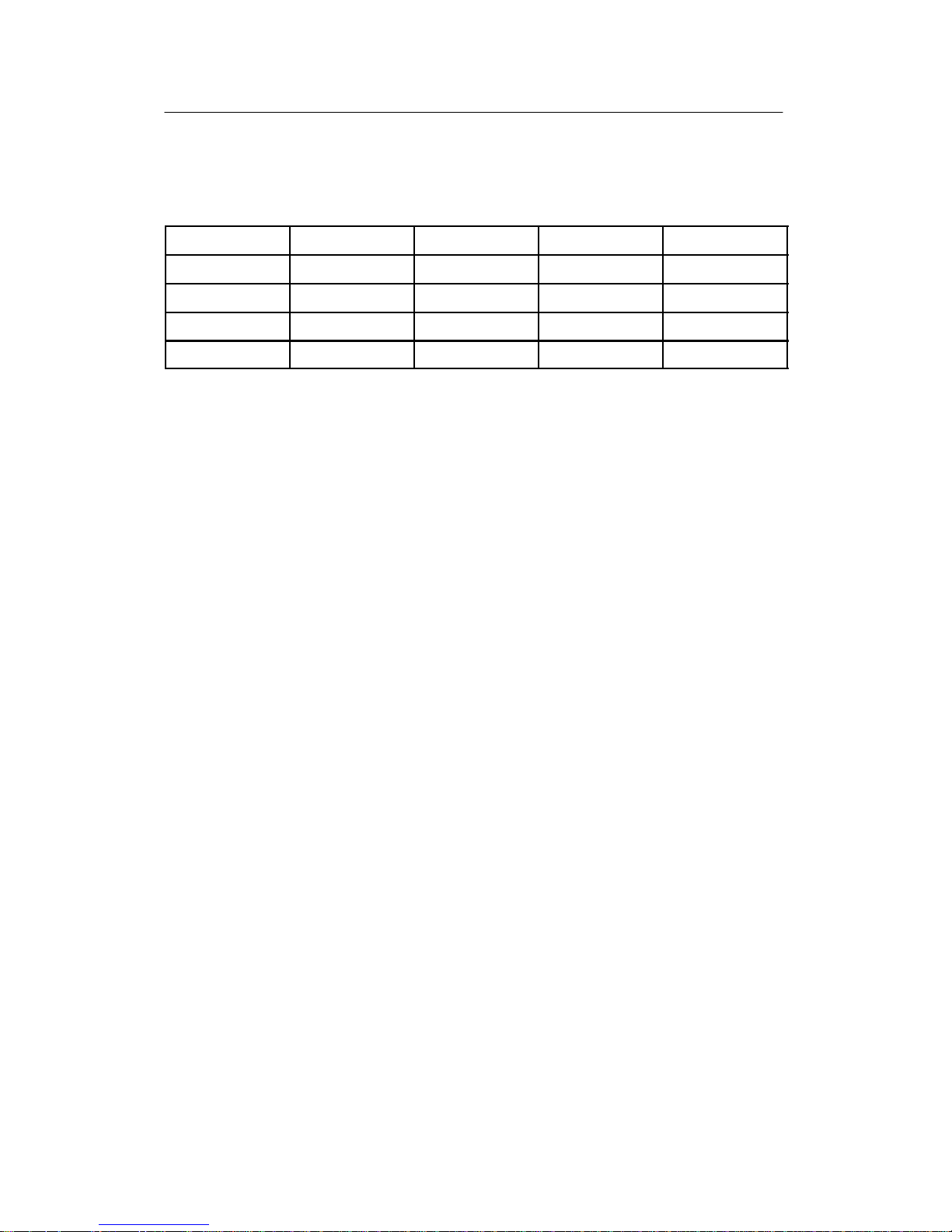

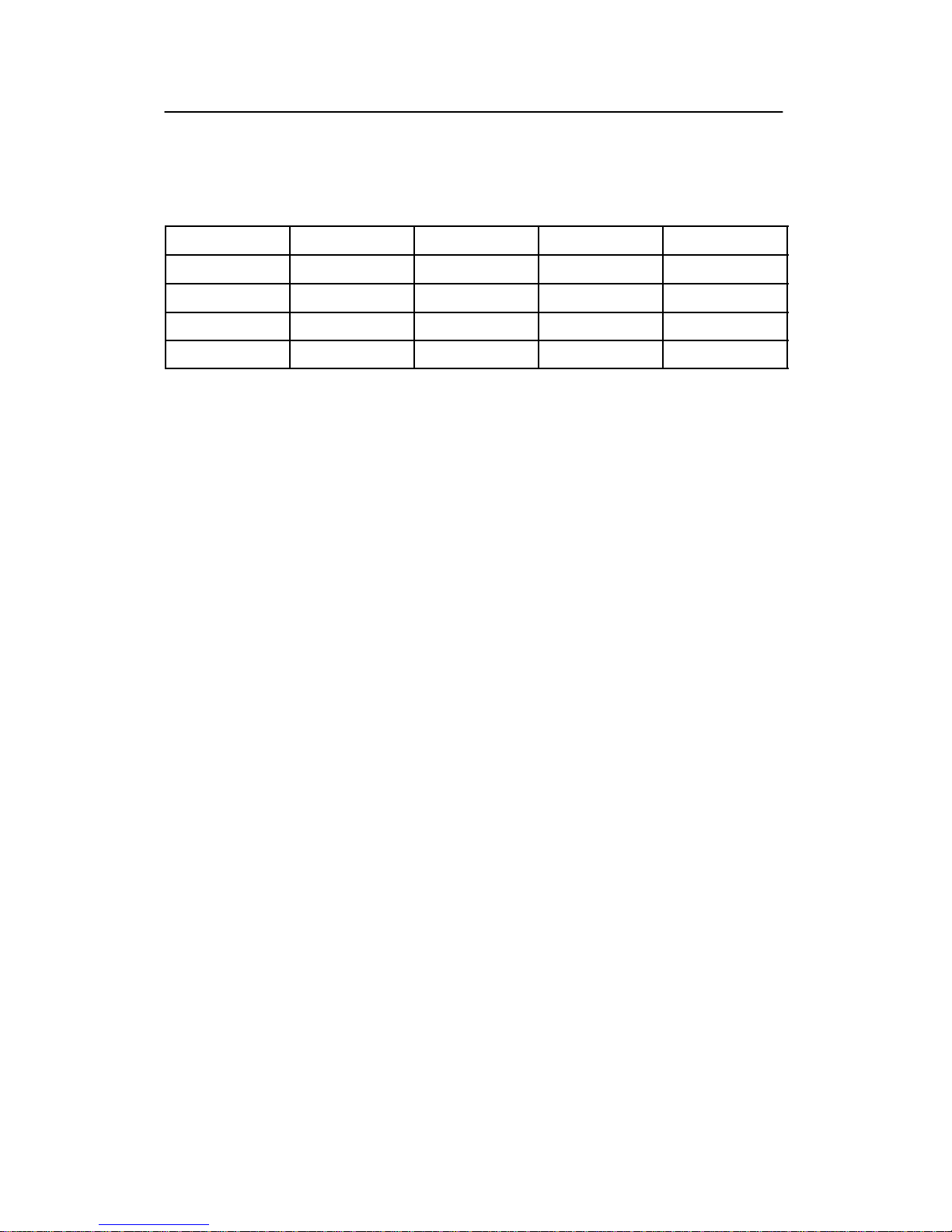

3.7 Technical specifications

Table 1 comprises the specifications required for the installation.

For further details, refer to the Operator Manual.

Sonar Control

Unit

Transceiver Unit Hull Unit

Voltage, nominal 115/230VAC

Single phase*

115/230 VAC

Single phase**

230/380/440 VAC

3--phase***

Voltage deviation ±15% of nominal ±15% of nominal 230V:±15%

380/440V:

340 -- 485V

Voltage transient ±20% of nominal

recovery time 3s

±20% of nominal

recovery time 3s

±20% of nominal

recovery time 3s

Power consumption

100 VA 500 VA 600 VA max.

Frequency 47 -- 63 Hz 47 -- 63 Hz 47 -- 63 Hz

Tem p .: S tor age

Operating

-- 4 0 t o + 7 0 °C

0to+40°C

-- 4 0 t o + 7 0 °C

0to+40°C

-- 2 0 t o + 7 0 °C

0to+40°C

Humidity 5--95% relative

non--condensing

5--95% relative

non--condensing

5--96% relative

non--condensing

Table 1 Technical specifications for the SD 570 / SE 570 sonars

Refer to the voltage, nominal line in table 1.

* Input voltage is automatically selected.

** Input voltage is selected with two switches.

*** Input voltage is selected on the motor connections

Page 24

Simrad SD570 / Base version

10

851--160115 / B

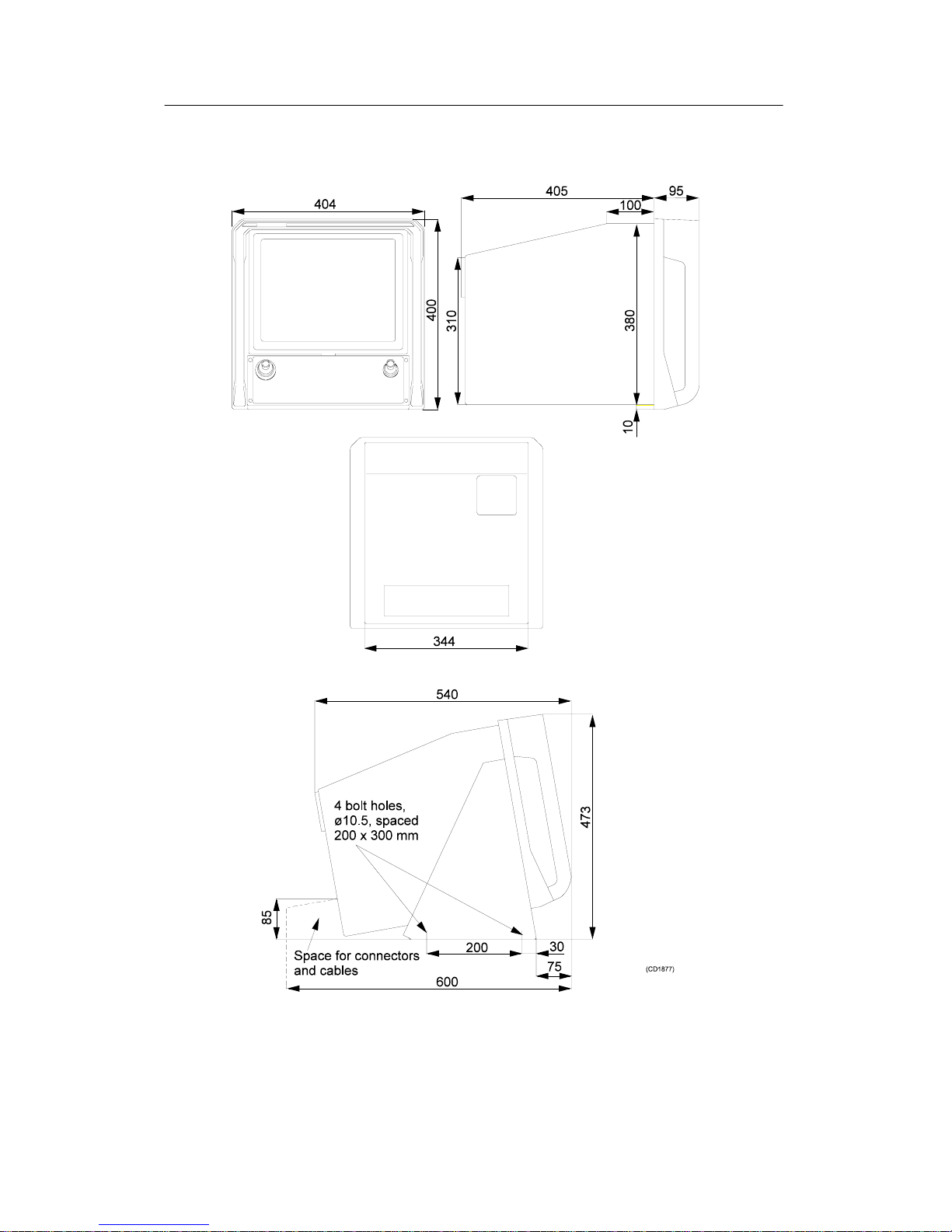

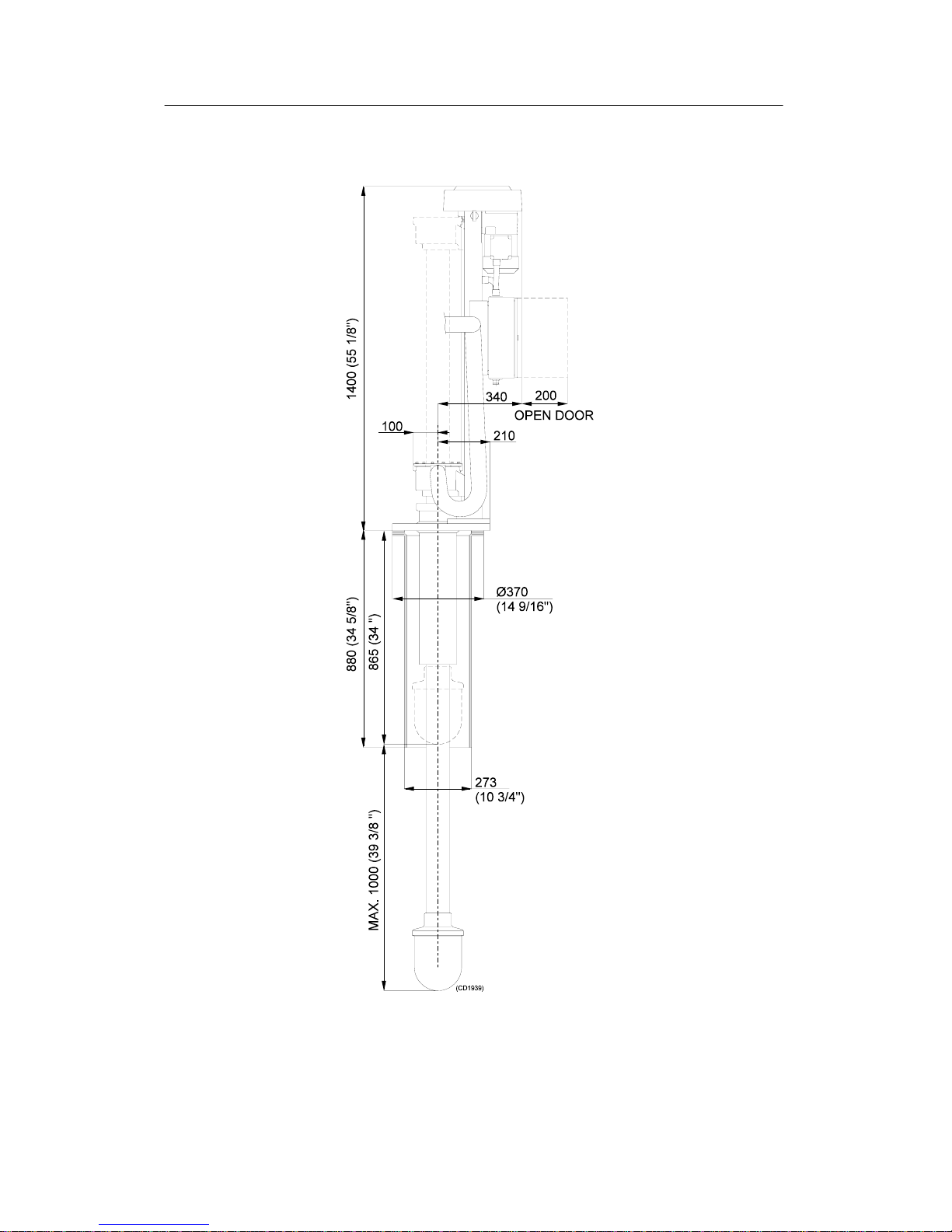

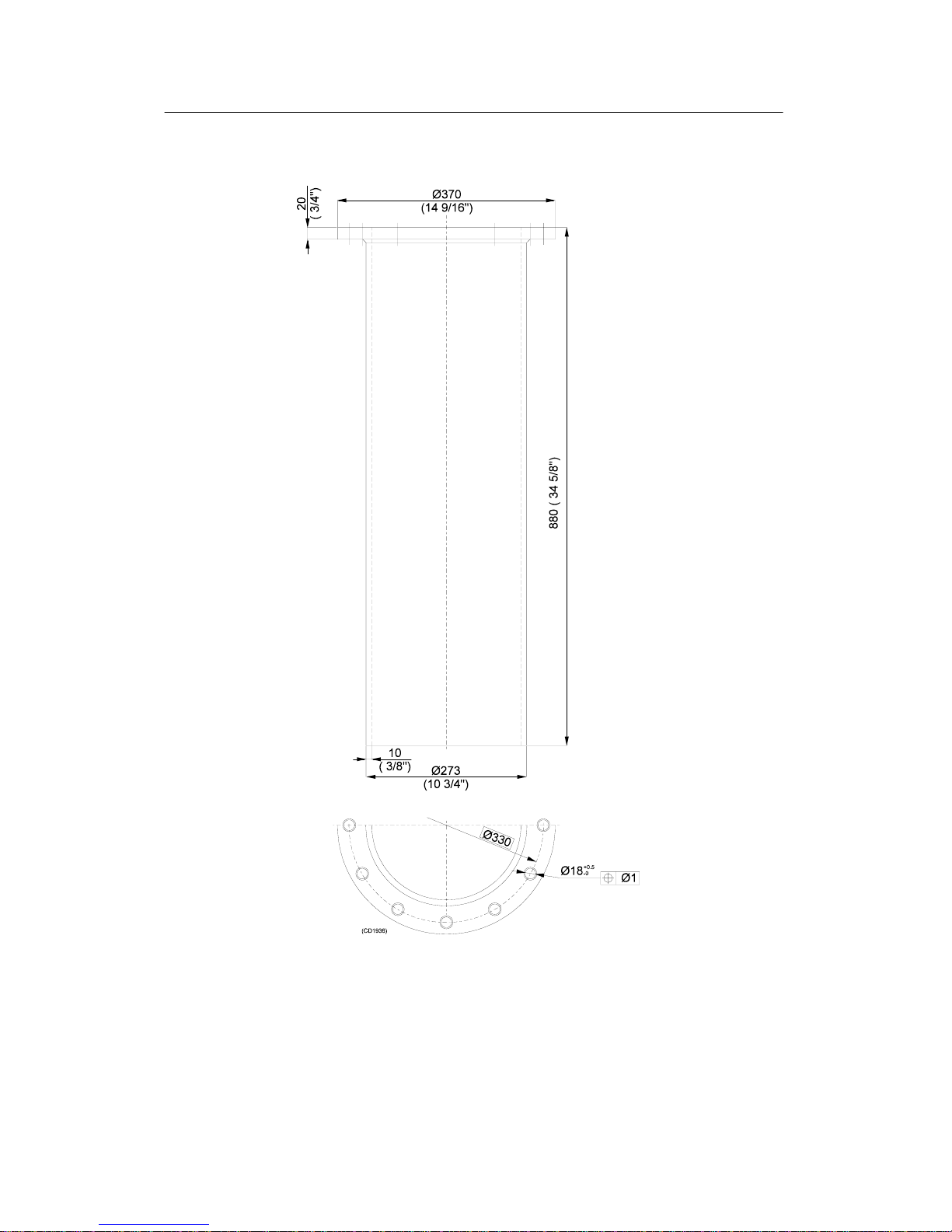

3.8 Weights and dimensions

Weight SD 570 Weight SE 570 Dimensions

Sonar Control

Unit

28 kg 28 kg Seefigure2

Transceiver Unit 75 kg 70 kg Seefigure3

Hull Unit 275 kg 265 kg Seefigure4

Trunk (optional) 68 kg 68 kg Seefigure5

Table 2 Weights of the SD 570 and SE 570 sonars SP 270 sonar

The figures 2, 3, 4 and 5 show the outline dimensions of the

SD 570 / SE 570 units.

Page 25

Introduction

11

851--160115 / B

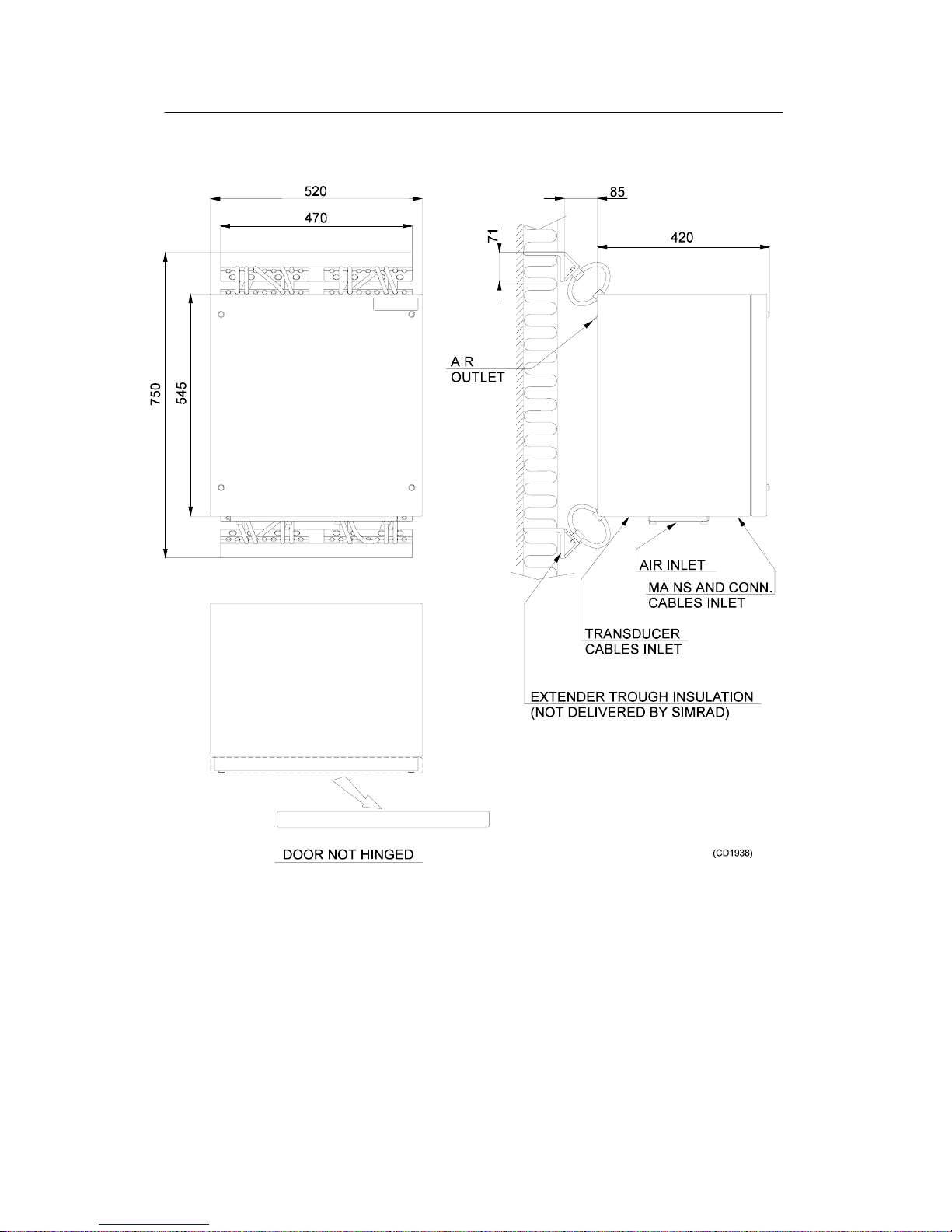

Figure 2 - Outline dimensions of the Sonar Control Unit

Page 26

Simrad SD570 / Base version

12

851--160115 / B

Figure 3 - Outline dimensions of the Transceiver Unit

Page 27

Introduction

13

851--160115 / B

Figure 4 - Outline dimensions of the Hull Unit

Page 28

Simrad SD570 / Base version

14

851--160115 / B

Figure 5 - Outline dimensions of the optional trunk

Page 29

Introduction

I

851--160116 / B

851- 160116 / AA000 / 3 - 11

Installation procedures

This section provides the necessary information for the

installation and cabling of the complete SD 570/ SE 570

sonar systems according to Simrad’s requirements.

Page 30

Simrad SD570 / Base version

II

851--160116 / B

Document revisions

Rev Date Written by Checked by Approved by

A Unknown

B 03.01.01 RBr ESB RBr

C

D

(The original signatures are recorded in the company’s logistic database)

Page 31

Introduction

III

851--160116 / B

Table of contents

1 INSTALLATION PLANNING 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 General 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Location of the Hull Unit 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Sonar room requirements 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 INSTALLATION OF THE SONAR TRUNK 5. . . . . . . . . . . . . . . . . . . . . . .

2.1 Mounting of the trunk 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Protecting blister 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Corrosion protection 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Trunk installation measurements 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 INSTALLATION OF THE HULL UNIT 9. . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Unpacking the Hull Unit 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Mounting the Hull Unit 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Staying 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Alignment of the transducer 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Installation checklist 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 INSTALLATION OF THE TRANSCEIVER UNIT 13. . . . . . . . . . . . . . . . . .

5 INSTALLATION OF THE SONAR CONTROL UNIT 16. . . . . . . . . . . . . .

5.1 Location of the Sonar Control Unit 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Mounting of the Sonar Control Unit 17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Desk top mounting 17. .. . . . .. . . .. . . . .. . . .. . . . .. . . .. . . . .. . .

Panel mounting 18. . .. . . .. . . . .. . . .. . . . .. . . .. . . . .. . . .. . . . ..

Bulkhead mounting 18. .. . . .. . . . .. . . .. . . . . . . . .. . . . . . . . .. . .

6 CABLING 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Cable plan 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 The Sonar Control Unit cabling 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 The Transceiver Unit cabling 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 The Hull Unit cabling 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 CONNECTING AUXILIARY EQUIPMENT 28. . . . . . . . . . . . . . . . . . . . . . .

7.1 General 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Connecting the course gyro 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting a course gyro with synchro output 29. .. . . .. . . . ..

Connecting a course gyro with stepper output 33. .. . . .. . . . .. .

Connecting a course gyro with serial line output 36. .. . . .. . . .

7.3 Connecting the speed log 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the pulse log 39. . . . . . .. . . . . . . . .. . . .. . . . .. . . .. . .

Page 32

Simrad SD570 / Base version

IV

851--160116 / B

Connecting a speed log with serial line output 40. . . .. . . . .. . .

7.4 Connecting other auxiliary equipment 42. . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Remounting the electronic drawer unit 42. . . . . . . . . . . . . . . . . . . . . . . . .

Page 33

Introduction

V

851--160116 / B

Document history

(The information on this page is for internal use)

Rev.A Original issue for Base version.

Rev.B Document transferred to Interleaf. No changes made to the text or

illustrations.

Page 34

Simrad SD570 / Base version

VI

851--160116 / B

Blank page

Page 35

Introduction

1

851--160116 / B

1 INSTALLATION PLANNING

Note ! For installation in an already installed trunk system, first read through

chapter 1.3 about the sonar room requirements. Then, for an already

installed SLor SX trunk system, continue to procedure 3 Installation

of the Hull Unit .

For installationin an already installed SK, SB or SQ trunk system,

refer to section Trunk systems in this manual.

1.1 General

This chapter provides the necessary information for the ship

designer to plan and carry out the installation of the SD 570/SE

570 hull system according to Simrad’s requirements. Study this

chapter thoroughly to achieve the recommended knowledge of

the procedures.

Note that individual installation drawings must be designed by

the shipyard, and the construction must be approved by the

classification authorities at the customer’s expense.

Simrad offers free advice for installation planning. The proposal

for the arrangement may be sent to Simrad for comments, or may

be worked out by Simrad. If such assistance is required, the

following drawings should be submitted:

· General arrangement

· Body plan and drawings of bottom tanks and cofferdam

· Sheer drawing

1.2 Location of the Hull Unit

The Hull Unit should preferably be located within 1/10 to 1/3 of

the ship’s length between perpendiculars (LBP), measured from

the fore perpendicular (FP). Refer to figure 1. Larger deviations

from this rule should not be made without consulting Simrad.

The Hull Unit may be located symmetrically on the centre line of

the vessel, or alongside the keel. When determining the exact

location, make sure that the transducer will have free view under

the keel (refer to figure 1).

The Hull Unit trunk must be installed such that it will be vertical

under normal operating conditions.

Water inlets and protruding details which create turbulence,

should not be located in front of the transducer. For the same

reason, check that the shell plating in front of the trunk is not

damaged.

Page 36

Simrad SD570 / Base version

2

851--160116 / B

Figure 1 - Location of the Hull Unit

1.3 Sonar room requirements

The sonar room should be dimensioned to house the Hull Unit

and the Transceiver Unit.This becausethe lengthof the flexi-hose

protected cabling from the Hull Unit to the Transceiver Unit is

limited to approximately 3.5 meters.

By installing the units in a well designed sonar room, the risk of

corrosion is reduced, the maintenance is simplified, and the

reliability is increased.

A suggested arrangement of the sonar room is shownin figure 2.

The free space should not be obstructed by girders or pipes etc.,

which might cause problems forthe installationand maintenance

work.

Access hatches

The sonar room must be accessible under all conditions, and the

doors or hatches should be so designed that the installed units can

be removed without being disassembled. A tackle carrier

designed for a load of a minimum of 2 tons should be mounted

above the Hull Unit. The tackle may be used to facilitate the

mounting of the trunk and Hull Unit, and is alsointended for use

in future service of the Hull Unit.

Heating

The sonar room should be furnished with a heating element of

1000 W, mounted close to the floor.

Insulation

The bulkhead must be insulated and plateddown to thefloor.The

insulation should equal a minimum of 50 mm of rock- wool.

Page 37

Introduction

3

851--160116 / B

Ventilation

The sonar room should preferably be connected to the ship’s

ventilation system. If this is not possible, two 3-inch vent pipes

must be laid from the sonar room to free air on deck. The air inlet

should be close to the floor, while the outlet should be placed as

high aspossible. Funnelsshould bemounted belowthe vent pipes

to collect condensed water.

To ensure the best possible ventilation, the outlet pipe should run

at least 4meters higher than the inletpipe. To keep rain and water

splash out, the pipes should be fitted with goosenecks or cowls.

Cable pipes

If the cable between the wheelhouse and the sonar room passes

through hatches or places where it can be damaged, it should be

run through pipes (2” pipes are recommended).

Bilge pump

The sonar room should be connected to the ship’s main bilge

pump system.If this is not possible, a separatebilge pump for the

sonar room must be installed.

Lighting

To simplify the installation and future maintenance, the sonar

room should be equipped with suitable lighting.

Docking

Make sure that there is ample space below the keel for mounting

the hull system, when docking the vessel.

To facilitate future docking, mark the position of the trunk as

indicated in figure 1

Flooring

When the installation is completed, the sonar room should be

suitably floored.

Page 38

Figure 2 - Example of sonar room arrangement,

seen from the bow

Simrad SD570 / Base version

4

851--160116 / B

Page 39

Introduction

5

851--160116 / B

2 INSTALLATION OF THE SONAR TRUNK

2.1 Mounting of the trunk

The location of the sonar trunk has to be carefully selected, as

described in chapter 1.2. Refer also to figures 4 and 5.

Note the orientation of the centre line of the trunk with regard to

the mounting bolts, shown in figure 3.

Note ! Remove the gasket on the top flange during the welding.

Figure 3 - Orientation of the sonar

trunk

The height from the topof the trunk flange to the underside of the

protection blister must be minimum 920 mm (361/4”) as shown

in figures 4 and 5.

The top flange must be parallel tothe construction loadline in the

fore- and- aft as well as the athwartships direction.

The installation trunk must be welded to an inserted plate which

should be 1.5 timesas thick asthe originalshell plate.The sizemay

be determined by the shipyard or the responsible maritime

authorities. The trunk must be stiffened to the inserted plate by

welding knee-plates on the trunk in both fore-and- aft and

athwartships directions.

Page 40

Simrad SD570 / Base version

6

851--160116 / B

2.2 Protecting blister

As illustrated in figures 4 and 5, a steel blister must be fitted for

protection. The blister shown in figure 4 is welded to the shell

plating and then filled with oil to prevent corrosion. This method

provides excellent protection and simplifies maintenance. The

blister shown in figure 5 is of the open type, to be welded to the

shell plating.

2.3 Corrosion protection

As soon as the trunk is mounted, and welding and grinding are

finished, the trunk should be painted with a quality protective

paint.

2.4 Trunk installation measurements

For future use, the measurements of the distance A, and the

heights B and Cshown in figures4 and5 haveto becarried outand

put into the table on the next page.

mm inches

Distance A

Height B

Height C

In case of an other installation solution, make a scheme with

dimensions below.

Page 41

Introduction

7

851--160116 / B

Figure 4 - Installation of trunk with extension

and oil- filled blister

Page 42

Simrad SD570 / Base version

8

851--160116 / B

Figure 5 - Installation of the trunk with open

protection blister. No trunk extension.

Page 43

Introduction

9

851--160116 / B

3 INSTALLATION OF THE HULL UNIT

3.1 Unpacking the Hull Unit

In order to prevent damage of the transducer and the transducer

cables while handling the Hull Unit, these parts are especially

protected. This means thatboth the transducer protection and the

cable protection should still be mounted to the Hull Unit when it

is being lowered down into the sonar room (see figure 6).

Figure 6 - Lifting the Hull Unit

Page 44

Simrad SD570 / Base version

10

851--160116 / B

j WhenunpackingtheHullUnit, first removethetopcover

fromthe woodenbox,then pulloutthe nailsmarkedwith

Indianink. Fasten thelifting deviceto the twolifting eye

bolts onthe top of the gallows andlift the Hull Unit with

the protections carefully out from the transport box.

3.2 Mounting the Hull Unit

The Hull Unit should normally be oriented with the

hoisting/lowering motor pointing aft (see figure 7). If this

orientation makes the motor control unit onthe HullUnit difficult

to access, the Hull Unit may be oriented in the most suitable

position.

Note ! The motor control unit should never be dismounted from the Hull Unit

(see text above).

j Use a tackle to lower the Hull Unit with the protections

downintothe sonarroom(seefigure 6).Removethe blind

cover from the trunk, and check that the gasket is not

damaged. Store the blind cover in the sonar room for

possible future use.

Figure 7 - Recommended orientation of the Hull Unit

j Removethetransportprotectionfromthetransducerand

lower the Hull Unit carefully down into the trunk.

Tightenthe flange nuts witha torque ofapproximately 6

kpm.

Page 45

Introduction

11

851--160116 / B

j Remove the cable protection box. The transducer cables

andconnectorshave tobekeptdry andhandledwithcare

to avoid mechanical damage.

3.3 Staying

The Hull Unit is constructed to be in the lower position with a

maximum speed of 15 knots.Toprevent unwanted vibrations, the

Hull Unit has to be stayed off against the bulkhead. Remove the

lifting rings onthe top of the gallows on the Hull Unitand use the

holes for fastening of the staying in the fore- and- aft direction. In

case of serviceon the Hull Unit,it should be possibleto removethe

staying.

3.4 Alignment of the transducer

Note that the transducer should not be mechanically aligned even

if the Hull Unit is oriented differently from figure 7.

The transducer alignment will be carried out later by turning the

echo picture in the computer.

Page 46

Simrad SD570 / Base version

12

851--160116 / B

3.5 Installation checklist

For the following check list, refer to the sonar room requirements

in chapter 1.3.

INSTALLATION CHECKLIST YES NO

Are the access hatches satisfactory?

Is the heating satisfactory?

Is the insulation satisfactory?

Is the ventilation satisfactory?

Are the access hatches satisfactory?

Is a bilge pump installed?

Is the lighting satisfactory?

Is the sonar room suitably floored?

If the answer to any of the questions is NO, make a note in the

installation certificate at the end of section Start-up procedures.

Page 47

Introduction

13

851--160116 / B

4 INSTALLATION OF THE TRANSCEIVER UNIT

Note ! The Transceiver Unit must be mounted as a complete unit, i.e. the door

should not be opened until the unit is securely fastened to the bulkhead.

Before starting the mounting of the Transceiver Unit, note that the

distance between the HullUnit and the Transceiver Unitis limited

because of the flexible transducer cables. Also remember to take

into consideration the necessary slack for lowering of the

transducer.

Do not fasten the transducer cables into the Transceiver Unit

before mentioned later in the start- up procedure.

The Transceiver Unit cabinet requires a minimum free bulkhead

space, which is shown in figure 8.

j Dismountthe twomounting bracketswhich arefastened

to theshock absorbers on theTransceiverUnit. An Allen

key is located in the plastic bag which is fastened to the

upper shock absorber.

j Weld the mounting brackets safely to the bulkhead as

shown in figure 8.

j Use a tackle carrier to lift the Transceiver Unit in

position, and bolt it to the mounting brackets with the

boltsincluded inthe delivery. These8 boltsare locatedin

the plastic bag that was fastened to the upper shock

absorber. Remember to fasten the grounding cable from

the Transceiver Unit to the mounting bracket as shown

in figure 9.

Page 48

Simrad SD570 / Base version

14

851--160116 / B

Figure 8 - Mounting the brackets for the

Transceiver Unit

Page 49

Introduction

15

851--160116 / B

Figure 9 - Mounting the Transceiver Unit

Page 50

Simrad SD570 / Base version

16

851--160116 / B

5 INSTALLATION OF THE SONAR CONTROL

UNIT

5.1 Location of the Sonar Control Unit

The Sonar Control Unit may bemounted on a desk top, ina panel,

or to the bulkhead. The necessary hardware for desk top and

panel mounting of the unit is included inthe delivery.It shouldbe

noted that the unit weighs approximately 28 kg, and this weight

must be considered when deciding how to mount it.

In order to secure the best location according to the routines on

board, the location of the Sonar Control Unit should be

thoroughly discussed with the skipper. Make sure that proper

operating and viewing height is provided.

Remember to include the ”Compass Safe Distance” when

planning the location:

· Sonar Control Unit with internal display

Standard compass: 1.4 m

Steering compass: 0.9 m

· Control Unit without display:

Standard compass: 1.1 m

Steering compass: 0.6 m

When mounting the unit, ensure that it is located to allow easy

access to the cable connection panel at the rear of the unit.

Ensure that the installation area is dry, and free from excessive

dust and vibration.

Page 51

Introduction

17

851--160116 / B

5.2 Mounting of the Sonar Control Unit

Desk top mounting

Refer to figure 10 for minimum space for the desk top mounting

of the cabinet.

j Dismount the mounting bracket from the Sonar Control

Unit by unscrewing the four bolts on the front. An Allen

key is located in the spare parts box.

j Bolt the mounting bracket securely to the desk top with

the four 10x30mm bolts which are located in the spare

parts box.

j Mountthe cabineton themounting bracketwith thefour

bolts.

Figure 10 - Desk top mounting

Page 52

Simrad SD570 / Base version

18

851--160116 / B

Panel mounting

j Dismount the mounting bracket from the Sonar Control

Unit by unscrewing the four bolts on the front. An Allen

key is located in the spare parts box.

j Cut the panel opening to the following size:

Width: 345 mm

Height: 380 mm

j Place the cabinet into the opening to mark the four

fastening holes.

j Remove the cabinet and drill the four fastening holes in

the panel.

Metal panel: Drill 5mm holes for threading with M6 tap, or

7mm holes if through- bolts with nuts are preferred.

Wooden panel: Drill 9mm holes for the four thread inserts

which are located in the spare parts box. Refer to figure 11 for

information about mounting the thread inserts.

Figure 11 - Mounting the thread inserts

j Place the cabinet into the opening and fasten it with the

four bolts.

Bulkhead mounting

To obtain the best operation position of the cabinet, the cabinet

should be mounted with a tilt angle of approximately 20 . An

optional mounting bracket can be delivered from Simrad.

j Dismount the mounting bracket from the Sonar Control

Unit by unscrewing the four bolts on the front. An Allen

key is located in the spare parts box.

Page 53

Introduction

19

851--160116 / B

j Bolt the bulkhead mounting bracket securely to the

bulkhead.

j Mountthe cabineton themounting bracketwith thefour

bolts.

Page 54

Simrad SD570 / Base version

20

851--160116 / B

6 CABLING

6.1 Cable plan

Figure 12 shows the cable plan for the SD 570 and SE 570 sonars.

The cable numbers also refer to the interconnection diagram,

drawing no. 824- 112979. This drawing is located in section

Drawings in thismanual. The cable specifications arelisted in the

table below.

Note that cable no. 4 is delivered with a standard length of 50

meters, and has a preconnected plug in the Sonar Control Unit

(wheelhouse) end. Thiscable is includedin the Sonar ControlUnit

package. As an option, cable no. 4 can be delivered in lengths of

75 or 100 meters.

Note that the length of the flexible transducer cables 7 and 8 is

fixed to approximately 3.5 meters.

Cable no. Cable type Cable dia (mm)

1 Screened cable, 2x0.5 mm

2

6

2 RCOP 5x1 mm

2

12

3,5 Mains cable, length 2 m 7

4,6 Data cable 8x(2+1)x0.5 mm

2

14

7,8 Flexi--cable, 3.5 m fixed length. Mounted

to Hull Unit

62

9

RCCP/750V 4x2.5 mm@

17

Page 55

Introduction

21

851--160116 / B

Figure 12 - Cable plan for the SD 570 / SE 570 sonars

Page 56

Simrad SD570 / Base version

22

851--160116 / B

6.2 The Sonar Control Unit cabling

All the cables to the Sonar Control Unit are to be plug connected

to the electronic drawer unit at the rear of the cabinet (see figure

13). The numbers on the figure refer to the cable numbers on the

cable plan.

Note ! In order to make service onthe Sonar Control Unit,the cables must have

a slack so the electronic drawer unit can have all the cables connected

while it is outside the cabinet. This couldbe either by pulling it out from

the front, or by reconnecting the cables with the drawer at floor level.

Note that cable no. 4 (refer to figure 12) is delivered with a

standard length of 50 meters, and has a preconnected plug in the

Sonar Control Unit (wheelhouse) end.

j Pull cable no. 4 from the wheelhouse to the sonar room.

Note that the preconnected plug should be connected to

the Sonar Control Unit in the wheelhouse. Remember to

include the slack for service purpose.

j The mains power cable (3) may be connected to a normal

mains outlet in the wheelhouse. If the delivered cable

does not fit, put on a suitable connector. Note that the

mainspower totheSonar ControlUnit can be115VAC or

230 VAC, and that this unit will automatically sense the

voltage.

The connection of the speed log (1) and the course gyro (2) will be

described in chapter 7.

Page 57

Introduction

23

851--160116 / B

Figure 13 - Cable connections to the Sonar Control Unit

Page 58

Simrad SD570 / Base version

24

851--160116 / B

6.3 The Transceiver Unit cabling

The cable numbers on figure 14 and in the following procedures

refer to the numbers on the cable plan and the interconnection

diagram.

Figure 14 - The cable connection in the bottom of the Transceiver

Unit

j All cable connections to the TransceiverUnit must have

aslack to allowthe TransceiverUnit to move up to10 cm

because of the flexible shock mounting.

j Start the termination with cable no. 6. This because this

cable is connected to the lowest row of the terminals on

E201. Use the surplus of cable no. 4, or a similar type of

cable. Use the cable gland on the left hand side (refer to

figure 14) and terminate the main screen of the cable as

shown in figure 15. For termination of each cable pair

with screen, refer to the interconnection diagram. Use a

part of the enclosed cable sleeve on the screen of each

cable pair.

Page 59

Introduction

25

851--160116 / B

Figure 15 - Termination of the cable main screen

j Continue with cable no. 4 throughthe cable gland on the

righthand side (seefigure 14) andmake the termination

of the main screen according to figure 15. Make the

connections to terminal E201 according to the

interconnection diagram.

Note that themains power connection to the Transceiver Unit can

be 115 VAC or 230 VAC. Use the following procedure for the

connection of the mains power:

j Pull out the mains input connector P201 on the power

supply in the Transceiver Unit. For location of the

connector, refer to figure 16.

j Set the mains voltage selector switch S201 on the Power

Supply and S203 on the HV Power Unit to correspond to

thecorrect mainsvoltage(115Vor230V), andreplace the

switch lock to secure the switch in the correct position.

j Set the service switch S202 on the Power Supply to OFF

(middle) position.

Page 60

Simrad SD570 / Base version

26

851--160116 / B

Figure 16 - The Power Supply and the HV Power Unit

j The mains power cable (3) may be connected to a normal

mains outlet in the sonar room. If the delivered cable

connector does not fit, put on a suitable connector.

j Do not mount the flexible transducer cables to the

T ransceiver Unit.

Page 61

Introduction

27

851--160116 / B

6.4 The Hull Unit cabling

Connection of cable no. 6 in the motor control unit:

j Usethe cableglandonthe right--handside,and makethe

termination of the main screen according to figure 15.

j Makea slackon thecableinside themotorcontrol unitas

shown on figure 17, and make the connections to the

terminalE301 accordingtothe interconnectiondiagram.

Connection of cable no. 9 in the motor control unit:

j Use the cable gland on the left--hand side, and make the

termination of the cable screen in the cable gland.

j Make the connections of the three--phase mains power

directly to the motor overload switch S303 according to

theinterconnection diagram. Thegrounding wireshould

be connected to the ground terminal beside the overload

switch.

Figure 17 - Connections to the Hull Unit

Page 62

Simrad SD570 / Base version

28

851--160116 / B

7 CONNECTING AUXILIARY EQUIPMENT

7.1 General

It is not necessary to make the connection of the auxiliary

equipment before the start-up procedure is finished, and this

equipment may therefore be connected later. Anyhow, do not

connect the plugs for the auxiliary equipment to the Sonar

Control Unit before mentioned in a later chapter.

The SD 570 / SE 570 sonars require connection of a speed log and

a course gyro. An inaccurate log or gyro input will cause

inaccurate indication of the vessel and target movements.

Speed log:

· Pulse log: 100, 200 or 400 pulses/nm.

· Serial line, standard NMEA 0183; RS232, RS422 or Current

loop.

Course gyro:

· 3- phase synchro signal, 20- 220V L- L, 50/60/400Hz.

· Gear ratio 1:360, 1:180, 1:90, 1:36.

· 3- phase stepper signal, 20-220V L- L.

Gear ratio 1:360, 1:180, 1:90, 1:36.

· Serial line, standard NMEA 0183; RS232, RS422 or Current

loop.

Echo sounder:

In order to get a depth indication on the catch control page on the

sonar, one of the following Simrad echo sounders can be

connected:

· EQ50, EQ55, EQ100, ES60, ES380 series, ES500 (RS232 serial

line).

Trawl system:

In order to get the trawl information on the sonar display, one of

the following Simrad trawl systems can be connected:

· FS Trawl sonar (RS 232 serial line or 20mA current loop).

· ITI Integrated Trawl Instrumentation (RS232 serial line).

Page 63

Introduction

29

851--160116 / B

7.2 Connecting the course gyro

The Sonar Control Unit can be connected to a course gyro with

one of the following outputs (tick off for the type which will be

connected):

j 3--phase synchro signal See chapter 7.2.1

j 3--phase stepper signal See chapter 7.2.2

j Serial line (NMEA 0183) See chapter 7.2.3

Connecting a course gyro with synchro output

j First, get the specifications of the gyro to fill in the

following data:

SYNCHRO DATA SPECIFICATIONS LEGAL VALUES

OUTPUT VOLTAGE 20 to 220 VAC

FREQUENCY 50/60/400 Hz

GEAR RATIO 1:360/1:180/1:90/1:36

If it is difficult to find the specifications for the gyro, the output

voltage and frequency can be measured in the following way:

j The output voltage can be measured by an AC voltmeter

or by an oscilloscope on the reference output R1 & R2.

Notethat ifanoscilloscopeisused,thereferenceprobe on

the oscilloscope must not be connected to the mains

ground, and the measured peak to peak value of the

output voltage must be divided by 2 Ö2 to get the RMS

voltage.

j Fill the output voltage value into the table above.

j The frequencycan be measured by an oscilloscope onthe

reference output R1 & R2. Note that the referenceprobe

on the oscilloscope must not be connected to the mains

ground.Calculate thefrequency1/T(T isthe timefor one

sine wave) and fill the result into the table above.

j If the gear ratio of the gyro output also is unknown, this

has to be tried out later when testing the readout of the

gyroon theSonarControlUnit. Insuch case,set thegear

ratio to 1:360.

When connecting the gyro cable to the 15 pin D-connector, note

that each of the three phases S1, S2, S3 and the reference R1 has

three different connection pins, marked L (Low), M (Medium)

and H (High). These pins are used for different gyro output

voltage values as indicated for the connections below:

Page 64

Simrad SD570 / Base version

30

851--160116 / B

Signal phase 1: S1-L (20- 70V) pin 2

S1- M (80- 140V) pin 9

S1- H (150- 220V) pin 1

Signal phase 2: S2-L (20- 70V) pin 11

S2- M (80- 140V) pin 3

S2- H (150- 220V) pin 10

Signal phase 3: S3-L (20- 70V) pin 5

S3- M (80- 140V) pin 12

S3- H (150- 220V) pin 4

Reference 1: R1- L (20- 70V) pin 14

R1- M (80- 140V) pin 6

R1- H (150-220V) pin 13

Reference 2: R2 pin 8

j Locate the 15 pin D--connector, the connector housing

and the shrink tube in the spare parts box. Refer to the

output voltage in the table for the synchro data, and

make the connections to the 15 pin D--connector with

reference to the pin--connection list above. Also refer to

figure 18, which shows the pin location of the connector

seenfromthewiresolderingside.Thecable screenshould

be connected to the connector housing.

Figure 18 - Connections for a gyro with

synchro output

In order to read the data from the gyro, some DIL switches on the

printed circuit board in the electronic drawer unit behind the

operator panel must be selected. Use the following procedure to

set the switches:

Page 65

Introduction

31

851--160116 / B

j Set the switch S101 at the rear panel on the Sonar

Control Unit to OFF position. For location of the switch,

refer to figure 13.

j Disconnect allconnections tothe rear panelon the Sonar

Control Unit.

j Usethe 3mmAllenkeywhichislocatedin the spareparts

boxto unscrewthe fourscrewsonthefrontoftheoperator

panel, and pull the electronic drawer carefully out. Note

thetwocablesto thedisplayonthetopof thedrawerunit.

j Disconnect the two display cable plugs on the drawer

unit, and dismount the top cover of the drawer.

j Locate the DIL switch S2 (referto figure 19), and setthe

switches according to table.

DIL SWITCH S2

GYR

O

1 2 3 4 5 6 7 8

50/60 Hz OFF OFF OFF OFF OFF OFF OFF ON

1:360

400 Hz OFF OFF OFF OFF OFF OFF OFF OFF

50/60 Hz OFF OFF OFF ON OFF OFF OFF ON

SYN-

1:180

400 Hz OFF OFF OFF ON OFF OFF OFF OFF

CHR

O

50/60 Hz OFF OFF OFF OFF ON OFF OFF ON

1:9

0

400 Hz OFF OFF OFF OFF ON OFF OFF OFF

50/60 Hz OFF OFF OFF ON ON OFF OFF ON

1:3

6

400 Hz OFF OFF OFF ON ON OFF OFF OFF

Do not insert the electronic drawer unit until mentioned in a later

chapter.

Page 66

Simrad SD570 / Base version

32

851--160116 / B

Figure 19 - The electronic drawer unit

Page 67

Introduction

33

851--160116 / B

Connecting a course gyro with stepper output

j First, get the specification of the gyro to fill in the

following data:

STEPPER DATA SPECIFICATIONS LEGAL VALUES

OUTPUT VOLTAGE 20 to 220 VAC

REF. POLARITY + REF. or -- REF

GEAR RATIO 1:360/1:180/1:90/1:36

If it is difficult to find the specifications for the gyro, the output

voltage and the referencepolarity canbe measuredby avoltmeter

in the following way:

j Connect the positive probe from the voltmeter to the

stepper reference output, and the negative probe to one

of the three signal phases which have a signal output.

Note that one or two signalphases always should have a

signal output voltage.

j Fill the highest measured output voltage value into the

table above.

j When readingthe signal outputvoltage, note thevoltage

polarity. If it is positive,the reference polarity is positive

(+ REF), and if it is negative, the reference polarity is

negative (-- REF). Fill the result into the table above.

j If the gyro output is specified to 6 step/degree, this is

equal to a gear ratioof 1:360. If the gear ratioof the gyro

output is unknown, this has to be tried out later when

testing the readout from the gyro on the Sonar Control

Unit. In such case, set the gear ratio to 1:360.

j Note that for somesteppertypegyros,the outputvoltage

is only half--wave rectified. This has to be checked by an

oscilloscope and ticked off below

j Full--wave rectified.

j Half--wave rectified.

Page 68

Simrad SD570 / Base version

34

851--160116 / B

When connecting the gyro cable to the 15 pin D-connector, note

that each of the three phases S1, S2, S3 has three different

connection pins, marked L (Low), M (Medium) and H (High).

These pins are used for different gyro output voltage values as

indicated for the connections below:

Signal phase 1: S1-L (20- 70V) pin 2

S1- M (80- 140V) pin 9

S1- H (150- 220V) pin 1

Signal phase 2: S2-L (20- 70V) pin 11

S2- M (80- 140V) pin 3

S2- H (150- 220V) pin 10

Signal phase 3: S3-L (20- 70V) pin 5

S3- M (80- 140V) pin 12

S3- H (150- 220V) pin 4

Reference : +/- REF pin 7

-/+ REF(see note) pin 15

Note ! If the output voltage is only half-wave rectified, the other reference from

the gyro which is not used for the three phases must be connected to pin

15.

j Locate the 15 pin D--connector, the connector housing

and the shrink tube in the spare parts box. Refer to the

output voltage which was written into the table for the

stepperdata specifications,and make the connections to

the 15--pin D--connector with reference to the

pin--connection list above. Also refer to figure 20 which

showsthepinlocationofthe connectorseenfromthewire

soldering side. The cable screen should be connected to

the connector housing.

Figure 20 - Connections for a gyro with stepper output

Page 69

Introduction

35

851--160116 / B

In order to read the data from the gyro, some DIL switches on the

printed circuit board in the electronic drawer unit behind the

operator panel must be selected. Use the following procedure to

set the switches:

j Set the switch S101 at the rear panel on the Sonar

Control Unit to OFF position. For location of the switch,

refer to figure 13.

j Disconnect allconnections tothe rear panelon the Sonar

Control Unit.

j Use the3mm Allenkey to unscrewthe fourscrewson the

frontoftheoperator panel,andpullthe electronicdrawer

carefullyout.Notethetwo cablestothedisplayonthe top

of the drawer unit.

j Disconnect the two display cable plugs on the drawer

unit, and dismount the top cover of the drawer.

j Refer to figure 19, and set the links LK19, LK20 and

LK21 to position A.

j Locate the DIL switch S2 (referto figure 19), and setthe

switches according to the table below.

DIL SWITCH S2

GYR

O

1 2 3 4 5 6 7 8

+ REF ON OFF OFF OFF OFF OFF OFF OFF

1:360

-- REF ON ON OFF OFF OFF OFF OFF OFF

+ REF ON OFF OFF ON OFF OFF OFF OFF

STEP-

1:180

-- REF ON ON OFF ON OFF OFF OFF OFF

PER

+ REF ON OFF OFF OFF ON OFF OFF OFF

1:9

0

-- REF ON ON OFF OFF ON OFF OFF OFF

+ REF ON OFF OFF ON ON OFF OFF OFF

1:3

6

-- REF ON ON OFF ON ON OFF OFF OFF

Do not insert the Control Unit drawer until mentioned in a later

chapter.

Page 70

Simrad SD570 / Base version

36

851--160116 / B

Connecting a course gyro with serial line

output

The Sonar ControlUnit can read the course gyro data (and/or the

speed log data) from a serial line with on ofthe followingoutputs

(tick off for the type which will be connected):

j RS232 Serial line

j RS422 Serial line

j 20mA current loop

The format of the serial line data is standard NMEA 0183, and the

telegram can contain both the course and speed data (refer to the

telegram format in the end of this chapter).

When connecting the 9-pin D- connector, note that each of the

three types of serial lines has different connection pins:

RS232: Serial line signal PORT B pin-2

Signal reference PORT B pin- 5

RS422: RS422+ PORT B pin- 1

RS422$ PORT B pin- 4

20mA current loop: CLI+ PORT B pin- 6

CLI- PORT B pin-9

j Use a 9--pin D--connector, male type, for connecting the

serial line to port B on the Sonar Control Unit (this

connector is not included in the delivery). To make the

connections, refer to the pin connection list above, and

figure 21 which shows the pin location of the connector

seenfromthewiresolderingside.Thecable screenshould

be connected to the connector housing.

j In order to read the data from the gyro, some DIL

switches and links on the printed circuit board in the

electronicdrawerunitbehind theoperatorpanel mustbe

selected.Use the followingprocedureto set the switches:

j Set the switch S101 at the rear panel on the Sonar

Control Unit to OFF position. For location of the switch,

refer to figure 13.

j Disconnect allconnections tothe rear panelon the Sonar

Control Unit.

j Use the3mm Allenkey to unscrewthe fourscrewson the

frontoftheoperator panel,andpullthe electronicdrawer

carefullyout.Notethetwo cablestothedisplayonthe top

of the drawer unit.

Page 71

Introduction

37

851--160116 / B

Figure 21 - Connections for a gyro with

serial line output

j Disconnect the two display cable plugs on the drawer

unit, and dismount the top cover of the drawer.

j Locate the DIL switch S2 (referto figure 19), and setthe

switches according to the table on next page.

DIL SWITCH S2

GYR

O

1 2 3 4 5 6 7 8

SERIAL LINE OUTPUT OFF OFF OFF OFF OFF ON OFF OFF

Locate the links LK2, LK3 and LK6 on the Control Unit Board,

(see figure 19) and set the links according to the table below.

GYRO LINK SETTING

LK2 LK3 LK6

RS232 OUT IN OUT

RS422 OUT OUT IN

20 mA current loop IN OUT OUT

Do not insert the Control Unit drawer until mentioned in a later

chapter.

Page 72

Simrad SD570 / Base version

38

851--160116 / B

The serial line telegram format for the course and speed data:

$xxHDT,ggg.g,T<cr><1f> Heading, Degrees True

$xxHDM,ggg.g,M<cr><1f> Heading, Degrees Magnetic

$xxVGT,ggg.g,T,ggg.g,M,nn.n,N,kk.k,K<cr><1f> Actual track

and ground speed

$xxVHW,ggg.g,T,ggg.g,M,nn.n,N,kk.k,K<cr><1f> Heading

and water speed

xx is indicator for transmitter, for instance:

’HE’ = gyro, earth seeking

’GP’ = Precision Global Positioning System

Heading data:

ggg.g is heading in degrees.

The gyro value can have variable amounts of digits in front of

comma (max. 3), and after comma (min. 0). Comma can also be

omitted. Leading zeroes and spaces are accepted.

In the twolast telegrams, the ”True” valueis used ifboth true and

magnetic values are transmitted.

Speed data:

nn.n is speed in Nautical miles

kk.k is speed in Kilometer per hour

The speed value should have min. 1, max. 2 digits in front of

comma, and 1 after. Leading zeroes and spaces are accepted.

Page 73

Introduction

39

851--160116 / B

7.3 Connecting the speed log

The Sonar Control Unit can be connected to a speed log with one

of the following outputs (tick off for the type which will be

connected):

j Pulse log (100, 200 or 400 pulses per nautical mile)

j Serial line (RS232, RS422 or 20mA current loop)

The connection of these different speed log outputs is described

in the following chapters.

Connecting the pulse log

The Sonar Control Unit can be connected to a pulse log with one

of the following outputs (tick off for the type which will be

connected):

j 100 pulses per nautical mile

j 200 pulses per nautical mile

j 400 pulses per nautical mile

For anytype of log output (relay, open collector, or opto-coupler),

the output must be free from other connections.

Figure 22 shows the connection of a pulse log with relay output.

For connection of open collector, or opto- coupler outputs, be

aware of the polarization (see figure 23).

j Locatethe9--pinD --connector,theconnectorhousingand

the shrink tube in the spare parts box, and make the

plug--connections. The cable screen should be connected

to the connector housing.

Figure 22 - Connections for a pulse log with

relay output

j Locate the DIL switch S1 on the Control Unit Board

(refer to figure 19), and set the switches according to the

table below.

Page 74

Simrad SD570 / Base version

40

851--160116 / B

DIL SWITCH S1

SPEED

1 2 3 4 5 6 7 8

100 pulses per nautical

mile

OFF OFF ON OFF OFF OFF OFF OFF

200 pulses per nautical

mile

OFF OFF OFF ON OFF OFF OFF OFF

400 pulses per nautical

mile

OFF OFF ON ON OFF OFF OFF OFF

Do not insert the Control drawer unit before mentioned in a later

chapter.

Figure 23 shows the pulse log interface circuit on the ControlUnit

Board.

Figure 23 - Pulse log interface

When the system is started up, an oscilloscope can be connected

to the test point TP5 to check if the pulse log signal is coming

through the comparator U45 (TP4 is GND). If the signal is not

coming through the comparator, try to adjust the 10- turn

potmeter R45. In case of noise problems, R45 can be adjusted for

noise limitation .

Connecting a speed log with serial line output

The Sonar Control Unit can read the speed log data (and/or the

course gyro data) from a serial line with on of the following

outputs (tick off for the type which will be connected):

j RS232 serial line

j RS422 serial line

j 20mA current loop

The format of the serial line data is standard NMEA 0183, and the

telegram can contain both the course and speed data (refer to the

telegram format in the end of chapter 7.2.3).

Page 75

Introduction

41

851--160116 / B

When connecting the 9-pin D- connector, note that each of the

three types of serial lines has different connection pins:

RS232: Serial line signal PORT B pin-2

Signal reference PORT B pin- 5

RS422: RS422+ PORT B pin- 1

RS422- PORT B pin- 4

20mA current loop: CLI+ PORT B pin- 6

CLI- PORT B pin- 9

j Use a 9--pin D--connector, male type, for connecting the

serial line to port B on the Sonar Control Unit (this

connector is not included in the delivery). To make the

connections, refer to the pin connection list above, and

figure 24 which shows the pin location of the connector

seenfromthewiresolderingside.Thecable screenshould

be connected to the connector housing.

Figure 24 - Connections for a speed log with

serial line output

j Locate the DIL switch S1 on the Control Unit Board

(refer to figure 19), and set the switches according to the

table below.

DIL SWITCH S1

SPEED

1 2 3 4 5 6 7 8

SERIAL LINE OUTPUT OFF OFF OFF ON ON OFF OFF OFF

j Locate the links LK2, LK3 and LK6 on the Control Unit

Board, (see figure 19) and set the links according to the

table below.

Page 76

Simrad SD570 / Base version

42

851--160116 / B

SPEED LINK SETTING

LK2 LK3 LK6

RS232 OUT IN OUT

RS422 OUT OUT IN

20 mA current loop IN OUT OUT

Do not insert the Control drawer unit before mentioned in a later

chapter.

7.4 Connecting other auxiliary equipment

If any other optional equipment is to be connected (echo

sounderortrawlsystem),refertotheappendixesin thismanual.

7.5 Remounting the electronic drawer unit

When the DIL switches and link settings for all auxiliary

equipment are correct, use the following procedure to remount

the electronic drawer unit:

j Remount the top cover on the drawer unit.

j Reconnect the two display cables.

j Lock the two display cables in the cable locker, and

arrange the cables as shown in figure 25. Enter the

drawer unit carefully into the cabinet, and check the

cables while entering the drawer. Note that the two

guiding pins at the inside of the rear wall in the cabinet

should enter the two guiding holes at the rear of the

drawer unit.

j Fasten the electronic drawer unit with the four 3mm

Allen screws on the front of the operator panel.

Page 77

Introduction

43

851--160116 / B

Figure 25 - Mounting the electronic drawer

unit

Page 78

Simrad SD570 / Base version

44

851--160116 / B

Blank page

Page 79

Introduction

I

851--160117 / B

851- 160117 / AA000 / 3 - 11

Start- up procedures

This section contains the start- up procedures to be

carried out after installation of the SD570/SE570 sonar.

Page 80

Simrad SD570 / Base version

II

851--160117 / B

Document revisions

Rev Date Written by Checked by Approved by

A Unknown

B 03.01.01 RBR ESB RBR

C

D

(The original signatures are recorded in the company’s logistic database)

Page 81

Introduction

III

851--160117 / B

Table of contents

1 PREPARING THE START--UP 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Before start- up check list 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Starting up the stand- by power supply 2. . . . . . . . . . . . . . . . . . . . . . . . .

2 THE HULL UNIT 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Starting up the Hull Unit 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Adjusting the middle position switch 10. . . . . . . . . . . . . . . . . . . . . . . . . . .

3 THE SONAR CONTROL UNIT 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Starting up the sonar control unit 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Checking the control panel 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 CHECKING THE HOISTING/LOWERING SYSTEM 17. . . . . . . . . . . . . . .

4.1 Checking the bridge functions 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Checking the sonar room functions 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 THE TRANSCEIVER UNIT 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Starting up the Transceiver Unit 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Self- noise test 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Connecting the transducer 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 SYSTEM START--UP 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Air- bleeding of the sonar trunk 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Preparing the system start- up 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Starting up the transmitter 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Actions on the sonar control unit 27. .. . . .. . . . .. . . .. . . . . . . . .

Actions on the Transceiver Unit 29. . .. . . .. . . . .. . . .. . . . .. . . .

6.4 Alignment of the sonar picture 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 TESTING THE AUXILIARY EQUIPMENT 32. . . . . . . . . . . . . . . . . . . . . . .

7.1 General 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Checking the course gyro readout 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Checking the speed log readout 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Checking the echo sounder and trawl system readout 34. . . . . . . . . . . .

7.5 Remounting the electronic drawer unit 35. . . . . . . . . . . . . . . . . . . . . . . . .

8 FINAL TESTS AND MEASUREMENTS 37. . . . . . . . . . . . . . . . . . . . . . . . .

8.1 General 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Source level (SL) measurements 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Receiving voltage response (VR) 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 Noise/speed curve 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 INSTALLATION REMARKS AND SIGNATURE 48. . . . . . . . . . . . . . . . . .

Page 82

Simrad SD570 / Base version

IV

851--160117 / B

Document history

(The information on this page is for internal use)

Rev.A Original issue for Base version.

Rev.B Document transferred to Interleaf. No changes made to text or illustra-

tions.

Page 83

Introduction

1

851--160117 / B

1 PREPARING THE START--UP

1.1 Before start--up check list

Before beginning with the start- up procedure, check the

following:

Sonar Control Unit:

j Check thatno connectionsare madetothe SonarControl

Unit.

Transceiver Unit:

j Checkthat theship’smainsfuses to theTransceiverUnit

are disconnected.

j Check thatthe mains inputconnector P201 on the power

supply in the Transceiver Unit is disconnected.

j Check thatthe transducer plugsare not connectedto the

front of the transceiver PCBs.

Hull Unit:

j Check that the ship’s mains fuses to the Hull Unit are

disconnected.

Page 84

Simrad SD570 / Base version

2

851--160117 / B

1.2 Starting up the stand--by power supply

In order to start up the sonar units, the 24 VDC stand-by power

supply in the Transceiver Unit has to be started up first. Refer to

figure 1 and use the following procedure to start up the stand-by

power supply:

j Check that the mains input connector P201 on the front

of the power supply in the Transceiver Unit is

disconnected.

j Check that the switch S202 on the front of the power

supply is set to OFF (middle) position.

j Insert the mains fuses to the Transceiver Unit on the

ship’s mains switchboard.