Page 1

Instruction manual

Simrad PI Remote/Depth

Sensor for depth and spread measurements

TE CH NO LO GY FO R SUS TA IN AB LE FI SH ER IE S

www.simrad.com

(CD012201F)

Page 2

Page 3

Simrad PI Remote/Depth

Instruction manual

This document gives you the necessary information for

mounting, charging and maintaining the PI Remote/Depth

sensor. It also explains how to set up the PI44 andPI54ca

tch

monitoring systems to receive and display the information

provided by the sensor.

316870/A

19 November 2007

Page 4

Document history

Document number: 316870 / ISBN-10: 82-8066-096-8 / ISBN-13: 978-82-8066-096-1

Rev.A

19 November 2007 First release.

Copyright

©2007 Kongsberg Maritime AS

The information contained in this document remains the sole property of Kongsberg Maritime AS. No part

of this document may be copied or reproduced in any form or by any means, and the info r mation contained

within it is not to be communicated to a third party, without the prior written consent of Kongsberg

Maritime AS. The document, or any part of it, may not be translated to any other language without the

written approval from Kongsberg M aritime AS.

Disclaimer

Kongsberg Maritime AS endeavours to ensure that all information in this docum ent is correct and fairly

stated, but does not accept liability for any errors or omissions.

Warning

The equipment to which this manual applies must only be used for the purpose for which it wa

s

designed. Improper use or maintena nce may cause damage to the equipment and/or injury to personnel.

The user mu st be familiar with the contents of the appropriate manuals before attempting to install,

operate or work on the equipment.

Kongsberg Maritime AS disclaims any responsibility for damage or injury caused by improper

installation, use or maintenance of the equipment.

Support

If you require maintenance on your Simrad equipment, contact your local dealer. You can also contact

Simrad using the following address:s

imrad.support@simrad.com.Ifyo

u need other information about

this product, or any other Simrad products, visit w

ww.simrad.com. On our web site you will also find

a list of our dealers and distributors.

Kongsberg Maritime AS

Strandpromenaden 50

P. O. Bo x 1 11

N-3191 Horten, Norway

Simrad

Telephone:+4733034000

Telefax:+4733042987

simrad.sales@simrad.com

www.simrad.com

Page 5

Instruction manual

Table of contents

INTRODUCTION ................................................................ 5

Purpose and applications..........................................................................................5

Main parts identification...........................................................................................6

Information on the sensor label................................................................................7

INSTALLATION ................................................................. 8

Sensor installation ....................................................................................................8

Adapter installation ..................................................................................................8

Installation principles ...............................................................................................9

CONFIGURATION ............................................................ 10

Basic configuration.................................................................................................10

Configuration of the PI32.......................................................................................10

Configuration of the PI44 and PI54........................................................................11

Adding a Spread/Depth sensor ...............................................................................13

About sensor configuration ....................................................................................14

Default communication channelsand updaterates.........................................14

Changing a communication channel ............................................................. 15

Changing the update rate ............................................................................. 15

PI Configurator ........................................................................................... 16

DISPLAY PRESENTATIONS.............................................. 17

Numerical presentation...........................................................................................17

Graphical presentation on PI32 ..............................................................................17

Graphical presentation on PI44 and PI54...............................................................19

Depth marker line.......................................................................................20

Spread marker line ...................................................................................... 21

CHARGING AND MAINTENANCE ...................................... 23

PI Remote/Depth maintenance...............................................................................23

PI Remote/Depth charging .....................................................................................24

How to use the Simrad PI Charger.........................................................................25

Daily operation........................................................................................... 25

Indicators................................................................................................... 26

Automatic configuration.............................................................................. 27

How to use the Simrad PI MaxiCharger.................................................................28

Daily operation........................................................................................... 28

Indicators................................................................................................... 29

316870/A 3

Page 6

Simrad PI Remote/Depth

4

316870/A

Page 7

Introduction

INTRODUCTION

Efficient fishery with trawl and purse seine assumes professional

and adequate instrumentation on the gear. Simrad has provided

professional instruments for fish finding for more than sixty years.

This user manual described installation, use and maintenance of

the PI Remote/Depth sensor when put to use with the PI catch

monitoring systems.

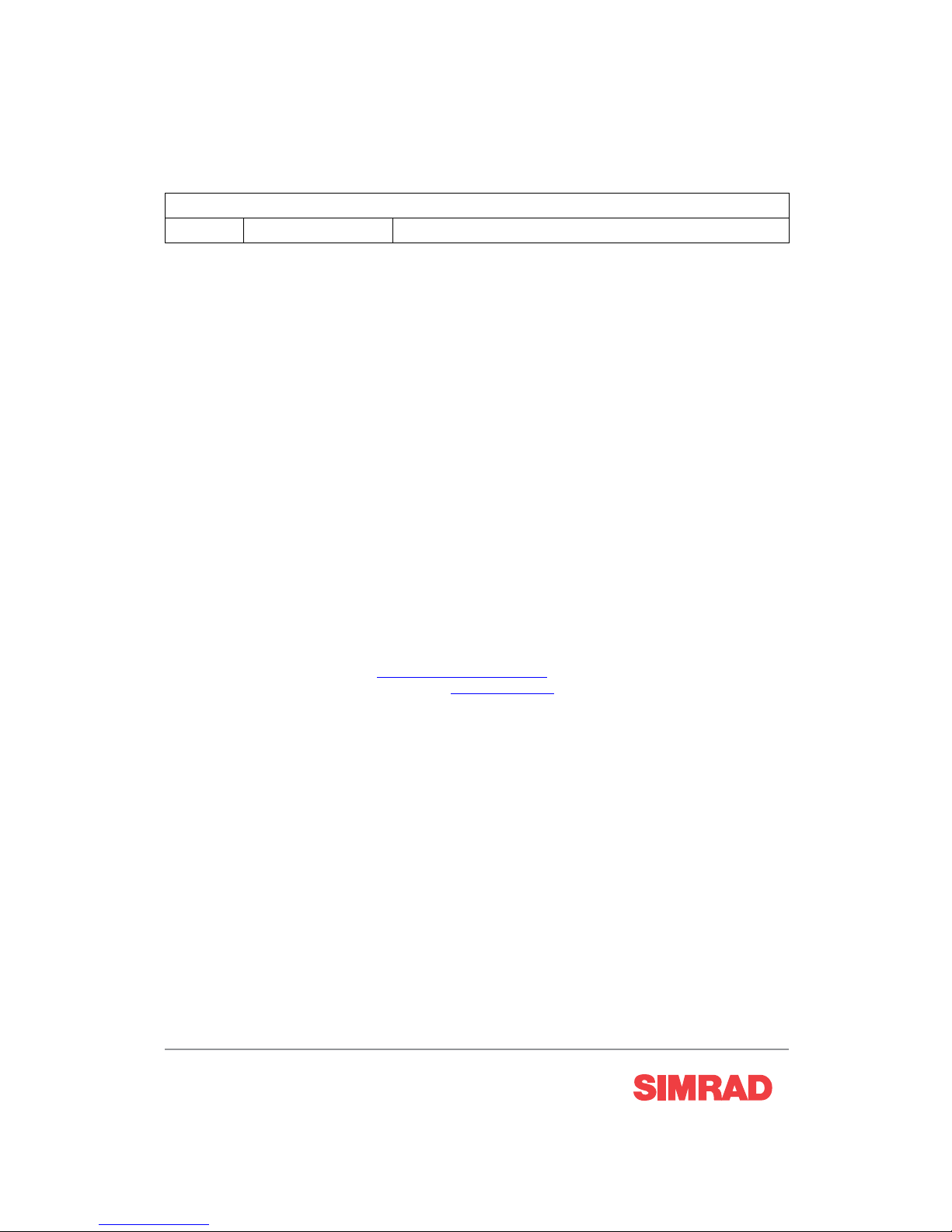

Purpose and applications

The purpose of the PI Remote/Depth sensor is to achieve accurate

measurements of both the water depth and the distance between

the two trawl doors. In order to measure the distance, it must be

installed in a pair with a PI Spread or PI Spread/Depth sensor.

Figure 1 The PI Remote/Depth sensor application

C

(CD012201B)

A

B

D

E

(A) The Spread sensor is mou

nted in a special adapter on the

port trawl door.

(B) The Remote/Depth se

nsor is mounted in a special adapter on

the starboard trawl do

or.

(C) The Spread sensor c

ommunicates the distance between the

trawl doors to the PI s

ystem on the vessel.

(D) The Remote/Dep

th sensor communicates the current depth of

the trawl door to t

he PI system on the vessel.

(E) Using the tran

sverse communication link, the two sensors

measure the phys

ical distance between the trawl doors.

316870/A 5

Page 8

Simrad PI Remote/Depth

The PI Remote/Depth thus contains both a pressure sensor to

measure the water depth, and a transducer to communicate with

the PI Spread sensor. The sensor in the PI Spread sensor will then

measure the distance between the trawl doors. The results from

these measurements are transmitted by acoustic signals to the PI

catch monitoring system mounted on the vessel.

Note

Each Spread sensor can be configured to communicate with one

of two Remote/Depth sensors; Remote 1 or Remote 2. Label the

Spread sensor accordingly, and ensure that you only use the

sensors in the correct pairs.

The PI Remote/Depth has been developed to be used on both

bottom and pelagic trawls. The sensor is installed on the

starboard trawl door using an adapter.

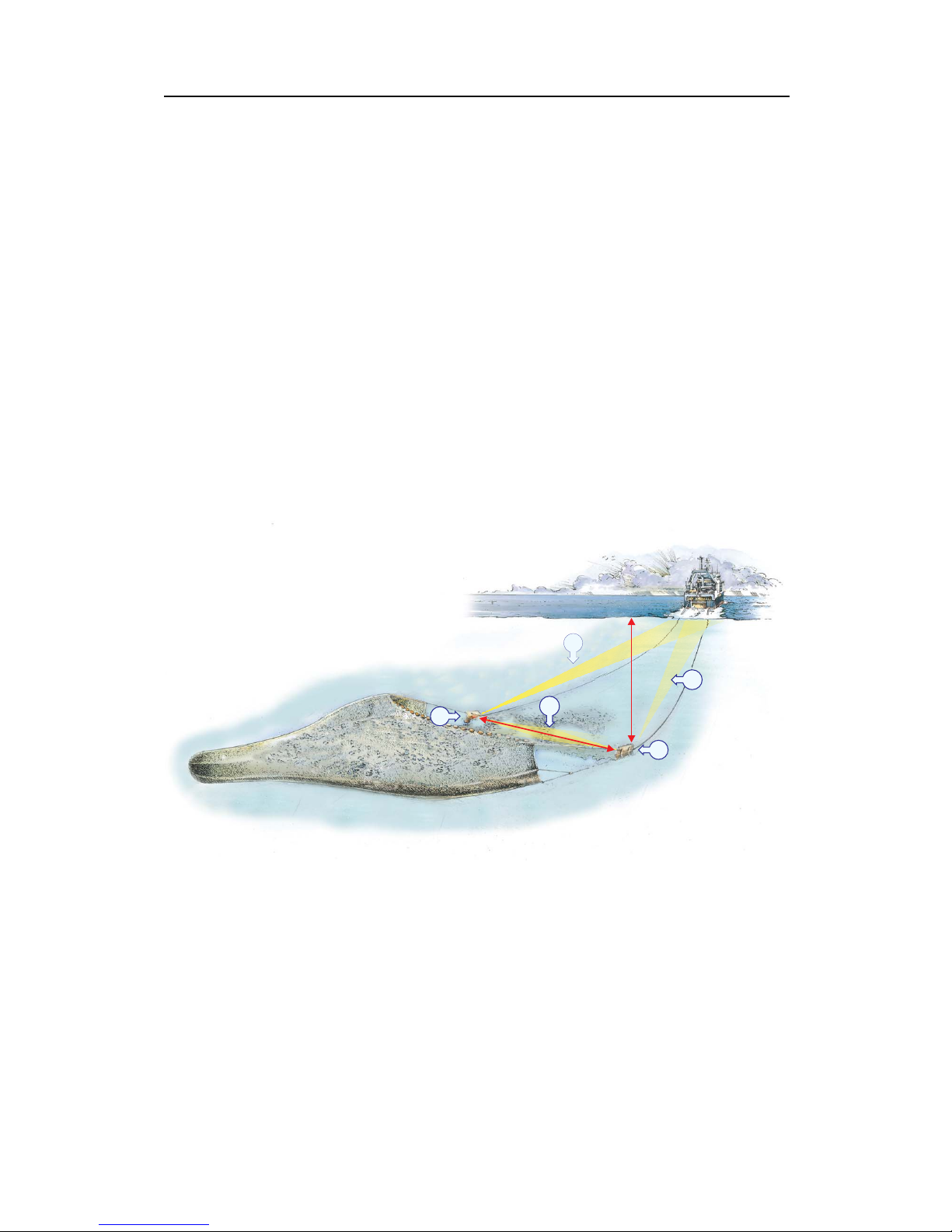

Main parts identification

Figure 2 PI Remote/Depth sensor

(A) Negative charging and fastening lug

(B) Positive charging and fastening lug

(C) Communication link to the vessel

(D) Transverse communication link

(E) Spread and Remote set identification

(F) Water switch with sacrificial bolt

(G) Sensor identification label

B

C

E

D

F

G

A

(CD012201A)

6 316870/A

Page 9

Introduction

Information on the sensor label

The sensor label provides the following information.

Figure 3 The PI Remote/Depth sensor label

B

D

(CD012201D)

A

C

E

F

(A) Channel identification. You must write down the channel

currently used by the sensor to communicate with the PI system.

The green background colour on the label is chosen to remind

you that the sensor is mounted on the starboard trawl door.

(B) This information identifies the sensor type. Three types are

available:

• PI-RD300: PI Remote/Depth for maximum depth 300 m

• PI-RD600: PI Remote/Depth for maximum depth 600 m

• PI-RD1000: PI Remote/Depth for maximum depth 1000 m

(C) Order number.

(D) Opening for the water to access the pressure sensor.

(E) Water switch. This is a sacrificial bolt. Check it from time to

time to make sure that it has not worn out.

(F) The sensor’s serial number.

316870/A 7

Page 10

Simrad PI Remote/Depth

INSTALLATION

The PI Remote/Depth sensor is mounted on the starboard

trawl door using a special adapter. From this position, it will

communicate with a Spread or a Spread/Depth sensor on the port

trawl door, and with the hydrophone beneath the vessel.

Sensor installation

The PI Remote/Depth sensor and the Spread or Spread/Depth

sensors must be mounted in dedicated adapters on each trawl

door. These adapters must be installed beforehand. Detailed

information on how to install the adapters are provided with the

installation kit.

The PI Remote/Depth sensor is mounted on the s

tarboard door,

while the PI Spread (or PI Spread/Depth) sensor is mounted on

the p

ort door.

Note

It is essential that there is a clear line of sight between the two

transverse communication “eyes” (one on each sensor). It is

also important that both the PI Spread ( or Spread/Depth) and

the PI Remote/Depth sensors have a clear line of sight to the

hydrophone on the vessel.

The two rubber inserts provided at the bottom of each sensor

adapter must not be replaced with any other types or designs.

It is essential that these inserts provide a secure cradle for the

sensors, but they must also allow for free water circulation to

allow the sensor’s water switch to engage. Also, the design of

the inserts allows sand and mud to flow out when the trawl doors

are pulled up from the water.

Adapter installation

The installation of the sensor adapter is described in the dedicated

instruction manual provided with the adapter. The document can

also be downloaded from w

ww.simrad.com.

Note

The adapter used to install the PI Remote/Depth sensor is not the

same as the adapter used for the standard PI Remote sensor.

The PI Remote/Depth sensor uses the same physical housing

as the PI Spread and PI Spread/Depth sensors, but it must be

mounted “upside down” to establish free view between the two

transducers used for the transverse communication.

8 316870/A

Page 11

Installation

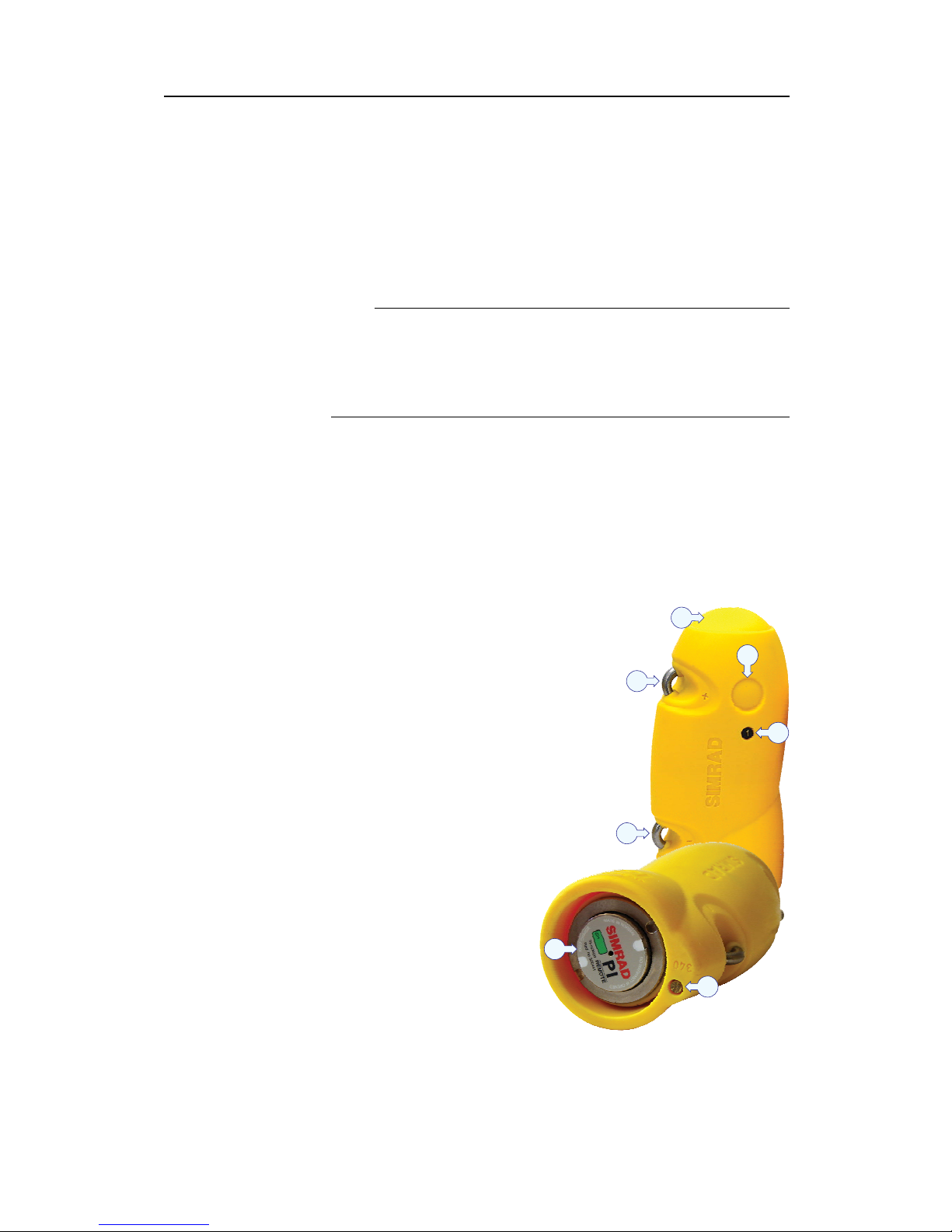

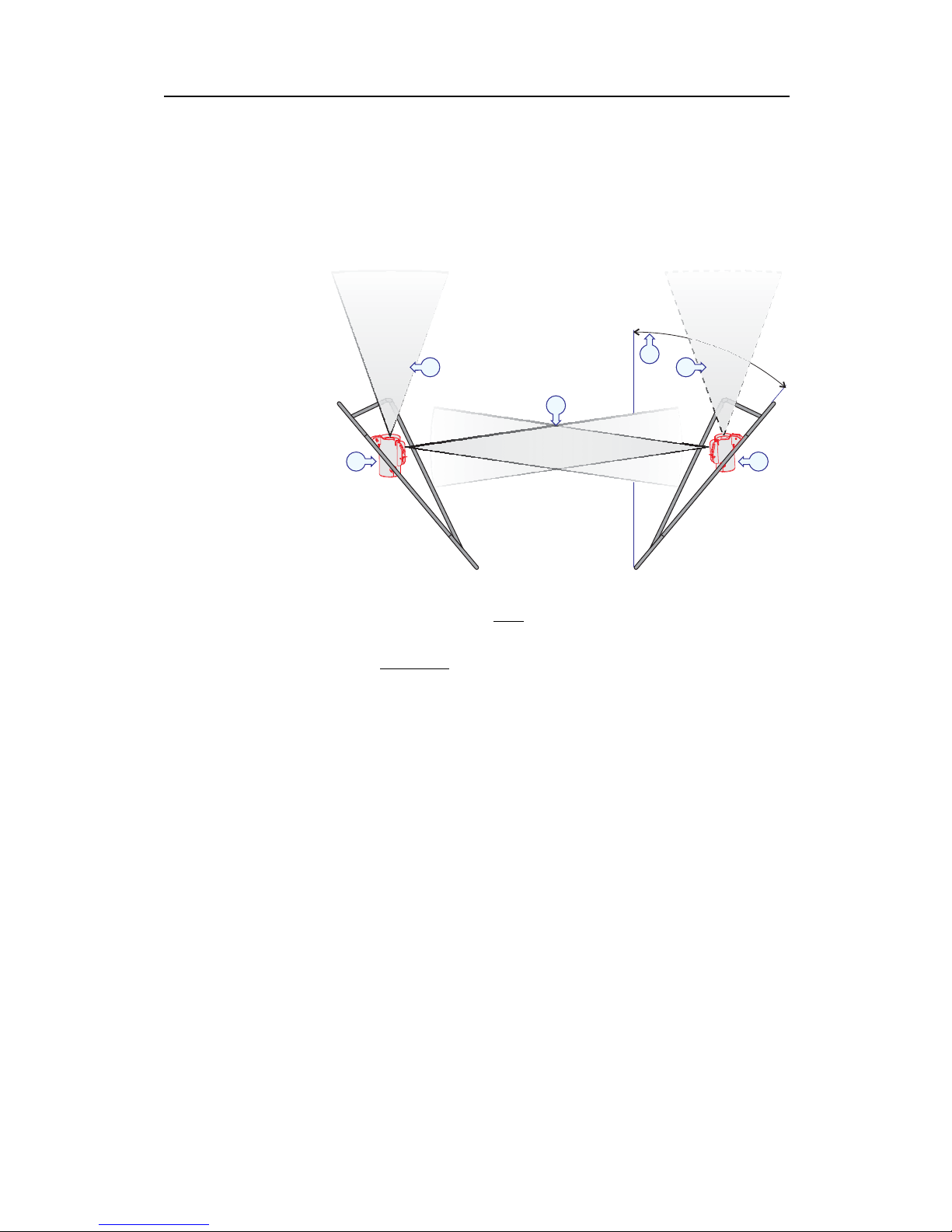

Installation principles

Observe the installation principles in the illustration.

Figure 4 Installation principles

(CD012200K)

A

B

C

E

F

D

(A) The PI Spread (or Spread/Depth) sensor is mounted in a

special adapter on the p

ort door.

(B) The PI Remote/Depth sensor is mounted in a special adapter

on the s

tarboard door.

(C) Communication link between the PI Spread (or Spread/Depth)

sensor and the PI hydrophone.

(D) Communication link between the PI Remote/Depth sensor

and the PI hydrophone.

(E) Communication link between the two sensors.

(F) Angle of attack.

316870/A 9

Page 12

Simrad PI Remote/Depth

CONFIGURATION

In order to allow the information from the PI Remote/Depth

sensor to be accepted and understood by the PI catch monitoring

system, the PI receiver must be set up correctly. This means that

you must tell the receiver that the sensor exists by entering the

sensor type, communication channels and update rate.

Upon delivery, all PI Remote/Depth sensors are set up with

factory default channels and update rates. Refer to the table in

section About sensor configuration on page 14.

Note

The sensor and the PI system setup must correspond, otherwise

the communication will not work. To change the sensor setup

(channel selection and update rate), use the PI Configurator

utility. See PI Configurator on page 16.

Basic configuration

Observe the following basic configuration settings:

• When you put the PI Remote/Depth to use, you must set it

up with a unique sensor number. Select the update rate, and

use a channel number according to the sensor’s configuration.

Write down this configuration for future reference. For

default settings, refer to the table in section About sensor

configuration on page 14.

• On the receiver, the Interference filter must be switched

on.SetittoLevel9 if you have noise problems from other

hydroacoustic sources. Note that this filters will influence the

signal spectrum shown in the

Status display.

• We recommend that you set the sensor filter to Light.

Configuration of the PI32

This procedure explains how to set up the PI32 catch

monitoring system to access the information provided by the PI

Remote/Depth sensor. For more detailed information about the

PI32 settings and parameters, refer to the PI32 Operator manual.

Note

In order to set up the PI system you must know what kind of

sensors you have, which communication channels they use, and

how often they communicate (the update rate). You need this

information b

efore you start the configuration.

Do not carry out sensor configuration unless absolutely

necessary.

10 316870/A

Page 13

Configuration

We recommend that you use the form at the beginning of the

PI32 Operator manual to write down the sensors you have and

their respective communication channels and update rates.

Figure 5 PI Remote/Depth configuration example, PI32

2

11

FAST

FAST

Sensor 1:

SINGLE - Update:

SINGLE Update:-

NONE - Update:

Measure 1:

Measure 2:

Sensor 2:

Sensor 3:

Sensor setup:

(CD012103A04)

SPREAD - Channel:

DEPTH 300M - Channel:

This example shows how the PI32 is set up to receive information

from a PI Spreadsensor and a PI Remote/Depth sensor. Standard

communication channels and update rates are used.

To access the

Sensor Setup menu:

1 Press the

MENU button to open the main menu.

2 On the

Setup menu, select Sensor setup.

3 Press the

ENT button to allow for changes, and then the

same button one more time to accept the warning.

• You must now use the circular navigation button to

move the cursor between the parameters, and the + and

- buttons to select values.

To set up the depth readings from the PI Remote/Depth sensor:

1 Choose an available sensor; 1, 2 or 3.

2 Define the sensor type (by default None)toSingle.

3 Set

Update to the correct update rate.

4 Set

Measure to the chosen sensor type Depth 300M, Depth

600M or Depth 1000M depending on the depth rating on

your PI Remote/Depth sensor.

5 Set the communication

Channel to its correct value.

All sensors are provided with default communication channels

and update rates. Refer to the table in section About sensor

configuration on page 14.

Configuration of the PI44 and PI54

This procedure explains how to set up the PI44 and PI54 catch

monitoring systems to access the information provided by the PI

Remote/Depth sensor. For more detailed information about the

settings and parameters, refer to the relevant Operator manuals.

We recommend that you use the form at the beginning of the PI44

or PI54 Operator manual to write down the sensors you have and

their respective communication channels and update rates.

316870/A

11

Page 14

Simrad PI Remote/Depth

Note

In order to set up the PI system you must know what kind of

sensors you have, which communication channels they use, and

how often they communicate (the update rate). You need this

information b

efore you start the configuration.

Do not carry out sensor configuration unless absolutely

necessary.

Figure 6 PI Remote/Depth configuration example

Sensor 1:

Demo mode:

Measure 1:

- Update:

- Update:

SINGLE

SINGLE

NONE

NONE

NONE

NONE

- Channel:

- Channel:

SPREAD

DEPTH 300M

FAST

OFF

02

Sensor 2:

Measure 2:

FAST

11

Sensor 3:

Sensor 4:

Sensor 5:

Sensor 6:

Sensor setup

Accept ENT

MENU Exit

GAIN- GAIN+

(CD012105D01)

This example shows how the PI44 (or PI54) is set up t o

receive information from a standard PI Spread sensor and a PI

Remote/Depth sensor. Standard communication channels and

update rates are used.

To access the

Sensor Setup menu:

1 Press the

MENU button to open the main menu.

2 On the

Setup menu, select Sensor setup.

3 Press the

ENT button to allow for changes, and then the

same button one more time to accept the warning.

To set up the depth readings from the PI Remote/Depth sensor:

1 Choose an available sensor; 1 to 6.

2 Define the sensor type (by default None)toSingle.

3 Set

Update to the correct update rate.

4 Set

Measure x1 to the chosen sensor type Depth 300M,

Depth 600M or Depth 1000M depending on the depth rating

on your PI Remote/Depth sensor.

5 Set the communication

Channel to its correct value.

6 Press the

ENT button to save the changes and exit.

12

316870/A

Page 15

Configuration

All sensors are provided with default communication channels

and update rates. Refer to the table in section About sensor

configuration on page 14.

Adding a Spread/Depth sensor

In order to achieve full control of the trawl, you may wish to

add a Spread/Depth sensor on the port trawl door. This sensor

will communicate with the Remote/Depth sensor to establish the

distance between the trawl doors, and it will provide you with the

accurate depth of the port trawl door. The Spread/Depth sensor

will occupy one additional channel on your PI system.

Note

You will not be able to add a PI Spread/Depth sensor on a PI32

system.

Figure 7 PI44 Spread/Depth and Remote/Depth configuration

example

Sensor 1:

Demo mode:

Measure 1:

Measure 3:

- Update:

- Update:

DUAL

NONE

SINGLE

NONE

NONE

NONE

- Channel:

- Channel:

- Channel:

SPREAD

DEPTH 300M

DEPTH 300M

FAST

FAST

OFF

02

Sensor 2:

Measure 2: 16

17

Sensor 3:

Sensor 4:

Sensor 5:

Sensor 6:

Sensor setup

Accept ENT

MENU Exit

GAIN- GAIN+

(CD012105C02)

This example shows how the PI44 (or PI54) is set up to receive

information from a PI Spread/Depth sensor (using two channels)

and a PI Remote/Depth sensor (using a single channel). Standard

communication channels and update rates are used.

To access the

Sensor Setup menu:

1 Press the

MENU button to open the main menu.

2 On the

Setup menu, select Sensor setup.

3 Press the

ENT button to allow for changes, and then the

same button one more time to accept the warning.

To set up the depth and distance (spread) readings from the PI

Spread/Depth sensor:

316870/A 13

Page 16

Simrad PI Remote/Depth

1 To reset the unit, set all six sensors to default sensor type

None.

2 Choose the sensor you wish to use for the PI Spread/Depth

sensor; 1 to 6.

3 Define the sensor type (by default None)toDual.

4 Set

Update to the correct update rate.

5 Set

Measure 1 to the chosen sensor type Spread.

6 Set the communication

Channel to its correct value.

7 Set

Measure 2 to the chosen sensor type Depth 300M, Depth

600M or Depth 1000M depending on the depth rating on

your PI Remote/Depth sensor.

8 Set the communication

Channel to its correct value.

9 Press the

ENT button to save the changes and exit.

All sensors are provided with default communication channels

and update rates. Refer to the table in section About sensor

configuration on page 14.

About sensor configuration

All sensors are provided from Simrad with predefined

communication channels and update rates.

Default communication channels and

update rates

See the table below for the initial values for the communication

channels and update rates for the various sensors.

Table 1 Default communication channels and update rates

Sensor Com.channel(s)

Update rate

PI Bottom Contact

6Normal

PI Catch

4Normal

PIDepth(300m)

16 Fast

PIDepth(600m)

12 Fast

PI Depth (1000 m )

10 Fast

PI Height 14 Fast

PI Remote/Depth

Depth 300M: 11

Depth 600M: 15

Depth 1000M: 13

Fast

PI Spread

2Fast

PI Spread/Depth

Depth 300M: 16

Depth 600M: 12

Depth 1000M: 10

Spread: 2

Fast

PI Twin Spread

2 and 7 Fast

14

316870/A

Page 17

Configuration

Table 1 Default communication channels and update rates (cont’d.)

Sensor Com.channel(s)

Update rate

PI Temperature 8 Fast

PI SeineSounder

Depth 300M: 5

Depth 600M: 9

Depth 1000M: 1

Height: 14

Fast

Changing a communication channel

It may be required to change one or more communication

channels, and there may be many reasons for this.

• You have more than one of each sensor. For example, if you

have three temperature sensors, they MUST communicate

on three different channels.

• Other vessels near your use the same PI catch monitoring

system (or a similar), and they have one or more of their

sensors set up to the same communication channels as you

have. This will create interference, as you will "read" each

others sensors.

• If your sensors are set up to use communication channels too

close to each other (for example, you have chosen channels 4,

5 and 6), this will limit the vessel’s speed. The reason for this

is the Doppler effect. If the speed is too high, the Doppler will

cause the transmission frequencies to change so much that

they overlap, and this will create interference. The PI catch

monitoring system will provide a warning if this is about to

happen! You must then either change to other communication

channels further apart, or reduce the maximum shooting speed.

• If you operate at the maximum range of the sensors, you

may be able to increase this range slightly if you use

lower communication channels. This is because the lower

communication channels user lower transmission frequencies.

Changing the update rate

It may be required to c hange the update rate on a sensor, that is

how often it sends information back to the PI catch monitoring

system. A high update rate will give frequent information

updates, but the sensor will use more battery power. If you need

your batteries to last as long as possible, you must consider

lowering the update rate.

• A low update rate will provide you with fewer information

updates, but the battery will last very long.

• A high update rate will give you frequent information updates,

but the battery will run out faster.

316870/A 15

Page 18

Simrad PI Remote/Depth

All sensors are provided from Simrad with a default update rate

setting. In some cases you may find that this update rate does not

suit your operational needs. This is a decision you have to make

depending on the local fishing conditions.

PI Configurator

Simrad has developed a dedicated computer utility to change

the sensor configurations. By means of an ordinary desktop

computer and a few special cables you can do this job yourself. If

you do not require frequent configurations, you can also contact

you local dealer for assistance. Contact the dealer for more

information.

16

316870/A

Page 19

Display presentations

DISPLAY PRESENTATIONS

The information provided by the PI Remote/Depth sensor is

shown on the PI catch monitoring system’s colour display. Two

presentations are available:

• Numerical presentation

• Graphical presentation with or without echogram

Numerical presentation

The numerical presentation of the PI Remote/Depth data is

automatically shown in the relevant display modes. It is identical

to the presentation provided by the PI Depth sensor.

Figure 8 Numerical presentation, example

18

D1 [m]

25.6

q

(CD012206G)

A

B

C

E

D

F

G

H

(A) Sensor identification

(B) Unit of measurement

(C) Depth

(D) Depth change per minute

(E) Arrow pointing “down” means that the depth i

s increasing,

arrow pointing “up” means that depth is de

creasing.

(F) Visual alarm

(G) Interference warning

(H) Sensor transmission indicator

When the readings are stable, the digi

tsareshowninblack

colour. If the contact is lost, the ch

aracters *** are shown in grey.

If the depth is out of range, the disp

lays shows ???.

Graphical presentation on PI32

This section contains a proced

ure to explain how you can set

up the PI32 to show you a graphi

cal presentation of the PI

Remote/Depth data providin

gdepthmarkers.

316870/A 17

Page 20

Simrad PI Remote/Depth

Figure 9 Graphical presentation on PI32

C3

45.9

D1m

S2m

0

25

50

75

100

10

15

5

(CD012102D)

25.6

This example shows how the trawl door is located at 45.9 m

depth, and that the distance between the trawl doors is 25.6

meters. You can also see how these values have changed during

the last 20 minutes.

The purpose of the depth- and distance markers on the graphical

presentation is to keep an eye on how deep and how far apart the

trawl doors are situated. The depth sensor in the PI Remote/Depth

measures the distance from the sea surface and down. The PI

Spread sensor communicates with the PI Remote/Depth sensor to

measure the distance between the trawl doors.

1 Identify the sensor you wish to use, and make sure that the

sensor is connected to the PI32 with correct communication

channels and update rates.

2 Ensure that you have a graphical presentation active on your

PI unit.

3 Press the

ENT button to open the Graphic setup menu.

•The

Marker line parameter allows you to switch the

marker lines on or off for sensors S1, S2 and S3.

4 Use the

Marker line parameter to switch the requested

marker line(s) On.

5 Enter the requested values for the marker line

Marker line

thickness

and Marker line delay.

•

Marker line thickness: Use this parameter to control the

thickness (in pixels) of the marker line(s).

18

316870/A

Page 21

Display presentations

• Marker line delay: The echo sounder information is

provided by the transducer located below the vessel’s

hull. The sensor is however located on the gear, and may

be position several hundred meters behind the vessel. In

order to compensate for this physical distance you can

add the

Marker line delay. You must calculate this delay

based on the vessel’s speed, the distance from the aft

stern to the gear, and the current depth of the gear.

6 Press the

ENT button to s ave the chosen parameters and

return to the graphical presentation.

The depth- and spread marker lines are shown in the graphical

presentation using solid lines and the same colours as the

background in the numerical presentation. In order to read the

accurate depth you can observe the depth scale on the right hand

side, or read the value in the numerical presentation.

Graphical presentation on PI44 and PI54

This section contains a procedure to explain how you can set up

the PI44 and PI54 to show you a graphical presentation of the PI

Remote/Depth data providing depth markers. It also explains

how you can set up a spread marker line using the information

from a PI Spread sensor.

The purpose of the depth- and distance markers on the graphical

presentation is to keep an eye on how deep the trawl doors are

situated, and how far apart they are. The depth sensor in the PI

Remote/Depth sensor measures the distance from the sea surface

and down to the sensor, while the PI Spread sensor communicates

with the PI Remote/Depth sensor to measure the distance.

316870/A 19

Page 22

Simrad PI Remote/Depth

Figure 10 Graphical presentation on PI44/PI54

17.5 12.5

10

7.5

5

2.5

15

min

38kHz 1000W MEDIUM

T 22.5 C

o

S 7.2kn DK 1050 m

(CD012106F)

D1[m]

167

5

0

50

100

150

200

250

S2[m]

5

49.5

This illustration shows that the trawl doors are presently situated

at 167 meters below the surface, and they are ascending with 5

meters per minute. The distanc e between the two trawl doors

is 49.5 meter, and this distance is increasing with 5 meters per

second.

Depth marker line

1 Identify the sensor you wish to use, and make sure that

the sensor is connected to the PI system with correct

communication channels and update rates.

2 Ensure that you have a graphical presentation active on your

PI system.

3 Press the

ADJ button to open the Graphic setup menu.

4 Press the

GAIN+ button repeatedly to reach the Marker line

dialogue.

5 Observe the list of sensors that appear. Only those sensors

that can provide a marker line are listed.

6 Set

Auto to On.

• This allows the PI unit to use the Trawl Calculator to

estimate the correct time delay. (This is not applicable

for purse seiners.)

• If you wish to calculate the delay yourself, set

Auto to

Off. You must then enter the calculated value into the

Delay column.

7 Enter requested value for

Width.

20 316870/A

Page 23

Display presentations

• Use this parameter to control the thickness (in pixels)

of the marker line(s).

8 For every marker line, set

Show to On.

9 If you wish to see the marker lines in the expanded views

(bottom expansion, zoom and phased range), set

Sensor

marker in expansion

to On.

10 If you wish the PI system to draw a thin white line over and

under the marker lines, sett

Marker white zone to On.

11 If you wish to see the height marker only in expanded views,

set

Height marker in main echogram to Off..

12 Select requested

Height reference.

• The height sensor measures the distance from the

headrope to the bottom. If you use the echo sounder in the

PI system, set

Height reference to Bottom, and the height

marker will follow the bottom contour. With correct time

delay you will then see the trawl i n “true motion”.

• If you can not use the PI echo sounder, set

Heightreference

to Surface. The height is now shown using 0 m depth as

reference. The distance from the 0 meter line and down

to the marker line is then the current height of the gear.

13 Press the

ENT button to s ave the chosen parameters and

return to the graphical presentation.

Spread marker line

1 Identify the sensor you wish to use, and make sure that

the sensor is connected to the PI system with correct

communication channels and update rates.

2 Ensure that you have a graphical presentation active on your

PI system.

3 Press the

ADJ button to open the Graphic setup menu.

4 Press the

GAIN+ button repeatedly to reach the Marker line

dialogue.

5 Observe the list of sensors that appear. Only those sensors

that can provide a marker line are listed.

6 Locate the Spread sensor, and set

Show to On.

7 Enter the preferred settings for

Marker line thickness and

Marker line delay.

8 Press the

ENT button to s ave the chosen parameters and

return to the graphical presentation.

The Spread marker line is presented on the graphic display

with a continuous line. The colour of the line is the same as

the background colour in the numeric presentation. To read the

distance between the trawl doors, consult the depth range on the

316870/A

21

Page 24

Simrad PI Remote/Depth

right side of the display, or the read-out in the numeric display. If

the trawl door distance is reduced or increased, this will be easily

detected as the marker line moves up or down. Note that you do

not monitor the depth of the trawl doors even though you use the

depth scale, the scale is used as a range scale.

22

316870/A

Page 25

Charging and maintenance

CHARGING AND MAINTENANCE

This chapter explains how you shall recharge the battery in the

PI Remote/Depth sensor, and how you shall best maintain the

sensor.

PI Remote/Depth maintenance

Once installed and put to use, the sensor will automatically be

switched on once the water switch is activated. After an initial

start-up, the sensor starts transmission of the current depth and

distance.

When the sensor is not in use, check that the sensor lamp is not

flashing, as this indicates that the sensor is active and discharging

its batteries. In this case, wash the sensor in fresh water.

All sensors are equipped with a water switch, and two different

types are used. If your sensor is equipped with a brass screw,

observe the following procedure for replacement.

1 Turn the sensor upside down, and locate the brass screw.

2 Inspect the screw for wear and tear.

3 If replacement is required, locate a new screw.

Before a new screw is inserted,

Aqua Shield (or a similar

underwater lubricant) must be applied. Due to the size of

the tube, we recommend that the grease is applied from

a syringe.

4 Apply

Aqua Shield to the screw threads.

5 Insert the screw, mount firmly, but not too hard. Use

maximum torque 1.5 NM

A pack with ten screws and a tube of

Aqua Shield can be

ordered from Simrad as a spare parts kit.

Aqua Shield is manufactured by D.A.Stuart, Warrenville,

Illinois, USA.

Visit w

ww.d-a-stuart.com.

No other maintenance of the sensor is required.

Note

You must never attempt to open the sensor. There are no user

serviceable parts inside, and you may easily cause a leak.

316870/A 23

Page 26

Simrad PI Remote/Depth

PI Remote/Depth charging

The PI Remote/Depth sensor must be charged between operation.

The battery lifetime depends on the update rate you have chosen.

Note

To charge the PI Remote/Depth sensor, use the Simrad PI

Charger or the Simrad PI MaxiCharger.

Table 2 Battery lifetime for the PI Remote/Depth sensor

Update rate

Approximate lifetime between

charging

Fast 40 hours

Normal 80 hours

Slow

110 hours

Optimal sensor charging temperature is from +10 to +25° C.

Note

Charging sensors at sub zero temperatures can create explosive

gasses. Simrad assumes no liability for improper charging of

sensors, or the use of chargers not specified in our sensor or

charger documentation.

24

316870/A

Page 27

Charging and maintenance

How to use the Simrad PI Charger

The Simrad PI Charger is an intelligent battery charger for

fast and secure charging of the PI sensors. The charger will

automatically set up the correct charging current depending on

the sensor type and the battery temperature. A “fuel meter”

shows the status of the battery during the charge.

Figure 11 The PI Charger set up to charge a PI sensor

Even though the PI Charger is designed for fast charging of the

PI sensors, it can also charge the PS sensors, but only at normal

charge rate.

Daily operation

Observe the following pr

ocedure for daily operation.

1 Attach the charging clam

ps to the sensor as follows:

• Red clamp: Positive (+)f

astening lug

• Black clamp: Negative (–

) fastening lug

• On every sensor the pola

rity of the fastening lugs are

engraved on the sensor

body using + and – characters.

2 Ensure that mounting m

aterials do not short circuit the

charging lugs.

316870/A 25

Page 28

Simrad PI Remote/Depth

• This may be ropes, wires, chains or other items that

obstruct or short circuit the electrical connections.

3 When the charger is connected to the sensor, check the

charger lamps.

• Once connected, the charger will identify whether the

sensor connected can be fast charged or not. This is

shown by the yellow lamps. If the top lamp flashes

rapidly, the sensor is fast charged.

• If your sensor can be fast charged, the charger will

also check the internal temperature of the sensor. The

temperature is shown on the “thermometer” on the

charger’s front panel. If you charge a sensor that can not

be fast charged, this “thermometer” does not work.

4 Observe the charge times and temperature limitations!

• Fast charge: The PI Charger will first recharge the

sensor battery for approximately one hour to reach 70%

battery capacity, then approximately three hours to reach

100% capacity. Once fully charged, a constant trickle

charge will compensate for self discharging.

Note

Fast charging only applies to PI s ensors!

• Normal charge: The PI Charger will first recharge the

sensor battery for 16 hours for full battery capacity. This

mode applies for charging PI sensors outside specified

temperature range, and for all PS sensors.

• Charging must only take place within the specified

temperature range. For best results, keep the ambient

temperature between +10 and +25°C.

Note

Do not charge sensors in temperatures above +50°C or

below 0°C!

Indicators

(A) 12 to 32 Vdc connected

(B) “Fuel meter”, the number of LEDs illuminated shows the

current charging status. A complete charging cycle is indicated

with all “full” battery. Charging is indicated as follows:

•Fastflashing: Fast charging in progress

•Slowflashing: Normal charging in progress

• On/off every four seconds: Trickle charging in progress

26

316870/A

Page 29

Charging and maintenance

A

B

C

(C) Battery temperature indicators during fast charging of PI

sensors:

• Green: Battery temperature between +5 and +40°C. Fast

charge is enabled.

• Green and Blue: Battery temperature between 0 and +5°C.

Fast charge is disabled, normal charge is used.

• Green and Red: Battery temperature between +40 and +50°C.

Fast charge disabled, normal charge is used.

• Blue: Battery temperature is below 0°C. No charging takes

place.

• Red: Battery temperature is above +50°C. No charging takes

place.

WARNING

Charging a sensor at sub zero temperature might

develop explosive gases representing a potential

danger. Simrad assumes no liability for improper

charging, or the use of other chargers than those

approved by us.

Automatic configuration

The charger communicates with the sensor at regular intervals.

The fast c harge cycle is controlled by data exchanged between

the PI sensor and the charger, and a series of safety mechanisms

controls the termination of the fast charging current.

The PS sensors do not communicate with the charger. A constant

charge current of 58 m A is then set up by the charger regardless

of the battery temperature.

316870/A 27

Page 30

Simrad PI Remote/Depth

HowtousetheSimradPIMaxiCharger

The Simrad PI MaxiCharger is a plain battery charger to be used

with large PI sensors.

Figure 12 Simrad PI MaxiCharger

Caution

The Simrad PI MaxiCharger must only be used to charge

the l

arge PI sensors: PI Spread, PI Spread/Depth, PI

Remote/Depth, PI Height and PI SeineSounder. You

must NOT use this charger to recharge the “small” PI

sensors and the PS sensors, as the high charging current

may cause damage to the batteries in these sensors.

The Simrad PI MaxiCharger is provided with a small booklet

from the manufacturer (Mascot). Read this booklet before you

put the charger to work!

Daily operation

Observe the following procedure for daily operation.

1 Connect the charger to 230 Vac, and check that the charger

lamp is lit in yellow.

2 Ensure that mounting materials do not short circuit the

charging lugs.

• This may be ropes, wires, chains or other items that

obstruct or short circuit the electrical connections.

3 Attach the charging clamps to the sensor as follows:

• Red clamp: Positive (+) f astening lug

• Black clamp: Negative (–) fastening lug

• On every sensor the polarity of the fastening lugs are

engraved on the sensor body using + and – characters.

28

316870/A

Page 31

Charging and maintenance

4 When the charger is connected to the sensor, check the

charger lamps.

• After a few seconds, the lamp on the charger will change

from yellow to orange/red. This means that fast charging

is in progress.

• When the battery in the sensor has reached 90% capacity

the lamp will change from orange/red to green with

short yellow flashes. This means that top charging is in

progress.

• When the battery is fully charged, the lamp turns green.

Trickle charging is now active. You can safely allow

trickle charging for long periods of time.

Indicators

The Simrad PI MaxiCharger is only equipped with a single

indicator lamp, this lamp will however change colour to show the

status of the charging process.

• Yellow: The charger is connected to 230 Vac, it has not been

connected to the sensor, and it is ready for use.

• Orange/Red: The charger is connected to a sensor, and fast

charging is in progress.

• Green with short yellow flashes: Top charging is in progress.

• Green: Trickle charging is in progress.

316870/A 29

Page 32

Simrad PI Remote/Depth

A

Applications, 5

C

Charging, 23–24

Communication

channel

default values, 14

why change?, 15

Configuration, 10

PI32, 10

PI44, 11

PI54, 11

Remote/Depth, 13

sensor, 14

D

Default

communication

channels, 14

update rate, 14

Depth

marker line, 20

Display presentation

graphical

PI32, 17

PI44/PI54, 19

numerical, 17

Display presentations, 17

G

Graphical

display presen tation

PI32, 17

PI44/PI54, 19

H

How to

set up a depth marker

line, 20

set up a spread marker

line, 21

I

Identification

main parts, 6

Installation, 8

Introduction, 5

M

Main parts

identification, 6

Maintenance, 23

Marker line

depth, 20

spread, 21

N

Numerical

presentation, 17

P

Parts

identification, 6

PI Charger

use, 25

PI MaxiCharger

use, 28

PI32

configuration, 10

PI44

configuration, 11

PI54

configuration, 11

Presentations, 17

Procedure

configuration

PI32, 10

PI44, 11

PI54, 11

Remote/Depth, 13

set up a d epth marker

line, 20

set up a spread marker

line, 21

Purpose, 5

R

Remote/Depth

configuration, 13

S

Sensor

configuration, 14

Spread

marker line, 21

U

Update rate

default values, 14

why change?, 15

30 316870/A

Page 33

Page 34

Page 35

Page 36

ISBN-10: 82-8066-096-8

ISBN-13: 978-82-8066-096-1

©

2007 Kongsberg Maritime AS

Kongsberg Maritime AS

Strandpromenaden 50

P. O. Bo x 1 11

N-3191 Horten, Norway

Simrad

Telephone:+4733034000

Telefax:+4733042987

simrad.sales@simrad.com

www.simrad.com

Loading...

Loading...