Page 1

INSTALLATION MANUAL

SIMRAD SD10

Sailboat Drive

20222683/A English

Page 2

Simrad SD10 Sailboat Drive

About this document

Rev. A First issue

© 2007 Navico AS. All rights reserved.

No part of this work covered by the copyright hereon may be reproduced or otherwise

copied without prior permission from Navico AS.

The information contained in this document is subject to change without prior notice.

Navico AS shall not be liable for errors contained herein, or for incidental or consequential

damages in connection with the furnishing, performance, or use of this document.

ii 20222683 / A

Page 3

Installation Manual

Contents

1. SYSTEM DESCRIPTION..........................................................................1

2. IMPORTANT INFORMATION................................................................

2.1 Operation...............................................................................................

Manual Override Procedure..................................................................

2.2 Mechanical Quick Release....................................................................

2.3 Recommended maximum yacht displacement and length....................

2.4 Cable .....................................................................................................

3. INSTALLATION.........................................................................................

3.1 Installation Planning .............................................................................

Determine Mounting Site for Drive Unit..............................................

Determine Mounting Site for Connection Kit ......................................

Determine Routing Path for Steering Cable .........................................

3.2 Installation of Drive Unit - Steering Cable & Spent Cable Tube.........

Step 1 - Install Drive Unit.....................................................................

Step 2 - Install Steering Cable ..............................................................

Step 3 - Install Spent Cable Tube .........................................................

3.3 Installation of Cable connection kit......................................................

3.4 Installation of electrical connections ..................................................

Cable Motor and Clutch Power Supply..............................................

2

2

2

2

3

3

4

4

4

5

6

7

7

8

9

9

10

10

4. MECHANICAL CALIBRATION PROCEDURE.................................

5. MAINTENANCE.......................................................................................

6. SERVICEABLE PARTS ..........................................................................

7. TECHNICAL SPECIFICATIONS..........................................................

20222683 / A iii

11

12

13

14

Page 4

Simrad SD10 Sailboat Drive

iv 20222683 / A

Page 5

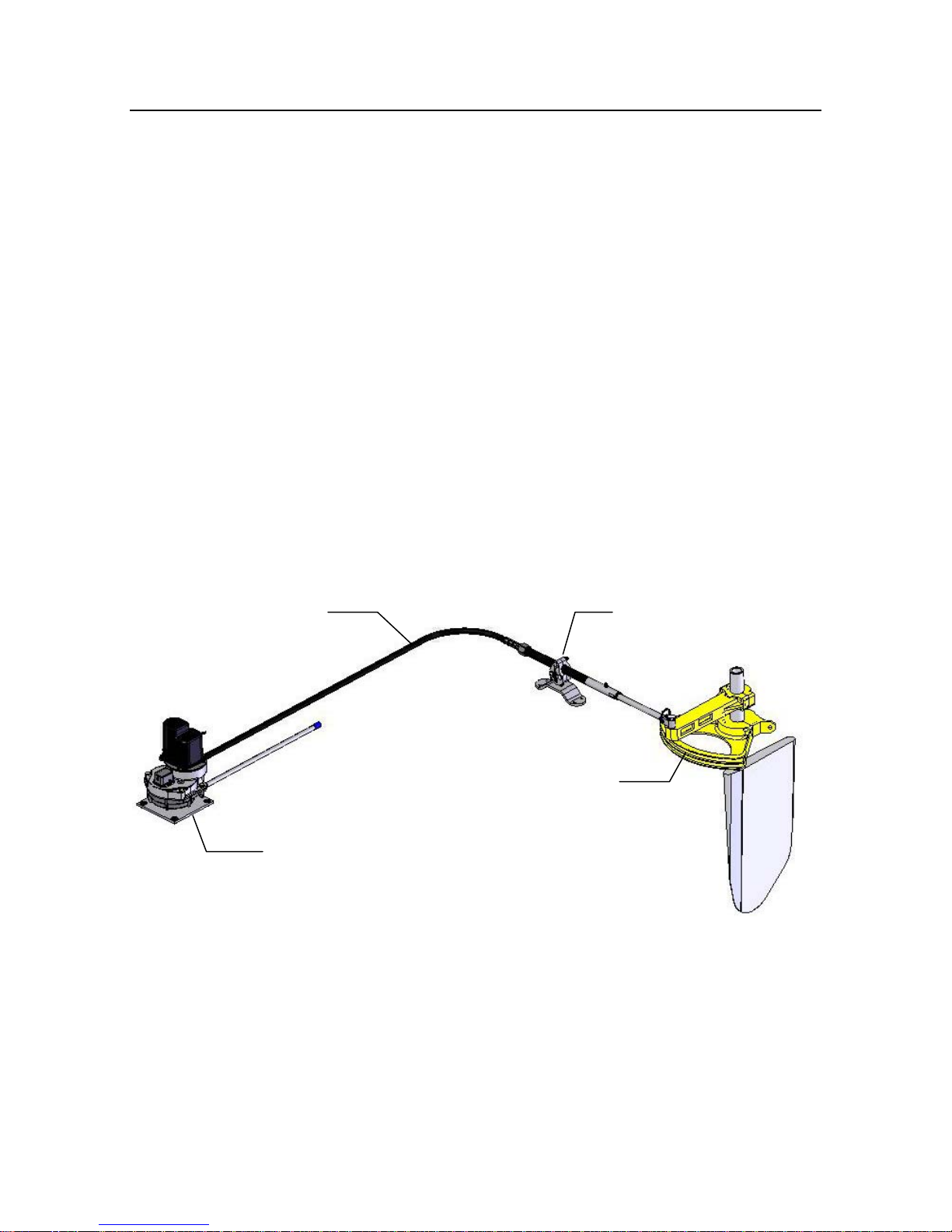

1. SYSTEM DESCRIPTION

The SD10 Sailboat Drive system makes it easy and

economical to install an autopilot on small to medium size

sailboats with access to a quadrant or tiller. The drive system

is powerful and fast - capable of delivering over 180 kg/400

lbs of cable thrust, with a normal H.O. to H.O. time of 12-15

seconds.

The system comprises of a Drive Unit, a Steering Cable and a

Universal Connection Kit. The drive unit can be installed in

any convenient location. The steering cable and connection kit

transmit the steering forces to the quadrant or tiller. Standard

steering cable length is 2 m (6 feet) – other lengths available

on request. The drive unit has a drive motor and solenoid

clutch which allows hand steering when disengaged. The drive

unit also has a built in adjustable thrust limiter and an integral

rudder feedback (RFB) device.

System Description

STEERING CABLE

SD10 DRIVE UNIT

UNIVERSAL

CONNECTION KIT

TYPICAL RUDDER AND TILLER

20222683 / A 1

Page 6

Simrad SD10 Sailboat Drive

2. IMPORTANT INFORMATION

The Drive System will fit a large number of vessels, but please

note the following important information on operation,

installation and maintenance of the drive system.

2.1 Operation

In the event of uncontrolled automatic steering or other

emergency situations, automatic return to MANUAL steering

is provided by switching the autopilot to STBY, or by using

the Manual Override procedure.

Note ! It is strongly advised that the helmsman be formally

familiarized with this manual override procedure.

Manual Override Procedure

The helmsman can overcome the steering action of the drive

unit by exerting force on the steering wheel in the opposite

direction to the drive. With this action the drive unit thrust

limit will ‘slip’ allowing the helmsman to take control.

2.2 Mechanical Quick Release

The Cable end that attaches to the steering quadrant or Tiller

arm has a quick release pin that can be used to disengage the

cable from the main steering system therefore releasing the

Autopilot drive (see page

Note ! It is very important that the helmsman is formally familiarized

with the location of this during any passage.

5).

2 20222683 / A

Page 7

Important Information

2.3 Recommended maximum yacht

displacement and length

The SD10 Sailboat Drive is designed to produce a maximum

cable push/pull of 180 kg/400 lbs, which requires a peak

power of 90 watts. This makes the unit capable of handling the

vast majority of sailboats up to 6500 kg / 14300 lbs

displacement fully laden and 11 m / 37 ft length.

Note ! Fully Laden = The displacement of the yacht including all

added accessories and crew. Any attempt to ignore this fact

may reduce the autopilot performance and overload the unit.

2.4 Cable

The cable is an accessory item which should be replaced at

regular intervals as required. Note that incorrect installation,

high torques or lack of maintenance will affect the life of the

cable. Follow the maintenance recommendation and normal

replacement will be required after 150-200 hours of use or

every two seasons. For extensive cruising and long passage

making we recommend that a spare cable is kept onboard.

20222683 / A 3

Page 8

Simrad SD10 Sailboat Drive

3. INSTALLATION

3.1 Installation Planning

When planning an installation, it is recommended that you

follow 3 steps:

• Determine mounting site for the drive unit.

• Determine mounting site for the connection kit.

• Determine routing path for the steering cable.

Determine Mounting Site for Drive Unit

The mounting site should provide adequate

space to accommodate the drive envelope

including the entry and exit points for the

steering cable. The drive can be mounted at

any angle. See detailed graphics of drive

225mm

envelope (left) and mounting samples

below. Note that no access for maintenance

purposes is required.

150mm

The selection of the steering cable entry/exit port does not have a preference. To

provide more flexibility for routing the steering cable, the entry/exit port

arrangement can be reversed. If ports are reversed, the steering direction will

also be reversed. The Simrad autopilot software will automatically compensate

for this.

REVERSIBLE CABLE

ENTRY-EXIT

TYPICAL VERTICAL

MOUNT

REVERSIBLE CABLE

ENTRY-EXIT

TYPICAL HORIZONTAL

MOUNT

4 20222683 / A

Page 9

Installation

Determine Mounting Site for Connection

Kit

The Universal Connection Kit must be mounted to stable hull

structure. Any orientation is acceptable as long as the HO

positions do not force the connection kit beyond its rotation

limits. Ideally the connection kit should be mounted so that the

thrust from the steering cable is tangential to the tiller arc at

mid stroke. It is acceptable to mount the connection kit

without using the base plate provided adequate support is

available for the hub. The clevis bracket can be mounted to a

separate tiller arm or directly to the quadrant if a suitable site

is available.

THREADED GUIDE TUBE

(+/- 3 inches of adjustment)

GREASE NIPPLE

BASE PLATE

CAN BE MOUNTED IN ANY

ORIENTATION

(hub can be installed directly onto

suitable structure without use of

base plate)

UNIVERSAL HUB

(360 degree freedom about vertical axis

+/- 40 degrees from horizontal plane)

QUICK RELEASE

HAIR PIN

CLEVIS BRACKET

Connection Kit Installation

20222683 / A 5

Page 10

Simrad SD10 Sailboat Drive

Determine Routing Path for Steering

Cable

After the locations for the Connection Kit and Drive Unit have

been established, the routing of the Steering Cable must be

determined.

The cable routing should take into consideration the extreme

movements of the steering mechanism during HO to HO

steering. Care should be taken to maximize the bend radius

and to avoid more than one bend. If more than one bend is

required, bends should not be smaller than the minimum bend

radius (6”) and the total angle of all bends combined be no

larger than 270 degrees. See drawing below showing preferred

routing and bend definition.

Steering Cable length supplied with system is 6 feet (2

metres). Other lengths are available on request.

‘B’ DIMENSION

Determine Length of Custom Steering Cable

If suitable site for drive unit based on a 6 foot steering cable is

not available. A custom cable length may be considered.

‘A’ DIMENSION

MID STROKE

150 mm MIN

RADIUS

SPENT CABLE TUBE

Preferred Cable Routing

Use a length of rope or electrical cable to simulate the routing,

then measure the total length required. See graphic of cable

length definition.

6 20222683 / A

Page 11

CABLE LENGTH

Installation

MID STROKE

Cable Length Definition

Example of steering cable length calculation:

Add ‘A’ + ‘B’ dimensions and subtract 4” for a 90 degree

bend. Round UP result to nearest full foot size.

For steering cable x length in feet or meter order 21120076

and add x m (ft)

3.2 Installation of Drive Unit - Steering Cable &

Spent Cable Tube

Step 1 - Install Drive Unit

20222683 / A 7

1. Remove 2 x lock bolts, nuts and washers

from ports and retain.

2. Position drive unit in final location. Verify

position by simulating the steering cable

connection whilst steering cable is NOT

connected.

3. Transfer bolt pattern from the drive base plate

(4 x 7 mm (0.28”) diameter holes) into

mounting structure.

4. Remove drive unit and prepare holes in

mounting structure to receive mounting

fasteners (screws, bolts). Note that this

Page 12

Simrad SD10 Sailboat Drive

Step 2 - Install Steering Cable

connection does NOT transmit any steering

loads.

5. Re-position drive unit and install fasteners,

tighten and torque.

1. Either port can be used for steering cable

entry. The most convenient for the

installation should be selected. The spent

cable tube attaches to the opposite port.

Steering direction can be reversed either by

reversing the motor brush leads or by

software in the course computer setup.

2. Apply some grease on the inner cable and

install steering cable into drive port. Guide

inner cable into port and exert moderate force

using 2 hands to drive cable around the

driving hub. This action will back drive the

unit and the inner cable will appear out of the

opposite port. To complete the cable

installation, the cable outer jacket will enter

the port and butt against the drive housing.

This will enable the insertion of the lock bolt.

3. Note that undue force required to drive the

inner cable around the driving hub may be

caused by the leading edge of the inner cable

gouging into outer face of the nylon guide.

Remove the cable and inspect the leading

edge for sharp edges, if possible, twist the

cable and re insert with sharp edge towards

inside of radius or using a burr type tool

remove the sharp edges.

8 20222683 / A

Page 13

Step 3 - Install Spent Cable Tube

1. Install spent cable tube in exit port.

2. Install 2 x lock bolt, nut and washers into

ports. Tighten and torque to 40-45 in-lbs

(4 Nm).

3.3 Installation of Cable connection kit

Installation

For best performance the following dimensions should be

followed.

932 mm

RUDDER

786 mm MIN

RUDDER POST

640 mm

105 mm105 mm

R150 MIN

UNIVERSAL CONNECTION KIT

STEERING CABLE

254 mm MAX

Note ! It is desirable that the cable connector kit is perpendicular to

the Tiller arm or quadrant at mid stoke. This geometry will

give the optimum performance.

20222683 / A 9

Page 14

Simrad SD10 Sailboat Drive

3.4 Electrical connections

Cable Motor and Clutch Power Supply

CLUTCH

(WHITE)

CLUTCH

(GREEN)

+ 12V

MOTOR

(RED)

+12V

BROWN

(RF+ or RF-

SHIELD

(ground)

-

MOTOR

(BLACK)

- 12V

Motor & Clutch Cable

Rudder Feedback Signal Cable

WHITE

(RF+ or RF-)

RFB cable

Following autopilot installation guide and

wiring diagram, connect 4 x 4 mm (AWG10)

wires with the autopilot computer.

Following autopilot installation guide,

perform electrical tests.

Following autopilot installation guide and

wiring diagram, connect 2 x 0.2 mm

(AWG24) wires + shield core with the

autopilot computer.

Following autopilot installation guide,

perform electrical tests.

10 20222683 / A

TB3

TB4 TB6

Sol.-Motor

Sol.-Motor

RED

BLACK

Autopilot Computer Wiring Diagram

AUTOPILOT COMPUTER

Drive

Engage

GREEN

WHITE

TB11

Rudder

Feedb.

RF

4 x 4 mm

RF

2

2 x 0.2 mm

2

(AWG10) Motor & Clutch Cable

(AWG24)

RFB Cable

Page 15

Mechanical Calibration Procedure

4. MECHANICAL CALIBRATION PROCEDURE

1. Before installing the drive unit

into the vessel, disassemble

the RFB module from the

drive housing, by removing 2

attach screws.

2. Install the drive unit into the

vessel and install the remote

RFB MODULE

COMPLETE

INSTALLATION

3. Complete the electrical hook up of

the drive following the autopilot

computer wiring diagram.

4. Centre the gear on the RFB module

by aligning the red paint mark on the

gear with the red paint mark on the

housing as shown in underside view

(left).

steering cable following the

drive installation guide.

ALIGN 2 RED DOTS

VERTICALLY

UNDERSIDE

VIEW

5. By turning the steering wheel of the

helm unit, centre the rudder.

6. Reassemble the RFB module to the

drive housing and install and tighten

the 2 attach screws. Ensure that the

mesh between the RFB module and

the drive gear is not excessive.

7. See autopilot manual for instructions

on rudder feedback calibration and

rudder test.

20222683 / A 11

Page 16

Simrad SD10 Sailboat Drive

5. MAINTENANCE

Grease the Universal connector kit on installation by applying

a grease gun to the grease nipples and at regular intervals

thereafter (see page

After a few hours of operation and at frequent intervals

thereafter, check all fasteners and the complete steering system

for security and integrity.

Keep all moving parts free from build-up of salt and other

foreign material. Build up of salt will effect their operation and

create steering problems. Pay particular attention to the

Universal connector kit. Periodically remove the cable, clean

the connector tube and thoroughly lubricate with waterproof

grease.

Inspect periodically for corrosion. Any parts affected by

corrosion must be replaced. When replacing hardware, selflocking hardware must be used.

5).

Inspect steering cable periodically for cracks or other damage.

If any is found the cable must be replaced.

WARNING ! Do NOT cover cracks in the cable with tape or other

sealants; this will only delay a fatal failure of the cable.

Always replace the cable.

12 20222683 / A

Page 17

6. SERVICEABLE PARTS

CLUTCH

SOLENOID

Serviceable Parts

RFB – PCB

DRIVE

MOTOR

RFB – MODULE

Main Components

Part numbers

21120001 SD10 Complete drive

21120027 SD10 Rudder feedback module

21120035 SD10 Drive Motor

21120043 SD10 Rudder Feedback PCB

21120050 SD10 Solenoid

21120068 SD10 Linear Universal Kit

21120076 SD10 Cable, 2 m (6’)

20222683 / A 13

Page 18

Simrad SD10 Sailboat Drive

7. TECHNICAL SPECIFICATIONS

Weight: .......................................................................................................4.9 kg (10,8 lb)

Maximum stroke:.................................................................................305 mm (12 inches)

Peak thrust fro cable:................................................................................180 kg (400 lbs)

Max Rudder Torque: ............................................................................ 450 Nm (333 lb ft)

Hard Over Time:........................................................................................12 – 18 seconds

Tiller Arm Radius:...............................................................................254 mm (10 inches)

Max Boat Displacement Fully Laden:................................................ 6500 kg (14300 lbs)

Max Boat Length:.........................................................................................11 m (37 feet)

Voltage: .................................................................................................................12V DC

Peak Power:...................................................................................................................7 A

Average Power: ..........................................................................................................2.5 A

Clutch Circuit Power:...............................................................................................0.85 A

14 20222683 / A

Loading...

Loading...